Page 1

Global Specification Controller

X-SEL-KT

X-SEL-KT

X-SEL-KT

X-SEL-KT

X-SEL-KT

XSEL-KT/KET

XSEL-KT/KET

XSEL-KT/KET

XSEL-KT/KET

Eighth Edition

Tenth Edition

Tenth Edition

Operation Manual Seventh Edition

Tenth Edition

Page 2

Page 3

INTELLIGENT ACTUATOR

Please Read Before Use

Thank you for purchasing our product.

This Operation Manual explains the handling methods, structure and maintenance of this product, among

others, providing the information you need to know to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained herein

to ensure safe use of the product.

The CD that comes with the product contains operation manuals for IAI products.

When using the product, refer to the necessary portions of the applicable operation manual by printing

them out or displaying them on a PC.

After reading the Operation Manual, keep it in a convenient place so that whoever is handling this product

can reference it quickly when necessary.

[Important]

This Operation Manual is original.

The product cannot be operated in any way unless expressly specified in this Operation Manual. IAI

shall assume no responsibility for the outcome of any operation not specified herein.

Information contained in this Operation Manual is subject to change without notice for the purpose of

product improvement.

If you have any question or comment regarding the content of this manual, please contact the IAI

sales office near you.

Using or copying all or part of this Operation Manual without permission is prohibited.

The company names, names of products and trademarks of each company shown in the sentences

are registered trademarks.

Page 4

CAUTION

Operator Calls Regarding Low Battery Voltage

This controller uses the following backup batteries to retain data after the power is cut off:

[1] System-memory backup battery

For retention of position data, global variables/flags, error lists, strings, etc.

[2] Absolute-encoder backup battery (optional)

For retention of encoder rotation data.

Each battery is of non-rechargeable type, so unless the battery is replaced before its life is fully consumed,

the battery voltage will eventually drop to a level where data can no longer be retained after the power is

cut off.

(The specific life of each battery varies depending on the operating time.)

Once data is lost, the controller cannot operate properly the next time the power is turned on, in which

case additional time will be required for recovery operation.

(Reference)

System-memory backup battery --- A voltage low warning will generate when the voltage drops to

approx. 2.6 V from the rated voltage of 3.0 V, and data will be lost

once the voltage drops to approx. 2.3 V.

Absolute-encoder backup battery --- A voltage low warning will generate when the voltage drops to

approx. 3.2 V from the rated voltage of 3.6 V, and data will be lost

once the voltage drops to approx. 2.7 V.

In view of the above, this controller provides functions that allow voltage low warnings for the two batteries

to be output from I/O ports.

To output this signal from I/O ports, I/O parameter must be set.

Warning output of system-memory backup battery

Set I/O parameter No. 59 to 1 --- Output port No. 313

Warning output of encoder battery

Set I/O parameter No. 60 to 1 --- Output port No. 314

(Note) When these settgins are made, they cannot be used as general-purpose ports.

It is requested that the aforementioned functions be used to prevent unnecessary problems caused by low

battery voltage (consumption of battery life).

In particular, design engineers responsible for coordinating the system components should reflect, in the

design specifications, appropriate means for warning the operator using the I/O output signals utilizing the

above functions. Electrical design engineers should ensure that such means are reflected in the electrical

circuits.

For the battery replacement procedure, refer to the applicable section in the Operation Manual.

It is recommended that the latest data be constantly backed up to a PC in case of low system-memory

backup battery voltage or unexpected controller failure.

(note)

is assigned as the dedicated port.

(note)

is assigned as the dedicated port.

Page 5

INTELLIGENT ACTUATOR

CE Marking

If a compliance with the CE Marking is required, please follow Overseas Standards Compliance Manual

(ME0287) that is provided separately.

Page 6

INTELLIGENT ACTUATOR

Page 7

INTELLIGENT ACTUATOR

Table of Contents

Table of Contents

Safety Guide............................................................................................................................................

Introduction.................................................................................................................................................... 1

Part 1 Installation........................................................................................................................................... 3

Chapter 1 Safety Precautions .............................................................................................................. 3

Chapter 2 Warranty Period and Scope of Warranty............................................................................. 4

Chapter 3 Installation Environment and Noise Measures .................................................................... 5

Chapter 4 Name and Function of Each Part ........................................................................................ 9

1. Front View of Controller.............................................................................................................. 9

2. Explanation of Codes Displayed on the Panel Window ........................................................... 17

Chapter 5 Specifications..................................................................................................................... 19

1. Controller Specifications........................................................................................................... 19

2. External I/O Specifications........................................................................................................ 20

3. Power-Source Capacity and Heat Output of the Controller...................................................... 24

4. External Dimensions................................................................................................................. 26

Chapter 6 System Setup .................................................................................................................... 27

1. Connection Method of Controller and Actuator (Standard Specification) ................................. 27

2. Drive-Power Cutoff Control Circuit ........................................................................................... 32

Chapter 7 How to Perform An Absolute Encoder Reset..................................................................... 52

Pre-1

Chapter 8 Maintenance ...................................................................................................................... 57

Part 2 Operation .......................................................................................................................................... 62

Chapter 1 Operation........................................................................................................................... 62

1. Starting a Program by Auto-Start via Parameter Setting .......................................................... 63

2. Starting via External Signal Selection....................................................................................... 64

3. Drive-Source Recovery Request and Operation-Pause Reset Request.................................. 66

Part 3 Controller Data Structure .................................................................................................................. 71

Chapter 1 How to Save Data.............................................................................................................. 72

1. Factory Settings: When the System-Memory Backup Battery is Used .................................... 72

2. When the System-Memory Backup Battery is Not Used.......................................................... 73

3. Points to Note ........................................................................................................................... 74

Chapter 2 X-SEL Language Data....................................................................................................... 75

1. Values and Symbols Used in SEL Language........................................................................... 75

2. Position Part ............................................................................................................................. 88

3. Command Part.......................................................................................................................... 89

Part 4 Commands ....................................................................................................................................... 91

Chapter 1 List of SEL Language Command Codes by Function ....................................................... 91

Page 8

Table of Contents

INTELLIGENT ACTUATOR

Chapter 2

Explanation of Commands .............................................................................................. 101

1. Commands ............................................................................................................................. 101

Chapter 3 Key Characteristics of Actuator Control Commands and Points to Note ........................ 244

1. Continuous Movement Commands [PATH, CIR, ARC, PSPL, CIR2, ARC2, ARCD, ARCC,

CIRS, ARCS] ...................................................................................................................... 244

2. PATH/PSPL Commands ......................................................................................................... 246

3. CIR/ARC Commands ............................................................................................................. 246

4. CIR2/ARC2/ARCD/ARCC Commands................................................................................... 246

Chapter 4 Palletizing Function ......................................................................................................... 247

1. How to Use ............................................................................................................................. 247

2. Palletizing Setting ................................................................................................................... 247

3. Palletizing Calculation ............................................................................................................ 253

4. Palletizing Movement ............................................................................................................. 254

5. Program Examples ................................................................................................................. 256

Chapter 5 Pseudo-Ladder Task........................................................................................................ 264

1. Basic Frame............................................................................................................................ 264

2. Ladder Statement Field .......................................................................................................... 265

3. Points to Note ......................................................................................................................... 265

4. Program Example................................................................................................................... 266

Chapter 6 Application Program Examples ....................................................................................... 267

1. Operation by Jog Command................................................................................................... 267

2. Operation by Point Movement Command .............................................................................. 270

3. Palletizing Operation .............................................................................................................. 273

Part 5 Multi-Tasking................................................................................................................................... 276

Chapter 1 Real-Time Multi-Tasking .................................................................................................. 276

1. SEL Language ........................................................................................................................ 276

2. Multi-Tasking ........................................................................................................................... 277

3. Difference from a Sequencer.................................................................................................. 278

4. Release of Emergency Stop................................................................................................... 279

5. Program Switching.................................................................................................................. 280

Chapter 2 Example of Building a System......................................................................................... 281

1. Equipment............................................................................................................................... 281

2. Operation ................................................................................................................................ 281

3. Overview of the Screw-Tightening System............................................................................. 282

4. Hardware ................................................................................................................................ 283

5. Software.................................................................................................................................. 285

Appendix 287

Actuator Specification List ........................................................................................................ 287

Programming Method............................................................................................................... 292

1. Position Table ......................................................................................................................... 292

2. Program Format...................................................................................................................... 293

3. Positioning to Five Positions................................................................................................... 294

4. How to Use TAG and GOTO .................................................................................................. 295

Page 9

INTELLIGENT ACTUATOR

Reciprocating Operation between Two Points........................................................................ 296

5.

Table of Contents

6. Path Operation........................................................................................................................ 297

7. Output Control during Path Movement................................................................................... 298

8. Circular/Arc Operation ............................................................................................................ 299

9. Home return Complete Output ............................................................................................... 300

10. Axis Movement with Input Waiting and Complete Output ...................................................... 301

11. Travel Speed Change ............................................................................................................. 302

12. Speed Change during Operation............................................................................................ 303

13. Local/Global Variables and Flags........................................................................................... 304

14. How to Use Subroutines......................................................................................................... 305

15. Pause...................................................................................................................................... 306

16. Abort 1 (CANC)....................................................................................................................... 307

17. Abort 2 (STOP)....................................................................................................................... 308

18. Movement by Position Number Specification ......................................................................... 309

19. Movement by External Position Data Input ............................................................................ 310

20. Coordinate Value Output .........................................................................................................311

21. Conditional Jump.................................................................................................................... 312

22. Wait for Multiple Inputs ........................................................................................................... 313

23. How to Use Offset................................................................................................................... 314

24. Repetition of Operation N Times ............................................................................................ 315

25. Constant Pitch Feed Operation .............................................................................................. 316

26. Jogging ................................................................................................................................... 317

27. Program Switching.................................................................................................................. 318

28. Program Abort......................................................................................................................... 319

Expansion Board (Optional) ..................................................................................................... 320

Expanded SIO Specification (Optional).................................................................................... 321

Number of Regenerative Resistance Units (REU-1s) to Be Connected .................................. 327

Synchro Function...................................................................................................................... 328

1. Common Items (Applicable to both the absolute specification and incremental specification)

............................................................................................................................................ 328

2. Incremental Specification........................................................................................................ 328

3. Absolute Specification (When both the master axis and slave axis are of the absolute

specification)....................................................................................................................... 328

Absolute Reset of A Synchro Controller ................................................................................... 329

1. Synchro Axes.......................................................................................................................... 329

2. Position Adjustment of Synchro-Axis Sliders.......................................................................... 330

3. Special Absolute-Reset Procedure......................................................................................... 330

4. Standard Absolute-Reset Procedure...................................................................................... 333

5. Notes on Use of the Synchro Function................................................................................... 334

List of Parameters .................................................................................................................... 335

1. I/O Parameters ....................................................................................................................... 336

2. Parameters Common to All Axes ............................................................................................ 348

3. Axis-Specific Parameters........................................................................................................ 350

4. Driver Card Parameters.......................................................................................................... 355

5. Encoder Parameters............................................................................................................... 359

6. I/O-Slot Card Parameters ....................................................................................................... 360

7. Other Parameters ................................................................................................................... 361

8. Manual Operation Types......................................................................................................... 367

9. Use Examples of Key Parameters.......................................................................................... 368

Page 10

Table of Contents

INTELLIGENT ACTUATOR

Servo Gain Adjustment........................................................................................................... 374

10.

Combination Table of X-SEL Linear/Rotational Control Parameters........................................ 377

Error Level Control ................................................................................................................... 378

Error List ................................................................................................................................... 380

Troubleshooting of X-SEL Controller........................................................................................ 409

Trouble Report Sheet............................................................................................................................. 413

Change History.......................................................................................................................................... 414

Page 11

INTELLIGENT ACTUATOR

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or property

damage beforehand. Make sure to read it before the operation of this product.

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

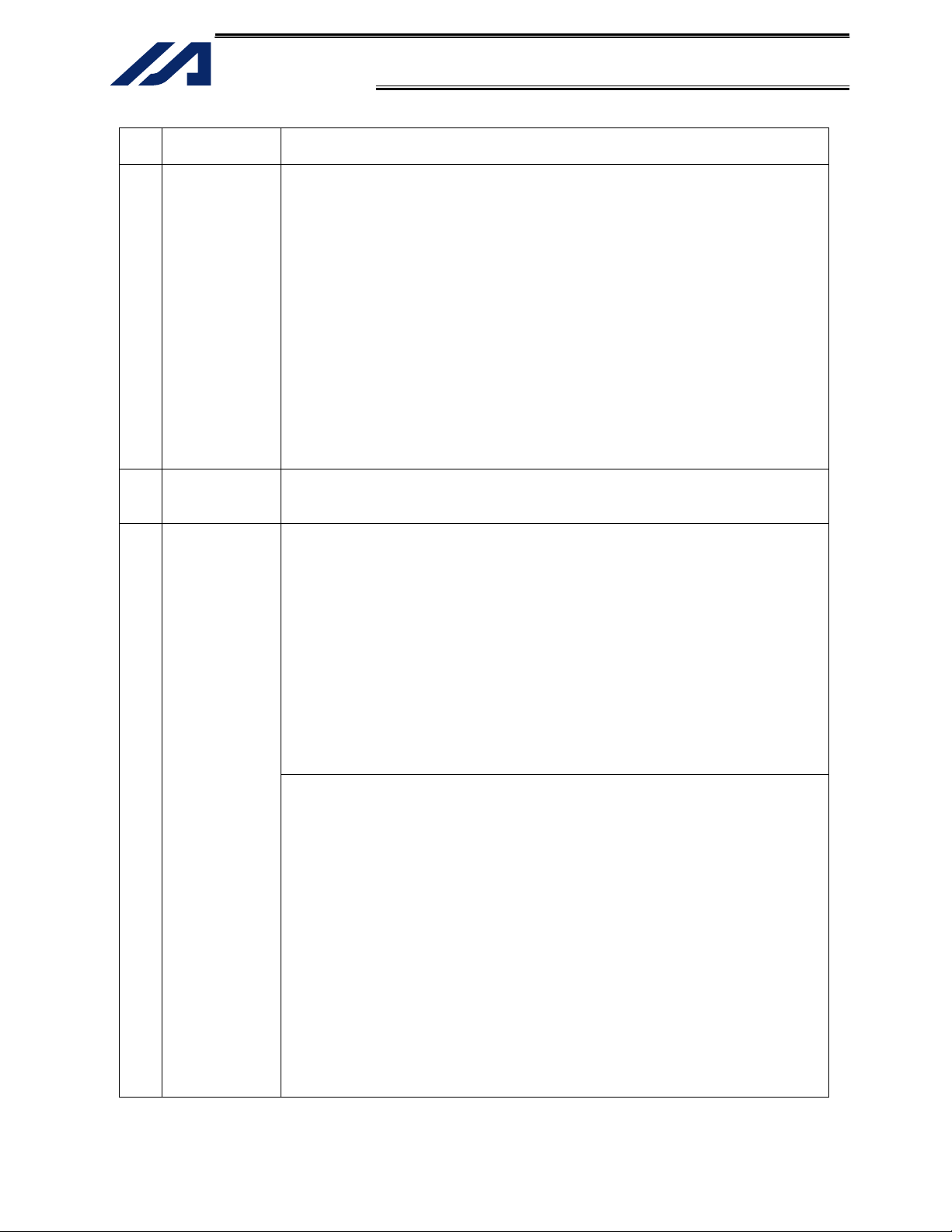

No.

1 Model

Operation

Description

Selection

Description

● This product has not been planned and designed for the application where

high level of safety is required, so the guarantee of the protection of

human life is impossible. Accordingly, do not use it in any of the following

applications.

1) Medical equipment used to maintain, control or otherwise affect human

life or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation facility)

3) Important safety parts of machinery (Safety device, etc.)

● Do not use it in any of the following environments.

1) Location where there is any inflammable gas, inflammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding

the specification range

4) Location where radiant heat is added from direct sunlight or other large

heat source

5) Location where condensation occurs due to abrupt temperature

changes

6) Location where there is any corrosive gas (sulfuric acid or hydrochloric

acid)

7) Location exposed to significant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

● Do not use the product outside the specifications. Failure to do so may

considerably shorten

Pre-1

Page 12

INTELLIGENT ACTUATOR

Introduction

No.

Operation

Description

Description

2 Transportation ● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● Consider well so that it is not bumped against anything or dropped during

the transportation.

● Transport it using an appropriate transportation measure.

● Do not step or sit on the package.

● Do not put any heavy thing that can deform the package, on it.

● When using a crane capable of 1t or more of weight, have an operator who

has qualifications for crane operation and sling work.

● When using a crane or equivalent equipments, make sure not to hang a

load that weighs more than the equipment’s capability limit.

● Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

● Do not get on the load that is hung on a crane.

● Do not leave a load hung up with a crane.

● Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

● The storage and preservation environment conforms to the installation

environment.

However, especially give consideration to the prevention of condensation.

4 Installation

and Start

(1) Installation of Robot Main Body and Controller, etc.

● Make sure to securely hold and fix the product (including the work part). A

fall, drop or abnormal motion of the product may cause a damage or injury.

● Do not get on or put anything on the product. Failure to do so may cause

an accidental fall, injury or damage to the product due to a drop of

anything, malfunction of the product, performance degradation, or

shortening of its life.

● When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

(2) Cable Wiring

● Use our company’s genuine cables for connecting between the actuator

and controller, and for the teaching tool.

● Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not

coil it around. Do not insert it. Do not put any heavy thing on it. Failure to

do so may cause a fire, electric shock or malfunction due to leakage or

continuity error.

● Perform the wiring for the product, after turning OFF the power to the unit,

so that there is no wiring error.

● When the direct current power (+24V) is connected, take the great care of

the directions of positive and negative poles. If the connection direction is

not correct, it might cause a fire, product breakdown or malfunction.

● Connect the cable connector securely so that there is no disconnection or

looseness. Failure to do so may cause a fire, electric shock or malfunction

of the product.

● Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so may

cause the product to malfunction or cause fire.

Pre-2

Page 13

INTELLIGENT ACTUATOR

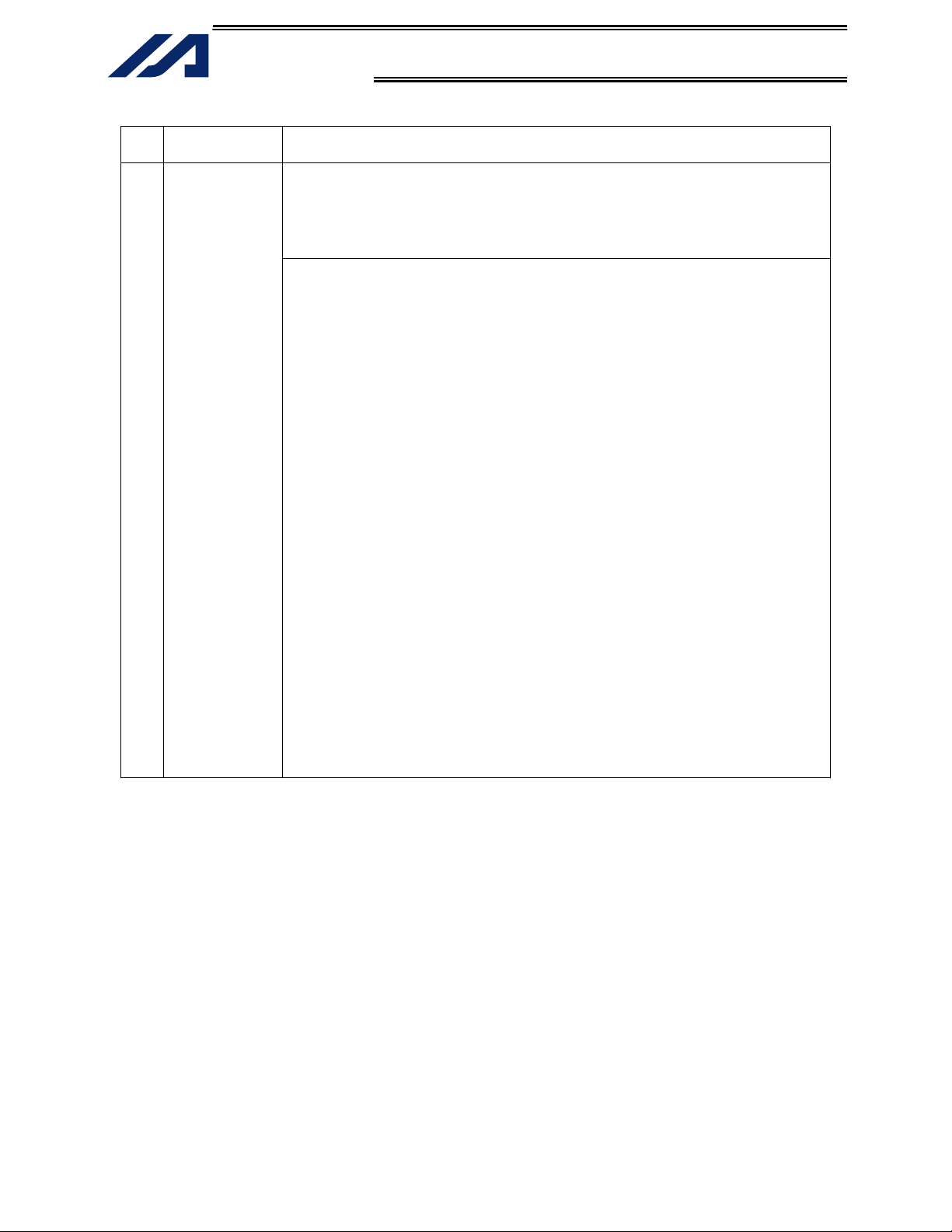

No.

Operation

Description

4 Installation

and Start

Description

(3) Grounding

● Make sure to perform the grounding of type D (Former Type 3) for the

controller. The grounding operation should be performed to prevent an

electric shock or electrostatic charge, enhance the noise-resistance ability

and control the unnecessary electromagnetic radiation.

(4) Safety Measures

● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● When the product is under operation or in the ready mode, take the safety

measures (such as the installation of safety and protection fence) so that

nobody can enter the area within the robot’s movable range. When the

robot under operation is touched, it may result in death or serious injury.

● Make sure to install the emergency stop circuit so that the unit can be

stopped immediately in an emergency during the unit operation.

● Take the safety measure not to start up the unit only with the power turning

ON. Failure to do so may start up the machine suddenly and cause an

injury or damage to the product.

● Take the safety measure not to start up the machine only with the

emergency stop cancellation or recovery after the power failure. Failure to

do so may result in an electric shock or injury due to unexpected power

input.

● When the installation or adjustment operation is to be performed, give

clear warnings such as “Under Operation; Do not turn ON the power!” etc.

Sudden power input may cause an electric shock or injury.

● Take the measure so that the work part is not dropped in power failure or

emergency stop.

● Wear protection gloves, goggle or safety shoes, as necessary, to secure

safety.

● Do not insert a finger or object in the openings in the product. Failure to do

so may cause an injury, electric shock, damage to the product or fire.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

Pre-3

Page 14

INTELLIGENT ACTUATOR

Introduction

No.

Operation

Description

Description

5 Teaching ● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● Perform the teaching operation from outside the safety protection fence, if

possible. In the case that the operation is to be performed unavoidably

inside the safety protection fence, prepare the “Stipulations for the

Operation” and make sure that all the workers acknowledge and

understand them well.

● When the operation is to be performed inside the safety protection fence,

the worker should have an emergency stop switch at hand with him so that

the unit can be stopped any time in an emergency.

● When the operation is to be performed inside the safety protection fence,

in addition to the workers, arrange a watchman so that the machine can be

stopped any time in an emergency. Also, keep watch on the operation so

that any third person can not operate the switches carelessly.

● Place a sign “Under Operation” at the position easy to see.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

6 Trial

Operation

● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● After the teaching or programming operation, perform the check operation

one step by one step and then shift to the automatic operation.

● When the check operation is to be performed inside the safety protection

fence, perform the check operation using the previously specified work

procedure like the teaching operation.

● Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

● Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

● Before the automatic operation is started up, make sure that there is

nobody inside the safety protection fence.

● Before the automatic operation is started up, make sure that all the related

peripheral machines are ready for the automatic operation and there is no

error indication.

● Make sure to perform the startup operation for the automatic operation, out

of the safety protection fence.

● In the case that there is any abnormal heating, smoke, offensive smell, or

abnormal noise in the product, immediately stop the machine and turn OFF

the power switch. Failure to do so may result in a fire or damage to the

product.

● When a power failure occurs, turn OFF the power switch. Failure to do so

may cause an injury or damage to the product, due to a sudden motion of

the product in the recovery operation from the power failure.

Pre-4

Page 15

INTELLIGENT ACTUATOR

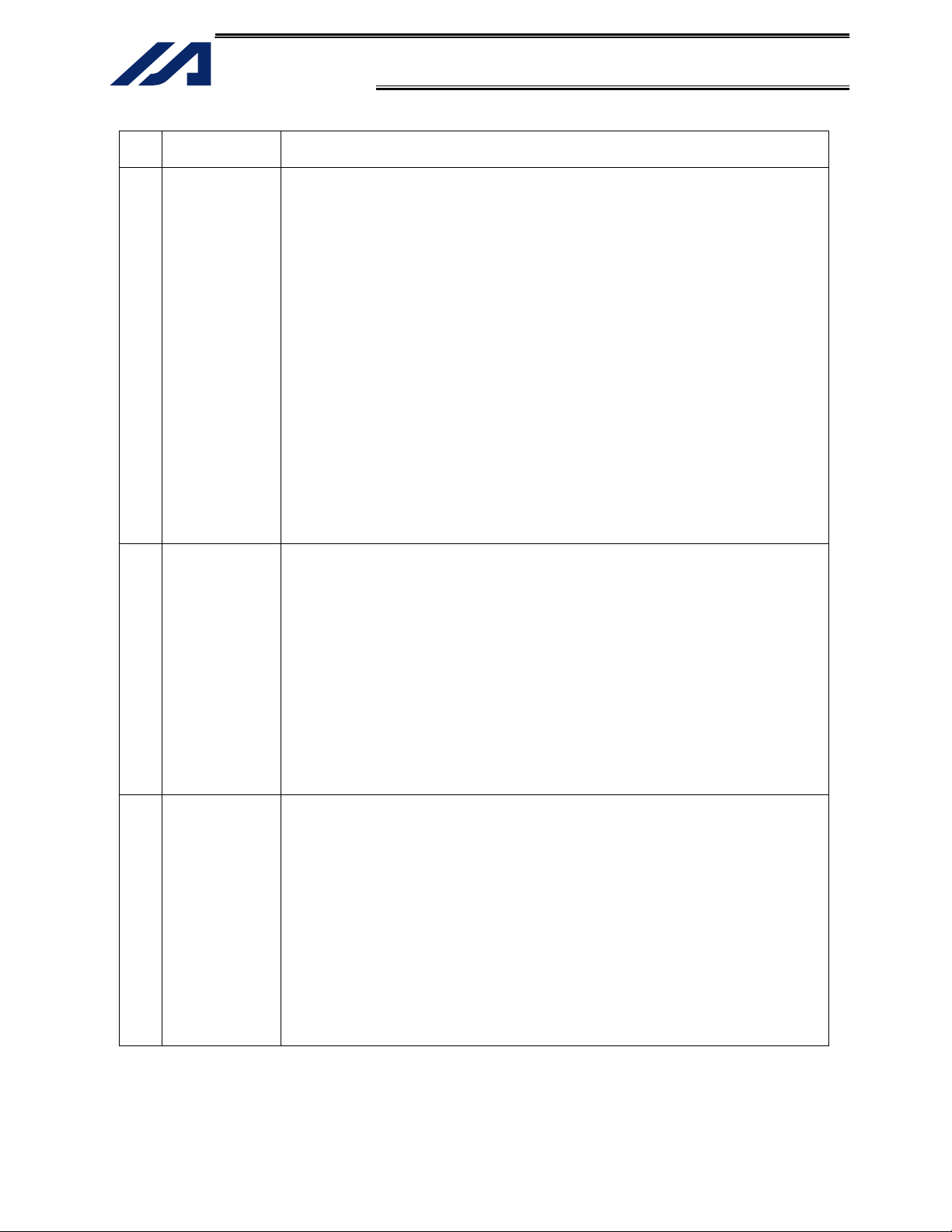

No.

Operation

Description

8 Maintenance

and Inspection

● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

Description

each other to ensure the safety of the workers.

● Perform the work out of the safety protection fence, if possible. In the case

that the operation is to be performed unavoidably inside the safety

protection fence, prepare the “Stipulations for the Operation” and make

sure that all the workers acknowledge and understand them well.

● When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

● When the operation is to be performed inside the safety protection fence,

the worker should have an emergency stop switch at hand with him so that

the unit can be stopped any time in an emergency.

● When the operation is to be performed inside the safety protection fence,

in addition to the workers, arrange a watchman so that the machine can be

stopped any time in an emergency. Also, keep watch on the operation so

that any third person can not operate the switches carelessly.

● Place a sign “Under Operation” at the position easy to see.

● For the grease for the guide or ball screw, use appropriate grease

according to the Operation Manual for each model.

● Do not perform the dielectric strength test. Failure to do so may result in a

damage to the product.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

9 Modification

and Dismantle

● Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal ● When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

● Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

Pre-5

Page 16

Introduction

INTELLIGENT ACTUATOR

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to the

warning level, as follows, and described in the Operation Manual for each model.

lobmyS egamaD dna regnaD fo eergeD leveL

Danger

Warning

Caution

Notice

This indicates an imminently hazardous situation which, if the

product is not handled correctly, will result in death or serious injury.

This indicates a potentially hazardous situation which, if the product

is not handled correctly, could result in death or serious injury.

This indicates a potentially hazardous situation which, if the product

is not handled correctly, may result in minor injury or property

damage.

This indicates lower possibility for the injury, but should be kept to

use this product properly.

Danger

Warning

Caution

Notice

Pre-6

Page 17

INTELLIGENT ACTUATOR

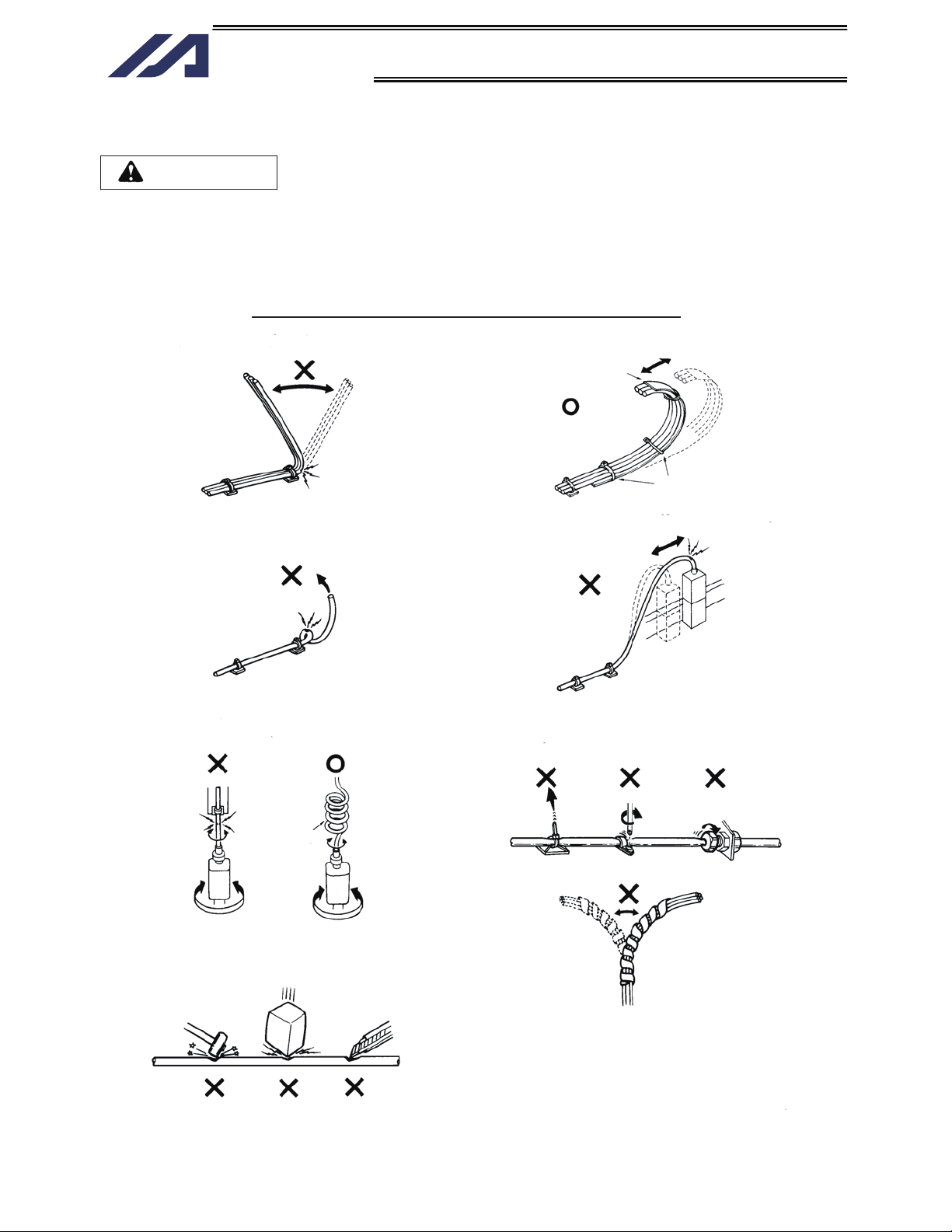

Prohibited Handling of Cables

Caution

When designing an application system using actuators and controllers, incorrect wiring or connection of

each cable may cause unexpected problems such as a disconnected cable or poor contact, or even a

runaway system. This section explains prohibited handling of cables. Read the information carefully to

connect the cables properly.

Ten Rules for Handling Cables (Must be Observed!)

1. Do not let the cable flex at a single point.

2. Do not let the cable bend, kink or twist.

4. Do not let the cable receive a turning force at a

single point.

Steel band

(piano wire)

Bundle loosely.

3. Do not pull the cable with a strong force.

5. When fixing the cable, provide a moderate slack

and do not tension it too tight.

Use a curly

cable.

6. Do not pinch, drop a heavy object onto or cut the

cable.

Do not use a spiral tube where

the cable flexes frequently.

Pre-7

Page 18

Introduction

INTELLIGENT ACTUATOR

7. Do not let the cable get tangled or kinked in a cable track or flexible tube. When bundling the cable,

keep a certain degree of flexibility (so that the cable will not become too taut when bent).

8. Do not cause the cables to occupy more than

60% of the space in the cable track.

Cable track

Cable

10. Always use a robot cable

if the cable is likely to flex significantly.

9. Do not lay signal lines together with circuit lines

that create a strong electric field.

Power line

Duct

Signal lines (flat cable)

[Standard structure of cable]

The standard structure of

Cover

Signal line (copper + tin)

cable will vary depending on

the manufacturer and type of

cable.

Protective layer

Shield

Absorbing material (When the

cable is bent, this material is

crushed by the surrounding signal

lines to maintain the shape of the

signal lines.)

Need for Robot Cables

A cable connected to a moving part of an actuator system will inevitably receive repeated bending loads at

the base of the cable. As a result, the cores in the cable may break over time. To minimize the risk of

cable breakage, we strongly recommend that a robot cable

offering significantly higher flexibility be used

in this type of application.

Pre-8

Page 19

INTELLIGENT ACTUATOR

Page 20

n

Introduction

INTELLIGENT ACTUATOR

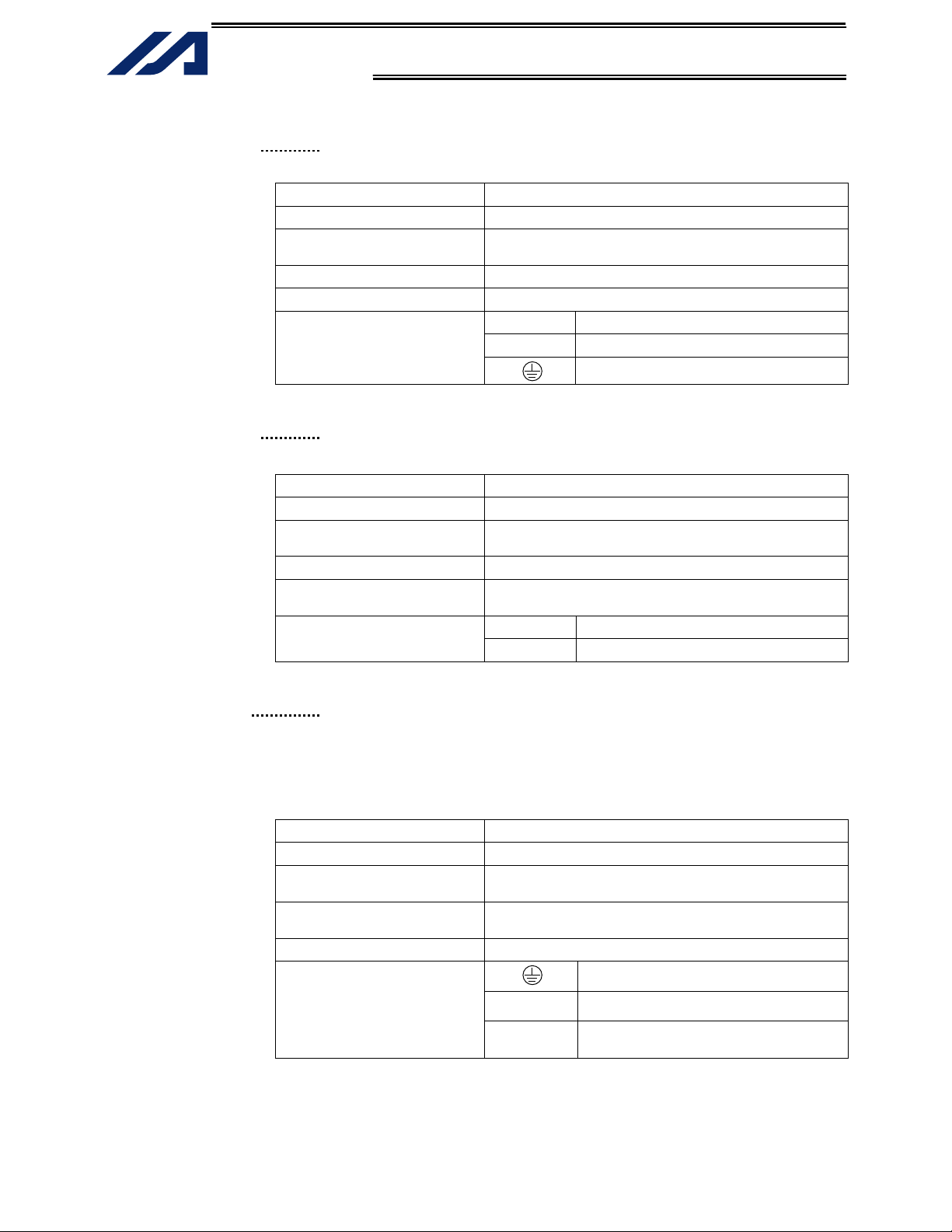

Introduction

Thank you for purchasing the X-SEL Controller.

Inappropriate use or handling will prevent this product from demonstrating its full function and may even

cause unexpected failure or result in a shortened service life. Please read this manual carefully, and

handle the product with due care and operate it correctly. Keep this manual in a safe place and reference

relevant items when needed.

The X-SEL Controller you have purchased is a new-generation controller that uses a 32-bit RISC

(Reduced Instruction Set Computer) CPU and an advanced version of the proven “SEL” language to

perform a range of high functions such as multi-tasking, sequencer-less operation, palletizing function and

pseudo-sequence function.

Refer to the table below for the details of models.

Model

Series

name

XSEL

Controller

type

KT

Global

specification

KET

CE-compliant

global

specification

Number of

axes

1

(1 axis)

2

(2 axis)

3

(3 axis)

4

(4 axis)

Motor

wattage

20

(20 W)

30D

(DS type,

30 W)

30R

(RS type,

30 W)

60

(60 W)

100

(100 W)

150

(150 W)

200

(200 W)

300

(300 W)

400

(400 W)

600

(600 W)

750

(750 W)

(Axis 1) (Axis 3)

Details of Axes 1 to 6

type

A

I

Brake

Blank

(Without

brake)

B

(With brake)

(With creep

Encoder

(Incremental)

(Absolute)

Creep

sensor

Blank

(Witho ut

creep

sensor)

C

sensor)

(Axis 2)

Home

sensor

(LS)

Blank

(Without

home

sensor)

L

(With h ome

sensor)

Synchro

specification

Blank

(Witho ut

synchro)

M

(Master axis

specification)

S

(Slave axis

specification)

Network

(dedicated

slot)

(None)

Standard I/O

(Slot 1)

N1

Expansion PIO

32 inputs/16

outputs

NPN board

P1

Expansion PIO

32 inputs/16

outputs

PNP board

DV

DeviceNet 256/256

board

CC

CC-Link

256/256 board

PR

ProfiBus

256/256 board)

ET

Ethernet

ata communicatio

board

Slot 2

E

(not used)

C

CC-Link

connection

16/16 board

N1

Expansion I/O

32 inputs/

16 outputs

NPN board

N2

Expansion I/O

16 inputs/

32 outputs

NPN board

N3

Expansion I/O

48 inputs/

48 outputs

NPN board

P1

Expansion I/O

32 inputs/

16 outputs

PNP board

P2

Expansion I/O

16 inputs/

32 outputs

PNP board

P3

Multi-point I/O

PNP 48/48

SA

Expansion SIO

Type A

SB

Expansion SIO

Type B

SC

Expansion SIO

Type C

Expansion I/O slot

Slot 3 Slo t 4

E

(not used)

C

CC-Link

connection

16/16 board

N1

Expansion I/O

32 inputs/

16 outputs

NPN board

N2

Expansion I/O

16 inputs/

32 outputs

NPN board

N3

Expansion I/O

48 inputs/

48 outputs

NPN board

P1

Expansion I/O

32 inputs/

16 outputs

PNP board

P2

Expansion I/O

16 inputs/

32 outputs

PNP board

P3

Multi-point I/O

PNP 48/48

SA

Expansion SIO

Type A

SB

Expansion SIO

Type B

SC

Expansion SIO

Type C

E

(not used)

C

CC-Link

connection

16/16 board

N1

Expansion I/O

32 inputs/

16 outputs

NPN board

N2

Expansion I/O

16 inputs/

32 outputs

NPN board

N3

Expansion I/O

48 inputs/

48 outputs

NPN board

P1

Expansion I/O

32 inputs/

16 outputs

PNP board

P2

Expansion I/O

16 inputs/

32 outputs

PNP board

P3

Multi-point I/O

PNP 48/48

SA

Expansion SIO

Type A

SB

Expansion SIO

Ty

pe B

SC

Expansion SIO

Type C

I/O flat

cable

length

2: 2 m

(standard)

3: 3 m

5: 5 m

0: None

Power-

supply

voltage

2: Singlephase 200 V

1

Page 21

Introduction

INTELLIGENT ACTUATOR

The X-SEL Controller is available with one to four axes. As with the conventional SEL Controller, it can be

used with various actuators. When connecting actuators, always use dedicated cables.

Actuator duty

IAI recommends that our actuators be used at a duty of 50% or less in view of the relationship of

service life and precision. The duty is calculated by the formula below:

Duty (%) =

hours Operating

X 100

hours Stopped hours Operating

After turning off the main power, be sure to wait for at least 5 seconds before turning it on.

Any shorter interval may generate “E88: Power system error (Other).”

Do not plug in/out the connectors while the power is still supplied to the controller. Doing so may result

in malfunction.

Item to note when installing the absolute-data backup battery (absolute specification)

The battery installation procedure specified below must be followed to initialize the battery circuit and

thereby prevent premature consumption of the battery. Install the battery according to this procedure:

[1] Connect the encoder cable.

[2] Turn on the power.

[3] Install the absolute-data backup battery.

The above operation must be performed every time the encoder cable was unplugged to relocate the

system, etc.

Read the operation manual for each actuator. If you have purchased our optional PC software and/or

teaching pendant, read the respective operation manuals, as well.

* Utmost effort has been made to ensure that the information contained in this manual is true and

correct. However, should you find any error or if you have any comment regarding the content,

please contact IAI.

2

Page 22

Part 1 Installation

INTELLIGENT ACTUATOR

Part 1 Installation

Caution

Chapter 1 Safety Precautions

The X-SEL Controller can be combined with a maximum of four actuators of different types, and is able to

provide integrated control over the entire system including peripherals. In other words, the X-SEL

Controller has the ability to control systems of all sizes ranging from a small system to a large factory

automation system. In general, however, the occurrence rate of accidents due to wrong operation or

carelessness will rise as the system becomes larger and more complex. Please give due consideration to

safety measures.

This system product was developed as a drive unit for an automated machine, etc., and as such the

maximum torque and speed are limited to levels acceptable for an automatically driven machine. However,

strict observance of the following items is requested to prevent unforeseen danger. Also read the

appendix entitled, “Safety Rules and Others.”

1. Do not handle this product in manners not specified in this manual. If you have any question regarding

the content of this manual, please contact IAI.

2. This controller is designed to perform all cutoff controls of the motor drive power to actuate an

emergency stop, enable the controller operation, etc., using an external circuit. Be sure to provide a

drive-power cutoff circuit externally to the main controller circuit.

The customer must determine and install an appropriate safety circuit meeting the required safety

category according to the operating condition of the final system.

The motor drive-power circuit has no built-in protective element such as a fuse. The customer must

provide appropriate circuit protection.

3. Always use the specified, genuine IAI cables for wiring between the controller and the actuator.

4. Do not enter the operation area of the machine while the machine is operating or ready to operate (the

controller power is on). If the machine is used in a place accessible to other people, provide an

appropriate safety measure such as enclosing the machine with a cage.

5. When assembling/adjusting or maintaining/inspecting the machine, always turn off the controller power

at the source beforehand. The operator should display in a conspicuous place a plate or other sign

saying that operation is in progress and that the power should not be turned on. The operator should

keep the entire power cable beside him or her to prevent another person from inadvertently plugging in

the cable.

6. When two or more operators are to work together, set call-out signals to ensure safety of all personnel

during the work. In particular, a person turning on/off the power or moving an axis—either via a motor

or manually—must always say what he or she is going to do out loud and confirm the responses from

the others first before actually performing the operation.

3

Page 23

Part 1 Installation

INTELLIGENT ACTUATOR

Chapter 2 Warranty Period and Scope of Warranty

The X-SEL Controller you have purchased passed our strict outgoing inspection. This unit is covered by

the following warranty:

1. Warranty Period

The warranty period shall be either of the following periods, whichever ends first:

18 months after shipment from our factory

12 months after delivery to a specified location

2. Scope of Warranty

Should the product fail during the above period under a proper use condition due to a fault on the part

of the manufacturer, IAI will repair the defect free of charge. However, the following cases are

excluded from the scope of warranty:

Discoloration of paint or other normal aging

Wear of consumable parts due to use

Subjective imperfection, such as noise not affecting mechanical function

Defect caused by inappropriate handling or use by the user

Defect caused by inappropriate or erroneous maintenance/inspection

Defect caused by use of a part other than IAI’s genuine part

Defect caused by unauthorized modification, etc., not approved by IAI or its agent

Defect due to an act of God, accident, fire, etc.

The warranty covers only the product as it is delivered. IAI shall not be liable for any loss arising in

connection with the delivered product. The user must bring the defective product to our factory to

receive a warranty repair.

3. Scope of Service

The price of the delivered product does not include costs incurred in association with program

generation, dispatch of technician, etc. Therefore, a separate fee will be chargeable in the following

cases even during the warranty period:

Guidance on installation/adjustment and witnessing of test operation

Maintenance/inspection

Technical guidance and training on operation, wiring method, etc.

Technical guidance and training regarding programs, such as program generation

Other services and operations where IAI finds a need to charge a separate fee

4

Page 24

Part 1 Installation

INTELLIGENT ACTUATOR

Chapter 3 Installation Environment and Noise Measures

1. Installation Environment

*1

As for the use environment, this product can be used in an environment of pollution degree 2

equivalent.

*1 Pollution degree 2: Normally only non-conductive pollutants exist, which are expected to be

temporarily conductive due to condensation. (IEC60664-1)

(1) When installing and wiring the controller, do not block the ventilation holes provided for cooling.

(Insufficient ventilation will not only prevent the product from functioning fully, but it may also result in

failure.)

(2) Prevent foreign matter from entering the controller through the ventilation holes. Since the controller is

not designed as dustproof or waterproof (oilproof), avoid using it in a dusty place or place subject to

oil mist or splashed cutting fluid.

(3) Do not expose the controller to direct sunlight or radiant heat from a high heat source such as a heat-

treating furnace.

(4) Use the controller in a non-condensing environment free from corrosive or inflammable gases.

(5) Use the controller in an environment where it will not receive external vibration or impact.

(6) Prevent electrical noise from entering the controller or its cables.

or

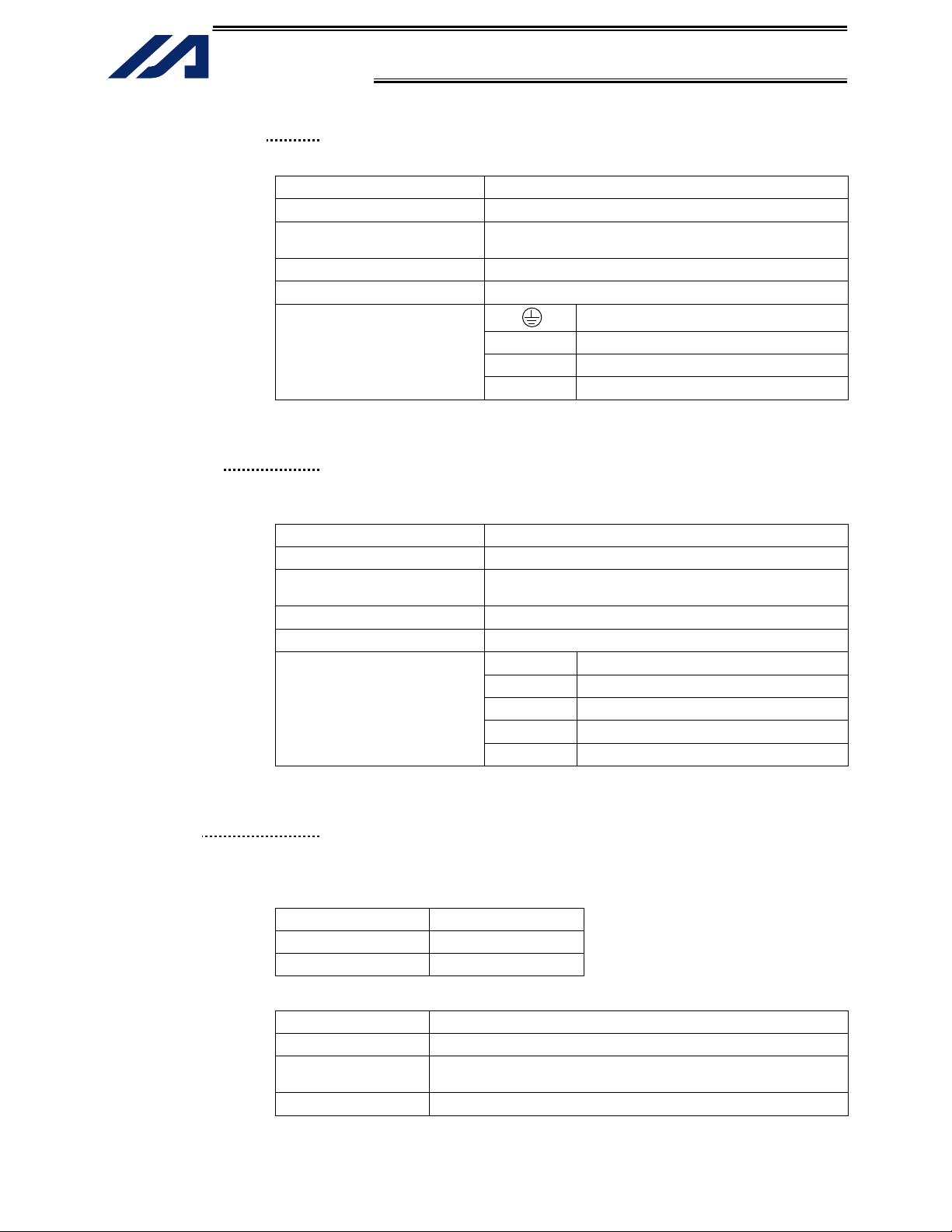

Environmental Condition of Controller

noitacificepS metI

Surrounding air temperature range

Forced air-cooling

Surrounding humidity range 30% ~ 85%

Storage temperature range

Dust protection structure IP20

Power-source voltage 230 VAC, single-phase

Operating power-source voltage

Rated operating power-source

frequency

24 VDC fan x 5 (2-axis type)

24 VDC fan x 6 (4-axis type)

0?C ~ 40?C

-10?C ~ 65?C

? 10%

50 Hz/60 Hz

2. Heat Radiation and Installation

Design the control panel size, controller layout and cooling method so that the surrounding air

temperature around the controller will be kept at or below 40°C.

Install the controller vertically on a wall, as illustrated below. The controller will be cooled by forced

ventilation (exhaust air will be discharged from the top). Be sure to install the controller in the

aforementioned direction and provide a minimum clearance of 150 mm above and 150 mm below the

controller.

If multiple controllers are to be installed side by side, providing additional suction fans on top of the

controllers will help maintain a uniform surrounding air temperature.

Provide a minimum clearance of 150 mm between the front side of the controller and a wall

(enclosure).

5

Page 25

Part 1 Installation

INTELLIGENT ACTUATOR

Airflow direction

Fan

150 mm min.

150 mm

min.

150 mm min.

Airflow

If multiple controllers are to be connected on top of one another, prevent the controller above from

taking in the exhaust air from the controller below.

3. Power Source

Provide a 230-VAC, single-phase power source.

4. Noise Measures and Grounding

(1) Wiring and power source

PE on the power terminal block is used for protective grounding. Provide Class D grounding from this

terminal.

Use a grounding cable with a wire size of 1.0 mm

than the AC power cable.

Install an AC line noise filter to prevent noise generating in the controller from traveling through the

power line to affect other devices.

230-VAC power source

Class D grounding

(protective grounding)

Drivepower

cutoff

control

circuit

Install a noise filter (MXB-1210-33 by Densei-Lambda) near the power connector on the X-SEL controller

side.

2

(#AWG17) or more, which should not be smaller

X-SEL controller

C.POWER M.POWER

N

L

N

L

Noise

filter

Accessory

6

Page 26

Part 1 Installation

INTELLIGENT ACTUATOR

* Notes on wiring method

Use twisted cables for the AC power cable and 24-VDC external power cable. Wire the controller

cables separately from lines creating a strong electric field such as power circuit lines (by not bundling

them together or placing in the same cable duct).

If you wish to extend the motor cable or encoder cable beyond the length of each supplied cable,

please contact IAI.

(2) Noise-elimination grounding

C.POWER

AC power source

N

L

PE

Connect the FG terminal

with the metal enclosure

using a cable of a maximum

allowable size over the

shortest distance.

Class D grounding

Metal enclosure

Provide a dedicated grounding of the FG or PE grounding point.

X-SEL

controller

Other

equipment

X-SEL

controller

Other

equipment

Do not use this method.

(3) Noise sources and noise elimination

There are many noise sources, but solenoid valves, magnet switches and relays are of particular

concern when building a system. Noise from these parts can be eliminated using the measures

specified below:

a. AC solenoid valve, magnet switch, relay

Measure --- Install a surge killer in parallel with the coil.

Surge killer

Point

Wire from each coil over the shortest distance.

Installing a surge killer on the terminal block,

etc., will be less effective because of a longer

distance from the coil.

7

Page 27

Part 1 Installation

INTELLIGENT ACTUATOR

b. DC solenoid valve, magnet switch, relay

Measure --- Install a diode in parallel with the coil. Determine the diode capacity in accordance with

the load capacity.

In a DC circuit, connecting a diode in reversed polarity will

damage the diode, internal parts of the controller and DC

power supply. Exercise due caution.

Diode

The above noise elimination measures are particularly important when a 24-VDC relay is driven

directly by a controller output and there is also a 100-VAC solenoid valve, etc.

Reference Circuit Diagram

Controller

OUT

COM

CR

+24 V

0 V

100 VAC

CR

SOL

Surge absorber

0 V

Solenoid valve

8

Page 28

Part 1 Installation

INTELLIGENT ACTUATOR

Chapter 4 Name and Function of Each Part

1. Front View of Controller

4-axis type

(5)

(6)

RB

CONTROLLER

M4

C.POWER

FUSE

M.POWER

LS4M3LS3M2LS2M1LS1

PG1

BK1

PG2

BK2

(1)

(2)

(3)

(4) (8)

(9)

(10) (18)

(1) FG terminal

This terminal is used to ground FG on the enclosure. The enclosure is

connected to PE in the AC input part inside the controller.

FG Terminal Specifications

Item Overview

M4 3-point SEMS screw, 5 mm

Cable size 2.0 ~ 5.5 mm2

Grounding method Class D grounding

(2) Fuse holder

This half-cut fuse holder is used to protect overcurrent in the AC controlpower input part.

It prevents inflow of abnormal current generated by ground fault, etc., and

uses a slow-blow fuse specified by IAI.

Overview of Fuse Holder Specifications

Item Description

Holder F-220-01A2 by Sato Parts

Fuse type SG5013 3.15 by Sky Gate

Melting characteristics Time lag type

(11)

PG3

BK3

I/O1 I/O2 I/O3 I/O4

PG4

BK4

(12) (13) (14)

CODE

MODE

TP

HOST

(19)

(15)

(16)

(17)

9

Page 29

INTELLIGENT ACTUATOR

(3) AC control-power

input connector

AC Control-Power Input Connector Specifications

Connector name C.POWER

Connector GMSTB2.5/3-STF-7.62 by Phoenix Contact

Supported cable size 1.25 ~ 2.5 mm2 (AWG12 ~ 16)

Connected to AC power source

Terminal assignments

(4) AC motor drive-power

input connector

AC Motor Drive-Power Input Connector Specifications

Connector name M.POWER

Connector PC4/2-7.62

Supported cable size 1.25 ~ 2.5 mm2 (AWG12 ~ 16)

Connected to

Terminal assignments

(5) External regenerative

unit connector

External Regenerative Unit Connector Specifications

Connector name RB

Connector GIC2.5/3-STF-7.62 by Phoenix Contact

Cable size 1.0 mm2 (AWG17 or equivalent), included in the

Connected to External regenerative box

Terminal assignments

Part 1 Installation

An input connector for 230-VAC, single-phase control power.

Item Overview

3-pin, 2-piece connector

N AC power input, N side

L AC power input, L side

PE (Protective grounding line)

An input connector for 230-VAC, single-phase motor drive power.

Item Overview

2-pin, 2-piece connector

AC power source (Noise filter, drive-power cutoff

control circuit)

N AC power input, N side

L AC power input, L side

This connector is used to connect a regenerative resistance unit that may

be required when the controller is used in a high-speed/high-load

environment, etc., and the built-in regenerative resistance capacity is not

sufficient. Whether or not an external regenerative resistance is necessary

will be determined by the specific application such as axis configuration.

Item Overview

3-pin, 2-piece connector

external regenerative box

Grounding terminal

10

RB– Regenerative resistance –

RB+

Regenerative resistance + (Motordriving DC voltage)

An insufficient regenerative resistance capacity will cause “E65, F63:

Regenerative resistance temperature error.” An insufficient regenerative

resistance capacity is also suspected when “E88: Power system error (Other)”

occurs.

Page 30

INTELLIGENT ACTUATOR

(6) Motor connector

Overview of Motor Connector Specifications

Connector name M

Connector GIC2.5/4-STF-7.62 by Phoenix Contact

Cable Dedicated motor cable

Connected to Actuator

Terminal assignments

(7) Axis-sensor

connector

Axis-Sensor Connector Specifications

Connector name LS

Connector MC1.5/6-ST-3.5 by Phoenix Contact

Cable Dedicated LS cable

Connected to Actuator

Terminal assignments

(8) Absolute-data backup

battery

Battery Capacity: 1000 mAh

Current consumption

Operating

Power is off

Absolute-Battery Connector Specifications

Connector name BAT

Connector 3-pin connector

Connected to Absolute-data battery unit by IAI

Part 1 Installation

This connector is used to drive the motor inside the actuator.

Item Description

4-pin, 2-piece connector

PE (Protective grounding line)

U Motor-driving phase U

V Motor-driving phase V

W Motor-driving phase W

This connector is used to connect axis sensors such as LS, CREEP and

OT.

Item Description

6-pin, 2-piece connector

24VOUT 24-V power source for driving contacts

0V 24-V ground

LS LS-contact input

CREEP CREEP-contact input

OT OT-contact input

When an absolute encoder is used, this battery unit will be used to back up

the encoder data. Nothing is connected here for a non-absolute axis.

Model: IA-XAB-BT

3 A

100 A

Item Description

03JQ-ST by Nichiatu

11

Page 31

Part 1 Installation

INTELLIGENT ACTUATOR

(9) Brake switch

This alternate switch with lock is used to release the axis brake. To operate

the switch, pull it toward you and tilt.

Tilting the switch upward (RLS side) will release the brake forcibly, while

tilting it downward (NOM) will enable an automatic brake control by the

controller.

(10) Axis-driver status

LEDs

These LEDs monitor the operating status of the driver CPU that controls the

motor drive. The following three LEDs are provided.

Name Color Meaning when lit

An error is detected by the driver. Although this LED

ALM Orange

flashes when the power limiter level is exceeded, this does

not indicate a problem as long as no error is present.

SVON Green The servo is on and the motor is being driven.

BAT ALM Orange The voltage of the absolute-data backup battery is low.

(11) Encoder connector

This 15-pin, D-sub connector is used to connect the actuator’s encoder.

Encoder Connector Specifications

Item Description

Connector name PG

Connector High-density D-sub, 15-pin (female)

Maximum

connection distance

Interface standard Conforming to RS422

Connected to Actuator

Connection cable

Terminal

assignments

10 m

(Built-in encoder unit inside the actuator)

Dedicated PG cable

Pin No. Signal name Description

1 A+ Phase-A differential + input (Phase U+)

2 A– Phase-A differential – input (Phase U–)

3 B+ Phase-B differential + input (Phase V+)

4 B– Phase-B differential – input (Phase V–)

5 Z+ Phase-Z differential + input (Phase W+)

6 Z– Phase-Z differential – input (Phase W–)

7 SRD+

8 SRD–

9 BATT Backup-battery power supply

10 BATTGND Battery ground

11 VCC Encoder power source

12 GND GND

13 BK–

14 BK+

15 FG Not used

Send/receive line+ (Pulse/magneticpole switching+)

Send/receive line– (Pulse/

magnetic-pole switching–)

Brake output

12

Page 32

Part 1 Installation

INTELLIGENT ACTUATOR

(12) System I/O connector

This connector is used to connect an emergency-stop switch, ENABLE

contact, ready relay, etc.

Connector MC1.5/6-ST-3.5 by Phoenix Contact; 6-pin, 2-piece connector

Terminal assignments

Pins +24V OUT and EMG IN form a contact-B emergency-stop input. Operation is enabled

when the pins are shorted.

Pins +24V OUT and EMG IN form a contact-B safety-gate input. Operation is enabled

when the pins are shorted.

Pins RDY OUT form a contact-A output that turns ON under the following condition:

SYSRDY is output (software = PIO trigger program can be run) and hardware is normal

(emergency stop is not being actuated and hardware error is not being detected).

+24-V OUT and EMG IN, and +24 V OUT and ENB IN, are shorted by a cable before the

shipment.

+24V OUT +24-V power output for emergency stop

EMG IN Emergency-stop input

+24V OUT +24-V power output for safety gate

ENB IN Safety-gate input

RDY OUT

RDY OUT

Ready-status output contact

(13) I/O24V power

connector

This connector is used to externally supply I/O power to the insulated part

when DI and DOs are mounted in the I/O connectors explained in (18) and

(19) (2-pin, 2-piece connector by Phoenix Contact). 24 V must be supplied

externally.

Supported cable size 0.75 ~ 1.25 mm

Connector MC1.5/6-ST-3.5 by Phoenix Contact; 2-pin, 2-piece connector

Terminal assignments

2

(AWG16)

24VIN +24-V power input for I/Os

0V I/O GND

(14) Panel window This window consists of a 4-digit, 7-segment LED display and five LED

lamps that indicate the status of the equipment.

For the information shown on the display, refer to 2, “Explanation of Codes

Displayed on the Panel Window” or the “Error Code Table.”

Meanings of Five LEDs

Name Status when the LED is lit

RDY CPU ready (program can be run)

ALM CPU alarm (system-down level error), CPU hardware error

EMG

PSE Power-system hardware error

CLK System clock error

Emergency stop has been actuated, CPU hardware error, power-system hardware error

(15) Mode switch This alternate switch with lock is used to command a controller operation

mode. To operate the switch, pull it toward you and tilt.

Tilting the switch upward will select MANU (manual mode), while tilting it

downward will select AUTO (auto mode). Teaching can be performed only

in the MANU mode, but auto program start is not enabled in the MANU

mode.

(Refer to the types of manual operations explained on p. 348.)

13

Page 33

INTELLIGENT ACTUATOR

(16) Teaching-pendant

connector

Interface Specifications of Teaching Serial Interface

Connector name TP

Connector DSUB-25 XM3B-2542-502L (Omron)

Communication method RS232C-compliant, start-stop synchronous method

Baud rate 38.4 kbps max.; half-duplex communication

Maximum connection

distance

Interface standard RS232C

Connected to X-SEL teaching pendant

Interface Specifications of Teaching Serial Interface

Part 1 Installation

When an optional teaching pendant or PC is connected, this D-sub, 25-pin

connector will be used to input program and position data in the MANU

mode.

Item Description

10 m (38.4 kbps)

Item No. Direction Signal name Description

Terminal

assignments

1 FG Frame ground

2 Out TXD Transmitted data

3 In RXD Received data

4 Out RTS Request to send

5 In CTS Clear to send

6 Out DSR Equipment ready

7 SG Signal ground

8

9 In Connection prohibited

10 In Connection prohibited

11

12 Out EMGOUT Emergency stop

13 In EMGIN

14

15 Out Connection prohibited

16 Out Connection prohibited

17 Out Connection prohibited

Power output

18 Out VCC

(5-V power source for teaching

pendant)

19 In ENBTBX Enable input

20 In DTR Terminal ready

21

22

23 Out EMGS Emergency-stop status

24

25 SG Signal ground

14

Page 34

INTELLIGENT ACTUATOR

(17) PC connector

This D-sub, 9-pin connector is used to perform serial communication

(RS232C) with the host equipment when AUTO is selected as the operation

mode.

* (16) and (17) cannot be used simultaneously.

RS232 Host Connector Specifications

This connector is used to establish a serial connection with a PC or PLC to enable

controller control.

Item Description

Connector name HOST

Connector D-sub, 9-pin (DTE); XM2C-0942-502L by Omron

Maximum connection

distance

Interface standard RS232C

Connected to AT-compatible PC, etc. (half-duplex communication)

Connection cable Dedicated cable

Terminal assignments

10 m (38.4 kbps)

Pin No. I/O Signal name Description

1 NC

2 In RD Received data (RXD)

3 Out SD Transmitted data (TXD)

4 In DR Data set ready (DSR)

5 In SG Signal ground

6 Out ER Equipment ready (DTR)

7 Out RS Request to send (RTS)

8 In CS Clear to send (CTS)

9 NC Not used

A dedicated cable must be used if an AT-compatible PC is to be connected.

The PC connector (D-sub, 9-pin) (17) will become available for use by the user

only when the teaching-pendant connector (D-sub, 25-pin) (16) is not in use.

The PC connector (D-sub, 9-pin) (17) and teaching-pendant connector (D-sub,

25-pin) (16) cannot be used simultaneously. Setting the mode switch (15) to

MANU will select the teaching-pendant connector (16), while setting it to AUTO

will select the PC connector (17).

Part 1 Installation

(18) Standard I/O

connector

This connector consists of a 50-pin flat connector and comprises 32input/16-output DIOs.

Overview of Standard I/O Interface Specifications

Item Description

Connector name I/O

Connector Flat connector, 50-pin

Power supply

Input 32 points (including general-purpose and dedicated inputs)

Output 16 points (including general-purpose and dedicated outputs)

Connected to External PLC, sensor, etc.

Power is supplied through the I/O24V power connector

(13).

15

Page 35

INTELLIGENT ACTUATOR

The functions are at the time

of shipment. The functions

assigned to port Nos. 000 to

015, 300 to 308, 313 and 314

can be changed via I/O

parameters. (Refer to Nos.

30 to 54, No. 59 and No. 60

in 1, “I/O Parameters,” of

Appendix, “List of

Parameters.”)

(19) Expansion I/O

connectors

Part 1 Installation

Standard I/O Interface List

Pin No. Category Port No. Function Cable color

1 -

2 000

3 001

4 002

5 003

6 004

7 005

8 006

9 007

10 008

11 009

12 010

13 011

14 012

15 013

16 014

17 015

18 016

19 017

20 018

21 019

22 020

23 021

24 022

25 023

26 024

27 025

28 026

29 027

30 028

31 029

32 030

33

34 300

35 301

36 302

37 303

38 304

39 305

40 306

41 307

42 308

43 309

44 310

45 311

46 312

47 313

48 314

49 315

50

Input

Output

NC Brown-1

Program start Red-1

General-purpose input Orange-1

General-purpose input Yellow-1

General-purpose input Green-1

General-purpose input Blue-1

General-purpose input Purple-1

General-purpose input Gray-1

Program specification (PRG No. 1) White-1

Program specification (PRG No. 2) Black-1

Program specification (PRG No. 4) Brown-2

Program specification (PRG No. 8) Red-2

Program specification (PRG No. 10) Orange-2

Program specification (PRG No. 20) Yellow-2

Program specification (PRG No. 40) Green-2

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

General-purpose input

031

Alarm output Yellow-4

Ready output Green-4

Emergency-stop output Blue-4

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

General-purpose output

NC Black-5

-

Blue-2

Purple-2

Gray-2

White-2

Black-2

Brown-3

Red-3

Orange-3

Yellow-3

Green-3

Blue-3

Purple-3

Gray-3

White-3

Black-3

Brown-4

Red-4

Orange-4

Purple-4

Gray-4

White-4

Black-4

Brown-5

Red-5

Orange-5

Yellow-5

Green-5

Blue-5

Purple-5

Gray-5

White-5

These connectors are used to install I/O expansion boards.

16

Page 36

Part 1 Installation

INTELLIGENT ACTUATOR

2. Explanation of Codes Displayed on the Panel Window

2-1. Application

Display Priority (*1) Description

1

1 System-down level error

2 Writing data to the flash ROM.

3 Emergency stop is being actuated (except during the update mode).

4 Safety gate is open (except during the update mode).

5 Cold-start level error

5 Cold-start level error

5 Operation-cancellation level error

AC power is cut off (including momentary power failure or drop in

power-source voltage).

5 Operation-cancellation level error

6

6

Waiting for a drive-source cutoff reset input (except during the

update mode).

Operation is in pause (waiting for restart) (except during the update

mode).

7 All servo axes are interlocked (except during the update mode).

8 Message level error

8 Message level error

9 Core update mode

9 Core update is in progress.

9 Core update has completed.

9 Slave update mode

9 Slave update is in progress.

9 Slave update has completed.

9

Running a program (last started program); “No.” indicates program

number.

9 Initialization sequence number

9 Debug mode

9 Ready status (auto mode)

9 Ready status (manual mode)

10 Deadman switch OFF (manual mode)

(*1) The priority increases as the number decreases.

17

Page 37

INTELLIGENT ACTUATOR

2-2. Core

play Priority (*1) Description

Dis

1

AC power is cut off (including momentary power failure or drop in

power-source voltage).

1 Cold-start level error

1 Cold-start level error

1 Operation-cancellation level error

1 Operation-cancellation level error

2 Message level error

2 Message level error

2 Application update mode

2 Application update is in progress.

Part 1 Installation

2 Application update has completed.

2 Hardware test mode process

2 Clearing the application flash ROM.

2 Application flash ROM has been cleared.

2 Jump to the application

2 Core flash-ROM check process