Page 1

X-SEL Controller P/Q/R/S

Vision System I/F Function

Instruction Manual Sixth Edition

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Instruction Manual describes all necessary information to operate this product safely such as

the operation procedure, structure and maintenance procedure.

Before operation, read this manual carefully and fully understand it to operate this product safely.

The enclosed CD or DVD in this product package includes the Instruction Manual for this product.

For the operation of this product, print out the necessary sections in the Instruction Manual or

display them using the personal computer.

After reading through this manual, keep this Instruction Manual at hand so that the operator of this

product can read it whenever necessary.

[Important]

x This Instruction Manual is original.

x The product cannot be operated in any way unless expressly specified in this Instruction

Manual.

IAI shall assume no responsibility for the outcome of any operation not specified herein.

x Information contained in this Instruction Manual is subject to change without notice for

the purpose of product improvement.

x If you have any question or comment regarding the content of this manual, please

contact the IAI sales office near you.

x Using or copying all or part of this Instruction Manual without permission is prohibited.

x The company names, names of products and trademarks of each company shown in the

sentences are registered trademarks.

x CV-2000, CV-3000, CV-5000 and XG-7000 are the registered trademarks of Keyence

Corporation.

x F210-CIO, FZ3 are the registered trademarks of OMRON Corporation.

x In-Sight 5000 Series and In-Sight Explorer are the registered trademarks of Cognex

Corporation.

Page 4

Page 5

Table of Contents

Safety Guide ·····················································································································1

Precautions in Handling···································································································· 8

1. Overview ·······················································································································9

2. Work Flow before Operation Start···············································································10

2.1 Starting Procedures ····································································································10

2.2 Items to Prepare Beforehand······················································································ 11

3. Coordinates·················································································································13

3.1 Coordinate Axes for Orthogonal Robot······································································· 13

4. Installation ··················································································································· 14

4.1 Wiring·························································································································· 14

4.1.1 Example of wiring layout when connecting Cognex camera ·······························14

4.1.2 Example of wiring layout when connecting Keyence camera······························ 15

4.1.3 Example of wiring layout when connecting OMRON camera······························ 16

4.2 Installing XSEL Controller PC Software······································································ 17

4.3 Installing the Camera·································································································· 18

4.3.1. Cognex Camera··································································································· 18

4.3.2 Keyence Camera ·································································································19

4.3.3 OMRON Camera·································································································· 20

5. Vision System I/F Function Setting ············································································· 21

5.1 Setting Procedure ······································································································· 21

5.2 About Parameter Change ···························································································23

5.2.1 Regarding to Value Setting ··················································································23

5.2.1.1 Binary Number ····························································································· 23

5.2.1.2 Hexadecimal Number ·················································································· 23

5.3 Communication Channel Setting ················································································24

5.3.1 When Ethernet TCP/IP Message Communication is Used··································24

5.3.2 When Standard SIO (RS232C) Channel Communication is Used ······················ 26

5.4 Communication Format Setting ·················································································· 27

5.5 Unit Conversion (pixel mm) ···················································································· 29

5.6 Coordinate Setting ······································································································ 29

5.7 Detailed Function Settings·························································································· 30

Page 6

5.8 Vision System I/F adjustment ·····················································································32

5.8.1 Initial Settings for Simple Calibration

(When EZ-110XL camera is used) ·······································································33

5.8.2 When Camera Not Mounted on Robot

(When EZ-110XL is used) ····················································································37

5.8.3 When Camera Mounted on Robot

(When EZ-110XL is used) ····················································································57

5.8.4 When Camera Not Mounted on Robot

(When camera other than EZ-110XL is used)······················································77

5.8.5 When Camera Mounted on Robot

(When camera other than EZ-110XL is used)······················································85

5.9 Variance Adjustment ··································································································· 92

6. Program Construction for Operation ··········································································· 94

6.1 SEL Command············································································································94

6.1.1 SLVS (Select Vision System I/F) Command ························································94

6.1.2 GTVD (Vision System I/F Image-Capture Data Acquirement) Command ··········· 96

6.2 Outline for SEL Program Construction (Basic Frame)················································98

7. Error Treatment········································································································· 100

7.1 Common Errors for All Vision Systems ·····································································100

7.2 Simple Calibration Execution Error for EZ-110XL·····················································105

7.3 Return Code List in READ Command (SEL Language) Execution ··························109

8. Appendix··················································································································· 110

8.1 Communication Format Setting Values····································································· 110

8.2 General-purpose RS232C Port················································································· 117

8.3 Operation of High Speed Cartesian Robot (CT4) ····················································· 118

9. Change History ········································································································· 119

Page 7

1

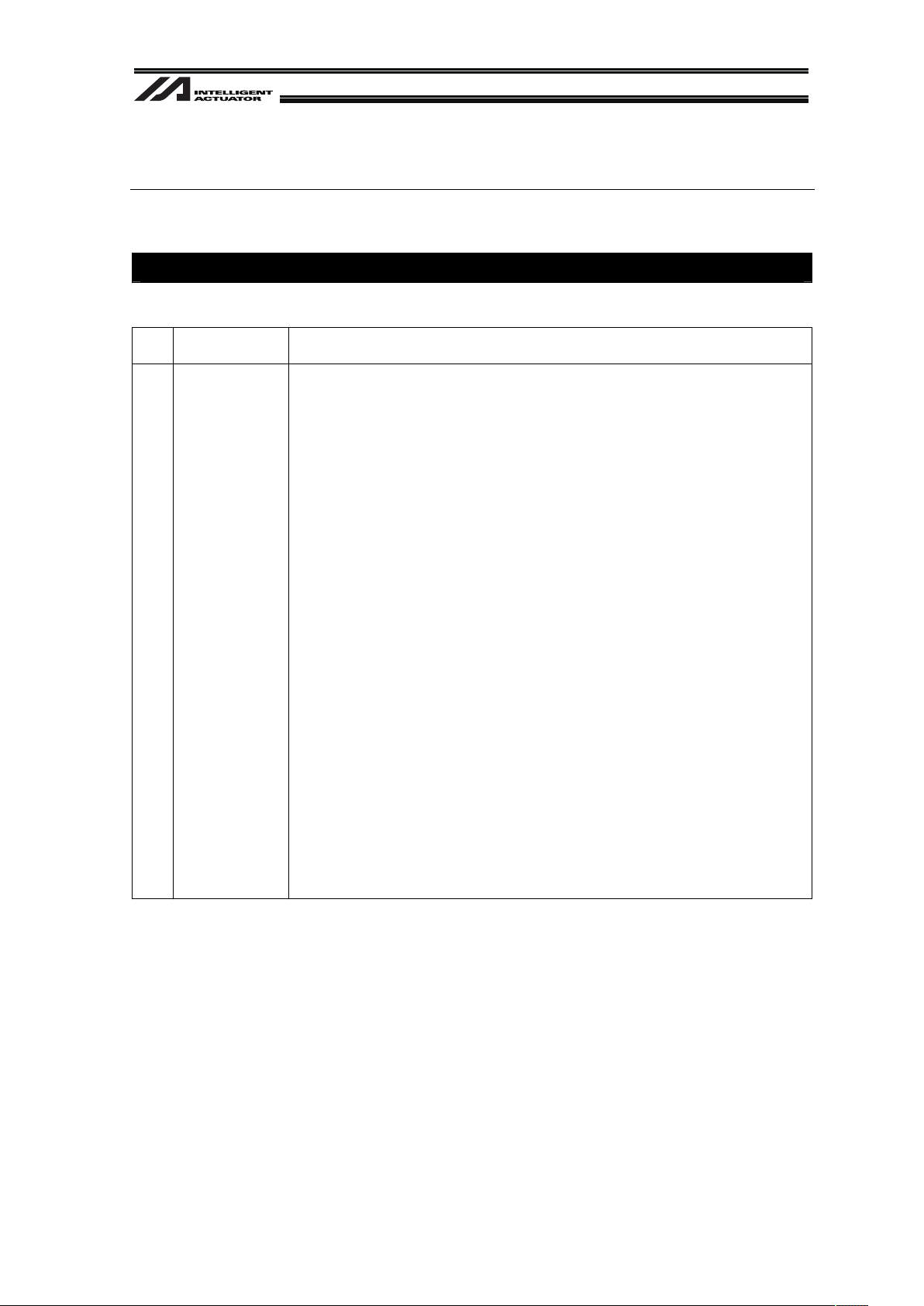

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or

property damage beforehand. Make sure to read it before the operation of this product.

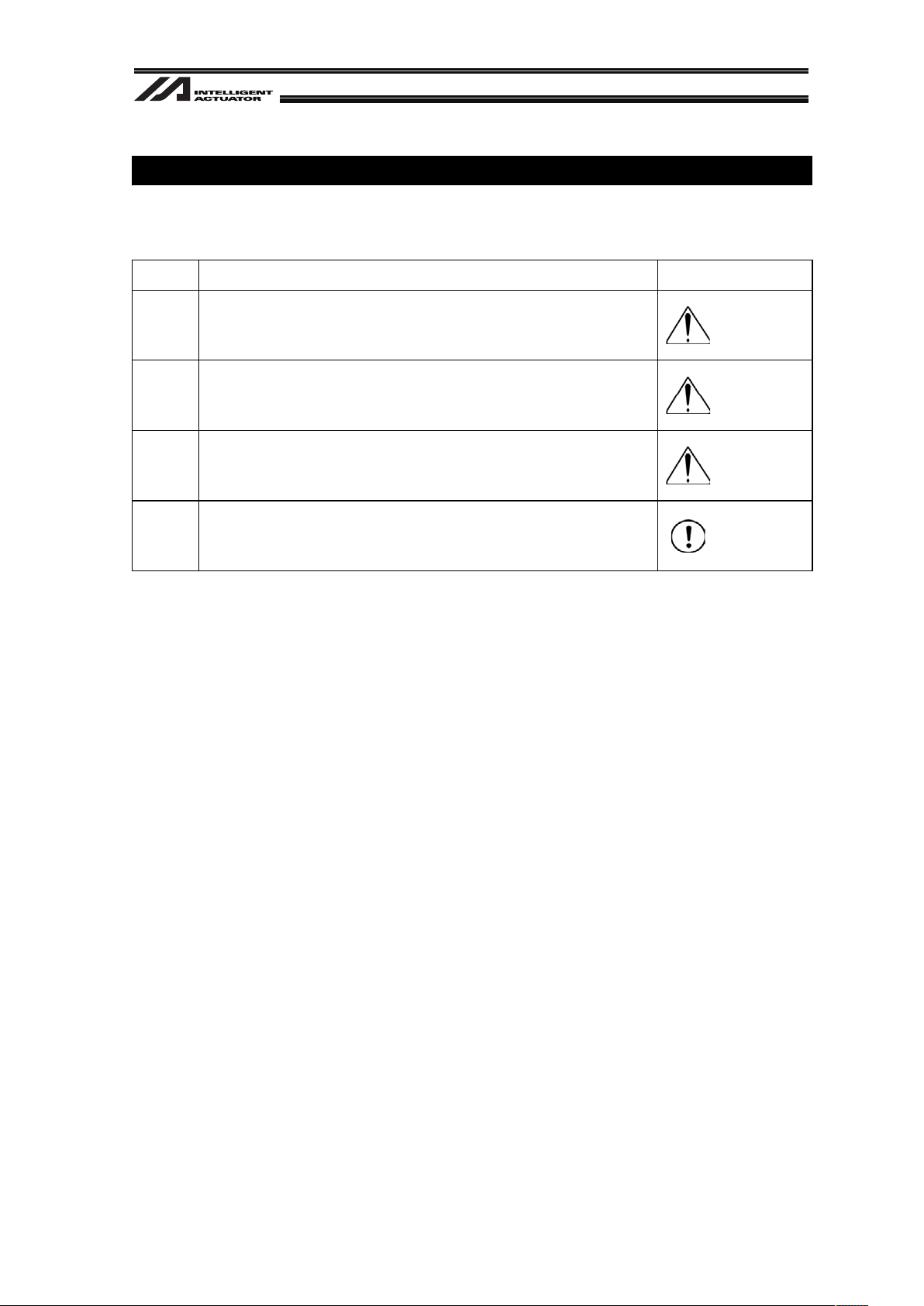

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

No.

Operation

Description

Description

1 Model

Selection

Ɣ This product has not been planned and designed for the application

where high level of safety is required, so the guarantee of the protection

of human life is impossible. Accordingly, do not use it in any of the

following applications.

1) Medical equipment used to maintain, control or otherwise affect

human life or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation

facility)

3) Important safety parts of machinery (Safety device, etc.)

Ɣ Do not use the product outside the specifications. Failure to do so may

considerably shorten the life of the product.

Ɣ Do not use it in any of the following environments.

1) Location where there is any inflammable gas, inflammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding

the specification range

4) Location where radiant heat is added from direct sunlight or other

large heat source

5) Location where condensation occurs due to abrupt temperature

changes

6) Location where there is any corrosive gas (sulfuric acid or

hydrochloric acid)

7) Location exposed to significant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

Ɣ For an actuator used in vertical orientation, select a model which is

equipped with a brake. If selecting a model with no brake, the moving

part may drop when the power is turned OFF and may cause an

accident such as an injury or damage on the work piece.

Page 8

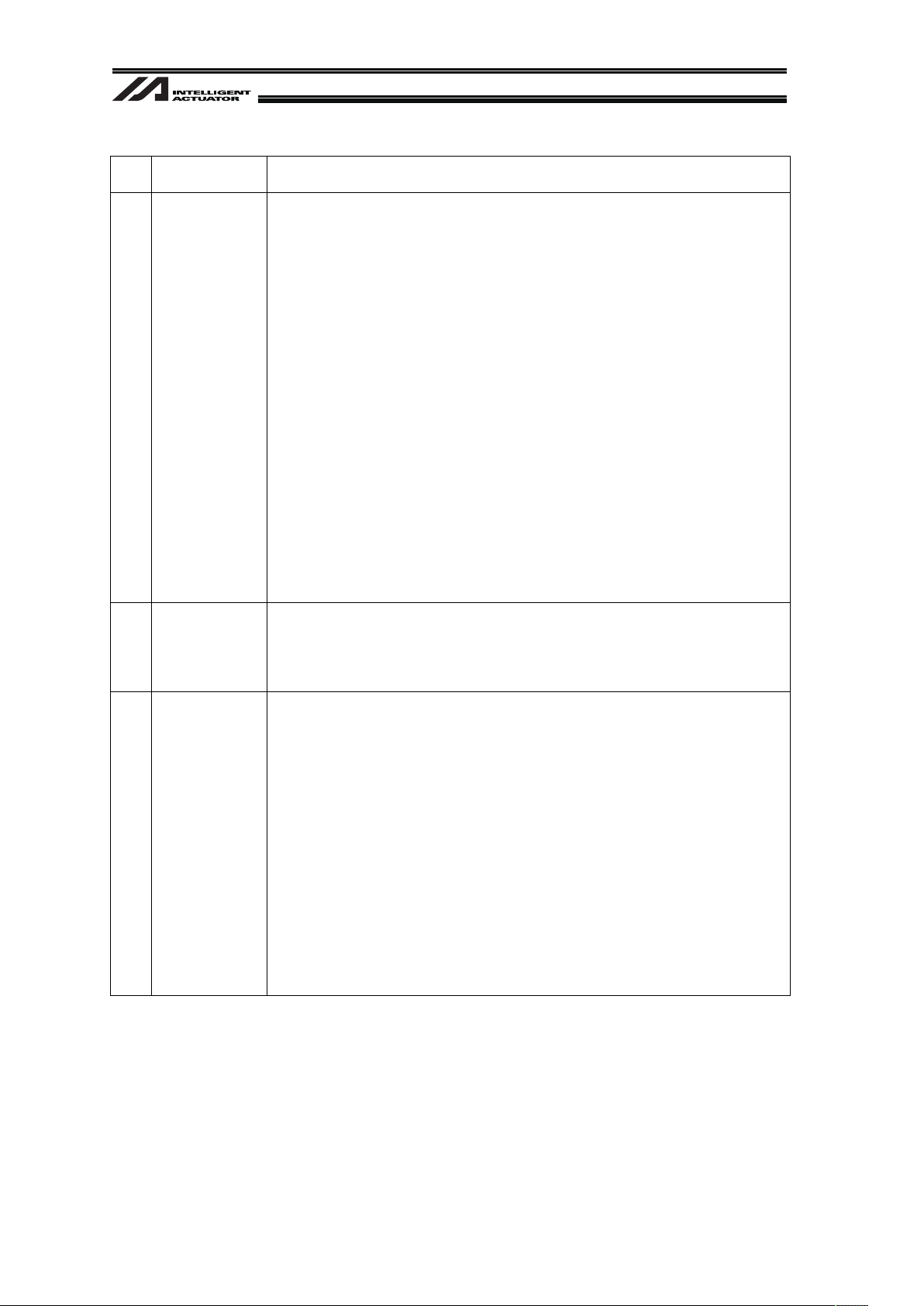

2

No.

Operation

Description

Description

2 Transportation Ɣ When carrying a heavy object, do the work with two or more persons or

utilize equipment such as crane.

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ When in transportation, consider well about the positions to hold,

weight and weight balance and pay special attention to the carried

object so it would not get hit or dropped.

Ɣ Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts

attached or there are tapped holes to attach bolts. Follow the

instructions in the instruction manual for each model.

Ɣ Do not step or sit on the package.

Ɣ Do not put any heavy thing that can deform the package, on it.

Ɣ When using a crane capable of 1t or more of weight, have an operator

who has qualifications for crane operation and sling work.

Ɣ When using a crane or equivalent equipments, make sure not to hang a

load that weighs more than the equipment’s capability limit.

Ɣ Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

Ɣ Do not get on the load that is hung on a crane.

Ɣ Do not leave a load hung up with a crane.

Ɣ Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

Ɣ The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention

of condensation.

Ɣ Store the products with a consideration not to fall them over or drop due

to an act of God such as earthquake.

4 Installation

and Start

(1) Installation of Robot Main Body and Controller, etc.

Ɣ Make sure to securely hold and fix the product (including the work part).

A fall, drop or abnormal motion of the product may cause a damage or

injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

Ɣ Do not get on or put anything on the product. Failure to do so may

cause an accidental fall, injury or damage to the product due to a drop

of anything, malfunction of the product, performance degradation, or

shortening of its life.

Ɣ When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

Page 9

3

No.

Operation

Description

Description

(2) Cable Wiring

Ɣ Use our company’s genuine cables for connecting between the actuator

and controller, and for the teaching tool.

Ɣ Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do

not coil it around. Do not insert it. Do not put any heavy thing on it.

Failure to do so may cause a fire, electric shock or malfunction due to

leakage or continuity error.

Ɣ Perform the wiring for the product, after turning OFF the power to the

unit, so that there is no wiring error.

Ɣ When the direct current power (+24V) is connected, take the great care

of the directions of positive and negative poles. If the connection

direction is not correct, it might cause a fire, product breakdown or

malfunction.

Ɣ Connect the cable connector securely so that there is no disconnection

or looseness. Failure to do so may cause a fire, electric shock or

malfunction of the product.

Ɣ Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so

may cause the product to malfunction or cause fire.

4 Installation

and Start

(3) Grounding

Ɣ The grounding operation should be performed to prevent an electric

shock or electrostatic charge, enhance the noise-resistance ability and

control the unnecessary electromagnetic radiation.

Ɣ For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair

cable with wire thickness 0.5mm

2

(AWG20 or equivalent) or more for

grounding work. For security grounding, it is necessary to select an

appropriate wire thickness suitable for the load. Perform wiring that

satisfies the specifications (electrical equipment technical standards).

Ɣ Perform Class D Grounding (former Class 3 Grounding with ground

resistance 100: or below).

Page 10

4

No.

Operation

Description

Description

4 Installation

and Start

(4) Safety Measures

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ When the product is under operation or in the ready mode, take the

safety measures (such as the installation of safety and protection

fence) so that nobody can enter the area within the robot’s movable

range. When the robot under operation is touched, it may result in

death or serious injury.

Ɣ Make sure to install the emergency stop circuit so that the unit can be

stopped immediately in an emergency during the unit operation.

Ɣ Take the safety measure not to start up the unit only with the power

turning ON. Failure to do so may start up the machine suddenly and

cause an injury or damage to the product.

Ɣ Take the safety measure not to start up the machine only with the

emergency stop cancellation or recovery after the power failure. Failure

to do so may result in an electric shock or injury due to unexpected

power input.

Ɣ When the installation or adjustment operation is to be performed, give

clear warnings such as “Under Operation; Do not turn ON the power!”

etc. Sudden power input may cause an electric shock or injury.

Ɣ Take the measure so that the work part is not dropped in power failure

or emergency stop.

Ɣ Wear protection gloves, goggle or safety shoes, as necessary, to

secure safety.

Ɣ Do not insert a finger or object in the openings in the product. Failure to

do so may cause an injury, electric shock, damage to the product or

fire.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

5 Teaching Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ Perform the teaching operation from outside the safety protection

fence, if possible. In the case that the operation is to be performed

unavoidably inside the safety protection fence, prepare the “Stipulations

for the Operation” and make sure that all the workers acknowledge and

understand them well.

Ɣ When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch

on the operation so that any third person can not operate the switches

carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

Page 11

5

No.

Operation

Description

Description

6 Trial

Operation

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ After the teaching or programming operation, perform the check

operation one step by one step and then shift to the automatic

operation.

Ɣ When the check operation is to be performed inside the safety

protection fence, perform the check operation using the previously

specified work procedure like the teaching operation.

Ɣ Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

Ɣ Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

Ɣ Check before starting the automatic operation or rebooting after

operation stop that there is nobody in the safety protection fence.

Ɣ Before starting automatic operation, make sure that all peripheral

equipment is in an automatic-operation-ready state and there is no

alarm indication.

Ɣ Make sure to operate automatic operation start from outside of the

safety protection fence.

Ɣ In the case that there is any abnormal heating, smoke, offensive smell,

or abnormal noise in the product, immediately stop the machine and

turn OFF the power switch. Failure to do so may result in a fire or

damage to the product.

Ɣ When a power failure occurs, turn OFF the power switch. Failure to do

so may cause an injury or damage to the product, due to a sudden

motion of the product in the recovery operation from the power failure.

Page 12

6

No.

Operation

Description

Description

8 Maintenance

and

Inspection

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ Perform the work out of the safety protection fence, if possible. In the

case that the operation is to be performed unavoidably inside the safety

protection fence, prepare the “Stipulations for the Operation” and make

sure that all the workers acknowledge and understand them well.

Ɣ When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

Ɣ When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch

on the operation so that any third person can not operate the switches

carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ For the grease for the guide or ball screw, use appropriate grease

according to the Instruction Manual for each model.

Ɣ Do not perform the dielectric strength test. Failure to do so may result in

a damage to the product.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

Ɣ The slider or rod may get misaligned OFF the stop position if the servo

is turned OFF. Be careful not to get injured or damaged due to an

unnecessary operation.

Ɣ Pay attention not to lose the cover or untightened screws, and make

sure to put the product back to the original condition after maintenance

and inspection works.

Use in incomplete condition may cause damage to the product or an

injury.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

9 Modification

and Dismantle

Ɣ Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal Ɣ When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

Ɣ When removing the actuator for disposal, pay attention to drop of

components when detaching screws.

Ɣ Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

11 Other Ɣ Do not come close to the product or the harnesses if you are a person

who requires a support of medical devices such as a pacemaker. Doing

so may affect the performance of your medical device.

Ɣ See Overseas Specifications Compliance Manual to check whether

complies if necessary.

Ɣ For the handling of actuators and controllers, follow the dedicated

instruction manual of each unit to ensure the safety.

Page 13

7

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to

the warning level, as follows, and described in the Instruction Manual for each model.

Level Degree of Danger and Damage Symbol

Danger

This indicates an imminently hazardous situation which, if the

product is not handled correctly, will result in death or serious

injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the

product is not handled correctly, could result in death or serious

injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the

product is not handled correctly, may result in minor injury or

property damage.

Caution

Notice

This indicates lower possibility for the injury, but should be kept to

use this product properly.

Notice

Page 14

8

Precautions in Handling

x The number of work pieces that the camera can detect in 1 shot of image capturing is as

described below:

Cognex In-Sight EZ110 8 pieces at max.

Cognex In-Sight 5000 12 pieces at max.

Keyence CV-2000 7 pieces at max.

Vision systems of Keyence other than CV-2000 and I/F applicable vision systems 12 pieces at max.

OMRON vision systems 12 pieces at max.

x Build the system with care so that the work after being captured would not get moved off the

position by an external force (vibration, air blow, crash of another work, etc.).

x If the image-capturing conditions, such as the light (diffusers), focus, diaphragm, shutter speed,

etc., are inefficient, such problems like the work not being detected or inaccurate position

detection may occur. (Please refer to the Instruction Manual for Vision System to have the

appropriate adjustments.)

x Please ask each vision system supplier for the adjustment of Vision System (detection settings,

format settings indicated for our products [refer to Section 8.1], etc.).

When using Cognex In-Sight EZ110, the sample job data is available to download from the

enclosed CD or IAI homepage. (* Please ask the distributor to have the detection settings done

for you so it suits to the work that you will use.)

x Regarding Operation of High Speed Cartesian Robot CT4

Refer to 8.3 Operation of High Speed Cartesian Robot (CT4) for the details.

Page 15

9

1. Overview

Vision System I/F Function is a function to store the coordinate data

(Note 1) (Note 2)

sent from the work

directly to the position data.

When using the vision system, the specialized window in the PC software always backups the

adjustment (calibration) of coordinates of the necessary camera and robot

(Note 3)

.

(Note 1) In the existing systems, the data from Vision System needs to be treated as characters

and the user needs to convert the values to store the position data. In Vision System I/F

Function, the user does not need to convert the values, and the coordinates are directly

stored to the position data.

(Note 2) It is necessary to send the data in the format indicated by our products.

(Note 3) If conducting the dedicated calibration with EZ-110XL, the procedure of manual

alignment of the work to the robot which is necessary for the existing models will be

dramatically reduced.

This manual explains how to set up the system to utilize Vision System I/F Function.

1. Overview

Page 16

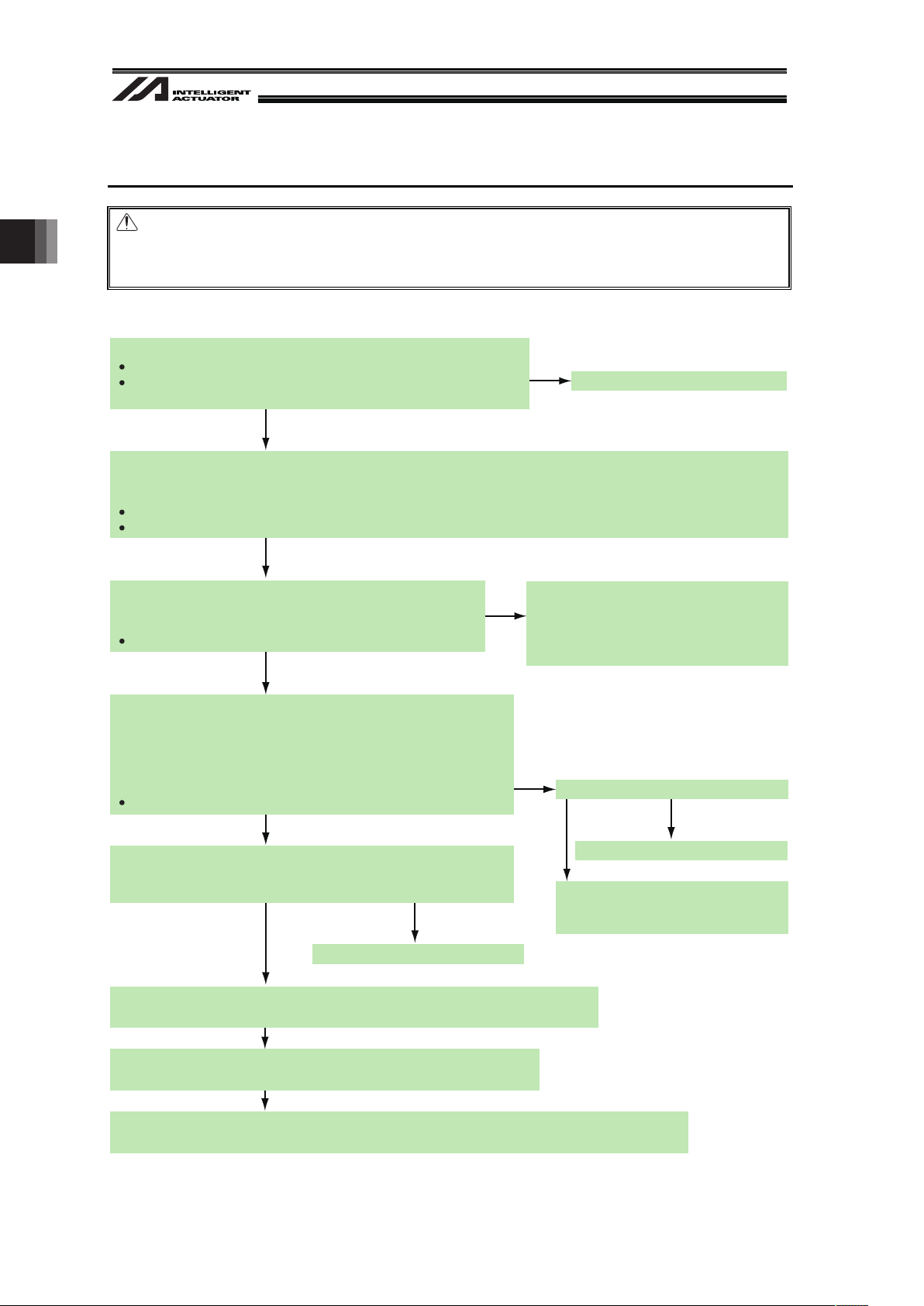

2. Work Flow before Operation Start

10

2. Work Flow before Operation Start

Note

Make sure to have the settings of the vision system such as the work detection setting and

communication setting done before having the vision system I/F function settings.

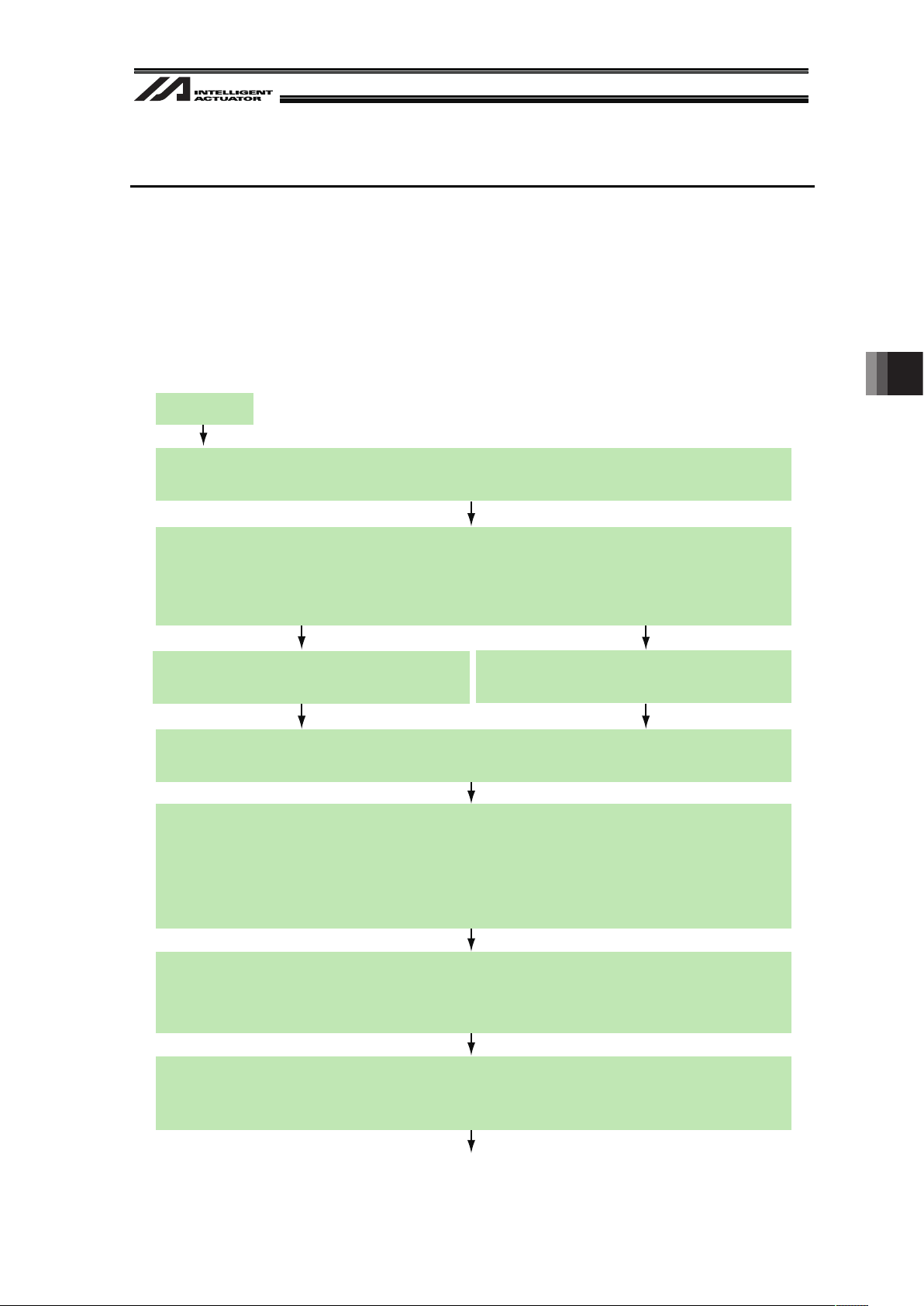

2.1 Starting Procedures

No

No

No

Yes

Check of Packed Items

Are there all the delivered items?

Do you have all the equipment listed in Section 2.2 that needs to be

prepared beforehand?

Yes

Yes

Yes

Yes

Yes

Installation and Wiring

Have the actuator and encoder installed and connected following the instructions in XSEL Controller Instruction

Manual, Actuator Instruction Manual and this manual (see Section 4).

Are the frame grounding (FG) and protection earthing (PE) conducted?

Has the noise countermeasure been taken?

Power Supply and Alarm Check

Connect the PC, put AUTO/MANU switch to “MANU” side and

turn the power on.

Is the status display showing “rdy” ?

Check of Safety Circuit

Actuator Setting

Check that the emergency stop circuit (or motor drive power cutoff

circuit) operates normally to turn off the servo.

Vision System I/F Function Setting (Refer to Section 5)

The setting details differ depending if the camera is mounted to the robot or not.

Creating Program (Refer to Section 6)

Create a program based on SEL program construction capacity.

Power-up and Operation Check

Have the program run to check the sensor input, axis data from the camera and tracking position.

Have an appropriate treatment following

the content of the status display.

[Refer to the trouble shootings in Instruction Manuals for XSEL Controller and PC

Software.]

No

Is the motor cable connected?

No

Contact the sales shop.

Connect the motor cable.

Check the emergency stop circuit.

Check the alarm content on the PC to

have an appropriate treatment if an

alarm is generated.

Write the target position to the position table.

Press the SV button in the button display for each axis in the PC

software to turn the servo on.

After the servo is on, press the HM button in the button display for

each axis to conduct a home-return operation.

Did the servo turn on and home without error?

Now, the operation adjustment is complete.

Conduct an adjustment by the system.

Page 17

11

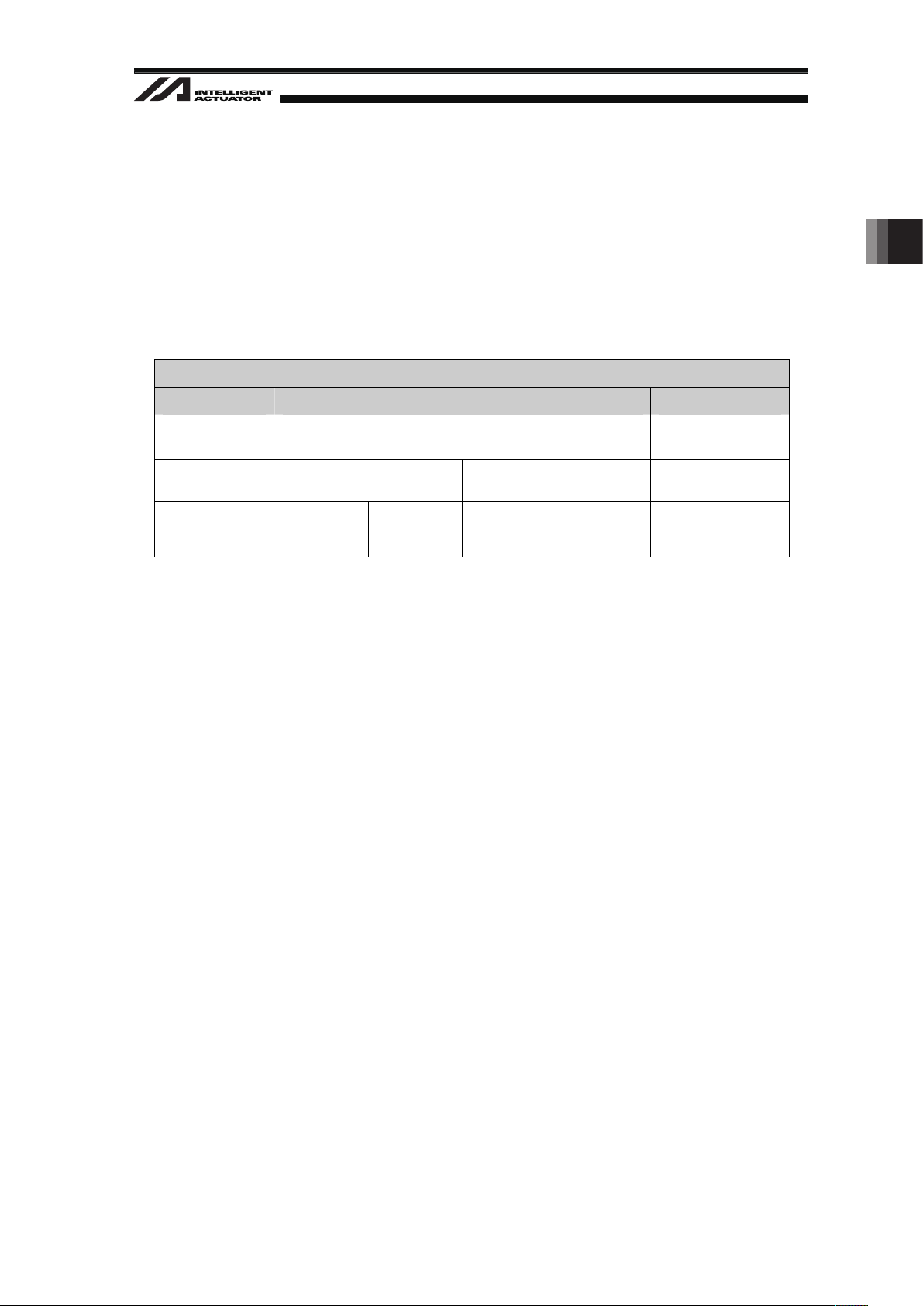

2.2 Items to Prepare Beforehand

The Vision System explained in this manual is in regard to the equipment’s operation and its

program. The equipment and components that construct the system need to be prepared

separately.

1) Vision System

Corresponding Product

(Note) Please ask each vision system supplier to have the settings on Vision System such as the work

detection setting and the output communication format indicated by our products [refer to Section

8.1].

x PIO Cable

(There are some cases that the dedicated accessary is required. Please refer to the

Instruction Manual for each Vision System.

e.g. FZ-VP, Parallel I/O cable dedicated for OMRON FZ3)

x For Ethernet Connection

LAN cable (Category 5 or higher)

Hub

x For RS232C Connection

Apply a cable that has a connector suitable for the camera controller on one end and D-sub

9-pin connector (female) on the other end (XSEL end).

[Refer to the Instruction Manual for each Vision System for the wiring on the camera controller

side.]

[Refer to the Appendix at the end for the wiring on XSEL side.]

x If Using Work Detection Sensor

Photoelectric sensor

Examples of Vision System Models

Supplier Model Interface

Cognex

In-Sight EZ-110 (EZ-110XL)

In-Sight 5000 Series

Ethernet

OMRON F210-C10 FZ3 RS232C

Keyence CV2000 CV3000 CV5000 XG-7000

Ethernet

RS232C

2. Work Flow before Operation Start

Page 18

12

2) Other Requirement of IAI Products

x XSEL Controller

(Main application Version XSEL-P/Q : V1.05 or later

XSEL-R/S : V1.04 or later)

x Ethernet Board

(Option … If Ethernet is used for communication between the vision system and XSEL)

x XSEL controller PC software

(If the vision system is In-Sight EZ110 (EZ-110XL);

• XSEL-P/Q : Version V7.07.08.00 or later

• XSEL-R/S : Version V9.0.0.0 or later

(If the vision system is not In-Sight EZ110 (EZ-110XL);

• XSEL-P/Q : Version V7.06.08.00 or later

• XSEL-R/S : Version V9.0.0.0 or later

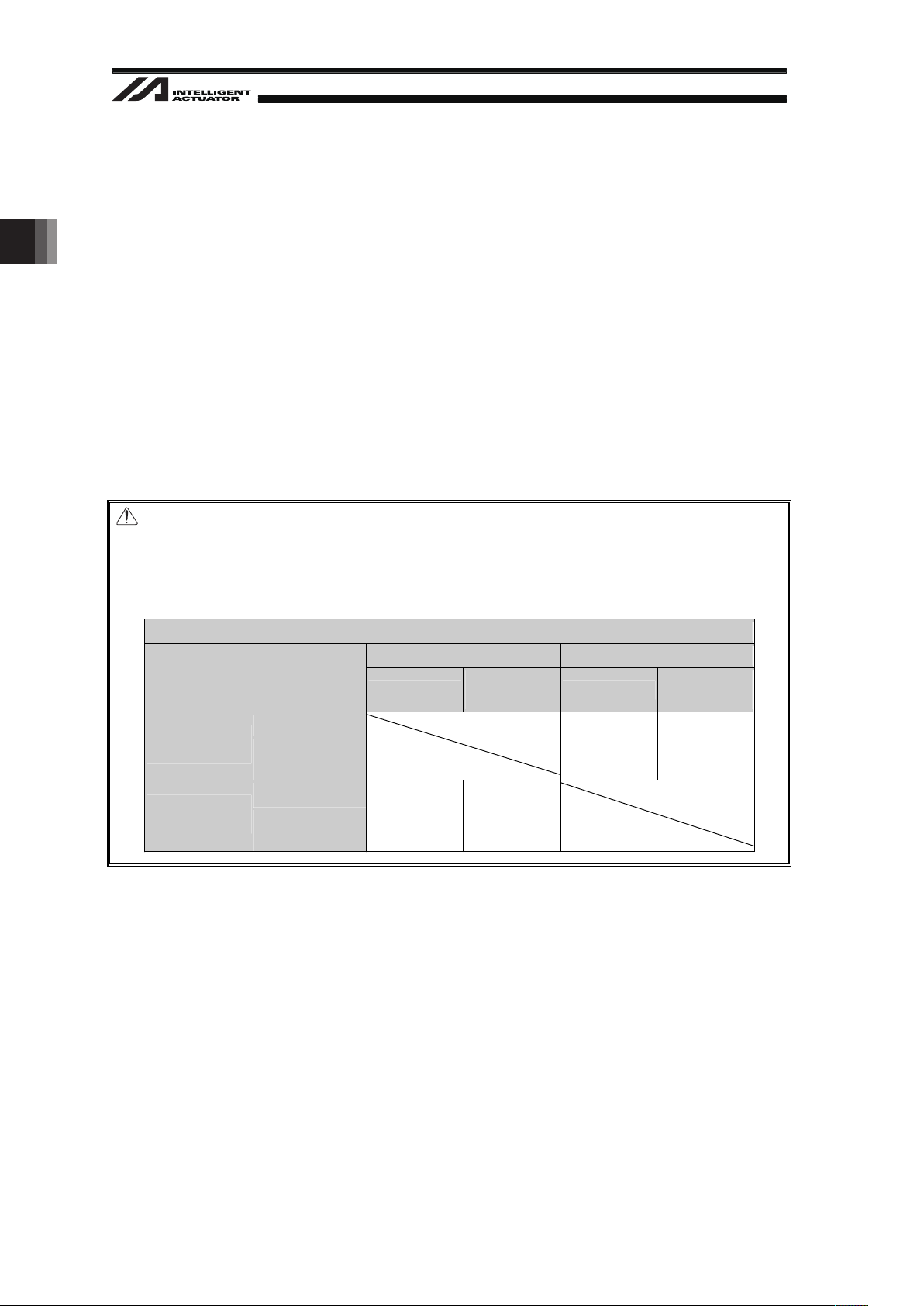

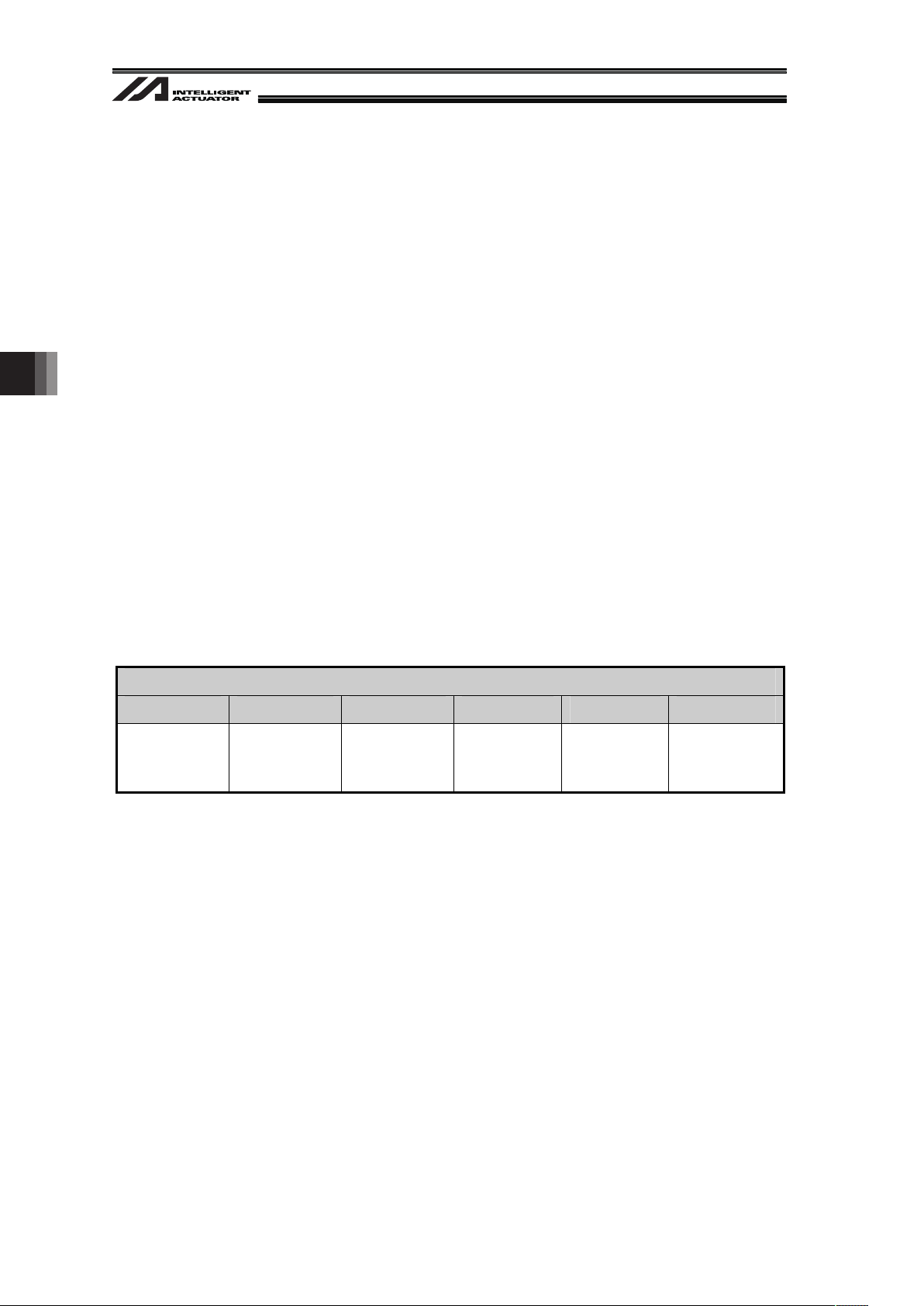

Note

When using the conveyor tracking function and the vision system I/F function at the same time, it

is not possible to have Ethernet to both of the functions as the communication interface. Connect

one of them with RS232C.

Available interface combination when using vision system

Conveyer Tracking Vision System I/F

Interface

Ethernet

Standard SIO

(RS232C)

Ethernet

Standard SIO

(RS232C)

Ethernet × ż

Conveyer

Tracking

Standard SIO

(RS232C)

ż ż

Ethernet

× ż

Vision System

I/F

Standard SIO

(RS232C)

ż ż

If the vision system is EZ-110XL and the dedicated software is used, the simple adjustment function

that enables to reduce the procedure of manual alignment in the matching process of the robot and

the vision system coordinates can be used.

When using the simple adjustment function, the work to be used in the adjustment process and a

tool to hold the work (chuck, grip, etc.) are necessary for the settings.

2. Work Flow before Operation Start

Page 19

13

3. Coordinates

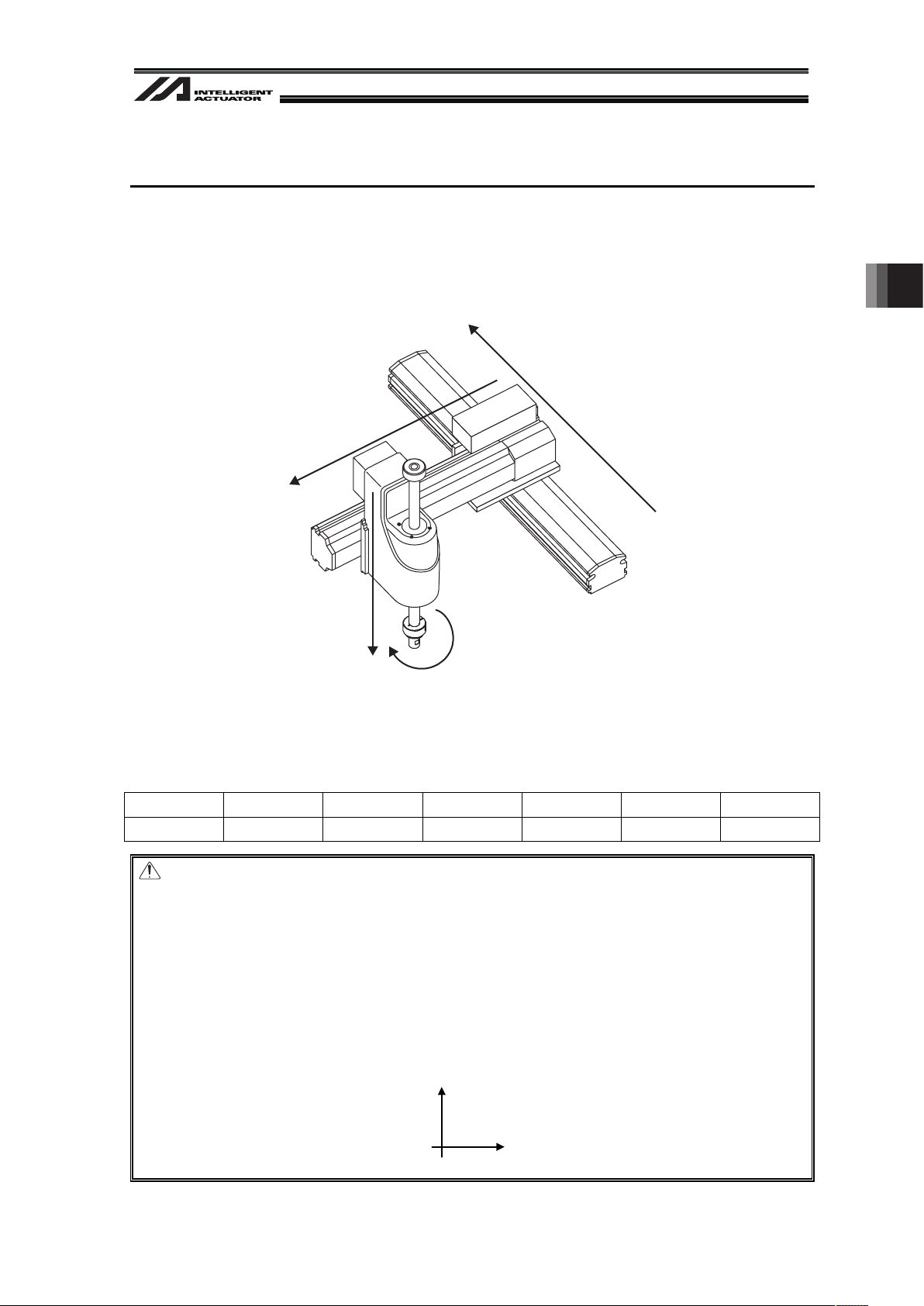

3.1 Coordinate Axes for Orthogonal Robot

The coordinate axes are fixed. (Refer to table below.)

Y-axis (2-axis)

X-axis (1-axis)

Rotary Axis (4-axis)

Z-axis (3-axis)

+

+

+

+

The work coordinates data received from the vision system (position information) is saved to the

position data as shown below.

No. (Name)

Axis1 (1-axis) Axis2 (2-axis) Axis3 (3-axis) Axis4 (4-axis)

Axis5 Axis6

1 ( ) 10.000 0.000 45.000

Note

x The position data of the axes that are not indicated as the valid axis pattern (All-Axes Parameter

No.1) (invalid axes) do not get updated.

x If there is an axis that is not to be used in Axis1, Axis2 and Axis4, declare the axis that uses the

position data in GRP Command.

x Ensure the applied actuators lie across each other in the right angle. Failure to do so may

disable to obtain accurate work coordinate data.

x The positive directions are premised as shown below for the robot X and Y axes coordinates.

㪯

㪰

Work X

Coordinate

ω

Work Y

Coordinate

ω

Work

T

Coordinate

ω

3. Coordinates

Page 20

4. Installation

14

4. Installation

4.1 Wiring

Shown below is an example of the vision system wiring layout when each camera controller is

connected.

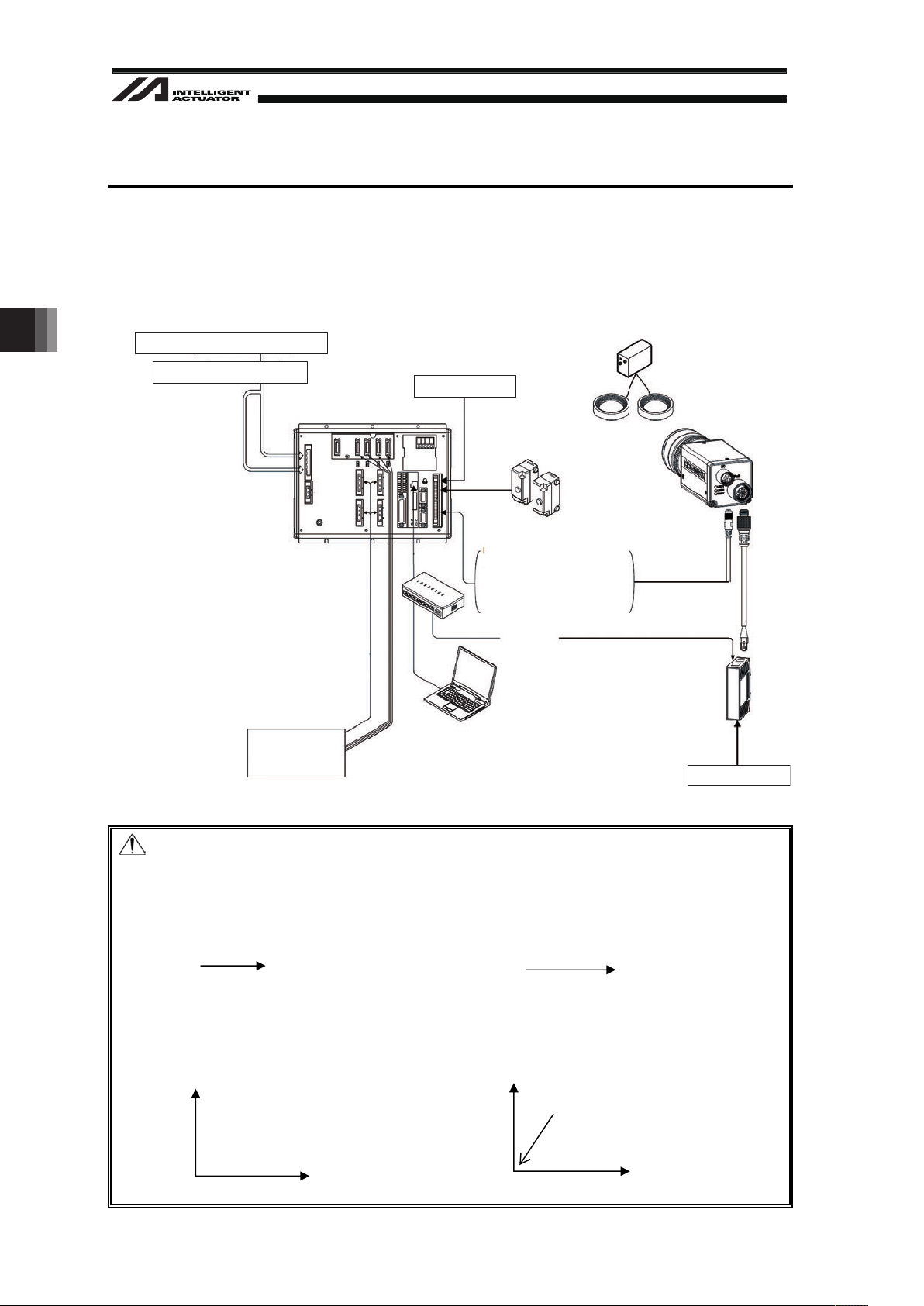

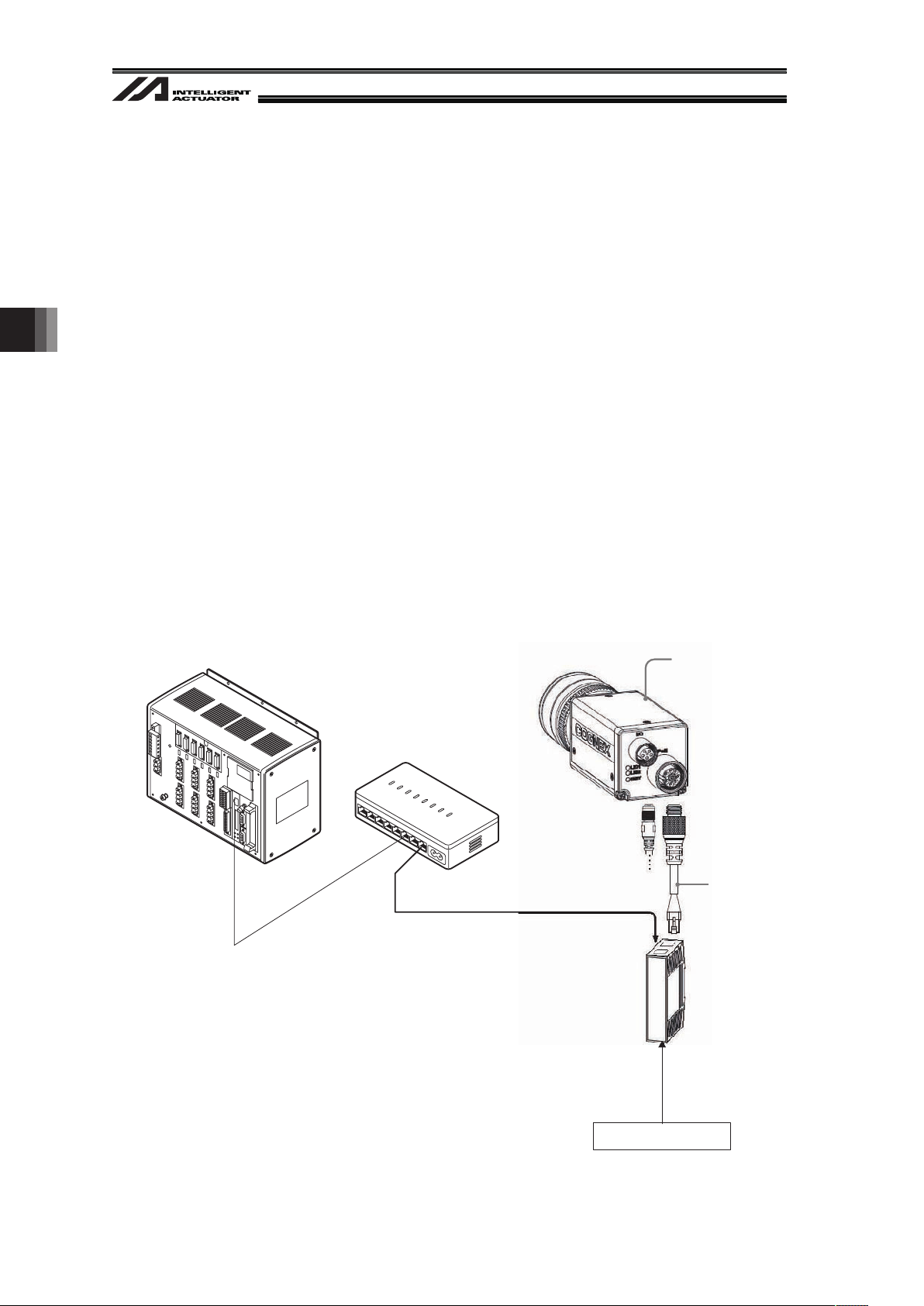

4.1.1 Example of wiring layout when connecting Cognex camera

Example for Vision System Wiring (Cognex)

Note:

• 24V I/O signal (PIO) is used for the capture command to the camera. Use the dedicated I/O

cable for the vision systems if it is equipped with a dedicated cable.

• For EZ-110XL

Set the robot axes and the vision system X-axes so they are orienting the same directions.

Robot Axes Vision System Axes

• For those other than In-Sight EZ110

Set the robot axes and the vision system axes so they are orienting the same directions.

Also, allocate the vision system origin to the bottom left of the screen.

Robot Axes Vision System Axes

Y

X

Allocate the origin to

bottom left of screen

(Utilize the spread sheet)

X

Y

X

X

Power Supply Supprtive Circuit

3-phase 200V AC to 230V power supply

+24V Power Supply

Brake and

Power Supply for I/O

Camera

Work Detection Sensor

(when applied as the

image-capture trigger)

Light

PIO Signals (2 signals)

• Camera start-up signal

(Camera → XSEL)

(Note)

• Image Capturing Command

(XSEL → Camera)

PoE Injector

Robot

+24V Power Supply

Ethernet

M Cable

PC

Hub

Power Supply Unit for

Light Equipment

(Note) The setting not to use the camera startup signal is

also available. (It is described later.)

Page 21

15

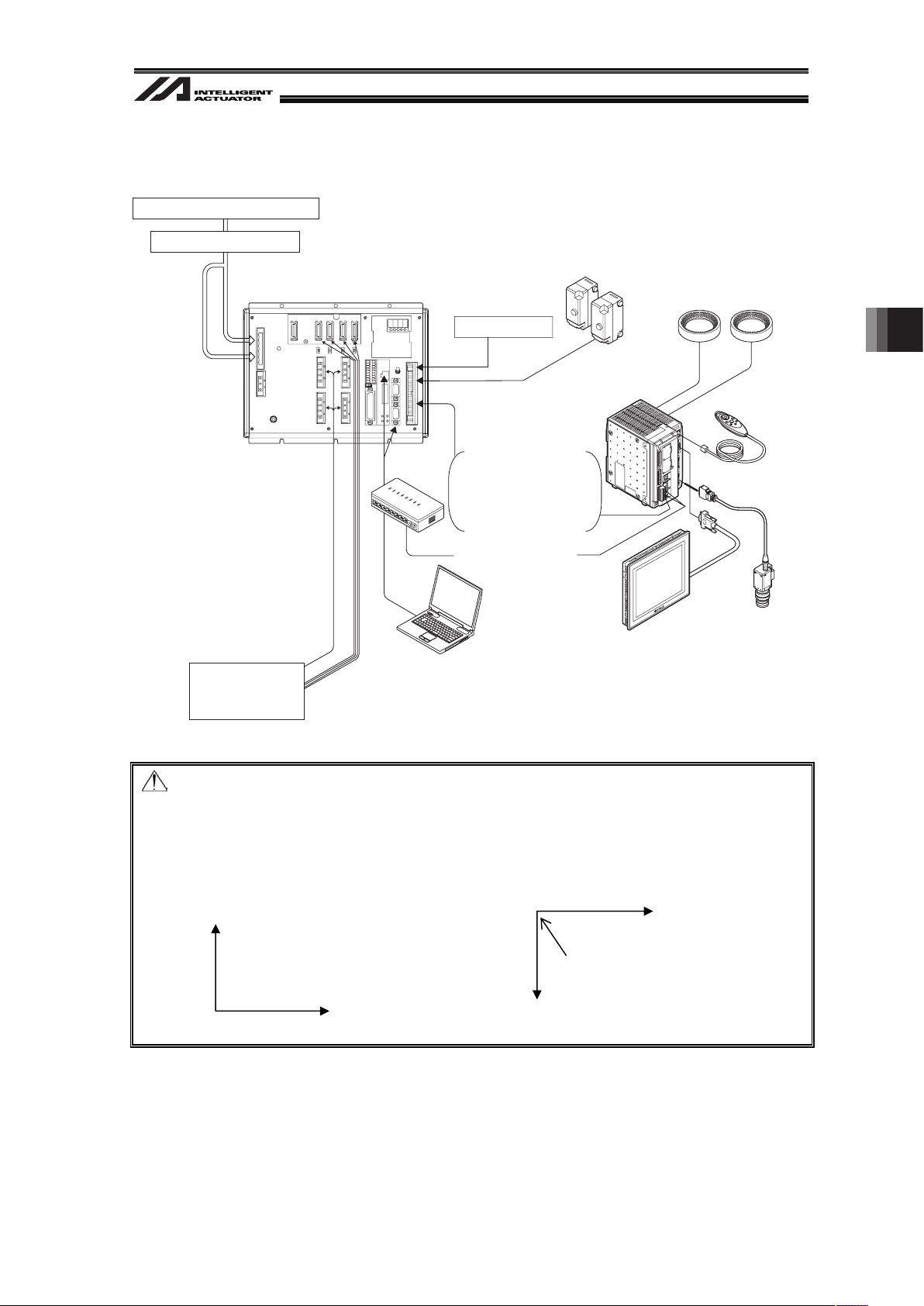

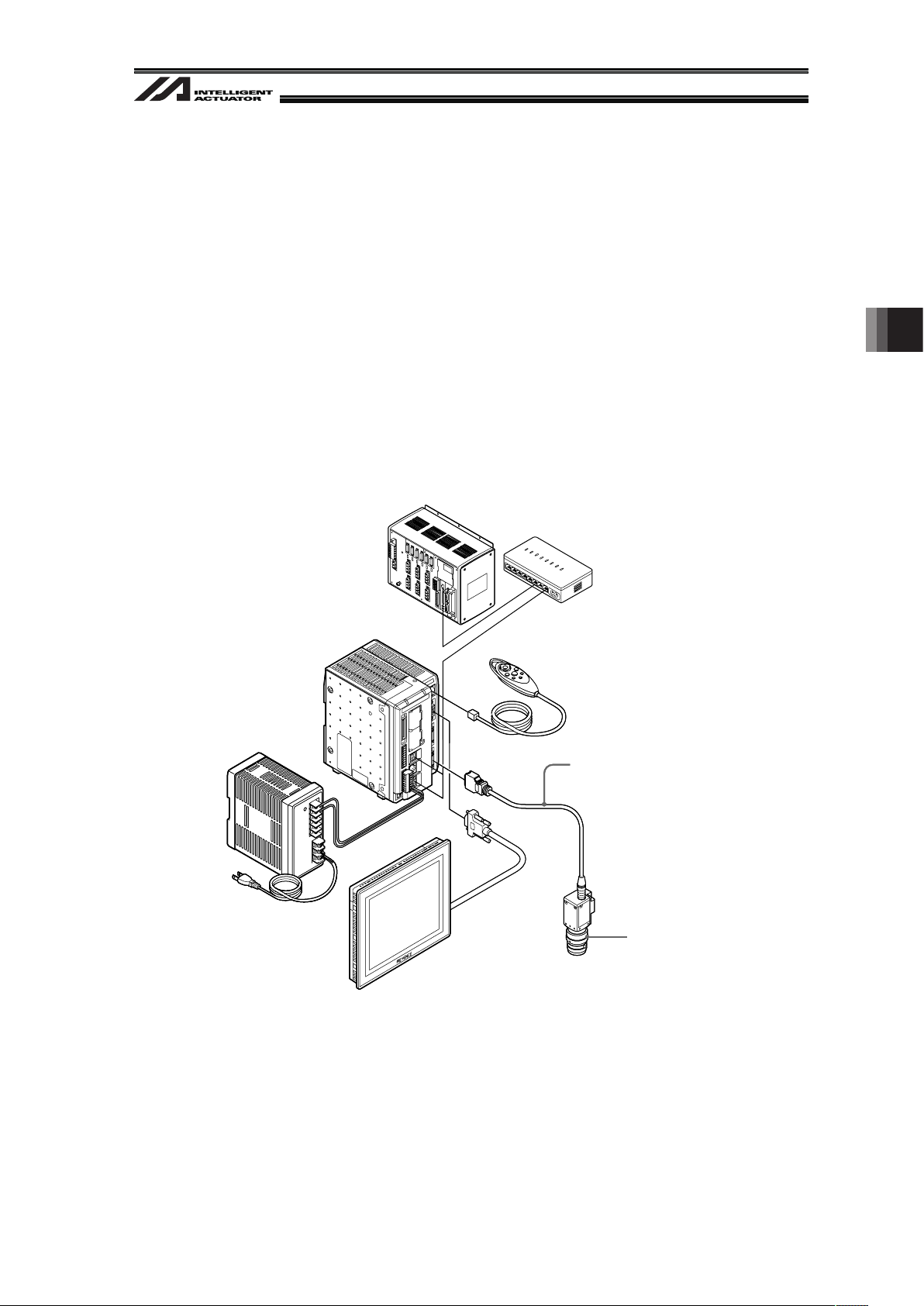

4.1.2 Example of wiring layout when connecting Keyence camera

Example for Vision System Wiring (Keyence)

Note:

• 24V I/O signal (PIO) is used for the capture command to the camera. Use the dedicated I/O

cable for the vision systems if it is equipped with a dedicated cable.

• Set the robot axis and the vision system axes directions so the X-axes are orienting the same

direction and Y-axes the opposite. Also, allocate the vision system origin to the top left of the

screen.

Robot Axes Vision System Axes

Y

X

Y

X

Allocate the origin to top

left of screen

Power Supply Supprtive Circuit

PIO Signals (2 signals)

• Camera Controller

Startup Complete Signal

(Camera Controller→XSEL)

(Note 1)

• Image Capturing Command

(XSEL→Camera Controller)

Ethernet or RS232C

(Note 2)

M Cable

Robot

Monitor

Camera

PC

Hub

+

24V

3-phase 200V AC to 230V power supply

Brake and

Power Supply for I/O

Power Supply

Work Detection Sensor

(when applied as the image-capture trigger)

Light

Console

Camera Controller

Main Body

(Note 1)

(Note 2)

The setting not to use the camera controller startup signal is

also available. (It is described later.)

There is no need for a hub for RS232C connection.

Refer to the Appendix at the end for wiring on XSEL side.

Refer to the Instruction Manual for each Vision System for

wiring on camera controller side.

4. Installation

Page 22

4. Installation

16

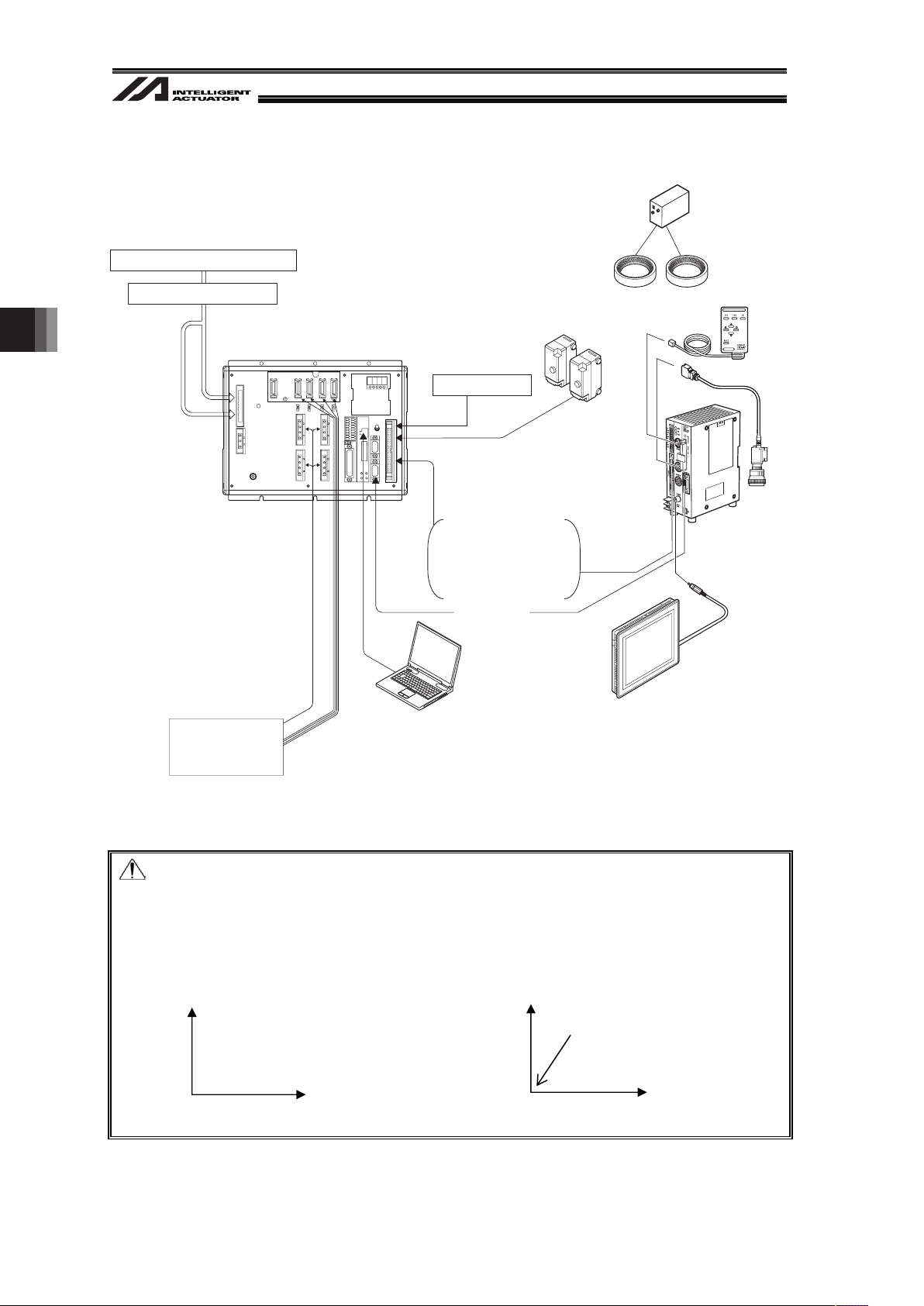

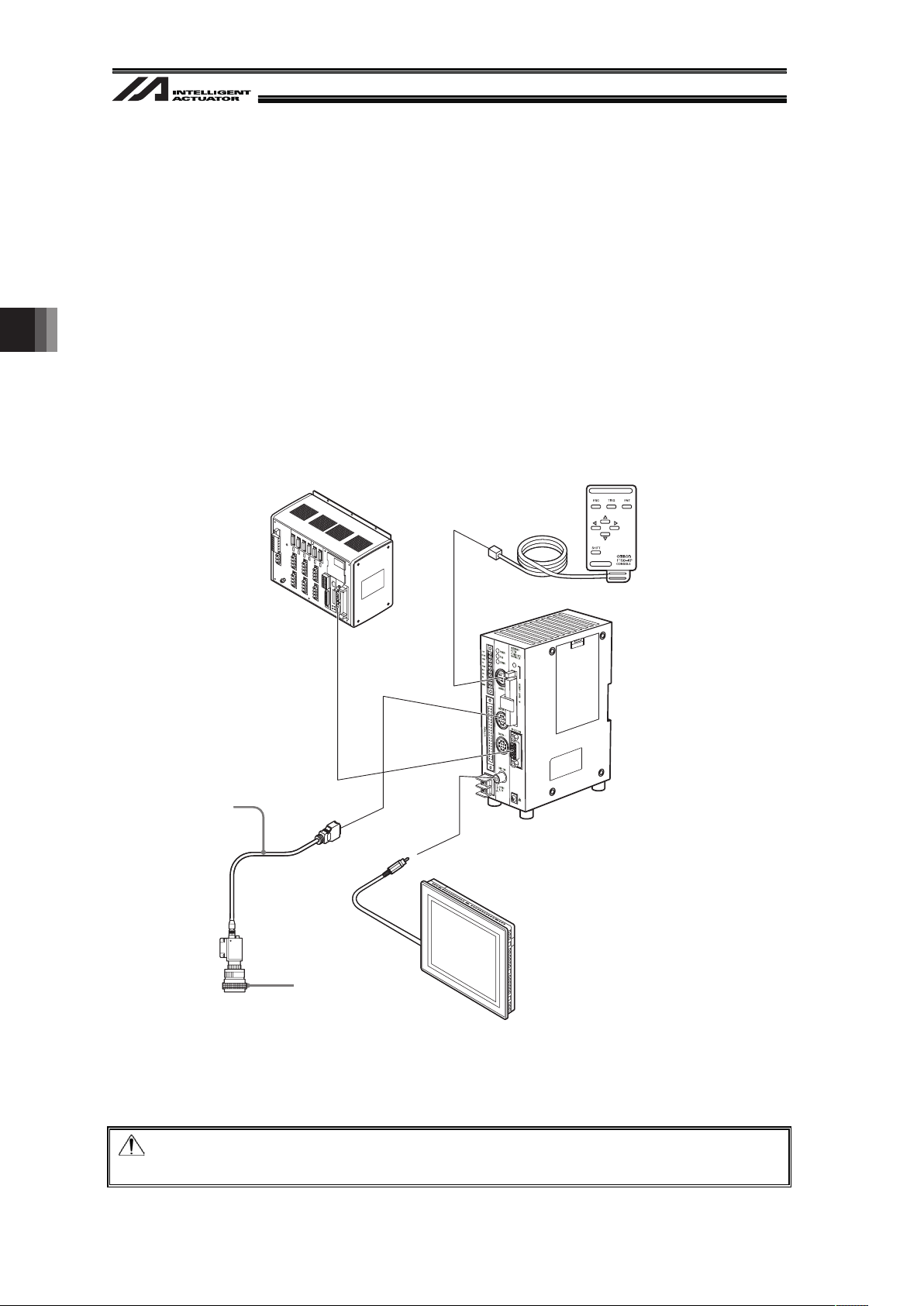

4.1.3 Example of wiring layout when connecting OMRON camera

Example for Vision System Wiring (OMRON)

Note:

• 24V I/O signal (PIO) is used for the capture command to the camera. Use the dedicated I/O

cable for the vision systems if it is equipped with a dedicated cable.

• Set the robot axes and the vision system axes so they are orienting the same directions. Also,

allocate the vision system origin to the bottom left of the screen.

Robot Axes Vision System Axes

Y

X

Y

X

Allocate the origin to

bottom left of screen

RS232C

(Note 3)

Power Supply Supprtive Circuit

M Cable

Robot

Monitor

Camera

PC

24V

+

3-phase 200V AC to 230V power supply

Power Supply

Light

Console

Camera Controller

Main Body

Work Detection Sensor

(when applied as the image-capture trigger)

Power Supply Unit for Light Equipment

(Pin Input)

PIO Signals (2 signals)

(Note1)

• Camera Controller

Startup Complete Signal

(Camera Controller→XSEL)

(Note 2)

• Image Capturing Command

(XSEL→Camera Controller)

Brake and

Power Supply for I/O

(Note 1)

(Note 2)

(Note 3)

There are some cases that the dedicated parallel I/O

cable is required.

[Refer to the Instruction Manual for Vision System]

The setting not to use the camera controller startup signal is

also available. (It is described later.)

Refer to the Appendix at the end for wiring on XSEL side.

Refer to the Instruction Manual for each Vision System for

wiring on camera controller side.

Page 23

17

4.2 Installing XSEL Controller PC Software

Refer to the Instruction Manual for XSEL Controller PC Software for how to install XSEL Controller

PC Software and how to implement the initial settings.

4. Installation

Page 24

4. Installation

18

4.3 Installing the Camera

4.3.1 Cognex Camera

The camera products of Cognex Corporation applicable to the vision system are limited only to

“In-Sight EZ110 (EZ110-XL)” and “In-Sight 5000 Series”.

The way to install the camera can be selected from mounting on the robot and fixing on the

equipment.

Install the camera considering how to use it.

Lighting equipment is separately required when capturing an image with the camera.

It is possible to identify the following numbers of work pieces in 1 shot of image capturing.

• In-Sight EZ110 (EZ110-XL) : 8 pieces at max.

• In-Sight 5000 Series : 12 pieces at max.

Refer to the following Cognex instruction manuals for the details of how to connect the devices.

• In-Sight EZ110 (EZ110-XL) : “In-Sight EZ Series Vision System Installation Guide”

• In-Sight 5000 Series : “In-Sight 5000 Series Vision System Installation Guide”

“CIO-1400C I/O Expansion Module Instruction Manual”

Shown below is an example of the basic construction of Vision System with one unit of camera

connected.

XSEL P/Q Controller Main Unit

Hub

100V AC Power Supply

PoE Injector

Camera

Camera

Cable

Example for Cognex Camera Controller Basic Construction

Page 25

19

4.3.2 Keyence Camera

The camera manufactured by Keyence Corporation that is applicable for Vision System is

“In-CV-2000/CV-3000/CV-5000/XG-7000” only.

The way to install the camera can be selected from mounting on the robot and fixing on the

equipment.

Install the camera considering how to use it.

Lighting equipment is separately required when capturing an image with the camera.

12 pieces (0 to 7 pieces for CV-2000) of works can be identified at maximum in 1 shot.

Shown below is an example of the basic construction of Vision System with one unit of camera

connected.

XSEL P/Q Controller Main Unit or Hub, etc.

Camera Cable

Camera Controller Monitor

24V DC Power Supply

SD Card

(Inserted to SD1 Slot

on the main unit of controller)

Lens

Camera

Camera Controller

Main Body

Console

Example for Keyence Camera Controller Basic Construction

4. Installation

Page 26

4. Installation

20

4.3.3 OMRON Camera

The camera manufactured by OMRON Corporation that is applicable for Vision System is OMRON

Camera Controller “F210-C10 or FZ3” only.

The way to install the camera can be selected from mounting on the robot and fixing on the

equipment.

Install the camera considering how to use it.

Lighting equipment is separately required when capturing an image with the camera.

12 pieces of works can be identified at maximum in 1 shot.

Shown below is an example of the basic construction of Vision System with one unit of camera

connected.

Example for OMRON Camera Controller Construction(for F210-C10)

Note:

USB and Ethernet are not supported for the camera connection.

XSEL P/Q

Controller Main Body

SD Card

(Inserted to SD1 Slot

on the main unit of controller)

Monitor

Camera

Camera Cable

Console

Camera Controller

Main Body

Lens

(Pin Input)

Page 27

21

5. Vision System I/F Function Setting

Refer to the materials such as the Instruction Manual for the connected camera controller for the

details of how to set up on the camera controller side.

This manual explains how to set up the system to utilize the vision system I/F function.

The setting is to be conducted using XSEL Controller, PC software and the setting tool of each

vision system.

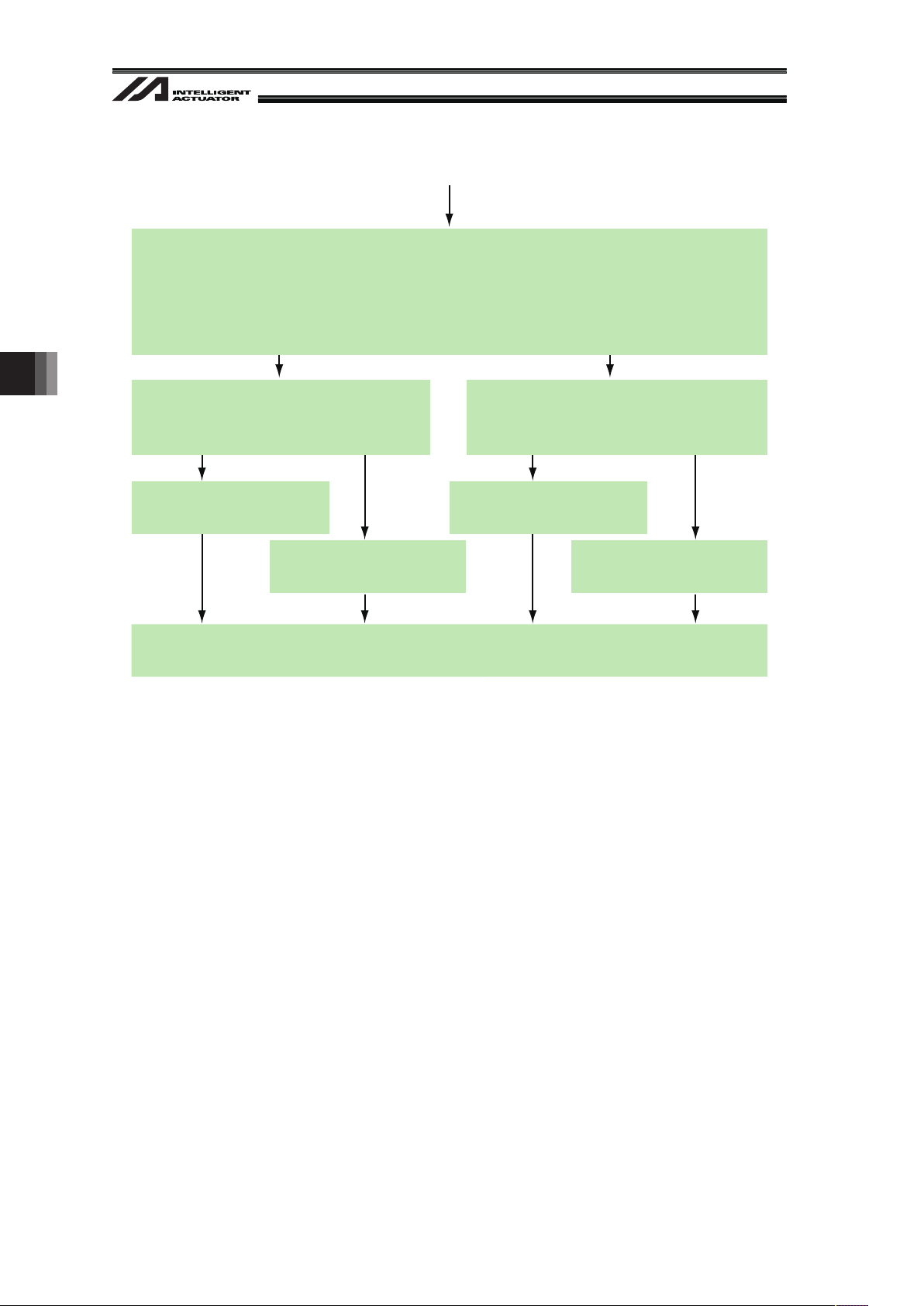

5.1 Setting Procedure

Continues to the next page

RS232C Channel Setting (setting on XSEL)

Follow Section 5.3.2.

Which of the following is used for the communication between the vision system (camera)

and XSEL Controller?

1) Ethernet 2) RS232C

(Cognex or Keyence) (OMRON or Keyence)

Start up the PC software and connect with XSEL Controller.

Start up the vision system setting tool and connect with the vision system.

Supplier Setting of Connected Camera (setting on XSEL)

Set the supplier name of the connected camera following Section 5.4.

Vision System Check and Communication Setting (setting on vision system)

Perform the necessary settings such as image setting, tool setting, inspection, input,

output and communication with using the vision system setting tool.

Set the unit of the output of the coordinate data from the vision system to mm except for

when using the dedicated calibration with EZ-110XL. (Refer to Section 5.5)

Coordinate Setting (setting on vision system)

Set the coordinate origin of the vision system following Section 5.6.

This setting is not necessary when using the dedicated calibration with EZ-110XL.

Detailed Function Settings (setting on XSEL)

Set the image-capture command input port number and other necessary numbers

following Section 5.7.

Ethernet Channel Setting (setting on XSEL)

Follow Section 5.3.1.

Setting Start

5. Vision System I/F Function Setting

Page 28

5. Vision System I/F Function Setting

22

Continued from the previous page

Perform the adjustment

following Section 5.8.3.

Perform the adjustment

following Section 5.8.2.

Adjustment of Vision System Coordinates and Robot Coordinates

(setting on XSEL and Vision System)

Which vision system of the following is to be used?

1) Cognex 2) Other (except for 1))

EZ-110XL

In which way the camera is installed?

1) On the robot 2) Not on the robot

(Fix on equipment)

In which way the camera is installed?

1) On the robot 2) Not on the robot

(Fix on equipment)

Perform the adjustment

following Section 5.8.1.

Perform the adjustment

following Section 5.8.4.

Program Edit (setting on XSEL)

Create the program by following the SEL Program construction guideline.

Page 29

23

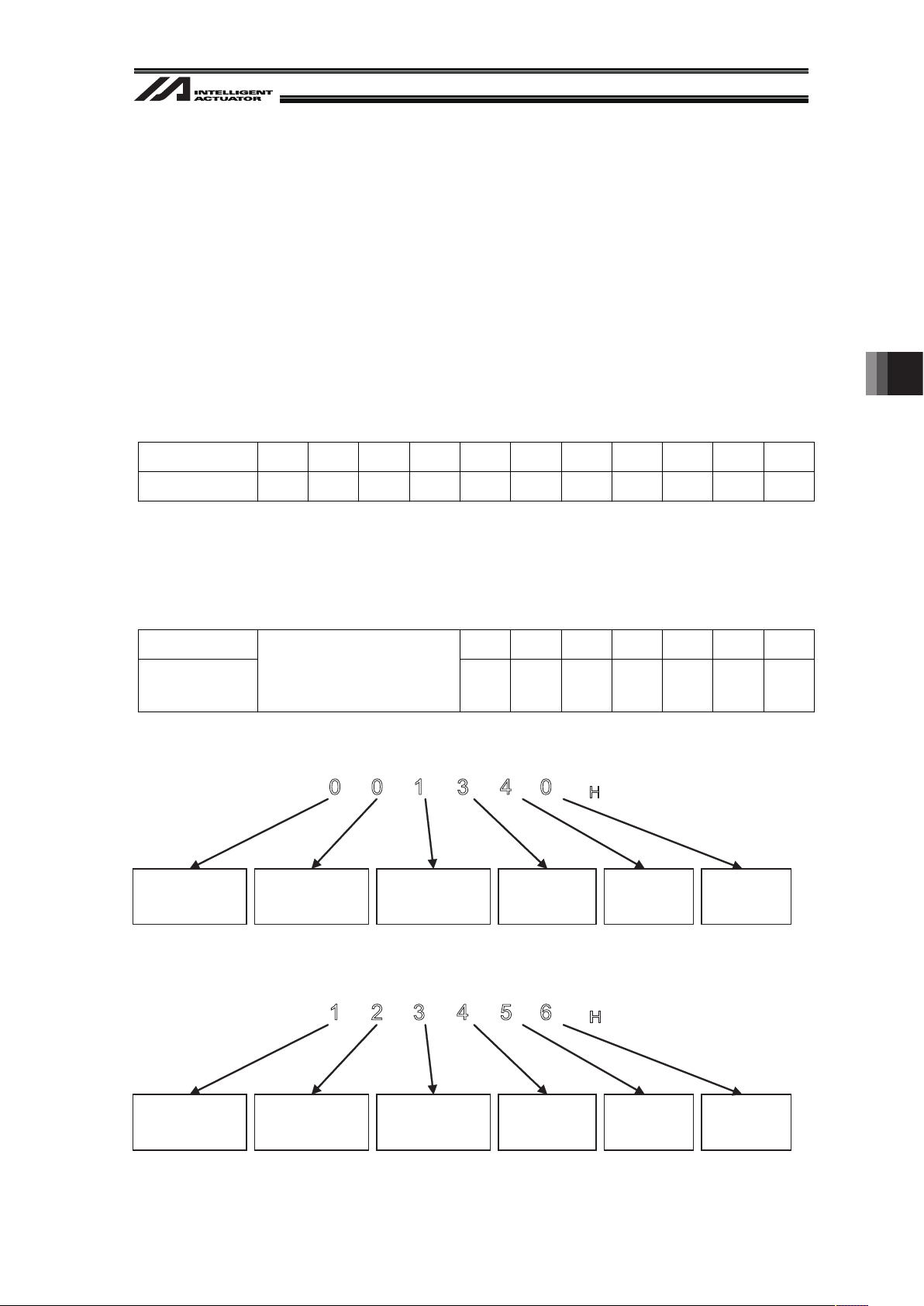

5.2 About Parameter Change

5.2.1 Regarding to Value Setting

If the last digit of the set value is H, set with hexadecimal number.

Refer to the following.

Input the value of hexadecimal number transformed from the binary number.

5.2.1.1 Binary Number

Binary number expresses a numeral figure with using 2 numbers, 0 and 1.

The number increases in the order of 0, 1, and then the number of digit increases, and goes 10, 11

…

Decimal Number 0 1 2 3 4 5 6 7 8 9 10

Binary Number 0 1 10 11 100 101 110 111 1000 1001 1010

5.2.1.2 Hexadecimal Number

Hexadecimal number expresses a numeral figure with using numbers from 0 to 9 and alphabets

from A to F. The number increases in the order of 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B,C, D, E, F, and then

the number of digit increases, and goes 10, 11, …

Decimal Number 10 11 12 13 14 15 16

Hexadecimal

Number

0 to 9

(Same for decimal and

hexadecimal numbers)

A B C D E F 10

Example 1 : 001340

H

Bit

20-23

0000

Bit

16-19

0000

Bit

12-15

0001

Bit

8-11

0011

Bit

4-7

0100

Bit

0-3

0000

0 0 1 3 4 0

H

Example 2 : 123456

H

Bit

20-23

0001

Bit

16-19

0010

Bit

12-15

0011

Bit

8-11

0100

Bit

4-7

0101

Bit

0-3

0110

1 2 3 4 5 6

H

5. Vision System I/F Function Setting

Page 30

5. Vision System I/F Function Setting

24

5.3 Communication Channel Setting

Either RS232C (standard for XSEL), Ethernet Communication Board

(*1)

(option for XSEL-P/Q type)

or EtherNet/IP Communication Board (option for XSEL-R/S type) is used for the vision system I/F

function.

*1 Not applicable for XSEL-R/S

If using Ethernet, follow the instructions in Section 5.3.1 to perform the settings.

If using RS232C, follow the instructions in Section 5.3.2 to perform the settings.

5.3.1 When Ethernet TCP/IP Message Communication is Used

When using the Ethernet TCP/IP message communication (Cognex or Keyence), set the XSEL

parameters in the right order.

[Setting 1] Ethernet TCP/IP Message Communication Attribute [compulsory] (I/O Parameter

No.124)

Set the Ethernet TCP/IP message communication attribute in I/O Parameter No.124.

Select one channel from channels 31 to 34 and set it as the client (setting value = 1).

(Note) When using Cognex In-Sight EZ110 (EZ-110XL), set the parameter to;

I/O Parameter No.124 = 003100

H

I/O Parameters No.124

Bit 20-23 Bit 16-19 Bit 12-15 Bit 8-11 Bit 4-7 Bit 0-3

Free-for-User

Channel 34

Set Value=1

Free-for-User

Channel 33

Set Value=1

Free-for-User

Channel 32

Set Value=1

Free-for-User

Channel 31

Set Value=1

Set Value=0 Set Value=0

Set Value = 0 : Channel not in use

Set Value = 1 : Set X-SEL as the client

Set Value = 3 : Set X-SEL as the server

(Example 1) When using the channel 31 for Vision System I/F

I/O Parameter No.124 = 000100

H

(Example 2) When using the channel 32 for Vision System I/F and 31 for another program

(server) (and not using 33 and 34)

I/O Parameter No.124 = 001300

H

Page 31

25

[Setting 2] Ethernet Operation Prescription [compulsory] (I/O Parameters No.129)

Set the Ethernet operation prescription in I/O Parameters No.129.

Set the bits 4-7 to “1”.

I/O Parameter No.129 = 10

H

I/O Parameters No.129

Bit 4-7 Bit 0-3

TCP/IP Message Communication is Used

Set Value=1

Set Value 0

[Setting 3] Controller Network Address Setting [compulsory]

(I/O Parameters No.132 to 143,146)

Set the I/O Parameters No.132 to 143 and 145 to 148 following the network

environment.

I/O Parameters No.132 to 135 Self IP Address (IP address of X-SEL)

I/O Parameters No.136 to 139 Subnet Mask

I/O Parameters No.140 to 143 Default Gateway

I/O Parameters No.146

Free-for-User Channel 32 (TCP/IP)

Self-Port Number

(Note)

Set it in

accordance with

the network

environment to

be used

(Note) Do not change I/O Parameter No.146 from “64513” (initial setting value) when using

EZ-110XL.

[Setting 4] Vision System Network Address Setting [compulsory] (I/O Parameters No.160 to 164)

Set the parameters such as the network address of the vision system to be connected in

I/O Parameters No.160 to 164.

Refer to the IP address settings on the controller side (I/O Parameters No.132 to 134) for

the IP address to set it to have the controller and the vision system exist on the same

network.

(Note) When setting the IP addresses, be sure not to duplicate the entire address.

(Example) IP address of Vision System 192.168. 0. 11 (I/O Parameter No.160 to 163)

IP address of X-SEL 192.168. 0. 12 (I/O Parameter No.132 to 135)

I/O Parameters

No.160 to 163

Vision System I/F connected IP address

Input Vision System IP

address setting value

I/O Parameters

No.164

Vision System I/F Connected Port Number

(Example)

Cognex

:3000

H

Keyence :8500

H

Continue to Section 5.4 to complete the setting procedures.

A

void duplication

5. Vision System I/F Function Setting

Page 32

5. Vision System I/F Function Setting

26

5.3.2 When Standard SIO (RS232C) Channel Communication is Used

When using the standard SIO (RS232C) channel communication (OMRON or Keyence), set the

XSEL parameters in the right order.

[Setting 1] Free-for-User SIO Channel Attribute 1 [compulsory] (I/O Parameters No.201 and 213)

Set the parameters in accordance with the application environment.

Note :

x Do not fail to have the same communication setting as that on the camera controller

side.

x Set I/O Parameter No.201 if Channel 1 is used, and No.213 if Channel 2 is used.

I/O Parameter No.201 (when Standard SIO Channel 1 is used)

I/O Parameter No.213 (when Standard SIO Channel 2 is used)

Bit 28-31 Bit 24-27 Bit 20-23 Bit 16-19 Bit 4-15 Bit 0-3

Baud Rate Type

[kbps]

Set Value=2

(Default)

*Set Value

Set Value=0 (9.6)

Set Value=1 (19.2)

Set Value=2 (38.4)

Set Value=3 (57.6)

Set Value=4 (76.8)

Set Value=5 (115.2)

Data Length

(7 to 8)

Set Value=8

(Default)

Stop Bit Length

(1 to 2)

Set Value=1

(Default)

Parity Type

Set Value=0

(Default)

*Set Value

Set Value=0 (None)

Set Value

=

1

(Odd Number)

Set Value

=

2

(Even Number)

For future

extension

Set Value=000

(Default)

Standard SIO

Usage Selection

Set Value=1

*Set Value

Set Value=0

(Not used)

Set Value=1

(Used)

(Example) Example of using the standard SIO channel 1 and establishing the

communication with the following conditions:

<Conditions>

Communication Speed : 115.2kbps (Set Value 5)

Data Length : 8 (Set Value 8)

Stop Bit Length : 1 (Set Value 1)

Parity Type : None (Set Value 0)

<Set Value>

I/O Parameter No.201 = 58100001

H

Page 33

27

5.4 Communication Format Setting

There are fixed formats for the communication format and can be set by I/O Parameters.

[Setting 1] Vision System I/F Function Selection 2 [compulsory] (I/O Parameters No.352)

Select the communication format to receive from the vision system on I/O Parameter

No.352, Bits 0 to 7. The setting values differ depending on the vision system supplier.

I/O Parameters No.352

Bit 0-7

Communication Format Select

Set Value=0

: Vision System of Cognex (including EZ-110XL)

Set Value=1

: Vision System of OMROM

Set Value=2

: Vision System of Keyence

5. Vision System I/F Function Setting

Page 34

5. Vision System I/F Function Setting

28

[Setting 2] Vision System I/F Function Selection 3 [compulsory] (I/O Parameters No.353)

Set the header and delimiter for the communication format to receive from the vision

system.

The setting values differ depending on the vision system supplier.

I/O Parameters No.353

Bit 16-31 Bit 8-15 Bit 0-7

Vision System I/F

Communication Header 2

(Effective when Keyence is

selected in Setting 1)

Set Value=5431 (Default)

Setting change is not

necessary.

Vision System I/F

Communication Header 1

(Effective when Cognex or

OMRON is selected in Setting 1)

Set Value=3C (Default)

Cognex : 3C

OMRON : 39

Vision System I/F

Communication Delimiter

Set Value=0D (Default)

Setting change is not

necessary.

[Setting 3] Vision System Settings [compulsory]

Perform the settings on the vision system so the specified communication format can be

output.

(1) When using EZ-110XL and simple (dedicated) calibration (refer to Section 5.8)

Refer to [Setting 1] in 8.1 Appendix

(2) When using the vision system of Cognex or OMRON

Refer to [Setting 2] in 8.1 Appendix

(3) When using the Keyence vision system

Refer to [Setting 3] in 8.1 Appendix

(Note) Move to Section 5.7 if using Cognex In-Sight EZ110.

Page 35

29

5.5 Unit Conversion (pixel mm)

This manual is provided on the premise that the unit of the coordinate data that is received in Vision

System I/F Function is [mm]. Provide a setting on the camera controller side to have the unit of the

output coordinate data in [mm]. [Refer to the Instruction Manual for the Vision System to be

connected for the details.]

(Note) The setting is not necessary when using the simple (dedicated) calibration with EZ-110XL

since the setting is conducted in Section 5.8.

5.6 Coordinate Setting

Set the coordinate axes of the vision system.

Refer to the following to set the coordinates on the camera controller side in accordance with the

parameter settings in Vision System I/F Function. [Refer to the Instruction Manual for the Vision

System to be connected for the details.]

(Note) The setting is not necessary when using the simple (dedicated) calibration with EZ-110XL

since the setting is conducted in Section 5.8.

[For Cognex (except for EZ-110XL) or OMRON : I/O Parameter No.352=0 or 1]

Conduct the setting to place the origin on the bottom left of the captured data.

㪯

㪰

[For Keyence : I/O Parameter No.352=2]

Conduct the setting to place the origin on the upper left of the captured data.

㪯

㪰

5. Vision System I/F Function Setting

Page 36

5. Vision System I/F Function Setting

30

5.7 Detailed Function Settings

To operate Vision System I/F Function properly, set the following parameters.

Note :

Do not fail to set the following parameters.

x Vision System I/F Function Selection 1(I/O Parameters No.351)

x Setting of Vision System I/F Image-Capture Command Physical Output Number (I/O

Parameters No.357)

[Setting 1] Vision System I/F Function Selection 1 [compulsory] (I/O Parameters No.351)

Set I/O Parameter No.351.

(Note) Set the Bit 4-7 to “2” when using EZ-110XL and simple (dedicated) calibration

(refer to Section 5.8).

I/O Parameters No.351

Bit 24-31 Bit 20-23 Bit 12-19 Bit 8-11 Bit 4-7 Bit 0-3

Number of tries

for Image-Capture

Command

[times]

Image-Capture

Delay Estimation

Timer Value

[msec]

Image-Capture

Command Cutoff

Extension Timer

Value

[msec]

Response timeout

value

[sec]

Communication

Device Selection

(Note1)

Function Usage

Selection

No need to

change

Set Value=3

(Default)

No need to

change

Set Value=1

(Default)

No need to

change

Set Value=05

(Default)

No need to

change

Set Value=5

(Default)

Set Value=0

(Channel 1)

Set Value=1

(Channel 2)

Set Value=2

(Channel 31)

Set Value=3

(Channel 32)

Set Value=4

(Channel 33)

Set Value=5

(Channel 34)

Set Value=1

(to use Vision

System I/F)

Set Value=0

(not to use Vision

System I/F)

Note 1 : Match the setting to the channels that are set to Usage Selection (either one in Channels 31 to 34)

in Parameter No.124 if the communication with Vision System is performed with Ethernet.

Set the channel (channel 1 or 2) to the selected one when the communication is established with

the standard SIO (RS232C). (I/O Parameters No.201 = Channel 1, No.213 = Channel 2)

[Refer to Section 5.3]

Page 37

31

[Setting 2] Setting of Vision System I/F Image-Capture Command Physical Output Number

[compulsory] (I/O Parameters No.357)

Set the Output port number to be used as the image-capture trigger to the vision system.

I/O Parameters No.357

Set Value=Output Port No.

[Setting 3] Setting of Vision System I/F Initializing Complete Status Physical Input Port Number

[Option] (I/O Parameters No.356)

By having I/O Parameter No.356 set, the operation complete judgment of the vision

system becomes enabled.

Note :

If this parameter is used and the vision system is not switched on when SLVS command is

executed, Return Code 23 (Vision System Initializing Incomplete Error) will be issued.

I/O Parameters No.356

Set Value=Input Port No.

* Set the value to 0 when not to be used.

[Setting 4] Vision System I/F Control 1 [Option] (All-Axes Parameter No.129)

Set if the signal of rotary axis is to be reversed or not.

All-Axes Parameters No.129

Bit 20-23 Bit 12-19 Bit 4-11 Bit 0-3

Rotary Axis Correction

Direction Reverse

(0

= no signal reverse

1

= signal to be reversed)

Set Value

=0

(Default)

System

Reservation

No need to

change

Set Value

=00

(Default)

System

Reservation

No need to

change

Set Value

=00

(Default)

System

Reservation

No need to

change

Set Value

=0

(Default)

5. Vision System I/F Function Setting

Page 38

5. Vision System I/F Function Setting

32

5.8 Vision System I/F adjustment

To make the relation to the robot coordinates and the vision system coordinates, adjustment

(calibration) of the vision system I/F is required.

The method of Vision system I/F adjustment differs depending on the vision system model and the

location of the camera installation.

If using EZ-110XL, “Simple Calibration” is available which enables you to reduce the steps of

manual adjustment of positions of the robot tool tip and the work. [Refer to Section 5.8.1 to 5.8.3]

In the case of using a vision system other than those mentioned above, refer to Section 5.8.4 or

Section 5.8.5.

Precautions

1) Vision system IF adjustment puts a relation of the robot X, Y and T coordinates to the vision

system coordinates. It is not applied when the center of the rotation and that of the tool to

retain the work are offset.

2) Camera cannot be mounted on the robot rotation axis.

3) Make sure to execute the vision system I/F adjustment after parameter settings are

completed.

4) For absolute type actuator, execute it after the absolute reset is completed.

5) Applicable PC software is required for the vision system I/F adjustment.

6) The vision system I/F adjustment includes steps to capture images of the work piece with the

vision system. Register the work piece to the vision system in advance so it can be detected.

Also, when using a vision system other than EZ-110XL, unit conversion (from pixel to mm) is

to be conducted on the camera controller side.

7) The following parameters are updated automatically by executing the vision system I/F

adjustment. It is no need to change them manually.

All-Axes Parameters Description

No.122

Vision System I/F 1 Coordinate Datum Point

Offset X

No.123

Vision System I/F 1 Coordinate Datum Point

Offset Y

No.124

Vision System I/F 1 Coordinate Datum Point

Offset Angle

No.125

Vision System I/F 1 Robot Vision Mounted

Z-axis Direction Vision Position Judgment

Datum

No.130

Vision System I/F 1 Control 2

Bits 8 to 11 Vision Installation Type

( 0 (Camera being installed on a position other

than on the robot))

( 1 (Camera being installed on the robot))

Updated

automatically by

execution of “Vision

System I/F

adjustment”

Page 39

33

5.8.1 Initial Settings for Simple Calibration

(When EZ-110XL camera is used)

Conduct the initial settings following the steps below with using the Cognex Setup software (In-Sight

Explorer) or PC software for XSEL.

(Note) It is necessary to redo the initial settings (1) to (3) if the version of In-Sight Explorer is

updated.

ڏ Please contact us for the files necessary for the initial settings.

[Initial Setting 1]

Copy the file “IAIClassLibrary.dll” stored in the PC software installation CD and put it into the folder

stated below:

¥Program Files¥Cognex¥In-Sight¥In-Sight Explorer *.*.*

(*.*.* indicates the software version: applied in 4.4.1 and later)

[Initial Setting 2]

Copy the file “IAICalib_EN.cxd” stored in the PC software installation CD and put it into the folder

stated below:

¥Program Files¥Cognex¥In-Sight¥In-Sight Explorer *.*.*¥Snippets¥EasyBuilder

(*.*.* indicates the software version: applied in 4.4.1 and later)

[Initial Setting 3]

Start up In-Sight Explorer.

Select Options in In-Sight Explorer System Menu and tick on “Use English Symbolic Tags for

EasyBuilder” in the User Interface items.

5. Vision System I/F Function Setting

Page 40

5. Vision System I/F Function Setting

34

[Initial Setting 4]

In this calibration, the adjustment is conducted by actually moving the work using the robot within

the image capturing range of the camera.

Therefore, it is necessary to create a program considering the method of retaining the work (gripping,

chucking, etc.). Please contact IAI for a program file you need.

Make sure to write the program for “Hold” and “Release” to the specified points.

(Note 1) The program can be edited even if the controller is not connected to the PC software

(offline).

(Note 2) Make sure to conduct the relative interlock of Hold and Release in the SEL program that

you edit.

Write the program for “Hold” here

(Z-axis is lowered enough to hold the work.)

If a sensor to judge the success/fail of the hold is to be added, add;

• a command to jump to TAG 52 after success (Write GOTO 52), and

• a command to jump to TAG 53 if fail (Write GOTO 53)

(Rise of Z-axis is conducted automatically later on.)

Page 41

35

Example 1 : When holding with grip

(grip when I/O Port 314 is ON and release when 315 is ON)

BTOF (315) ĸI/O Port No. (315) turns OFF

TIMW (0.1) ĸKeep time for electromagnetic valve to turn OFF

BTON (314) ĸI/O Port No. (314) turns ON (grip)

TIMW (0.3) ĸRetain the gripping time

GOTO 52 ĸTo the process for work hold success

Example 2 : When holding with an electrical gripper connectable to XSEL (connected to the

4th axis)

GRP (1000) ĸCommand to make only gripper available for operation

PAPR (10) (20) ĸPressing (10) : approach distance

(20) : approach speed

PUSH (30) (900) ĸ (30) : Position number of the pressing position

(900) : Turns ON when pressing succeeded

Turns OFF when failed

GRP (111) ĸCommand to make all the operations available except for gripper

(900) GOTO 52 ĸTo the process for work hold success

N (900) GOTO 53 ĸTo the process of work hold fail

5. Vision System I/F Function Setting

Page 42

5. Vision System I/F Function Setting

36

Example 1 : When holding with grip

(grip when I/O Port 314 is ON and release when 315 is ON)

BTOF (314) ĸI/O Port No. (314) turns OFF

TIMW (0.1) ĸKeep time for electromagnetic valve to turn OFF

BTON (315) ĸI/O Port No. (315) turns ON (release)

TIMW (0.03) ĸRetain the release time

BTOF (315) ĸI/O Port No. (315) turns OFF

GOTO 57 ĸTo the process of work release success

Example 2 : When holding with an electrical gripper connectable to XSEL (connected to the

4th axis)

GRP (1000) ĸCommand to make only gripper available for operation

MOVP (30) ĸPosition number when the gripper is open

GRP (111) ĸCommand to make all the operations available except for gripper

GOTO 57 ĸTo the process of work release success

Write the program for “Release” here

(Z-axis is lowered enough to hold the work.)

If a sensor to judge the success/fail of the release is to be added, add;

• a command to jump to TAG 57 after success (Write GOTO 57), and

• a command to jump to TAG 58 if fail (Write GOTO 58)

(Rise of Z-axis is conducted automatically later on.)

Page 43

37

5.8.2 When Camera Not Mounted on Robot

(When EZ-110XL is used)

This section explains how to setup when the camera is installed as shown in the picture below.

Conduct the home return of the incremental type robot in advance.

If the camera is to be mounted on the robot, refer to “5.8.3 When Camera Mounted on Robot”.

When Camera Not Mounted on Robot

[Procedure 1] Select Vision System I/F easy adjustment from the PC software.

A warning dialog box opens.

Note :

In the case “Vision System I/F easy adjustment” is not displayed in the main menu,

check the version of the PC software and the settings of related I/O parameters.

I/O Parameter

No.351 Bit 0-3=1

PC software version for

Vision System I/F Adjustment

XSEL-P/Q: V7.07.08.00 or later

XSEL-R/S: V9.0.0.0 or later

Camera being

mounted on a place

such as the frame

5. Vision System I/F Function Setting

Page 44

5. Vision System I/F Function Setting

38

[Procedure 2] Finish all operations and click “OK” button.

Vision System I/F easy adjustment window opens.

[Procedure 3] Click “OK” button.

Vision System I/F easy adjustment opens. [See the next page]

Note :

If no vision system I/F number is displayed, check the parameter settings [5.7

Parameter Settings] on the controller.

Activate this one.

Set this to “1”

Page 45

39

Vision System I/F easy adjustment Window

ڏ For those items pointed with a red arrow, confirm the contents or acquire the necessary values

and click the button on the right to proceed to the next one.

5. Vision System I/F Function Setting

Page 46

5. Vision System I/F Function Setting

40

[Procedure 4] Start up the Cognex Setup Software (In-Sight Explorer).

After it is confirmed the software is open, click “OK” button.

[Procedure 5] Connect the camera and conduct the settings following the instructions (1) to (3)

indicated below.

Click “OK” button.

(1) In Application Step in In-Sight Explorer, select “Start” ĺ “Get Connected”.

(2) In “Select an In-Sight Sensor or Emulator”, select “ez110” and then select “Connect”.

(3) Select “New Job…” from “File” in the menu bar or “Open Job…” if there is an existing job.

Page 47

41

[Procedure 6] Conduct the settings following the instructions (1) to (3) indicated below.

Click “OK” button.

(1) Confirm “Online” shown at the bottom of the camera image display screen of In-Sight Explorer

and then select “Sensor” ĺ “Online” from the menu bar.

A message box asking “Are you sure you want to go Offline?”. Click “Yes” button.

(2) Select “Start” ĺ “Set Up Image” in Application Steps.

5. Vision System I/F Function Setting

Page 48

5. Vision System I/F Function Setting

42

(3) In “Acquire/Load Image”, click “Trigger” to capture the image.

Page 49

43

[Procedure 7] Select the necessary tools

(Note)

from the positioning or inspection of the tool setting.

(At this stage, do not select the IAI Robot Tool in the inspection.)

Click “OK” button.

(Note) In this manual, explains with an example of when using PatMax pattern from

the positioning tool. For other tools, refer to the instruction manual selected

from Windows start menu ĺ Program ĺ Cognex ĺ In-Sight ĺ In-Sight

Explorer*.*.* ĺ “Document”.

(1) Select “Set Up Tools” ĺ “Locate Part” in Application Steps of In-Sight Explorer.

(2) In “Add Tool”, select “PatMax® Pattern” ĺ “Add”.

(3) Surround the area of the work that you wish to detect with the model area. Also, set the search

area to the desired range. Click “OK” in Usage Method.

Search area

Model area

5. Vision System I/F Function Setting

Page 50

5. Vision System I/F Function Setting

44

[Procedure 8] Now perform the settings for Inspection Tool. Follow the following instructions.

After all the settings are complete, click “OK” button.

(1) In Application Steps in In-Sight Explorer, select “Set Up Tools” ĺ “Inspect Part”.

(2) From IAI Robot Tool in Tool Setting Inspection, select IAI N-Point Calibration and click “Add”.

Page 51

45

(3) Select the detection point set by either the positioning or the inspection tool and click “OK” in

Usage.

(Example) When the detection point is set at the center of the work with using the positioning

pattern tool PatMax, click on the cross cursor on the screen (the cursor color

changes) and click “OK”.

(4) In Calibration General window, confirm that Tool Enabled is On.

5. Vision System I/F Function Setting

Page 52

5. Vision System I/F Function Setting

46

(5) Set the IP address and Port Number of XSEL in the Calibration Setting Window.

Input the value set in I/O Parameters No.132 to 135 for the IP address.

Input the value set in I/O Parameter No.146 for the Port Number.

(Note) The set value is displayed at the item that is currently set (it is displayed with an arrow

ψ) in the Vision System I/F Simple Adjustment Window in the PC software.

(6) Set the number of points. It should basically be 4 points, however, in the case an improvement

in the accuracy is required the number of point can be increased to 16 at the maximum.

(Allocate the points evenly as much as possible in the range that the work can be detected and

that for image capturing.)

Input the value set in I/O Parameters No.132 to

135 in XSEL

Input the value set in I/O Parameter No.146 in

XSEL

Input a number from 4 to 16

Page 53

47

(7) Set the amount of robot movement

(Note 1 and 2)

considering the set points are in the image

capturing range.

(Note 1) The movement is relative movement.

(Note 2) In the case the camera is mounted on the robot and the case not, the movement

directions may be opposite in up/down, right/left directions.

Example1 : Number of Calibration Points = 4 points (When Camera Not Mounted on Robot)

In this example, select the Move tag and set the values as shown below for Move1.X to

Move3.Y in the right order.

indicates the image capturing range

(60 u 60mm)

X

Coordinates of

Vision System

Y

Ԙ

ԙԚ

Moves 50mm in X direction

60mm

60mm

Moves -40mm in Y direction

Moves -50mm in X direction

0

5. Vision System I/F Function Setting

Page 54

5. Vision System I/F Function Setting

48

Example 2 : Number of Calibration Points = 16 points (When Camera Not Mounted on Robot)

In this example, select the Move tag and set the values as shown below for Move1.X to

Move15.Y in the right order.

Click here and the

boxes for Move 8-15

will appear.

X

Coordinates of

Vision System

Y

60mm

60mm

Ԙ ԙ Ԛ

ԛ

Ԣ

ԣ

ԜԝԞ

ԟ

Ԡ

ԡ

Ԥԥ

Ԧ

15mm 15mm 15mm

15mm

15mm

15mm

indicates the image capturing range

(60 u 60mm)

0

Page 55

49

(8) Confirm that “Default” is shown in the file name on the top of the export window.

If a different name or nothing is shown, type it manually.

(9) Confirm a tick mark in the check box.

If not, put a tick mark in it.

(10) Select “File” ĺ “Save Job” or “Save Job As…” from the menu bar.

Store the created job file to the camera and PC (for backup).

5. Vision System I/F Function Setting

Page 56

5. Vision System I/F Function Setting

50

[Procedure 9] Set the vision system to the continuous capturing mode.

Select “Live Video” in Acquire/Load Image in In-Sight Explorer.

Click “OK” button.

(1) Toggle button

to online/offline

ψ Set it to offline.

(2)

(3)

Page 57

51

[Procedure 10] Click “OK” button.

[Procedure 11] Click “OK” button if the IP addresses of the vision system are correct.

If incorrect, set the right IP addresses to XSEL I/O Parameters No.160 to 163.

[Procedure 12] Input the program number that is not used in XSEL to the forwarding program

number.

After inputting, click “OK” button.

The programs not in use can be found with the method stated below.

From the menu of XSEL PC software, select “Program” ĺ “Edit”.

Program Number Select Window opens. In the list, the numbers with 0 in Step

Number column are not in use. If all the lines are occupied, make a backup to the

PC temporarily to ensure an empty program field.

Not in use

No.2

No.9

No.10

5. Vision System I/F Function Setting

Page 58

5. Vision System I/F Function Setting

52

[Procedure 13] Input the position number not in use. (Select a position number that 10 positions in

a row can be ensured.)

After inputting, click “OK” button.

If all the lines are occupied, make a backup to the PC temporarily to ensure an

empty program field.

[Procedure 14] (1) Please contact IAI for a program file you need.