Page 1

IBM 3745 Communication Controller

Models 130 to 17A

IBM

Maintenance Information Procedures

SY33-2070-09

Page 2

Page 3

IBM 3745 Communication Controller

Models 130 to 17A

IBM

Maintenance Information Procedures

SY33-2070-09

Page 4

Note!

Before using this information and the product it supports, be sure to read the general information under “Notices”

on page xv.

Tenth Edition (June 1997)

The information contained in this manual is subject to change from time to time. Any such changes will be reported in subsequent

revisions.

Changes have been made throughout this edition, and this manual should be read in its entirety.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not stocked at the

address given below.

A form for readers' comments appears at the back of this publication. If the form has been removed, address your comments to:

IBM France

Centre d'Etudes et de Recherches

Service 0798 - BP 79

06610 La Gaude

France

FAX: 33 4 93 24 77 97

E-mail: FRIBMQF5 at IBMMAIL

IBM Internal Use: LGERCF at LGEPROFS

Internet: rcf_lagaude@vnet.ibm.com

When you send information to IBM, you grant IBM a non-exclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1989, 1997. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

European Union (EU) Statement ........................... xv

Electronic Emission Notices .............................. xv

Trademarks and Service Marks ........................... xvi

Product Safety Information ............................. xvii

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Service Inspection Safety Procedures ...................... xvii

Service Inspection Safety Procedures for the 3745, 3746-900, and Controller

Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Control Panel LED Status Versus 3746-900 States .............. xxx

3745/3746-900 Power Supply CP/CB and Fuse Reference .......... xxx

Controller Expansion Fuse Reference ...................... xxx

Sicherheitsüberprüfungen für IBM 3745, 3746-900 und die Erweiterung der

Steuereinheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

Einführung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

Bedeutung der LEDs am Bedienungsfeld der 3746-900 ............ xlii

Stromversorgung der 3745/3746-900, Sicherungsautomaten (CB),

Überstromschutzschalter (CP) und Sicherungen (F) ............. xliii

Sicherungen der Erweiterung der Steuereinheit ................. xliii

Safety Label Locations ............................... lvii

Safety Labels on the 3745 ............................. lvii

Safety Label on the 3746-900 ........................... lix

Safety Label on LCB ................................ lix

3745/3746-900 Safety Label Identifications .................... lx

LCB Safety Label .................................. lxii

Controller Expansion Label Location ....................... lxii

Safety Label Part Numbers by Country ..................... lxiii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . lxv

About this Manual .................................. lxv

Who Should Read this Manual .......................... lxv

How this Manual Is Organized ........................... lxv

Summary of Changes ............................... lxvii

Chapter 1. START: How to Begin Troubleshooting .............. 1-1

Console Use for Maintenance ........................... 1-1

Service Processor Window Overview ........................ 1-3

Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3745 Maintenance Actions ............................. 1-6

Problems During Machine, EC, or MES Installation ................ 1-7

Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Symptom Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

General Verbal Symptoms ............................. 1-8

Copyright IBM Corp. 1989, 1997 iii

Page 6

3745 Console Symptoms ............................. 1-10

3745 Control Panel Symptoms ......................... 1-11

3745 Power Symptoms .............................. 1-12

Miscellaneous Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Using Reference Codes ............................... 1-14

3745 Control Panel Codes ............................. 1-15

Using the MIP FRU Group Table .......................... 1-48

3745 FRU Group Table ............................. 1-49

3745 Cable Location ............................... 1-52

3745 FRU List ................................... 1-53

3745 and Service Processor Maintenance Using a CPN .......... 1-55

Service Processor Maintenance Using an SRC Sequence Number .... 1-57

Engineering Data Transfer ............................. 1-58

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Transferring Engineering Data from the Local Service Processor ..... 1-58

Transferring 3745 Engineering Data to MOSS-E ............... 1-58

Logon on the Remote Service Processor ................... 1-58

Transferring Engineering Data to the Remote Service Processor ..... 1-59

3745 Diagnostic Requirement .......................... 1-60

Disabling Procedure 0110: Preparing a CA for Maintenance ........ 1-61

Disabling Procedure 0120: Preparing a TSS/HPTSS/ESS for Maintenance 1-62

Disabling Procedure 0130: How to Put the MOSS Offline: Preparing the

MOSS for Maintenance ............................. 1-65

Disabling Procedure 0140: Preparing a TRSS for Maintenance ...... 1-66

Disabling Procedure 0150: Preparing LIC Type 1, 3, 4, 5, 6 for

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-69

LIC/Line Address Table ............................. 1-73

3745 Control Panel Use ............................... 1-78

Purpose of the Control Panel .......................... 1-78

Uses of the Control Panel ............................ 1-78

Explanation of 3745 Panel Keys, LEDs, and Switches ............ 1-79

Power On Indicator ................................ 1-79

Control Panel Display Description ........................ 1-79

How to Perform 3745 Control Panel Operations ................. 1-82

Power On Reset .................................. 1-82

General IPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-82

MOSS IML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-82

MOSS Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-82

Request Local Console .............................. 1-83

Force Local Console ............................... 1-83

Panel Test and Console Link Tests ....................... 1-83

Load from Diskette ................................ 1-83

Loop on MOSS Diagnostics ........................... 1-83

Display Stacked Errors .............................. 1-83

Chapter 2. Map for FRU Isolation ......................... 2-1

IOC Bus MAPs ..................................... 2-1

MAP 0100: IOC Bus Trouble Shooting ..................... 2-1

3745 MOSS MAPs ................................... 2-3

MAP 3200: MOSS Control Panel Code 001 .................. 2-3

MAP 3210: MOSS Control Panel Code 059 .................. 2-4

MAP 3220: Undefined Panel Message ..................... 2-5

MAP 3230: Console Link Procedure ....................... 2-6

3745 Line Adapter MAPs ............................... 2-7

iv 3745 Models 130 to 17A: MIP

Page 7

MAP 3500: Activate/Deactivate Line Problem or Line Errors on the TSS .. 2-7

MAP 3520: Activate/Deactivate Ring Problems or Ring Errors on the TRSS 2-8

MAP 3530: Activate/Deactivate Line Problems or Line Errors on the

HPTSS/ESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3745 Channel MAPs ................................. 2-10

MAP 3700: CA Isolation Procedure ...................... 2-10

3745 Power MAPs .................................. 2-12

MAP 3900: Overcurrent on Power Supply 1 ................. 2-12

MAP 3905: Power ON Problem in Host Mode or Host Power Sequence

Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

MAP 3910: Overcurrent on Power Supply 2 ................. 2-18

Power MAP 3920: Air Flow Detector Fault .................. 2-19

Power MAP 3925: Scheduled Power on Problems ............. 2-20

Power MAP 3930: Power Control Subsystem Problems .......... 2-21

Power MAP 3935: Power OFF not Possible in Host Mode ......... 2-25

Power MAP 3945: Power OFF not Possible in Local Mode ........ 2-26

Power MAP 3950: PCC-Detected Error on MOSS Reset .......... 2-27

Power MAP 3960: Power OFF not Possible in Network Mode ....... 2-28

Power MAP 3970: PCC-Detected Error on CCU Reset or on Remote

Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

3745 LAN MAP .................................... 2-31

MAP 4500: 3745 Models 17A Permanent Console Link Problem ..... 2-31

3745 Control Panel Code ............................ 2-32

3745 RSF MAP .................................... 2-33

MAP 4510: 3745 Model 17A Manual Call ................... 2-33

3745/3746-900/Service Processor MAPs ..................... 2-37

MAP 5200: 3745/3746-900/Service Processor/Network Node Processor

Icon Color Symptoms .............................. 2-37

MAP 5205: LAN Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Service Processor MAPs .............................. 2-42

MAP 5600: LAN Problem on the LAN Attached to the Service Processor 2-42

Chapter 3. How to Run 3745 Diagnostics .................... 3-1

Diagnostic Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3745 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Errors During Diagnostics ............................. 3-2

Diagnostic Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Checkout Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

CBA Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

How to Run MOSS Diagnostics ........................... 3-4

How to Loop MOSS Diagnostics ........................... 3-5

How to Run the Console Link Test for 3745 Models 130, 150, 160, and 170 . 3-6

Local/Remote or Alternate/RSF Link Tests ................... 3-6

How to Run the Control Panel Test ......................... 3-8

How to Run Internal Function Tests ......................... 3-9

How to Run the LIC Wrap Test with IFTs ..................... 3-13

How to Run the Wrap Test (WTT) for TSS, HPTSS, or 3746-900 ....... 3-15

Wrap Test Initial Selection for TSS ....................... 3-16

Wrap Test Initial Selection for HPTSS ..................... 3-18

Wrap Test Initial Selection for 3746-900 .................... 3-19

Available Wrap Options ............................. 3-20

How to Run the Channel Wrap Test ........................ 3-25

Chapter 4. 3745 FRU Exchange .......................... 4-1

Contents v

Page 8

Exchange Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

List of 3745 FRUs .................................. 4-2

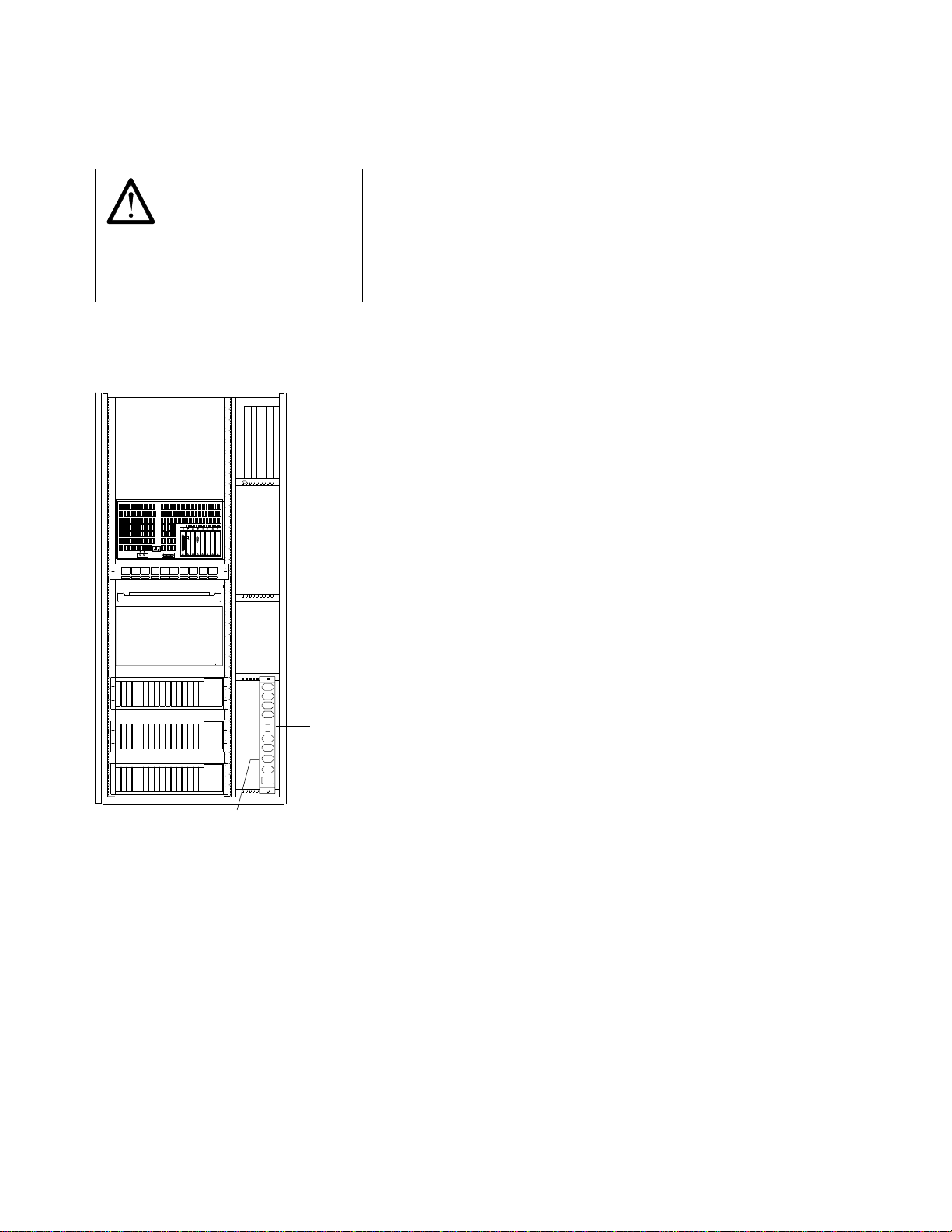

FRU Physical Locations ................................ 4-3

3745 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Basic Board, Cards, Connectors, and Crossovers ............... 4-5

MOSS Board, Cards, and Connectors ..................... 4-11

LIC Board Type 1 ................................. 4-13

LIC Board Type 2 ................................. 4-13

LIC Board Type 3 ................................. 4-14

DMUX and SMUX Packaging .......................... 4-14

LIC Board Type 1 Packaging for LICs Type 1 to 4 .............. 4-15

LIC Board Type 2 Packaging for LIC Type 5 ................. 4-18

LIC Board Type 2 Packaging for LIC Type 6 (Low Speed) ......... 4-19

LIC Board Type 2 Packaging for LIC Type 6 (High Speed) ......... 4-20

LIC Board Type 3 Packaging for LIC Types 1 to 4 .............. 4-21

Ethernet Lines Tailgate .............................. 4-22

High Speed Lines Tailgate ............................ 4-23

Token-Ring Tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Channel Tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Console Operator Tailgate For 3745 Models 1X0 .............. 4-26

Console Operator Tailgate for 3745 Model 17A ................ 4-26

EPO Tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

3745 Control Panel ................................ 4-28

Flexible Diskette Drive .............................. 4-29

Hard Disk Drive .................................. 4-29

Primary Power Box ................................ 4-30

Power Supply 1 .................................. 4-31

3745 Power Supply Cross Reference ..................... 4-31

Power Supply 2 .................................. 4-32

Fan 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Fan 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

3745 FRU Exchange Procedures ......................... 4-34

Card Exchange Procedure ............................ 4-34

DCREG Exchange Procedure .......................... 4-38

DMUX Exchange Procedure ........................... 4-39

SMUXA/B Exchange Procedure ......................... 4-41

LIC Exchange Procedure ............................. 4-44

Control Panel Exchange Procedure ....................... 4-46

Battery Exchange Procedure .......................... 4-48

Fan 1 Exchange Procedure ........................... 4-50

Fan 2 Exchange Procedure ........................... 4-51

FDD Exchange Procedure ............................ 4-52

HDD Exchange Procedure ............................ 4-56

TERMC/TERMR Exchange Procedure ..................... 4-61

TERMD/TERMI Exchange Procedure ..................... 4-62

ESS Tailgate Exchange Procedure ....................... 4-64

PS1 Exchange Procedure ............................ 4-67

PS2 and Primary Power Box Exchange Procedure .............. 4-69

EPO Exchange Procedure ............................ 4-73

Basic Board Exchange Procedure ....................... 4-77

LIC Board Type 1 and 3 Exchange Procedure ................ 4-84

LIC Board Type 2 Exchange Procedure .................... 4-88

MOSS Board Exchange Procedure ....................... 4-92

Channel Tailgate Exchange Procedure ..................... 4-96

vi 3745 Models 130 to 17A: MIP

Page 9

Action to Take After a Diagnostic Run or an FRU Exchange .......... 4-99

Diagnostic and Exchange Result Analysis 0000 ............... 4-99

CE Leaving Procedure ............................. 4-102

Appendix A. Maintenance Aids . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Contacting Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Control Program Maintenance Aids ........................ A-1

MOSS Microcode Maintenance Aids ........................ A-2

Scanner Microcode Maintenance Aids ....................... A-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

General Purpose Tools .............................. A-3

ESD Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Shipping Group Tools ............................... A-4

PKD (Portable Keypad Display) Maintenance Aids for LIC 5 and 6 ...... A-5

Appendix B. 3745 Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Service Personnel Definitions ............................ B-1

Customer Documentation for the 3745 (Models 130, 150, 160, 170, and 17A)

and 3746 (Model 900) ............................... B-2

Service Documentation for the 3745 (Models 130, 150, 160, 170, and 17A)

and 3746 (Model 900) ............................... B-6

Related Signal Converter Product Information .................. B-9

Related NCP Service Information ......................... B-10

World Wide Web ................................. B-10

List of Abbreviations ................................ X-1

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-7

Contents vii

Page 10

viii 3745 Models 130 to 17A: MIP

Page 11

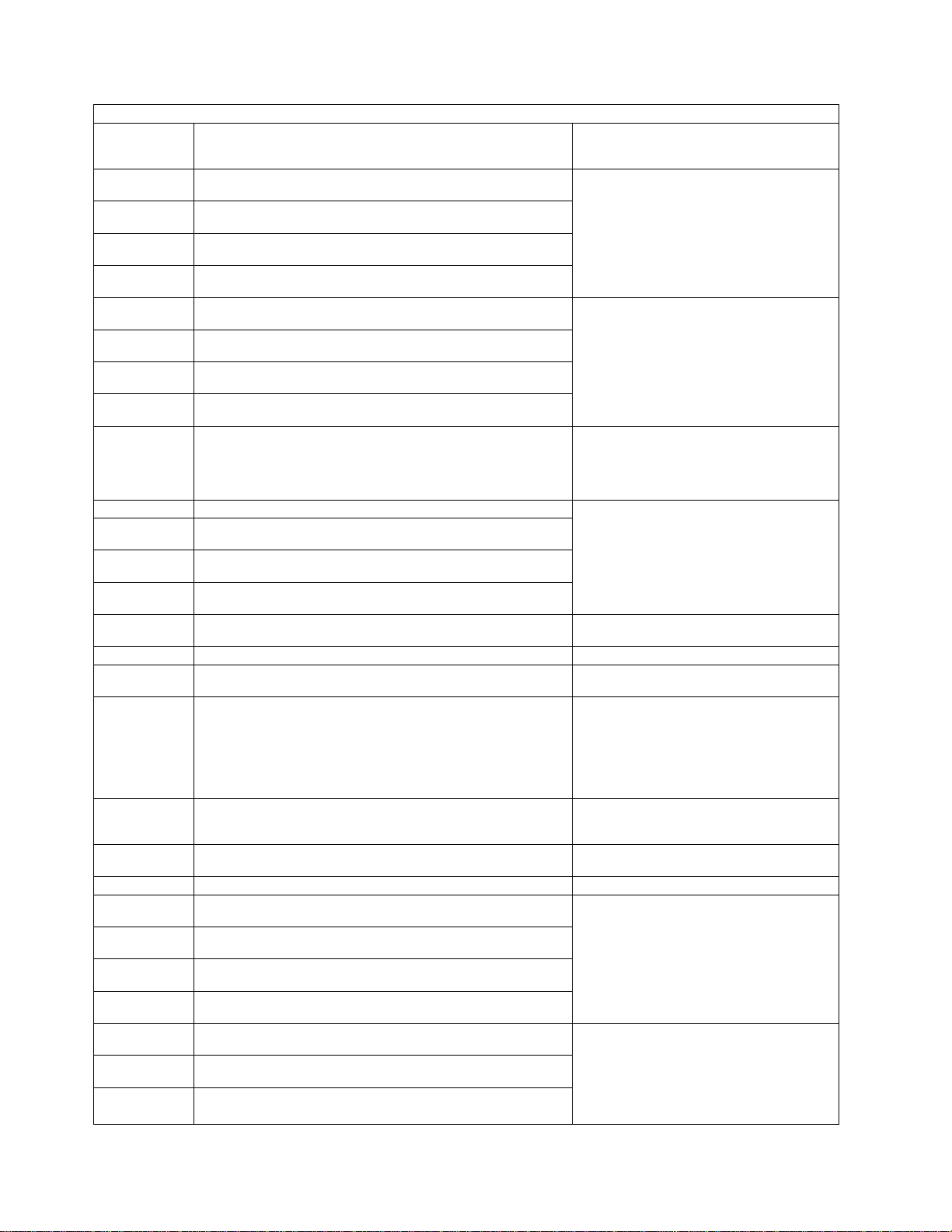

Figures

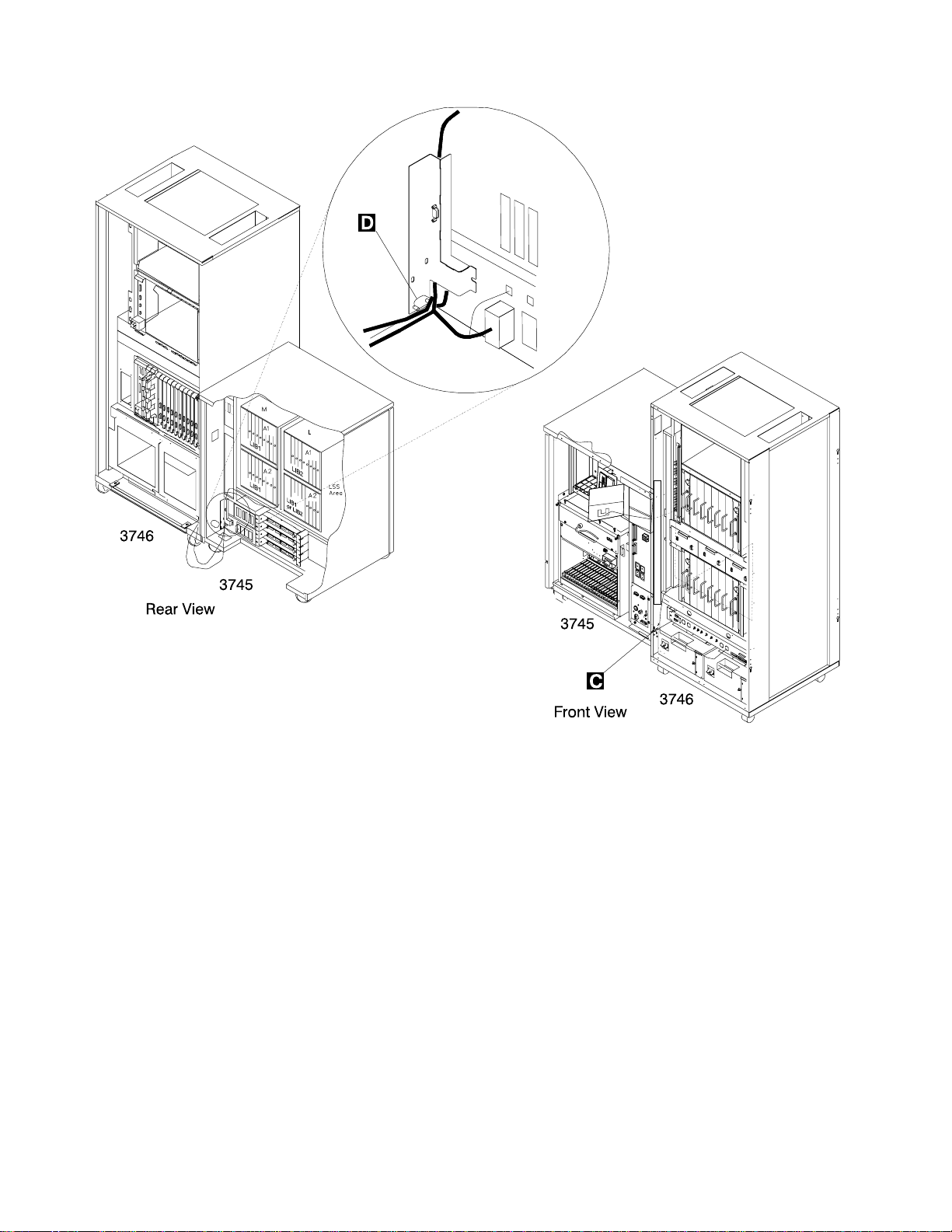

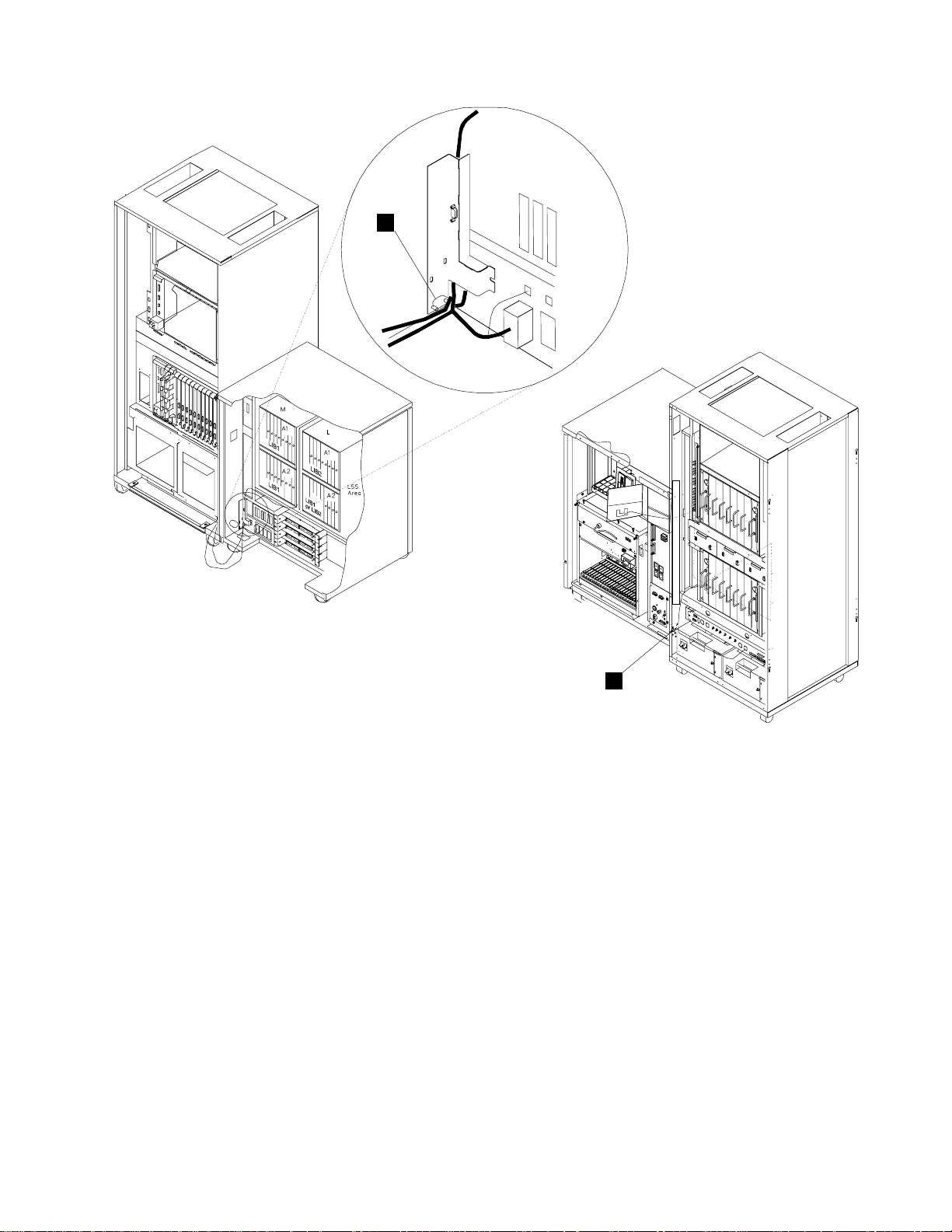

0-1. 3745/3746-900 Power Control Cable Routing .............. xx

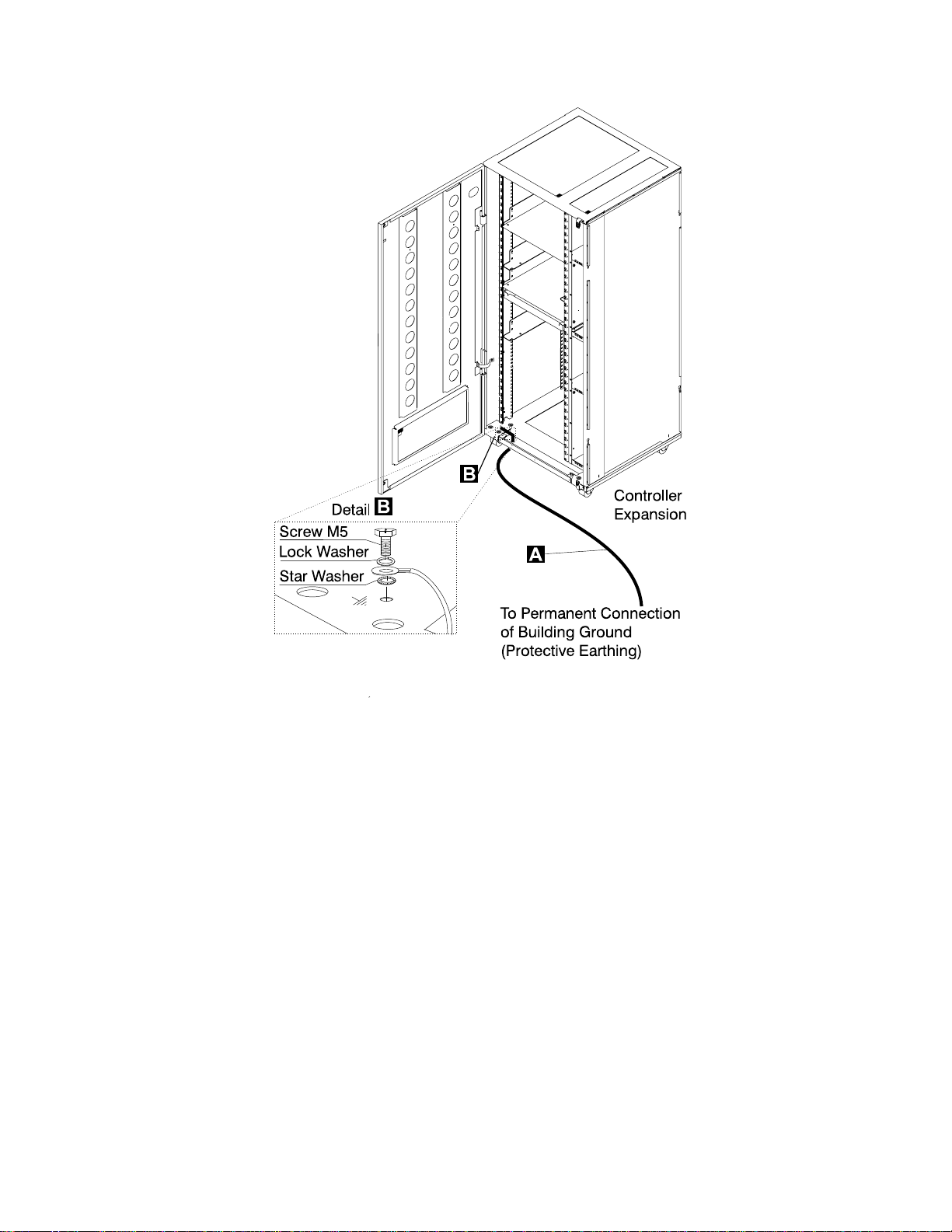

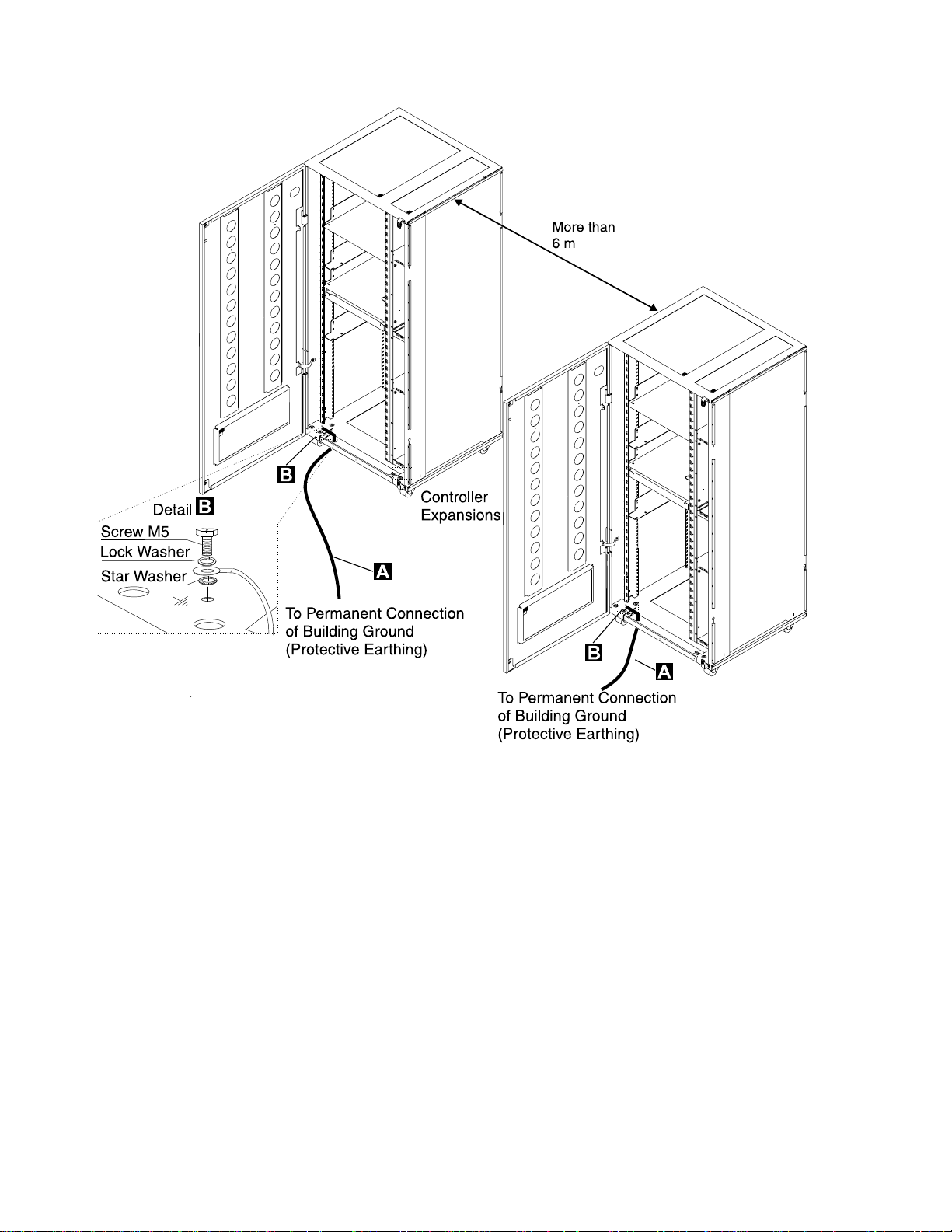

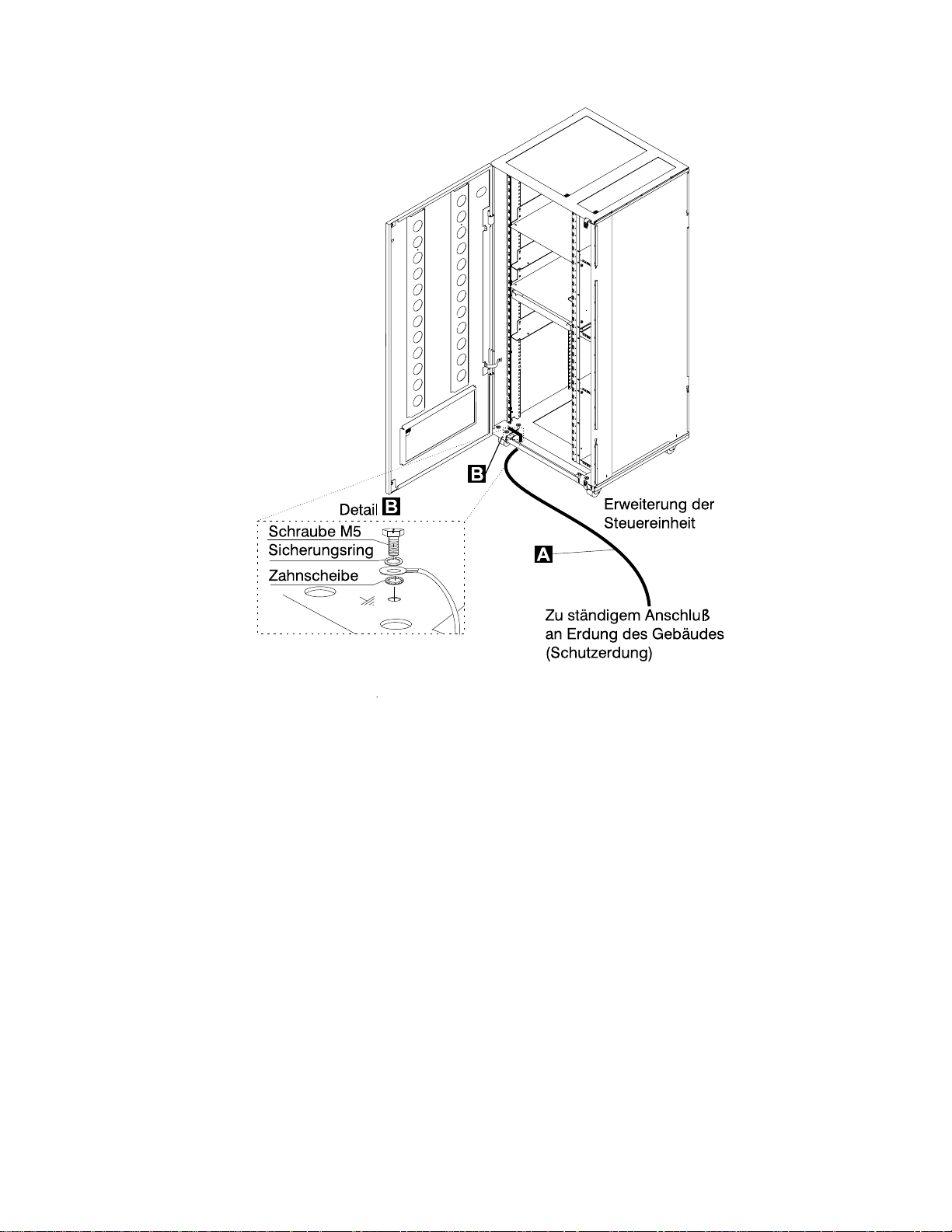

0-2. Ground Wire Connection on Controller Expansion ........... xxi

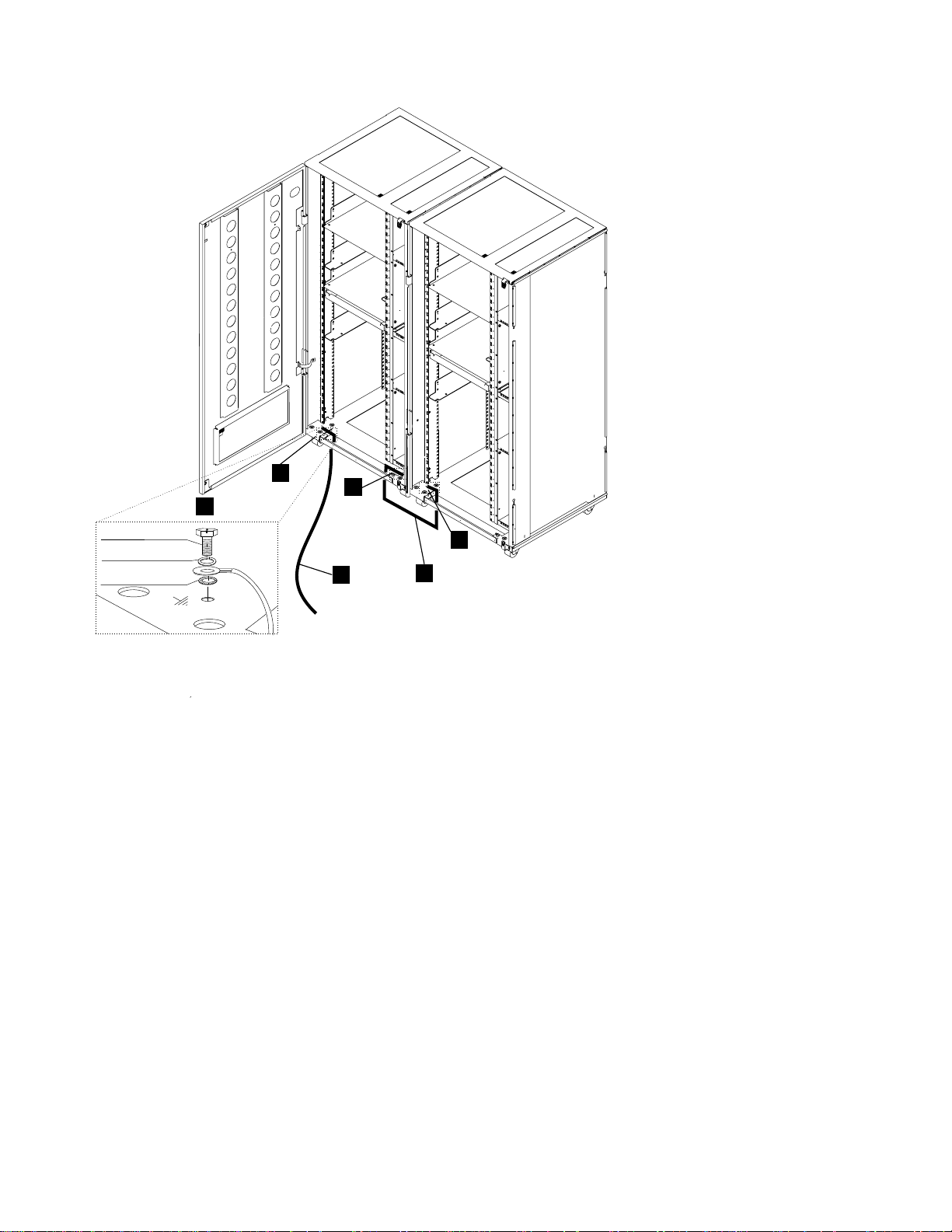

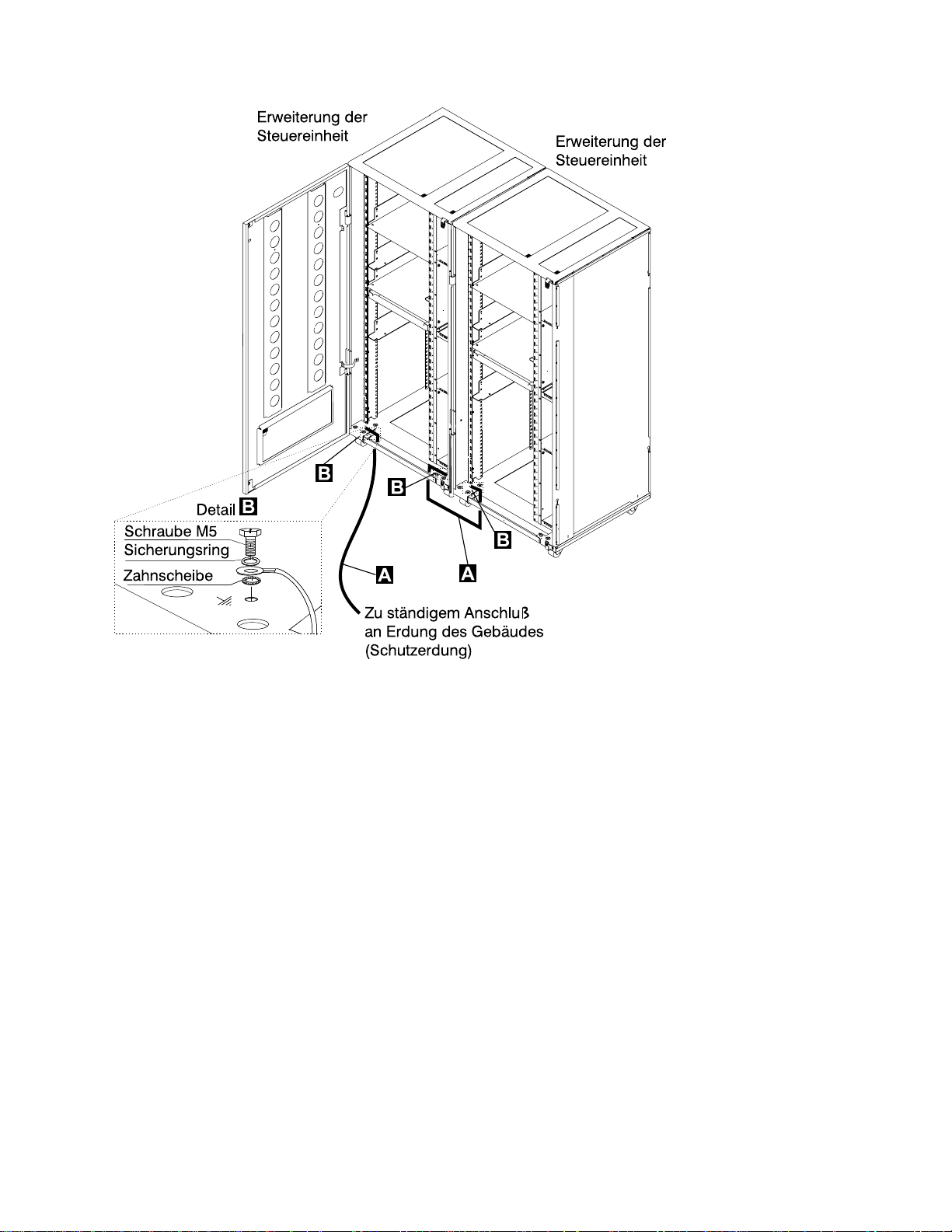

0-3. Ground Wire Connection Between Attached Controller Expansions . xxii

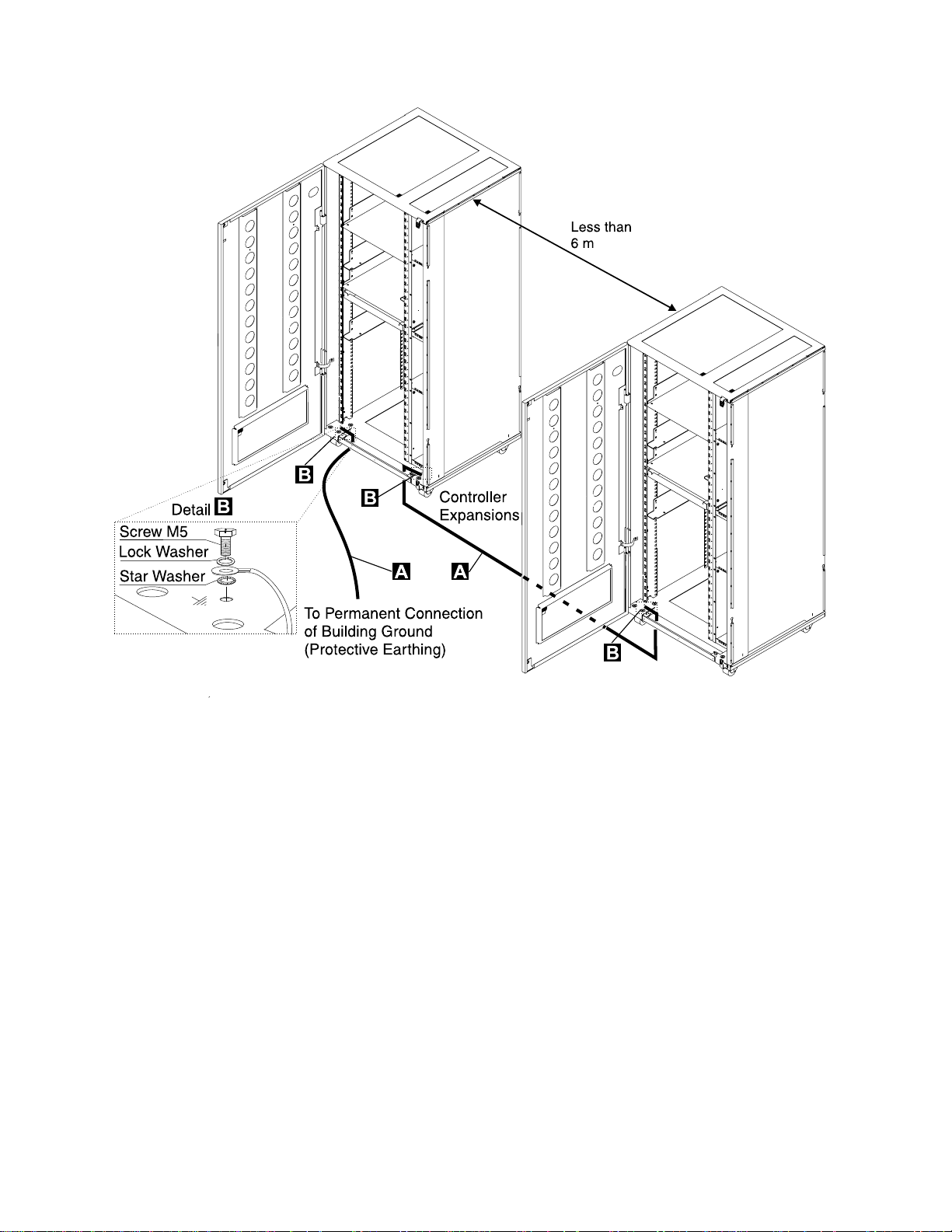

0-4. Ground Wire Connection Between Controller Expansions at Less

than Six Meters .............................. xxiii

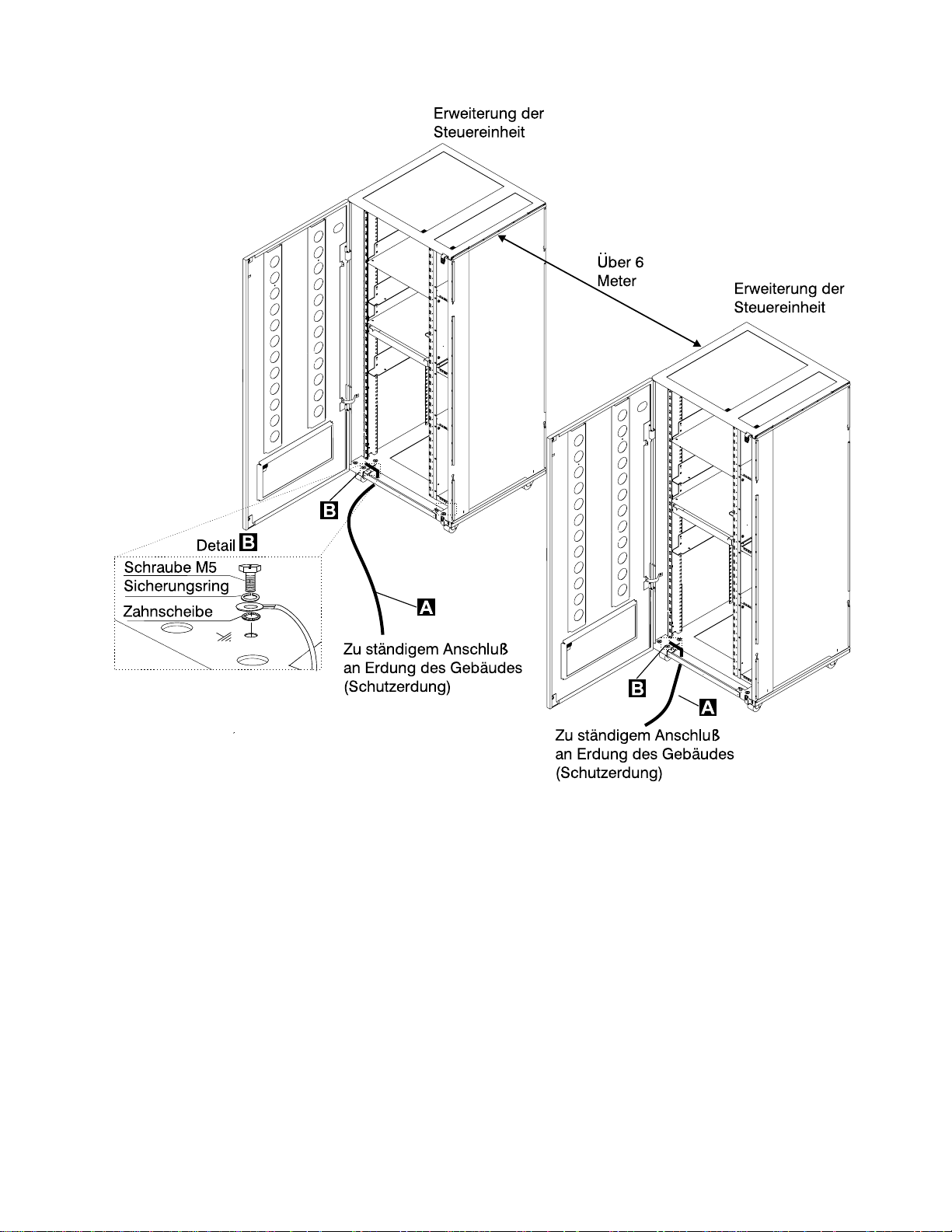

0-5. Ground Wire Connection Between Controller Expansions at More

than Six Meters .............................. xxiv

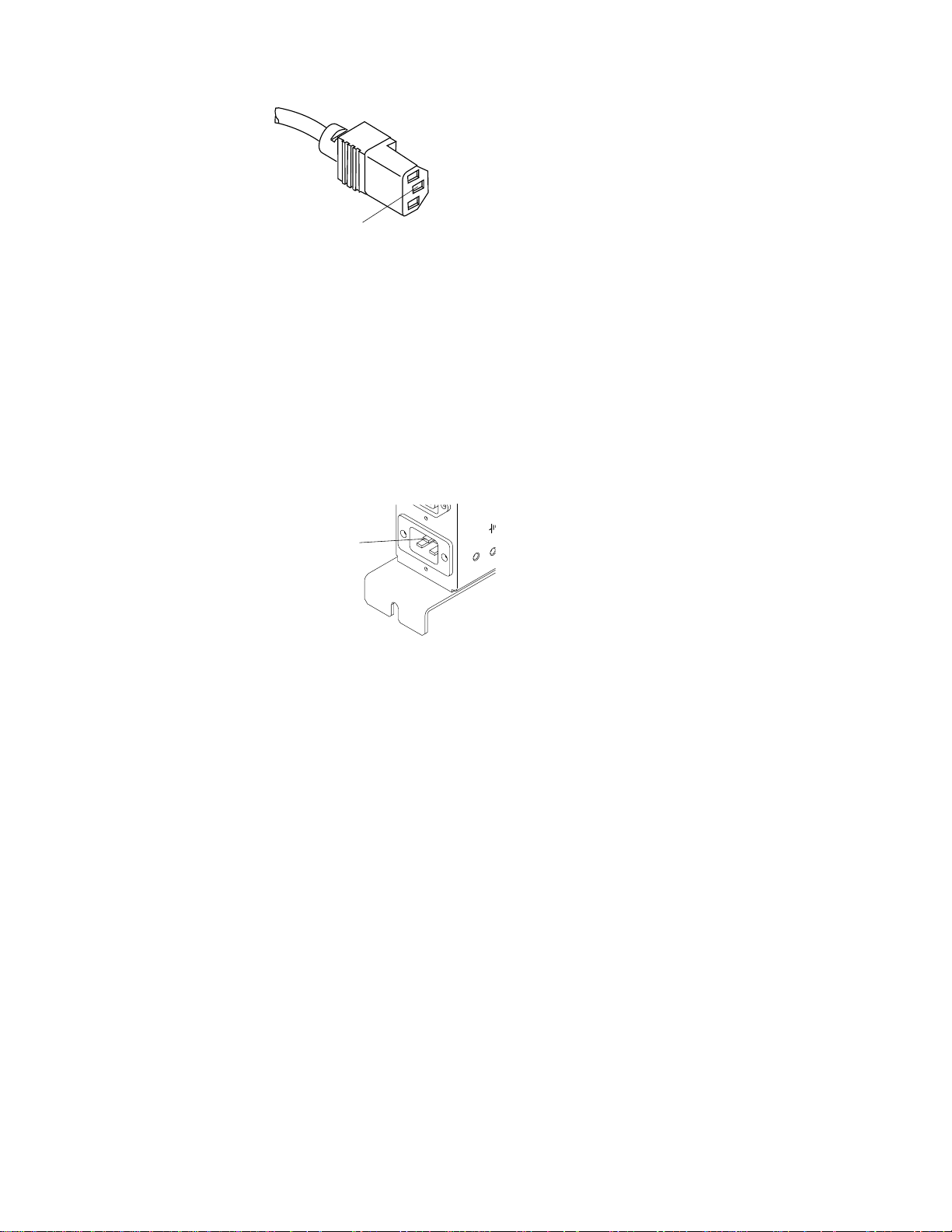

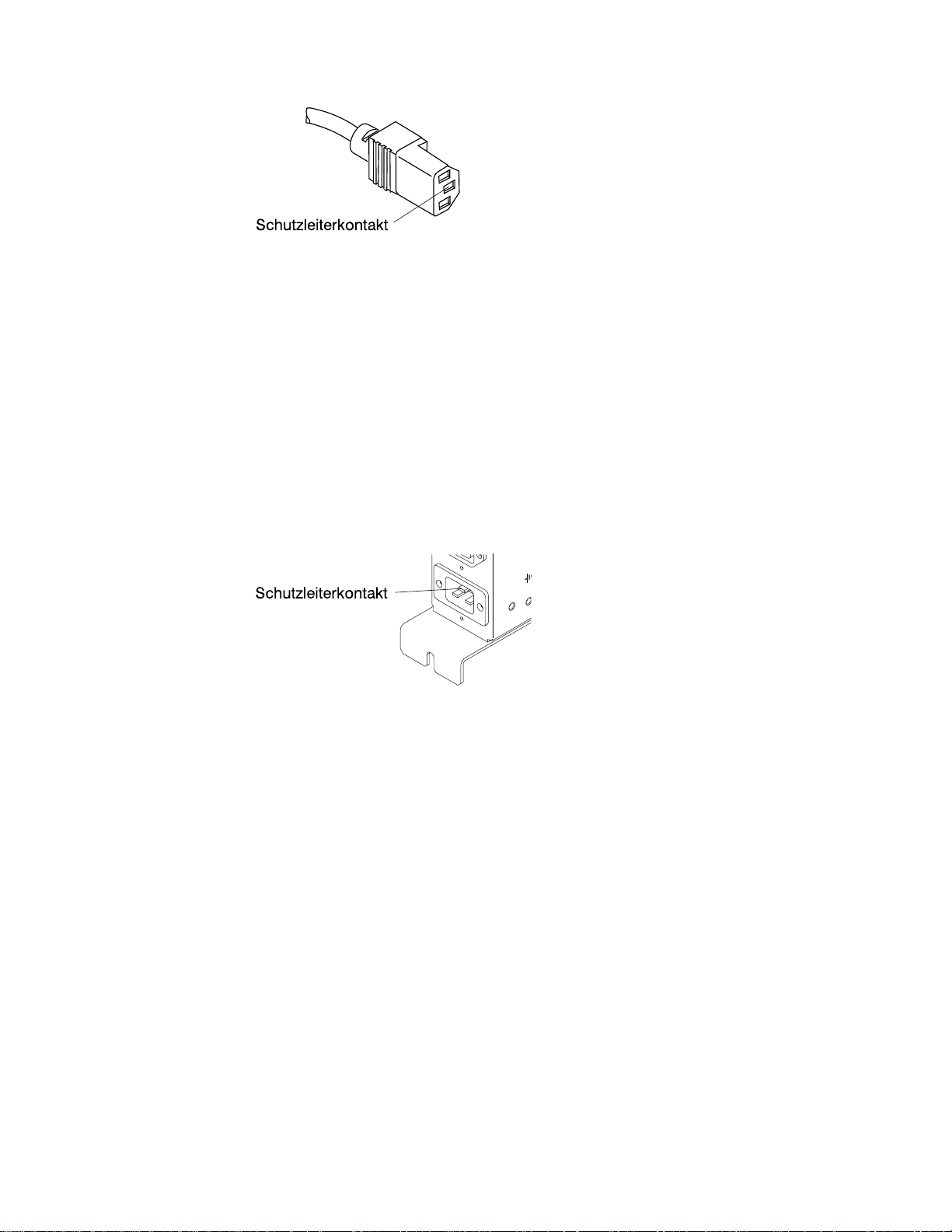

0-6. Ground Pin on Mainline ac/dc Power Cable ............... xxv

0-7. Ground Pin of the Controller Expansion ac Outlet Distribution Box .. xxv

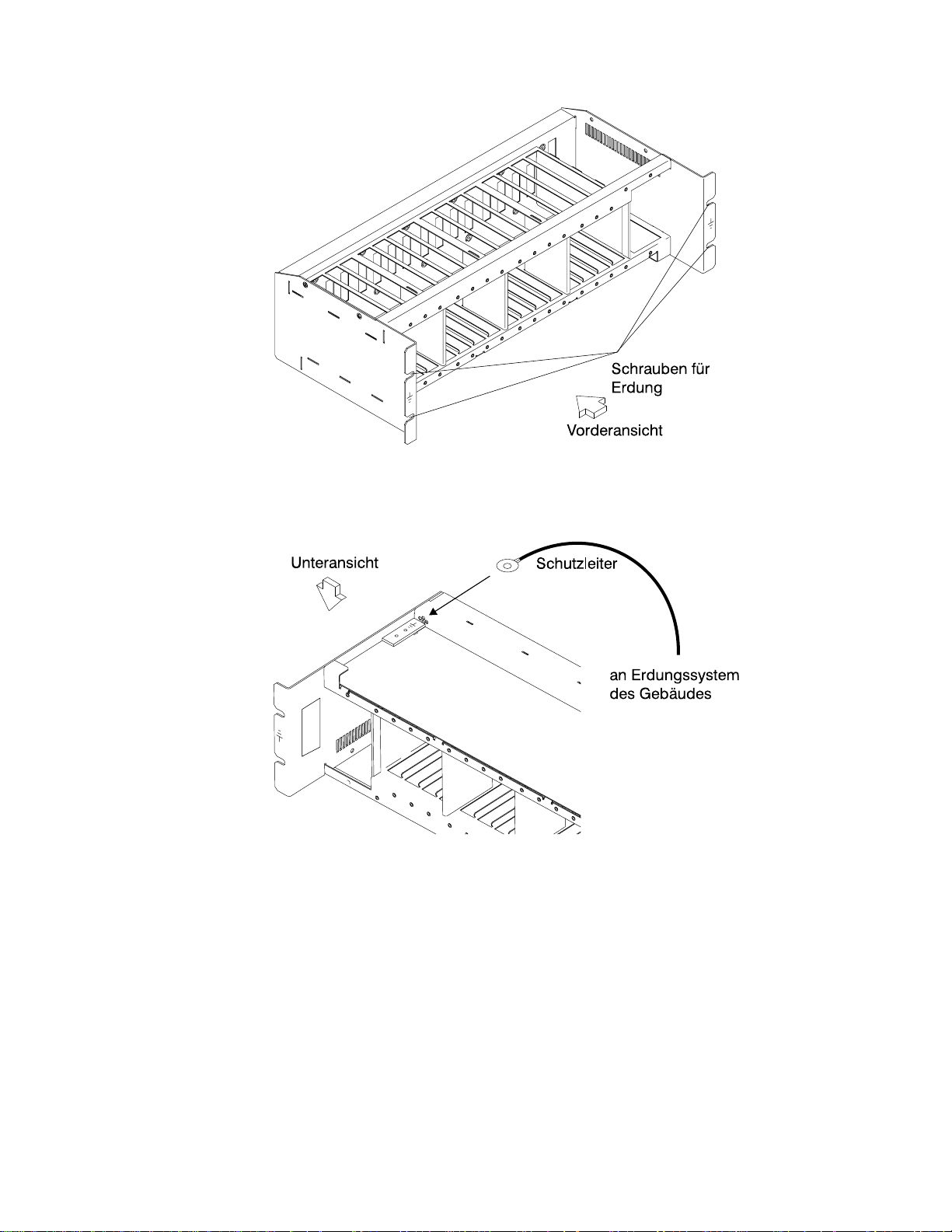

0-8. LCB Grounding Via Screws ....................... xxvi

0-9. LCB Grounding Via Ground Wire .................... xxvi

0-10. Ground Wire Connection ......................... xxvii

0-11. Führung des Stromversorgungskabels bei der 3745/3746-900 ... xxxiii

0-12. Schutzleiteranschluß an der Erweiterung der Steuereinheit ..... xxxiv

0-13. Schutzleiteranschluß zwischen angeschlossenen Erweiterungen der

Steuereinheit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxv

0-14. Schutzleiteranschluß bei einem Abstand von weniger als 6 Meter

zwischen den Erweiterungen der Steuereinheit ............ xxxvi

0-15. Schutzleiteranschluß bei einem Abstand über 6 Meter zwischen den

Erweiterungen der Steuereinheit .................... xxxvii

0-16. Schutzleiterkontakt am Hauptstromversorgungskabel ........ xxxviii

0-17. Schutzleiterkontakt des Wechselstromverteilerkastens der

Erweiterung der Steuereinheit ..................... xxxviii

0-18. Erdung des Verteilerkastens über Schrauben ............. xxxix

0-19. Erdung des Verteilerkastens über Schutzleiter ............. xxxix

0-20. Schutzleiteranschluß . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xl

0-21. 3745 Label and Power Rating Plate Locations (Back) ......... lvii

0-22. 3745 Label and Power Rating Plate Locations (Front) ......... lviii

0-23. 3746 Model 900 (Frame 07) Label Locations .............. lix

0-24. LCB Safety Label Location ......................... lix

0-25. 3745/3746-900 Safety Labels ........................ lx

0-26. 3745/3746-900 Safety Labels ....................... lxi

0-27. LCB Safety Label (PN 80G3928) ..................... lxii

0-28. Controller Expansion Power Rating Plate Location ........... lxii

1-1. Reference Code Screen ......................... 1-14

1-2. TSS Service Screen ............................ 1-63

1-3. Select/Release Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

1-4. Mode Control Screen ........................... 1-64

1-5. TSS/HPTSS/ESS Diagnostic Selection Screen ............ 1-64

1-6. TRSS Service Screen ........................... 1-67

1-7. Select Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-67

1-8. Connect/Disconnect Screen . . . . . . . . . . . . . . . . . . . . . . . 1-68

1-9. TRSS Diagnostic Selection Screen ................... 1-68

1-10. TSS/HPTSS Diagnostic Selection Screen ............... 1-72

1-11. TSS Service Screen ............................ 1-74

1-12. Select/Release Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 1-74

1-13. Mode Control Screen ........................... 1-75

1-14. LIC Types 1 and 4 Wrap Plug (PN 65X8927) ............. 1-75

1-15. LIC Type 3 Wrap Cable (PN 65X8928) ................. 1-75

1-16. LIC Types 5 and 6 Wrap Plug (PN 11F4815) ............. 1-76

Copyright IBM Corp. 1989, 1997 ix

Page 12

1-17. LIC Types 1, 3, and 4 ........................... 1-76

1-18. LIC Types 5 and 6 ............................. 1-77

1-19. 3745 Control Panel Layout ........................ 1-80

2-1. Console Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-2. EPO Location 01S ............................. 2-16

2-3. UEPO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2-4. EPO Location 01S ............................. 2-25

2-5. LAN Attached to the Service Processor ................ 2-42

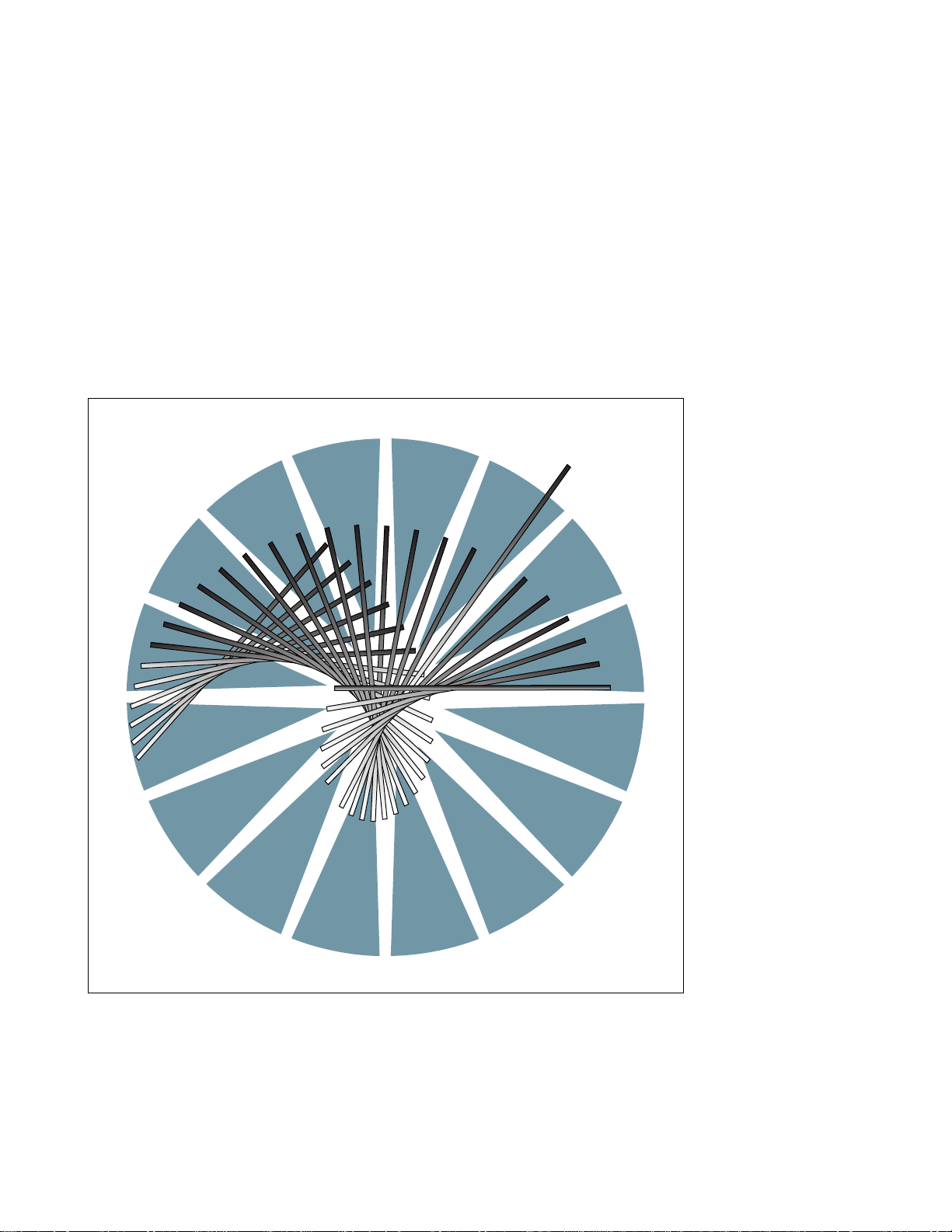

3-1. CBA Diagnostic Coverage ......................... 3-3

3-2. Console Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-3. Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-4. Maintenance Functions Menu ....................... 3-9

3-5. How to Select Diagnostics ........................ 3-10

3-6. How to Enter Options ........................... 3-11

3-7. Error Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-8. LICs Type 1 and 4 (Wrap Plug PN 65X8927) ............. 3-23

3-9. LIC Type 3 (Wrap Cable PN 65X8928) ................. 3-23

3-10. LIC Types 1, 3, and 4 ........................... 3-23

3-11. LICs Type 5 and 6 (Wrap Plug PN 11F4815) ............. 3-24

3-12. LIC Types 5 and 6 ............................. 3-24

4-1. 3745 Frame (Front) ............................. 4-3

4-2. 3745 Frame (Back) ............................. 4-4

4-3. Card Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-4. 3745 Model 17X Basic Board (without TPS, HPTSS, or ESS) ..... 4-6

4-5. 3745 Model 17X (Basic Board with TPS and HPTSS or ESS) .... 4-7

4-6. 3745 Model 130 (Basic Board with TPS) ................. 4-8

4-7. 3745 Model 150 (Basic Board) ....................... 4-9

4-8. 3745 Model 160 (Basic Board) ...................... 4-10

4-9. 3745 Models 130, 150, 160, and 170 (MOSS Board, Cards, and

Connectors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-10. 3745 Model 17A (MOSS Board, Cards, and Connectors) ...... 4-12

4-11. 3745 LIC Unit Type 1 Board and Connectors (for LIC Types 1,3, and

4 in Models 150, 160, and 170) ..................... 4-13

4-12. 3745 LIC Unit Type 2 Board and Connectors (for LIC Types 5 and 6

in Models 150 and 170) .......................... 4-13

4-13. 3745 LIC Unit Type 3 Board and Connectors (for LIC Types 1,3, and

4 in Model 150) .............................. 4-14

4-14. 3745 LIC Board 01M-A2 Packaging ................... 4-15

4-15. 3745 LIC Board 01M-A1 Packaging ................... 4-16

4-16. 3745 LIC Board 01L-A2 Packaging ................... 4-17

4-17. 3745 LIC Board 01L-A2 Packaging (LICs Type 5) .......... 4-18

4-18. 3745 LIC Board 01L-A1 Packaging (LIC type 5) ............ 4-18

4-19. 3745 LIC Board 01L-A2 Packaging (LICs Type 6 Low Speed) ... 4-19

4-20. 3745 LIC Board 01L-A1 Packaging (LICs Type 6 Low Speed) ... 4-19

4-21. 3745 LIC Board 01L-A2 Packaging (LIC Type 6 High Speed) .... 4-20

4-22. 3745 LIC Board 01L-A1 Packaging (LIC Type 6 High Speed) .... 4-20

4-23. 3745 LIC Board 01M-A2 Packaging ................... 4-21

4-24. 3745 Ethernet Lines Tailgate ....................... 4-22

4-25. 3745 High-Speed Lines Tailgate ..................... 4-23

4-26. 3745 Token-Ring Tailgate ........................ 4-24

4-27. 3745 Channel Tailgate .......................... 4-25

4-28. 3745 Channel Tailgate Details. For more details see YZ052 Sheet

2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4-29. 3745 Models 1X0 Console Operator Tailgate ............. 4-26

x 3745 Models 130 to 17A: MIP

Page 13

4-30. 3745 Models 17A Console Operator Tailgate ............. 4-26

4-31. 3745 EPO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4-32. 3745 Control Panel ............................ 4-28

4-33. 3745 Flexible Diskette Drive ....................... 4-29

4-34. 3745 Hard Disk Drive ........................... 4-29

4-35. 3745 Primary Power Box Components ................. 4-30

4-36. 3745 Power Supply 1 Components ................... 4-31

4-37. 3745 Power Supply 2 Components ................... 4-32

4-38. 3745 Fan 1 Components ......................... 4-33

4-39. 3745 Fan 2 Components ......................... 4-33

4-40. CB1 Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4-41. Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4-42. Shipping Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4-43. Channel Tailgate Location ........................ 4-36

4-44. Select Out Switch ............................. 4-36

4-45. Basic Board and CB1 Locations ..................... 4-38

4-46. Location of the LIC Boards ........................ 4-39

4-47. DMUX Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

4-48. DMUX Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4-49. DMUX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4-50. Location of the LIC Boards Type 2 ................... 4-41

4-51. SMUX Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

4-52. SMUX Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4-53. SMUX Link and Cable ........................... 4-42

4-54. Location of the LIC Boards ........................ 4-44

4-55. LIC 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4-56. LIC Board Type 1 and 2 ......................... 4-45

4-57. LIC Board Type 3 ............................. 4-45

4-58. Panel, MOSS, and CB1 Locations .................... 4-46

4-59. MOSS Right Cover ............................ 4-46

4-60. Panel Cable Location on MOSS Board ................. 4-47

4-61. Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

4-62. Panel Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4-63. Battery Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4-64. Power Services Screen .......................... 4-49

4-65. Acknowledge Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

4-66. Fan 1 and CB1 Locations ......................... 4-50

4-67. Fan 1 Air Flow Detector and Power Cables .............. 4-50

4-68. Fan 2 and CB1 Locations ......................... 4-51

4-69. Fan 2 Air Flow Detector and Power Cables .............. 4-51

4-70. FDD and CB1 Location .......................... 4-52

4-71. PS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4-72. MOSS Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4-73. FDD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4-74. FDD Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4-75. HDD and CB1 Locations ......................... 4-56

4-76. HDD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

4-77. New Type of HDD ............................. 4-58

4-78. HDD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4-79. HDD Connectors and Jumpers ...................... 4-60

4-80. HDD Connectors and Jumpers ...................... 4-60

4-81. Basic Board and CB1 Locations .................... 4-61

4-82. CB1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

4-83. Basic Board Grid .............................. 4-62

Figures xi

Page 14

4-84. Terminator Card Locations ........................ 4-62

4-85. CB1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

4-86. ESS Tailgate Location ........................... 4-64

4-87. ESS Tailgate and Basic board ...................... 4-65

4-88. ESS Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

4-89. EAC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

4-90. Power Supply 1 (PS1) and CB1 Locations ............... 4-67

4-91. Power Supply 1 (PS1) Cover ....................... 4-67

4-92. Primary Power Box ............................ 4-68

4-93. Power Supply 1 .............................. 4-68

4-94. Primary Power Box, Power Supply 2, and CB1 Locations ...... 4-69

4-95. Cable Locations on Primary Power Box ................ 4-70

4-96. PS2 in Primary Power Box ........................ 4-70

4-97. PS2 and Primary Power Box Assembly ................. 4-71

4-98. Primary Power Box and CB1 Locations ................. 4-73

4-99. EPO Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

4-100. Cables on Primary Power Box ...................... 4-74

4-101. Primary Power Box and PS2 Cover Removal ............. 4-74

4-102. EPO Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

4-103. Basic Board, MOSS Board, and CB1 Locations ............ 4-77

4-104. Basic Board and MOSS Covers ..................... 4-78

4-105. Basic Board Grid .............................. 4-78

4-106. FDS and Multivoltage Cable Locations on the PS1 .......... 4-78

4-107. Fan2 Air Flow Detector and Power Connectors ............ 4-79

4-108. MOSS to Basic Cable Locations ..................... 4-79

4-109. Basic Board Enclosure .......................... 4-79

4-110. Basic Board Cables ............................ 4-80

4-111. Basic Assembly 1 ............................. 4-81

4-112. Basic Assembly 2 ............................. 4-82

4-113. Y and Z Rows ............................... 4-83

4-114. CB1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

4-115. LIC Board Type 1 Locations ....................... 4-84

4-116. DMUX Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

4-117. LIC Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

4-118. LIC Board Assembly ............................ 4-87

4-119. CB1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

4-120. SMUX Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

4-121. LIC Board Type 2 Locations ....................... 4-89

4-122. SMUX Link and Cable ........................... 4-89

4-123. LIC Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

4-124. LIC Board Assembly ............................ 4-90

4-125. MOSS Board and CB1 Locations .................... 4-92

4-126. MOSS Board Covers ........................... 4-92

4-127. MOSS Board Cards and Cables ..................... 4-93

4-128. MOSS Board Enclosure .......................... 4-94

4-129. CB1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

4-130. Select Out Switch ............................. 4-96

4-131. Channel Tailgate and Basic Board Grid ................ 4-97

4-132. Channel Tailgate, Cables, and Basic Board .............. 4-97

xii 3745 Models 130 to 17A: MIP

Page 15

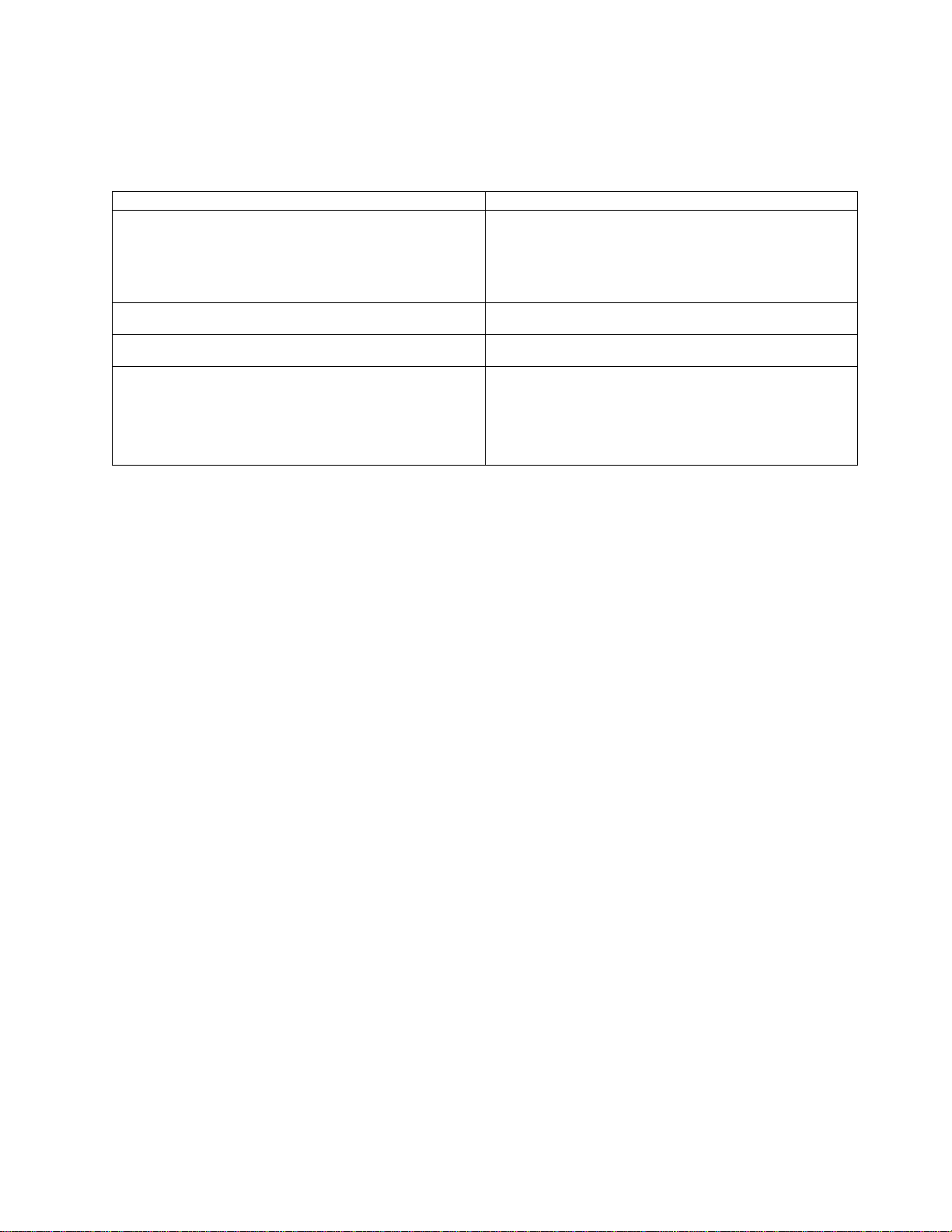

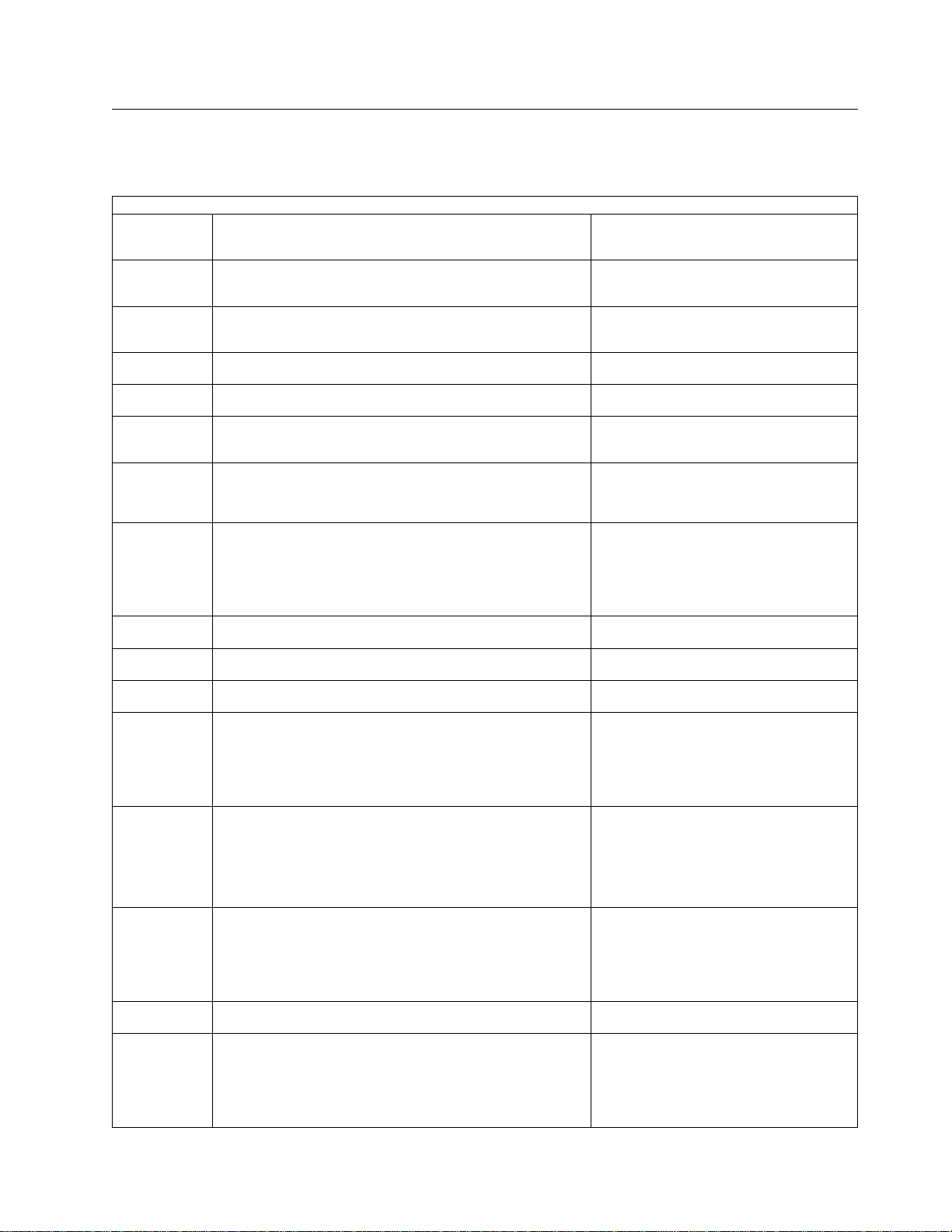

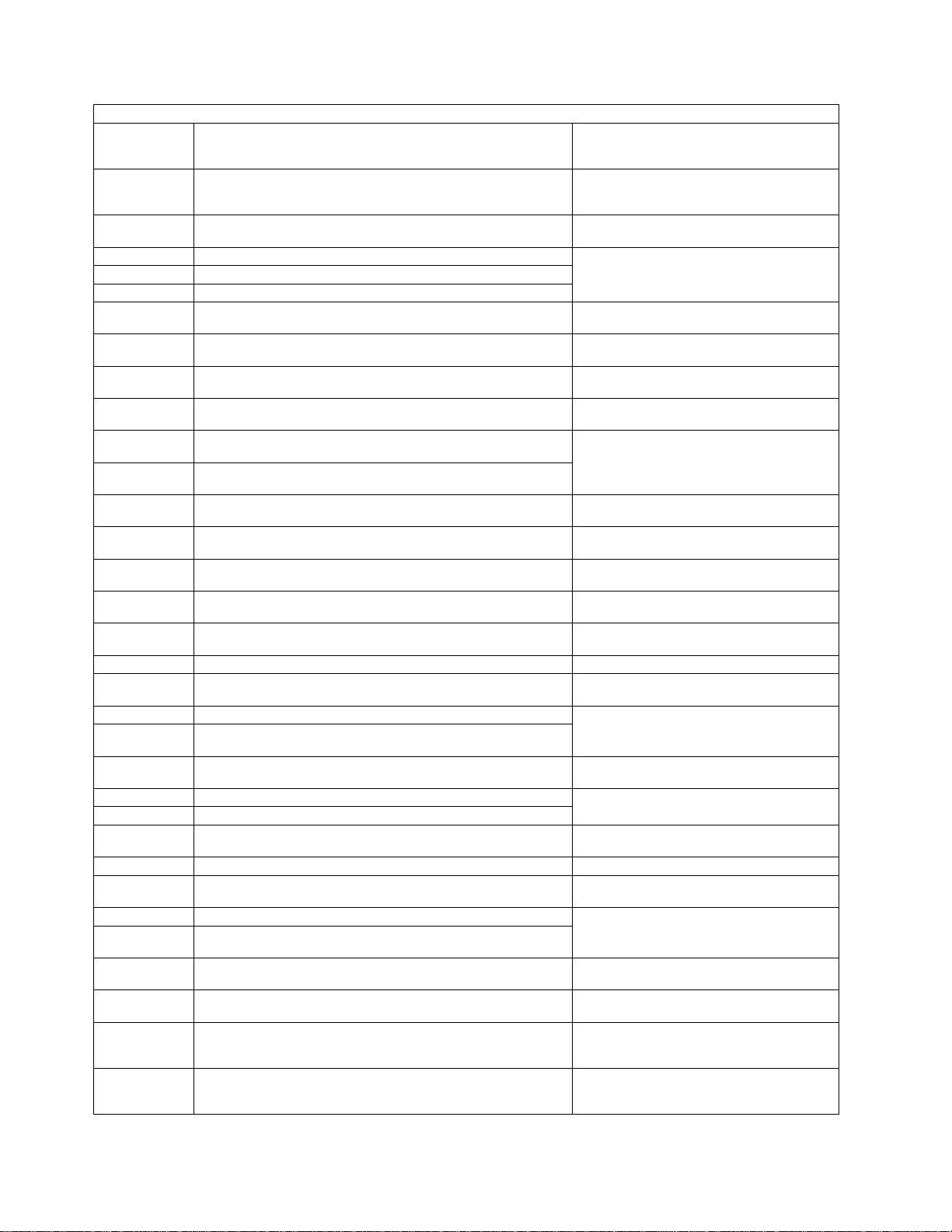

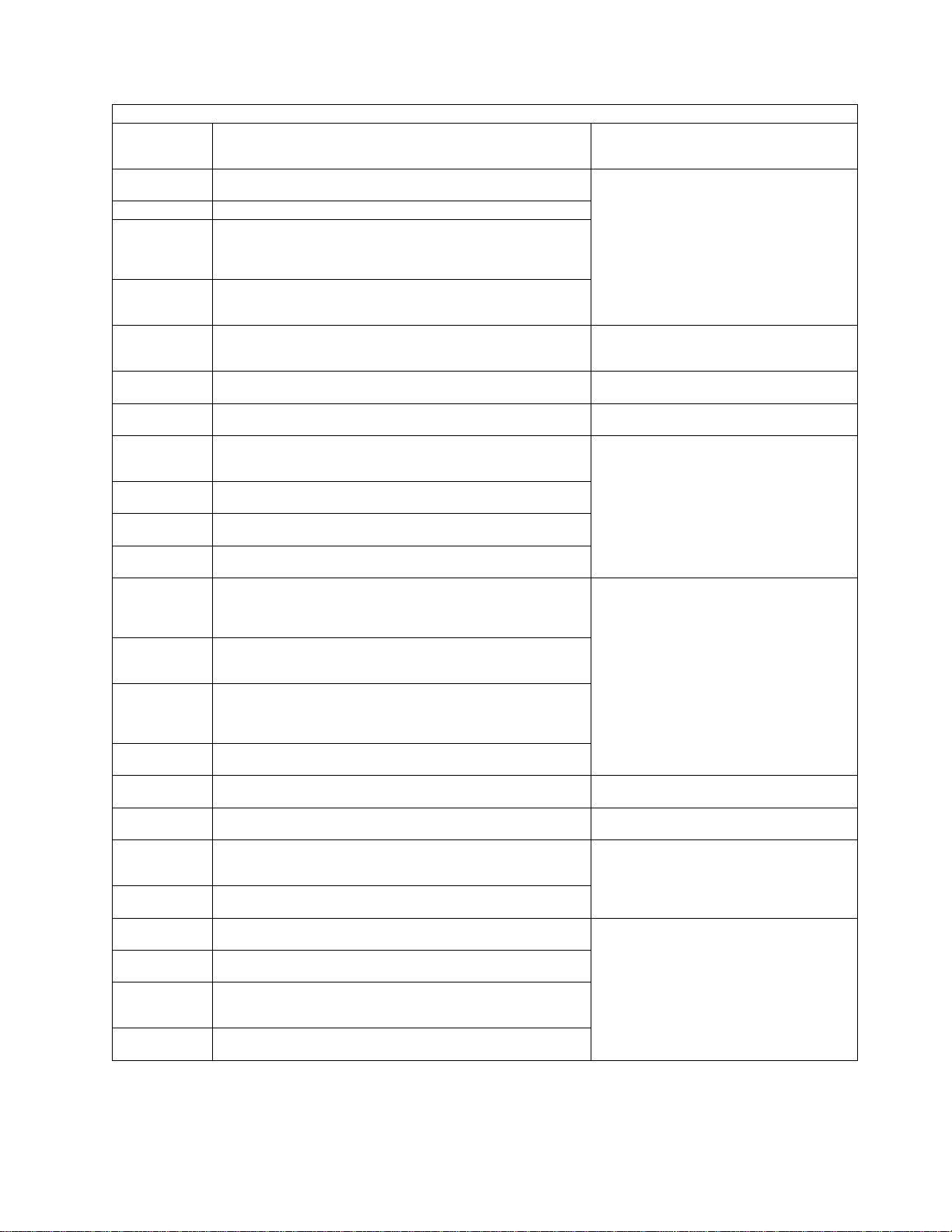

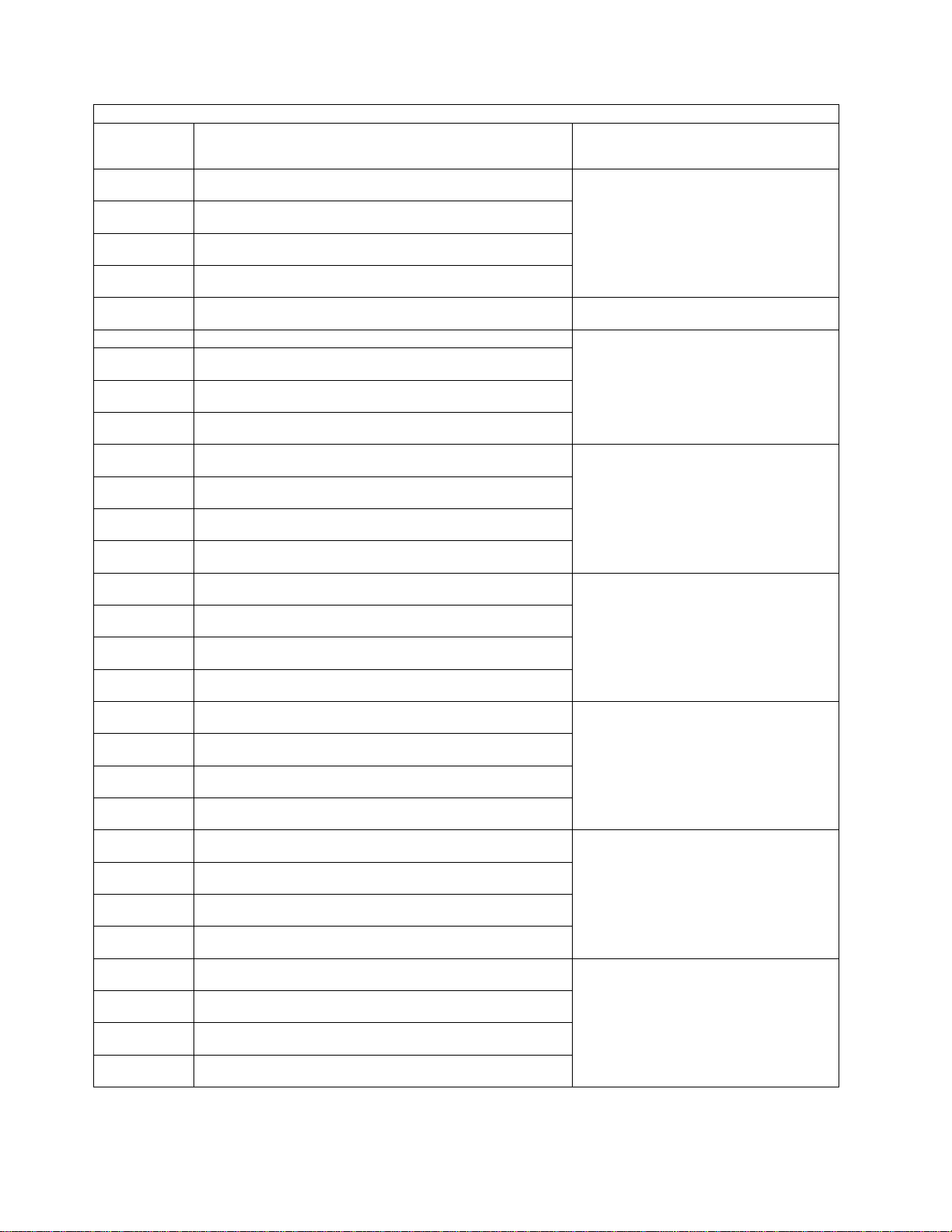

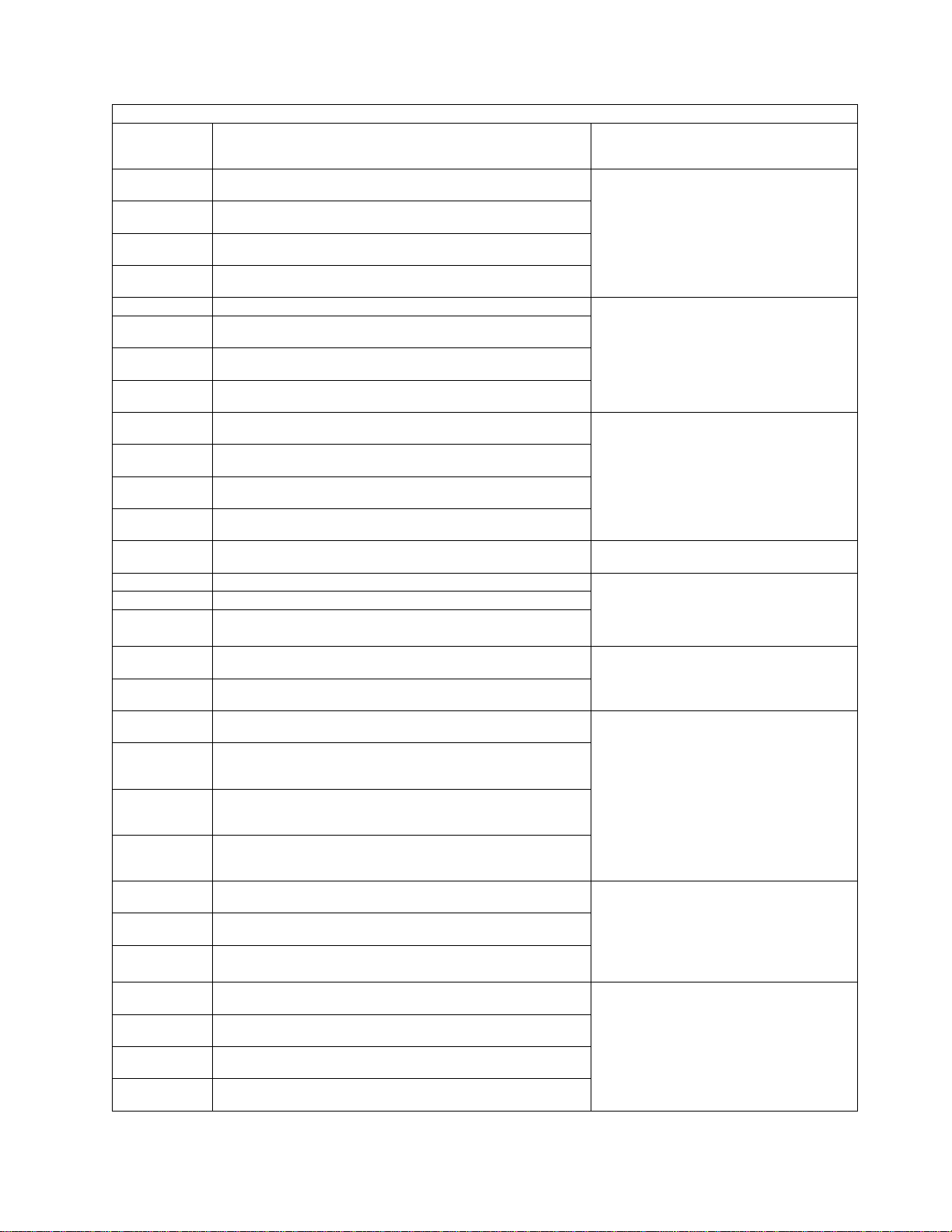

Tables

0-1. Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

0-2. ac Input Adjustment ............................ xxviii

0-3. LED Status Versus 3746-900 States ................... xxx

0-4. 3745 Power Supply CP/CB and Fuse Reference ............ xxx

0-5. Teilenummern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xli

0-6. Einstellung der Spannung des Wechselstromeingangs ......... xli

0-7. Bedeutung der LEDs am Bedienungsfeld der 3746-900 ........ xlii

0-8. Stromversorgung der 3745, Sicherungsautomaten (CB),

Überstromschutzschalter (CP) und Sicherungen (F) .......... xliii

0-9. Safety Label Numbers by Country ..................... lxiii

1-1. General Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-2. 3745 Console Symptoms ......................... 1-10

1-3. Control Panel Symptoms ......................... 1-11

1-4. Power Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-5. Panel Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1-6. 3745 FRU Table .............................. 1-49

1-7. 3745 Cable Location ........................... 1-52

1-8. 3745 Diagnostic Requirements ...................... 1-60

1-9. Diagnostic Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-65

1-10. Panel Display Values ........................... 1-81

2-1. Wrap plug PN ................................ 2-6

2-2. 3745 Control Panel Code ......................... 2-32

2-3. Icons Color Selection Table ....................... 2-38

3-1. Wrap Plugs for Testing ARC Assembly A and ARC Assembly B (with

Cable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3-2. Wrap Plugs for LIC Testing ........................ 3-22

3-3. Wrap Plugs for Testing ARC Assembly B (without Cable) ...... 3-22

4-1. TIC Position and Ring Address ...................... 4-5

4-2. Basic Board Configurations ......................... 4-6

4-3. DMUX Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-4. SMUX Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-5. 3745 Ethernet Line Locations ...................... 4-22

4-6. 3745 High-Speed Line Locations .................... 4-23

4-7. 3745 Token-ring Line Locations ..................... 4-24

4-8. Channel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4-9. 3745 Power Supply Cross Reference .................. 4-31

4-10. Select Out Switches According to CADR Cards ............ 4-36

4-11. Voltage Test Points ............................ 4-53

B-1. Customer Documentation for the 3745 Models 130 to 17A and 3746

Model 900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B-2. Service Documentation for the 3745 Models 1x0 and 17A, and 3746

Model 900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Copyright IBM Corp. 1989, 1997 xiii

Page 16

xiv 3745 Models 130 to 17A: MIP

Page 17

Notices

References in this publication to IBM products, programs, or services do not imply

that IBM intends to make these available in all countries in which IBM operates.

Any reference to an IBM product, program, or service is not intended to state or

imply that only IBM's product, program, or service may be used. Any functionally

equivalent product, program, or service that does not infringe any of IBM's intellectual property rights may be used instead of the IBM product, program, or service.

Evaluation and verification of operation in conjunction with other products, except

those expressly designated by IBM, is the user's responsibility.

IBM may have patents or pending patent applications covering subject matter in

this document. The furnishing of this document does not give you any license to

these patents. You can send license inquiries, in writing, to the IBM Director of

Licensing, IBM Corporation, 500 Columbus Avenue, Thornwood, New York 10594,

U.S.A.

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council Directive 89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility. IBM can not accept responsibility for any failure to

satisfy the protection requirements resulting from a non-recommended modification

of the product, including the fitting of non-IBM option cards.

Electronic Emission Notices

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. IBM is not responsible for any radio or television interference caused by using other than recommended cables and connectors or by

unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Copyright IBM Corp. 1989, 1997 xv

Page 18

Industry Canada Compliance Statement

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Avis de conformité aux normes d'Industrie Canada

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement

sur le matériel brouilleur du Canada.

Japanese Voluntary Control Council For Interference (VCCI) Statement

This equipment is in the 1st Class category (information equipment to be used in

commercial and/or industrial areas) and conforms to the standards set by the Voluntary Control Council for Interference by Information Technology Equipment aimed

at preventing radio interference in commercial and industrial areas.

Consequently, when used in a residential area or in an adjacent area thereto, radio

interference may be caused to radios and TV receivers, and so on.

Read the instructions for correct handling.

Korean Communications Statement

Please note that this device has been approved for business purpose with regard to

electromagnetic interference. If you find this is not suitable for your use, you may

exchange it for a non-business one.

New Zealand Radiocommunications (Radio) Regulations

Attention: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate

measures.

Trademarks and Service Marks

The following terms, denoted by an asterisk (*), used in this publication, are trademarks or service marks of IBM Corporation in the United States or other countries:

ESCON IBM OS/2

NetView RETAIN

The following terms, denoted by a double asterisk (**), used in this publication, are

trademarks of other companies:

Hayes Hayes Microcomputer Products, Inc.

Tektronix Tektronix, Incorporated.

xvi 3745 Models 130 to 17A: MIP

Page 19

Safety

Product Safety Information

General Safety

This product meets IBM safety standards.

For more information, see the following manual:

IBM 3745 Communication Controller All Models

IBM 3746 Nways Multiprotocol Controller Models 900 and 950

Safety Information

Service Inspection Safety Procedures

, GA33-0400.

Service Inspection Safety Procedures for the 3745, 3746-900, and Controller Expansion English

Sicherheitsüberprüfungen für IBM 3745, 3746-900 und die Erweiterung der Steuereinheit Deutsch

xviii

xxxi

xliii

Copyright IBM Corp. 1989, 1997 xvii

Page 20

Service Inspection Safety Procedures for the 3745, 3746-900, and

Controller Expansion

Important

This procedure addresses the 3745, 3746-900, and the controller expansion. If one of these machines

is not present, ignore the statement concerning this machine in the following procedure.

Introduction

A safety inspection procedure for the 3745, 3746-900, and controller expansion should be performed:

When it is inspected for an IBM agreement

When IBM service is requested and no service has recently been performed by IBM

When an alterations and attachments review is performed

When changes have been made to the equipment that might affect its safety.

If the inspection indicates unacceptable safety conditions, the conditions must be corrected before IBM

services the machine.

Note: The correction of any unsafe condition is the responsibility of the owner of the equipment.

Safety

The 3745, 3746-900, and controller expansion areas and functions checked through these procedures are:

1. External covers

2. Safety labels

3. Safety covers and shields

4. Grounding (earthing)

5. Circuit breaker and protector rating

6. Input power voltage

7. Power control switch

8. Power ON indicator.

Note: The 3746-900 is powered ON and OFF through the basic 3745 frame, from a host, locally, or from

the service processor.

Hazardous voltages are still present in some areas of the 3745 and the 3746-900 when power is

OFF.

Steps 1 through 6 must be performed after power OFF as follows:

CB1s are switched OFF on the 3745 and 3746-900.

All equipment installed in the controller expansion (if present) is powered OFF.

Power supplies for the 3745, 3746-900, and controller expansion at customer's premises are

switched OFF.

Do not remove the power cord and ground strap .A/ of the controller expansion in order to maintain

the ground protection (see Figure 0-2 on page xxi, Figure 0-3 on page xxii, Figure 0-4 on page xxiii,

or Figure 0-5 on page xxiv).

1External Covers

Check that:

They are all present on the 3745, 3746-900, and controller expansion.

They are locked with two kinds of locks: flat blade screw for the IBM access area and hex head

for the customer access area (refer to the

17A, Parts Catalog

They can be fully opened.

, S135-2012).

xviii 3745 Models 130 to 17A: MIP

IBM 3745 Communication Controller Models 130 to

Page 21

Safety

Appropriate service clearance and access are provided around the frames with external covers

opened.

Leave all external covers opened to allow further safety inspection steps.

2Safety Labels

Check that:

All the safety labels are at the places indicated by letters in “Safety Label Locations” on

page lvii.

Each label is of the model corresponding to the letter as shown in “3745/3746-900 Safety Label

Identifications” on page lx.

3 Safety Covers and Shields

Referring to the FRU location (Chapter 4), check that:

All the safety covers are present and secured with screws.

All the voltage terminal boards (TBs) are protected by a plastic shield screwed on top of the TB.

4Grounding (Earthing)

Note

In this book, "ground" means that the equipment must be connected to the earth.

a Grounding on the 3745

Refer to YZ110 for grounding jumper/contact locations. .

Check that:

Electrical continuity is assured between the frame ground and the terminals indi-

cated on the ground distribution diagrams.

Electrical continuity is assured between the 3745, frame grounds, and to the premises

grounding system, through the 3745 power cord.

b Grounding on the 3746-900 and Controller Expansion to the Premises Grounding

System

Electrical continuity is assured between their frame ground and premises grounding

system through their power cords.

The 3746-900 is grounded to the 3745 via the power control cable (see Figure 0-1 on

page xx).

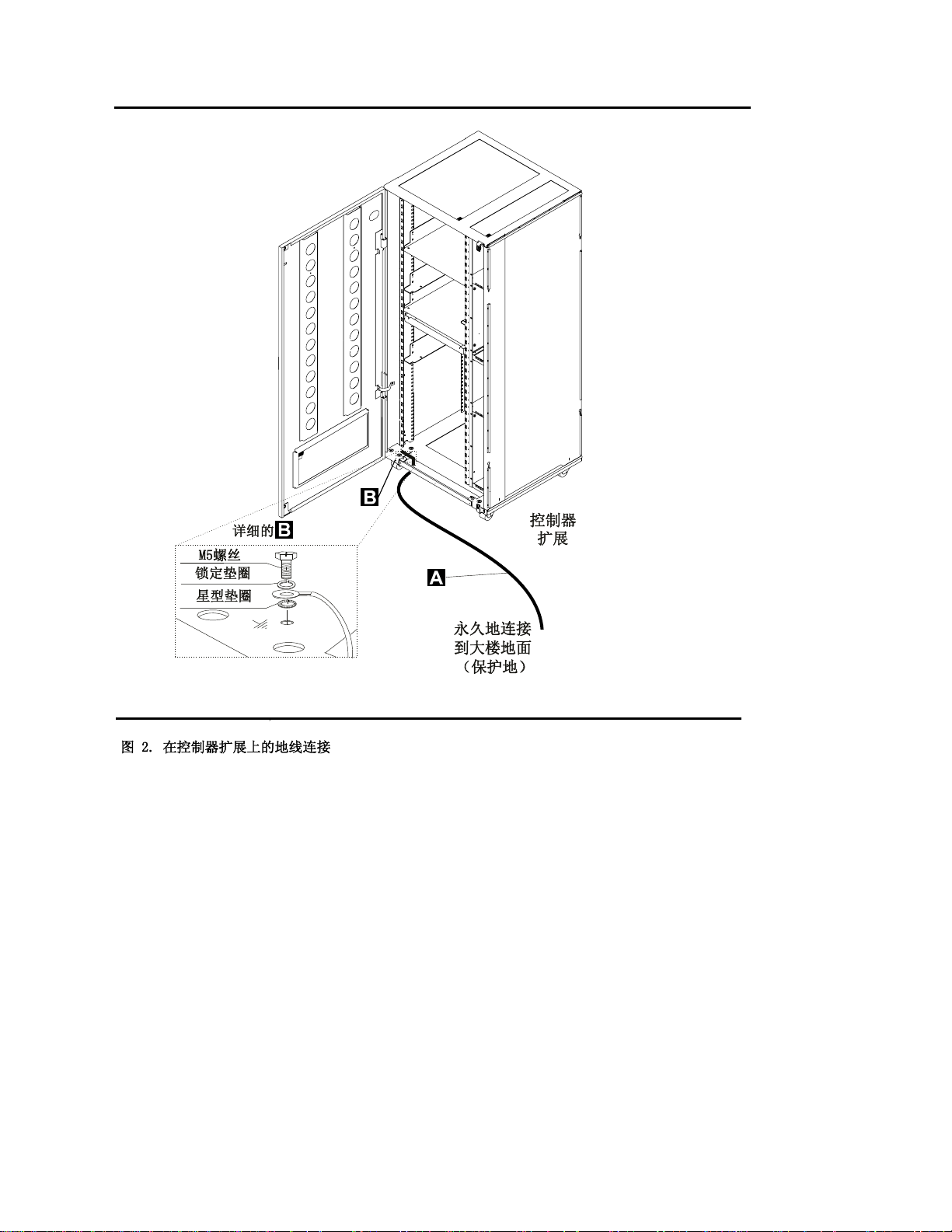

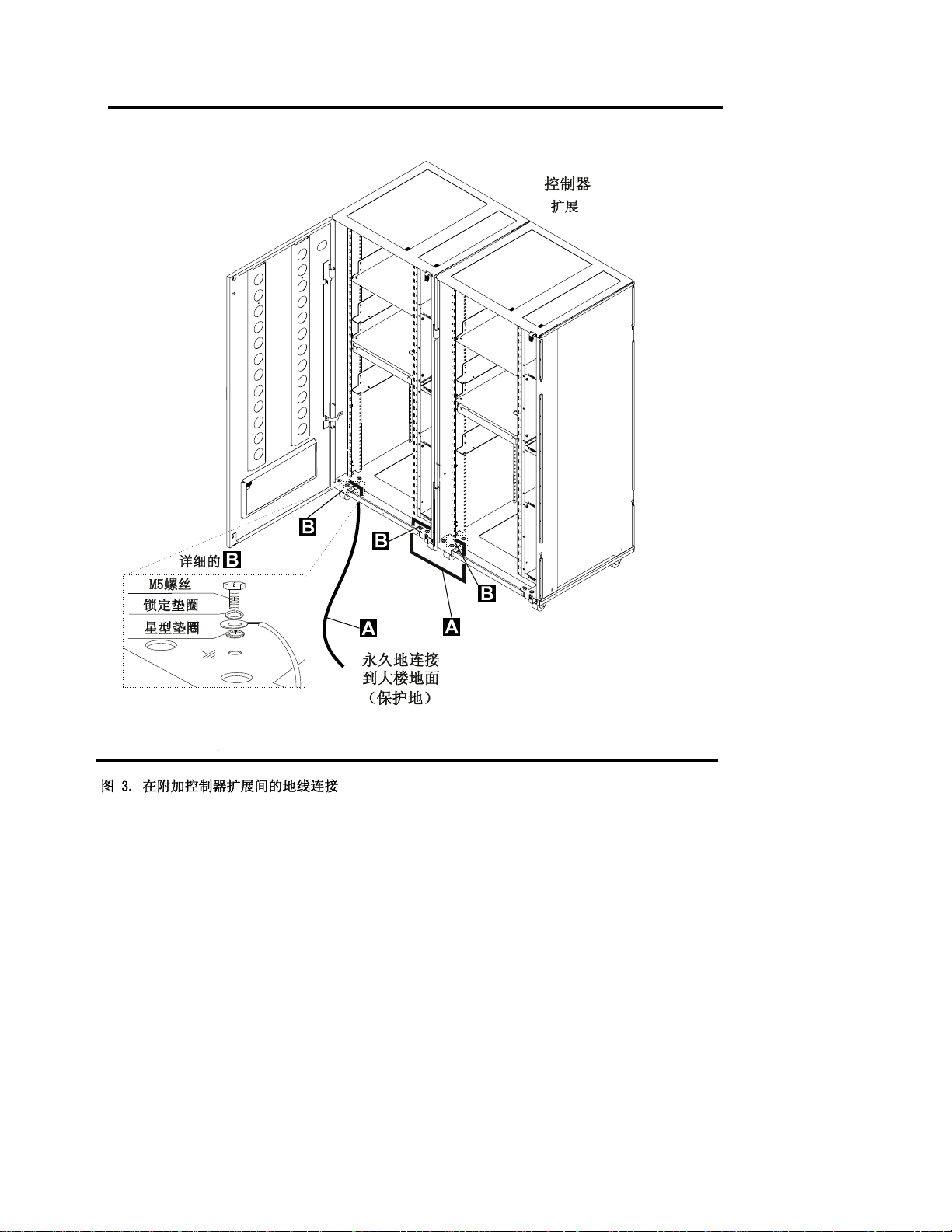

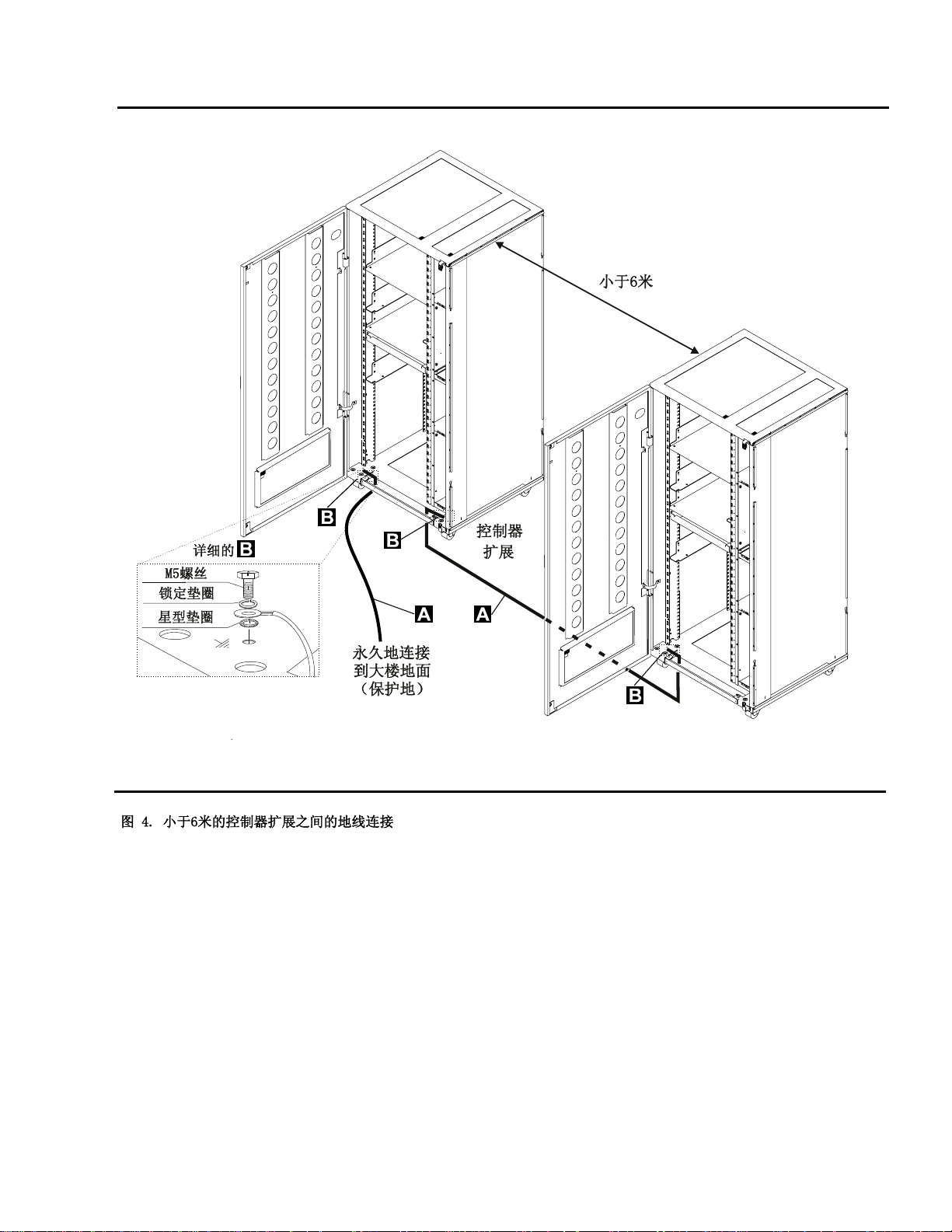

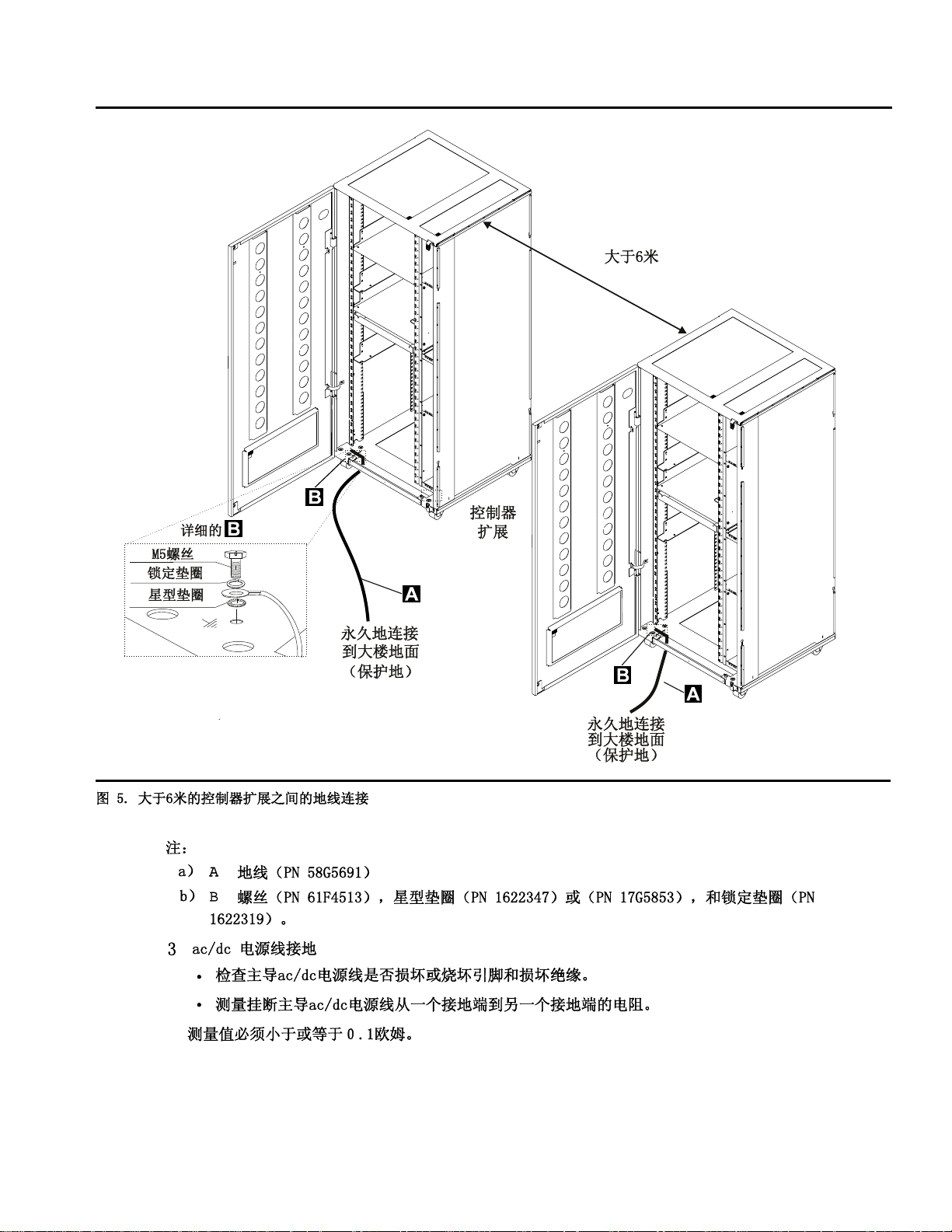

For the controller expansion, an additional ground wire .A/ is also used (see Figure 0-2 on

page xxi, Figure 0-3 on page xxii, Figure 0-4 on page xxiii, or Figure 0-5 on page xxiv).

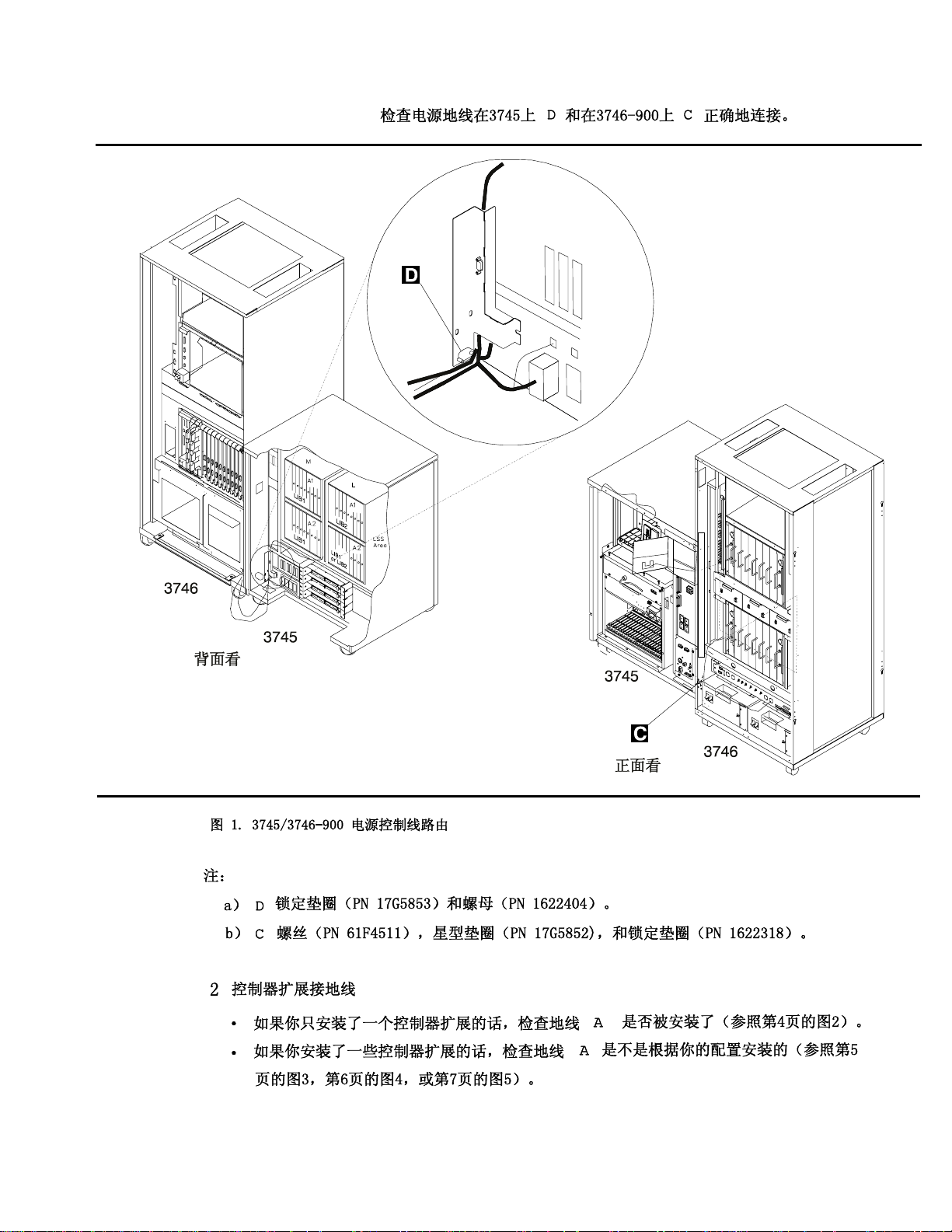

1 3745/3746-900 Power Control Cable

Check that the power ground cable is correctly connected in the 3745 .D/ and in the

3746-900 .C/.

Safety xix

Page 22

Safety

Figure 0-1. 3745/3746-900 Power Control Cable Routing

Notes:

a) .D/Lock washer (PN 17G5853) and nut (PN 1622404).

b) .C/Screw (PN 61F4511), star washer (PN 17G5852), and lock washer

(PN 1622318).

2 Controller Expansion Ground Wire Cable

If you have only one controller expansion installed, check that the ground wire .A/ is

installed (see Figure 0-2 on page xxi).

If you have several controller expansions installed, check that the ground wires .A/

are installed according to your configuration (see Figure 0-3 on page xxii,

Figure 0-4 on page xxiii, or Figure 0-5 on page xxiv).

xx 3745 Models 130 to 17A: MIP

Page 23

Safety

Figure 0-2. Ground Wire Connection on Controller Expansion

Safety xxi

Page 24

Controller

Expansion

Safety

B

B

B

Detail

Screw M5

Lock Washer

Star Washer

A

Figure 0-3. Ground Wire Connection Between Attached Controller Expansions

A

To Permanent Connection

of Building Ground

(Protective Earthing)

B

A

xxii 3745 Models 130 to 17A: MIP

Page 25

Safety

Figure 0-4. Ground Wire Connection Between Controller Expansions at Less than Six Meters

Safety xxiii

Page 26

Safety

Figure 0-5. Ground Wire Connection Between Controller Expansions at More than Six Meters

Notes:

a) .A/Ground wire (PN 58G5691)

b) .B/Screw (PN 61F4513), star washer (PN 1622347) or (PN 17G5853), and lock

washer (PN 1622319).

3 ac/dc Power Cable Ground Wire

Check the mainline ac/dc power cable for damaged or burned pins and broken insu-

lation.

Measure the resistance of the disconnected mainline ac/dc power cable from ground

pin on one end to the ground pin on the other end.

The measurement should be 0.1 ohm or less.

xxiv 3745 Models 130 to 17A: MIP

Page 27

Safety

Ground Pin

Figure 0-6. Ground Pin on Mainline ac/dc Power Cable

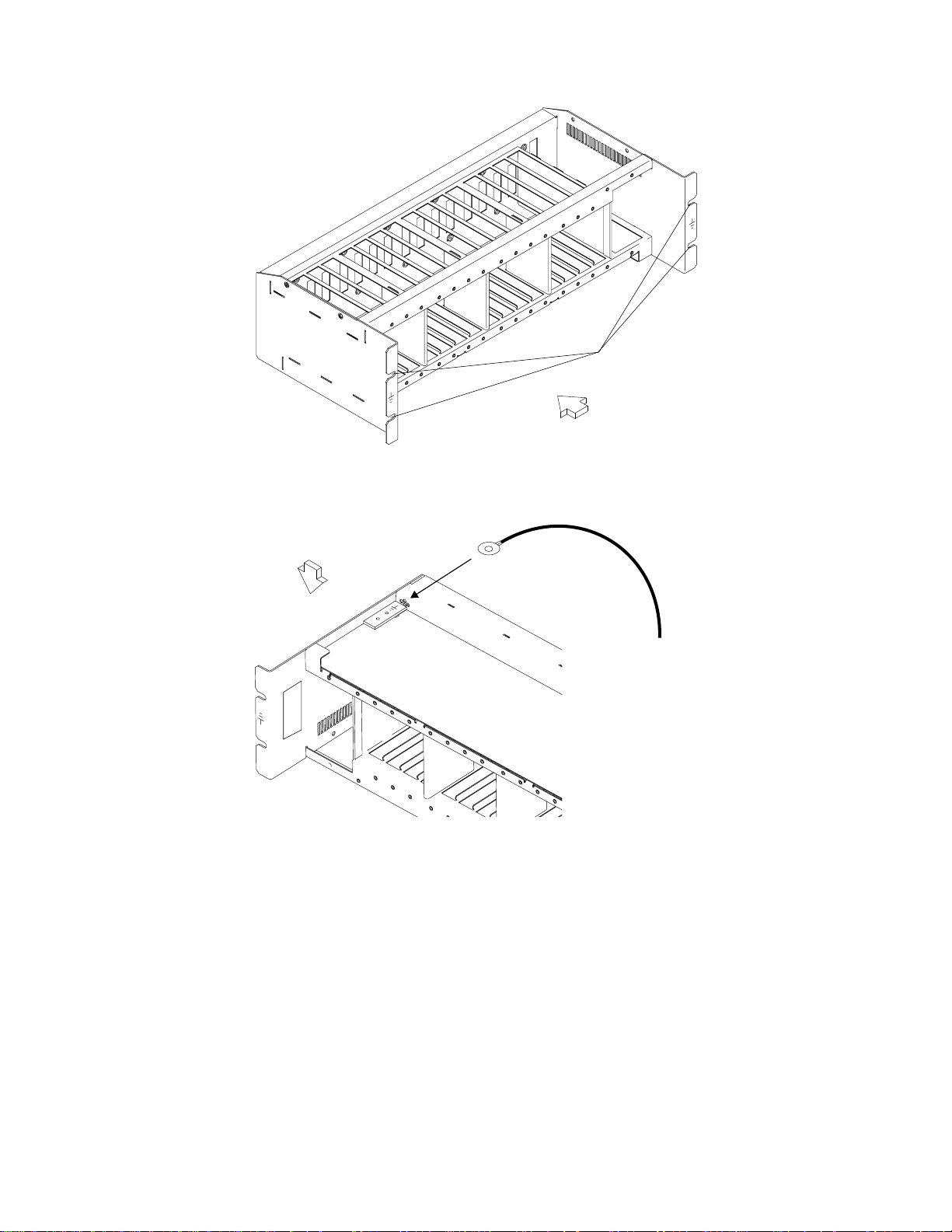

c Internal Grounding in the 3746-900 and Controller Expansion

On the 3746-900

Check that electrical continuity is assured between the LCB housing and 3746-900 frame,

if LCBs are present. This operation must be performed before any network connection.

On the Controller Expansion

Check that electrical continuity is assured between each machine installed in the controller

expansion (service processor, network node processor, modem, optical disk drive, and so

on) and the ground pin of the ac outlet distribution box (see Figure 0-7).

Check that electrical continuity is assured between the ground pin of the ac outlet distrib-

ution box and the controller expansion mount frame.

Ground Pin

Figure 0-7. Ground Pin of the Controller Expansion ac Outlet Distribution Box

Check that electrical continuity is assured between the LCB housing and the controller

expansion frame, if LCBs are present. This operation must be performed before any

network connection (see Figure 0-8 on page xxvi).

Note: All the previous measurements should indicate 0.1 ohm or less.

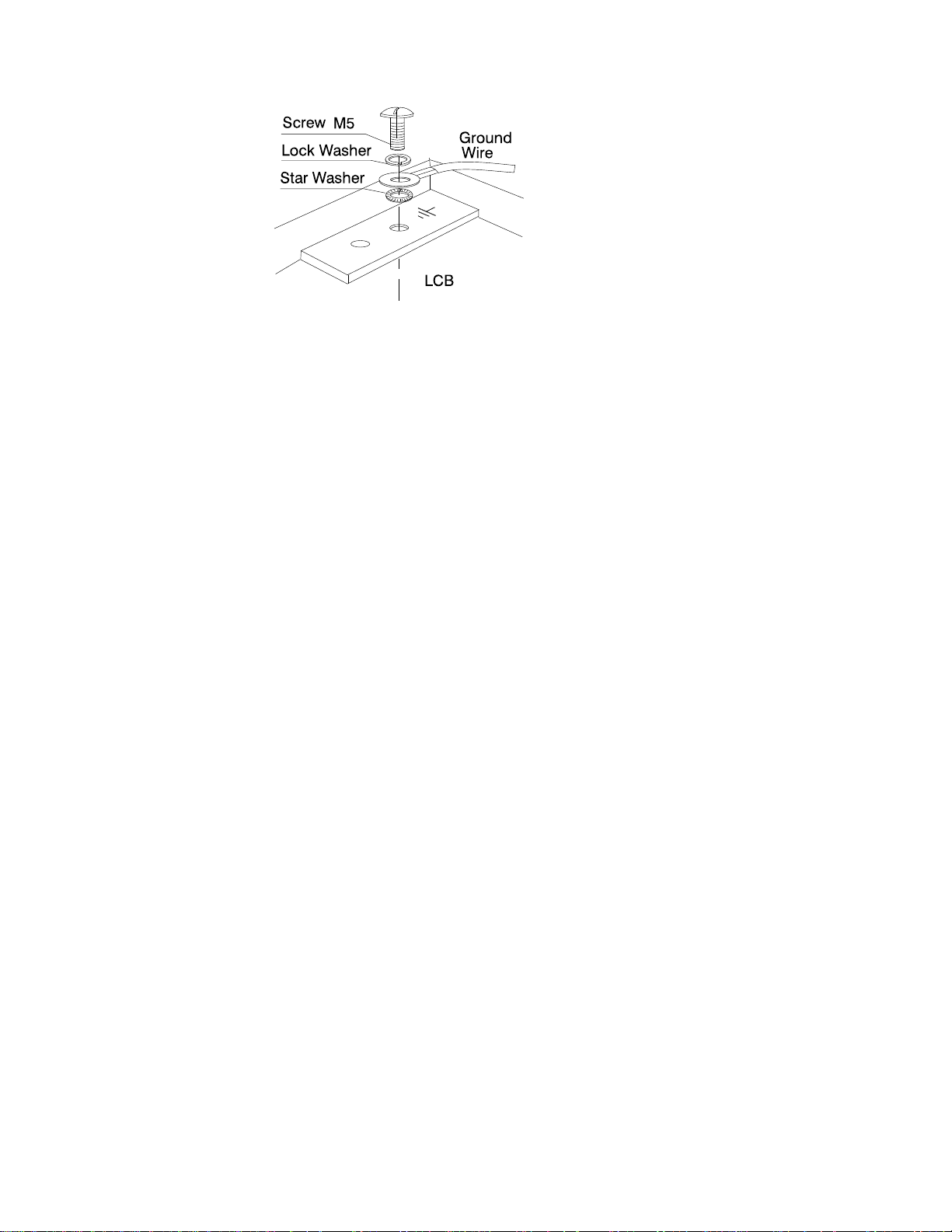

d Grounding of Line Connection Boxes (LCBs) not Installed in the 3746-900 or Controller

Expansion

Check that electrical continuity is assured between the LCB housing and the premises

grounding system.

There are two ways to ensure proper grounding of the LCB depending on where it is installed:

1) Grounding is ensured by the four screws which secure the LCB on the rack if the frame of

the rack is connected to the premises ground system.

Safety xxv

Page 28

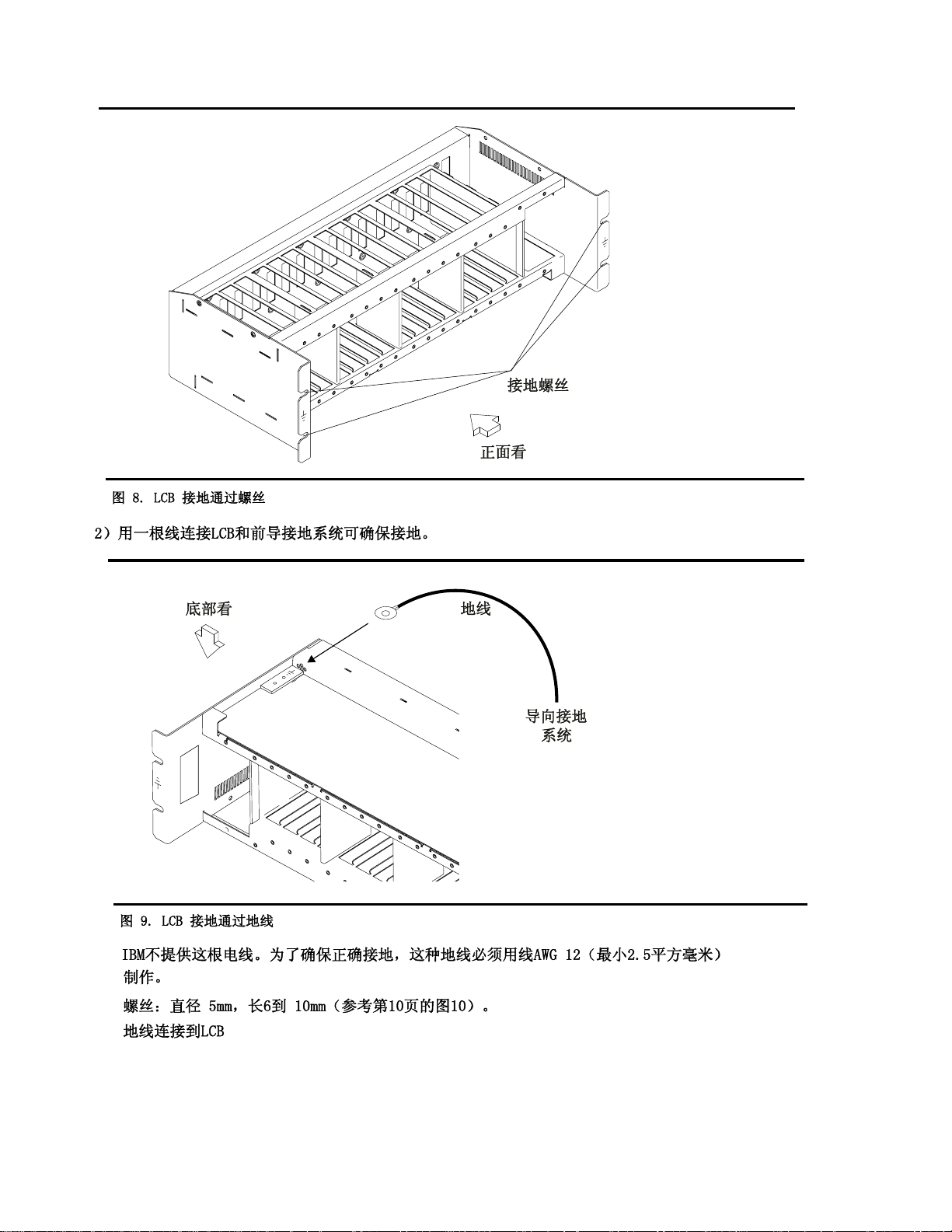

Figure 0-8. LCB Grounding Via Screws

Safety

Screws for

Grounding

Front View

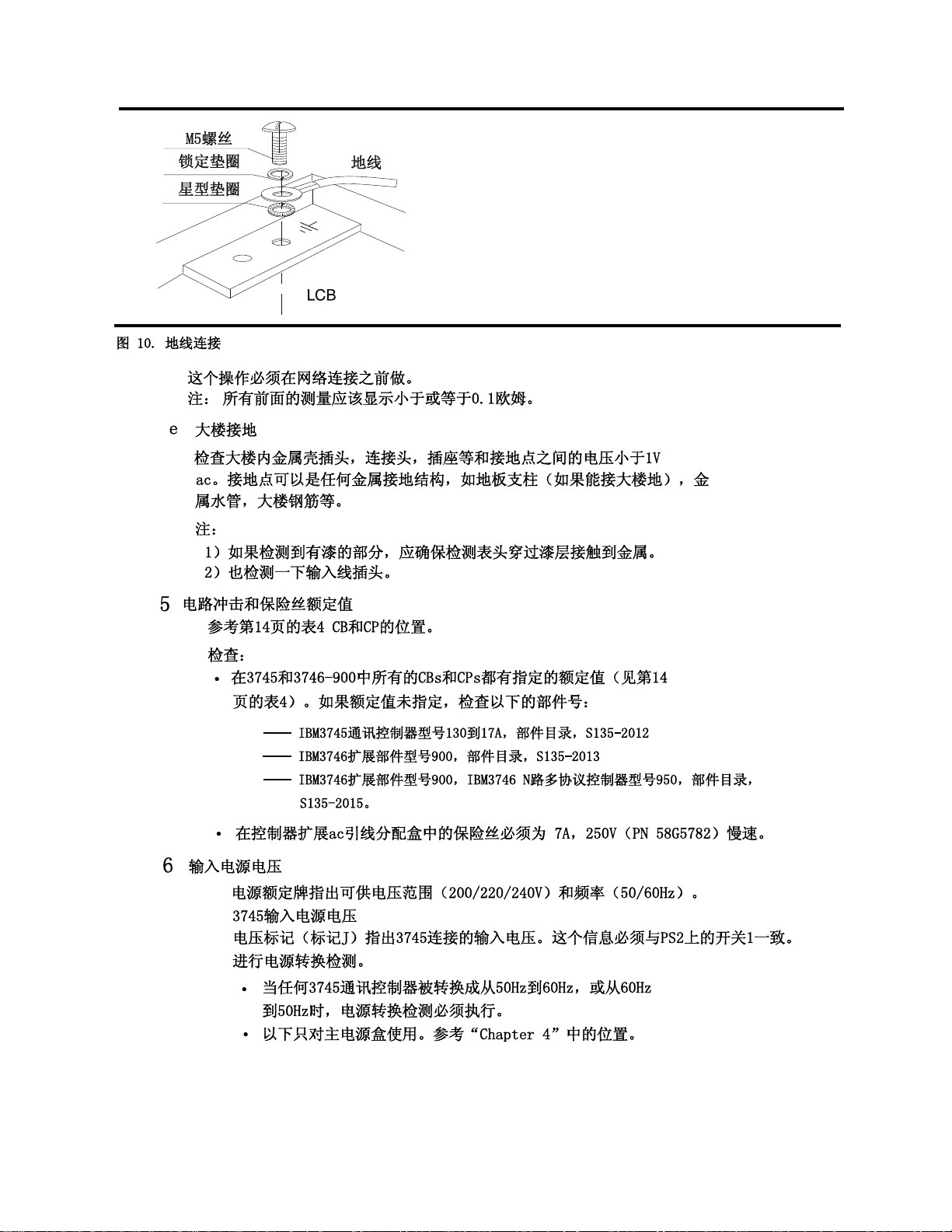

2) Grounding is ensured by a wire connected from the LCB to the premises ground system.

BottomView

Ground

Wire

ToPremises

Grounding

System

Figure 0-9. LCB Grounding Via Ground Wire

IBM does not provide this wire. In order to ensure correct grounding, this ground wire

must be made using a wire AWG 12 (minimum 2.5 square millimeters).

Screw: 5 mm in diameter, length from 6 to 10 mm (refer to Figure 0-10 on page xxvii).

Connection of Ground Wire to LCB

xxvi 3745 Models 130 to 17A: MIP

Page 29

Safety

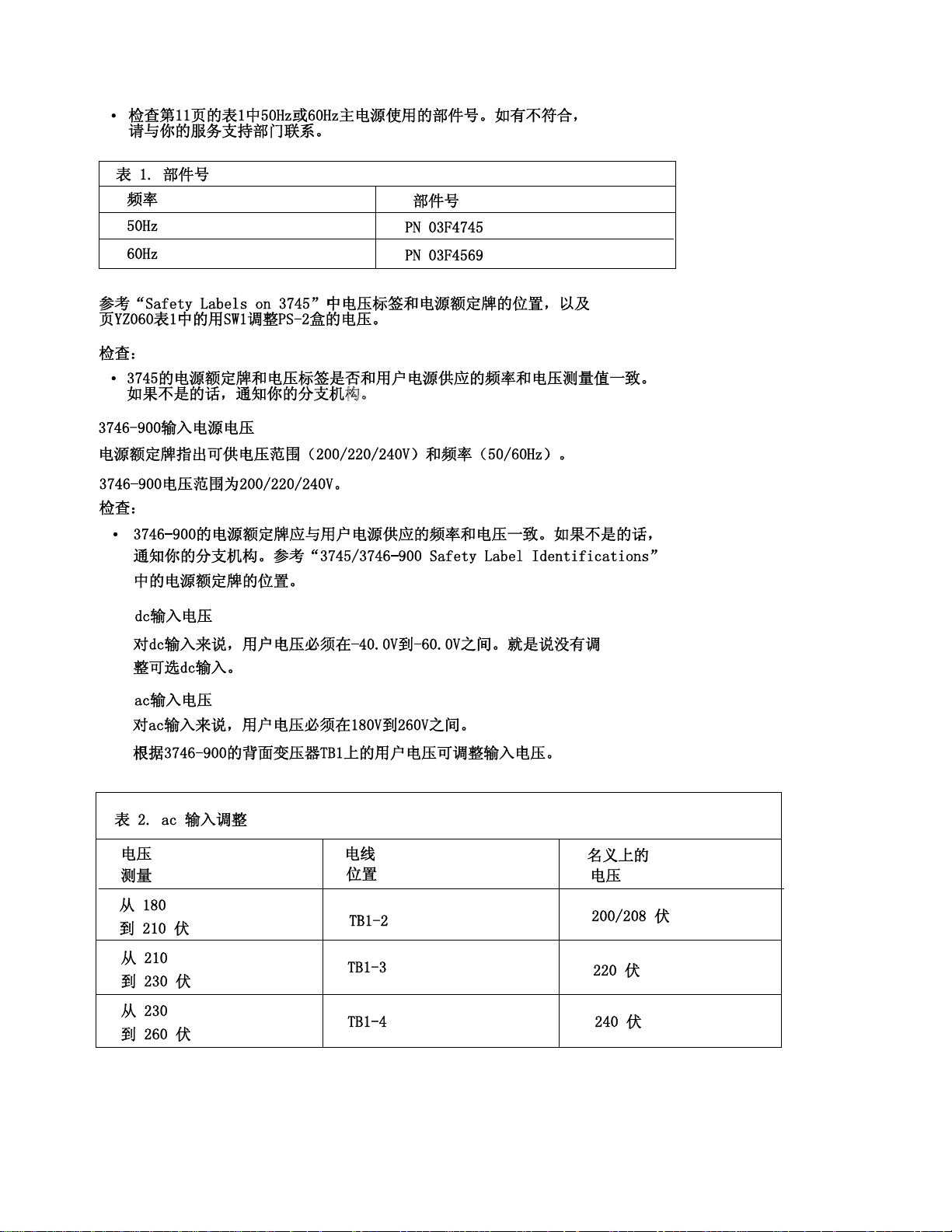

Figure 0-10. Ground Wire Connection

This operation must be performed before any network connection.

Note: All the previous measurements should indicate 0.1 ohm or less.

eBuilding Grounding

Check that there is less than 1 V ac between the metal housings of plugs, connec-

tors, receptacles, and so on., and any grounded point in the building. This can be

any grounded metal structure, such as the stanchions of a raised floor (if they are

electrically connected to building ground), a metal water pipe, building steel, and so

on.

Notes:

1) When probing a painted metal part, ensure that the meter probe tip penetrates the

paint.

2) Also check plugs of incoming cables.

5 Circuit Breaker and Protector Rating

Refer to Table 0-4 on page xxx for CB and CP locations.

Check that:

All CBs and CPs in the 3745 and 3746-900 are rated at the indicated value in Table 0-4 on

page xxx. If the rating is not indicated, check the part number against one of the following:

–

IBM 3745 Communication Controller Models 130 to 17A, Parts Catalog

–

IBM 3746 Expansion Unit Model 900, Parts Catalog

–

IBM 3746 Nways Multiprotocol Controller Models 900 and 950, Parts Catalog

The fuses in the controller expansion ac outlet distribution box must be 7 A, 250 V slow

(PN 58G5782).

, S135-2013

, S135-2012

, S135-2015.

6 Input Power Voltage

The power rating plate indicates the voltage range available (200/220/240) and the frequency

(50/60 Hz).

3745 Input Power voltage

The voltage label (label J) indicates the input voltage for which the 3745 is wired. This information

must be in accordance with Switch 1 on PS2.

Performing a power conversion Inspection.

A power conversion inspection must be performed on any 3745 Communication Controller that

has been converted from 50 Hz to 60 Hz, or from 60 Hz to 50 Hz.

The following is used only for the primary power box. Refer to Figure 4-1 on page 4-3 for

location.

Check Table 0-1 on page xxviii for the correct part numbers for the specified 50 Hz or 60 Hz

use. In case of discrepancy, contact your support structure.

Safety xxvii

Page 30

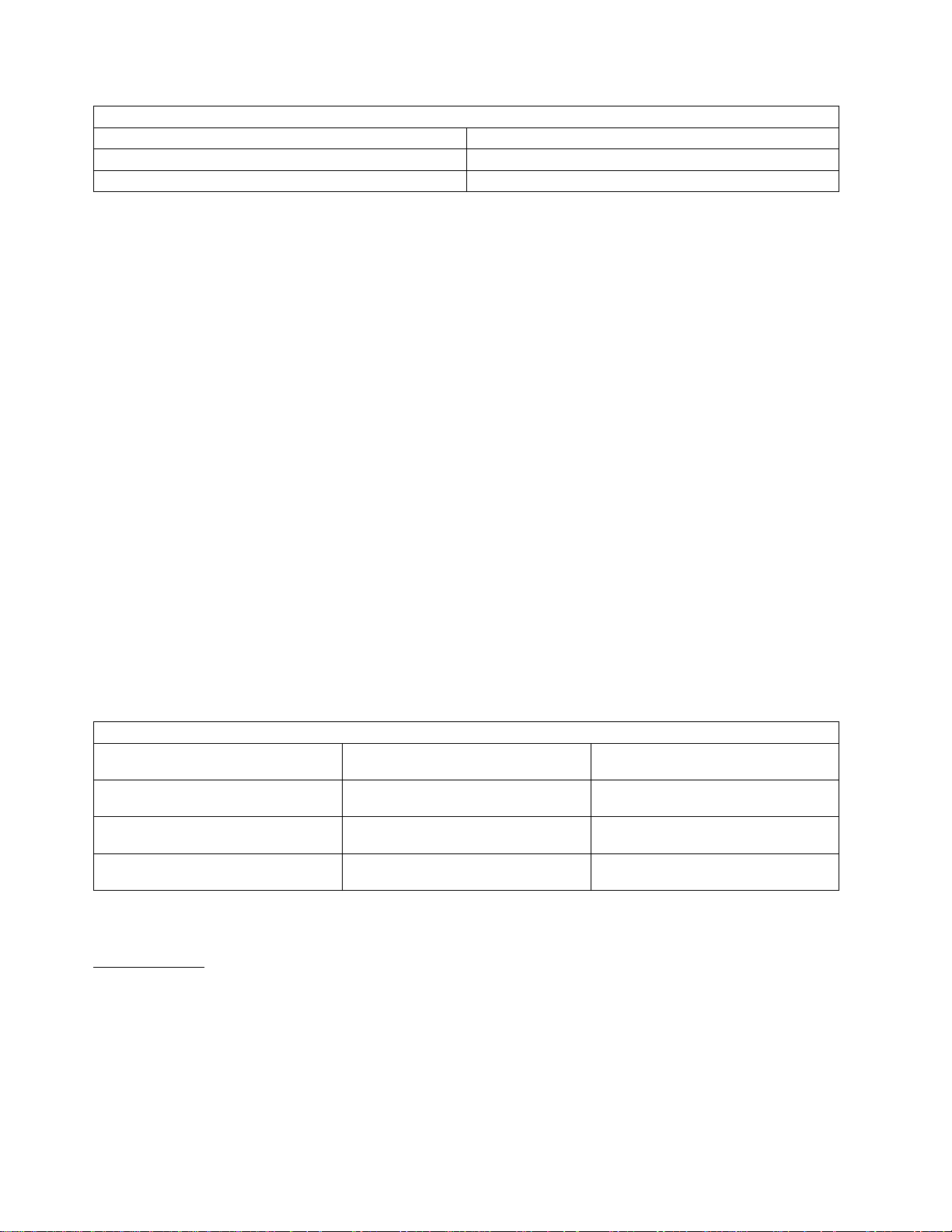

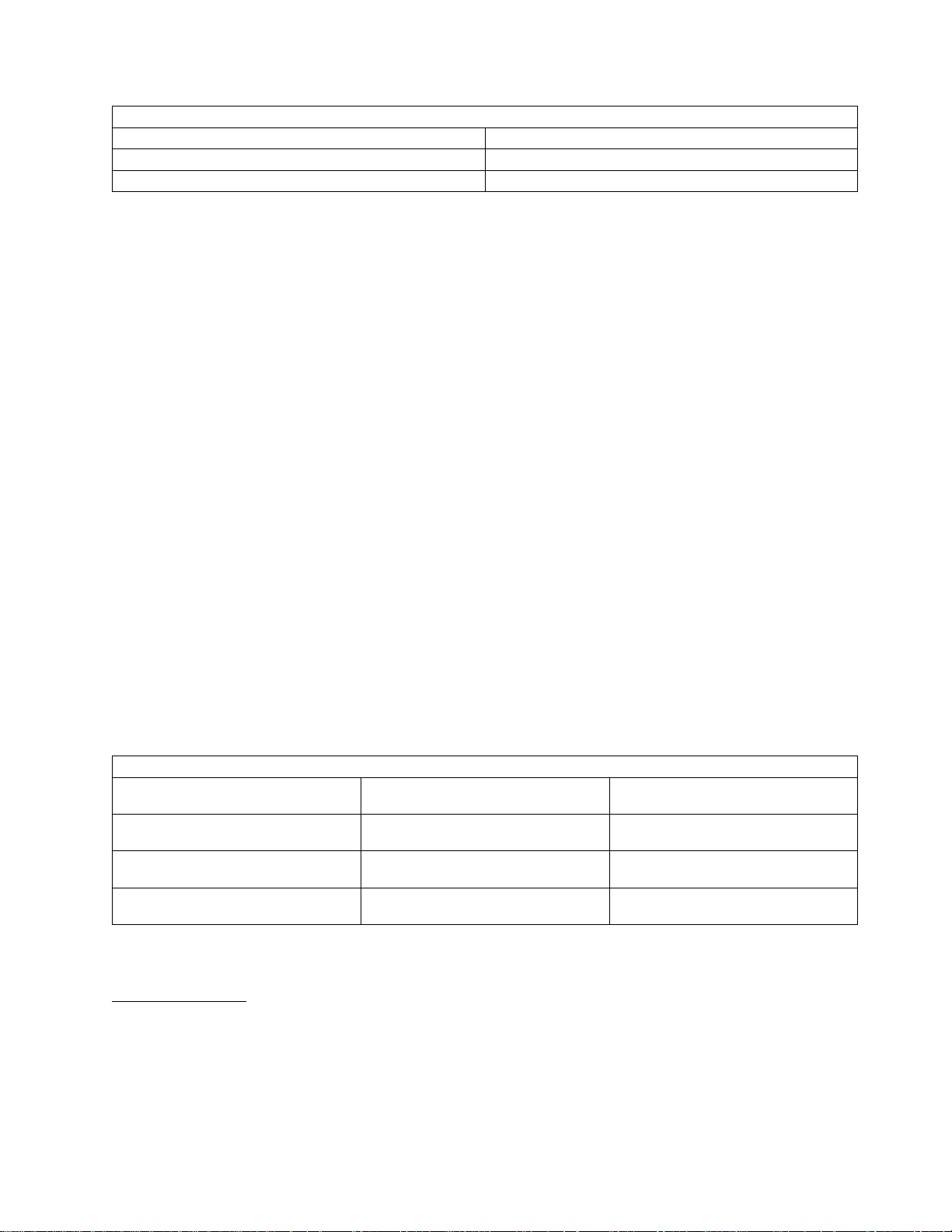

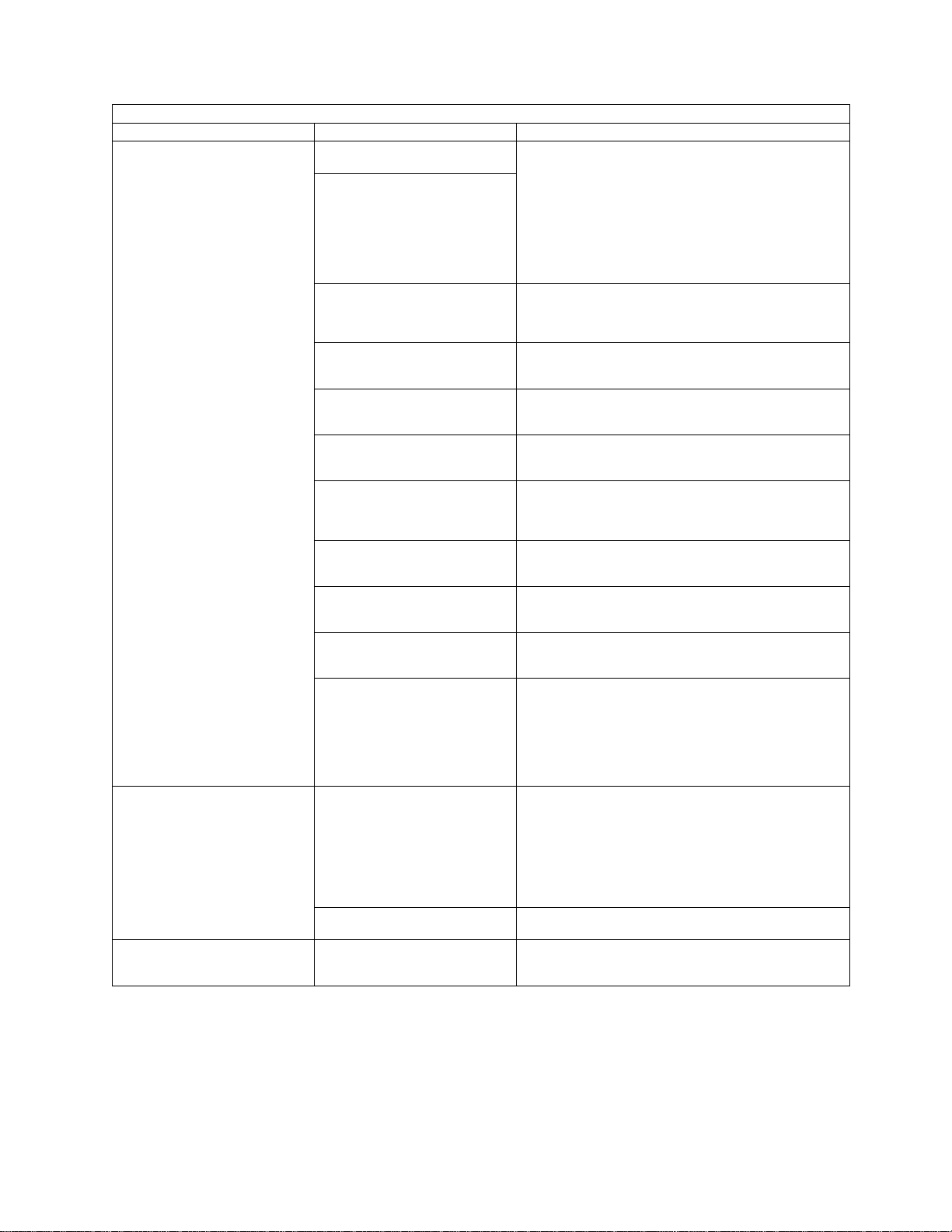

Table 0-1. Part Numbers

Frequencies Part Numbers

50 Hz PN 03F4745

60 Hz PN 03F4569

Refer to Figure 0-21 on page lvii for voltage label and power rating plate location, and to page

YZ060, sheet 1 for the PS2 box voltage adjustment by SW1.

Check that:

The power rating plate and the voltage label of the 3745 are consistent with the frequency and

the voltage measured at the customer's power supply. If they are inconsistent, inform your

branch office.

3746-900 Input Power voltage

The power rating plate indicates the voltage range available (200/220/240) and the frequency

(50/60&rlb.Hz).

The 3746-900 voltage range is 200/220/240.

Check that:

The power rating plate of the 3746-900 is consistent with the frequency and the voltage meas-

ured at the customer's power supply. If they are inconsistent inform your branch office. Refer to

“3745/3746-900 Safety Label Identifications” on page lx for the power rating plate location.

dc Input Voltage

For dc input, the customer's voltage must be within -40.0 V to -60.0 V. There is no adjustment

for the optional dc input.

ac Input Voltage

For ac input, the customer's voltage must be within 180 V to 260 V.

Adjustment of the input voltage can be done according to the customer voltage on TB1 of the

transformers located at the rear of the 3746-900.

Safety

Table 0-2. ac Input Adjustment

Voltage

Measured

From 180

to 210 Volts

From 210

to 230 Volts

From 230

to 260 Volts

Important Note

:

Wire

Position

TB1-2 200/208 Volts

TB1-3 220 Volts

TB1-4 240 Volts

Nominal

Voltage

Since the 3745 can be remotely powered ON, all the following procedures must be performed with the

power control function on the 3745 and the 3746-900 control panel set to local mode.

Controller Expansion Input Power Voltage

The power rating plate indicates the voltage range available (200/240) and the frequency (50/60 Hz).

Check that the power rating plate of the controller expansion is consistent with the frequency and the

voltage measured at the customer's power supply. If they are inconsistent inform your branch office.

Refer to “Controller Expansion Label Location” on page lxii for power rating plate location.

7 Test of the Emergency Power OFF

xxviii 3745 Models 130 to 17A: MIP

Page 31

Safety

a. Ask the customer to connect the power cord to the customer's mains supply.

b. Put CB1 ON.

c. Power ON the 3745 and the 3746-900 (power control function to Local on the control panel).

d. Operate the EMERGENCY switch to POWER OFF (O) and check that:

1) The 3745 and the 3746-900 are powered OFF.

Note

In the 3746-900, the primary powers (ACDC) or filters section (DCDC) stay energized.

For total disconnection:

1. Turn the CBs OFF.

2. Remove all the power plugs from supply outlets or shutdown the installation.

2) The diskette and disk drives are stopped.

3) All the fans are stopped.

e. Relatch the EMERGENCY switch, then power ON the controller.

8 Power ON Indicator

Once the controller is powered ON, check that:

a. The Power ON indicator on the 3745 control panel is lit.

b. The Ready LED and the Standby LED (on the 3746-900 control panel) are lit according to the

table shown in “Control Panel LED Status Versus 3746-900 States” on page xxx.

Safety xxix

Page 32

Control Panel LED Status Versus 3746-900 States

Table 0-3. LED Status Versus 3746-900 States

Standby

LED

Blinking OFF AC ON Initialization of the CBSP hardware, and the 3746-900 waits for

ON OFF Standby The 3746-900, initially recognized by the MOSS-E, waits for a

OFF Blinking Power ON IML loading in all 3746-900 processors.

OFF ON Ready The 3746-900 is now available.

Ready LED 3746-900

State

Comment

first recognition by the MOSS-E on LAN connection.

power ON condition (only the CBSP EEPROM code is

running).

3745/3746-900 Power Supply CP/CB and Fuse Reference

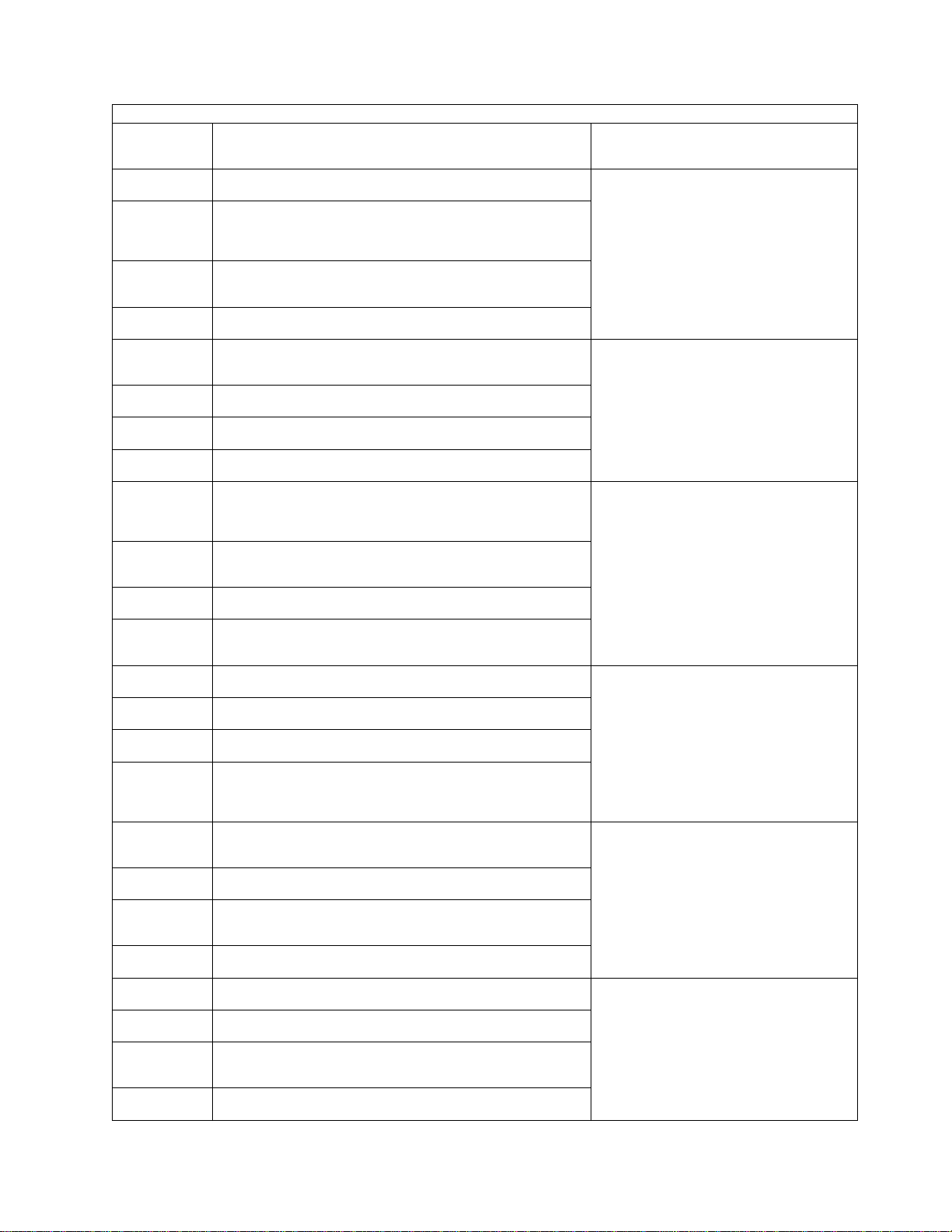

Table 0-4. 3745 Power Supply CP/CB and Fuse Reference

Frame CB/CP/F Location Rating PS

Frame 1 CB1 01H-A1 10A ALL

CP2 01H-A1 1,5 A PS2

CP3 01H-B1 2A Fans

F1 01H-B1 0.2 A PS2

Frame 7:

3746-900

CB1 AC 07K-A1/07J-A1 15 A/220 V ac Power

CB1 DC 07J-A1 50 A dc Power

CP1 07K-A1/07J-A1 5 A dc Power

CP2 07H-A1 12 A dc Power

CP3 07H-A1 12 A dc Power

CP4 07H-A1 12 A dc Power

CP5 07H-A1 12 A dc Power

Safety

Controller Expansion Fuse Reference

The ac outlet distribution box of the controller expansion contains two fuses: 7 A 250 V slow.

xxx 3745 Models 130 to 17A: MIP

Page 33

Safety

Sicherheitsüberprüfungen für IBM 3745, 3746-900 und die Erweiterung

der Steuereinheit

Wichtige Informationen

Dieses Verfahren bezieht sich auf IBM 3745, 3746-900 und die Erweiterung der Steuereinheit. Sollte

eine dieser Maschinen nicht vorhanden sein, die diesbezügliche Anweisung im folgenden Verfahren

ignorieren.

Einführung

Sicherheitsprüfungen für 3745, 3746-900 und die Erweiterung der Steuereinheit sind in folgenden

Fällen erforderlich:

Bei einer Prüfung nach Absprache mit IBM

Wenn eine IBM Wartungsleistung angefordert wird und in der letzten Zeit keine Wartung durch IBM

durchgeführt worden war.

Wenn Änderungen am Gerät oder Anschlüsse überprüft werden.

Wenn Änderungen am Gerät vorgenommen worden sind, die möglicherweise die Sicherheit

beeinträchtigen.

Wenn bei der Überprüfung ein unzureichender Sicherheitszustand festgestellt wird, müssen die Mängel

behoben werden, bevor IBM das Gerät wartet.

Anmerkung: Für die Behebung von Sicherheitsmängeln ist der Besitzer des Geräts verantwortlich.

Folgende Bereiche und Funktionen der 3745, 3746-900 und der Erweiterung der Steuereinheit werden

geprüft:

1. Äußere Abdeckungen

2. Sicherheitsaufkleber

3. Sicherheitsabdeckungen

4. Erdung

5. Sicherungsautomat und Überstromschutzschalter

6. Netzeingangsspannung

7. Netzkontrollschalter

8. Betriebsanzeige

Anmerkung: Die IBM 3746-900 wird über den Grundrahmen der IBM 3745, von einem Host, lokal oder

vom Serviceprozessor aus ein- und ausgeschaltet.

Auch nach dem Ausschalten liegt in einigen Bereichen der 3745 und 3746-900 eine gefährliche

Spannung an.

Vor der Ausführung der Schritte 1-6 muß die Stromzufuhr wie folgt unterbrochen werden:

Die Sicherungsautomaten (CB1) der 3745 und 3746-900 ausschalten (Stellung: OFF).

Alle Geräte in der Erweiterung der Steuereinheit (wenn vorhanden) ausschalten.

Stromversorgungen der 3745, 3746-900 und der controller expansion beim Kunden ausschalten

Netzkabel und Schutzleiter .A/ der Erweiterung der Steuereinheit nicht entfernen, damit die Erdung

gewährleistet ist (siehe Figure 0-12 on page xxxiv, Figure 0-13 on page xxxv, Figure 0-14 on

page xxxvi bzw. Figure 0-15 on page xxxvii).

1Äußere Abdeckungen

Prüfen, ob

Safety xxxi

Page 34

alle äußeren Abdeckungen an der 3745, 3746-900 und an der Erweiterung der Steuereinheit

angebracht sind.

die äußeren Abdeckungen auf zwei Arten verschlossen sind: mit Schlitzschrauben im IBM

Zugriffsbereich und mit Sechskantschrauben im Zugriffsbereich des Kunden (siehe

Communication Controller Models 130 to 17A, Parts Catalog

die Abdeckungen vollständig geöffnet werden können.

um die Rahmen genügend Raum und Zugänge für Wartungsarbeiten sind, wenn die äußeren

Abdeckungen geöffnet sind.

Alle äußeren Abdeckungen für weitere Überprüfungen offen lassen.

, S135-2012).

2Sicherheitsaufkleber

Prüfen, ob

sich alle Sicherheitsaufkleber an den mit Buchstaben gekennzeichneten Stellen befinden, wie

unter “Safety Label Locations” on page lvii beschrieben.

die Aufkleber dem jeweiligen Buchstaben gemäß “3745/3746-900 Safety Label Identifications” on

page lx entsprechen.

3Sicherheitsabdeckungen

Bezüglich des Standorts der durch den Kundendienst austauschbaren Funktionseinheit (Kapitel 4)

prüfen, ob

alle Sicherheitsabdeckungen vorhanden und mit Schrauben gesichert sind.

alle Spannungsklemmleisten durch eine Plastikabdeckung an der Oberseite der Klemmleiste

geschützt sind.

Safety

IBM 3745

4Erdung

Hinweis

Im vorliegenden Handbuch bedeutet "erden", daß das Gerät mit der Schutzerdung verbunden

werden muß.

a Erdung der 3745

Positionen der Erdungsbrücken/Kontakte siehe YZ110. .

Prüfen, ob

b Schutzleiterverbindung der 3746-900 und der Erweiterung der Steuereinheit an das

Erdungssystem des Gebäudes

der elektrische Durchgang zwischen der Rahmenerdung und den Anschlüssen, die

auf den Schemazeichnungen für Erdung eingezeichnet sind, sichergestellt ist .

der elektrische Durchgang zwischen 3745, den Rahmenerdungen und dem Erdungssystem

des Gebäudes durch das Netzkabel der 3745 sichergestellt wird.

Der elektrische Durchgang zwischen der Rahmenerdung und dem Erdungssystem des

Gebäudes wird über die Netzkabel sichergestellt.

Die 3746-900 wird über das Stromversorgungskabel an der 3745 geerdet (siehe

Figure 0-11 on page xxxiii).

Bei der Erweiterung der Steuereinheit wird zusätzlich ein Schutzleiter .A/ verwendet (siehe

Figure 0-12 on page xxxiv, Figure 0-13 on page xxxv, Figure 0-14 on page xxxvi bzw.

Figure 0-15 on page xxxvii).

1 Stromversorgungskabel für 3745/3746-900

Prüfen, ob der Schutzleiter des Stromversorgungskabels ordnungsgemäß an die 3745

(.D/) und die 3746-900 (.C/) angeschlossen ist.

xxxii 3745 Models 130 to 17A: MIP

Page 35

Safety

D

3746

3745

Hinteransicht

3745

Vorderansicht

Figure 0-11. Führung des Stromversorgungskabels bei der 3745/3746-900

Anmerkungen:

a) .D/ Sicherungsring (Teilenummer 17G5853) und Mutter (Teilenummer 1622404).

b) .C/ Schraube (Teilenummer 61F4511), Zahnscheibe (Teilenummer 17G5852) und

Sicherungsring (Teilenummer 1622318)

2 Schutzleiter für die Erweiterung der Steuereinheit

Wenn nur eine Erweiterung der Steuereinheit installiert ist, prüfen, ob der

Schutzleiter .A/ angeschlossen ist (siehe Figure 0-12 on page xxxiv).

Wenn mehrere Erweiterungen der Steuereinheit installiert sind, prüfen, ob die

Schutzleiter .A/ gemäß Konfiguration angebracht wurden (siehe Figure 0-13 on

page xxxv, Figure 0-14 on page xxxvi bzw. Figure 0-15 on page xxxvii).

C

3746

Safety xxxiii

Page 36

Safety

Figure 0-12. Schutzleiteranschluß an der Erweiterung der Steuereinheit

xxxiv 3745 Models 130 to 17A: MIP

Page 37

Safety

Figure 0-13. Schutzleiteranschluß zwischen angeschlossenen Erweiterungen der Steuereinheit.

Safety xxxv

Page 38

Safety

Figure 0-14. Schutzleiteranschluß bei einem Abstand von weniger als 6 Meter zwischen den Erweiterungen der

Steuereinheit

xxxvi 3745 Models 130 to 17A: MIP

Page 39

Safety

Figure 0-15. Schutzleiteranschluß bei einem Abstand über 6 Meter zwischen den Erweiterungen der Steuereinheit

Anmerkungen:

a) .A/ Schutzleiter (Teilenummer 58G5691)

b) .B/ Schraube (Teilenummer 61F4513), Zahnscheibe (Teilenummer 1622347) oder

(Teilenummer 17G5853) und Sicherungsring (Teilenummer 1622319).

3 Schutzleiter des AC/DC Stromversorgungskabels

Hauptstromversorgungskabel auf beschädigte oder verbrannte Kontakte und

beschädigte Isolierung prüfen.

Den Widerstand des nicht angeschlossenen Hauptstromversorgungskabels zwischen

dem Schutzleiterkontakt am einen und dem Schutzleiterkontakt am anderen Ende

messen.

Der Widerstand darf maximal 0,1 Ohm betragen.

Safety xxxvii

Page 40

Figure 0-16. Schutzleiterkontakt am Hauptstromversorgungskabel

c Interne Erdung in der 3746-900 und der Erweiterung der Steuereinheit

An der 3746-900

Prüfen, ob der elektrische Durchgang zwischen dem Gehäuse des Verteilerkastens und

dem Rahmen der 3746-900 gewährleistet ist, sofern Verteilerkästen vorhanden sind.

Dieser Schritt muß vor dem Anschluß von Signalkabeln erfolgen.

An der Erweiterung der Steuereinheit

Prüfen, ob der elektrische Durchgang zwischen allen in der Erweiterung der Steuereinheit

installierten Einheiten (Serviceprozessor, Netzknotenprozessor, Modem, optisches

Plattenlaufwerk usw.) und dem Schutzleiterkontakt des Wechselstromverteilerkastens

gewährleistet ist (siehe Figure 0-17).

Prüfen, ob der elektrische Durchgang zwischen dem Schutzleiterkontakt des

Wechselstromverteilerkastens und dem Montagerahmen der Erweiterung der Steuereinheit

gewährleistet ist.

Safety

Figure 0-17. Schutzleiterkontakt des Wechselstromverteilerkastens der Erweiterung der

Steuereinheit

Prüfen, ob der elektrische Durchgang zwischen dem Gehäuse des Verteilerkastens und

dem Rahmen der Erweiterung der Steuereinheit gewährleistet ist, sofern Verteilerkästen

vorhanden sind. Dieser Schritt muß vor dem Anschluß von Signalkabeln erfolgen (siehe

Figure 0-18 on page xxxix).

Anmerkung: Bei allen vorherigen Prüfungen sollten maximal 0,1 Ohm gemessen werden.

d Erdung der nicht in der 3746-900 oder in der Erweiterung der Steuereinheit installierten

Verteilerkästen

Prüfen, ob der elektrische Durchgang zwischen dem Gehäuse des Verteilerkastens und dem

Erdungssystem des Gebäudes gewährleistet ist.

Je nach Installationsort kann der Verteilerkasten auf zweierlei Arten geerdet werden:

1) Erdung über die vier Schrauben, mit denen der Verteilerkasten am Gehäuse befestigt ist,

falls der Gehäuserahmen mit dem Erdungssystem des Gebäudes verbunden ist.

xxxviii 3745 Models 130 to 17A: MIP

Page 41

Safety

Figure 0-18. Erdung des Verteilerkastens über Schrauben

2) Erdung über einen Schutzleiter, der den Verteilerkasten mit dem Erdungssystem des

Gebäudes verbindet.

Figure 0-19. Erdung des Verteilerkastens über Schutzleiter

IBM liefert diesen Schutzleiter nicht mit. Der Schutzleiter muß aus einem

AWG12-Leiter (mind. 2,5 mm2) bestehen, damit eine korrekte Erdung gewährleistet ist.

Schraube: Durchmesser 5 mm, Länge 6 bis 10 mm (siehe Figure 0-20 on page xl).

Verbindung des Schutzleiters mit dem Verteilerkasten

Safety xxxix

Page 42

Figure 0-20. Schutzleiteranschluß

Dieser Schritt muß vor dem Anschluß von Signalkabeln erfolgen.

Anmerkung: Bei allen vorherigen Prüfungen sollten maximal 0,1 Ohm gemessen werden.

eGebäudeerdung

Sicherstellen, daß zwischen den Metallgehäusen von Steckern, Buchsen usw. und

jeder geerdeten Stelle im Gebäude eine Wechselspannung von weniger als 1 V

anliegt. Dies kann jedes geerdete Metallteil sein, wie z.B. die Stützen eines

Doppelbodens (wenn sie mit dem Gebäudeerder verbunden sind), ein metallisches

Wasserrohr, Baustahl usw..

Anmerkungen:

1) Beim Prüfen an einem lackierten Metallteil sicherstellen, daß die Prüfspitze die Farbe

durchbohrt.

2) Stecker der anzuschließenden Kabel ebenfalls prüfen.

Safety

5 Sicherungsautomat und Überstromschutzschalter

Positionen der Sicherungsautomaten (CB) und Überstromschutzschalter (CP) siehe Table 0-8 on

page xliii.

Prüfen, ob

alle Sicherungsautomaten und Überstromschutzschalter in der 3745 und 3746-900 die unter

Table 0-8 on page xliii angegebene Leistung haben. Wenn die Leistung nicht aufgeführt ist, die

Teilenummer in einem der folgenden Kataloge prüfen:

–

IBM 3745 Communication Controller Models 130 to 17A, Parts Catalog

–

IBM 3746 Expansion Unit Model 900, Parts Catalog

–

IBM 3746 Nways Multiprotocol Controller Models 900 and 950, Parts Catalog

Bei den Sicherungen im Wechselstromverteilerkasten der Erweiterung der Steuereinheit muß es

sich um träge Sicherungen mit 7 A, 250 V handeln (Teilenummer 58G5782).

, S135-2013

, S135-2012

, S135-2015.

6Eingangsspannung

Der zulässige Spannungsbereich (200/220/240V) und die Frequenz (50/60 Hz) sind dem

Typenschild zu entnehmen.

Eingangsspannung an der 3745

Der Aufkleber für die Versorgungsspannungen (Aufkleber J) gibt die Eingangsspannung für die 3745

an. Die Angaben müssen Schalter 1 an PS2 entsprechen.

Stromumwandlung prüfen

Die Stromumwandlung muß bei jeder DFV-Steuereinheit IBM 3745 geprüft werden, die von 50

Hz auf 60 Hz oder von 60 Hz auf 50 Hz umgerichtet wurde.

Folgendes bezieht sich ausschließlich auf das Netzspannungsgehäuse. Die Position kann

Figure 4-1 on page 4-3 entnommen werden.

Die entsprechenden Teilenummern für die Verwendung bei 50 oder 60 Hz sind Table 0-5 on

page xli zu entnehmen. Bei Unstimmigkeiten das KD-Unterstützungspersonal benachrichtigen.

xl 3745 Models 130 to 17A: MIP

Page 43

Safety

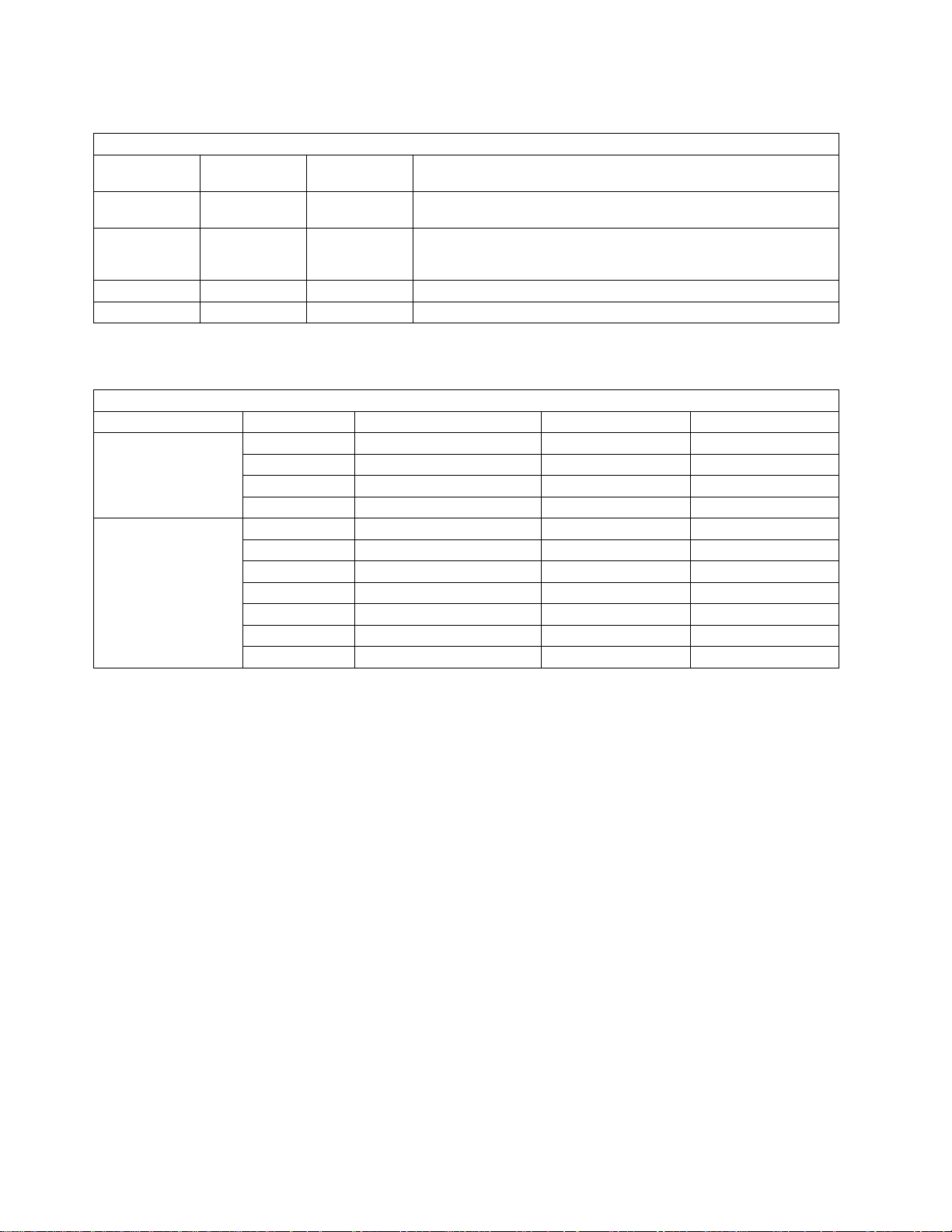

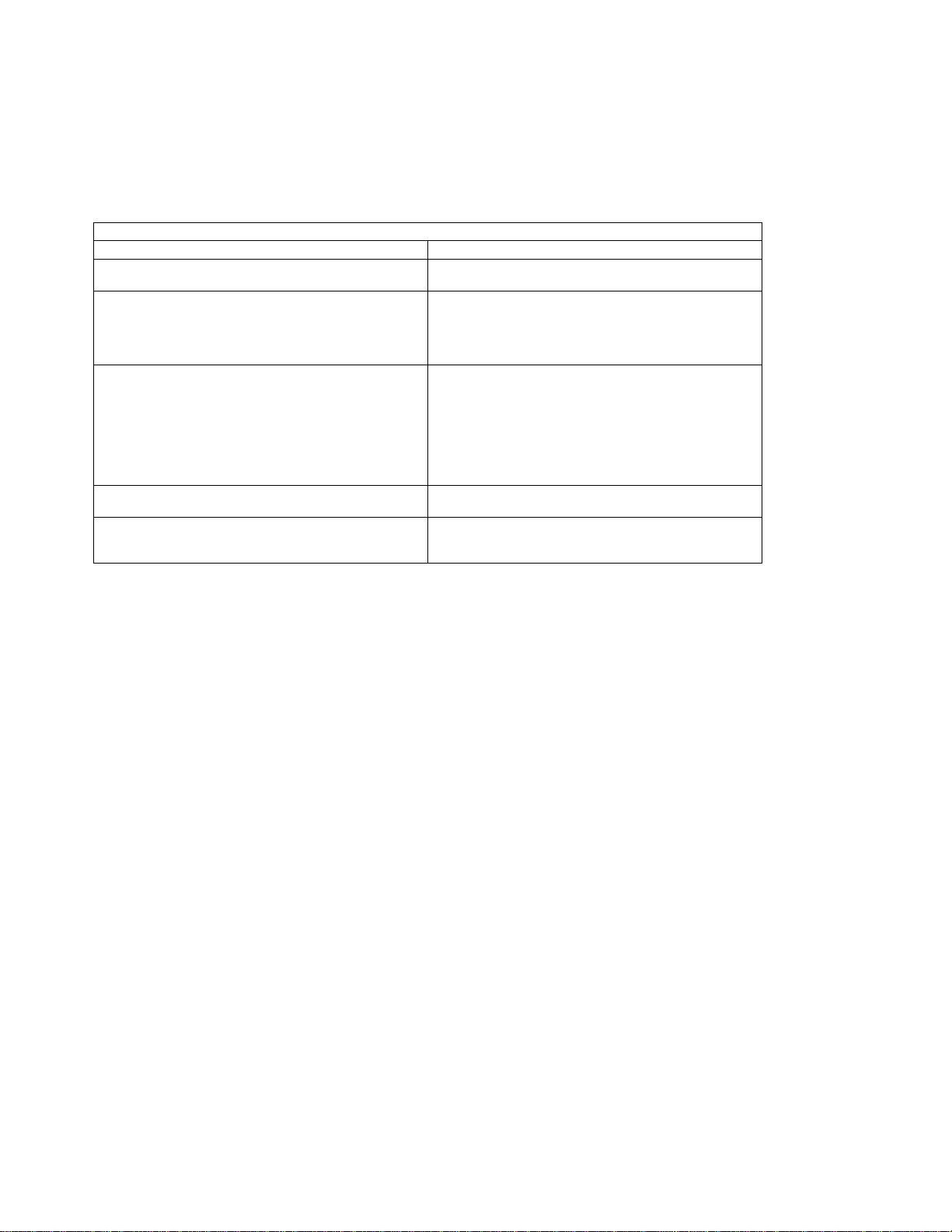

Table 0-5. Teilenummern

Frequenzen Teilenummern

50 Hz 03F4745

60 Hz 03F4569

Die Positionen des Auflebers für die Versorungsspannungen und des Typenschildes sind

Figure 0-21 on page lvii zu entnehmen. Informationen zur Spannung?? im Netzteil PS-2 durch

SW1 siehe Seite YZ060, Blatt 1.

Prüfen, ob

die Angaben auf dem Typenschild und dem Spannungsaufkleber der 3745 mit der an der

Netzstromversorgung des Kunden gemessenen Frequenz und Spannung übereinstimmen.

Wenn dies nicht der Fall ist, zuständige Geschäftsstelle informieren.

Eingangsspannung an der 3746-900

Der zulässige Spannungsbereich (200/220/240V) und die Frequenz (50/60 Hz) sind dem

Typenschild zu entnehmen.

Der Spannungsbereich für die 3746-900 liegt bei 200/220/240V.

Prüfen, ob

die Angaben auf dem Typenschild an der 3746-900 mit der am Netzteil des Kunden

gemessenen Spannung und Frequenz übereinstimmen. Wenn dies nicht der Fall ist, zuständige

Geschäftsstelle informieren. Die Position des Typenschildes ist “3745/3746-900 Safety Label

Identifications” on page lx zu entnehmen.

Spannung am Gleichstromeingang

Am Gleichstromeingang muß die Spannung beim Kunden zwischen -40,0 V und -60,0 V liegen.

Der optionale Gleichstromeingang kann nicht eingestellt werden.

Spannung am Wechselstromeingang

Am Wechselstromeingang muß die Spannung beim Kunden zwischen 180 V und 260 V liegen.

Die Einstellung der Eingangsspannung gemäß der Spannung beim Kunden kann an der

Klemmleiste 1 der Transformatoren an der Rückseite der 3746-900 erfolgen.

Table 0-6. Einstellung der Spannung des Wechselstromeingangs

Gemessene

Spannung

180

bis 210 Volt

210

bis 230 Volt

230

bis 260 Volt

Wichtiger Hinweis

:

Position des

Leiters

Klemmleiste TB 1-2 200/208 Volt

Klemmleiste TB 1-3 220 Volt

Klemmleiste TB 1-4 240 Volt

NennSpannung

Die 3745 kann über Fernsteuerung eingeschaltet werden. Deshalb muß bei Ausführung der folgenden

Verfahren die Stromsteuerfunktion am Bedienungsfeld der 3745 und 3746-900 auf Lokal eingestellt sein.

Eingangsspannung der Erweiterung der Steuereinheit

Der zulässige Spannungsbereich (200/240 V) und die Frequenz (50/60 Hz) sind dem Typenschild zu

entnehmen.

Prüfen, ob die Angaben auf dem Typenschild an der Erweiterung der Steuereinheit mit der an der

Netzstromversorgung des Kunden gemessenen Spannung und Frequenz übereinstimmen. Wenn dies

Safety xli

Page 44

nicht der Fall ist, zuständige Geschäftsstelle informieren. Die Position des Typenschildes ist “Controller

Expansion Label Location” on page lxii zu entnehmen.

7 Prüfung des Notaus-Schalters

a. Den Kunden bitten, das Netzkabel an die Netzstromversorgung anzuschließen.

b. Sicherungsautomat (CB1) einschalten.

c. Die 3745 und 3746-900 einschalten (Stromsteuerfunktion am Bedienungsfeld muß auf Lokal

eingestellt sein).

d. Den NOTSCHALTER ausschalten (O) und prüfen, ob:

1) die 3745 und die 3746-900 ausgeschaltet sind.

Hinweis

In der 3746-900 stehen die primären Versorgungs- (ACDC) oder die Filterbereiche

(DCDC) weiterhin unter Spannung.

Komplettes Abschalten:

1. Die Sicherungsautomaten (CBs) ausschalten.

2. Alle Netzstecker aus den Steckdosen ziehen oder die Netzstromversorgung

abschalten.

2) die Disketten- und Plattenlaufwerke angehalten sind.

3) die Lüfter abgeschaltet sind.

e. Notschalter entriegeln und Steuereinheit einschalten.

Safety

8Betriebsanzeige

Nach Einschalten der Steuereinheit prüfen, ob

a. die Betriebsanzeige am Bedienungsfeld der 3745 leuchtet.

b. die Betriebs-LED und die Bereitschafts-LED (am Bedienungsfeld des 3746-900) gemäß den

Angaben der Tabelle “Bedeutung der LEDs am Bedienungsfeld der 3746-900” leuchten.

Bedeutung der LEDs am Bedienungsfeld der 3746-900

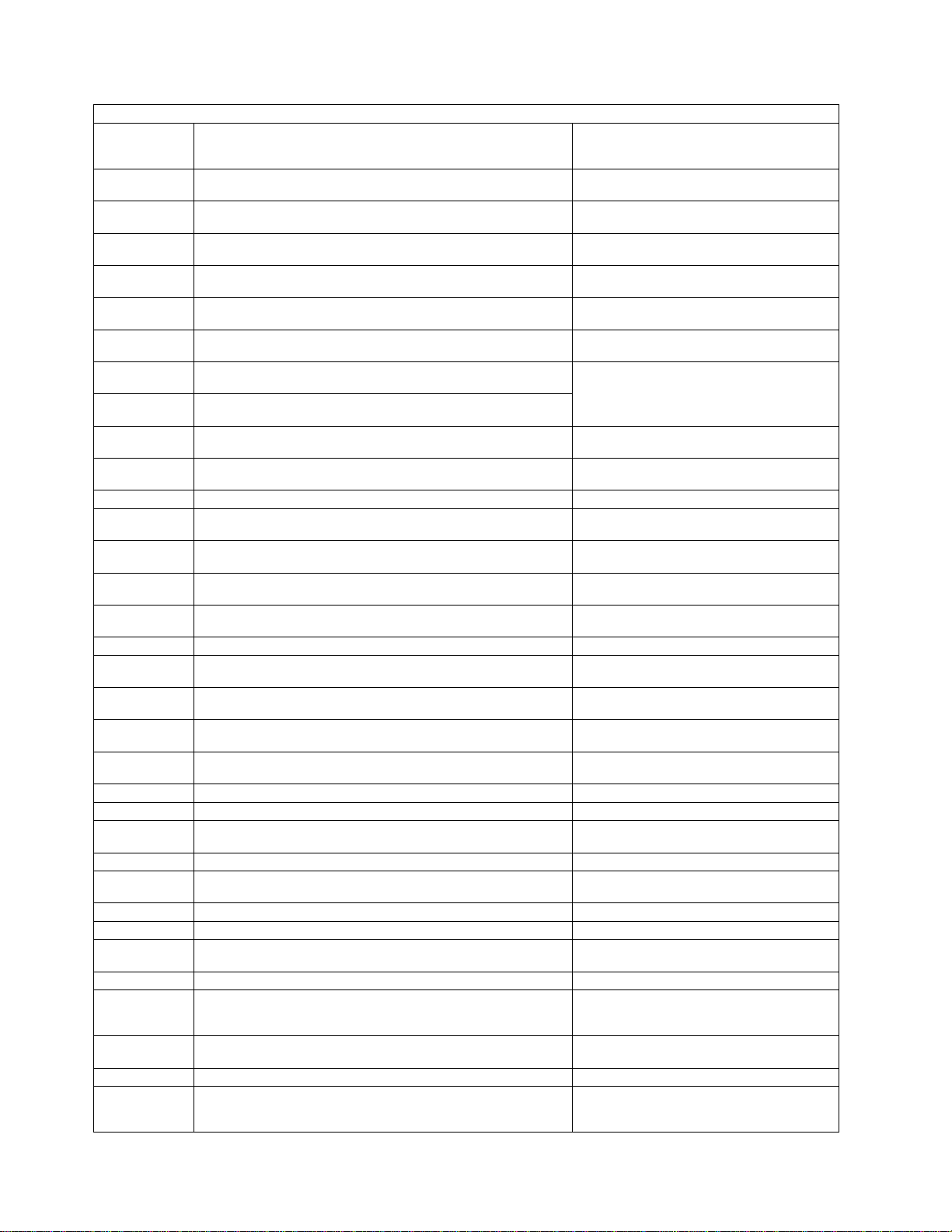

Table 0-7. Bedeutung der LEDs am Bedienungsfeld der 3746-900

LED

Bereitschaft

Blinken AUS Wechselstrom

EIN AUS Bereitschaft Die eingangs vom MOSS-E erkannte 3746-900 wartet auf das

AUS Blinken Einschalten Alle 3746-900-Prozessoren werden hochgefahren (IML).

AUS EIN Betrieb Die 3746-900 ist nun betriebsbereit.

LED

Betrieb

Status

3746-900

EIN

Kommentar

Initialisierung der CBSP-Hardware. Die 3746-900 wartet auf

erste Erkennung durch den MOSS-E beim LAN-Anschluß.

Einschalten (nur das CBSP EEPROM-Programm ist aktiv).

xlii 3745 Models 130 to 17A: MIP

Page 45

Safety

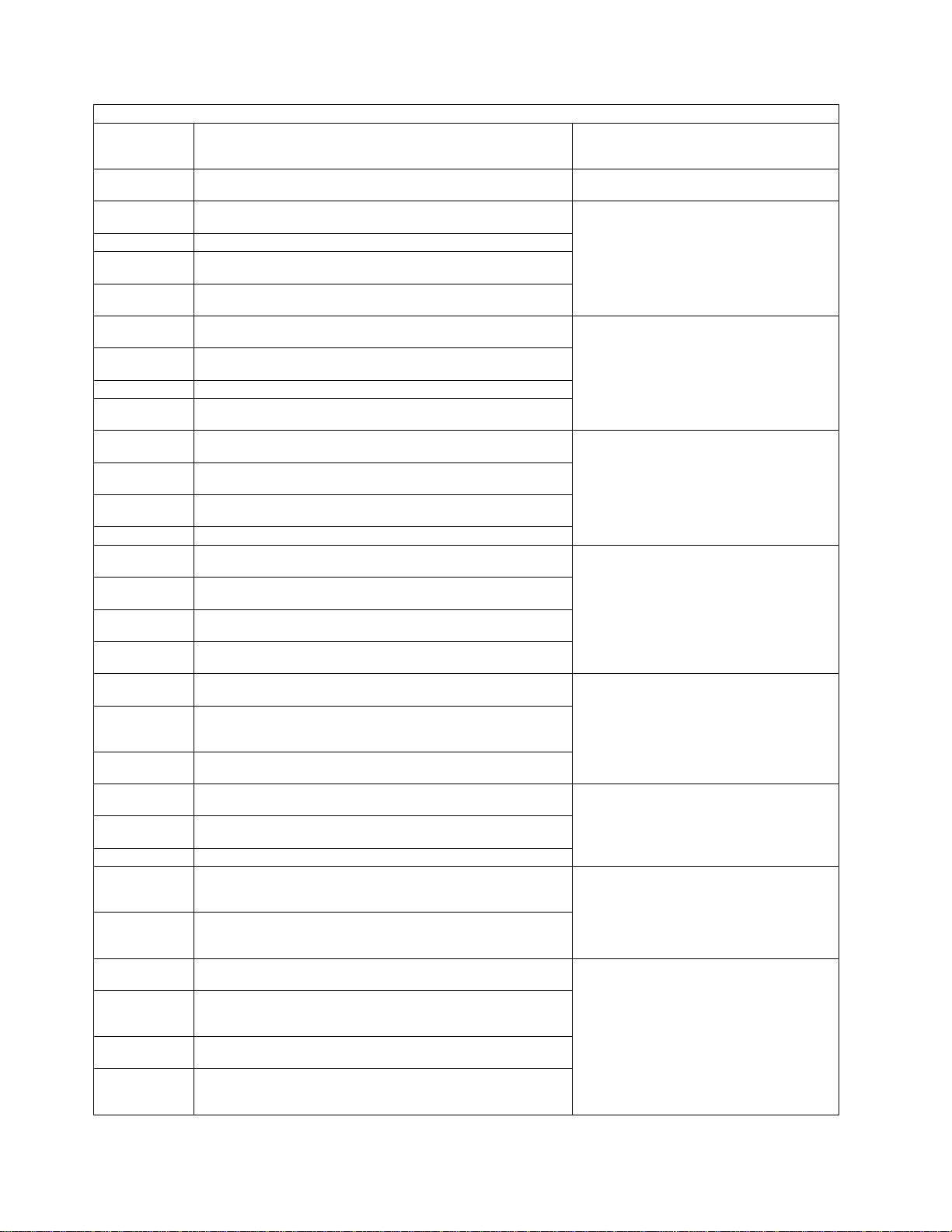

Stromversorgung der 3745/3746-900, Sicherungsautomaten (CB),

Überstromschutzschalter (CP) und Sicherungen (F)

Table 0-8. Stromversorgung der 3745, Sicherungsautomaten (CB), Überstromschutzschalter (CP) und

Sicherungen (F)

Rahmen CB/CP/F Position Nennwerte PS (Stromvers.)

Rahmen 1 CB1 01H-A1 10A ALLE

CP2 01H-A1 1,5 A PS2

CP3 01H-B1 2A Ventilatoren

F1 01H-B1 0,2 A PS2

Rahmen 7:

3746-900

CB1 AC 07K-A1/07J-A1 15 A/220 V Wechselstrom

CB1 DC 07J-A1 50 A Gleichstrom

CP1 07K-A1/07J-A1 5 A Gleichstrom

CP2 07H-A1 12 A Gleichstrom

CP3 07H-A1 12 A Gleichstrom

CP4 07H-A1 12 A Gleichstrom

CP5 07H-A1 12 A Gleichstrom

Sicherungen der Erweiterung der Steuereinheit

Der Wechselstromverteilerkasten der Erweiterung der Steuereinheit enthält zwei Sicherungen: 7 A 250 V

träge.

Safety xliii

Page 46

Safety

xliv 3745 Models 130 to 17A: MIP

Page 47

Safety

Safety xlv

Page 48

Safety

xlvi 3745 Models 130 to 17A: MIP

Page 49

Safety

Safety xlvii

Page 50

Safety

xlviii 3745 Models 130 to 17A: MIP

Page 51

Safety

Safety xlix

Page 52

Safety

l 3745 Models 130 to 17A: MIP

Page 53

Safety

Safety li

Page 54

Safety

lii 3745 Models 130 to 17A: MIP

Page 55

Safety

Safety liii

Page 56

Safety

liv 3745 Models 130 to 17A: MIP

Page 57

Safety

Safety lv

Page 58

Safety

lvi 3745 Models 130 to 17A: MIP

Page 59

Safety

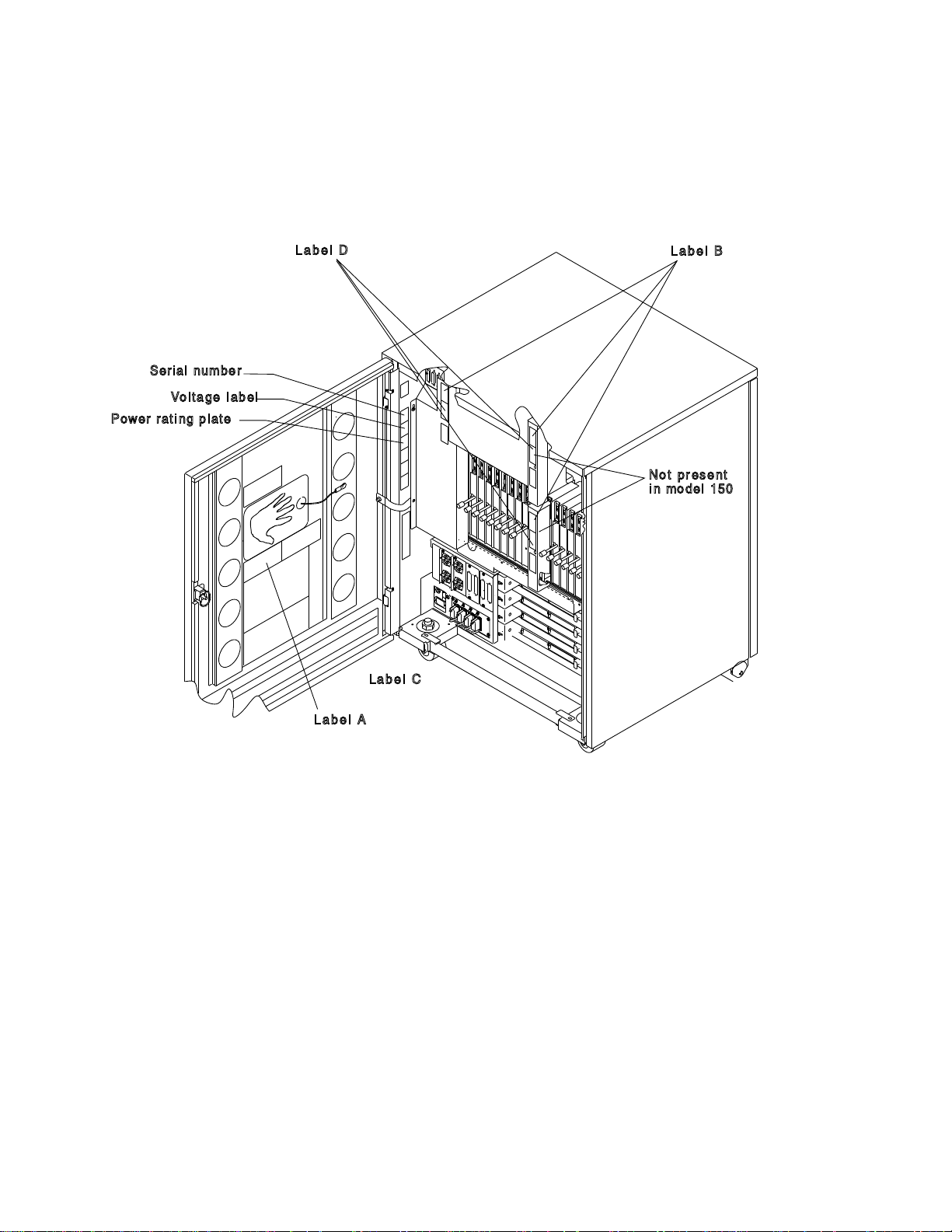

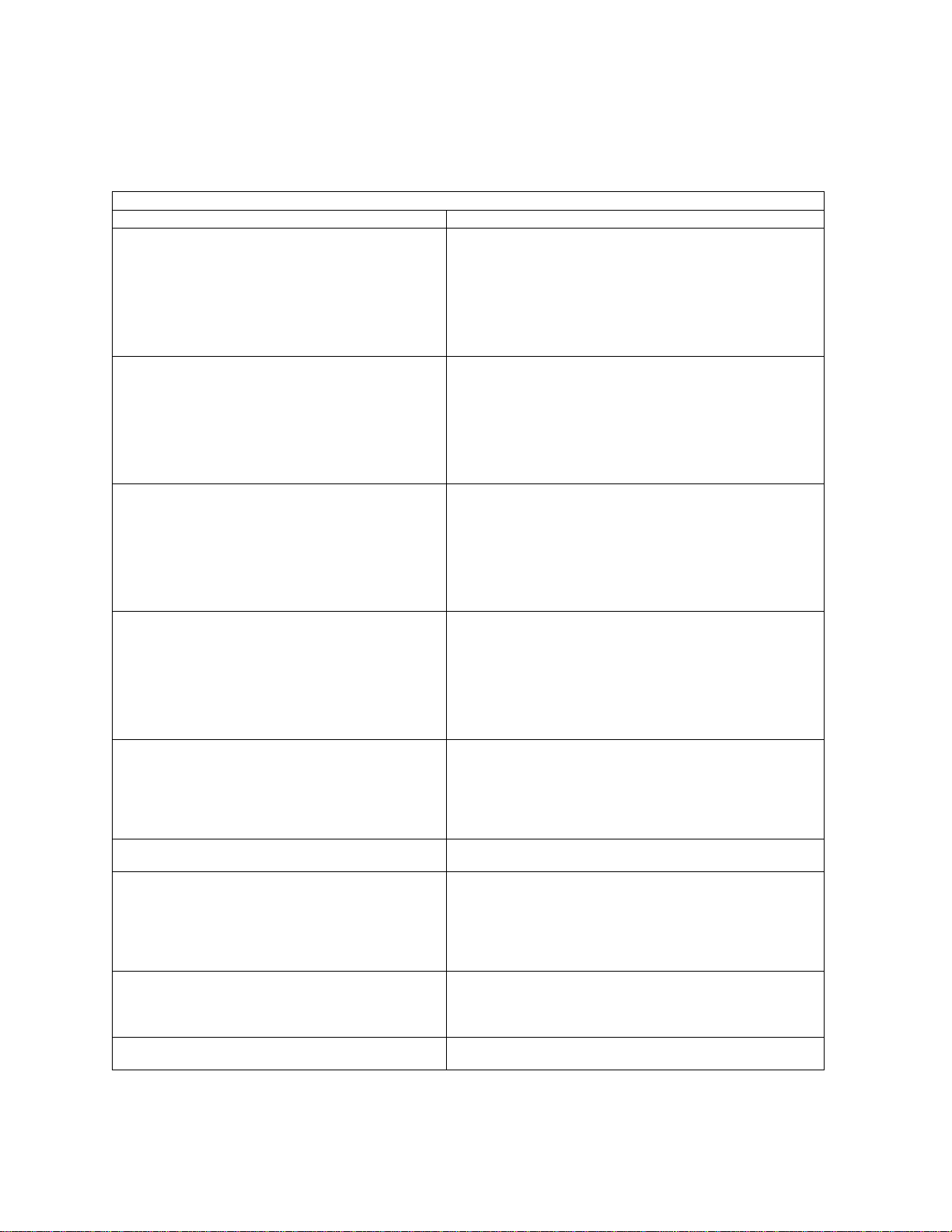

Safety Label Locations

Safety Labels on the 3745

On the following figures, labels are designated by letters. A particular wording corresponds to each letter

(see “3745/3746-900 Safety Label Identifications” on page lx).

Figure 0-21. 3745 Label and Power Rating Plate Locations (Back)

Safety lvii

Page 60

Safety

Figure 0-22. 3745 Label and Power Rating Plate Locations (Front)

lviii 3745 Models 130 to 17A: MIP

Page 61

Safety

Safety Label on the 3746-900

On the following figures, labels are designated by letters. A particular wording corresponds to each letter

(see “3745/3746-900 Safety Label Identifications” on page lx).

Power Rat ing Pl ate

(Under t he cover)

Front View

Figure 0-23. 3746 Model 900 (Frame 07) Label Locations

Safety Label on LCB

S