Hy-Gain TH-7DX Service manual

TABLE OF CONTENTS

(

)

g

Cont.

CHAPTER 4..................................................................……............................................................4-1

Installation...........................................................................…........................................................4-1

Installation on a Crank-Up Tower............….…….…………........................................................4-1

Attaching the Antenna to the Mast ...............…………………….................................................4-1

Other Types of Towers .........................................………..............................................................4-3

Lightning Protection...............................................……….............................................................4-3

Attachment of Feedline ..........................................…….................................................................4-3

VSWR Curves.....................................................……......................................................................4-3

VSWR/Front-to-Back Charts...............................………………………........................................4-4

CHAPTER

5..............................................................................................................................................5-1

Overation ......................................................................................................5-1

CHAPTER 6.....................................................................………......................................................6-1

Troubleshooting ..............................................................……….…….............................................6-1

TroubleshootingChart..........................................……….................................................................6-1

Page

CHAPTER 7..................................................................…............……….........................................7-1

Service Information.…………...........................................................................................................7-1

Parts Identification Information.............................................……….............................................7-2

Converting American Measurements to metric ...........................................................:.................7-2

Bolt and Nut Sizes.............……….....................................................................................................7-2

Parts List....................................................................................................................................7-3

LIST OF ILLUSTRATIONS

Figure Pa

1 Boom-to-Mast Bracket ..................................................................................................3-1

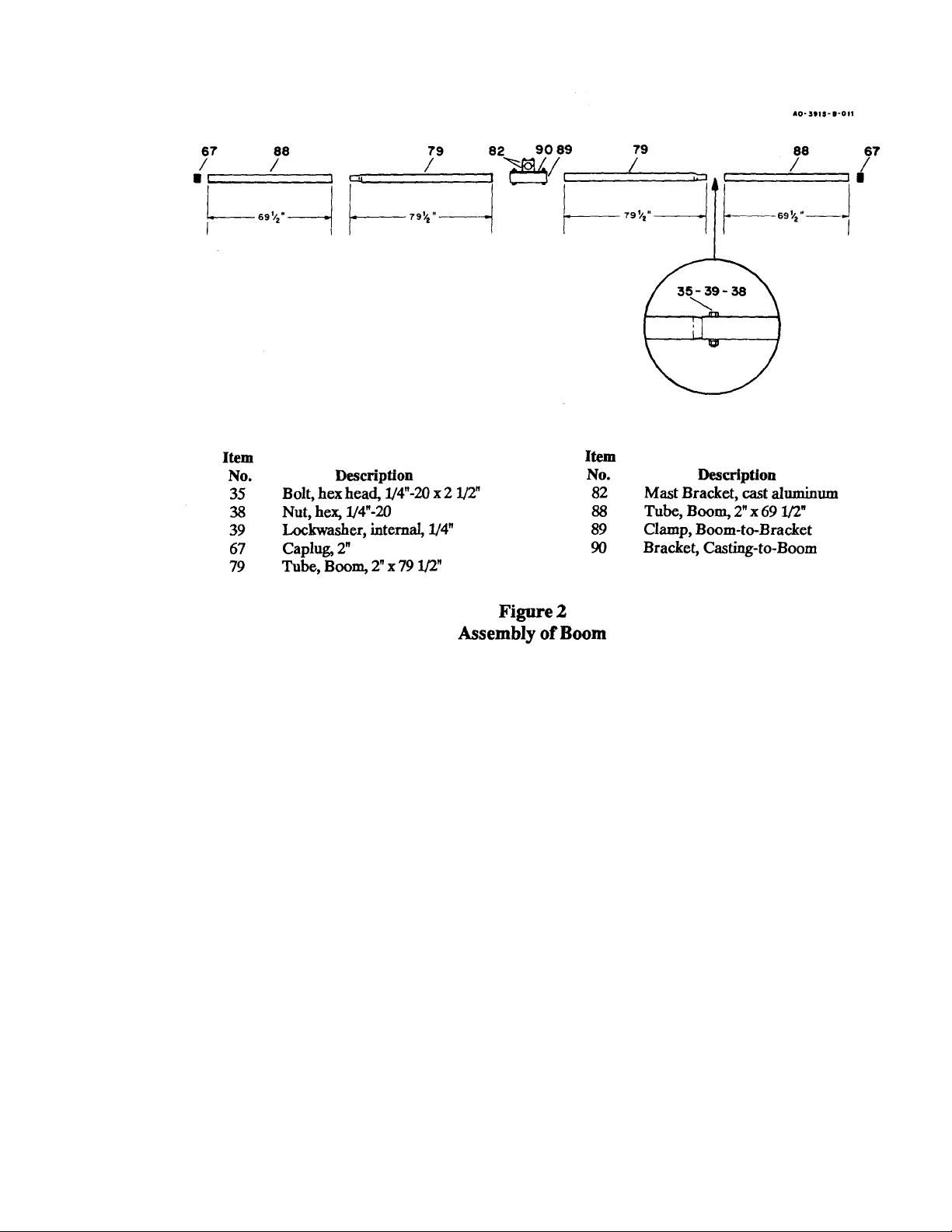

2 Assembly of Boom .........................................................................................................3-2

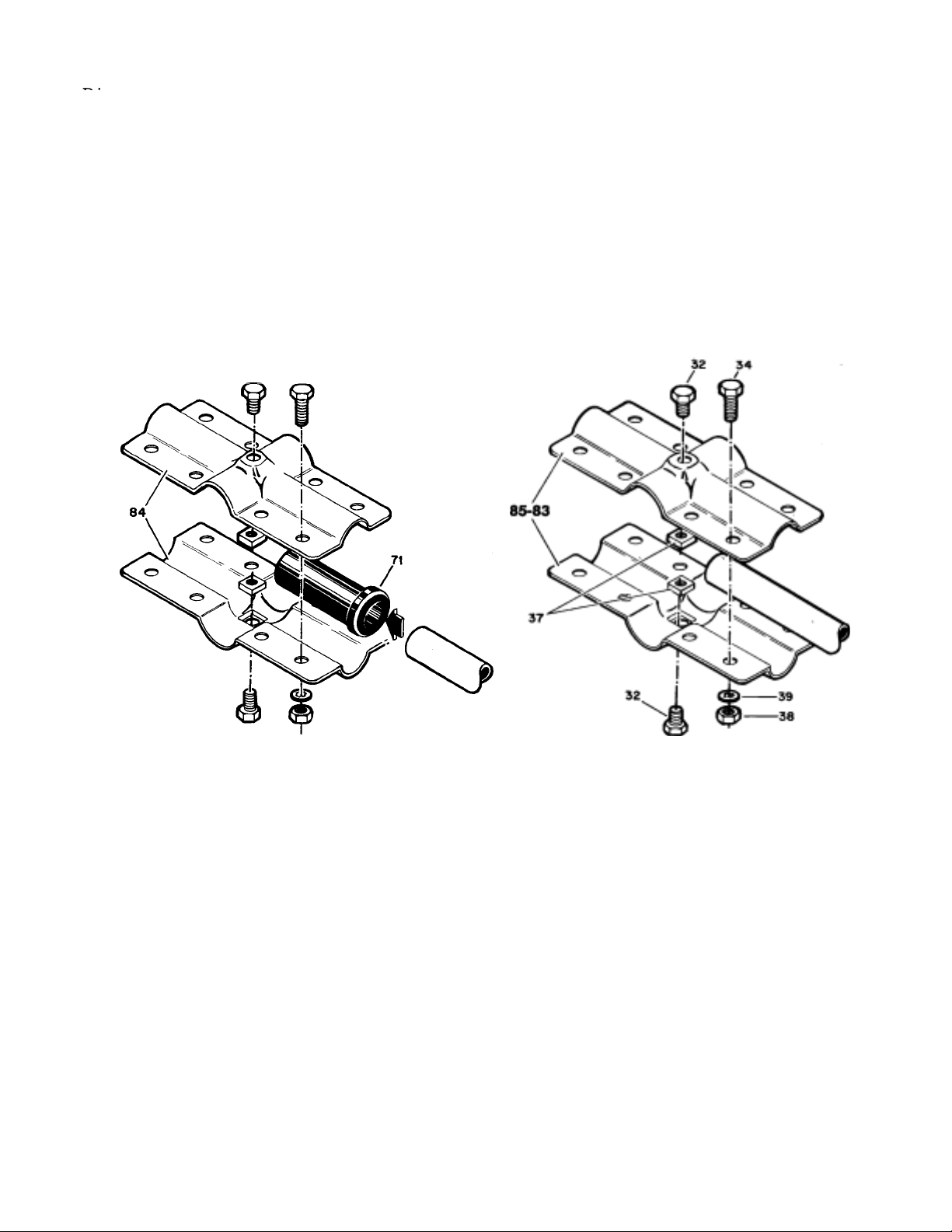

3 Element-to-Boom. Brackets ..........................................................................................3-3

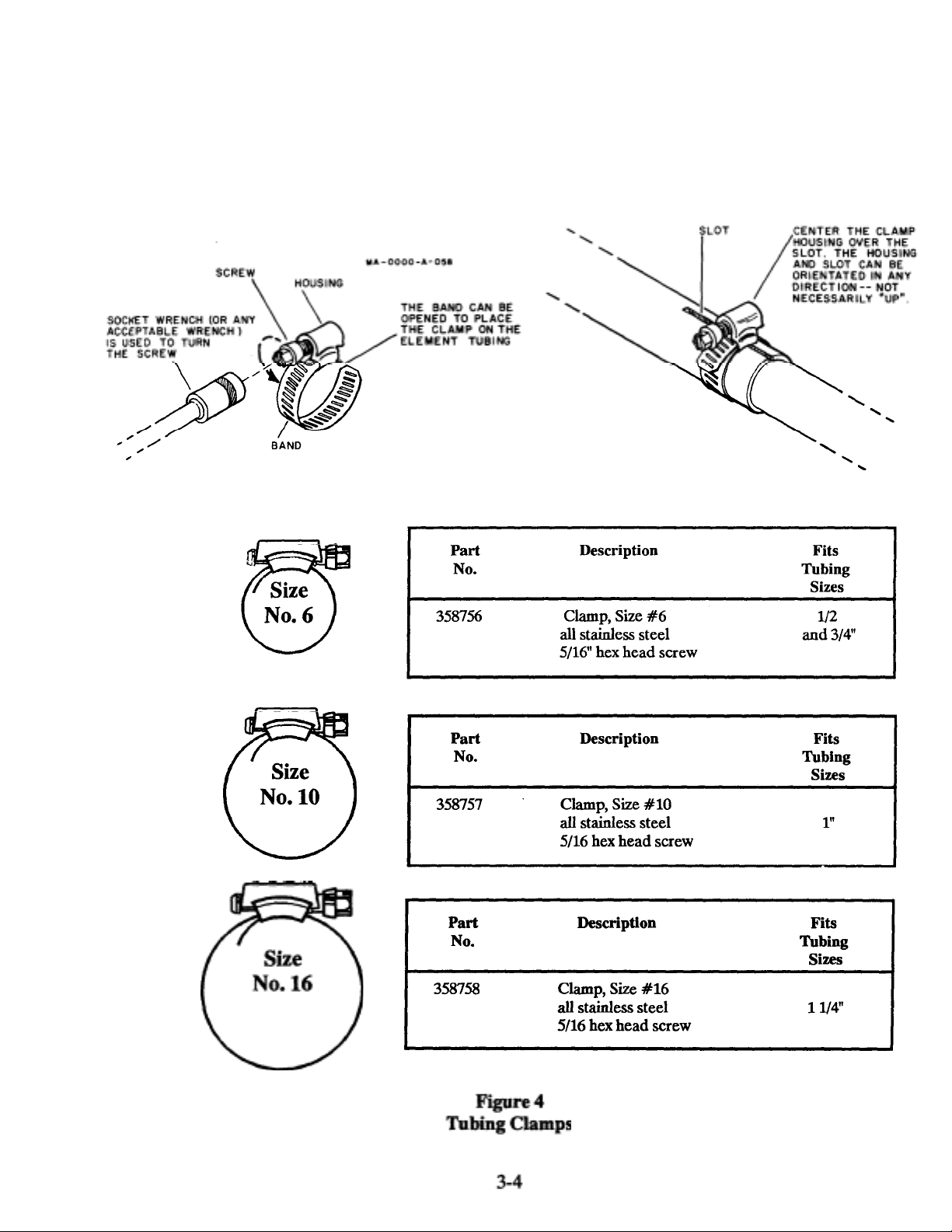

4 Tubing Clamps ................................................................................................................3-

5 Trap Detail .............................................................:........................................................3-

6 Overall View - Element Assembly and Antenna Dimensions .................................3-7

7 Rope Dampener .............................................................................................................3-8

8 Overall View of Beta Match and Phasing Tubes .......................................................3-9

9 Crossover Straps .......................................................................................................... 3-

10

11 Pigtail to Balun Connection and Front Driven Element ...................................... 3-12

12 Boom Support Assembly ........................................................................................... 3-14

13 Raising Antenna to Top of Tower ..............................................................................4-2

Pigtail Assembly to Rear Driven Element ............................................................. 3-11

DETAIL A - Beta Support Clamps and Insulator Assembly ........................... 3-12

DETAIL B - Beat Shorting Clamp Assembly ................................................... 3-12

General

*

CHAPTER 4

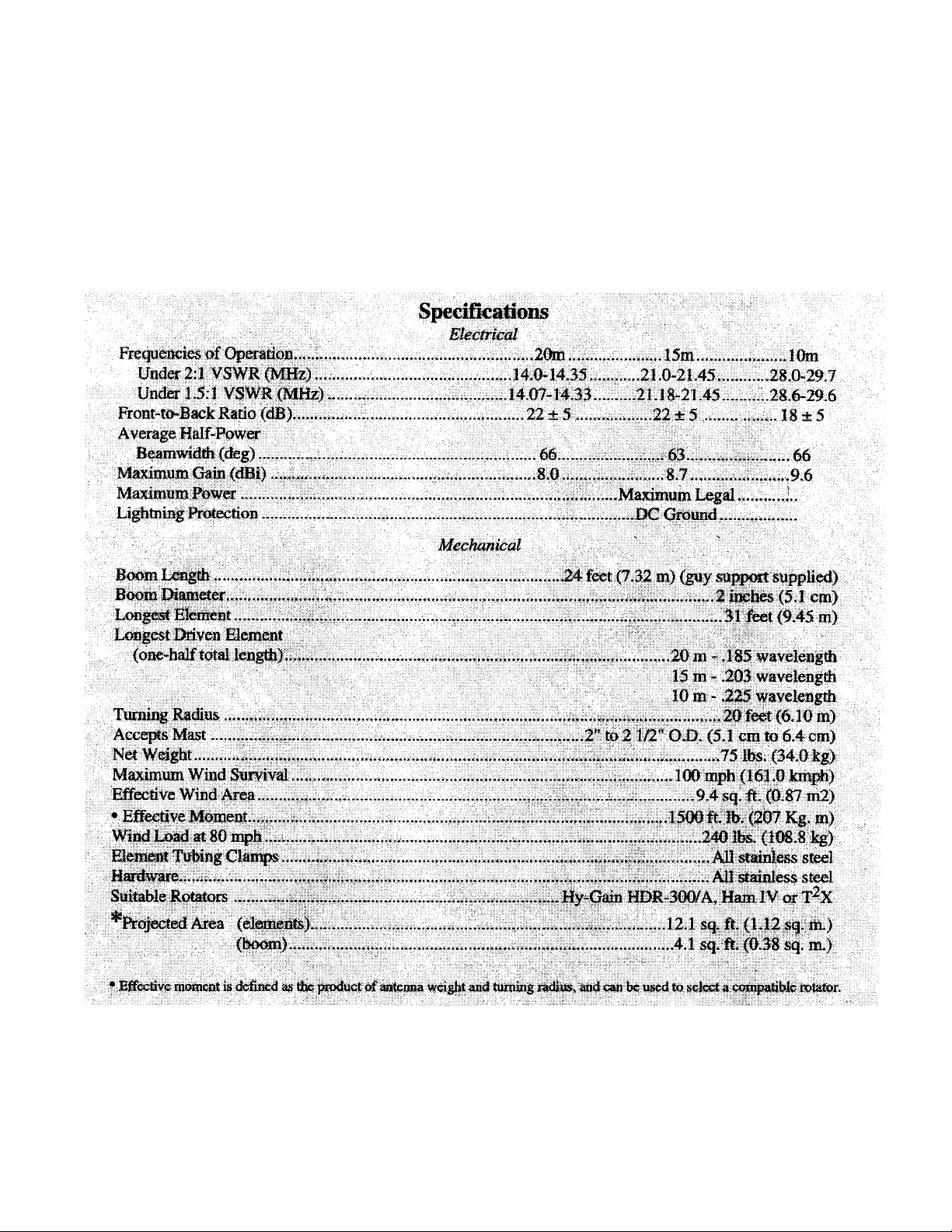

The Hy-Gain TH7DX is a 7 element, 3 band beam

antenna designed for broadband, high performance

operation on the Amateur 10, 15, and 20 meter

bands. Broadbanding is accomplished through the

use of two fully trapped driven elements. Stainless

steel hardware and clamps are used on all

Hy-Gain's 50 ohm BN-86 balun and preformed

feed straps are supplied. The TH7DX also comes

with a wire boom support for additional strength.

The antenna is designed to fit masts from 2" to 2

1/2" in diameter and can be rotated with HyGains's

HDR-300/A, Ham IV or T2X rotators.

Projected Area is the actual (flat) projected area of either the elements or boom (highest value)

without any shape factor included. this area may be used with EIA/TIA-222-D and later versions and

with the UBC formulas to determine tower and mast loading. On HF beams, the element area is

usually higher. On VHF/UHF beams, the boom area is usually higher. When stacking HF and VHF

beams, use the element area of all beams at their attachment points to determine loading at zero

-

-

Preparation for

p

gg

g

FOR OUR OVERSEAS CUSTOMERS: The

United States uses American units of measurement. Please see page 7-2 of this manual for

assistance in identifying the hardware and com-

onents supplied with this product.

Choose a large, clear area to assemble the

TH7DX. The area must be at least 24'x 31' (7.3

m x 9.5 m). You may wish to use sawhorses or

chairs to support the boom during assembly. A

concrete driveway is an excellent area for assembly. If you assemble this antenna over a

grassy area, precautions should be taken so that

hardware is not accidentally lost during assembly.

All tubing supplied with the TH7DX telescopes

together. Make all measurements to the given

dimensions, plus or minus, no more than 1/8

The TH7DX is a highly sophisticated and complex array consisting of more than 700 parts.

The superb performance engineered into this

array is totally dependent on accurate assembly.

All components and hardware must be used as

directed in the instruction manual. The key to

success is to allow yourself plenty of time.

We suggest that the assembly be done over a 2day period. We further suggest that you read this

manual thoroughly, in its entirety, then go

through the manual the second time and identify

and familiarize yourself with all of the antenna

components, and then start assembling the antenna. A few hours invested in the assembly

process will insure many years of satisfaction

When unpacking your antenna, check inside of

all tubing (traps, smaller tubing, etc.). To conserve space, these smaller articles are

sometimes put inside larger pieces. Check all

parts against the parts list to make sure no parts

are missing. The hardware supplied with this

antenna is ba

ed by thread size for your

NOTE: An extra Figure 6, Overall View - Element Assembly and Antenna Dimensions, has

been inserted in this manual for use when

assemblin

NOTE: Refer to the maintenance section on

page 5-2 for information on using anti-oxidants

and other methods of obtaining longer product

the antenna.

-

-

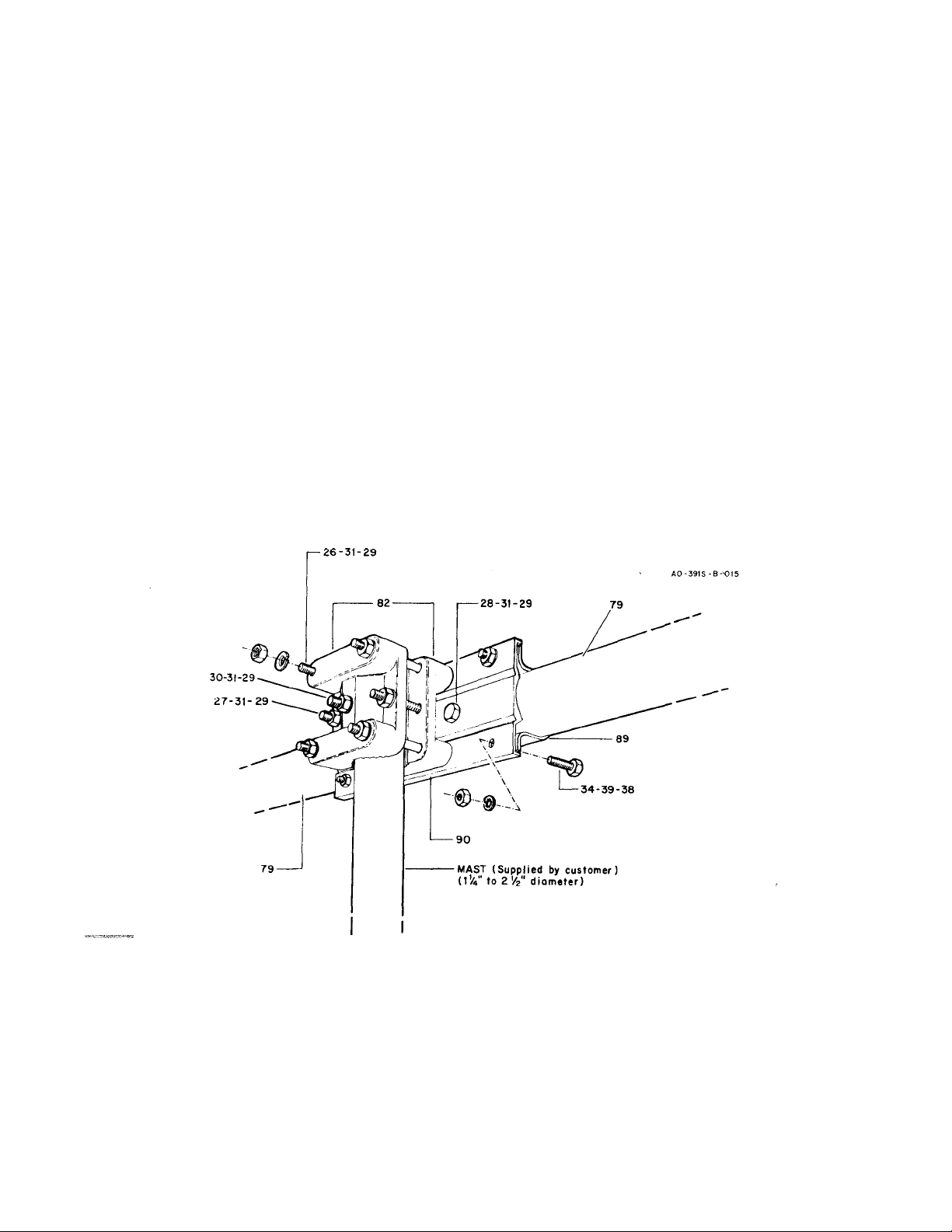

Assembly of the Boom-to-Mast

show

.

,

,

,

p

Select the boom-to-bracket clamp parts (Item Nos.

89 & 90). Loosely assemble them on the boom

ends (Item No. 79), as shown in Figure 1. Line up

the holes on both brackets and both boom ends.

Secure the two brackets together with four (4)

1/4"-20 x 3/4" bolts, lockwashers and nuts (Item

Nos. 34, 39 & 38). Secure the brackets to the two

boom ends using the 5/16"-18 x 2 3/4" bolts,

lockwashers and nuts (Item Nos. 28, 31 & 29).

Tighten these six bolts securely.

Assemble the two cast aluminum brackets (Item

No. 82) on the mast at the desired height above

your tower. Secure the two brackets together using

the two (2) 5/16"-18 x 3 " bolts, lockwashers and

nuts (Item Nos. 27,31 & 29). You may wish to drill

a 5/16" hole through the cast brackets' center hole

and through the mast and secure using a 5/16"-18 x

3 3/4" bolt, lockwasher, and nut (Item Nos. 30, 31

& 29). This bolt will prevent the antenna from

twisting on the mast in high winds. See Figure 1.

The four (4) 5 inch bolts will be installed when the

antenna is installed on the mast.

NOTE: The use of heavy motor oil on stainless

steel threads will prevent galling of threads.

Slip the two remaining boom sections (Item No.

88) over the two swaged ends of the assembled

boom and secure using a 1/4"-20 x 2 1/2" bolt,

lockwasher and nut (Item Nos. 35, 39 & 38), as

n in Figure 2

Ite

m

No.

26

27

28

29

30

31

Bolt

Bolt, hex head, 5/16"-1 8 x 3 " 39 Lockwa s he r, internal

Bolt, hex head, 5/16"-18 x 2 3/4" 79 Tube, Boom, 2" x 79 1/2"

Nut, hex, 5/16"-18 82 Mast Bracket, cast

Bolt

Lockwasher, s

Description No. Description

hex head, 5/16"-1 8 x 5 " 38 Nut, hex, 1/4"--20

hex head, 5/16"-1 8 x 3 3 / 4" 89 Clamp, Boom-to-Bracket

lit, 5/16" 90 Bracket, Casting-to-

"-

"

Figure 1 Boom-to-Mast

Assembly of the Elements-to-Boom

Front Driven

Select one pair of the largest element-toboom brackets (Item No. 85). These are

marked with a number 14. Assemble the

bracke ts on t he boom 20 i nc hes to th e l eft o f

the mast bracket (center-to-center). The

curved side of the mast bracket must be

facing you. Refer to Figure 3 for

identification of hardware. DO NOT

Rear Driven

Select another pair of the largest elementtoboom br ack ets (It em No. 8 5). As s embl e

these brackets on the boom 35 inches to the

right of the center of the mast bracket.

Refer to Figure 3. DO NOT tighten the

10-Meter Reflector:

Select a pair of the smallest element-toboom brackets (Item No. 83). These are

marked with a number 4. Assemble these

brackets on the boom 581/2 inches to the

right of the rear driven element brackets.

10-Meter Director.

Select another pair of the smallest elementto-boom bracket (Item No. 83). Assemble

these 44 1/2 inches to the left of the front

driven el em ent b rack et s. Refe r to Fig u res 3

15-Meter

g

g

p

10-20 Director and 15-20

Select another pair of the smallest element-

to-boom brackets (Item No. 83). Assemble

these 371/2 inches to the left of the 10-

meter director brackets. Refer to Figures 3

and 6. DO NOT ti

hten at this time.

Select two sets of medium sized elementtoboom brackets (Item No. 84) and loosely

assemble these on the boom ends. The front

set should be 39 1/2 inches to the left of the

15meter director brackets. The rear set

should be 48 inches to the right of the 10meter reflector brackets. Refer to Figures 3

and 6. DO NOT ti

hten now.

-

-

-

Item Item

No. Description

32 Bolt, hex h ead, 1/4"- 20 x 3/8"

34 Bolt, hex head, 1/4"-2 0 x 3/4"

37 Nut, square, 1/4"-2 0

38 Nut, hex, 1/4"-20 84 Bracket, Element-to-Boom, #13

No.

39

71

83

85 Bracket, Element-to-Boom, #14

Lockwasher, internal, 1/4"

Insulator, Driven Element

Bracket, Element-to-Boom, #4

Description

Figure 3 Element-to-

Boom Brackets

Remove the top anchor bolt from the 10meter director bracket. The beta tubes will be

installed over this bracket in a later ste

.

Installation of Tubing Clamps

p

Select the proper size tubing clamp as shown

in the chart. When installing the clamps, place

the clamp near the tube end with the top of the

clamp over the slot in the tube as shown in

Figure 4.

After adjustment of the tubing lengths, tighten

the clamp with a 5/16 inch nut driver, socket,

or open end wrench until the tubing will not

twist or telesco

e. DO NOT overtighten!

Element Assembl

y

s.

To take ad van tag e of t he b road ban d nat ur e of

the TH7DX, use the su ppl i ed di mens ions as

shown in Figure 6. If assembled correctly, the

VSWR will be below 2:1 on any frequency on

these 3 bands. However, if you wish to

optimize the TH7DX for the DX portions of

these 3 bands, use the following "DX setting"

for the RDE-2 and FDE-2 dimensions:

RDE-2 = 33" (83.8 cm)

FDE-2 = 42" (106.7

Use 10-meter trap, Part Number 878749, and

15 meter trap, Part Number 878637, in this

assembly. Make sure all insulators and trap

caps are firmly seated.

NOTE:

facing the ground and the trap labels should

be on the boom s id e of th e trap . Also , on al l

tubing attached to traps, make sure all slots

are facing the ground and the small drain

holes are aligned with the slots. See Figure 5.

The drain holes and slots should be

The DX se tt in g wi ll r es ul t in min imu m

VSWR at 14.150, 21.260 and 29.000 MHz.

However, VSWR near 14.350 and 29.700 may

be slightly above 2:1. The front-to-back ratio

and gain will not change.

The following steps will be in singular form.

Do each element assembly step, first for one

side of the boom and then for the other side.

The dimensions shown in Figure 6 are in

English uni ts on th e ri ght sid e and met ri c on

the left side. After each. element is assembled

to the boom, tighten the eight (8) 1/4"-20 x

3/4" bolts (Item No. 34). After all elements

are assembles, make sure that they all lie in a

horizontal plane, then tighten the anchor bolt

Select th e FD E-1 sect io n (1 1/ 4" x 35") and a

driven element insulator (see Figure 3). Slip

the DE insulator on the unslotted end of the

FDE1, then slip the insulated end of the FDE1 into the bracket which is 20 inches to the

left of t h e mas t b ra ck et. Tig h ten th e ei gh t (8 )

bolts to hold the element in place.

Install a No. 16 tubing clamp on the slotted

end of the FDE-1 and insert the unslotted end

of the FDE-2 (11/8" x 48") to the dimension

shown in Figure 6. Tighten th e No. 16 tubing

clamp securely and recheck the FDE-2

Assemble the remainder of the Front Driven

Element in the same manner using

dimensions from Figure 6. Use Figure 5 and

Detail A as guides.

Rear Driven Element

Select the RDE -2 s ec tion (1 1/ 4" x 48" ) and a

driven element insulator. Slip the DE

insulator on the unslotted end of the RDE-1,

then slip the insulated end of the RDE-1 into

the bracket which is 35 inched to the right of

the mast bracket. Make sure the insulator

seats completely onto the tube and into the

bracket. Tighten the eight (8) bolts to hold the

Install a No. 16 tubing clamp on the slotted

end of the RDE-1 and insert the unslotted end

of the DRE-2 (11/8" x 36") to the dimension

shown in Figure 6. Tighten the No. 16 tubing

clamp securely and recheck the RDE-2

dimension. Assemble the remainder of the

Rear Driven Element in the same manner

using dimensions from Figure 6. Use Figure 5

and Detail A as guides. Use the same traps as

on the Front Driven Element.

10-Meter Reflector Element

Select the R2-1 section (7/8" x 55") and slip

the unswaged end of the R2-1 completely into

the bracket (Item No. 83) assembled on the

boom 58 1/2" inches to the right of the RDE.

Tighten the eight (8) bolts to hold the element

onto the boom

Assemble the remainder of the 10-meter

reflector as shown in Figure 6 using No. 6

tubing clamps. Tighten all element tubing

clamps with the slots facing the ground and

recheck all dimension

-

Loading...

Loading...