Hydac FPU-1 Operating Manual

97

E 3.501.26/03.12

1. DESCRIPTION

1.1. FUNCTION

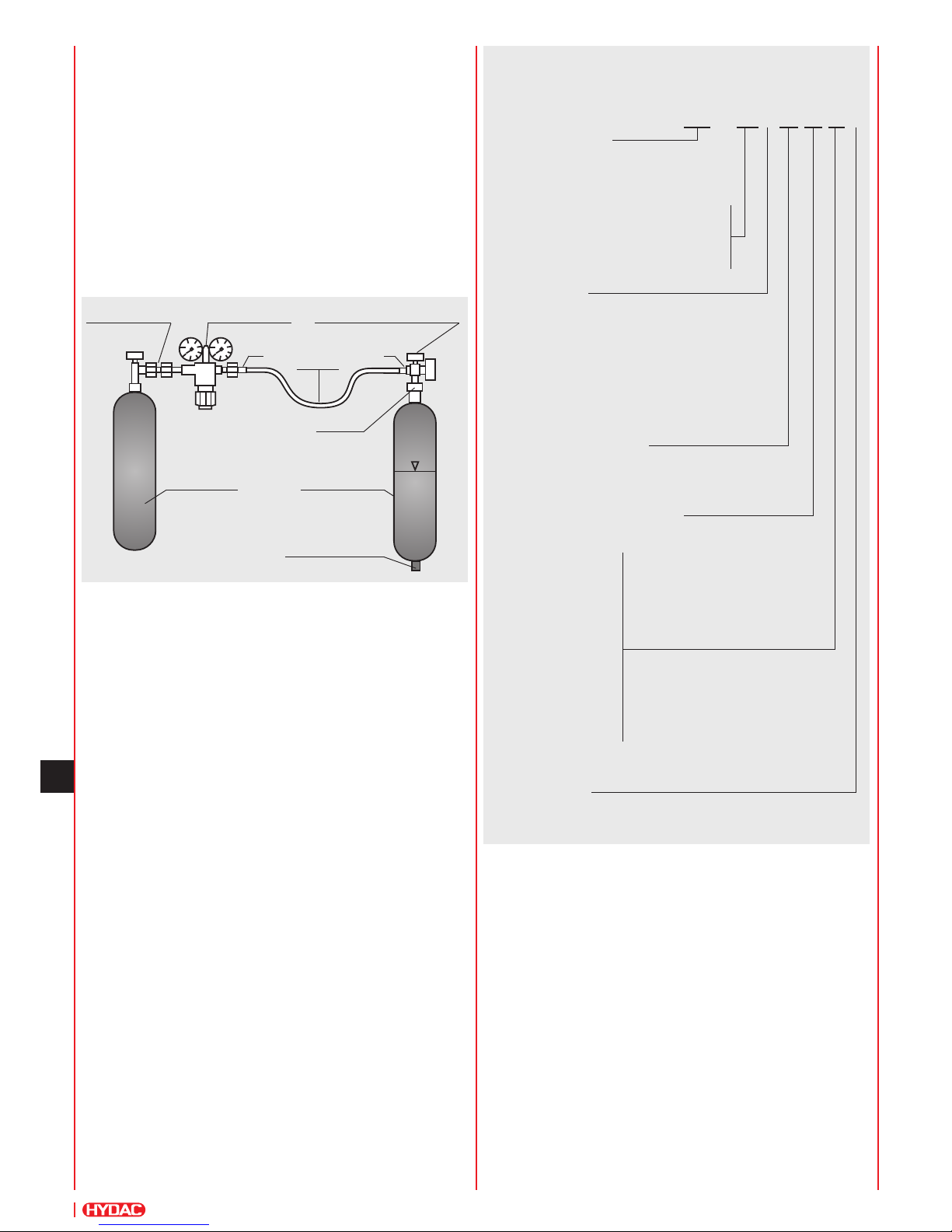

The HYDAC charging and testing unit

FPU-1 is used to charge accumulators with

nitrogen or to check or to change the

existing pre-charge pressure in

accumulators.

For this purpose the charging and testing

unit is screwed onto the gas valve of the

hydraulic accumulator and connected via a

hose to a commercial nitrogen bottle.

If the nitrogen pressure is only to be

checked or reduced, the charging hose

does not need to be connected. The unit

has a screw-type tting with a built-in

gauge, check valve and a spindle for

opening the accumulator gas valve to

control the pressure.

HYDAC piston and diaphragm

accumulators can be charged and checked

without the need for adapters. Bladder

accumulators, however, require an A3

adapter.

Please read the Operating Manual!

No. 3.501.CE

Universal Charging

and Testing Unit FPU-1

for Bladder, Piston and Diaphragm

Accumulators

1.3. SPECIAL MODELS1.2. DESIGN

The HYDAC charging and testing unit

for bladder, piston and diaphragm

accumulators consists of:

z Valve body

z Spindle

z Check valve

z Release valve

z Pressure gauge

z Charging hose

z A3 adapter for bladder accumulators

Release valve

Spindle

Check valve

Pressure gauge

For higher pressures, the following special

models are available:

z FPS 600

for bladder accumulators up to 600 bar

max. pre-charge pressure (see technical

information 293715).

z FPK 600

for piston, diaphragm and

SB800-1.5 accumulators up to 600 bar

max. pre-charge pressure (see

technical information 297248).

z FPH 800

for high pressure bladder accumulators

up to 800 bar max. pre-charge pressure

(see technical information 242948).

The photo top left shows a possible order

option, including accessories.

98

E 3.501.26/03.12

2. TECHNICAL SPECIFICATIONS

2.1. MODEL CODE

(also order example)

FPU-1 - 250 F 2,5 G2 A1 K

Universal charging

and testing unit

p

max

= 350 bar

Gauge indication range

0 - 10 bar 0 - 145 psi 10

0 - 25 bar 0 - 363 psi 25

0 - 100 bar 0 - 1450 psi 100

0 - 250 bar 0 - 3625 psi 250

0 - 400 bar 0 - 5800 psi 400

Charging hose

F = for 200 bar nitrogen bottle

with connection W24.32x1/14

(DIN 477, Part 1)

FM = for 300 bar nitrogen bottle

with connection M30x1.5

(DIN 477, Part 5 up to April 2002)

FW = for 300 bar nitrogen bottle

with connection W30x2

(DIN 477, Part 5 from April 2002)

Length of charging hose

2.5 = 2.5 m

4.0 = 4 m

Special lengths on request

Adapter G for nitrogen bottles

See table, Point 3.6.

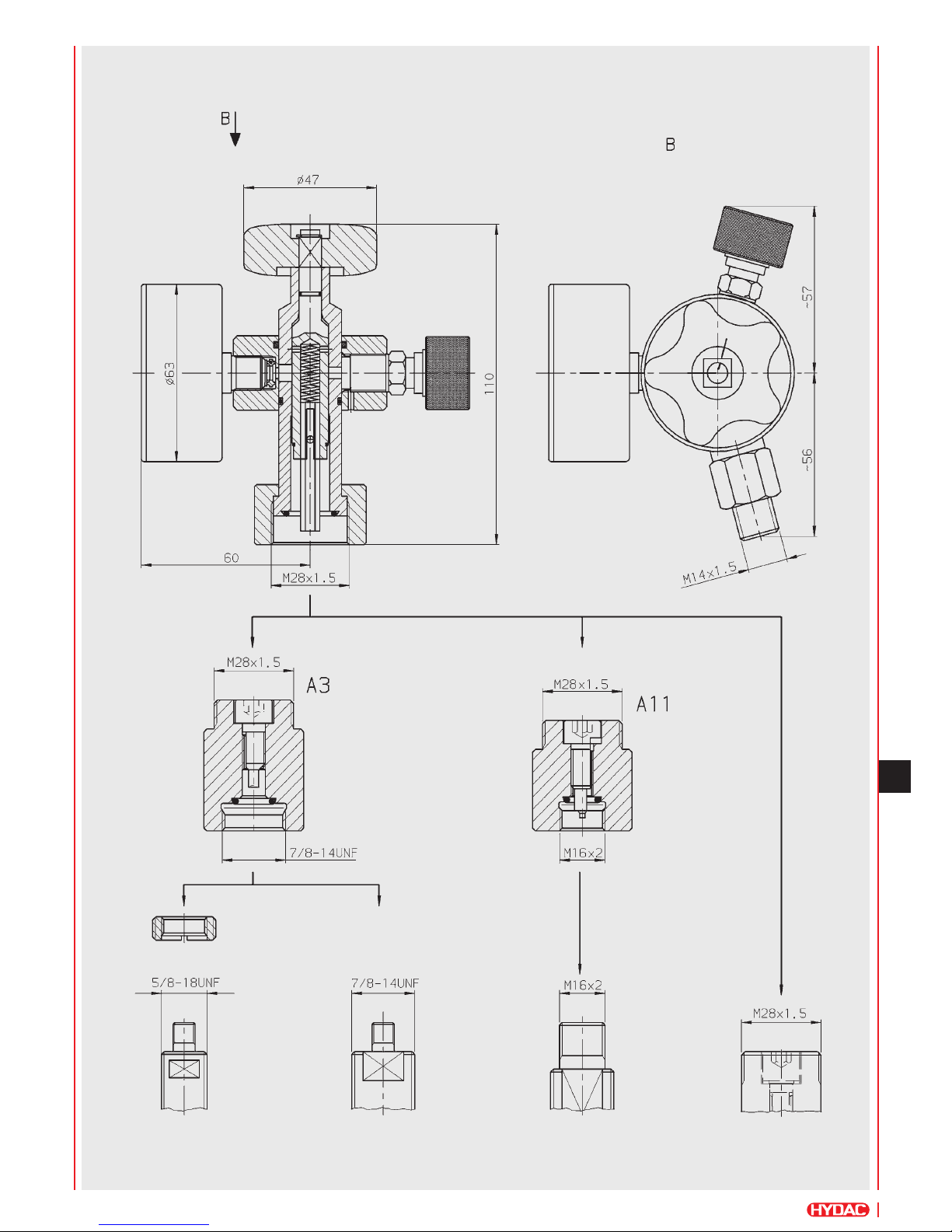

Adapter A

A1 = M16x1.5

A2 = 5/8 - 18 UNF

A3 = 7/8 - 14 UNF

A4 = 7/8 - 14 UNF

A5 = M8x1

A6 = G 3/4 A

A7 = G 1/4

A8 = G 3/4

A9 = Vg 8

A10 = 7/8 - 14 UNF

A11 = M16x2

A12 = M16x2

D4 = 5/8 - 18 UNF

(Part no. 366374)

other adapters on request

Protective case

Accessories - please give full details when ordering

(see Point 4.)

(A3 is supplied as standard)

1.4. TESTING INTERVALS

In general, nitrogen losses on HYDAC hydraulic accumulators are

very low. However, a regular check of the gas lling pressure is

recommended to prevent the piston from hitting the end cap, or

the bladder or diaphragm from becoming too deformed if there is

a drop in the pressure p

0.

The pre-charge pressure p0 as shown on the label or the

accumulator body, must be re-set after every new installation or

repair and then checked at least once during the following week. If

no nitrogen loss is detected, a further check should be made after

approx. 4 months. If after this period no change in the pressure is

found, a yearly check should be sufcient.

1.5. SCHEMATIC DRAWING

Fluid connection

Nitrogen bottle

Hydraulic

accumulator

Adapter A

MG1

Charging

hose

Adaptor G Pressure reducer Charging and testing unit FPU-1

N

2

N

2

99

E 3.501.26/03.12

3. DIMENSIONS

3.1. CHARGING AND TESTING UNIT FPU-1 WITH ADAPTER FOR HYDAC ACCUMULATORS

Bladder accumulators

330-0.5 / 400-0.5

Bladder accumulators

≥ 1l

Gas valve

to ISO 10945

Piston and diaphragm

accumulators

D4 Adapter

Loading...

Loading...