Page 1

Ethernet

Operation Manual Third Edition

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Operation Manual explains the handling methods, structure and maintenance of this product, among others,

providing the information you need to know to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained herein to

ensure safe use of the product.

The CD that comes with the product contains operation manuals for IAI products.

When using the product, refer to the necessary portions of the applicable operation manual by printing them out

or displaying them on a PC.

After reading the Operation Manual, keep it in a convenient place so that whoever is handling this product can

reference it quickly when necessary.

[Important]

This Operation Manual is original.

The product cannot be operated in any way unless expressly specified in this Operation Manual. IAI

shall assume no responsibility for the outcome of any operation not specified herein.

Information contained in this Operation Manual is subject to change without no tice for the purpose of

product improvement.

If you have any question or comment regarding the content of this manual, please contact the IAI

sales office near you.

Using or copying all or part of this Operation Manual without permi ssion is prohibited.

The company names, names of products and trademarks of each company shown in the sentences

are registered trademarks.

Page 4

Page 5

Table of Contents

Safety Guide 1

1. Overview 9

2. Interface Specifications 11

3. Interface Board 12

3.1 Name of Each Part 12

3.2 Monitor LED Indications 13

4. Remote I/O (Modbus/TCP EtherNet/IP) 14

4.1 Setup of Ethernet Environment 14

4.2 Remote I/O Setup Procedure 15

4.3 Setup Procedure for Exception Status Support 17

4.4 Correspondence of Modbus/TCP Address and X-SEL I/O 18

4.5 Installation to a Modbus/TCP System 23

4.6 Installation to an EtherNet/IP System 23

5. IAI Protocol B/TCP 24

5.1 Setup of Ethernet Environment 24

5.2 Ethernet Connection of X-SEL PC Software 28

6. Transmission by SEL Program 32

6.1 Setup of Ethernet Environment 32

6.2 Ethernet Option SEL Commands 35

7. Common Items to Note (Be Sure to Read This Section.) 43

Appendix: X-SEL (Cartesian/IX SCARA) Ethernet Option Parameters 45

Page 6

Page 7

Safety Guide

When designing and manufacturing a robot system, ensure safety by following the safety Guidess

provided below and taking the necessary measures.

Regulations and Standards Governing Industrial Robots

Safety measures on mechanical devices are generally classified into four categori es un der the International

Industrial Standard ISO/DIS 12100, “Safety of machinery,” as follows:

Safety measures Inherent safety design

Protective guards --- Safety fence, etc.

Additional safety measures --- Emergency stop device, etc.

Information on use --- Danger sign, warnings, operation manual

Based on this classification, various standards are established in a hierarchical manner under the International

Standards ISO/IEC. The safety standards that apply to industrial robots are as follows:

Type C standards (individual safety standards) ISO10218 (Manipulating industrial robots – Safety)

JIS B 8433

(Manipulating industrial robots – Safety)

Also, Japanese laws regulate the safety of industrial robots, as follows:

Industrial Safety and Health Law Article 59

Workers engaged in dangerous or harmful operations must receive special education.

Ordinance on Industrial Safety and Health

Article 36 --- Operations requiring special education

No. 31 (Teaching, etc.) --- Teaching and other similar work involving industrial robots (exceptions

apply)

No. 32 (Inspection, etc.) --- Inspection, repair, adjustment and similar work involving industrial robots

(exceptions apply)

Article 150 --- Measures to be taken by the user of an industrial robot

-1-

Page 8

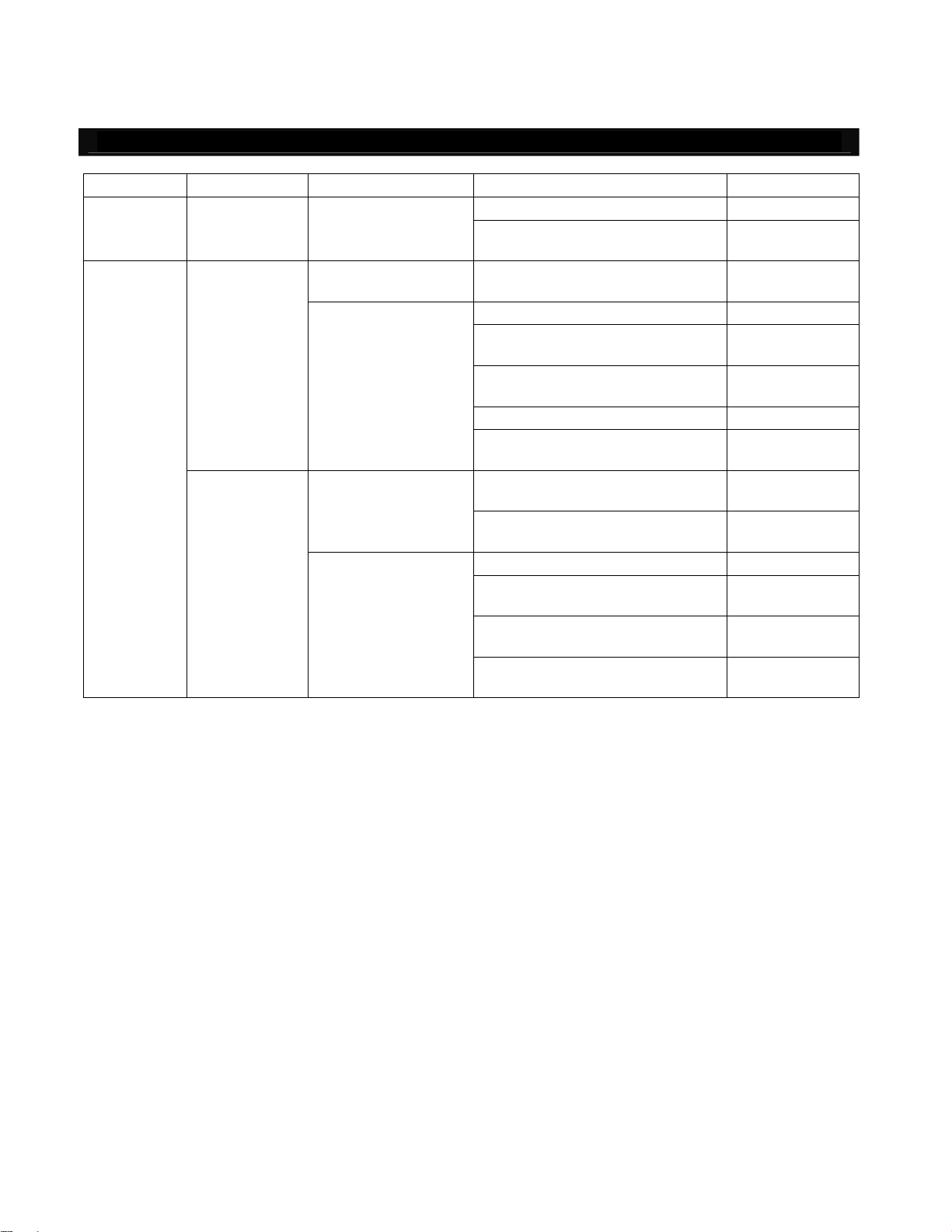

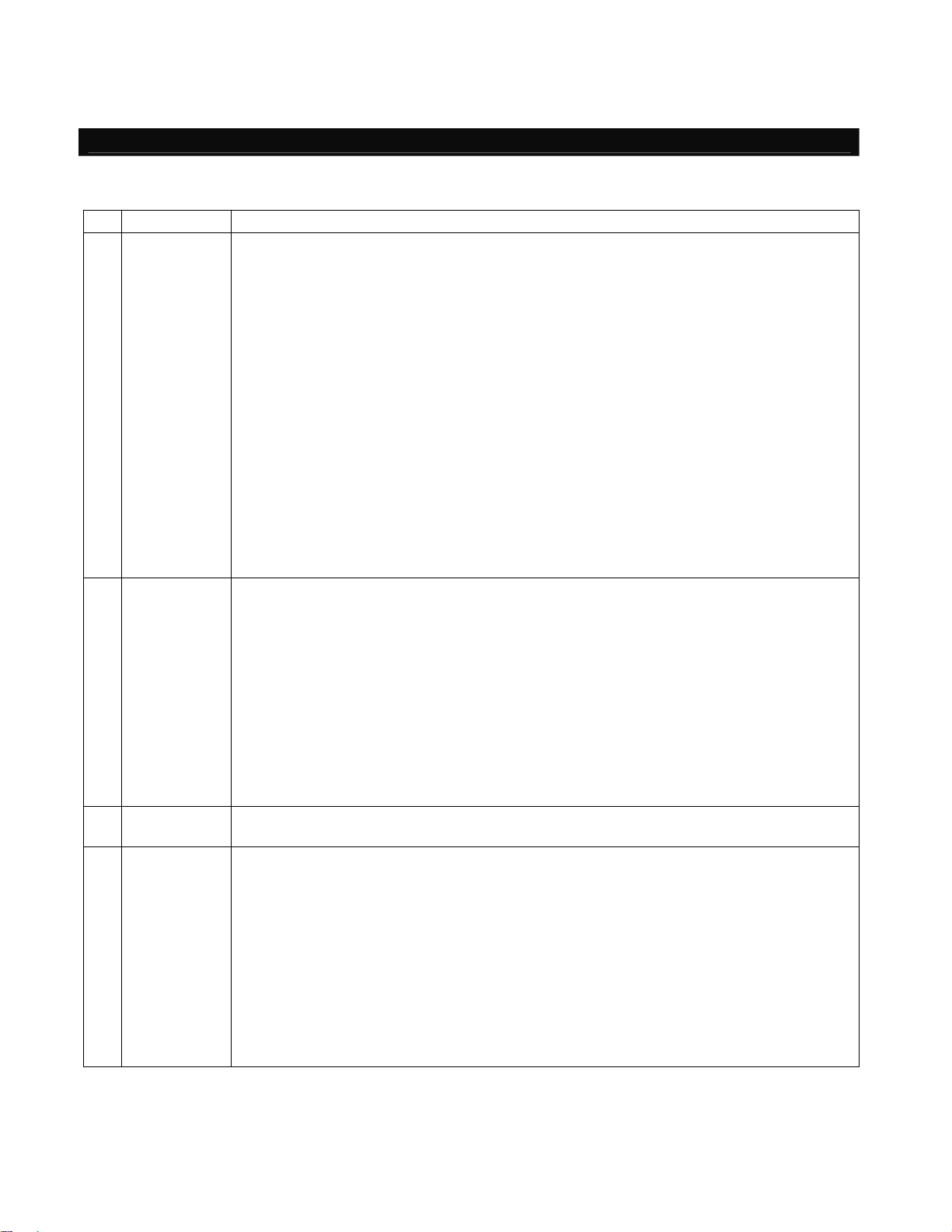

Requirements for Industrial Robots under Ordinance on Industrial Safety and Health

Work area Work condition Cutoff of drive source Measure Article

Outside

movement

range

Inside

movement

range

During

automatic

operation

During

teaching, etc.

During

inspection, etc.

Not cut off

Cut off (including

stopping of operation)

Not cut off

Cut off

Not cut off (when

inspection, etc., must

be performed during

operation)

Signs for starting operation Article 104

Installation of railings, enclosures,

etc.

Sign, etc., indicating that work is in

progress

Preparation of work rules Article 150-3

Measures to enable immediate

stopping of operation

Sign, etc., indicating that work is in

progress

Provision of special education Article 36-31

Checkup, etc., before

commencement of work

To be performed after stopping the

operation

Sign, etc., indicating that work is in

progress

Preparation of work rules Article 150-5

Measures to enable immediate

stopping of operation

Sign, etc., indicating that work is in

progress

Provision of special education

(excluding cleaning and lubrication)

Article 150-4

Article 150-3

Article 150-3

Article 150-3

Article 151

Article 150-5

Article 150-5

Article 150-5

Article 150-5

Article 36-32

-2-

Page 9

Applicable Models of IAI’s Industrial Robots

Machines meeting the following conditions are not classified as industrial robot s according to Notice of Ministry of

Labor No. 51 and Notice of Ministry of Labor/Labor Standards Office Director (Ki-Hatsu No. 340):

(1) Single-axis robot with a motor wattage of 80 W or less

(2) Combined multi-axis robot whose X, Y and Z-axes are 300 mm or shorter and wh ose rot ating p art, if any,

has the maximum movement range of within 300 mm

(3) Multi-joint robot whose movable radius and Z-axis are within 300 mm

Among the products featured in our catalogs, the following models are classified as industrial robots:

1. Single-axis ROBO Cylinders

RCS2/RCS2CR-SS8 whose stroke exceeds 300 mm

2. Single-axis robots

The following models whose stroke exceeds 300 mm and whose motor capacity also exceeds 80 W:

ISA/ISPA, ISDA/ISPDA, ISWA/ISPWA, IF, FS, NS

3. Linear servo actuators

All models whose stroke exceeds 300 mm

4. Cartesian robots

Any robot that uses at least one axis corresponding to one of the models specified in 1 to 3

5. IX SCARA robots

IX-NNN (NNW, NNC) 3515 (H)

IX-NNN (NNW, NNC) 50 (H) /60 (H) /70 (H) /80 (H)

IX-NSN5016(H) /6016 (H)

IX-TNN (UNN) 3015(H) /3515 (H)

IX-HNN (INN) 50 (H) /60 (H) /70 (H) /80 (H)

3

including the tip of the rotating part

-3-

Page 10

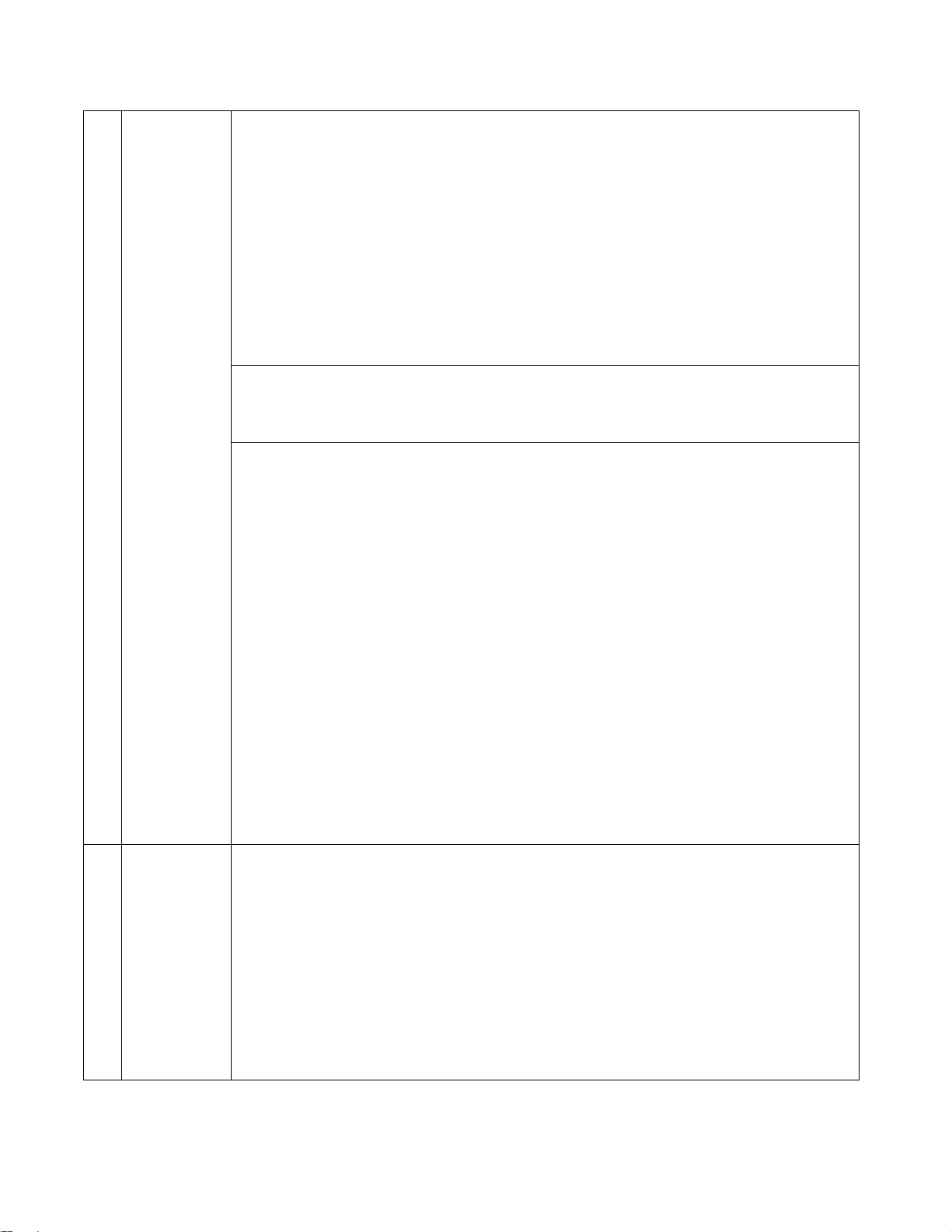

Notes on Safety of Our Products

Common items you should note when performing each task on any IAI robot are explained below.

No. Task Note

1 Model

selection

2 Transportation When transporting the product, exercise due caution not to bump or drop the product.

Storage/

3

preservation

4 Installation/

startup

This product is not planned or designed for uses requiring high degrees of safety.

Accordingly, it cannot be used to sustain or support life and must not be used in the

following applications:

[1] Medical devices relating to maintenance, management, etc., of life or health

[2] Mechanisms or mechanical devices (vehicles, railway facilities, aircraft facilities, etc.)

intended to move or transport people

[3] Important safety parts in mechanical devices (safety devices, etc.)

Do not use this product in the following environments:

[1] Place subject to flammable gases, ignitable objects, flammables, explosives, etc.

[2] Place that may be exposed to radiation

[3] Place where the surrounding air temperature or relative humidity exceeds the

specified range

[4] Place subject to direct sunlight or radiated heat from large heat sources

[5] Place subject to sudden temperature shift and bedewing

[6] Place subject to corrosive gases (sulfuric acid, hydrochloric acid, etc.)

[7] Place subject to excessive dust, salt or iron powder

[8] Place where the product receives direct vibration or impact

Do not use this product outside the specified ra nges. Doing so may significantly shorten

the life of the product or result in product failure or facility stoppage.

Use appropriate means for transportation.

Do not step on the package.

Do not place on the package any heavy article that may deform the package.

When using a crane with a capacity of 1 ton or more, the crane must be operated b y per sonnel

qualified to operate cranes and perform slinging operations.

When using a crane or other equipment, never use it to hoist any article exceeding the rated load

of the applicable crane, etc.

Use hoisting accessories suitable for the article to be hoisted. Select appropriate hoisting

accessories by making sure there is an ample allowance for safety in their cutting load, etc.

Do not climb onto the article being hoisted.

Do not keep the article hoisted.

Do not stand under the hoisted article.

The storage/preservation environment should conform to the installation environment.

Among others, be careful not to cause bedewing.

(1) Installing the robot, controller, etc.

Be sure to firmly secure and affix the product (including its load).

If the product tips over, drops, malfunctions, etc., damage or injury may result.

Do not step on the product or place any article on top. The product may tips over or the

article may drop, resulting in injury, product damage, loss of/drop in product

performance, shorter life, etc.

If the product is used in any of the following places, provide sufficient shielding

measures:

[1] Place subject to electrical noise

[2] Place subject to a strong electric or magnetic field

[3] Place where power lines or drive lines are wired nearby

[4] Place subject to splashed water, oil or chemicals

-4-

Page 11

4 Installation/

startup

(2) Wiring the cables

Use IAI’s genuine cables to connect the actuator and controller or connect a teaching

tool, etc.

Do not damage, forcibly bend, pull, loop round an object or pinch the cables or place

heavy articles on top. Current leak or poor electrical continuity may occur, resulting in

fire, electric shock or malfunction.

Wire the product correctly after turning off the power.

When wiring a DC power supply (+24 V), pay attention to the positive and negative

polarities.

Connecting the wires in wrong polarities may result in fire, product failure or malfunction.

Be sure to connect the cable connectors without fail and firmly. Failing to do so may

result in fire, electric shock or product malfunction.

Do not cut and reconnect the cables of the product to extend or shorten the cables.

Doing so may result in fire or product malfunction.

(3) Grounding

Be sure to provide class D (former class 3) grounding for the controller. Grounding is

required to prevent electric shock and electrostatic charges, improve noise re sistance

and suppress unnecessary electromagnetic radiation.

(4) Safety measures

Implement safety measures (such as installing safety fences, etc.) to prevent entry into

the movement range of the robot when the product is moving or can be moved.

Contacting the moving robot may result in death or serious injury.

Be sure to provide an emergency stop circuit so that the product can be stopped

immediately in case of emergency during operation.

Implement safety measures so that the product cannot be started only by turning on the

power. If the product starts suddenly, inj ury or product damage may result.

Implement safety measures so that the product will not start upon cancellation of an

emergency stop or recovery of power following a power outage. Failure to do so may

result in injury, equipment damage, etc.

Put up a sign saying “WORK IN PROGRESS. DO NOT TURN ON POWER,” etc.,

during installation, adjustment, etc. If the power is accidently turned on, electric shock or

injury may result.

Implement measures to prevent the load, etc., from dropping due to a power outage or

emergency stop.

Ensure safety by wearing protective gloves, protective goggles and/or safety shoes, as

necessary.

Do not insert fingers and objects into openings in the product. Doing so may result in

injury, electric shock, product damage, fire, etc.

When releasing the brake of a vertically installed actuator, be careful not to pinch your

hand or damage the load, etc., due to the slider dropping by its dead weight.

5 Teaching Whenever possible, perform teaching from outside the safety fences. If teaching must

be performed inside the safety fences, prepare “work rules” and make sure the operator

understands the procedures thoroughly.

When working inside the safety fences, the operator should carry a handy emergency

stop switch so that the operation can be stopped any time when an abnormality occurs.

When working inside the safety fences, appoint a safety watcher in addition to the

operator so that the operation can be stopped any time when an abnormality occurs.

The safety watcher must also make sure the switches are not operated inadvertently by

a third party.

Put up a sign saying “WORK IN PROGRESS” in a conspicuous location.

When releasing the brake of a vertically installed actuator, be careful not to pinch your

hand or damage the load, etc., due to the slider dropping by its dead weight.

* Safety fences --- Indicate the movement range if safety fences are not provided.

-5-

Page 12

6 Confirmation

operation

After teaching or programming, carry out step-by-step confirmation operation before

switching to automatic operation.

When carrying out confirmation operation inside the safety fences, follow the specified

work procedure just like during teaching.

When confirming the program operation, use the safety speed. Failure to do so may

result in an unexpected movement due to programming errors, etc., causing injury.

Do not touch the terminal blocks and various setting switches while the power is

supplied. Touching these parts may result in electric shock or malfunction.

7 Automatic

operation

Before commencing automatic operation, make sure no one is inside the safety fences.

Before commencing automatic operation, make sure all related peripherals are ready to

operate in the auto mode and no abnormalities are displayed or indicated.

Be sure to start automatic operation from outside the safety fences.

If the product generated abnormal heat, smoke, odor or noise, stop the product

immediately and turn off the power switch. Failure to do so may result in fire or product

damage.

If a power outage occurred, turn off the power switch. Otherwise, the product may move

suddenly when the power is restored, resulting in injury or product damage.

8 Maintenance/

inspection

Whenever possible, work from outside the safety fences. If work must be performed

inside the safety fences, prepare “work rules” and make sure the operator understands

the procedures thoroughly.

When working inside the safety fences, turn off the power switch, as a rule.

When working inside the safety fences, the operator should carry a handy emergency

stop switch so that the operation can be stopped any time when an abnormality occurs.

When working inside the safety fences, appoint a safety watcher in addition to the

operator so that the operation can be stopped any time when an abnormality occurs.

The safety watcher must also make sure the switches are not operated inadvertently by

a third party.

Put up a sign saying “WORK IN PROGRESS” in a conspicuous location.

Use appropriate grease for the guides and ball screws by checking the operation

manual for each model.

Do not perform a withstand voltage test. Conducting this test may result in pro duct

damage.

When releasing the brake of a vertically installed actuator, be careful not to pinch your

hand or damage the load, etc., due to the slider dropping by its dead weight.

* Safety fences --- Indicate the movement range if safety fences are not provided.

9 Modification The customer must not modify or disassemble/assemble the product or use

maintenance parts not specified in the manual without first consulting IAI.

Any damage or loss resulting from the above actions will be excluded from the scope of

warranty.

10 Disposal When the product becomes no longer usable or necessary, dispose of it properly as an

industrial waste.

When disposing of the product, do not throw it into fire. The product may explode or

generate toxic gases.

-6-

Page 13

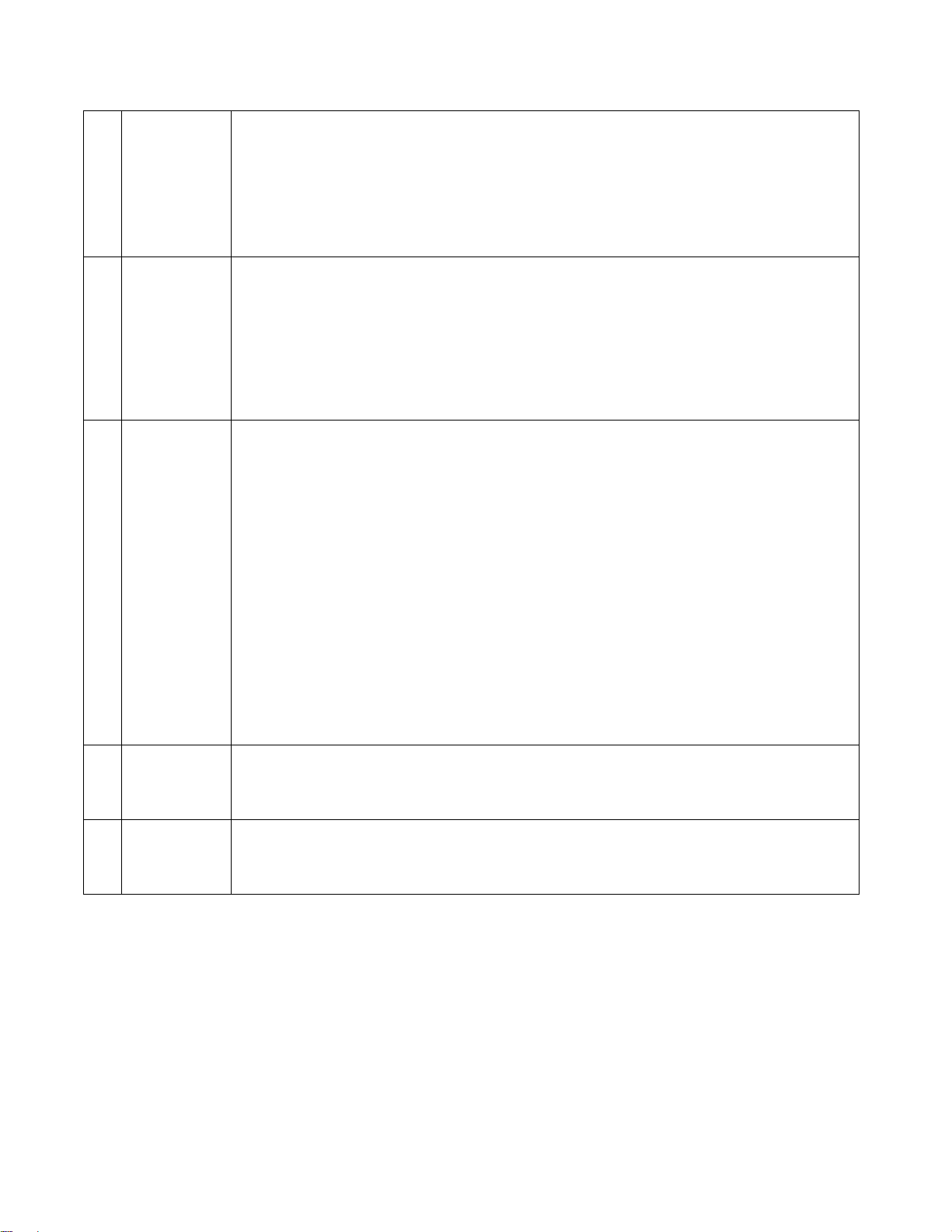

Indication of Cautionary Information

The operation manual for each model denotes safety Guides under “Danger,” “Warning,” “Caution” and “Note,” as

specified below.

Level Degree of danger/loss Symbol

Danger

Warning

Caution

Note

Failure to observe the instruction will result in an

imminent danger leading to death or serious injury.

Failure to observe the instruction may result in death or

serious injury.

Failure to observe the instruction may result in injury or

property damage.

The user should take heed of this information to ensure

the proper use of the product, although failure to do so

will not result in injury.

Danger

Warning

Caution

Note

-7-

Page 14

-8-

Page 15

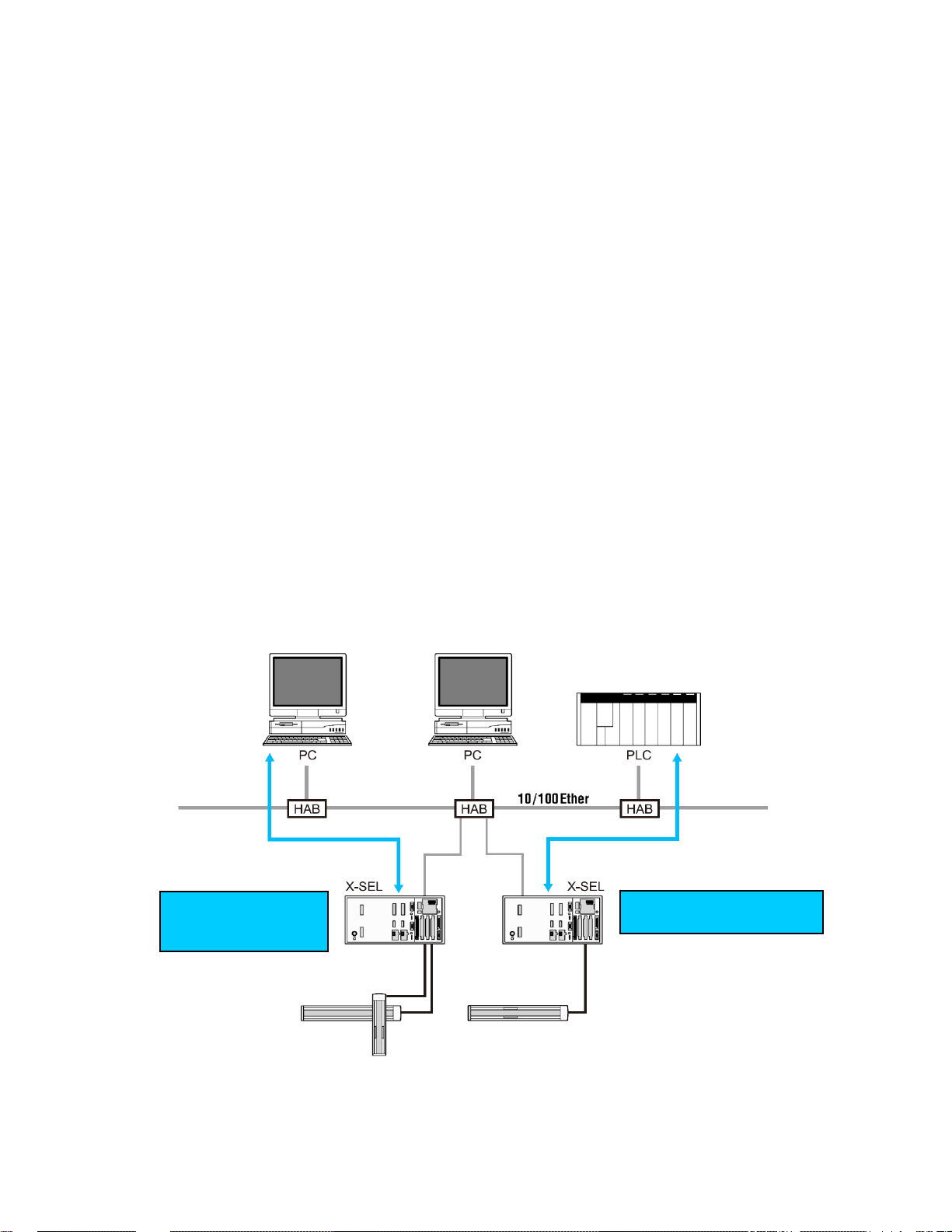

1. Overview

This option allows the X-SEL controller to perform control in an open network environment using the

Ethernet infrastructure, the de-facto standard and most common form of communication media for linking

PCs and host computers.

(1) Remote I/O control (Modbus/TCP EtherNet/IP)

The X-SEL controller supports remote I/O control (a maximum of 256 input points and 256 output

points) via Modbus/TCP.

Modbus/TCP is an Ethernet application of the Modbus protocol used in serial communicatio n.

* EtherNet/IP is supported only by X-SEL controllers of P/Q types (main application version 1.05 or

later). Also note that to use EtherNet/IP, you need an interface board compatible with EtherNet/IP.

(2) Message communication

The communication capabilities supported by the RS232C communication function of the X-SEL

controller can be implemented via Ethernet.

IAI protocol B/TCP

IAI protocol B for serial communication is supported.

The X-SEL controller can be connected to PC software.

Tra nsmission by SEL program (4 channels)

Four channels of ASCII-based, delimiter-controlled communication are supported, using a set of

transmission commands in a system roughly equivalent to that used in the X-SEL controller’s serial

communication.

Substitute programs

Send work data

(IAI protocol)

Send/receive I/O signals

(Modbus/TCP EtherNet)

- 9 -

Page 16

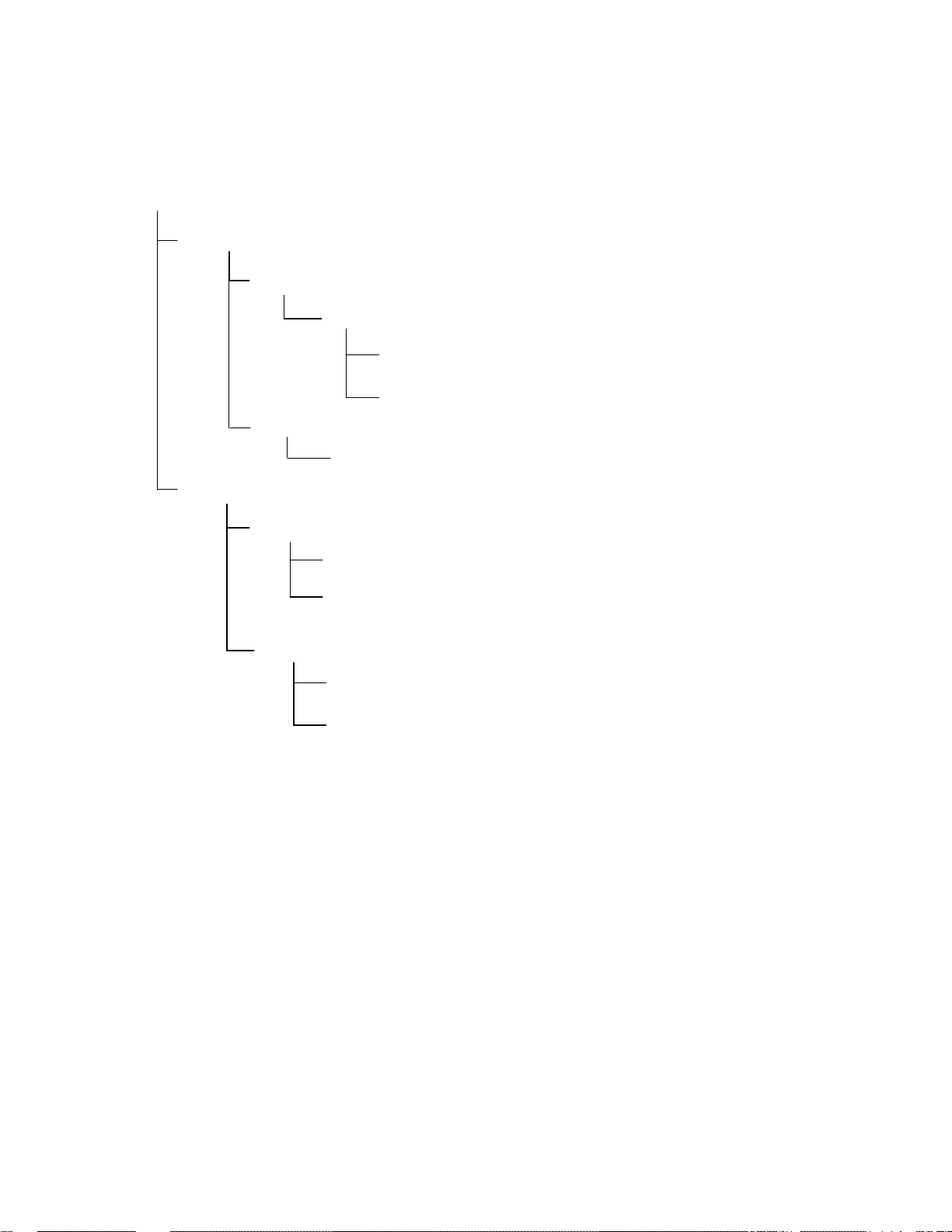

A hierarchy of the functions provided by the X-SEL Ethernet option is shown below.

Functions are selected by parameters. Additionally, the network environment parameters must be set.

Ethernet option

Remote I/O

Modbus/TCP

Server (slave unit)

EtherNet/IP

Adapter (equivalent to a slave)

EXCEPTION status invalid

EXCEPTION status (upper two digits of the error num ber) valid

Message communication

IAI protocol B/TCP

Client (PC software connection enabled)

Server

Transmission by SEL program (4 channels)

Client

Server

- 10 -

Page 17

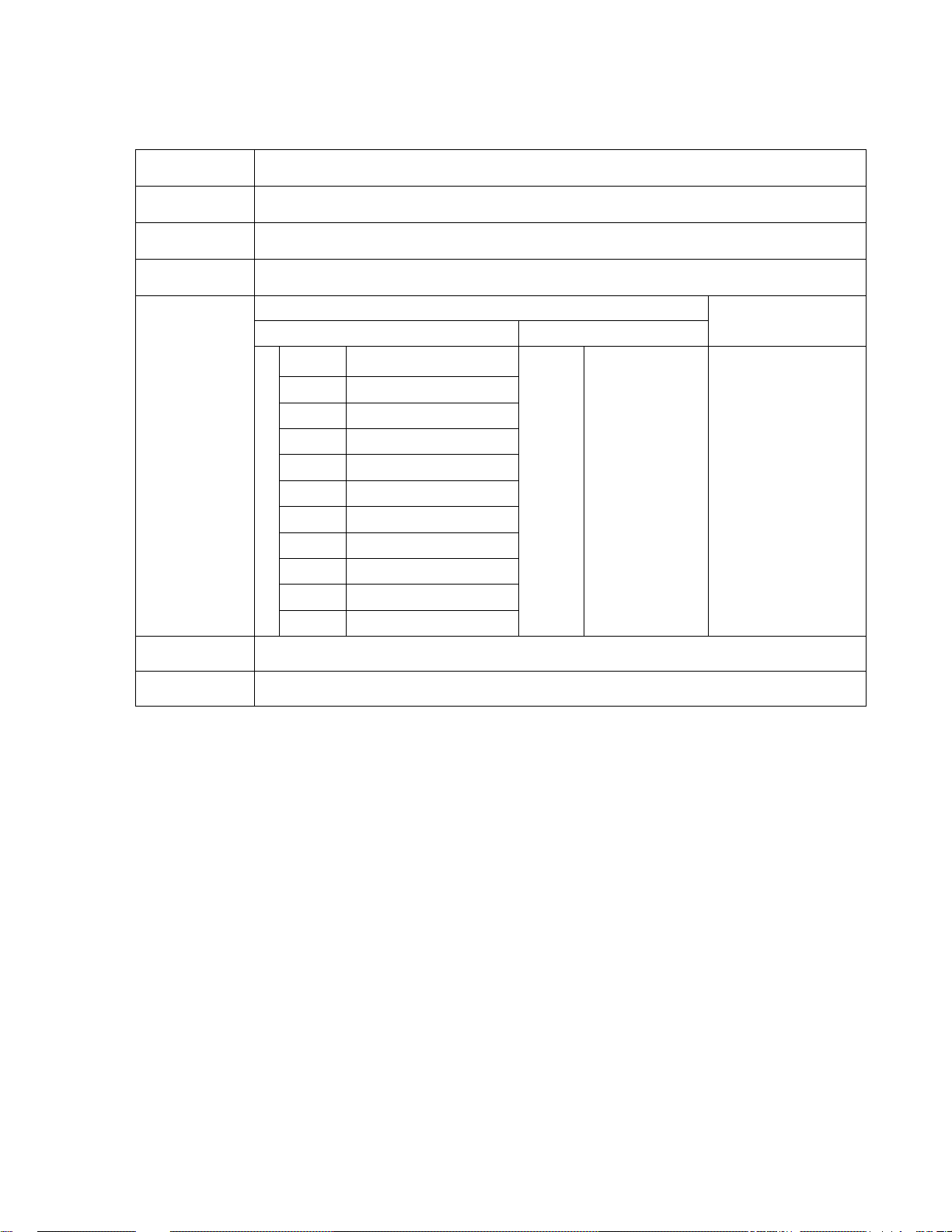

2. Interface Specifications

Item Specification

Network

specification

Communication

standard

Communication

speed

Protocol

10BASE-T/100BASE-T (Auto-negotiation)

IEEE802.3

10/100 Mbps (Auto-negotiation)

Remote I/O

Open Modbus/TCP EtherNet/IP

Class 1 Read Coil

Class 1 Read Input Discretes

Class 0 Read multiple registers

Class 1 Read Input registers

Class 1 Write Coils

Class 1 Write Single register

Class 1 Read Exception status

Class 2 Force multiple Coils

Supported commands

Class 0 Force multiple registers

Class 2 Mask Write register

Class 2 Read/Write registers

Class 1

Class 3

UCMM

Cyclic

communication

Connection type

Non-connection

type

TCP/IP message

communication

1. IAI protocol B/TCP

2. Transmission by

SEL program

(4 channels)

Connector RJ-45

Cable Category 5 UTP twisted cable (see note)

(Note) Use a straight or crossed Ethernet cable according to the conne ction enviro nment.

[Normal]

Controller HUB: Straight

Controller Controller: Crossed

Controller PC: Crossed

- 11 -

Page 18

3. Interface Board

3.1 Name of Each Part

(Note) The DIP switches are used to set the least significant byte of the IP address. With

the X-SEL system, however, the IP address is set by a controller parameter without

the use of DIP switches.

Set all switches to OFF. (Setting the switches in any other pattern will have no

effect.)

S1

/S0

NS

/MS

Communication connector

DIP switches

Monitor LEDs

- 12 -

Page 19

3.2 Monitor LED Indications

The operating condition of the interface board and its connection status to Ethernet can be checked

via the four LEDs provided on the front panel of the interface board.

* The LED indications of operating condition and connection con dition vary between Modbus/TCP

and EtherNet/IP.

Modbus/TCP or TCP/IP message communication

LED Color Status Definition Explanation (factor)

Open Modbus/TCP (Remote I/O) TCP/IP Message Communication

S0

(LINK)

S1

(TRX)

MS

NS

EtherNet/IP

LED Color Status Definition Explanation (factor)

S0

(LINK)

S1

(TRX)

MS

NS

The sections in represent indications during normal operation.

- Unlit Not linked

Green Lit Linked

- Unlit No packet

Green Lit Packet detected

- Unlit No power supply

Lit Default IP

Green

Blinking at 1 Hz

Lit Duplicate IPs

Red

Blinking Catastrophic

- Unlit No Modbus/

Green Blinking Modbus/

EtherNet/IP

- Unlit Not linked

Green Lit Linked

- Unlit No packet

Green Lit Packet detected

- Unlit No power supply

Lit Normal operation

Green

Blinking Not linked

Lit Catastrophic

Red

Blinking Minor failure

- Unlit No power supply

Lit connection

Green

Blinking Connection not

Lit Catastrophic

Red

Blinking Connection

operation

Normal operation

failure

TCP connection

TCP connection

established

failure

established

established

failure

timeout

The system is not connected to Ethernet.

The system is connected to Ethernet.

TCP/IP packets are not being transmitted.

TCP/IP packets are being transmitted.

Power is not supplied to the board from the X-SEL system.

Interface board initialization is not complete.

The interface board is be ing reset.

The UTP cable is not connected.

IP address is not specified fr om the controller during operation. (As a rule, this condition should not

occur.)

The server has started normally via the controller.

Duplicate IP addresses were detected on Ethernet.

Module MAC address error (LED blinking at 1 Hz)

Network definition read error (LED blinking at 2 Hz)

Other module error (LED blinking at 4 Hz)

The Modbus/TCP connection has not been

established.

A Modbus/TCP connection has been established.

(The blinking frequency indicates the number of

connections: 1 Hz 1 connection, 2 Hz

2 connections.)

The system is not connected to Ethernet.

The system is connected to Ethernet.

TCP/IP packets are not being transmitted.

TCP/IP packets are being transmitted.

Power is not supplied to the board from the X-SEL system.

Interface board initialization is not complete.

The interface board is be ing reset.

The UTP cable is not connected.

The adapter has started normally via control by the controller.

The network is not yet established or the system is idle.

A catastrophic, irreparable failure (module error, etc.) was detected

A minor, reparable failure (duplicated IP address, etc.) was detected.

Power is not supplied to the board from the X-SEL system.

IP address is not yet set.

The system is online and connection has been established.

The system is not online and connection has not been established.

A duplicated IP address, etc., was detected.

A connection timeout was detected.

The LED will not be lit in the case of

TCP/IP message communication.

- 13 -

Page 20

4. Remote I/O (Modbus/TCP EtherNet/IP)

4.1 Setup of Ethernet Environment

The X-SEL controller provides IP addresses and other network-definition areas in its I/O parameters

for control of Modbus/TCP EtherNet/IP operation.

Set the necessary parameters according to the network environmen t before connecting to the network.

Establishing a connection without setting the parameters may disa ble normal communication to and

from other devices on the network.

* EtherNet/IP is supported only by X-SEL controllers of P/Q types (main application version 1.05 or

later). Also note that to use EtherNet/IP, you need an interface board compatible with EtherNet/IP.

[I/O parameters]

No. Parameter name Setting Input range Remarks

Ethernet operation requirement

Bits 0 to 3: Remote I/O

0: Do not use

1: Use Modbus/TCP (EXCEPTION status invalid)

129 Network attribute 10 1H 0H~FFFFFFFFH

Own MAC address (H) 0030H

130

131 Own MAC address (L) 11H

132 Own IP address (H) 192 1~255 * Setting of “0” and “127” is prohibited.

Reference value

(HEX)

Reference value

(HEX)

2: Use Modbus/TCP (EXCEPTION status valid)

3: Use EtherNet/IP (main application version 1.05 or

later)

Bits 4 to 7: TCP/IP message communication

(0: Do not use, 1: Use)

Bits 8 to 31: Not used

Only the lower two bytes are valid. (This parameter is not

settable.)

(This parameter is not settable.)

133 Own IP address (MH) 168 0~255

134 Own IP address (ML) 0 0~255

135 Own IP address (L) 1 1~254 * Setting of “0” and “255” is prohibited.

136 Subnet mask (H) 255 0~255

137 Subnet mask (MH) 255 0~255

138 Subnet mask (ML) 255 0~255

139 Subnet mask (L) 0 0~255

140 Default gateway (H) 0 0~255

141 Default gateway (MH) 0 0~255

142 Default gateway (ML) 0 0~255

143 Default gateway (L) 0 0~255

(Note) 1. Always set I/O parameter No. 129 to “1” to perform Modbus/TCP EtherNet/IP operation.

2. The Modbus/TCP port number on the controller side is fixed at “502.”

3. 44818 or 2222 is used for the EtherNet/IP port number on the controller side.

- 14 -

Page 21

4.2 Remote I/O Setup Procedure

The system is configured only with the remote I/Os of Modbus/TCP EtherNet/IP, with the I/O port

numbers being specified according to fixed port assignment.

4.2.1 Configuration with Modbus/TCP EtherNet/IP Only (No expansion I/O board)

The following settings are applicable when the system is configured only with the remote I/Os of

Modbus/TCP EtherNet/IP and the standard I/O ports are mapped on Modbus/TCP EtherNet/IP

without connections to any external devices via expansion I/O boards.

[I/O parameters]

No.

1

I/O port assignment type

Parameter name Setting Input range Remarks

0: Fixed assignment

0 0~20

I/O numbers are specified by parameters.

1: Automatic assignment (priority sequence: slot 1~)

Standard I/O input-port start

2

number (I/O1)

Standard I/O output-port start

3

number (I/O1)

Expanded I/O1 input-port start

4

number based on fixed

assignment (I/O2)

Expanded I/O1 output-port

5

start number based on fixed

assignment (I/O2)

Expanded I/O2 input-port start

6

number based on fixed

assignment (I/O3)

Expanded I/O2 output-port

7

start number based on fixed

assignment (I/O3)

Expanded I/O3 input-port start

8

number based on fixed

assignment (I/O4)

Expanded I/O3 output-port

9

start number based on fixed

assignment (I/O3)

Standard I/O error monitor

10

(I/O1)

Expanded I/O1 error monitor

11

(I/O2)

Expanded I/O2 error monitor

12

(I/O3)

Expanded I/O3 error monitor

13

(I/O4)

Number of ports using network

14

I/F-card remote input

Number of ports using network

15

I/F-card remote output

0 -1~599

300 -1~599

-1 -1~599

-1 -1~599

-1 -1~599

-1 -1~599

-1 -1~599

-1 -1~599

1 0~5

0 0~5

0 0~5

0 0~5

n 0~256

m 0~256

0 + (Multiple of 8) (A neg ative value is invalid.)

0: Assign Modbus/TCP remote DIs from No. 0.

300 + (Multiple of 8) (A negative value is invalid.)

300: Assign Modbus/TCP remote DOs from No.

300.

0 + (Multiple of 8) (A neg ative value is invalid.)

-1: No expanded I/O1 DI

300 + (Multiple of 8) (A negative value is invalid.)

-1: No expanded I/O1 DO

0 + (Multiple of 8) (A neg ative value is invalid.)

-1: No expanded I/O2 DI

300 + (Multiple of 8) (A negative value is invalid.)

-1: No expanded I/O2 DO

0 + (Multiple of 8) (A neg ative value is invalid.)

-1: No expanded I/O3 DI

300 + (Multiple of 8) (A negative value is invalid.)

-1: No expanded I/O3 DO

0: Do not monitor

1: Monitor

2: Monitor (Do not monitor 24 V I/O power error)

3: Monitor (Monitor 24 V I/O power error only)

Specify the Modbus/TCP remote DI bits by a multiple

of 8 (8 n 256).

Specify the Modbus/TCP remote DO bits by a

multiple of 8 (8 n 256).

(Note) When word registers are to be used in Modbus/TCP, set the remote I/O head numbers (I/O port start

numbers: I/O parameters 2 and 3) on a 16-bit boundary, and also set the remote I/O bits (numbers of

ports using input/output: I/O parameters 14 and 15) as a multiple of 16.

- 15 -

Page 22

4.2.2 Combined Use of Expansion I/O Board (Modbus/TCP EtherNet/IP + Expanded I/O)

The following settings are applicable when the standard I/O ports are mapped on Modbus/TCP

EtherNet/IP (input-port start No. 0 and output-port start No. 300), while the expansion I/O boards

are used with port assignments starting with input-port start No. 200 and output-port start No. 500.

[I/O parameters]

No.

1

I/O port assignment type

Standard I/O input-port start

2

number (I/O1)

Standard I/O output-port start

3

number (I/O1)

Expanded I/O1 input-port start

4

number based on fixed

assignment (I/O2)

Expanded I/O1 output-port

5

start number based on fixed

assignment (I/O2)

Expanded I/O2 input-port start

6

number based on fixed

assignment (I/O3)

Expanded I/O2 output-port

7

start number based on fixed

assignment (I/O3)

Expanded I/O3 input-port start

8

number based on fixed

assignment (I/O4)

Expanded I/O3 output-port

9

start number based on fixed

assignment (I/O3)

Standard I/O error monitor

10

(I/O1)

Expanded I/O1 error monitor

11

(I/O2)

Expanded I/O2 error monitor

12

(I/O3)

Expanded I/O3 error monitor

13

(I/O4)

Number of ports using network

14

I/F-card remote input

Number of ports using network

15

I/F-card remote output

(Note) 1. Set the parameters so that the total number of DIs and that of DOs, respectively, will not exceed 300.

2. The last DI number should be 299 or below, while the last DO number should be 599 or below.

3. When word registers are to be used in Modbus/TCP, set the remote I/O head numbers (I/O port start

Parameter name Setting Input range Remarks

0: Fixed assignment

0 0~20

I/O numbers are specified by parameters.

1: Automatic assignment (priority sequence: slot 1~)

0 -1~599

0 + (Multiple of 8) (A neg ative value is invalid.)

0: Assign Modbus/TCP remote DIs from No. 0.

300 + (Multiple of 8) (A negative value is invalid.)

300 -1~599

300: Assign Modbus/TCP remote DOs from No.

300.

0 + (Multiple of 8) (A neg ative value is invalid.)

200 -1~599

Assign DIs of expanded I/O1 from No. 200.

0 + (Multiple of 8) (A neg ative value is invalid.)

500

-1 -1~599

-1 -1~599

-1 -1~599

-1 -1~599

1 0~5

1

0 0~5

0 0~5

n 0~256

m 0~256

-1~599

0~5

Assign DOs of expanded I/O1 from No. 500.

0 + (Multiple of 8) (A neg ative value is invalid.)

-1: No expanded I/O2 DI

300 + (Multiple of 8) (A negative value is invalid.)

-1: No expanded I/O2 DO

0 + (Multiple of 8) (A neg ative value is invalid.)

-1: No expanded I/O3 DI

300 + (Multiple of 8) (A negative value is invalid.)

-1: No expanded I/O3 DO

0: Do not monitor

1: Monitor

2: Monitor (Do not monitor 24 V I/O power error)

3: Monitor (Monitor 24 V I/O power error only)

Specify the Modbus/TCP remote DI bit s by a multiple

of 8 (8 n 256).

Specify the Modbus/TCP remote DO bits by a

multiple of 8 (8 n 256).

numbers: I/O parameters 2 and 3) on a 16-bit boundary, and also set the remote I/O bits (numbers of

ports using input/output: I/O parameters 14 and 15) as a multiple of 16.

- 16 -

Page 23

4.3 Setup Procedure for Exception Status Support

The X-SEL Ethernet option supports the function that notifies the host of an error condition (the upper

two digits of the error number) of the X-SEL controller using an ex ception code store d in Modbus/T CP.

By setting bits 0 to 3 of I/O parameter No. 129 to “2” (HEX), any error occurring in the X-SEL controller

can be indicated to the host controller via Modbus/TCP.

The EXCEPTION status stores the upper two digits (one byte) of the system error number (consisting

of three digits). When this EXCEPTION status is used, provide measures a ppropriate for the error

level by referring to the descriptions in the “Error Level Control” section of the operation manual for the

X-SEL controller.

(Note) The system error number cannot be specified from the EXCEPTION status (two digits). (This

is because the error number consists of three digits.)

- 17 -

Page 24

4.4 Correspondence of Modbus/TCP Address and X-SEL I/O

Modbus/TCP can address the same object using either bit addressing or word addre ssing.

The DI area (bit numbers from No. 0 up to No. 299 can be defined) of the X-SEL controller is mapped

in the word address 0x400 (1024) (coil and holding register as viewed from the PC side) un der

Modbus/TCP.

The DO area (bit numbers from No. 300 up to No. 599 can be defined) of the X-SEL controller is

mapped in the word address 0x000 (0) (input discrete and input register as viewed from the PC side)

under Modbus/TCP.

Since the DI addressing in the X-SEL controller and the addressin g via Modbu s are different, it is

important to note the following two points:

1. The number order of one byte in the byte boundary is reversed.

(Example)

X-SEL DI7 Modbus bit address 1 (Modbus/TCP bit address 0)

DI0 Modbus bit address 8 (Modbus/TCP bit address 7)

2. When register access is executed from the X-SEL controller using an IN, INB, OUT or OUTB

command, the upper and lower bytes will be reversed.

(Example)

Writing 0x1234 to 16 bits from X-SEL DO300

Modbus input register 0 (Modbus/TCP bit address 0)

DI0 Modbus bit address 8 (Modbus/TCP bit address 7)

Both the Motorola and Intel formats can be supported using an FMIO command. (Refer to Chapter 2,

“Explanation of Commands,” in the operation manual for the X-SEL controller.) The FMIO command

changes the endian in IN/OUT commands. Executin g input or output after an FMIO command

execution with the format type set to “1” will align the byte order with Modbus/TCP. Each FMIO

command is valid only with respect to the task for which the command is executed.

A table of correspondence is shown on the next page.

- 18 -

Page 25

4.4.1 Little Endian Operation

The default endian mode of DI/DO operation commands of the X-SEL controller is the little endian.

In the little endian mode, the remote I/O field accessed via word operation with an IN, INB, OUT or

OUTB command of the X-SEL controller will have its upper and lower bytes reversed in relation to

the X-SEL data if the same field is word-accessed via Modbus/TCP.

The following examples are based on 256-bit assignments from the head DO number (= 300) in

X-SEL as Modbus/TCP remote I/Os.

(Note) Remote I/Os can be defined only as consecutive numbers.

The assignable head number must satisfy: 300 + 8n (31 n 0).

The total number of assignable bits must satisfy: m + n < 32 & 32 m, where m represents

the number of assigned remote I/O bytes.

[Modbus/TCP input areas (assignment of X-SEL DO area 300 onward)]

Address

BIT7

(MSB)

6 5 4 3 2 1

X-SEL DO 307 306 305 304 303 302 301 300

Modbus/TCP bit address 0 1 2 3 4 5 6 7

Modbus/TCP word address 0 Lower byte

Modbus input status 10001 10002 10003 10004 10005 10006 10007 10008

Modbus input register 30001 Lower byte

X-SEL DO 315 314 313 314 315 310 309 308

Modbus/TCP bit address 8 9 10 11 12 13 14 15

Modbus/TCP word address 0 Upper byte

Modbus input status 10009 10010 10011 10012 10013 10014 10015 10016

Modbus input register 30001 Upper byte

:

:

X-SEL DO 547 546 545 544 543 542 541 540

Modbus/TCP bit address 240 241 242 243 244 245 246 247

Modbus/TCP word address 15 Lower byte

Modbus input status 10248 10249 10250 10251 10252 10253 10254 10255

Modbus input register 30016 Lower byte

X-SEL DO 555 554 553 552 551 550 549 548

Modbus/TCP bit address 15 Upper byte

Modbus/TCP word address 248 249 250 251 252 253 254 255

Modbus input status 10249 10250 10251 10252 10253 10254 10255 10256

Modbus input register 30016 Upper byte

Cannot be used

Input status: input discretes single bit, provided by an I/O system, read-only

Output coil: output discretes single bit, alterable by an application program, read-write

Input register: input registers 16-bit quantity, provided by an I/O system, read-only

Output register: output registers 16-bit quantity, alterable by an application pro gram, read-write

The output areas are described on the next page.

0

(LSB)

- 19 -

Page 26

[Modbus/TCP output areas (assignment of X-SEL DI area 300 onward), FMIO = 0]

Address

X-SEL DI 7 6 5 4 3 2 1 0

Modbus/TCP bit address 16384 16385 16386 16387 16388 16389 16390 16391

Modbus/TCP word address 1024 Lower byte

Modbus output coil 1 2 3 4 5 6 7 8

Modbus hold register 40001 Lower byte

X-SEL DI 15 14 13 14 15 10 9 8

Modbus/TCP bit address 16392 16393 16394 16395 16396 16397 16398 16399

Modbus/TCP word address 1024 Upper byte

Modbus output coil 9 10 11 12 13 14 15 16

Modbus hold register 40001 Upper byte

:

:

X-SEL DI 247 246 245 244 243 242 241 240

Modbus/TCP bit address 16624 16625 16626 16627 16628 16629 16630 16631

Modbus/TCP word address 1039 Lower byte

Modbus output coil 241 242 243 244 245 246 247 248

Modbus hold register 40016 Lower byte

X-SEL DI 255 254 253 252 251 250 249 248

Modbus/TCP bit address 16632 16633 16634 16635 16636 16637 16638 16639

Modbus/TCP word address 1039 Upper byte

Modbus output coil 249 250 251 252 253 254 255 256

Modbus hold register 40016 Upper byte

BIT7

(MSB)

6 5 4 3 2 1

(LSB)

Cannot be used

0

- 20 -

Page 27

4.4.2 Big Endian Operation

To align the word handling between Modbus/TCP and the X-SEL controller, the I/O operation mode

must be set to the big endian with an FMIO command before executing a DI/DO operation

command in any X-SEL ta sk.

With this setting the remote I/O field accessed via word operation with an IN, INB, OUT or OUTB

command of the X-SEL controller can be handl ed as the same data when the same field is

word-accessed via Modbus/TCP.

The following examples are based on 256-bit assignments from the head DO number (= 300) in

X-SEL as Modbus/TCP remote I/Os.

The only difference from the examples shown in 4.4.1, “Little Endian Operation,” is the byte order

of the word registers.

(Note) Remote I/Os can be defined only as consecutive numbers.

The assignable head number must satisfy: 300 + 8n (31 n 0).

The total number of assignable bits must satisfy: m + n < 32 & 32 m, where m represents

the number of assigned remote I/O bytes.

[Modbus/TCP input areas (assignment of X-SEL DO area 300 onward)]

Address

BIT7

(MSB)

6 5 4 3 2 1

X-SEL DO 307 306 305 304 303 302 301 300

Modbus/TCP bit address 0 1 2 3 4 5 6 7

Modbus/TCP word address 0 Upper byte

Modbus input status 10001 10002 10003 10004 10005 10006 10007 10008

Modbus input register 30001 Upper byte

X-SEL DO 315 314 313 314 315 310 309 308

Modbus/TCP bit address 8 9 10 11 12 13 14 15

Modbus/TCP word address 0 Lower byte

Modbus input status 10009 10010 10011 10012 10013 10014 10015 10016

Modbus input register 30001 Lower byte

:

:

X-SEL DO 547 546 545 544 543 542 541 540

Modbus/TCP bit address 240 241 242 243 244 245 246 247

Modbus/TCP word address 15 Upper byte

Modbus input status 10248 10249 10250 10251 10252 10253 10254 10255

Modbus input register 30016 Upper byte

X-SEL DO 555 554 553 552 551 550 549 548

Modbus/TCP bit address 15 Lower byte

Modbus/TCP word address 248 249 250 251 252 253 254 255

Modbus input status 10249 10250 10251 10252 10253 10254 10255 10256

Modbus input register 30016 Lower byte

Cannot be used

Input status: input discretes single bit, provided by an I/O system, read-only

Output coil: output discretes single bit, alterable by an application program, read-write

Input register: input registers 16-bit quantity, provided by an I/O system, read-only

Output register: output registers 16-bit quantity, alterable by an application pro gram, read-write

The output areas are described on the next page.

0

(LSB)

- 21 -

Page 28

[Modbus/TCP output areas (assignment of X-SEL DI area 300 onward), FMIO = 0]

Address

X-SEL DI 7 6 5 4 3 2 1 0

Modbus/TCP bit address 16384 16385 16386 16387 16388 16389 16390 16391

Modbus/TCP word address 1024 Upper byte

Modbus output coil 1 2 3 4 5 6 7 8

Modbus hold register 40001 Upper byte

X-SEL DI 15 14 13 14 15 10 9 8

Modbus/TCP bit address 16392 16393 16394 16395 16396 16397 16398 16399

Modbus/TCP word address 1024 Lower byte

Modbus output coil 9 10 11 12 13 14 15 16

Modbus hold register 40001 Lower byte

:

:

X-SEL DI 247 246 245 244 243 242 241 240

Modbus/TCP bit address 16624 16625 16626 16627 16628 16629 16630 16631

Modbus/TCP word address 1039 Upper byte

Modbus output coil 241 242 243 244 245 246 247 248

Modbus hold register 40016 Upper byte

X-SEL DI 255 254 253 252 251 250 249 248

Modbus/TCP bit address 16632 16633 16634 16635 16636 16637 16638 16639

Modbus/TCP word address 1039 Lower byte

Modbus output coil 249 250 251 252 253 254 255 256

Modbus hold register 40016 Lower byte

BIT7

(MSB)

6 5 4 3 2 1

(LSB)

Cannot be used

0

- 22 -

Page 29

4.5 Installation to a Modbus/TCP System

No special tools are required for operation of the X-SEL cont roller via Modbus/TCP on Ethernet.

Simply set the controller parameters, connect the Ethernet cable and turn on the power. The

Modbus/TCP server in the controller will be started, enabling remote I/O control.

The Ethernet port number of Modbus/TCP is fixed at “502.”

Modbus/TCP connection is esta blished by specifying IP address port 502 for the X-SEL controller via

an OPC (OLE for process control) server or other Modbus/TCP software.

To check whether the network setup of the controller is correct, use a “ping ” command (the command

for checking the status of communication on the IP level of TCP/IP using an MS-DOS prompt (or

command prompt in Windows NT/2000)) or similar command.

4.6 Installation to an EtherNet/IP System

EtherNet/IP is supported only by X-SEL controllers of P/Q types (main application version 1.05 or

later). Also note that to use EtherNet/IP, you need an interface board compatible with EtherNet/IP.

After assembling an interface board compatible with EtherNet/IP into the controller, set the controller

parameters, connect an Ethernet cable, and then turn on the power. The EtherNet/IP adapter of the

controller (equivalent to a slave) will start and the controller will be able to perform remote I/O control.

EtherNet/IP uses Ethernet port numbers 44818 and 2222.

You can establish EtherNet/IP connection by specifying the 44818 port corresponding to the IP

address of the X-SEL controller using the EtherNet/IP software.

Use the Ping command (a MS-DOS Prompt command that checks if TCP/IP communication is

enabled at the IP level), etc., to check if the network settings of the controller are appropriate.

- 23 -

Page 30

5. IAI Protocol B/TCP

This protocol uses TCP packets embedded with the message format of IAI protocol B for serial

communication. The controller supports the slaves under thi s protocol, re gardless of the connection

method (client or server). (The connected device always becomes the protocol master.)

5.1 Setup of Ethernet Environment

The X-SEL controller provides IP addresses and other network-definition areas in its I/O parameters

for control of the IAI protocol B/TCP operation.

To select the IAI protocol B/TCP function:

Set “I/O parameter No. 129: Network attribute 10, bits 4 to 7” to “1: Use TCP/IP message

communication.”

Then, set “I/O parameter No. 124: Network attribute 5, bits 0 to 3 (MANU mode) or bits 4 to 7 (AUTO

mode)” to “1: Client (Assign own port number automatically)” or “3: Server (S pecify own port numbe r).”

Set the necessary parameters according to the network environmen t before connecting to the network.

Establishing a connection without setting the parameters may disa ble normal communication to and

from other devices on the network.

- 24 -

Page 31

[I/O parameters]

No. Parameter name Setting Input range Remarks

124

Network attribute 5 (MANU

0H~FFFFFFFFH

mode)

1H or

3H

(AUTO

mode)

10H or

30H

Ethernet TCP/IP message communication attribute

Ethernet client/server type

0: Do not use

1: Client (Assign own port number automatically)

(2: Client (Specify own port number)

This setting is not recommended in view of

the associated device restrictions, such as a

forced-error detection if the port is opened

for approximately 10 minutes in a condition

where a close response cannot be confirmed

due to a power failure in the connected

device, etc.)

3: Server (Specify own port number)

* Note: Number of clients that can be

connected to one server-port channel

simultaneously = 1

Bits 0 to 3: IAI protocol B/TCP (MANU mode)

* PC software connection is enabled in the client

mode only.

Bits 4 to 7: IAI protocol B/TCP (AUTO mode)

* PC software connection is enabled in the client

mode only.

Bits 8 to 11: User-open channel 31

Bits 12 to 15: User-open channel 32

Bits 16 to 19: User-open channel 33

Bits 20 to 23: User-open channel 34

* IAI protocol B/TCP MANU/AUTO

The connection will be cut off briefly during

switching between the MANU and AUTO modes, if

the parameter settings of “own port number,”

“client/server type,” “IP address of connection

destination” and “port number of connection

destination” do not fully correspond between the

two modes.

…

…

…

…

…

Ethernet operation requirement

Bits 0 to 3: Remote I/O

0: Do not use

1: Use Modbus/TCP (EXCEPTION status

invalid)

129

Network attribute 10 10H 0H~FFFFFFFFH

2: Use Modbus/TCP (EXCEPTION status valid)

3: Use EtherNet/ IP (main application version

1.05 or later)

Bits 4 to 7: TCP/IP message communication

0: Do not use

1: Use

Bits 8 to 31: Not used

130

Own MAC address (H) 0030H

131

Own MAC address (L) 11H

132

Own IP address (H) 192 1~255 * Setting of “0” and “127” is prohibited.

133

Own IP address (MH) 168 0~255

134

Own IP address (ML) 0 0~255

135

Own IP address (L) 1 1~254 * Setting of “0” and “255” is prohibited.

136

Subnet mask (H) 255 0~255

137

Subnet mask (MH) 255 0~255

Reference value

(HEX)

Reference value

(HEX)

Only the lower two bytes are valid. (This parameter is

not settable.)

(This parameter is not settable.)

- 25 -

Page 32

138

Subnet mask (ML) 255 0~255

139

Subnet mask (L) 0 0~255

140

Default gateway (H) 0 0~255

141

Default gateway (MH) 0 0~255

142

Default gateway (ML) 0 0~255

143

Default gateway (L) 0 0~255

…

…

…

…

…

IAI protocol B/TCP: IP

address of connection

149

destination (MANU mode)

192 1~255 * Setting of “0” and “127” is prohibited.

(H)

IAI protocol B/TCP: IP

address of connection

150

destination (MANU mode)

168 0~255

(MH)

IAI protocol B/TCP: IP

address of connection

151

destination (MANU mode)

0 0~255

(ML)

IAI protocol B/TCP: IP

address of connection

152

destination (MANU mode)

100 1~254 * Setting of “0” and “255” is prohibited.

(L)

Mode setting in parameter No. 124:

IAI protocol B/TCP: Port

153

number of connection

destination (MANU mode)

64611 0~65535

* In the server mode “0” can be set.

0 = Ignore port number of connection destination

(Only the IP address is checked.)

* In the client mode “0” cannot be set.

IAI protocol B/TCP: IP

address of connection

154

destination (AUTO mode)

192 1~255 * Setting of “0” and “127” is prohibited.

(H)

IAI protocol B/TCP: IP

address of connection

155

destination (AUTO mode)

168 0~255

(MH)

IAI protocol B/TCP: IP

address of connection

156

destination (AUTO mode)

0 0~255

(ML)

IAI protocol B/TCP: IP

address of connection

157

destination (AUTO mode)

100 1~254

* Setting of “0” and “255” is prohibited.

(L)

Mode setting in parameter No. 124:

IAI protocol B/TCP: Port

158

number of connection

destination (AUTO mode)

64611 0~65535

* In the server mode “0” can be set.

0 = Ignore port number of connection destination

(Only the IP address is checked.)

* In the client mode “0” cannot be set.

(Note) 1. To connect the controller to IAI’s PC software, set the parameter to “1: Client (Assign own port number

automatically.”

2. IAI’s PC software will detect “Error No. ECF: Socket error (PC)” if the controller-side port is disabled due to

a mode change on the controller side, reception of an IAI protocol serial-communication message or other

reason while the controller is connected to the PC software. This does not indicate abnormal status.

3. The connection will be cut off briefly during switching between the MANU and AUTO modes under IAI

protocol B/TCP, if the parameter settings of “own port number,” “client/server type,” “IP address of

connection destination” and “port number of connection destination” do not fully correspond between the

two modes.

- 26 -

Page 33

4. One of the two ports will be used for connection, depending on the MANU/AUTO mode.

5. The port will be enabled at the following intervals:

When the initialization after power ON reset is complete

When no IAI protocol serial-communication message has been received for approximately five

seconds after the completion of controller initialization

6. The port will be disabled at the following intervals:

Upon reception of an IAI protocol serial-communication message (serial communication having

priority. If the PC software is connected via serial communication, Ethernet connection will be cut

off.)

Upon mode change

Upon software reset

7. If the controller is used as a client, a connection retry will be initiated within approximately two seconds

after the recognition of a connection failure (refused, timed out, failed, etc.).

8. For details on the message format, refer to the attached “X-SEL (Cartesian/IX SCARA) Serial

Communication Specification (Format B).”

[Example of operation check procedure when the controller is used as a server]

Set the port number for the host computer and utilize the telnet tool included with your windows operating

system to communicate to the host controller. Also, set the port on the X-SEL controller side to match by

setting I/O parameter #144 (MANU mode) or No. 159 (AUTO mode). Then perform data transfer in

accordance with the format defined in the Serial Communication in order to test communication.

The following is an example of a simple check using “telnet”:

“!992001234567890@@” + Enter = Send a “test call” Receive a response, “#99200123456789034”

CR/LF is appended at the end of the sending message by “telnet.”

Using “telnet” with “Local echo enabled” will make the operation easier.

- 27 -

Page 34

5.2 Ethernet Connection of X-SEL PC Software

5.2.1 Software Versions Supporting This Function

(1) PC software V2.1.0.0 or later (Japanese version)

V2.1.0.0E or later (English version)

5.2.2 Function

(1) Connection confirmation

a. Selecting the comm unication port

Select “Ethernet” in the port name list on the Connection Confirmation screen.

* Refer to (3) of 5.2.3, “Items to Note,” for details.

Figure 1

b. Entering the own port number

Selecting “Ethernet” will change the field label “Baud Rate (bps)” to “Port No.”

Figure 2

Enter the waiting port number of the PC software in this field.

The number should match the port number specified in I/O p a rameter No. 153 (M ANU mode) o r

No. 158 (AUTO mode).

* Enter a number between 1025 and 65535 not already used in anot her application.

- 28 -

Page 35

c. Selecting the controller

Entering the port number and clicking the [OK] button switches the display to the Select

Controller screen.

Figure 3

Each time a connection is established from a controller, the IP address of the connecting

controller is added to the list. Select the IP address of the controller with which you want to

communicate, and then click the [OK] button. Communication will be established with the

selected controller and the application will start in the online mode.

Clicking the [CANCEL] button will activate the offline mode. (Even after the application is st art ed

in the offline mode, you can still switch to the online mode through “reconnecti on.”)

If the checkbox “The controller connected will be chosen automatically next time” is selected,

the application will automatically establish connection with the controller that was conn ected

first.

* Check this option only when you are communicating with a single controller or using

peer-to-peer connection.

d. Changing the connection destination

If you want to switch between multiple controllers, the connecting controller can be changed via

the following procedure.

- 29 -

Page 36

(2) Connection destination change

Select “Controller (C)” “Request Release Pause (L)” from the menu.

* This menu item will be added only when connections have been established from two or more

controllers.

Figure 4

Select the IP address of the controller with which you want to communicate, and then click the [OK]

button. Communication will be established with the selected controller.

- 30 -

Page 37

5.2.3 Items to Note

(1) When connecting via Ethernet, the IP address parameter must be set via serial

connection beforehand in accordance with the applicable environment.

(2) If a firewall (including the firewall function of virus protection software) is installed in the

PC, etc., the port block must be canceled or the firewall function disabled before a

connection can be made.

(This is because the very purpose of firewall software is to block external connection to

the protecting device.)

(3) Ethernet connection is enabled only when the checkbox “The connection to the CTL by

Ethernet is supported (for expansion)” (see Fig. 5), as provided on the “Setting” tab

accessed by selecting “Tools” “Environment Setup” from the menu, is selected (PC

software V2.1.0.4 or later).

Figure 5

- 31 -

Page 38

6. Transmission by SEL Program

Four channels of ASCII-based, delimiter-controlled communication (CH31 through CH34) are supported,

using a set of transmission commands in a system roughly equivalent to that used in the X-SEL controller’s

serial communication.

(The specification of each SEL command may vary slightly from the corresponding command specification

in serial communication, so exercise due caution.)

6.1 Setup of Ethernet Environment

To select the transmission function by SEL program:

Set “I/O parameter No. 129: Network attribute 10, bits 4 to 7” to “1: Use TCP/IP message

communication.”

Then, set “I/O parameter No. 124: Network attribute 5, bit s 8 to 11 (CH31), bits 12 to 15 (CH32), bits

16 to 19 (CH33) or bits 20 to 23 (CH34)” to “1: Client (Assign own

port number automatically)” or “3: Server (Specify own port

number).”

* Data transmission is performed by SEL program based on the specifications of the following items:

CH (channel) selection

IP address of connection destination

Port number

For programming details, refer to 6.2, “Ethernet Option SEL Commands.”

- 32 -

Page 39

[I/O parameters]

No.

124

129

130

131

132

Parameter name Setting Input range Remarks

Network attribute 5

…

Network attribute 10

Own MAC address (H)

Own MAC address (L)

Own IP address (H)

…

00***100H

(Channel 31)

00**1*00H

(Channel 32)

00*1**00H

(Channel 33)

001***00H

(Channel 34)

Or,

00***300H

(Channel 31)

00**3*00H

(Channel 32)

00*3**00H

(Channel 33)

003***00H

(Channel 34)

0H~FFFFFFFFH

…

10H 0H~FFFFFFFFH

0030H

11H

192 1~255

Reference value

Reference value

…

(HEX)

(HEX)

Ethernet TCP/IP message communication attribute

Ethernet client/server type

0: Do not use

1: Client (Assign own port number automatically)

(2: Client (Specify own port number)

This setting is not recommended in view of

the associated device restrictions, such as a

forced-error detection if the port is opened

for approximately 10 minutes in a condition

where a close response cannot be confirmed

due to a power failure in the connected

device, etc.)

3: Server (Specify own port number)

* Note: Number of clients that can be

connected to one server-port channel

simultaneously = 1

Bits 0 to 3: IAI protocol B/TCP (MANU mode)

* PC software connection is enabled in the client

mode only.

Bits 4 to 7: IAI protocol B/TCP (AUTO mode)

* PC software connection is enabled in the client

mode only.

Bits 8 to 11: User-open channel 31

Bits 12 to 15: User-open channel 32

Bits 16 to 19: User-open channel 33

Bits 20 to 23: User-open channel 34

* IAI protocol B/TCP MANU/AUTO

The connection will be cut off briefly during

switching between the MANU and AUTO modes, if

the parameter settings of “own port number,”

“client/server type,” “IP address of connection

destination” and “port number of connection

destination” do not fully correspond between the

two modes.

…

Ethernet operation requirement

Bits 0 to 3: Remote I/O

0: Do not use

1: Use Modbus/TCP (EXCEPTION status

invalid)

2: Use Modbus/TCP (EXCEPTION status valid)

3: Use EtherNet/ IP (main application version

1.05 or later)

Bits 4 to 7: TCP/IP message communication

0: Do not use

1: Use

Bits 8 to 31: Not used

Only the lower two bytes are valid. (This parameter

is not settable.)

(This parameter is not settable.)

* Setting of “0” and “127” is prohibited.

133

Own IP address (MH)

168 0~255

- 33 -

Page 40

134

Own IP address (ML)

0 0~255

135

Own IP address (L)

136

Subnet mask (H) 255 0~255

137

Subnet mask (MH) 255 0~255

138

Subnet mask (ML) 255 0~255

139

Subnet mask (L) 0 0~255

140

Default gateway (H) 0 0~255

141

Default gateway (MH) 0 0~255

142

Default gateway (ML) 0 0~255

143

Default gateway (L) 0 0~255

1 1~254

* Setting of “0” and “255” is prohibited.

- 34 -

Page 41

6.2 Ethernet Option SEL Commands

OPEN (Channel open) [* When the Ethernet option is used]

[Function] Open the channel specified in operand 1.

(Note 1) Channel Nos. 31 through 34 can be specified in operand 1 with the Ethernet option.

Up to four channels can be opened simultaneously.

(Note 2) Be sure to design the program in such a way that the normal completion or abnormal completion

(Note 3) T o change the connection destination, the channel must be closed once using a CLOS command.

Executing an OPEN command for a given channel while the channel is already open will

(Note 4) To avoid occurrence of system trouble, it is recommended that the system be built by ensuring a

(Note 5) When the controller is used as a server, the number of clients that can be connected to one

(Note 6) If a firewall (including the firewall function of virus protection software) is installed in the PC, etc.,

(This is because the very purpose of firewall software is to block external connection to the

(Note 7) The client/server mode is determined upon reset via “I/O parameter No. 124: Network attrib ute 5,

* The “Ethernet Option SEL Commands” are supported in the following versions:

X-SEL (Cartesian) Main Application V0.79 or later

X-SEL (IX SCARA) Main Application V0.29 or later

X-SEL PC Software Ver. 2.1.1.0 or later

Extension

condition

(LD, A, O, AB, OB)

Input condition

(I/O, flag)

Command,

declaration

Optional Optional OPEN

Command, declaration

Operand 1 Operand 2

Channel

number

Transmission via the specified channel will hereafter be enabled.

Before executing this command, the end character must be set with an SCHA command and the

IP address/port address of connection destinatio n with an IPCN command.

of the return code will always be confirmed before moving on to the next process.

It may take approximately four seconds to reopen the closed channel.

generate a “B1B: Ethernet socket open-without-close error.”

sufficient period so that the port opening order of the connected device and controller will satisfy

“server port open client port open.”

(1) Server open

Opens the port and waits for a

connection request from the client

(specified with an IPCN command).

(HOST A)

OPEN 33

Connection request

(2) Client open

Opens the port and issues a connection

request to the server (specified with an

IPCN command).

(HOST B)

OPEN 31

server-port channel simultaneously is 1.

the port block must be canceled or the firewall function disabled before a connection can be

made.

protecting device.)

bits 8 to 11 (CH31), bits 12 to 15 (CH32), bits 16 to 19 (CH33) or bits 20 to 23 (CH34).” The

controller cannot be used during dynamic switching between the client and server modes.

Output

(Output, flag)

Prohibited CC

- 35 -

Page 42

(Note 8) The diagram below explains the mechanism of “socket interface.”

* Bear in mind that “socket,” “connect,” “write,” “read,” “close,” “bind,” “listen” and “accept” are not

SEL language commands (SEL commands).

(1) Client open

(OPEN command)

socket

connect

Error?

N

write

read

close

Y

Generation of socket

Establishment of connection

Decide whether to

close

Data transmission

End of socket communication

execute retry or perform

error handling in

accordance with the

system.

(2) Server open

(OPEN command)

socket

bind

listen

accept

Error?

N

read

write

close

Y

Generation of socket

Waiting for connection request

Acceptance of connection

Decide whether to

close

Data transmission

End of socket communication

execute retry or perform

error handling in

accordance with the

system.

Error handling

Retry

Error handling

- 36 -

Page 43

[Example]

LET 90 192 IP address of connection destination (H) = 192

LET 91 168 IP address of connection destination (M H) = 168

LET 92 72 IP address of connection destination (M L) = 72

LET 93 101 IP address of connection destination (L) = 101

LET 94 64514 Port number of connection destination = 64514

IPCN 31 90 Declare the IP address/port number storage area for the

connection destination of channel 31 = Local integer

variable between 90 and 94.

SCHA 10 Specify 10 (= LF) as the end character.

OPEN 31 990 Open channel 31.

TRAN 1 99 Store the return code in variable 1.

N 990 GOTO 15 OPEN failed Proceed to error handling or retry

process after closing.

Common return codes of OPEN, READ and WRIT commands [* When the Ethernet option is used]

The return code is stored in the local variable specified in “Other parameter No. 24.” The default setting is

variable 99.

0: Normal completion

1: Timeout

[Specification procedure of timeout value]

OPEN:

Client mode

I/O parameter No. 127: Network attribute 8, bits 0 to 7

(Use the default setting if it poses no particular problem.)

Server mode

I/O parameter No. 128: Network attribute 9, bits 0 to 15

(Use the default setting if it poses no particular problem.)

READ: TMRD command specification

WRIT: I/O parameter No. 127: Network attribute 8, bits 16 to 23

(Use the default setting if it poses no particular problem.)

2: Cancel timer (The wait status is canceled with a TIMC command.)

3, 4: (Undefined)

5: WAIT factor error (program aborting error)

(This error cannot be recognized through SEL commands.)

6: End task (program-end request, etc.)

(This error cannot be recognized through SEL commands.)

7~12: (Undefined)

- 37 -

Page 44

50~: Device error information

50 Invalid Message ID

51 Invalid Message Type

52 Invalid Command

53 Invalid Data Size

54 Invalid Frame Count

55 Invalid Frame Number

56 Invalid Offset

57 Invalid Address

58 Invalid Response

59 Flash Config Error

60~64 Invalid To Be Defined 1-7

101 Invalid IP-address or Subnet mask

102 Invalid socket type

103 No free socket

104 Invalid socket

105 Not connected

106 Command failed

107 Invalid data size

108 Invalid fragment type

109 Fragment error

110 Invalid timeout time

111 Can't send more

112~115 (reserved)

116 Command aborted

117 Too many registered objects

118 Object already registered

119 Deregistering invalid object

121 Unsupported Command

122 (reserved)

123 No timeout

124 Invalid port number

125 Duplicate port number

126 (reserved)

127 Mapping Failed

128 Reset notification unsupported

- 38 -

Page 45

CLOS (Channel close) [* When the Ethernet option is used]

Extension

condition

(LD, A, O, AB, OB)

Input condition

(I/O, flag)

Command,

declaration

Optional Optional CLOS

Command, declaration

Operand 1 Operand 2

Channel

number

Output

(Output, flag)

Prohibited CC

[Function] Close the channel specified in operand 1.

Transmission via the specified channel will hereafter be disabled.

(Note 1) Channel Nos. 31 through 34 can be specified in operand 1 with the Ethernet option.

[Example]

CLOS 31 Close channel 31.

LET 1 32 Assign 32 to variable 1.

CLOS *1 Close the content of variable 1 (channel 32).

- 39 -

Page 46

READ (Read) [* When the Ethernet option is used]

Extension

condition

(LD, A, O, AB, OB)

Input condition

(I/O, flag)

Command,

declaration

Optional Optional READ

Command, declaration

Operand 1 Operand 2

Channel

number

Column

number

Output

(Output, flag)

CC

[Function] Read a character string from the channe l spe cified in operand 1 to the column specified in

operand 2.

The reading will end upon reaching the character specified with an SCHA command.

Either a local or global column may be specified.

(Note 1) Channel Nos. 31 through 34 can be specified in operand 1 with the Ethernet option.

(Note 2) Be sure to design the program in such a way that the normal completion or abnormal completion

of the return code will always be confirmed before moving on to the next process.

[Example]

SCHA 10 Specify 10 (= LF) as the end character.

READ 31 5 991 Read a character string from channel 31 to column 5

until LF is reached.

TRAN 2 99 Store the return code in variable 2.

N 991 GOTO 16 READ failed Proceed to error handling or retry

process after closing.

Common return codes of OPEN, READ and WRIT commands [* When the Ethernet option is used]

The return code is stored in the local variable specified in “Other parameter No. 24.” The default setting is

variable 99. For details on the return code, refer to the page describing the “OPEN” command.

- 40 -

Page 47

WRIT (Write) [* When the Ethernet option is used]

Extension

condition

(LD, A, O, AB, OB)

Input condition

(I/O, flag)

Command,

declaration

Optional Optional WRIT

Command, declaration

Operand 1 Operand 2

Channel

number

Column

number

Output

(Output, flag)

CC

[Function] Write a character string from the column specified in operand 2 to the channel specified in

operand 1.

The writing will end when the character specified with an SCHA command is written.

Either a local or global column may be specified.

(Note 1) Channel Nos. 31 through 34 can be specified in operand 1 with the Ethernet option.

(Note 2) Be sure to design the program in such a way that the normal completion or abnormal completion

of the return code will always be confirmed before moving on to the next process.

[Example]

SCHA 10 Specify 10 (= LF) as the end character.

WRIT 31 5 992 Write a character string from column 5 to channel 31 until

LF is written.

TRAN 3 99 Store the return code in variable 3.

N 992 GOTO 17 WRIT failed Proceed to error handling or retry

process after closing.

Common return codes of OPEN, READ and WRIT commands [* When the Ethernet option is used]

The return code is stored in the local variable specified in “Other parameter No. 24.” The default setting is

variable 99. For details on the return code, refer to the page describing the “OPEN” command.

- 41 -

Page 48

IPCN (IP address/port number settings of connection destination) [* When the Ethernet option is used]

Extension

condition

(LD, A, O, AB, OB)

Input condition

(I/O, flag)

Command,

declaration

Optional Optional IPCN

Command, declaration

Operand 1 Operand 2

Channel

Integer variable

number

number

Output

(Output, flag)

CP

[Function] Set the storage areas of IP address/port number for the connection destination of the user-open

TCP/IP channel. The connection destination inform ation stored in the five consecutive integer

variables, beginning with the integer variable number specified in operand 2, is defined as the

connection destination of the user-open TCP/IP channel specified in operand 1.

This command must always be executed before an OPEN command.

Variable number

specified in operand 2

Variable

number

n

n + 1

n + 2

n + 3

n + 4

Variable that stores IP address of connection destination (H)

Variable that stores IP address of connection destination (MH)

Variable that stores IP address of connection destination (ML)

Variable that stores IP address of connection destination (L)

Variable that stores port number of connection destination

(Note 1) Channel Nos. 31 through 34 can be specified in operand 1 with the Ethernet option.

(Note 2) Executing this command while a channel or channels are already open will specify settings for the

next OPEN command.

[Example]

LET 90 192 IP address of connection destination (H) = 192

LET 91 168 IP address of connection destination (M H) = 168

LET 92 72 IP address of connection destination (M L) = 72

LET 93 101 IP address of connection destination (L) = 101

LET 94 64514 Port number of connection destination = 64514

IPCN 31 90 Declare the IP address/port number storage area for the

connection destination of channel 31 = Local integer

variable between 90 and 94.

In the above example, IP address 192.168.72.101 and

port number 64514 are set as the connection destination

of user-open TCP/IP channel No. 31.

- 42 -

Page 49

7. Common Items to Note (Be Sure to Read This Section.)