Page 1

X-SEL Controller

JX/KX Type

Operation Manual

Seventh Edition

Page 2

Page 3

and 60.

CAUTION

Operator Calls Regarding Low Battery Voltage

This controller uses the following backup batteries to retain data after the power is cut off:

[1] System-memory backup battery

For retention of position data, global variables/flags, error lists, strings, etc.

[2] Absolute-encoder backup battery

For retention of encoder rotation data.

Each battery is of no n-rechargeable type, so u nles s t h e bat tery is replaced befor e its l if e is f ul ly consumed,

the battery voltage will eventually drop to a level where data can no longer be retained after the power is

cut off.

(The specific life of each battery varies depending on the operating time.)

Once data is lost, the controller cannot operate properly the next time the power is turned on, in which

case additional time will be required for recovery operation.

(Reference)

System-memory backup battery --- A voltage low warning will generate when the voltage drops to

approx. 2.6 V from the rated voltage of 3.0 V, and data will be lost

once the voltage drops to approx. 2.3 V.

Absolute-encoder backup battery --- A voltage low warning will generate when the voltage drops to

approx. 3.2 V from the rated voltage of 3.6 V, and data will be lost

once the voltage drops to approx. 2.7 V.

In view of the above, this controller provides functions that allow voltage low warnings for the two batteries

to be output from I/O ports.

Output port No. 313 is assigned as the output of voltage low warning for system-memory backup battery.

Output port No. 314 is assigned as the output of voltage low warning for absolute-encoder backup

battery.

These warning output functions are available on controllers shipped on or after May 16, 2005. On

controllers shipped before this date, the functions can be enabled by setting “1” in I/O parameter Nos. 59

It is requested that the aforementioned functions be used to prevent unnecessary problems caused by low

battery voltage (consumption of battery life).

In particular, design engineers responsible for coordinating the system components should reflect, in the

design specifications, appropriate means for warning the operator using the I/O output signals utilizing the

above functions. Electrical design engineers should ensure that such means are reflected in the electrical

circuits.

For the battery replacement procedure, refer to the applicable section in the Operation Manual.

It is recommended that the latest data be constantly backed up to a PC in case of low system-memory

backup battery voltage or unexpected controller failure.

Page 4

Page 5

Danger

Safety Precautions

Please read the information in “Safety Precautions” carefully before selecting a model and using the

product.

The precautions described below are designed to help you use the product safely and avoid bodily injury

and/or property damage.

Directions are classified as “danger,” “warning,” “caution” and “note,” according to the degree of

risk.

Danger

Failure to observe the instruction will res ult in an imminent danger leading to

death or serious injury.

Warning

Caution

Note

Failure to observe the instruction may result in death or serious injury.

Failure to observe the instruction may result in injury or property damage.

The user should take heed of this information to ensure the proper use of the

product, although failure to do so will not result in injury.

This product has been designed and manufactured as a component for use in general industrial

machinery.

Devices must be selected and handled by a system designer, personnel in charge of the actual operation

using the product or similar individual with sufficient knowledge and experience, who has read both the

catalog and operation manual (particularly the “Safety Precautions” section). Mishandling of the product

poses a risk.

Please read the operation manuals for all devices, including the main unit and controller.

It is the user’s respo ns ib il ity to v er ify and determine the c ompatibility of this pr odu c t with the us er’s system,

and to use them properly.

After reading the catalog, operation manual and other materials, be sure to keep them in a convenient

place easily accessible to the personnel using this product.

When transferring or loaning this product to a third party, be sure to attach the catalog, operation manual

and other materials in a conspicuous location on the product, so that the new owner or user can

understand its safe and proper use.

The danger, warning and caution directions in this “Safety Precauti ons” do not cover every possible case.

Please read the catalog and operation manual for the given device, particularly for descriptions unique to it,

to ensure its safe and proper handling.

[General]

Do not use this product for the following applications:

1. Medical equipment used to maintain, control or otherwise affect human life or physical health

2. Mechanisms and machinery designed for the purpose of moving or transporting people

3. Important safety parts of machinery

This product has not been planned or designed for applications requiring high levels of safety. Use

of this product in such applications may jeopardize the safety of human life. The warranty covers

only the product as it is delivered.

Page 6

Warning

[Installation]

Do not use this product in a place exposed to ignitable, inflammable or explosive substances. The

product may ignite, burn or explode.

Avoid using the product in a place where the main unit or controller may come in contact with water or

oil droplets.

Never cut and/or reconnect the cables supplied with the product for the purpose of extending or

shortening the cable length. Doing so may result in fire.

[Operation]

If you are using a pace maker or other mechanical implant, do not come within one meter of the

product. The strong magnetic field generated by the product may cause the pace maker, etc., to

malfunction.

Do not pour water onto the product. Spraying water over the product, washing it with water or using it

in water may cause the product to malfunction, resulting in injury, electric shock, fire, etc.

[Maintenance, Inspection, Repair]

Never modify the product. Unauthorized modification may cause the product to malfunction, resulting in

injury, electric shock, fire, etc.

Do not disassemble and reassemble the components relating to the basic structure of the product or its

performance and function. Doing so may result in injury, electric shock, fire, etc.

[General]

Do not use the product outside the specifications. Using the product outside the specifications may

cause it to fail, stop functioning or sustain damage. It may also significantly reduce the service life of

the product. In particular, observe the maximum loading capacity and speed.

[Installation]

If the machine will stop in the case of system problem such as emergency stop or power failure, design

a safety circuit or other device that will prevent equipment damage or injury.

Be sure to provide Class D grounding for the controller and actuator (formerly Class 3 grounding:

Grounding resistance at 100 Ω or less). Leakage current may cause electric shock or malfunction.

Before supplying power to and operating the product, always check the operation area of the

equipment to ensure safety. Supplying power to the product carelessly may cause electric shock or

injury due to contact with the moving parts.

Wire the product correctly by referring to the operation manual. Securely connect the cables and

connectors so that they will not be disconnected or come loose. Failure to do so may cause the

product to malfunction or cause fire.

[Operation]

Do not touch the terminal block or various switches while the power is supplied to the product. Failure

to observe this instruction may result in electric shock or malfunction.

Before operating the moving parts of the product by hand (for the purpose of manual positioning, etc.),

confirm that the servo is turned off (using the teaching pendant). Failure to observe this instruction may

result in injury.

The cables supplied with the product are flexible, but they are not robot cables. Do not store the cables

in a movable cable duct (cable track , etc.) that bends more than the specified bending radius.

Do not scratch the cables. Scratching, forcibly bending, pulling, winding, crushing with heavy object or

pinching a cable may cause it to leak current or lose continuity, resulting in fire, electric shock,

malfunction, etc.

Page 7

Caution

If the product is generating heat, smoke or a strange smell, turn off the power immediately. Continuing

to use the product may result in product damage or fire.

If any of the internal protective devices (alarms) of the product has actuated, turn off the power

immediately. Continuing to use the product may result in product damage or injury due to malfunction.

Once the power supply is cut off, investigate and remove the cause and then turn on the power again.

If the LEDs on the product do not illuminate after turning on the power, turn off the power immediately.

The protective device (fuse, etc.) on the live side may remain active. Request repair to the IAI sales

office from which you purchased the product.

[Maintenance, Inspection, Repair]

Before conducting maintenance/inspection, parts replacement or other operations on the product,

completely shut down the power supply. At this time, take the following measures:

1. Display a sign that reads, “WORK IN PROGRESS. DO NOT TURN ON POWER” at a conspicuous

place, in order to prevent a person other than the operator from accidentally turning on the power

while the operation is working.

2. When two or more operators are to perform maintenance/inspection together, always call out every

time the power is turned on/off or an axis is moved in order to ensure safety.

[Disposal]

Do not throw the product into fire. The product may burst or generate toxic gases.

[Installation]

Do not use the product under direct sunlight (UV ray), in a place exposed to dust, salt or iron powder,

in a humid place, or in an atmosphere of organic solvent, phosphate-ester machine oil, sulfur dioxide

gas, chlorine gas, acids, etc. The product may lose its function over a short period of time, or exhibit a

sudden drop in performance or its service life may be significantly reduced.

Do not use the product in an atmosphere of corrosive gases (sulfuric acid or hydrochloric acid),

inflammable gases or ign ita ble liquids. Rust may form and reduce the structural strength or the motor

may ignite or explode.

When using the product in any of the places specified below, provide a sufficient shield. Failure to do

so may result in malfunction:

1. Place where large current or high magnetic field is present

2. Place where welding or other operations are performed that cause arc discharge

3. Place subject to electrostatic noise

4. Place with potential exposure to radiation

Install the main unit and controller in a place subject to as little dust as possible. Installing them in a

dusty place may result in malfunction.

Do not install the product in a place subject to large vibration or impact (4.9 m/s2 or more). Doing so

may result in the malfunctioning of the product.

Provide an emergency-stop device in a readily accessible position so the device can be actuated

immediately upon occurrence of a dangerous situation during operation. Lack of such device in an

appropriate position may result in injury.

Provide sufficient maintenance space when installing the product. Routine inspection and maintenance

cannot be performed without sufficient space, which will eventually cause the equipment to stop or the

product to sustain damage.

Do not hold the moving parts of the product or its cables during installation. It may result in injury.

Always use IAI’s genuine cables for connection between the controller and the actuator. Also use IAI’s

genuine products for the key component units such as the actuator, controller and teaching pendant.

Page 8

Note

Others

Before installing or adjusting the product or performing other operations on the product, display a sign

that reads, “WORK IN PROGRESS. DO NOT TURN ON POWER.” If the power is turned on

inadvertently, injury may result due to electric shock or sudden activation of an actuator.

[Operation]

Turn on the power to individual equipment one by one, starting from the equipment at the highest level

in the system hierarchy. Failure to do so may cause the product to start suddenly, resulting in injury or

product damage.

Do not insert a finger or object in the openings in the product. It may cause fire, electric shock or injury.

Do not bring a floppy disk or other magnetic media within one meter of the product. The magnetic field

generated by the magnet may destroy the data in the floppy disk, etc.

[Maintenance, Inspection, Repair]

When the power was turned off and the cover was opened to replace the battery, etc., do not touch the

condenser terminal in the product immediately after the power was turned off (within 30 seconds).

Residual voltage may cause electric shock.

Do not touch the terminals when performing an insulation resistance test. Electric shock may result.

(Do not perform any withstand voltage tes t, since the pr oduct uses DC vol tag e.)

[General]

If you are planning to use the product under a condition or environment not specified in the catalogs

and operation manual, or in an application requiring strict safety such as aircraft facility, combustion

system, entertainment machine, safety device or other equipment having significant impact on human

life or property, design operating ranges with sufficient margins from the ratings and design

specifications or provide sufficient safety measures such as fail-safes. Whatever you do, always

consult IAI’s sales representative.

[Installation]

Do not place objects around the controller that will block airflows. Insufficient ventilation may damage

the controller.

Do not configure a control circuit that will cause the load to drop in case of power failure. Configure a

control circuit that will prevent the table or load from dropping when the power to the machine is cut off

or an emergency stop is actuated.

[Installation, Operation, Maintenance]

When handling the product, wear protective gloves, protective goggles, safety shoes or other

necessary gear to ensure safety.

[Disposal]

When the product becomes no longer usable or necess ar y, dispose of it proper l y as an indus tria l was te.

IAI shall not be liable whatsoever for any loss or damage ari si ng fro m a fail ure t o

observe the items specified in “Safety Precautions.”

Page 9

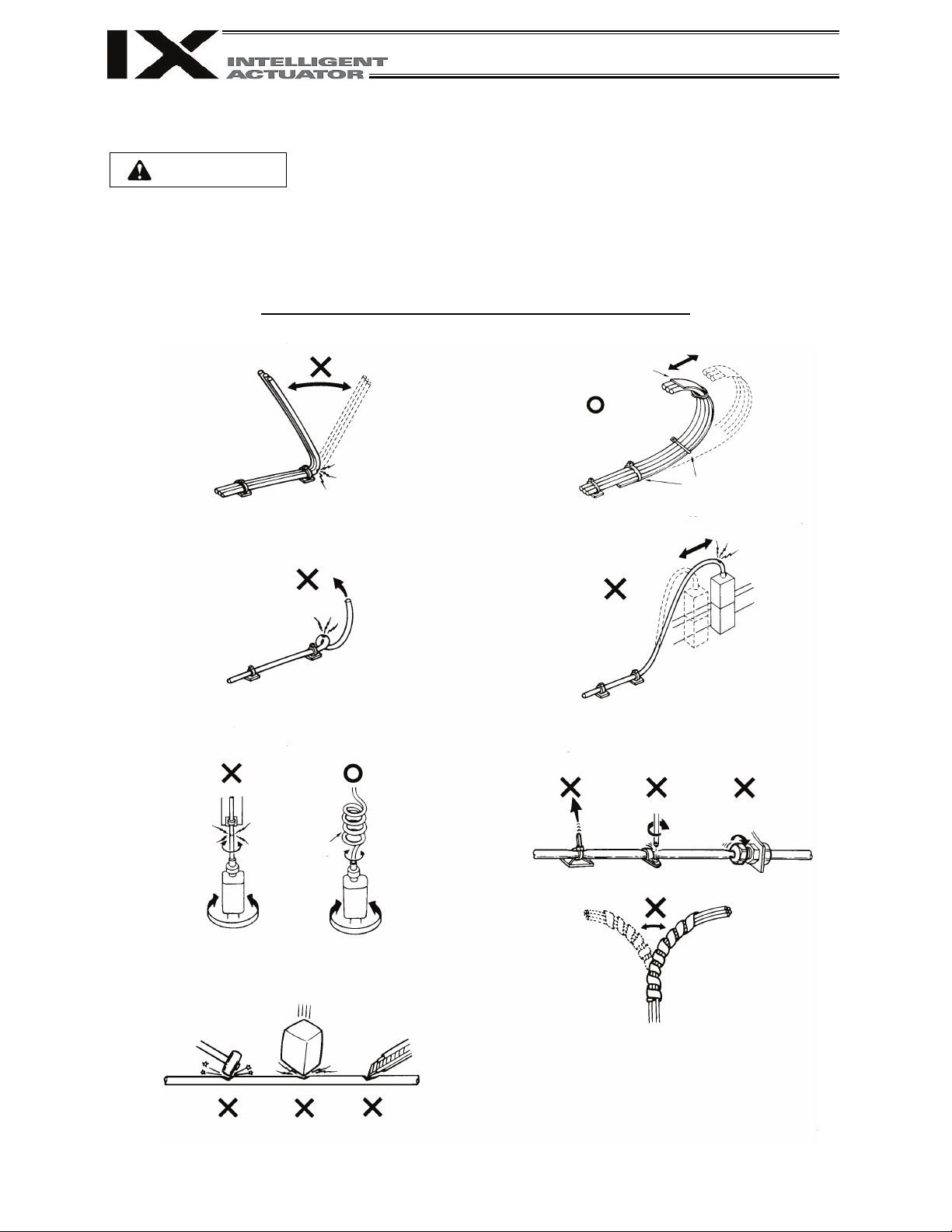

Caution

1. Do not let the cable flex at a single point.

4. Do not let the cable receive a turning force at a

5. When fixing the cable, provide a moderate slack

Steel band

Bundle loosely.

Do not use a spiral tube

Prohibited Handling of Cables

When designing an application system using actuators and controllers, incorrect wiring or connection of

each cable may cause unexpected problems such as a disconnected cable or poor contact, or even a

runaway system. This section explains prohibited handling of cables. Read the information carefully to

connect the cables properly.

Ten Rules for Handling Cables (Must be O bse r ved!)

2. Do not let the cable bend, kink or twist.

single point.

Use a curly

cable.

(piano wire)

3. Do not pull the cable with a strong force.

and do not tension it too tight.

6. Do not pinch, drop a heavy object onto or cut the

cable.

where the cable flexes

frequently.

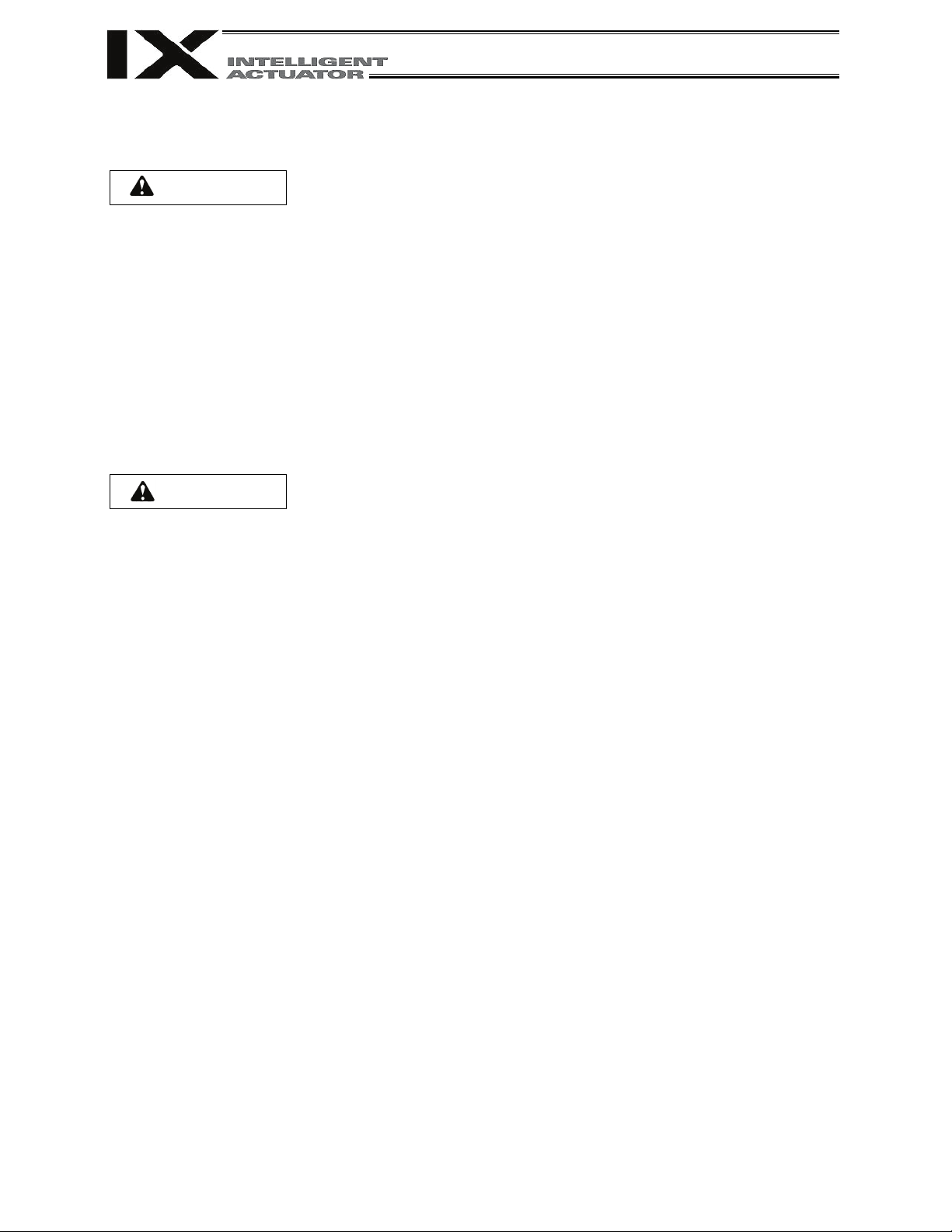

Page 10

8. Do not cause the cables to occupy more than

9. Do not lay signal lines together with circuit lines

Cable

Cable track

Power line

Signal lines (flat cable)

Duct

Cover

Protective layer

Signal line (copper + tin)

7. Do not let the cable got tangled or kinked in a cable track or flexible tube. When bundling the cable,

keep a certain degree of flexibility (so that the cable will not become too taut when bent).

60% of the space in the cable track.

that create a strong electric field.

10. Always use a robot cable

if the cable is likely to flex significantly.

[Standard structure of cable]

The standard structure of

cable will vary depending on

the manufacturer and t ype of

cable.

Shield

Absorbing material (When the

cable is bent, this material is

crushed by the surrounding signal

lines to maintain the shape of the

signal lines.)

� Need for Robot Cables

A cable connected to a moving part of an actuator system will inevitably receive repeated bending loads at

the base of the cable. As a result, the cores in the cable may break over time. To minimize the risk of

cable breakage, we strongly recom mend that a robot cable

offering significantly higher flexibility be used

in this type of application.

Page 11

Caution

Caution

Before Use

Caution

1. Be sure to read this operation manual to ensure the proper use of this product.

2. Unauthorized use or reproduction of a part or all of this operation manual is prohibited.

3. Always handle or operate the product in manners specified in this operation manual, by assuming that

whatever is not specified herein is not feasible. The warranty does not cover any defect arising from a

handling or operation not specif ied in this opera tio n manua l.

4. The information contained in this operation manual is subject to change without notice for the purpose

of modification and improvement.

* If you have purchased PC software:

Always back up the parameters after installing the product or changing the parameter settings.

5. The specifications in this manual may not apply to a custom product.

Action to Be Taken in Case of Emergency

If this product is found to be in a dangerous condition, immediately turn off all power switches of the

main unit and connected equipment or immediately disconnect all power cables from the outlets.

(“Dangerous condition” refers to a situation where the product is generating abnormal heat or smoke or

has ignited and a fire or danger to human health is anticipated.)

Page 12

Table of Contents

Table of Contents

Introduction ...................................................................................................................... 1

Part 1 Installation ........................................................................................................ 2

Chapter 1 Safety Precautions ............................................................................................................... 2

Chapter 2 Warranty Period and Scope of Warranty ............................................................................. 3

Chapter 3 Installation Environment and Noise Measures .................................................................... 4

Chapter 4 Name and Function of Each Part ......................................................................................... 8

1. Front View of Controller .......................................................................................................... 8

2. Explanation of Codes Displayed on the Panel Window ....................................................... 18

Chapter 5 Specifications ..................................................................................................................... 20

1. Controller Specifications ....................................................................................................... 20

2. External I/O Specifications ................................................................................................... 22

3. Power-Source Capacity and Heat Output of the Controller ................................................. 26

4. External Dimensions ............................................................................................................ 27

Chapter 6 System Setup ..................................................................................................................... 29

1. Connection Method of Controller and Robot (KX Type) ....................................................... 29

2. I/O Connection Diagram ....................................................................................................... 31

3. I/O Flat Cable ....................................................................................................................... 33

Chapter 7 Maintenance ...................................................................................................................... 34

Part 2 Operation ........................................................................................................ 41

Chapter 1 Operation ........................................................................................................................... 41

1. Starting a Program by Auto-Start via Parameter Setting ...................................................... 42

2. Starting via External Signal Selection .................................................................................. 43

3. Drive-Source Recovery Request and Operation-Pause Reset Request ............................. 45

Part 3 Controller Data Structure ................................................................................ 46

Chapter 1 How to Save Data .............................................................................................................. 47

1. Factory Settings: When the System-Memory Backup Battery is Used ................................ 47

2. When the System-Memory Backup Battery is Not Used ..................................................... 48

3. Points to Note ....................................................................................................................... 49

Chapter 2 X-SEL Language Data (IX-Series Controller) .................................................................... 50

1. Values and Symbols Used in SEL Language ....................................................................... 50

2. Position Part ......................................................................................................................... 63

3. Command Part ..................................................................................................................... 64

Page 13

Table of Contents

Part 4 Commands ..................................................................................................... 66

Chapter 1 List of SEL Language Command Codes ........................................................................... 66

Chapter 2 Explanation of Commands ................................................................................................. 78

1. Commands ........................................................................................................................... 78

Chapter 3 Key Characteristics of Horizontal Articulated Robot Operation ....................................... 234

1. CP Operation and PTP Operation ...................................................................................... 234

2. Arm System ........................................................................................................................ 237

3. Coordinate System ............................................................................................................. 245

4. Simple Interference Check Zone ........................................................................................ 255

5. Soft Limits ........................................................................................................................... 258

Chapter 4 Key Characteristics of Actuator Control Commands and Points to Note ......................... 262

1. Continuous Movement Commands

[P A TH, PSPL, CIR2, ARC2, CIRS, ARCS, ARCD, ARCC, CIR, ARC] ............................... 262

2. PATH/PSPL Commands ..................................................................................................... 264

3. CIR/ARC Commands ......................................................................................................... 264

4. CIR2/ARC2/ARCD/ARCC Commands ............................................................................... 264

Chapter 5 Palletizing Function .......................................................................................................... 265

1. How to Use ......................................................................................................................... 265

2. Palletizing Setting ............................................................................................................... 265

3. Palletizing Calculation ........................................................................................................ 271

4. Palletizing Movement ......................................................................................................... 272

5. Program Examples ............................................................................................................. 274

Chapter 6 Pseudo-Ladder Task ........................................................................................................ 278

1. Basic Frame ....................................................................................................................... 278

2. Ladder Statement Field ...................................................................................................... 279

3. Points to Note ..................................................................................................................... 279

4. Program Example ............................................................................................................... 280

Chapter 7 Multi-Tasking .................................................................................................................... 281

1. Difference from a Sequencer ............................................................................................. 281

2. Release of Emergency Stop ............................................................................................... 282

3. Program Switching ............................................................................................................. 283

Page 14

Table of Contents

Appendix...................................................................................................................... 284

Expansion I/O Board (Optional)............................................................................................... 284

Expanded SIO Specification (Optional) ................................................................................... 285

List of Parameters ................................................................................................................... 291

1. I/O Parameters ................................................................................................................. 292

2. Parameters Common to All Axes ..................................................................................... 302

3. Axis-Specific Parameters ................................................................................................. 304

4. Driver Card Parameters ................................................................................................... 308

5. Encoder Parameters ........................................................................................................ 314

6. I/O-Slot Card Parameters ................................................................................................ 315

7. Other Parameters ............................................................................................................ 316

8. Manual Operation Types .................................................................................................. 321

9. Use Examples of Key Parameters ................................................................................... 322

Error Level Control .................................................................................................................. 326

Error List ................................................................................................................................ 328

Trouble Report Sheet .............................................................................................................. 356

Page 15

Page 16

Page 17

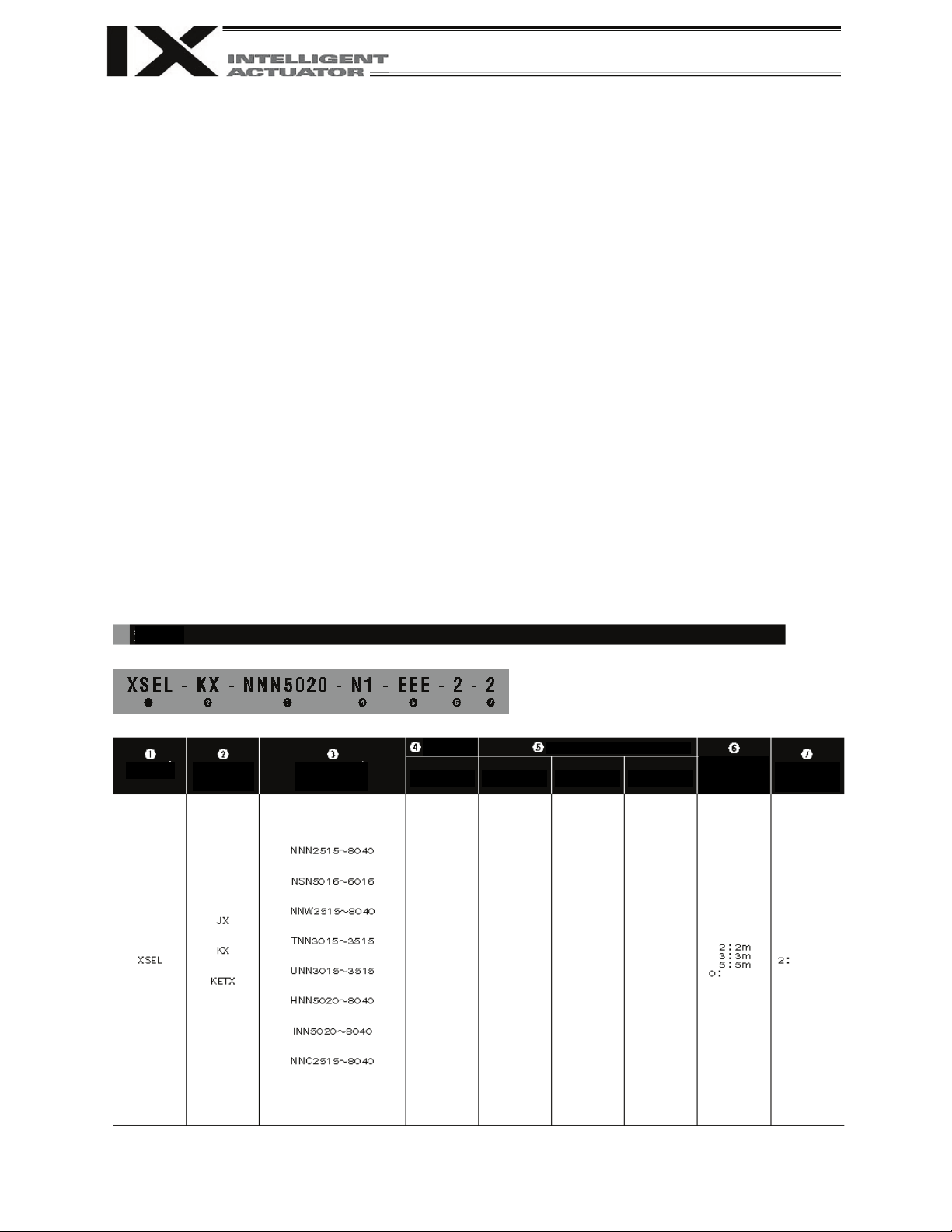

1

Introduction

hours Stopped hours Operating

hours Operating

+

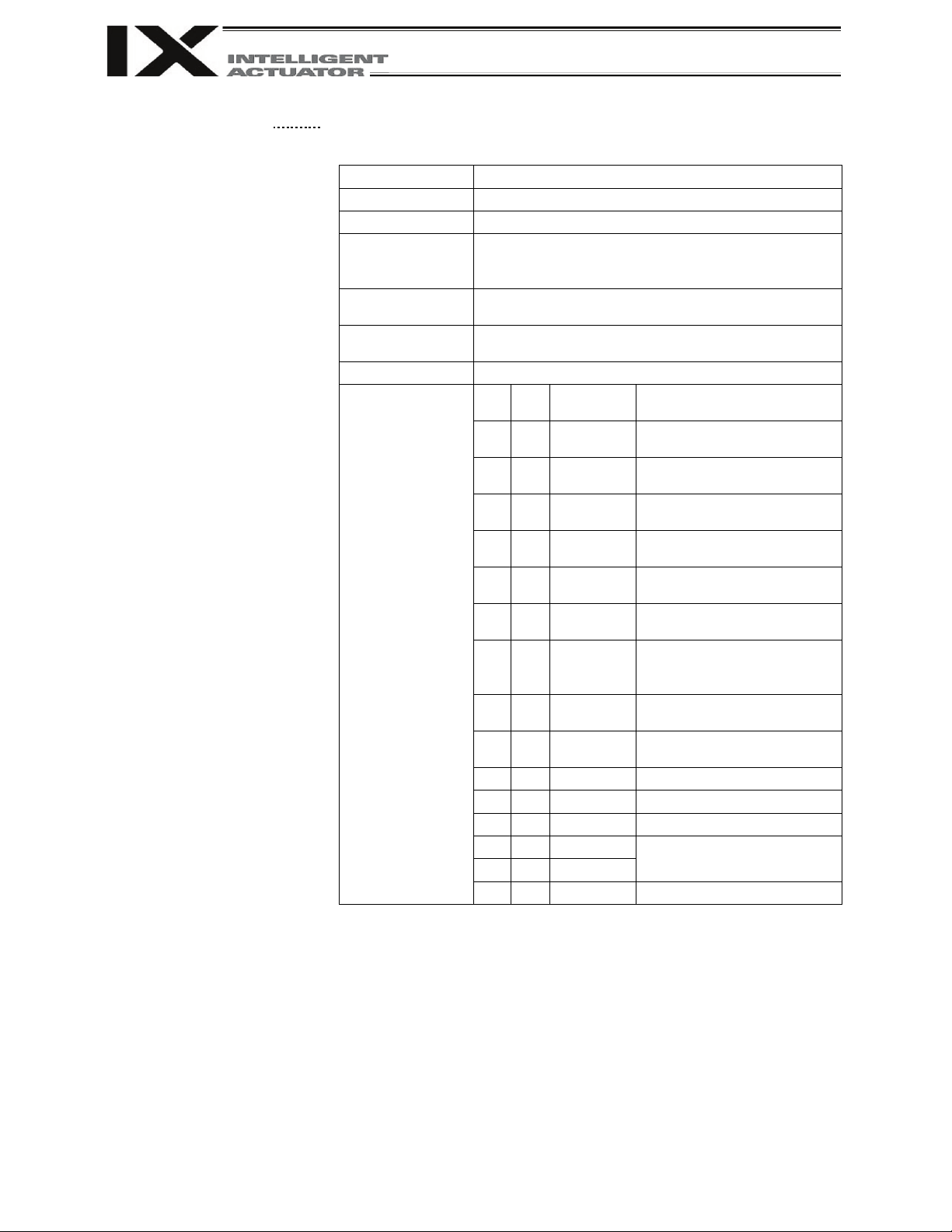

Model

Series

Controller

IX actuator

Standard I/O

specification

Slot 1

Slot 2

Slot 3

Slot 4

Expanded I/O specification (Note 1)

I/O flat cable

Supply

(Compact type)

purpose, global,

(Standard type)

No cable

Introduction

Thank you for purchasing the X-SEL IX-Series Controller.

Inappropriate use or handling will prevent this product from demonstrating its full function and may even cause

unexpected failure or result in a shortened service life. Please read this manual carefully, and handle the

product with due care and operate it correctly. Keep this manual in a safe place and reference relevant items

when needed.

The IX-Series Controller you have purchased is a new-generation controller that uses an advanced version of

the proven, innovative “SEL” language to perform a range of high functions such as multi-tasking, sequencerless operation, palletizing function and pseudo-sequence function.

Actuator duty

IAI recommends that our actuators be used at a duty of 50% or less in view of the relationship of service life

and accuracy. The duty is calculated by the formula below:

Duty (%) =

After turning off the main power, be sure to wait for at least 5 seconds before turning it on.

Any shorter interval may generate “E88: Power system error (Other).”

Do not plug in/out the connectors while the power is still supplied to the controller. Doing so may result in

malfunction.

Do not move the robot arms while the main controller power is still starting. An error, such as “C6C:

Movement error during absolute data acquisition” or “C70: Absolute coordinate non-confirmation error,” may

generate.

Read the operation manual for each actuator. If you have purchased our optional PC software and/or

teaching pendant, read the respective operation manuals, as well.

* Utmost effort has been made to ensure that the information contained in this manual is true and correct.

However, should you find any error or if you have any comment regarding the content, please contact IAI.

X 100

Example of model designation

Model table

type

(Dustproof/splash-proof type)

(General-

purpose type)

(General-

CE-compliant

type)

(Wall mount inverse type)

(Ceiling mount inverse type)

type

(High-speed type)

(Wall mount type)

(Ceiling mount type)

(Cleanroom type)

N1

[32 inputs/16 outputs

NPN board]

N3 (Note 3)

[48 inputs/48 outputs

NPN board]

P1

[32 inputs/16 outputs

PNP board]

P3 (Note 3)

[48 inputs/48 outputs

PNP board]

DV

[DeviceNet

256/256 board]

CC

[CC-Link

256/256 board]

PR

[ProfiBus

256/256 board]

ET

[Ethernet

Data communication

board]

E

(Not used)

C (Note 4)

[CC-Link

16/16 board]

N1

[Expanded I/O

NPN32/16]

N2

[Expanded I/O

NPN16/32]

N3 (Note 4)

[Multi-point I/O

NPN48/48]

P1

[Expanded I/O

PNP32/16]

P2

[Expanded I/O

PNP16/32]

P3 (Note 4)

[Multi-point I/O

PNP48/48]

SA (Note 4)

[Expanded SIO

Type A]

SB (Note 4)

[Expanded SIO

Type B]

SC (Note 4)

[Expanded SIO

Type C ]

E

(Not used)

C (Note 4)

[CC-Link

16/16 board]

N1

[Expanded I/O

NPN32/16]

N2

[Expanded I/O

NPN16/32]

N3 (Note 4)

[Multi-point I/O

NPN48/48]

P1

[Expanded I/O

PNP32/16]

P2

[Expanded I/O

PNP16/32]

P3 (Note 4)

[Multi-point I/O

PNP48/48]

SA (Note 4)

[Expanded SIO

Type A]

SB (Note 4)

[Expanded SIO

Type B]

SC (Note 4)

[Expanded SIO

Type C ]

E

(Not used)

C (Note 4)

[CC-Link

16/16 board]

N1

[Expanded I/O

NPN32/16]

N2

[Expanded I/O

NPN16/32]

N3 (Note 4)

[Multi-point I/O

NPN48/48]

P1

[Expanded I/O

PNP32/16]

P2

[Expanded I/O

PNP16/32]

P3 (Note 4)

[Multi-point I/O

PNP48/48]

SA (Note 4)

[Expanded SIO

Type A]

SB (Note 4)

[Expanded SIO

Type B]

SC (Note 4)

[Expanded SIO

Type C ]

length

(Note 2)

voltage

200-V

specification

Page 18

2

Caution

Part 1 Installation

Part 1 Installation

Chapter 1 Safety Precautions

This controller has been designed for use exclusively with IAI’s IX-Series Horizontal Articulated Robot,

and is able to provide integrated control over the entire system including peripherals. In other words , the

X-SEL Controller has the ability to control systems of all sizes ranging from a small system to a large

factory automation system. In general, however, the occurrence rate of accidents due to wrong operation

or carelessness will rise as the system becomes larger and more complex. Please give due consideration

to safety measures.

Strict observance of the following items is requested to prevent unforeseen danger. Also read the

appendix entitled, “Safety Rules and Others.”

1. Do not handle this product in manners not specified in this manual. If you have any question regarding

the content of this manual, please contact IAI.

2. Always use the specified, genuine IAI cables for wiring between the controller and the actuator.

3. Do not enter the operation area of the machine while the machine is operating or ready to operate (the

controller power is on). If the machine is used in a place accessible to other people, provide an

appropriate safety measure such as enclosing the machine with a cage.

4. When assembling/adjusting or maintaining/inspecting the machine, always turn off the controller power

at the source beforehand. The operator should display in a conspicuous place a plate or other sign

saying that operation is in progress and that the power should not be turned on. The operator should

keep the entire power cable beside him or her to prevent another person from inadvertently plugging in

the cable.

5. When two or more operators are to work together, set call-out signals to ensure safety of all personnel

during the work. In particular, a person turning on/off the power or moving an axis—either via a motor

or manually—must always say what he or she is going to do out loud and confirm the responses from

the others first before actually performing the operation.

Page 19

3

Part 1 Installation

Chapter 2 Warranty Period and Scope of Warranty

The X-SEL Controller you have purchased passed our strict outgoing inspection. This unit is covered by

the following warranty:

1. Warranty Period

The warranty period shall be either of the following periods, whichever ends first:

• 18 months after shipment from our factory

• 12 months after delivery to a specified location

2. Scope of Warranty

Should the product fail during the above period under a proper use condition due to a fault on the part

of the manufacturer, IAI will repair the defect free of charge. However, the following cases are

excluded from the scope of warranty:

• Discoloration of paint or other normal aging

• Wear of consumable parts due to use

• Subjective imperfection, such as noise not affecting mechanical function

• Defect caused by inappropriate handling or use by the user

• Defect caused by inappropriate or erroneous maintenance/inspection

• Defect caused by use of a part other than IAI’s genuine part

• Defect caused by unauthorized modification, etc., not approved by IAI or its agent

• Defect due to an act of God, accident, fire, etc.

The warranty covers only the product as it is delivered. IAI shall not be liable for any loss arising in

connection with the delivered product. The user must bring the defective product to our factory to

receive a warranty repair.

3. Scope of Service

The price of the delivered product does not include costs incurred in association with program

generation, dispatch of technician, etc. Therefore, a separate fee will be chargeable in the following

cases even during the warranty period:

• Guidance on installation/adjustment and witnessing of test operation

• Maintenance/inspection

• Technical guidance and trai nin g on operation, wiring method, etc.

• Technical guidance and training regarding programs, such as program generation

• Other services and operations where IAI finds a need to charge a separate fee

Page 20

4

24-VDC fan x 5 (compact type)

24-VDC fan x 6 (general-purpose type)

Part 1 Installation

Chapter 3 Installation Environment and Noise Measures

1. Installation Environment

(1) When installing and wiring the controller, do not block the ventilation holes provided for cooling.

(Insufficient ventilation will not only prevent the product from functioning fully, but it may also result in

failure.)

(2) Prevent foreign matter from entering the controller through the ventilation holes. Since the controller

is not designed as dustproof or waterproof (oilproof), avoid using it in a dusty place or place subject

to oil mist or splashed cutting fluid.

(3) Do not expose the controller to direct sunlight or radiant heat from a high heat source such as a heat-

treating furnace.

(4) Use the controller in a non-condensing environment free from corrosive or inflammable gases.

(5) Use the controller in an environm ent where it will not receive external vibration or impact.

(6) Prevent electrical noise from entering the controller or its cables.

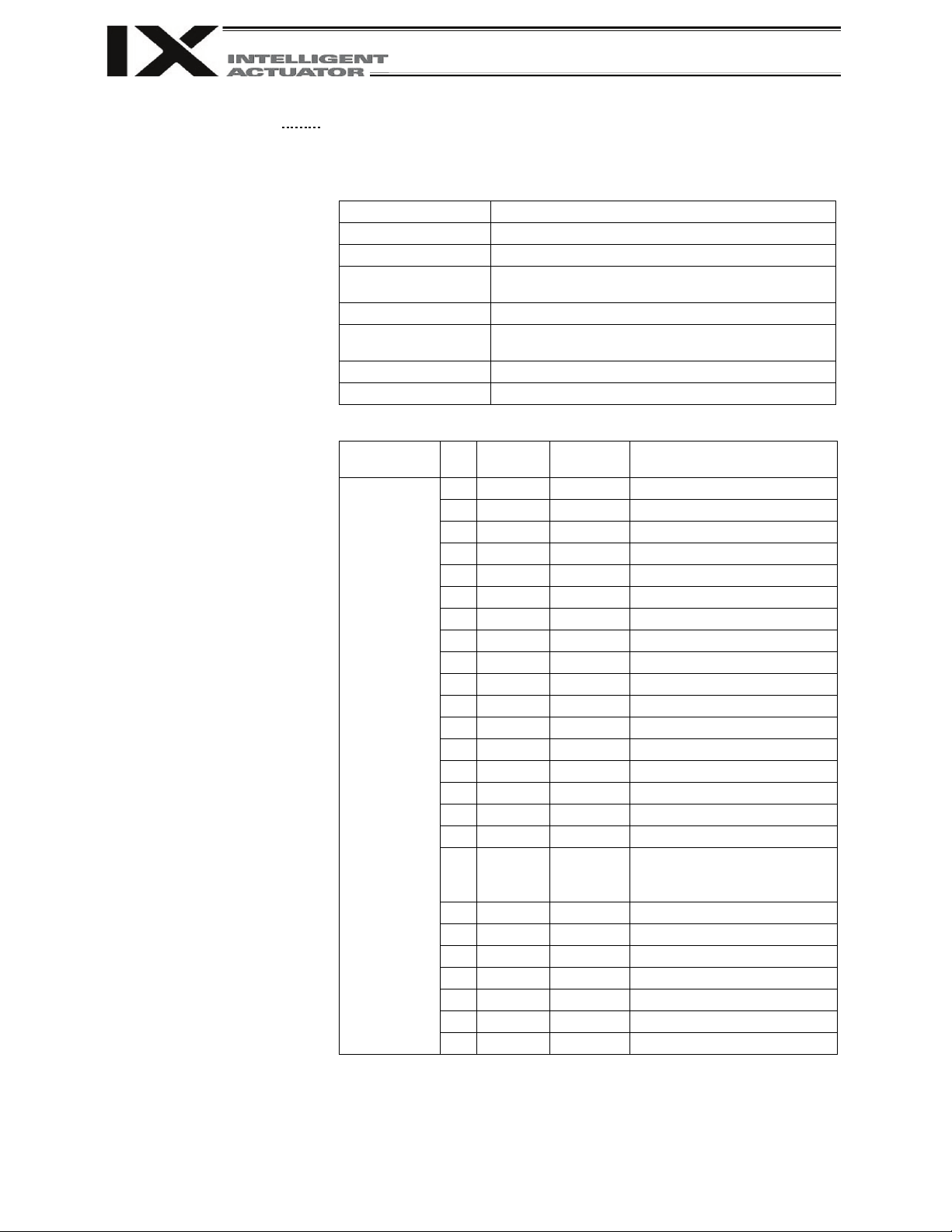

Environmental Condition of Controller

Item Specification

Surrounding air temperature range

Forced air-cooling

Surrounding humidity range 30% ~ 85%

Storage temperature range

Dust protection structure IP10

Power-sour c e volta ge 100 to 115/200 to 230 VAC, single-phase

Operating power-source voltage

Rated operating power-source frequency 50 Hz/60 Hz

0°C ~ 40°C

-10°C ~ 65°C

±10%

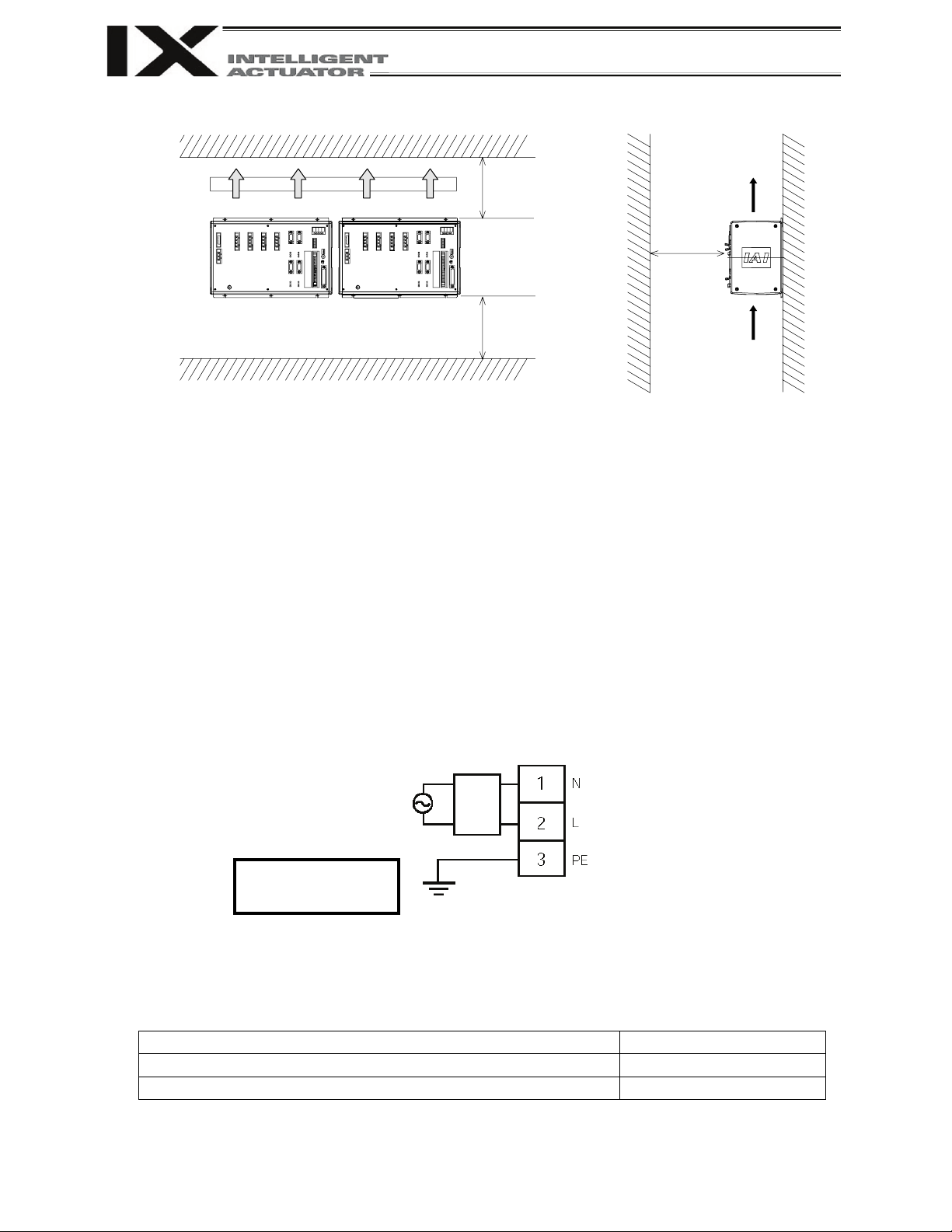

2. Heat Radiation and Installation

Design the control panel size, controller layout and cooling method so that the ambient temperature

around the controller will be kept at or below 40°C.

Install the controller vertically on a wall, as illustrated below. The controller will be cooled by forced

ventilation (exhaust air will be discharged from the top). Be sure to install the controller in the

aforementioned direction a nd pro vide a m inimum clearance of 150 mm above and 150 mm below the

controller.

If multiple controllers are to be installed side by side, providing additional suction fans on top of the

controllers will help maintain a uniform ambient temperature.

Provide a minimum clearance of 150 mm between the front side of the controller and a wall

(enclosure).

Page 21

5

POWERRBM4 M3 M2 M1

PG1

TP

PG2 PG4

I/02 I/01

PG3

CODE

POWERRBM4 M3 M2 M1

PG1

TP

PG2 PG4

I/02 I/01

PG3

CODE

Robot specification

Model

Arm length 700/800 specification, high-speed specification

MXB-1220-33

Other types

MXB-1210-33

Airflow direct io n

Airflow

150 mm min.

150 mm min.

150 mm

200-VAC power source

Class D grounding

Noise

Part 1 Installation

Fan

min.

If multiple controllers are to be connected on top of one another, prevent the controller above from

taking in the exhaust air from the controller below.

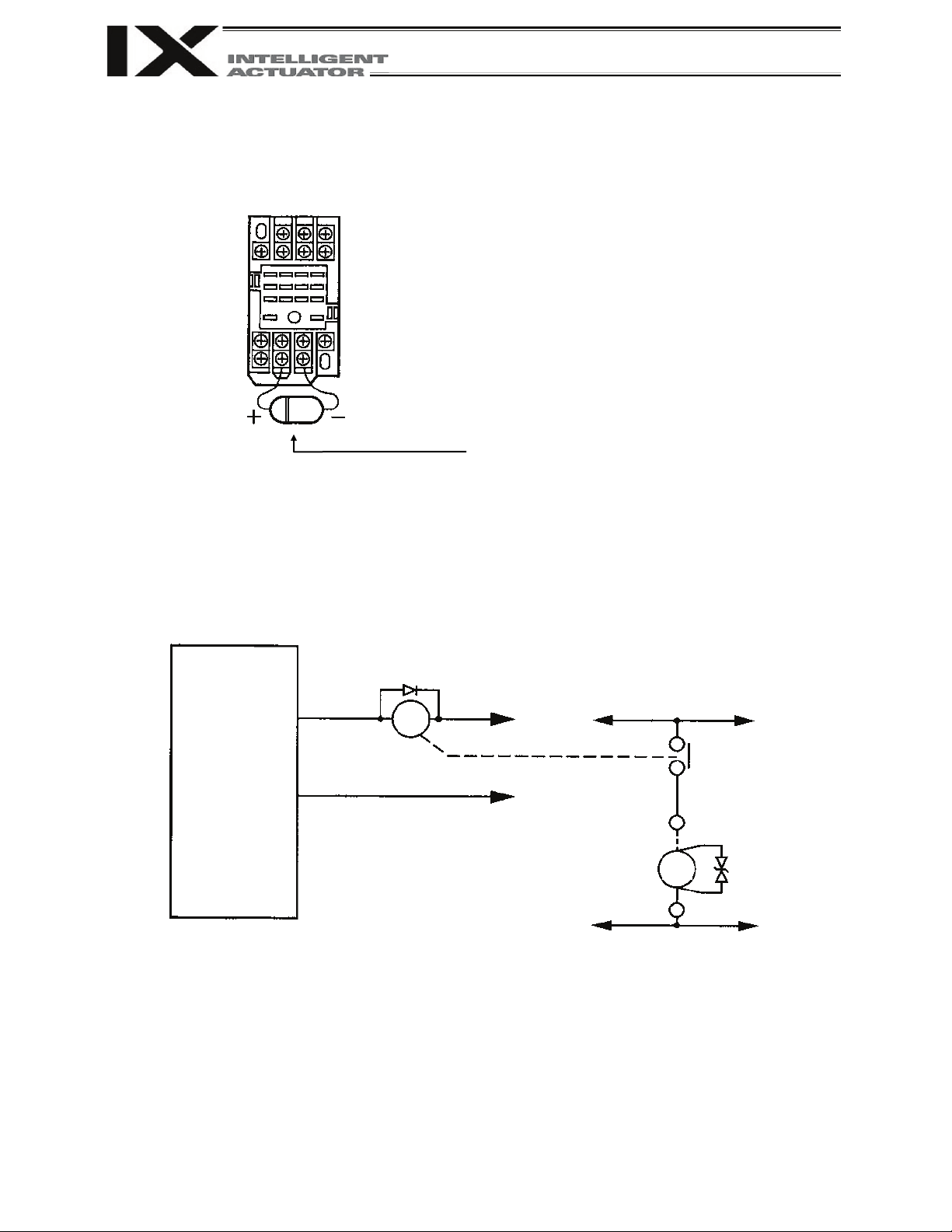

3. Power Source

Provide a single-phase power source of 200 to 230 VAC.

4. Noise Measures and Grounding

(1) Wiring and power source

PE on the power terminal block is used for protective grounding. Provide Class D grounding from this

terminal.

Use a grounding cable with a wire size of 1.0 mm

than the AC power cable.

Install a noise filter in the AC line to prevent the noise generating in the controller from traveling

through the power line to enter other unit.

(protective grounding)

Install the noise filter near the power connector on the X-SEL controller side.

Use of a noise filter by Densei-Lambda is recommended. The applicable noise filter model varies

depending on the robot specification, as shown below.

Recommended noise filter models (by Densei-Lambda)

2

(#AWG17) or more, which should not be smaller

filter

Page 22

6

AC power source

Class D grounding

Metal enclosure

Surge absorber

ACIN

N

X-SEL

Other

X-SEL

Other

Do not use this method.

Part 1 Installation

[2] Notes on wiring method

Use twisted cables for the AC power cable and 24-VDC external power cable. Wire the controller

cables separately from lines creating a strong electric field such as power circuit lines (by not

bundling them together or placing in the same cable duct).

If you wish to extend the motor cable or encoder cable beyond the length of each supplied cable,

please contact IAI.

(2) Noise-eliminat ion grou ndi n g

L

PE

Connect the FG terminal

with the metal enclosure

using a cable of a

maximum allowable size

over the shortest distance.

Provide dedicated FG or PE grounding.

equipment

equipment

controller

controller

(3) Noise sources and noise elimination

There are many noise sources, but solenoid valves, magnet switches and relays are of particular

concern when building a system. Noise from these parts can be eliminated using the measures

specified below:

[1] AC solenoid valve, magnet switch, relay

Measure --- Install a surg e absor ber in parallel with the coil.

← Point

Wire from each coil over the shortest distance.

Installing a surge killer on the terminal block,

etc., will be less effective because of a longer

distance from the coil.

Page 23

7

Diode

Controller

OUT

CR

+24 V

0 V

100 VAC

CR

0 V

Part 1 Installation

[2] DC solenoid valve, magnet switch, relay

Measure --- Install a diode in parallel with the coil. Determine the diode capacity in accordance with

the load capacity.

In a DC circuit, connecting a diode in reversed polarity will

damage the diode, internal parts of the controller and DC

power supply. Exercise due caution.

The above noise elimination measures are particularly important when a 24-VDC relay is driven

directly by a controller output and there is also a 100-VAC solenoid valve, etc.

Reference Circuit Diagram

COM

SOL

Surge absorber

Solenoid valve

Page 24

8

External regenerative unit

Motor connector

Encoder

System I/O

I/O24V power

Panel window (Refer to

FG terminal

Fuse holder

AC input

When this LED is lit in red, a system clock error is present.

gency stop is actuated or CPU hardware error or

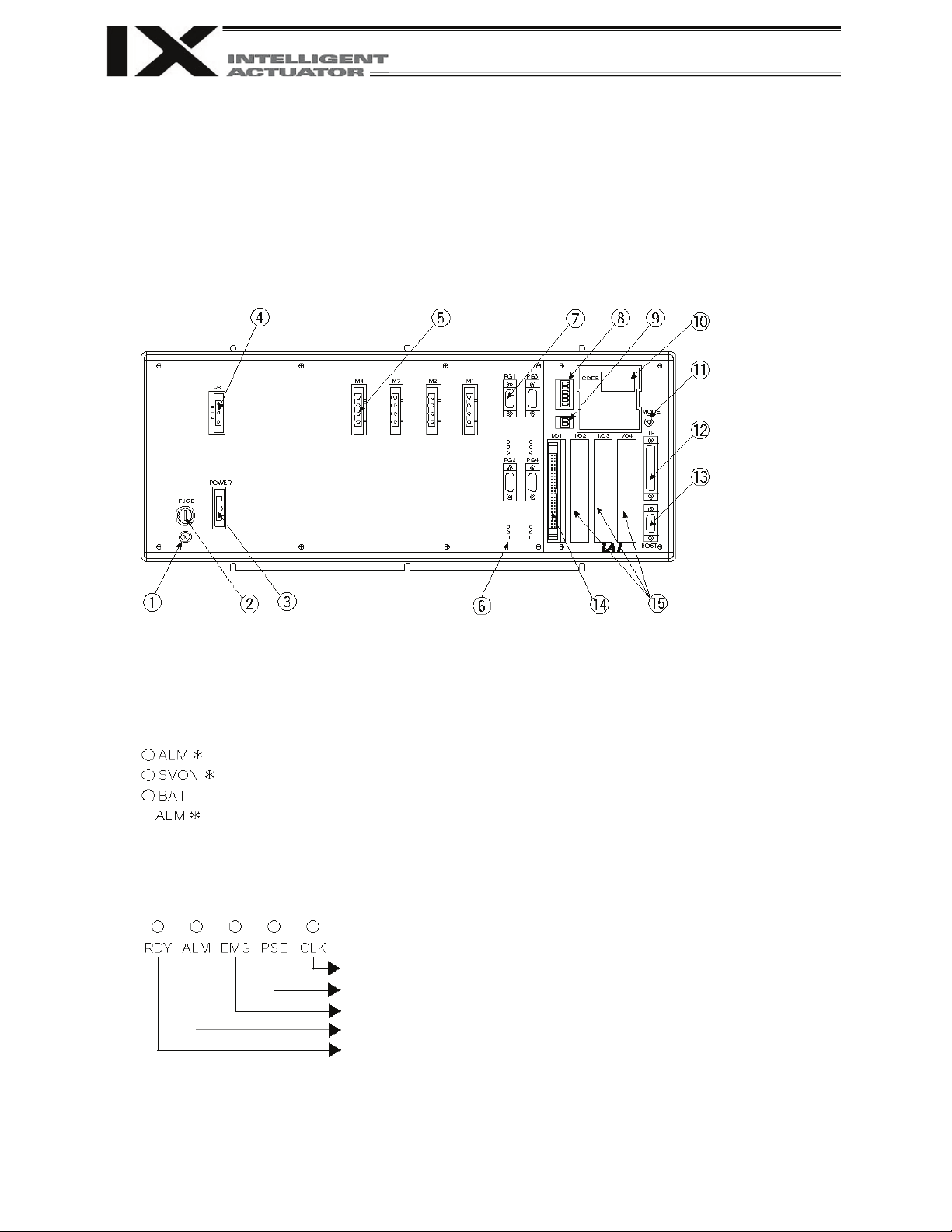

Chapter 4 Name and Function of Each Part

1. Front View of Controller

KX type (general-purpose type)

Applicable to robots of all strokes

Alarm and Other LED Indicators

[6] Driver status LEDs

[10] Panel window

4-digit, 7-segment LEDs: Refer to 2, “Explanation of Codes Displayed on the Panel Window.”

The following five LEDs are provided.

connector

connector

: When this LED is lit in orange, the driver is detecting an error.

: When this LED is lit in green, the servo is on and the motor is being driven.

: When this LED is lit in orange, the absolute-encoder b ac k up batter y voltage is lo w.

When this LED is lit in red, a power-system hardware error is present.

When this LED is lit in red, an emer

power-system hardware error is present.

When this LED is lit in red, a CPU alarm (system-down level error) or CPU

hardware error is present.

When this LED is lit in green, the CPU is ready (program operation is enabled).

Driver stat us LEDs

(Refer to the

explanation below.)

connector

Standard I/O

connector

connector

Part 1 Installation

connector

Expansion I/O

connectors

the explanation below.)

Mode switch

Teaching connector

PC connector

Page 25

9

External regenerative

Motor connector

Encoder

AC input

Driver stat us LEDs

Standard I/O

Expansion I/O

Panel window (Refer to

When this LED is lit in red, an emergency stop is actuated or CPU hardware error or

JX type (compact type)

Applicable to robots of 250/350 strokes

connector

the explanation below.)

connector

unit connector

System I/O connector

System-operation setting switches

Boot-target setting switch

Mode switch

Teaching connector

FG terminal

(Refer to the

explanation below.)

connectors

connector

Alarm and Other LED Indicators

[6] Driver status LEDs

: When this LED is lit in orange, the driver is detecting an error.

: When this LED is lit in green, the servo is on and the motor is being driven.

: When this LED is lit in orange, the absolute-encoder b ac k up batter y voltage is lo w.

[10] Panel window

4-digit, 7-segment LEDs: Refer to 2, “Explanation of Codes Displayed on the Panel Window.”

The following five LEDs are provided.

When this LED is lit in red, a system clock err or is pres ent.

When this LED is lit in red, a power-system hardware error is present.

power-system hardware error is present.

When this LED is lit in red, a CPU alarm (system-down level error) or CPU

hardware error is present.

When this LED is lit in green, the CPU is ready (program operation is enabled).

Part 1 Installation

Page 26

10

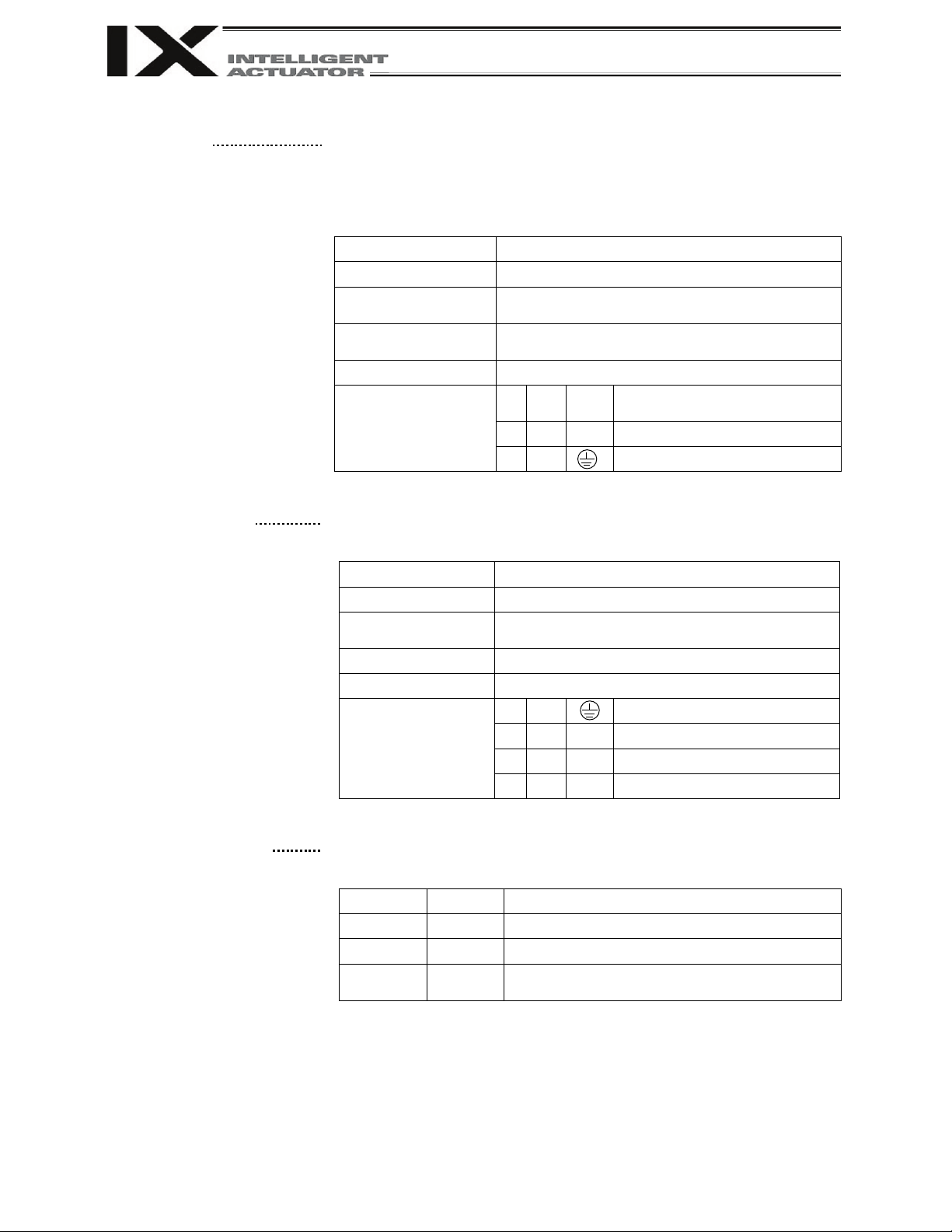

[1] FG terminal

This terminal is used to ground FG on the enclosure. With a general-

Be sure to ground the FG terminal.

[2] Fuse holder (general-

This half-cut fuse holder is used to protect overcurrent in the AC input

and uses a slow-blow fuse specified by IAI.

Melting

characteristics

[3] AC input connector

200-VAC, single-phase input connector.

3-pin, 2-piece connector

Terminal

*

Part 1 Installation

purpose type only)

purpose type, the enclosure is connected to PE in the AC input part inside

the controller.

With a compact type, FG and PE are not connected inside the controller.

FG Terminal Specifications

Item Overview

M4 3-point SEMS screw, 5 mm

Cable size 2.0 ~ 5.5 mm2

Grounding method Class D grounding

part. It prevents inflow of abnormal current generated by ground fault, etc.,

Overview of Fuse Holder Specifications

Item Description

Holder F-22001-A1 by Sato Parts

Fuse type TWO 250V20A by Fuji Terminal

Slow-blow

* With a compact type, the fuse holder is mounted on the board. Type:

FGMT5 AC250V10A by Fuji Terminal

AC Power Connector Specifications

Item Overview

Connector name POWER

Connector GMSTB2.5/3-STF-7.62 by Phoenix Contact

Supported cable size 1.25 ~ 2.5 mm2 (AWG12 ~ 16)

Connected to AC power source

assignments

1 In N AC power input, N side

2 In L AC power input, L side

3

PE (Protective grounding line)

Page 27

11

[4] External regenerative unit

This connector is used to connect a regenerative resistance unit that may

will be determined by the specific application such as axis configuration.

3-pin, 2-piece connector

Cable size

1.0 mm2 (AWG17 or equivalent), included in the

external regenerative box

(Motor-driving DC voltage)

[5] Motor connector

This connector is used to drive the motor inside the actuator.

Connector

GIC2.5/4-STF-7.62 by Phoenix Contact

4-pin, 2-piece connector

Terminal

the motor drive. The following three LEDs are provided.

The voltage of the absolute-data backup

battery is low.

Part 1 Installation

connector

be required when the controller is used in a high-speed/high-load

environment, etc., and the built-in regenerative resistance capacity is not

sufficient. Whether or not an external regenerative resistance is necessary

Overview of Fuse Holder Specifications

Item Overview

Connector name RB

Connector GIC2.5/3-STF-7.62 by Phoenix Contact

Connected to External regenerative box

Terminal

assignments

1 Out RB+

Regenerative resistance +

2 In RB– Regenerative resistance –

Overview of Motor Connector Specifications

Item Description

Connector name M

Cable Dedicated motor cable

Connected to Actuator

assignments

1

2 Out U Motor-driving phase U

PE (Protective grounding line)

3 Out V Motor-driving phase V

4 Out W Motor-driving phase W

[6] Driver status LEDs These LEDs monitor the operating status of the driver CPU that controls

Name Color Meaning when lit

ALM Orange The driver is detecting an error.

SVON Green The servo is on and the motor is being driven.

BAT ALM Orange

Page 28

12

[7] Encoder connector

This 15-pin, D-sub connector is used to connect the actuator’s encoder.

Connector name

PG

Maximum

distance

10 m

Interface

standard

Conforming to RS422

Connected to

Actuator

(Built-in encoder unit inside the actuator)

Connection cable

Terminal

Pin

No.

Signal

name

(Phase U+)

Phase-A differential – input

(Phase U–)

(Phase V+)

Phase-B differential – input

(Phase V–)

(Phase W+)

Phase-Z differential – input

(Phase W–)

switching+)

magnetic-pole switching–)

Backup-battery power

supply

Part 1 Installation

Encoder Connector Specifications

Item Description

Connector High-density D-sub, 15-pin (fem ale)

connection

Dedicated PG cable

assignments

I/O

1 In A+

Phase-A differential + input

Description

2 In A–

3 In B+

Phase-B differential + in pu t

4 In B–

5 In Z+

Phase-Z differential + input

6 In Z–

Send/receive line+

7 IO SRD+

8 IO SRD–

(Pulse/magnetic-pole

Send/receive line– (Pulse/

9 Out BATT

10 Out BATTGND Battery ground

11 Out VCC Encoder power source

12 Out GND GND

13 Out BK–

14 Out BK+

Brake output

15 FG Not used

Page 29

13

[8] System I/O connector

This connector is used to connect an emergency-stop switch, ENABLE

contact, ready relay, etc.

connector

1

RDY OUT

2

RDY OUT

3

ENB IN

Safety-gate input

4

+24V OUT

+24-V power output for safety gate

5

EMG IN

Emergency-stop input

+24-V power output for emergency

stop

Supported cable size

0.75 ~ 1.25 mm2 (AWG16)

MC1.5/2-ST-3.5 by Phoenix Contact; 2-pin, 2-piece

connector

1

0V

I/O GND

2

24V IN

+24-V power input for I/Os

[10] Panel window

This window consists of a 4-digit, 7-segment LED display and five LED

Name

Status when the LED is lit

RDY

CPU ready (program can be run)

ALM

CPU alarm (system-down level error), CPU hardware error

power-system hardware error

PSE

Power-system hardware error

CLK

System clock error

[11] Mode switch

This alternate switch with lock is used to command a controller operation

(Refer to the types of manual operations explained on p.324.)

Part 1 Installation

[9] I/O24V power connector

(general-purpose type

only)

Connector

Terminal assignments

Pins 1 and 2 form a contact-A output that turns ON under the following condition:

• SYSRDY is output (software = PIO trigger program can be run) and hardware is

normal (emergency stop is not being actuated and hardware error is not being

detected).

Pins 3 and 4 form a contact-B safety-gate input. Operation is enabled when the

pins are shorted, while the drive source is cut off when they are open.

Pins 5 and 6 form a contact-B emergency-stop input. Operation is enabled when

the pins are shorted, while an emergency stop is actuated when they are open.

Current flowing to the emergency stop contacts:

KX type (general-purpose ty pe ) : 43 mA ± 10%

JX type (compact type): 30 mA ± 10%

The controller is shipped with pins 3 and 4, and 5 and 6, shorted by a cable,

respectively.

MC1.5/6-ST-3.5 by Phoenix Contact; 6-pin, 2-piece

Ready-status output contact

6 +24V OUT

This connector is used to externally supply I/O power to the insulated part

when DI and DOs are mounted in the I/O connectors explained in [14] and

[15] (2-pin, 2-piece connector by Phoenix Contact). 24 V must be supplied

externally.

Connector

Terminal assignments

With a compact type, power is supplied externally to pin Nos. 1 and 50 of

the I/O connector in [14].

lamps that indicate the status of the equipment.

For the information shown on the display, refer to 2, “Explanation of

Codes Displayed on the Panel Window” or the “Error Code Table.”

Meanings of Five LEDs

EMG

Emergency stop has been actuated, CPU hardware error,

mode. To operate the switch, pull it toward you and tilt.

Tilting the switch upward will select MANU (manual mode), while tilting it

downward will select AUTO (auto mode). Teaching can be performed only

in the MANU mode, but auto program start is not enabled in the MANU

mode.

Page 30

14

[12] Teaching connector

When an optional teaching pendant or PC is connected, this D-sub, 25-

Communication

method

RS232C-compliant, start-stop synchronous

method

Maximum

connection distance

Signal

name

Terminal

Power output

teaching pendant)

pin connector will be used to input program and position data in the

MANU mode.

Interface Specifications of Teaching Serial Interface

Item Description

Connector name TP

Connector DSUB-25 XM3B-2542-502L (Omron)

Baud rate 38.4 kbps max.; half-duplex communication

Interface standard RS232C

Connected to X-SEL teaching pendant

Interface Specifications of Teaching Serial Interface

Part 1 Installation

10 m (38.4 kbps)

Item No. Direction

1 FG Frame ground

assignments

2 Out TXD Transmitted data

3 In RXD Received data

4 Out RTS Request to send

5 In CTS Clear to send

6 Out DSR Equipment ready

7 SG Signal ground

8

9 In Connection prohibited

10 In Connection prohibited

11

12 Out EMGOUT Emergency stop

13 In EMGIN

14

15 Out Connection prohibited

16 Out Connection prohibited

17 Out Connection prohibited

18 Out VCC

Description

(5-V power source for

19 In ENBTBX Enable input

20 In DTR Terminal ready

21

22

23 Out EMGS Emergency-stop status

24

25 SG Signal ground

Page 31

15

[13] PC connector (general-

This D-sub, 9-pin connector is used to perform serial communication

Maximum

distance

10 m (38.4 kbps)

user only when the teaching connector (D-sub, 25-pin) [12] is not in use.

[14] Standard I/O connector

This connector consists of a 50-pin flat connector and comprises 32-

With a general-purpose type, power is supplied from the

pin Nos. 1 and 50.

inputs)

16 points (including general-purpose and dedicated

outputs)

Part 1 Installation

purpose type only)

(RS232C) with the host equipment when AUTO is selected as the

operation mode.

* [12] and [13] cannot be used sim ultan eously.

RS232 Host Connector Specifications

This connector is used to establish a serial connection with a PC or PLC to enable

controller control.

Item Description

Connector name HOST

Connector D-sub, 9-pin (DTE); XM2C-0942-502L by Omron

connection

Interface standard RS232C

Connected to AT-compatible PC, etc. (half-duplex communication)

Connection cable Dedicated cable

Terminal

assignments

A dedicated cable must be used if an AT-compatible PC is to be

connected.

The PC connector (D-sub, 9-pin) [13] will become available for use by the

Pin No. I/O Signal name Description

1 NC

2 In RD Received data (RXD)

3 Out SD Transmitted data (TXD)

4 In DR Data set ready (DSR)

5 In SG Signal ground

6 Out ER Equipment ready (DTR)

7 Out RS Request to send (RTS)

8 In CS Clear to send (CTS)

9 NC Not used

The PC connector (D-sub, 9-pin) [13] and teaching connector (D-sub,

25-pin) [12] cannot be used simultaneously. Setting the mode switch

[11] to MANU will select the teaching connector [12], while setting it to

AUTO will select the PC connector [13].

input/16-output DIOs.

Overview of Standard I/O Interface Specifications

Item Description

Connector name I/O

Connector Flat connector, 50-pin

Power supply

Input

Output

Connected to External PLC, sensor, etc.

I/O24V power connector [9].

With a compact type, power is supplied from connector

32 points (including general-purpose and dedicated

Page 32

16

I/O Interface List

1

-

2

000

3

001

5

003

6

004

7

005

8

006

9

007

12

010

13

011

14

012

15

013

16

014

19

017

20

018

21

019

22

020

23

021

25

023

26

024

27

025

28

026

29

027

32

030

33

031

34

300

35

301

36

302

39

305

40

306

41

307

42

308

43

309

46

312

47

313

System-memory backup battery voltage-low

warning output

49

315

50

-

Part 1 Installation

These functions are based on

the factory settings. The

functions assigned to port

Nos. 000 to 014, 300 to 308,

313 and 314 can be changed

using the applicable I/O

parameters.

(Refer to Nos. 30 to 54, 59

and 60 in 1, “I/O Parameters”

of Appendix, “List of

Parameters.”)

Pin No. Category Port No. Function Cable color

General-purpose: NC, Compact: +24-V input Brown-1

Program start Red-1

General-purpose input Orange-1

4 002

10 008

11 009

Input

17 015

18 016

24 022

30 028

31 029

37 303

38 304

Output

44 310

45 311

48 314

General-purpose input Yellow-1

General-purpose input Green-1

General-purpose input Blue-1

General-purpose input Purple-1

General-purpose input Gray-1

Program specification (PRG No. 1) White-1

Program specification (PRG No. 2) Black-1

Program specification (PRG No. 4) Brown-2

Program specification (PRG No. 8) Red-2

Program specification (PRG No. 10) Orange-2

Program specification (PRG No. 20) Yellow-2

Program specification (PRG No. 40) Green-2

General-purpose input Blue-2

General-purpose input

General-purpose input

General-purpose input White-2

General-purpose input Black-2

General-purpose input Brown-3

General-purpose input Red-3

General-purpose input Orange-3

General-purpose input

General-purpose input Green-3

General-purpose input Blue-3

General-purpose input Purple-3

General-purpose input Gray-3

General-purpose input White-3

General-purpose input

General-purpose input

General-purpose input Red-4

General-purpose input Orange-4

Alarm output Yellow-4

Ready output Green-4

Emergency-stop output Blue-4

General-purpose output

General-purpose output

General-purpose output White-4

General-purpose output Black-4

General-purpose output Brown-5

General-purpose output Red-5

General-purpose output Orange-5

General-purpose output

General-purpose output

General-purpose output Blue-5

Absolute-encoder backup battery voltage-low

warning output

General-purpose output White-5

General-purpose: NC, Compact: 0 V Black-5

Purple-2

Gray-2

Yellow-3

Black-3

Brown-4

Purple-4

Gray-4

Yellow-5

Green-5

Purple-5

Gray-5

Page 33

17

[15] Expansion I/O connectors

These connectors are used to install I/O expansion boards.

[16] System-operation setting

These switches are used to set the system operation mode. Normally

set to “1.”

Part 1 Installation

I/O expansion boards are optional with a general-purpose type.

With compact types, on ly one expansion board can be installed.

Note) The connector pins are similar to those of the standard I/O

connector.

24 VDC must be input to pin Nos. 1 and 50.

switches (compact type only)

[17] Boot-target specification switch

(compact type only)

all switches should be set to OFF.

This switch is used to select the device that will be updated w he n the

system implements program update. Normally this switch should be

Page 34

18

Display

Priority (*1)

Description

AC power is cut off (including momentary power failure or drop in

power-source voltage).

Waiting for a drive-source cutoff reset input (except during the

update mode).

Operation is in pause (waiting for restart) (except during the update

mode).

Running a program (last started program); “No.” indicates program

number.

Part 1 Installation

2. Explanation of Codes Displayed on the Panel Window

2.1. Application

1

1 System-down level error

2 Writing data to the flash ROM.

3 Emergency stop is being actuated (except during the update mode).

4 Safety gate is open (except during the update mode).

5 Cold-start level error

5 Cold-start level error

5 Operation-cancellation level error

5 Operation-cancellation level error

6

6

7 All servo axes are interlocked (except during the update mode).

8 Message level error

8 Message level error

9 Core update mode

9 Core update is in progress.

9 Core update has completed.

9 Slave update mode

9 Slave update is in progress.

9 Slave update has completed.

9

9 Initialization sequence number

9 Debug mode

9 Ready status (auto mode)

9 Ready status (manual mode)

10 Deadman switch OFF (manual mode)

(*1) The priority increases as the number decreases.

Page 35

19

Display

Priority (*1)

Description

AC power is cut off (including momentary power failure or drop in

power-source voltage).

2.2. Core

1

1 Cold-start level error

1 Cold-start level error

1 Operation-cancellation level error

1 Operation-cancellation level error

2 Message level error

2 Message level error

2 Application update mode

2 Application update is in progress .

Part 1 Installation

2 Application update has completed.

2 Hardware test mode process

2 Clearing the application flash ROM.

2 Application flash ROM has been cleared.

2 Jump to the application

2 Core flash-ROM check process

2 Application flash-ROM check process

2 SDRAM check process

(*1) The priority increases as the number decreases.

Page 36

20

Total output when maximum

number of axes are connected

Operating power-sourc e vo ltag e

range

terminals and between the external terminals (together) and case)

Surrounding air temperature

range

For backup of absolute data: AB-3 by I AI

For backup of system memory: CR2032

Motor overcurrent, overload, motor-driver temperature check, overload

error

Teaching pendant, PC software, absolute-data backup battery unit, I/O

installed)

Part 1 Installation

Chapter 5 Specifications

1. Controller Specifications

1.1 JX Type (Compact Type) (for actuators of strokes from 250 to 350)

Type JX Type (Compact Type)

450 W

Power-sour c e volta ge Single-phase, 200 to 230 V

±10%

Power-source frequency 50 Hz/60 Hz

Insulation resistance

Withstand voltage 1500 VAC for 1 minute (Note)

Surrounding humidity range 30% to 85%

Storage temperature range

Axis control method AC full digital servo

Position detection methods Rotation data backup absolute encoder

10 MΩ min. (measured at 500 VDC between the power terminal and I/O

0°C to 40°C

-10°C to 65°C

Batteries

Speed setting 1 mm/sec to 2000 mm/sec

Acceleration/deceleration setting 0.01 G to 1 G

Programming language Super SEL language

Program steps 6000 steps (total)

Number of positions 3000 positions (total)

Number of programs 64 programs

Multi-tasking 16 programs

Storage device Flash ROM + SRAM battery backup

Data input methods Teaching pendant or PC software

Standard inputs 32 points (total of dedicated inputs + general-purpose inp uts)

Standard outputs 16 points (total of dedicated outputs + general-purpose outputs)

Expanded inputs/outputs Only one board can be installed.

Serial communication For connection of teaching pendant or PC

Other inputs/output Emergency-stop input, safety-gate input, system ready output

Protective functions

check, encoder-open detection, soft limit over, system error, battery

Drive-source cutoff method Semiconductor

Regenerative resistance

Built-in (1 kΩ, 20 W); external regenerative resistance supported

Accessory I/O flat cable

Optional parts and components

Note: The withstand voltage of the actuator motor is 1000 V for 1 minute.

When performing a withstand voltage test with the controller and actuator connected, make sure the test voltage and

duration will not exceed 1000 V and 1 minute, respectively.

shield cable, I/O expansion board (only one expansion board can be

Page 37

21

Total output when maximum

number of axes are connected

Operating power-sourc e vo ltag e

range

terminals and between the external terminals (together) and case)

range

For backup of absolute data: AB-3 by I AI

Motor overcurrent, overload, motor-driver temperature check, overload

error

Teaching pendant, PC software, absolute-data backup battery unit, I/O

shield cable, I/O expansion board

Part 1 Installation

1.2 KX Type (General-Purpose Type) (for actuators of strokes from 250 to 800)

Type KX Type (General-Purpose Type)

1750 W

Power-sour c e volta ge Single-phase, 200 to 230 V

±10%

Power-source frequency 50 Hz/60 Hz

Insulation resistance

Withstand voltage 1500 VAC for 1 minute (Note)

Surrounding air temperature

Surrounding humidity range 30% to 85%

Storage temperature range

Axis control method AC full digital servo

Position detection methods Rotation data backup absolute encoder

10 MΩ min. (measured at 500 VDC between the power terminal and I/O

0°C to 40°C

-10°C to 65°C

Batteries

For backup of system memory: CR2032

Speed setting 1 mm/sec to 2000 mm/sec

Acceleration/deceleration setting 0.01 G to 1 G

Programming language Super SEL language

Program steps 6000 steps (total)

Number of positions 3000 positions (total)

Number of programs 64 programs

Multi-tasking 16 programs

Storage device Flash ROM + SRAM battery backup

Data input methods Teaching pendant or PC software

Standard inputs 32 points (total of dedicated inputs + general-purpose inp uts)

Standard outputs 16 points (total of dedicated outputs + general-purpose outputs)

Expanded inputs/outputs 48 points per unit (a maximum of 3 units can be added)

Serial communication For connection of teaching pendant or PC

Other inputs/output Emergency-stop input, safety-gate input, system ready output

Protective functions

check, encoder-open detection, soft limit over, system error, battery

Drive-source cutoff method Relay

Regenerative resistance

Built-in (220 kΩ, 80 W); external regenerative resistance supported

Accessory I/O flat cable

Optional parts and components

Note: The withstand voltage of the actuator motor is 1000 V for 1 minute.

When performing a withstand voltage test with the controller and actuator connected, make sure the test voltage and

duration will not exceed 1000 V and 1 minute, respectively.

Page 38

22

Item

Specification

Input voltage

24 VDC ±10%

Input current

7 mA per circuit

ON voltage --- 16.0 VDC min.

OFF voltage --- 5.0 VDC max.

Insulation method

Photocoupler insulation

[4] Sequencer contact output (minimum load of approx. 5 VDC/1 mA)

*

General purpose

Compact

I/O24V connector

24V IN

Caution

Internal circuit

Input terminal

OFF duration

+

-

2. External I/O Specifications

2.1. NPN Specification

(1) Input part

External Input Specifications (NPN Specification)

ON/OFF voltage

[1] No-voltage contact (minimum load of approx. 5 VDC/1 mA)

External devices

[2] Photoelectric/proximity sensor (NPN type)

[3] Sequencer transistor output (open-collector type)

[Input circuit]

560 Ω

3.3 KΩ

Part 1 Installation

P24*

External power supply

24 VDC +10%

P24

If a non-contact circuit is connected externally, malfunction may result from leakage

current. Use a circuit in which leakage current in a switch-off state does not exceed 1 mA.

X-SEL controller’s input signal

At the default settings, the system recognizes the ON/OFF durations of input signals if they

are approx. 4 msec or longer. The ON/OFF duration settings can also be changed using I/O

parameter No. 20 (input filtering frequency).

ON duration

I/O interface pin No. 1

Page 39

23

Item

Specification

Load voltage

24 VDC

Maximum load current

100 mA per point, 400 mA per 8 ports Note)

Leakage current

0.1 mA max. per point

Insulation method

Photocoupler insulation

[1] Miniature relay

[2] Sequencer input unit

*

General purpose

Compact

24V IN

I/O24V connector

0V

Caution

Internal circuit

N*

P24*

+ - Surge absorber

Load

External power supply

(2) Output part

Part 1 Installation

External Output Specifications (NPN Specification)

TD62084 (or equivalent)

External devices

Note) 400 mA is the maximum total load current of every eight ports from output port No. 300. (The

maximum total load current of output port No. 300 + n to No. 300 + n + 7 is 400 mA, where n is 0

or a multiple of 8.)

[Output circuit]

D

10 Ω

Output terminal

24 VDC ± 10%

P24

N

In the event that the load is short-circuited or current exceeding the maximum load

current is input, the overcurrent protection circuit will be actuated to cut off the circuit.

However, give due consideration to the circuit connection layout to prevent short-circuit

or overcurrent.

I/O24V connector

I/O interface pin No. 1

I/O interface pin No. 50

Page 40

24

Item

Specification

Input voltage

24 VDC ±10%

Input current

7 mA per circuit

ON voltage --- 8 VDC max.

OFF voltage --- 19 VDC min.

Insulation method

Photocoupler insulation

[1] No-voltage contact (minimum load of approx. 5 VDC/1 mA)

[4] Sequencer contact output (minimum load of approx. 5 VDC/1 mA)

*

General purpose

Compact

I/O24V connector

0V

Internal circuit

Input terminal

External power supply

N*

OFF duration

+

-

2.2. PNP Specification

(1) Input part

ON/OFF voltage

Part 1 Installation

External Input Specifications (PNP Specification)

External devices

[2] Photoelectric/proximity sensor (PNP type)

[3] Sequencer transistor output (open-collector type)

[Input circuit]

N

560 Ω

3.3 KΩ

I/O interface pin No. 50

24 VDC +10%

Caution

If a non-contact circuit is connected externally, malfunction may result from leakage

current. Use a circuit in which leakage current in a switch-off state does not exceed 1 mA.

X-SEL controller’s input signal

At the default settings, the system recognizes the ON/OFF durations of input signals if they

are approx. 4 msec or longer. The ON/OFF duration settings can also be changed using I/O

parameter No. 20 (input filtering frequency).

ON duration

Page 41

25

Item

Specification

Load voltage

24 VDC

Maximum load current

100 mA per point, 400 mA per 8 ports Note)

Leakage current

0.1 mA max. per point

Insulation method

Photocoupler insulation

[1] Miniature relay

[2] Sequencer input unit

*

General purpose

Compact

I/O24V connector

24V IN

0V

Caution

N

P24

Surge absorber

Output terminal

External power supply

+

-

(2) Output part

Part 1 Installation

External Output Specifications

TD62784 (or equivalent)

External devices

Note) 400 mA is the maximum total load current of every eight ports from output port No. 300. (The

maximum total load current of output port No. 300 + n to No. 300 + n + 7 is 400 mA, where n is 0

or a multiple of 8.)

[Output circuit]

Internal circuit

10 Ω

24 VDC +10%

P24

N

In the event that the load is short-circuited or a current exceeding the maximum load