Page 1

Operation and Installation Guide

Documentation no.: 4366964

MCS /-C062

Metallic

Contamination Sensor

English (translation of original instructions)

Valid from hardware index B and

firmware version C09.30 up

Page 2

Imprint

HYDAC FILTER SYSTEMS GMBH

Industriegebiet

66280 Sulzbach / Saar

Germany

Telephone:

+49 6897 509 01

Fax:

+49 6897 509 9046

E-mail:

filtersystems@hydac.com

Homepage:

www.hydac.com

Court of Registration:

Saarbrücken, HRB 17216

Executive director:

Mathias Dieter,

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Telephone:

+49 6897 509 1511

Fax:

+49 6897 509 1394

E-mail:

guenter.harge@hydac.com

Imprint

Manufacturer / publisher and responsible for the content:

Dipl.Kfm. Wolfgang Haering

Documentation Representative

© HYDAC FILTER SYSTEMS GMBH

All rights reserved. No part of this work may be reproduced in any form (print,

photocopy or by other means) or processed, duplicated or distributed using

electronic systems without the written consent of the publisher.

These documents have been created and inspected with the greatest care.

However, errors cannot be ruled out completely.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 2 / 76

2018-06-25

Page 3

Content

Content

Imprint ............................................................................................................ 2

Documentation Representative ................................................................... 2

Content .......................................................................................................... 3

Preface ........................................................................................................... 7

Safety Information ........................................................................................ 9

Technical Support ........................................................................................ 7

Modifications to the Product ........................................................................ 7

Warranty ...................................................................................................... 7

Using the documentation ............................................................................. 8

Warning signs used ..................................................................................... 9

Others used symbols ................................................................................... 9

Signal words and their meaning in the general safety information ............. 10

Structure of the safety information and instructions ................................... 10

Observe regulatory information ................................................................. 11

Proper/designated use............................................................................... 11

Improper Use or Use Deviating from Intended Use ................................... 12

Qualifications of personnel / target group .................................................. 13

Transporting the sensor ............................................................................. 14

Storing the sensor ...................................................................................... 14

Decoding the model code label ................................................................. 15

Checking the scope of delivery ................................................................. 16

Scope of delivery for MCS 13xx ................................................................ 16

Scope of delivery for MCS 14xx ................................................................ 17

Scope of delivery for MCS 15xx ................................................................ 18

Sensor features ........................................................................................... 19

Functional principle .................................................................................... 19

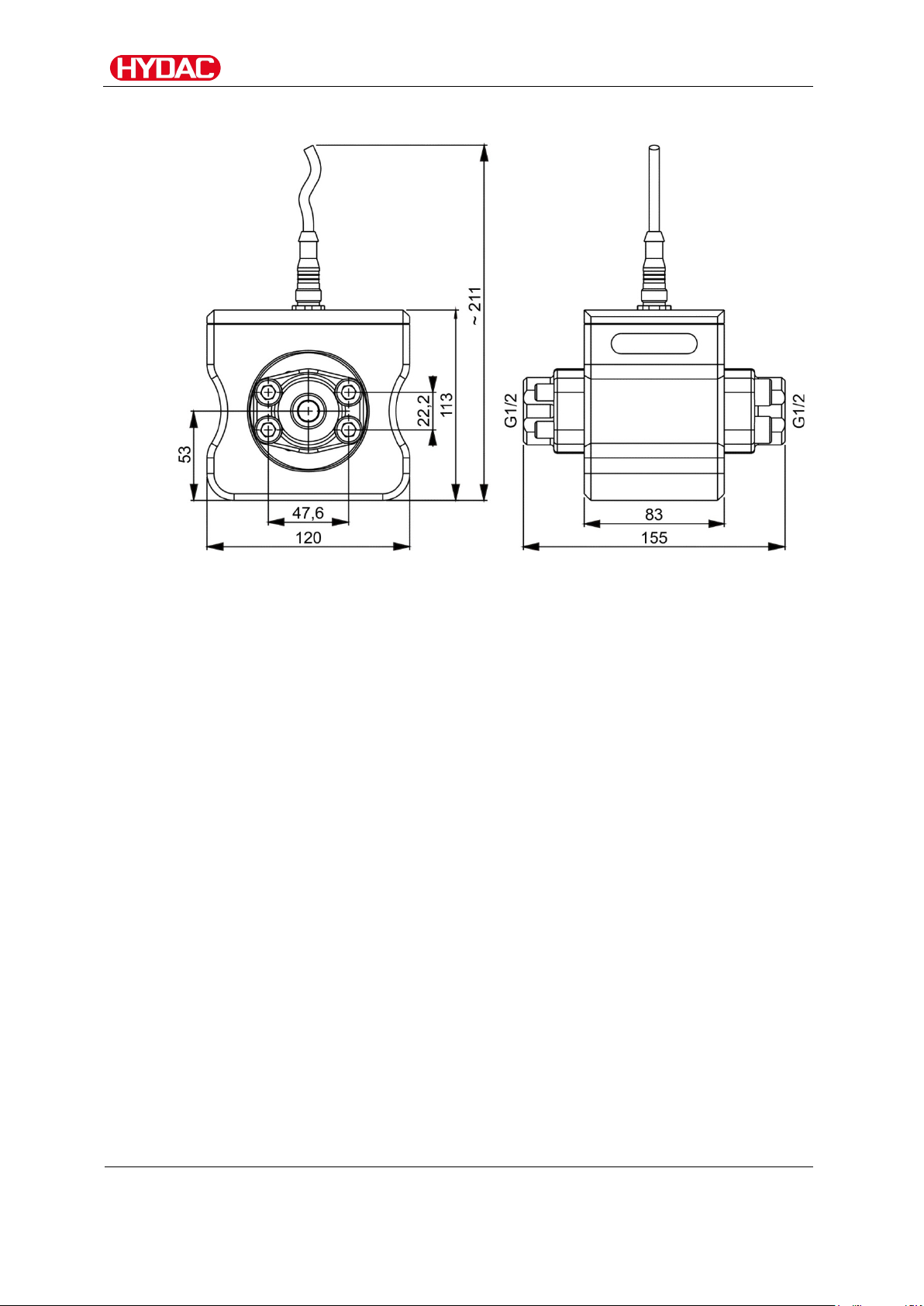

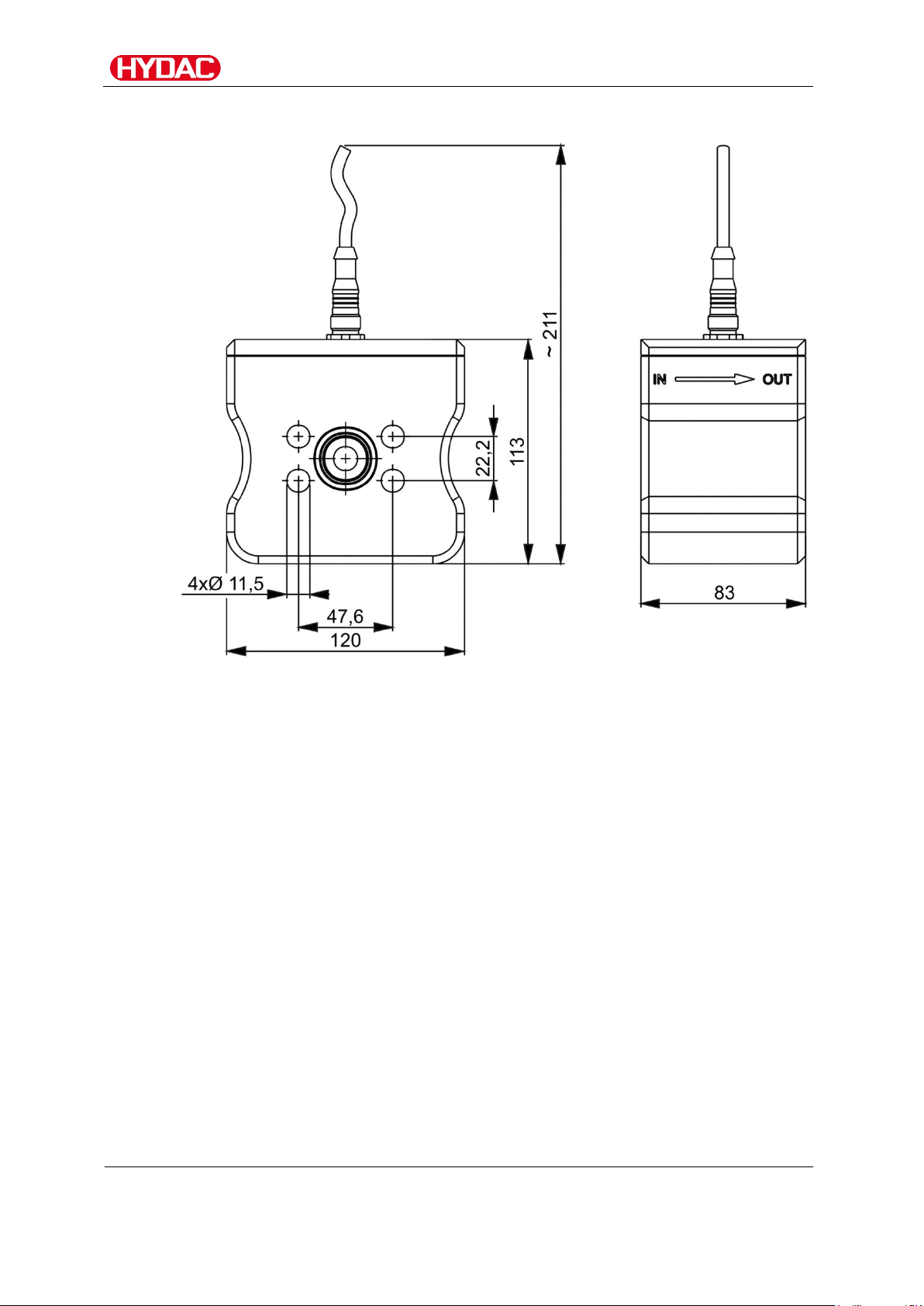

Sensor dimensions ..................................................................................... 20

Dimensions MCS 13xx .............................................................................. 20

Dimensions for MCS 13xx with Ethernet module ....................................... 21

Dimensions MCS 13xx with flange adapter set (optional

accessories) .............................................................................................. 22

Dimensions MCS 14xx .............................................................................. 23

Dimensions for MCS 14xx with Ethernet ................................................... 24

Dimensions MCS 14xx with flange adapter set (optional

accessories) .............................................................................................. 25

Dimensions MCS 15xx .............................................................................. 26

Dimensions for MCS 15xx with Ethernet ................................................... 27

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 3 / 76

2018-06-25

Page 4

Content

Dimensions MCS 15xx with flange adapter set (optional

accessories) .............................................................................................. 28

Mechanical installation/assembly ............................................................. 29

Connecting MCS13xx / 14xx via flange adapter set .................................. 30

Fastening sensor to underside .................................................................. 31

Fastening MCS 13xx / MCS 14xx .............................................................. 32

Fastening MCS 15xx ................................................................................. 32

Fastening MCS 15xx using angle fastening set ......................................... 33

Connecting MCS 15xx using pipe adapter set ........................................... 33

Connecting MCS 15xx using flange adapter plate (accessory) ................. 34

MCS 15xx via SAE 4" per ISO 6162-1 (4xM16) ......................................... 35

Hydraulic installation of sensor ................................................................. 36

Diagram - flow rate, differential pressure p∆ and viscosity ν .................. 36

Electrical connection of sensor ................................................................. 38

Plug pin assignment .................................................................................. 38

Connection cable - Assignment / Color coding .......................................... 39

Using the switching outputs ...................................................................... 40

Switching output - FE.NFE ........................................................................ 40

Switching output - ALL.RDY (factory setting) ............................................. 40

Switching output - ALARM ......................................................................... 40

Switching logic "active low" ........................................................................ 41

Example: Operation - 1 particle detected ............................................... 41

Example: Operation - no particle detected ............................................. 41

Example: Operation - several particles detected .................................... 42

Switching logic "active high" ...................................................................... 43

Example: Operation - 1 particle detected ............................................... 43

Example: Operation - no particle detected ............................................. 43

Example: Operation - several particles detected .................................... 44

Switching output "Device Ready" .............................................................. 44

Parameterizing sensor/reading measured values .................................... 45

Connecting MCS 1000 to SMU 1200 ......................................................... 45

Connecting MCS to CSI-D-5 (Condition Sensor Interface) ........................ 46

Connecting MCS to HMG 3000 ................................................................. 47

Evaluating measurement results ............................................................... 48

Menu structure ............................................................................................ 49

Overview - Power Up Menu ....................................................................... 49

Overview - Measuring Menu ...................................................................... 50

PowerUp Menu ............................................................................................ 51

MODE - select operating mode ................................................................. 51

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 4 / 76

2018-06-25

Page 5

Content

S.TIME - Set storing interval ...................................................................... 51

SEL.COM - Set protocol ............................................................................ 51

ADRESS – Set bus address ...................................................................... 51

DFAULT - Reset to factory setting ............................................................. 51

CANCEL - cancel without saving ............................................................... 51

SAVE - save changes ................................................................................ 51

Measuring menu ......................................................................................... 52

DSPLAY - Show measured variable .......................................................... 52

SWT.OUT – Set the switching output ........................................................ 53

SWT.LOG - Set logic at the switching output ............................................. 54

SWT.PLS - Set pulse length at the switching output ................................. 54

SWT.TST – Set test pulse at the switching output ..................................... 54

ALARM – Setting limit values .................................................................... 55

CANCEL - cancel without saving ............................................................... 55

SAVE - Save changes ............................................................................... 55

Error analysis / remedy .............................................................................. 56

Error status - "active high" and "active low" ............................................... 58

Error status 1 "active low"....................................................................... 58

Error status 1 "active high" ..................................................................... 59

Error status 2 "active low"....................................................................... 60

Error status 2 "active high" ..................................................................... 61

Error status - "Device Ready" .................................................................... 61

Performing maintenance ............................................................................ 62

Decommissioning the sensor .................................................................... 62

Disposing of sensor/packaging material .................................................. 62

Spare Parts and Accessories .................................................................... 63

Channel default settings ............................................................................ 66

Calibrating the sensor ................................................................................ 66

Customer Service/ Service ......................................................................... 66

Technical Data............................................................................................. 67

Detection limits .......................................................................................... 68

Model Code ................................................................................................. 69

EC declaration of conformity ..................................................................... 69

Glossary ...................................................................................................... 70

Ferromagnetic (Fe) .................................................................................... 70

Non-ferromagnetic (nFe) ........................................................................... 70

Certification ................................................................................................ 70

Basics of GL certification ........................................................................ 71

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 5 / 76

2018-06-25

Page 6

Content

Germanischer Lloyd Industrial Services GmbH, renewable

energies ..................................................................................................... 71

Index ............................................................................................................ 72

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 6 / 76

2018-06-25

Page 7

Preface

Fax:

+49 6897 509 9046

E-mail:

filtersystems@hydac.com

Preface

This operating manual was made to the best of our knowledge. Nevertheless

and despite the greatest care, it cannot be excluded that mistakes could have

crept in. Therefore please understand that in the absence of any provisions

to the contrary hereinafter our warranty and liability – for any legal reasons

whatsoever – are excluded in respect of the information in these operating

instructions. In particular, we shall not be liable for lost profit or other financial

loss. This exclusion of liability does not apply in cases of intent and gross

negligence. Moreover, it does not apply to defects which have been

deceitfully concealed or whose absence has been guaranteed, nor in cases

of culpable harm to life, physical injury and damage to health. If we

negligently breach any material contractual obligation, our liability shall be

limited to foreseeable damage. Claims due to Product Liability shall remain

unaffected.

Technical Support

Contact our technical sales department if you have any questions on our

product. When contacting us, please always include the model/type

designation, serial no. and part-no. of the product:

Modifications to the Product

We would like to point out that changes to the product (e.g., purchasing

options, etc.) may result in the information in the operating instructions no

longer being completely accurate or sufficient.

After modification or repair work that affects the safety of the product has

been carried out on components, the product may not be returned to

operation until it has been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product

whether by you or a third party.

Warranty

For the warranty provided by us, please refer to the terms of delivery of

HYDAC FILTER SYSTEMS GMBH.

You will find these under www.hydac.com -> Legal information.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 7 / 76

2018-06-25

Page 8

Preface

Note that the method described for locating specific information

these instructions prior to starting the unit up for the first time and

de

H

Y

D

A

C

F

i

l

t

e

r

t

e

c

h

n

i

k

G

m

b

H

B

e

W

a

1

2

3

4

5

6

a

d

e

Seite x

P

r

o

d

u

k

t /

K

a

p

i

t

e

l

200x-xx-xx

Chapter description

Page number

Document language

Documentation no.

Using the documentation

does not release you from your responsibility of carefully reading

at regular intervals in the future.

What do I want to know?

I determine which topic I am looking for.

Where can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Edition date

with index/

file name

The documentation number with its index enables you to order another copy

of the operating and maintenance instructions. The index is incremented

every time the manual is revised or changed.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 8 / 76

2018-06-25

Page 9

Safety Information

Safety Information

The device was built according to the statutory provisions valid at the time of

delivery and satisfies current safety requirements.

Any residual hazards are indicated by safety information and instructions and

are described in the operating instructions.

Observe all safety and warning instructions attached to the unit. They must

always be complete and legible.

Do not operate the unit unless all the safety devices are present.

Secure the hazardous areas which may arise between the unit and other

equipment.

Maintain the unit inspection intervals prescribed by law.

Document the results in an inspection certificate and keep it until the next

inspection.

Warning signs used

These signs are listed for all safety information and instructions in these

operating instructions which indicate particular hazards to persons, property

or the environment.

Others used symbols

The following symbols found you in this operation instructions.

Danger point warning

Dangerous electrical voltage warning

Tip for handling the product

Tools required

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 9 / 76

2018-06-25

Page 10

Safety Information

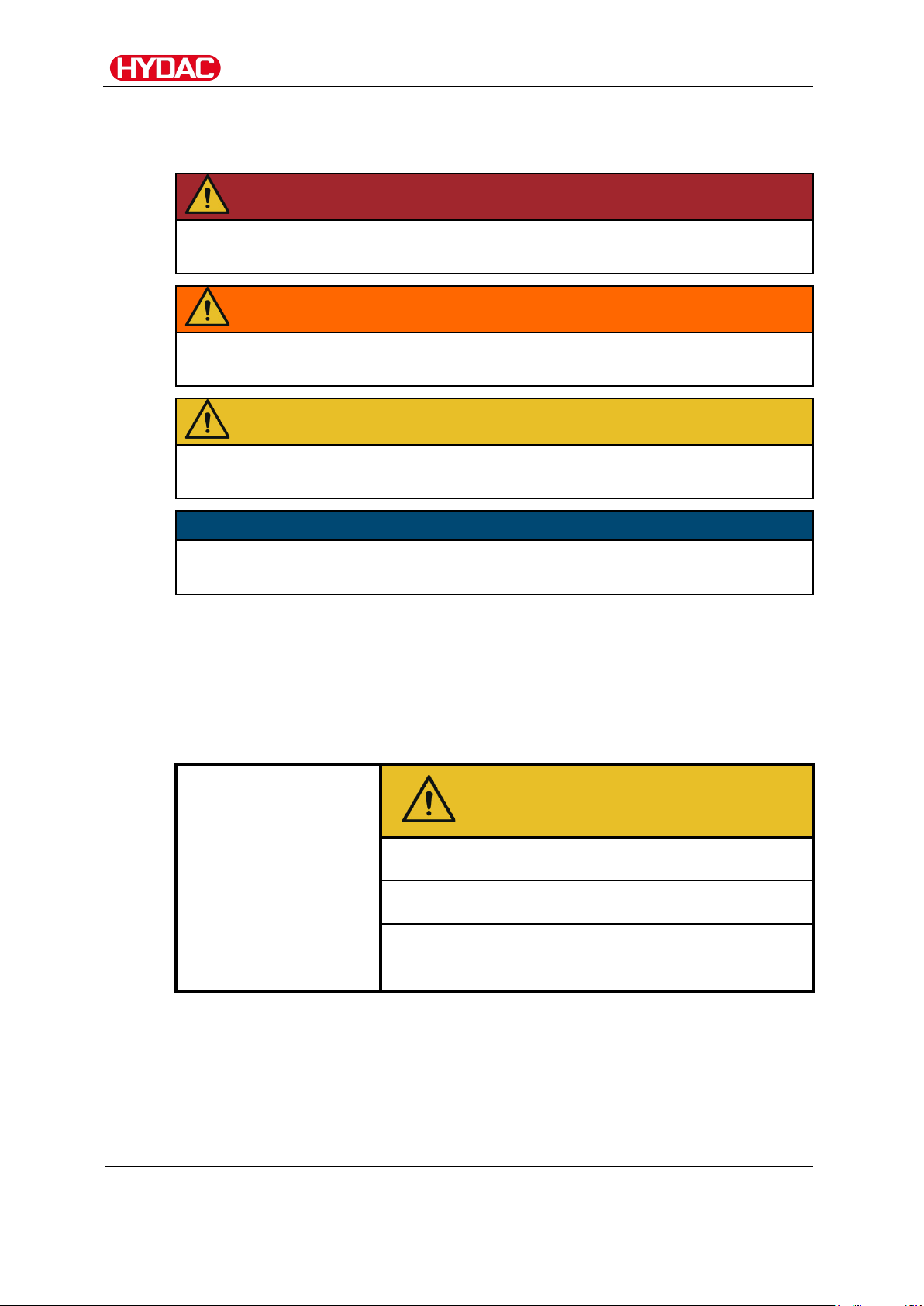

DANGER

DANGER – The signal word indicates a hazardous situation with a high level

of risk, which, if not avoided, will result lethal or serious injury.

WARNING

WARNING – The signal word indicates a hazardous situation with a medium

level of risk,

CAUTION

CAUTION – The signal word indicates a hazardous situation with a low level

of risk, which, if not avoided, can result in minor or moderate injury.

NOTICE

NOTICE – The signal word indicates a hazardous situation with a high level

of risk, which, if not avoided, will result in damage to property.

Signal words and their meaning in the general safety information

In these instructions you will find the following signal words:

which, if not avoided, can result lethal or serious injury.

Structure of the safety information and instructions

All warning instructions in this manual are highlighted with pictograms and

signal words. The pictogram and the signal word indicate the severity of the

danger.

Warning instructions listed before an activity are laid out as follows:

HAZARD SYMBOL

SIGNAL WORD

Type and source of danger

Consequence of the danger

► Measures to avert danger

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 10 / 76

2018-06-25

Page 11

Safety Information

Observe regulatory information

Observe the following regulatory information and guidelines:

• Legal and local regulations for accident prevention

• Legal and local regulations for environmental protection

• Country-specific regulations, organization-specific regulations

Proper/designated use

Only use the sensor for the application described in the following.

The MetallicContamination Sensor MCS is used for the constant monitoring

of particulate contamination in hydraulic and lubrication systems.

Proper or designated use of the product extends to the following:

• observing all instructions contained in the instruction manual.

• Only using with the permissible media.

• Operation within permissible technical conditions, such as operating

pressure, flow rate, media and ambient temperature.

The sensor is only to be used with the following media:

NOTICE

Impermissible operating media/conditions

The sensor will be damaged

► Use the sensor only in conjunction with mineral and synthetic oils

(for example: poly-alpha-olefins PAO and polyglycol, as used in the

wind energy industry).

► Note that the media used must be permanently compatible with the

MCS sealing material.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 11 / 76

2018-06-25

Page 12

Safety Information

Improper Use or Use Deviating from Intended Use

Any use extending beyond this or deviating therefrom shall not be considered

intended use. HYDAC FILTER SYSTEMS GMBH will assume no liability for

any damage resulting from such use. The user alone, shall assume any and

all associated risk.

Improper use or use deviating from intended may result in hazards and/or will

damage the sensor. Examples of improper use:

• Operation with a non-approved medium.

• Operation under impermissible operating conditions.

• Modifications to the sensor made by the user or purchaser.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 12 / 76

2018-06-25

Page 13

Safety Information

Activity

Person

Knowledge

Transport / storage

Forwarding

• No specialist knowledge

Hydraulic / electrical

Specialist

• Safe handling/use of tools

Operation

Specialist

• Product-specific knowledge

Disposal

Specialist

• Knowledge about reuse

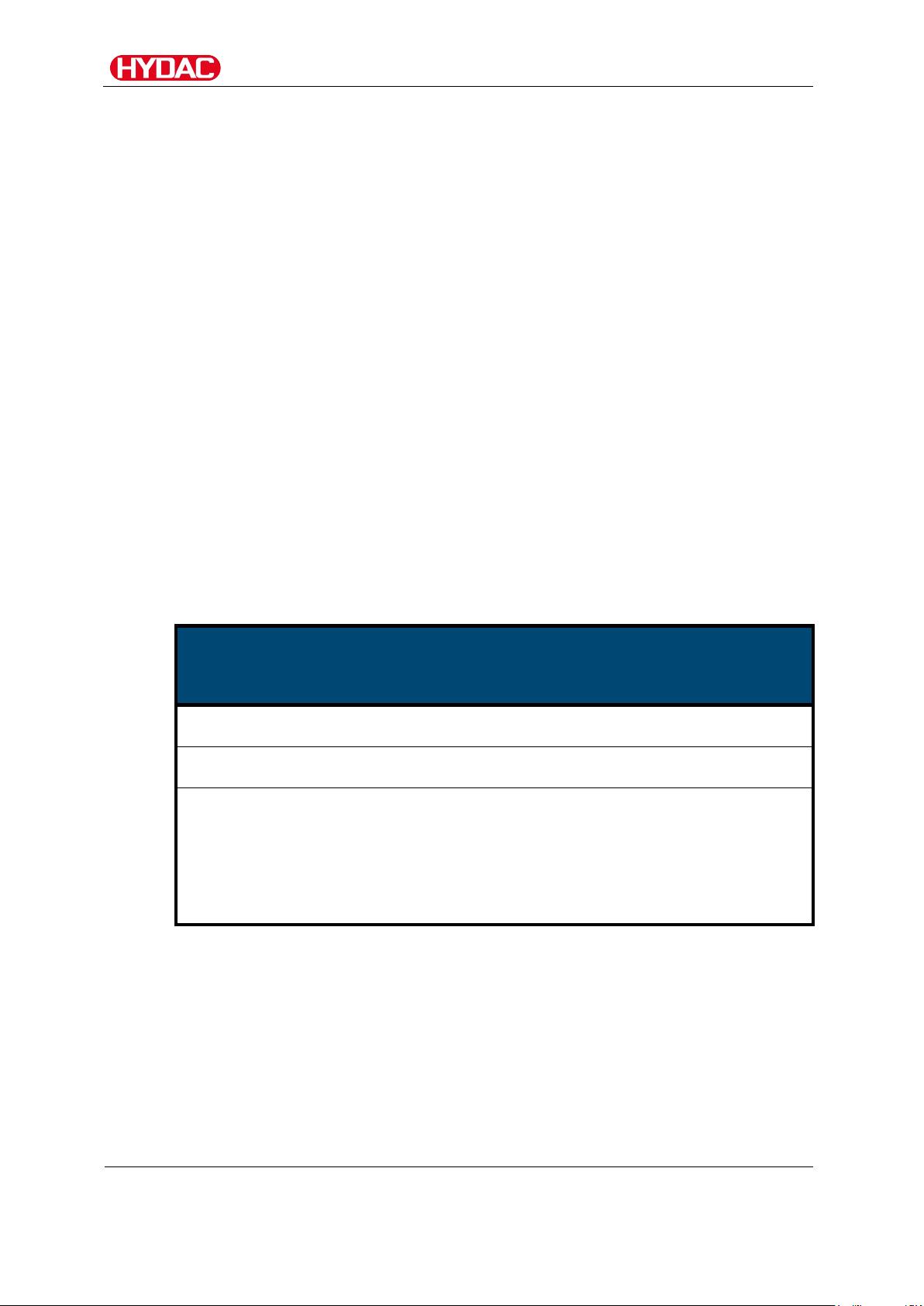

Qualifications of personnel / target group

Persons who work on the sensor must be aware of the associated hazards

when using it.

Auxiliary and specialist personnel must have read and understood the

operating instructions, in particular the safety information and instructions,

and applicable regulations before beginning work.

The operating instructions and applicable regulations are to kept so they are

accessible for operating and specialist personnel.

These operating instructions are intended for:

Auxiliary personnel: such persons have been instructed about the sensor

and are aware of potential hazards due to improper use.

Specialist personnel: such persons with corresponding specialist training

and several years' work experience. They are able to assess and perform the

work assigned to them, they are also able to recognize potential hazards.

installation,

First commissioning,

Maintenance,

Troubleshooting,

Repair,

decommissioning,

Disassembly

Operations control

agent

Auxiliary

personnel

personnel

personnel

personnel

required

• Fitting and connection of

hydraulic tubes and

connections

• Fitting and connection of

electrical lines, electrical

machinery, sockets, etc.

• Product-specific knowledge

• Knowledge about how to

handle operating media.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 13 / 76

2018-06-25

Page 14

Transporting the sensor

Transporting the sensor

Transport the sensor upright or on its side, and in the included packaging if

possible. Make sure the connection plug will not be subjected to any

mechanical strain or impact.

Unsafe transport

The connection plug will be damaged

► Transport the sensor in its original packaging.

► Secure the sensor during transport.

NOTICE

Storing the sensor

Store the sensor in a clean, dry place, in the original packing, if possible. Do

not remove the packing until you are ready to install the unit.

For storage conditions, refer to the chapter "Technical Data" on page 67.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 14 / 76

2018-06-25

Page 15

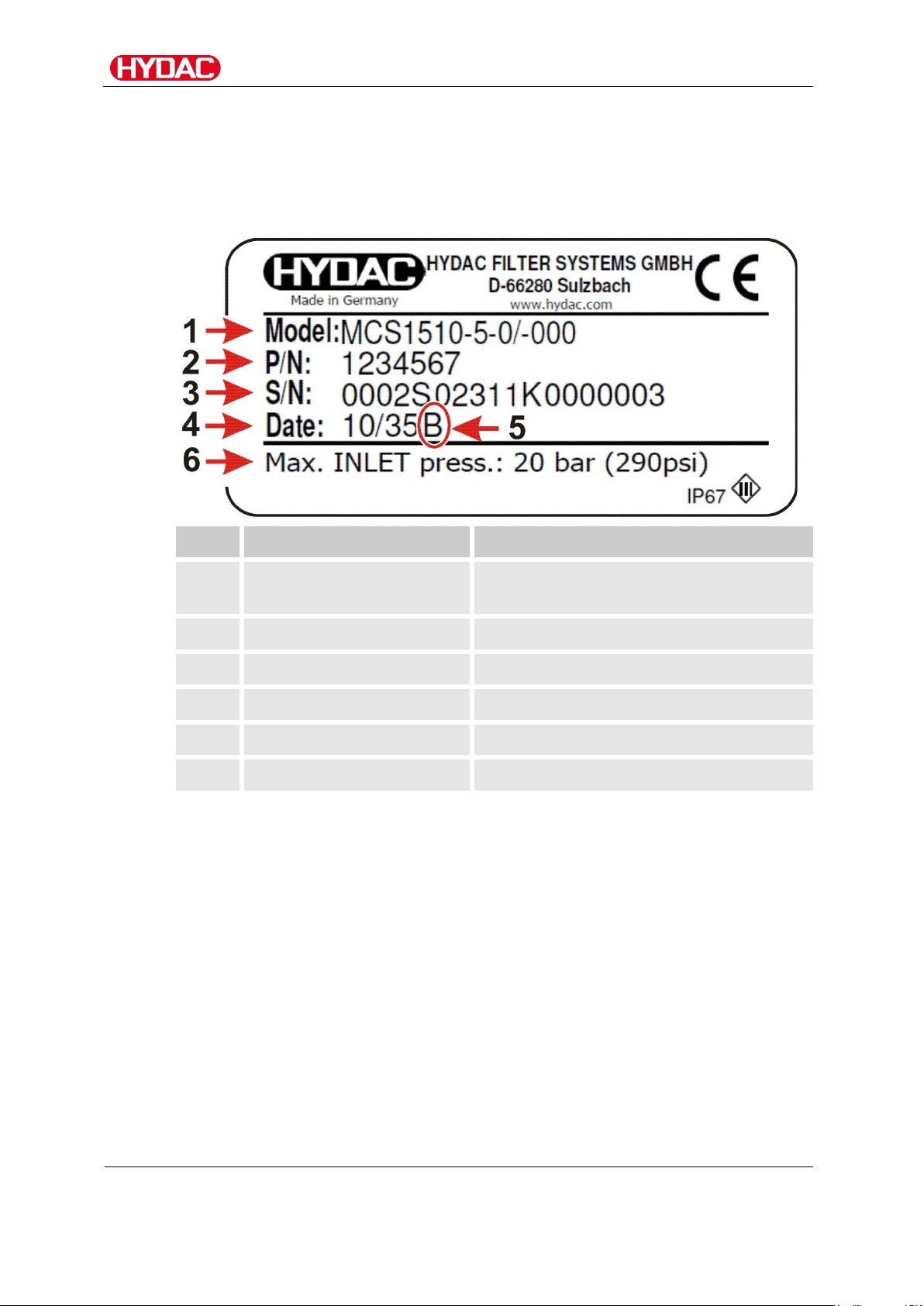

Decoding the model code label

Row

Definition

Description

1

Model

Model according to model code,

2

P/N

p/no.

3

S/N

Serial-no.

4

Date

Year/week of production

5

Index

Hardware index

6

Max. INLET press

Maximum operating pressure

Decoding the model code label

For identification details of the MetallicContamination Sensor, see the type

label. This is located on the top of the unit and contains the exact product

description and the serial number.

for details, see page 69.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 15 / 76

2018-06-25

Page 16

Checking the scope of delivery

Qty

Designation

1

MetallicContamination Sensor, MCS 13xx

1

O-ring (18.7 x 3.53 NBR 70 Shore)

1

Operation and Installation Guide (this document)

Checking the scope of delivery

The scope of delivery for the available sizes varies. Below is the scope of

delivery for each size.

Scope of delivery for MCS 13xx

The MetallicContamination Sensor MCS 13xx comes packed and factoryassembled. Before commissioning the sensor, please check no items are

missing from the package.

The following items are supplied:

EC declaration of conformity

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 16 / 76

2018-06-25

Page 17

Checking the scope of delivery

Qty

Designation

1

MetallicContamination Sensor, MCS 14xx

1

O-ring (25 x 3.53 NBR 70 Shore)

1

Operation and Installation Guide (this document)

Scope of delivery for MCS 14xx

The MetallicContamination Sensor MCS 14xx comes packed and factoryassembled. Before commissioning the sensor, please check no items are

missing from the package.

The following items are supplied:

EC declaration of conformity

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 17 / 76

2018-06-25

Page 18

Checking the scope of delivery

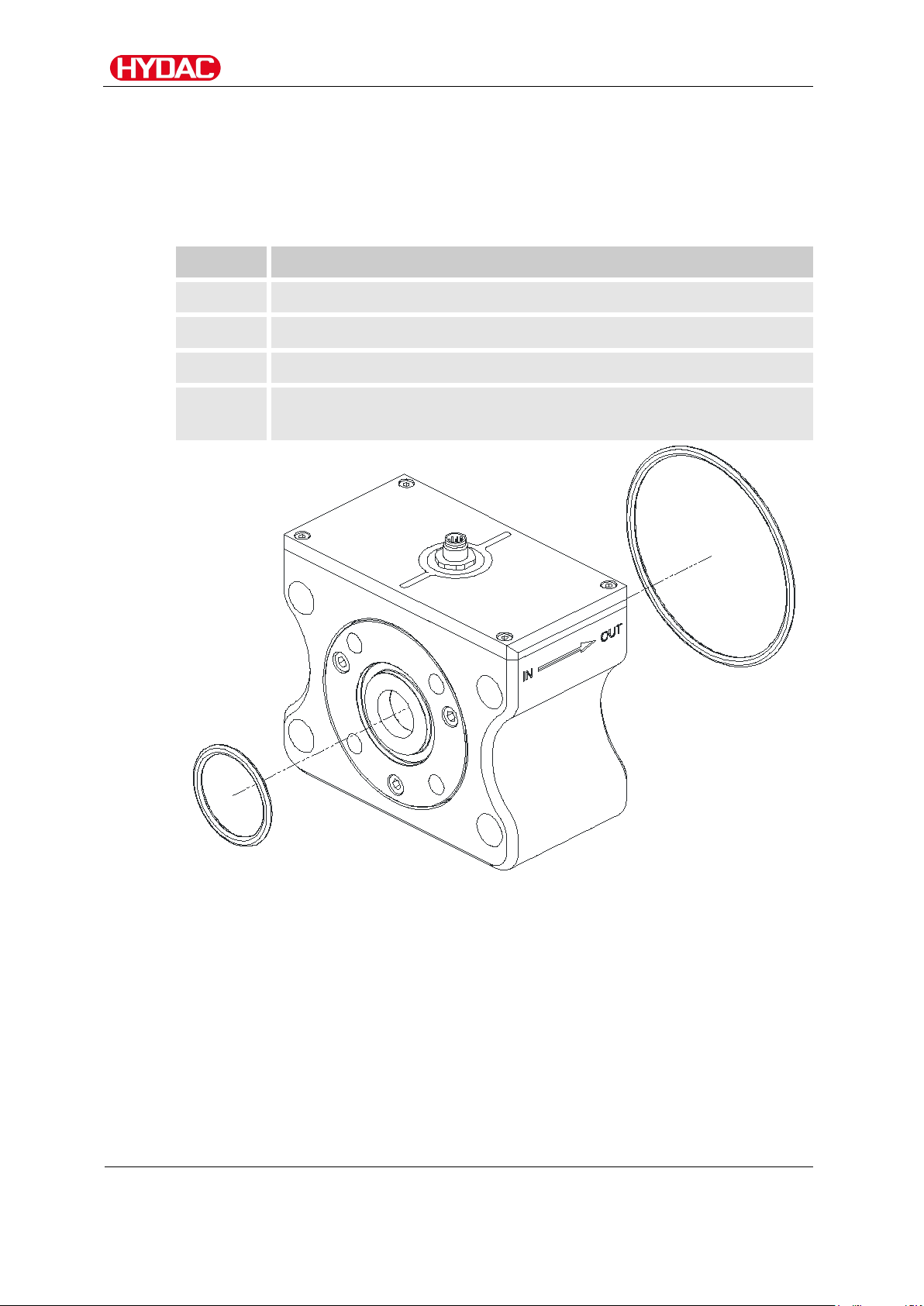

Qty

Designation

1

MetallicContamination Sensor, MCS 15xx

1

O-ring (47.22 x 3.53 NBR 70 Shore)

1

O-ring (110.72 x 3.53 NBR 70 Shore)

1

Operation and Installation Guide (this document)

Scope of delivery for MCS 15xx

The MetallicContamination Sensor MCS 15xx comes packed and factoryassembled. Before commissioning the sensor, please check no items are

missing from the package.

The following items are supplied:

EC declaration of conformity

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 18 / 76

2018-06-25

Page 19

Sensor features

Sensor features

The MetallicContamination Sensor MCS is a stationary sensor for continuous

monitoring of contamination of fluids – especially lubrication fluids – with

metallic particles.

With appropriate system knowledge of the monitored system, damage

resulting in detectable metallic particles can be discovered early.

The MCS uses digital signal processing to distinguish between ferromagnetic

(Fe) and non-ferromagnetic (nFe) particles.

Particle results are signaled via two switching outputs. In the factory setting

(default values), the ferromagnetic (Fe) particles are output via the first

switching output and the non-ferromagnetic (nFe) particles via the second

switching output. It is possible to make a switch in the menu so that the first

switching output is used for the total particles (Fe and nFe) and second

switch output is used as a "device ready signal". (For this, see also the

chapter Using switching output.)

In addition, the MCS has serial communication interfaces with which

connection to superordinate monitoring systems is possible.

The MCS is intended for incorporation in low-pressure circuits and test

benches.

Functional principle

Within the sensor, a high-frequency magnetic field is generated using a coil

system. Two sensor pulses measure changes in the field strength and output

certain signals as described below.

• A ferromagnetic (Fe) particle, the field strength increases depending

on the size of the particle.

• A non-ferromagnetic (nFe) particle, the field strength decreases

depending on the size of the particle.

• If a prespecified limit is exceeded, a particle event is signaled.

• The MCS is able to implement variable adjustments to the defined limit

in order to avoid faulty particle counter results. This makes it possible

to suppress the results for Dimension A and D temporarily (Noise

Suppression) in the event of a very strongly fluctuating field strength

(e.g. following excessive air intake into the system).

The output signal at the switching output is always the same and provides no

information about the size of the particle.

Using the serial interfaces (RS 485 or HSI) makes it possible to evaluate

appropriate particle size classes.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 19 / 76

2018-06-25

Page 20

Sensor dimensions

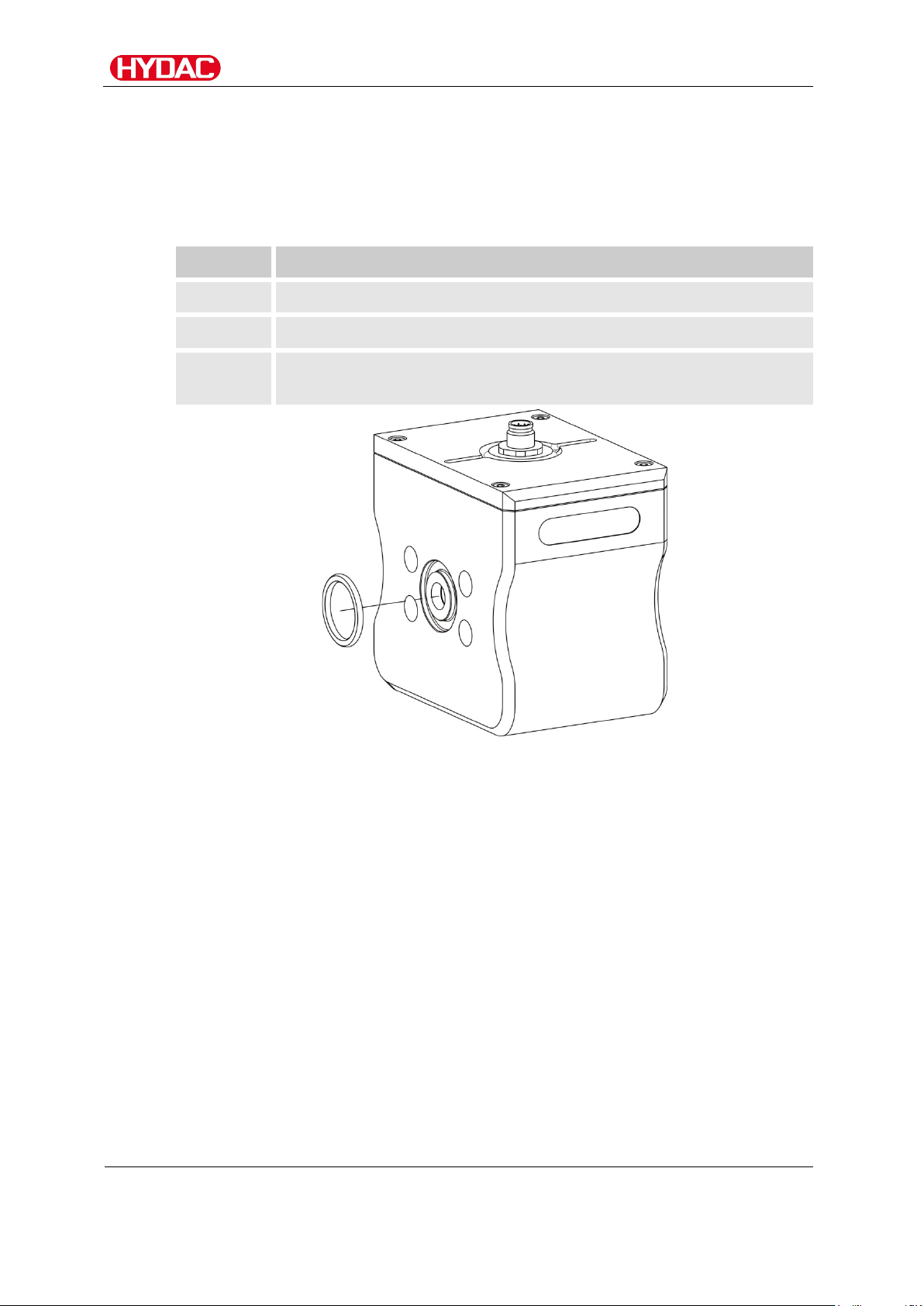

All dimensions in mm.

Sensor dimensions

The dimensions for the available sizes vary. The dimensions for each size

can be found below.

Dimensions MCS 13xx

Flange image SAE 1/2"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 20 / 76

2018-06-25

Page 21

Sensor dimensions

All dimensions in mm.

Dimensions for MCS 13xx with Ethernet module

Flange image SAE 1/2"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 21 / 76

2018-06-25

Page 22

Sensor dimensions

All dimensions in mm.

Dimensions MCS 13xx with flange adapter set (optional accessories)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 22 / 76

2018-06-25

Page 23

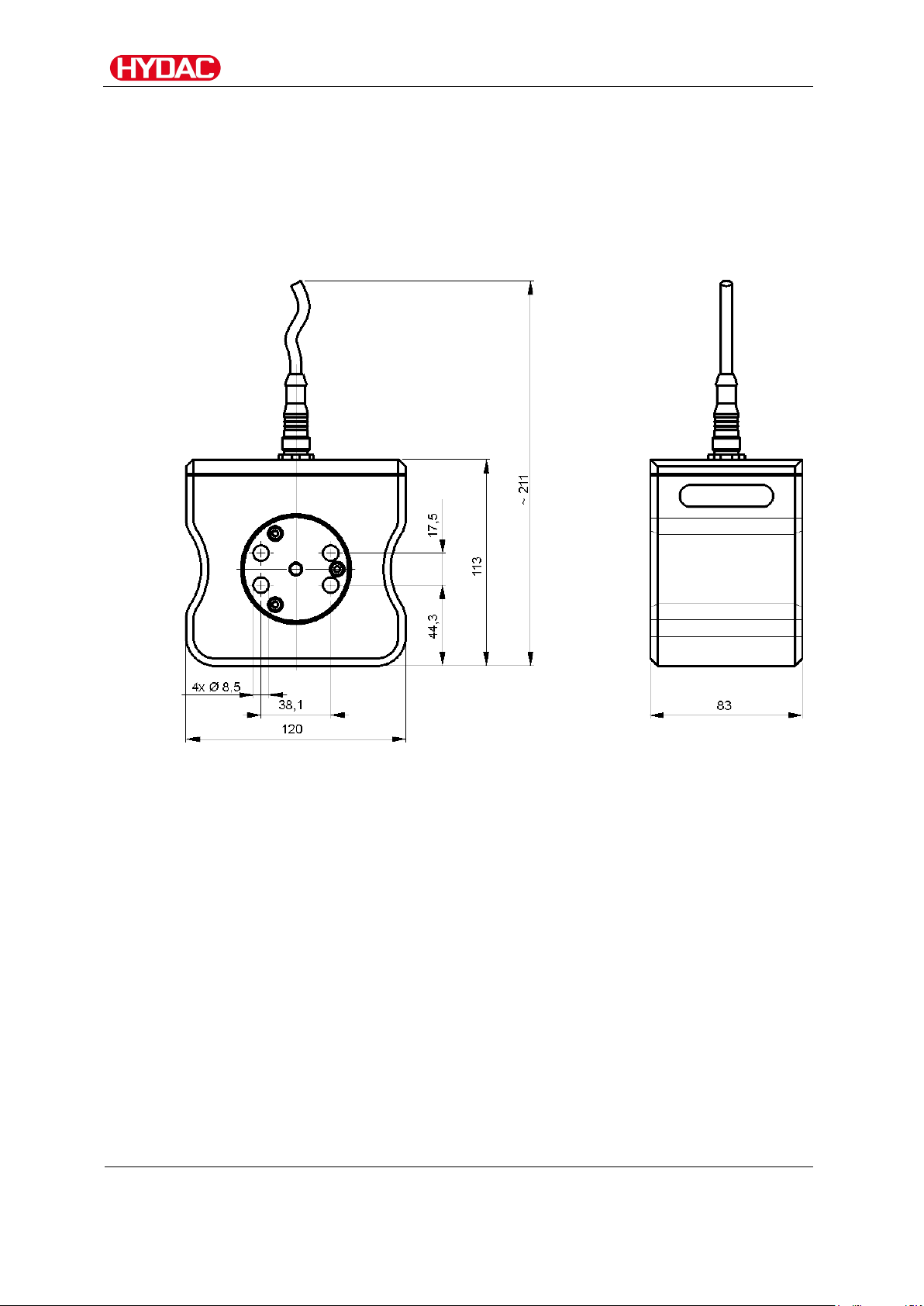

Sensor dimensions

All dimensions in mm.

Dimensions MCS 14xx

Flange image SAE 3/4"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 23 / 76

2018-06-25

Page 24

Sensor dimensions

All dimensions in mm.

Dimensions for MCS 14xx with Ethernet

Flange image SAE 3/4"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 24 / 76

2018-06-25

Page 25

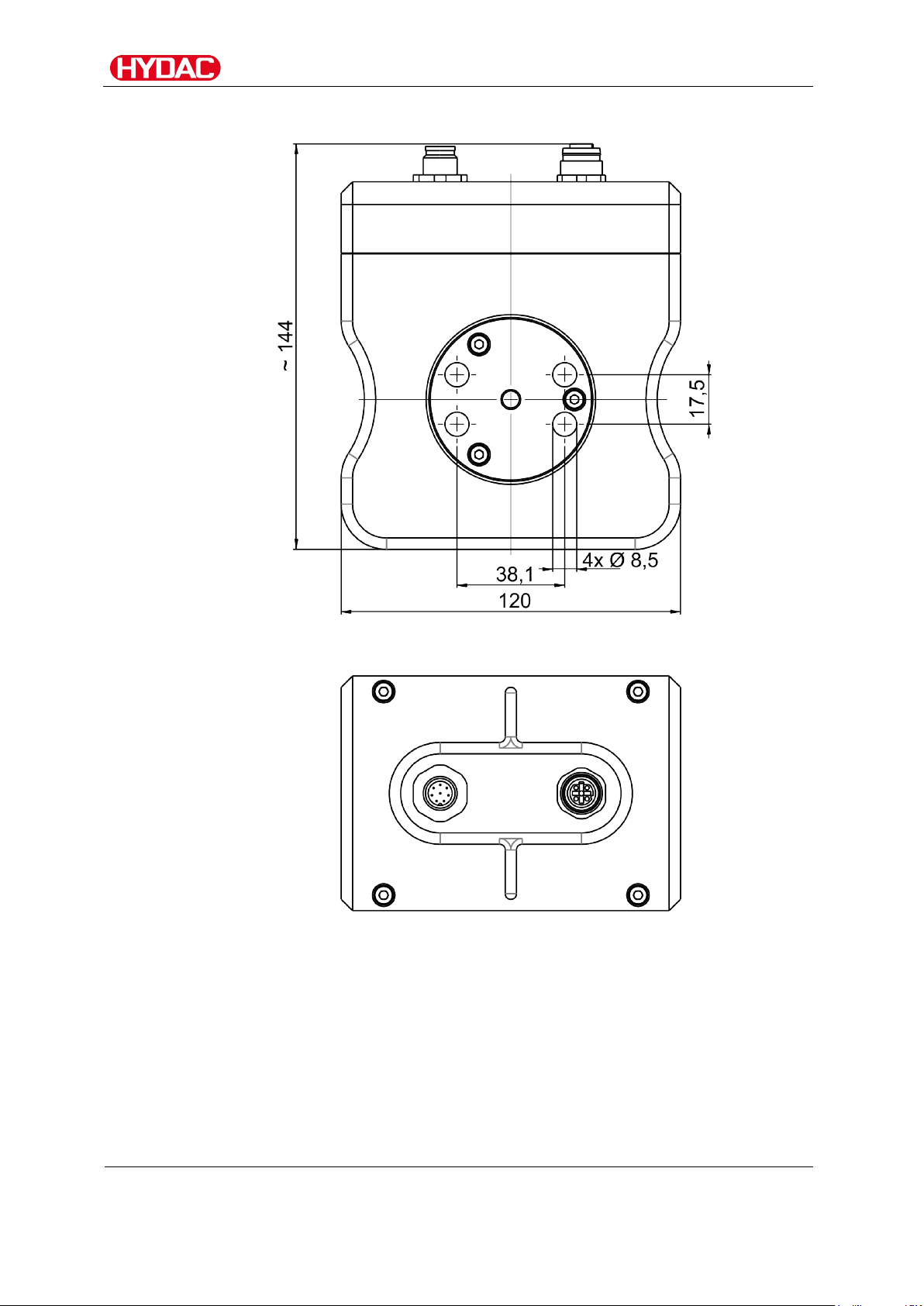

Sensor dimensions

All dimensions in mm.

Dimensions MCS 14xx with flange adapter set (optional accessories)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 25 / 76

2018-06-25

Page 26

Sensor dimensions

All dimensions in mm.

Dimensions MCS 15xx

Flange image SAE 4"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 26 / 76

2018-06-25

Page 27

Sensor dimensions

All dimensions in mm.

Dimensions for MCS 15xx with Ethernet

Flange image SAE 3/4"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 27 / 76

2018-06-25

Page 28

Sensor dimensions

All dimensions in mm.

Dimensions MCS 15xx with flange adapter set (optional accessories)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 28 / 76

2018-06-25

Page 29

Mechanical installation/assembly

Mechanical installation/assembly

During installation, always observe the direction of flow through the sensor.

The direction of flow is indicated by an arrow on the housing.

When selecting the installation site, take ambient factors like the

temperature, dust, water, etc., into account.

The sensor is designed for IP67 according to DIN 40050 / EN 60529 / IEC

529 / VDE 0470.

The sensor offers various options for mechanical installation. Below you can

find the possible mechanical installations permitted.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 29 / 76

2018-06-25

Page 30

Mechanical installation/assembly

Connecting MCS13xx / 14xx via flange adapter set

A flange adapter set is available as an accessory. You will find the part no. in

the "Spare Parts and Accessories" chapter on page 63.

This flange adapter set makes it possible for you to connect the MCS directly

to two pipes or hoses via the thread G1/2".

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 30 / 76

2018-06-25

Page 31

Fastening sensor to underside

Fastening sensor to underside

The sensors have 4 fixing holes on the underside. Use these to secure the

MCS.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 31 / 76

2018-06-25

Page 32

Fastening sensor to underside

Fastening MCS 13xx / MCS 14xx

Below you can see the drilling template for fastening the MCS 13xx/14xx.

(All dimensions in mm)

Fastening MCS 15xx

Below you can see the drilling template for fastening the MCS 13xx/14xx.

(All dimensions in mm)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 32 / 76

2018-06-25

Page 33

Fastening sensor to underside

Fastening MCS 15xx using angle fastening set

An angle fastening set is available as an accessory. HYDAC article no.

3477243.

Connecting MCS 15xx using pipe adapter set

A pipe adapter set is available as an accessory. HYDAC article no. 3435426.

This pipe adapter set makes it possible to connect the MCS directly to two

pipes or hoses via the thread 42L per ISO8431-1.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 33 / 76

2018-06-25

Page 34

Fastening sensor to underside

Connecting MCS 15xx using flange adapter plate (accessory)

A flange adapter set is available as an accessory. HYDAC article no.

3442518.

With the flange adapter set SAE4"-SAE1½" (1) you have the opportunity to

mount the MCS between the filter unit and the pump. The flange adapter

plate offers three ¼" connections for the integration of more sensors.

Example: installation in the filter cooling circuit between pump and partial flow

filter.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 34 / 76

2018-06-25

Page 35

Fastening sensor to underside

MCS 15xx via SAE 4" per ISO 6162-1 (4xM16)

Install the MCS with four screws (M16) to a component/unit. The drilling

template corresponds to the SAE 4" per ISO 6162-1.

Example: installing the MCS on an NF filter

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 35 / 76

2018-06-25

Page 36

Hydraulic installation of sensor

Q l/min

Hydraulic installation of sensor

During installation, observe the direction of flow through the MCS. The

direction of flow is indicated by an arrow on the housing.

NOTICE

Exceeding the permissible operating pressure

The sensor will be destroyed

► Note the maximum operating pressure of 20 bar / 290 psi.

Diagram - flow rate, differential pressure p∆ and viscosity ν

Observe the measured volumetric flow rate. For the MCS14xx this is

between 2 and 40 l/min and for the MCS15xx between 10 and 200 l/min. For

flow rates outside these limits, a detection of particles is no longer

guaranteed.

∆P mbar

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 36 / 76

2018-06-25

Page 37

Hydraulic installation of sensor

Q l/min

Q l/min

∆P mbar

∆P mbar

The diagram shows the resulting differential pressurep∆mbar as a function

of the flow rate Q l/min at different viscosities.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 37 / 76

2018-06-25

Page 38

Electrical connection of sensor

Pin

Assignment

1

Supply voltage 9-36 V DC

2

Switch output 2 (normally open)

3

GND for supply voltage

4

GND switching output

5

HSI (HYDAC Sensor Interface)

6

RS485 +

7

RS485 -

8

Switch output 1 (normally open)

Electrical connection of sensor

Plug pin assignment

The two switching outputs are in each case a passive, n-switching power

MOSFET.

The switching outputs are open without current. There is contact between the

plug housing and the housing.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 38 / 76

2018-06-25

Page 39

Electrical connection of sensor

Pin

Color

Connection to

1

White

Supply voltage 9-36 V DC

2

brown

Switching output 2

3

Green

GND supply voltage

4

Yellow

GND switching output

5

grey

HSI (HYDAC Sensor Interface)

6

Pink

RS485 +

7

Blue

RS485 -

8

Red

Switching output 1

Shield

-

Shield

Connection cable - Assignment / Color coding

In the accessories list you will find connection cables of various lengths with

one connection plug (M12x1, 8-pole, according to DIN VDE 0627) and an

open end.

In the table below you will find the color coding of the HYDAC accessory

cable ZBE42-xx:

(All dimensions in mm)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 39 / 76

2018-06-25

Page 40

Using the switching outputs

Particle

Switching output

ferromagnetic (Fe)

=

1

non-ferromagnetic (nFe)

=

2

Particle

Switching output

ferromagnetic (Fe)

non-ferromagnetic (nFe)

Device Ready

=

2

Particle

Switching output

Alarm

=

1

Device Ready

=

2

Using the switching outputs

The two switching outputs delivery pulses that can be counted or utilized in a

superordinate controller.

The logic of the signal outputs is parameterizable. You can select between

"active low" and "active high" (factory setting).

Details on setting the switching outputs can be found starting on page 53.

Choose among the following settings for the switching output:

Switching output - FE.NFE

A signal for all ferromagnetic (Fe) particles is output at switching output 1,

and a signal for all non-ferromagnetic (nFe) particles at switching output 2.

Switching output - ALL.RDY (factory setting)

A signal for all ferromagnetic (Fe) particles and all non-ferromagnetic (nFe)

particles is output at switching output 1.

The switching output 2 outputs the "Device Ready" signal indicating

readiness for use.

and

= 1

Switching output - ALARM

A warning is output on switching output 1 for the set threshold. Set the limit

values as stated in the "ALARM – Setting limit values" chapter on page 55.

The switching output 2 outputs the "Device Ready" signal indicating

readiness for use.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 40 / 76

2018-06-25

Page 41

Using the switching outputs

Note that after the sensor has been switched on or after voltage

0 V

0

U

t

70 s≈

U

M1/2

Δt

0 V

0

U

t

U

M1/2

Switching logic "active low"

Both switching outputs emit a currentless signal when a particle is detected.

You can set the duration of the signal between 5 and 200 ms.

This value is factory set to 7 ms.

The signal gives no indication of the shape and size of the particles.

has returned, a start-up phase of ≈ 70 seconds is necessary

before the first measurement can be made.

Example: Operation - 1 particle detected

Example: Operation - no particle detected

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 41 / 76

2018-06-25

Page 42

Using the switching outputs

0 V

0

U

M1/2

U

t

Δt

Δt Δt

Example: Operation - several particles detected

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 42 / 76

2018-06-25

Page 43

Using the switching outputs

Note that after the sensor has been switched on or after voltage

0 V

0

U

M1/2

U

t

≈70 s

Δt

≈3 s

0 V

0

U

t

U

M1/2

Switching logic "active high"

Both switching outputs emit a signal when a particle is detected.

You can set the duration of the signal Δt between 5 and 200 ms.

This value is factory set to 7 ms.

The signal gives no indication of the shape and size of the particles.

has returned, a start-up phase of ≈ 70 seconds is necessary

before the first measurement can be made.

Example: Operation - 1 particle detected

Example: Operation - no particle detected

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 43 / 76

2018-06-25

Page 44

Using the switching outputs

0 V

0

U

M1/2

U

t

Δt

Δt

Δt

0 V

0

U

M1/2

U

t

≈ 70 s

Example: Operation - several particles detected

Switching output "Device Ready"

When "Device Ready" is set, the buzzer signal of the ferromagnetic and nonferromagnetic particles is emitted on the switching output S1.

The signal indicating that the MCS is ready for use is emitted on the

switching output S2. The signal is always emitted in the same way regardless

of the switching logic "active low" or "active high".

Note that after the sensor has been switched on and after voltage has

returned after an interruption, a start-up phase of ≈ 70 seconds is necessary

before the signal can be evaluated.

After that, the switching output "Device Ready" goes to permanent "low"

potential.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 44 / 76

2018-06-25

Page 45

Parameterizing sensor/reading measured values

Parameterizing sensor/reading measured values

Connecting MCS 1000 to SMU 1200

The MCS 1000 can be connected to the HYDAC SensorMonitoring Unit

SMU 1200.

The SMU1200 makes it possible to:

• set parameters

• save the MCS measurement data with a time stamp

• read off stored data via USB memory stick

• forward the online measurement data to a PC

• forward the switching outputs to a superordinate controller

You can find more details in the SMU 1200 operating instructions.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 45 / 76

2018-06-25

Page 46

Parameterizing sensor/reading measured values

USB-A

USB-B

PS2

PC

CSI-D-5

MCS 1000

ZBE 43-05

CSI-D-5 Kit

Connecting MCS to CSI-D-5 (Condition Sensor Interface)

With the CSI-D-5 kit you have the opportunity to parameterize the MCS using

a PC and to read off online and stored measurement data.

Connect the CSI-D-5 kit, HYDAC article no. 3249563, in accordance with the

following connection diagram:

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 46 / 76

2018-06-25

Page 47

Parameterizing sensor/reading measured values

Connecting MCS to HMG 3000

You can use the HMG 3000 to set the parameters of the MCS.

Connect the HMG 3000 to the MCS in accordance with the following

connection diagram.

You can find more details in the HMG 3000 operating instructions.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 47 / 76

2018-06-25

Page 48

Evaluating measurement results

Evaluating measurement results

The counter readings of the MCS are not comparable with particle

concentrations as these are known from optical particle counters per ISO

4406.

If the counter reading stays the same, this does not mean that a constant

particle concentration is present, but rather the no further particles have been

detected.

Occurring particles need not have been generated immediately before being

detected by the sensor. Depending on the system, they may be sedimented

particles that were stirred up by shaking or vibration and then got into the

fluid stream.

For detailed evaluation of the measurement results, it is necessary to know

the following operating parameters of the system:

Is a constant, variable, or only temporarily existent fluid stream through the

sensor present?

Example: During the analysis of the particles occurring each day, the actual

operating duration of the system is to be considered. This can vary

significantly from day to day, for example, in gear transmissions in wind

energy plants.

Is it possible for particles to flow back?

Example: In case of depressurization from an incompletely bled system.

Is a fluid filter present that filters out the particles, or are they conveyed

through the circuit?

Example: Without filtration, an individual particle can be detected several

times by the MCS.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 48 / 76

2018-06-25

Page 49

Menu structure

Power Up Menu

MODE

M2

S.TIME

SEL.COM

HSI

ADRESS

HSI

DEFAULT

CANCEL

SAVE

Menu structure

This chapter gives you an overview of the menu structure of the Power Up

and Measuring menus.

Overview - Power Up Menu

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 49 / 76

2018-06-25

Page 50

Menu structure

Measuring menu

DSPLAY

FE A

FE B

FE C

NFE D

NFE E

NFE F

CYC A

CYC B

CYC C

CYC D

CYC E

CYC F

STATUS

FI TEMP C

TEMP F

SWT.OUT

FE.NFE

ALL.RDY

ALARM

SWT.LOG

ACT.HI

ACT.LOW

SWT.PLS

SWT.TST

Type

SWT.FE

SWT.NFE

NUM

START

ALARM

A

PERIOD

LIMIT

B

PERIOD

LIMIT

C

PERIOD

LIMIT

CANCEL

SAVE

Overview - Measuring Menu

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 50 / 76

2018-06-25

Page 51

PowerUp Menu

Function:

Adjustment not possible

Parameter:

None

Factory setting:

M2 (Measure and switch)

Function:

After the time interval set, the total number of

be seen from the parameter DSPLAY - CYC.

Parameter:

1 - 120 minutes

Factory setting:

60

Purpose:

Set transfer protocol to the superordinate system

Function:

Adjustment not possible.

Parameter:

None

Factory setting:

HSI

Parameter:

A - Z for the HSI bus

Factory setting:

D

Function:

Reset to the factory settings.

parameter.

Parameter:

None

Parameter:

None

PowerUp Menu

MODE - select operating mode

S.TIME - Set storing interval

particles is written to the memory of the MCS.

The number of particles within the time intervals can

SEL.COM - Set protocol

ADRESS – Set bus address

DFAULT - Reset to factory setting

You can find the factory setting at the corresponding

CANCEL - cancel without saving

SAVE - save changes

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 51 / 76

2018-06-25

Page 52

Measuring menu

Function:

Select the measured variable that is displayed after

Parameter:

FE A:

ferromagnetic

Class A

FE B:

ferromagnetic

Class B

FE C:

ferromagnetic

Class C

NFE D:

non-ferromagnetic

Class D

NFE E:

non-ferromagnetic

Class E

NFE F:

non-ferromagnetic

Class F

CYC A:

ferromagnetic

Class A

CYC B:

ferromagnetic

Class B

CYC C:

ferromagnetic

Class C

CYC D:

non-ferromagnetic

Class D

CYC E:

non-ferromagnetic

Class E

Measuring menu

DSPLAY - Show measured variable

switching the unit on and after voltage has returned.

The measured variables FE A to NFE F show a

summation of the particles in the corresponding

category. The counter starts when voltage is

switched on and is reset by the absence of voltage.

The counter readings are stored in the internal

memory after the passage of S.TIME in each case.

The parameter CYC (cycle) gives the number of

particles per variable that were counted within the

current measurement time (parameter S.TIME).

The measuring time begins when the voltage is

switched on or the power-up menu is exited. The

value of the current interval is always displayed.

particles (Fe)

particles (Fe)

particles (Fe)

particles (nFe)

particles (nFe)

particles (nFe)

particles (Fe)

particles (Fe)

particles (Fe)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

particles (nFe)

particles (nFe)

en(us)

Page 52 / 76

2018-06-25

Page 53

Measuring menu

CYC F:

non-ferromagnetic

Class F

STATUS:

Status byte

FI:

Field strength of the field coil in the MCS

TEMP C:

Medium temperature in °C (indirect

TEMP F:

Medium temperature in °F (indirect

Factory setting:

FE A

Function:

You can find a detailed description on page 40.

Parameter:

FE.NFE

S1 =

ferromagnetic (Fe)

S2 =

Non-ferromagnetic (nFe)

ALL.RDY

S1 =

ferromagnetic (Fe) and nonS2 =

Device Ready

ALARM

S1 =

Alarm

S2 =

Device Ready

Factory setting:

ALL.RDY

particles (nFe)

(00 at status = O.K.)

measurement via sensor in the spool)

measurement via sensor in the spool)

The value of 1000 µm is shown on the display as 1k.

SWT.OUT – Set the switching output

ferromagnetic (nFe)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 53 / 76

2018-06-25

Page 54

Measuring menu

Parameter:

ACT.HI

active high

ACT.LOW

active low

Factory setting:

ACT.HI

Function:

Setting the pulse length of the switching outputs

Parameter:

5 - 200 milliseconds

Factory setting:

7

Function:

Function test of the switching outputs

Parameter:

TYPE

FE = switching output 1

NUM

Number of pulses

START

Start of function test

Factory setting:

TYPE

FE

NUM

5

SWT.LOG - Set logic at the switching output

SWT.PLS - Set pulse length at the switching output

SWT.TST – Set test pulse at the switching output

NFE = switching output 2

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 54 / 76

2018-06-25

Page 55

Measuring menu

Function:

Set limit values.

limit value. The alarm indicates that the set limit value

has been exceeded and is not necessarily due to any

Parameter:

PERIOD

10 … 180

LIMIT

5 … 232

PERIOD

2 … 72

LIMIT

20 … 232

PERIOD

3 … 30

LIMIT

100 … 232

Factory setting:

PERIOD

30

LIMIT

20 B PERIOD

24

LIMIT

100

PERIOD

7

LIMIT

500

Parameter:

None

Parameter:

None

ALARM – Setting limit values

The signal is active for 30 seconds after exceeding a

damage to the monitored system.

A – Minute (min)

B – Hours (h)

C – Days (d)

A

C

CANCEL - cancel without saving

SAVE - Save changes

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 55 / 76

2018-06-25

Page 56

Error analysis / remedy

Designation

Description

Operation voltage

Voltage for operating the MCS (electronics, coil

Measurement

Voltage U

at switching output 1/2 for superordinate

Signal value

Measurement voltage on = high

Step

Pin

<->

Pin

Description

1 1 <->

3

Check the operation voltage.

2 2 <->

4

Check the measurement voltage UM1 at the

3 8 <->

4

Check the measurement voltage UM2 at the

1

7

6

5

4

3

2

8

Schirm

Shield

Blindage

1

2

3

4

5

6

7

8

Schirm / Shield / B

lindage

weiss / white /

blanc

grün / green /

vert

rosa / pink / rose

blau / blue /

bleu

grau / grey /

gris

braun / brown /

brun

gelb / ye llow /

jaune

rot / red /

rouge

1

2

3

Error analysis / remedy

Using several supply voltages makes it necessary to define the following

terms for error analysis:

system).

voltage

Remove the connection cable on the MCS for error analysis and check the

socket on the connection cable according to the following steps:

controllers.

Measurement voltage off = low

M1/2

switching output 1

switching output 2

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 56 / 76

2018-06-25

Page 57

Error analysis / remedy

Status

Remedy

The MCS is switched

measurement voltage

Reestablish the

voltage.

Switching logic

Signal value at

switching output

Step 1

Step 2 / 3

high ON ON

active low

low ON ON Error at MCS Contact HYDAC

low ON ON

active high

high ON ON Error at MCS Contact HYDAC

ON OFF

OFF ON

The MCS has not

detected any particles

The MCS has not

detected any particles

Error in measurement

voltage

The MCS is switched

off; error in operation

voltage

-

-

Reestablish the

measurement

voltage.

Reestablish the

operation voltage.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

OFF OFF

off; error in operation

voltage /

operation and

measurement

en(us)

Page 57 / 76

2018-06-25

Page 58

Error analysis / remedy

1.

Check the operation voltage to the sensor.

2.

Check the measurement voltage (U

) to the sensor.

3.

Perform a reset. Remove the connection cable of the MCS for 10

4.

If there is no change in the error status, contact HYDAC.

0 V

0

U

t

U

M1/2

Operation voltage

ON

Measurement voltage U

ON or OFF

Error status - "active high" and "active low"

In "active high" and "active low" operation, two errors can occur.

In case of error, proceed as follows:

M1/2

seconds. Reconnect the connection cable to the MCS.

Observe the starting phase of ≈ 70 seconds.

Error status 1 "active low"

The signal at the switching output is permanently free of voltage. The MCS

has detected an error.

M1/2

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 58 / 76

2018-06-25

Page 59

Error analysis / remedy

0 V

0

U

t

U

M1/2

Operation voltage

ON or OFF

Measurement voltage U

ON

Error status 1 "active high"

The signal at the switching output is permanently voltage-carrying. The MCS

has detected an error.

This error occurs also when operation voltage is switched off and

measurement voltage is switched on.

M1/2

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 59 / 76

2018-06-25

Page 60

Error analysis / remedy

0 V

0

U

t

U

M1/2

Operation voltage

OFF

Measurement voltage U

ON

Error status 2 "active low"

The signal at the switching output is permanently voltage-carrying. The MCS

has not detected any errors.

This error occurs also when operation voltage is switched off and

measurement voltage is switched on.

Only a superordinate controller can differentiate between this error signal and

normal operation without detection of a particle. Evaluate the signal duration

and the behavior of the two switching outputs S1 and S2 separately.

M1/2

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 60 / 76

2018-06-25

Page 61

Error analysis / remedy

0 V

0

U

t

U

M1/2

Operation voltage

ON

Measurement voltage U

OFF

0 V

0

U

M1/2

U

t

Error status 2 "active high"

The signal at the switching output is permanently free of voltage. The MCS

has not detected any errors.

This error occurs also when external measurement voltage is switched off.

Only a superordinate controller can differentiate between this error signal and

normal operation without detection of a particle. Evaluate the signal duration

and the behavior of the two switching outputs S1 and S2 separately.

M1/2

Error status - "Device Ready"

In the "Device Ready" error status there is a signal change from "low" to

"high"

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 61 / 76

2018-06-25

Page 62

Performing maintenance

1.

Remove the electric plug.

2.

Depressurize the unit.

3.

Remove the connected hoses/piping from the sensor.

4.

Remove the sensor.

Performing maintenance

Regularly inspect for leaks.

Replace defective cables, hoses or tubes.

The sensor is maintenance-free.

Decommissioning the sensor

To decommission the unit, proceed as follows:

Disposing of sensor/packaging material

Dispose of the packaging material in an environmentally friendly manner.

After removing the sensor and separating its various materials, dispose of it

in an environmentally friendly manner.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 62 / 76

2018-06-25

Page 63

Spare Parts and Accessories

Spare Parts and Accessories

The following spare parts and accessories are available for the sensor.

Description Qty p/no.

MCS14xx flange adapter set SAE ¾" - G 1/2",

comprised of:

1x SAE flange

1x O-ring (NBR)

4x hexagon screw

1 3588249

MCS15xx pipe adapter set, 42L, consisting of:

2x pipe adapter, 42L

2x O-ring (NBR)

8x cheese-head screw

8x washer

8x snap ring

1 3435426

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 63 / 76

2018-06-25

Page 64

Spare Parts and Accessories

Description Qty p/no.

MCS15xx flange adapter set, SAE 4" - SAW 1½",

consisting of:

2x O-ring (NBR)

4x cheese-head screw

4x washer

4x snap ring

4x cheese-head screw

1 3442518

MCS15xx angle plate set, consisting of:

1x angle plate

4x cheese-head screw

8x washer

4x snap ring

4x nut

1 3477243

O-ring (18.7 x 3.53 NBR 70 Shore) 1 3112091

O-ring (18.7 x 3.53 FPM low-temperature 70 Shore) 1 6140581

O-ring (25 x 3.53 NBR 70 Shore) 1 601905

O-ring (25 x 3.53 FPM low-temperature 70 Shore) 1 6140582

O-ring (47.22 x 3.53 NBR 70 Shore) 1 604815

O-ring (47.22 x 3.53 FPM low-temperature 70 Shore) 1 6140584

O-ring (110.72 x 3.53 NBR 70 Shore) 1 603576

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 64 / 76

2018-06-25

Page 65

Spare Parts and Accessories

Description Qty p/no.

O-ring (110.72 x 3.53 FPM low-temperature 70 Shore) 1 6140585

Socket plug (female) with 2 m line,

shielded, 8-pole, M12x1

Socket plug (female) with 5 m line,

shielded, 8-pole, M12x1

Extension cable 5 m,

Socket plug (female) 8-pole, M12x1 /

ZBE 42-02

ZBE 42-05

ZBE 43-05

1 3281220

1 3281239

1 3281240

Socket plug (male) 8-pole, M12x1

Socket plug (female) with screw clamp,

8-pole, M12x1

Connection cable – Ethernet,

Length 5 m, Patch

Socket plug 4-pole, M12x1 /

ZBE 44

ZBE 45-05

1 3281243

1 3346100

RJ45 plug

Connection cable – Ethernet,

Length 10 m, Patch

Socket plug 4-pole, M12x1 /

ZBE 45-10

1 3346101

RJ45 plug

CD with: "FluMoS light" software 1 3251484

ConditionSensor Interface CSI-D-5 kit 1 3249563

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 65 / 76

2018-06-25

Page 66

Channel default settings

Channel:

Particle

MCS13xx

MCS14xx

MCS15xx

Class A

Fe

70 … 100 µm

100 … 150 µm

200 … 300 µm

Class B

Fe

100 … 150 µm

150 … 200 µm

300 … 500 µm

Class C

Fe

> 150 µm

> 200 µm

> 500 µm

Class D

nFe

200 … 300 µm

300 … 450 µm

550 … 750 µm

Class E

nFe

300 … 400 µm

450 … 600 µm

750 … 1000 µm

Class F

nFe

> 400 µm

> 600 µm

> 1000 µm

Telephone:

+49 6897 509 883

Fax:

+49 6897 509 324

E-mail:

service@hydac.com

Channel default settings

Calibrating the sensor

The sensor does not require regular calibrating.

Customer Service/ Service

Use the following shipping address for repairs:

HYDAC SERVICE GMBH

Friedrichsthaler Straße 15a, Werk 13

66540 Neunkirchen-Heinitz

Germany

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 66 / 76

2018-06-25

Page 67

Technical Data

Hydraulic data

MCS13xx

MCS14xx

MCS15xx

Permissible flow rate

0.4 … 8 l/min

2 … 40 l/min

10 … 200 l/mi

Maximum operating

20 bar /

20 bar /

20 bar /

Permitted fluid temperature

-40 … 85°C /

-40 … 85°C /

-40 … 85°C /

Diameter / sensor cross-

1/4“

1/2“

1“

General data

Permitted ambient

-40 … 70°C /

-40 … 70°C /

-40 … 70°C /

Seal material in contact

FPM (low-

FPM (low-

FPM (low-

Mechanical connection

SAE 3/4“

SAE 3/4“

SAE 4“

Protection class to DIN

IP 67

IP 67

IP 67

Weight

≈ 3.0 kg

≈ 2.5 kg

≈ 3.5 kg

Dimensions (L x W x H)

83 x 120 x

83 x 120 x

83 x 162 x

Vibration

10 - 58 Hz

0.75 mm

0.75 mm

0.75 mm

58 - 500 Hz

10 g

10 g

10 g

Shock

40 g

40 g

40 g

Technical Data

n

pressure

range

section

temperature range

with the medium

40050

290 psi

-40 … 185°F

-40 … 170°F

temperature)

290 psi

-40 … 185°F

-40 … 170°F

temperature)

290 psi

-40 … 185°F

-40 … 170°F

temperature)

(4x M16)

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

120 mm

(amplitude)

(acceleration)

en(us)

120 mm

(amplitude)

(acceleration)

140 mm

(amplitude)

(acceleration)

Page 67 / 76

2018-06-25

Page 68

Technical Data

Electrical data

Operation voltage

9 … 36 V DC,

Power consumption

≤ 5 Watt

Electrical outputs

2 configurable switching

1 x Ferromagnetic (Fe) particle

Switching output, loadable

≤ 1.5 A, 40 V DC

RS485 interface

2 wire, half duplex

HSI interface

1 wire, half duplex

Ethernet

10Base-T / 100Base-TX

Storage

Permitted storage

-40 … 80°C / -40 … 176°F

Permitted relative humidity

≤ 95%, non condensing

MCS13xx

MCS14xx

MCS15xx

Particle size - Fe

> 70 µm

> 100 µm

> 200 µm

Particle size - nFe

> 200 µm

> 300 µm

> 550 µm

Particle rate

> 25 / s

> 25 / s

> 25 / s

Residual ripple < 10%

outputs

(n-switching Power

MOSFET, normally open)

temperature range

during storage

1 x Non-ferromagnetic (nFe) particle

or

1 x Particle (Fe + nFe)

1 x Device Ready signal

or

1 x Alarm

1 x Device Ready signal

Detection limits

Particle size = volume-equivalent ball diameter.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 68 / 76

2018-06-25

Page 69

Model Code

MCS

1 5 1 0 - 5 - 0 /

000

Product

Series

Contamination / sensor cross-section

Signal technology

Fluids

Mechanical connection

Electrical connection

Modification number

Model Code

MCS = MetallicContamination Sensor

1 = 1000

3 = Particle >70 µm / 1/4"

4 = Particle >100 µm / 1/2"

5 = Particle >200 µm / 1“

1 2x switching outputs /RS485

(HSI protocol)

7 2x switching outputs/RS485/Ethernet

(HSI TCP/IP protocol)

0 = Mineral and synthetic oils

(particularly used in wind power industry)

1 = Flange connection, SAE 1/2" according to ISO 6162-1

(only for MCS13xx)

2 = Flange connection, SAE 3/4" according to ISO 6162-1

(only for MCS14xx)

5 = Flange connection, SAE 4“ according to ISO 6162-1

(only for MCS15xx)

0 = Male connection M12x1, 8 pole

1 = M12x1 male connection, 8-pole and M12x1 Ethernet, 4-pole

D coded as per IEC61076-2-101

EC declaration of conformity

The CE declaration of conformity can be found in the product's scope of

delivery.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 69 / 76

2018-06-25

Page 70

Glossary

Glossary

Ferromagnetic (Fe)

A "ferromagnetic" material is one that turns into a magnet through the

influence of an external magnetic field. Examples are iron, cobalt, and nickel,

which have this property at room temperature.

These materials differ in their residual magnetism (remanence) after being

removed from the magnetic field. Materials with a high remanence are

described as "magnetically hard" and materials with a low remanence are

called "magnetically weak".

Non-ferromagnetic (nFe)

Many metals used in the industry do not have the above-mentioned

ferromagnetic property. Examples include aluminum alloys, copper, brass as

well as austenitic steels like stainless steel. Such metals are called "nonferromagnetic"; they can be easily checked with a commercially available

permanent magnet. If there is no adhesion, the metal is nFe.

Certification

The Metallic Contamination Sensor MCS 1000, a fluid sensor for detecting

metallic solid particle contamination in lubricating liquids according to the

inductive principle, was certified in February 2010 as an "add on" for

condition monitoring systems in wind power plants.

The certification was provided by Germanischer Lloyd Industrial Services

GmbH.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 70 / 76

2018-06-25

Page 71

Glossary

-

The Guideline for the Certification of Condition Monitoring

This guideline states that the sensors must be able to distinguish

-

Testing criteria

Device design

-

Retrofitting in GL-certified plants

Condition monitoring systems in wind power plants which have already

GL is one of the leading certification

Basics of GL certification

Systems (CMS) for Wind Turbines, Edition 2007.

between ferromagnetic and non-ferromagnetic particles and that the

installation location in the cooling filter circuit is upstream of the filter.

Manufacture

Calibration

Quality planning

Product documentation (comprising data sheet and operating and

maintenance instructions)

Proof of function for the MCS 1000

EMC test

been certified by GL do not lose their certification if the MCS 1000 is

built into the system after certification, as the component itself is

certified.

Germanischer Lloyd Industrial Services GmbH, renewable energies

authorities in the wind energy sector,

performing tests, certification procedures and

approvals for wind power plants and their

components.

MCS /-C062

BeWa MCS1000-C062 4366964 C0930x en-us 2018-06-

25.docx

en(us)

Page 71 / 76

2018-06-25

Page 72

Index

Index

A

Accessories .......................................................... 63

accident prevention .............................................. 11

Adjustment............................................................ 51

ambient temperature ...................................... 11, 67

Assignment ..................................................... 38, 39

Auxiliary personnel ............................................... 13

C

Hydraulic data ...................................................... 67

I

Imprint .................................................................... 2

INLET ................................................................... 15

installation ..................................... 13, 29, 34, 36, 71

installing ............................................................... 35

Interface ..............................................38, 39, 46, 65

IP 67

ISO ........................................................... 35, 48, 69

calibrating ............................................................. 66

Calibration ............................................................ 71

care .................................................................... 2, 7

Connection ..................................................... 39, 65

Connection cable ............................................ 39, 65

Content ................................................................... 3

CSI ................................................................. 46, 65

D

Date ...................................................................... 15

default setting ....................................................... 66

depressurization ................................................... 48

Description................................................ 15, 56, 63

Dimensions ...... 20, 21, 22, 23, 24, 25, 26, 27, 28, 67

DIN ........................................................... 29, 39, 67

Disposal ................................................................ 13

Documentation Representative .............................. 2

DSPLAY ................................................... 50, 51, 52

E

EC declaration of conformity............... 16, 17, 18, 69

Electrical data ....................................................... 68

Error ........................................56, 57, 58, 59, 60, 61

Ethernet ...................................21, 24, 27, 65, 68, 69

M

Maintenance ......................................................... 13

Manufacturer .......................................................... 2

Measure ............................................................... 51

Measurement ................................ 56, 58, 59, 60, 61

Measures .............................................................. 10

measuring ............................................................. 52

Measuring menu ....................................... 49, 50, 52

Menu structure ..................................................... 49

MODE ............................................................. 49, 51

O

OFF ............................................... 57, 58, 59, 60, 61

operating .. 7, 8, 9, 11, 12, 13, 15, 36, 45, 47, 48, 51,

56, 67, 71

Operation .... 1, 11, 12, 13, 16, 17, 18, 41, 42, 43, 44,

56, 58, 59, 60, 61, 68

Operations control ................................................ 13

Overview ........................................................ 49, 50

P

Power consumption .............................................. 68

Protection class .................................................... 67

F

Factory setting .................................... 51, 53, 54, 55