Page 1

INTELLIGENT ACTUA TOR

Super SEL Controller

(Type E & G)

Operating Manual

Super SEL Type E

Intelligent Actuator Inc.

Page 2

This publication was written to assist you in better understanding this part of your IA system. If you require further assistance, please

contact IA Technical Support. For Central and East Coast Time Zones, please call our Itasca, IL office at 1-800-944-0333 or F AX 630467-9912. For Mountain and Pacific Time Zones, please call our Torrance, CA office at 1-800-736-1712 or FAX 310-891-0815; Monday

thru Friday from 8:00 AM to 5:00PM.

Intelligent Actuator, Inc.

U.S. Headquarters

2690 W. 237th Street

Torrance, CA 90501

310-891-6015 / 310-891-0815 fax

Intelligent Actuator, Inc.

Midwest Regional Office

1261 Hamilton Parkway

Itasca, IL 60143

630-467-9900 / 630-467-9912 fax

www .intelligentactuator.com

© December 1996 Intelligent Actuator, Inc. All rights reserved.

No portion of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechnical, recording, or otherwise, without the prior written permission of Intelligent Actuator, Inc.

Disclaimer

The information and technical data contained herein are subject to change without notice. Intelligent Actuator, Inc. assumes no responsibility

for any errors or omissions regarding the accuracy of the information contained in this publication.

Page 3

Foreword

Thank you very much for purchasing the IA Super SEL Controller E·G Type. Without knowing beforehand how to correctly use

or operate the controller, not only will the user be unable to take full advantage of all the functions built into this product but he

might inadvertently cause damage to the controller or shorten its life. Please read this manual carefully to acquire an understanding of the proper method of handling and operating the controller. Keep the manual handy so that you can refer to the

appropriate sections as the need arises.

Your Super SEL Controller E·G Type has a built-in 32 bit RISC (Reduced Instruction Set Computer) CPU and uses SEL

language developed exclusively by IAI for programming. The Super SEL is a highly advanced, new generation of controller

that eliminates the need for a PLC, allows you to do multi-tasking (parallel processing), and allows you to network the controllers with the SEL NET option.

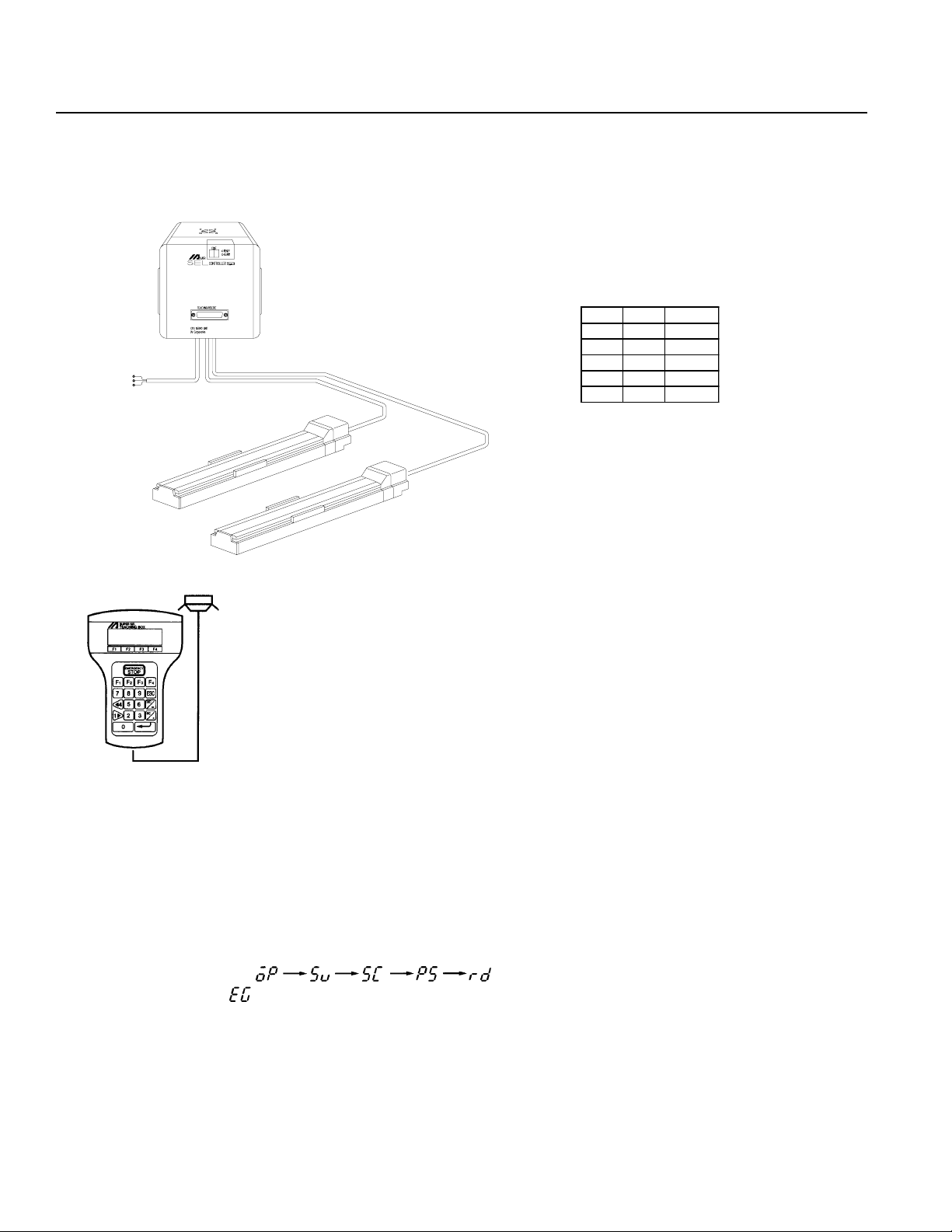

As with our other Super SEL controllers, the Super SEL E·G Type can be used with all IAI actuators. Type E is designed for

single axis control and Type G for multiple axes control. Please use the special cable provided to connect the actuator with the

controller.

*All precautions have been taken to ensure the accuracy of the contents of this manual. However, if you become aware of any

inaccuracies or discrepancies, please contact your IAI sales representative or technical service department.

Page 1

Page 4

Table of Contents

Foreword ................................................................................................................................................................. 1

Before You Begin...................................................................................................................................................... 4

Chapter 1 Setting Up ....................................................................................................................................... 5~63

Part 1 Safety Precautions ...............................................................................................................................................5

Part 2 Warranty Period and Scope.................................................................................................................................6

Part 3 Installation Environment and Noise Measures ..................................................................................................7

Part 4 Cabling Precautions ..........................................................................................................................................12

Part 5 Part Names and Functions ................................................................................................................................14

Part 6 Specifications ....................................................................................................................................................17

1 AC..................................................................................................................................................................17

2 DC..................................................................................................................................................................21

3 External I/O ................................................................................................................................................... 25

4 Servo ..............................................................................................................................................................26

5 Precautions When Using Emergency Stop ...................................................................................................27

6 Restarting the Controller After an Emergency Stop.....................................................................................27

Part 7 System Setup .....................................................................................................................................................28

1 Connecting the IA Controller and Actuator .................................................................................................28

2 Interface List..................................................................................................................................................29

3 I/O Wiring Diagram ......................................................................................................................................30

4 Teaching/RS232C Connector ........................................................................................................................ 33

5 Connector Pin Assignment ...........................................................................................................................34

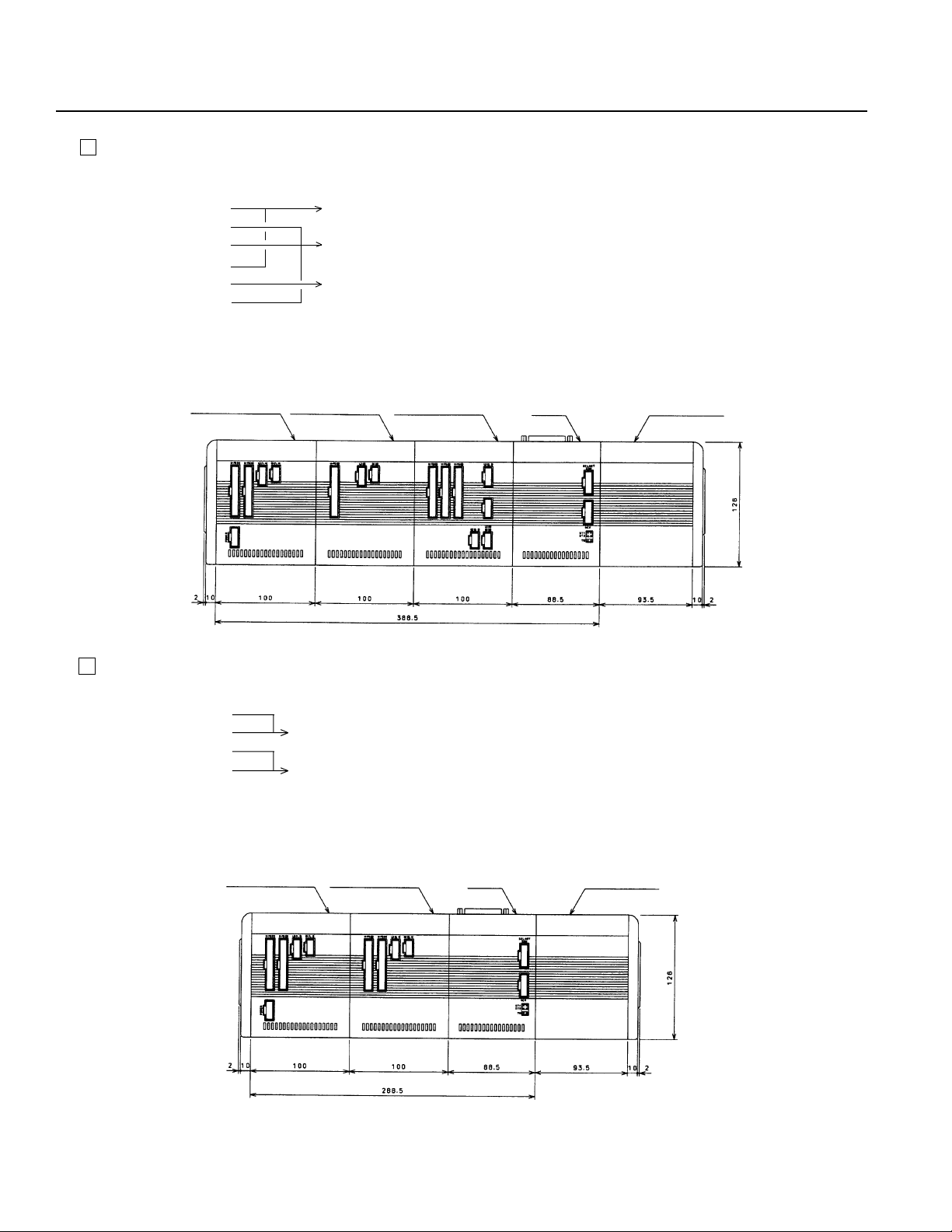

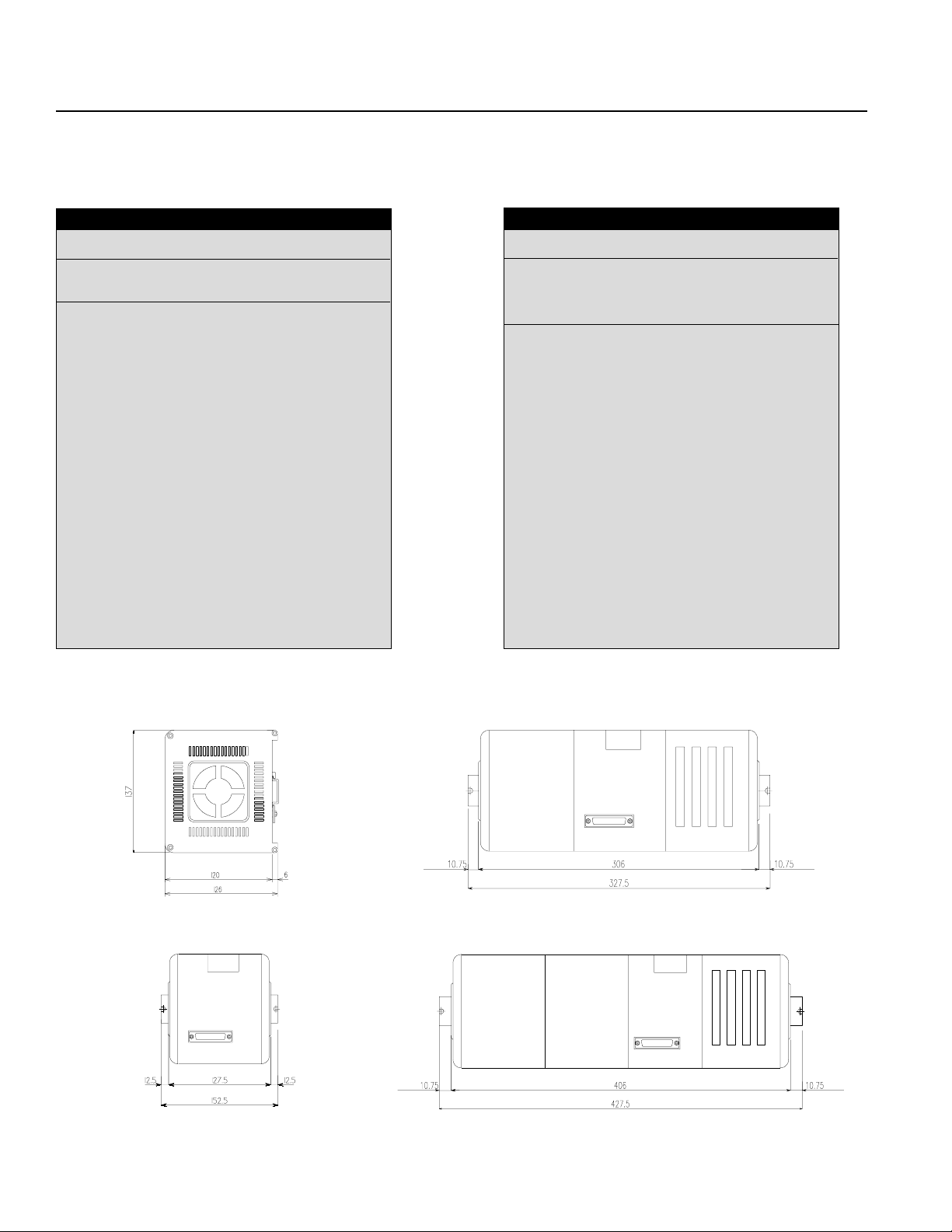

6 Controller Dimensions ..................................................................................................................................49

7 Unit Configurations and Limitations ............................................................................................................52

8 Type G (AC) Unit Configurations.................................................................................................................56

9 12-slot Expansion Unit .................................................................................................................................. 61

10 Bleeder Resistor .............................................................................................................................................62

Part 8 Maintenance ......................................................................................................................................................63

Chapter 2 Operation ......................................................................................................................................64~93

Part 1 Basics in Operating Your Super SEL Controller .............................................................................................64

Part 2 Teaching Pendant Operation ............................................................................................................................66

Part 3 System Operation .............................................................................................................................................. 91

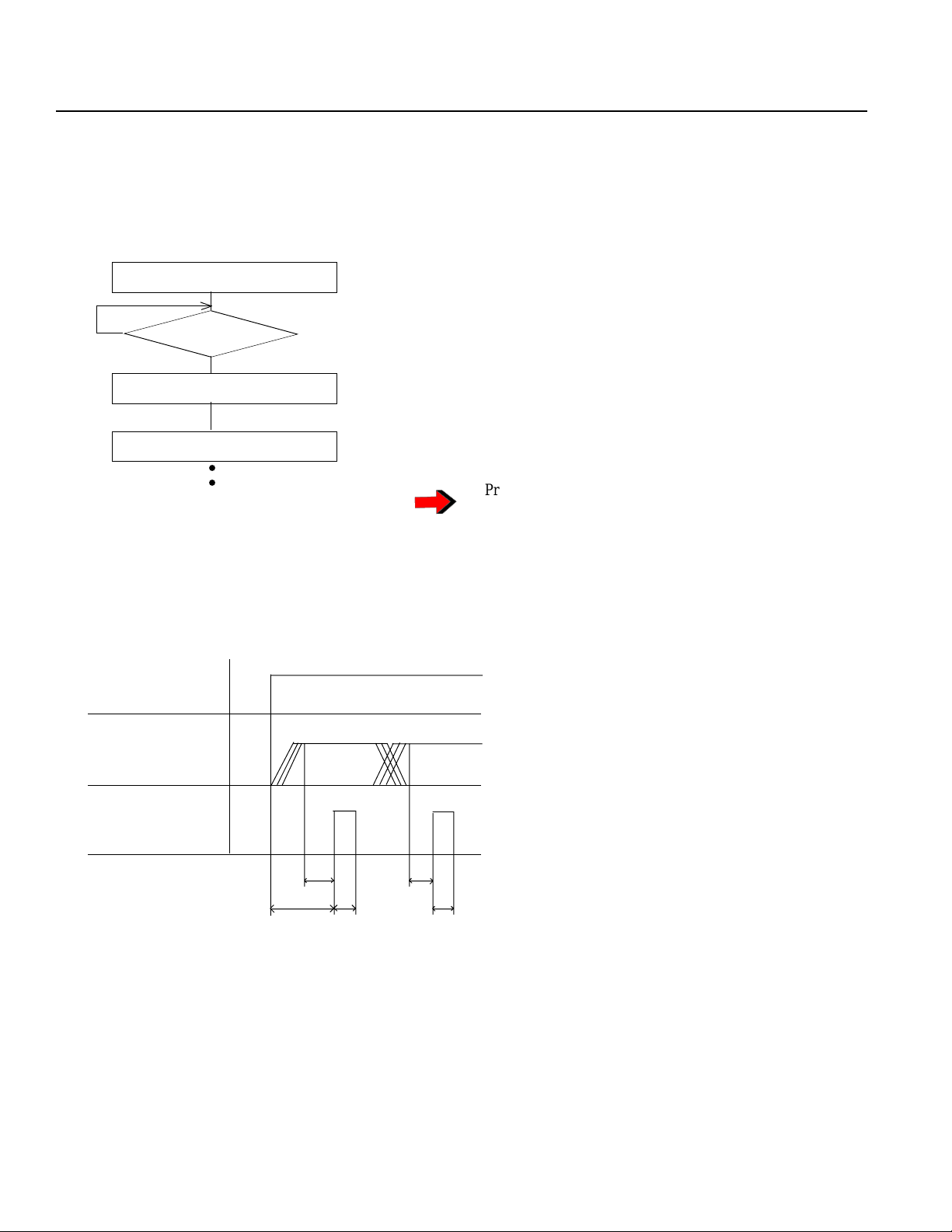

Chapter 3 Multi-tasking ............................................................................................................................. 94~105

Part 1 Real-time Multi-tasking ....................................................................................................................................94

1 Super SEL Programming Language .............................................................................................................94

2 Multi-Tasking ................................................................................................................................................ 95

3 Difference Between the Super SEL and a PLC.............................................................................................96

4 Emergency Stop Release ...............................................................................................................................97

5 Program Switching ........................................................................................................................................ 98

Part 2 Screwdriving Robot System .............................................................................................................................. 99

1 Components Used..........................................................................................................................................99

2 Operation .......................................................................................................................................................99

3 Screwdriving System Illustration ..................................................................................................................99

4 Hardware .....................................................................................................................................................100

5 Software .......................................................................................................................................................102

Page 2

Page 5

Table of Contents

Part 3 Multi-tasking Programming Tips ...................................................................................................................104

1 Inefficient Configuration.............................................................................................................................104

2 Most Efficient Configuration ......................................................................................................................105

Chapter 4 Programming .......................................................................................................................... 106~199

Part 1 Super SEL Language ......................................................................................................................................106

1 Numerals and Symbols................................................................................................................................106

2 I/O Ports....................................................................................................................................................... 107

3 Flags.............................................................................................................................................................108

4 Variable Register ......................................................................................................................................... 109

5 Tags.............................................................................................................................................................. 112

6 Subroutine.................................................................................................................................................... 113

7 Axis Designation .........................................................................................................................................114

Part 2 Super SEL Language Structure ......................................................................................................................116

1 Position Program .........................................................................................................................................116

2 Application Program ................................................................................................................................... 117

Part 3 Standard Commands .......................................................................................................................................119

1 Command Table ........................................................................................................................................... 119

2 Commands ...................................................................................................................................................121

Part 4 Expansion Commands ....................................................................................................................................162

1 Command Table ........................................................................................................................................... 162

2 Commands ...................................................................................................................................................163

Part 5 Parameter List .................................................................................................................................................185

Part 6 Application Program Examples......................................................................................................................188

1 Movement using Point Move Command .................................................................................................... 188

2 Palletizing Operation ..................................................................................................................................191

3 Circular Movement Command ....................................................................................................................194

4 Path Movement Command..........................................................................................................................195

5 BCD Code Signals Input and Output..........................................................................................................196

Chapter 5 Options ..................................................................................................................................... 200~236

1 Expansion I/O Card ...............................................................................................................................................200

2 High Speed Input Unit ...........................................................................................................................................201

3 SEL NET 2-Channel RS232C Unit .......................................................................................................................207

4 Flash Memory Card Unit .......................................................................................................................................230

5 PC Interface Software.............................................................................................................................................235

6 Optional I/O Expansion Module............................................................................................................................ 236

*Supplement ................................................................................................................................................ 237~254

1 Super SEL Controller 7 Segment Display .............................................................................................................237

2 Power Required by the Super SEL Controller .......................................................................................................238

3 Brake Specifications (Option)................................................................................................................................239

4 Heat Dissipation .....................................................................................................................................................243

5 I/O DC24V Power Supply......................................................................................................................................245

6 Emergency Stop......................................................................................................................................................247

7 Error Code List....................................................................................................................................................... 248

8 What to Do When an Error Code Occurs ..............................................................................................................249

Index ............................................................................................................................................................ 255~257

Page 3

Page 6

Before You Begin

Differences between the Super SEL Controller Type E/G and Type A/B

(Be sure to read this before you begin)

1. There is no built-in DC24V power supply for the I/O in the Super SEL Controller Type E/G. The DC24V power must be

supplied externally. Connect +24V to I/O connector Pin 1A, and 0V to Pin 25B. (Refer to "Supplement 5. I/O DC24V power

Supply" for more details.)

2. For the Super SEL Controller Type E·G, the Emergency Stop is normally closed. To release the Emergency Stop, Pin 2B and

0V must be short-circuited. To release the Emer gency Stop for testing, short-circuit the jumper post (ST1) placed at the bottom

of the controller CPU UNIT or CPU SERVO UNIT with a jumper pin. Even in this case, the Emergency Stop function from

the teaching pendant is still effective. (Refer to Supplement 6. Emergency Stop)

Note: After testing, please make sure to take the jumper pin out so that the Emergency Stop operates externally.

3. The Super SEL Type E·G Controllers are designed to be mounted inside of a control panel. For cooling, the heat sink method

or forced air current method is recommended. (Refer to Supplement 4. Heat Dissipation)

! A Word of Caution

Please read this manual carefully to operate the controller properly.

You are not allowed to use or reproduce this manual or any portion thereof without permission.

We cannot accept any responsibility for possible damage resulting from the use of this manual.

We reserve the right to change the information contained in this manual without prior notice.

! Emergency Procedures

If hazardous conditions arise while using the controller, immediately turn OFF all power switches for the controller and any

devices connected to it, or pull all the power plugs from the electric outlet. ("Hazardous condition" refers to excessive heat,

smoke or flames coming from the controller or any conditions which might lead to fire or cause damage to the controller.)

Page 4

Page 7

Chapter 1. Setting Up

Part 1 Safety Precautions

The IA Super SEL Controller Type E was designed to control any type single axis IAI actuator and Type G was designed to

control any type actuator in assembly configurations using a maximum of 8 axes or integrated with other peripheral devices. It

is capable of controlling everything from a simple single axis system to large scale FA (factory automation) system. As systems

become more complicated, the possibility of incorrect operation or accidents arising from carelessness also increases. Please

take sufficient care when operating your system.

Please follow the following safety precautions when operating your IA system:

(1) Any operation not specifically addressed in this manual should not be attempted. If you have any questions, please

contact your IA sales representative or contact IA technical support at: 1-800-736-1712.

(2) Use only IA cables when connecting IA actuators and controllers. IA cables are matched for use with IA actuators and

are specially designed to withstand repeated bending.

(3) Stand clear of your IA system when operating or preparing to operate. Surround your IA system with safety partitions

if there is any possibility that someone may become injured by an operating IA system.

(4) Before assembling, adjusting, or performing maintenance on your IA system, please make sure that people around you

are aware that the system is not to be powered up or turned on. You may want to disconnect the power cable completely, keep the power cable close to the operator, or use a safety plug to ensure that the power cable will not be

plugged in inadvertently.

(5) When more than one person is working on your IA system, use signs to inform everyone of the operating status of the

equipment. Make sure that everyone stands clear prior to operation. Operate your system only after you are sure that

everyone knows that you are initiating system start-up and that everyone is clear of the system.

(6) In situations where the cables must be lengthened, be sure to double check all connections before powering up your IA

system.

Page 5

Page 8

Chapter 1. Setting Up

Part 2 Warranty Period and Scope

The Super SEL controller undergoes stringent testing before it is shipped from our factory. IAI provides the following warranty.

1. Warranty Period

The warranty period is 12 months from the date the unit is shipped to the customer.

2. Scope of Warranty

If within the period specified above, a breakdown occurs while operating the controller under normal conditions and is

clearly the responsibility of the manufacturer, IAI will repair the unit at no cost. However, the following items are not

covered by this warranty.

•Faded paint or other changes that occur naturally over time.

•Consumable components that wear out with use (battery, etc.).

•Unit seems to be noisy or similar impressions that do not affect machinery performance.

•Damage resulting from improper handling or use.

•Damage resulting from user error or failure to perform proper maintenance.

•Any alterations not authorized by IAI or its representatives.

•Damage caused by fire and other natural disasters or accidents.

The warranty pertains to the purchased product itself and does not cover any loss that might arise from a breakdown of the

product. Any repairs will be done at our factory.

3. Service

The purchase price of the product does not include programming or expenses for sending technicians to the customer's site.

Even if the product is still under the warranty period, separate charges will be assessed for the following services.

•Assistance with unit installation or trial operation.

•Inspection and maintenance.

•Technical instruction and training for controller operation and wiring.

•Writing programs or technical instruction and training for programming.

•Any other services or work for which IAI normally assesses separate charges.

Page 6

Page 9

Chapter 1. Setting Up

Part 3 Installation Environment and Noise Measures

1. Installation Environment

(1) Do NOT block the air vents of your controller when installing your IA system.

(2) Your Super SEL Controller is NOT dust, water, or oil proof. Take steps to prevent foreign matter from getting into the

controller air vents. A void using your IA system in environments subject to contamination by dust, oil mist, or cutting oil.

(3) Do not expose your IA system to direct sunlight or place it near a heat source.

(4) Avoid placing your IA system under conditions of extreme tempreratures above 50

o

C (120oF) or below 0oC (32oF). The

area level of humidity should not be above 85%. Do NOT expose to corrosive or inflammable gas.

(5) Avoid external vibration, unnecessary impact, or excessive shocks to your IA system.

(6) Take steps to shield all cables and wires from electromagnetic noise.

2. Power Source

Make certain that an AC line voltage of 90 ~ 127V (Rated 100 ~ 120V) is maintained. If the power supply tends to fluctuate

substantially, use a constant-voltage transformer.

3. Electromagnetic Noise Supression

(1) Wiring and Power Supply

For grounding, please use a dedicated ground of Class 3 or better. The thickness of the cable should be

2.0~5.5mm

2

or larger.

IA Controller

Other

Devices

IA Controller

Other

Devices

Class 3 ground Correct

Avoid this method

Page 7

Page 10

Chapter 1. Setting Up

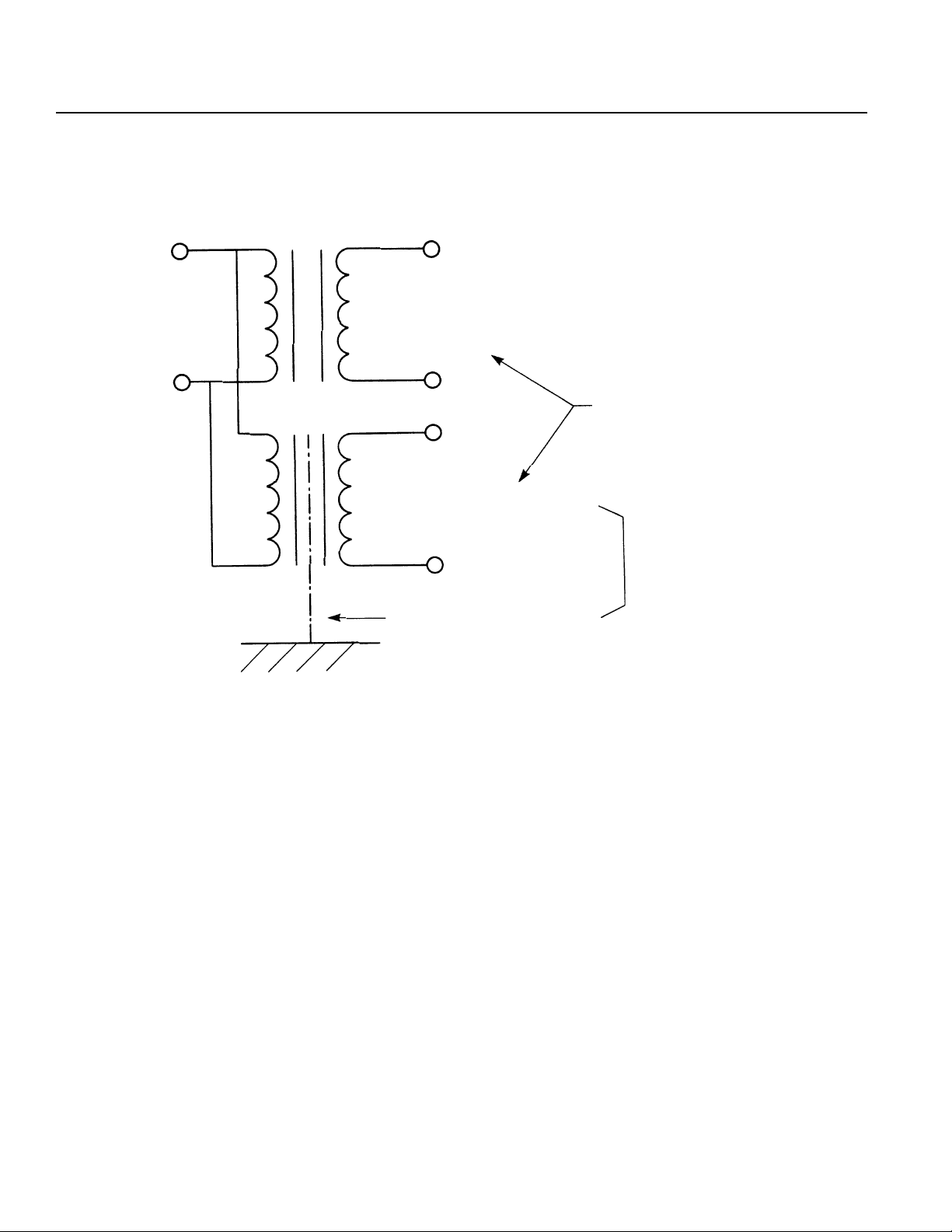

If you need to use a stepdown transformer to lower the power voltage from 240V to 117V, use a dedicated, insulated

transformer for the IA controller. (For further details, please contact your IA sales representative or technical support).

240V

117V

1 17V

Insulated transformer

with static shield

Other devices

IA Controller

Separate

Dedicated

transformer

Page 8

Page 11

Chapter 1. Setting Up

Please use a dedicated and insulated power transformer when the system has a 240V power source.

AC 117V

Main power

source

IA

power

Other

devices

Other

power

AC 240V

Main power

source

IA

power

240V 240V

117V

devices

Other

power

1 17V

1 17V

Main

circuit

240V

devices

IA Controller

Wiring Notes

1. To reduce noise problems, the AC117V and the DC24V external power cable should be a twisted pair.

2. Isolate the SEL cables from the power line.

3. For DC motors, isolate the encoder cable from the motor cable.

4. For AC motors, the motor and encoder cables are partially wired together but when the length of the cable

extends more than 5m, please wire them separately.

5. Consult with IAI if you need to extend the motor and encoder cables beyond the length that comes with the

controller.

IA Controller

Page 9

Page 12

Chapter 1. Setting Up

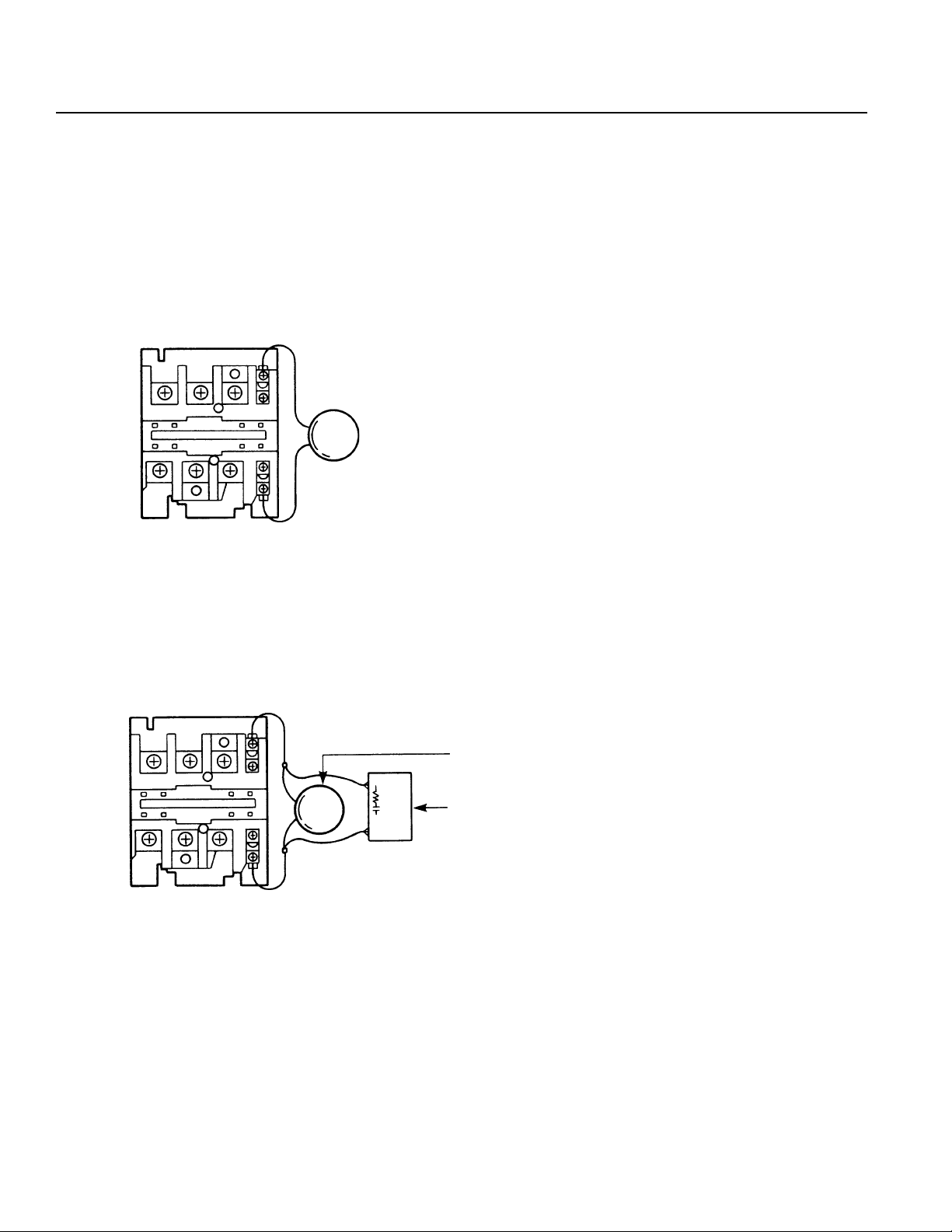

(2) Noise Source and Noise Suppression

When using electrical components such as electromagnets, solenoids, or relays which create electromagnetic noise,

some type of noise supression device should be used.

AC solenoid valve · magnetic switch · relay

• Install a surge absorber parallel to the reactance load (solenoid and relay coils).

*Note* Use the shortest possible wiring between the surge absorber

and the noise-creating device. Use of excessively long wiring will decrease the performance of the surge absorber.

• The most effective method is to install a surge absorber and surge killer in parallel to the reactance load (solenoid

and relay coils). This will reduce noise in a wide band of frequencies.

Surge Absorber (Metal Oxide Varistor or Transzorb).

Surge Killer (Resistor Capacitor Snubber)

Page 10

Page 13

Chapter 1. Setting Up

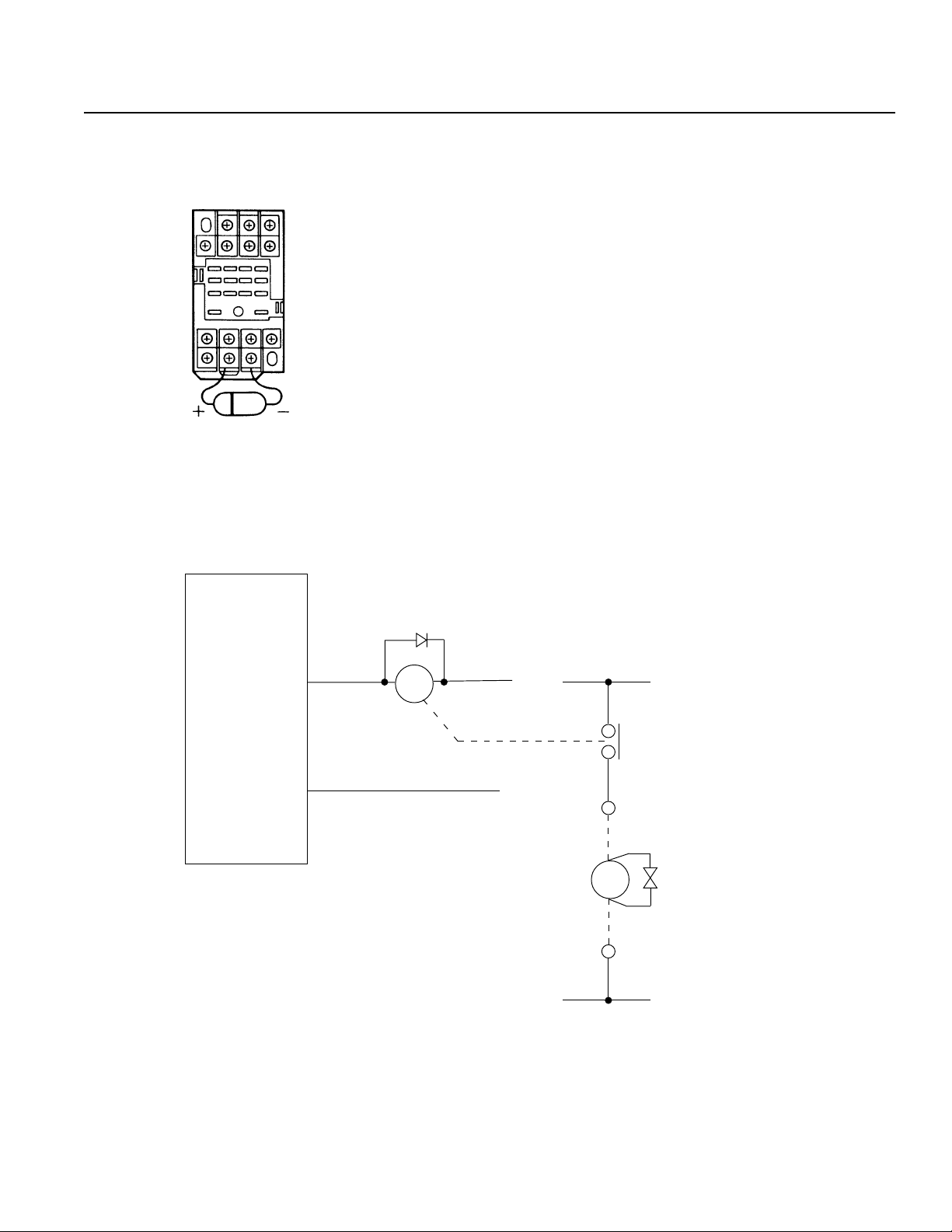

DC solenoid valve · magnetic switch · relay

• Install a diode parallel with a reactive/inductive load.

Circuit Example

• Select a diode with the proper voltage rating. The voltage rating is

determined by the loading capacity of the system.

• When installing the diode, pay careful attention to the polarity of the

diode. A diode installed in reverse polarity could damage your IA

System's internal circuitry.

• If the Controller output will be driving a 24V relay or a 120V solenoid valve, the diode must be installed to reduce any noise made by

these devices.

IA Super SEL

Controller

OUT

COM

MY2

DC24V

CR

24V

0V

AC 117V

CR

SOL

0V

Solenoid Valve

ENB221D-14A

Page 11

Page 14

Chapter 1. Setting Up

Part 4 Cabling Precautions

When using the IA actuator and controller to build an application system, it is important to position and lay out the cable correctly.

If this is not done, the cable may snap or have a faulty connection that could lead to a variety of problems which in turn could cause

the actuator to run out of control. Below, we explain the things not to do to ensure that the cables are connected in the correct

fashion.

Ten “Do’s and Don’ts” When Laying Out Cable (Please make sure to observe these rules!)

1 Make sure there is no excessive bending at one spot.

Steel band

(piano wire)

Bundle loosely

2 Do not twist or crease the cable. 3 Do not stretch the cable too tautly.

4 Do not exert rotational force at a single spot on the cable.

Use a

spiral cord

6 Do not cut, dent or let the cable get caught in something.

5 When affixing the cable, do not clamp it too tightly.

Do not use spiral tubing on a section

of the cable that bends frequently.

Page 12

Page 15

Chapter 1. Setting Up

7 If placing cable in a cableveyor or flexible tube, make sure it does not twist around. Also, make sure the cables have some

freedom of movement and are not bunched up (cable should not project out at bending points).

8 The amount of cable placed inside a cableveyor should

9

Do not mix the signal line with a high voltage circuit.

be about 60% of the space capacity of the cableveyor.

Cableveyor

Power supply circuit

Cable

Signal line

(flat cable, etc.)

Duct

10 In a case where the cable will be subject to forced bending, always use robot cable.

[Standard structure]

Outer covering

Varies according to

manufacturer and type

Protective layer

Shield

* When to use Robot Cable

When assembling two or three axes and connecting cable to the moving parts, bending weight will be repeatedly applied to the

base of the cable. In this case, the cable core is very likely to snap. T o prevent this from happening, we strongly recommend the

use of robot cable which has greatly improved capacity to withstand bending.

Signal line (copper + tin)

Absorption material

(when the cable bends

and there is pressure

from the outside signal

line, this absorbs the inner and outer difference)

Page 13

Page 16

Chapter 1. Setting Up

Part 5 Part Names and Functions

1. IA Controller Front View

Code (Code Display)

Controller operating status display (2 digit, 7 segment)

Ready (Ready Display LED)

Indicates if the controller is operable.

Alarm (Alarm Display LED)

Alerts the operator of any abnormality in the system.

Teaching/RS232C Connector

Connector for Teaching Pendant or PC.

Page 14

Page 17

Chapter 1. Setting Up

2. Controller Bottom View

LS (Limit Switch Connector) (Option)

5 pins, limit switch connector (Model: Nippon Molex 53258-0520)

BK (Brake Connector) (Option)

4 pins, brake output connector to a brake unit (option) (Model: Nippon Molex

53258-0420)

M·PG (Servo Motor Output/Encoder Input Connector)

14 pins, servo motor output/encoder input combined type connector (Axis 1 is

on the left and Axis 2 is on the right) (Model: Nippon Molex 53258-1420)

Power (Power Cable Connector)

3 pins, AC power supply cable connector

Since Type E and Type G are designed to be mounted inside of a controller

panel, no plug is provided for the power cable on the other end of the controller.

(Terminal Type) (Model: Nippon Molex 53265-0320)

I/O (I/O Connector)

50 pins, external I/O connector. This is used for Type E and Type G (2 axis)

up to 100W only. For other models, it is attached to the I/O Unit Box.

(Model: Sumitomo 3M 7950-6500FL)

SEL NET (Optional SEL Network Connector)

SEL. Network transmission connector. (Model: Nippon Molex 53259-0620)

*Power Cable, Terminal

No. Color Signal

1BlackAC117V

2--- --3 White AC117V

4--- --5Green FG

ST1

Emergency Stop release jumper post. Refer to "Supplement 6. Emergency Stop".

Page 15

Page 18

Chapter 1. Setting Up

3. Teaching Pendant (Option)

LCD Display

4 lines with a 20 character per line capacity display. Shows program and Motion status.

Emergency Stop

When the emergency stop button is pressed, servos will disengage and all programmable outputs will be turned OFF.

To release the emergency stop, press Restart (F1) on the LCD Display.

F1, F2, F3, F4 (Function Key)

Multi-function keys which correspond with the LCD Display.

ESC (Escape)

The escape key allows the operator to go backwards in one-step increments to previous displays to make corrections or

to switch to different modes.

= <

Dual function keys for use in data input and axis Jog functions.

↵ ↵

↵ (Return Key)

↵ ↵

Return key is used to change operations and to move the cursor position.

Page 16

Page 19

Chapter 1. Setting Up

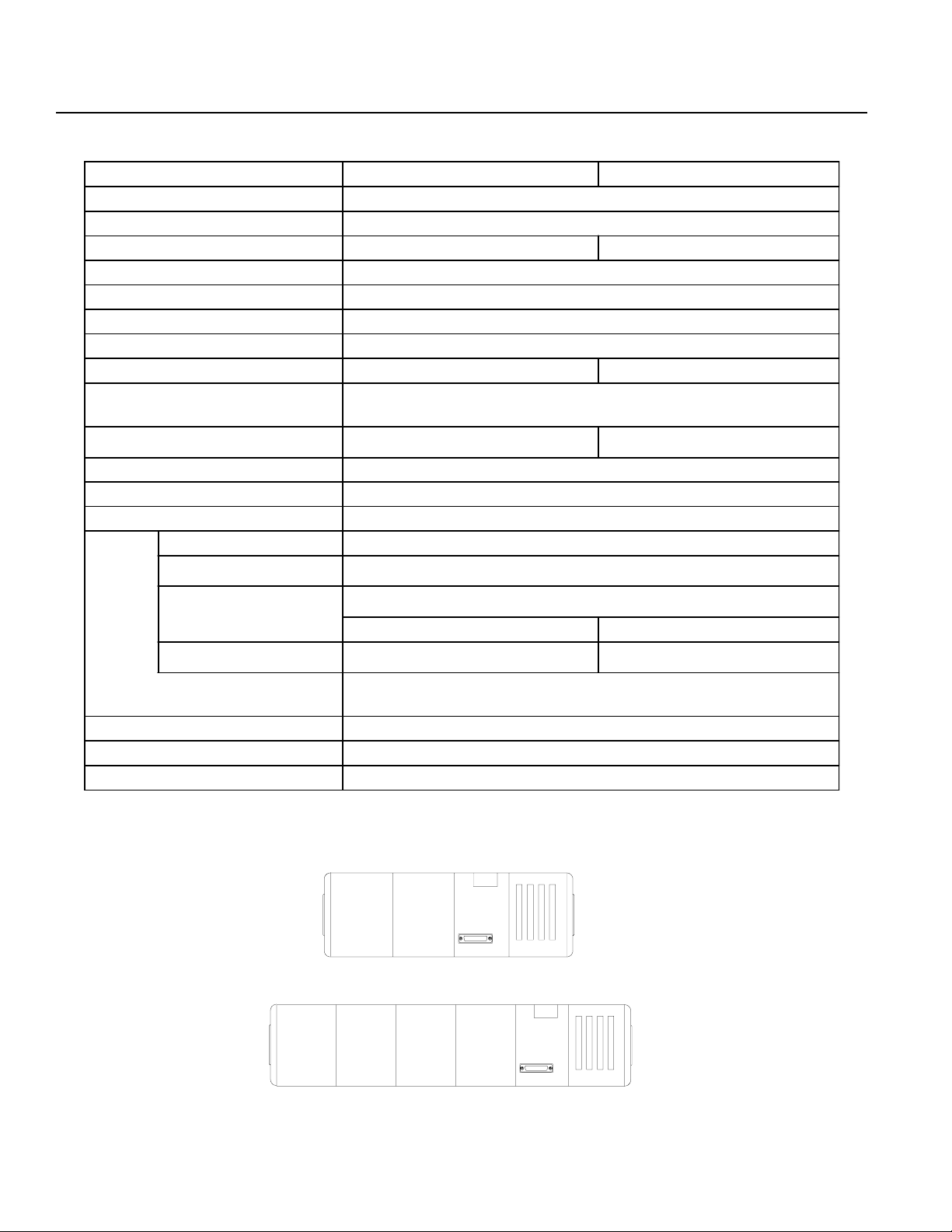

Part 6 Specifications

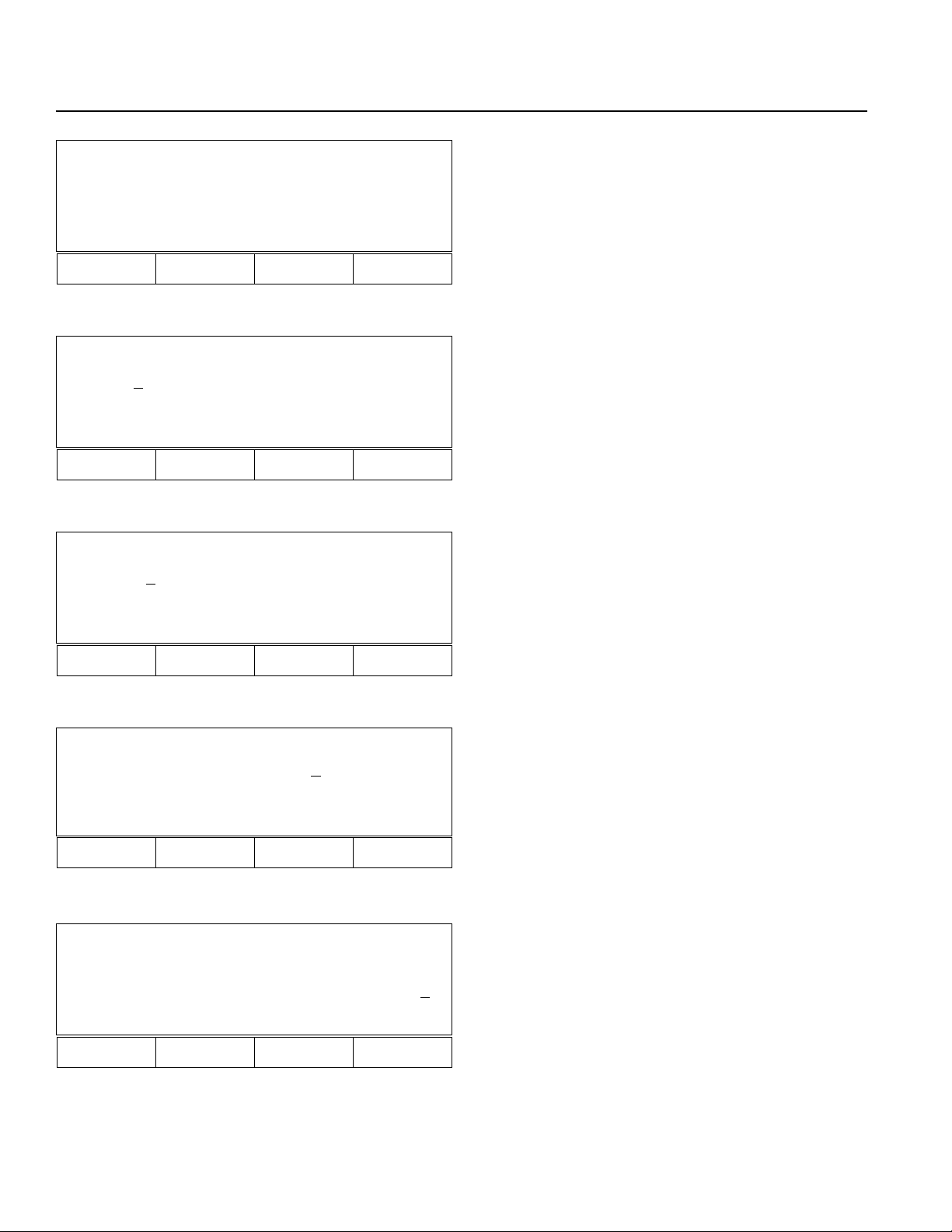

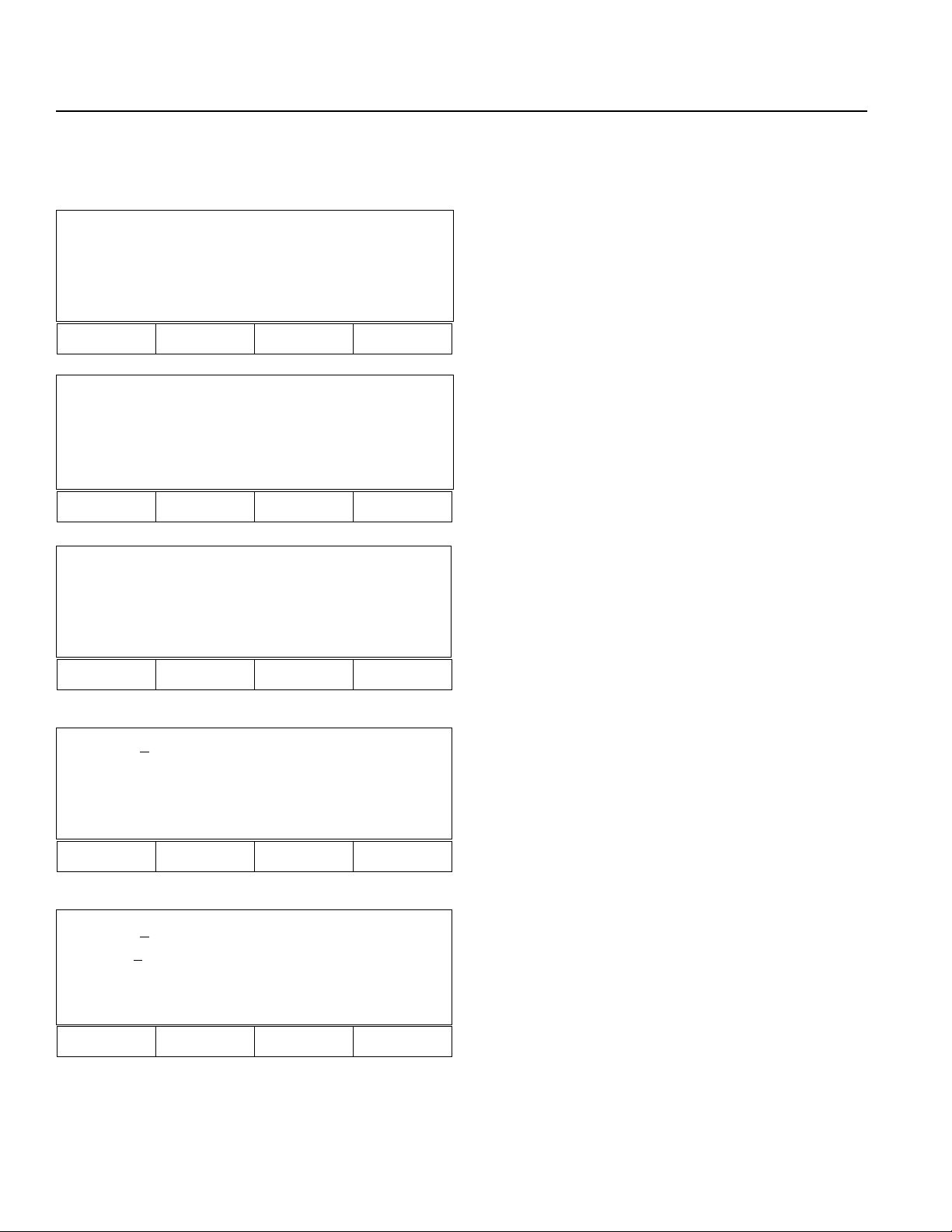

1. AC Specifications

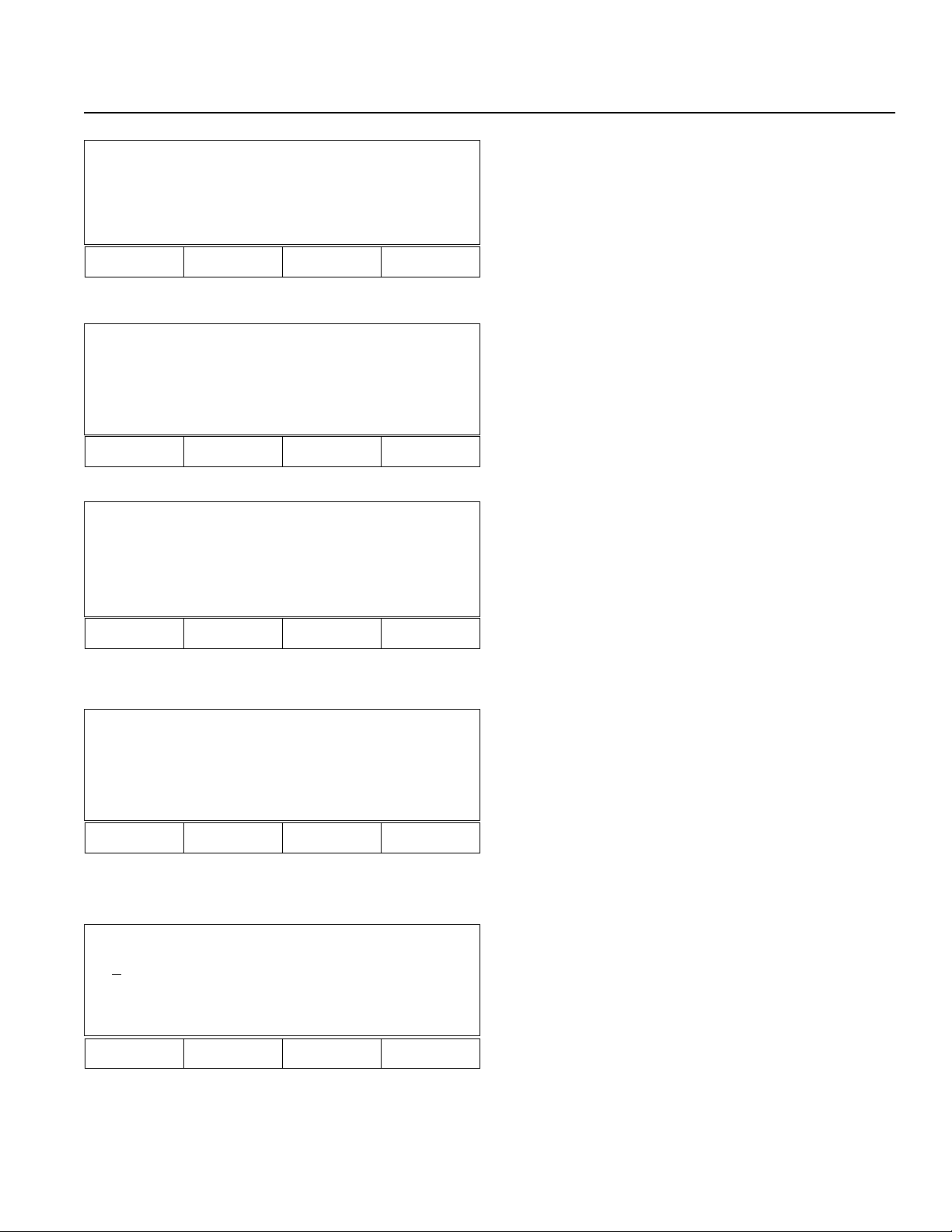

(1) Type E (1 Axis)

Number of Axes AC60W ·100W x1 AC200W x1 AC400Wx1

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consumption

Ambient Temperature and Humidity Temperature 0~40°C, Humidity less than 85%RH

Am bient Environment No corrosive gas, minimal dust

Isolation Resistance 500V 10MΩ or more

Noise Im munity*1 1500V 1µsec pulse by no ise simulator

Unit Weight (kg) 1.2 2.5 3.0

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Number of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input External start · Emergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input M ethod Teaching pendant or RS232C communications

Expansion I/O

Maximum I/O

(including dedicated I/O)

Comm unications EIA RS232C Asynchronous, Full duplex

Network SEL NET RS232C network

175W (100Wx1)

≈

AC servo motor

60W · 100W

Extended I/O: 1 module 24 inputs, 24 outputs

--- 3 3

24 inputs *3

24 outputs

Output maximum load current 100mA/1 point

345W

≈

Driver temperature check

Overload check

S oftw a re lim it c he ck

AC servo motor

200W

24 inputs (including dedicated inputs)

24 outputs (including dedicated outputs)

96 inputs

96 outputs

(Recommended 20mA/1 point)

Transistor array: TD62083AF compatible

600W

≈

AC servo motor

400W

96 inputs

96 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

*3 96 inputs and 96 outputs are available by connecting an optional expansion unit box.

60W·100W

200W

400W

Page 17

Page 20

Chapter 1. Setting Up

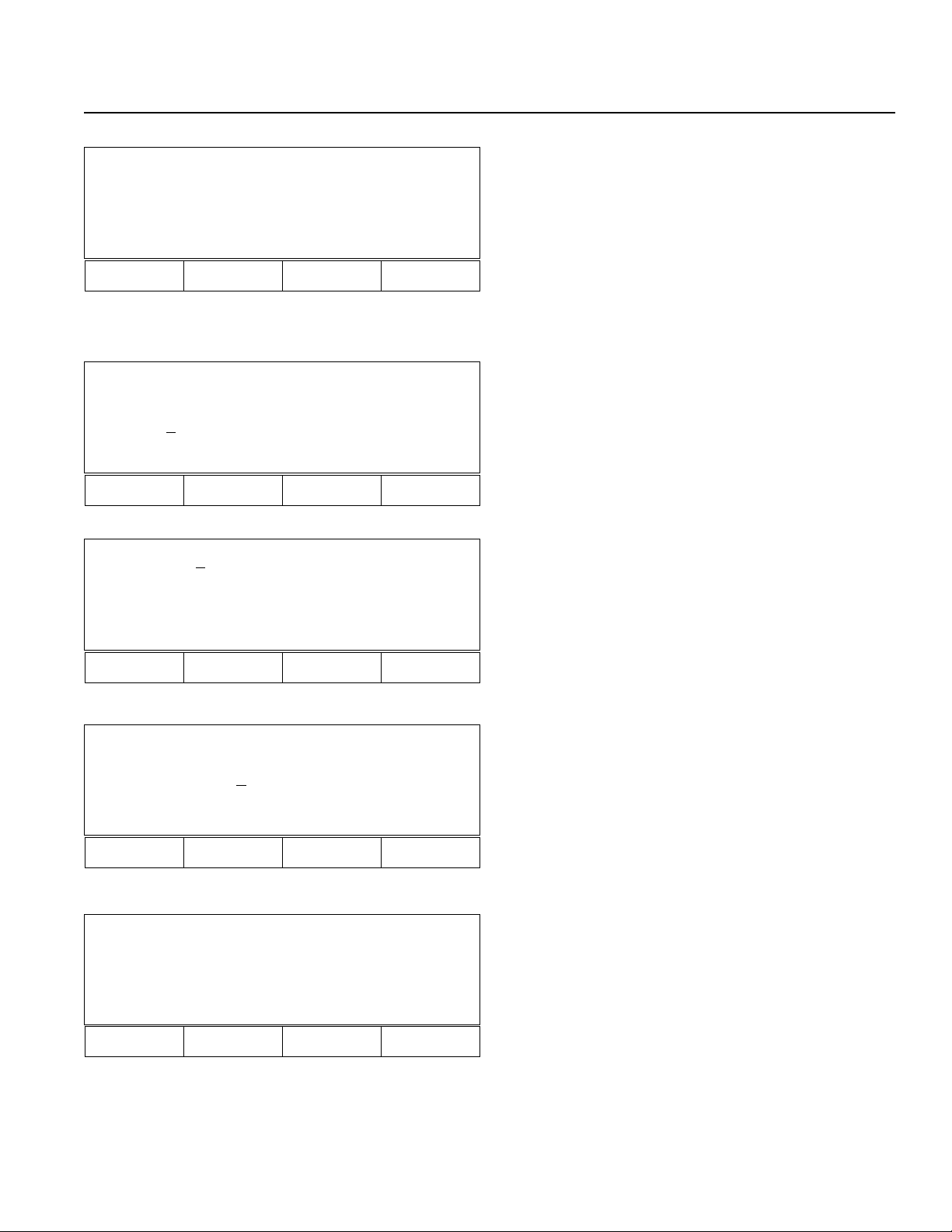

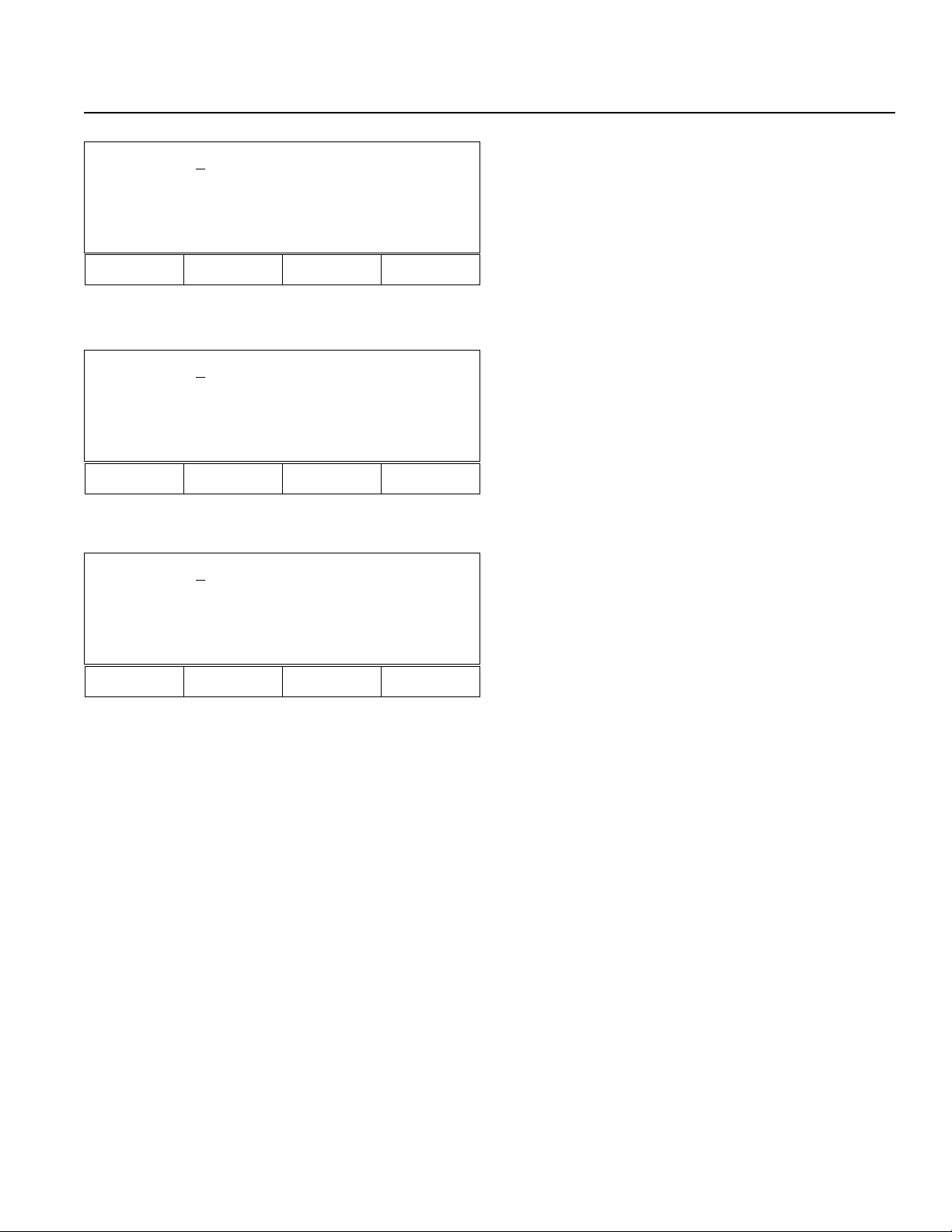

(2) Type G (2-Axis)

Number of Axes AC60W ·100W x2 AC200W x2 AC400Wx2

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consumption

Am bient Temperature and Humidity Tem perature 0~40°C, Humidity less than 85% RH

Am bient Environment No corrosive gas, minim al dust

Isolation Resistance 500V 10M

Noise Im munity*1 1500V 1µsec pulse by noise simulator

Unit W eight (kg) 1.2 2.7 3.5

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Number of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input E xternal start · Emergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O)

Comm unications E IA RS 232C Asynchronous, Full duplex

Network SEL NET RS232C network

300W (100W x2)

≈

AC servo motor

60W · 100W x2

Extended I/O : 1 module 24 inputs, 24 outputs

--- 3 3

24 inputs *3

24 outputs

Output maximum load current 100m A/1 point

590W

≈

or more

Ω

Driver temperature check

Overload check

S oftw a re lim it ch e ck

AC servo motor

200Wx2

24 inputs (including dedicated inputs)

24 outputs (including dedicated outputs)

96 inputs

96 outputs

(Recommended 20mA /1 point)

Transistor array: TD62083AF compatible

11 0 0W

≈

AC servo motor

400Wx2

96 inputs

96 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

*3 96 inputs and 96 outputs are available by connecting an expansion unit box (option).

60W·100Wx2

200Wx2

Page 18

400Wx2

Page 21

Chapter 1. Setting Up

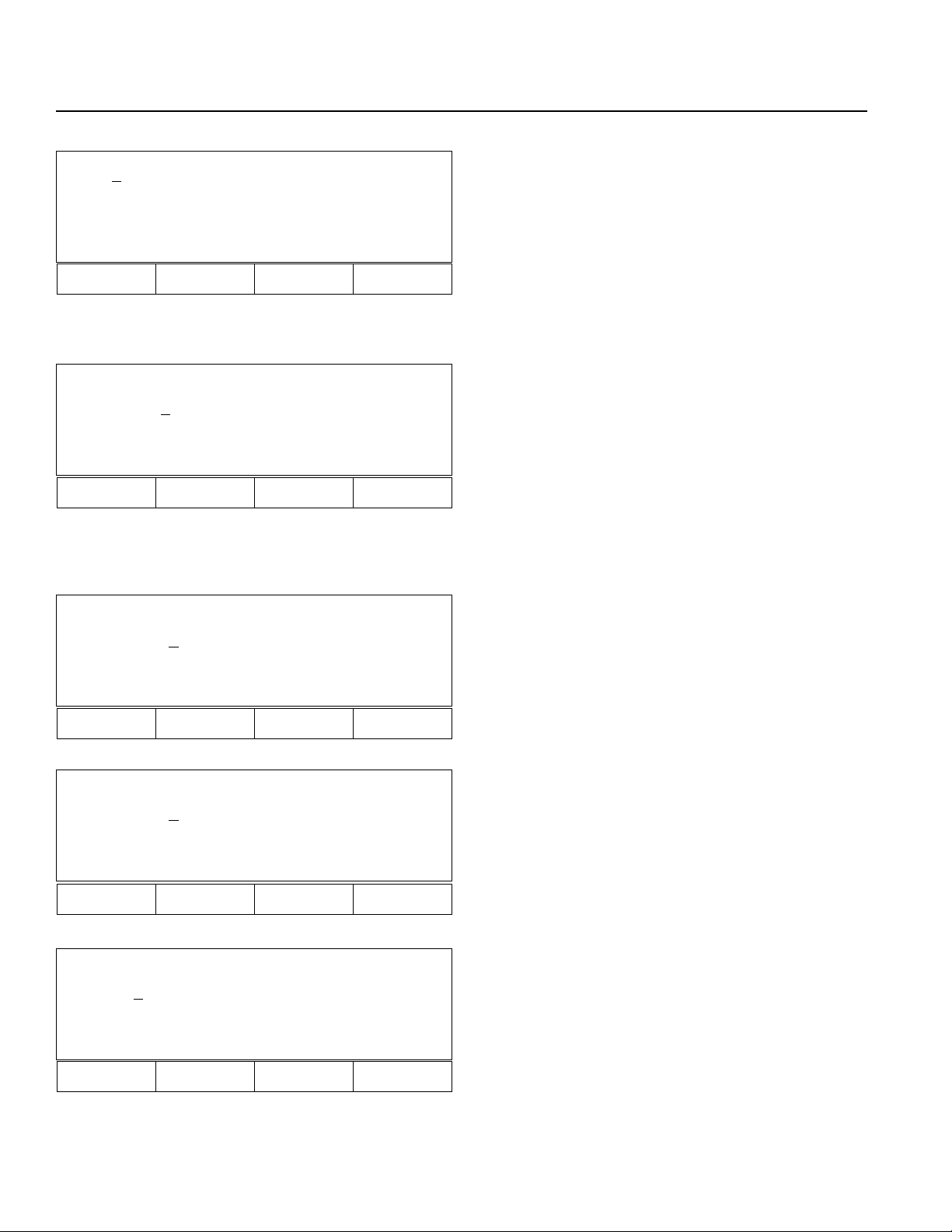

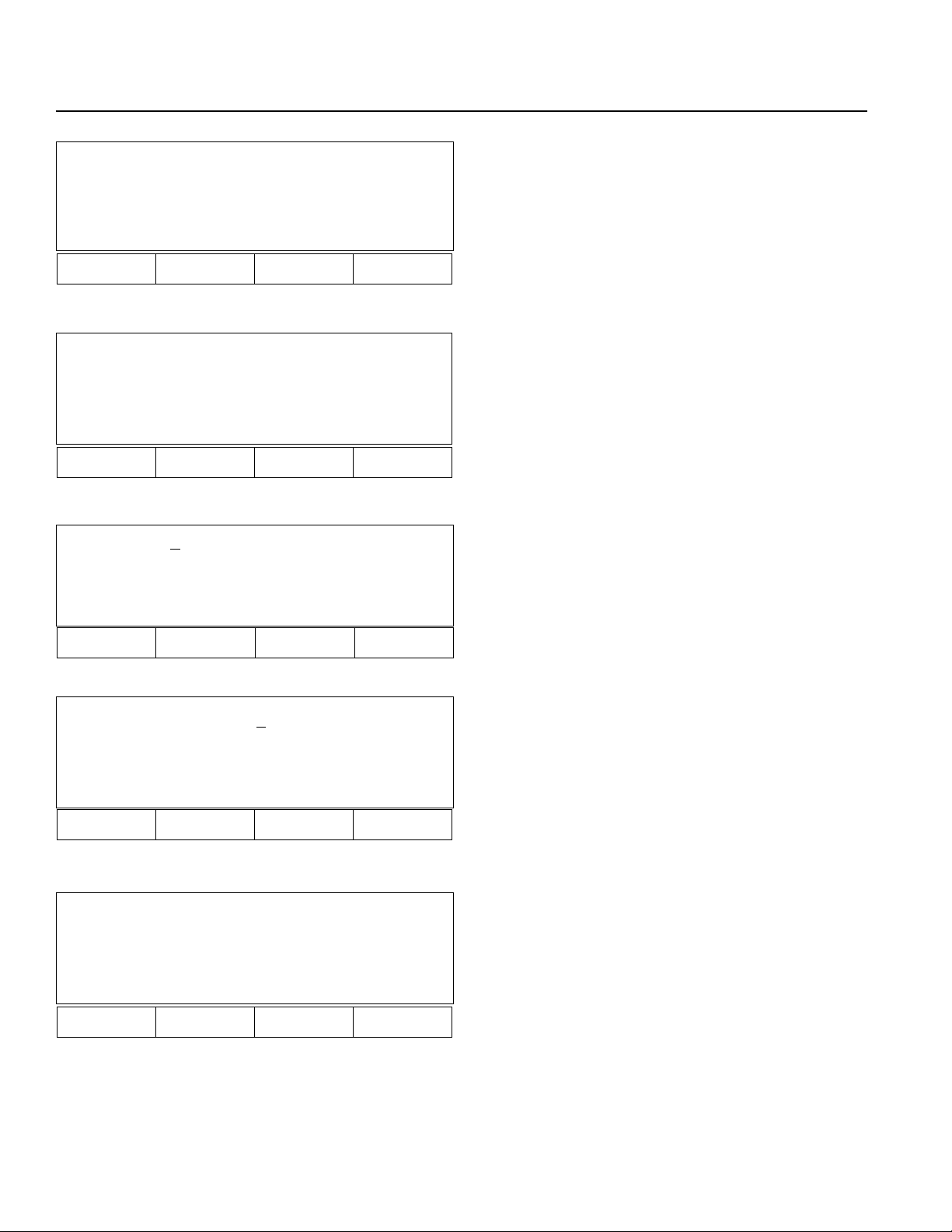

(3) Type G (4-Axis)

Number of Axes AC60W ·100W x4 AC200W x4 AC400Wx4

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consumption

Am bient Temperature and Humidity Tem perature 0~40°C, Humidity less than 85% RH

Am bient Environment No corrosive gas, minim al dust

Isolation Resistance 500V 10M

Noise Im munity*1 1500V 1µsec pulse by noise simulator

Unit W eight (kg) 2.7 3.5 4.7

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Number of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input E xternal start · Emergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O)

Comm unications E IA RS 232C Asynchronous, Full duplex

Network SEL NET RS232C network

600W (100W x4)

≈

AC servo motor

60W · 100W x4

Extended I/O : 1 module 24 inputs, 24 outputs

333

96 inputs

96 outputs

Output maximum load current 100m A/1 point

1080W

≈

or more

Ω

Driver temperature check

Overload check

S oftw a re lim it ch e ck

AC servo motor

200Wx4

24 inputs (including dedicated inputs)

24 outputs (including dedicated outputs)

96 inputs

96 outputs

(Recommended 20mA /1 point)

Transistor array: TD62083AF compatible

2100W

≈

AC servo motor

400Wx4

96 inputs

96 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

60W·100Wx4 200Wx4

400Wx4

Page 19

Page 22

Chapter 1. Setting Up

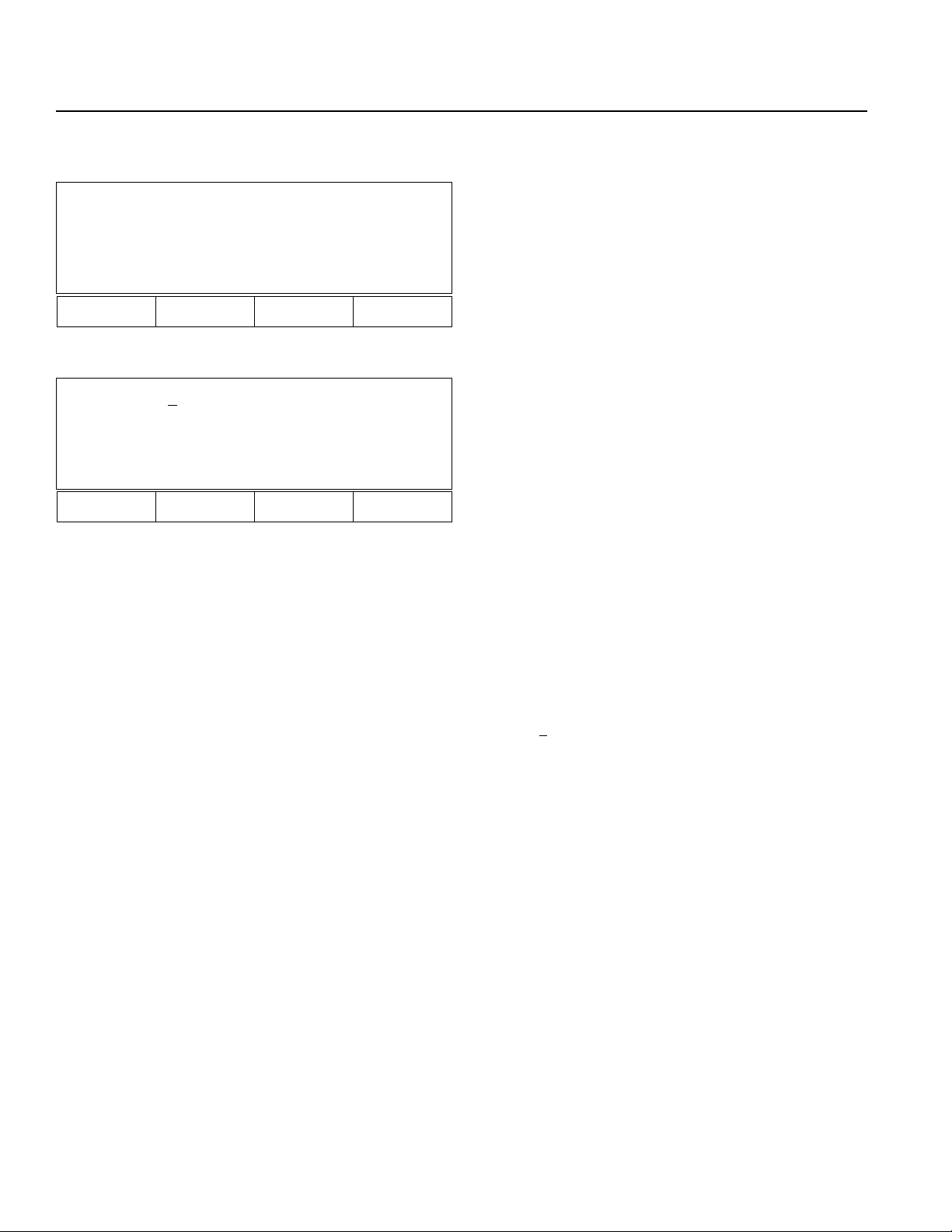

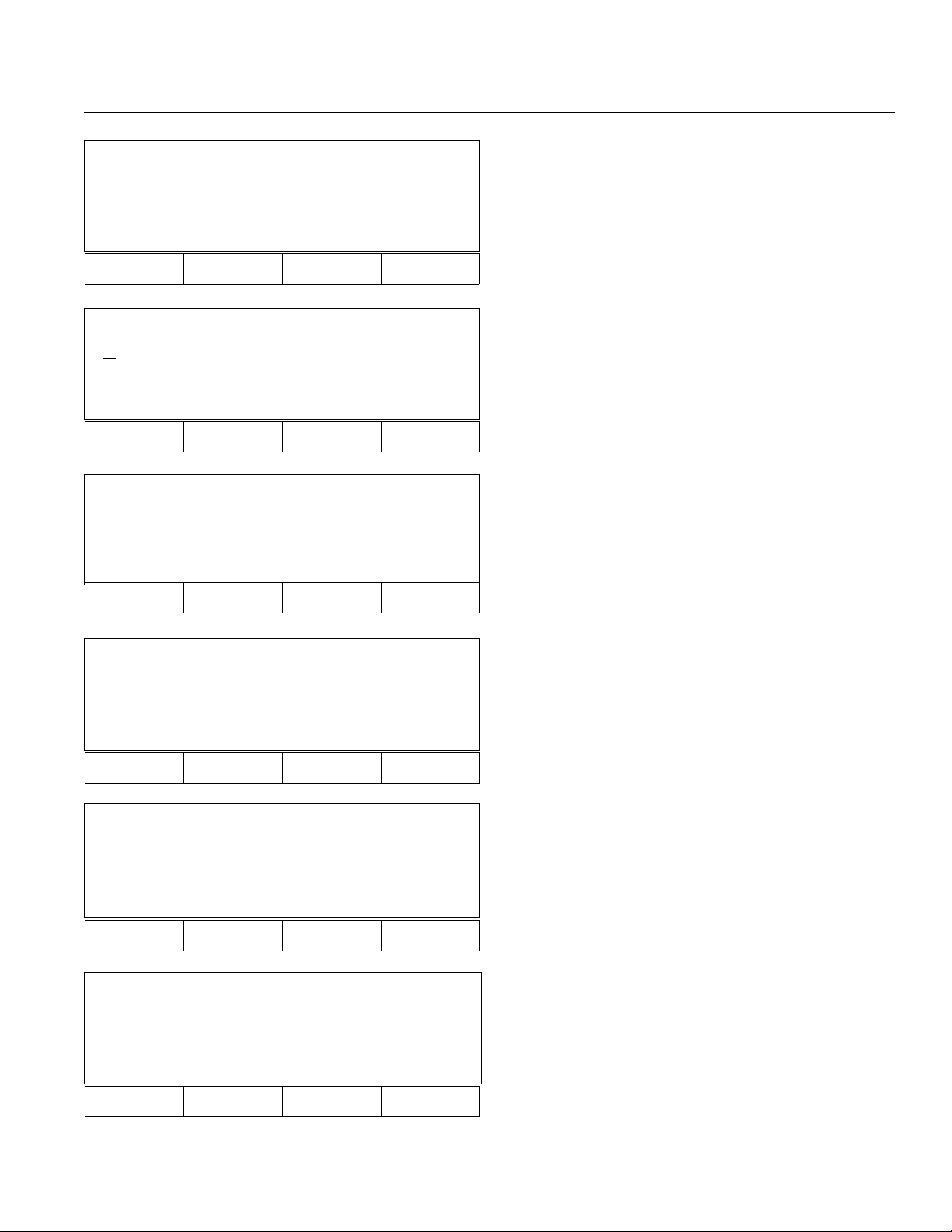

(4) Type G (8-Axis)

Num ber of Axes A C60W ·100W x8 A C200Wx8

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consum ption

Am bient Tem perature and Hum idity Temperature 0~40°C, Humidity less than 85%RH

Am bient Environment No corrosive gas, m inimal dust

Isolation Resistance 500V 10M

Noise Imm unity*1 1500V 1µ sec pulse by noise sim ulator

Unit W eight (kg) 4.5 5.7

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Num ber of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input External start · Em ergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS 232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O )

Com munications EIA R S232C Asynchronous, Full duplex

Network SEL N ET RS232C netw ork

1100W (100W x8)

≈

or more

Ω

Driver temperature check

Overload check

S o ftw a re lim it c he c k

AC servo motor

60W · 100W x8

48 inputs (including dedicated inputs)

48 outputs (including dedicated outputs)

Extended I/O : 1 m odule 24 inputs, 24 outputs

10 10

288 inputs

288 outputs

Output m axim um load current 100mA/1 point

(Recomm ended 20mA/1 point)

Transistor array: TD62083AF com patible

AC servo motor

2000W

≈

200W x8

288 inputs

288 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

± A 12-slot expansion unit is available as an option (please see P. 61).

60W·100Wx8

200Wx8

Page 20

Page 23

Chapter 1. Setting Up

2. DC Specifications

(1) Type E (1 Axis)

Num ber of Axes DC 20W~100W x1 DC 200Wx1

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consum ption

Am bient Tem perature and Hum idity Temperature 0~40°C, Humidity less than 85%RH

Am bient Environment No corrosive gas, m inimal dust

Isolation Resistance 500V 10M

Noise Imm unity*1 1500V 1µ sec pulse by noise sim ulator

Unit W eight (kg) 1.2 2.5

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Num ber of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input External start · Em ergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS 232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O )

Com munications EIA R S232C Asynchronous, Full duplex

Network SEL N ET RS232C netw ork

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

*3 96 inputs and 96 outputs are available by connecting an expansion unit box (option).

210W (100W x1)

≈

or more

Ω

Driver temperature check

Overload check

S o ftw a re lim it c he c k

DC servo motor

20~100W

24 inputs (including dedicated inputs)

24 outputs (including dedicated outputs)

Extended I/O : 1 m odule 24 inputs, 24 outputs

--- 3

24 inputs *3

24 outputs

Output m axim um load current 100mA/1 point

(Recomm ended 20mA/1 point)

Transistor array: TD62083AF com patible

DC servo motor

370W

≈

200W

96 inputs

96 outputs

20W~100W

200W

Page 21

Page 24

Chapter 1. Setting Up

(2) Type G (2-Axis)

Num ber of Axes DC 20W~100W x2 DC 200Wx2

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consum ption

Am bient Tem perature and Hum idity Temperature 0~40°C, Humidity less than 85%RH

Am bient Environment No corrosive gas, m inimal dust

Isolation Resistance 500V 10M

Noise Imm unity*1 1500V 1µ sec pulse by noise sim ulator

Unit W eight (kg) 1.2 2.7

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Num ber of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input External start · Em ergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS 232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O )

Com munications EIA R S232C Asynchronous, Full duplex

Network SEL N ET RS232C netw ork

370W (100W x2)

≈

or more

Ω

Driver temperature check

Overload check

S o ftw a re lim it c he c k

DC servo motor

20~100W x2

24 inputs (including dedicated inputs)

24 outputs (including dedicated outputs)

Extended I/O : 1 m odule 24 inputs, 24 outputs

--- 3

24 inputs *3

24 outputs

Output m axim um load current 100mA/1 point

(Recomm ended 20mA/1 point)

Transistor array: TD62083AF com patible

DC servo motor

640W

≈

200W x2

96 inputs

96 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

*3 96 inputs and 96 outputs are available by connecting an expansion unit box (option).

20W~100W

200W

Page 22

Page 25

Chapter 1. Setting Up

(3) Type G (4-Axis)

Num ber of Axes DC 20W~100W x4 DC 200Wx4

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consum ption

Am bient Tem perature and Hum idity Temperature 0~40°C, Humidity less than 85%RH

Am bient Environment No corrosive gas, m inimal dust

Isolation Resistance 500V 10M

Noise Imm unity*1 1500V 1µ sec pulse by noise sim ulator

Unit W eight (kg) 2.7 3.5

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Num ber of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input External start · Em ergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS 232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O )

Com munications EIA R S232C Asynchronous, Full duplex

Network SEL N ET RS232C netw ork

740W (100W x4)

≈

or more

Ω

Driver temperature check

Overload check

S o ftw a re lim it c he c k

DC servo motor

20~100W x4

24 inputs (including dedicated inputs)

24 outputs (including dedicated outputs)

Extended I/O : 1 m odule 24 inputs, 24 outputs

33

96 inputs

96 outputs

Output m axim um load current 100mA/1 point

(Recomm ended 20mA/1 point)

Transistor array: TD62083AF com patible

DC servo motor

11 80 W

≈

200W x4

96 inputs

96 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

20W~100Wx4 200Wx4

Page 23

Page 26

Chapter 1. Setting Up

(4) Type G (8-Axis)

Num ber of Axes DC 20W~100W x8 DC 200Wx8

Power Voltage AC 117V±10%

Power Frequency 50/60Hz

Power Consum ption

Am bient Tem perature and Hum idity Temperature 0~40°C, Humidity less than 85%RH

Am bient Environment No corrosive gas, m inimal dust

Isolation Resistance 500V 10M

Noise Imm unity*1 1500V 1µ sec pulse by noise sim ulator

Unit W eight (kg) 4.5 5.7

Protective Functions

Motor Capacity

Mem ory Capacity Total 3,000 steps 2,000 positions *2

Num ber of Programs 64 programs, 16 multi-tasking programs

Memory Device CMOS RAM battery backup

Dedicated Input External start · Em ergency stop · Limit switch

Standard I/O

I/O

(DC24V)

Data Input Method Teaching pendant or RS 232C comm unications

Expansion I/O

Maximum I/O

(including dedicated I/O )

Com munications EIA R S232C Asynchronous, Full duplex

Network SEL N ET RS232C netw ork

1380W (100W x8)

≈

or more

Ω

Driver temperature check

Overload check

S o ftw a re lim it c he c k

DC servo motor

20~100W x8

48 inputs (including dedicated inputs)

48 outputs (including dedicated outputs)

Extended I/O : 1 m odule 24 inputs, 24 outputs

10 10

288 inputs

288 outputs

Output m axim um load current 100mA/1 point

(Recomm ended 20mA/1 point)

Transistor array: TD62083AF com patible

DC servo motor

2260W

≈

200W x8

288 inputs

288 outputs

*1 Controller unit test

*2 The maximum number of steps that can be compiled per unit is 1999.

± A 12-slot expansion unit is available as an option (please see P. 61).

20W~100Wx8

200Wx8

Page 24

Page 27

Chapter 1. Setting Up

3. External I/O Specifications

(1) Input

Input Specifications

Dedicated Input...4 Points

Point

Power Voltage DC24V +/-20%

Current 7mA/DC24V

ON/OFF Power Voltage ON....Min DC16.0V OFF....Max DC5.0V

ON/OFF Response Time ON....Max 20m sec OFF....Max 20m sec

Isolation Method Photocoupler

Internal Circuit

User Input....20 Points

Expansion Input (Option)....Max 72 Points

External power

Internal

Circuit

Each input

1) The power must be supplied externally for the standard I/O board and the expansion I/O board.

2) For the external circuit connection (no contact point), the leakage per 1point must be kept lower than 1mA when the

switch is OFF.

Guaranteed operation width of the Super SEL Controller input signal

Time Width while ON

30msec

Time Width while OFF

30msec

Generally, the input signal operates within 25msec but the guaranteed operation width is 30msec.

Page 25

Page 28

Chapter 1. Setting Up

(2) Output

Output Point

Rated Power DC24V

Maximum Load Current 100m A/1point

Recom mended Load Current 20mA /1 point

Leakage 0.1mA (maximum )

Residual Voltage 3.1V/40m A (maximum)

Insulation Method Photocoupler

Internal Circuit

Specifications

Dedicated output.....2 points

User output.....22 points

Expansion output (option).....m aximum 72 points

External power

Each output

The power must be supplied externally for the standard I/O board and the expansion I/O board.

*You will damage the output element if you overload or underload it.

4. Servo

Specifications

Control Method Semi-closed loop control

Position Feedback Rotary encoder A · B · Z phase

Internal

Circuit

Repeatability ± 2 pulses

Velocity 1m/sec ~ 1500m/sec *

Acceleration 0.01G ~ 1G

*Max velocity differs depending on actuator specifications.

Page 26

Page 29

Chapter 1. Setting Up

5. Precautions When Using the Emergency Stop

As a rule, emergency stops should only be applied from the I/O.

Do not turn the power (AC117V) ON/OFF to effect an emergency stop.

If you stop the actuator by turning the power OFF, wait at least 15 seconds before turning the power ON again. If you

disregard this warning, and repeatedly turn the power ON/OFF without waiting a sufficient amount of time, you may damage

the controller.

6. Restarting the Controller After an Emergency Stop (refer to part 3, 1-4 "Emergency Stop Release" for details)

The Super SEL controller and Table Top type (TT-300) both use a "hard reset" to restart after an emergency stop. The

operation is nearly the same as turning the power OFF/ON. (Homing is required).

(1) Emergency Stop from the teaching pendant

Press EMERGENCY STOP on the teaching pendant. Continue pressing and the screen will display the following.

T eaching pendant display

EMG STOP.

ReStart (Flashing dis play)

F1 F2 F3 F4

Controller code display

EG

(A red *ALARM lamp lights up)

Take your finger off the EMERGENCY STOP button to do a hard reset and the following screen appears.

T eaching pendant display

EMG STOP.

ReStart (Flashing dis play)

F1 F2 F3 F4

Controller code display

rd

(A green *READY lamp lights up)

If you press the F1 key (ReStart) on the teaching pendant, the initial screen reappears.

T eaching pendant display

IA.S u p e r.SE L

Teach v1.00 07/18/94

Start (Flashing display)

Controller code display

rd

(A green *READY lamp lights up)

F1 F2 F3 F4

(2) Pressing the controller emergency stop button or an emergency stop condition caused by an external signal

When the emergency stop is released after pressing the emergency stop button on the controller front panel, you must

follow the same procedure as described above or the teaching pendant will not reset (you cannot operate the teaching

box if the code display on the controller front panel reads EG .

! Warning

If you are using the Auto Start PRG in the system program parameter mode, always write the program so that movement will not resume unless there is some kind of input condition. This is to avoid sudden startup of movement

because of the automatic start program right after the emergency stop is released.

Page 27

Page 30

Chapter 1. Setting Up

Part 7 System Setup

1. Connecting the IA Controller and Actuator

* Since Type E and T ype G Controllers are designed to be mounted

inside of a control panel, no plug is provided for the power cable

on the other end of the controller.

*Power Cable·Terminal

No. C olor S ignal

1 Black AC117V

2--- --3 W hite AC117V

4--- --5GreenFG

Teaching Pendant

Connect controller and actuator cables. Use only IA supplied cables. These cables include:

a. Motor cable

b. Encoder cable

c. Teaching pendant cable

d. Brake cable (optional)

e. Limit switch cable (optional)

Connect the power cord.

The CODE display shows in sequence. The Super SEL controller is ready to operate.

If the CODE display is release the Emergency Stop input.

Note: The Emergency Stop is normally closed (b contact point input). In order to release the emergency stop, short the jumper

post (ST1) at the bottom of the controller CPU UNIT or CPU SERVO UNIT with the jumper pin. Refer to Supplement

6 for the actual procedure.

Page 28

Page 31

Chapter 1. Setting Up

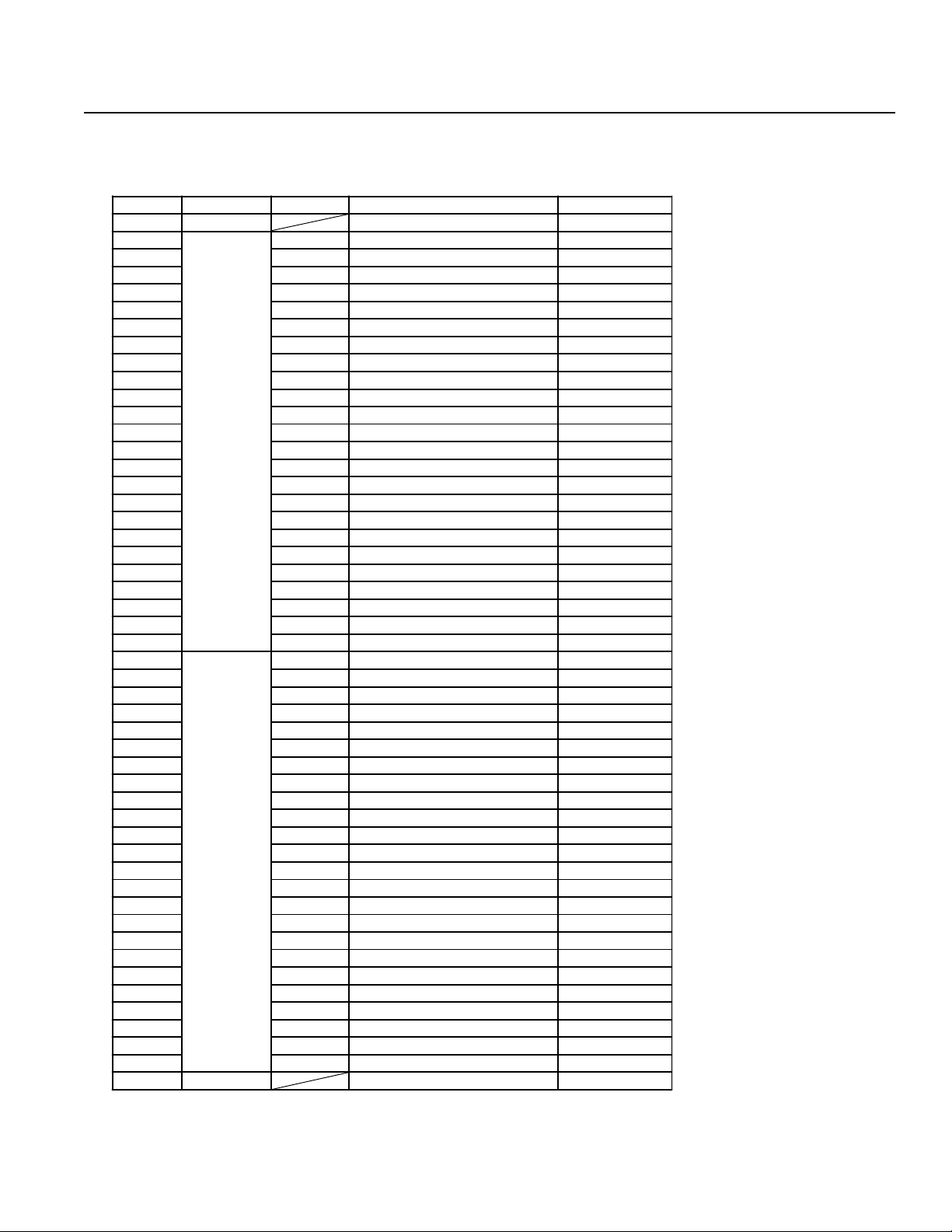

2. Interface List

I/O Connector (NPN-Sinking)

Pin No. Category Port No. Function Cable

1A P24 --- 1-Brown

1B

2A 001 User Input 1-Orange

2B 002 Emergency Stop b Contact Input * 1-Yellow

3A 003 SystemReserve 1-Green

3B 004 SystemReserve 1-Blue

4A 005 User Input 1-Purple

4B 006 User Input 1-Gray

5A 007 User Input 1-White

5B 008 PRG No. 1 (User Input) 1-Black

6A 009 PRG No. 2 (User Input) 2-Brown

6B 010 PRG No. 4 (User Input) 2-Red

7A 011 PRG No. 8 (User Input) 2-Orange

7B 012 PRG No. 10 (User Input) 2-Yellow

8A 013 PRG No. 20 (User Input) 2-Green

8B 014 PRG No. 40 (User Input) 2-Blue

9A 015 User Input 2-Purple

9B 016 User Input 2-Gray

10A 017 User Input 2-White

10B 018 User Input 2-Black

11A 019 User Input 3-Brown

11B 020 User Input 3-Red

12A 021 User Input 3-Orange

12B 022 User Input 3-Yellow

13A 023 User Input 3-Green

13B

14A 30 1 Ready Output 3-Purple

14B 302 User Output 3-Gray

15A 303 User Output 3-White

15B 304 User Output 3-Black

16A 305 User Output 4-Brown

16B 306 User Output 4-Red

17A 30 7 User Output 4-Orange

17B 308 User Output 4-Yellow

18A 309 User Output 4-Green

18B 310 User Output 4-Blue

19A 311 User Output 4-Purple

19B 312 User Output 4-Gray

20A 313 User Output 4-White

20B 314 User Output 4-Black

21A 315 User Output 5-Brown

21B 316 User Output 5-Red

22A 31 7 User Output 5-Orange

22B 318 User Output 5-Yellow

23A 319 User Output 5-Green

23B 320 User Output 5-Blue

24A 321 User Output 5-Purple

24B 322 User Output 5-Gray

25A 323 User Output 5-White

25B N24 --- 5-Black

Input

Output

000 External Start Input 1-Red

300 Em ergency Stop /Alarm Outp ut 3-Blue

* Emergency Stop (normally

closed). T o release the emergency stop, short circuit the

jumper post with a jumper pin or

connect pin 2B and pin 25B.

Refer to Supplement 6.

* Pin No.3A (Port No.003) and Pin

No.3B (Port No.004) cannot be

used as user input.

* Connector:

Sumitomo 3M7950-6500SC or

Yamaichi F AP-5001-1202

Page 29

Page 32

Chapter 1. Setting UpChapter 1. Setting Up

Caution ! NPN I/O wirings and PNP wirings are DIFFERENT

3. I/O Wiring Diagram

Standard I/O (NPN - Sinking)

Pin No. Category Port No. Functio n

1A P24 --1B

2A 001 User Input

2B 002 Emergency Stop b Contact Input *

3A 003 S ystemR eserve

3B 004 S ystemR eserve

4A 005 User Input

4B 006 User Input

5A 007 User Input

5B 008 P RG N o. 1 (User Input)

6A 009 P RG N o. 2 (User Input)

6B 010 P RG N o. 4 (User Input)

7A 011 P RG N o. 8 (User Input)

7B 012 PRG No. 10 (User Input)

8A 013 PRG No. 20 (User Input)

8B 014 PRG No. 40 (User Input)

9A 015 User Input

9B 016 User Input

10A 017 User Input

10B 018 User Input

11A 019 User Input

11B 030 User Input

12A 021 User Input

12B 022 User Input

13A 023 User Input

13B

14A 301 Ready Output

14B 302 User Output

15A 303 User Output

15B 304 User Output

16A 305 User Output

16B 306 User Output

17A 307 User Output

17B 308 User Output

18A 309 User Output

18B 310 User Output

19A 311 User Output

19B 312 User Output

20A 313 User Output

20B 314 User Output

21A 315 User Output

21B 316 User Output

22A 317 User Output

22B 318 User Output

23A 319 User Output

23B 320 User Output

24A 321 User Output

24B 322 User Output

25A 323 User Output

25B N24 ---

Input

Output

000 External Start Input

300 Em ergency Stop/Alarm O utput

External 24V power

R

W

RY

∆

SV

∆

P24

0

•

•

•

•

•

Digital SW

•

•

G

RY

∆

SV

∆

•

•

•

•

•

•

•

•

Note:The same cable colors

are used for the standard

cables and the expansion cables.

*Standard I/O Pin No.3A

(Port No.003), and Pin

No.3B(Port No.004) cannot be used as user

puts.

•

in-

Page 30

Page 33

Chapter 1. Setting Up

Expansion I/O * (NPN - Sinking)

Pin No. Category Port No. Function

1A P24 External Power Supply +24V Input

1B

2A 025 User Input

2B 026 User Input

3A 027 User Input

3B 028 User Input

4A 029 User Input

4B 030 User Input

5A 031 User Input

5B 032 User Input

6A 033 User Input

6B 034 User Input

7A 035 User Input

7B 036 User Input

8A 037 User Input

8B 038 User Input

9A 039 User Input

9B 040 User Input

10A 041 User Input

10B 042 User Input

11A 043 User Input

11B 044 User Input

12A 045 User Input

12B 046 User Input

13A 047 User Input

13B

14A 325 User Output

14B 326 User Output

15A 327 User Output

15B 328 User Output

16A 329 User Output

16B 330 User Output

17A 331 User Output

17B 332 User Output

18A 333 User Output

18B 334 User Output

19A 335 User Output

19B 336 User Output

20A 337 User Output

20B 338 User Output

21A 339 User Output

21B 340 User Output

22A 341 User Output

22B 342 User Output

23A 343 User Output

23B 344 User Output

24A 345 User Output

24B 346 User Output

25A 347 User Output

25B N24 E xternal Pow er Supply 0V

* This is the first expansion I/O. In the second expansion I/O,

the port numbers continue on from these numbers.

Input

Output

024 User Input

324 User Output

External 24V power

P24

0

•

•

•

•

•

•

Page 31

Page 34

Chapter 1. Setting Up

4. Interface List (PNP Sourcing)

Pin No. Category Port No. Function C able Color

1A N24 External power 0V 1-Brown

1B

2A 001 User input 1-Orange

2B 002 E mergency Stop b contact input *1 1-Yellow

3A 003 System reserve 1-Green

3B 004 System reserve 1-Blue

4A 005 User input 1-Purple

4B 006 User input 1-Gray

5A 007 User input 1-W hite

5B 008 P RG No. 1 (user input) 1-Black

6A 009 P RG No. 2 (user input) 1-Brown

6B 010 P RG No. 4 (user input) 2-Red

7A 011 PRG No. 8 (user input) 2-Orange

7B 012 PRG N o. 10 (user input) 2-Yellow

8A 013 PRG N o. 20 (user input) 2-Green

8B 014 PRG N o. 40 (user input) 2-Blue

9A 015 User input 2-Purple

9B 016 User input 2-Gray

10A 017 User input 2-White

10B 018 User input 2-Black

11A 019 User input 3-Brown

11B 020 User input 3-Red

12A 021 User input 3-Orange

12B 022 User input 3-Yellow

13A 023 User input 3-Green

13B

14A 301 Ready output 3-Purple

14B 302 Use r output 3-Gray

15A 303 Use r output 3-White

15B 304 Use r output 3-Black

16A 305 Use r output 4-Brown

16B 306 Use r output 4-Red

17A 307 Use r output 4-Orange

17B 308 Use r output 4-Yellow

18A 309 Use r output 4-Green

18B 310 Use r output 4-Blue

19A 311 Use r output 4-Purple

19B 312 Use r output 4-Gray

20A 313 Use r output 4-White

20B 314 Use r output 4-Black

21A 315 Use r output 5-Brown

21B 316 Use r output 5-Red

22A 317 Use r output 5-Orange

22B 318 Use r output 5-Yellow

23A 319 Use r output 5-Green

23B 320 Use r output 5-Blue

24A 321 Use r output 5-Purple

24B 322 Use r output 5-Gray

25A 323 Use r output 5-White

25B P24 External power +24V 5-Black

Input

Output

000 External start input 1-Red

300 Emergency stop/Alarm output 3-Blue

Emergency Stop is a b-contact in-

*

put (normally closed). To release

the emergency stop, short circuit

the jumper post with the jumper pin.

Refer to Supplement 7.

Pin No.3A (Port No.003), and Pin

*

No.3B (Port No.004) cannot be used

as user inputs.

Connector: Sumitomo 3M 7950-

*

6500SC or Yamaichi FAP-5001-

1202.

Page 29-A

Page 35

Chapter 1. Setting Up

5. Wiring Diagram

Pin No. Category Port No. Function Cable Color

1A N24 External power 0V 1-Brown

1B

2A 001 User input 1-Orange

2B 002 Emergency Stop b contact input 1-Yellow

3A 00 3 Sy stem re serv e 1-G reen

3B 004 System reserve 1-Blue

4A 005 User input 1-Purple

4B 006 User input 1-Gray

5A 007 User input 1-W hite

5B 008 PRG No. 1 (user input) 1-Black

6A 009 PRG No. 2 (user input) 1-Brown

6B 010 PRG No. 4 (user input) 2-Red

7A 011 PR G No. 8 (user input) 2-Orange

7B 012 PRG No . 10 (user input) 2-Yellow

8A 013 PR G No. 20 (user input) 2-Green

8B 014 PR G No. 40 (user input) 2-Blue

9A 015 User input 2-Purple

9B 016 User input 2-Gray

10A 017 User input 2-White

10B 018 User input 2-Black

11A 019 User input 3-Brown

11B 020 User input 3-Red

12A 021 User input 3-Orange

12B 022 User input 3-Yellow

13A 023 User input 3-Green

13B

14A 301 Ready output 3-Purple

14B 302 U ser output 3-Gray

15A 303 U ser output 3-White

15B 304 U ser output 3-Black

16A 305 U ser output 4-Brown

16B 306 U ser output 4-Re d

17A 307 U ser output 4-Orange

17B 308 U ser output 4-Yellow

18A 309 U ser output 4-Green

18B 310 U ser output 4-Blue

19A 311 U ser output 4-Purple

19B 312 U ser output 4-Gray

20A 313 U ser output 4-White

20B 314 U ser output 4-Black

21A 315 U ser output 5-Brown

21B 316 U ser output 5-Re d

22A 317 U ser output 5-Orange

22B 318 U ser output 5-Yellow

23A 319 U ser output 5-Green

23B 320 U ser output 5-Blue

24A 321 U ser output 5-Purple

24B 322 U ser output 5-Gray

25A 323 U ser output 5-White

25B P24 External power +24V 5-Black

Note: The same cable colors are used for the standard cables and the expansion cables.

Inp ut

Output

000 External start input 1-Red

300 Emergency stop/Alarm output 3-Blue

Standard I/O (PNP - Sourcing)

*Standard I/O Pin No.3A (Port No.003), and Pin No.3B(Port No.004) cannot be used as user inputs.

R

W

RY

∇

SV

∇

BCD SW

G

RY

∇

SV

∇

P24

0

NOTE:

•

•

•

•

•

•

•

•

•

For the SEL EU controller, if the

motor/encoder cables are not connected to the controller, the controller will be in a permanent emergency stop condition (even if the Estop input is jumpered to 24VDC

for a PNP I/O board).

•

•

•

•

•

•

•

•

Page 30-A

Page 36

Chapter 1. Setting Up

I/O Expansion * (PNP-Sourcing)

Pin No. Category Port No. Function Cable Color

1A N24 External power 0V 1-Brown

1B

2A 025 User input 1-Orange

2B 026 User input 1-Yellow

3A 027 User input 1-Green

3B 028 User input 1-Blue

4A 029 User input 1-Purple

4B 030 User input 1-Gray

5A 031 User input 1-White

5B 032 User input 1-Black

6A 033 User input 1-Brown

6B 034 User input 2-Red

7A 035 User input 2-Orange

7B 036 User input 2-Yellow

8A 037 User input 2-Green

8B 038 User input 2-Blue

9A 039 User input 2-Purple

9B 040 User input 2-Gray

10A 041 User input 2-White

10B 042 User input 2-Black

11A 043 User input 3-Brown

11B 044 User input 3-Red

12A 045 User input 3-Orange

12B 046 User input 3-Yellow

13A 047 User input 3-Green

13B

14A 325 User output 3-Purple

14B 326 User output 3-Gray

15A 327 User output 3-White

15B 328 User output 3-Black

16A 329 User output 4-Brown

16B 330 User output 4-Red

17A 331 User output 4-Orange

17B 332 User output 4-Yellow

18A 333 User output 4-Green

18B 334 User output 4-Blue

19A 335 User output 4-Purple

19B 336 User output 4-Gray

20A 337 User output 4-White

20B 338 User output 4-Black

21A 339 User output 5-Brown

21B 340 User output 5-Red

22A 341 User output 5-Orange

22B 342 User output 5-Yellow

23A 343 User output 5-Green

23B 344 User output 5-Blue

24A 345 User output 5-Purple

24B 346 User output 5-Gray

25A 347 User output 5-White

25B P24 External power +24V 5-Black

* This is the first expansion I/O. In the second expansion I/O,

the port numbers continue on from these numbers.

Inpu t

Output

024 User input 1-Red

324 User output 3-Blue

Page 31-A

•

•

∇

•

•

•

P24

0

•

Page 37

Chapter 1. Setting Up

DC24V Electromagnetic Valve Wiring Precautions (Example)

Super SEL

I/O Unit

24V Switching Power

Cable size

0.75° or greater

Output Relay Circuit

Separate

Wiring should be a separate system

Large Voltage Electromagnetic V alve Circuit

In a situation where the I/O unit drives the relay and the relay drives the electromagnetic valve, separate the output relay

circuit and the large voltage electromagnetic valve circuit as shown in the diagram above.

Page 32

Page 38

Chapter 1. Setting Up

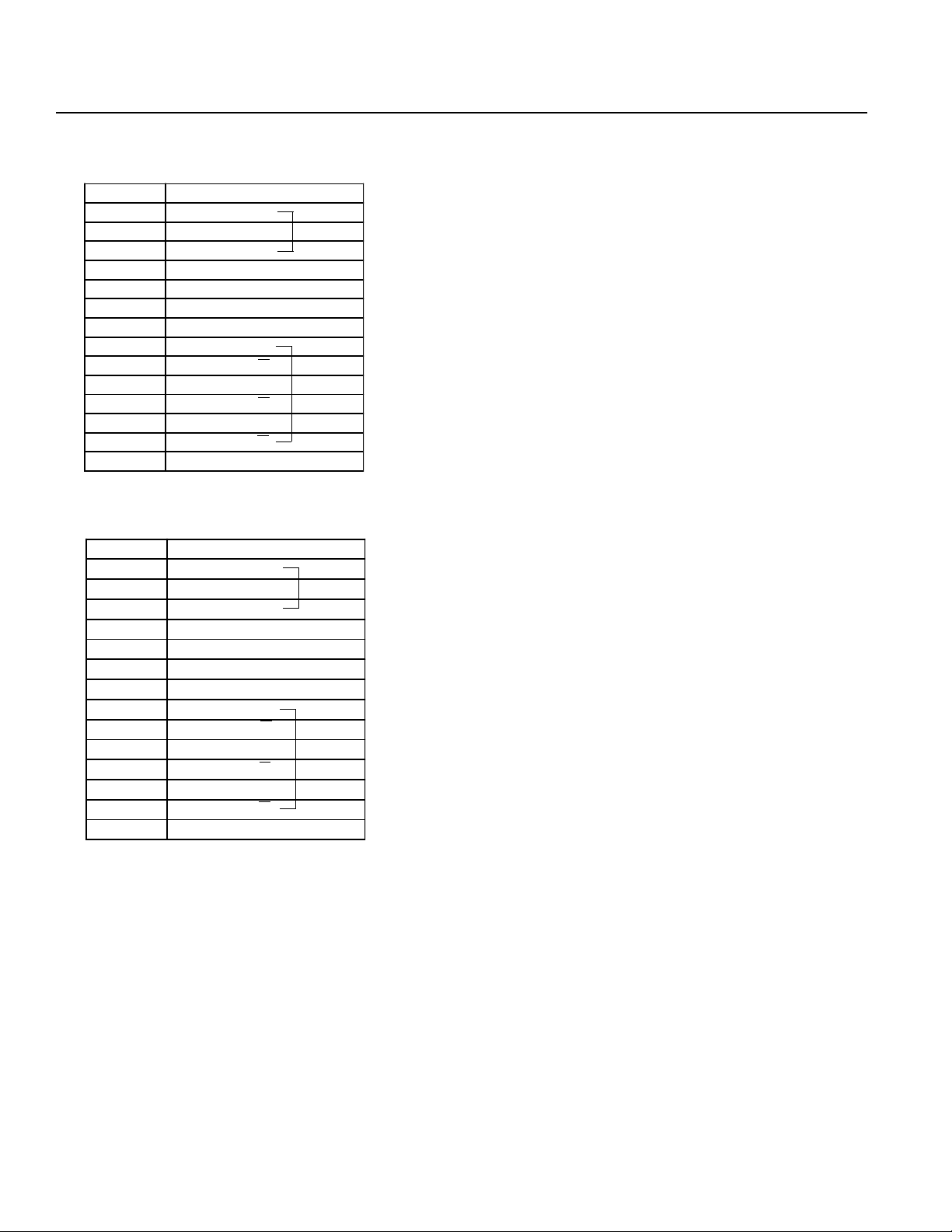

4. Teaching/RS232C Connector (D-Sub 25 DTE Special *)

Pin No. Signal

1 FG

2 TXD

3 RXD

4 (RTS)

5 (CTS)

6 DSR

7 SG

8 NC

9 NC

10 NC

11 NC

12 NC

13 NC

Pin No. Signal

14 NC

15 NC

16 NC

17 NC

18 +6.2V Output

19 NC

20 DTR

21 NC

22 NC

23

Emergency Stop

Switch (EMG.SW)

24 NC

25 0V (+6.2V)

*

*

*

* Pin numbers 18, 23, and 25 are for use with the teaching pendant signal. Do not connect these pins.

• Pin numbers 4 and 5 are short-circuited.

nn

nRS232C Cable

nn

Use RS232C cable pin configuration (between controller and computer serial port)

RS232C Adapter

(25 Pin Male)

1

Shield

l

Earth

2

l

TXD

3

l

RXD

4

l

RTS

5

l

CTS

6

l

DSR

7

l

GND

20

l

DTR

IBM PC

(9 Pin Female)

l

2

l

3

l

4

l

5

l

6

l

7

l

8

l

Earth

RXD

TXD

DTR

GND

DSR

RTS

CTS

RS232C Adapter

(25 Pin Male)

1

l

Earth

2

l

TXD

3

l

RXD

4

l

RTS

5

l

CTS

6

l

DSR

7

l

GND

20

ll

DTR

IBM PC

(25 Pin Female)

1

l

2

l

3

l

4

l

5

l

6

l

7

l

20

Earth

TXD

RXD

RTS

CTS

DSR

GND

DTR

Page 33

Page 39

Chapter 1. Setting Up

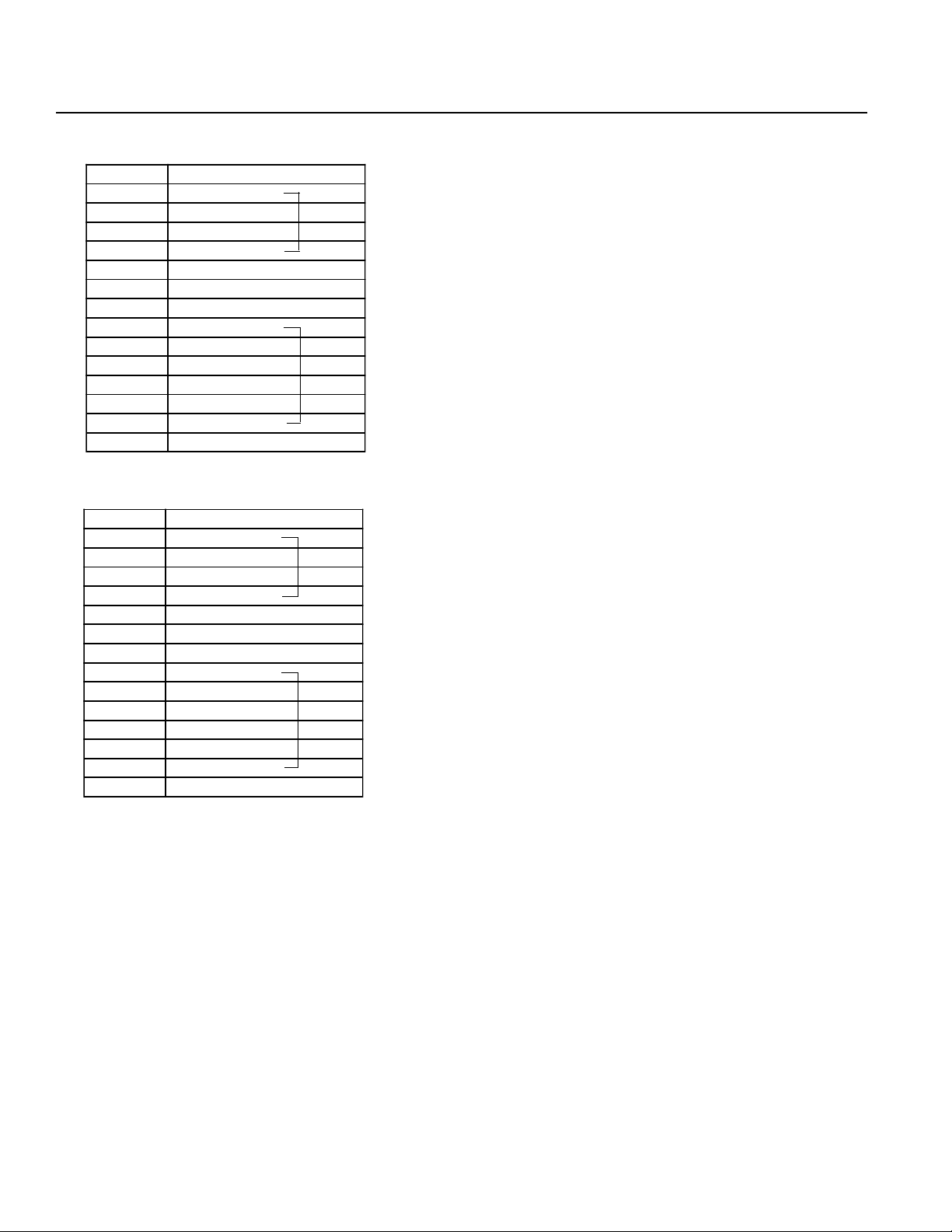

5. Connector Pin Assignment

The bottom view of the Super SEL Type E/G on the left shows the placement of the connectors. Please refer to Page 29 and

31 for the I/O connector and the I/O wiring (including the I/O expansion).

The connector pin assignment for the other parts are shown below.

(1) AC100W 2-Axis specifications

Power Supply Connector

Pin No. Signal

1AC117V

3AC117V

5FG

Nippon Molex 53265-0320 (3P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 3 Terminal

LS Connector (Option)

Pin No. Signal

1P24V

2N

3XLS

4YLS

5 E MG stop contact point input*

* The Emergency Stop is normally open.

BK Connector (Option)

Pin No. Signal

160V

2GD

3 XBK

4 YBK

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

X (1) Axis

X (1) Axis

Nippon Molex 53258-0520 (5P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 5 Terminal

Nippon Molex 53258-0420 (4P) (Body side)

51067-0500 Housing (4P)

50217-8100 x 4 Terminal

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Page 34

Page 40

Chapter 1. Setting Up

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

SEL NET SND Connector (Option)

Pin No. Signal

1NC

2NC

3RD

4TD

5GD

6FG

Y (2) Axis

Y (2) Axis

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Nippon Molex 53259-0620 (6P) (Body side)

51067-0600 Housing (6P)

50217-8100 x 6 Terminal

SEL NET RCV Connector (Option)

Pin No. Signal

1NC

2NC

3RD

4TD

5GD

6FG

Nippon Molex 53259-0620 (6P) (Body side)

51067-0600 Housing (6P)

50217-8100 x 6 Terminal

Page 35

Page 41

Chapter 1. Setting Up

(2) AC100W 4-Axis specifications

Power Supply Connector

Pin No. Signal

1AC117V

3AC117V

5FG

Nippon Molex 53265-0320 (3P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 3 Terminal

LS Connector (Option)

Pin No. Signal

1P24V

2N

3XLS

4YLS

5 EM G stop contact point input*

* The Emergency Stop is normally open.

LS Connector (Option)

Pin No. Signal

1P24V

2N

3ZLS

4

5 EM G stop contact point input*

* The Emergency Stop is normally open.

θ

LS

BK Connector (Option)

Pin No. Signal

1 60V

2GD

3 XBK

4 YBK

Nippon Molex 53258-0520 (5P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 5 Terminal

Nippon Molex 53258-0520 (5P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 5 Terminal

Nippon Molex 53258-0420 (4P) (Body side)

51067-0400 Housing (4P)

50217-8100 x 4 Terminal

Page 36

Page 42

Chapter 1. Setting Up

BK Connector (Option)

Pin No. Signal

160V

2GD

3 XBK

4

M·PG Connector (Motor/Encoder Signal)

θ

BK

Nippon Molex 53258-0420 (4P) (Body side)

51067-0400 Housing (4P)

50217-8100 x 4 Terminal

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

X (1) Axis

X (1) Axis

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

Y (2) Axis

Y (2) Axis

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Page 37

Page 43

Chapter 1. Setting Up

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

Z (3) Axis

Z (3) Axis

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

θ (4) Axis

θ (4) Axis

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Page 38

Page 44

Chapter 1. Setting Up

(3) AC200W 2-Axis specifications

Power Supply Connector

Pin No. Signal

1AC117V

3AC117V

5FG

Nippon Molex 53265-0320 (3P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 3 Terminal

LS Connector (Option)

Pin No. Signal

1P24V

2N

3XLS

4YLS

5 EM G stop contact point input*

* The Emergency Stop is normally open.

BK Connector (Option)

Pin No. Signal

160V

2GD

3 XBK

4 YBK

Nippon Molex 53258-0520 (5P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 5 Terminal

Nippon Molex 53258-0420 (4P) (Body side)

51067-0400 Housing (4P)

50217-8100 x 4 Terminal

Page 39

Page 45

Chapter 1. Setting Up

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

X (1) Axis

X (1) Axis

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

Y (2) Axis

Y (2) Axis

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Nippon Molex 53258-1420 (14P) (Body side)

51067-1400 Housing (14P)

50217-8100 x 14 Terminal

Page 40

Page 46

Chapter 1. Setting Up

(4) AC400W 1-Axis specifications

Power Supply Connector

Pin No. Signal

1AC117V

3AC117V

5FG

LS Connector (Option)

Pin No. Signal

1P24V

2N

3XLS

4YLS

5 EM G stop contact point input*

* The Emergency Stop is normally open.

Nippon Molex 53265-0320 (3P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 3 Terminal

Nippon Molex 53258-0520 (5P) (Body side)

51067-0500 Housing (5P)

50217-8100 x 5 Terminal

BK Connector (Option)

Pin No. Signal

160V

2GD

3 XBK

4 YBK

M·PG Connector (Motor/Encoder Signal)

Pin No. Signal

1U

2V

3W

4NC

5FG

6 PV5

7GD

8A

9A

10 B

11 B

12 Z

13 Z

14 FG

X (1) Axis

X (1) Axis

Nippon Molex 53258-0420 (4P) (Body side)

51067-0400 Housing (4P)

50217-8100 x 4 Terminal