Hydac FAM 5 Operating And Maintenance Instructions Manual

FAM 5

FluidAqua Mobil

Operating and Maintenance Instructions

English (translation of original instructions)

Documentation no.: 4166129

HYDAC FILTER SYSTEMS GMBH

Postfach 1251

66273 Sulzbach / Saarland

Germany

Telephone:

+49 6897 509 01

Fax:

+49 6897 509 9046

E-mail:

filtersystems@HYDAC.com

Homepage:

www.HYDAC.com

Court of Registration:

Saarbrücken, HRB 17216

Executive director:

Mathias Dieter,

Mr. Günter Harge

c/o HYDAC International GmbH, Industriegebiet, 66280 Sulzbach / Saar

Telephone:

+49 6897 509 1511

Fax:

+49 6897 509 1394

E-mail:

guenter.harge@HYDAC.com

Imprint

Publisher and responsible for the content:

Imprint

Dipl.Kfm. Wolfgang Haering

Documentation Representative

© HYDAC FILTER SYSTEMS GMBH

All rights reserved. No part of this work may be reproduced in any form (print,

photocopy or by other means) or processed, duplicated or distributed using

electronic systems without the written consent of the publisher.

These documents have been created and inspected with the greatest care.

However, errors cannot be ruled out completely.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 2 / 114

Content

Imprint ............................................................................................................ 2

Documentation Representative ................................................................... 2

Content .......................................................................................................... 3

Preface ........................................................................................................... 7

Safety information ........................................................................................ 9

Content

Technical Support ........................................................................................ 7

Product modification .................................................................................... 7

Warranty ...................................................................................................... 7

Using the documentation ............................................................................. 8

Hazard symbols ........................................................................................... 9

Signal words and their meaning in the safety information and

instructions ................................................................................................ 10

Structure of the safety information and instructions ................................... 10

Observe regulatory information ................................................................. 11

Proper/Designated Use ............................................................................. 11

Improper Use or Use Deviating from Intended Use ................................... 12

Qualifications of personnel / target group .................................................. 13

Wear suitable clothing ............................................................................... 14

Stoppage in an emergency (EMERGENCY STOP) ................................... 14

Unpacking the FAM .................................................................................... 15

Transporting the FAM ................................................................................. 15

Horizontal transport ................................................................................... 15

Vertical transport ....................................................................................... 16

Transport suspended on a crane ............................................................... 17

Checking the scope of delivery ................................................................. 17

FAM description .......................................................................................... 18

FAM Versions ............................................................................................ 18

FAM features ............................................................................................. 19

FAM system components .......................................................................... 20

Dimensions – stationary unit ..................................................................... 22

Dimensions – mobile unit .......................................................................... 23

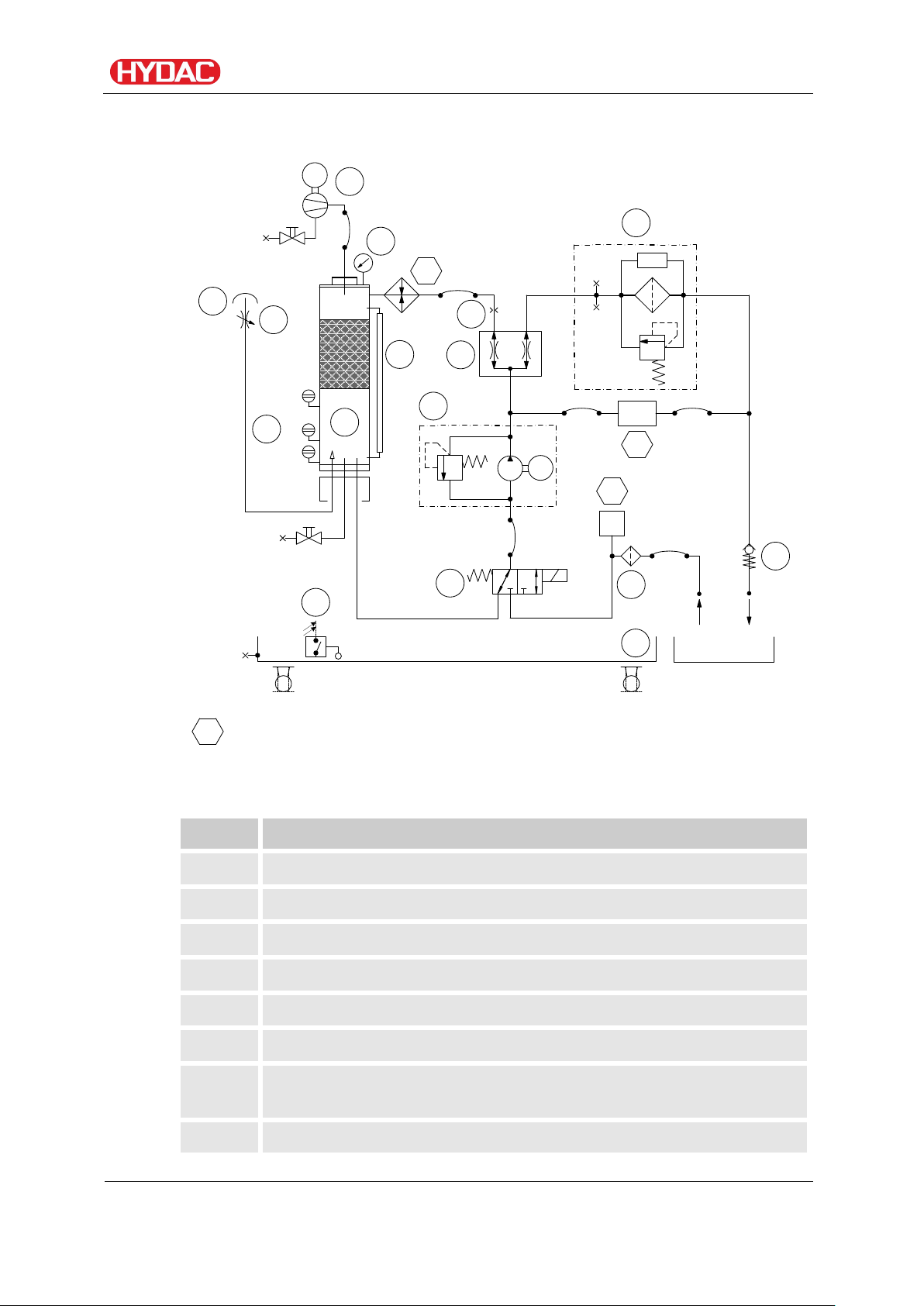

Hydraulic circuit .......................................................................................... 24

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 3 / 114

Content

Working principle of FAM .......................................................................... 25

Possible applications ................................................................................. 26

Bypass purification ................................................................................. 26

Transfer by Pumping .............................................................................. 26

FAM set-up and connection ....................................................................... 27

Setting up the FAM .................................................................................... 27

Notes on pipes and hoses ......................................................................... 28

Connecting the inlet (IN) ......................................................................... 30

Connect outlet (OUT) ............................................................................. 31

Preparing the Vacuum Pump ..................................................................... 31

Check air outlet of the vacuum pump ..................................................... 32

Electrical connection of the FAM ............................................................... 32

Check direction of rotation ......................................................................... 33

Operating elements on the FAM ................................................................ 34

Starting up the unit ..................................................................................... 36

Switching on the FAM ................................................................................ 36

FAM start screen (HOME) and menu layout .............................................. 37

Starting operation of the FAM .................................................................... 38

Setting the pressure in the vacuum column ............................................... 40

Recommended vacuum setting .............................................................. 40

Pressure information in the vacuum range .......................................... 42

Venting the filter housing ........................................................................... 43

Switching on the heater / Checking setting (optional) ................................ 43

Stopping operation of the FAM .................................................................. 45

Switching off FAM ....................................................................................... 46

Selecting operating mode .......................................................................... 46

"Dewater" operating mode (optional) ......................................................... 47

"Filter" operating mode (optional) .............................................................. 49

Limits on ContaminationSensor CS ........................................................ 49

ContaminationSensor CS1000 menu layout .......................................... 51

Setting times for "Dewater/Filter until" (optional) ....................................... 52

"Heat" operating mode (optional) ............................................................... 53

Manual Operation ...................................................................................... 54

Emptying the vacuum column ................................................................ 54

Manually controlling components ........................................................... 55

Settings – Language, operating hours, program version ....................... 56

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 4 / 114

Content

Loading new program version/language version .................................... 57

Inserting micro-SD card and loading program ........................................... 57

Configuration menu .................................................................................... 58

Changing configuration .............................................................................. 59

Exiting the Configuration menu .................................................................. 59

FAM menu layout ........................................................................................ 60

Changing values and parameters in menus ............................................. 61

Connection of an external AquaSensor AS(EXT) ..................................... 61

Network connection (Ethernet) .................................................................. 62

Web server ................................................................................................ 62

Troubleshooting .......................................................................................... 66

Error notifications ....................................................................................... 68

03 Empty vacuum column ...................................................................... 69

04 Vacuum pump level sensor ............................................................... 70

05 Vacuum column sensor ..................................................................... 71

12 Measured AS temp value/13 Measured AS %S value ...................... 72

18 H pump motor protection switch/19 V pump motor protection

switch V-pump ........................................................................................ 73

23 Filter clogged ..................................................................................... 74

24 V pump min. ...................................................................................... 75

25 V pump max. ..................................................................................... 75

26 Heater thermostat .............................................................................. 76

28 Heater motor protection switch .......................................................... 77

32 Fill column ......................................................................................... 79

33 Vacuum column alarm ....................................................................... 80

34 Drip tray full ....................................................................................... 81

Performing maintenance ........................................................................... 82

Maintenance intervals ................................................................................ 82

Check fault signal lamps ............................................................................ 85

Change Air filter ......................................................................................... 85

Vacuum pump ........................................................................................... 85

Replace the active carbon filter cartridge (accessory) ............................ 85

Rotary vane vacuum pump FAM-5-x-x-x-xx-R-x-x-x-x ........................... 86

Checking the oil level .......................................................................... 87

Filling/Refilling vacuum pump oil ........................................................ 88

Emptying the vacuum pump ................................................................ 90

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 5 / 114

Content

Changing the vacuum pump oil ........................................................... 91

Replacing the air de-oiling element of the vacuum pump .................... 92

Dry-running rotary vane vacuum pump FAM-5-x-x-x-xx-RD-x-x-x-

x ............................................................................................................. 93

Replacing the filter .............................................................................. 94

Blowing off the filter ............................................................................. 94

Inspecting/replacing vanes .................................................................. 95

Clean the suction screen ........................................................................... 96

Replacing the filter element on the fluid filter ............................................. 96

Heater maintenance (optional) ................................................................ 101

Inspecting/Cleaning the heating element ............................................. 101

Removing/Installing the heating element .......................................... 101

Emptying the heater ............................................................................. 103

Checking the AquaSensor AS1000 ......................................................... 104

Checking the float switch in the oil pan .................................................... 104

Spare parts ................................................................................................ 106

FAM ......................................................................................................... 106

Fluid filter (OLF 5/10) ............................................................................... 106

Vacuum pump ......................................................................................... 106

Rotary vane vacuum pump FAM-5-x-x-x-xx-R-x-x-x-x ......................... 106

Dry-running rotary vane vacuum pump FAM-5-x-x-x-xx-RD-x-x-x-

x ........................................................................................................... 107

Contact / Service ....................................................................................... 107

Storing the unit / taking it out of operation ............................................ 107

Disposing of the unit ................................................................................ 108

Technical data ........................................................................................... 108

Connection overview ................................................................................ 110

Model code ................................................................................................ 111

EC declaration of conformity ................................................................... 112

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 6 / 114

Fax:

+49 6897 509 9046

E-mail:

filtersystems@HYDAC.com

Preface

These operating instructions were made to the best of our knowledge.

Nevertheless and despite the greatest care, it cannot be excluded that

mistakes could have crept in. Therefore please understand that, in the

absence of any provisions to the contrary hereinafter, our warranty and

liability – for any legal reasons whatsoever – are excluded in respect of the

information in these operating instructions. In particular, we shall not be liable

for lost profit or other financial loss. This exclusion of liability does not apply

in cases of intent and gross negligence. Moreover, it does not apply to

defects which have been deceitfully concealed or whose absence has been

guaranteed, nor in cases of culpable harm to life, physical injury and damage

to health. If we negligently breach any material contractual obligation, our

liability shall be limited to foreseeable damage. Claims due to Product

Liability shall remain unaffected.

Technical Support

Preface

Contact our technical sales department if you have any questions on our

product. When contacting us, please always include the model code, serial

no. and part no. of the product:

Product modification

We would like to point out that changes to the product (e.g. purchasing

options, etc.) may result in the information in the operating instructions no

longer being completely accurate or sufficient.

After modification or repair work that affects the safety of the product has

been carried out on components, the product may not be returned to

operation until it has been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product

whether by you or a third party.

Warranty

For the warranty provided by us, please refer to the General Terms of Sale

and Delivery of HYDAC FILTER SYSTEMS GMBH.

You will find these under www.HYDAC.com -> General Terms and

Conditions.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 7 / 114

Note that the method described for locating specific information

de

HYD

A

C

F

i

l

t

e

r

t

e

c

h

n

i

k

G

m

b

H

B

e

W

a

1

2

3

4

5

6

a

d

e

Seite x

P

r

o

d

u

k

t

/

K

a

p

i

t

e

l

200x-xx-xx

Chapter description

Page number

Document language

Documentation No.

Using the documentation

does not release you from your responsibility of carefully reading

all these instructions prior to starting the unit up for the first time

and at regular intervals in the future.

What do I want to know?

I determine which topic I am looking for.

WHERE can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Safety information

Edition date

with Index /

File name

The documentation number with its index enables you to order another copy

of the operating and maintenance instructions. The index is incremented

every time the manual is revised or changed.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 8 / 114

Safety information

The unit was built according to the statutory provisions valid at the time of

delivery and satisfies current safety requirements.

Any residual hazards are indicated by safety information and instructions and

are described in the operating instructions.

Observe all safety and warning instructions attached to the unit. They must

always be complete and legible.

Do not operate the unit unless all the safety devices are present.

Secure the hazardous areas which may arise between the unit and other

equipment.

Maintain the unit inspection intervals prescribed by law.

Document the results in an inspection certificate and keep it until the next

inspection.

Safety information

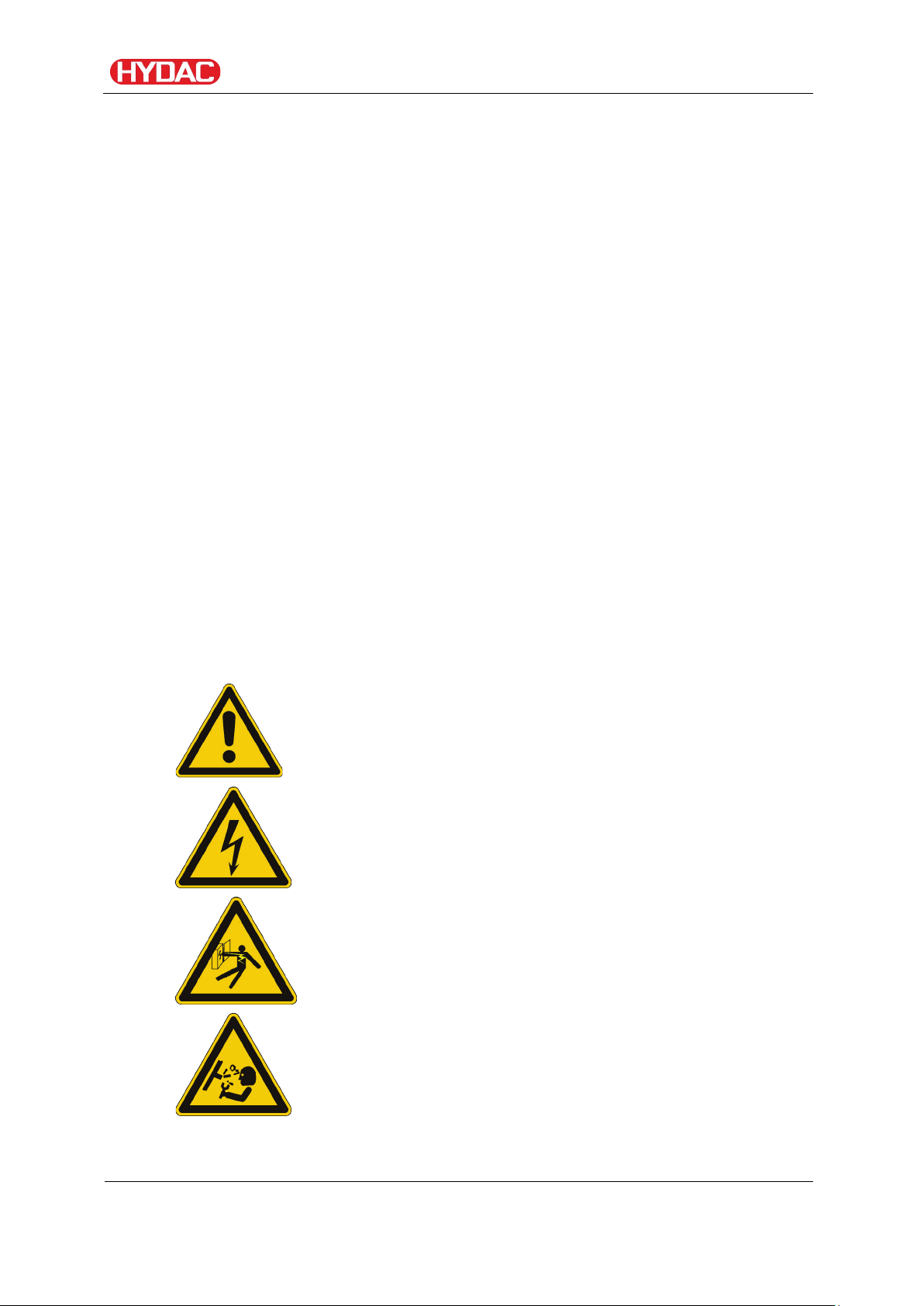

Hazard symbols

These symbols are listed for all safety information and instructions in these

operating instructions which indicate particular hazards to persons, property

or the environment.

Observe these instructions and act with particular caution in such cases.

Pass all safety information and instructions on to other users.

General hazard

Danger due to electrical voltage / current

Exposed electrical components

Danger of electrical shock

Danger due to operating pressure

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 9 / 114

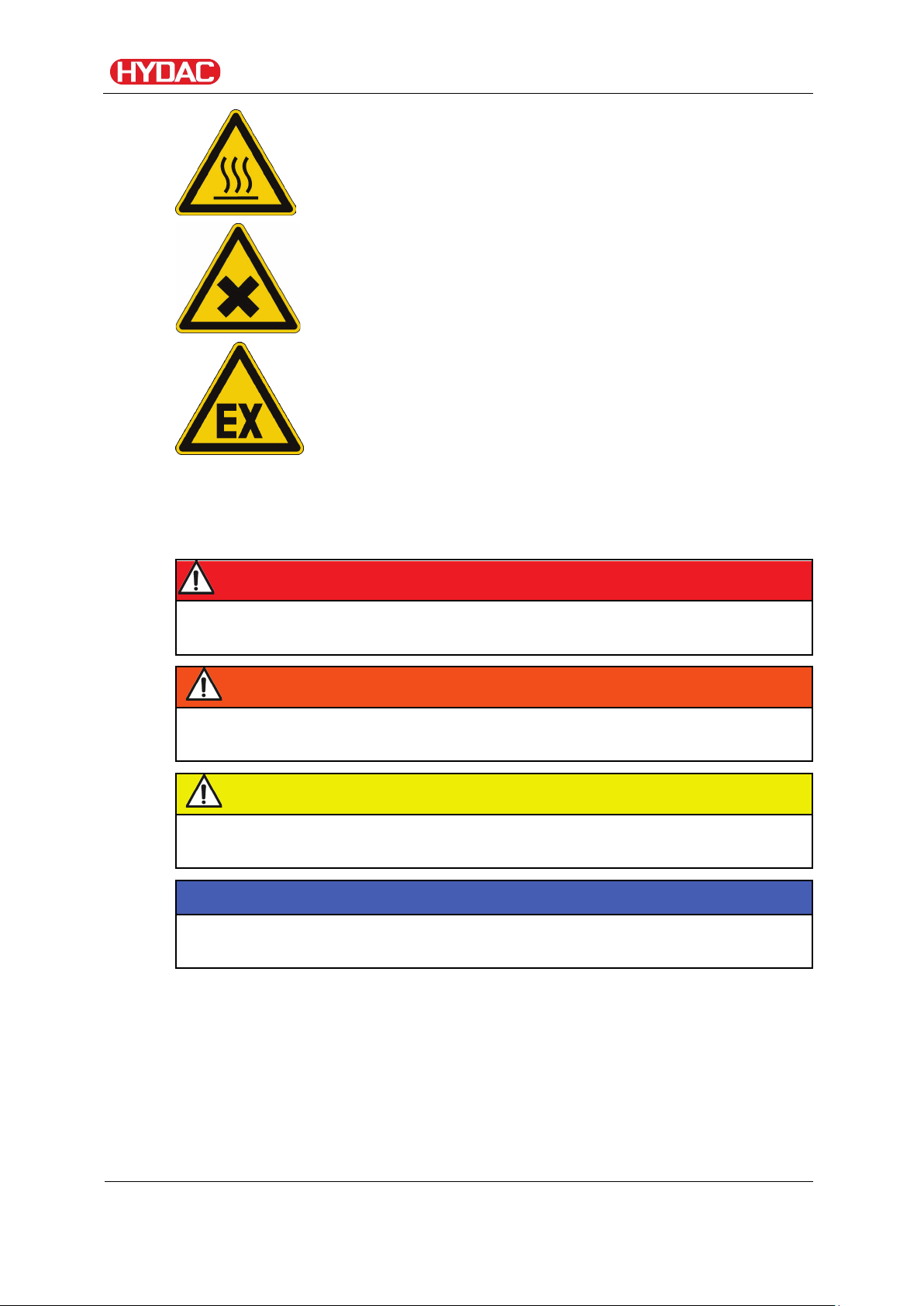

DANGER

DANGER indicates a danger with a high risk which will lead to death or

serious injury if not avoided.

WARNING

WARNING indicates a danger with a medium risk which can lead to death or

serious injury if not avoided.

CAUTION

CAUTION indicates a danger with a low risk which can lead to minor injury if

not avoided.

NOTICE

NOTICE indicates a danger which will lead to damage to property if not

avoided.

Safety information

Risk of burns due to hot surfaces

Substances that are health hazards or irritants

Danger from explosive atmosphere

Signal words and their meaning in the safety information and instructions

Structure of the safety information and instructions

All warning instructions in this manual are highlighted with pictograms and

signal words. The pictogram and the signal word indicate the severity of the

danger.

Warning instructions listed before an activity are laid out as follows:

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 10 / 114

F

S

o

m

Sealing

material

Hoses

FFAAMM--xxxx--MM-

-

MMiinneerraall ooiill,, tteesstteedd wwiitthh mmiinneerraall ooiill..

•• OOtthheerr hhyyddrraauulliicc aanndd lluubbrriiccaattiioonn ooiillss wwhhiicchh

NBR

NBR

HAZARD SYMBOL

SIGNAL WORD

Observe regulatory information

Observe the following regulatory information and guidelines:

• Legal and local regulations for accident prevention

• Legal and local regulations for environmental protection

• Country-specific regulations, organization-specific regulations

Safety information

Type and source of danger

Consequence of the danger

► Measures to avert danger

Proper/Designated Use

Use the unit only for the application described in the following.

The FAM is for dewatering, filtering and degassing hydraulic and lubricating

oils. In addition, it removes free water, emulsified water and a large

percentage of the water found in solution.

Proper or designated use of the product extends to the following:

• Observing all instructions contained in the instruction manual.

• performing inspection and maintenance work.

Depending on the version (see model code), you may use the FAM only in

connection with the following media:

e

e

p

p

y

y

t

t

M

M

A

A

e

e

l

l

b

b

a

a

t

t

i

i

u

u

g

g

n

n

i

i

m

m

t

t

u

u

a

a

i

i

r

r

d

d

e

e

e

e

p

p

……

•• MMiinneerraall ooiillss aacccc.. ttoo DDIINN 5500552244

•• GGeeaarr ooiillss aacccc.. ttoo DDIINN 5511551177,, 5511552244

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 11 / 114

rreeqquuiirree oorr aarree ccoommppaattiibbllee wwiitthh NNBBRR sseeaallss

FFAAMM--xxxx--II--……

IInnssuullaattiioonn ooiill,, cchheecckkeedd wwiitthh ((ee..gg.. SShheellll DDiiaallaa))..

NBR

NBR

FFAAMM--xxxx--BB--……

BBiioollooggiiccaallllyy tteesstteedd wwiitthh ffaasstt--bbiiooddeeggrraaddiinngg

FKM

NBR

FFAAMM--xxxx--XX--……

HHFFDD--RR fflluuiiddss,, tteesstteedd wwiitthh ((ee..gg.. FFyyrrqquueell))..

FKM

UPE/

Safety information

•• MMiinneerraall ooiillss aacccc.. ttoo DDIINN 5500552244

•• GGeeaarr ooiillss aacccc.. ttoo DDIINN 5511551177,, 5511552244

•• OOtthheerr hhyyddrraauulliicc aanndd lluubbrriiccaattiioonn ooiillss wwhhiicchh

rreeqquuiirree oorr aarree ccoommppaattiibbllee wwiitthh NNBBRR sseeaallss

UUnniitt iiss nnoott ssuuiittaabbllee ffoorr ""OOnnlliinnee"" aanndd ""OOnnllooaadd""

ooppeerraattiioonn oonn ttrraannssffoorrmmeerr..

fflluuiidd oonn aann eesstteerr bbaassiiss..

•• SSyynntthheettiicc eesstteerr ((HHEEEESS)) DDIINN 5511552244//22

•• VVeeggeettaabbllee ooiillss ((HHEETTGG,, HHTTGG))

•• HHyyddrraauulliicc aanndd lluubbrriiccaattiioonn ooiillss wwhhiicchh

rreeqquuiirree oorr aarree ccoommppaattiibbllee wwiitthh VViittoonn sseeaallss..

NNoott ffoorr pphhoosspphhaattee eesstteerrss tthhaatt rreeqquuiirree EEPPDDMM

sseeaallss..

(FPM,

Viton®)

(FPM,

Viton®)

PEPA

Improper Use or Use Deviating from Intended Use

Any use extending beyond this or deviating therefrom shall not be considered

intended use. HYDAC Filter Systems GmbH will assume no liability for any

damage resulting from such use. The owner alone, shall assume any and all

associated risk

DANGER

Danger due to unanticipated use of the unit

Bodily injury and damage to property will result

when operated improperly.

► Never operate the unit in potentially

explosive atmospheres.

► The unit is only to be used with permissible

media.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 12 / 114

Activity

Person

Knowledge

Transport / storage

Forwarding

• Proof of knowledge of

Hydraulic / electrical

Specialist

• Safe handling/use of

• Checking the phase

Improper use or use deviating from intended may result in hazards and/or will

damage the unit. Examples of improper use:

• Operation in potentially explosive atmospheres.

• Operation with a non-approved medium.

• Operation under non-approved operational conditions.

• Operation when the safety devices are defective.

• Modifications to the power unit made by the user or purchaser.

• Inadequate monitoring of parts that are subject to wear and tear

• Improperly performed repair work.

Qualifications of personnel / target group

Persons who work on the power unit must be aware of the associated

hazards when using the power unit.

Operating and specialist personnel must have read and understood the

operating instructions, in particular the safety information and instructions,

and applicable regulations before beginning work.

Safety information

The operating instructions and applicable regulations are to kept so they are

accessible for operating and specialist personnel.

These operating instructions are intended for:

Operating personnel: such persons have been instructed in power unit

operation and are aware of potential hazards due to improper use.

Specialist personnel: such persons with corresponding specialist training and

several years work experience. They are able to assess and perform the

work assigned to them, they are also able to recognize potential hazards.

agent

Specialist

personnel

cargo securing

instructions

• Safe handling/operation

of hoisting and lifting

equipment

installation,

personnel

tools

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

first commissioning,

maintenance,

troubleshooting,

repair,

decommissioning,

en(us)

• Fitting and connection of

hydraulic lines and

connections

• Fitting and connection of

electrical lines, electrical

machinery, sockets, etc.

Page 13 / 114

Disassembly

sequence

Operation

Specialist

• Product-specific

Disposal

Specialist

• Proper and

In the event of an emergency, turn the main

clockwise direction to

Safety information

• Product-specific

knowledge

Operations control

Wear suitable clothing

Loosely worn clothing increases the danger of getting caught or wound up in

rotating parts and the danger of getting snagged on projecting parts. You can

be severely injured or killed.

personnel

personnel

knowledge

• Knowledge about how to

handle operating media.

• Knowledge about

contamination due to

solids and water

environmentally-friendly

disposal of materials and

substances

• Decontamination of

contaminants

• Knowledge about reuse

• Wear close-fitting clothing.

• Do not wear any rings, chains or any other jewelry.

• Wear work safety shoes.

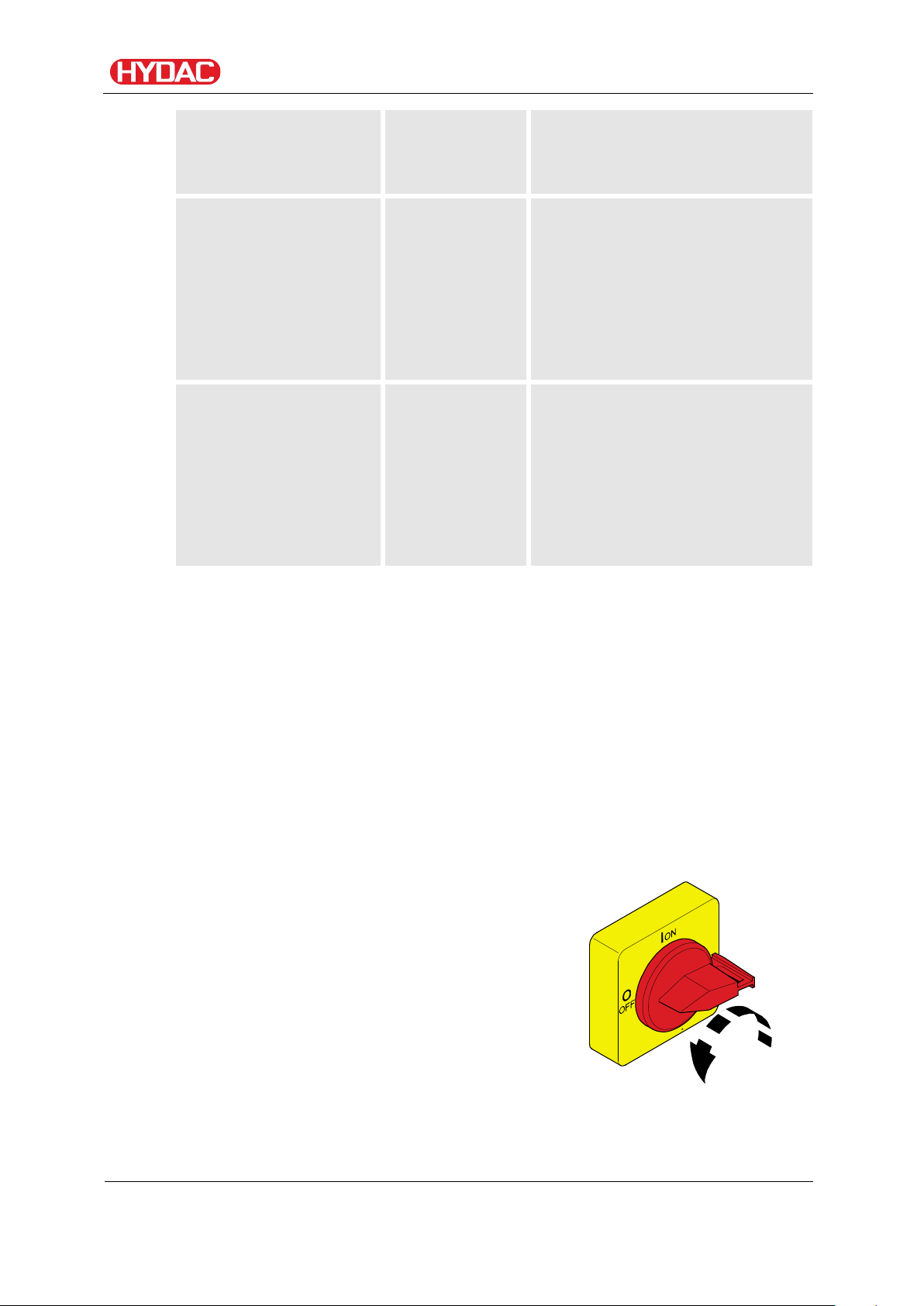

Stoppage in an emergency (EMERGENCY STOP)

switch by 90° in a countershut down the entire unit. The entire unit

downstream of this switch is voltage-free and

depressurized.

Normal pressure is restored to the vacuum column after ≈ 1 minute.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 14 / 114

Unpacking the FAM

Before delivery, the FAM is inspected for leaks and proper functioning at the

factory, then carefully packed for shipment.

When receiving and unpacking the unit, check it for damage in transit.

Dispose of the packaging material in an environmentally friendly manner.

Transporting the FAM

Using components for pushing/pulling

The FAM will be damaged

► Never use the components to push or pull the FAM.

Unpacking the FAM

NOTICE

► Use the grips provided for shifting.

Wind the suction and pressure hose and the connection cable around the

holders provided for this purpose and either fasten them in place or remove

the hoses from the FAM.

Move the FAM manually using the rollers. Only ever use the FAMs handle to

move it.

Before shifting the unit, make sure to release the hand brake on the swivel

casters.

Once the FAM is in the new, desired position, actuate the hand brake on the

swivel casters.

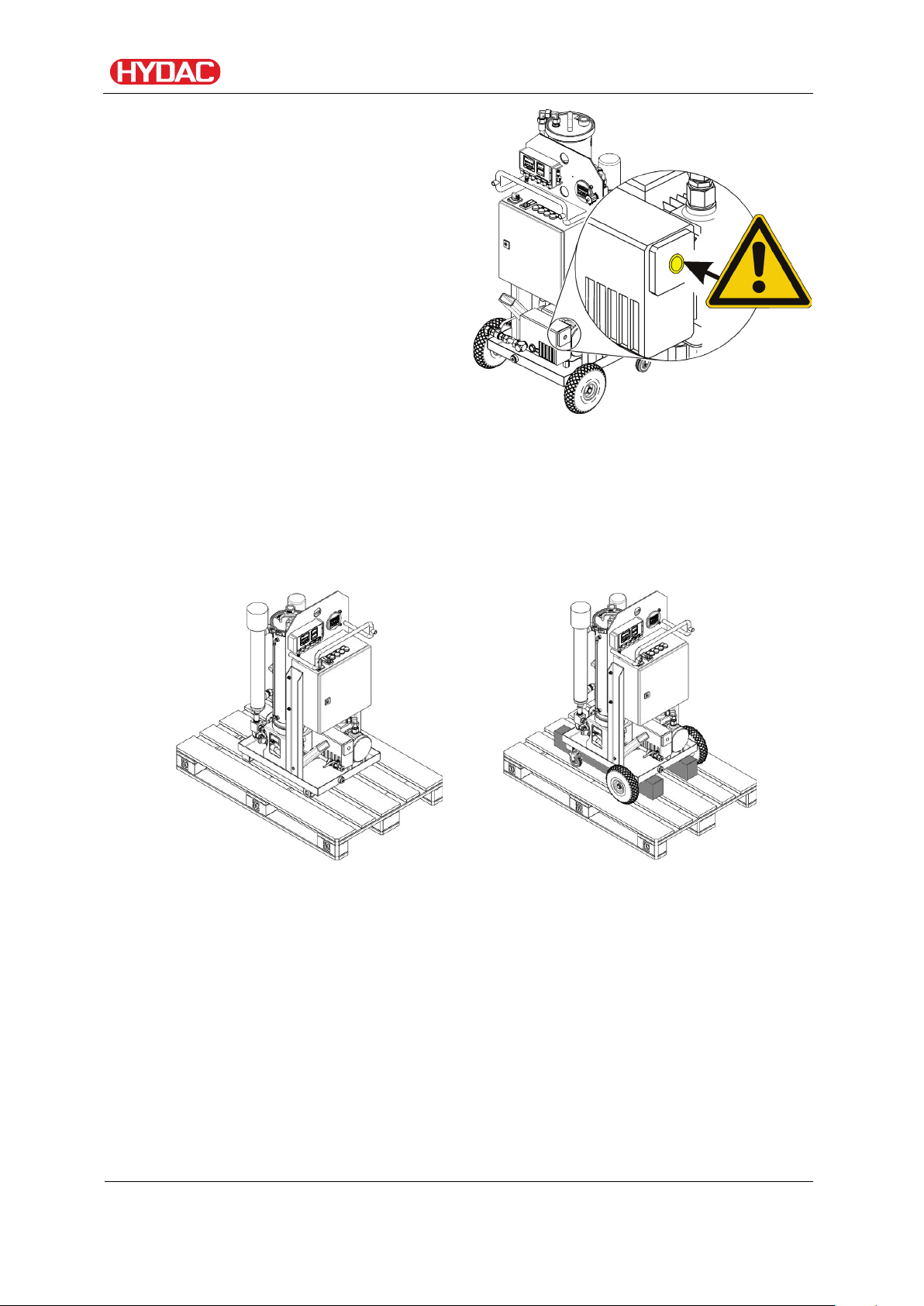

Horizontal transport

Completely empty the FAM as well as the rotary vane vacuum pump before

horizontal transport, e.g., in a vehicle, and close off all connections.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 15 / 114

Close the air outlet of the vacuum

Stationary version

Mobile version

pump using the matching suitable

screw plugs.

Ensure the FAM is fixed tight to the car using load restraint belts at the

suitable lashing points in the car.

Vertical transport

Transporting the FAM

For transport by rail or truck, supports must be placed under the mobile FAM

so that none of the rollers are subjected to load pressure. Secure the FAM

with suitable belts.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 16 / 114

Qty

Designation

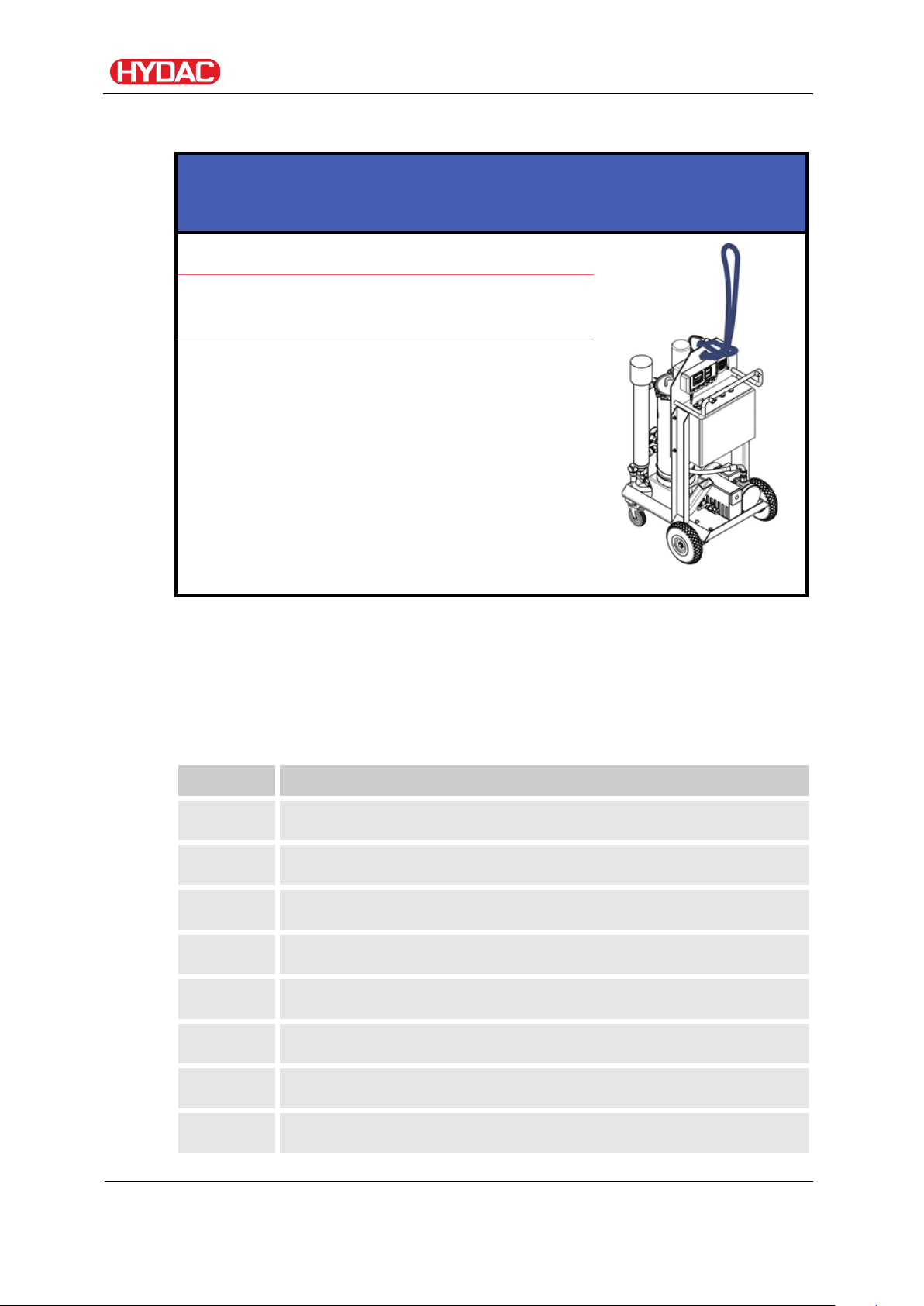

Transport suspended on a crane

NOTICE

Unsuitable lifting accessories

The unit/components will be

damaged/destroyed

► Use only suitable lifting accessories to

raise or lash the FAM.

► Take care to ensure that the lifting

accessories do not cause any pressures to

be brought to bear against the components

on the FAM.

Checking the scope of delivery

Checking the scope of delivery

Upon receiving the FAM check it for any damage in transit. Immediately

report any damage in transit to the forwarding agent or the HYDAC

department in charge.

The following items are supplied:

1

1

1

1

1

FluidAqua Mobil

Key to the control cabinet

Vacuum pump oil, 1 liter (FAM-5-x-x-x-x-R-x-x-x-x only)

Suction and return hose (mobile FAM-5-x-2-… only)

Operation and Maintenance Instructions (this document)

1

1

1

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

Electrical wiring diagram situated in the control cabinet

EC declaration of conformity

Test certificate

en(us)

Page 17 / 114

-

2x

Wheels

-

2x

Swivel casters

-

1x

Suction hose

-

1x

Return hose

FAM description

The FluidAqua FAM was developed for the dewatering, filtration and

degassing of hydraulic and lubricating oils. It removes free water, emulsified

water and a large proportion of the water in solution. The Fluidfilter that is

installed provides efficient particulate separation.

The fluid is degassed through a vacuum in the vacuum chamber.

FAM Versions

FAM description

Stationary (FAM-x-1-..) Mobile (FAM-x-2-..)

In comparison to the stationary version, the mobile version of the FAM also

has:

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 18 / 114

Hydraulic and lubrication oils

<100 ppm

Turbine oil (ISO VG32/46)

< 50 ppm

Transformer oil (unit is not suitable for "Online" and

<10 ppm

Dewatering speed

Water content

Fluid temperature

Detergent additives

Tank volume in liters

Filter Size

< 2,000

FAM 5

1,000 … 7,000

FAM 10, FAM 10/15

7,000 … 15,000

FAM 25

15,000 … 25,000

FAM 45 / FAM-45E

25,000 … 35,000

FAM 60

35,000 … 45,000

FAM 75 / FAM-75E

> 45,000

FAM 95

FAM features

The FAM is able to reduce fluids described in the chapter "Suitable fluids"

typically to the following attainable residual water contents:

"Onload" operation on transformer)

The typical dewatering rate is up to 0.8l/h at 1% (10,000 ppm) water content

(ISO VG32, 50°C).

Dewatering performance/Dewatering speed depends in particular on the oil

type, oil temperature, oil quantity, tank condition, water content and the

environmental conditions and can differ considerably from the indicated

values depending on use.

The dewatering speed is dependent on:

FAM description

As an approximate guideline, the dimensioning of the FluidAqua Mobil can be

defined in accordance with the tank volume.

Note that free water, e.g. on the bottom of the tank, can have an influence on

the entire water content in the system and thus on the length of time it takes

to dewater. Drain off free water completely.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 19 / 114

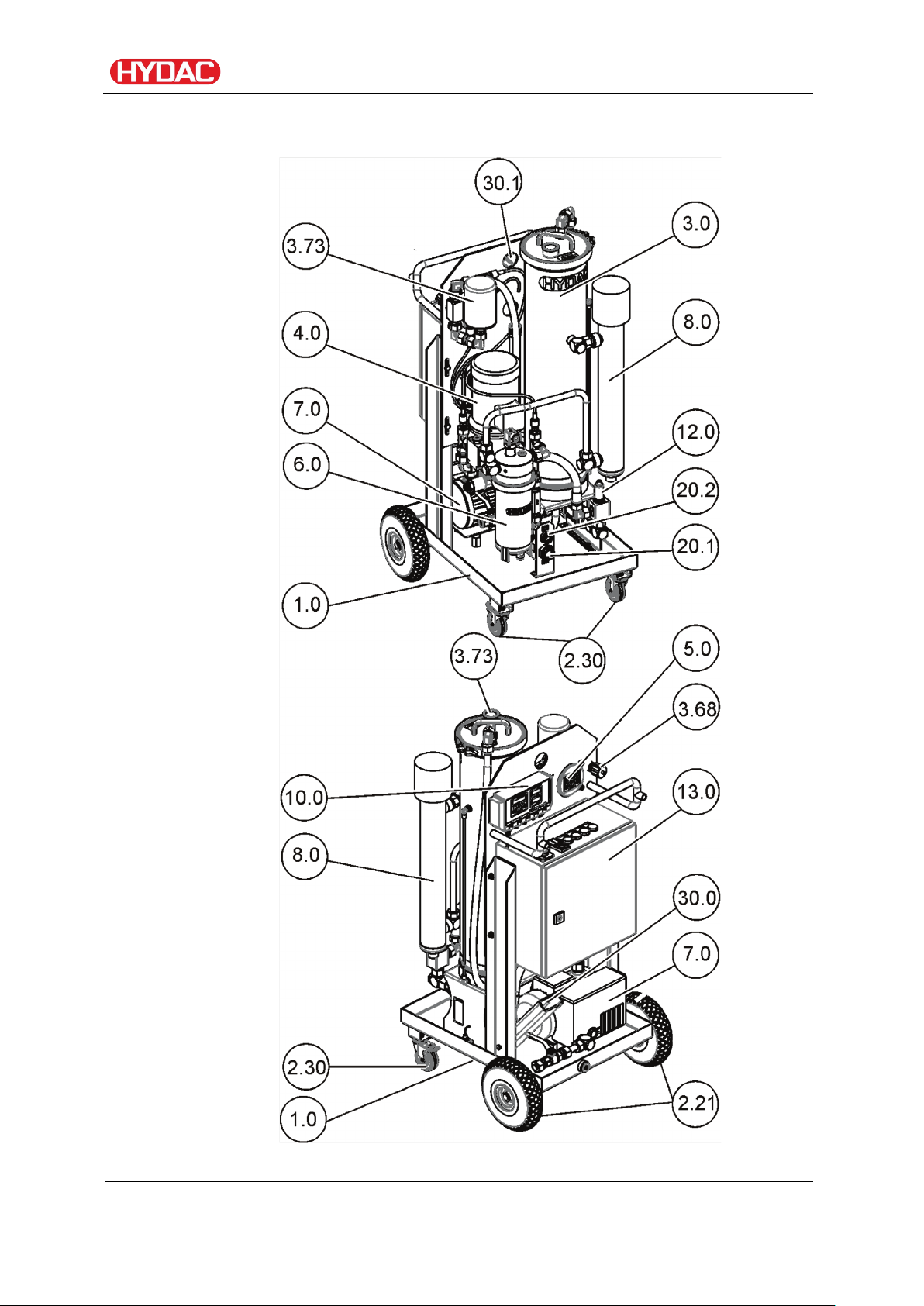

FAM system components

FAM description

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 20 / 114

Item

Designation

1.0

Drip tray

2.21

Pneumatic tire

(mobile version only)

2.30

Guide roll

(mobile version only)

3.0

Vacuum column

3.68

Vacuum gauge

3.73

Air filter

3.85

3/2-directional control valve

4.0

Motor pump assembly

5.0

ContaminationSensor CS

(optional)

6.0

Fluid filter for separating solid particles

OLF5

7.0

Vacuum pump

8.0

Heater

(optional)

10.0

SensorMonitoring Unit SMU

(optional)

12.0

AquaSensor AS

(optional)

13.0

Electrical switch box with main switch

20.1

Inlet

IN

20.2

Outlet

OUT

30.0

Holder for lances

(Accessories)

31.0

Lifting eye

FAM description

(underpressure setting in the vacuum

column)

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 21 / 114

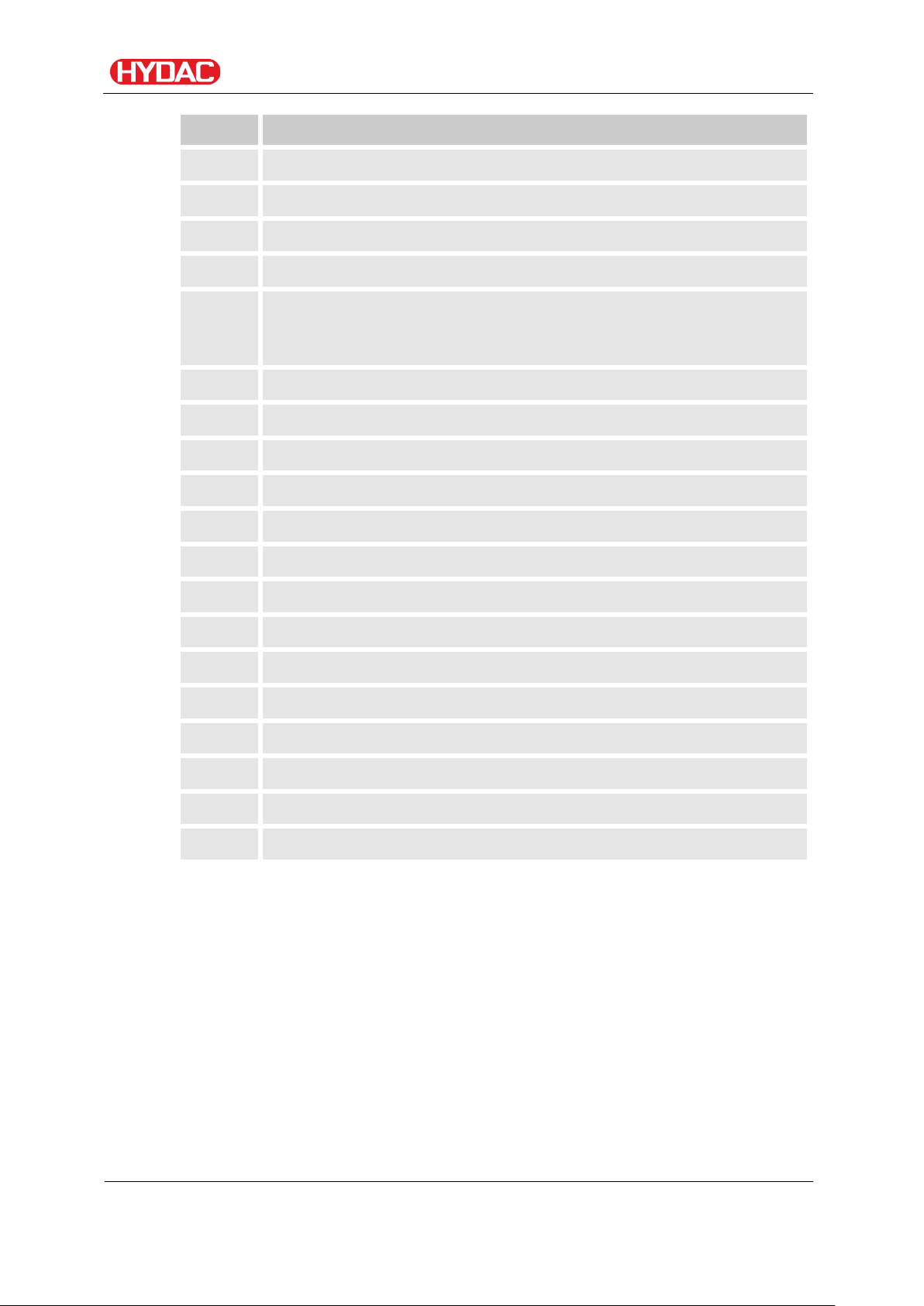

Dimensions – stationary unit

Dimensions – stationary unit

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 22 / 114

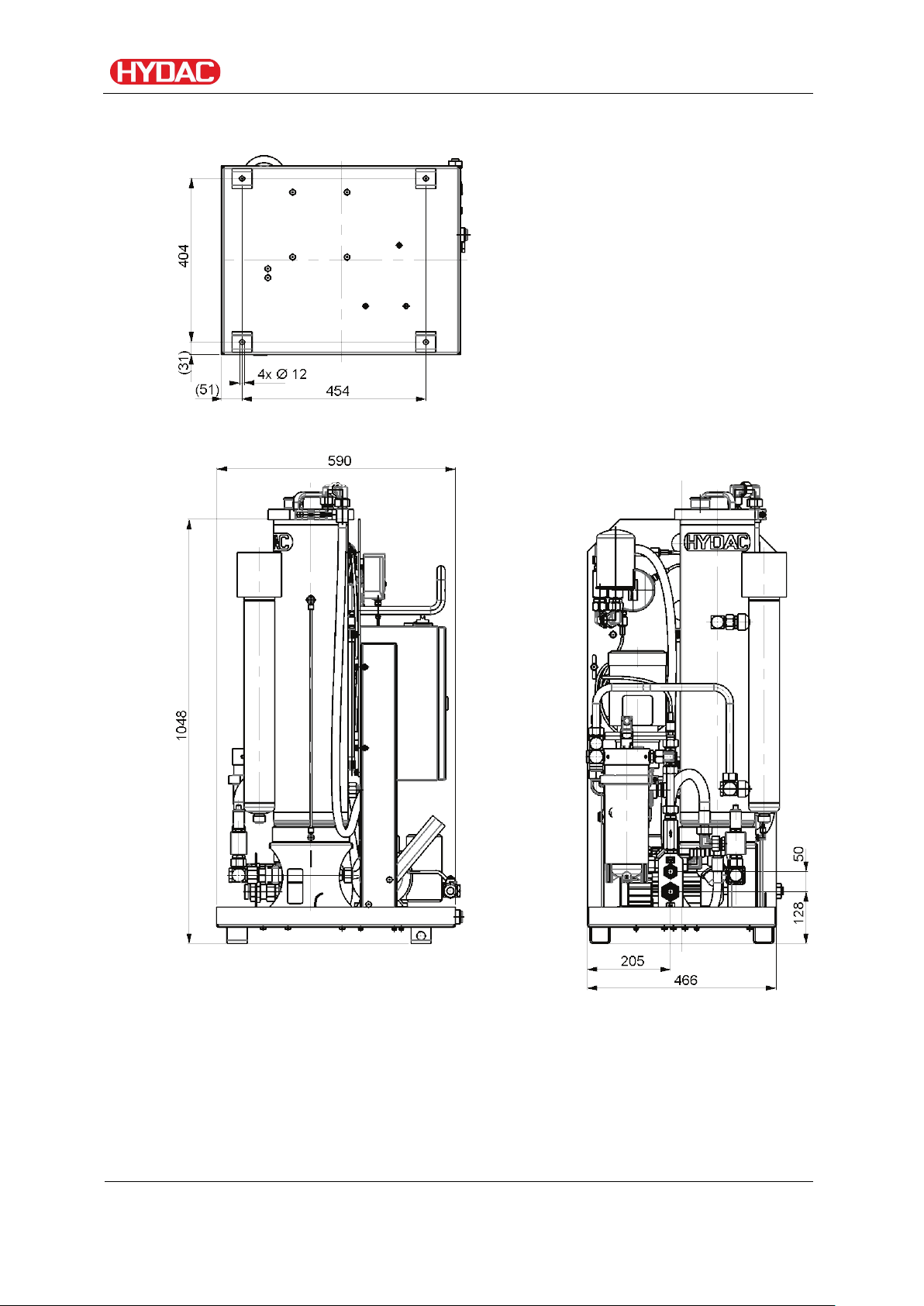

Dimensions – mobile unit

Dimensions – mobile unit

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 23 / 114

Einlass

Inlet

Auslass

Outlet

Entleerung

Drain

Lufteinlass

Air intake

Min.

Max.

Alarm

M

Entleerung

Drain

Luftauslass

Air outlet

1.04

1.0

3.68

3.73

3.38

3.0

4.0

4.02

4.54

6.0

7.0

6.23

AS

CS

M

3.37

DPI

Entleerung

Drain

Entlüftung

Vent

Entleerung

Drain

3.43

4.70

3.85

P

R A

8.0*

5.0*

12.0*

Optionale Bauteile

Optional components

x.x*

Item

Designation

1.0

Drip tray

1.04

Float switch in oil pan

3.0

Vacuum column

3.37

Vacuum pressure gauge

3.38

Level switch in the vacuum column

3.43

Fluid level indication of the vacuum column

Vacuum gauge

3.73

Air filter

Hydraulic circuit

Hydraulic circuit

3.68

(underpressure setting in the vacuum column)

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 24 / 114

3.85

3/2-directional control valve

4.0

Motor pump assembly

4.02

Suction strainer

4.54

Flow divider

4.70

Orifice

5.0

ContaminationSensor CS

(optional)

6.0

Fluid filter for separating solid particles

OLF5

6.23

Non-return valve

7.0

Vacuum pump

8.0

Heater

(optional)

12.0

AquaSensor AS

(optional)

Working principle of FAM

Working principle of FAM

After you switch on the FAM, the motor pump assembly (4.0), depending on

the fill level in the vacuum column, starts to suck either from the vacuum

column or the tank via the suction strainer (4.02) or from the vacuum column

and the 3/2 directional valve (3.85).

The flow rate is split up in the flow divider (4.54). One part is transported via

the optional heater (8.0) into the vacuum column (3.0), the other back into the

tank via the fluid filter (6.0).

The vacuum pump (7.0) builds up the negative pressure in the vacuum

column (3.0) required for dewatering and degassing.

The underpressure is set using the needle valve (3.68) and shown in the

pressure gauge on the cover of the vacuum column (3.0).

The fluid percolates downwards in the vacuum column (3.0) over a special

tower packing and collects in the lower area. After reaching the maximum

level (3.38), the 3/2 directional valve (3.85) will switch and the motor pump

assembly (4.0) will start sucking the oil out of vacuum column (3.0).

Air is drawn in through the air filter (3.73) as a result of the negative pressure

in the vacuum column (3.0). This air absorbs the moisture of the fluid and is

then sucked out by the vacuum pump (7.0). The gases removed from the

fluid as well as the water that is absorbed is expelled (as water vapor) from

the vacuum pump.

The saturation level of the aspirated fluid is continuously measured via the

optional AquaSensor (12) and displayed on the control panel. The saturation

level indicates what percent of maximum possible water is dissolved in the

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 25 / 114

In order to achieve optimum purity results, always operate the

oil. A value of 0% would indicate water-free oil and 100% would mean oil that

is completely saturated with water.

Once the STOP button is pressed, the unit runs until the "Min" fill level in the

vacuum column is reached. The run-down phase status is shown in the

display.

Exception: If the integrated heater is switched on, then a cooling phase of 60

seconds will intervene during which the heater is first shut off.

If the fill level "Min" in the vacuum column is reached, the power unit will be

switched off.

The FAM is voltage-free downstream from the main switch when the FAM is

switched off with the main switch.

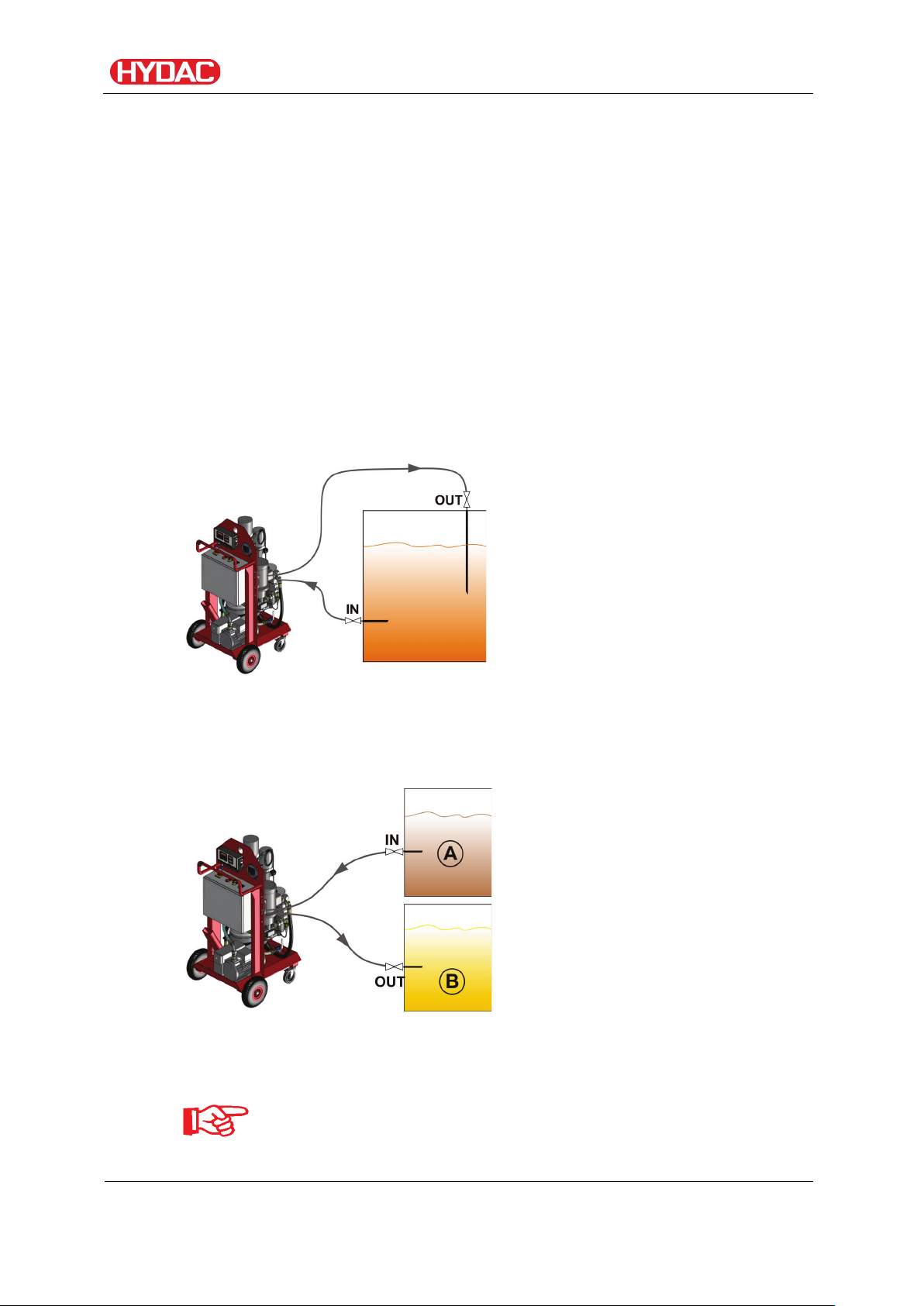

Possible applications

Bypass purification

Working principle of FAM

Attach the FAM to the tank which is to be cleaned by means of a suction and

pressure line and switch it on. The permanent bypass purification means you

always get optimum purity results.

Transfer by Pumping

Connect up the FAM to a contaminated oil tank by means of a suction line

and pump the fluid into the clean oil tank via the FAM.

To avoid overfilling the tank (B), permanently monitor the oil level.

FAM in bypass current after transfer by pumping.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 26 / 114

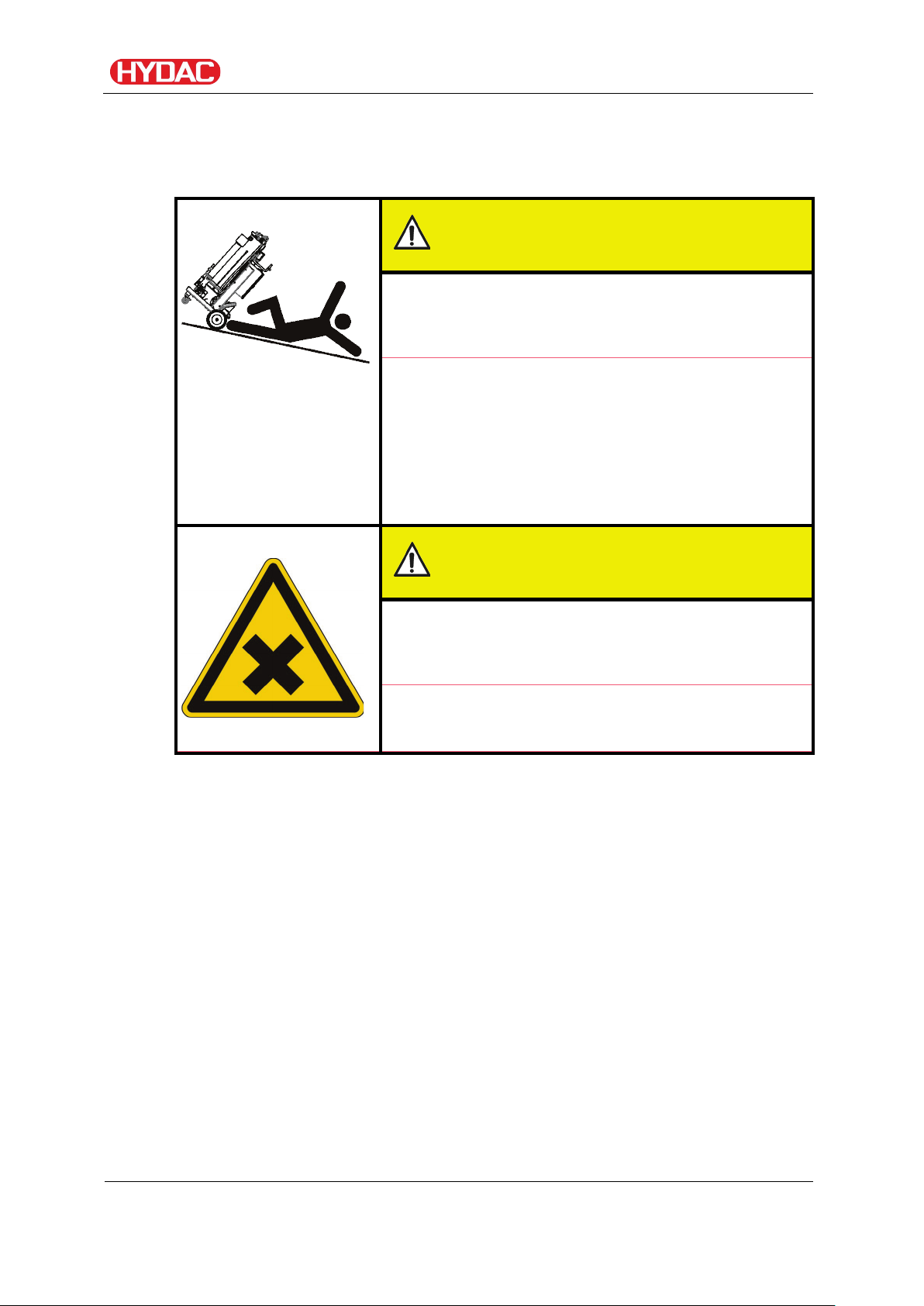

FAM set-up and connection

Setting up the FAM

CAUTION

Danger of tipping on inclines

Crushing hazard

► Operate the power unit only on an even,

► Do not set the unit down on an inclined

► Always set the brakes on the swivel casters.

FAM set-up and connection

level surface.

surface.

CAUTION

Outlet air of the vacuum pump

Hazardous to health

► Always make sure there is sufficient

ventilation in the surrounding area of the unit.

Observe the following points when setting up the unit:

• Place the unit on a horizontal and level surface.

Special mounting is not required.

• Keep an area of at least 0.8 m around the unit free for maintenance

purposes.

• Mobile version only - Lock the immobilization brakes on the wheels to

avoid unintended movement/rolling away of the unit.

• Position the unit in the immediate vicinity of the tank to be cleaned.

Observe the maximum permitted suction pressure. See page 30.

• Observe the ambient temperature on the name plate of the unit.

• Ensure that the main switch is free and accessible at all times.

• Make sure there is sufficient ventilation around the area where the unit is

set up.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 27 / 114

The hydraulic system must be depressurized

∆

Air coming out of the vacuum pump can contain particles of vacuum pump oil

and/or the fluid.

Depending on the composition of the oil and the composition of the gas,

there is a danger of damage to health if the emergent gas is inhaled over an

extended period of time.

Notes on pipes and hoses

FAM set-up and connection

WARNING

Hydraulic systems are under pressure

Danger of bodily injury

►

before performing any work on the hydraulic

system.

NOTICE

Non-permitted pressure at the inlet IN/outlet OUT

Failure malfunction

► Determine the pressure to be anticipated at the inlet / outlet with the

prescribed values.

Note that the cross-section of the connected hoses/piping must be at least as

large as the cross-section of the inlet/outlet port sizes.

In order to keep the pressure loss as low as possible, use few threaded

connections.

The pressure at the inlet/outlet depends on the height differential between

the suction connection on the FAM and the fluid surface in the tank

(aspiration height ∆P

If the FAM is above the fluid surface in the tank, estimate the pressure as

follows: P = 1 bar - ∆P

) and the line losses (∆P

(height)

(height)

- ∆P

(line)

(line)

).

If the FAM is below the fluid surface in the tank, estimate the pressure as

follows: P = 1 bar - ∆P

Determine the pressure loss ∆P(height) as follows:

(height)

- ∆P

(line)

P

(height)

[bar] = h [m] / 10.

h stands here for the distance between the suction connection on the FAM

and the fluid surface in the tank and is given in meters.

For the sake of simplicity, these calculations assume an ambient pressure of

1 bar and a density of 1 kg/m³.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 28 / 114

Δp(line) ≈ 6.8 * L / d4 * Q * V * D

Δp

=

Pressure differential in [bar]

L = pipe length [m]

d = internal pipe diameter [mm]

Q = Flow rate [l/min]

V = Kinematic viscosity [mm²/s]

D = Density [kg/dm³]

Mineral oil-based hydraulic oil has a density

Mineral hydraulic oil HLP

0.85 … 0.90

kg/dm³

Phosphate ester HFD-R

1.00 … 1.10

kg/dm³

Insulation oil

0.90 … 1.00

kg/dm³

Lubricating oil

0.90 … 0.95

kg/dm³

The pressure differential in a hydraulic line (∆P

FAM set-up and connection

) depends on the

(line)

following:

• flow rate

• kinematic viscosity

• Pipe dimensions

• Fluid density

The pressure loss in straight pipes (∆P

of ≈ 0.9 kg/dm³.

The density (D) is:

) can be calculated as follows:

(line)

Additional threaded connections and pipe bends increase the pressure

differential and must be taken into account.

Keep the height difference between the pump and the oil level in the tank as

small as possible.

Avoid constrictions in the connected hoses. They compromise output and

increase the risk of cavitation.

Make sure that no tension or vibrations are carried over to the pump or filter

housing when the pipes are connected. Use hoses or expansion joints if

necessary.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 29 / 114

The greatest contamination is found on the bottom of the tank.

Connecting the inlet (IN)

Moving unsecured hoses / lances in the tank

The hoses/lances fall out of the tank

► Attach the hoses/lances to the tank and secure them against falling

out.

Contamination in the medium too high

The FAM will be damaged

FAM set-up and connection

NOTICE

NOTICE

► Do not prime directly at the bottom of the tank

► Do not prime in the sump

► Never prime without a built-in suction screen

► Never suck in free water

All impurities and other particles are deposited on the bottom of

the tank. All impurities like water or solid particles are deposited

on the bottom of the tank. Drain out the deposited, free water at

the bottom of the tank.

The suction pressure at the FAM inlet must be -0.2 bar.

Use a negative pressure-resistant, flexible hose or a pipe for the suction-side

connection.

Note that the cross-section of the connected hoses/piping must be at least as

large as the cross-section of the inlet/outlet port sizes.

The shape of the tank connection should be set up in such a way that it will

always be lower than the level of the oil.

FAM 5

BEWA FAM5 4166129 en-us 2016-07-28 te.doc 2016-07-28

en(us)

Page 30 / 114

Loading...

Loading...