Page 1

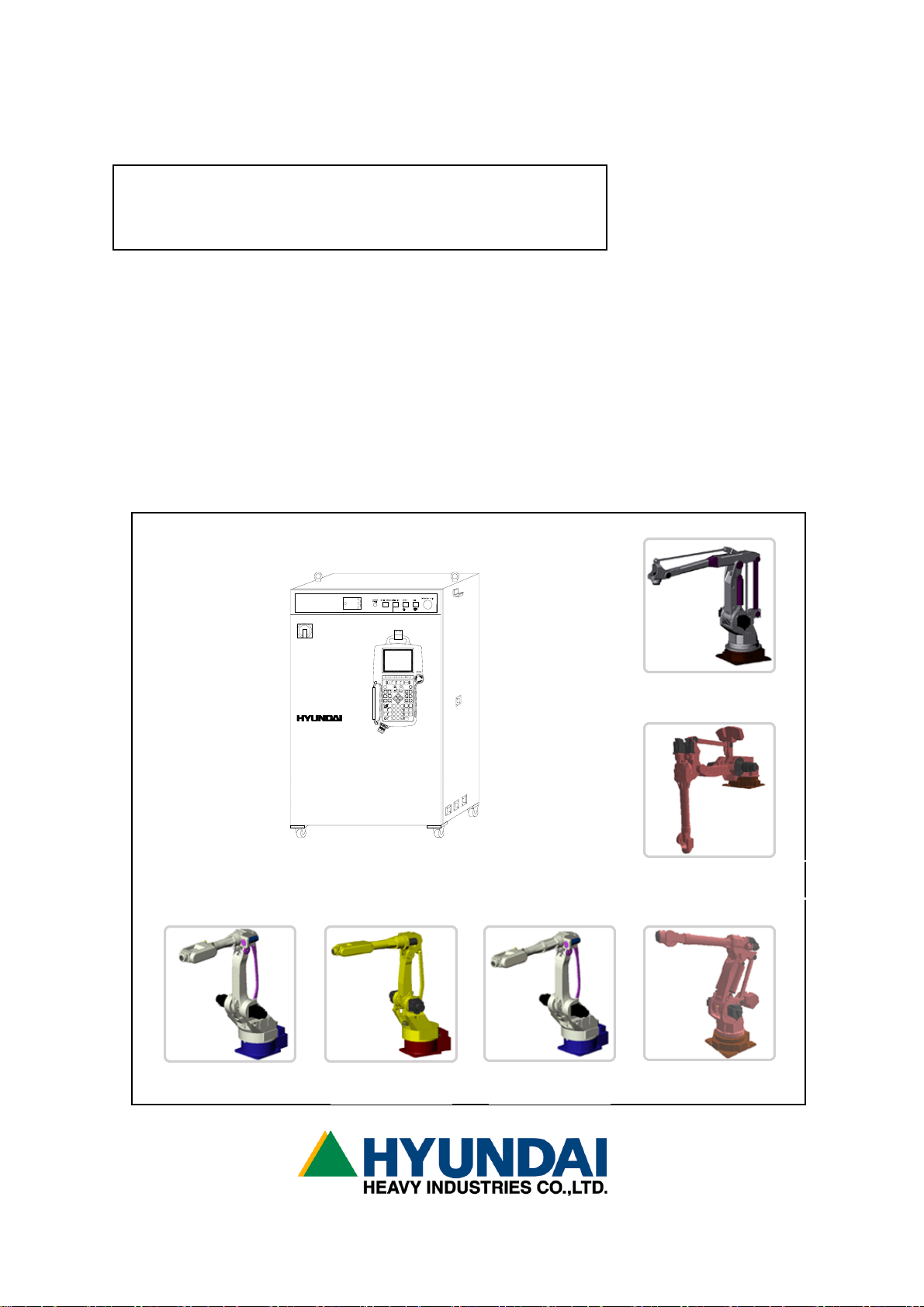

Hi40402JO1E

Robot Operation Manual

HYUNDAI Robot

Hi4

TP300

HYUNDAI

PF1

PF2

PF4

PF3

축

좌표계

직교

보조축

GUN 연속

TOOL

SHIFT

후진

(고속)

속도

스텝

EN. SW

전진

MOTOR

보조점9I,V변경

*

f1

7

8

ARCON

송출( )WEAVON

4

526

?

ARCOF

후퇴( )

WEAVOF

교시

/

1

3

재생f2f3

+

삭제 프로그램

LCD

.

0

f4

Hi4 CONTROLLER

E.STOP

PF5

OFF

ACC

직선

보간

원호

취소

Rx+

Rx-

Ry+

Ry-

Rz+

Rz-

명령수정

위치수정

CMD

MOVE

정지

문/변/함

수동출력

지난화면

STEP

HR100P

HR120S/150S

HR006

HR015

HR010L

HX130/165

Page 2

The information presented in the manual is the property

of HHI. Any copy or even partial is not allowed without

prior written authorization from HHI. HHI reserves the

right to modify without prior notification.

Printed in Korea - April/2002. 1st Edition

Copyright

2002 by Hyundai Heavy Industries Co.,Ltd.

Page 3

■ HEAD OFFICE ■ 본사

1, JEONHA-DONG, DONG-GU, 울산광역시 동구 전하동 1번지

ULSAN, KOREA

TEL: 82-52-230-7901~11 TEL: 052-230-7901~11

FAX: 82-52-230-7900 FAX: 052-230-7900

■ SEOUL OFFICE ■ 서울사무소

140-2,GYE-DONG, JONGNO-GU, 서울특별시 종로구 계동 140-2

SEOUL,KOREA 현대빌딩 14층

TEL: 82-2-746-4711~5 TEL: 02-746-4711~5

FAX: 82-2-746-4720 FAX: 02-746-4720

■ DAEGU OFFICE ■ 대구사무소

223-5, BUMEO 2-DONG, 대구광역시 수성구 범어 2동 235-5번지

SUSUNG-GU,DAEGU,KOREA 동일산업빌딩 6층

TEL : 82-53-746-6232 TEL: 053-746-6232

FAX : 82-53-746-6231 FAX: 053-746-6231

■ CHEONAN OFFICE ■ 천안사무소

355-15,DAGA-DONG,CHEONAN-SI, 충청남도 천안시 다가동 355-15번지

CHUNGCHEONGNAM-DO,KOREA 3층

TEL: 82-41-576-4294~5 TEL: 041-576-4294~5

FAX: 82-41-576-4296 FAX: 041-576-4296

■ GWANGJU OFFICE ■ 광주사무소

415-12,NONGSUNG-DONG, 광주광역시 서구 농성동 415-12번지

SEO-GU,GWANGJU,KOREA 현대빌딩 별관 3층

TEL: 82-62-363-5272 TEL: 062-363-5272

FAX: 82-62-363-5273 FAX: 062-363-5273

Page 4

------------------------------------------------------------------------------------------------

Contents

Chapter 1. Safety, Operation panel, Teach Pendant

1.1 Safety ..................................................... 1 - 2

1.1.1 General .................................................... 1 - 2

1.1.2 Relevant safety standard ................................... 1 - 5

1.1.3 Safety training ............................................ 1 - 5

1.1.4 Safety marking ............................................. 1 - 5

1.1.5 Definition of safety functions ............................. 1 - 7

1.1.6 Installation of robot ...................................... 1 - 8

1.1.7 Safety working procedures ................................. 1 - 15

1.1.8 Safety measures for entering safety fence ................. 1 - 20

1.1.9 Safety measures for maintenance and repair ................ 1 - 21

1.1.10 Safety function ........................................... 1 - 24

1.1.11 Safety related to end effectors ........................... 1 - 28

1.1.12 Liabilities ............................................... 1 - 29

1.2 Operation Panel............................................ 1 - 31

1.2.1 External shape of operation panel ......................... 1 - 31

1.2.2 Buttons of operation panel ................................ 1 - 31

1.3 Teach pendant ............................................. 1 - 33

1.3.1 External shape of teach pendant ........................... 1 - 33

1.3.2 Screen of teach pendant ................................... 1 - 34

1.3.3 Keys of teach pendant ..................................... 1 - 35

Chapter 2. Basic operation of robot

2.1 Basic operation............................................ 2 - 2

2.1.1 Controller's power/motor ON/OFF ........................... 2 - 2

2.1.1.1 Power ON/Motor ON ........................................ 2 - 2

2.1.1.2 Power OFF/Motor OFF ....................................... 2 - 2

2.1.2 How to initiate the system ................................ 2 - 3

2.1.3 Teaching .................................................. 2 - 3

2.1.4 Step and function ......................................... 2 - 4

----------------------------------------------------------------------------------------

- 1 -

Page 5

------------------------------------------------------------------------------------------------

2.2

Basic things for step

....................................... 2 - 5

2.2.1 The parameter of STEP command line ........................ 2 - 5

2.2.1.1 Interpolation-locus from between step and step ............ 2 - 6

2.2.1.2 Pose ..................................................... 2 - 7

2.2.1.3 Speed .................................................... 2 - 8

2.2.1.4 Accuracy ................................................. 2 - 8

2.2.1.5 Tool number .............................................. 2 - 8

2.2.1.6 Output option ............................................ 2 - 8

2.2.1.7 Stop condition ............................................ 2 - 9

2.2.1.8 Stop state variable ...................................... 2 - 9

2.2.2 Step position validation/modification method.............. 2 - 10

2.2.2.1 Encoder coordinate system ................................ 2 - 10

2.2.2.2 Base/Robot coordinate system ............................ 2 - 11

2.1.4 Coordinate system ........................................ 2 - 13

2.3.1 JOG operation key ....................................... 2 - 13

2.3.2 Axis coordinate ......................................... 2 - 14

2.3.3 Robot coordinate ........................................ 2 - 15

2.3.4 User coordinate ......................................... 2 - 17

2.3.5 Tool coordinate ......................................... 2 - 18

2.4 Auto tool setting ........................................ 2 - 19

Chapter 3. Service menu

3.1 Monitoring .................................................... 3 - 4

3.2 Register ..................................................... 3 - 15

3.2.1 XYZ Shift register ................................... 3 - 16

3.2.2 Shift buffers ........................................ 3 - 18

3.2.3 On-line shift register Group.......................... 3 - 20

3.2.4 Palletizing register.................................. 3 - 22

3.2.5 Frequency condition register.......................... 3 - 25

3.2.6 Conveyor data ........................................ 3 - 26

3.3 Variable ...................................................... 3 - 28

3.4 Edit program .................................................. 3 - 29

3.4.1 Modify writing condition totally...................... 3 - 30

3.4.2 Modify speed in record totally........................ 3 - 31

3.4.3 Modify position in record totally..................... 3 - 32

3.4.4 Step copy ........................................... 3 - 34

----------------------------------------------------------------------------------------

- 2 -

Page 6

------------------------------------------------------------------------------------------------

3.4.5 Step reverse copy ..................................... 3 - 36

3.4.6 Edit program in running (Hot edit) ................... 3 - 38

3.5 File management................................................ 3 - 43

3.5.1 Internal memory file name ............................ 3 - 44

3.5.2 Program first data .................................... 3 - 45

3.5.3 Internal program axis no. ............................. 3 - 46

3.5.4 Rename ............................................... 3 - 47

3.5.5 Copy.................................................. 3 - 51

3.5.6 Delete ............................................... 3 - 53

3.5.7 Protect............................................... 3 - 55

3.5.8 Storage media format ................................. 3 - 58

3.5.9 Save/Load (SRAM Card) ................................ 3 - 59

3.6 Program conversion............................................. 3 - 61

3.6.1 Coordinate transformation ............................ 3 - 62

3.6.2 Mirror Image.......................................... 3 - 64

3.6.3 Off-Line XYZ shift ................................... 3 - 67

3.7 System checking ............................................... 3 - 69

3.7.1 System version ........................................ 3 - 70

3.7.2 Run time ............................................. 3 - 71

3.7.3 Diagnosis of troubles ................................. 3 - 74

3.7.4 Error logging ........................................ 3 - 76

3.7.5 Stop history ......................................... 3 - 78

3.7.6 Operation history .................................... 3 - 80

3.8 Date setting (Date, Time) ..................................... 3 - 81

Chapter 4. Condition setting

4.1 Cycle type ...................................................... 4-3

4.2 Step go/back max. speed .......................................... 4-3

4.3 Function in step go/back .........................................4-4

4.4 Speed rate....................................................... 4-4

4.5 Robot lock....................................................... 4-5

4.6 Record speed type................................................4-5

4.7 Interpolation base...............................................4-6

4.8 User coordinate ................................................. 4-6

----------------------------------------------------------------------------------------

- 3 -

Page 7

------------------------------------------------------------------------------------------------

Chapter 5. Application condition

5.1 Conveyor operation .......................................... 5 - 3

5.2 Search range ................................................ 5 - 4

5.3 Search reference position record ............................. 5 - 4

5.4 Spot welding ................................................ 5 - 5

5.5 Gun search reference record .................................. 5 - 6

5.6 Output(DO) signal clear ...................................... 5 - 7

5.7 Online shift register clear .................................. 5 - 7

Chapter 6. System setting

6.1 User configuration .......................................... 6 - 5

6.1.1 Display language ..................................... 6 - 6

6.1.2 Pose reocrd type .................................... 6 - 6

6.1.3 Start type ........................................... 6 - 7

6.1.4 Change of cursor position in auto mode ............... 6 - 7

6.1.5 Confirm when the command delete....................... 6 - 8

6.1.6 WAIT(DI/WI) forcible release ......................... 6 - 8

6.1.7 Dettachment of Teach Pendant ......................... 6 - 9

6.1.8 Power failure detection(Not changeable) .............. 6 - 9

6.1.9 External program selection ........................... 6 - 9

6.1.10 Using the program strobe signal .................... 6 - 10

6.1.11 Step set alarm type................................. 6 - 11

6.1.12 Lowest position proportion of the cursor ........... 6 - 11

6.1.13 Using the collision sensor ......................... 6 - 12

6.2. Controller parameter ....................................... 6 - 13

6.2.1 Input/output signal selection ....................... 6 - 14

1: Input signal logic ............................... 6 - 15

2: Output signal logic .............................. 6 - 16

3: The attribution of output signal ................. 6 - 17

4: Setting the pulse table .......................... 6 - 18

5: Setting the delay table .......................... 6 - 19

6: Output signal assignment ......................... 6 - 20

7: Input signal assignment .......................... 6 - 21

8: Setting the earlier output ....................... 6 - 23

9: DIO name edit..................................... 6 - 24

----------------------------------------------------------------------------------------

- 4 -

Page 8

------------------------------------------------------------------------------------------------

10: Setting the field bus ............................. 6 - 26

6.2.2 Serial port ......................................... 6 - 31

1: Teach Pendant (CNTP) ............................. 6 - 31

2: Private serial port for I/O board ................ 6 - 31

3: Serial port #1 (CNSIO) ........................... 6 - 32

4: Serial port #2 (OPSIO) ........................... 6 - 33

6.2.3 Robot ready ......................................... 6 - 34

6.2.4 Home position registration .......................... 6 - 35

6.2.5 Return to the previous position ..................... 6 - 36

6.2.6 End relay output time ............................... 6 - 37

6.2.7 Interlock error time ................................ 6 - 38

6.2.8 External error output ............................... 6 - 39

6.2.9 Power Saving : PWM OFF .............................. 6 - 42

6.2.10 Shift limit ........................................ 6 - 43

6.2.11 Setting the user key ............................... 6 - 44

6.2.12 Coordination system registration ................... 6 - 46

1: User coordination registration ................... 6 - 46

2: Pedestal tool coordination system ................ 6 - 48

6.3 Machine parameter............................................ 6 - 49

6.3.1 Tool data ........................................... 6 - 50

6.3.2 Axis Constant ....................................... 6 - 54

6.3.3 Soft limit .......................................... 6 - 55

6.3.4 Arm interference angle .............................. 6 - 56

6.3.5 Encoder offset calibration .......................... 6 - 57

6.3.6 Accel./Decel. speed parameter ....................... 6 - 59

6.3.7 B축 axis dead zone .................................. 6 - 60

6.3.8 Accuracy ............................................ 6 - 61

6.3.9 Speed ............................................... 6 - 64

6.3.11 Additional load per each axis ...................... 6 - 65

6.4 Application parameter ....................................... 6 - 67

6.4.1 Spot & Stud ......................................... 6 - 68

1: Welding parameter ................................ 6 - 69

2: Servo gun parameter .............................. 6 - 71

3: Spot welding data(condition,sequence) ............ 6 - 76

4: Equalizing parameter ............................. 6 - 81

----------------------------------------------------------------------------------------

- 5 -

Page 9

------------------------------------------------------------------------------------------------

6.4.2 Arc ................................................ 6 - 83

6.4.3 Palletizing ........................................ 6 - 85

1: Palletizing pattern register ..................... 6 - 86

2: Pallete dip angle measurement .................... 6 - 90

6.4.6 Conveyor ........................................... 6 - 91

1: Conveyor constant setting ........................ 6 - 92

2: Automatic setting of conveyor parameter .......... 6 - 95

6.4.7 Speed proportion voltage output ..................... 6 - 96

6.5 System format ............................................... 6 - 98

6.5.1 System format ....................................... 6 - 99

6.5.2 Robot type selection ................................ 6 - 100

6.5.4 Use setting ........................................ 6 - 103

6.5.5 Positioner group setting ............................ 6 - 104

6.6 Automatic constant setting ................................. 6 - 106

6.6.1 The optimization axis constant ...................... 6 - 107

6.6.4 Positioner calibration .............................. 6 - 109

Chapter 7. R code

7. 1 (1) R0 Step counter reser ............................ 7 - 5

7. 2 (2) R5 External start selection ...................... 7 - 5

7. 3 (3) R6 External program selection ..................... 7 - 6

7. 4 (4) R10 Run time display............................... 7 - 7

7. 5 (5) R17 File name display in internal memory ......... 7 - 10

7. 6 (6) R18 Frequency condition register .................. 7 - 11

7. 7 (7) R29 Tool number setting .......................... 7 - 12

7. 8 (8) R44 Conveyor data clear .......................... 7 - 13

7. 9 (9) R45 Conveyor register manual input ............... 7 - 14

7.10 (10) R46 Manual conveyor limit switch on .............. 7 - 15

7.11 (11) R49 Speed variation setting ...................... 7 - 16

7.12 (12) R55 Palletize counter reset ...................... 7 - 17

7.13 (13) R71 Recorded speed selection...................... 7 - 18

7.14 (14) R107 Program head data display .................... 7 - 19

7.15 (15) R115 Program copy ................................. 7 - 19

7.16 (16) R116 Program number modification .................. 7 - 20

7.17 (17) R117 Program delete ............................... 7 - 21

----------------------------------------------------------------------------------------

- 6 -

Page 10

------------------------------------------------------------------------------------------------

7.18 (18) R123 Robot lock ................................... 7 - 22

7.19 (19) R136 Modify accuracy in steps ..................... 7 - 23

7.20 (20) R137 Modify MX in steps ............................ 7 - 24

7.21 (21) R138 Modify GUN in steps .......................... 7 - 25

7.22 (22) R162 Shift register value change .................. 7 - 26

7.23 (23) R163 On-line shift cancel ......................... 7 - 26

7.24 (24) R204 Spot welding condition manual output ......... 7 - 27

7.25 (25) R210 Serovo gun number selection .................. 7 - 28

7.26 (26) R211 Squeeze force setting ........................ 7 - 28

7.27 (27) R212 Moving-tip consumption preset ................. 7 - 29

7.28 (28) R213 Fixed-tip consumption preset .................. 7 - 29

7.29 (29) R219 Equalizerless gun number selection ........... 7 - 30

7.30 (30) R220 Equalizerless tip consumption preset .......... 7 - 30

7.31 (31) R245 Monitor mode selection ........................ 7 - 31

7.32 (32) R269 Memory protection setting ..................... 7 - 32

7.33 (33) R286 Software version display ...................... 7 - 33

7.34 (34) R310 Manual output of GO-signal .................... 7 - 34

7.35 (35) R320 Set max. speed of step go/back ................ 7 - 35

7.36 (36) R323 Robot interrupt function record ............... 7 - 36

7.37 (37) R341 Execution code back-up ....................... 7 - 40

Chapter 8. Programming

8.1 Edit step..................................................... 8 - 3

8.2 Summary of operation keys ..................................... 8 - 4

8.3 Edit command.................................................. 8 - 6

8.4 Example - move sentence ....................................... 8 - 7

8.5 Variable, numerical formula and string edit .................. 8 - 13

8.6 Line number edit............................................. 8 - 17

8.7 Block edit................................................... 8 - 18

Chapter 9. Quick open function

9.1 Function summary............................................ 9 - 2

9.2 Move - step position ........................................ 9 - 4

9.3 Welding start con. - execution at ASF#=X .................... 9 - 5

9.4 Welding end con. - execution at AEF#=X ...................... 9 - 7

----------------------------------------------------------------------------------------

- 7 -

Page 11

------------------------------------------------------------------------------------------------

9.5 Welding aux. con. - retry .................................. 9 - 9

9.6 Welding aux. con. - restart................................ 9 - 11

9.7 Welding aux. con. - auto. wire stick release. .............. 9 - 14

9.8 Weaving condition file .................................... 9 - 15

9.9 Program edit in running ................................... 9 - 17

9.10 Spot welding function ..................................... 9 - 18

9.10.1 Welding condition ........................................ 9 - 18

9.10.2 Welding sequence .......................................... 9 - 19

Chapter 10. Menu tree

10.1 MENU LIST .................................................. 10 - 2

10.2 MOTION I/O ................................................. 10 - 3

10.3 FLOW CONTROL ............................................... 10 - 5

10.4 ETC. ....................................................... 10 - 7

10.5 ARC ........................................................ 10 - 8

10.6 SUSTITUTIAL STATEMENT ..................................... 10 - 10

Chapter 11. Robot language explanation

11.1 BASIC ELEMENTS ............................................ 11 - 3

11.1.1 LINE ............................................. 11 - 3

11.1.2 CHARACTER ........................................ 11 - 3

11.1.3 ADDRESS .......................................... 11 - 3

11.1.4 CONSTANT ........................................ 11 - 4

11.1.5 ROBOT CONFIG. INFORMATION.......................... 11 - 5

11.1.6 VARIABLE ......................................... 11 - 6

11.1.7 OPERATOR ........................................ 11 - 10

11.1.8 FORMULA ......................................... 11 - 10

11.2 COMMAND LINE .............................................. 11 - 11

11.2.1 SUSTITUTIONAL ................................... 11 - 11

11.2.2 ROBOT CONTROL ................................... 11 - 12

11.2.3 INPUT/OUTPUT .................................... 11 - 14

11.2.4 PROGRAM FLOW CONTROL ............................. 11 - 16

11.2.5 COMMENT ......................................... 11 - 21

11.2.6 ARC WELDING ..................................... 11 - 21

11.3 OTHERS. ................................................... 11 - 25

----------------------------------------------------------------------------------------

- 8 -

Page 12

------------------------------------------------------------------------------------------------

11.4 FUNCTION................................................... 11 - 40

11.4.1 ARITHEMATIC FUNCTION ............................. 11 - 40

11.4.2 STRING FUNCTION .................................. 11 - 41

11.4.3 ROBOT LANGUAGE SUBTITUTION OF OLD MIT FUNCTION CODE 11 - 42

Chapter 12. Signal connection

12.1 EXTERNAL INPUT SIGNAL (BD430/BD431) ......................... 12 - 2

12.2 EXTERNAL OUTPUT SIGNAL (BD430/BD431) ........................ 12 - 7

12.3 BD481 CIRCUIT ............................................. 12 - 17

----------------------------------------------------------------------------------------

- 9 -

Page 13

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

Chapter 1.Safety, Operation

panel, Teach pendant

Contents

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

1.1 Safety ..................................................... 1 - 2

1.1.1 General .................................................... 1 - 2

1.1.2 Relevant safety standard ................................... 1 - 5

1.1.3 Safety training ............................................ 1 - 5

1.1.4 Safety marking ............................................. 1 - 5

1.1.5 Definition of safety functions ............................. 1 - 7

1.1.6 Installation of robot ...................................... 1 - 8

1.1.7 Safety working procedures ................................. 1 - 15

1.1.8 Safety measures for entering safety fence ................. 1 - 20

1.1.9 Safety measures for maintenance and repair ................ 1 - 21

1.1.10 Safety function ........................................... 1 - 24

1.1.11 Safety related to end effectors ........................... 1 - 28

1.1.12 Liabilities ............................................... 1 - 29

1.2 Operation Panel ............................................ 1 - 31

1.2.1 External shape of operation panel ......................... 1 - 31

1.2.2 Buttons of operation panel ................................ 1 - 31

1.3 Teach pendant ............................................. 1 - 33

1.3.1 External shape of teach pendant ........................... 1 - 33

1.3.2 Screen of teach pendant ................................... 1 - 34

1.3.3 Keys of teach pendant ..................................... 1 - 35

------------------------------------------------------------------------------- 1 - 1

Page 14

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

Chapter 1. Safety, Operation panel, Teach Pendant

1.1 Safety

1.1.1 General

The primary purpose of this Chapter is to define the safety of the user and operating

personnel when using Hyundai Industrial Robots i. e. HR series and HX series robot

together with Hi-4 Controller (Hereinafter referred to "the Robotics System").

This manual covers any functions and safety measures required for the operation and

maintenance of the Robotics System itself. However, this manual does neither cover

how to design, install and operate a complete work cell, nor all peripheral equipment

and tooling which can influence the safety of the complete work cell.

This manual enumerates the safety instructions and/or recommendations for robot

manipulator and controller in strictly accordance with the American National Standard

Safety Requirements for industrial robots "ANSI/RIA R15.06-1999".

The technical description and installation method of the Robotics System are

presented in detail at this Operation Manual and the relevant specifications for the

robot manipulator and controller.

All personnel who intend to install, operate, program, repair, adjust, maintain or

otherwise use the Robotics System must be trained in an approved Hyundai Robotics

training course and have a good understanding and knowledge of this Operation Manual

and the Maintenance Manual, and further pay their special attention and observation

to the articles marked with the symbol which are of paramount importance among

the articles in this Chapter 1 "Safety".

Installation, replacement, adjustment, operation, maintenance and repair of the

Robotics System must be performed by the personnel who was duly trained in an approved

Hyundai robotics training course and become familiar with the proper operation of

the Robotics System according to the instructions specified in Operation and

-------------------------------------------------------------------------------1 - 2

Page 15

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

Maintenance Manual. Hyundai maintains its various application-specific training

courses for domestic and foreign customers respectively.

All owners, employers or users of the Robotics System have the responsibility to

review and observe any appliable safety laws and regulations in each country and to

take the necessary steps to guarantee the correct design, installation and operation

of all safety devices which can secure safety of all personnel in the workplace.

In accordance with the American National Standard Safety Requirements for industrial

robots "ANSI/RIA R15.06-1999", the dangerous zones of the Robotics System, i. e. the

working range in which the robot together with tools, accessories and additional

equipment moves, must in all cases be safeguarded to prevent persons or objects from

entering the dangerous zones or to ensure that the robot system is immediately shut

down by Emergency Stop system if a person or object should nevertheless enter a

dangerous zone. All owners, employers or users of the Robotics System have the

responsibility to take all necessary steps to make correct installation, examination

and operation of the relevant safety equipments.

This manual provides specific information regarding the operation of Hyundai Hi-4

Controller together with the following robot manipulator models for the possible

application usages as mentioned below;

Available manipulator Type

HR006F(floor mounting type, 6kg)

HR006V(wall mounting type, 6kg)

HR015F(floor mounting type, 15kg)

HR015V(wall mounting type, 15kg)

HR050F(floor mounting type, 50kg)

HR050V(wall mounting type, 50kg)

HR100P(for palletizing application, 100kg)

HR130IIF(floor mounting type, 130kg)

HR130IIV(wall mounting type, 130kg)

HR120S (shelf mounting type, 120kg)

HR150S (shelf mounting type, 150kg)

HX130F (floor mounting type, 130kg)

------------------------------------------------------------------------------- 1 - 3

Page 16

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

HX130V (wall mounting type, 130kg)

HX130S (shelf mounting type, 130kg)

HX165F (floor mounting type, 165kg)

HX165V (wall mounting type, 165kg)

HX165S (shelf mounting type, 165kg)

Possible Application Usages

The Robotics System is a standard six-axis but additional axis available industrial

robot for installation on the floor, on the wall or on the shelf. It is suitable for

both point-to-point and continuous-path controlled tasks.

The main areas of application are

- Spot welding

- Material Handling

- Assembly

- Application of adhesives, sealants and preservatives

- MIG/MAG welding

- Palletizing and Depalletizing

- Grinding

All owners, employers or users who intend to use the Robotics System for any other

purposes than the above-mentioned must request Hyundai's prior consideration and

confirmation whether it can be applied without failure and/or problems or not.

Please contact our Customer Satisfaction Department or your local distributor in

order to check and confirm it before any users implement any special applications

of the Robotics System.

Invalid environments

The Robotics System is strictly prohibited to be located, installed, maintained,

used or operated in an explosive environment and any areas contaminated by oil,

flammable material or chemical material.

-------------------------------------------------------------------------------1 - 4

Page 17

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

1.1.2 Relevant Safety Standards

The Robotics System is designed as per ISO 10218, January 1992 edition that specifies

the Safety Requirements for Industrial Robots and furthermore in strictly accordance

with the ANSI/RIA 15.06 -1999 Safety Requirements.

1.1.3 Safety Training

All the personnel who intend to teach, operate or examine the Robotics System must

be trained in an approved Hyundai Robotics operation and safety training course before

starting the teaching, operation or examination of the Robotics System.

The objective of the operation and safety training course is to provide information

on:

- the purpose of safety devices and their function

- safety procedures for handling the Robotics System

- performances of the robot or the Robotics System and possible hazards

- tasks associated with any specific robot applications

- safety concepts

1.1.4 Safety Marking

1.1.4.1 Safety Symbols

For the purpose of effective safety instructions, the following safety symbols are

used in this manual.

------------------------------------------------------------------------------- 1 - 5

Page 18

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

!

1.1.4.2 Safety Marking

means

WARNING:

means

MANDATORY:

means

PROHIBTED:

Indicate a potentially hazardous situation which,

if not avoided, could result in death or serious

injury to personnel and damage to equipment.

The special attention to the careful operation and

handling must be paid by owner, employer,

operator or user.

Indicate the compulsory measures that should

be performed by owner, employer, operator and

user

Indicate the prohibited actions and/or

operations that should not be performed by

Identification plates, warning labels and safety symbols are attached to the robot

manipulator and to the inside and outside of control cabinet. The designation labels

and position marks are also attached to the following cables.

- Wire harness between the robot manipulator and the control cabinet

- All the electric cables in and outside both robot manipulator and control

cabinet

All of these plates, labels, symbols and marks constitute safety-relevant parts of

the Robotics System. They must remain attached to the robot manipulator or control

cabinet at their cleary visible positions all the time.

The painted markings on the floor and the signs indicating the dangerous zones must

be clearly different in form, color and style from other markings on the machine near

to the Robotics System or inside the plant facilities where the Robotics System is

installed.

It is forbidden to remove, erase, cover, paint over or alter by way of

editing or spoiling the cleary visible identification plates, warning labels,

safety symbols, designation labels and cable marks

-------------------------------------------------------------------------------1 - 6

Page 19

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

1.1.5. Definition of Safety Functions

Emergency Stop Function- IEC 204-1,10,7

There is one emergency stop button on the controller and another on the teach pendant.

If necessary, additional emergency buttons can be connected to the robot's safety

chain circuit. The emergency stop function, which overrides all other robot controls,

removes drive power from robot axis actuators, stop all moving parts and disconnect

power in order not to use other dangerous functions controlled by the robot.

Safety Stop Function-ISO 10218(EN 775), 6.4.3

When a safety stop circuit is provided, each robot must be delivered with the

necessary connections for the safeguards and interlocks associated with this circuit.

The robot has a number of electrical inputs which can be used to connect external

safety equipment, such as safety gates and light curtains. This allows the robot's

safety functions to be activated both by peripheral equipment and by the robot itself.

Speed Limitation Function-ISO 10218(EN 775), 3.2.17

In manual mode, the speed of robot is strictly limited to 250 mm per second as a

maximum. The speed limitation applies not only to the TCP(Tool Center Point), but

to all parts of robot. The speed of equipment mounted on the robot can be monitored.

Working Envelope Restriction- ANSI/RIA R15.06-1999

The working envelop of each robot axes can be restricted using software limits. Axis

1,2,3 can also be restricted by means of mechanical stops.

Operation Mode Selection- ANSI/RIA R15.06-1999

The robot can be operated either manually or automatically. In manual mode, the robot

can be operated by using the teach pendant only, i. e. not by any external equipment.

------------------------------------------------------------------------------- 1 - 7

Page 20

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

1.1.6. Installation of Robot

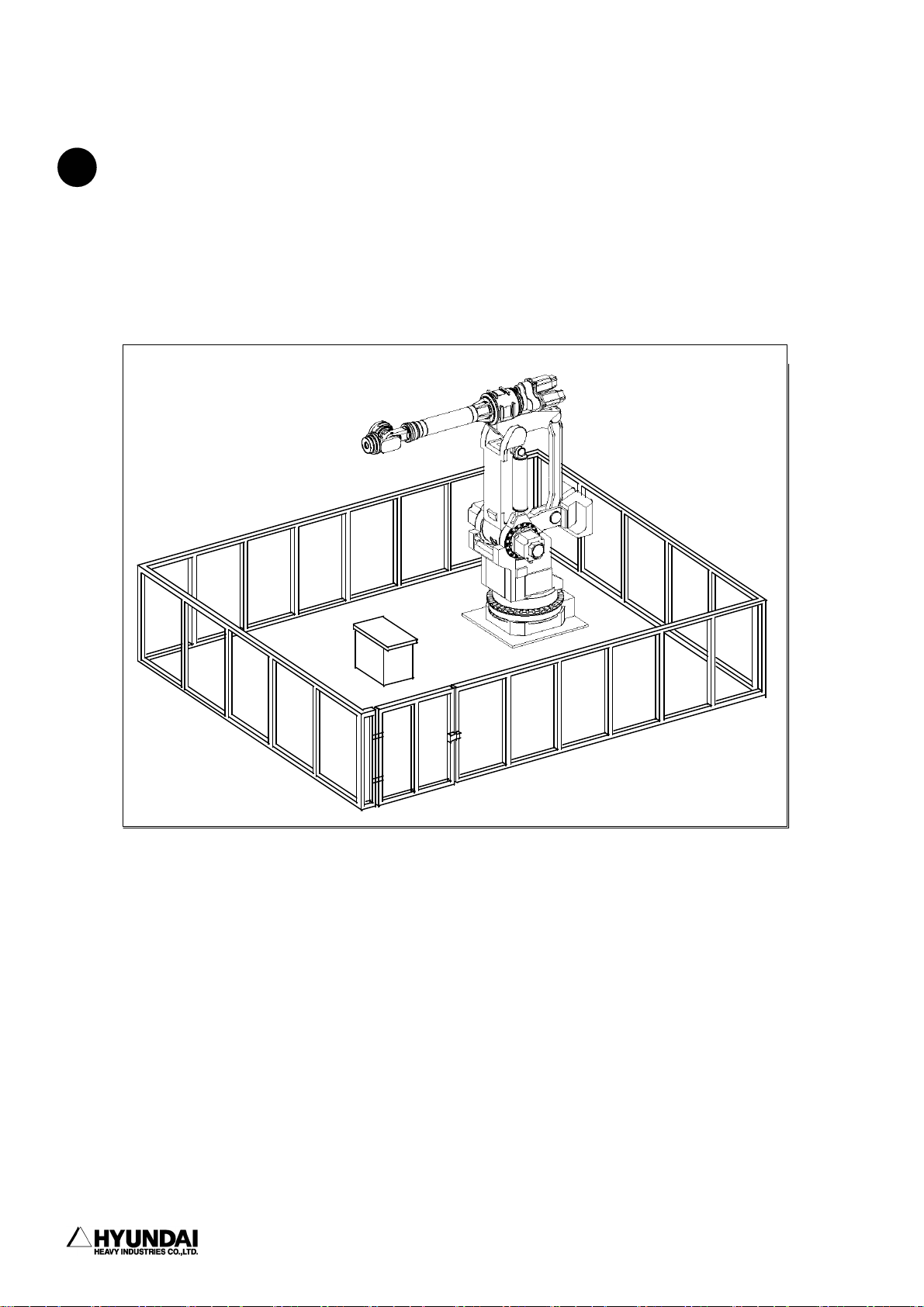

1.1.6.1 Safety Fence

!

(1) Install Safety Fence away from the working space of robot in order to prevent

from any possible collision and interface between workers and robot during the robot

operation.

Any accidents can be take place when any workers or any other persons enter inside

the safety fence without protective actions. Safety fence shall be equipped with the

emergency stop mechanism that can activate emergency stop of robot if any workers

would get into the safety fence for examination of robot and welding equipment and

replacement of tip dresser and tip etc. during robot operation.

(2) Safety Fence shall fully cover the working space of robot and be installed to

secure the enough space in order to evade any interference with robot during

teaching and repair operation of workers within the safety fence. And it shall be

-------------------------------------------------------------------------------1 - 8

Page 21

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

tightly fixed to the floor and have the relevant structure not to easily get over

the safety fence.

(3) Safety fence shall be fixed installation type and have no dangerous elements such

as sharp edges and rough profile etc.

(4) Gate shall be installed at Safety Fence. Safety plug shall be attached to gate.

Unless unplug the safety plug from gate, gate shall not be opened. In case of

unplugging the safety plug, robot shall be motor off by interlock signal. It shall

be hard-wired to cause motors off the robot whenever the gate is opened. (Please

refer to Chapter 12.)

(5) In case of robot operation at the state of unplugging safety plug, it shall be

hard-wired to become a low speed playback mode. (Please refer to Chapter 12)

(6) Emergency stop button shall be installed at workers' easily accessible distance.

(7) If there is no safety fence, a photoelectric switch or mat switch instead of safety

plug shall be installed at all the spaces within the working range of robot. Whenever

workers enter the working range of robot, robot will be automatically stopped.

(8) Working space of robot as the dangerous area shall be clearly marked by painting

on the floor.

1.1.6.2. Installation of robot and peripheral equipment

!

(1) Execute the connection work after ensuring the power-off status. There are many

risks of receiving electric shock due to the usage of high voltage power source

such as 220V, 440V, 80V etc. in case of primary power source connection to robot

controller or peripheral equipment.

(2) Attach the warning tag "No-Access during Operation" at the gate of safety fence

and further educate it as a precaution

(3) Locate controller, interlock panel and any other operation panels outside safety

fence.

------------------------------------------------------------------------------- 1 - 9

Page 22

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

(4) In case of installation of operation stand, attach emergency stop button on it.

Emergency stop shall be available at any time from any locations that can operate

the robot.

(5) Execute cabling and piping work in proper way for robot manipulator, controller,

interlock panel, timer etc. Any loose or protruded cables and/or wires can cause

workers' slippery or disconnection of cable by fork lift.

(6) Locate robot manipulator, controller and operation stand where workers can

!

clearly see the movement of robot manipulator. When operator do not acknowledge

abnormal situation of robot or other workers' working at the robot due to the

invisible situation, operator's robot operation can cause a large accident.

(7) Limit the workable space of robot by utilizing soft limit or mechanical stopper

etc. when the required work space of robot is smaller than the workable space of

robot. In case of abnormal operation, any excessive working out of the workable

space can be stopped previously. (Please refer to Operation and Manipulator

Maintenance Manual)

(8) Install safety curtain or cover for spatters made during welding work which can

cause personal injury or fire accident. In any case, safety curtain or cover shall

be installed to allow operator to clearly see the movement of robot manipulator.

(9) Automatic operation and manual operation which mean the actual operation state

of robot shall be notified to workers even in the distance by easily visible light

or device. Install buzzer or alarming light for sign of starting automatic operation

of robot.

(10) Remove any protrusions, sharp edges at equipments, devices around the robot which

can cause personal injury or any other accidents.

(11) Input and output of workpiece by inserting worker's hands inside safety fence

shall be strictly prohibited due to the risks of pressure or cutting injury

accident.

--------------------------------------------------------------------------------

1 - 10

Page 23

------------------------------------------------------------------------------------------------

1.1.6.3. Robot installation

!

1. Safety, Operation Panel, Teach Pendant (1) Safety

Install robot as per the planning and layout which has been previously reviewed and

studied for the optimized performance and functionality of the robot. In case of bad

installation situation of robot, the serious problems can take place as follows;

- Error of relative position between robot and workpiece during operation.

- Bad performance quality of robot caused by vibration.

- Shortening lifetime of robot

- Cause of serious accidents

The following lists the safety precautions to which careful consideration must be

made by operator, worker or installation persons.

General Safety Precautions

(1) Design and install the robot system in completely compliance with laws,

regulations and safety requirements being valid in the country where the robot

system is installed.

(2) All the workers for the robot system must have the good knowledge on the

information specified in the operation and maintenance manual and also have a good

command of operation and maintenance of the robot.

(3) Installation workers of robot must follow the safety requirements when they face

any safety problems in installation.

(4) System Supplier must ensure that all the circuits utilizing safety function

perfectly perform their functionalities in a safe way.

(5) Install primary power supply which can be disconnected from the place outside

the operation area of the robot.

(6) System supplier must ensure that all the circuits utilizing emergency stop

function perform their functionalities in a safe way.

------------------------------------------------------------------------------- 1 - 11

Page 24

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

(7) For immediate emergency stop, install emergency stop button within operator's

easily accessible distance.

Technical Safety Precautions

(1) Remove any interference problems with peripheral equipments considering

dimension and operating space of the robot.

(2) Evade the installation of robot at the places where have direct ray of sun, many

oil, chemical material, explosives, metal powder or humid and wet atmosphere.

(3) Install at the place where ambient temperature is 0∼ 45℃.

(4) Secure sufficient space for facilitation of disassembly and examination of the

robot.

(5) Install safety fence with a gate so that no worker can enter into the operating

range of robot without permission.

(6) Remove any obstacles out of operating space of robot.

(7) Take the special measure considering heat dynamics in case of installation of

robot at the places where have direct ray of sun or near heating equipment.

(8) Take the special measure in case of installation of robot at the place where there

are a lot of dusty metal powder, chemical dusts in the air.

(9) Install robot not to receive any short circuit from welding gun and equipment.

(Insulate robot arm between spot sun completely)

(10) Grounding is very important for preventing from abnormal operation or electric

shock caused by noise. Observe the following installation method.

- Install exclusive grounding terminal using class 3 or higher grounding

method.(In case of input voltage of 400V or higher, observe special class 3

or higher grounding method.)

-------------------------------------------------------------------------------1 - 12

Page 25

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

- Connect Grounding line into the grounding bus-bar inside the controller.

- In case of direct grounding of the robot by anchoring at floor, two point

grounding both by robot manipulator and by controller can produce closed circuit

and further cause abnormal operation of the robot on the contrary. In this

case, connect the grounding line to the base of robot manipulator and disconnect

to the controller. When robot trembles during stopping operation, check and

examine the grounding status immediately since the possible main causes are

incomplete grounding or closed circuit.

- In using built-in transformer gun, primary power cable can be easily worn out

by directly contacting with the gun. In this case, connect the grounding line

to the base of robot directly and disconnect to controller in order to protect

controller and preventing from any electric shock.

------------------------------------------------------------------------------- 1 - 13

Page 26

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

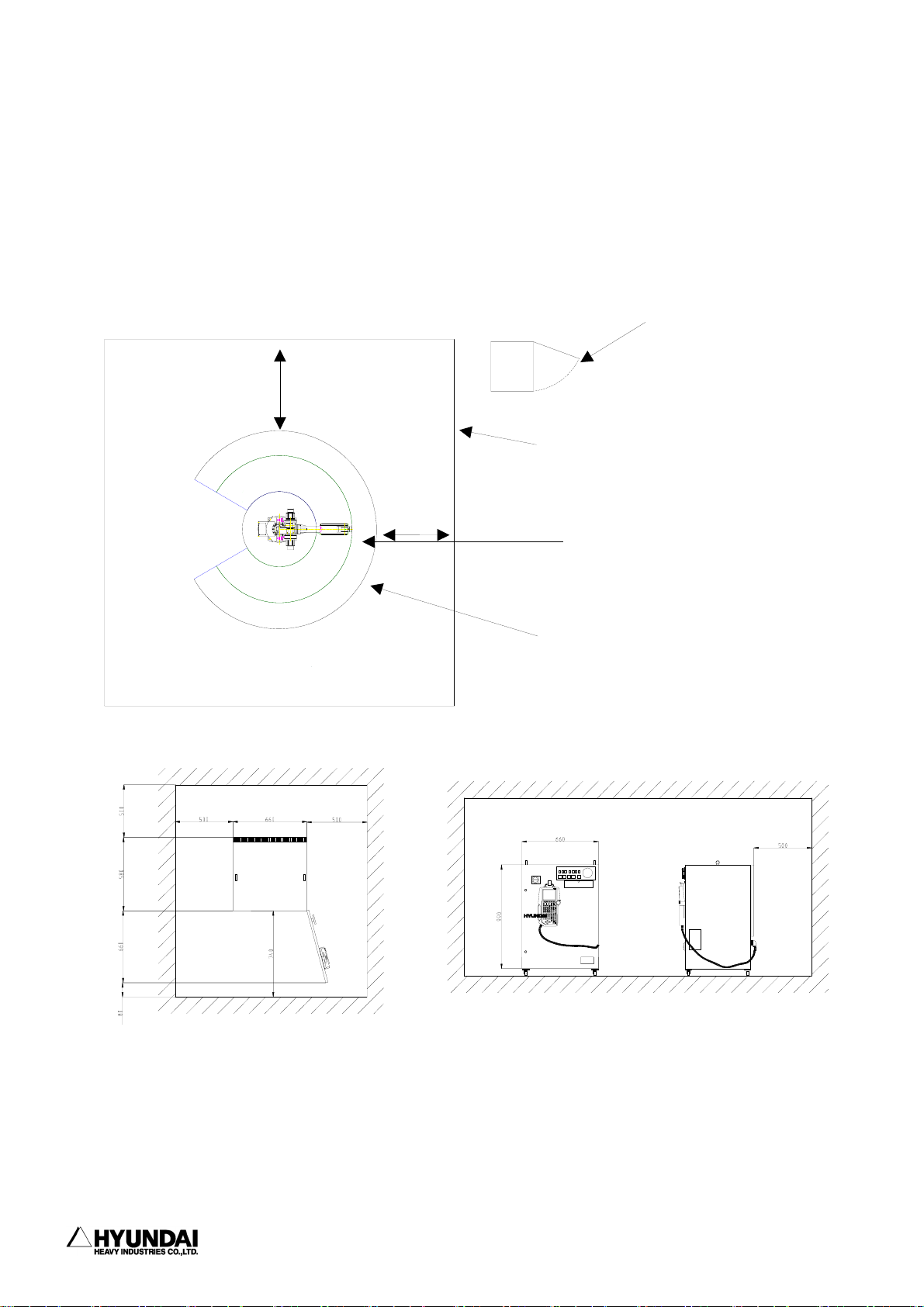

1.1.6.4 Space for robot installation

Install robot manipulator, controller, other peripheral equipment. Be sure that

there are sufficient rooms for maintenance on the manipulator, controller and other

peripheral equipment. Install robot manipulator and controller as per the guideline

as described in the figure below.

1000mm

1000mm

Hi4

controller

Door

Enclosure

Working envelope of

manipulator

Maximum working envelope of

manipulator including Tool or

Workpiece.

Install controller in order that maintenance work can be easily performed when

door open. Secure the maintenance free area whenever robot need to be maintained.

Dimension of controller as specified in the above figure can be changed according

to the kind of controller.

-------------------------------------------------------------------------------1 - 14

Page 27

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

1.1.7. Safety Working Procedures

Safety working procedures must be observed to prevent from any accidents. Safety

device or circuit shall not be modified and disregarded by workers or operators at

any time.

Be careful of any possible accidents caused by electric shock. All normal operations

in automatic mode must be executed outside safety fence. Prior to operation, be sure

there are no personnel within the manipulator's working envelope.

1.1.7.1. Safety measure for robot operation

!

(1) Have the robot system operators, any workers who is possible to operate or any

superintendents attend the training courses held by Hyundai in order that they can

have a good command of safety and robot functions. Do not allow workers who do not

attend the training courses to operate the robot.

(2) Wear safety helmet, safety glass, safety boots during operation.

(3) 2 workers as a team must work together. One worker must supervise through operation

panel while another worker make teaching operation. One worker always must be in

a position to push emergency stop button while another worker execute operation

work inside or outside the operation space of the robot with sufficient cautions.

Furthermore, all the workers must have a good knowledge on escaping route before

their operation work.

(4) Supply power-on after certainly ensuring that there is no persons within operating

space of the robot.

(5) Do teaching work outside the working envelope of the robot, in principle. However,

after motor-off, you may execute work within the working envelope of the robot by

hand-carrying key switch or safety plug, which will prevent from automatic

operation which can be made by any third parties. Furthermore, pay your special

attention to direction of movements which can be made by abnormal or error situation,

if any.

------------------------------------------------------------------------------- 1 - 15

Page 28

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

(6) Superintendent must observe the followings;

- Stay at the place where he can see robot entirely and concentrate on his job of

superintendence.

- Press emergency stop button if there is any abnormal situation.

- keep any people other than the workers who are working for the robot, away from

the working envelope of the robot.

(7) In manual mode, teaching must be made not more than the speed of 250mm/sec.

(8) Do the teaching work by laying of "Under Teaching Operation" signboard all the

time.

(9) Any workers who enter inside safety fence must unplug and bring the safety plug

into the safety fence.

(10) Do not use any equipment which can produce any noise around the place for teaching

work.

(11) Do not operate teach pendant by feeling of hand only but operate it by watching

the keypads clearly.

(12) Pay your careful attention to the movement of the robot. Do not work for the

!

robot under the situation the robot is behind yourself.

(13) Watch your step during your teaching work. In case of high ground teaching work

more than 2 meters, start your work after securing the sufficient safety space for

workers' step-on.

(14) Followings are the counter measures which must be taken in case of any abnormal

!

situations

- Press emergency stop button immediately after finding any abnormal operation.

- When you want to check the abnormal situation after emergency stop, confirm the

stop status of the robot without any fail.

- Robot can stop automatically due to the abnormal power supply. In this case, check

-------------------------------------------------------------------------------1 - 16

Page 29

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

first the stop status of the robot and further investigate the cause to execute

relevant measure.

- When the emergency stop function does not work, disconnect the power supply

immediately and further investigate the cause to execute relevant measure.

- No one who have no operation and maintenance training provided by Hyundai can be

authorized to do the investigation of the cause for abnormal situations. In the

event of emergency stop, re-start of motor must be made by the defined procedure

only after implementing the measure as a result of the detailed investigation

to the cause for abnormal operation.

(15) Prepare relevant working manual on robot operation, working method and the

required action for abnormal situations according to the installation places and

working contents. Proceed with any works as per the relevant working manual.

(16) Precautions during the stop of robot

Do not access to the robot even though the robot is just stopping. There can be

a serious accident caused by sudden movement of robot when you access to the stopped

robot without any precaution. Followings are the cases that the robot is under the

stop status.

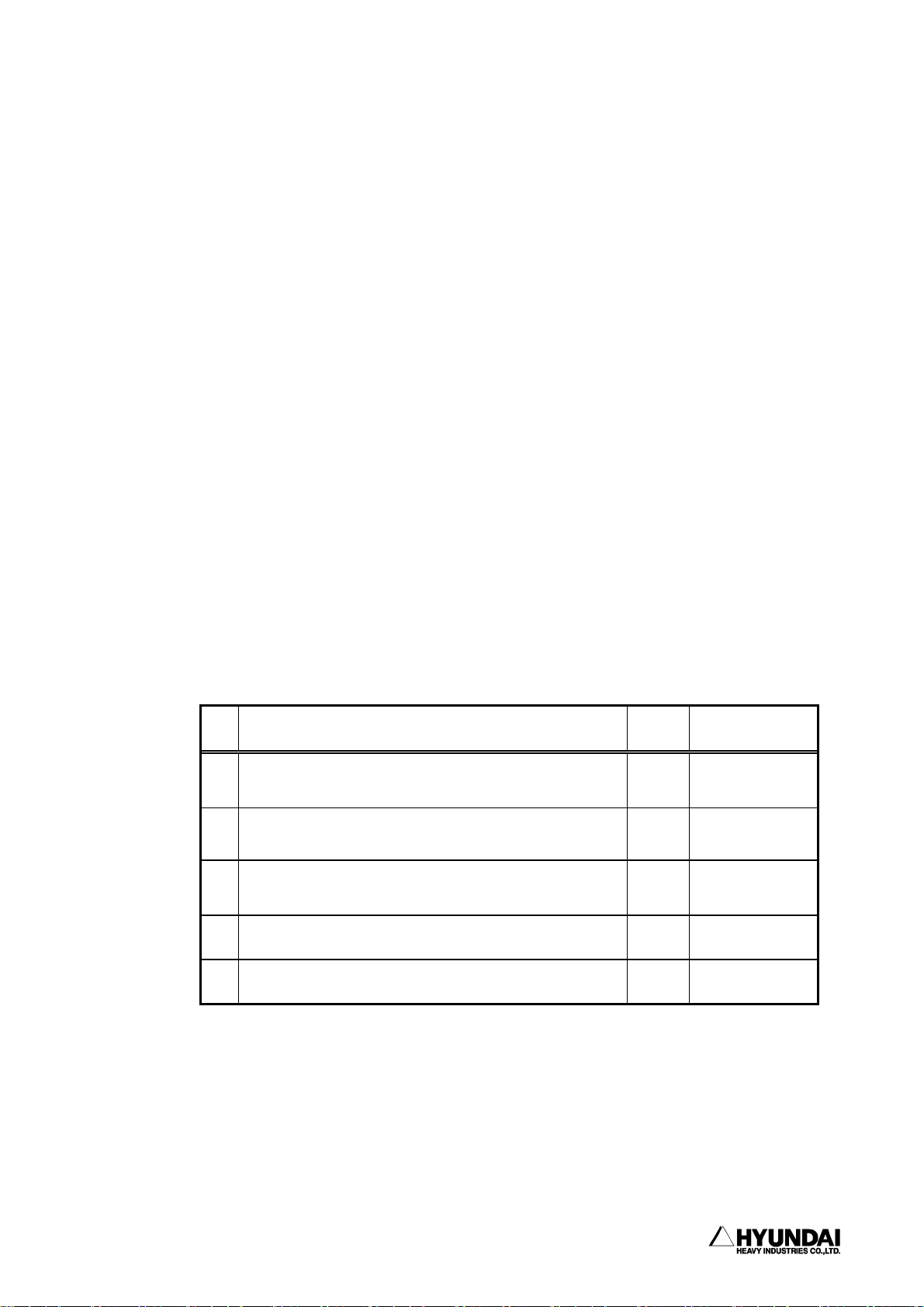

No. Robot Situation Motor Accessible or not

Temporary stopping

1

(small problem,Temporary stop switch)

Emergency stopping (Serious problem, Emergency stop

2

switch, safety gate)

Input Signal Stand-by from peripheral equipment (START

3

INTERLOCK)

4 During Playback completion ON Not accessible

5 During Stand-by ON Not accessible

ON Not accessible

OFF Accessible

ON Not accessible

Always, pay your careful attention to the unexpected movement of the robot even

though it is the above situation which you can enter to working envelope. Entering

to the working envelope of the robot without any preparation for unexpected

emergency situation must be prohibited at any time.

--------------------------------------------------------------------------------

1 - 17

Page 30

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

Note) As specified in the above table, in case of temporary stopping,

access to the working envelope of the robot is not allowed. However,

when you try to get inside the working envelope of the robot in order

to make corrections for minor problems such as nozzle contact and arc

trouble, enter the working envelope of robot only after following the

same method as you enter the working envelope for teaching work.

(17) When you finish the operation work of robot, do cleaning work for the area inside

the safety fence to remove any tools, oil or foreign material which left on the

floor. Contamination of working area by oil and any left tools can cause slippery

and personal injury. Please do your cleaning and proper arrangement regularly,

1.1.7.2 Safety Measure for Robot Try-out

!

Engineering error, Teaching error and manufacturing defects on the total system

including teaching program, jig and sequence etc. can be found during try-out of the

robot. Therefore, do your try-out operation taking your due consideration into the

safety matter. Safety related accident can took place due to the combined reasons.

(1) Check first the functions of signals and buttons such as emergency stop button

and stop button etc. before robot operation and further check error detection

function. Checking of all the signals for stopping the robot is the most important

thing. When you can foresee the possible accident previously, the most important

thing is to stop the robot.

(2) For the try-out of robot, operate in the lower speed of 20%∼30% and further check

movement more than 1 cycle repeatedly. When you find any problems, modify them

immediately. Afterwards, make speed-up by the order of first 50%, second 75% and

final 100% and further check movement more than 1 cycle for each speed set-up

respectively. When you make speed set-up of high speed at the beginning, the

unexpected accident can take place.

(3) You can not foresee any problems to be made during try-out. Do not enter inside

-------------------------------------------------------------------------------1 - 18

Page 31

------------------------------------------------------------------------------------------------

the safety fence during try-out. Unexpected accidents can take place easily due

to the unreliable situations.

1.1.7.3 Safety measure for automatic operation

!

(1) Educate all the workers not to get inside the safety fence during the operation

while the sign-board "No Access During Operation" must be placed at the gate of

safety fence. When robot is stopping, you can get inside the safety fence after

careful judgment of the situation.

(2) First check and confirm whether there are any persons inside the safety fence

!

when you start your automatic operation. There can be any serious personal injury

when you operate without checking whether there are any persons inside the safety

fence.

1. Safety, Operation Panel, Teach Pendant (1) Safety

(3) Start any automatic operation after confirming that the conditions such as program

No., step No., mode, start selection etc. is relevant for automatic operation. When

you make start operation under the selection of the program or step which is not

valid for automatic operation, there can be serious accidents which is caused by

the unexpected movements of robot.

(4) First confirm whether robot is located at the place where it can be operated in

automatic mode. Further confirm whether program No., step No. and robot location

are correct. Even though program No. and step No. are correct, the wrong location

of robot can cause any serious accident by way of abnormal movement.

(5) You are ready to press emergency stop button during automatic operation. Press

emergency stop button immediately when you face any unexpected abnormal robot

movement or situations.

(6) Check any errors or abnormal status of moving path, moving situation and moving

sound etc. While robot can be failed suddenly, it also can be failed by way of

showing certain sympton of failure. Have your good understanding and recognition

on the normal operation situations of robot.

(7) When you find any abnormal situations, press emergency stop button immediately

!

------------------------------------------------------------------------------- 1 - 19

Page 32

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

and make the necessary action to the abnormal situations. Unless you make any

necessary action, there can be a failure which possibly result in serious personal

accident as well as stop of production.

(8) When you make necessary action for any abnormal situation and check the normal

!

operation, you can check in low speed operation whether abnormal situation is fixed.

However, it must not be checked even in low speed operation under the situation

that any workers stay inside the safety fence. Since it is not reliable situation,

another abnormal situation or any unexpected accident can take place.

1.1.8. Safety Measures for Entering Inside the Safety Fence

!

The robot is extremely heavy and powerful, even at low speed. When entering inside

working envelope of the robot, the applicable safety regulations of the country

concerned must be observed.

Operators must be aware of the fact that the robot can make unexpected movements.

A pause(stop) of robot in pattern of movements may be followed by a movement at high

speed. Operators must be aware of the fact that external signals can affect robot

programs in such a way that a certain pattern of movement change without warning.

During programming and testing, the enabling device must be released as soon as there

is no need for the robot to move.

The programmer must always take the teach pendant with him/her when entering through

the safety gate to the robot's working envelope so that no-one else can take over

control of the robot without his/her knowledge. Hang up the sign-board "Under robot

operation work" in front of the controller.

When you enter inside the working envelope of the robot, keep in mind the following

considerations.

(1) Any workers other than programmer must not be allowed within the working

envelope of the robot.

(2) The operation selector on the teaching pendant must be in the teach lock mode

-------------------------------------------------------------------------------1 - 20

Page 33

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

position.

(3) The operating mode selector on the controller must be in the manual mode position

to block operation from remote control panel.

(4) Always wear approved work clothes(no loose fitting clothes).

(5) Do not wear gloves when operating the Controller.

(6) Do not allow underwear, shirts, or neckties to hang out from the work clothes.

(7) Do not wear large jewelry, such as earring , rings, or pendants.

(8) Always wear protective safety equipment such as helmets, safety shoes(with

slip-proof shoes), face shields, safety glasses, and safety gloves as

necessary.

(9) Before operating the manipulator, confirm that the emergency stop circuit is

functioning by pressing the emergency stop button on the operation panel and

teach pendant, and confirm that MOTOR lamp is turned off.

(10) Always view the manipulator from the front when you execute any work.

(11) Follow the predetermined operating procedure.

(12) Always have an escape method and place in mind in case the manipulator comes

toward you unexpectedly.

1.1.9. Safety Measures for Maintenance and Repair

1.1.9.1. Safety measures for Maintenance and Repair of Controller

!

(1) Have all the workers who wish to maintenance and repair work of the robot attend

the special maintenance training course held by Hyundai.

------------------------------------------------------------------------------- 1 - 21

Page 34

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

(2) Proceed with all the work according to the maintenance and repair procedures.

(3) Check safety conditions around the workers and secure the escaping route and

place in case of any dangerous situation before starting maintenance and repair

work.

(4) Turn OFF the power supply when you start regular maintenance or repair, part

replacement work. To prevent anyone inadvertently turning ON the power supply

during maintenance, put up a warning sign such as "DO NOT TURN ON THE POWER"

at the primary power supply.

(5) Always use the designated part for the replacement of failed part.

(6) Turn OFF when you open the door of Controller.

(7) After turning OFF, wait at least 3 minutes to start any work.

(8) Do not touch the SERVOPACK heat sink and the regeneration resistor since they

become very hot.

(9) After maintenance is completed, carefully check that no tools are left inside

the controller and that the doors are firmly closed.

1.1.9.2 Safety Measures for Maintenance and Repair of robot systems and manipulators

!

(1) Refer to the safety measures for maintenance and repair of controller.

(2) Proceed with any maintenance or repair work of robot system and manipulator

strictly in accordance with the established procedures.

(3) The main power switch on the robot controller must be "OFF". To prevent from

power ON caused by any unauthorized persons, put up the warning sign such as

"DO NOT TURN ON THE POWER" at the primary power supply.

(4) Do your maintenance or repair work after fixing the robot arm in order that you

-------------------------------------------------------------------------------1 - 22

Page 35

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

can be safe from any possible accidents caused by falling down or unexpected

moving of robot arm.

1.1.9.3 Necessary Actions after Completion of Maintenance and Repair

!

(1) Check there are no abnormally connected cables or assembled parts of Controller.

(2) After maintenance is completed, carefully check that no tools are left inside

the Controller and that the door is firmly closed.

(3) Do not turn on the robot if you discover any problems or potential hazards.

(4) Prior to turning ON the power, be sure that there is no one within the working

envelope of manipulator, and be sure that you are in a safe place yourself.

(5) Turn ON the main circuit breaker on the control panel.

(6) Check current position and status of the robot

(7) Operate the manipulator at low speed.

------------------------------------------------------------------------------- 1 - 23

Page 36

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

1.1.10. Safety Functions

1.1.10.1 Safety Control Chain of Operation

The robot's safety system is based on a two-channel safety circuit that is

continuously monitored. If an error is detected, the power supply to the motors is

switched off and the brakes engage. To return the robot to MOTORS ON mode, the two

identical chains of switches must be closed. As long as these two chains differ, the

robot will remain in the MOTORS OFF mode. Furthermore, when safety cuicuit is

disconnected, interrupting call will be sent automatically to the Controller to find

out the reason for the interruption.

Arm

Limit Switch

Emergency A

Emergency B

interference

Contactor

Drive

Unit

&

Safe guard A

Safe guard B

AUTO

MANUAL

MOTORS ON

Motor

The safety control chain of operation is based on dual electrical safety chains which

interact with the robot controller and the MOTORS ON mode.

Electrical safety chain consist of several switches connected in such a way that all

of them must be closed before the robot can be set to MOTORS ON mode. MOTORS ON mode

means that drive power is supplied to the motors.

If any contact in the safety chain of operation is open, the robot always reverts

to MOTORS OFF mode. MOTORS OFF mode means that drive power is removed from the robot's

motors and the brakes are applied. MOTORS OFF mode means the status that there is

no power supply to motor of robot while brake of motor is woking. The status of the

switches is displayed on the teach pendant (Refer to the I/O monitoring screen of

Service Menu in Chapter 6).

-------------------------------------------------------------------------------1 - 24

Page 37

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

The Safety Chain of Operation

The emergency stop buttons on the operator's panel and on the teach pendant and

external emergency stop buttons are included in the safety chain of operation. You

are recommended to install safety devices such as safety plug and safety stop device

while entering inside the working envelope etc. which can be operated in the AUTO

operating mode. You can connect the general safety stop devices that is active in

all operating modes.

No workers/persons can enter inside the working envelope of robot in automatic

operation mode due to the unconditional operation of the safety devices(door, safety

mat, safety plug etc.). In manual mode, maximum speed of robot is completely

restricted to 250mm/s. The aim of this safeguarded stop function is to make the area

around the manipulator safe while still being able to access it for maintenance and

programming.

When the robot is stopped by a limit switch, it can be moved from this position by

jogging it with the move key in CONSTANT mode(refer to the Parameter Setting 1 of

Chapter 9). Status indication is available on the teach pendant display.

The safety chains must never be bypassed, modified or changed in any other way.

MANUAL

<250mm/s

AUTO

External

Em. stop

Mode select

switch

Emergency

stop

Motor

safeguard

------------------------------------------------------------------------------- 1 - 25

Page 38

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

1.1.10.2. Emergency Stop

An emergency stop should be activated when people or equipment is located at dagerous

area. Built-in emergency stop buttons are located both on the operator's panel of

the robot controller and on the teach pendant.

External emergency stop devices(buttons, etc.) can be connected to the safety chain

with the applicable standards for emergency stop circuits.

All controls, such as emergency stops, the control panel and control cabinet, must

be located outside working envelope and easily accessible at any time.

Emergency Stop

Button

Status of Emergency stop

When you press the emergency stop button,

- Robot stops immediately in any cases

- Power of the robot servo system turn off

- Motor brake of the robot is activated.

- Message of emergency stop is displayed on screen

-------------------------------------------------------------------------------1 - 26

Page 39

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

1.1.10.3. Operating Speed

To program the robot, the operating mode switch must be turned to MANUAL position.

Then the maximum velocity of robot is limited to 250mm/s.

1.1.10.4. Connection of Safety Device

External safety devices such as light, curtains, light beams or sensitive mats which

can be adapted by the system builder execute interlocking the Controller by way of

connecting with safety chain of operation within the Controller. The above devices

are used for safety device during execution of normal program in automatic mode.

1.1.10.5 Limitation of Working Envelope

When robot is not necessary to reach certain area for specific applications, working

envelope of the robot can be limited to secure the sufficient safety working area.

This will reduce the damage or loss in case of robot's collision with external safety

arrangement such as safety fence, etc.

Movement about axes 1, 2 and 3 can be limited with adjustable mechanical stops or

by means of electrical limit switches. If working space is limited by means of stops

or switches, the corresponding software limitation parameters must also be changed.

If necessary, movement of the three wrist axis can also be limited by the central

processing unit. Limitation of working envelope for all the axes must be carried out

by the user. Hyundai Robot is delivered to customer as the status of full working

envelope setting.

Manual mode : Maximum speed is 250mm/s

The manual mode must be selected whenever anyone

enters the robot's safeguarded space.

Auto mode : The robot can be operated via a remove control device.

All safety equipments such as safety gates, safety mats,

etc., are active. No one can enter the robot's safeguarded

space.

------------------------------------------------------------------------------- 1 - 27

Page 40

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

1.1.10.6. Monitoring Function

1) Motor Monitoring Function

The motors are protected against overload by means of temperature sensors in the

motor windings.

2) Voltage Monitoring Function

For the protection of power devices such as transistor etc. the servo amp module

automatically triggers off the power switch when the voltage is too low or high.

1.1.11 Safety Related to End Effectors

1.1.11.1 Gripper

(1) When a gripper is used to grip a workpiece, the relevant measure for preventing

from the unexpected dropping of the loaded workpiece due to loose gripper design

must be taken by users.

(2) When any end effectors or devices are installed on robot arm, the followings must

be observed by users.

- Use the required size and quantity of bolt.

- Securely fasten as per the required torque by using torque wrench.

- Do not use the bolt which have rust or dirt.

(3) End effector must be designed and manufactured not to exceed the maximum allowable

load at the wrist of robot. Even though power or air supply stop, the gripped

workpiece must not be dropped from the gripper. In order to remove any risks and

problems which cause personal injury and/or physical damage, the sharp edge and

projection part of end effector must be made dull and smoothly.

-------------------------------------------------------------------------------1 - 28

Page 41

------------------------------------------------------------------------------------------------

1. Safety, Operation Panel, Teach Pendant (1) Safety

1.1.11.2. Tools and Workpiece

(1) It must be possible to replace tools, such as milling cutters, etc., in a safe

manner. Make sure that safety devices are working correctly until the cutters stop

rotating.

(2) Grippers must be designed to keep on gripping workpiece securely even though a

power failure or a control failure take place. It must be possible to release

workpiece from the gripper in manual mode.

1.1.11.3 Pneumatic and Hydraulic Systems

(1) Design and install pneumatic and hydraulic system according to the safety

regulations.

(2) Since, after stop of robot, residual energy of pneumatic and hydraulic systems

can be still remaining, particular care and attention must be paid by user. Pressure

must be removed whenever you start repair work of pneumatic and hydraulic systems.

1.1.12. Liabilities

The robot system has been built in accordance with the latest technical standards

and safety rules. Nevertheless, the serious accidents such as death or personal injury

of operators/workers can take place due to the collision between the robot system

and peripheral equipment.

The robot system must be used by operator who has perfect technical knowledge and

good understanding on its designated use and also pay his careful attention to the

possible dangers and risks involved in its operation. Use of the robot system is

subject to compliance with these operating instructions and the Operation and

Maintenance Manual supplied together with the robot system. The safety related

functions of the robot system must not be used for any purposes other than safety.

------------------------------------------------------------------------------- 1 - 29

Page 42

1. Safety, Operation Panel, Teach Pendant (1) Safety

------------------------------------------------------------------------------------------------

When you use the robot system for any other or additional purpose than its designated

usage, at first, you must review whether it is valid in accordance with design criteria.

The manufacturer can not be held liable for any damage or loss which resulted from

such misuse or improper use.

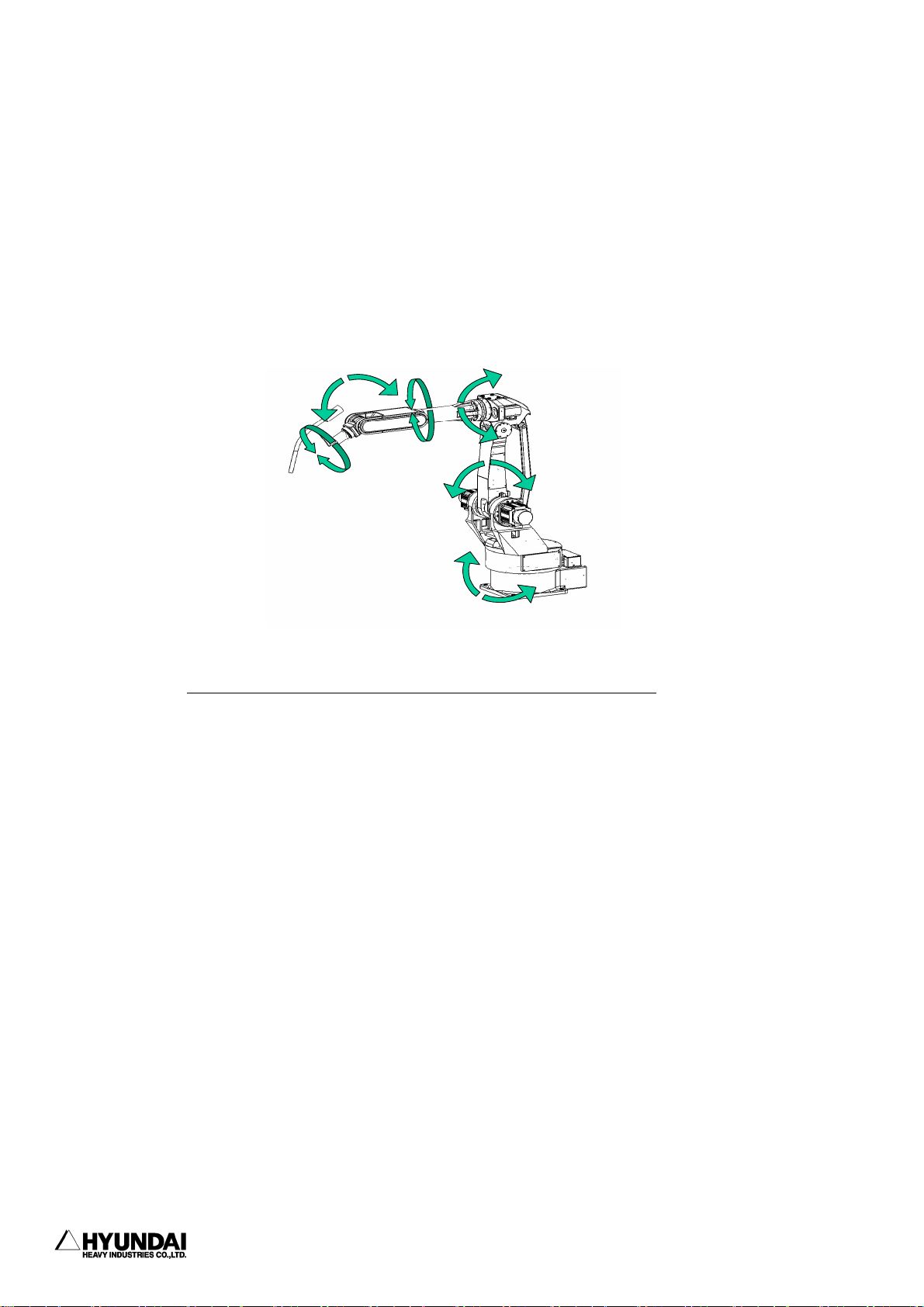

The user, operator, workers shall have the full responsibility for the risks caused