HYDAC FPO 414 User Manual

3

1-877-GO HYDAC

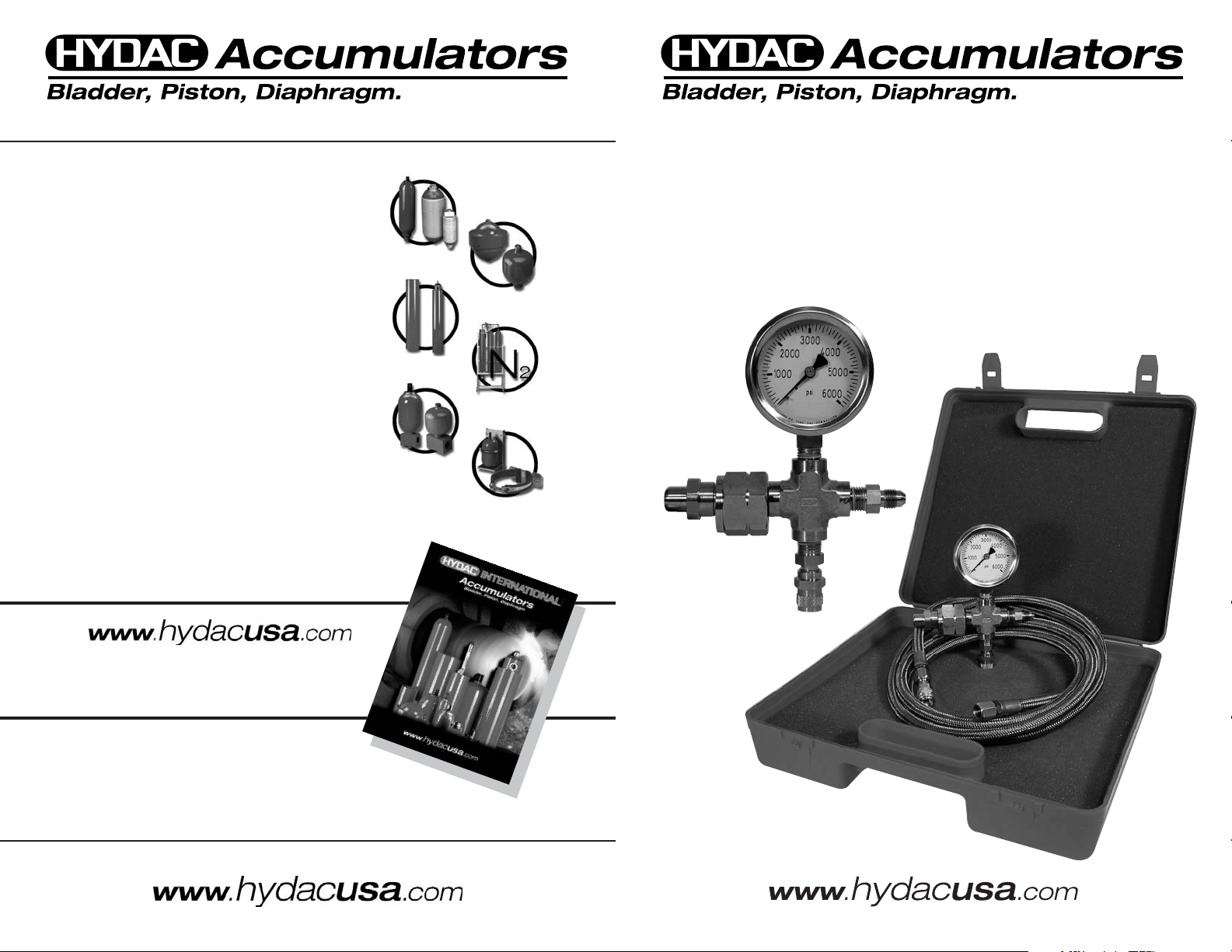

Charging & Gauging Units

2

Charging & Gauging Units

Operating and

Installation Instruction

Preparation

To check the gas precharge pressure in

an accumulator, it must first be isolated

from the system shut off, and all hydraulic

pressure relieved.

HYDAC gas valve version 11

Unscrew the valve protection cap (where

applicable) and the valve seal cap.

Charging

Warning!

Never use oxygen or air - this could

cause an explosion! Use dry nitrogen or

other recommended gases.

HYDAC recommends the use of a pressure

regulator on the commercially available

nitrogen bottle to regulate pressure to the

charging and gauging unit.

Note: Full nitrogen pressure may damage

the gauge.

Initial Charging

When charging an accumulator that has no

initial gas precharge, allow 20 to 30 minutes

for the gas temperature and thus pressure

to stabilize. Recheck the gas precharge

pressure and adjust if necessary.

General Warning!

Hydraulic accumulators are pressurized

vessels and only qualified technicians

should perform maintenance. For additional

information refer to HYDAC Operating and

Installation Instructions and HYDAC

Maintenance Instructions. Read all instructions

thoroughly before before beginning any type

of service or repair.

Intervals Between Checking

Gas Precharge Pressure

The proper gas precharge pressure should

be set after each new installation or repair

by following the instructions under the

Operating and Installation Instructions

below. It should be rechecked at least once

during the first week of operation. If there is

no loss of gas precharge pressure, it should

be rechecked again in 3 to 4 months.

Thereafter, it should be checked at least

once a year. Recharge accumulator when

necessary.

Temperature Effect

To ensure that the recommended gas

precharge pressure is maintained, even at

relatively low or high operating temperatures,

the gas precharge pressure should be

adjusted for temperature. The formula

below relates the precharge temperature

(T

0

) to the operating temperature (T).

Fahrenheit

P

0,T

0

= P

0,T

2

x (T0+ 460) / (T2+ 460)

Celsius

P

0,T

0

= P

0,T

2

x (T0+ 273) / (T2+ 273)

T

0

= precharge temperature

T

2

= maximum operating temperature

P0,T0= gas precharge pressure at

precharge temperature

P0,T2= gas precharge pressure at

maximum operating temperature

Pressure Increase

When charging an accumulator that has an

existing gas precharge, allow 5 to 10 minutes

for the gas temperature and thus pressure

to stabilize.

Filling

1. Attach the gland & nut portion of the

charging assembly, CGA-677 to a dry

nitrogen bottle, tighten securely.

2. Attach the air chuck to the accumulator

bladder gas valve by hand tightening its

swivel hex connection.

3. Open the gas valve by turning its top

(small) hex nut, counter-clockwise.

4. Set nitrogen bottle gas regulator (if

attached) to 25 psig. (The use of nitro-

gen gas regulator is strongly recommended!)

5. Open nitrogen bottle gas valve. (If you

are not using a nitrogen regulator, care

should be taken to slowly “crack” the

valve open.) With a regulator, valve can

be opened fully.

6. Pre-charge slowly (25 psig) using dry

nitrogen gas, until bladder is fully inflated.

Caution: Initial Precharging Above 25 psig

Will Cause The Bladder to Burst!

7. Continue precharging to desired pressure

by increasing gas flow slowly.

8. Close the valve by turning its top (small)

hex nut, clockwise. Close nitrogen gas

bottle valve.

9. Open bleed valve to release pressure in

the hose and charging head.

10. Remove the charge assembly. Check for

gas leakage. (The use of gas leak detection

fluid or soapy water is recommended.)

11. Replace the valve cap and protective

cap. Tighten, hand tight.

12. Pressurize system. Operate.

Caution:

Precharge Maintenance

For cycling applications check the precharge

weekly. For non-cycling applications, monthly.

You will normally lose some gas over time

due to performance.

A more rapid loss may indicate a gas valve

problem.

1. Release system pressure.

Not gas precharge.

2. Remove gas protective cap (valve guard)

and valve cap.

3. Install gauging device on gas valve stem.

4. For 3000 pis accumulators, screw down

air chuck “T” handle, check pressure.

For 4000 psi or higher, open gas valve

hex fitting (do not loosen from bladder).

Check pressure.

5. Add additional dry nitrogen gas if

necessary, using the above procedures.

6. To release excess nitrogen gas (if any)

open up bleeder valve, located on gauging

head, until desired pressure is achieved.

Pressure Release

With the charging and gauging unit attached

as previously described, gas precharge

pressure can be released by carefully opening manual bleed valve. Release the gas

precharge pressure very slowly until the

desired gas precharge pressure is reached (this

insures that the gas temperature does not fluctuate greatly, providing and accurate gas

precharge pressure). Close the manual

bleed valve. Allow the gas precharge pressure

to stabilize. (5 to 10 minutes) recheck, adjust if

required. Once the desired gas precharge

pressure is reached, refer to steps 8 to 12

under Filling to remove Charging and

Gauging Unit.

Failure to follow proper service and

installation instructions will void

HYDAC product warranty.

• Bladder Accumulators

• Diaphragm Accumulators

• Piston Accumulators

• Nitrogen Bottles

• Dampeners

• Shock Absorbers

• Safety & Shut-off Blocks

• Mounting Components

• Thermal Fuse Caps

• Charging & Gauging Units

• Permanent Gauging Blocks

• Spare Parts, Seal Kits, & Tools

Visit

to download the complete

HYDAC Accumulators Catalog!

Charging and Gauging Unit

FPO 414

Operating Manual

Part No. 02084351

Loading...

Loading...