Page 1

Accumulators

Charging & Gauging Units

FPK / FPS Operating Manual

1.877.GO.HYDAC www.HYDACusa.com 1.888.99.HYDAC www.HYDAC.ca

PN#02068202 • ACU1403-1605 / 03.14

Page 2

2

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

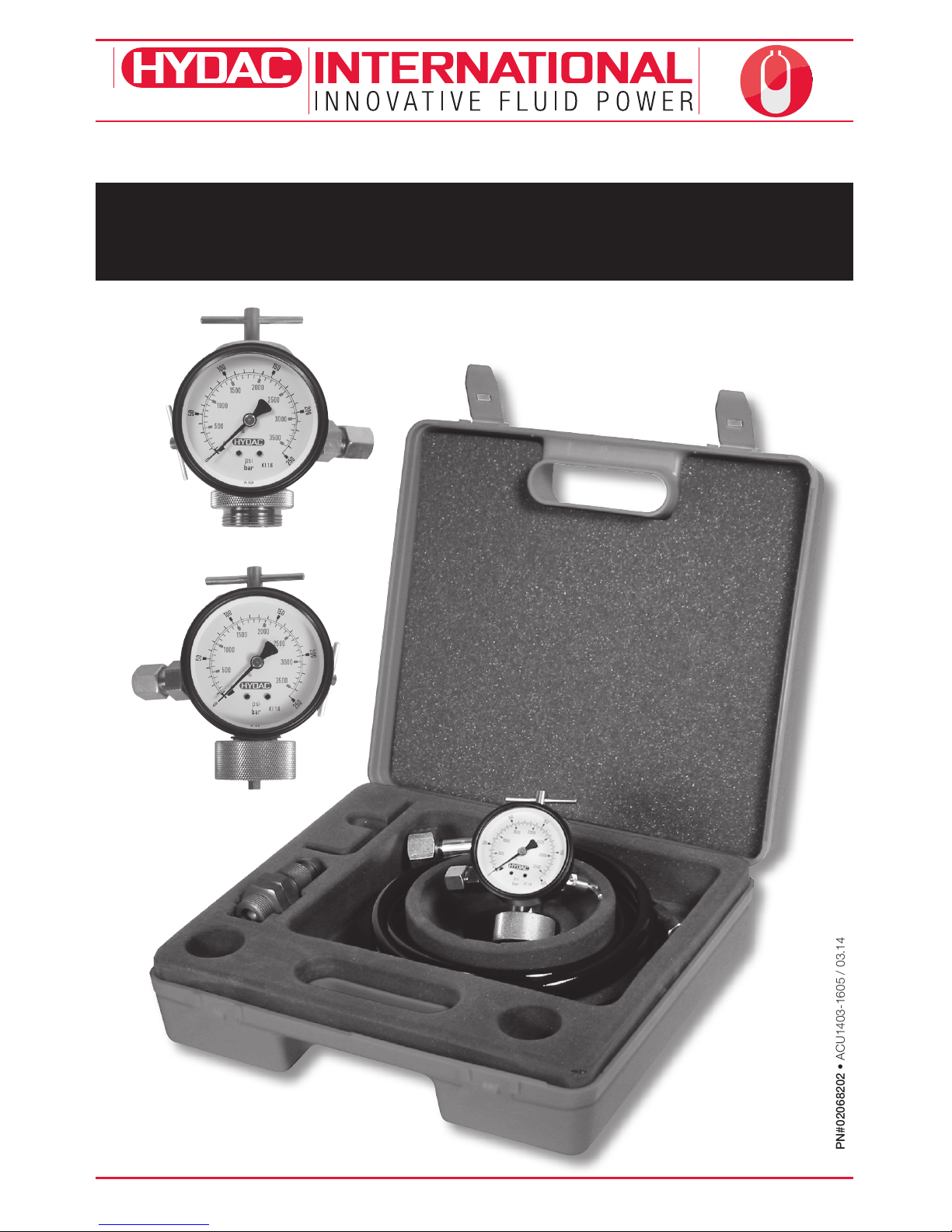

FPS

Version 4

FPK

Version 1

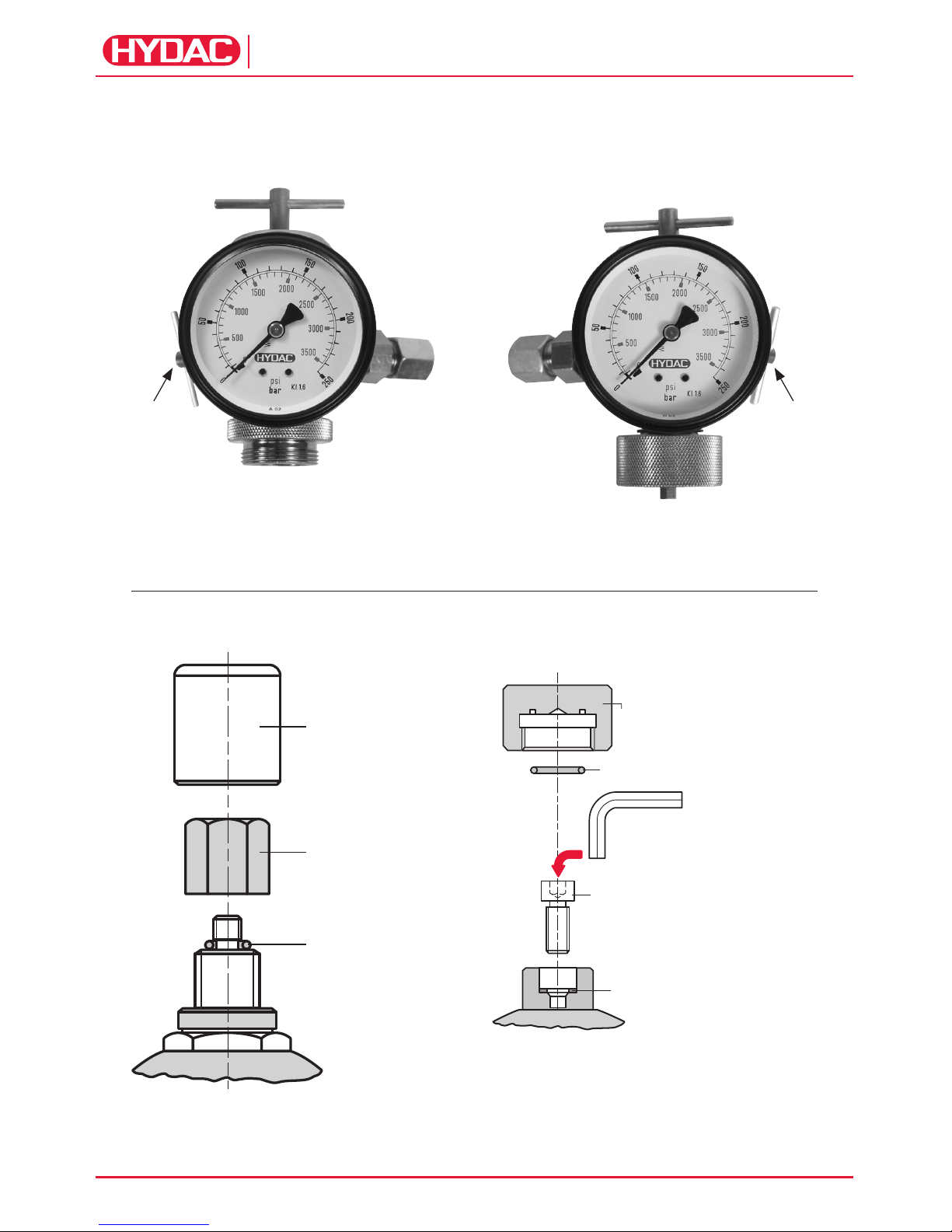

valve

protection

cap

(where applicable)

Valve

seal cap

O-ring

Allen Wrench 6 mm

(to be used to crack open M8 SHCS.

T handle on FPK Charging is not robust

enough to overcome recommended torque)

Valve protection cap

(where applicable)

O-ring (where applicable)

Socket Head

Cap Screw (M8)

Seal ring

T-Handle T-Handle

Check

Valve

Cap Nut Cap Nut

Manual

Bleed

Valve

Manual

Bleed

Valve

Figure 1

Figure 2

Page 3

3

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

General Warning!

Hydraulic accumulators are pressurized

vessels and only qualified technicians

should perform maintenance. For additional

information refer to HYDAC Operating

and Installation Instructions and HYDAC

Maintenance Instructions. Read all

instructions thoroughly before before

beginning any type of service or repair.

Tools Required

1. Gas Valve Core Tool.

2. Torque Wrenches.

3. Wrench(es).

Intervals Between Checking

Gas Precharge Pressure

The proper gas precharge pressure should

be set after each new installation or repair

by following the instructions under the

Operating and Installation Instructions

below. It should be rechecked at least once

during the first week of operation. If there

is no loss of gas precharge pressure, it

should be rechecked again in 3 to 4 months.

Thereafter, it should be checked at least

once a year. Recharge accumulator when

necessary.

Temperature Effect

To ensure that the recommended gas

precharge pressure is maintained,

even at relatively low of high operating

temperatures, the gas precharge pressure

should be adjusted for temperature. The

formula below relates the precharge

temperature (T0) to the operating

temperature (T).

Fahrenheit

P

0,T 0

= P

0,T 2

x (T0 + 460) / (T2 + 460)

Celsius

P

0,T 0

= P

0,T 2

x (T0 + 273) / (T2 + 273)

T0 = precharge temperature

T2 = maximum operating temperature

P

0,T 0

= gas precharge pressure at

precharge temperature

P

0,T 2

= gas precharge pressure at

maximum operating temperature

Operating and

Installation Instruction

Preparation

To check the gas precharge pressure in

an accumulator, it must first be isolated

from the system shut off, and all hydraulic

pressure relieved.

HYDAC gas valve version 4 (see fig. 2)

Unscrew the valve protection cap (where

applicable) and the valve seal cap.

HYDAC gas valve version 1 (see fig. 2)

Unscrew the valve protection cap (where

applicable). Slightly loosen the socket head

cap screw with a 6 mm Allen wrench (approx.

1/6 turn, see fig. 2).

NOTE: In order to connect the charging

hose to the FPK/FPS charging unit body,

the small ferrule must first be removed.

FPS Unit

Prior to connecting the charging and

gauging unit to an accumulator, turn

T-handle counter-clockwise until resistance

is felt. Close manual bleed valve by

hand tightening. Connect the unit to the

accumulator by screwing cap nut onto

HYDAC gas valve version4; hand tighten

(see fig. 1).

FPK Unit

Prior to connecting the charging and

gauging unit to an accumulator, close

manual bleed valve by hand tightening.

Connect the unit to the accumulator by

screwing cap nut onto HYDAC gas valve

version 1; hand tighten

(see fig. 1).

FPK Unit (with adapter FPK/SB)

Prior to connecting the charging and

gauging unit to an accumulator, take

adapter FPK/SB and unscrew the socket

head cap screw 3 full turns counter

clockwise using the 6 mm Allen wrench.

This is done to prevent gas valve damage

and leakage upon installation. Screw the

adapter FPK/SB onto HYDAC gas valve

version 4, hand tighten. Close manual bleed

valve on the FPK unit hand tight. Connect

FPK unit to adapter FPK/SB by screwing

cap nut onto the adapter; hand tighten.

Page 4

4

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

Checking Gas

Precharge Pressure

Connect the appropriate charging and

gauging unit to the accumulator following

the instructions under “Preparation” (see

page 2). Note: Temperature affects the

gas precharge pressure, please refer to

“Temperature Effect” (see page 2).

FPS Unit

Turn T-handle “A” clockwise a maximum of

3 full turns from the full counterclockwise

position. The gauge needle should indicate

the existing gas precharge pressure. If there

is no gas precharge pressure indicated

or if it is too low or too high, please follow

instructions under the appropriate section,

either “Pressure Release” (see below)

or “Charging” (to right). If desired gas

precharge pressure registers, please follow

the instructions under “Removal of Charging

and Gauging Unit” (see page 5).

FPK Unit

Turn T-handle counter clockwise a

maximum of 3 full turns. The gauge needle

should indicate the existing gas precharge

pressure. If there is no gas precharge

pressure indicated or if it is too low or

too high, please follow instructions under

the appropriate section, either “Pressure

Release” (see page 3) or “Charging” (see

page 3 ). If desired gas precharge pressure

registers, please follow the instructions

under “Removal of Charging and Gauging

Unit” ( see page 4).

Pressure Release

With the appropriate charging and gauging

unit attached as previously described,

gas precharge pressure can be released

by carefully opening manual bleed valve.

Release the gas precharge pressure very

slowly until the desired gas precharge

pressure is reached (this insures that the

gas temperature does not fluctuate greatly,

providing and accurate gas precharge

pressure). Close the manual bleed valve.

Allow the gas precharge pressure to

stabilize. (5 to 10 minutes) recheck, adjust if

required. Once the desired gas precharge

pressure is reached, please follow the

instructions under “Removal of Charging

and Gauging Unit” (see page 5).

Charging

Warning!

Never use oxygen or air - this could

cause an explosion! Use dry nitrogen or

other recommended gases.

HYDAC recommends the use of a pressure

regulator on the commercially available

nitrogen bottle to regulate pressure to the

charging and gauging unit.

Note: Full nitrogen pressure may damage

the gauge. Connect the charging hose to

a commercially available nitrogen bottle

by means of the G4 adapter (other adapters

are available, check with factory for type); the

adapter connects to the cap screw “G1”.

Connect cap nut of the charging hose to

check valve of the charging and gauging

unit (see fig. 1). Connect the appropriate

charging and gauging unit to the

accumulator by following the instructions

previously described (see page 2).

Initial Charging

When charging an accumulator that has no

initial gas precharge, allow 20 to 30 minutes

for the gas temperature and thus pressure

to stabilize. Recheck the gas precharge

pressure and adjust if necessary.

FPS Unit

Turn T-handle clockwise 3 full turns.

Proceed to “Filling”.

FPK Unit

Turn T-handle counter clockwise 3 full turns.

Proceed to “Filling”.

FPK Unit (with adapter FPK/SB)

Turn T-handle clockwise 3 full turns.

Proceed to “Filling”.

Page 5

5

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

Pressure Increase

When charging an accumulator that has

an existing gas precharge, allow 5 to 10

minutes for the gas temperature and thus

pressure to stabilize.

FPS Unit

Turn T-handle clockwise until the gauge

needle begins to deflect, then turn it another

full turn. Proceed to “Filling”.

FPK Unit

Turn T-handle counter clockwise until the

gauge needle begins to deflect, then turn it

another full turn. Proceed to “Filling”.

FPK Unit (with adapter FPK/SB)

Turn T-handle clockwise until the gauge

needle begins to deflect, then turn it another

full turn. Proceed to “Filling”.

Filling

Open the shut-off valve on the commercially

available nitrogen bottle and slowly fill the

accumulator with dry nitrogen gas.

Precharge very slowly until the pressure

in the accumulator reaches 100 psi. Once

100 psi is reached, the charging rate can

increase. Charging too quickly may damage

the accumulator.

Note: The gauge registers the line pressure,

not necessarily the accumulator pressure

while charging.

After allowing the appropriate time for

the gas temperature and thus pressure to

stabilize, adjust the gas precharge pressure

as required, refer to “Pressure Increase” (see

page 4) or “Pressure Release” (see page 3 ).

Once the desired gas precharge pressure

is reached close the shutoff valve on the

commercially available nitrogen bottle.

Remove the charging and gauging unit from

the gas valve as described under “Removal

of Charging and Gauging Unit” (see page 5).

Removal of Charging and

Gauging Unit

Close the shut-off valve on the commercially

available nitrogen bottle before removing

the charging and gauging unit.

FPS Unit

Turn T-handle counter clockwise until

resistance is felt to close the gas valve.

Open manual bleed valve to relieve pressure

in the charging and gauging unit. Proceed to

“Disconnecting”.

FPK Unit

Turn T-handle clockwise until resistance

is felt to close the socket head cap screw,

hand tighten. Open manual bleed valve to

relieve pressure in the charging and gauging

unit. Proceed to “Disconnecting”.

FPK Unit (with adapter FPK/SB)

Turn T-handle counter clockwise until

resistance is felt to close the gas valve.

Open manual bleed valve to relieve pressure

in the charging and gauging unit. Proceed to

“Disconnecting”.

Disconnection

Unscrew the charging and gauging unit

from the gas valve. Note: For FPK unit with

adapter FPK/SB it may be necessary to

loosen the connection between cap nut

and the adapter to remove the charging

and gauging unit. Check for leaks. None are

permissible.

Completion

HYDAC gas valve version 1 (see fig. 1)

Tighten socket head screw cap to 20 Nm

(15 lb-ft), and screw on valve protection cap

(where applicable); hand tighten.

HYDAC gas valve version 4 (see fig. 1)

Screw on valve seal cap torquing to 30 Nm

(22 lb-ft), and valve protection cap (where

applicable); hand tighten.

Page 6

6

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

Spare Parts

Item Description Part No.

9 O-Ring 006 01032

10 Seal-Ring 00601228

11 Gauge (select pressure range below)

10 (0 to 145 psi) 00606759

25 (0 to 350 psi) 00606760

100 (0 to 1400 psi) 00606761

250 (0 to 3500 psi) 00606762

400 (0 to 5800 psi) 00606763

12 Check Valve 00610004

13 Manual Bleed Valve 00236445

23

O-Ring - FPS 00626488

O-Ring - FPK 00601049

- 2.5m Hose 00236514

- 4m Hose 00236515

- 10m Hose 00373405

- ADAPTER G4 02068737

- ADAPTER A3 (FPK/SB) 00291533

- O-Ring - ADAPTER A3 (FPK/SB) 00601964

Page 7

7

Charging & Gauging Units

PN#02068202 • ACU1403-1605 / 03.14

ACCUMULATORS

M28x1.5

7/8-14UNF

A10

PN 02128849

M28x1.5

M16x2

A11

PN 03018210

M28x1.5

M16x2

(Test Point)

A12

PN 03930191

M28x1.5

Vg8

A9

PN 02128638

M28x1.5

7/8-14UNF

A

3 (ADAPTER FPK/SB)

PN 00291533

M28x1.5

M16x1.5

A

1

PN 00361619

M28x1.5

5/8-18UNF

A

2

PN 00361605

M28x1.5

7/8-14UNF

A

4

PN 00291536

M28x1.5

G1/4

A7

PN 02110629

M28x1.5

G3/4

A8

PN 02124524

M28x1.5

G3/4A

A6

PN 02108819

M28x1.5

M8x1

A5

PN 00291531

A Adapters (Gauge to Accumulator)

Page 8

1.877.GO.HYDAC www.HYDACusa.com 1.888.99.HYDAC www.HYDAC.ca

© Copyright 2014 HYDAC CORPORATION • FPK/FPS Operating Manual PN#02068202 • ACU1403-1605

PN#02068202 • ACU1403-1605 / 03.14

W24.32x1/14"

M14x1.5

G1

SW32

M

Germany

Poland

Others

SW 32

SW 32

G2

PN 00236376

81

W24.32x1/14"

G5/8 - ISO 228

seal ring A6x10

Australia

Argentina

Great Britain

Vietnam

Others

52

G7

PN 00236377

W24.32x1/14"

W23x1/14"

SW 32

Korea

W24.32x1/14"

W21.8x1/14"

SW 32

37

G3

PN 02103421

Egypt

Lebanon

Israel

Others

W24.32x1/14"

SW 32

40

G8

PN 02103425

G1/2 - ISO 228

Brazil

Chile

Columbia

Others

SW 32

SW 32

G4

PN 02068737

81

W24.32x1/14"

W24.5x1/14"

seal ring A6x10

USA

Canada

Puerto Rico

SW 30

SW 32

G9

PN 00241168

58

W24.32x1/14"

M22x1.5

seal ring A6x10

Taiwan

SW 32

SW 32

G5

PN 00236373

79

W24.32x1/14"

W21.8x1/14"

seal ring A6x10

Italy

W24.32x1/14"

SW 36

45

G10

PN 02103427

ISO 228-G 3/4"

Russia

Trinidad

Tobago

Venezeula

seal ring A6x10

W24.32x1/14"

68

G6

PN 02103423

W22x1/14"

SW 32SW 32

Japan

SW 32

SW 32

G11

PN 03018678

64

W24.32x1/14"

G5/8-ISO228

seal ring A6x10

China

G Adapters (Charging to Accumulator)

Charging Hoses

Loading...

Loading...