Page 1

Operation Manual Fourteenth Edition

SCON Controller

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Operation Manual explains the handling methods, structure and maintenance of this product, among others,

providing the information you need to know to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained herein to

ensure safe use of the product.

The CD that comes with the product contains operation manuals for IAI products.

When using the product, refer to the necessary portions of the applicable operation manual by printing them out

or displaying them on a PC.

After reading the Operation Manual, keep it in a convenient place so that whoever is handling this product can

reference it quickly when necessary.

[Important]

This Operation Manual is original.

The product cannot be operated in any way unless expressly specified in this Operation Manual. IAI shall

assume no responsibility for the outcome of any operation not specified herein.

Information contained in this Operation Manual is subject to change without notice for the purpose of

product improvement.

If you have any question or comment regarding the content of this manual, please contact the IAI sales

office near you.

Using or copying all or part of this Operation Manual without permission is prohibited.

The company names, names of products and trademarks of each company shown in the sentence s are

registered trademarks.

Page 4

Page 5

1. PC Software and Teaching Pendant Models

New functions have been added to the entire SCON controller series.

To support these new features, the communication protocol has been changed to the general Modbus

(Modbus-compliant) mode. As a result, the existing PC software programs and teaching pendants

compatible with RCS/E-Con controllers can no longer be used.

If you are using this controller, use a compatible PC software program and/or teaching pendant selected

from the following models.

Model Remarks

PC software (with RS232C

communication cable)

PC software (with USB communication

cable)

Teaching pendant CON-T

Teaching pendant RCM-T

Simple teaching pendant RCM-E

Data setting unit RCM-P

Touch panel display RCM-PM-01

2. Recommendation for Backing up Latest Data

This product uses nonvolatile memory to store the position table and parameters. Normally the memory will

retain the stored data even after the power is disconnected. However, the data may be lost if the nonvolatile

memory becomes faulty.

(We strongly recommend that the latest position table and parameter data be backed up so that the data

can be restored quickly in the event of power failure, or when the controller must be replaced for a given

reason.)

The data can be backed up using the following methods:

[1] Save to a CD or FD from the PC software.

[2] Hand write the position table and parameter table on paper.

3. Using a Rotary Actuator of Multi-rotation Specification

Rotary actuators available in the multi-rotation specification allow the user to select the multi-rotation mode

or limited-rotation mode using a parameter.

For the parameter setting, refer to 3.2.5, “Linear/Rotary Control” under 3, “Parameter Settings” in Appendix.

When using a rotary actuator of multi-rotation specification, the user should take note of the following

points:

[1] Rotational axes of absolute specification do not support the index mode. Accordingly, these axes

cannot perform multi-rotation operations.

[2] In solenoid valve mode 2 [3-point type]: PIO pattern 5 (parameter No. 25), rotary operations cannot be

performed by means of relative coordinate specification.

Actuator

RCM-101-MW

RCM-101-USB

All are compatible with existing RCS/E-Con

controllers.

Cannot be connected to conventional RCS

controller

Applicable models

RS-30/60

RCS2-RT6/RT6R/RT7/RT7R

RCS2-RTC8L/RTC8HL/RTC10L/RTC12L

CAUTION

Page 6

±

2

6

3

1

Precautions

Please use rotary actuators of multi-rotation specification within the range where the following formula is

satisfied. Moreover, the maximum rotation angle is ±9999 [deg]

23

±2

Maximum rotation angle [deg]

≥

Unit Travel Distance [deg/pulse]

• Maximum rotation angle: Set the usage conditions (maximum -9999 to 9999 [deg]).

Note 1 :The following models can not be rotated up to ±9999.99 [deg].

deceleration

ratio

1/24

1/30

1/50

1/100

Maximum rotation angle

corresponding model

[deg]

±7679.99 RCS2-RTC8、RCS2-RTC10

±6143.99

±3685

RCS2-RTC12

RS-30、RS-60

±1842

• Unit movement: The amount of movement per command pulse.

Example) In case RCS2-RTC8L-I-12-24(deceleration ratio:1/24) is operated maximum rotation

angle 6000 [deg].

223

Maximum rotation angle [deg]

≥

Unit Travel Distance [deg/pulse]

23

≥

±2

Maximum rotation angle [deg]

23

±2

6000

≥

23

±2

≥

553600

×

16384

60

×

4

Therefore, the actuator can be operated in this case.

(NOTE1)

(maximum software stroke limit).

No. of Encoder Pluses [pulse/rev]

×

360[deg/rev] × Rotary Axis

deceleration

Ratio

Page 7

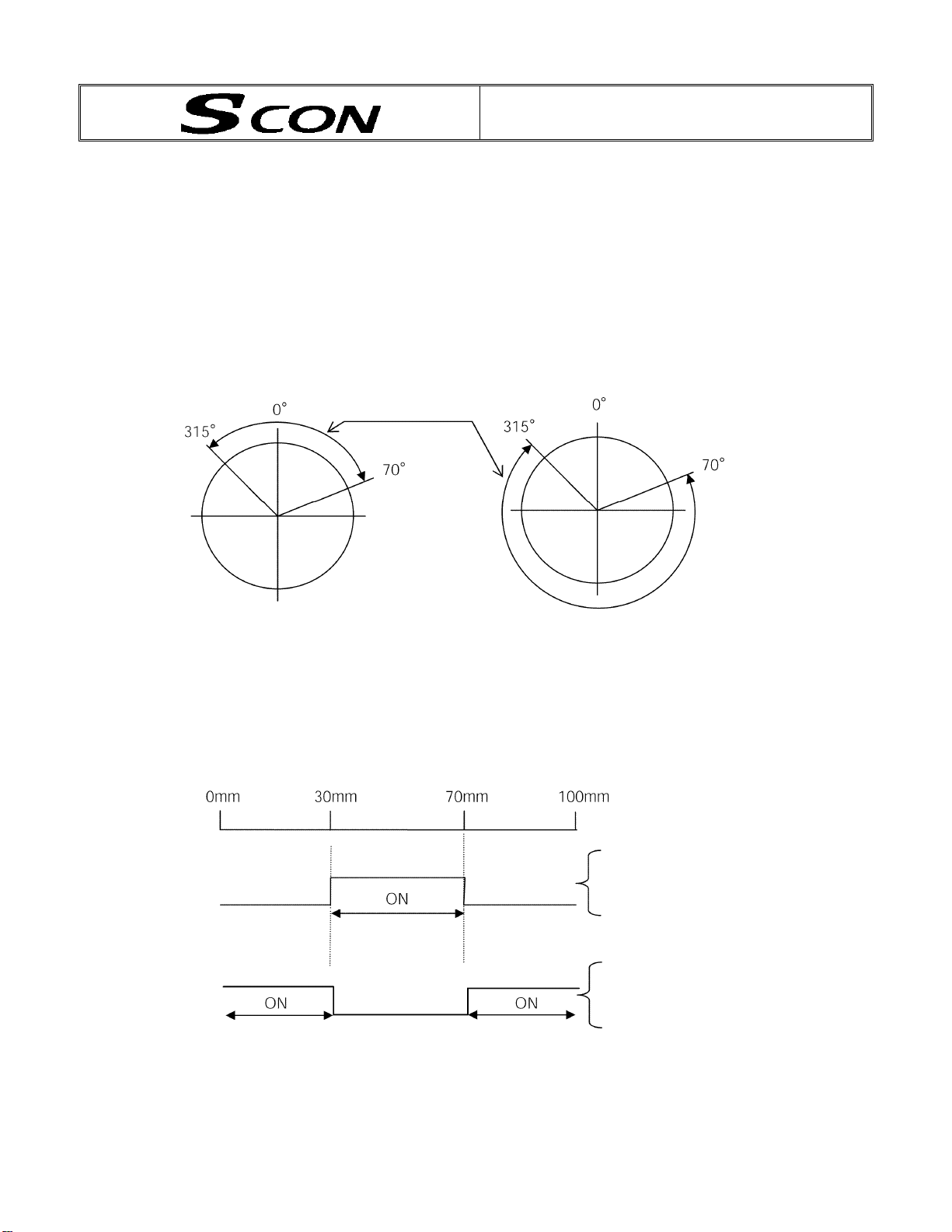

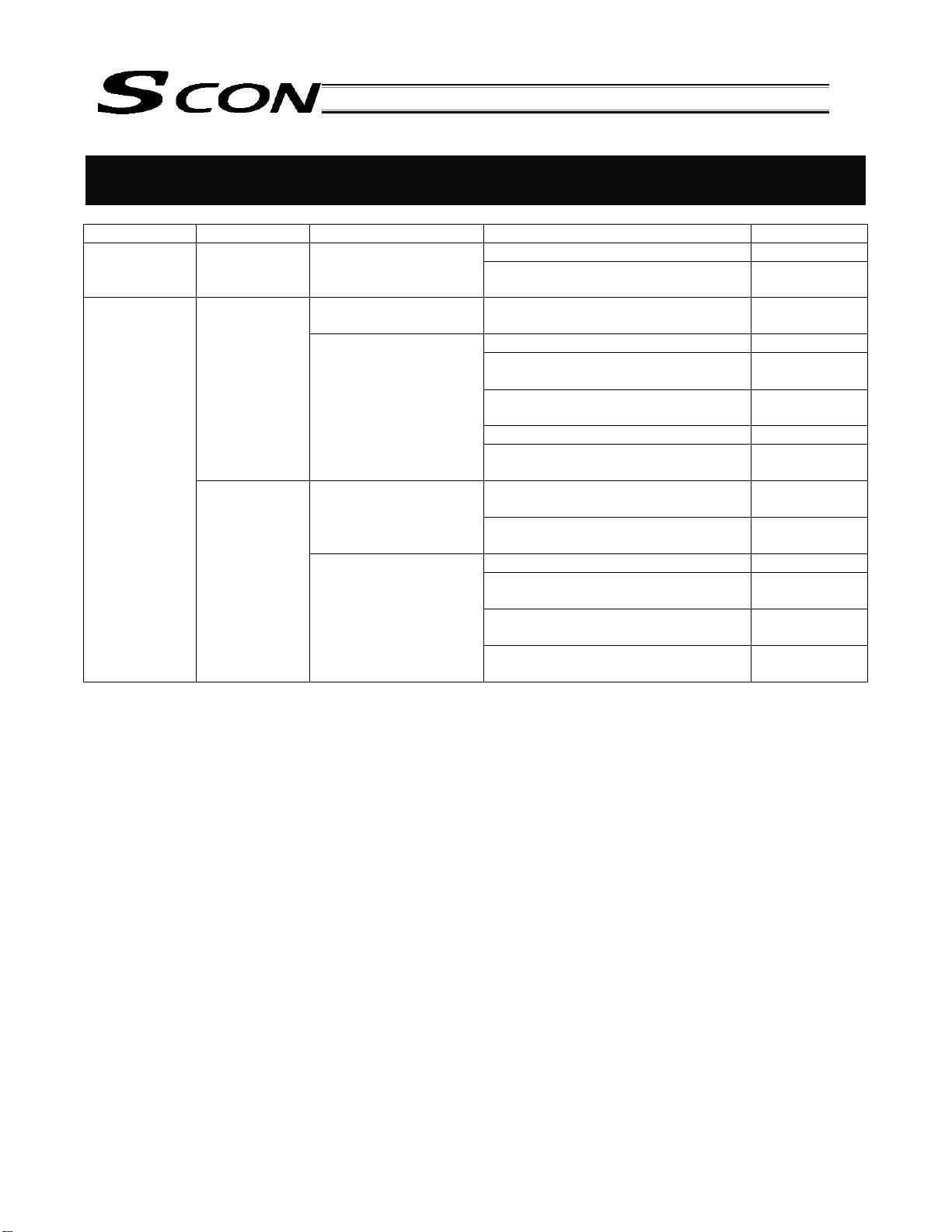

About zone function change

Applicable application version: From V001E

In zone signal settings, it is now valid to specify plus side zone setting smaller than minus side zone setting.

Up to V001D: Zone signals are not output in the case of plus side zone settin g minus side zone setting only.

From V001E: Zone signals are not output in the case of plus side zone settin g = minus side zone setting o nly.

With this arrangement, zone output is enabled even if the zone single ON range spans over 0 in the index mode

of rotary actuators.

An example is shown below.

[In index mode of rotary actuators]

Setting value

Plus side zone setting: 70

Minus side zone setting: 315

[In case of translation axis]

Current position

Zone signal output

Zone signal output

Range of

zone signal ON

Setting value

Plus side zone setting: 315

Minus side zone setting: 70

Setting value

Plus side zone setting: 70 mm

Minus side zone setting: 30 mm

Setting value

Plus side zone setting: 30 mm

Minus side zone setting: 70 mm

CAUTION

Page 8

Page 9

Table of Contents

Safety Guide....................................................................................................Pre-1

Chapter 1 Introduction .........................................................................................1

1. Overview.................................................................................................................................1

1.1 Introduction........................................................................................................................... 1

1.2 SCON Functions ..................................................................................................................1

1.3 How to Read the Model Specification ..................................................................................4

1.4 System Configuration........................................................................................................... 5

1.5 Procedure from Unpacking to Test Operation and Adjustment............................................ 6

1.6 Warranty Period and Scope of Warranty.............................................................................. 8

2. Specifications..........................................................................................................................9

2.1 Basic Specifications..............................................................................................................9

2.2 Name and Function of Each Part....................................................................................... 10

2.3 External Dimensions ..........................................................................................................21

3. Installation and Wiring...........................................................................................................23

3.1 Installation Environment..................................................................................................... 23

3.2 Heat Radiation and Installation ..........................................................................................23

3.3 Noise Elimination Measures and Grounding...................................................................... 24

3.4 Wiring the Power Supply....................................................................................................26

3.5 Connecting the Actuator..................................................................................................... 28

3.6 Connecting the PIO Cable (I/O)......................................................................................... 29

3.7 External Input/Output Specifications.................................................................................. 30

3.8 Connecting the Emergency Stop Input (Wiring to the System I/O Connector).................. 32

3.9 Connecting the Regenerative Unit (RB)............................................................................. 48

3.10 Connecting the Brake Box (RCB-110-RA13-0)..............................................................50

Chapter 2 Positioner Mode................................................................................52

1. I/O Signal Control and Signal Functions...............................................................................52

1.1 PIO Patterns and Signal Assignments ...............................................................................52

1.2 Connecting the I/O Cable................................................................................................... 61

1.3 Details of I/O Signal Functions...........................................................................................67

2. Data Entry.............................................................................................................................77

2.1 Description of Position Table..............................................................................................77

2.2 Explanation of Modes......................................................................................................... 84

2.3 Power-saving Modes at Standby Positions........................................................................ 94

3. Operation..............................................................................................................................96

3.1 How to Start........................................................................................................................96

3.2 How Return Operation...................................................................................................... 107

3.3 Positioning Mode (Back and Forth Movement between Two Points)...............................109

3.4 Push & Hold Mode ............................................................................................................111

3.5 Speed Change during Movement..................................................................................... 114

3.6 Operation at Different Acceleration and Deceleration Settings........................................ 116

3.7 Pause ............................................................................................................................... 118

3.8 Zone Signal Output .......................................................................................................... 120

3.9 Incremental Moves........................................................................................................... 123

Page 10

Jogging/Teaching Using PIO........................................................................................ 129

3.10

3.11 Operations in Solenoid Valve Mode 1 [7-point Type]....................................................131

3.12 Operations in Solenoid Valve Mode 2 [3-point Type]....................................................135

Chapter 3 Pulse-train Input Mode....................................................................142

1. Overview.............................................................................................................................142

1.1 Features ........................................................................................................................... 142

1.2 Standard Accessories.......................................................................................................143

1.3 Options .............................................................................................................................143

2. Wiring..................................................................................................................................147

2.1 External Connection Diagram..........................................................................................147

2.2 Command Pulse-train Input Specifications ......................................................................148

2.3 Feedback Pulse Output Part ............................................................................................149

3. I/O Signal Control and Signal Functions.............................................................................150

3.1 Input Signals.....................................................................................................................150

3.2 Output Signals..................................................................................................................156

4. How to Switch to the Pulse-train Control Mode...................................................................161

5. Parameters .........................................................................................................................162

5.1 Parameter Settings Required for Operation..................................................................... 162

5.2 Effective Parameters in the Pulse-train Mode.................................................................. 166

* Appendix ..........................................................................................................169

1. Actuator Specification List...................................................................................................169

2. Battery Backup Function.....................................................................................................174

2.1 Absolute-encoder Backup Battery....................................................................................175

3. Parameter Settings.............................................................................................................177

3.1 Parameter Table...............................................................................................................177

3.2 Detail Explanation of Parameters.....................................................................................179

4. PC/Teaching Pendant Connection Method in Multi-axis Configurations.............................202

4.1 Connection Example........................................................................................................202

4.2 Name and Function of Each Part of the SIO Converter...................................................203

4.3 Address Switch.................................................................................................................205

4.4 Connection Cables........................................................................................................... 205

4.5 Detail Connection Diagram ..............................................................................................206

5. Troubleshooting..................................................................................................................207

5.1 Action to Be T aken upon Occurrence of Problem............................................................207

5.2 Alarm Level Classification................................................................................................208

5.3 Alarm Description Output Using PIO................................................................................209

5.4 Alarm Description and Cause/Action ............................................................................... 211

5.5 Messages Displayed during Operation Using the Teaching Pendant..............................220

5.6 Specific Problems.............................................................................................................222

6. Basic Example of Positioning Sequence ............................................................................224

Recording of Parameters ...........................................................................................................227

Change History...................................................................................................229

Page 11

Safety Guide

This “Safety Guide” is intended to ensure the correct use of this product and prevent dangers and property

damage. Be sure to read this section before using your product.

Regulations and Standards Governing Industrial Robots

Safety measures on mechanical devices are generally classified into four categori es under the International

Industrial Standard ISO/DIS 12100, “Safety of machinery,” as follows:

Safety measures Inherent safety design

Protective guards --- Safety fence, etc.

Additional safety measures --- Emergency stop device, etc.

Information on use --- Danger sign, warnings, operation manual

Based on this classification, various standards are established in a hierarchical manner unde r the International

Standards ISO/IEC. The safety standards that apply to industrial robots are as follows:

Type C standards (individual safety standards) ISO10218 (Manipulating industrial robots – Safety)

JIS B 8433

(Manipulating industrial robots – Safety)

Also, Japanese laws regulate the safety of industrial robots, as follows:

Industrial Safety and Health Law Article 59

Workers engaged in dangerous or harmful operations must recei ve special education.

Ordinance on Industrial Safety and Health

Article 36 --- Operations requiring special education

No. 31 (Teaching, etc.) --- Teaching and other similar work involving industrial robots (exceptions

apply)

No. 32 (Inspection, etc.) --- Inspection, repair, adjustment and similar work involving industrial robots

(exceptions apply)

Article 150 --- Measures to be taken by the user of an industrial robot

Pre-1

Page 12

Requirements for Industrial Robots under Ordinance on Industrial Safety and

Health

Work area Work condition Cutoff of drive source Measure Article

Signs for starting operation Article 104 Outside

Installation of railings, enclosures,

etc.

Sign, etc., indicating that work is in

progress

Preparation of work rules Article 150-3

Measures to enable immediate

stopping of operation

Sign, etc., indicating that work is in

progress

Provision of special education Article 36-31

Checkup, etc., before

commencement of work

To be performed after stopping the

operation

Sign, etc., indicating that work is in

progress

Preparation of work rules Article 150-5

Measures to enable immediate

stopping of operation

Sign, etc., indicating that work is in

progress

Provision of special education

(excluding cleaning and lubrication)

Article 150-4

Article 150-3

Article 150-3

Article 150-3

Article 151

Article 150-5

Article 150-5

Article 150-5

Article 150-5

Article 36-32

movement

range

Inside

movement

range

During

automatic

operation

During

teaching, etc.

During

inspection, etc.

Not cut off

Cut off (including

stopping of operation)

Not cut off

Cut off

Not cut off (when

inspection, etc., must

be performed during

operation)

Pre-2

Page 13

Applicable Modes of IAI’s Industrial Robot

Machines meeting the following conditions are not classified as industrial robots according to Notice of Ministry

of Labor No. 51 and Notice of Ministry of Labor/Labor Standards Office Director (Ki-Hatsu No. 340):

(1) Single-axis robo with a motor wattage of 80 W or less

(2) Combined multi-axis robot whose X, Y and Z-axes are 300 mm or shorter and whose rotating part, if

any, has the maximum movement range of within 300 mm

(3) Multi-joint robot whose movable radius and Z-axis are within 300 mm

Among the products featured in our catalogs, the following models are classified as industrial robots:

1. Single-axis ROBO Cylinders

RCS2/RCS2CR-SS8

2. Single-axis robots

The following models whose stroke exceeds 300 mm and who se motor capacity also exceeds 80 W:

ISA/ISPA, ISDA/ISPDA, ISWA/ISPWA, IF, FS, NS

3. Linear servo actuators

All models whose stroke exceeds 300 mm

4. Cartesian robos

Any robot that uses at least one axis corresponding to one of the models specified in 1 to 3

5. IX SCARA robots

All models whose arm length exceeds 300 mm

(All models excluding IX-NNN1205/1505/1805/2515, NNW2515 and NNC1205/1 505/1805/2515)

whose stroke exceeds 300 mm

3

including the tip of the rotating part

Pre-3

Page 14

Notes on Safety of Our Products

Common items you should note when performing each task on any IAI robot are explained below.

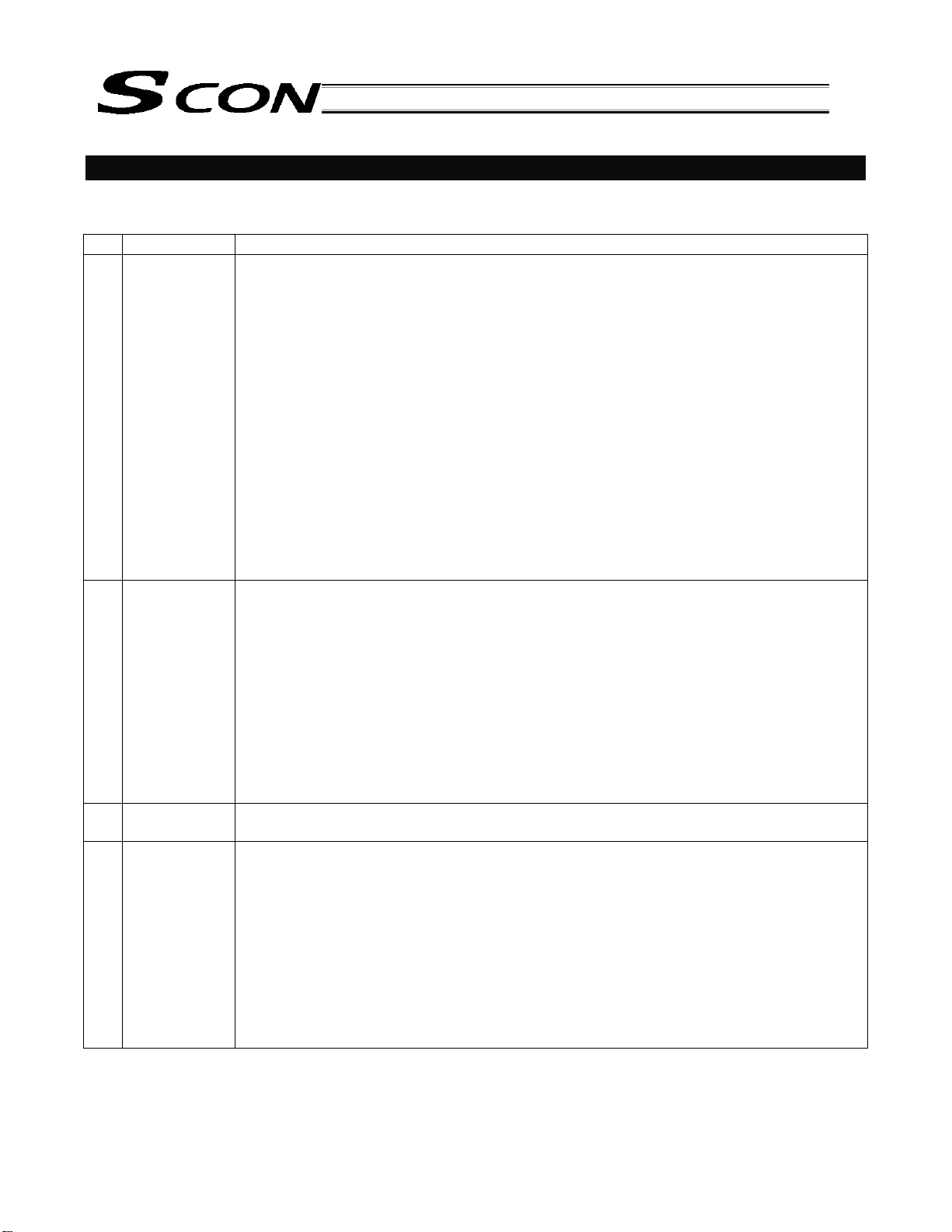

No. Task Note

1 Model

selection

2 Transportation

3 Storage/

preservation

4 Installation/

startup

This product is not planned or designed for uses requiring high degrees of safety.

Accordingly, it cannot be used to sustain or support life and must not be used in the

following applications:

[1] Medical devices relating to maintenance, management, etc., of life or health

[2] Mechanisms or mechanical devices (vehicles, railway facilities, aircraft facilities, etc.)

intended to move or transport people

[3] Important safety parts in mechanical devices (safety devices, etc.)

Do not use this product in the following environments:

[1] Place subject to flammable gases, ignitable objects, flammables, explosives, etc.

[2] Place that may be exposed to radiation

[3] Place where the surrounding air temperature or relative humidity exceeds the specified

range

[4] Place subject to direct sunlight or radiated heat from large heat sources

[5] Place subject to sudden temperature shift and condensation

[6] Place subject to corrosive gases (sulfuric acid, hydrochloric acid, etc.)

[7] Place subject to excessive dust, salt or iron powder

[8] Place where the product receives direct vibration or impact

Do not use this product outside the specified ranges. Doing so may significantly shorten

the life of the product or result in product failure or facility stoppage.

When transporting the product, exercise due caution not to bump or drop the product.

Use appropriate means for transportation.

Do not step on the package.

Do not place on the package any heavy article that may deform the package.

When using a crane of 1 ton or more in capacity, make sure the crane operators are

qualified to operate cranes and perform slinging work.

When using a crane, etc., never hoist articles exceeding the rated load of the crane, etc.

Use hoisting equipment suitable for the article to be hoisted. Calculate the load needed

to cut off the hoisting equipment and other loads incidental to equipment operation by

considering a safety factor. Also check the hoisting equipment for damage.

Do not climb onto the article while it is being hoisted.

Do not keep the article hoisted for an extended period of time.

Do not stand under the hoisted article.

The storage/preservation environment should conform to the installation environment.

Among others, be careful not to cause condensation.

(1) Installing the robot, controller, etc.

Be sure to firmly secure and affix the product (including its work part).

If the product tips over, drops, malfunctions, etc., damage or injury may result.

Do not step on the product or place any article on top. The product may tip over or the

article may drop, resulting in injury, product damage, loss of/drop in product

performance, shorter life, etc.

If the product is used in any of the following places, provide sufficient shielding

measures:

[1] Place subject to electrical noise

[2] Place subject to a strong electric or magnetic field

[3] Place where power lines or drive lines are wired nearby

[4] Place subject to splashed water, oil or chemicals

Pre-4

Page 15

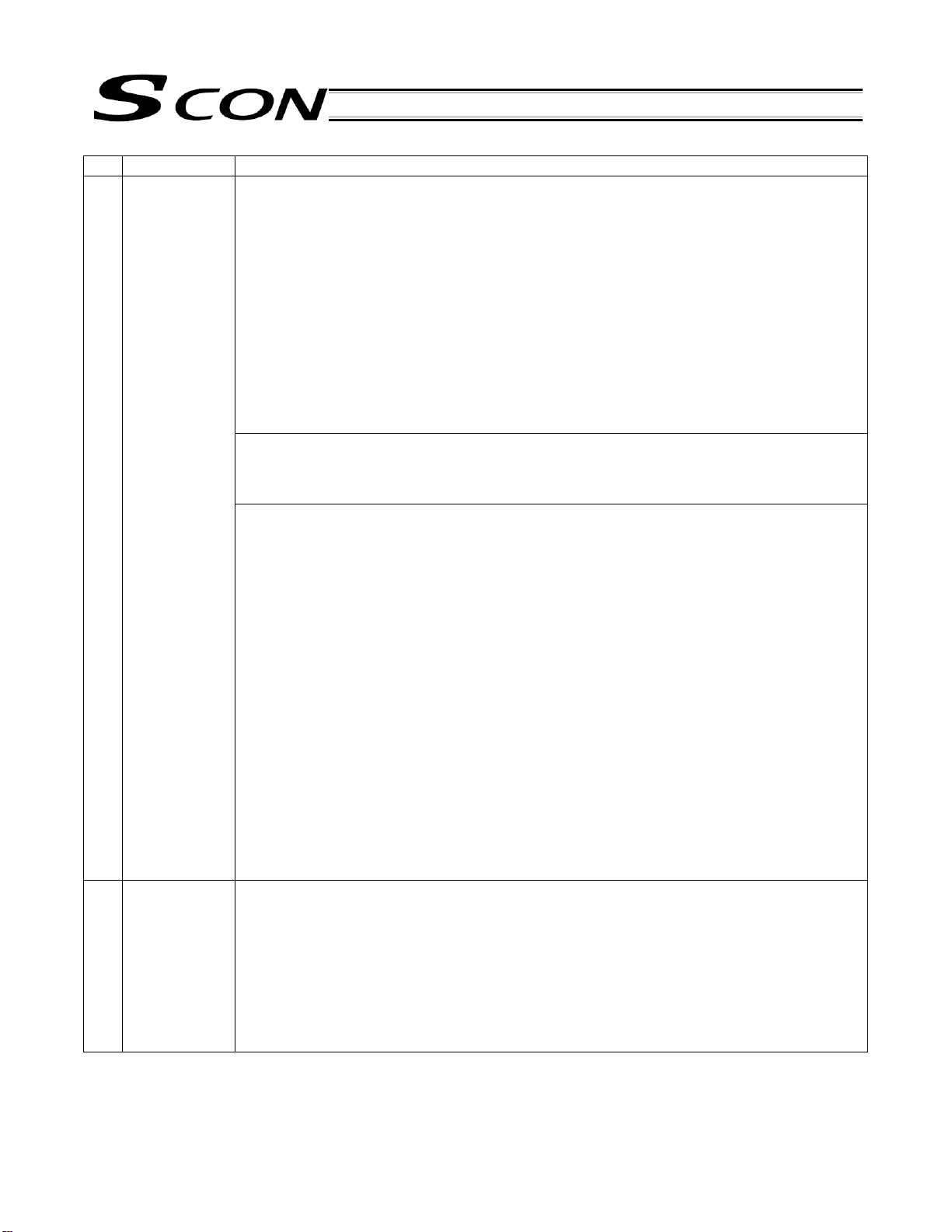

No. Task Note

4 Installation/

startup

(2) Wiring the cables

Use IAI’s genuine cables to connect the actuator and controller or connect a teaching

tool, etc.

Do not damage, forcibly bend, pull, loop round an object or pinch the cables or place

heavy articles on top. Current leak or poor electrical continuity may occur, resulting in

fire, electric shock or malfunction.

Wire the product correctly after turning off the power.

When wiring a DC power supply (+24 V), pay attention to the positive and negative

polarities.

Connecting the wires in wrong polarities may result in fire, product failure or

malfunction.

Securely connect the cables and connectors so that they will not be disconnected or

come loose. Failing to do so may result in fire, electric shock or product malfunction.

Do not cut and reconnect the cables of the product to extend or shorten the cables.

Doing so may result in fire or product malfunction.

(3) Grounding

Be sure to provide class D (former class 3) grounding for the controller. Grounding is

required to prevent electric shock and electrostatic charges, improve noise resistance

and suppress unnecessary electromagnetic radiation.

(4) Safety measures

Implement safety measures (such as installing safety fences, etc.) to prevent entry into

the movement range of the robot when the product is moving or can be moved.

Contacting the moving robot may result in death or serious injury.

Be sure to provide an emergency stop circuit so that the product can be stopped

immediately in case of emergency during operation.

Implement safety measures so that the product cannot be started only by turning on the

power. If the product starts suddenly, injury or product damage may result.

Implement safety measures so that the product will not start upon cancellation of an

emergency stop or recovery of power following a power outage. Failure to do so may

result in injury, equipment damage, etc.

Put up a sign saying “WORK IN PROGRESS. DO NOT TURN ON POWER,” etc.,

during installation, adjustment, etc. If the power is accidently turned on, electric shock or

injury may result.

Implement measures to prevent the work part, etc., from dropping due to a power

outage or emergency stop.

Ensure safety by wearing protective gloves, protective goggles and/or safety shoes, as

necessary.

Do not insert fingers and objects into openings in the product. Doing so may result in

injury, electric shock, product damage, fire, etc.

When releasing the brake of the vertically installed actuator, be careful not to let the

actuator drop due to its dead weight, causing pinched hands or damaged work part, etc.

5 Teaching

Whenever possible, perform teaching from outside the safety fences. If teaching must

be performed inside the safety fences, prepare “work rules” and ma ke sure the operator

understands the procedures thoroughly.

When working inside the safety fences, the operator should carry a handy emergency

stop switch so that the operation can be stopped any time when an abnormality occurs.

When working inside the safety fences, appoint a safety watcher in addition to the

operator so that the operation can be stopped any time when an abnormality occurs.

The safety watcher must also make sure the switches are not operated inadvertently by

a third party.

Put up a sign saying “WORK IN PROGRESS” in a conspicuous location.

Pre-5

Page 16

No. Task Note

5 Teaching When releasing the brake of the vertically installed actuator, be careful not to let the

actuator drop due to its dead weight, causing pinched hands or damaged lo ad, etc.

* Safety fences --- Indicate the movement range if safety fences are not provided.

6 Confirmation

operation

After teaching or programming, carry out step-by-step confirmation operation before

switching to automatic operation.

When carrying out confirmation operation inside the safety fences, follow the specified

work procedure just like during teaching.

When confirming the program operation, use the safety speed. Failure to do so may

result in an unexpected movement due to programming errors, etc., causing injury.

Do not touch the terminal blocks and various setting switches while the power is

supplied. Touching these parts may result in electric shock or malfunction.

7 Automatic

operation

Before commencing automatic operation, make sure no one is inside the safety fences.

Before commencing automatic operation, make sure all related peripherals are ready to

operate in the auto mode and no abnormalities are displayed or indicated.

Be sure to start automatic operation from outside the safety fences.

If the product generated abnormal heat, smoke, odor or noise, stop the product

immediately and turn off the power switch. Failure to do so may result in fire or product

damage.

If a power outage occurred, turn off the power switch. Otherwise, the product may move

suddenly when the power is restored, resulting in injury or product damage.

8 Maintenance/

inspection

Whenever possible, work from outside the safety fences. If work must be performed

inside the safety fences, prepare “work rules” and make sure the operator understands

the procedures thoroughly.

When working inside the safety fences, turn off the power switch, as a rule.

When working inside the safety fences, the operator should carry a handy emergency

stop switch so that the operation can be stopped any time when an abnormality occurs.

When working inside the safety fences, appoint a safety watcher in addition to the

operator so that the operation can be stopped any time when an abnormality occurs.

The safety watcher must also make sure the switches are not operated inadvertently by

a third party.

Put up a sign saying “WORK IN PROGRESS” in a conspicuous location.

Use appropriate grease for the guides and ball screws by checking the operation

manual for each model.

Do not perform a withstand voltage test. Conducting this test may result in product

damage.

When releasing the brake of the vertically installed actuator, be careful not to let the

actuator drop due to its dead weight, causing pinched hands or damaged work part, etc.

* Safety fences --- Indicate the movement range if safety fences are not provided.

9 Modification The customer must not modify or disassemble/assemble the product or use

maintenance parts not specified in the manual without first consulting IAI.

Any damage or loss resulting from the above actions will be excluded from the scope of

warranty.

10 Disposal When the product becomes no longer usable or necessary, dispose of it properly as an

industrial waste.

When disposing of the product, do not throw it into fire. The product may explode or

generate toxic gases.

Pre-6

Page 17

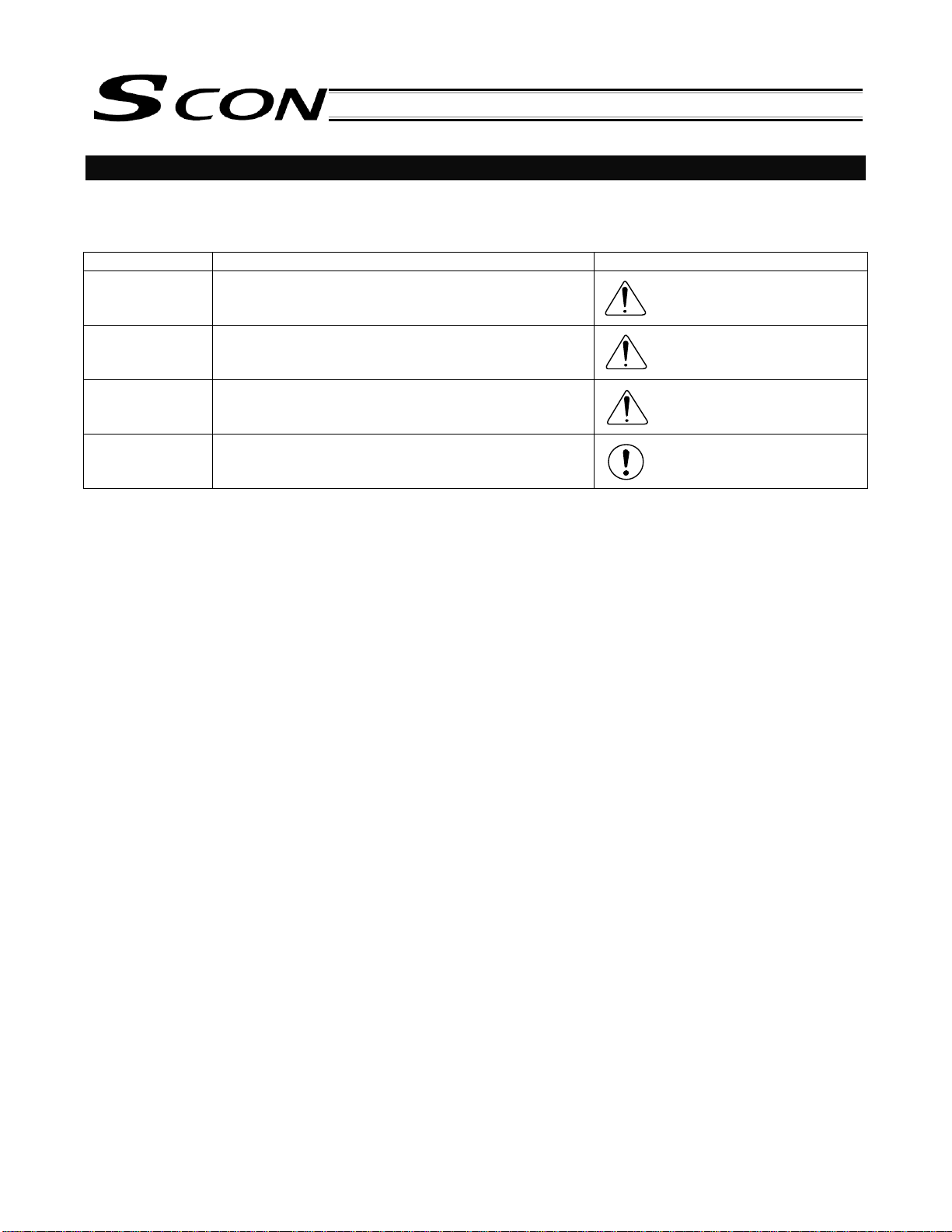

Indication of Cautionary Information

The operation manual for each model denotes safety precautions under “Danger,” “Warning,” “Caution” a nd

“Note,” as specified below.

Level Degree of danger/loss Symbol

Danger

Warning

Caution

Note

Failure to observe the instruction will result in an

imminent danger leading to death or serious injury.

Failure to observe the instruction may result in death

or serious injury.

Failure to observe the instruction may result in injury

or property damage.

The user should take heed of this information to

ensure the proper use of the product, although failure

to do so will not result in injury.

Danger

Warning

Caution

Note

Pre-7

Page 18

CE Marking

CE Marking

If a compliance with the CE Marking is required, please follow Overseas Standards Compliance Manual

(ME0287) that is provided separately.

Pre-8

Page 19

Chapter 1 Introduction

1. Overview

1.1 Introduction

Thank you for purchasing the SCON controller.

Please read this manual carefully to handle the controller with due care while ensuring the correct operation of

the controller.

Keep this manual with you so that you can reference the applicable sections whenever necessary.

Should you encounter any trouble when actually starting up your system, also refer to the manuals for the

teaching pendant, PC software and other components included in your system, in addition to this manual.

This manual does not cover all possible operations other than normal operations, or unexpected events such as

complex signal changes resulting from use of critical timings.

Accordingly, you should consider items not specifically explained in this manual as “prohibited.”

* We have made every effort to ensure precision of the information provided in this manual. Should you find an

error, however, or if you have any comment, please contact IAI.

Keep this manual in a convenient place so it can be referenced readily when necessary.

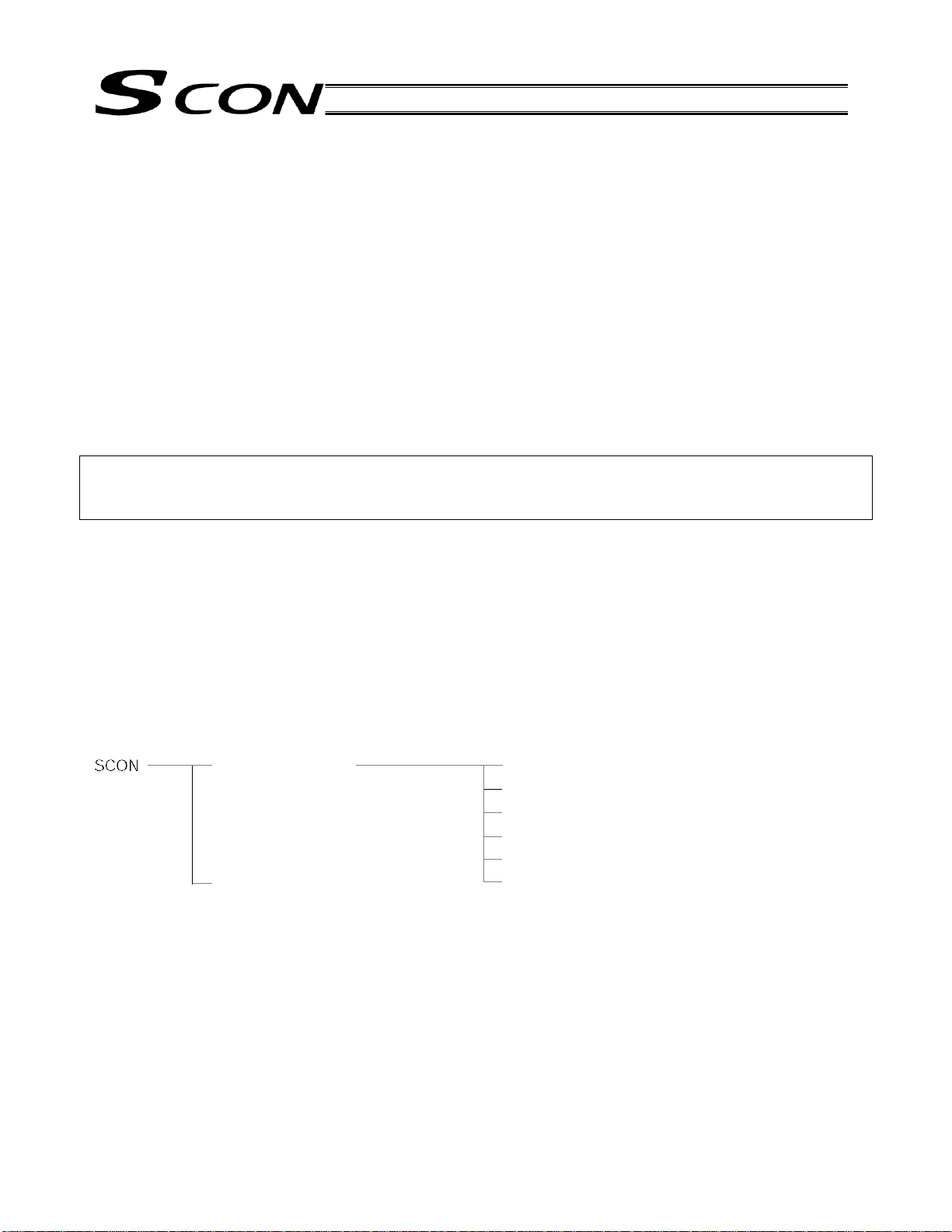

1.2 SCON Functions

The SCON is a single-axis AC servo controller capable of controlling actuators in the position er mode or the

pulse-train input mode.

The functions of SCON are as follows:

The positioner mode and the pulse-train input mode cannot be used at the same time.

Switching of modes uses the piano switch located on the front face of the controller.

Positioner mode

Pulse-train input mode

Positioning mode [Standard type]

Teaching mode [Teaching type]

256-point mode [256-point type]

512-point mode [512-point type]

Solenoid valve mode 1 [7-point type]

Solenoid valve mode 2 [3-point type]

1

Page 20

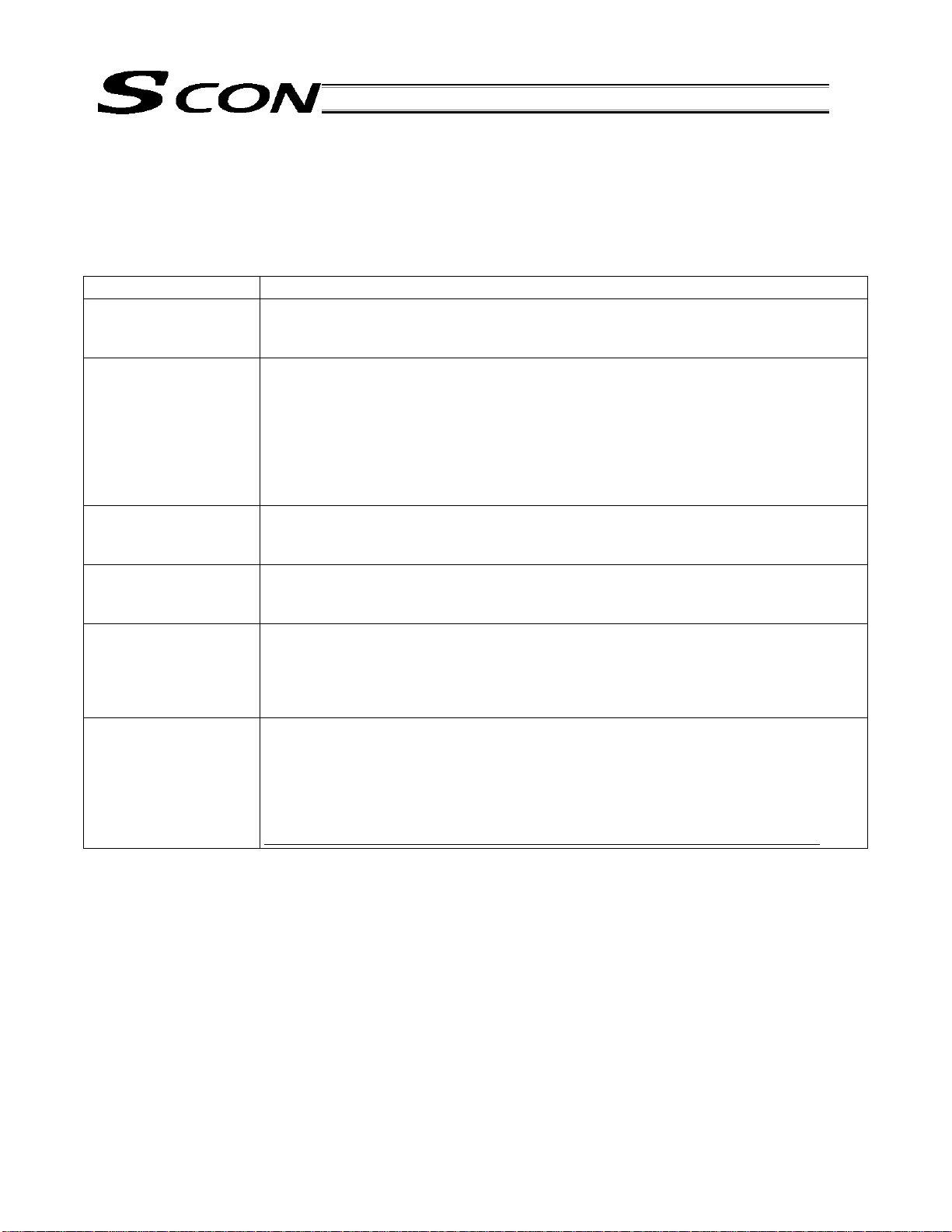

1.2.1 Features of the Positioner Mode

In the positioner mode, one of five PIO patterns is selected using a parameter.

The number of positioning points and input/output functions vary depending on the PIO pattern selected.

The table below lists the parameter settings and corresponding PIO patterns, as well as the features of each PIO

pattern.

Parameter setting Features of PIO pattern

0 Positioning mode [Standard type]

64 positioning points are supported.

Available output functions include the moving output and zone output.

1 Teaching mode [Teaching type]

64 positioning points are supported.

Normal positioning operation can be performed, along with jogging via I/O operation

and writing of the current position to the position table.

The MODE input signal is used to switch between the normal positioning operation

mode and the teaching mode.

The zone output (set by parameters) and brake forced-release input accessible in the

standard type are not available in this type.

2 256-point mode [256-point type]

The moving output and zone output (set by parameters) accessible in the standard

type are not available in this type.

3 512-point mode [512-point type]

The moving output and zone output (set by parameters/position data) accessible in the

standard type are not available in this type.

4 Solenoid valve mode 1 [7-point type]

Seven positioning points are supported.

Direct command inputs and position complete outputs are provide d separately for

different target positions to simulate air-cylinder control.

The moving output accessible in the standard type is not available in this type.

5 Solenoid valve mode 2 [3-point type]

Three positioning points are supported.

The function of position complete output signals is different from how these signals

function in the 7-point type.

The “position detection” function, which operates just like an auto-switch of an air

cylinder, is also available.

Take note that incremental positioning commands are not supported in this mode.

2

Page 21

1.2.2 Features of the Pulse-train Input Mode

Dedicated home return signal

Home return operation is supported in this mode.

When this function is used, home return can be performed automatically without having to program a

complex sequence or use an external sensor, etc.

Brake control function

The electromagnetic brake power is supplied to the controller from a power supply different from the main

power. Since the controller controls the brake, there is no need to program a separate sequence. Also, the

electromagnetic brake can be released freely after the main power has been cut off.

Torque limiting function

The torque can be limited (a desired limit can be set by a parameter) using an external signal. When the

torque reaches the specified level, a signal will be output. This function permits push & hold operation, pressfit operation, etc.

Feed-forward control function

With this function, response can be improved in certain situations such as when the load inertia ratio is high.

Increasing the parameter value will reduce the deviation (difference between th e position command and the

position feedback), thereby improving response.

Position-command primary filter function

Soft start and stop can be achieved even when the actuator is operated in the command-pulse input mode

where acceleration and deceleration are not considered.

Feedback function

Position detection data is output using pulse trains (differential).

The current actuator position can be read in real time from the host controller.

3

Page 22

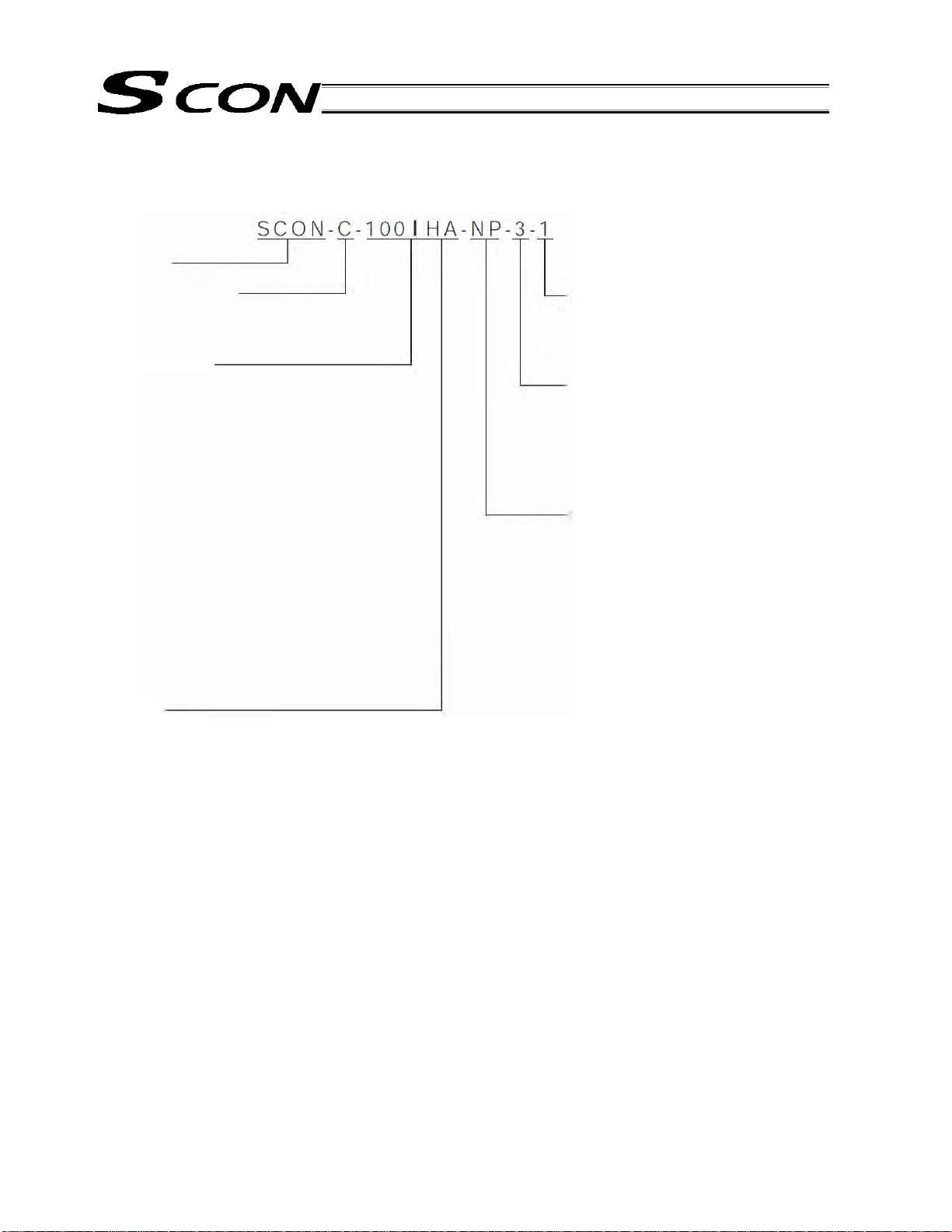

1.3 How to Read the Model Specification

<Series>

<Controller type>

C: Standard type

<Motor capacity>

20: 20W

30D: 30 W for DS

30R: 30 W for RS

60: 60W

100: 100W

150: 150W

200: 200W

200S: 200 W for linear

300S: 300 W for linear

400: 400W

600: 600W

750: 750W

<Encoder type>

I: Incremental

A: Absolute

<Option>

HA: High acceleration/deceleration specification

<Power-supply voltage>

1: Single phase 100 VAC

2: Single phase 200 VAC

<I/O cable length>

2: 2 m

3: 3 m

5: 5 m

0: Not supplied

<I/O types>

NP: NPN specification

PN: PNP specification

DV: DeviceNet specification

CC: CC-Link specification

RR: PROFIBUS connection specification

4

Page 23

A

A

r

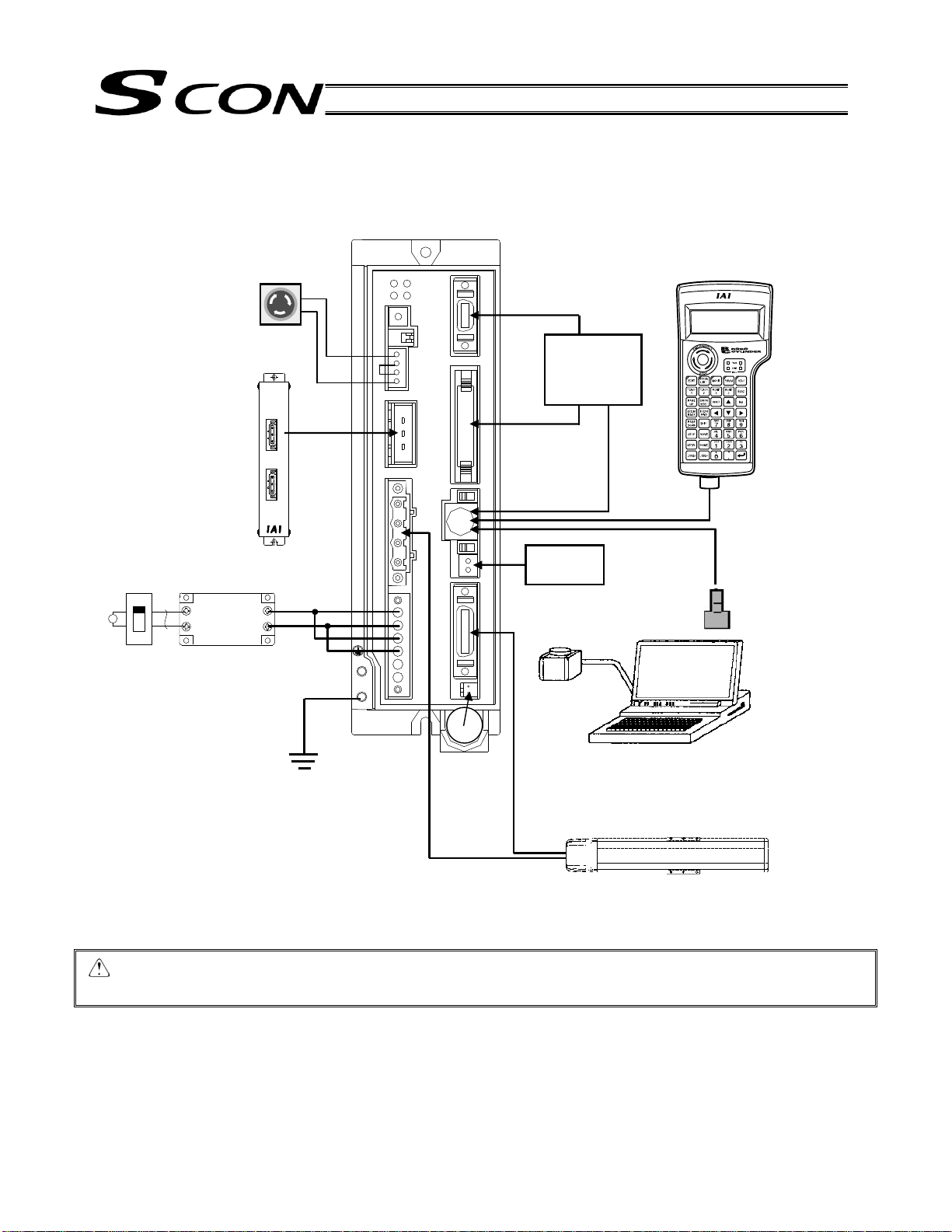

1.4 System Configuration

Regenerative

resistance unit

It may become

necessary depending

on the use condition.

Breaker

Note) Noise filter

MC1210 by

Densei-Lambda

EMG switch

Grounded

Absolute

battery

Host control

system

DC24V

bsolute battery

Brake power

supply

PC

ctuato

Teaching

pendant

Caution: The customer must provide a noise filter. A noise filter is always required at the minimum, even

when your system need not conform to the EC Directives. Also add clamp filters, etc., if necessary.

5

Page 24

1.5 Procedure from Unpacking to Test Operation and Adjustment

If you are using this product for the first time, carry out each step by referring to the procedure below to ensure

that all necessary items are checked and all wires are connected corre ctly. The procedure below covers the flow

from unpacking to trial operation using a PC or teaching pendant.

(1) Check the content in the package

If you found any missing part or part specified for a different model, please contact your dealer.

* Check that the model specification pasted on the controller and the model specification of the delivered

actuator match.

Controller SCON-*-

Motor cable

Encoder cable

I/O flat cable

Pulse-train control connector plug: 10114-3000PE (Sumitomo 3M)

Pulse-train control connector housing: 10314-52F0-008 (Sumitomo 3M)

Actuator

Options

Pulse converter AK-04, JM-08

Teaching pendant COM-T RCM-T RCM-E RCM-P

PC software RCM-101-MW, RCM-101-USB

Regenerative unit

Touch panel display RCM-PM-01 (supported from system software version V0015)

(2) Installation

[1] Affix the actuator.

[2] Install the controller.

(3) Wiring/connection

Connect the motor cable and encoder cable.

Wire the AC power supply.

Connect the grounding wire to ground.

Wire the emergency stop circuit.

Connect the I/O flat cable (wiring with the host PLC and 24-V I/O power supply).

Connect the 24-V brake power supply (only if the actuator is equipped with a brake).

Connect the regenerative unit(s). The need for regenerative unit will vary depending on the use condition.

(4) Turn on the power and check for alarms

[1] If the SCON is to be used in the positioner mode, set piano switch 1 to the OFF position (ri ght side).

[2] Connect the PC or teaching pendant, and then set the AUTO/MANU switch to the MANU position.

[3] Input the 24-V I/O power.

[4] If the actuator is equipped with a brake, turn on the 24-V power supply for the brake.

[5] Input the AC power (control power, drive power).

If an emergency stop is actuated, the EMG LED indicator will illuminate in red.

If an alarm generates, the ALM LED indicator will illuminate in orange. Check the nature of the alarm using the

PC or teaching pendant and remove the cause by referring to Appendix 5, “Troubleshooting.”

System I/O shorting connector

Power connector

Brake connector

6

Page 25

(5) Set parameters

Before the 24-V I/O power supply is connected, PIO power monitor can be disabled temporarily by changing

the applicable parameter setting.

Parameter No. 74, “PIO power monitor”: 0 (Enable) 1 (Disable)

Note) After the 24-V I/O power supply has been connected, be sure to reset parameter No. 74 to “0” to

enable PIO power monitor.

If the host PLC or other host controller is not yet wired and the servo-on signal cannot be input, the servo-on

input can be disabled temporarily by changing the applicable parameter setting.

Parameter No. 21, “Servo-on input”: 0 (Enable) 1 (Disable)

Note) After the host PLC, etc., has been wired, be sure to reset parameter No. 21 to “0” to enable the

servo-on input.

Change the safety speed, if necessary.

The factory-set safety speed is “100 mm/sec.” (If the maximum speed is less than 100 mm/sec, the safety speed

conforms to the maximum speed.)

Select a desired PIO pattern using the applicable parameter.

Parameter No. 25, “PIO pattern selection”: 0 to 5

When a parameter has been changed, the new setting will become effective once the power is reconnected or

software is reset.

(6) Check the servo-on status

When the servo turns on, the SV LED indicator will illuminate in green. (In the MANU teaching mode, the servo

will not turn on even when the servo-on signal is input after the AC power has been turned on. )

If the servo-on input is disabled by the parameter and the controller is in the AUTO mode, the servo will turn on

automatically after the controller has started.

(7) Operate with the PC or teaching pendant

While the servo is on, perform the operation check specified below. For details on the operating method, refer to

the operation manual for your PC software or teaching pendant.

[1] Use the PC or teaching pendant to set a target position in the “Position” field of the position table.

[2] Perform home return.

[3] Move the actuator to the specified position.

(8) Check the actuation of the emergency stop circuit

While the actuator is operating, press the emergency stop button to confirm that an emergency stop will be

actuated.

Caution: When the teaching pendant is disconnected, an emergency stop is actuated momentarily. The

emergency stop will be cancelled immediately thereafter, but the actuator and other equipment that

are operating when the teaching pendant is disconnected will stop.

Therefore, do not disconnect the teaching pendant when an actuator or any other equipment is

operating.

Also pay attention to the design of the emergency stop circuit that includes the emergency stop

switch on the teaching pendant.

7

Page 26

1.6 Warranty Period and Scope of Warranty

The SCON controller you have purchased passed IAI’s shipping inspection implemented under the strictest

standards. The unit is covered by the following warranty:

1. Warranty Period

The warranty period shall be one of the following periods, whichever ends first:

18 months after shipment from our factory

12 months after delivery to a specified location

2. Scope of Warranty

The scope of warranty shall cover our products delivered at cost. If an obvious manufacturing defect is found

during the above period under an appropriate condition of use, IAI will repair the defect free of charge. Note,

however, that the following items are excluded from the scope of warranty.

Aging such as natural discoloration of coating

Wear of a consumable part due to use

Noise or other sensory deviation that doesn’t affect the mechanical function

Defect caused by inappropriate handling or use by the user

Defect caused by inappropriate or erroneous maintenance/inspection

Defect caused by use of a part other than IAI’s genuine part

Defect caused by an alteration or other change not approved by IAI or its agent

Defect caused by an act of God, accident, fire, etc.

The warranty covers only the product as it has been delivered and shall not cover any losses arising in

connection with the delivered product. The defective product must be brought to our factory for repair.

Please read carefully the above conditions of warranty.

8

Page 27

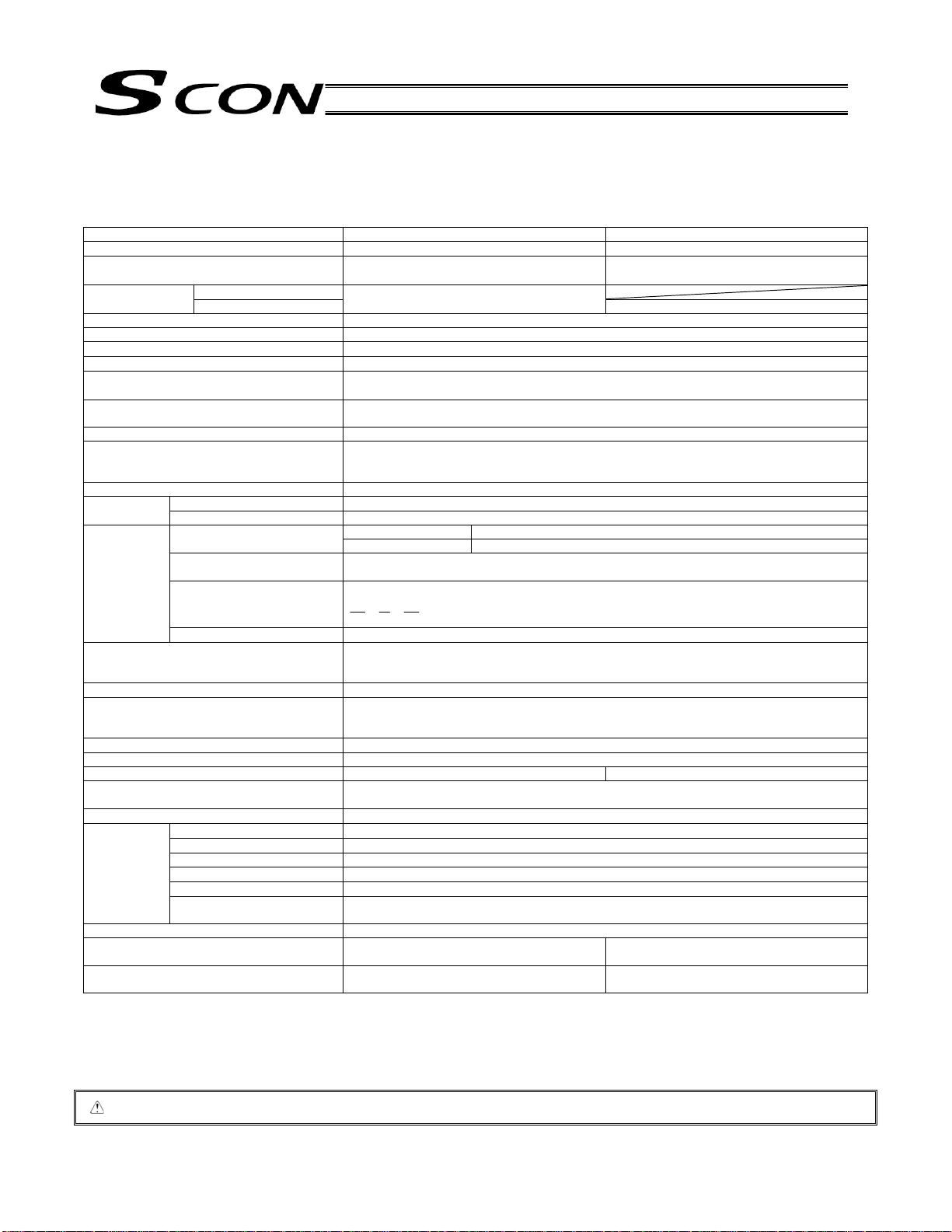

2. Specifications

2.1 Basic Specifications

Item Less than 400 W 400 W or more

Applicable motor capacity 20 W to 399 W 400 W to 750 W

Power-supply voltage

100 VAC Rush current *1

Leak current *2 3.0 mA (Primary side when noise filter is connected to the power supply line)

Heat output 30 W to 58 W

Power supply frequency 50/60 Hz

PIO interface power supply *3

Solenoid brake power supply

(in case of actuators equipped with brake)

Resistance against temp orary electric power

failure

Motor control method Sine wave PWM vector current control

Supported encoders Incremental serial encoder

Operation mode Positioner mode/pulser-train control mode (Operation mode is switched with the DIP switch.)

mode

Pulse-train

mode

Serial communication interface RS485: 1 channel (conforming to Modbus protocol RTU/ASCII)

I/O (PIO) cable length 10 m or less

Communication cable length Total cable length shall be 100 m or less (RS485).

Data input method Teaching pendant, PC software

Protective functions Overvoltage, motor overcurrent, motor overload, driver temperature error, encoder error, etc.

Air cooling method Natural cooling Forced cooling

Withstand voltage Between primary and secondary: 1500 VAC, 1 minute

Insulation resistance

Environment

Protection class IP20

Weight Approximately 800 g (approximately 25 g more

External dimension 58 (W) x 194 (H) x 121 (D)

*1 Rush current flows approximately 20 ms after turning the power supply on (guideline at 40C).

*2 Leak power supply changes depending on the capacity of connected motor, cable length, and surrounding environment. If protection against leak

current is installed, measure leak current at installation location of leak current breaker.

*3 Power supply for I/O signals is not necessary if the controller is operated using field network (CC-Link, DeviceNet, PROFIBUS), gateway unit, or

SIO converter, without using PIO. In this case, set “1” (disabled) for parameter No. 74 (PIO power supply monitoring).

200 VAC

Number of positions 512 points (maximum) Positioner

Inputs/outputs 16 dedicated input points / 16 dedicated output points

Feedback pulse frequency The maximum speed with differential pulse is 500 kpps (up to 109 kpps can be output linearly

Command pulse multiplier

(electronic gear: A/B)

Dedicated I/O (PIO) 8 input points / 12 output points

Surrounding air temperature

Surrounding humidity 85%RH or less (no condensation)

Surrounding environment (See the installation environment section.)

Storage ambient temperature

Storage ambient humidity 90%RH or less (no condensation)

Vibration resistance XYZ directions, 10 to 57 Hz, one side width 0.035 mm (continuous), 0.075 mm (intermittent)

Caution: Position data, parameters, etc. are written in EEPROM. The number of writings is limited to approximately 100,000 times.

Single-phase 100 to 115 VAC 10%

Single-phase 200 to 230 VAC 10%

20 A (control), 70 A (drive)

24 VDC 10% (Externally supplied)

24 VDC 10% 1 A (peak value)

(Externally supplied)

10 ms (50 Hz), 8 ms (60 Hz)

Absolute serial encoder

ABZ (UVW) parallel encoder

Differential pulse MAX. 500 kpps Input pulse frequency

Open-collector pulse MAX. 200 kpps (Pulse converter AK-04 is required.)

following the speed of actuators).

A, B = 1 to 4096 (Parameter settings)

1

50

Speed: 9.6 kpps to 230.4 kpps

Control via serial communication is possible with the positioner mode.

Length in case of Fieldbus specifications (CC-Link, DeviceNet, PROFIBUS) depends on each

Fieldbus specification.

Between primary and FG: 1500 VAC, 1 minute

Between secondary and FG: 500 VDC 100 M or more

0C to 40C

-10C to 65C

in case of absolute specifications)

(Installation pitch: 184)

50

A

1

B

57 to 150 Hz 4.9 m/s2 (continuous), 9.8 m/s2 (ongoing)

Single-phase 200 to 230 VAC 10%

20 A (control), 80 A (drive)

Approximately 1100 g (approximately 25 g more

in case of absolute specifications)

72 (W) x 194 (H) x 121 (D)

(Installation pitch: 184)

9

Page 28

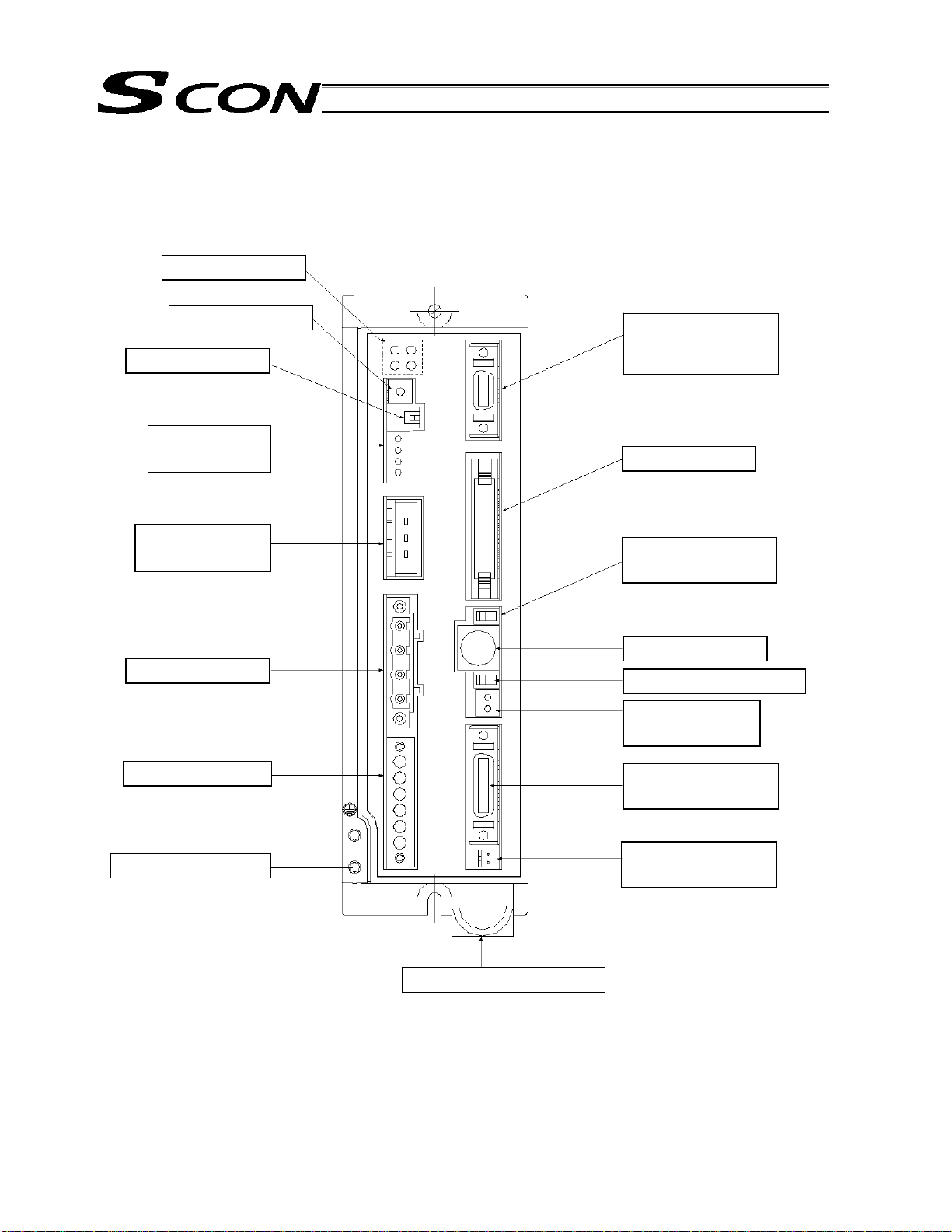

2.2 Name and Function of Each Part

[17] Grounding screw

[1] LED indicators

[2] Rotary switches

[3] Piano switches

[4] System I/O

connector

[5] Regenerative

unit connector

[6] Motor connector

[7] Power connector

[16] Absolute battery holder

[8] Dedicated pulse-

train control

connector

[9] PIO connector

[10] AUTO/MANU

selector switch

[11] SIO connector

[12] Brake release switch

[13] Brake power

connector

[14] Encoder/sensor

connector

[15] Absolute battery

connector

10

Page 29

[1] LED indicators

These LEDs indicate the condition of the controller.

Name Color Description

PWR Green

This LED illuminates when the system has become ready (after the power has

been input and the CPU has started normally).

SV Green This LED illuminates when the servo has turned on.

ALM Orange This LED illuminates while an alarm is present.

EMG Red This LED illuminates while an emergency stop is actuated.

[2] Rotary switches

These switches are used to set the controller address.

If two or more controllers are linked via serial communication, set a unique address for each controller.

* The address set by the switches will become effective after the power is reconnected or software is reset.

[3] Piano switches

These switches are used to set the various modes of the controller system.

Name Description

Operation mode selector switch

1

OFF: Positioner mode, ON: Pulse-train control mode

* The mode set by the switch will become effective after the power is reconnected.

2 Reserved by the system. (This switch must be set to “OFF.”)

Caution: When controlling the SCON controller via serial communication, a lways set the controller in the

“positioner mode” (piano switch 1: OFF).

If it happens to be in the “pulse-train mode” by mistake, the SCON controller may operate

erratically because it is operated according to the “pulse-train mode” parameters.

[4] System I/O connector

This connector is used to connect the emergency stop switch, etc.

Connector (controller side): MC1.5/4-G-3.5 (Phoenix Contact)

Connector (plug-in side): FMC1.5/4-ST-3.5 (Phoenix Contact)

Applicable cable diameter: 0.2 to 1.3 mm

2

(AWG24 to 16)

Pin No. Signal name Description

1 S1 Emergency-stop switch contact output for teaching pendant

2 S2 Emergency-stop switch contact output for teaching pendant

3 EMG+ 24-V output for emergency stop

4 EMG- Emergency sop input

11

Page 30

[5] Regenerative unit connector

This connector is used to connect an external regenerative resistance unit. The need for regenerative unit

will vary depending on the use condition.

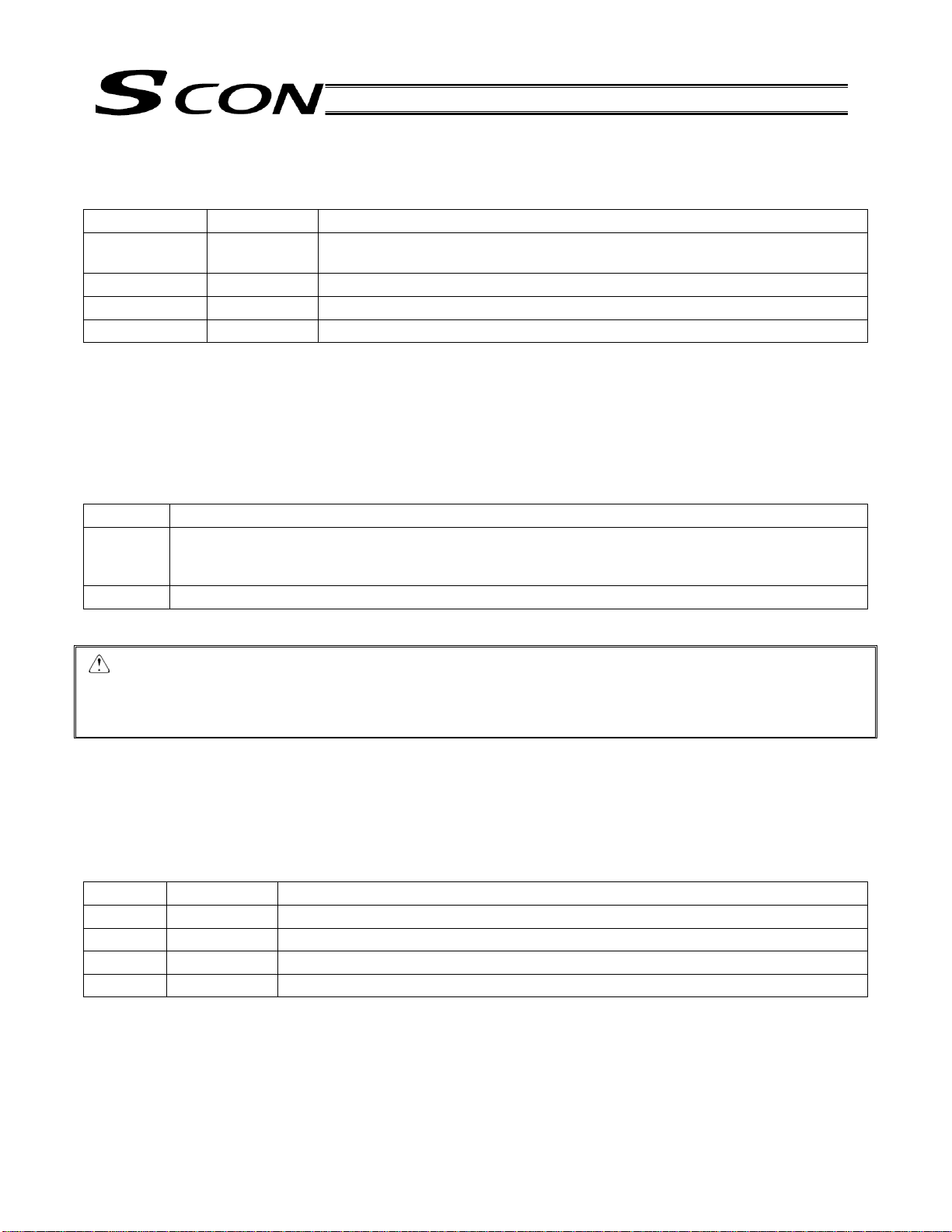

[6] Motor connector

This connector is used to connect the motor power cable of the actuator.

Motor connector specifications

Item Overview Description

Connector (cable side) GIC2.5/4-STF-7.52 4-pin, 2-piece connector by Phoenix Contact

Connector name M1 to 2 Motor connector

Cable size 0.75 mm2 (AWG18

or equivalent)

Connected unit Actuator

Terminal assignments

1 PE Protective grounding wire

2 Out U Motor drive phase U

3 Out V Motor drive phase V

4 Out W Motor drive phase W

Supplied with the actuator

[7] Power connector

This power connector accepts a 100/200-VAC single-phase power supply. The pins a re divid ed into control

power inputs and motor power inputs.

Item Specification Remarks

Connector

(cable side)

Applicable cable

size

6-pin, 2-piece connector MSTB2.5/6-STF-5.08

connector by Phoenix Contact

Control power: 0.75 mm

(AMG18)

Motor power: 2 mm

2

Recommended stripped wire length:

2

7 mm

(AMG14)

Terminal

assignments

Pin No. Signal name

1 L1 Motor power AC input

2 L2 Motor power AC input

3 L1C Control power AC input

4 L2C Control power AC input

5 NC Not connected

6 PE Grounding terminal

Signal names are indicated on the mating connector.

[8] Dedicated pulse-train input mode connector

This connector is used when the controller is to be operated in the pulse-train input mode. Do not conn ect it

if the controller is to be operated in the positioner mode.

[9] PIO connector

This connector is used to connect to the host controller (PLC, etc.) via the PIO (parallel input/output) cable.

It consists of a 40-pin flat connector and constitutes a DIO group of 16 inputs and 16 outputs.

12

Page 31

[10] AUTO/MANU switch

The operating mode using the teaching pendant/PC (software) connected to the SIO connector, and PIO

input, will change as follows in accordance with the setting of this switch.

Prohibition/permission of PIO activation is specified using the PC software/teaching pendant.

MANU

AUTO

PIO activation inhibited

(teaching mode 1 or teaching

mode 2)

PIO activation permitted

(monitor mode 1 or monitor

mode 2)

Only monitoring operations are possible using the PC software/teaching pendant. PIO inputs are

accepted.

All operations are possible using the PC software/teaching pendant.

PIO inputs are not accepted.

Only monitoring operations are possible using the PC

software/teaching pendant. PIO inputs are accepted.

* The emergency stop switch on the teaching pendant is enabled when the switch is co nnected,

regardless of the AUTO/MANU mode. Take note that although an emergency stop is actuated

momentarily when the teaching pendant or SIO cable is removed, this does not indicate an error

condition.

Therefore, the actuator and other equipment that are currently operating will stop.

Do not disconnect the teaching pendant or SIO communication cable while an actuator or any other

equipment is operating.

[11] SIO connector

This connector is used to connect the dedicated communication cable for teaching pendant/PC. It is also

used when two or more controllers are linked via serial communi cation.

[12] Brake release switch

This switch forcibly releases the electromagnetic brake of an actuator with brake.

RLS: Power is supplied to the brake to forcibly release the brake.

NOM: The co ntroller controls ON/OFF of the brake. This setting should be used in normal conditions of use.

* A 24-VDC power supply must be connected to drive the brake.

Even if the controller power is not turned on, you can still move the slider or rod manually by turning on

the 24-VDC power supply for driving the brake and then forcibly releasing the brake.

[13] Brake power connector

This connector supplies the 24-VDC brake powe r. If an actuator with brake is connected, 24 VDC must be

supplied externally.

MC1.5/4-G-3.5

(Phoenix Contact)

* Turn on the 24-VDC brake power before turning on the SCON controller power.

[14] Encoder/sensor connector

This connector is used to connect the encoder/sensor cabl es of the actuator.

With the SCON, encoder voltage is adjusted using a parameter (one of four levels is set in accordance with

the encoder type and cable length).

13

Page 32

A

14

Encoder sensor cable

Cable model: CB-X1-PA ***

Controller end

Plug connector:

Hood:

(Sumitomo 3M)

(Sumitomo 3M)

Wiring diagram

Wire Color Signal

(soldered)

Orange

Green

Purple

Gray

Red

Black

Blue

Yellow

Connect the shield to the hood using

a clamp.

Drain wire and braided shield wire

Plug housing:

Socket contact:

Retainer:

Signal Color Wire

Purple

Gray

Orange

Green

(pressure-

Red

welded)

Black

Drain

Blue

Yellow

(JST)

(JST)

ctuator end

(JST) X 9

Page 33

A

A

Cable model: CB-X1-PLA ***

Controller end

Plug connector:

Hood:

(Sumitomo 3M)

(Sumitomo 3M)

Wiring diagram

Wire Color Signal

White/Blue

White/Yellow

White/Red

White/Black

White/Purple

White/Gray

(soldered)

Orange

Green

Purple

Gray

Red

Black

Blue

Yellow

Connect the shield to the hood using

a clamp.

Drain wire and braided shield wire

ctuator end

LS side

Plug housing:

Socket contact:

Retainer:

Plug housing:

Socket contact:

Retainer:

Signal Color Wire

White/Blue

White/Yellow

White/Red

(pressure-

White/Black

welded)

White/Purple

White/Gray

Signal Color Wire

Purple

Gray

Orange

Green

Red

(pressure-

welded)

Black

Drain

Blue

Yellow

(JST)

(JST)

(JST)

(JST)

LS side

ctuator end

(JST) X 9

(JST) X 6

15

Page 34

A

16

Cable model: CB-X2-PA ***

Controller end

Plug connector:

Hood:

(Sumitomo 3M)

(Sumitomo 3M)

Wiring diagram

Wire Color Signal

(soldered)

White/Blue

White/Yellow

White/Red

White/Black

White/Purple

White/Gray

Orange

Green

Purple

Gray

Red

Black

Blue

Yellow

Connect the shield to the hood

using a clamp.

Drain wire and braided shield wire

Plug housing:

Socket contact:

Retainer:

Color Wire

Signal

White/Blue

White/Yellow

White/Red

White/Black

White/Purple

White/Gray

Drain

Orange

Green

Purple

Gray

Red

Black

Blue

Yellow

(JST) X 2

(pressure-

welded)

(JST)

ctuator

end

(JST) X 15

Page 35

A

A

Cable model: CB-X2-PLA ***

Controller end

17

Plug connector:

Hood:

(Sumitomo 3M)

(Sumitomo 3M)

Wiring diagram

Wire Color Signal

White/Orange

White/Green

Brown/Blue

Brown/Yellow

Brown/Red

Brown/Black

White/Blue

White/Yellow

White/Red

White/Black

White/Purple

White/Gray

Orange

Green

Purple

Gray

Red

Black

Blue

Yellow

(soldered)

Connect the shield to the hood using

a clamp.

Ground wire and braided shield wire

ctuator end

LS side

Plug housing:

Socket contact:

Retainer:

Plug housing:

Socket contact:

Retainer:

Signal Color Wire

White/Orange

White/Green

Brown/Blue

Brown/Yellow

Brown/Red

Brown/Black

Signal Color Wire

White/Blue

White/Yellow

White/Red

White/Black

White/Purple

White/Gray

Drain

Orange

Green

Purple

Gray

Red

Black

Blue

Yellow

(JST) X 2

(JST)

(pressure-

welded)

(pressure-

welded)

(JST)

(JST)

LS

side

ctuator

end

(JST) X 15

(JST) X 6

Page 36

A

18

Cable model: CB-RCS2-PA ***

Controller end

Plug connector:

Hood:

(Sumitomo 3M)

(Sumitomo 3M)

Wiring diagram

Wire Color Signal

(soldered)

Connect the shield to the hood using

a clamp.

White/Green

Brown/White

Pink

Purple

White

Blue/Red

Orange/White

Green/White

Blue

Orange

Black

Yellow

Green

Brown

Gray

Red

Drain wire and braided shield wire

Plug housing:

Socket contact:

Retainer:

Signal Color Wire

Pink

Purple

White

Blue/Red

Orange/White

Green/White

Brown/White

Drain

Blue

Orange

Black

Yellow

Green

Brown

Gray/White

Gray

Red

(JST) X 2

(pressure-

welded)

(JST)

ctuator

end

(JST) X 17

Page 37

A

A

Cable model: CB-RCS2-PLA ***

Controller end

19

Plug connector:

Hood:

(Sumitomo 3M)

(Sumitomo 3M)

Wiring diagram

Wire Color Signal

Brown/White

Gray/White

Red/White

Black/White

Yellow/Black

Pink/Black

Pink

Purple

(soldered)

Connect the shield to the hood using

a clamp.

White

Blue/Red

Orange/White

Green/White

Blue

Orange

Black

Yellow

Green

Brown

Gray

Red

Drain wire and braided shield wire

ctuator end

LS side

Plug housing:

Socket contact:

Retainer:

Plug housing:

Socket contact:

Retainer:

Color Wire

Signal

BrownWhite

Gray/White

Red/White

(pressure-

welded)

Black/White

Yellow/Black

Pnk/Black

Signal Color Wire

Pink

Purple

White

Blue/Red

Orange/White

Green/White

(pressure-

welded)

Drain

Blue

Orange

Black

Yellow

Green

Brown

Gray

Red

(JST) X 2

(JST)

(JST)

(JST)

LS side

ctuator end

(JST) X 15

(JST) X 6

Page 38

[15] Absolute battery connector

This connector is used to connect the absolute-encoder backup battery (required when the controller is of

absolute encoder specification).

[16] Absolute battery holder

This battery holder is used to install the absolute-encoder backup battery.

[17] Grounding screw

This screw is used to implement protective grounding. It is connected inside the controlle r to the PE

terminal in the power connector. Use this terminal if protective grounding based on a 2-piece connector is

not feasible due to conflict with the safety standard or for any other reason.

Item Description

Cable size 2.0 to 5.5 mm2 or larger

Grounding method Class D grounding

20

Page 39

2.3 External Dimensions

External dimensions of models with a power output of less than 400 W

4.2

When the absolute battery is installed

(absolute encoder specification)

21

Page 40

External dimensions of models with a power output of 400 W or more

4.2

When the absolute battery is installed

(absolute encoder specification)

Fan

22

Page 41

3. Installation and Wiring

3.1 Installation Environment

(1) When installing and wiring the controller, do not block the ventilation holes for cooling. (Insufficient

ventilation may not only prevent the controller from demonstrating its design performance fully, but it may

also cause a breakdown.)

(2) Prevent foreign matter from entering the controller through the ventilation holes. This controller is not

dustproof or splashproof (against water or oil), so avoid using the controller in a place subject to large

amounts of dust, oil mist or splashes of cutting fluid.

(3) Keep the controller from direct sunlight or irradiated heat from large heat sources such as heat treatment

furnaces.

(4) Use the controller in an environment of 0 to 40C in surrounding air temperature and 85% or below in

humidity (non-condensing), where the surrounding air is free fro m corrosive or flammable gases.

(5) Use the controller in an environment where it does not receive external vibration or impact.

(6) Prevent electrical noise from entering the controller or connected cables.

3.2 Heat Radiation and Installation

Design the control panel size, controller layout and cooling method so that the temperatures around the

controller will always be kept to 40C or below.

Mount the controller on a wall vertically as shown below. This controller implements cooling by means of f orced

ventilation (air is blown out from the top). When installing the controller, observe the aforementioned direction

and provide a minimum clearance of 100 mm above and 50 mm below the controller, and 30 mm from an

adjacent controller.

If you are installing multiple controllers side by side, provide a fan on top of the controllers to agitate the

airflows as an effective way to keep the surrounding air temperatures constant.

Provide a minimum clearance of 150 mm between the front face of the controller and the wall (cover).

Regenerative boxes

If multiple controllers are linked with the controllers arranged vertically, make sure the exhaust air from a given

controller is not sucked into the controller above it.

Provide a clearance of approx. 50 mm between a controller and a regenerative b ox, or 10 mm between

regenerative boxes.

Air direction

Fan

At least 100 mm

At least 50 mm

At least

150 mm

Airflow

23

Page 42

3.3 Noise Elimination Measures and Grounding

The following explains the noise elimination measures that should be taken when using this co ntroller.

(1) Wiring and power connection

[1] Provide dedicated class-D grounding (former class-3 grou nding: Grounding resistance 100 or less) using

a grounding wire with a size of 1.6 mm

Controller

Attach the

grounding

wire to the

mounting

screw of the

main unit.

Connect a cable of

the largest possible

size over the shortest

possible distance

Grounding terminal Grounding terminal

equip-

Class-D grounding

(Former class-3 grounding:

Grounding resistance 100 or less)

[2] Cautions on wiring method

Separate the controller wiring from high-power lines of motive power circuits, etc. (Do not tie them together

or place in the same cable duct.)

If the supplied motor or encoder cable is to be extended, consult IAI’s Engineering Service Section or Sales

Engineering Section.

(2) Noise sources and elimination

Noise generates from many sources, but the most common sources of noise you should consider when

designing a system are solenoid valves, magnet switches and relays. Noise generation from these components

can be prevented by the method explained below.

[1] AC solenoid valves, magnet switches, relays

Method --- Mount a noise killer in parallel with the coil.

Other

ment

2

or larger.

Controller

Ground the grounding wire for each controller:

do not share with or connect to other equipment.

Other

equip-

ment

Noise killer

Connect to each coil over the shortest possible wiring distance.

When a surge absorber is installed on the terminal block, etc., its

noise elimination effect will decrease if the distance from the coil

is long.

24

Page 43

[2] DC solenoid valve/magnet switch relay

Action --- Install a diode in parallel with the coil or use valve/relay with built-in diode.

In a DC circuit, connecting a diode in reverse polarities may damage the

diode, internal controller parts, or DC power supply. Exercise due caution

when connecting a diode.

25

Page 44

3.4 Wiring the Power Supply

3.4.1 Connecting the Power Cable

As shown to the left, insert the stripped end of the cable into the

connector and screw in the cable using a screwdriver.

Recommended cable diameter

Motor power (L1, L2): 2 mm (AWG14)

Control power (L1C, L2C): 0.75 mm (AWG18)

Recommended stripped wire length: 7 mm

As shown to the left, tighten the screws to secure the connector.

Caution: Always install a noise filter.

Recommended noise filter: MC1210 by Densei-Lambda

The power-supply voltage of the controller (100 or 200 V) has been set prior to the shipment.

26

Page 45

3.4.2 Power-supply Capacities and Heat Output

Rated power-supply capacity = Motor power-supply capacity + Control power-supply capacity

Maximum momentary power-supply capacity = Maximum momentary motor power-supply capacity + Control

power-supply capacity

Actuator motor

wattage

Motor power-

supply capacity

[VA]

Maximum

momentary motor

power-supply

capacity [VA]

Control power-

supply capacity

[VA]

Rated power-

supply capacity

[VA]

Maximum

momentary power-

supply capacity

[VA]

Heat

output

[W]

(Excluding RS)

(Excluding RS)

RS: Rotational axis

200L: 200-W linear actuator

300L: 300-W linear actuator

400L: 400-W linear actuator

3.4.3 Selecting a Breaker

Follow the guidance below when selecting a breaker.

Current 3 times more than the rated current flows in the controller during acceleration/deceleration. Select a

breaker that does not trip when this current is conducted. If a trip occurs, select a breaker with rated current

one rank higher.

Select a breaker that does not trip due to rush current. (Refer to operation characteristic curves described in

catalogues by manufacturers.)

Select a breaker with rated breaking current values that can break without fails even if short-circuit current is

conducted.

Rated breaking current > short-circuit current = primary side power supply capacity / power supply voltage

Select a circuit breaker with rated current with sufficient margin.

Rated breaker current > (Rated motor power-supply capacity [VA] + Control power-sup ply capacity

[VA]) / AC input voltage

Moreover, leak current breakers must be selected with specific purposes such as protection again st fire,

protection of humans and so on. Furthermore, leak current shall be measured at the location where a leak

current breaker is installed. Please use a leak current breaker supporting higher harm onics.

27

Page 46

3.5 Connecting the Actuator

3.5.1 Connecting the Motor Cable (MOT1, 2)

Connect the motor cable of the actuator to the motor connector on

the front face of the controller.

Use a screwdriver to tighten the screws at the top and bottom of the

connector to secure the connector.

2.

3.5.2 Connecting the Encoder Cable (PG1, PG2)

28

Connect the encoder cable of the actuator to the encoder connector

on the front face of the controller.

Note) If the controller is of absolute specification, disconnect the

absolute battery connector before connecting the encoder

cable.

Page 47

3.6 Connecting the PIO Cable (I/O)

Connect the supplied flat cable. Connect the opposite end of the

cable (no connector) to an appropriate peripheral (host PLC, etc.).

Brown-1

Red-1

Orange-1

Yellow-1

Green-1

Blue-1

Purple-1

Gray-1

White-1

Black-1

Brown-2

Red-2

Orange-2

Yellow-2

Green-2

Blue-2

Purple-2

Gray-2

White-2

Black-2

Half-pitch MIL socket: HIF6-40D-1.27R

(Hirose)

Signal Color Wire

Flat cable

[A]

(pressure-

welded)

I/O flat cable (supplied) Model: CB-PAC-PIO

indicates the cable length (L). A cable length of up to 30 m is supported.

*

Example: 080 = 8 m

Flat cable: KFX-20 (S) (color) (Kaneko Cord)

No connector

No connector

Flat cable (20 cores) x 2

Signal Color Wire

Brown-3

Red-3

Orange-3

Yellow-3

Green-3

Blue-3

Purple-3

Gray-3

White-3

Black-3

Brown-4

Red-4

Orange-4

Yellow-4

Green-4

Blue-4

Purple-4

Gray-4

White-4

Black-4

Flat cable

[B]

(pressure-

welded)

29

Page 48

3.7 External Input/Output Specifications

The standard interface specification of the controller is NPN, but the PNP specification is also available as an

option.

To prevent confusion during wiring, the NPN and PNP specifications use the same power line configuration.

Accordingly, there is no need to reverse the power signal assignments for a PNP controller.

3.7.1 External Input Specifications

Item Specification

Number of input points 16 points

Input voltage

Input current 4 mA/point

Insulation method Photocoupler

Internal circuit configuration

[NPN specification]

Each input

Each input

[PNP specification]

Each input

Each input

24 VDC 10%