Hydac FPK, FPS Operating Manual

Accumulators

Charging & Gauging Units

FPK / FPS Operating Manual

1.877.GO.HYDAC www.HYDACusa.com 1.888.99.HYDAC www.HYDAC.ca

PN#02068202 • ACU1403-1605 / 03.14

2

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

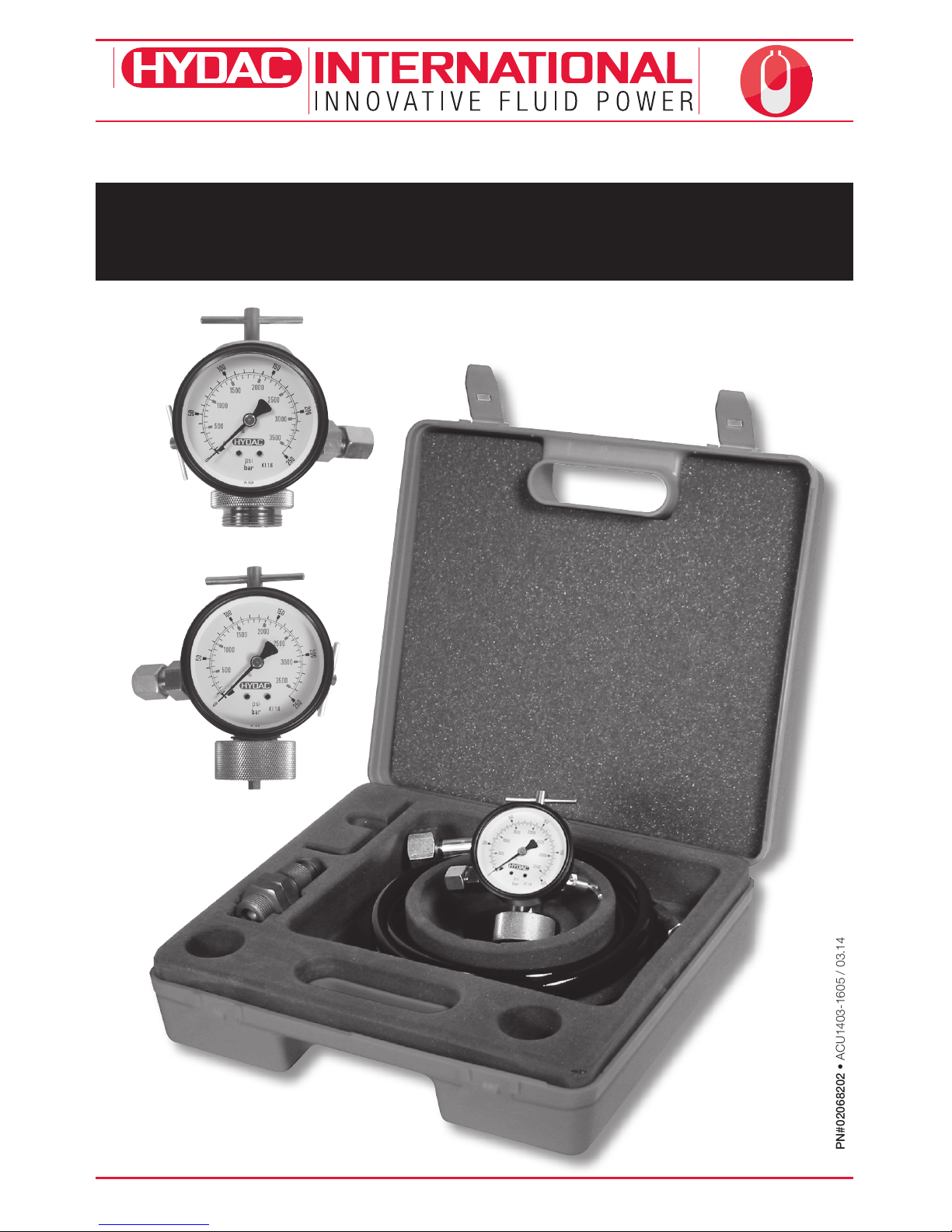

FPS

Version 4

FPK

Version 1

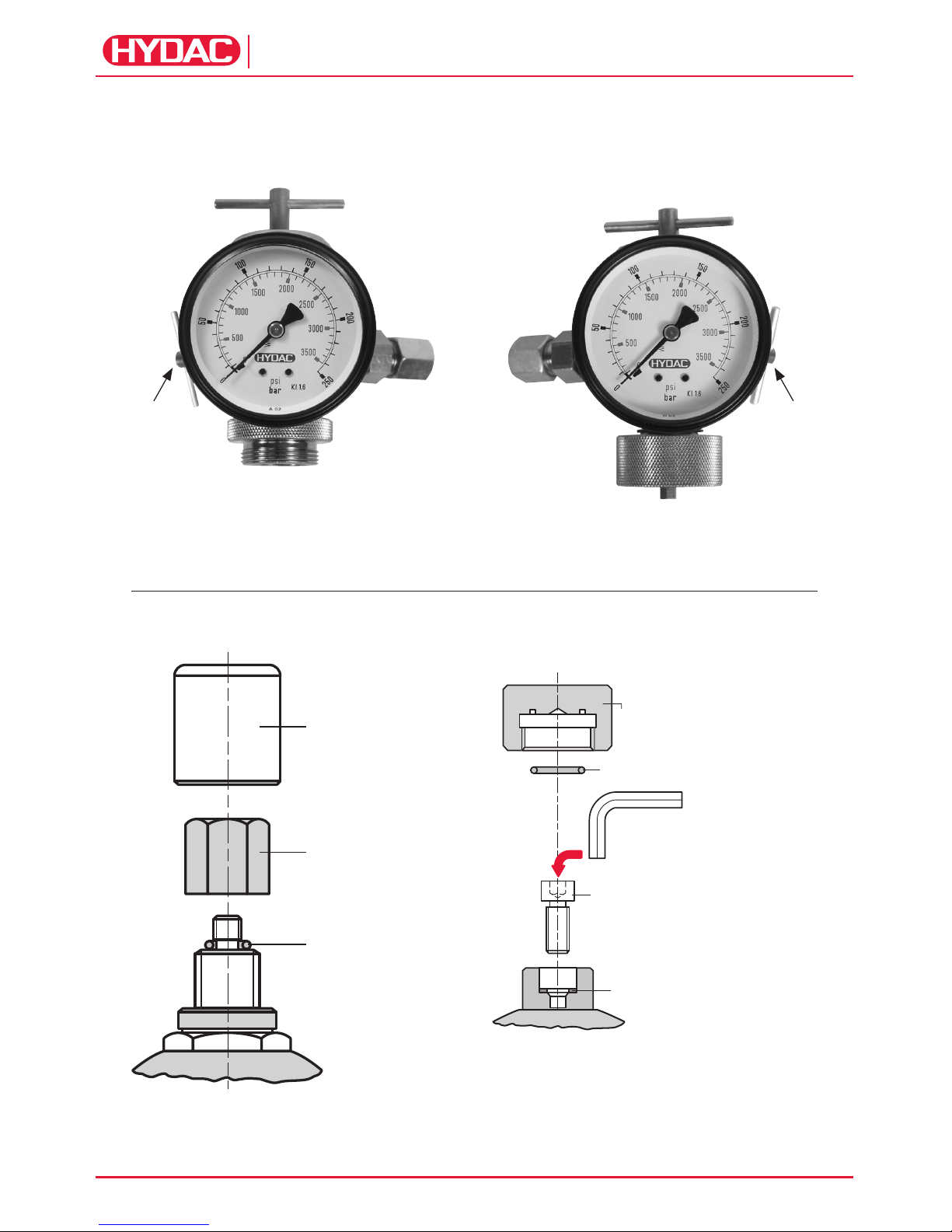

valve

protection

cap

(where applicable)

Valve

seal cap

O-ring

Allen Wrench 6 mm

(to be used to crack open M8 SHCS.

T handle on FPK Charging is not robust

enough to overcome recommended torque)

Valve protection cap

(where applicable)

O-ring (where applicable)

Socket Head

Cap Screw (M8)

Seal ring

T-Handle T-Handle

Check

Valve

Cap Nut Cap Nut

Manual

Bleed

Valve

Manual

Bleed

Valve

Figure 1

Figure 2

3

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

General Warning!

Hydraulic accumulators are pressurized

vessels and only qualified technicians

should perform maintenance. For additional

information refer to HYDAC Operating

and Installation Instructions and HYDAC

Maintenance Instructions. Read all

instructions thoroughly before before

beginning any type of service or repair.

Tools Required

1. Gas Valve Core Tool.

2. Torque Wrenches.

3. Wrench(es).

Intervals Between Checking

Gas Precharge Pressure

The proper gas precharge pressure should

be set after each new installation or repair

by following the instructions under the

Operating and Installation Instructions

below. It should be rechecked at least once

during the first week of operation. If there

is no loss of gas precharge pressure, it

should be rechecked again in 3 to 4 months.

Thereafter, it should be checked at least

once a year. Recharge accumulator when

necessary.

Temperature Effect

To ensure that the recommended gas

precharge pressure is maintained,

even at relatively low of high operating

temperatures, the gas precharge pressure

should be adjusted for temperature. The

formula below relates the precharge

temperature (T0) to the operating

temperature (T).

Fahrenheit

P

0,T 0

= P

0,T 2

x (T0 + 460) / (T2 + 460)

Celsius

P

0,T 0

= P

0,T 2

x (T0 + 273) / (T2 + 273)

T0 = precharge temperature

T2 = maximum operating temperature

P

0,T 0

= gas precharge pressure at

precharge temperature

P

0,T 2

= gas precharge pressure at

maximum operating temperature

Operating and

Installation Instruction

Preparation

To check the gas precharge pressure in

an accumulator, it must first be isolated

from the system shut off, and all hydraulic

pressure relieved.

HYDAC gas valve version 4 (see fig. 2)

Unscrew the valve protection cap (where

applicable) and the valve seal cap.

HYDAC gas valve version 1 (see fig. 2)

Unscrew the valve protection cap (where

applicable). Slightly loosen the socket head

cap screw with a 6 mm Allen wrench (approx.

1/6 turn, see fig. 2).

NOTE: In order to connect the charging

hose to the FPK/FPS charging unit body,

the small ferrule must first be removed.

FPS Unit

Prior to connecting the charging and

gauging unit to an accumulator, turn

T-handle counter-clockwise until resistance

is felt. Close manual bleed valve by

hand tightening. Connect the unit to the

accumulator by screwing cap nut onto

HYDAC gas valve version4; hand tighten

(see fig. 1).

FPK Unit

Prior to connecting the charging and

gauging unit to an accumulator, close

manual bleed valve by hand tightening.

Connect the unit to the accumulator by

screwing cap nut onto HYDAC gas valve

version 1; hand tighten

(see fig. 1).

FPK Unit (with adapter FPK/SB)

Prior to connecting the charging and

gauging unit to an accumulator, take

adapter FPK/SB and unscrew the socket

head cap screw 3 full turns counter

clockwise using the 6 mm Allen wrench.

This is done to prevent gas valve damage

and leakage upon installation. Screw the

adapter FPK/SB onto HYDAC gas valve

version 4, hand tighten. Close manual bleed

valve on the FPK unit hand tight. Connect

FPK unit to adapter FPK/SB by screwing

cap nut onto the adapter; hand tighten.

Loading...

Loading...