Hyundai CIT-3500 User Manual

HYUNDAI CIT-3500

Common Rail Injector Tester

User’s Manual

A, U, D, J, S, R Engine & U-II, A-II

Digital Controller

Contents

1. PRODUCT COMPOSITION

2. INJECTION TEST

1) Injection Comparison Test ( Low Pressure Mode )

2) Injection Comparison Test ( Low & High Pressure Mode )

3) Test & Diagnostic

4) How to use digital CRDI HP controller

3. HIGH PRESSURE & BACK LEAK TEST

1) High Pressure Test for each system

2) High Pressure Test for each system

3) Cleaning procedure of injector

4) Injector Back Leak Test (Dynamic)

4. DIAGNOSTIC / REPAIR / INJECTOR CLEAN & ASSEMBLY & TIPS

1) Diagnostic & Repair procedure of CRDi system

2) Cleaning procedure of injector

3) Injector assembly (Nozzle area)

4) Injector assembly (Nozzle area)

5) Tips for Injector assembly (Nozzle area)

5. TECHNICAL INFORMAITON

6. PIEZO INJECTOR

1) PIEZO Injector test

2) Measurement Test of injected-fuel-quantity

3) PIEZO Injector Low Fuel Test

1

This new Injector Tester has developed in order to improve diagnostic efficiency and

accuracy for Common Rail System in the vehicle.

Enables Injection Amount Comparison Test under Low and High fuel pressure conditions

that was not possible with GDS/G-Scan .

Also Cylinder compression and Rail pressure regulator test are additionally available.

1. CIT-3500 Composition

Tool Case

CRDI HIGH

PRESSURE

CONTROLLER

INJECTOR MESS

CYLINDER

TYPE-A

PIPE(M12*M12)

TYPE-B PIPE

(M12*M14)

TYPE-C PIPE

(M14*M14)

TYPE-D PIPE

(M14*M14)

BOSCH/DELPHI

DUMMY INJECTOR

NEW DELPHI

DUMMY INJECTOR

“L” DUMMY

INJECTOR &

ADAPTER

Engine

Compression Gauge

LOW PRESSURE

GAUGE

VACUUM GAUGE

BOSCH

CONNECTOR

PIEZO CONNECTOR

NEW DELPHI

CONNECTOR

RPS BOSCH

DUMMY

CONNECTOR

RPS NEW DELPHI

DUMMY

CONNECTOR

DUMMY

REGISTER(PRV)

DUMMY REGISTER

(HP SENSOR)

BACK LEAK

CONNECTOR

& ADAPTER

PIEZO RETURN LINE

CONNECTOR &

ADAPTER

Back Leak Test

bottle

LOW PRESSURE

GAUGE

CONNECTION TUBE

CONNECTION

ADAPTER

FUEL FILTER PLUG

(For DELPHI)

Connection

ADAPTER WITH

HOSE

COMMONRAIL

PLUG (FOR BOSCH

/ M12)

COMMONRAIL

PLUG

(FOR DELPHI / M14)

DUMMY INJECTOR

ADAPTER

Injector Return Line

Block Hose

Dust Cap SPARE PART Kit User’s Manual

1.

7.6.

5.4.

3.

2.

10.

9.8.

13.12.11. 14. 15.

18.

17.16.

21.20.19.

24.23.

22.

27.

26.

25.

28.

29.

30.

31. 32.

33.

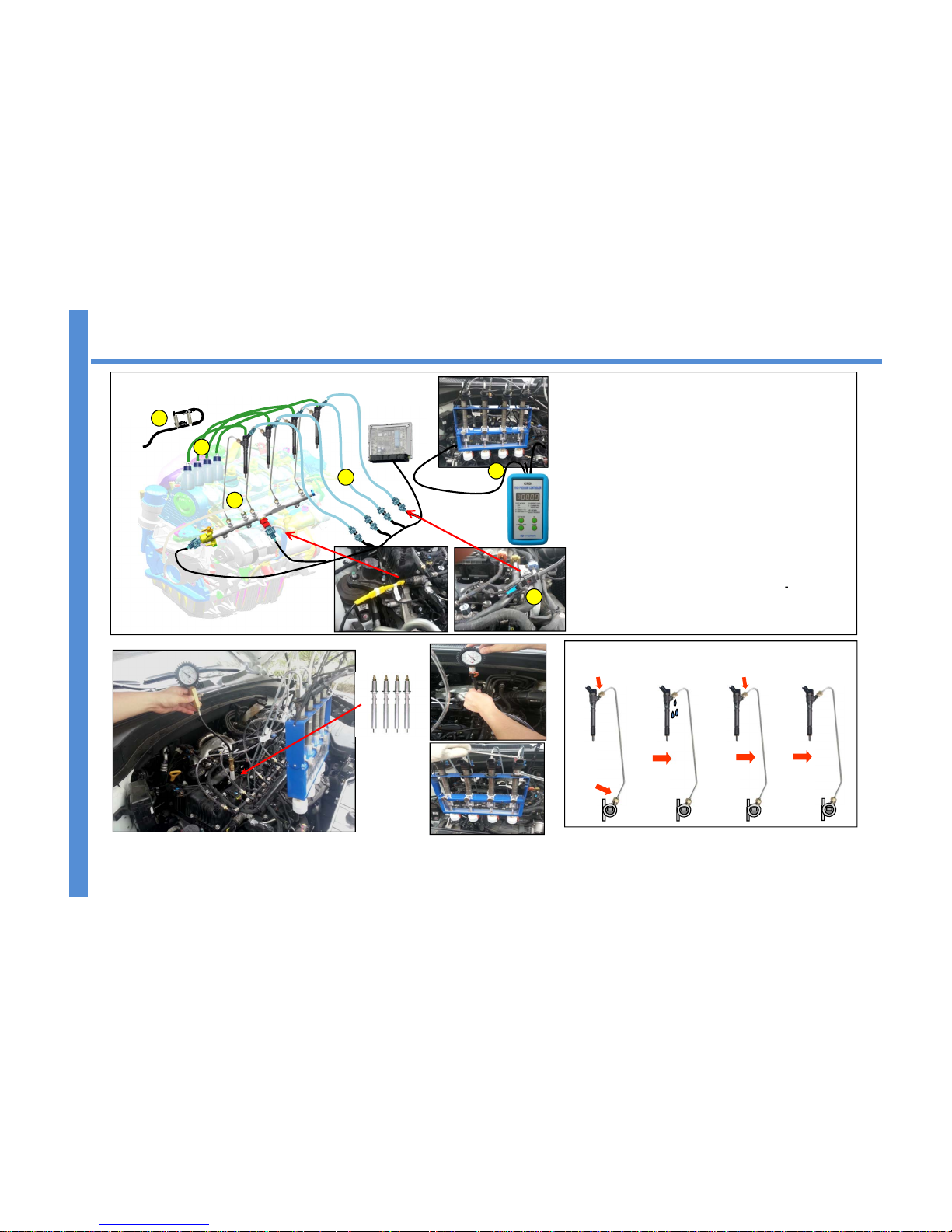

1) LOW PRESSURE MODE TEST

LOW PRESSURE MODE TEST

1. Remove the injectors from the engine

2. ① Block the return line of injectors

3. ② Install the test pipes in the rail (4ea)

and Install Test Body in injectors.

4. Install the Back Leak ③ bottle in the Injectors

5. ④ Connect the injector control wire and

holding the housing with o-ring.⑤

6. Crank the engine until the injection amount up

to the target level.⑥

NOTE :

Rail pressure will be maintained 250~350bar

automatically by vehicle’s ECU. Thus, you don’t

need to use HP controller during the test.

2-1 INJECTION COMPARISON TEST ( LOW PRESSURE MODE )

ECU

※ All the pipes must be cleaned

before installed .

( Clean it with an Air gun )

Tighten

Loosen

Flushing

IG on or Cranking

Tighten

Flushing : Crank the engine and find

the fuel leaks from the fitting area

for flushing purpose.

Remove injectors and install the dummy injectors

on the Injector hole. Block the fuel return line of

injectors to prevent fuel leaking.

2

Install Test Body

1

2

3

4

5

6

1) LOW & HIGH PRESSURE MODE TEST

ECU

2-2 INJECTION COMPARISON TEST (LOW & HIGH PRESSURE MODE )

Drain Valve

1

2

3

4

2

TEST PROCEDURE

1) Select MAX HIGH mode and crank engine for 2-3seconds.

2) Crank engine and adjust the rail pressure in Low and High

mode while engine cranking.

- LOW = 250 ~ 350 bar

- HIGH = 800 ~ 1000 bar

※ Select injection pressure using the up & down button

3) Drain the fuel from the test body.

4) Perform test for each mode: LOW & HIGH.

LOW PRESSURE MODE TEST

1) Disconnect the PRV’s & rail pressure sensor’s

connector from the rail

2) Install ① Dummy Resister and ② Rail Pressure

Sensor Dummy in each wiring connectors.

3) Connect HP controller’s wire to the ③PRV & ④ rail

pressure sensor.

5) Connect HP controller’s ⑤ power cable to battery.

4) Crank the engine until the injection amount level

of 1 or 2 test body are close to target level.

(5 scale in LOW, 8 scale in HIGH)

NOTE :

- Rail pressure can be adjusted from 100 to 1000bar by

pressure adjust knob.

- In the old model, you must use rail pressure

sensor dummy, otherwise injector will not work while

cranking.

NOTE: Battery must be fully charged before test

5

3

UP(Hold)

Test Mode

DOWN

Current data

1

1

2

Injectors Holding screw

NOTE : Perform the test more than 2 ~ 4 times to get accurate data.

LOW PRESSURE MODE JUDGMENT

HIGH PRESSURE MODE JUDGEMENT

Target

8 scale

5

6

10

11

4

3

Test & Judgment

Crank the engine until the highest level of one or more test tubes are close

to targeted level. (① LOW : 5

th

/ ② HIGH : 8thscale )

Judgment will automatically be made once you fill out measured values CRDI

diagnosis check sheet in GDS (Global Diagnosis System)

2-3 Test & Diagnostic

Select the correct groove according to engine type when

you install dummy injectors.

Quick coupling on dummy injector will help you to perform

cylinder compression test easily and quickly.

Judgments

- Please note that the engine compression standard is

showed on the shop manual.

Compression Test

Crank the engine until the injection amount of 2ndlargest fuel amount

injector is close to target level. (5 scale when low pressure mode, 8

scale when high pressure mode)

Measure the other injector’s injection amount and judge as below.

LOW PRESSURE MODE : 0.15 ㎖ ( 1.5 scale ) or higher is normal

HIGH PRESSURE MODE : 0.5 ㎖ ( 5 scale) or higher is normal

For user who has no GDS

4

Adapter for

New (A-ENG) Injectors

2

1

LOW PRESSURE GAUGE

Engine Compression Gauge

Loading...

Loading...