Page 1

Service Guide

Crawler Excavator

Page 2

INDEX

Ⅰ. Specification Comparisions --------------------------------------------------------------------------------------------- 3

Ⅱ.Hydraulic System -------------------------------------------------------------------------------------------------------------- 7

1.Outline of Hydraulic system ------------------------------------------------------------------------------------------------- 8

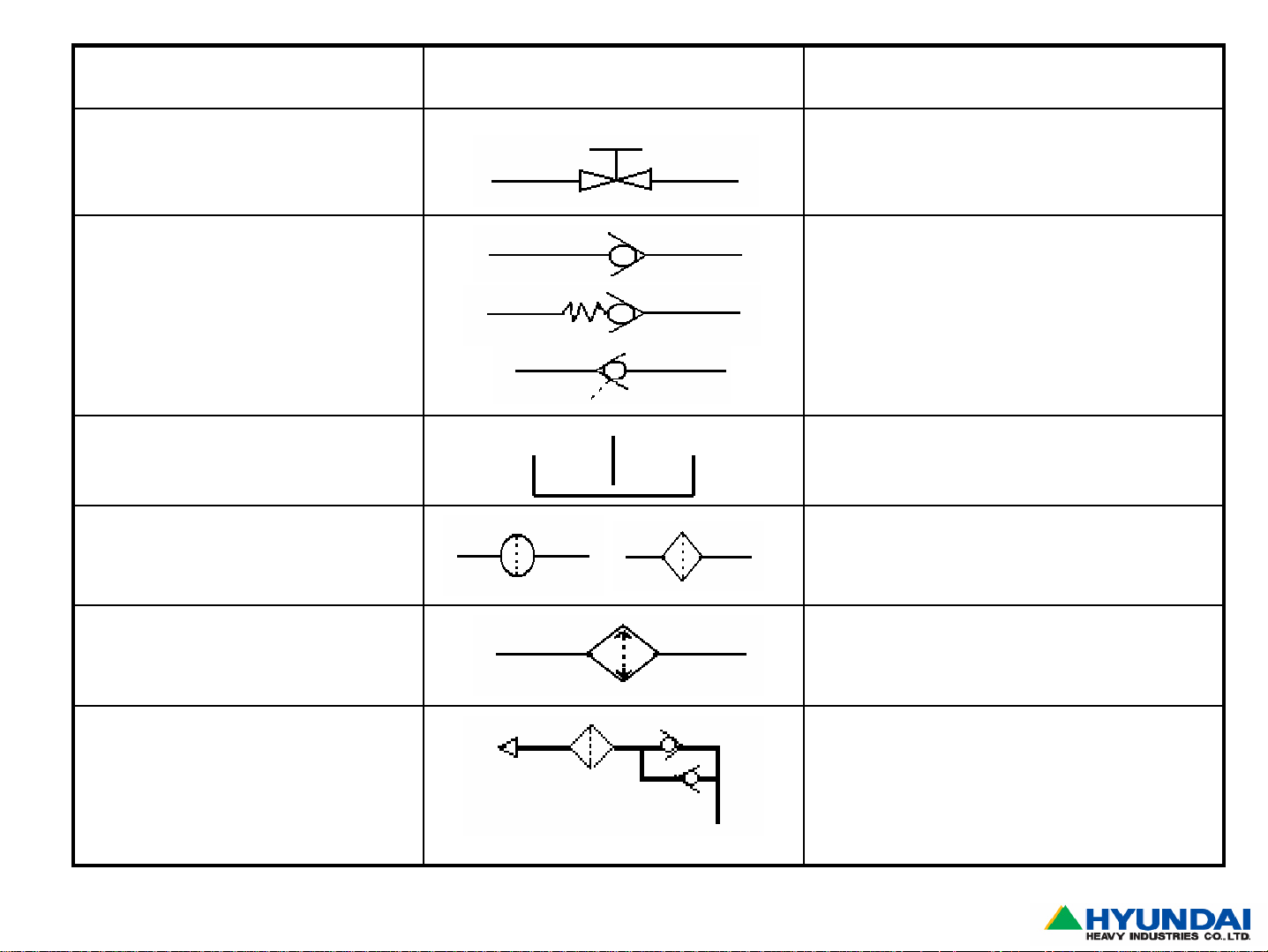

2.Hydraulic Symbol --------------------------------------------------------------------------------------------------------------- 9

3.Hydraulic Circuit ---------------------------------------------------------------------------------------------------------------- 15

3-1.Main Circuit

3-2.Pilot Circuit (Crawler Type)

3-3.Pilot Circuit (Wheel Type)

3-4.Oil Return Circuit

4.Main Components --------------------------------------------------------------------------------------------------------------- 19

4-1.Main Control Valve

4-2.Main Pump

4-3.Pilot Circuit

4-4.Swing Motor

4-5.Travel Motor

4-6.Remote Control Valve

4-7.Remote Control Pedal

4-8.Turning Joint

4-9.Safety Valve

4-10.Others

Page1

5.Breaker /Double Function Piping ----------------------------------------------------------------------------------------- 152

5-1.Breaker /Clamshell Piping

5-2.Single Acting Circuit

5-3.Double Acting

5-4.Comparison Table

5-5.Oil Flow / rpm

Ⅲ.Electric & New CAPO System ---------------------------------------------------------------------------------------- 159

1.CAPO System ------------------------------------------------------------------------------------------------------------------- 160

1-1. Power Mode Selection System

1-2. Switches on Joy Stick Lever

Construction Equipment

Page 3

1-3. Monitor Panel (Cluster)

1-4. Communication

1-5. Automatic Deceleration System

1-6. Power Boost System

1-7. Travel Speed Control System

1-8. Automatic Warming Up & Engine Overheat prevention

1-9. Anti - R estart Function

1-10. Location of Solenoid Valves

1-11. Work/Power Mode Selection

1-12. Monitoring Display on Cluster

1-13. Malfunction of Cluster or Mode Sele ction System

1-14. Accel. Actulator

1-15. Engine Speed Sensor (not for excavators with QS-engines)

1-16. Engine rpm control System

1-17. Hydraulic Oil Flow Control system

1-18. Input & Output Signal

1-19. Intake Air Warming up System

1-20. Troubleshooting Guide

2.Electric System --------------------------------------------------------------------------------------------------------------------- 216

2-1. Component Location (Cabin)

2-2. Fuses & Relays

2-3. Continual Circuit

2-4. IG Circuit

2-5. Start Circuit

2-6. Charging Circuit

2-7. Lights Circuit

2-8. Monitoring Circuit

2-9. Wiper & Washer Circuit

Page2

Construction Equipment

Page 4

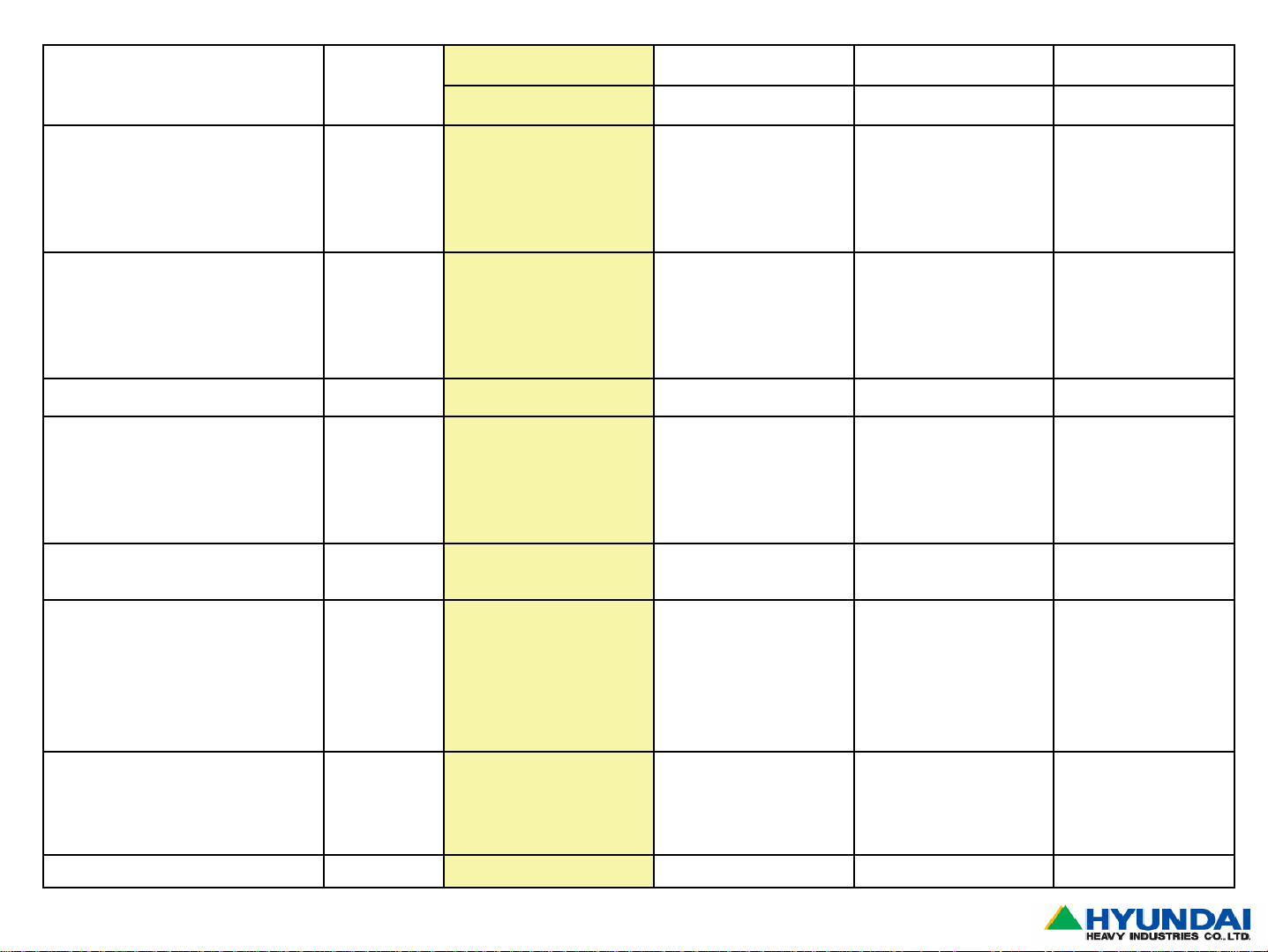

Ⅰ.Specification Comparisions

Page3

Construction Equipment

Page 5

R140LC-7

Unit

Hyundai Komastu CAT Hitachi

R140-7

PC130-6 312C ZX120

Oper. Weight

Power, SAE net

DIN net

Bucket PCSA

CECE

Engine

Model

Cyl*Bore*Stroke

Displacement

Max. torque

Hydraulic pump LPM

Oper. Pressure

Attachment

Power boost

Travel

Swing

Swing speed

Travel speed

Standard machine

Boom

Arm

Track shoe width

Track gauge

Tumbler distance

Ground pressure

Max traction force

Bucket digging force,SAE

Arm crawd force,SAE

Fuel tank liter

Kg

HP/rpm

PS

cu m

cu m

mm

cc

Kgf.m/rpm

Kg/cm2

rpm

Km/h

m

m

mm

mm

mm

kg/cm2

ton

ton

ton

13980

102/2100

103/2100

0.58

0.5

Cummins

B3.9-C

4*102*120

3920

46.2/1500

2*130

330

360

330

240

13.6

3.3/5.5

4600

2500

600

2000

3000

0.36

13.3

9.27

9.27

270

13050

86/2200

87/2200

Komatsu

S4D102E

4*102*120

3920

1*226

325

325

275

12.0

2.7/3.6/5.5

4600

2500

500

1960

2750

0.41

10.2

8.5

8.5

230 250 250

12200

91/1950

0.5

0.45

CAT

3064-E1T

4250

305

-

350

12.9

3.8/5.5

4650

2500

500

1990

2780

0.4

11.0

12200

85/2100

0.5

0.45

Isuzu

CC-4BG1TC

4329

350

-

13.7

3.4/5.5

2000

500

1990

0.38

Page4

Construction Equipment

Page 6

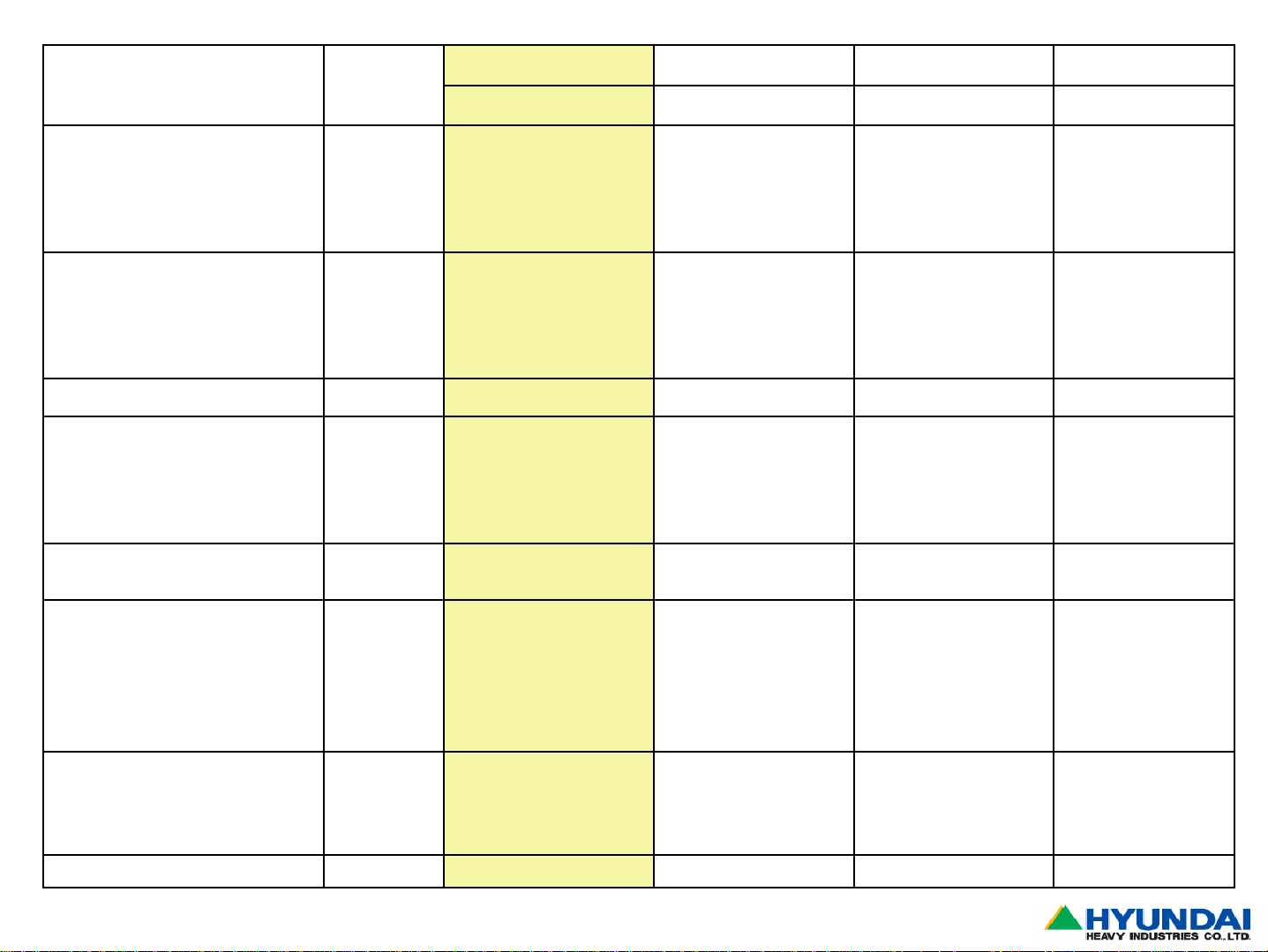

R160LC-7

Unit

Hyundai Komastu CAT Hitachi

R160LC-7

PC160-6 315C ZX160LC

Oper. Weight

Power, SAE net

DIN net

Bucket PCSA

CECE

Engine

Model

Cyl*Bore*Stroke

Displacement

Max. torque

Hydraulic pump LPM

Oper. Pressure

Attachment

Power boost

Travel

Swing

Swing speed

Travel speed

Standard machine

Boom

Arm

Track shoe width

Track gauge

Tumbler distance

Ground pressure

Max traction force

Bucket digging force,SAE

Arm crawd force,SAE

Fuel tank liter

Kg

HP/rpm

PS

cu m

cu m

mm

cc

Kgf.m/rpm

Kg/cm2

rpm

Km/h

m

m

mm

mm

mm

kg/cm2

ton

ton

ton

17400

116/2100

118/2100

0.70

0.60

Mitsubishi

S6S-DT

4*94*1200

4996

42.5/1500

2*168

330

360

330

240

12.1

3.7/5.6

5100

2600

600

1990

3190

0.42

15.7

12.08

8.35

260

16530

104.5/2100

106/2100

0.58

0.53

Komatsu

SA4D102E

4*102*120

3920

-

276

325

355

355

325

12.0

2.7/4.0/5.5

5150

2600

600

1990

2880

0.44

13.8

12.54

8.393

250 285 280

16000

-

111/2150

0.65

0.55

CAT

3046-E3DT

-

4990

-

350

-

350

10.2

3.4/5.6

5100

2600

500

1990

2880

0.51

-

-

-

15600

-

100/1950

0.6

0.55

Isuzu

A-4BG1TC

-

4329

-

350

-

13.6

3.1/5.3

5100

2580

500

1990

3100

0.46

-

9.2

8.1

Page5

Construction Equipment

Page 7

R210LC-7

Unit

Hyundai Komastu CAT Hitachi

R210LC-7

PC210-6 320B EX200-5

Oper. Weight

Power, SAE net

DIN net

Bucket PCSA

CECE

Engine

Model

Cyl*Bore*Stroke

Displacement

Max. torque

Hydraulic pump LPM

Oper. Pressure

Attachment

Power boost

Travel

Swing

Swing speed

Travel speed

Standard machine

Boom

Arm

Track shoe width

Track gauge

Tumbler distance

Ground pressure

Max traction force

Bucket digging force,SAE

Arm crawd force,SAE

Fuel tank liter

Kg

HP/rpm

PS

cu m

cu m

mm

cc

Kgf.m/rpm

Kg/cm2

rpm

Km/h

m

m

mm

mm

mm

kg/cm2

ton

ton

ton

21700

143/2100

145/2100

0.92

0.8

Cummins

B5.9-C

6*102*120

5880

62.0/1600

2*220

330

360

330

240

12.5

3.4/5.3

5880

2920

600

2390

3650

0.46

21.1

14.84

10.8

320

21570

133/2200

0.86

Komatsu

S6D102E

6*102*120

5880

2*206 2*180 2*185

325

355

355

280

12.4

3.2/4.5/5.5

5700

2930

600

2380

3640

0.45

17.7

15.0

10.1

340 340 310

20518

128/1800

130/1800

0.80

0.70

CAT

3116T

6*105*127

6600

350

350

235

10.7

3.4/5.5

5680

2900

600

2200

3265

0.48

18.1

13.5

10.1

133/1950

135/1950

A-6BG1T

6*105*125

47/1600

18800

0.80

0.70

Isuzu

6494

350

370

350

13.9

3.8/5.5

5680

2910

600

2200

3370

0.43

17.3

12.2

Page6

Construction Equipment

Page 8

Ⅱ.Hydraulic System

Page7

Construction Equipment

Page 9

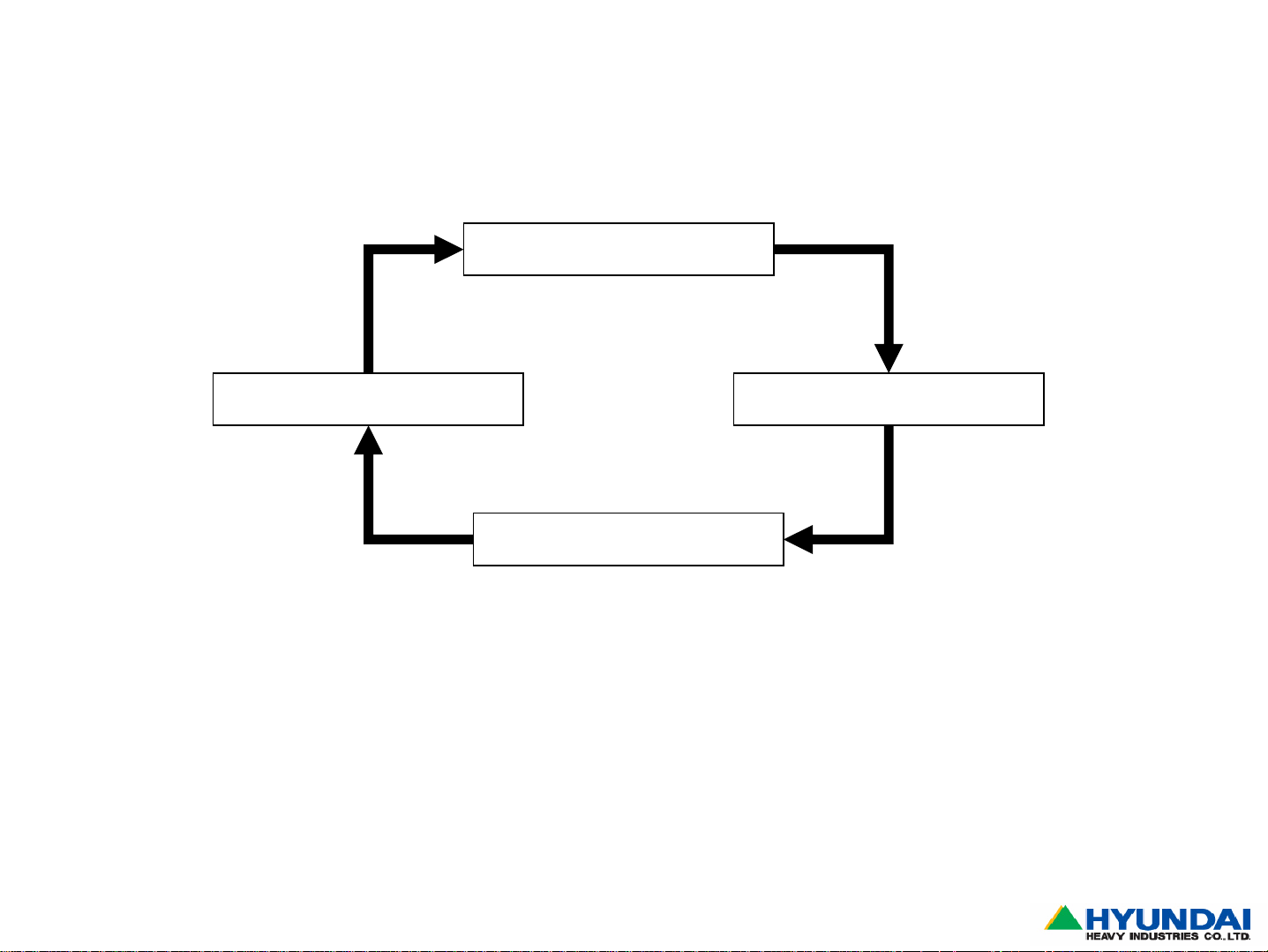

1.Outline of Hyd. System:

-Charecteristic of hydraulic oil : incompressible,automatic lubrication,less friction loss, higher

cooling efficiency,more safety for overload,silent operation,precise control

the equipment to transmit the power by oil flow

Hydraulic Tank

Actuator

Hydraulic Pump

Control Valve

-Hydraulic Tank : Oil Storage

-Hyd. Pump : Create oil flow to transmit the power

-Control Valve : Direction control of actuator

-Actuator : Working device such as cylinder,motor and etc

Cylinder - Inline movement

Motor – Rotating movement

Page8

Construction Equipment

Page 10

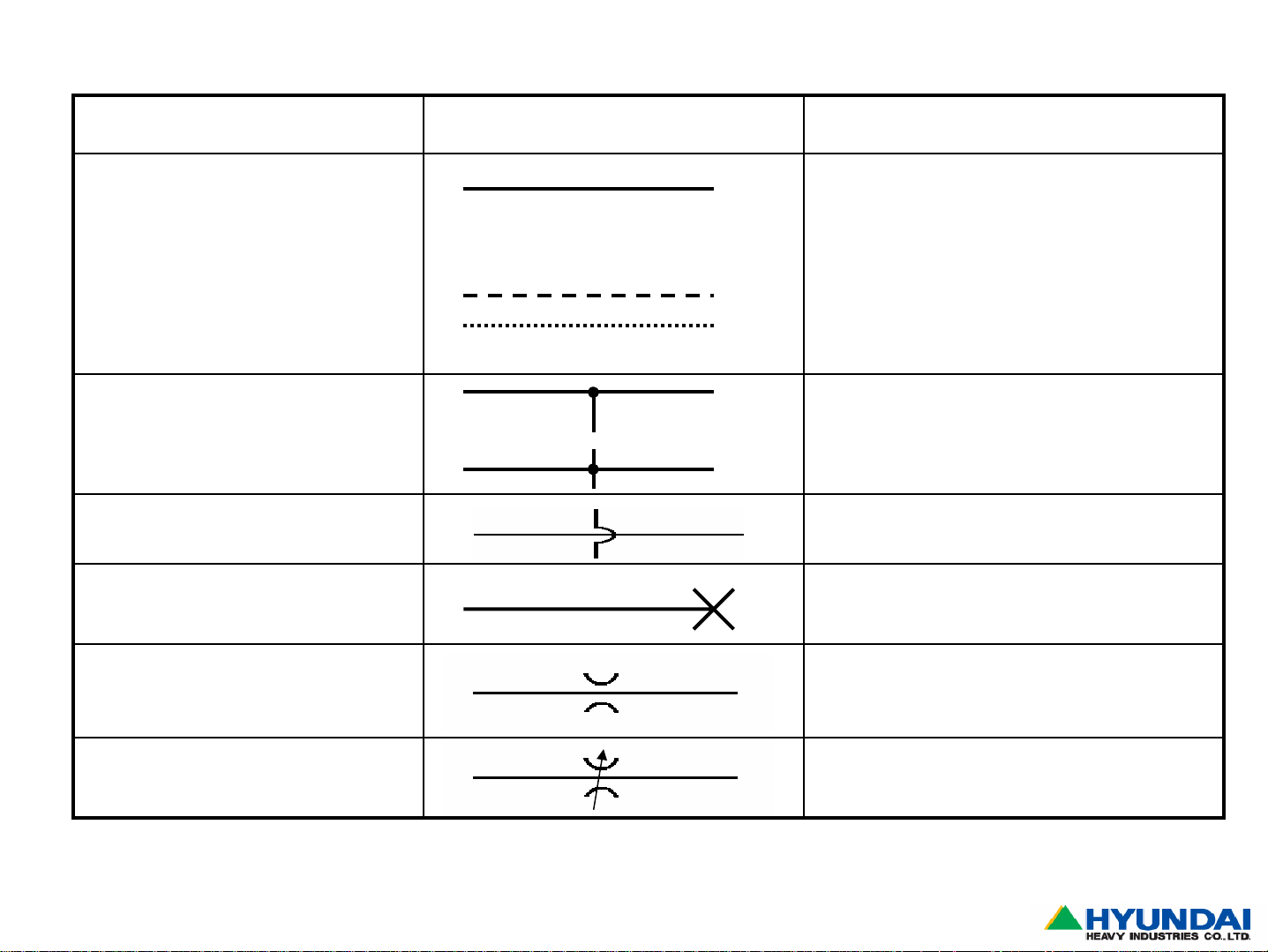

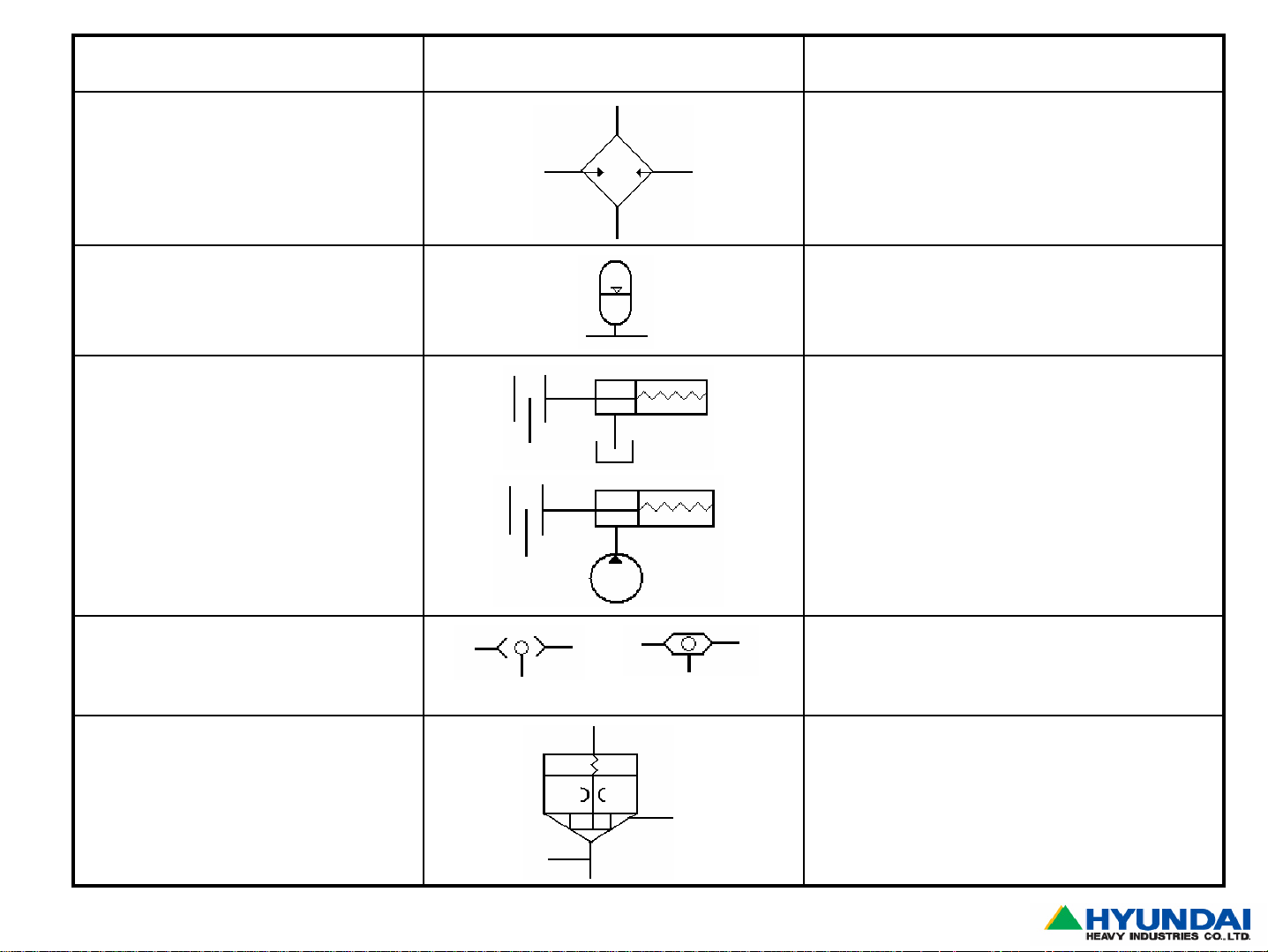

2.Hydraulic Symbol

Component Symbol Explanation

Pipe or hose

-Main line

-Pilot line

-Drain or internal leakage

Orifice Reduced diameter of oil passage to

Color code

-Supply line : red

-Return line : blue

-Suction line : green

-Pilot line : brown

-Drain or internal leakage line : green

Line connected each other : Tee joint or

drilled hole

Line cross over without connection

Line closed or plugged for future usuage

or special purpose

reduce oil flow

Page9

Adjustable orifice Adjustable(or variable)

Construction Equipment

Page 11

Component Symbol Explanation

Shut off valve

Check valve

-Without spring

Direction controlling device to prevent

reverse flow

-With spring

-Pilot check valve

One check valve & pilot line in one block

Hyd. tank Hyd. oil storage

Filter Filtering all the dirt in hydraulic system

Cooler Exhaust the heat of hyd. oil

Breather Maintain the pressure inside of hydraul i c

tank same as atmospheric pressure

Page10

Construction Equipment

Page 12

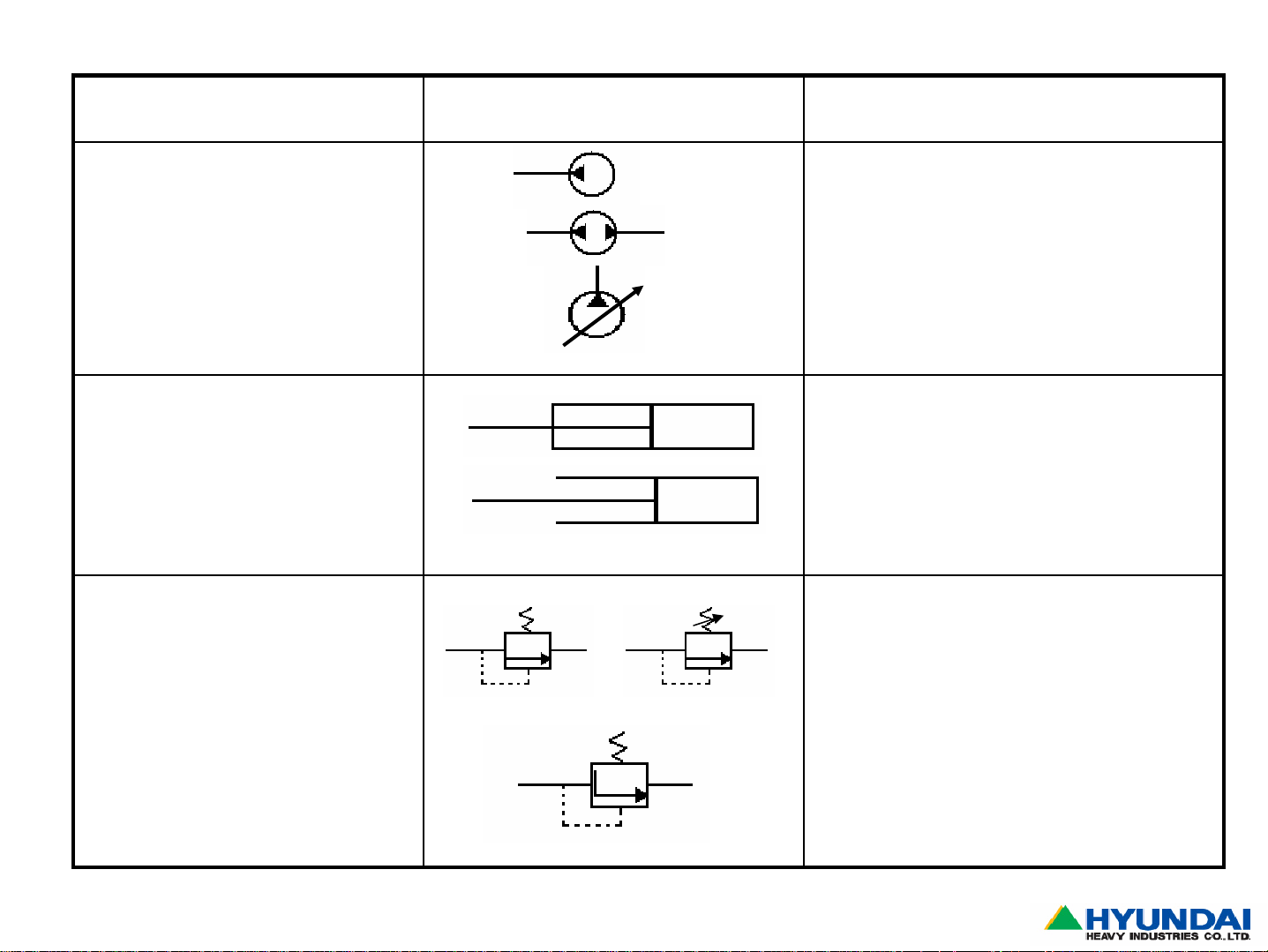

Component Symbol Explanation

Hydraulic pump

-fixed flow pump

-One direction

-Both direction, depending on rotation of

pump

Discharge amount of pump are flexible

-Variable flow pump

dependng on the pressure at actuator

such as cylinder and motor

Cylinder -Double acting : retract and extend by

direction of oil supply

-Single acting : retract by weight and

extend by oil supply

Pressure control valve

-Relief valve

Safety device to protect hyd. component

such as hose,pipe,cylinder and etc

When the hyd. system overloaded, relief

valve is open and circuit oil go to the tank

through opened passage

Page11

-Regulating valve

Maintain the required pressure all the time

to activate system for transmission clutch

and etc. by increasing decreasing the size

of overflow passage

Construction Equipment

Page 13

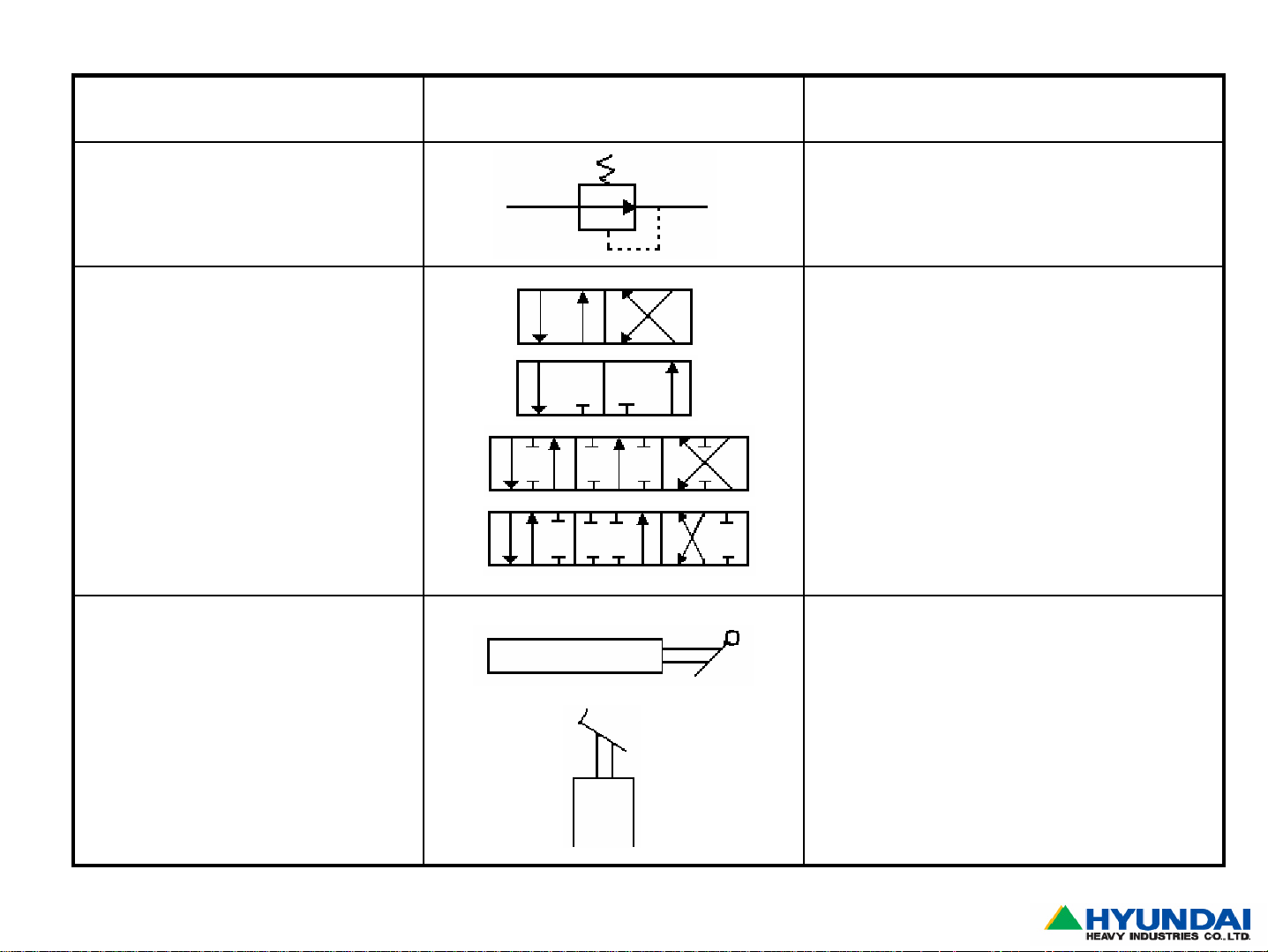

Component Symbol Explanation

-Reducing vave It is used for low pressure circuit.

When the supplied pressure reach to

required value, supplied oil is cut off

Direction valve

-2 way

-3 way

For double acting

For single acting

Double acting

Controlling method of direction control

valve

Hand control lever

Foot control pedal

Page12

Construction Equipment

Page 14

Component Symbol Explanation

Button control

Hydraulic control by pilot pressure

Electro-magnet control by electricity

Automatic return control by spring tension

Control valve is fixed with selected

direction

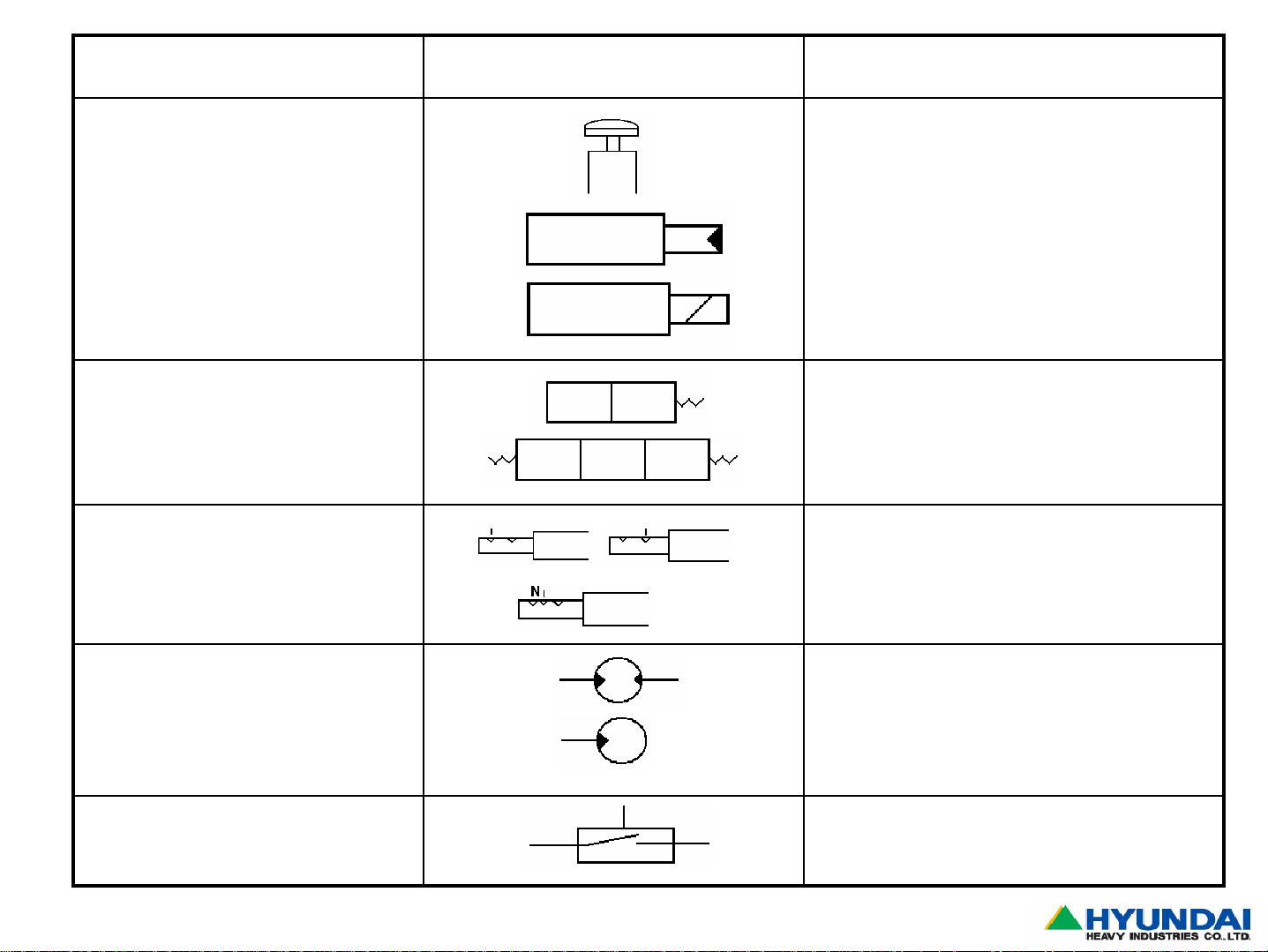

Page13

N : neutral position

Motor Rotating device

-Reversible motor

-Irreversible motor : rotate one direction

only

Pressure switch

Construction Equipment

Page 15

Component Symbol Explanation

Heater

Accumulator

Brake and clutch Applied by spring force

Released by hydraulic pressure

Page14

Shuttle valve Two check valve in one block

Oil flow achieved by pressure difference

between left & light hand side

Logic valve Is combined with piston and orifice

Area difference operates direction control

valve

Construction Equipment

Page 16

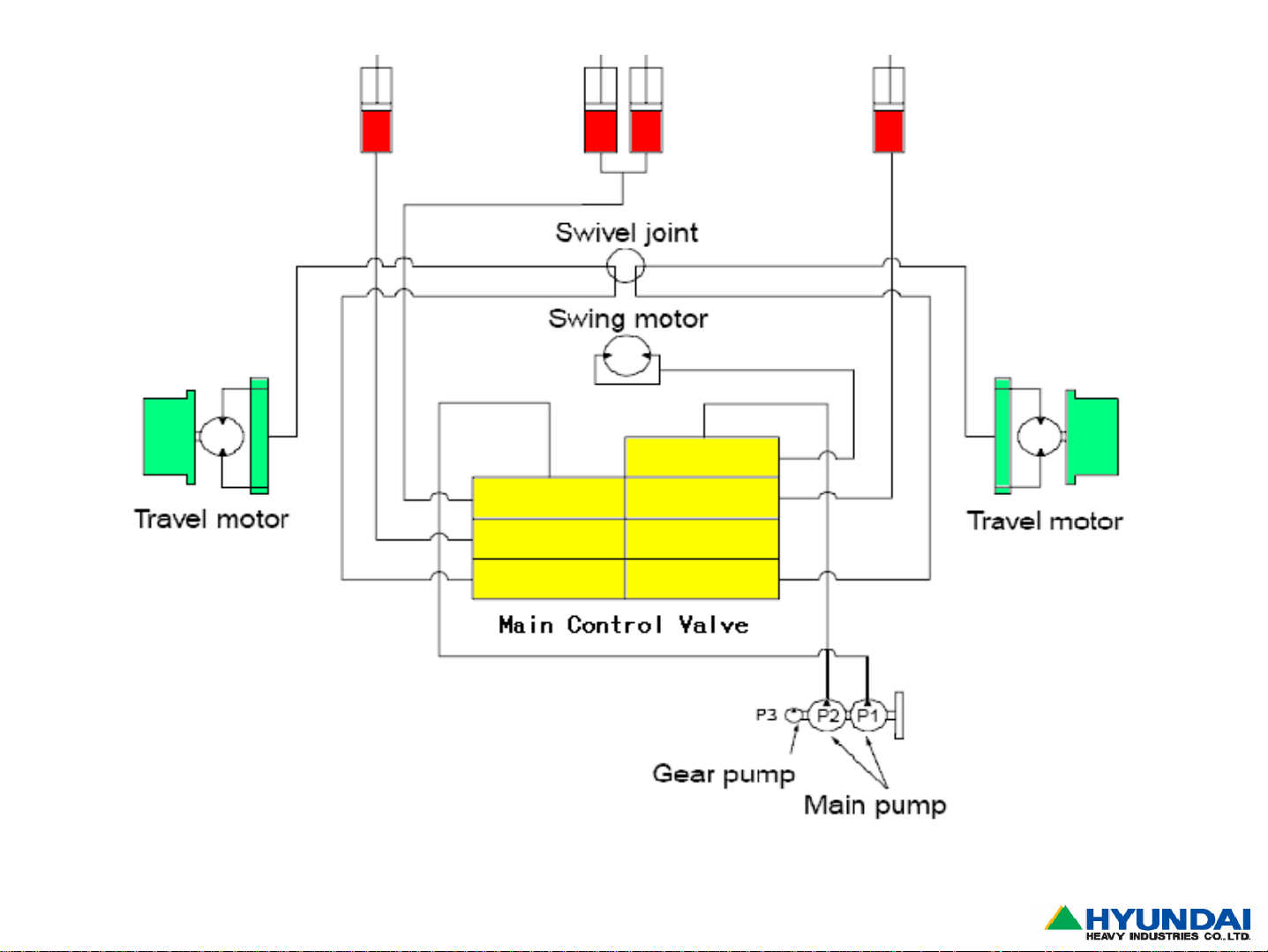

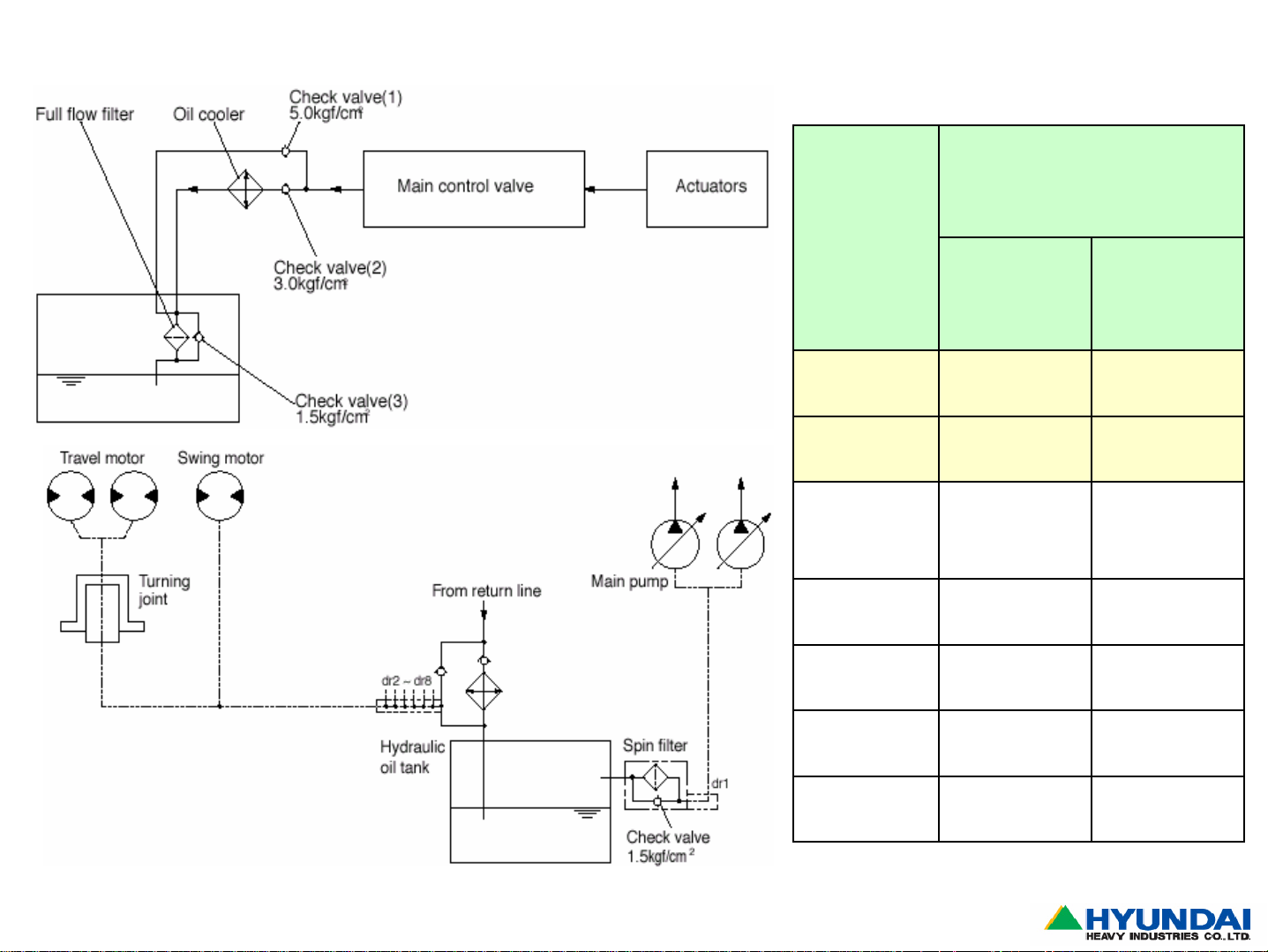

3. Hydraulic Circuit

3-1.Main Circuit

Page15

Construction Equipment

Page 17

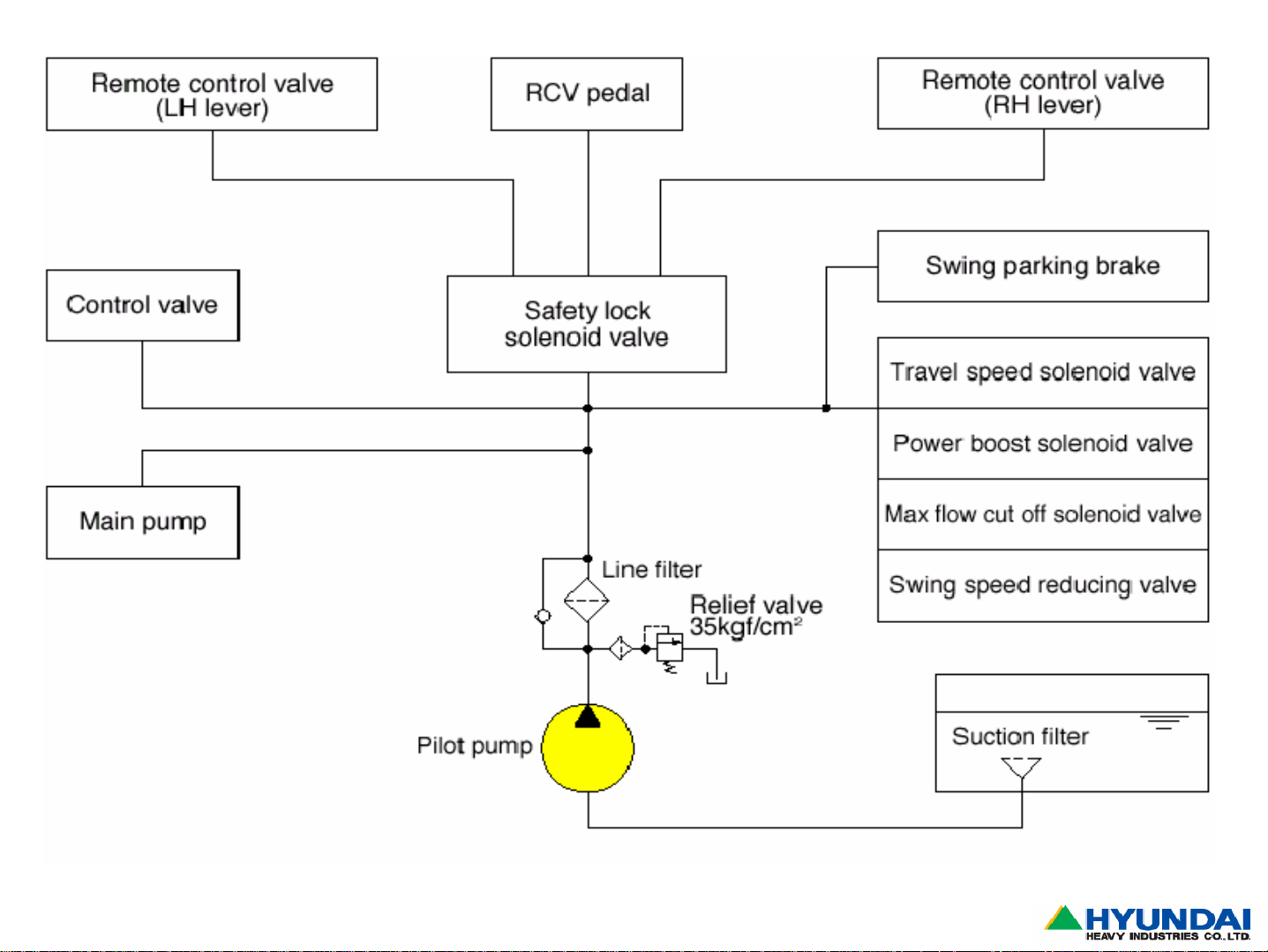

3-2.Pilot Circuit (Crawler Type)

Page16

Construction Equipment

Page 18

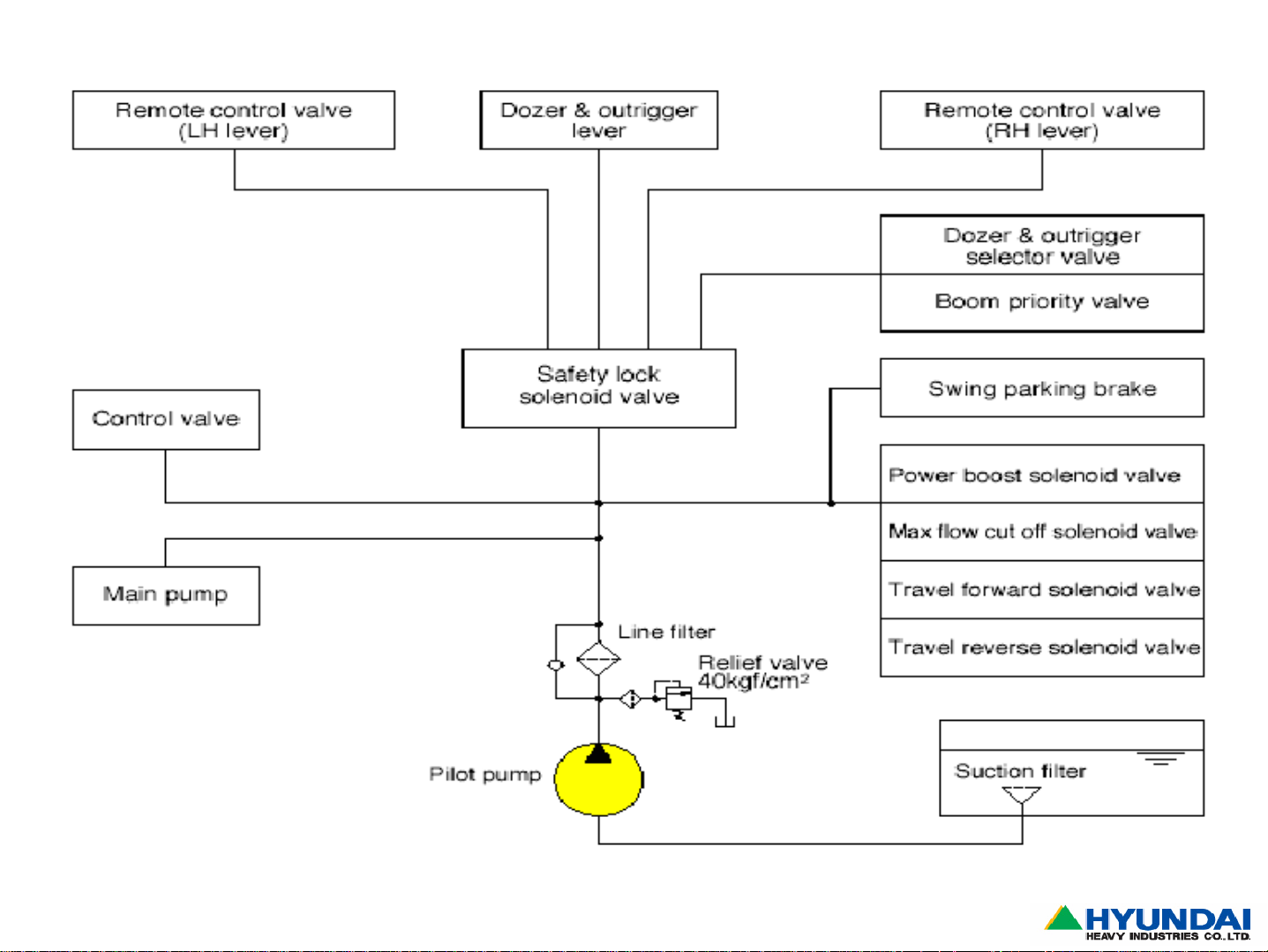

3-3.Pilot Circuit (Wheel Type)

Page17

Construction Equipment

Page 19

3-4.Oil Return Circuit

Return Pressure (Bar)

Model

Oil Cooler By-pass

R450LC-7

R360LC-7

R320LC-7

R200W-7

R290LC-7A

R210LC-7

R180LC-7

R140LC-7

3

5

3 5

3

5

1.5 3

35

1.5

1.5

3

3

Page18

Construction Equipment

Page 20

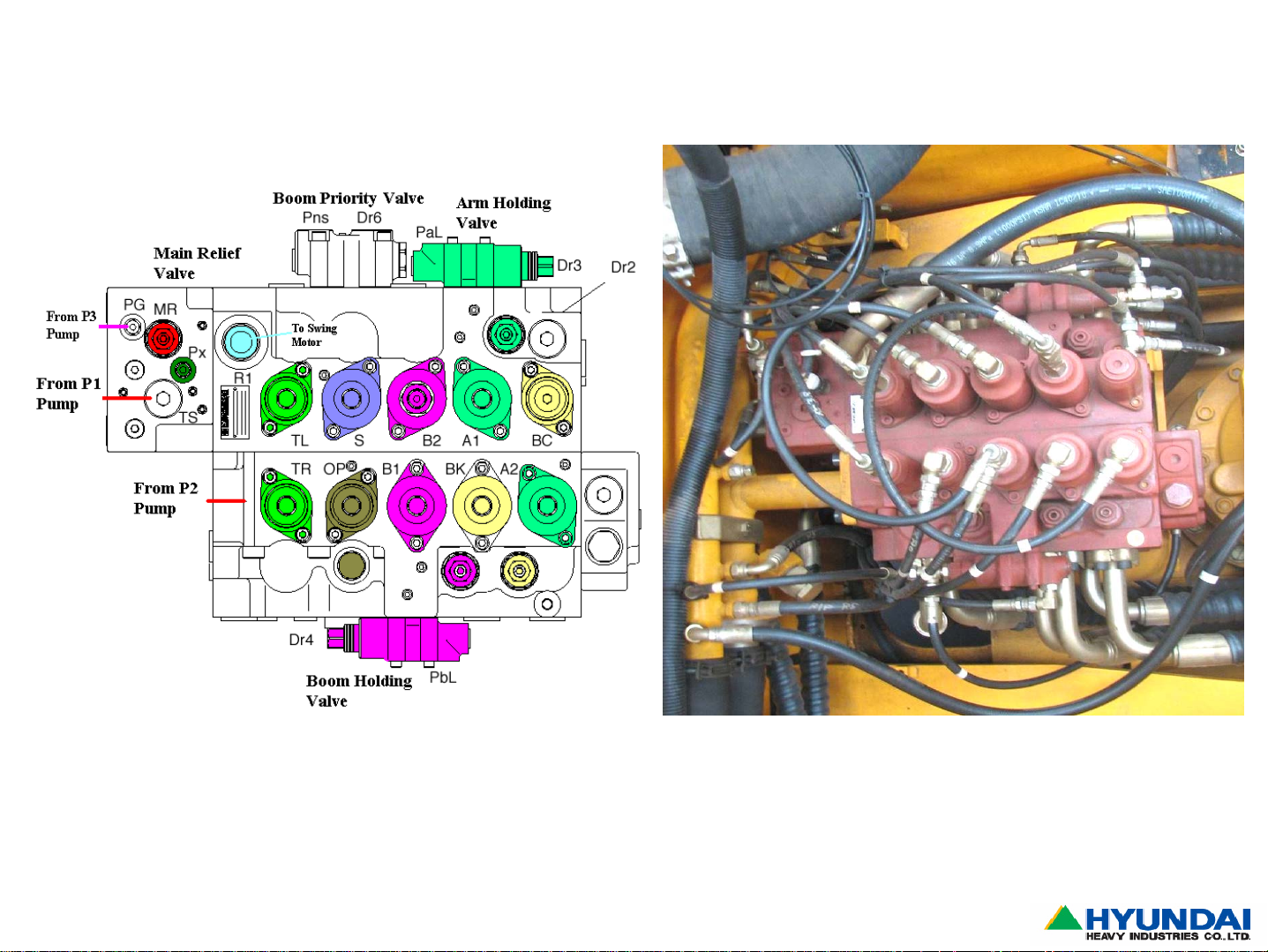

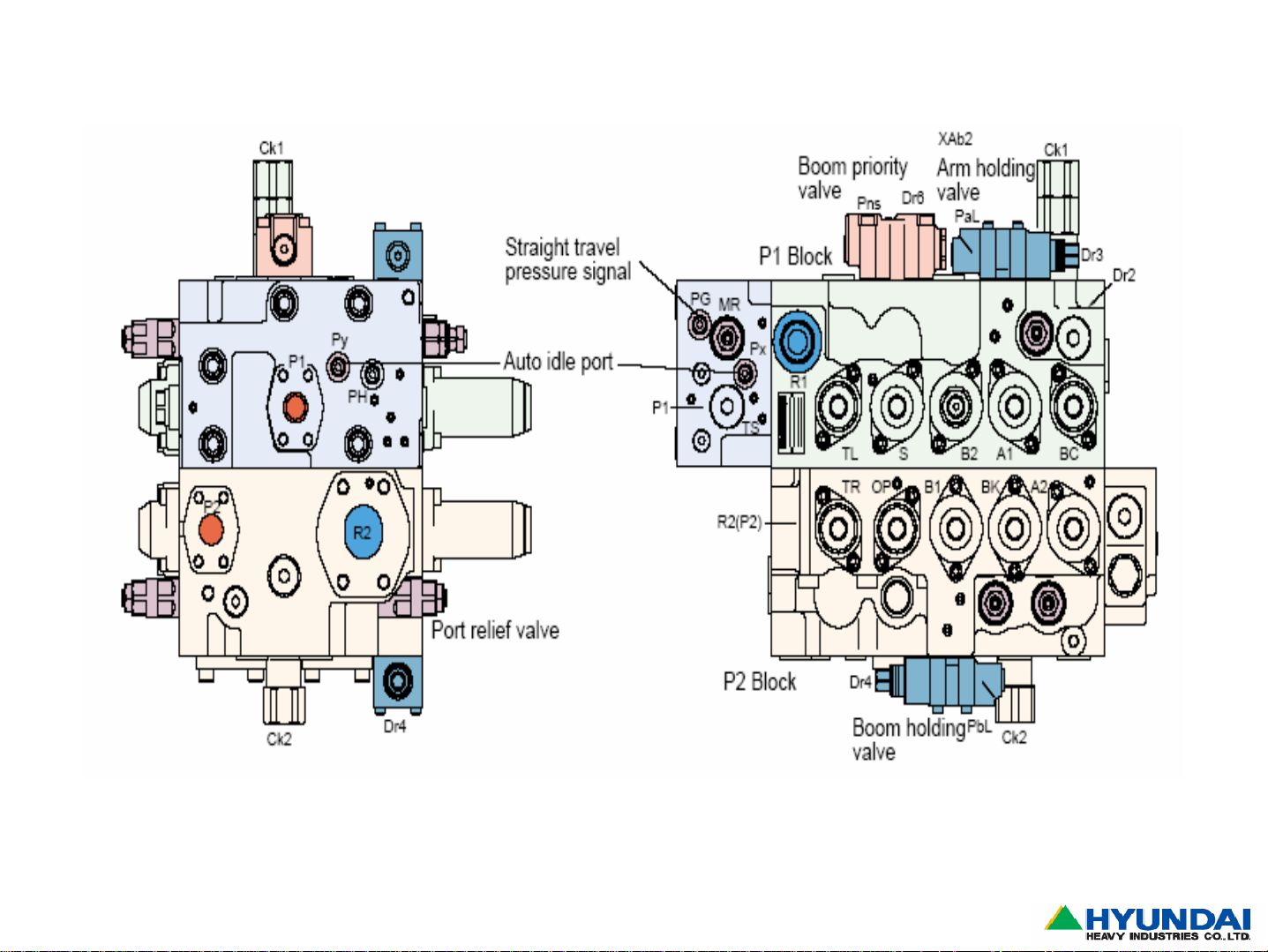

4. Main Components

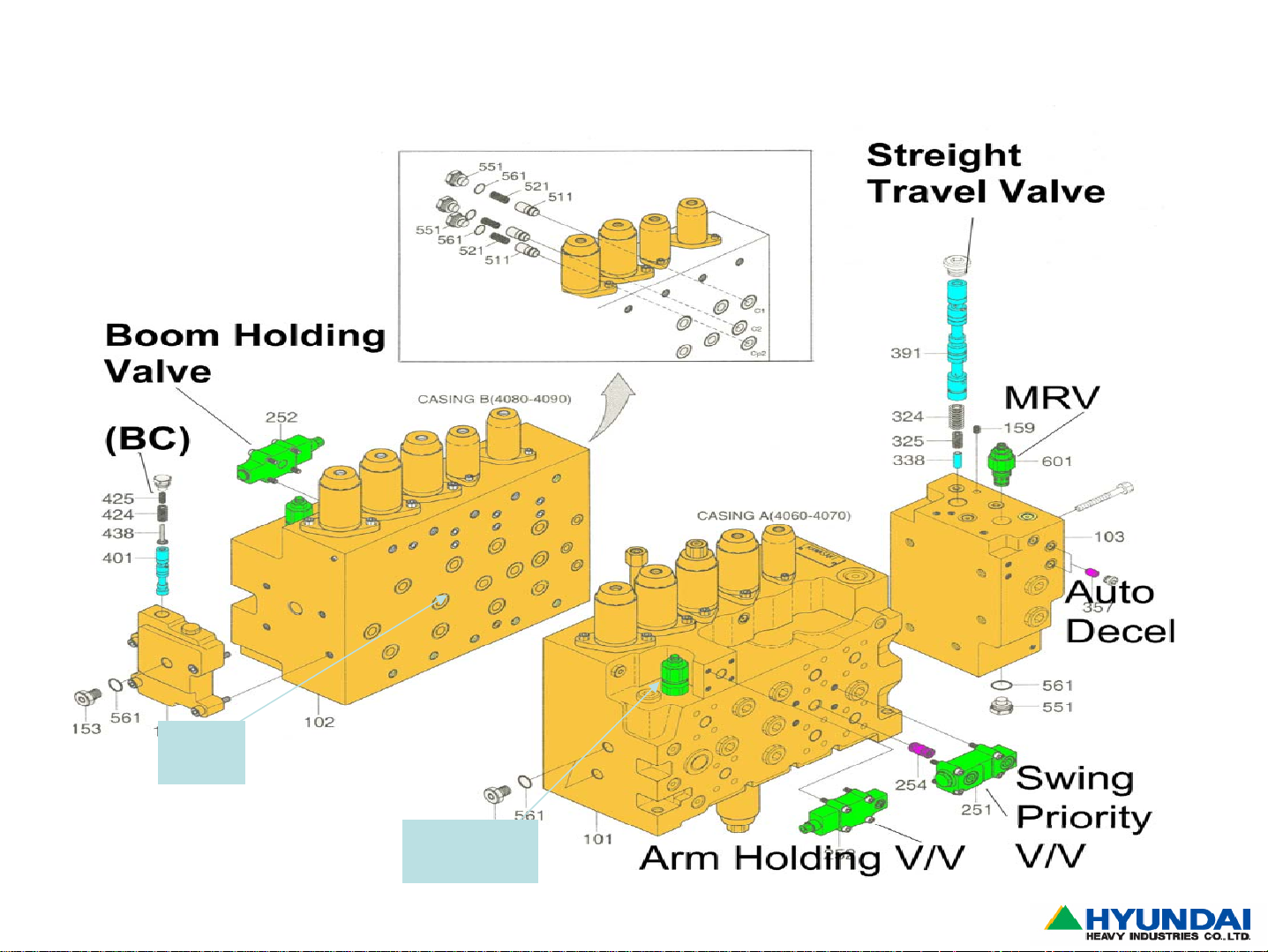

4-1A.Main Control Valve (Kawasaki)

R210LC-7

Page19

Construction Equipment

Page 21

R210LC-7

Page20

Upper viewSide view

Construction Equipment

Page 22

R210LC-7

Page21

Bottom view

Side view

Construction Equipment

Page 23

R210LC-7

Page22

RH

LH

Construction Equipment

Page 24

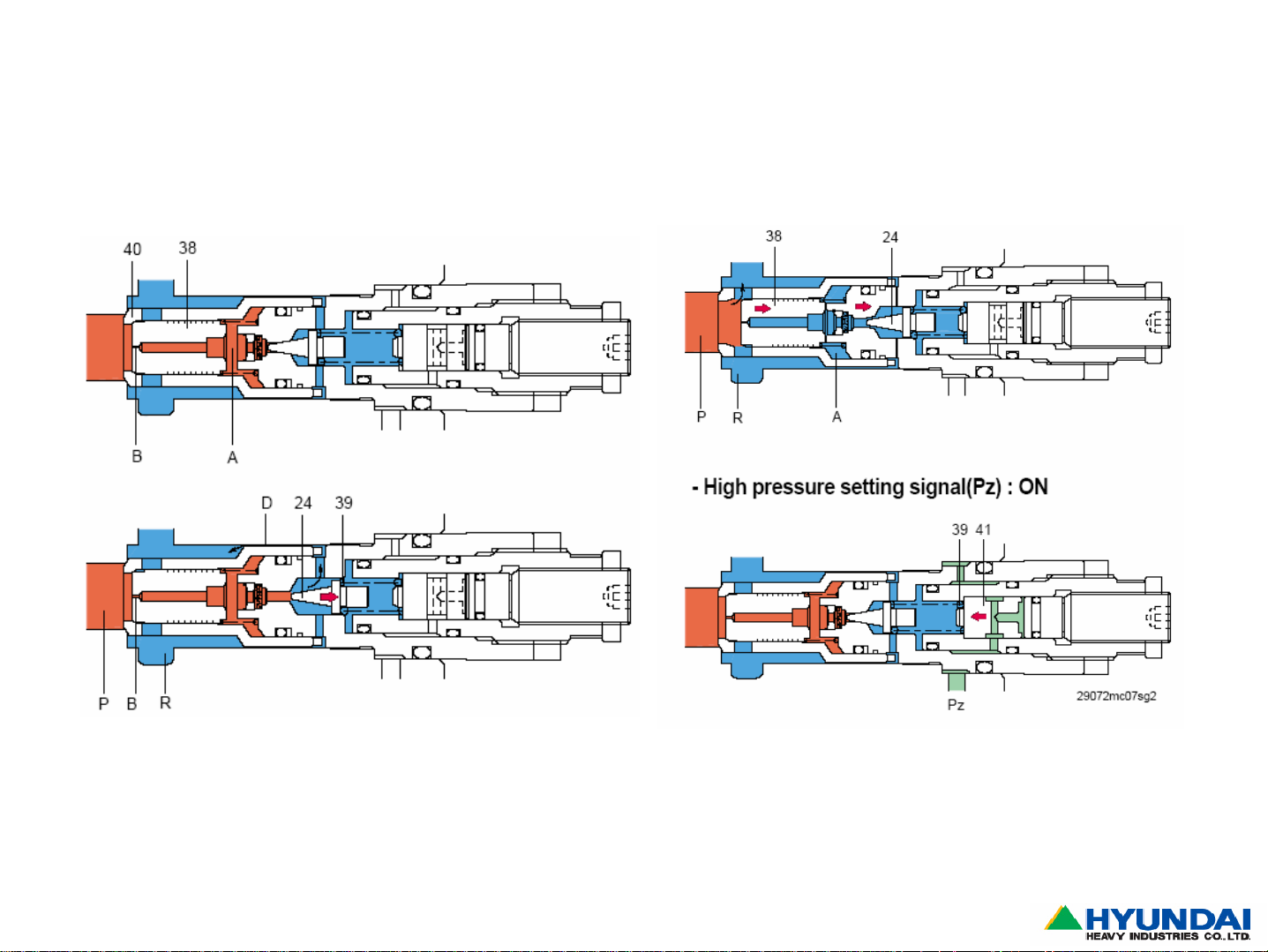

1)Foot Relief Valve

R210LC-7,R290LC-7A

Page23

Construction Equipment

Page 25

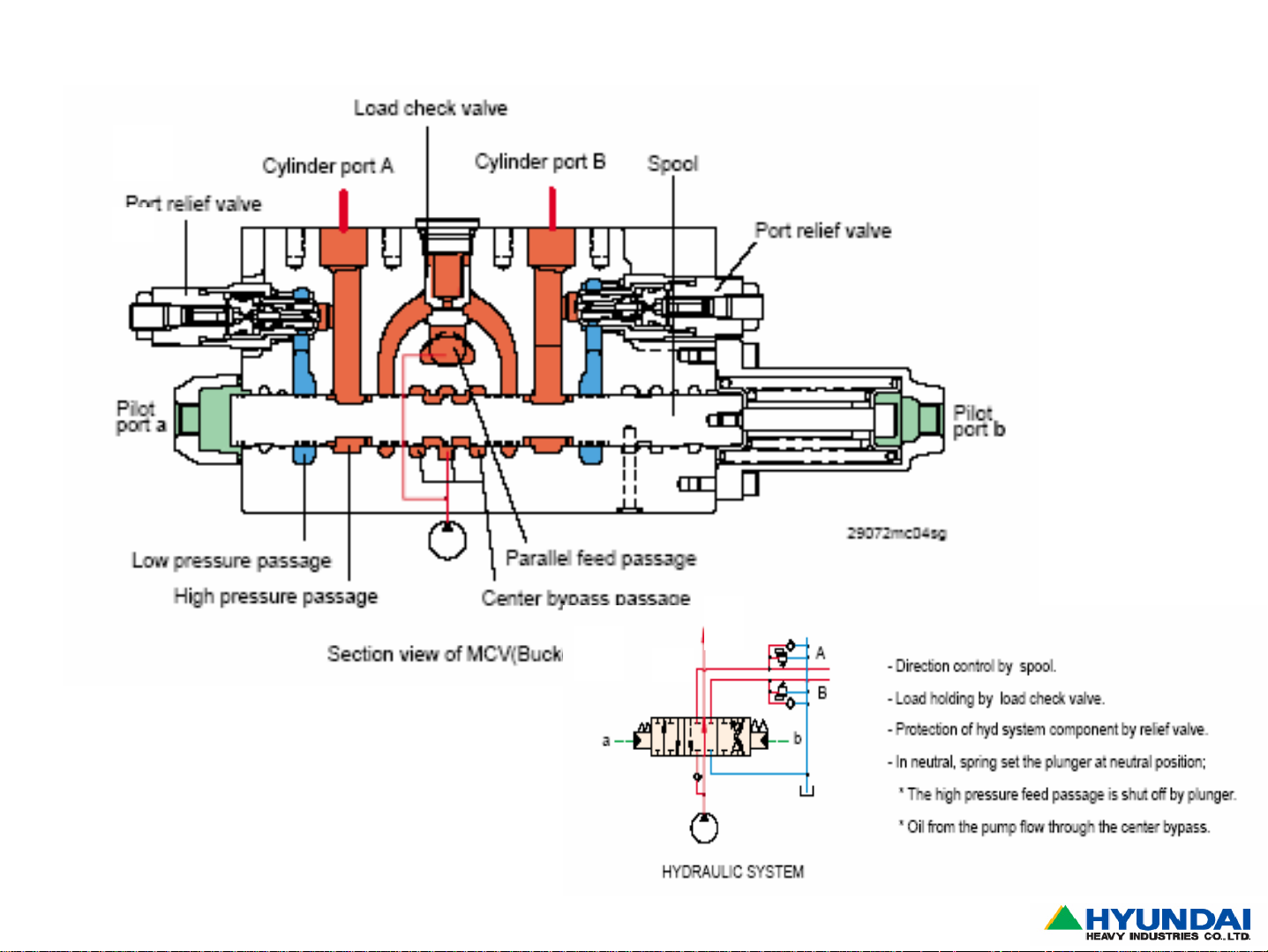

2)Direction Control Valve

R210LC-7,R290LC-7A

Page24

Construction Equipment

Page 26

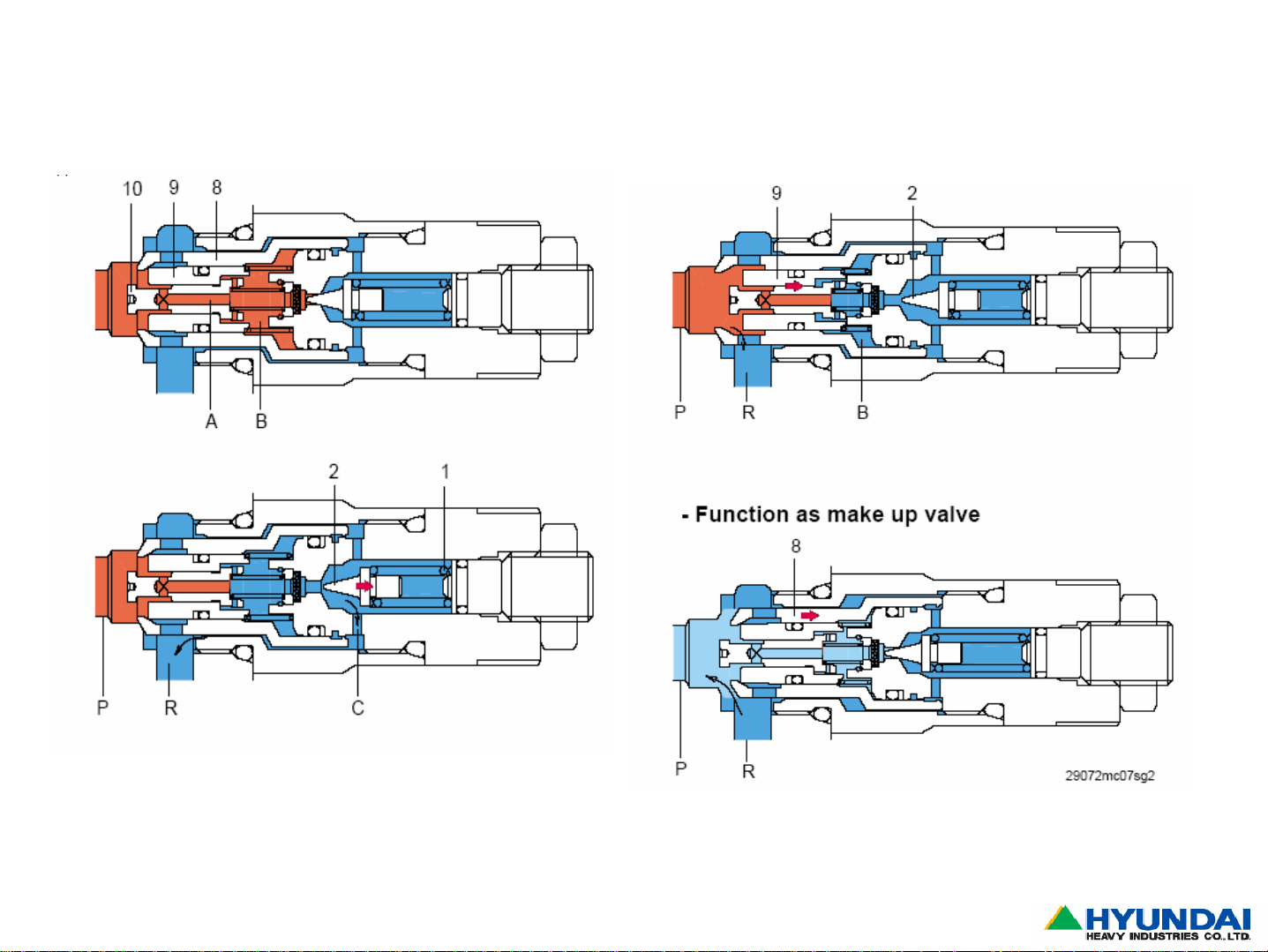

3)Port Relief Valve

R210LC-7,R290LC-7A

Neutral Position

Port Relief

valve

Load check

valve

Port Relief

valve

Operation Position

Port Relief

valve

Load check

valve

Port Relief

valve

Center Bypass valv e

Page25

Construction Equipment

Page 27

R210LC-7,R290LC-7A

Page26

Construction Equipment

Page 28

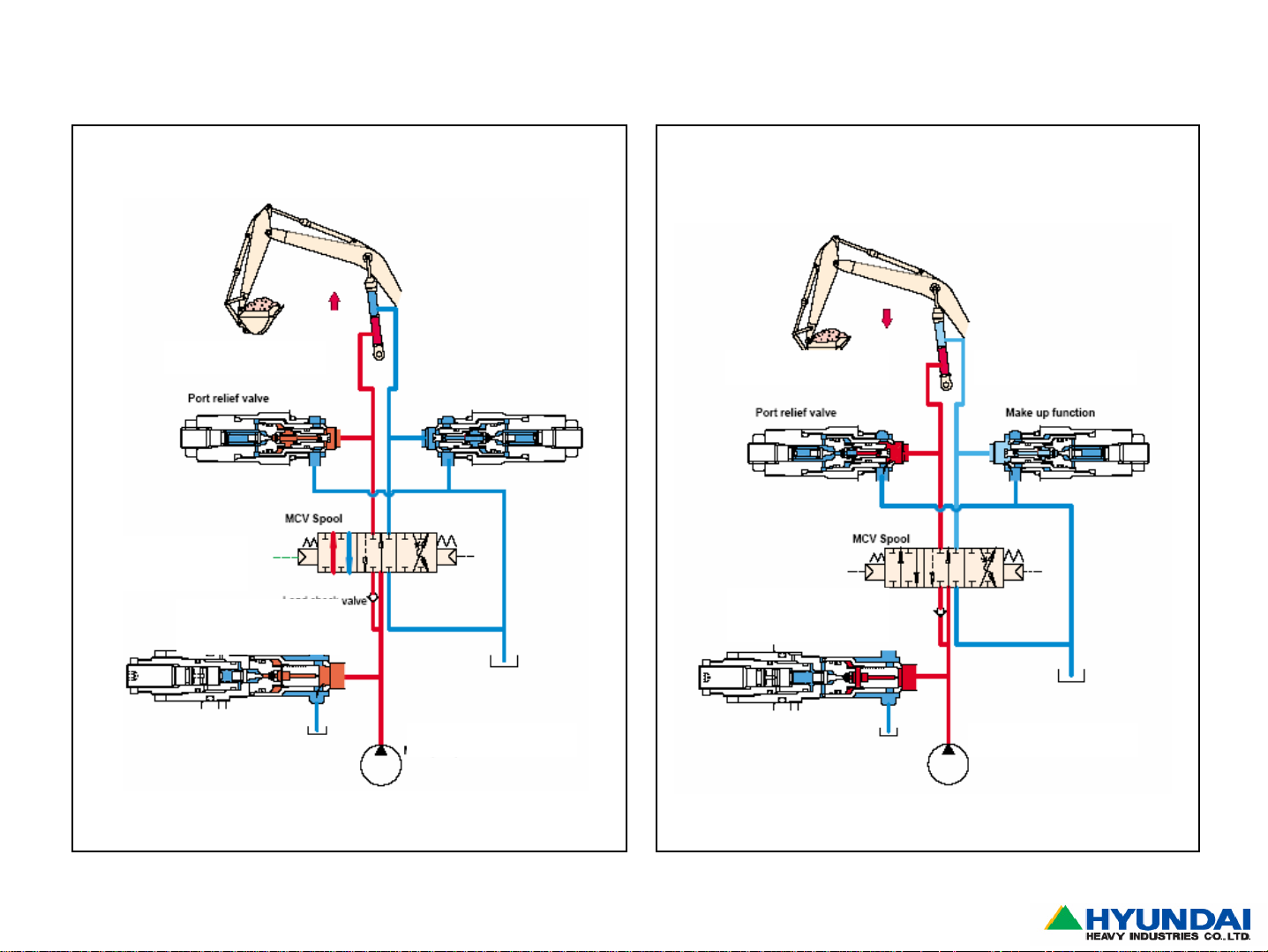

4)Main Relief Valve & Load Check Valve

R210LC-7,R290LC-7A

Port Relief valve

Load check

V/V

Main Relief

valve

Main Pump

Make Up valvePort Relief valve

Main Relief

valve

Main Pump

Page27

Construction Equipment

Page 29

R210LC-7,R290LC-7A

Page28

Construction Equipment

Page 30

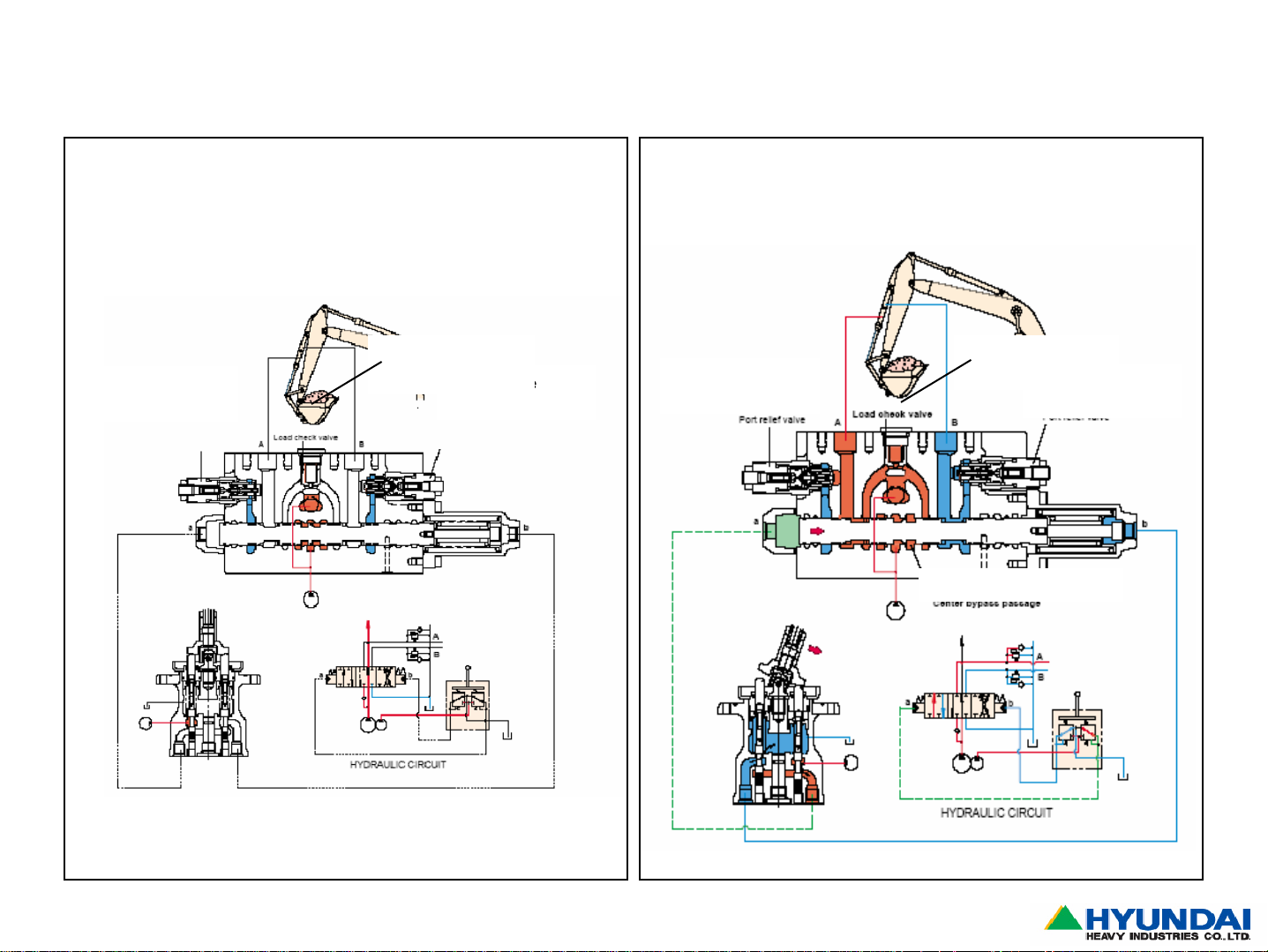

5)Arm-In Operation ( Regeneration)

-Improve arm-in speed

-Prevent arm cylinder cavitation

Page29

Construction Equipment

Page 31

Page30

Construction Equipment

Page 32

Arm Roll Out

Page31

Construction Equipment

Page 33

6)Boom Priority System ( Boom & Swing Operation)

Page32

Construction Equipment

Page 34

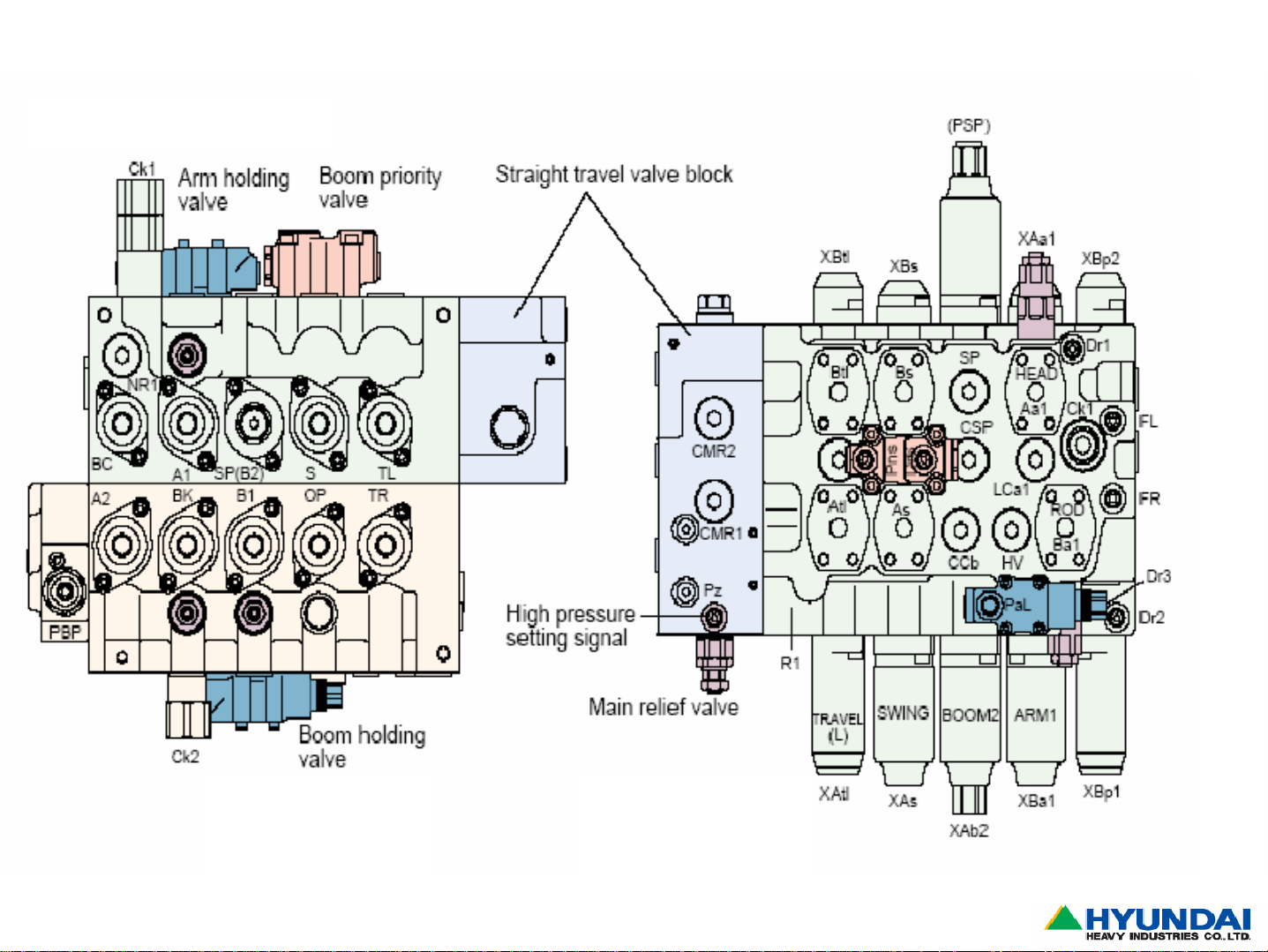

7)Straight Travel Valve

Page33

Construction Equipment

Page 35

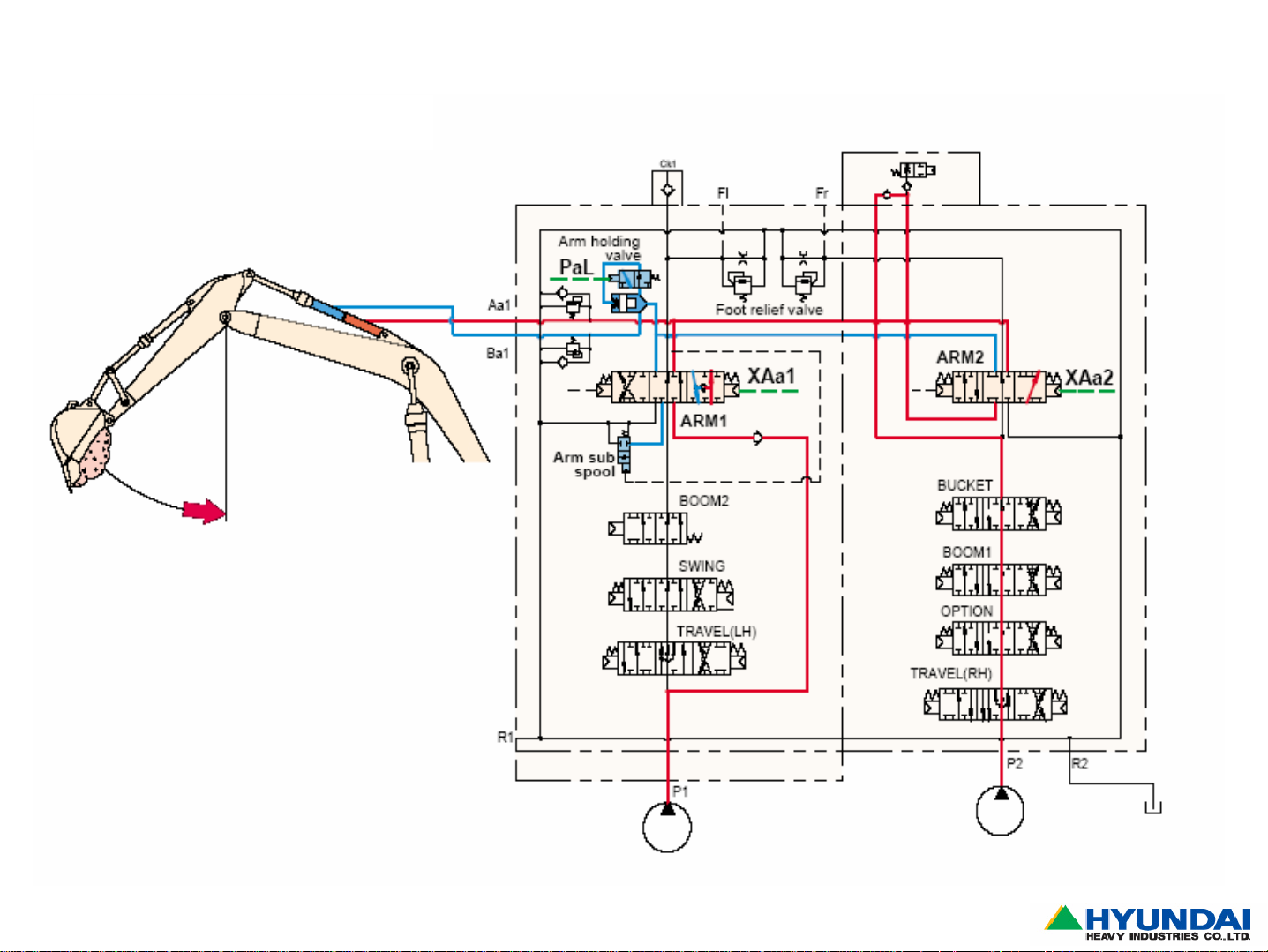

8)Boom & Arm Holding Valve

Boom

spool

R290LC-7A

Pal

Pal

Page34

Pal

Boom Holding valve open

Boom Holding valve closed

Construction Equipment

Page 36

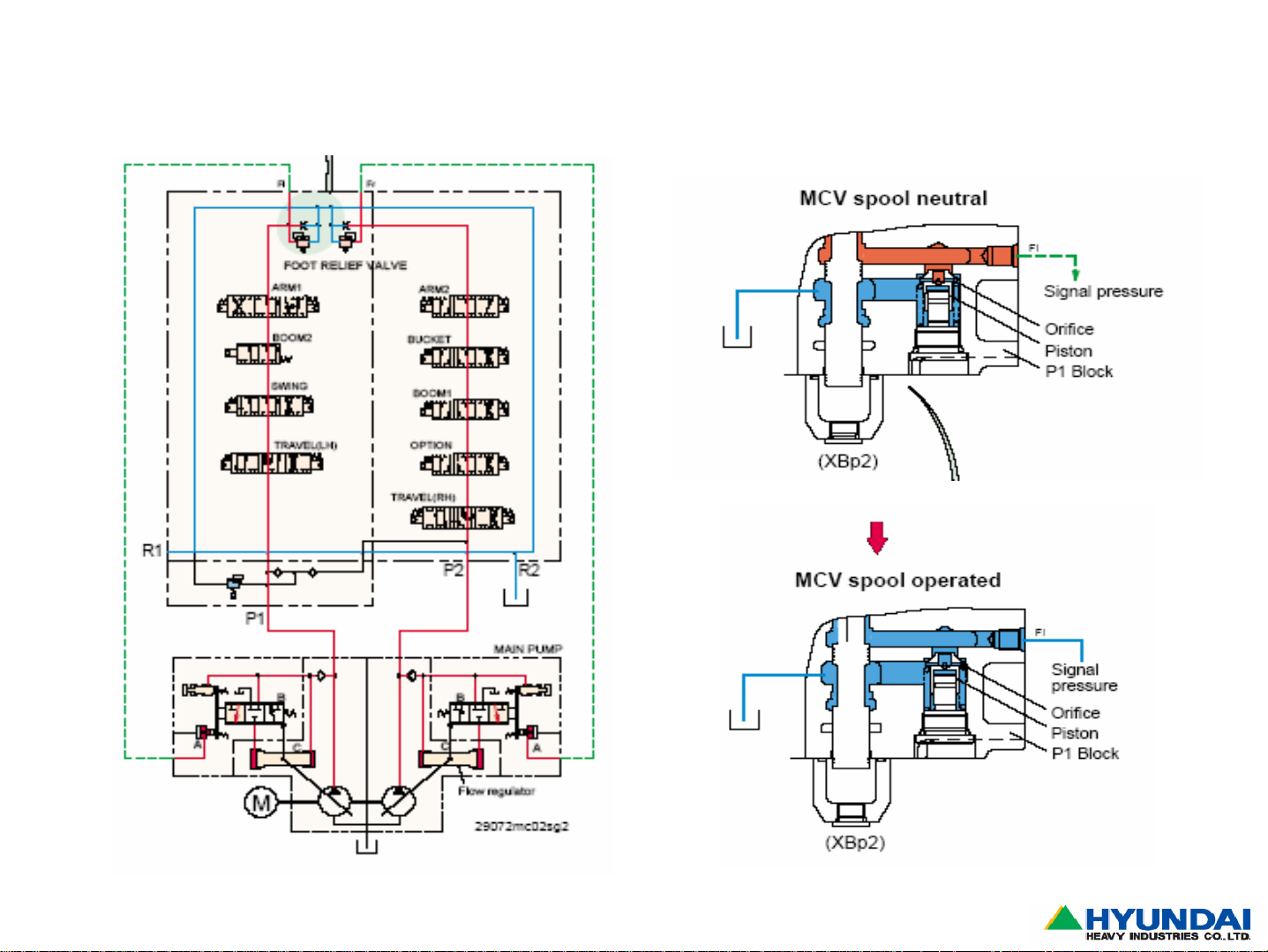

9)Auto Idling Control System

Neutral Position Operated Position

R290LC-7A

Page35

Construction Equipment

Page 37

10)Straight Travel Valve at Neutral position

R290LC-7

Page36

Construction Equipment

Page 38

11)Travel and Swing Simultaneously

R290LC-7

Page37

Construction Equipment

Page 39

4-1B. Hanil-MCV

R110/140/160/180LC-7

Signal to

open v/v

Pc41

Drain3

Option PS 37

(NO, auto decel)

NEGATIVE

RELIEF

VALVE 2

Neg Contrl Sig Pn2

Neg Contrl Sig Pn1

OPTION C

NEGATIVE

RELIEF

VALVE 1

Arm Holding

Valve (AHV)

DOZER

BUCKET

LOW

F

-

2

P

ARM1

TRAVEL

RIGHT

BOOM2

OPTION A

(1 side)

LOW

F

-

1

P

SEC.

RELIEF

V/V BUCK

DRAIN

SWING

PORT

SWING

ARM2

OPTION

PORT

Trav alarm PS

BOOM 1

SEC.

RELIEF

V/V BM

Straight Travel

Valve (TS)

TRAVEL

LEFT

Boom Holding

Valve (BHV)

Drain2

(Sw Prior &

Boom2)

Main Relief

Valve

Signal to

open v/v

Pb21

Power

Boost

Signal

Drain1

chek v/v ‘s

MR

FRONT VIEW

Regen. Command Sign

ARM

REGENERATION

SEC.

RELIEF

V/V BUCK

Pc42 (From Arm-In)

OPTION C

BUCKET

DOZER

ARM1

BACK VIEW

RETURN

P2 (ENG

SIDE

PUMP)

Regen. Cut Sign Pb4

ARM2

SWING

PRIORITY

SEC.

RELIEF

V/V ARM

BOOM1

SWING

Work PS CD7

(NO, auto decel)

PO (PILOT

OIL

ENTRANCE

)

P1 (OUTER

PUMP)

relief valve option A

location

Swing

prior sig

SEC.

RELIEF

V/V BOOM

TRAV

LEFT

TRAV

RIGHT

Drain0

Straight

Trav V/V

Page38

BOTTOM VIEW

Construction Equipment

Page 40

TRAVEL

LEFT

R110/140/160/180LC-7

Orifice

BUCKET

Lb1

DRAIN

SWING

PORT

OPTION

(1 side)

BOOM 1

ARM2

Qr

Regeneration

L01

OPTION

PORT

K1

Zm

PLUG

PLUG

K4

K3

Power

boost

K1

K4

Lb1

Lb2

EXTRA A (OPTION)

& ARM

REGENERATION

L01

Zm

K3

Page39

Lb2

Construction Equipment

Page 41

STRAIGHT

TRAVEL

TRAVEL

DOZER

RIGHT

ARM1

SWING

BOOM2

BOOM2

&

SWING

PRIORITY

DOZER

(EXTRA B)

OPTION

ARM1

SWING

OPTION

(EXTRA C)

Qr

REGENERATION)

(

PO (PILOT OIL

ENTRANCE)

PLUGS

p 2-23

p 2-25

Ks

V3 PLUG

Q2

PLUG

Q1

Q2 (SUMM)

summation

line for arm

(arm 2)

Q1

Ks

Page40

Construction Equipment

Page 42

15

R110/140/160/180LC-7

ARM

1

9

10

11

CYL

ARM1

2

BOOM2

(OPT)

TANK

STRAIGHT

TRAV V/V

12

SWING

TRAVEL LEFT

3

6

4

7

8

ARM2

BUCKET

OPTION

13

BOOM1

14

BOOM

HOLDING

VAVLE

17

TRAVEL RIGHT

Page41

16

Pilot Press

Construction Equipment

Page 43

R140W-7

⑥

⑤

④

③

②

①

⑪

⑩

⑨

⑧

⑦

⑪

⑩

⑨

⑧

⑦

⑥

⑤

④

③

②

①

Page42

Construction Equipment

Page 44

1) SPOOLS

① OPTION (Dozer for Wheel

excavator)

② BOOM1

③ ARM2

④ ARM REGENERATION

⑤ BUCKET

⑥ TRAVEL

⑦ SWING

Page43

⑧ BOOM2

⑨ ARM1

⑩ OPTION

⑪ OPTION

Construction Equipment

Page 45

2) SPOOL Location-1

Dr0

PORT Relief v/v

Negative Relief

v/v

Pb1

Pc1

Pb20 Pc2

Pb3

Pb4Pc42

Pb5 Pc5

Pn1

Pc3

Pc40

Pc6

PORT Relief v/v

Pb1 Dozer up

Pb20 Boom down

Pb3 ARM-In confluence

Pc42 ARM Regeneration

Pb4 ARM Regeneration cut

Pb5 BUCKET Out

Dr0 Drain

Pc1 TRAVEL Reverse

Pc2 RH SWING

Pc3 SWING Priority

Pc40 ARM-In

Pc5 OPTION B

Pc6 OPTION C

Page44

Construction Equipment

Page 46

3) SPOOL Location-2

Ai

Main relief v/vStraight

Travel spool

AUTO IDLE

S/W

PORT Relief v/v

Pd1

Pd6

Pa1

Pa20Pd2

Pd41Pa21

Pa4Pd40

Pa5Pd5

Pn2

Negative Relief v/v

PORT

Relief v/v

Pd1 TRAVEL Reverse

Pd2 SWING(LH)

Pa21 BOOM RAISE confluence(BOOM2)

Pd40 ARM Out

Pd5 OPTION B

Pd6 OPTION C

Pa1 DOZER Down

Pa20 BOOM Raise

Pd41 ARM Out confluence(ARM2)

Pc40 OPTION(Breaker)

Pc6 BUCKET In

Page45

Construction Equipment

Page 47

4) ATTACHMENT Supply port-1

Rs

B5 A5

B4

Dr2

Page46

B2

B1 A1

Rs SWING Make-up

B5 BUCKET Out

B4 OPTION A(BREAKER)

B2 BOOM Down

Dr2 Drain

B1 OPTION(DOZER Raise)

A2

Dr1 Pb21

A5 BUCKET In

A2 BOOM Raise

A1 OPTION(DOZER Down)

Dr1 Drain

Pb21 BOOM Holding release

Construction Equipment

Page 48

5) ATTACHMENT SUPPLY port-2

D1C1

C2

C4

C5

C6

C1 TRAVEL Reverse

C2 SWING(LH)

C4 ARM In

C5 OPTION B

C6 OPTION C

D2

V3

D4

Pc41Dr3

D5

D6

D1 TRAVEL Forward

D2 SWING(RH)

D4 ARM Out

D5 OPTION B

D6 OPTION C

Dr3 Drain

PC41 ARM Holding release

Page47

Construction Equipment

Page 49

6) NEGATIVE Control port

Plug

2-8. P1,P2 Port

Plug

Pn1

Pn2

오리피스

P2

T1

P1

Page48

Construction Equipment

Page 50

7) CHECK Valves -1

OPTION”C”

Plug

OPTION”B”

ARM 1

BOOM2

(SWING

Priority)

Q1

Q2

Ks

SWING

TRAVEL

BUCKET

ARM

Regeneration

OPTION”A”

ARM 2

BOOM 1

DOZER

Page49

Construction Equipment

Page 51

8) CHECK Valves -2

Rs SWING Make-up

B5 BUCKET Out

B4 OPTION A(BREAKER)

B2 BOOM Down

Dr2 Drain

B1 OPTION(DOZER Raise)

Plug

A5 BUCKET In

A2 BOOM Raise

A1 OPTION(DOZER Down)

Dr1 Drain

Pb21 BOOM Holding release

OPTION”C”

OPTION”B”

LB1,LB2

BUCKET

Page50

K1

Pu

CMR1,CMR2

ARM 1

Qr

BOOM2

(SWING

Priority)

K3

SWING

K4

TRAVEL

ARM

Regeneration

OPTION”A”

L01

ARM 2

ZM

BOOM 1

DOZER

Construction Equipment

Page 52

9) BUCKET Orifice

; When combined operation with BUCKET,

it allow to supply much oil to ARM/BOOM.

OPTION”C”

OPTION”B”

ARM 1

BOOM2

(SWING

Priority)

SWING

BUCKET

ARM

Regeneration

OPTION”A”

ARM 2

BOOM 1

Page51

TRAVEL

DOZER

Construction Equipment

Page 53

10) NEGATIVE Relief Valve

● RCV Neutral : Bypass pressure up-Pump flow decrease

● RCV Operation : Bypass pressure down-Pump flow increase

Drain

28 bar

()

Page52

Bypass

passage

Construction Equipment

Page 54

11) Holding valve

11-1) Composition

(Drain)

Piston “B”

Piston “A”

Sest-poppet

Poppet

Check

v/v

Spring”B”

Spring

Pb21DR3 Holding release

port

Page53

Construction Equipment

Page 55

11-2) ARM

Holding release

ARM 1 SPOOL

Page54

ARM In pilot

port(Pc40)

Holding release Pilot port

(Pc41)

Drain Port

Drain Port

Holding release

Pilot Port (Pc41)

ARM Cyl.

When ARM In operation, PILOT pressure can

act on Pc40(ARM 1 Spool),Pc41(Holding

release port) and ARM will be lower down.

Construction Equipment

Page 56

11-3) ARM Holding

The Return oil from ARM CYL.(A) is blocked by the Check valve(C) and so it can

not flow to the ARM Spool section(B).

Ⓑ

Ⓐ

Page55

Check

Ⓒ

ARM CYL.

Spring

Construction Equipment

Page 57

12) ARM Regeneration

12-1) Concept

A

B

While the ARM moves down from “A” to “B”

position as the figure, Return oil quantity will

exceed the supply oil amount cause of the

ARM gravity. It can make a Cavitation.

To make stop Cavitation, Return oil from

cylinder flow to the supply line.

Page56

(ARM Regeneration-Check v/v)

Construction Equipment

Page 58

12-2) ARM Regeneration circuit

* PILOT Supply port

when ARM In operation

① Pc40 ARM 1 Spool

①

②

ARM 1

④

ARM

Regen.

ARM 2

② Pc41 ARM Holding release

③ Pc42 Selection v/v

③

④ Pb3 ARM 2 Spool

Pc42

Page57

Construction Equipment

Page 59

12-3) ARM Regeneration - Action

Pc42

Pc42

Page58

ARM 1

ARM

Regen.

ARM 2

Construction Equipment

Page 60

13) AUTO IDLE

; One for Attachment, the other one for travel operation check.

Page59

Construction Equipment

Page 61

4-1C. Pressure Settings

UNIT: BAR

110LC-7 140LC-7 160LC-7 180LC-7 210LC-7 250LC-7 290LC-7 320LC-7 360LC-7 450LC-7

*500LC-7

MAIN CONTROL MAIN RELIEF 330 330 330 330 330 330 330 330 330 330

VALVE POWER BOOST 360 360 360 360 360 360 360 360 360 360

PORT RELIEF 380 380 380 380 390 390 390 390 390 390

(arm, boom, bucket) *380

SWING MOTOR RELIEF PRESS 240 240 240 240 240 275 265 265 260 285

(measured on swing motor)

BRAKE RELEASE 33~50 30~50 20 20 33~50 33~50 29~32 26 30 20~50

TRAVEL MOTOR RELIEF PRESS 330 330 330 330 365 365 375 330 335 345

BRAKE RELEASE < 9 6 6 6 6 6 16 16 9 17~50

PILOT PUMP RELIEF PRESS 35 35 35 35 35 35 35 35 35 33 - *35

OVERLOAD RELIEF PRESSURES FOR LONG REACH MODELS:

MODEL

R210LC/LR-7

R290LC/LR-7

Page60

ARM IN & OUT

300 bar

230 bar 270 bar

BUCKET IN & OUT

280 bar

Construction Equipment

Page 62

Subject 1 : Only one attachment speed is slow

1.Problem : attachment speed is slow

2.Check & Measure : Only one attachment speed is slow

1) Condition : S Mode, max rpm

2) Test Items and Specifications

Page61

Pressure

Measuring Point

Pilot Main

Boom

Arm

40Kg/㎠ 330Kg/㎠

40Kg/㎠ 330Kg/㎠

Travel 40Kg/㎠ 330Kg/㎠

Deviation 40Kg/㎠ 330Kg/㎠

Test result

Remedy (If not)

(Kg/㎠)

Construction Equipment

Page 63

3) Measuring point for pilot pressure

※ How to measure

(1) disconnect Pilot Hose

(2) connect the disconnect

hose to Gauge “T” fitting

(3) start the engine

※ Test Items and Specifications

Page62

Pilot Pressure

Attachment

In Neutral Full

Boom

0Kg/㎠ 40Kg/㎠Arm

Test result

Remarks (If Not)

(Kg/㎠)

See RCV

See RCV

Bucket See RCV

Construction Equipment

Page 64

4) Measuring point for main pressure

※ How to measure

1) disconnect pilot hose

2) connect the disconnect

hose to gauge “T” fitting

3) start the engine

※ Test Items and specifications

Main

relief

Main 330/360Kg/㎠ Adjust if need

Boom 330/360Kg/㎠

Arm 330/360Kg/㎠

Bucket 330/360Kg/㎠

Page63

Relief

Valve

Pressure

(Kg/㎠)

Remarks

Bucket

relief

Arm

relief

Construction Equipment

Page 65

Subject 2 : All attachment speeds are slow

1.Problem : All attachment speeds(boom,arm,bucket) are slow

2.Check & Measure :

1) Condition : H Mode, max rpm

2) Pressure check of attachment

Kgf/㎠

Page64

R/H

Travel

L/H

Travel

Swing

Bucket

out

Bucket

In

Arm

In/Out

Boom

+ L/H

Up

Travel

Swing

P1 330

fr 30/35 - -

P2 30

150 250 170 330 320 320 220

150/35 3/35 70/35 70/35 150

280 30 240 360 180 180 200

fl - - - 0/35 0/35 0/35 0/35 2

Construction Equipment

Page 66

3.Cause

1)Abnormal result of pressure check : L/H travel, bucket out, arm in, boom up

2)Check the pressure for swing and L/H relief to find if the pump 2 oil flows to pump1.

As a result, it was found that pump 2 oil flows to pump1 side of main control valve

-bucket confluence check valve broken

4.Remedy

Replaced bucket confluence check valve

Bucket confluence

check valve

Negative control signal

port

Page65

Construction Equipment

Page 67

4-2.Pump assembly

1)View of Pump assembly

Connect to

Engine

Regulator 1

M

Pi1=Neg. Control

Pm1=Flow Cut Off

Regulator 2

Pm2=Flow Cut Off

P1 P2 Pi

Pi2=Neg. Control

EPPR Pressure

Page66

EPPR Valve

P1 front

35 bar

P2 rear Pilot Pump

Construction Equipment

Page 68

2) The Type and circuit of regulator

2) The Type and circuit of regulator

①

①

X

Y

⑤

②

④

⑦

③

⑤

③

①

⑦

⑥

Section X-X

⑥

X

②

Y

⑥

⑥

Section Y-Y

** ①~⑦ Regulator Parts Name **

① : Lever 1

② : Lever 2

③ : Compensator Piston

④ : Pilot Piston

⑤ : Adjust Screw(QMC)

⑥ : Feed Back Lever

⑦ : Spool

Page67

④

②

Construction Equipment

Page 69

3)View of regulator

3)View of regulator

The Portion of Horse Power Control

The Portion of Flow Control

Page68

Construction Equipment

Page 70

4) HHI Pump--

4) HHI Pump

regulator adjustment

regulator adjustment

Model/type

R140LC-7A

K5V80DT-1LCR-9C01

R140W-7A

K5V80DTP1LHR-9C01

R160/180LC-7A

K5V80DT-1LCR-9C05

R170W-7A

K5V80DTP1LHR-9C05

R210LC-7A

K3V112DT-1LHR-9C32

Adjustment of max.

flow control

Tightening

amount of

rpm

min-1 MPa

2,000

2,000

2,100

2,100

1,900

adjusting

screw

(954)

Turn

+1/4

+1/4

+1/4

+1/4

+1/4

Flow

change

amount

L/min Turn

-3.2 +1/4 1.44

-3.2 +1/4 1.44

-3.4 +1/4 1.54

-3.4 +1/4 1.54

-5.5 +1/4 1.48

Adjustment of min.

flow control

Tightening

amount of

adjusting

screw

(953)

Turn

+1/4

+1/4

+1/4

+1/4

+1/4

Flow

change

amount

L/min

+3.2

+3.2

+3.4

+3.4

+4.4

Tightening

amount of

adjusting

screw

(628)

Adjustment of outer spring

Compensating

control starting

pressure

change

amount

+1.88

+1.88

+1.74

+1.74

+1.56

Input

torque

change

amount

Nᆞm

+32.7

+35.1

+34.7

+34.7

+39.1

A

R250LC-7A

K3V112DT-1LHR-9C52

Page69

1,900

+1/4

-5.5 +1/4 1.48

+1/4

+1.56

50.5+4.4

Construction Equipment

Page 71

Adjustment of inner spring Adjustment of flow control characteristic

Model/type

R140LC-7A

K5V80DT-1LCR-9C01

R140W-7A

K5V80DTP1LHR-9C01

R160/180LC-7A

K5V80DT-1LCR-9C05

R170W-7A

K5V80DTP1LHR-9C05

R210LC-7A

K3V112DT-1LHR-9C32

R250LC-7A

K3V112DT-1LHR-9C52

rpm

min-1

2,000

2,000

2,100

2,100

1,900

1,900

Tightening

amount of

adjusting

screw

(627)

Turn Nᆞm

+1/4

+1/4

+1/4

+1/4

+1/4

+1/4

Flow

change

amount

L/min

+9

+9

+8.9

+8.9

+11.3

+10.7

Input torque

change

amount

+40.1

+43.0

+37.0

+37.0

+45.5

+57.9

Tightening

amount of

adjusting

screw

(924)

Turn

+1/4

+1/4

+1/4

+1/4

+1/4

+1/4

Flow control

starting

pressure

change

amount

MPa L/min

+0.17

+0.17

+0.15

+0.15

+0.15

+0.13

Flow change

amount

+9.5(-9.5)

+9.5(-9.5)

+10.0(-10.0)

+10.0(-10.0)

+12.3(-12.3)

+12.3(-12.3)

Page70

Construction Equipment

Page 72

5) Structure of pump

5) Structure of pump

Servo Piston

Swash Plate

Drive Shaft

Support

Shoe

Cylinder Block

Piston

Gear Pump Ass`y

Valve Plate

Page71

Construction Equipment

Page 73

6) View & main components of pump

6) View & main components of pump

Drive Shaft

Support

Servo Piston

Shoe

Piston

Swash Plate

Cylinder Block

Valve Plate

Page72

Construction Equipment

Page 74

Page73

Construction Equipment

Page 75

7)Symbol of Pump Assembly

Actuator,Cylinders,Motors

R210LC-7,R290LC-7A

Page74

Construction Equipment

Page 76

Drain

R210LC-7

Page75

Drain

P1

Pf (EPPR)

P2

Construction Equipment

Page 77

8)Pump Regulation Schematic

R290LC-7

Page76

Construction Equipment

Page 78

9)Pump Regulating System

A. Opening of a spool in the Main Control Valve results in flow

increase of the pump, which supplies oil to the relevant spool.

This flow increase is accomplished by

pressure decrease in front of the foot relief valve.

= NEGATIVE CONTROL SYSTEM signals: F1 & F2

B. The pump power changes, according to the selected mode on

the cluster (H, S, M, U) and work condition of the machine.

Therefore the CPU sets relevant currents towards the Electric

Proportional Pressure Reducing Valve (EPPR valve), which

establishes the pump power for P1 and P2.

= POWER SHIFT SYSTEM signal: P

EPPR

C. If P1 or P2 pressure rises significantly, both pump flows will

be reduced, according to the Pressure-Flow diagram.

= TOTAL POWER CONTROL signal: P1 & P2

Page77

Construction Equipment

Page 79

Regulator consists of the negative flow control, total horse power control and power

shift control(EPPR)

Page78

Construction Equipment

Page 80

10)Regulating Circuit

FOOT RELIEF VALVE 1 FOOT RELIEF VALVE 1

F1=NEG CONTROL SIGNAL

(0..30 bar)

Remark

The Main Relief Valve (MR) limits the

general working pressure to max. 330

bar & 360 bar for POWER BOOST.

This valve is situated on the MCV and

has 2 adjust screws. When the power

boost button (left joystick, on side) is

pushed, the MR opens at 360 bar

instead of 330 bar (only 8 sec). This is

realised by an additional pilot signal at

the back of the MR. (Find more info in

290-7MCV.pdf)

MR 210LC-7

Power Boost

Signal

F2=NEG CONTROL SIGNAL

(0..30 bar)

MODE SELECTION

H, S, M, U

SPEED SENSOR

CPU

EPPR Valve

35 bar

RPM

SETTING

35

bar

Page79

Power Boost

Solenoid

PUMP POWER

SETTING

0...35 bar

Construction Equipment

Page 81

11)Flow Pressure Chart R210LC-7

The flow pressure chart of the pump depends on the active program version of the

cluster.

400

R210LC-7, default ( = version 1.X) R210LC-7, other case ( = version 2.X)

350

300

R210LC-7(standard)

118K

92K

250

2100rpm

200

2000rpm

150

Flow Rate(l/min)

100

50

0

0 50 100150200250300350

Emergency mode

206L

217L

161K

215L

S mode

177K

114L

H mode

246K

111L

202K

107L

Deliv ery Pres sure(kgf/cm2)

EPPR (bar )

H0

S13

Emergency 15

400

350

300

92K

250

200

150

Flow Rate(l/min)

100

50

0

0 50 100 150 200 250 300 350

92K

217L

217L

93K

207L

Emerg e ncy mode

R210LC-7(standard)

105K

217L

S mode

175K

110L

H mode

177K

114L

161K

215L

190K

S mode

113L

177K

114L

202K

107L

Emergency mode

H mode

246K

111L

Deliv ery Pres sure(kgf/cm2)

EPPR (bar )

H18

S22

Emergency 15

Page80

Construction Equipment

Page 82

12)Pump Regulator

Qmax control, Qmin control, Qmax Cut control

Qmax control

Qmax Cut control

Qmin control

Page81

Construction Equipment

Page 83

13)Control and Adjustment of Regulator

13)Control and Adjustment of Regulator

-Flow Control

-

Pilot Flow Adjust.

screw(③)

Max. Flow Adjust.Screw(①)

Page82

Min. Flow Adjust.Screw(②)

Q

* Max Flow Screw Adjustment(①) *

Q

Screw Loosen (Flow ↑)

Screw Tighten (Flow ↓)

* Min Flow Screw Adjustment(②) *

Screw Tighten (Flow ↑)

Screw Loosen (Flow ↓)

Pilot P

※Gradient is not changed

* Flow Cut Off Adjustment Screw(④) *

Screw Tighten(Flow ↑)

Screw Loosen(Flow ↓)

Flow Cut Off Adjust. Screw(④)

* Pilot Flow Adjust. Screw(③) *

Screw Tighten(Flow ↑)

Screw Loosen(Flow ↓)

Pilot P

Construction Equipment

Page 84

14) Control & adjustment of regulator

14) Control & adjustment of regulator

- Horsepower Control

-

First Horse Power Adjust.

Screw(⑤)

Second Horse Power Adjust.

Screw(⑥)

Second Horse Power Adjust.

Screw(⑥)

First Horse Power Adjust.

Screw(⑤)

Page83

Q

※Gradient is not changed

* First Horse Power Adjust.Screw(⑤)

Screw Tighten (Flow ↑)

Screw Loosen(Flow ↓)

* Second Horse Power Adjust. Screw(⑥) *

Screw Tighten (Flow ↑)

Screw Loosen (Flow ↓)

Pd

Construction Equipment

Page 85

Minimum flow Maximum flow

REGULATOR

REGULATOR

max

Page84

Construction Equipment

Page 86

15)Maximum flow

-When a machine is operating, oil is supplied to the actuator(cylinder or

motors) so that no oil pressure reaches piston A.

-Then, the piston B goes back to the neutral position by the spring and the

oil in the large chamber of the piston C is returned to the tank

-Now the oil is supplied to LH side of the cylinder C.

-That pressure moves the piston C to RH side, therefore the swash plate

is positioned at maximum flow angle during operation

Page85

Construction Equipment

Page 87

16)Over Load Preventing Function (Minimazing)

-When a machine is under load or the cylinder arrives at

the end of stroke, the pressure is increased

Cylinder pressure > spring pressure (B + D)

The pressure is applied at the piston D and compresses

the spring D and B

So, the valve B moves to LH side and the oil enters the

piston C through the passage at piston B

The piston C moves the swash plate to reduce the angle

upon the angle upon the load of cylinder.

Page86

Construction Equipment

Page 88

17)Flow Control

Minimum

flow

-When the engine is running, the swash plate moves to minimum angle

position as per the following steps

1.the pressure is created by restriction of the foot relief valve

2.the pressure apply to the piston A

3.the piston A is moved to LH side

4.the valve B is opened

5.the pressure flows to the piston C

6.the piston C is moved to LH side. Therefore the swash plate is

positioned at minimum flow angle

Page87

Construction Equipment

Page 89

18)Flow Reset Function (Maximazing)

-When the load at the cylinder is gone, the pressure

in

the cylinder and in the position D is decreased

Cylinder pressure < spring force (B+D)

Then, the oil in the cylinder C returns to the tank as

shown in figure, and the swash plate angle is

increased

to give maximum flow

Page88

Construction Equipment

Page 90

19)Regulator: “Flow” Control System

When operating the excavator equipment, the negative control pressure Fi inside

regulator 1 or 2, drops, which results in displacement of the pilot piston and

increasement of the pump flow.

PRESSURE

Pm=FLOW CUT OFF

PRESSURE

Fi=NEG CONTROL

PILOT PISTON

NEG CONTROL

ADJUST SCREW

PILOT SPRING

STOPPER

PISTON

FLOW CUT-OFF

ADJUST SCREW

FLOW CUT- OFF WORKING (BREAKER mode) :

When selecting BREAKER mode on the cluster, the CPU brings in the MAX FLOW

solenoid, which supplies pilot pressure towards both regulators (= Pm signal). As a

result, the max. flows will be cut off.

Pm

Fi

FLOW

MAX

NEG CONTROL PRESSURE fi

Page89

Construction Equipment

Page 91

Flow Control Signals

35 bar

MAX FLOW CUT-OFF

SIGNAL for P1

(35 bar ON / 0 bar OFF)

MAX FLOW CUT-OFF

SIGNAL for P2

(35 bar ON / 0 bar OFF)

NEG CONTROL

SIGNAL FOR

P1(0…40bar)

Page90

REAR PUMP

(P1)

On –7 models: Max flow cut off Sig is “ON” after selecting BREAKER OPERATION

MODE

On R210/250LC-3: Max flow cut off Sig automatically “ON” in L mode

FRONT PUMP

(P2)

NEG CONTROL

SIGNAL FOR

P2 (0…40bar)

Construction Equipment

Page 92

20)Regulator: “Power” Control System

By changing the mode (H,S,M,U) the CPU varies the current towards the EPPR valve (Electric Proportional Pressure

Reducing Valve). This results in varying EPPR pressures, which work (together with P1 & P2 pressure) on the power

piston inside each regulator. The power piston & pilot piston are situated near each other and control the swash plate

angle.

In case of significant drop of engine speed, the CPU will automatically increase the current, in order to lower the pump

power and it will do this until the engine speed reaches the set-value again

REGULATOR 2REGULATOR 1

EPPR PRESSURE

0…35 bar

PEPPR

P2

P1

=

PEPPR

P1

P2

SERVO PRESSURE

35 bar

24V

fuse

(or CPU pinEPPR+)

CURRENT

0…700 mA

CPUpin EPPR-

OUPUT

Power Piston

(Compensating

Piston)

REGULATOR 1

EPPR Valve = Pf (Power Shift ) Valve

REGULATOR 2

INPUT

TABLE EPPR CURRENTS & PRESSURES

Page91

In case of faulty CPU: put machine in emergency

Construction Equipment

Page 93

-When one of the power modes is selected during operation,

the EPPR valve pressure is applied at the piston D

The piston D compresses the spring and move the valve B to

LH side

Therefore, the pump oil enters to the piston C and reduces

the

angle of swash plate

So, oil delivery of the pump is reduced.

Page92

Construction Equipment

Page 94

Page93

Construction Equipment

Page 95

21)Flow Increasing Function

R210LC-7

Page94

Construction Equipment

Page 96

22)Flow Reducing Function

R210LC-7

Page95

Construction Equipment

Page 97

23)Overload Prevention Function

R210LC-7

Page96

Construction Equipment

Page 98

24)Flow Reset Function

R210LC-7

Page97

Construction Equipment

Page 99

25)Regulator

1.Negative flow control

1.Negative flow control

2.Total horsepower control

2.Total horsepower control

3.Adjustment of input horsepower

3.Adjustment of input horsepower

①Adjustment of outer spring

②Adjustment of inner spring

Page98

4.Power shift control

4.Power shift control

5.Qmax cut control

5.Qmax cut control

6.Adjustment of maximum and minimum flows

6.Adjustment of maximum and minimum flows

Construction Equipment

Page 100

Subject 1 : Attachment operating speed for R290LC-7A is slow

1.Problem : All attachment speed is slow

2.Check & Measure

1)Test condition : S Mode, max rpm

2) Test Items and Specifications

Page99

Test

Measuring Point Condition

Spec’ Remedy (If not)

Result

Unload 1750rpm

EPPR Valve

Full 1700rpm

Unload 1850rpm

Engine RPM

Full 1800rpm

Main Relief V/V 330Kg/㎠

Pilot pressure 40Kg/㎠ Adjust pilot relief V/V

Fr & Fl pressure

In neutral 38Kg/㎠

In full 5Kg/㎠

Construction Equipment

Loading...

Loading...