Page 1

MM-KKE-M-C-U

Measuring

microscope

Operating and Maintenance Instructions

English (translation of original instructions)

Document no.: 3239239b

Page 2

MM-KKE-M-C-U Trademarks

r

Trademarks

The trademarks of other companies are exclusively used for the products of those

companies.

Copyright © 2011 by HYDAC Filter Systems GmbH all rights reserved

All rights reserved. This manual may not be reproduced in part or whole without the

express written consent of HYDAC FILTER SYSTEMS GMBH. Contraventions are

liable to compensation.

Exclusion of Liability

We have made every endeavor to ensure the accuracy of the contents of this

document. However, errors cannot be ruled out. Consequently, we accept no

liability for such errors as may exist nor for any damage or loss whatsoever which

may arise as a result of such errors. The content of the manual is checked regularly.

Any corrections required will be incorporated in future editions. We welcome any

suggestions for improvements.

All details are subject to technical modifications.

Technical specifications are subject to change without notice.

HYDAC FILTER SYSTEMS GMBH

Postfach 12 51

66273 Sulzbach / Saa

Germany

Documentation Representative

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Telephone: ++49 (0)6897 509 1511

Telefax: ++49 (0)6897 509 1394

E-mail: guenter.harge@hydac.com

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 2/32

Page 3

MM-KKE-M-C-U Content

Content

Trademarks ...............................................................................................................2

Documentation Representative...............................................................................2

Content...................................................................................................................... 3

Preface ......................................................................................................................4

Technical Support................................................................................................... 5

Modifications to the Product ...................................................................................5

Warranty ................................................................................................................. 5

Using the Documentation .......................................................................................6

Safety information and instructions....................................................................... 7

Obligations and liability ...........................................................................................7

Explanation of Symbols and Warnings, etc. ........................................................... 8

Proper/Designated Use ..........................................................................................8

Improper Use ..........................................................................................................8

Transporting the microscope.................................................................................. 9

Storing the microscope ...........................................................................................9

Checking the Scope of Delivery............................................................................ 10

Microscope features ..............................................................................................11

System requirements............................................................................................ 11

Components on the microscope...........................................................................12

Installing the microscope ...................................................................................... 16

Assembling the illuminator (cold light source) ................................................... 17

Installing and setting the camera .........................................................................19

Installing the image processing software.............................................................. 20

Operating the microscope..................................................................................... 21

Performing a measurement................................................................................... 22

Evaluating a filter membrane / sample................................................................. 23

Performing Maintenance .......................................................................................24

Cleaning / maintaining the microscope................................................................. 24

Replacing the bulb on the microscope.................................................................. 25

Replacing the illuminator bulb............................................................................... 27

Disposing of your microscope.............................................................................. 28

Model Code ............................................................................................................. 29

Technical Data ........................................................................................................30

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 3/32

Page 4

MM-KKE-M-C-U Preface

Preface

For you, as the owner of a product manufactured by us, we have produced this

manual, comprising the most important instructions for its operation and

maintenance.

It will acquaint you with the product and assist you in using it as intended in an

optimal manner.

Keep it in the vicinity of the product so it is always available.

Note that the information on the unit's engineering contained in the documentation

was that available at the time of publication.There may be deviations in technical

details, figures, and dimensions as a result.

If you discover errors while reading the documentation or have additional comments

or suggestions, contact us at:

HYDAC FILTER SYSTEMS GMBH

Technische Dokumentation

Postfach 12 51

66273 Sulzbach / Saar

Germany

We look forward to receiving your input.

“Putting experience into practice”

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 4/32

Page 5

MM-KKE-M-C-U Preface

Technical Support

If you have any questions, suggestions, or encounter any problems of a technical

nature, please don't hesitate to contact us. When contacting us, please always

include the model/type designation, serial no. and part-no. of the product:

Fax: ++49 (0) 6897 / 509 - 846

E-mail: filtersystems@hydac.com

Modifications to the Product

We would like to point out that changes to the product (e.g. purchasing options, etc.)

may result in the information in the operating instructions no longer being completely

accurate or sufficient.

After modification or repair work that affects the safety of the product has been

carried out on components, the product may not be returned to operation until it has

been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product whether by

you or a third party.

Warranty

For the warranty provided by us, please refer to the General Terms of Sale and

Delivery of HYDAC FILTER SYSTEMS GmbH.

They are available at: www.hydac.com -> Legal information.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 5/32

Page 6

MM-KKE-M-C-U Preface

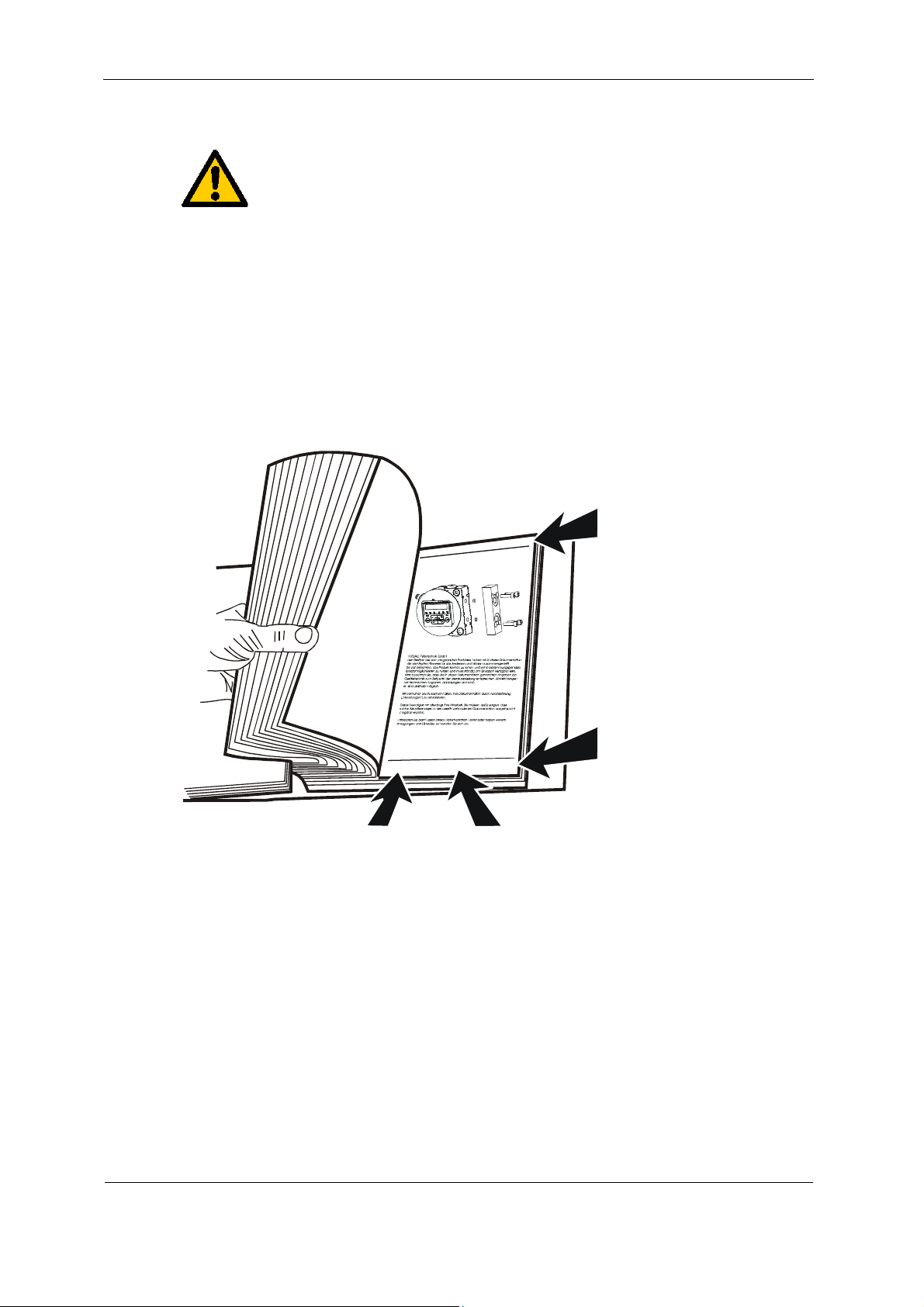

Using the Documentation

Note that the method described for locating specific information does

not release you from your responsibility of carefully reading these

instructions prior to starting the unit up for the first time and at regular

intervals in the future.

What do I want to know?

I determine which topic I am looking for.

Where can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Chapter description

l

t

e

i

p

a

K

t

/

k

d

u

o

P

r

Page number

i

l

t

e

t

e

c

r

h

n

i

k

G

m

b

H

H

Y

D

C

A

F

B

2

a

1

4

e

a

d

3

6

W

5

de

e

200x-xx-xx

Seite x

Edition date

Documentation no.

Document language

with index/

file name

The documentation number with its index enables you to order another copy of the

operating and maintenance instructions.

The index is incremented every time the manual is revised or changed.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 6/32

Page 7

MM-KKE-M-C-U Safety information and instructions

Safety information and instructions

These operating instructions contain the key instructions for properly and safely

operating the measuring microscope.

Obligations and liability

The basic prerequisite for the safe and proper handling and operation of the

measuring microscope is knowledge of the safety instructions and warnings.

When handling the measuring microscope, please observe in particular these

operating and maintenance instructions, in particular the rules and regulations on

accident prevention applicable for the place of operation.

The measuring microscope has been designed and constructed in accordance with

current state of the art technology and recognized safety regulations. Nevertheless,

hazards may be posed to the life and limb of the individual using the unit, or the

ROCS or other material assets may be damaged.

Only use the measuring microscope as follows:

Only for proper or designated use.

Only when in safe, perfect condition.

Immediately remedy any malfunctions that might impair safety.

Our General Terms and Conditions apply. Any and all warranty and liability claims

for personal injuries and damage to property shall be excluded in the event they are

attributable to one or more of the following causes.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 7/32

Page 8

MM-KKE-M-C-U Safety information and instructions

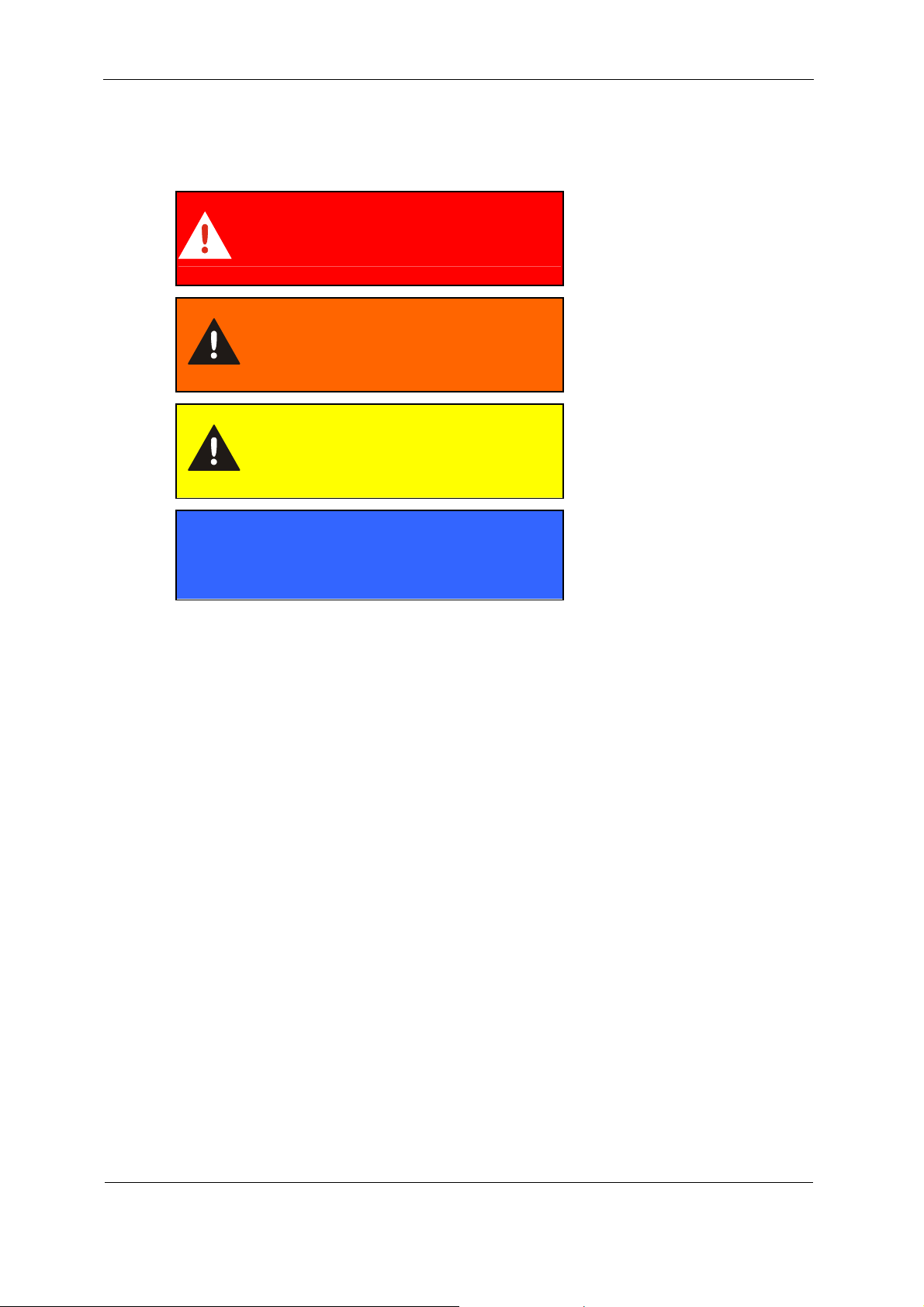

Explanation of Symbols and Warnings, etc.

The following designations and symbols are used in this manual to designate

hazards, etc.:

DANGER denotes situations

which can lead to death if

DANGER

WARNING

CAUTION

NOTICE

safety precautions are not

observed.

WARNING denotes situations

which can lead to death if

safety precautions are not

observed.

CAUTION denotes situations

which can lead to severe

injuries if safety precautions

are not observed.

NOTICE denotes situations

which can lead to property

damage if instructions are not

followed.

Proper/Designated Use

Use the measuring microscope for optical evaluation of filter membranes and for the

enlargement / visualization of particles etc.

Analyzing the type, size and quantity of contamination enables quality standards to

be verified and documented, and the requisite optimization measures to be

implemented.

Improper Use

Never look into the sun /sunlight using the microscope. This may damage your

eyesight.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 8/32

Page 9

MM-KKE-M-C-U Transporting the microscope

Transporting the microscope

NOTICE

Transporting the microscope without a transport container

The measuring microscope will be damaged.

► Transport the measuring microscope only in a closed transport container;

carry it in vertical position or by the handle.

Storing the microscope

NOTICE

Storing the microscope without a transport container

The measuring microscope will be damaged.

► Store the microscope in a clean and dry location in its closed transport case

and in a horizontal or vertical position. The microscope must not be exposed

to any shaking or vibration.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 9/32

Page 10

MM-KKE-M-C-U Checking the Scope of Delivery

Checking the Scope of Delivery

The measuring microscope comes packed and partially factory-assembled. Before

commissioning, check the contents of the package to make sure it has not been

damaged during transport and that it is complete.

The following items are supplied:

Item Qty Description

1 1 Microscope stand with trinocular optical head, specimen stage,

objective lens turret and illuminator

2 2 Eyepiece

3 1 Objective lens 4:1 (already mounted on the objective lens turret)

4 1 Objective lens 10:1 (already mounted on the objective lens turret)

5 1 Objective lens 20:1 (already mounted on the objective lens turret)

6 2 Connection cable, L=1.5 m

7 1 Camera with micrometer eyepiece

8 1 Power supply for camera

9 1 S-VHS connection cable, L = 5 m

10 1 Cold light illuminator, 100 W

11 1 Fiber optic gooseneck, dual-arm

12 1 WinTV USB (external TV card) including

USB connection cable, L=1.8 m

13 1 CD-ROM containing the software for on-screen image viewing

14 1 Transport case

- 1 Replacement bulb, replacement fuse, ground glass plate (transparent /

blue-tinted)

1

14

8

10

11

9

12

13

6

2

7

6

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 10/32

Page 11

MM-KKE-M-C-U Microscope features

Microscope features

The microscope system consists of a trinocular microscope which is used with an

external cold light illuminator in incident light mode to examine the filter membranes

of oil samples. The microscope enables you to examine filter membranes with a

selectable magnification of 40x, 100x and 200x via a stereo microscope.

You can also examine filter membranes using the image processing system. The

image processing system consists of a CCD color camera and an external video/TV

tuner which is connected to your PC via the USB (Universal Serial Bus ) port.

The measurement scale integrated into the camera eyepiece enables the size of the

particles being examined to be precision-determined. The conversion table in mm

per graduation mark on the objective lens can be found on page 23.

The images recorded via the PC can be postprocessed as b

in MS-Word documents, for example.

System requirements

The following system requirements must be fulfilled for the installation:

Operating system: Windows 98, ME, 2000, XP, VISTA or 7

Hardware: Pentium 800 MHz

Free USB port 2.0

CD-ROM drive

itmaps and embedded

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 11/32

Page 12

MM-KKE-M-C-U Components on the microscope

Components on the microscope

Item Description

1 Camera with micrometer eyepiece

2 Switch-over between binocular / camera eyepiece

3 Power connection

4 Power switch for internal lighting

5 Illumination intensity adjustment dial for internal lighting

6

Adjustment lever for limiting the height setting of the x/y mechanical

stage

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 12/32

Page 13

MM-KKE-M-C-U Components on the microscope

Item Description Description

a) Eyepieces The eyepieces project the intermediate image on

the viewer's retina. Consequently it is the interface

between the microscope and the user.

b) Tube In this case the trinocular tube contains special

prisms which split the image produced by the

objective lens and supply the intermediate image to

both eyepieces.

In order to use the camera eyepiece the tube slider

has to be pulled out.

c) Dovetail ring Enables components to be quickly changed, in

addition to providing for a swivel range of 360°.

d) Stand Carries all components. Main components: arm and

base.

e) Objective lens turret

and objective lenses

The turret contains specially sized holes with an

internal thread for mounting the objective lenses. In

so doing it enables the objective lenses to be

"swiveled" into place.

f) Specimen stage

including x/y

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

The specimen stage generally consists of a square

shaped plate featuring a hole or slit in the center

en

Page 13/32

Page 14

MM-KKE-M-C-U Components on the microscope

Item Description Description

mechanical stage through which the light from the light source can

shine for the purpose of illuminating the specimen.

The specimen slides are therefore guided precisely

using the x/y mechanical stage adjustment knob.

g) X/y mechanical

stage

Like the height adjustment of the specimen stage,

the x/y mechanical stage is equipped with a

precision mechanism, enabling the specimens to be

micrometer-precision-guided under the objective

lens even at large magnifications by virtue of the x/y

mechanical stage adjustment knob. The microscope

has a specimen clamp. The specimen slides are

clamped beneath it.

h) X/y mechanical

stage adjustment

knob

The two adjustment knobs enable the microscope to

be operated using one hand, with the lower knob

being used for horizontal adjustment and the upper

knob for vertical adjustment.

i) Condenser In addition to the eyepieces, prisms and objective

lenses it is the fourth optical component of the

microscope and important for illuminating the

specimen. The specimen could not be properly

illuminated without it.

The condenser is located underneath the specimen

stage and consists of a lens system and an iris stop,

or aperture diaphragm. The condenser serves to

optimally collect the microscope light for the

respective objective lens. When the aperture is

opened, resolution increases while contrast

decreases. The opposite effect is created when it is

closed, i.e. resolution decreases while contrast

increases. Consequently, the purpose of the

condenser is to enable an optimal compromise

between resolution and contrast to be set for the

respective specimen. The aperture diaphragm has

to be readjusted every time the objective lens is

changed.

j) Condenser

adjustment knob

k) Coarse and fine

adjustment knob

Enables the condenser to be precision-raised and

lowered.

This knob enables the specimen stage to be heightadjusted with micrometer precision. The coarse and

fine adjustment is featured as a separate series of

knobs, with the fine adjustment knob being smaller

than and mounted onto the larger coarse adjustment

knob. They enable the specimen to be precisionfocused.

l) Internal lighting

source

A light source is needed to illuminate a specimen,

the light being projected through the condenser into

the specimen and then projected by this in turn into

the objective lens and the eyepiece. The

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 14/32

Page 15

MM-KKE-M-C-U Components on the microscope

Item Description Description

microscope possesses a special artificial light

source featuring a collector and field diaphragm,

making using the microscope easier and the user

more independent.

m) Aperture diaphragm

Used for centering the field diaphragm image.

adjuster

n) Ground glass plate Serves to diffuse light and is slid into a specially

constructed slit between the lamp and collector. It

enables light to be distributed evenly without colored

fringes.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 15/32

Page 16

MM-KKE-M-C-U Installing the microscope

Installing the microscope

Proceed as follows to install the microscope:

1. Place the microscope stand on a stable

surface.

2. Remove the covers.

Push both of the eyepieces into the

binocular tube.

3. Insert the connection cable into the

microscope.

You require this power supply only for

the internal, lower lighting.

The microscope has a condenser and a

source of lighting for transmitted light

mode.

This light source is normally not suitable

for examining filter membranes.

4. The assembly of your microscope is

complete.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 16/32

Page 17

MM-KKE-M-C-U Assembling the illuminator (cold light source)

Assembling the illuminator (cold light source)

Proceed as follows to install the illuminator:

1. The illuminator consists of a base unit

with a 12 V 100 W halogen lamp and a

fiber optic gooseneck.

Please check the connection voltage

according to the technical data on the

type label.

2. The front of the base unit contains a

mount for the fiber optic gooseneck.

First loosen the setscrew on the mount

so that the mounting pin can be slid into

the mounting hole.

Ensure that the flexible fiber optic arms

face vertically upwards. Flatten the top

of the mounting pin to secure it against

twisting.

Screw the setscrew in and tighten it

gently.

3. Plug the connector cable into the

illuminator.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 17/32

Page 18

MM-KKE-M-C-U Assembling the illuminator (cold light source)

4. Switch on the illuminator using the

rotary button [a] at the front and regulate

the brightness.

The illuminator has a fan to cool the

lamp. This fan makes a small amount of

noise when in operation.

5. The illuminator is now ready for use.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 18/32

Page 19

MM-KKE-M-C-U Installing and setting the camera

Installing and setting the camera

Check the camera settings as shown in the following illustration:

Factory settings — Camera configuration settings

Proceed as follows to install the camera:

1. Undo the knurled pin [2]

counterclockwise until the protective

cap [1] can easily be removed.

2. Place the camera [3] with the

measuring eyepiece [4] onto the

trinocular and tighten the knurled pin [2]

lightly by hand.

3. The microscope can be operated using

either the stereo eyepiece or the

camera eyepiece.

Switch between the two eyepieces by

inserting or pulling out the knurled pin

on the right of the trinocular optical

head.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

When operating the microscope using

the camera eyepiece, the knurled pin of

the trinocular optical head has to be

pulled out.

4. Connect the external adaptor to supply

power to the camera. To do this, use

only the adaptor included in the

measuring microscope scope of

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

delivery.

Plug the power supply into the POWER

IN jack of the camera using the right

plug, and then plug the power plug into

the wall outlet. The camera’s POWER

indicator light should now light up and

stay lit..

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 19/32

Page 20

MM-KKE-M-C-U Installing and setting the camera

5. Connect the camera with the S-VHS

connection cable with the "Y/C OUT"

camera jack and …

6. ..... and the C-Video IN jack of the TV

tuner.

7. Connect the external TV tuner to a nonused USB 2.0 port of your PC using the

USB cable.

8. The camera is now connected to your

PC and ready for operation.

Installing the image processing software

To install the image processing software, read the installation instructions which

come with the microscope or the camera.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

Fehler! Es ist nicht möglich,

durch die Bearbeitung von

Feldfunktionen Objekte zu

erstellen.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 20/32

Page 21

MM-KKE-M-C-U Operating the microscope

Operating the microscope

Switch on the cold light illuminator and set the illumination intensity desired using

the dial. Position the fiber optic arms so that no shadows are cast on the specimen

being examined.

Fix the membrane to be examined along with the membrane support on the x/y

mechanical stage. To do this, swivel the curved x/y mechanical stage arm outwards

and then clamp the specimen slide in place.

Adjust the interpupillary spacing of the two eyepiece tubes as required for viewing.

To do this, slide the two tubes into one another or pull them apart as needed.

The microscope can be operated using either the stereo eyepiece or the camera

eyepiece. Lenses can be selected by pushing in or pulling out the silver-colored

knurled pin on the right of the trinocular optical head. When operating the

microscope using the binocular tube for direct visual examination, the knurled pin

has to be inserted.

Rotate the turret to the objective lens with the lowest magnification and focus it on

the specimen. Focusing takes place using the coarse and fine adjustment, which is

operated using the wheels mounted on the right and left-hand sides of the stand.

Coarse adjustment is done using the larger wheel. Fine adjustment is carried out

using the smaller wheel located on top of the larger wheel for coarse adjustment.

Dioptric compensation on the eyepieces is carried out to compensate for the

difference in vision between the user’s eyes. This has to be individually adjusted for

everyone using the microscope.

The x/y mechanical stage provides for adjustment in an X and Y direction.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 21/32

Page 22

MM-KKE-M-C-U Performing a measurement

Performing a measurement

Three different objective lenses (magnification: 4:1, 10:1 and 20:1) can be selected.

The eyepieces on the microscope possess a magnification of 10x. Both scale ratios

are multiplied so that the total magnifications 40x, 100x and 200x result.

This results in the following scale ratios:

Objective lens Total magnification 1 scale graduation line

corresponds to:

4 : 1 40x ~ 25 µm

10 : 1 100x ~ 10 µm

20 : 1 200x ~ 5 µm

Place the filter membrane to be examined along with the membrane support on the

specimen stage. If present, remove the see-through protective cover from the

membrane support. Pull the spring-loaded x/y mechanical stage clip outwards using

your finger and slip the membrane support into the holder. The membrane support is

fixed in place as soon as you let go of the stage clip.

Examining the specimen under the microscope is facilitated by the illuminator.

Rotate the turret to the objective lens with the lowest magnification (4:1) and focus it

on the specimen. Focusing is carried out using the coarse and fine adjustment knob.

The micrometer eyepiece of the camera can be used to gauge the size of the

specimen under the microscope. This is done by taking a reading of the particle size

via the micrometer scale and multiplying the number of graduated scale lines by the

scale associated with the respective magnification. The scale can also be found by

referring to the type plate affixed to the back of the stand or on the camera.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 22/32

Page 23

MM-KKE-M-C-U Evaluating a filter membrane / sample

Evaluating a filter membrane / sample

Particle size ~ 1.2 scale graduation lines

Particle size ~ 2 scale graduation lines

Conversion of the measurement results: (example)

Objective lens

used

1 scale

graduation line

corresponds to:

X Particle size

measured

(in scale graduation

= Accords with

lines)

4 : 1 25 µm X ~ 1.2 = 30 µm

4 : 1 25 µm X ~ 2 = 50 µm

10 : 1 10 µm X ~ 1.2 = 12 µm

10 : 1 10 µm X ~ 2 = 20 µm

20 : 1 5 µm X ~ 1.2 = 6 µm

20 : 1 5 µm X ~ 2 = 10 µm

particle size

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 23/32

Page 24

MM-KKE-M-C-U Performing Maintenance

Performing Maintenance

Prior to all maintenance and cleaning work, disconnect the power plug to the

microscope / illuminator.

DANGER

Electric shock

Danger of fatal injury

► Disconnect the power plug on the unit before

performing any maintenance work.

► Any work involving the electrical equipment may

only be done by a properly trained, certified

electrician.

Cleaning / maintaining the microscope

Clean the microscope surface regularly using a soft cloth or brush. Use only a mild

soap solution for stubborn contamination.

The optical components are to be cleaned using a clean, dry lint-free linen cloth or

lens cleaning paper. Remove any stubborn coating with extreme care using a cloth

soaked in alcohol.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 24/32

Page 25

MM-KKE-M-C-U Performing Maintenance

Replacing the bulb on the microscope

Proceed as follows to change the bulb on the microscope:

1. Pull power plug.

2. Remove the eyepieces from the microscope

tubes.

3. Loosen the knurled pin and remove the

camera unit.

4. Let the lamp in the microscope cool down.

Slowly turn the microscope on its side so that

the underside of the microscope is easily

accessible.

[A] Open the knurled pin to the lamp flap.

[B] Knurled pin for adjusting the lamp..

[C] Temperature fuse plug for lamp.

5. Undo the knurled pin [A] by turning it in a

counterclockwise direction and open the lamp

flap.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 25/32

Page 26

MM-KKE-M-C-U Performing Maintenance

6. Remove the cooled, defective bulb by pulling

it.

7.

Touch the new bulb only in a cloth

and not with your bare fingers. Fingerprints

burn in during operation.

Plug the lamp into the base.

Replacement bulb: Type: 10W 6V OSRAM

no. 644410 S

8. The bulb replacement is complete..

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 26/32

Page 27

MM-KKE-M-C-U Performing Maintenance

Replacing the illuminator bulb

Proceed as follows to change the bulb on the illuminator:

1. Switch off the illuminator.

Pull power plug.

Allow the unit to cool down.

2. Remove the 4 Phillips head screws on the two

side panels of the housing and lift up the upper

part of the housing by the handle.

3. Disconnect the plug from the bulb.

Push the bulb upwards out of the fitting.

Slide the new bulb into the light fitting from

above.

(Replacement bulb Type: 12V 100W Philips

No. 6834 )

Connect the plug to the lamp again.

4. Mount the housing lid and screw in the 4

Phillips head screws again.

Plug in the power plug and switch on the

illuminator.

5. The bulb replacement is complete..

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 27/32

Page 28

MM-KKE-M-C-U Disposing of your microscope

Disposing of your microscope

Dispose of the packaging material as appropriate for your area.

When decommissioning and/or disposing, observe all local guidelines and

regulations pertaining to occupational safety and environmental protection. This

applies in particular to the oil in the unit, components covered with oil and

electronical components.

After disassembling the unit and separating the various materials, reuse them or

dispose of them properly in accordance with local regulations.

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 28/32

Page 29

MM-KKE-M-C-U Model Code

Model Code

MM - KKE - M - C - U

Basic type

MM = Measuring microscope

Lens system

KKE = Trinocular

Supply voltage

O = 240 V AC / 50 Hz / 1 Phase (Australia)

M = 230 V AC / 50 Hz / 1 Phase (Europe)

P = 100 V AC / 50 Hz / 1 Phase (Japan)

Accessories

C = Cold light lighting

Z = Without

Supply voltage

U = CCD camera with USB port

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 29/32

Page 30

MM-KKE-M-C-U Technical Data

Technical Data

Measuring microscope

Huygens eyepiece 10 x M

Achromatic lenses 4x 10x 20x

Magnifications 40x 100x 200x

Tube length 160 mm

Total height 330 mm

Paint colour light grey

PC interface USB port 2.0

Ambient temperature range 0° … +45° C / 32° … 113° F

Storage temperature range -40° … +80 C / -40° … 176° F

Relative humidity max. 90%, non-condensing

Weight ~ 13 kg

Electrical data

Supply voltage 24 V DC, ± 20%, residual ripple ≤ 10%

Power consumption / electricity 100 W max. / 4 A max.

IP class IP 50 (open, in operation)

IP 67 (closed)

Protection class III (safety extra-low voltage)

HYDAC FILTER SYSTEMS GMBH

BeWa MM-KKE-M-C-U 3239239b en-us 2011-10-10.doc 2011-09-27

en

Page 30/32

Page 31

Page 32

HYDAC FILTER SYSTEMS GMBH

Industriegebiet Postfach 1251

66280 Sulzbach/Saar 66273 Sulzbach/Saar

Germany Germany

Phone: +49 (0) 6897 509 01 Central

Fax: +49 (0) 6897 509 846 (Technical Department)

Fax: +49 (0) 6897 509 577 (Sales Department)

Internet: www.hydac.com

Email: filtersystems@hydac.com

Loading...

Loading...