Page 1

RCS Series

ROBO Cylinder Controller

RCS-E Type

Operation Manual Seventh Edition

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Operation Manual explains the handling methods, structure and maintenance of this product, among others,

providing the information you need to know to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained herein to

ensure safe use of the product.

The CD that comes with the product contains operation manuals for IAI products.

When using the product, refer to the necessary portions of the applicable operation manual by printing them out

or displaying them on a PC.

After reading the Operation Manual, keep it in a convenient place so that whoever is handling this product can

reference it quickly when necessary.

[Important]

This Operation Manual is original.

The product cannot be operated in any way unless expressly specified in this Operation Manual. IAI shall

assume no responsibility for the outcome of any operation not specified herein.

Information contained in this Operation Manual is subject to change without no tice for the purpose of

product improvement.

If you have any question or comment regarding the content of this manual, please contact the IAI sales

office near you.

Using or copying all or part of this Operation Manual without permi ssion is prohibited.

The company names, names of products and trademarks of each company shown in the sentences are

registered trademarks.

Page 4

CAUTION

(1) Hold · Servo ON Signal

When operating the RCS (ROBO cylinder) controller, you will need to turn ON the Hold &

Servo ON signal Input Signal of PIO.

In case the Hold Stop Input Signal of PIO remains OFF, RCS controller will not move due to

hold status. Therefore, please be careful.

(2) Position 0 may be output regardless of the actual position. At the timings specified below,

the positioning completion signal turns ON no matter where the actual position is. As a

result, the output status becomes “Position 0.”

1. When the power is turned on

2. When the emergency stop is reset

3. When the alarm is reset

4. When a reset is performed after hold

Be extra careful when using Position 0.

(3) With the absolute type, 0E5 (Encoder Reception Error) will be displayed under certain

conditions, such as when the power is first turned on after disconnecting the battery or PG

cable. This display does not indicate fault. Perform an absolute reset in accordance with

the specified procedure.

(4) Recommendation for backing up latest data

This controller uses nonvolatile memory to store position table data and parameters.

Although data in the memory is retained even after the power is cut off, the stored data will

be lost if the nonvolatile memory is damaged.

It is therefore recommended that you regularly back up the latest position table data and

parameters in case of accidental data loss. Regular backup will also let you restore data

quickly if the controller must be replaced for other reasons.

Use the following methods to back up data:

[1] Use the PC software to save the data to a CD or FD.

[2] Create a position table sheet or parameter sheet and keep a written record of backup.

Page 5

Table of Contents

Safety Guide.......................................................................................................1

1. Overview........................................................................................................1

1.1 Forward .....................................................................................................................................................1

1.2 How to Read Model Number.....................................................................................................................2

1.3 Safety Precautions ....................................................................................................................................3

1.4 Warranty Period and Scope of Warranty...................................................................................................4

1.5 Setting Environment and Noise Measures................................................................................................5

1.6 Heat Radiation and Installation .................................................................................................................8

2. Specification .................................................................................................. 9

2.1 Base Specifications...................................................................................................................................9

2.1.1 Backup Battery (Absolute Specification)..........................................................................................10

2.2 Names and Functions of Parts................................................................................................................11

2.2.1 Names..............................................................................................................................................11

2.2.2 Functions .........................................................................................................................................11

2.2.3 Pin Assignments of the Communication Ports.................................................................................14

2.3 External Dimensions................................................................................................................................16

2.4 Connection Method .................................................................................................................................17

2.4.1 Standard Type..................................................................................................................................17

2.4.2 Absolute Specification......................................................................................................................18

2.5 Supplied Cable........................................................................................................................................19

2.5.1 I/O Flat Cable...................................................................................................................................19

2.5.2 Motor Extension Cable ....................................................................................................................19

2.6 Wiring ......................................................................................................................................................21

2.6.1 Wiring for Power Supply/Emergency Stop.......................................................................................21

2.6.2 External Connection Diagram..........................................................................................................22

2.6.3 PIO Interface....................................................................................................................................23

2.6.4 Non-isolated External I/O Specification...........................................................................................26

3. Data Entry <Basics>.................................................................................... 28

3.1 Description of Position-Data Table ..........................................................................................................29

3.2 Explanation of Modes..............................................................................................................................33

3.3 Timing Chart............................................................................................................................................37

4. Using the Controller <Practical Steps>........................................................ 38

4.1 How to Start (Standard Type)..................................................................................................................38

4.2 How to Execute Absolute Reset (Absolute Specification).......................................................................39

4.3 Movement after Power On (Standard T ype)............................................................................................41

4.4 Positioning Mode (Back and Forth Movement between Two Points)......................................................43

4.5 Push & Hold Mode...................................................................................................................................45

4.6 Speed Change during Movement............................................................................................................47

4.7 Operation at Different Acceleration and Deceleration Settings...............................................................49

4.8 Pause ......................................................................................................................................................51

4.9 Zone Signal Output..................................................................................................................................53

4.10 Returning Home ......................................................................................................................................55

4.11 Incremental Moves..................................................................................................................................57

4.12 Notes on Incremental Mode ....................................................................................................................59

Page 6

Parameters.................................................................................................. 61

5.

5.1 Parameter Classification .........................................................................................................................61

5.2 Parameter List.........................................................................................................................................61

5.3 Parameter Settings..................................................................................................................................62

5.3.1 Parameters Relating to Actuator Stroke Range...............................................................................62

5.3.2 Parameters Relating to Actuator Operating Characteristics............................................................63

5.3.3 Parameters Relating to External Interface.......................................................................................66

5.3.4 Servo Gain Adjustment....................................................................................................................66

6. Troubleshooting...........................................................................................67

6.1 What to Do When A Problem Occurs ............................................................................................... .......67

6.2 Alarm Level Classification ..................................................................................................... .................. 68

6.3 Alarm Output by PIO ...............................................................................................................................68

6.4 Alarms, Causes and Actions ...................................................................................................................69

6.5 Messages Displayed during Operations Using Teaching Pendant or PC Software................................75

* Appendix......................................................................................................... 77

Specification List of Supported Actuators ...........................................................................................................77

Flat Type (F45) - Moments and Loading Capacity..............................................................................................78

Example of Basic RCS Positioning Sequence....................................................................................................79

Position Table Record (1/2).................................................................................................................................82

Parameter Record...............................................................................................................................................83

Change History.................................................................................................86

Page 7

Safety Guide

This “Safety Guide” is intended to ensure the correct use of this product and prevent dangers and property

damage. Be sure to read this section before using your product.

Regulations and Standards Governing Industrial Robots

Safety measures on mechanical devices are generally classified into four categori es un der the International

Industrial Standard ISO/DIS 12100, “Safety of machinery,” as follows:

Safety measures Inherent safety design

Protective guards --- Safety fence, etc.

Additional safety measures --- Emergency stop device, etc.

Information on use --- Danger sign, warnings, operation manual

Based on this classification, various standards are established in a hierarchical manner under the International

Standards ISO/IEC. The safety standards that apply to industrial robots are as follows:

Type C standards (individual safety standards) ISO10218 (Manipulating industrial robots – Safety)

JIS B 8433

(Manipulating industrial robots – Safety)

Also, Japanese laws regulate the safety of industrial robots, as follows:

Industrial Safety and Health Law Article 59

Workers engaged in dangerous or harmful operations must receive special education.

Ordinance on Industrial Safety and Health

Article 36 --- Operations requiring special education

No. 31 (Teaching, etc.) --- Teaching and other similar work involving industrial robots (exceptions

apply)

No. 32 (Inspection, etc.) --- Inspection, repair, adjustment and similar work involving industrial robots

(exceptions apply)

Article 150 --- Measures to be taken by the user of an industrial robot

Pre-1

Page 8

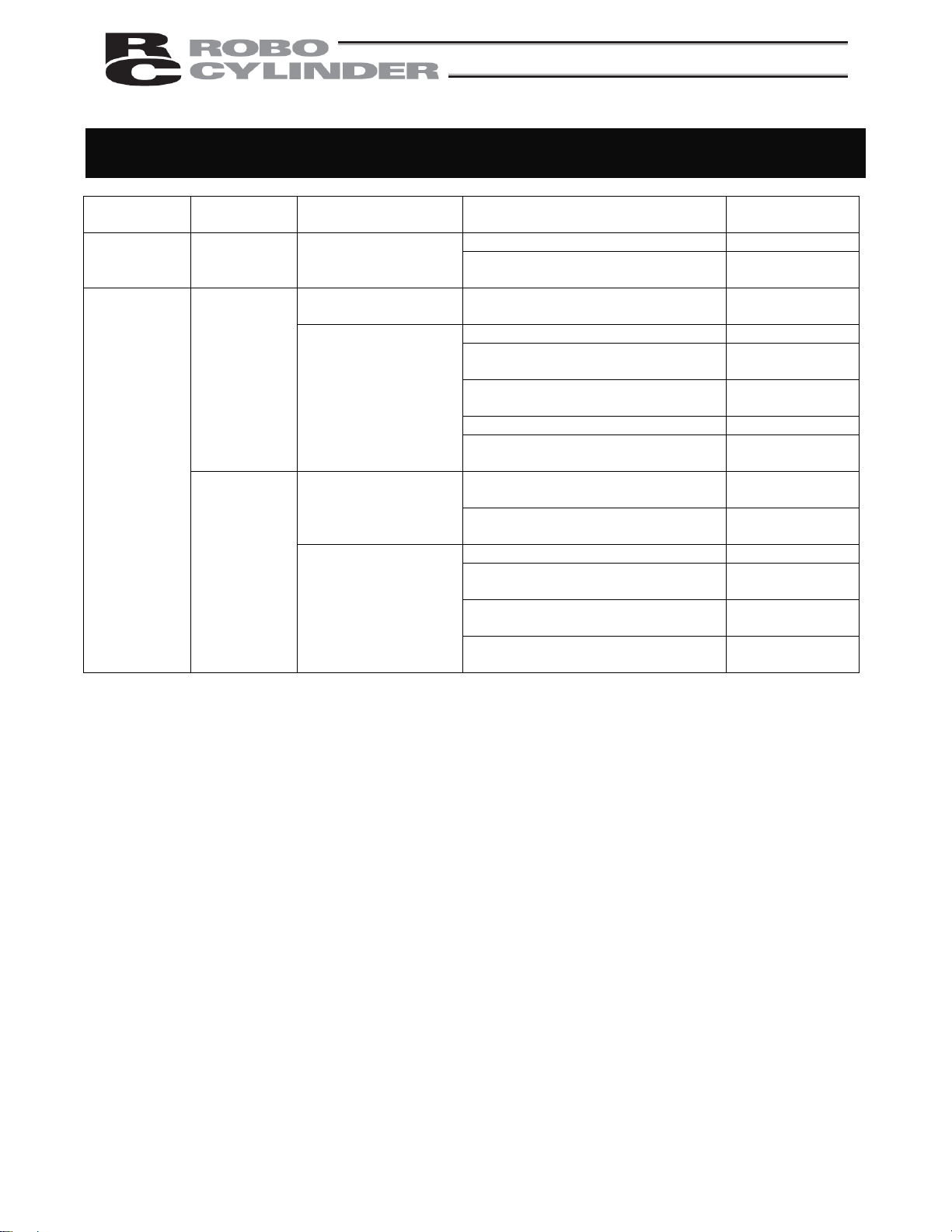

Requirements for Industrial Robots under Ordinance on Industrial Safety and

Health

Work area

movement

range

Inside

movement

range

Work

condition

During

automatic

operation

During

teaching, etc.

During

inspection,

etc.

Cutoff of drive source Measure Article

Signs for starting operation Article 104 Outside

Not cut off

Cut off (including

stopping of operation)

Not cut off

Cut off

Not cut off (when

inspection, etc., must

be performed during

operation)

Installation of railings, enclosures,

etc.

Sign, etc., indicating that work is in

progress

Preparation of work rules Article 150-3

Measures to enable immediate

stopping of operation

Sign, etc., indicating that work is in

progress

Provision of special education Article 36-31

Checkup, etc., before

commencement of work

To be performed after stopping the

operation

Sign, etc., indicating that work is in

progress

Preparation of work rules Article 150-5

Measures to enable immediate

stopping of operation

Sign, etc., indicating that work is in

progress

Provision of special education

(excluding cleaning and lubrication)

Article 150-4

Article 150-3

Article 150-3

Article 150-3

Article 151

Article 150-5

Article 150-5

Article 150-5

Article 150-5

Article 36-32

Pre-2

Page 9

Applicable Modes of IAI’s Industrial Robot

Machines meeting the following conditions are not classified as industrial robot s according to Notice of Ministry of

Labor No. 51 and Notice of Ministry of Labor/Labor Standards Office Director (Ki-Hatsu No. 340):

(1) Single-axis robo with a motor wattage of 80 W or less

(2) Combined multi-axis robot whose X, Y and Z-axes are 300 mm or shorter and wh ose rot ating p art, if any,

has the maximum movement range of within 300 mm

(3) Multi-joint robot whose movable radius and Z-axis are within 300 mm

Among the products featured in our catalogs, the following models are classified as industrial robots:

1. Single-axis ROBO Cylinders

RCS2/RCS2CR-SS8 whose stroke exceeds 300 mm

2. Single-axis robots

The following models whose stroke exceeds 300 mm and whose motor capacity also exceeds 80 W:

ISA/ISPA, ISDA/ISPDA, ISWA/ISPWA, IF, FS, NS

3. Linear servo actuators

All models whose stroke exceeds 300 mm

4. Cartesian robos

Any robot that uses at least one axis corresponding to one of the models specified in 1 to 3

5. IX SCARA robots

All models whose arm length exceeds 300 mm

(All models excluding IX-NNN1205/1505/1805/2515, NNW2515 and NNC1205/1505/1805/2515)

3

including the end of the rotating part

Pre-3

Page 10

Notes on Safety of Our Products

Common items you should note when performing each task on any IAI robot are explained below.

No. Task Note

1 Model

selection

2 Transportation

3 Storage/

preservation

4 Installation/

startup

This product is not planned or designed for uses requiring high degrees of safety.

Accordingly, it cannot be used to sustain or support life and must not be used in the

following applications:

[1] Medical devices relating to maintenance, management, etc., of life or health

[2] Mechanisms or mechanical devices (vehicles, railway facilities, aircraft facilities, etc.)

intended to move or transport people

[3] Important safety parts in mechani cal devices (safety devices, etc.)

Do not use this product in the following environments:

[1] Place subject to flammable gases, ignitable objects, flammables, explosives, etc.

[2] Place that may be exposed to radiation

[3] Place where the surrounding air temperature or relative humidity exceeds the

specified range

[4] Place subject to direct sunlight or radiated heat from large heat sources

[5] Place subject to sudden temperature shift and condensation

[6] Place subject to corrosive gases (sulfuric acid, hydrochloric acid, etc.)

[7] Place subject to excessive dust, salt or iron powder

[8] Place where the product receives direct vibration or impact

Do not use this product outside the specified ranges. Doing so may significantly

shorten the life of the product or result in product failure or facility stoppage.

When transporting the product, exercise due caution not to bump or drop the product.

Use appropriate means for transportation.

Do not step on the package.

Do not place on the package any heavy article that may deform the package.

When using a crane of 1 ton or more in capacity, make sure the crane operators are

qualified to operate cranes and perform slinging work.

When using a crane, etc., never hoist articles exceeding the rated load of the crane,

etc.

Use hoisting equipment suitable for the article to be hoisted. Calculate the load

needed to cut off the hoisting equipment and other loads incidental to equipment

operation by considering a safety factor. Also check the hoisting e quipment for

damage.

Do not climb onto the article while it is being hoisted.

Do not keep the article hoisted for an extended period of time.

Do not stand under the hoisted article.

The storage/preservation environment should conform to the installation environment.

Among others, be careful not to cause condensation.

(1) Installing the robot, controller, etc.

Be sure to firmly secure and affix the product (including its work part).

If the product tips over, drops, malfunctions, etc., damage or injury may result.

Do not step on the product or place any article on top. The product may tip over or the

article may drop, resulting in injury, product damage, loss of/drop in product

performance, shorter life, etc.

If the product is used in any of the following places, provide sufficient shielding

measures:

[1] Place subject to electrical noise

[2] Place subject to a strong electric or magnetic field

[3] Place where power lines or drive lines are wired nearby

[4] Place subject to splashed water, oil or chemicals

Pre-4

Page 11

No. Task Note

4 Installation/

startup

(2) Wiring the cables

Use IAI’s genuine cables to connect the actuator and controller or connect a teaching

tool, etc.

Do not damage, forcibly bend, pull, loop round an object or pinch the cables or place

heavy articles on top. Current leak or poor electrical continuity may occur, resulting in

fire, electric shock or malfunction.

Wire the product correctly after turning off the power.

When wiring a DC power supply (+24 V), pay attention to the positive and negative

polarities.

Connecting the wires in wrong polarities may result in fire, product failure or

malfunction.

Securely connect the cables and connectors so that they will not be disconnected or

come loose. Failing to do so may result in fire, electric shock or product malfunction.

Do not cut and reconnect the cables of the product to extend or shorten the cables.

Doing so may result in fire or product malfunction.

(3) Grounding

Be sure to provide class D (former class 3) grounding for the controller. G roun ding is

required to prevent electric shock and electrostatic charges, improve noise re sistance

and suppress unnecessary electromagnetic radiation.

(4) Safety measures

Implement safety measures (such as installing safety fences, etc.) to prevent entry into

the movement range of the robot when the product is moving or can be moved.

Contacting the moving robot may result in death or serious injury.

Be sure to provide an emergency stop circuit so that the product can be stopped

immediately in case of emergency during operation.

Implement safety measures so that the product cannot be started only by turning on

the power. If the product starts suddenly, injury or product damage may result.

Implement safety measures so that the product will not start upon cancellation of an

emergency stop or recovery of power following a power outage. Failure to do so may

result in injury, equipment damage, etc.

Put up a sign saying “WORK IN PROGRESS. DO NOT TURN ON POWER,” etc.,

during installation, adjustment, etc. If the power is accidently turned on, electri c shock

or injury may result.

Implement measures to prevent the work part, etc., from dropping due to a power

outage or emergency stop.

Ensure safety by wearing protective gloves, protective goggles and/or safety shoes,

as necessary.

Do not insert fingers and objects into openings in the product. Doing so may result in

injury, electric shock, product damage, fire, etc.

When releasing the brake of the vertically installed actuator, be careful not to let the

actuator drop due to its dead weight, causing pinched hands or damaged work part,

etc.

5 Teaching

Whenever possible, perform teaching from outside the safety fences. If teaching must

be performed inside the safety fences, prepare “work rules” and make sure the

operator understands the procedures thoroughly.

When working inside the safety fences, the operator should carry a handy emergency

stop switch so that the operation can be stopped any time when an abnormality

occurs.

When working inside the safety fences, appoint a safety watcher in addition to the

operator so that the operation can be stopped any time when an abnormality occurs.

The safety watcher must also make sure the switches are not operated inadvertently

by a third party.

Put up a sign saying “WORK IN PROGRESS” in a conspicuous location.

Pre-5

Page 12

No. Task Note

When releasing the brake of the vertically installed actuator, be careful not to let the

actuator drop due to its dead weight, causing pinched hands or damaged load, etc.

* Safety fences --- Indicate the movement range if safety fences are not provided.

6 Confirmation

operation

7 Automatic

operation

8 Maintenance/

inspection

9 Modification The customer must not modify or disassemble/assemble the product or use

10 Disposal When the product becomes no longer usable or necessary, dispose of it properly as an

After teaching or programming, carry out step-by-step confirmation operation before

switching to automatic operation.

When carrying out confirmation operation inside the safety fences, follow the specified

work procedure just like during teaching.

When confirming the program operation, use the safety speed. Failure to do so may

result in an unexpected movement due to programming errors, etc., causing injury.

Do not touch the terminal blocks and various setting switches while the power is

supplied. Touching these parts may result in electric shock or malfunction.

Before commencing automatic operation, make sure no one is inside the safety

fences.

Before commencing automatic operation, make sure all related peripherals are ready

to operate in the auto mode and no abnormalities are displayed or indicated.

Be sure to start automatic operation from outside the safety fences.

If the product generated abnormal heat, smoke, odor or noise, stop the product

immediately and turn off the power switch. Failure to do so may result in fire or pr oduct

damage.

If a power outage occurred, turn off the power switch. Otherwise, the product may

move suddenly when the power is restored, resulting in injury or product damage.

Whenever possible, work from outside the safety fences. If work must be performed

inside the safety fences, prepare “work rules” and make sure the operator underst ands

the procedures thoroughly.

When working inside the safety fences, turn off the power switch, as a rule.

When working inside the safety fences, the operator should carry a handy emergency

stop switch so that the operation can be stopped any time when an abnormality

occurs.

When working inside the safety fences, appoint a safety watcher in addition to the

operator so that the operation can be stopped any time when an abnormality occurs.

The safety watcher must also make sure the switches are not operated inadvertently

by a third party.

Put up a sign saying “WORK IN PROGRESS” in a conspicuous location.

Use appropriate grease for the guides and ball screws by checking the operation

manual for each model.

Do not perform a withstand voltage test. Conducting this test may result in product

damage.

When releasing the brake of the vertically installed actuator, be careful not to let the

actuator drop due to its dead weight, causing pinched hands or damaged work part,

etc.

* Safety fences --- Indicate the movement range if safety fences are not provided.

maintenance parts not specified in the manual without first consulting IAI.

Any damage or loss resulting from the above actions will be excluded from the scope

of warranty.

industrial waste.

When disposing of the product, do not throw it into fire. The product may explode or

generate toxic gases.

Pre-6

Page 13

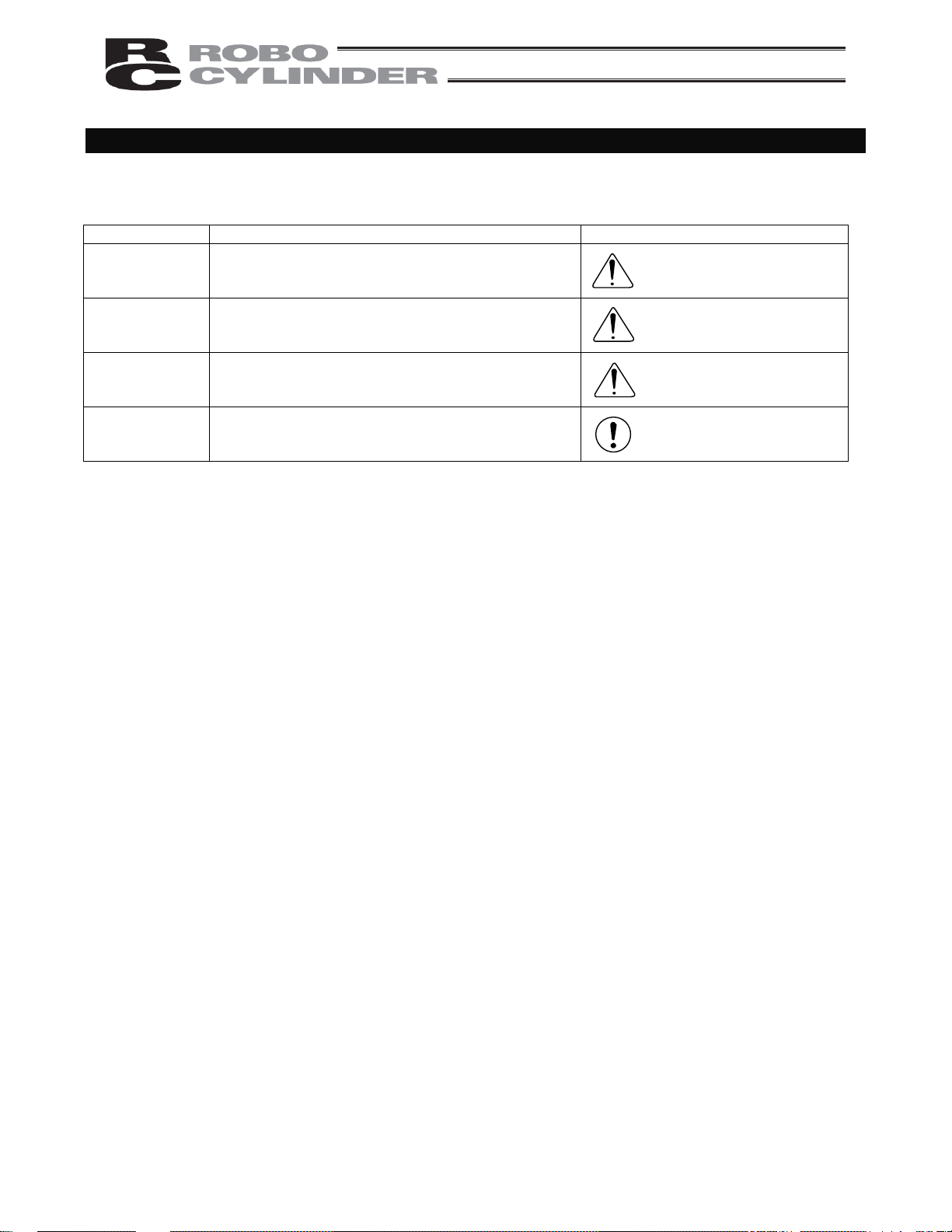

Indication of Cautionary Information

The operation manual for each model denotes safety precautions under “Danger,” “Warning,” “Caution” and

“Note,” as specified below.

Level Degree of danger/loss Symbol

Danger

Warning

Caution

Note

Failure to observe the instruction will result in an

imminent danger leading to death or serious injury.

Failure to observe the instruction may result in death

or serious injury.

Failure to observe the instruction may result in injury

or property damage.

The user should take heed of this information to

ensure the proper use of the product, although failure

to do so will not result in injury.

Danger

Warning

Caution

Note

Pre-7

Page 14

Page 15

Page 16

Page 17

1. Overview

1.1 Forward

Thank you very much for purchasing the RCS controller . Thi s manual explains the features of this machine a nd its

operating procedures.

Without knowing beforehand how to correctly use or operate the controlle r, not only will the user be unable to take

full advantage of all the functions built into this product but the user might also, inadvertently cau se damage to the

robot or shorten its life. Please read this manual as well as other manuals carefully pert aining to the product to

acquire an understanding of the proper method of handling and operating the controller. Keep this manual handy

so that you can refer to the appropriate sections as the need arises.

Also refer to the operation manuals for the various actuators you ar e using, as well as the operation ma nual(s) for

the optional PC software and/or teaching pendant if applicable.

Absolute Specifications:

With the absolute home controller, once power is applied, and absolute reset is executed, you can execute

positioning without the need to home after reapplying the power. Other basic functions are the same as the

standard RCS controller.

Absolute reset is not set at time of shipment. Please execute absolute reset by yourself.

Only RCS actuators of absolute specification can be used with the absolute RCS controller. The standard RCS

actuator cannot be used.

Actuator duty

It is recommended that IAI’s actuators be used at a duty of 50% or below as a guideline in view of the

relationship of service life and accuracy.

Duty is calculated by the formula below:

Duty (%) =

* We have paid utmost attention to ensure accuracy of this manual. Should you find any error, however, or if you

have any input, please contact IAI.

We recommend that you keep this manual in a convenient place so that you can reference it readily when

needed.

hours Operating

x 100

hours operating-Non hours Operating

1

Page 18

1.2 How to Read Model Number

<Series>

<Controller type>

E: Economy type

<Input power-supply voltage>

0: 24 VDC

<Applicable actuators>

[1] Actuator type

Slider type

SA4

SA5

SA6

Rod type

RA35 RA35R

RA45 RA45R

RB7525

Flat type

F45

[2] Encoder type

I: Incremental

A: Absolute

[3] Motor capacity

20 (20 W)

30 (30 W)

2

Page 19

1.3 Safety Precautions

Please read the following information carefully in order to gain an understanding of safety precaution s.

This product was developed as components fo r driving automated equipment and is designed not to produce

greater torque or speed than is necessary. However, strictly observe the following items to prevent any accidents

from occurring.

1. As a rule, any handling or operating methods not described in this manual should be viewed as things that

should not be attempted. Please contact IAI if any portion of the contents of this manual are unclear.

2. Use only the products specified for wiring between the actuator and controller.

3. Stand clear of the operating range of the machine when it is in motion or is ready to operate (when the control

power is on). Surround the system with safety partitions if there is a possibility that people can enter the area

where the machine is being used.

4. When assembling, adjusting, or performing maintenance on the machine, always disengage the power supply

to the controller. During work, display a sign stating work in progress where it is readily visible. Also, keep the

power cable close to the operator so that another person cannot inadvertently switch on the power.

5. When more than one person is working on the system, agree on signals beforehand to ensure everyone's

safety before beginning work. In particular, when doing work involving axis movement, always call out for

everyone's safety regardless of whether power is ON or OFF, or the axis is to be mechanically driven or

manually moved.

6. When the user needs to lengthen the cables, check the wiring carefully to make sure it is correct before turning

the power ON since miswiring can lead to malfunction.

3

Page 20

1.4 Warranty Period and Scope of Warranty

The RCS controller undergoes stringent testing before it is shipped from our factory. IAI provides the following

warranty:

1. Warranty Period

The warranty period expires upon elapse of one of the following periods, whichever occurs first.

18 months after the shipment from IAI

12 months after delivery to the location specified by the use r.

2. Scope of Warranty

If within the period specified above, a breakdown occurs while operating the controller under normal conditions

and is clearly the responsibility of the manufacturer, IAI will repair the unit at no cost. However, the following items

are not covered by this warranty:

Faded paint or other changes that occur naturally over time.

Consumable components that wear out with use (battery , etc.).

Unit seems to be noisy or similar impressions that do not affect machinery perf ormance.

Damage resulting from improper handling or use.

Damage resulting from user error or failure to perform proper maintenance.

Use of any part which is not a genuine part of IAI

Any alterations not autho rized by IAI or its representatives, including parameters.

Damage caused by fire and other natural disasters or accidents.

The warranty pertains to the purchased product itself and does not cover any loss that might arise from a

breakdown of the product. Any repairs will be done at our factory.

Make sure you understand the foregoing terms of warranty.

4

Page 21

1.5 Setting Environment and Noise Measures

Please be careful for controller setting environment

1.5.1 Installation Environment

This controller can be used in an environment of pollution degree 2*1 or equivalent.

*1 Pollution degree 2: Normally only nonconductive pollution occurs. Temporary conductivity caused by

condensation is to be expected.

(EN60947-5-1)

(1) Do NOT block the air vents of your controller when installing your IA system.

(Unavailability of sufficient ventilation not only prevents the controller from demonstrating its designed

performance, but it may also lead to a controller failure.)

(2) Prevent foreign matters from entering the controller through the vent holes. Your controller is NOT dust,

water, or oil proof. Avoid using your IA system in environments subj ect to contamination by dust, oil, mist, or

cutting oil.

(3) Do not expose your IA system to direct sunlight or radiation heat from a large heat source such as heat treat

furnace, etc.

(4) Avoid placing your IA system under conditions of extreme temperatures above 40C or below 0C. The level

of humidity should not be exceed 85%. Do NOT expose to corrosive or inflammable gas.

(5) Avoid external vibration, unnecessary impact, or excessive shocks to your controller.

(6) Take steps to shield controllers and wiring cabl es from electromagnetic noise.

1.5.2 Power Source

The supplied voltage is 24 VDC 10%.

5

Page 22

1.5.3 Noise Elimination Measures and Grounding

(1) Noise Elimination Grounding

1. Directly screw the main body to the metal box.

[3] Precautions regarding wiring method

Use a twisted cable for connection to the 24-VDC external power supply.

Separate the controller cables from high-power lines such as a cable connecting to a power circuit. (Do not

bundle together the controller cables with high-power lines or place them in the same cable duct.)

When extending the supplied motor cable or encoder cable, consult IAI’s Technical Support or Sales

Engineering Section.

Use as thick a cable as

practically possible and wire

it over the shortest possible

distance.

Metal frame

24-V

controller

[2] If the controller cannot be

screwed onto the frame,

connect it to the frame as

shown in the figure at left.

6

Page 23

(2) Noise sources and elimination

Among the numerous noise sources, solenoid valves, magnet switches and relays are of p articular concern

when building a system. Noise from these sources can be eliminated by implementing the measures

specified below.

[1] AC solenoid valves, magnet switches and relays

Measure: Install a surge absorber in parallel with the coil.

[2] DC solenoid valves, magnet switches and relays

Measure: Install a diode in parallel with the coil. Determine the diode capacity in accordance with the load

capacity.

Point

Install a surge absorber to each coil over a minimum wiring length.

Installing a surge absorber to the terminal block or other part will be

less effective because of a longer distance from the coil.

In a DC circuit, connecting a diode in reverse polarity will damage the

diode, internal parts of the controller and/or DC power supply, so exercise

due caution.

7

Page 24

1.6 Heat Radiation and Installation

Design the control panel size, controlle r layout and cooling method in su ch a way that the temperatu re aroun d the

controller will not exceed 40C.

Install the controller vertically on a wall, as shown below. Since cooling is provided by way of natural convection,

always observe this installation direction and provide a minimum clearance of 50 mm above and bel ow the

controller to ensure sufficient natural airflows.

When installing multiple controllers side by side, providing a ventilation fan or fans above the controllers will help

maintain a uniform temperature around the controllers.

Keep the front panel of the controller away from the wall (enclosure) by at least 100 mm.

Regardless of whether your system consists of a single controller or multiple controllers, provide sufficient

clearances around each controller so that it can be installed/removed easily.

Fan

50 mm or more

50 mm or more

100 mm or

more

Airflow

8

Page 25

2. Specification

2.1 Base Specifications

Item Specification

Supply voltage

Type RA35 RA45, F45 RB75 (60 W) SA4, SA5 SA6

24 VDC 10%

Supply current [A]

Rating Peak

1.8 4.3 2.4 6.0 3.9 7.5 1.2 3.7 1.4 3.9

Maximum motor output 60 W (Torque limit x 2) / Other (x 3)

Surrounding air

temperature/humidity

0 to 40C, 85%RH or less

Surrrounding environment IP10, free from corrosive gases

Weight 540 g

Protective functions

Regenerative voltage error, motor overcurrent, power-stage overheat,

encoder error , motor overload, overspeed

LED indicators RDY (green), RUN (green), ALM (red), ENC (orange)

DI/DO interface 24 VDC, isolated

Start

8 dedicated

input ports

Command position number (4-bit binary)

* Pause

Reset

Servo-ON

Completed position number (4-bit binary)

Input/output

Position complete

Home return completion

10 dedicated

output ports

Zone

* Alarm

* Emergency stop

Moving

Serial interface input/output

Number of positions 16

Data entry method Teaching pendant, PC software

Storage device EEPROM 8 kbytes, S-RAM 128 kbytes

Note: Supplying the power-supply port or any I/O port with a voltage beyond the specified level may

result in controller failure.

* indicates a b-contact signal.

9

Page 26

2.1.1 Backup Battery (Absolute Specification)

(1) Battery Specification

Item Description

Type Lithium battery

Manufacturer Toshiba Battery Co., Ltd.

Model number ER3VP

Nominal voltage 3.6 V

Rated capacity 2000 mAh

Weight Approx. 8.5 g

Battery retention time Note 1)

Note 1) Approx. 100 A of current is consumed while data is backed up by the absolute data backup

battery (as opposed to approx. 4 A consumed while the main controller power is on).

* Do not modify or extend the wires. It may cause failure.

* The battery is replaced together with the board. Since what you will replace is not the battery alone,

always use the product specified by IAI.

An absolute reset must be performed after the battery has been replaced.

Approx. 20,000 hours (at a surrounding air temperature of

20C).

10

Page 27

2.2 Names and Functions of Parts

2.2.1 Names

[1] Motor connector (M)

[8] LED indicators

[2] Brake release switch (BK)

(option)

[9] Encoder/brake connector

[3] SIO connector (SIO)

[4] Port switch (PORT)

[5] Main communication port connector

[10] PIO connector (PIO)

[6] Regenerative resistor connector

(RB)

[11] Piano switches

[7] Power/emergency-stop terminal

block

2.2.2 Functions

[1] Motor connector (MBK)

A connector for the actuator’s motor power cable.

[2] Brake release switch (BK) This switch is available only when the brake option is selected.

RLS: Brake is forcibly released

NOM: Brake is in use (Normal setting)

[3] SIO connector (SIO)

A connector for linking another controller when two or more controllers are conne cted.

[4] Port switch (PORT)

ON: The PORT IN port (teaching pendant/PC software) becomes active. If a dedicated teaching

pendant or cable is not connected to this port, the controller will recognize an emergency-stop

condition.

OFF: The PORT IN port (teaching pendant/PC software) becomes inactive. (Controller-to-controller

communication is possible.)

11

Page 28

[5] Main communication port connector (PORT IN)

A connector for receiving the communication cable from a dedicated teaching pendant or external

equipment. It also receives a controller link cable when two or more axes are connected.

[6] Regenerative resistor conn ect or (RB)

A connector for regenerative discharge resistor.

The controller will come with a regenerative resistor if the specified actuator capacity is 30 W or above.

However, connection is basically optional, and it should be connected when a regene rative discharge error

occurs. The error code of the regenerative discharge error is “0C9.”

[7] Power/emergency-stop terminal block

EMG: Both terminals are used to connect an emergency-stop switch.

(EMG terminals are short-circuited at default.)

24V: Connect the positive side of the 24-VDC power supply.

This becomes the common terminal for the PIO input circuit

N: Connect the negative side of the 24-VDC power sup ply.

This becomes the common terminal for the PIO output circuit.

[8] LEDs

RDY (green): Indicate that the CPU is operating normally.

RUN (green): This LED turns on while the actuator is moving.

The LED also turns on when the voltage of the absolute-data backup battery

drops.

ALM(red): This LED remains lit while an alarm is present.

ENC (orange): This LED turns on when the encoder cable is open or otherwise the encoder

cannot be recognized.

[9] Encoder/brake connector (ENC)

An encoder/brake (optional) cable connector.

[10] PIO connector (PIO)

A PIO cable connector.

[11] Piano switches (SW)

There are six piano switches. The role of each switch is shown below.

Piano switch number Role

6 FWP: Write protect switch

5 ABS-CLR: Absolute data clear switch (absolute specification)

4

3

2

1

Actuator address setting switches

Note: All piano switche s are de signated as Nos. 1, 2, etc., from the bottom.

With the piano switch in front of you, tilt it to the right side to turn on the switch, or tilt it to the left

side to turn off the switch.

12

Page 29

Piano switches 1 to 4 --- Address switches

Use these switches to set the address of the applicable actuator if two or more axes are connected to the

SIO connector. A desired address between 0 to 15 can be set.

(The factory setting is OFF for all of switch Nos. 1 to 4. This setting represents a condition where only one

axis is used.)

Use these switches to set a desired address for each controller . Make sure no addre ss is duplicated amon g

the controllers. As long as they are unique, the addresses may not be contiguou s and missing numbers are

allowed.

Address

1 2 3 4

Piano switch numbers

0 OFF OFF OFF OFF

1 ON OFF OFF OFF

2 OFF ON OFF OFF

3 ON ON OFF OFF

4 OFF OFF ON OFF

5 ON OFF ON OFF

6 OFF ON ON OFF

7 ON ON ON OFF

8 OFF OFF OFF ON

9 ON OFF OFF ON

10 OFF ON OFF ON

11 ON ON OFF ON

12 OFF OFF ON ON

13 ON OFF ON ON

14 OFF ON ON ON

15 ON ON ON ON

The controller link cable is 200 mm

long.

A maximum of 16 controllers ca n

be connected.

Piano switche 5 ABS-CLR (absolute specification)

(Second from the top)

This switch clears the data of the absolute encoder. Use it to perform an absolute reset. Normally this switch

should be in the OFF position.

Piano switche 6

(First from the top)

Write protect switch. This switch is used for remote update. Normally this switch should be in the OFF position.

13

Page 30

2.2.3 Pin Assignments of the Communication Ports

Pin assignments of the SIO connector

Pin No. Signal name Function

1 (+5V) (5-VDC power output) or (preliminary signal termin al)

2 SGA Positive logic side of the line transceiver I/O

3 GND Communication ground

4 SGB Negative logic side of the line transceiver I/O

5 GND Communication ground

6 (+5V) 5-VDC power output

Pin assignments of the main communication port

Pin No. Signal name Function

1 SGA Serial communication

2 SGB Serial communication

3 5V 5-V power output

4 EMGS Emergency-stop status

5 EMGA *1

6 24V 24-V power output

7 GND Ground

*1 Used to actuate an emergency stop (contact b).

Short these pins to cancel an emergency stop.

Motor connector [Molex 5569-04A1]

8 ENGB *1

Pin No. Signal name Connected wire

1 U Motor phase U

2 V Motor phase V

3 W Motor phase W

4 (-)

14

Page 31

Encoder/brake connector [JST S11B-XASK-1]

Pin No. Signal name Connected wire

1 EN A+ Encoder A+

2 EN B+ Encoder B+

3 EN Z+ Encoder Z+

4 EN Z– Encoder Z-

5 SD+ Encoder SD+

6 SD– Encoder SD7 EN 5V Encoder 5V+

8 EN GND Encoder COM-

9 BK N Brake10 BK P Brake+

11 FG Shield

Power/emergency-stop terminal block [Sato ML-800S IH (4P)]

Signal name Connected wire

[2]

[1]

These terminals are connected to the emergency stop

circuit.

24 V is output to [1].

(These terminals have been shorted prior to shipment.)

24 V Positive side of the 24-V power supply

N Negative side of the 24-V power supply

24 V and ENG [1] are connected internally.

15

Page 32

2.3 External Dimensions

16

Page 33

2.4 Connection Method

2.4.1 Standard Type

Teaching pendant

<RCA-T/TD>

Optional

Cable length: 5 m

PC

PC software

<RCA-101-MW>

Optional

EMG switch

24-VDC

power

supply

ROBO Cylinder <RCS>

The cables are optional.

Host system <PLC>

Supplied flat

cable

Cable length: 2 m

External unit

RCB-105-2 (2 m)

RCB-105-5 (5 m)

Do not insert/remove the

connectors when the power is

on, except for the main

communication port connector

(PORT IN). To insert/remove the

PORT IN connector, do so after

turning the PORT switch to OFF.

17

Page 34

2.4.2 Absolute Specification

ROBO Cylinder <RCS>

The absolute specification

cannot be used with a

standard actuator.

The cables are optional.

Other connections are the same as those

of the standard type.

Battery

holder

18

Page 35

2.5 Supplied Cable

2.5.1 I/O Flat Cable

NO. Signal Color NO. Signal Color

1 - Brown-1 14 - Yellow-2

2 - Red-1 15 - Green-2

3 Start Orange-1 16 Completed position 1 Blue-2

4 Command position 1 Yellow-1 17 Completed position 2 Purple-2

5 Command position 2 Green-1 18 Completed position 4 Gray-2

6 Command position 4 Blue-1 19 Completed position 8 White-2

7 Command position 8 Purple-1 20 Position complete Black-2

8 - Gray-1 21 Home return completion Brown-3

9 - White-1 22 Zone Red-3

10 *Pause Black-1 23 * Alarm Orang-3

11 Reset Brown-2 24 *Emergency stop Yellow-3

12 Servo ON Red-2 25 Moving Green-3

13 - Orange-2 26 - Blue-3

2.5.2 Motor Extension Cable

Controller end

Cable color

Receptacle: 5557-04R (Molex)

Female terminal: 5556-TL (Molex)

Actuator end

Red

White

Black

Signal

abbriviation

Pin No.

Flat cable

Pin No.

Plug housing: SLP-03V (JST)

Socket contact: BSF-21T-P1.4 (JST)

Signal

abbriviation

Cable color

Red

White

Black

19

Page 36

2.5.3

Encoder Extension Cable

Controller end

Actuator end

Cable color

Pink

White

Orange/white

Green/white

Blue

Orange

Purple

Blue/red

Gray

Ground

Red

Signal

abbriviation

Pin No.

Cable color

Signal

abbriviation

Pin No.

Plug housing: SMP-02V-BC (JST)

Socket contact (gold plated): SHF-001T-0.8BS (JST)

Ground and braided

shield wires

Pin No.

Plug housing: XMP-18V (JST)

Socket contact: BXA-001T-P0.6 (JST)

Retainer: XMS-09V (JST)

Signal

abbriviation

Cable color

Pink

White

Orange/white

Green/white

Ground

Blue

Orange

Black

Yellow

Purple

Blue/red

Gray

Red

20

Page 37

2.6 Wiring

2.6.1 Wiring for Power Supply/Emergency Stop

* The two EMG terminals are contact-b inputs used for connecting an emergency-stop switch. The controller is

shipped with these terminals shorted, so that an emergency stop will not be actuated.

Note: When performing power connection, make sure the following specifications for power cable, etc.,

are satisfied.

Power/emergency-stop terminal block

Applicable cable

Allowable wire size

Standard stripped-wire length 11 mm

Button operation tool

Note: This controller has no power switch.

Single wire --- 1.0 (AWG18)

Stranded wire --- 0.75 mm

Single wire --- 0.4 (AWG26) to 1.2 (AWG16)

Stranded wire --- 0.3 mm2 (AWG22) to 1.25 mm2 (AWG16)

Element wire diameter --- 0.18 or larger

Flathead screwdriver (shaft diameter 3, blade tip wid th 2.6)

2

(AWG18)

21

Page 38

r

r

r

2.6.2 External Connection Diagram

Teaching pendant

Conversion adapter

Host

system

(PLC)

Output

Input

External EMG button

Input voltage

(Note) *Pause, *Alarm and *Emergency stop are contact-b signals.

PC

Conversion

adapter

Moto

connecto

Encoder/brake

connecto

Main

communication port

RS485

communication

Start

Command position 1

Command position 2

Command position 4

Command position 8

* Pause

Reset

Servo ON

Completed position 1

Completed position 2

Completed position 4

Completed position 8

Position complete

Home return completion

Zone

* Alarm

* Emergency stop

Moving

Brake

To the next controller

22

Page 39

2.6.3 PIO Interface

A PIO interface list is given below.

The PIO cable is a flat cable with no connector attached on the end connecte d to the external equipment.

PIO connector (26 pins)

Pin No. Category Signal name

1 Brown-1

2

3 Start

4 Command position 1 Yellow-1

5 Command position 2 Green-1

6 Command position 4 Blue-1

7 Command position 8

8 Gray-1

9

10 [2] * Pause

11 [3] Reset

12 [4] Servo ON

13

14

15

16 Completed position 1 Blue-2

17 Completed position 2 Purple-2

18 Completed position 4 Gray-2

19 Completed position 8

20 [6] Position complete

21 [7] Home return completion

22 Zone

23 [8] * Alarm

24 [9] *Emergency stop

25

26

Input

Output

Not used Do not connect anything to this terminal.

Input for movement start signal

Input the position number you want to select.

[1]

Not used Do not connect anything to this terminal.

The moving actuator is paused.

Alarms are set.

The servo is turned on.

Not used

Not used

Orange-2

Do not connect anything to this terminal.

Do not connect anything to this terminal.

The position number to which the positioning

has completed is output. [5]

This signal is output upon completion of

movement.

This signal is output upon completion of home

return.

This signal is output within the range set by

parameters.

This signal is output when a controller error is

detected.

This signal is output when an emergency stop

is actuated.

[10] Moving

This signal is output while the motor is running.

Not used Do not connect anything to this terminal.

Model number of controller-end connector: Hirose HIF6-26 PA-1.27DS

Cable color

Red-1

Orange-1

Purple-1

White-1

Black-1

Brown-2

Red-2

Yellow-2

Green-2

White-2

Black-1

Brown-3

Red-3

Orange-3

Yellow-3

Green-3

Blue-3

Note: Note: The ports de noted by * operate on the negative (cont act-b) logic. Neve r connect the sig nal

of any of these ports to an unused port.

23

Page 40

[1] Command position

Relationship of input pin numbers and selected position numbers (4-bit binary)

One of 16 positions from 0 to 15 can be input/selected.

1: ON 0: OFF

Pin No.

Command position 1

4

Command position 2

5

Command position 4

6

Command position 8

7

0 1 0101010101 0 1 01

0 0 1100110011 0 0 11

0 0 0011110000 1 1 11

0 0 0000001111 1 1 11

Selected position No. 0 1 234567891011 12 13 1415

Note: The actuator will not operate if the start input is turned ON after sel ecting a position number for

which no position data is entered. (A bank 31 error (alarm code: 0B1) will occur.)

[2] Pause

This is a contact-b input. Keep the signal ON while the actuator is moving, and cause it to turn OFF when the

movement pauses.

[3] Reset

An alarm will be reset once a rise of this signal is detected. If the cause of the alarm is not yet removed, the

alarm will come back after the reset action. (Only the overcurrent alarm

When this signal is input while the actuator is in pause, the remaining travel will be cancelled.

[4] Servo ON

The servo is ON while this signal is ON.

[5] Completed position

All completed position signals will turn OFF the moment the position complete signal turns OFF.

All completed position signals remain OFF while an emerg en cy stop is actuated or du ring the direct teachin g

mode.

When the controller returns to the ready mode thereafter, the completed position signal corresponding to the

current actuator position will be output if the current actuator position is within the positioning band from the

last position complete position. If the current actuator position is outside the positioning band, all completed

position signals will remain OFF.

In the push & hold mode, all completed position signals will remain OFF when the controller returns to the

ready mode from an emergency-stop status or the direct teaching mode, regardless of the curre nt actuator

position.

When an alarm occurs, a corresponding alarm code (short form) is output by the four bits of completed

positions 1, 2, 4 and 8. The meanings of these signals vary in a normal state and when an alarm is present,

so exercise caution when writing a sequence program. (Refer to 6.3, “PIO Alarm Outputs.”)

[6] Position complete

This signal will turn ON when the controller becomes ready following a power connection. It will turn OFF

when a start signal is input, and turn ON when a movement is completed

24

Page 41

[7] Home return completion

This signal will turn ON when the initial home return is completed after a po wer connection. Thereafter, an

alarm generated and this signal will remain ON until the power is turned off. It will not turn OFF following a n

emergency-stop signal input.

If the home return completion signal is OFF, it means home return will be performed before the next

movement operation.

Note: With the ab solute specification, once the home position has been taught the home return

complete signal will turn ON every time the power is turned on. If the home return complete

signal turns OFF due to an alarm, the home position must be taught again.

[8] Alarm

This signal will turn OFF when an alarm occurs. It remains ON as long as the controller is operating properly.

To reset an alarm, remove the cause of the alarm, and then input a reset signal or reconnect the power.

[9] Emergency stop

This signal will turn OFF when an emergency stop is actuated. It remains ON as long as the controller is

operating properly.

When the emergency stop is cancelled, the signal will turn ON.

[10] Moving

After the actuator starts moving, the start signal will turn OFF once this signal turns ON.

Use this signal if you want to detect stopping of the motor during pause.

25

Page 42

2.6.4 Non-isolated External I/O Specification

Input Part

Item Specification

Number of inputs 8 points

Input voltage

Input current 7 mA/1 circuit

Operation voltage

Isolation method Not isolated

Output Part

There are two specifications for the output part, namely Group 1 and Group 2.

Group 1: Output circuit based on TD62084 (or equivalent) (8 points)

Item Specification

Signal name

Rated load voltage 24 VDC (built-in flywheel diode)

Rated load current 40 mA/1 point

Recommended load current 20 mA/1 point

Leak current 0.1 mA (max.)

Residual voltage 3.1 V/40 mA (max.)

Isolation method Not isolated

Overcurrent protection

Group 2: 100-mA output circuit based on MOSFET (2 points)

Item Specification

Signal name Emergency stop, moving

24 VDC 10%

ON voltage --- 18 V min.

OFF voltage --- 6 V max.

Complete positions 1, 2, 4, 8, positioning complete, home return

complete, zone, alarm

47-, 0.1-W fuse resistance

Maximum output voltage 60 V (peak) (Open drain, no flywheel diode)

Maximum load current 100 mA/1 point

Residual voltage 1.1 V/100 mA

Isolation method Not isolated

Overcurrent protection

26

10-, 0.1-W fuse resistance

Page 43

I/O Circuits

Power

Pin No.

Start

Command position 1

Command position 2

Command position 4

Command position 8

NC

NC

* Pause

Reset

Servo ON

Completed position 1

Completed position 2

Completed position 4

Completed position 8

Position complete

Home return completion

Zone

* Alarm

*Emergency stop

Moving

Multi-fuse

Group 1

8 circuits

Group 2

2 circuits

Noise

filter

Internal power supply

27

Page 44

3. Data Entry <Basics>

This controller doesn’t use command words, so there is no need to create a program.

All you need is to enter position data in the position-data table, and the actuator will move to the specified

position.

Position data consists of number (No.), position (Position), speed (Speed), acceleration/deceleration (ACC), push

(Push), positioning band (Pos. band), and acceleration only MAX (ACC MAX). The description in pa rentheses is

as displayed on the teaching pendant.

Position data can be specified in two different modes: by absolute coordinate specification (absolute mode) in

which the distance from the home is entered, or by relative coordinate specification (incremental mode) in which

the incremental movement from the current position is entered.

No.

Position Note

Speed

0 0 100 0.3 0 0.1 0

1 30 100 0.3 0 0.1 0

=

2 10 100 0.3 0 0.1 0

~

~

15

100

100

When data is entered in the position column of the position-data table, the default values will be automatically

entered in the remaining columns. Change the default values as necessary.

To change a default value, change the corresponding parameters starting with “Default.”

The default values vary depending on the actuator type.

This indicates that the incremental mode is active. (This symbol is displayed only on the teaching pendant.

Separate columns for incremental specification are provided in the PC software.)

Position-data table

Acceleration/

deceleration

0.3

Push

0

Positioning

band

0.1

Acceleration

only MAX

0

~

~

Note: Enter position data first. Any attempt to enter other data before position data will be rejected.

You can enter position data containing two decimal places.

However, the controller only recognizes position data as a multiple of its minimum resolution.

The minimum resolution of the controller varies depending on the actuator lead.

For the above reason, the second decimal place in the entered position data may be rewritten in

accordance with the actuator lead.

Example: Entered value Stored value

50.01 50.03

28

Page 45

3.1 Description of Position-Data Table

(1) No.

(2) Position (Position)

(3) Speed (Speed)

(4) Acceleration/deceleration

(ACC)

Caution: When setting speed and acceleration/deceleration, refer to the supplied specification list of

supported actuators and also consider the installation conditio n and load shape to determine

appropriate values that will not cause the actuator to receive excessive impact or vibration.

To set values higher than the recommended values, the payload should be considered and

the actuator characteristics vary depending on the model. Therefore, for the maximum

settings allowed for each actuator model, please contact IAI’s Sales Engineering Section.

Indicate the position data number.

To enter an incremental movement, press the minus key in this column.

On the teaching pendant, a “=” will be displayed between the number

and position columns.

The minus key need not be pressed in the absolute mode.

Enter the target position to move the actuator to, in [mm].

Absolute mode: Enter the distance to the target actuator position from

the home. Negative values cannot be entered.

Incremental mode: Enter the distance to the target actuator position from

the current position. A negative value can also be

entered (for movement in the negative direction along

the displayed coordinate axis).

No. Position

0

1 10 Incremental mode +10 mm from the current position

2 -10 Incremental mode -10 mm from the current position

3

30 Absolute mode 30 mm from the home

=

=

100 Absolute mode 100 mm from the home

Enter the speed at which the actuator will be moved, in [mm/sec].

The default value varies depending on the actuator type.

Enter the acceleration/deceleration at which the actuator will be moved,

in [G].

The acceleration should basically conform to the rating specified in the

catalog.

With RCS controllers, an acceleration level above the rating can be used

to shorten the tact time only if the actuator is used in a condition where

“the payload is significantly smaller than the rated loading capacity .”

To deal with this situation, the “Acc” field in the position table allows for

input of values greater than the rated acceleration.

Speed

(Speed)

Acceleration/deceleration G

Acceleration/deceleration (ACC)

Start Completion Time

Acceleration/deceleration G --- MIN 0.01 G (Slow rise)

MAX 1.00 G (Quick rise)

29

Page 46

(5) Push (Push)

Select the positioning mode or push & hold mode.

The default value is “0.”

0: Positioning mode (= Normal operation)

Other than 0: Push & hold mode [%]

In the push & hold mode, enter the current-limiting value to be applied to

the servo motor while the load is being pushed. With the RCS, set the

current-limiting value to approx. 70%. The controller will not operate

properly if this value is 30% or below.

The table on page 33 lists the push force at standstill for each controller

type when the current-limiting value is set to 70%. Be sure to reference this

table to set an appropriate value for your controller.

Note: If the push force is too small, a false detection of push & hold

condition may occur due to slide resistance, etc., so exerci se

caution.

(6) Positioning band

(Pos. band)

The function of the positioning band varies depending on whether the

push & hold setting in (5) is “0” or “other than 0.”

[A] Push = 0 (Positioning mode)

In the positioning mode, enter the position-complete detection width

(distance to the target position), in [mm].

The distance to the target position indicates the range prior to the target

position, upon entry of the actuator in which range a position complete

signal will be output.

The default value is “0.1 [mm]” (Fig. A).

[B] Push = Other than 0 (Push & hold mode)

Enter the maximum push amount (distance from the target) in the push &

hold mode, in [mm] (Fig. B).

If the push direction corresponds to the negative direction along the

displayed coordinate axis, add a – (minus) sign to the entered value.

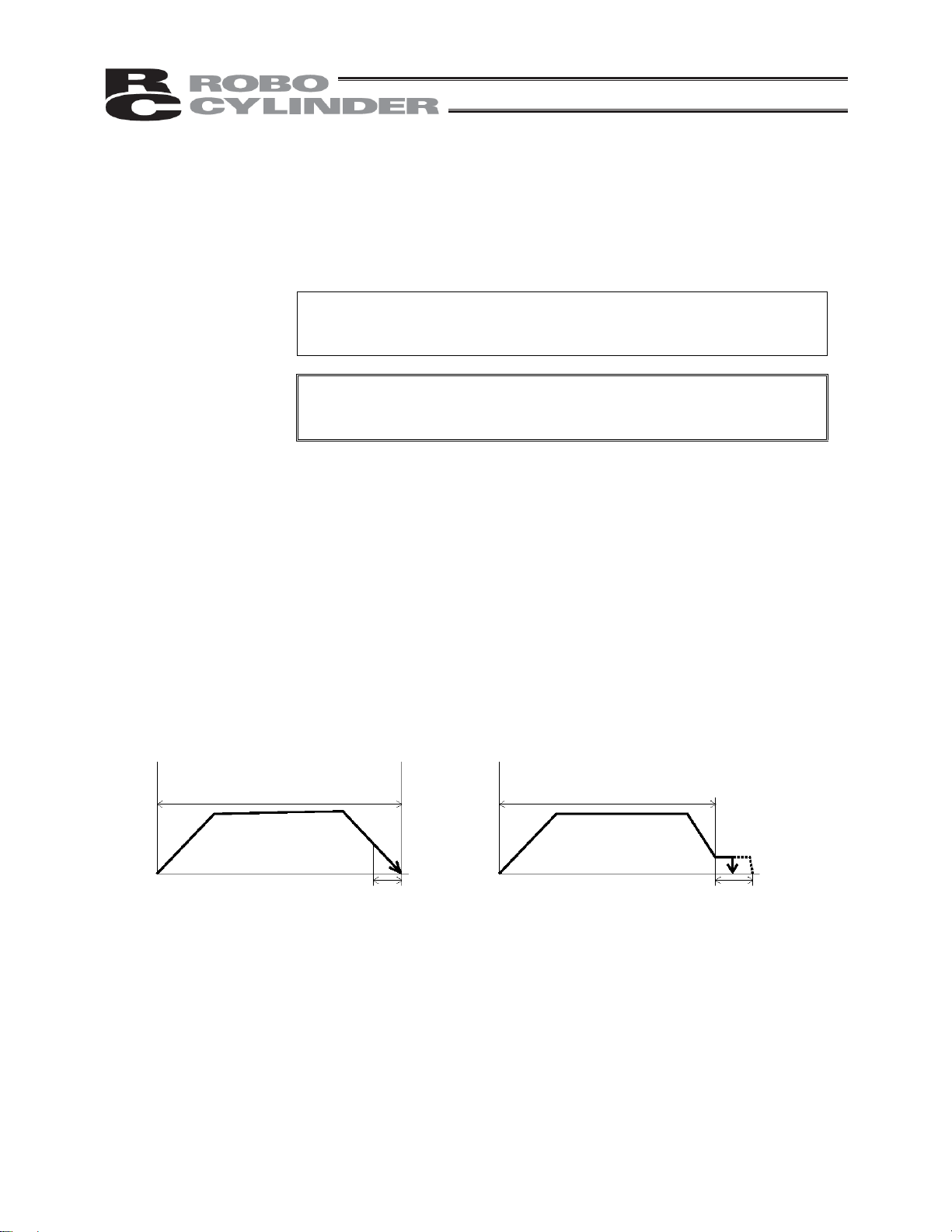

(A) Push = 0

Distance to the position set in (2)

Speed

Moving distance

Fig. A Fig. B

(B) Push = Other than 0

(6) Positioning band (6) Positioning band

Distance to the position set in (2)

Speed

Moving distance

30

Page 47

(7) Acceleration only MAX

(ACC MAX)

(7) Acceleration only MAX = 0 (7) Acceleration only MAX = 1

Speed

Acceleration/deceleration

set in (4)

Select the specified acceleration or maximum acceleration by entering

“0” or “1.”

The default value is “0.”

0: Specified acceleration --- The value entered in (4) becomes the

actual acceleration/deceleration.

1: Maximum acceleration --- The maximum acceleration set according

to the load is used.

The deceleration conforms to the value

entered in (4).

Moving distance

Maximum acceleration

according to the load

Speed

Acceleration/deceleration

set in (4)

Moving distance

Caution: As a rough guide, enable the acceleration only MAX setting when the actual payload is no more than

one-third of the rated loading capacity.

Check the rated loading capacity of your actuator by referring to the supplied specification list of

supported actuators.

31

Page 48

3.1.1 Push Force at Standstill

In the push & hold mode, enter a current-limiting value (%) in the position-data table under “Push.”

With the RCS, use a push force at standstill corresponding to a current-limiting value of approx. 70%.

The push force at standstill can be increased or decreased by increasing or decreasing the current-limiting value.

However, take note that the controller will not operate properly if the current-limiting value is 30% or below.

The table below lists the push force at standstill for each controller type when the current-limiting value is set to

70%.

Type Motor (W) Speed type

RA35 20

RA45 30

Rod type

Flat type F45 30

RB7525 60

60

RB7530

100

L 95 (9.7)

M 47 (4.8)

H 23 (2.4)

L 142 (14.5)

M 70 (7.2)

H 35 (3.6)

M 143 (14.6)

H 71 (7.3)

L 238 (24.3)

M 118 (12.1)

H 59 (6.1)

M 198 (20.2)

H 99 (10.1)

L 142 (14.5)

M 70 (7.2)

H 35 (3.6)

Push force

(N (kgf))

Note: The accuracy of push force at standstill is not guaranteed. The values are provided for

reference purposes only.

32

Page 49

3.2 Explanation of Modes

3.2.1 Positioning Mode Push = 0

Speed

Position complete signal

Completed position number

Moving OFF

Output

(1) The position complete output will turn

ON and moving output will turn OFF at

a position preceding the target position

by the positioning band. A completed

position number signal will be output at

the same time.

Moving distance

Positioning band

3.2.2 Push & Hold Mode Push = Other than 0

(1) Load was contacted successfully

Speed

Moving distance

Note: The time set in the parameter “Push & hold stop judgment period.” The default value of “255 msec” is

already entered.

The actuator is holding the load in position while pushing it.

The actuator continues to push the load at the push force at standstill determined by the

Warning

current-limiting value. Since the actuator is not inactive, exercise due caution when

handling the machine in this condition.

The push speed is set as follows in accordance with the speed set in the position-data table:

Push speed 20 mm/sec Set speed

Position complete signal

Completed position number

Moving OFF

Output

Positioning band

20 mm/sec or more Less than 20 mm/sec

(1) After reaching the target position, the actuator

will move at low speed.

When the Pos. band set in the data table (see

Note) is reached after the actuator contacts the

load and the servo motor current has reached

the current-limiting value, the position complete

output will turn ON. A completed position

number signal will be output at the same time.

The moving output will turn OFF.

Set speed

33

Page 50

r

f

(2) Load was not contacted (missed)

Speed

Completed position numbe

Moving OFF

Output

Moving distance

Positioning band

(1) After reaching the target position, the

actuator will move at low speed.

Even after contacting the load, the actuator

will move to the end of the positioning band i

the servo motor current is yet to reach the

current-limiting value.

The position complete output will not turn ON

even when the end of the positioning band is

reached. In this case, only the completed

position number will be output. The moving

output will turn OFF.

Check if the load has stopped moving based

on whether the moving output has turned

OFF.

(3) Load moves during push & hold operation

[1] Load moves in the pushed direction

Position complete signal

Completed position number

Speed

Output

Moving OFF

Moving distance

Positioning band

If the load moves in the pushed direction after

the position complete output has turned ON

(moving has turned OFF), the actuator will

push the load within the positioning band.

The moving output will turn ON.

The position complete output will remain ON

and the completed position number will be

output continuously.

Once the load stops moving, the moving

output will turn OFF.

[2] Load moves in the opposite direction from the push force

(Actuator is pushed back by the reactive force of the load)

Position complete signal

Completed position number

Speed

Moving distance

Output

If the actuator is pushed back after the position

complete output has turned ON because the

actuator thrust is smaller than the reactive force of

the load, the actuator will be pushed back all the

way until its thrust balances out with the reactive

force of the load.

The position complete output will remain ON and

the completed position number will be output

continuously.

The moving output will remain ON until the load

stops moving.

34

Page 51

(4) Positioning band was entered with a wrong sign

If the positioning band is entered with a wrong sign,

Speed

the position will deviate by twice the positioning

band, as shown to the left, so exercise due caution.

Moving distance

Positioning

band

Positioning

band

3.2.3 Speed Change during Movement

Speed control involving multiple speed levels is possible in a single operation. The actuator speed can be

decreased or increased at a certain point during movement.

However, the positio n at which to implement each speed change must be set.

Position 1 Position 2 Position 1 Position 2 Position 1 Position 2 Position 3

3.2.4 Operation at Different Acceleration and Deceleration Settings

The actuator will accelerate and decelerate at diff erent speeds if “1” is entered under “Acceleration only MAX” in

the position data.

The acceleration corresponds to the maximum acceleration. The deceleration is the value input in the “Acc/Dec”

field of the position data table.

Caution: Although the specific value differs depending on the actuator, the maximum acceleration cannot be more

than three times the rated acceleration.

Accordingly, this function should be enabled only when the payload is no more than one-third of the rated

loading capacity and the actuator needs to be stopped gradually at slow deceleration.

If this function is enabled when the payload is equivalent to the rated loading capacity, an overload error may

occur.

Even if an overload error does not occur, the actuator will still receive excessive impact loads that may

negatively affect the life of the actuator. Therefore, exercise due caution when enabling this function.

Check the rated loading capacity of your actuator by referring to the supplied specification list of supported

actuators.

Speed

Maximum acceleration

according to the load

Time

Deceleration can be set

freely

35

Page 52

3.2.5 Pause

This signal can be used to stop the actuator in case of emergency.

The movement of the actuator can be paused via an external input signal (pause).

For safety reasons, this signal is provided as a contact-b input (based on the negative logic).

The actuator will decelerate to a stop when the pause input is turned OFF, and resume movement when the

pause input is turned ON.

Pause signal

Actuator operation

The remaining movement of the actuator can be cancelled by turning ON the reset input during pause (the

movement will be cancelled upon rise of the reset input signal).

Pause signal

Reset

Actuator operation

3.2.6 Zone Signal Output