Page 1

Filtromat

OF5F / OF5L

Operating and Maintenance Instructions

English (translation of original instructions)

Document No.: 3160337e

Page 2

OF5F / OF5L Trademarks

r

Trademarks

The trademarks of other companies are exclusively used for the products of those

companies.

Copyright © 2011 by HYDAC FILTER SYSTEMS GMBH all rights reserved

All rights reserved. This manual may not be reproduced in part or whole without the

express written consent of HYDAC FILTER SYSTEMS GMBH. Contraventions are

liable to compensation.

Exclusion of Liability

Wir haben unser Möglichstes getan, die Richtigkeit des Inhalts dieses Dokuments

zu gewährleisten, dennoch können Fehler nicht ausgeschlossen werden.

Consequently, we accept no liability for such errors as may exist nor for any damage

or loss whatsoever which may arise as a result of such errors. The content of the

manual is checked regularly. Any corrections required will be incorporated in future

editions. We welcome any suggestions for improvements.

All details are subject to technical modifications.

Technical specifications are subject to change without notice.

HYDAC FILTER SYSTEMS GMBH

Postfach 12 51

66273 Sulzbach / Saa

Germany

Documentation Representative

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Telephone: ++49 (0)6897 509 1511

Telefax: ++49 (0)6897 509 1394

E-mail: guenter.harge@hydac.com

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 2 / 36

Page 3

OF5F / OF5L Content

Content

Trademarks ...............................................................................................................2

Documentation Representative...............................................................................2

Content...................................................................................................................... 3

Preface ......................................................................................................................5

Customer Service ................................................................................................... 6

Modifications to the Product ...................................................................................6

Warranty ................................................................................................................. 6

Using the Documentation .......................................................................................7

Safety Information and Instructions....................................................................... 8

Obligations and Liability.......................................................................................... 8

Explanation of Symbols and Warnings, etc. ........................................................... 9

Proper/Designated Use ..........................................................................................9

Improper Use ........................................................................................................10

Informal Safety Precautions.................................................................................. 10

Structural modifications to the unit........................................................................ 10

Training and Instruction of Personnel ...................................................................11

Electrical Hazards................................................................................................. 11

Transporting the OF5............................................................................................. 12

Storing the OF5 ......................................................................................................12

Checking the Scope of Delivery............................................................................ 13

OF5 features ...........................................................................................................14

Items supplied....................................................................................................... 14

OF5 F.................................................................................................................... 14

OF5 L.................................................................................................................... 14

OF5 components/dimensions ............................................................................... 15

Hydraulic diagram ..................................................................................................16

OF5 L.................................................................................................................... 16

OF5F..................................................................................................................... 16

Preparing the OF5 for operation ........................................................................... 17

Inserting the filter element ....................................................................................17

Hanging / connecting the suction hose................................................................. 17

Hanging / connecting the pressure hose .............................................................. 17

Electrical connection of the OF5........................................................................... 18

Checking the direction of rotation ......................................................................... 18

Switching on the OF 5............................................................................................ 19

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 3 / 36

Page 4

OF5F / OF5L Content

Switchover mode.................................................................................................... 20

OF5 L.................................................................................................................... 20

OF5 F.................................................................................................................... 20

Setting the circulation pumping operating mode ...............................................21

Operating mode – circulation pumping and filtration......................................... 22

Performing Maintenance .......................................................................................23

Cleaningthe Suction Screen.................................................................................. 24

Changing the Filter Element.................................................................................. 26

Errors and Troubleshooting.................................................................................. 30

Spare Parts List ...................................................................................................... 31

Disposing of the OF5 .............................................................................................32

Technical data ........................................................................................................33

Model Code ............................................................................................................. 34

EC declaration of conformity ................................................................................ 35

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 4 / 36

Page 5

OF5F / OF5L Preface

Preface

For you, as the owner of a product manufactured by us, we have produced this

manual, comprising the most important instructions for its operation and

maintenance.

It will acquaint you with the product and assist you in using it as intended in an

optimal manner.

Keep it in the vicinity of the product so it is always available.

Note that the information on the unit's engineering contained in the documentation

was that available at the time of publication.There may be deviations in technical

details, figures, and dimensions as a result.

If you discover errors while reading the documentation or have additional comments

or suggestions, contact us at:

HYDAC FILTER SYSTEMS GMBH

Technische Dokumentation

Postfach 12 51

66273 Sulzbach / Saar

Germany

We look forward to receiving your input.

“Putting experience into practice”

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 5 / 36

Page 6

OF5F / OF5L Preface

Customer Service

Contact our technical sales department if you have any questions on our product.

When contacting us, please always include the model/type designation, serial no.

and part-no. of the product:

Fax: ++49 (0) 6897 / 509 – 846

E-mail: filtersystems@hydac.com

Modifications to the Product

We would like to point out that changes to the product (e.g. purchasing additional

options, etc.) may mean that the information in the operating instructions is no

longer applicable or adequate.

After modification or repair work that affects the safety of the product has been

carried out on components, the product may not be returned to operation until it has

been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product whether by

you or a third party.

Warranty

For the warranty provided by us, please refer to the General Terms of Sale and

Delivery of HYDAC Filter Systems GmbH.

Refer to these at www.hydac.com General terms and conditions.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 6 / 36

Page 7

OF5F / OF5L Preface

Using the Documentation

Note that the method described for locating specific information does

not release you from your responsibility of carefully reading these

instructions prior to starting the unit up for the first time and at regular

intervals in the future.

What do I want to know?

I determine which topic I am looking for.

Where can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Chapter description

Page number

Edition date

Documentation no.

with index/

file name

Document language

The documentation number with its index enables you to order another copy of the

operating an

d maintenance instructions. The index is incremented every time the

manual is revised or changed.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 7 / 36

Page 8

OF5F / OF5L Safety Information and Instructions

Safety Information and Instructions

These operating instructions contain the most important information for operating

the OF in a proper, safe manner.

Obligations and Liability

The basic prerequisite for the safe and proper handling and operation of the unit is

knowledge of the basic safety instructions and safety regulations.

These operating instructions in general, and the safety instructions in particular, are

to be adhered by all those who work with the unit.

Adherence is to be maintained to pertinent accident prevention regulations

applicable at the site where the product is used.

The safety instructions listed here are restricted to use of the unit.

The OF has been designed and constructed in accordance with the current state of

the art and recognized safety regulations. Nevertheless, hazards may be posed to

the life and limb of the individual using the product or to third parties. Risk of

damage may be posed to the product or other equipment and property.

Ensure that the unit is used:

solely for its designated use

only when in a safe, perfect condition

Immediately remedy any malfunctions that might impair safety.

Our General Terms and Conditions apply. They are made available to the owner

upon concluding purchase of the unit at the latest. Any and all warranty and liability

claims for personal injuries and damage to property shall be excluded in the event

they are attributable to one or more of the following causes:

improper use of the unit or use deviating from its designated use

improper assembly/installation, start up, operation and maintenance of the unit

operating the OF when the system equipment or systems are defective

modifications made by the user or purchaser

Improper monitoring of unit components that are subject to wear and tear

improperly performed repair work

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 8 / 36

Page 9

OF5F / OF5L Safety Information and Instructions

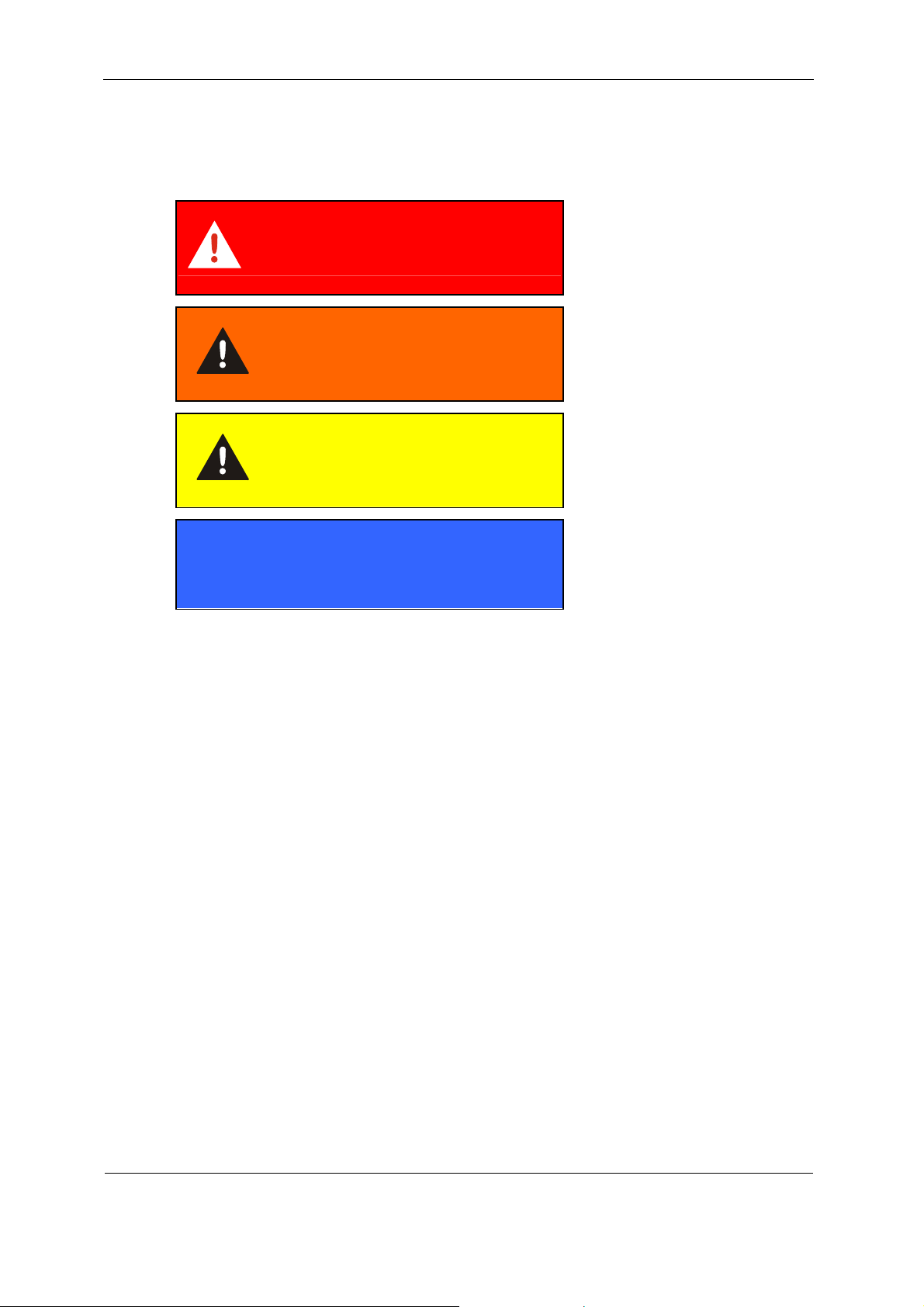

Explanation of Symbols and Warnings, etc.

The following designations and symbols are used in this manual to designate

hazards, etc.:

DANGER denotes situations

which can lead to death if

DANGER

WARNING

CAUTION

NOTICE

safety precautions are not

observed.

WARNING denotes situations

which can lead to death if

safety precautions are not

observed.

CAUTION denotes situations

which can lead to severe

injuries if safety precautions

are not observed.

NOTICE denotes situations

which can lead to property

damage if safety precautions

are not observed.

Proper/Designated Use

The unit is a mobile filter unit used for simultaneously circulating and filtering oil.

Any other use shall be deemed to be improper and not in keeping with the product's

designated use.

The manufacturer will not assume any liability for any damage resulting from such

use.

Proper or designated use of the product extends to the following:

Maintaining adherence to all the instructions contained herein.

Performing requisite inspection and maintenance work.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 9 / 36

Page 10

OF5F / OF5L Safety Information and Instructions

Improper Use

Any use deviating from the proper/designated use described above is prohibited.

Improper use may result in hazard to life and limb.

Example of improper use:

Commissioning without a suction strainer

Operation with non-approved fluids

Informal Safety Precautions

Make sure to always keep the operating instructions in the vicinity of the unit.

Apart from the operating instructions, any and all general and local regulations

pertaining to accident prevention and environmental protection are to be made

available and observance is to be maintained to them.

Make sure to keep the safety and hazard symbols and warnings on the product in a

legible condition.

Structural modifications to the unit

Do not make any modifications (design modifications, extensions) to the OF without

the approval of the manufacturer.

Immediately replace any unit components which are not in perfect condition.

Only use original (OEM) spare parts and consumables. When using non-OEM

components it cannot be ensured that they have been designed and manufactured

so as to comply with loading and safety requirements.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 10 / 36

Page 11

OF5F / OF5L Safety Information and Instructions

I

di

id

l

ith

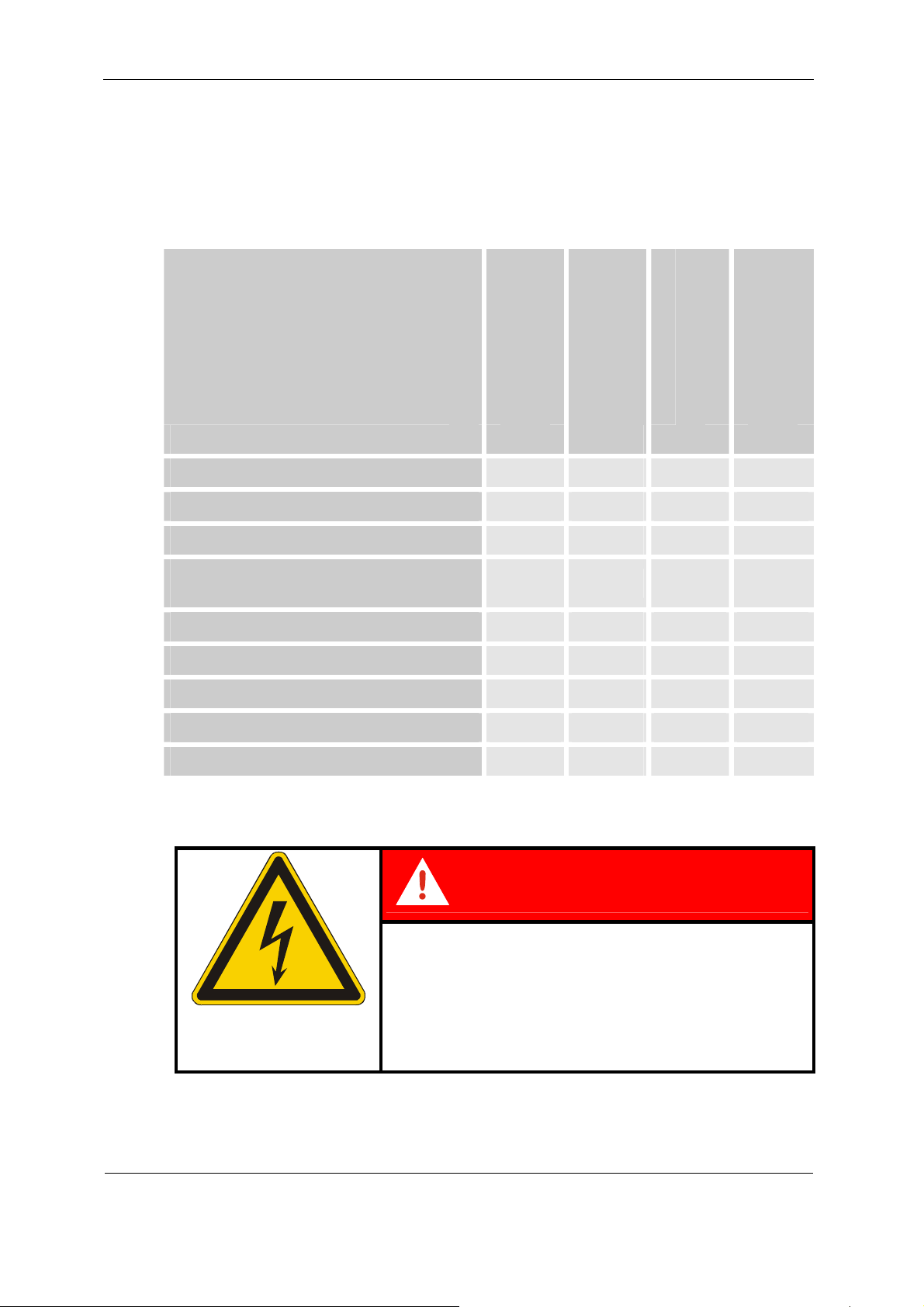

Training and Instruction of Personnel

The OF may only be operated by properly trained and instructed personnel. The

areas of responsibility of your staff must be established in a clear-cut manner.

Staff undergoing training may not use the OF unless supervised by an experienced

staff member.

s w

ua

v

undergoing training

n

technical training/

engineering

background

Electrician

Supervisor with the

appropriate authority

Activity

Individuals

Individuals

Packing / transportation

Commissioning

Operation

Troubleshooting/

locating the source of malfunction

Remedying of mechanical faults

Remedying of electrical faults

Maintenance

Repair work

Decommissioning / Storage

Electrical Hazards

X X X

X X X

X X X X

X X X

X X

X X

X X X X

X

X X X X

DANGER

Electric shock

Danger of fatal injury

► Pull power plug before performing any work.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 11 / 36

Page 12

OF5F / OF5L Transporting the OF5

Transporting the OF5

Transport the unit upright on the built-in

wheels or by rolling it.

Storing the OF5

Remove the filter element and drain the unit completely before putting it into

storage.

Pull out the power plug to the unit and wind up the power cord.

Wind up the suction and pressure hoses and secure them to the unit.

Store the unit upright in a clean, dry

place.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 12 / 36

Page 13

OF5F / OF5L Checking the Scope of Delivery

Checking the Scope of Delivery

The filtration unit is supplied ready for connection and immediate operation with

hoses and a mains connection.

Check the unit for damage upon delivery. A unit may only be put into operation if it

shows no signs of damage. Report any damage in transit to the forwarding agent or

responsible party.

The following items are supplied:

Item Qty. Description

1 1 OF5 with power cable, suction hose and pressure hose

2 1 Filter element

- 1 Operating and Maintenance Instructions

1

2

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 13 / 36

Page 14

OF5F / OF5L OF5 features

OF5 features

The filtration unit OF 5 mobile is designed for the filling of hydraulic tanks, whilst

simultaneously filtering the fluid. It also provides offline filtration and can be used for

draining hydraulic tanks as well as for pumping out hydraulic and lubrication oils

without filtration.

Items supplied

NOTICE

Impermissible operating media

The unit will be damaged

► The unit is only to be used with mineral oils or mineral oil-based raffinates.

OF5 F

OF5 L

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 14 / 36

Page 15

OF5F / OF5L OF5 components/dimensions

OF5 components/dimensions

7 8

6

Item Designation

10

12

9

11

45

2

1

3

1 Filter housing

2 Filter cover

3 Draining

4 Suction hose

5 Pressure hose

6 Floor plate with oil pan

7 Manometer

8 Star knob

9 Power cable

10 Lever

11 Switchover via three-way ball valve (OF 5 F only)

12 Motor Protection Switch

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 15 / 36

Page 16

OF5F / OF5L Hydraulic diagram

Hydraulic diagram

OF5 L

OF5F

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 16 / 36

Page 17

OF5F / OF5L Preparing the OF5 for operation

Preparing the OF5 for operation

Consult and observe the following chapter in order to prepare the OF5 for operation.

Inserting the filter element

The unit has no filter element installed upon delivery from the factory. Prior to start

up, check to see whether a filter element is contained in the filter housing.

Information on changing a filter element can be found on page 26.

Hanging / connecting the suction hose

NOTICE

Severe contamination

The unit will be destroyed

► Do not prime directly at the bottom of the tank (in the sump).

The greatest contamination is found on the bottom of the tank. All

impurities and other particles are deposited on the bottom of the tank.

Pull the suction hose (thick hose) with lance out of the mounting in the floor plate.

Put the suction hose with lance, without tension and or twist, into the appropriate

container and secure it.

Hanging / connecting the pressure hose

Pull out the pressure hose (thin hose) with lance from the mounting in the floor plate

and insert it in the appropriate receptacle.

Put the pressure hose with lance, without tension and or twist, into the appropriate

container and secure it.

To prevent air from entering the medium, make sure that the pressure

hose with lance is always below the oil level in operation.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 17 / 36

Page 18

OF5F / OF5L Preparing the OF5 for operation

Electrical connection of the OF5

Check or compare the local mains voltage and frequency specifications with the

specifications on the type label of the unit.

Plug the power plug of the OF5 into a suitable power outlet.

The unit has a motor protection switch in the on / off switch. If the nominal current is

exceeded, the motor protection switch trips.

Checking the direction of rotation

Check the direction of rotation of the motor by switching it on briefly (jog mode). An

arrow on the fan cover shows the correct direction of rotation for the unit.

If the direction of rotation is opposite to the direction of the arrow, correct it using the

phase inverter contained in the connection plug, as shown in the diagram below.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 18 / 36

Page 19

OF5F / OF5L Switching on the OF 5

Switching on the OF 5

After switching on the OF5, monitor the suction action via the transparent suction

hose.

If the unit is not feeding medium after several minutes of operation, the pump must

be pre-filled. Switch the motor off and fill the pump via the suction hose.

The special element receptacle renders it unnecessary to vent the filter housing.

Pay particular attention to the clogging indicator during operation. As soon as the

clogging indicator enters the red zone, the filter element must be changed

immediately.

The pressure relief valve in the pump returns the medium to the suction side if the

maximum operating pressure is exceeded.

The motor protection switch contained in the main switch permanently monitors the

nominal current and switches the unit off in case of overload.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 19 / 36

Page 20

OF5F / OF5L Switchover mode

Switchover mode

OF5 L

The oil service unit OF 5 L has no facility for switching between operating modes.

Operate this unit in the circulation pumping and filtration mode.

OF5 F

The oil service unit OF 5 F has the following two modes.

- Transfer by Pumping

- Circulation pumping and filtration

You can switch between the different operating modes via the internal and external

switchovers.

Internal switchover:

Unlock the change-over valve by pulling

on the locking pin (x).

External switchover:

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 20 / 36

Page 21

OF5F / OF5L Switchover mode

Setting the circulation pumping operating mode

For the circulation pumping operating mode, the switchovers must be set as follows:

Internal switchover:

External

switchover:

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 21 / 36

Page 22

OF5F / OF5L Switchover mode

Operating mode – circulation pumping and filtration

For the circulation pumping and filtration operating mode, the switchovers must be

set as follows:

Internal switchover:

External

switchover:

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 22 / 36

Page 23

OF5F / OF5L Performing Maintenance

Performing Maintenance

WARNING

The unit is pressurized

Danger of bodily injury

► Depressurize the system before performing any

work on it.

DANGER

Electric shock

Danger of fatal injury

► Disconnect the power plug before performing

any work on the unit.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 23 / 36

Page 24

OF5F / OF5L Cleaningthe Suction Screen

Cleaningthe Suction Screen

NOTICE

Operation without a suction screen

The unit will be destroyed

► Never operate the filtration unit without a suction screen.

► Clean the suction screen regularly.

To protect the pump from coarse contamination or foreign bodies, a suction screen

is installed in the suction lance. Clean the suction screen regularly and check it

immediately in the event of insufficient suction or delivery action.

6

5

Item Description

1

2

3

4

5

6

Hose

Suction lance

O-ring

Suction screen

Protection pipe

Suction strainer set

1

2

3

4

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 24 / 36

Page 25

OF5F / OF5L Cleaningthe Suction Screen

To clean the suction screen, proceed as follows:

6

1

2

3

4

5

1. Rotate the protection pipe (5) away from the suction lance (2) in a clockwise

direction.

2. Remove the suction screen (4) from the protection pipe.

3. Clean the suction screen (4) by washing it out and then blowing it dry with

compressed air.

4. Insert the suction screen (4) into the protection pipe (5) with the tip facing

forwards.

5. Screw the protection pipe (5) on to the suction lance (2) in a

counterclockwise direction.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 25 / 36

Page 26

OF5F / OF5L Changing the Filter Element

Changing the Filter Element

NOTICE

Unsuitable/incorrect filter element

The medium is not filtered

► Use only filter elements with the type code suffix -KB

(for example: 1300 R 003 BN4HC /-KB)

Depending on the version, the unit has an optical back-pressure indicator (2)

(red/green) or a scale in the filter cover. The version with switchover may have an

optional differential pressure gauge (1).

Change the filter element as soon as the back-pressure indicator or differential

pressure gauge is in the red area.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 26 / 36

Page 27

OF5F / OF5L Changing the Filter Element

To change the filter, proceed as follows:

1. Switch the unit off.

2. Depressurize the filter housing.

Remove the air bleed plug (1) in the

filter cover for this purpose.

The residual oil is drained through the

drain ball valve (2) into a suitable

container.

3. Loosen the four screws on the cover

counterclockwise.

4. Fold the screws down and press them

against the filter housing.

This pushes the cover of the filter

housing up.

5. Take the cover off and remove the

filter element.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 27 / 36

Page 28

OF5F / OF5L Changing the Filter Element

6. Clean:

the inside of the filter bowl of

coarse dirt

the sealing surfaces on the filter

head and on the cover.

7.

For easier installation of the

filter element, wet the O-ring on the

filter element with the operating

medium.

8. Press the new filter element down into

the filter mount by turning it slightly.

Do not use excessive force or a

hammer, etc.

9. Check the O-ring on the cover for

damage and replace it if necessary.

Lightly wet the O-ring on the cover

with medium.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 28 / 36

Page 29

OF5F / OF5L Changing the Filter Element

10. Put the cover on.

Observe correct placement of the

O-ring on the filter cover while doing

so. It must not be damaged.

11. Fold the four screws up and turn them

clockwise evenly crosswise.

12. Close the drain valve.

13. Switch the unit on.

14. Check the unit for any leaks.

15. The unit is ready for operation.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 29 / 36

Page 30

OF5F / OF5L Errors and Troubleshooting

Errors and Troubleshooting

Error Cause(s) Remedy

Differential pressure > 2.5

bar

The fluid is heavily

contaminated.

The contamination

retention capacity of the

filter element has been

reached.

The viscosity of the fluid is

too high.

No flow

The pump is conveying in

the wrong direction.

The suction hose is

positioned above the fluid.

No function No electrical connection.

No voltage available.

Replace the filter element.

Replace the filter element.

Warm the oil.

Check the direction of

rotation of the motor. If

necessary, rotate the

phases using the phase

inverter in the connection

plug.

Sufficiently immerse the

suction hose in the

medium.

Check the electrical

connection; plug, cable

and socket.

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 30 / 36

Page 31

OF5F / OF5L Spare Parts List

Spare Parts List

Description Part no.

Suction strainer set for suction lance

Suction screen for suction lance

Filter element 0330 R 003 BN4HC/-V-KB

Filter element 0330 R 003 BN4HC/-KB

Filter element 0330 R 005 BN4HC/-KB

Filter element 0330 R 005 BN4HC/-V-KB

FFiilltteerr eelleemmeenntt

00333300 RR 001100 BBNN44HHCC//--KKBB

Filter element 0330 R 010 BN4HC/-V-KB

Filter element 0330 R 020 BN4HC/-KB

Filter element 0330 R 020 BN4HC/-V-KB

Filter element 0330 R 040 AM/-KB

Filter element 0330 R 040 AM/-KB

Filter element 0330 R 003 BN/AM/-KB

Filter element 0330 R 003 BN/AM/-V-KB

349759

250 µm 380385

3 µm NBR 1262999

3 µm FPM 1263640

5 µm NBR 1263000

5 µm FPM 1263641

1100 µµmm

NNBBRR

1263001

10 µm FPM 1263642

20 µm NBR 1263002

20 µm FPM 1263643

40 µm NBR 1272067

40 µm FPM 1266563

3 µm NBR 1272069

3 µm FPM 1276690

Filter element 0330 R 010 BN/AM/-KB

Filter element 0330 R 010 BN/AM/-V-KB

Filter element 1300 R 003 BN4HC/-KB

Filter element 1300 R 003 BN4HC/-V-KB

Filter element 1300 R 005 BN4HC/-KB

Filter element 1300 R 005 BN4HC/-V-KB

Filter element 1300 R 010 BN4HC/-KB

Filter element 1300 R 010 BN4HC/-V-KB

Filter element 1300 R 020 BN4HC/-KB

Filter element 1300 R 020 BN4HC/-V-KB

Filter element 1300 R 040 AM/-KB

Electric motor 230V / 50Hz, 1 Ph

Electric motor 400V / 50Hz, 3 Ph

10 µm NBR 1272068

10 µm FPM 301227

3 µm NBR 1263059

3 µm FPM 1263760

5 µm NBR 1263060

5 µm FPM 1263761

10 µm NBR 1263061

10 µm FPM 1263762

20 µm NBR 1263062

20 µm FPM 1263763

40 µm NBR 1267699

3041675

3038709

Vane pump 80/20

NBR 721206

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 31 / 36

Page 32

OF5F / OF5L Disposing of the OF5

Description Part no.

Vane pump

Vane pump

Vane pump

Pressure hose

Pressure hose

Pressure hose

Suction hose

Suction hose

Dynamic pressure gauge

Dynamic pressure gauge

Differential pressure gauge - version 1

Differential pressure gauge - version 1

Differential pressure gauge - version 2

Differential pressure gauge - version 2

90/30 FPM 721207

80/20 NBR 721317

90/30 FPM 721281

L= 3 m 381465

L= 5 m 349004

L= 10 m 91061

L= 3 m 381464

L= 5 m 349070

Green/red 36198

0 - 16 bar 39173

VM 2 B.1 NBR 303191

VM 2 B.1 FPM 303197

VM 2 C.0 NBR 311645

VM 2 C.0 FPM 304632

Differential pressure gauge - version 3 (230V)

Differential pressure gauge - version 3 (230V)

Differential pressure gauge - version 3 (24V)

Differential pressure gauge - version 3 (24V)

Disposing of the OF5

When decommissioning and/or disposing of the unit, observe all local guidelines and

regulations pertaining to occupational safety and environmental protection. This

applies in particular to the oil contained in the unit, to components coated in oil and

to electronic components.

After disassembling the unit and separating the various materials, reuse them or

dispose of them properly in accordance with local regulations.

VM 2 D.0 NBR 307847

VM 2 D.0 FPM 304651

VM 2 D.0 NBR 312682

VM 2 D.0 FPM 316556

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 32 / 36

Page 33

OF5F / OF5L Technical data

Technical data

Power supply voltage

Power consumption

Maximum flow rate

Pump types

Operating pressure

Permissible suction pressure at suction

port

Viscosity range

Fluid temperature

Ambient temperature

Seals, gaskets

1x 230V, 50 Hz

3x 380 / 420V, 50 Hz

3x 500 / 600V, 50 / 60 Hz

0.75 kW

1.5 kW

30 l/min

40 l/min

Vane pump

4.5 bar max.

-0.4 – +0.6 bar

15 … 250 mm²/s

15 … 800 mm²/s

-10 … +80°C

-10 … +40°C

NBR / FPM

IP class

Power cable, length

Length of suction / pressure hose

Hose connections

Weight

Filter element type

Filter element size

Clogging indicator

IP 54

6 m

3 m (standard)

Suction hose NW30 with lance

Pressure hose NW 25 with lance

~ 75 kg

Betamicron (BN4HC)

Aquamicron (BN/AM)(AM)

0330 / 1300

Differential pressure gauge

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 33 / 36

Page 34

OF5F / OF5L Model Code

Model Code

OF5 F 10 P 6 N 2 B 05 E

Basic type

OF 5

Version

F = Mobile with switchover

L = Mobile without switchover

Type code

10 = Standard

Special models on request

Sealing material

P = NBR (Perbunan)

V = FPM (Viton)

Motor-pump group

3 = 30 l/min / to max. 250 mm²/s / 0.5 kW

4 = 40 l/min / to max. 800 mm²/s / 1.5 kW

Electromotor voltage

M = 230 V / 50 Hz (1 Ph + PE)

N = 380 - 420 V / 50 Hz (3 Ph + PE)

440 - 480 V / 60 Hz (3 Ph + PE)

S = 500 - 600 V / 50 Hz (3 Ph + PE)

500 - 600 V / 60 Hz (3 Ph + PE)

X = other voltage

Filter size

1 = Filter size 0330

2 = Filter size 1300

Filter material of element

B = Betamicron (BN4HC)

A = Aquamircon (BN/AM), (AM)

Filtration rating

03 = 3 µm BN4HC, BN/AM

05 = 5 µm BN4HC, BN

10 = 10 µm BN4HC, BN/AM

20 = 20 µm BN4HC, BN

40 = 40 µm, AM

Clogging indicator

E = Standard, pressure gauge

B = Differential pressure indicator - visual (VM2B.1)

C = Differential pressure indicator - electrical (VM2C.0)

D = Differential pressure indicator, visual/electrical (VM2D.0)

B, C and D not available for version "L"

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 34 / 36

Page 35

OF5F / OF5L EC declaration of conformity

EC declaration of conformity

HYDAC FILTER SYSTEMS GMBH

Postfach 12 51

66273 Sulzbach / Saar

Germany

Industriegebiet

66280 Sulzbach / Saar

Germany

Telefon: ++49 (0) 6897 509 01

Internet: www.hydac.com

EC declaration of conformity FS / 37 / 09

No.

We hereby declare that the following designated product, on the basis of its design and

construction, and in the version which we have brought to market, corresponds to the

fundamental safety and health requirements contained in the standards listed below.

Any modification of this product that is not coordinated with us in writing will cause this

declaration to lose its validity.

Designation Filter aggregate

Type OF 5 mobile series

Part no. -

Serial-no. -

EU Machinery Directive 2006/42/EC

EU Electrical Equipment Regulations 2006/95/EC

EMC Guideline 2004/108/EC

Safety of machinery and devices EN 12100-1/2

2009-12-22 Dr. Andreas Schunk

Date Name (CE-authorized person)

Executive director: Documentation Representative:

Mathias Dieter, Dipl.Kfm. Wolfgang Haering Mr. Günter Harge

Registered seat of company: 66280 Sulzbach / Saar - Germany c/o HYDAC International GmbH, Industriegebiet , 66280 Sulzbach / Saar

Registry Court: Saarbrücken, HRB 17216 Telephone: ++49 (0) 6897 509 1511

Value added tax identification number : DE 815001609 Fax: ++49 (0) 6897 509 1394

Tax number : 040/110/50773 E-mail: guenter.harge@hydac .com

Page 1 / 1

HYDAC FILTER SYSTEMS GMBH

BeWa OF5 F_L 3160337e en-us 2011-01-17.doc 2011-01-17

en(us)

Page 35 / 36

Page 36

HYDAC FILTER SYSTEMS GMBH

Industriegebiet Postfach 1251

66280 Sulzbach/Saar 66273 Sulzbach/Saar

Germany Germany

Phone: +49 (0) 6897 509 01 Central

Fax: +49 (0) 6897 509 846 (Technical Department)

Fax: +49 (0) 6897 509 577 (Sales Department)

Internet: www.hydac.com

E-Mail: filtersystems@hydac.com

Loading...

Loading...