Page 1

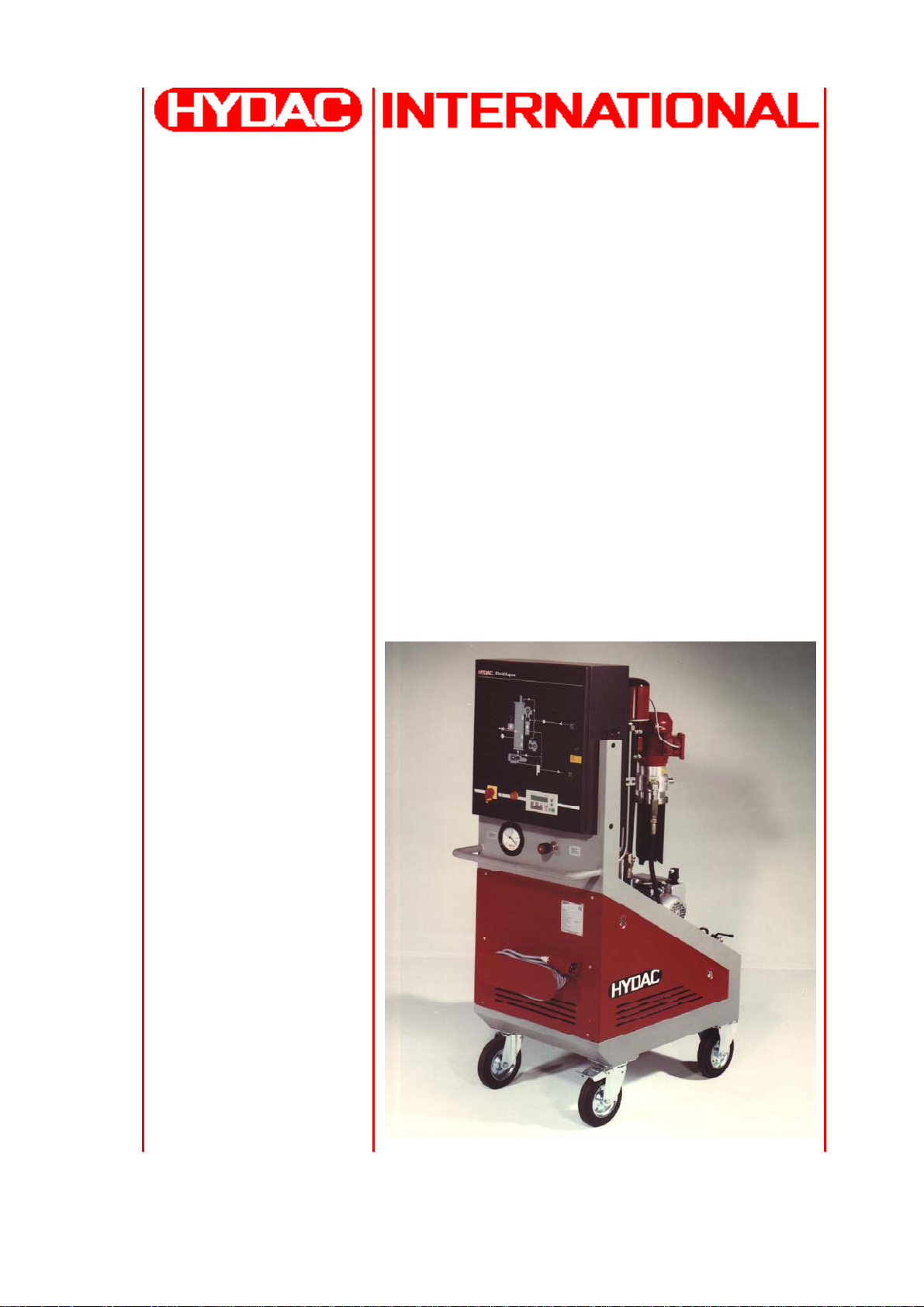

FAM 10/15 Series

FluidAqua Mobil

+ AquaSensor AS1000

+ ContaminationSensor CS 1000

Operating and Maintenance Instructions

English (translation of German original)

Dokumentation no.: 3417360

Page 2

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Trademarks

Trademarks

The trademarks of other companies are exclusively used for the products of those

companies.

Copyright © 2008 by

HYDAC Filtertechnik GmbH

all rights reserved

All rights reserved. This manual may not be reproduced in part or whole without the

explicit written agreement from HYDAC Filtertechnik. Contraventions are liable to

compensation.

Exclusion of liability

We made every endeavor to ensure the accuracy of the contents of this document.

However, errors cannot be ruled out. Consequently, we accept no liability for such

errors as may exist nor for any damage or loss whatsoever which may arise as a result of such errors. The content of the manual is checked regularly. Any corrections

required will be incorporated in future editions. We welcome any suggestions for improvements.

All details are subject to technical modifications.

Technical specifications are subject to change without notice.

HYDAC Filtertechnik GmbH

Industriegebiet

D-66280 Sulzbach / Saar

Germany

Phone: ++49 (0) 6897 / 509 – 01

Fax: ++49 (0) 6897 / 509 – 846

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 2 / 80

Page 3

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Contents

Contents

Trademarks.............................................................................................................................2

Contents..................................................................................................................................3

Preface ....................................................................................................................................6

Customer Service ................................................................................................................. 7

Modifications to the Product .................................................................................................7

Warranty ............................................................................................................................... 7

Using the documentation ...................................................................................................... 8

Safety Information and Instructions.....................................................................................8

Obligations and Liability........................................................................................................9

Explanation of Symbols and Warnings ................................................................................. 9

General Safety Precautions................................................................................................ 10

Proper/Designated Use ......................................................................................................11

Improper Use ......................................................................................................................11

Safety Devices....................................................................................................................11

Informal Safety Precautions................................................................................................ 12

Training and Instruction of Personnel................................................................................. 13

Safety Measures to Be Followed during Normal Operation................................................ 13

Electrical Hazards............................................................................................................... 14

Maintenance, Servicing and Troubleshooting..................................................................... 14

Modifications to the FluidAqua Mobil ..................................................................................14

How to behave in case of emergency................................................................................. 15

Packing, Transportation......................................................................................................15

Unpacking the FAM ............................................................................................................ 15

Transporting the FAM ......................................................................................................... 15

Moving the FAM ..............................................................................................................16

Scope of Delivery.................................................................................................................17

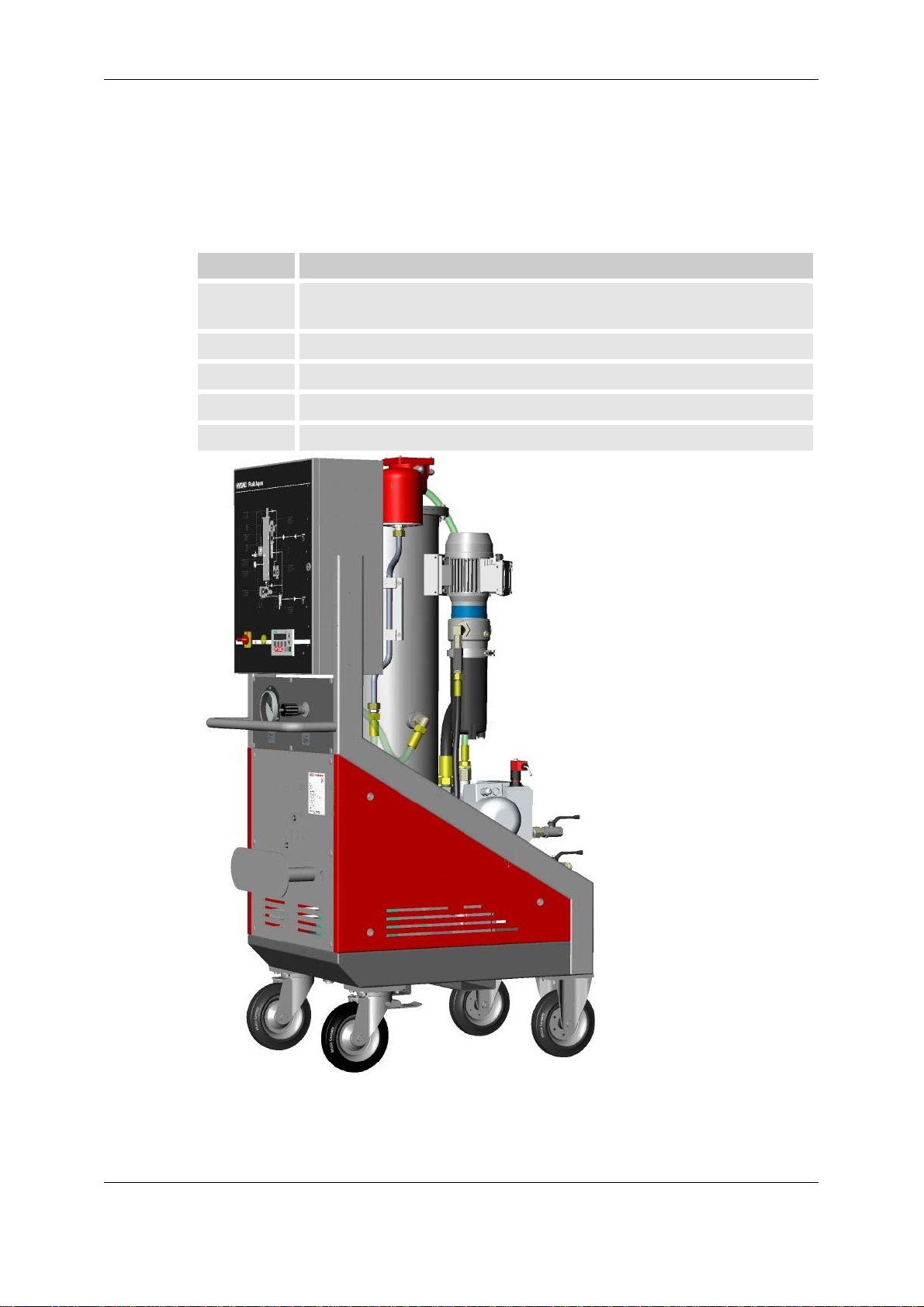

FAM Description...................................................................................................................18

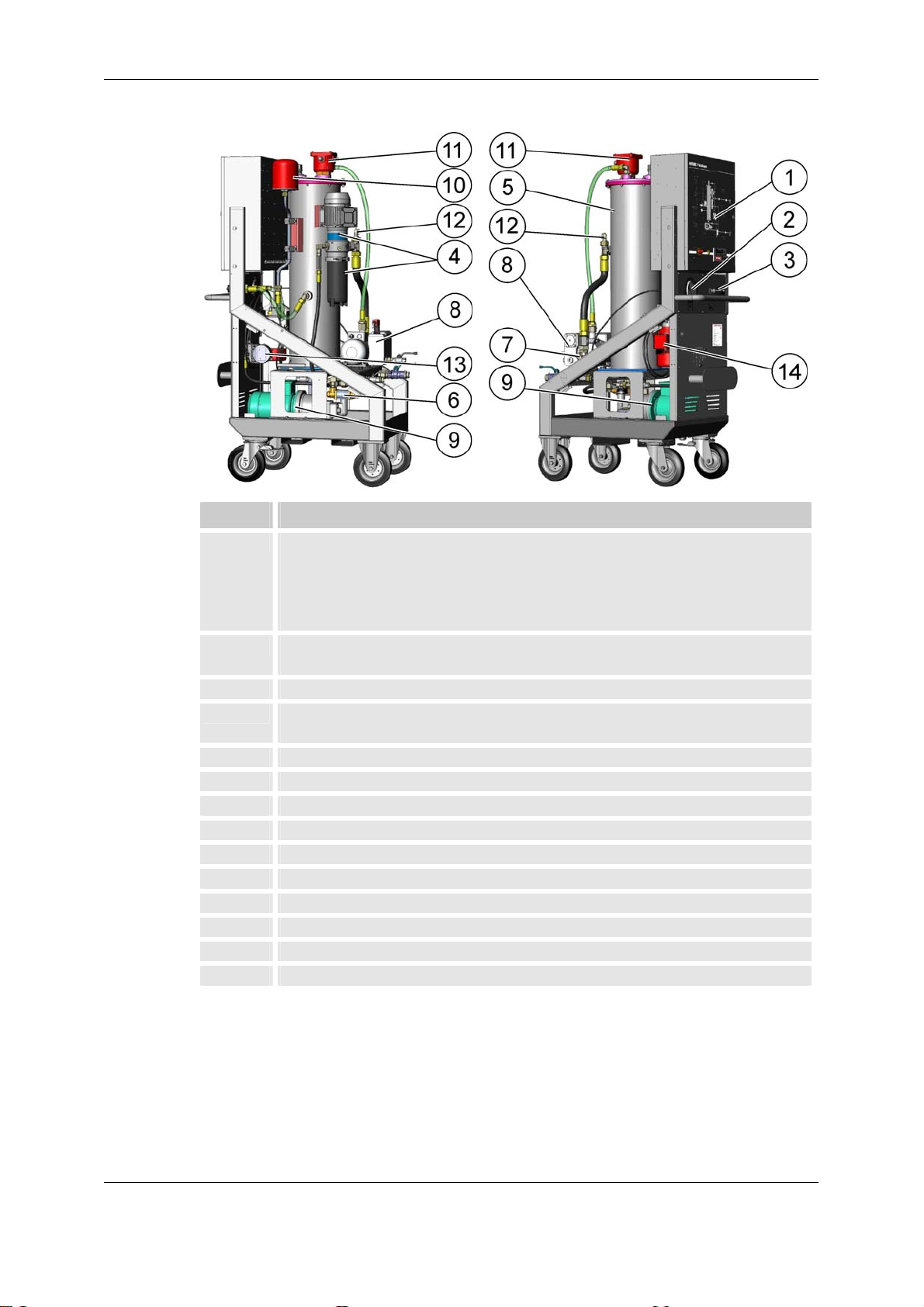

FAM components................................................................................................................ 19

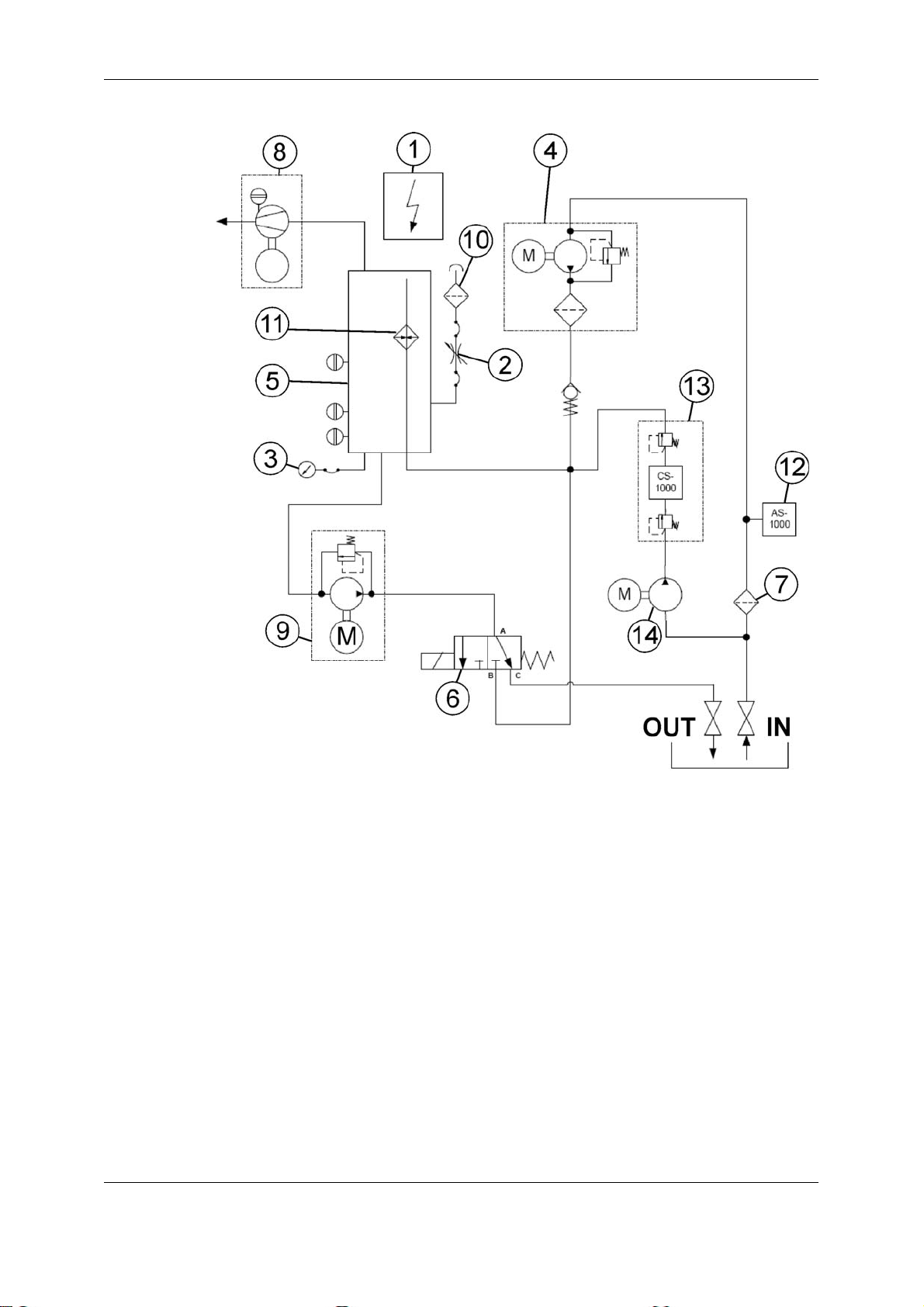

Hydraulic schematic............................................................................................................20

Technical specifications......................................................................................................21

Suitable Fluids .................................................................................................................... 21

FAM Function description ................................................................................................... 22

Possible Applications.......................................................................................................... 22

Bypass purification (dewatering, filtration and degassing).............................................. 23

Transfer by pumping (dewatering, filtration and degassing) ........................................... 23

FAM Set-up and Connection ...............................................................................................24

Setting up the FAM ............................................................................................................. 24

Hydraulic Connection of the FAM .......................................................................................24

Connecting the suction port connection (IN)................................................................... 24

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 3 / 80

Page 4

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Contents

Connecting the return port connection (OUT) ................................................................. 24

Preparing the Vacuum Pump.............................................................................................. 25

Checking the settings on the heater (optional) ................................................................... 26

Electrical Connection of the FAM .......................................................................................27

Starting up the FAM.............................................................................................................28

Switching on the FAM......................................................................................................... 28

Shutting off the FAM ........................................................................................................... 29

Control Panel - SIMATIC PANEL .......................................................................................30

Operating the FAM from the Control Panel ........................................................................30

Start screen..................................................................................................................... 31

Menu1 ............................................................................................................................. 32

Menu2 ............................................................................................................................. 32

Operating Mode (OM) ..................................................................................................... 33

Manual Menu (MANUAL) ................................................................................................ 34

OPERATOR (MANUAL1)................................................................................................ 35

OPERATOR (MANUAL2)................................................................................................ 35

LANGUAGE .................................................................................................................... 36

RH+P (Relative Humidity + Pressure)............................................................................. 37

Contamination (Selection Contamination)....................................................................... 38

ISO.................................................................................................................................. 38

Intervals...........................................................................................................................39

an operating-hours counter, and..................................................................................... 40

Operating Mode "Cleaning until" ..................................................................................... 40

General Operating Instructions - SIEMENS PANEL........................................................... 41

System Keys ................................................................................................................... 41

Entries and Help.............................................................................................................. 42

Numerical Values ........................................................................................................42

Alphanumerical Values................................................................................................ 42

Date and Time ............................................................................................................. 42

Entering and Modifying Numerical and Alphanumerical Values.................................. 43

Enter Value.................................................................................................................. 44

Partial Value Changes................................................................................................. 44

Character Call-up Sequence .......................................................................................44

Entering and Changing Date and Time .......................................................................46

Safety Queries............................................................................................................. 46

Error messages....................................................................................................................48

Vacuum Chamber Overflow................................................................................................ 52

FAM tray too full..................................................................................................................53

FAM outlet blocked ............................................................................................................. 54

FAM entry blocked..............................................................................................................55

Dry-running Evacuation Pump............................................................................................ 56

Dry run drain pump .............................................................................................................57

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 4 / 80

Page 5

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Contents

Fault on vacuum column level probe .................................................................................. 58

Level switch in the vacuum pump....................................................................................... 59

Oil filter contaminated .........................................................................................................60

Motor Protection Switch...................................................................................................... 61

Cable break ........................................................................................................................ 63

Safety thermostat................................................................................................................65

Electrical fuses....................................................................................................................67

Reset safety thermostat on the heater (Optional)............................................................... 68

Maintenance..........................................................................................................................69

Visual checks...................................................................................................................... 69

Vacuum pump.....................................................................................................................69

Rotary Vane Vacuum Pump ...............................................................................................70

Changing oil and oil filter.................................................................................................71

Replacing the Air De-oiling Element ...............................................................................71

Clean the suction strainer. .................................................................................................. 72

Fluid filter (OLF-5)...............................................................................................................72

Changing the Filter Element............................................................................................ 72

Heater (Option) ................................................................................................................... 73

Storing the FAM....................................................................................................................73

Disposing of the FAM ..........................................................................................................73

Technical data ......................................................................................................................74

Type label ........................................................................................................................... 75

Spare parts............................................................................................................................76

FAM 10 ............................................................................................................................... 76

Fluid filter (OLF 5/10)..........................................................................................................76

Vacuum pump.....................................................................................................................76

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 5 / 80

Page 6

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Preface

Preface

For you, as the owner of a product manufactured by us, we have produced this

manual, comprising the most important instructions for its operation and mainte-

nance.

It will acquaint you with the product and assist you in using it as intended in an optimal manner.

Keep it in the vicinity of the product so it is always available.

Note that the information on the unit's engineering contained in the documentation

was that available at the time of publication. There may be deviations in technical

details, figures, and dimensions as a result.

If you discover errors while reading the documentation or have additional comments

or suggestions, contact us at:

HYDAC Filtertechnik GmbH

Division Service technology / Filter systems

Technical Documentation Department

Postfach 12 51

66273 Sulzbach/Saar - Germany

Fax: ++49 (0) 6897 509 846

Email: filtersysteme@hydac.com

We look forward to receiving your input.

“Putting experience into practice”

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 6 / 80

Page 7

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Preface

Customer Service

Contact our technical sales department if you have any questions on our product.

When contacting us, please always include the model/type designation, serial no.

and part-no. of the product:

Fax: ++49 (0) 6897 509 846

Email: filtersysteme@hydac.com

Modifications to the Product

We would like to point out that changes to the product (e.g. purchasing additional

options, etc.) may mean that the information in the operating instructions is no

longer applicable or adequate.

After modification or repair work that affects the safety of the product has been carried out on components, the product may not be returned to operation until it has

been checked and released by a HYDAC technician.

Please notify us immediately of any modifications made to the product whether by

you or a third party.

Warranty

For the warranty provided by us, please refer to the General Terms of Sale and Delivery of HYDAC Filtertechnik GmbH.

They are available at:

www.hydac.com Legal information.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 7 / 80

Page 8

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

/

Using the documentation

Note that the method described for locating specific information does

not release you from your responsibility of carefully reading these instructions prior to starting the unit up for the first time and at regular

intervals in the future.

What do I want to know?

I assign the information I require to a subject area.

Where can I find the information I’m looking for?

The documentation has a table of contents at the beginning. There, I select

the chapter I'm looking for and the corresponding page number.

Product

l

e

t

i

p

a

K

/

t

k

d

u

o

r

P

ilt

e

t

n

r

e

h

i

k

c

b

m

G

H

H

Y

D

A

C

F

e

W

B

a

2

3

1

4

5

6

d

a

Documentation no.

de

e

Document language

with index

file name

The documentation number with its index enables you to order another copy of the

operating and maintenance instructions. The index is incremented every time the

manual is revised or changed.

Safety Information and Instructions

These operating instructions contain the key instructions for properly and safely operating the FluidAqua Mobil.

200x-xx-xx

Page number

Seite x

Edition date

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 8 / 80

Page 9

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

y p

The safety of the FAM largely depends on maintenance. Regular required maintenance is described in this manual. We will support you if the unit needs repair and

will provide original spare parts.

Obligations and Liability

The basic prerequisite for the safe and proper handling and operation of the FAM is

knowledge of the safety instructions and warnings.

These operating instructions in general, and the safety precautions in particular, are

to be adhered by all those who work with the FluidAqua Mobil.

Adherence is to be maintained to pertinent accident prevention regulations applicable at the site where the product is used.

The safety precautions listed herein are limited solely to using the FluidAqua Mobil.

The FluidAqua Mobil has been designed and constructed in accordance with the

current state of the art and recognized safety regulations. Nevertheless, hazard may

be posed to the life and limb of the individual using the product or to third parties.

The FluidAqua Mobil is only to be used:

• solely for its designated use

• only in accordance with the designated equipment group, equipment category

and zone indicated above

• only when in a safe, perfect condition

• Any faults or malfunctions which might impair safety are to be properly re-

paired or remedied immediately.

Our General Terms and Conditions apply. They are made available to the owner

upon concluding purchase of the unit at the latest. Any and all warranty and liability

claims for personal injuries and damage to property shall be excluded in the event

they are attributable to one or more of the following causes:

• Improper use of the FluidAqua Mobil or use deviating from its designated use

• Improper commissioning, operation and maintenance of the FluidAqua Mobil

• Operating the FluidAqua Mobil when the safety systems are defective

• Modifications to the FluidAqua Mobil made by the user or purchaser

• Improper monitoring of unit components that are subject to wear and tear

• improperly performed repair work

Explanation of Symbols and Warnings

Basic Symbols

DANGER denotes situations

which can lead to death if

DANGER

WARNING

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

safety precautions are not

observed.

WARNING denotes situations which can lead to

death if safet

recautions

Page 9 / 80

Page 10

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

are not observed.

CAUTION denotes situations which can lead to se-

CAUTION

NOTE

vere injuries if safety precautions are not observed.

TIP denotes situations

which can lead to property

damage if safety precautions are not observed.

General Safety Precautions

Operation, adjustment and calibration work may only be carried out by technically

skilled and trained personnel.

The safe operation of this unit can only be ensured if it is used for the purpose it was

intended. If there is any question about the use, please contact the manufacturer.

The manufacturer will not accept responsibility for damages resulting from misuse of

this equipment.

The following applies to all work performed using the unit: adherence to pertinent

national regulations pertaining to accident prevention and safety at the workplace in

addition to any applicable internal rules and regulations of the owner/operator, even

though they are not specifically cited herein.

Leaks of dangerous materials must be properly collected and disposed of so as not

to harm any persons or the environment. The corresponding statutory regulations

are to be followed.

Before any maintenance or repair work is carried out on the unit, electrical power to

the unit must be disconnected, and all hydraulic pressures relieved.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 10 / 80

Page 11

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

Proper/Designated Use

The FAM was developed for the dewatering, filtration and degassing of hydraulic

and lubricating oils. It removes free water, emulsified water and a large percentage

of the water to be found in solution.

Any other use shall be deemed to be improper and not in keeping with the product's

designated use; the manufacturer accepts no liability for any damage resulting from

such use.

Proper or designated use of the product extends to the following:

• Maintaining adherence to all the instructions contained herein.

• Performing requisite inspection and maintenance work.

Improper Use

Any use deviating from the proper/designated use described above is prohibited.

Improper use may result in hazard to life and limb.

Example of improper use:

• Operation with non-approved fluids.

Safety Devices

Prior to starting up the FAM unit each time, make sure that all the protective safety

devices are properly installed and are in proper working order.

Safety devices may not be removed until the product has been shut down and secured against being restarted (e.g. warning sign or padlock on the main switch).

When the product is supplied in partial consignments, the safety devices are to be

applied by the operator as specified by law/pertinent regulations.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 11 / 80

Page 12

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

Informal Safety Precautions

Make sure to always keep the operating instructions in the vicinity of the FluidAqua

Mobil unit.

Apart from the operating instructions, any and all general and local regulations pertaining to accident prevention and environmental protection are to be made available and observance to be maintained to them.

Make sure to keep the safety and hazard symbols and warnings on the FluidAqua

Mobil in a legible condition.

FluidAqua Mobil components may not be opened except in normal, noncontaminated environments. The mains cable must be pulled out before the FluidAqua Mobil is opened. Only trained specialist electricians may be carry out tests

with the housing opened. This also applies to repair work and to modifications of

electrical system parts that we have approved.

The hoses and connection fittings are to be checked daily for leakage (visual check).

The electrical components of the FluidAqua Mobil are to also be regularly checked

(visual check once a month). Any loose connections or damaged cables are to be

replaced immediately.

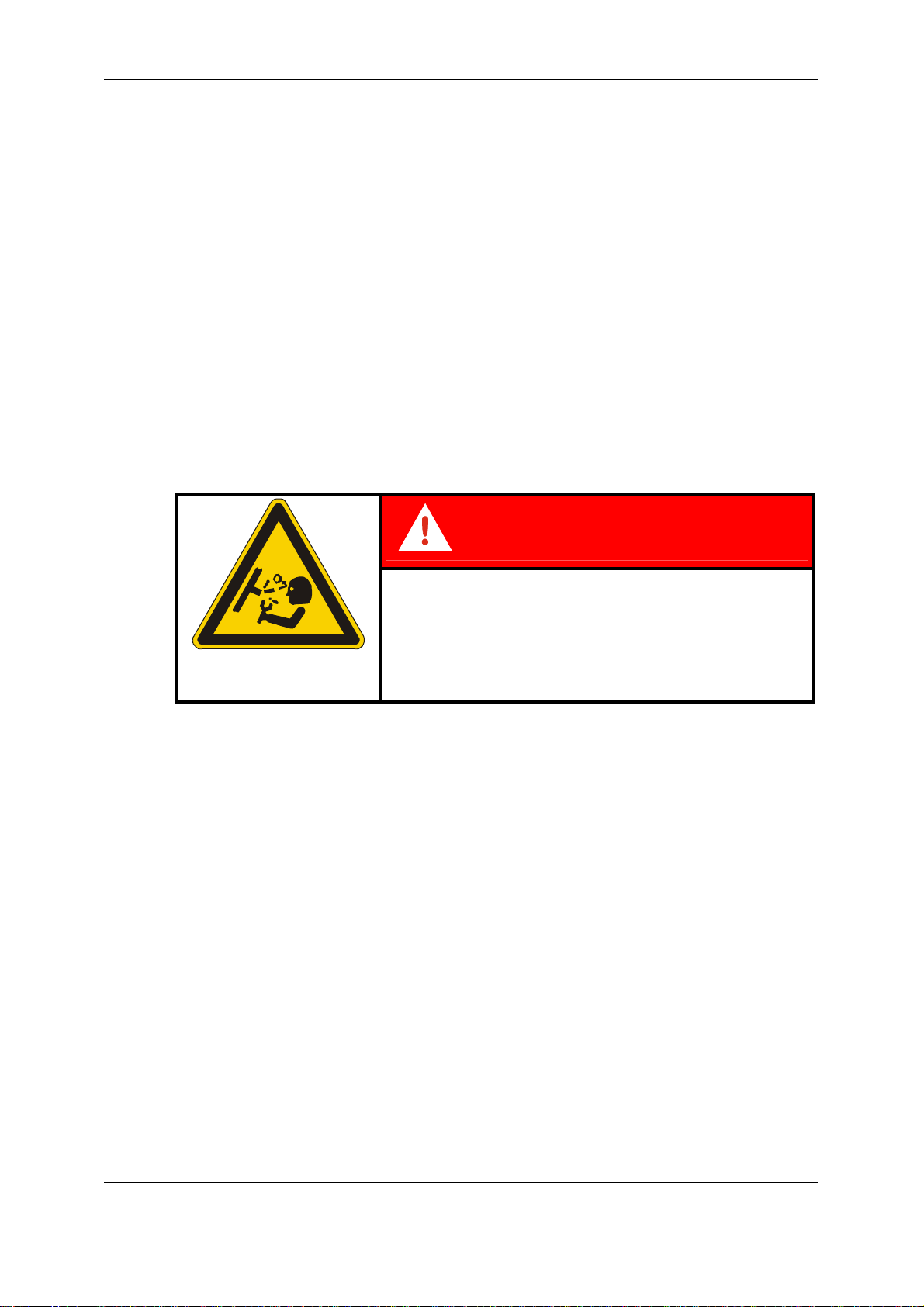

DANGER

Hydraulic systems are under pressure

The hydraulic system must be depressurized

before performing any work

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 12 / 80

Page 13

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

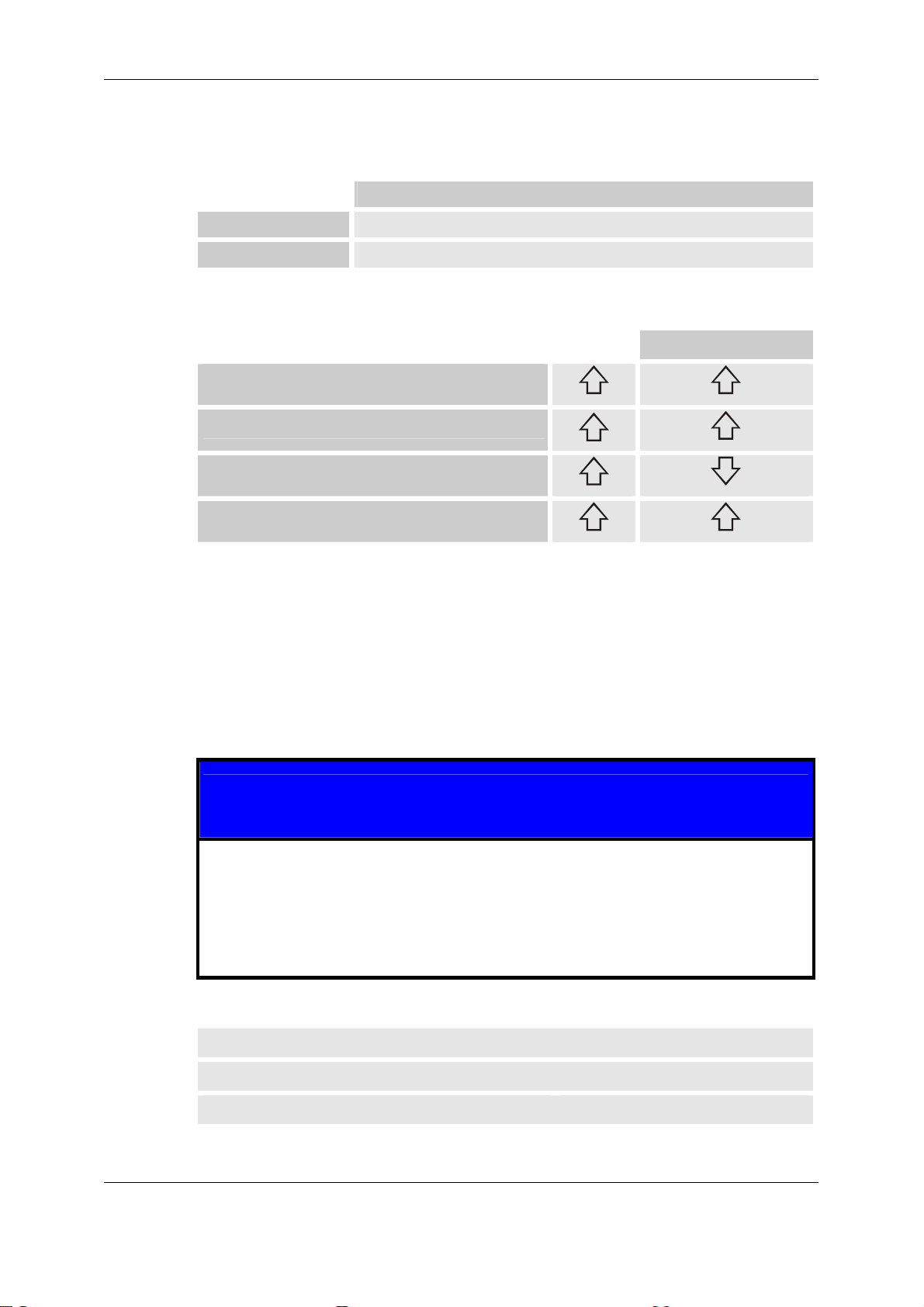

Training and Instruction of Personnel

The FluidAqua Mobil may only be operated by properly trained and instructed personnel.

The areas of responsibility of your staff must be established in a clear-cut manner.

Staff undergoing training may not use the FluidAqua Mobil unless supervised by an

experienced staff member.

Individuals

Activity

Individuals

undergoing

training

Individuals

with technical training/

engineering

Electrician Supervisor

background

Packing Transportation

Commissioning

Operation

X X

X X X

X X X X

Troubleshooting /

locating the source of

X X X

malfunction

Remedying of mechanical faults

Remedying of electrical faults

Maintenance

X

X X X X

Repair work

with the

appropriate

authority

X

X

X X

X

Shutdown/

decommissioning

X X X X

Safety Measures to Be Followed during Normal Operation

Do not operate the FAM unless all the safety devices function properly.

The product is to be checked once a day for external damage and the proper functioning of the safety devices.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 13 / 80

Page 14

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Safety Information and Instructions

Electrical Hazards

DANGER

Electric shock

All work on the voltage-carrying parts may only

be carried out by a qualified electrician.

The electrical equipment of the product must be checked on a regular basis. Any

loose connections or damaged cables must be remedied/replaced immediately.

Maintenance, Servicing and Troubleshooting

The prescribed adjustment, maintenance/servicing and inspection work is to be

conducted in a timely fashion.

All operating media are to be protected in case the product is accidentally started

up.

The FluidAqua Mobil is to be disconnected from the power supply and protected

against being inadvertently switched back on when performing any maintenance,

servicing, inspection or repair work.

Check any screwed fittings which have been removed to see that they have been

properly secured.

Always check the product to see that it functions properly when performing maintenance and servicing work.

Modifications to the FluidAqua Mobil

Do not make any modifications (design modifications, extensions) to the FluidAqua

Mobil without the prior consent of the manufacturer.

Any design modifications or extensions may not be made without HYDAC Filtertechnik GmbH’s express prior written approval.

Immediately replace any machine components which are not in perfect condition.

Only use original (OEM) spare parts and consumables. When using non-OEM components it cannot be ensured that they have been designed and manufactured so as

to comply with loading and safety requirements.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 14 / 80

Page 15

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Packing, Transportation

How to behave in case of emergency

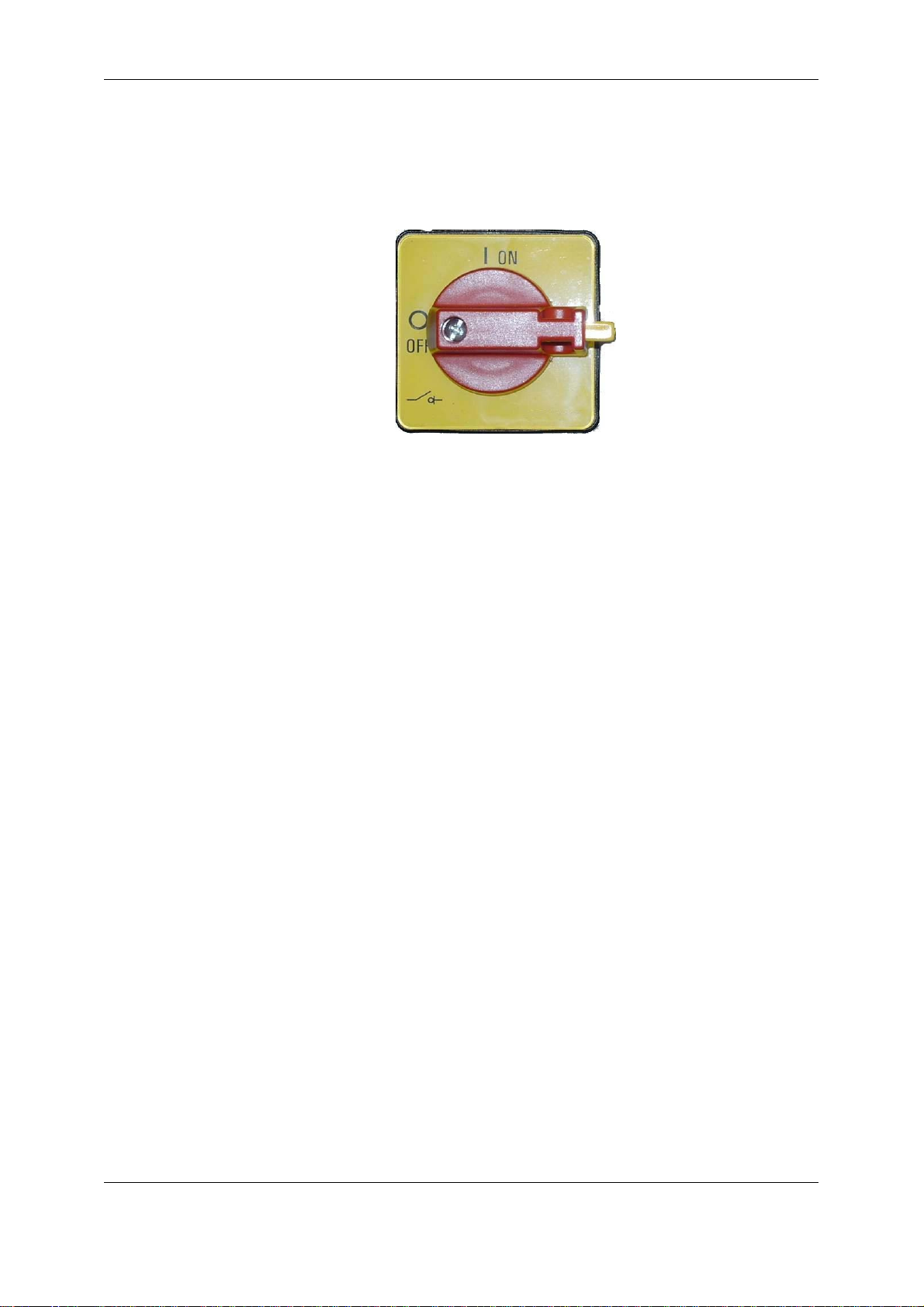

In the event of an emergency, rotate the main and E-STOP switch 90° to the left in

order to shut down the entire system. The entire system is then voltage-free downstream from this switch.

Normal pressure is restored to the vacuum chamber after about 1 minute.

Packing, Transportation

Unpacking the FAM

The FAM is inspected for leaks and proper functioning at the factory, then carefully

packed for shipment. The connectors/ports are closed off so that no contamination

can enter the unit while it is in transit.

When receiving and unpacking the unit check it for damage in transit. Report any

damage to the forwarding agent immediately.

The packaging material should be re-used/re-cycled as appropriate for your area.

Transporting the FAM

The unit must be evacuated completely and the inlets and outlets must be closed

before transport.

Suction and pressure hoses and connection cables are coiled on the holders provided for that purpose and fastened in place.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 15 / 80

Page 16

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Packing, Transportation

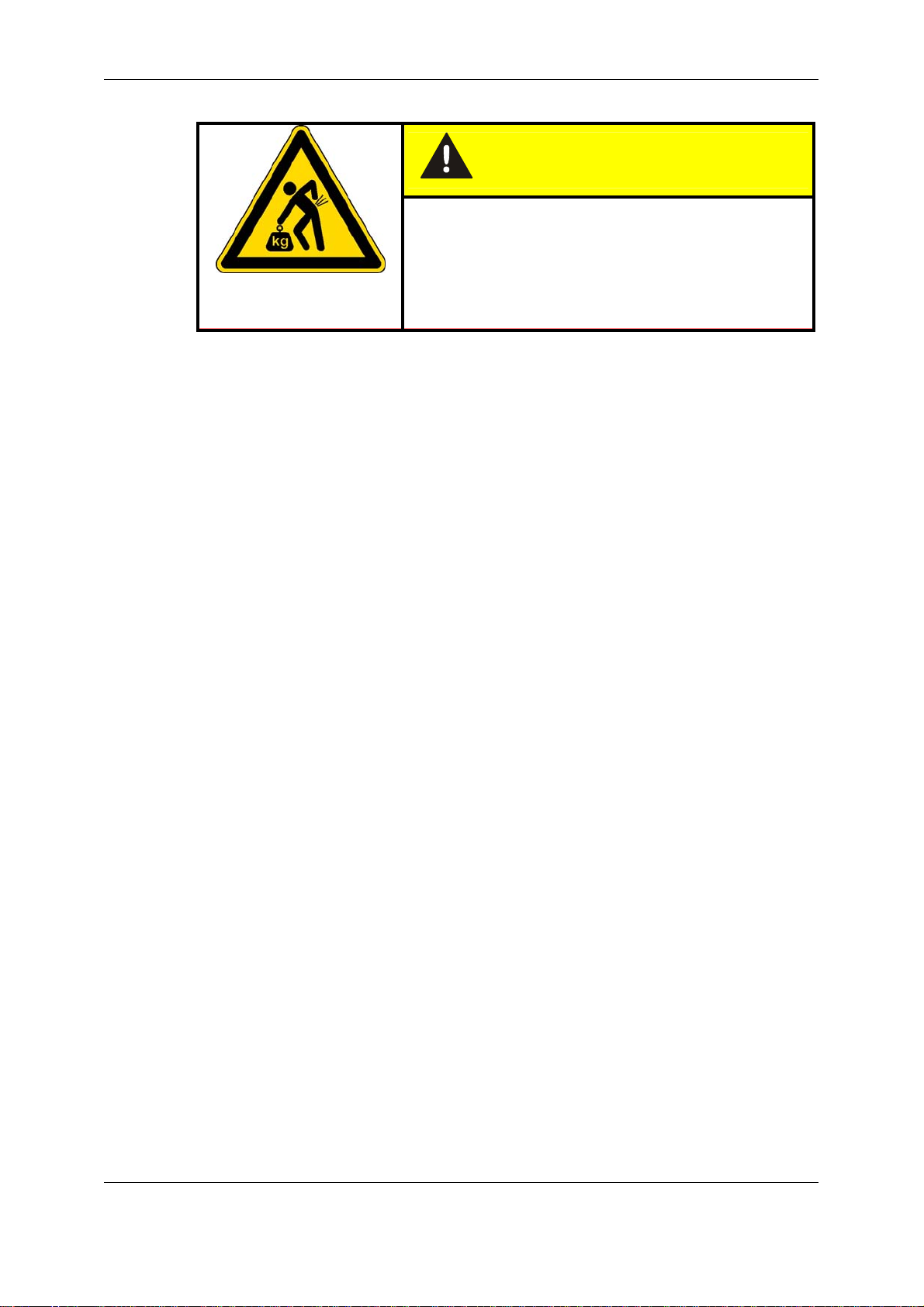

Moving the FAM

CAUTION

High empty weight

(≈ 400 … 850 kg, depending on the version)

A minimum of 2 persons is required for

transport.

The FAM can be moved manually by pushing thanks to two steerable castors and

two fixed castors for heavy loads. The grips for pushing on the frame of the FAM are

to be used for this purpose in all cases without exceptions. The immobilization

brakes on the steerable castors are to be released prior to transport and then fixed

again in place after it has been completed.

None of the components should ever be used as grips for pushing or pulling the

FAM, because this will cause damage to it.

Fork lift

If the FAM is moved with a forklift, then this may only be used in conjunction with the

forklift eyes located on the device.

Crane

If the FAM is moved with a crane, then this may only be used in conjunction with the

crane eyes or the forklift eyes located on the device and with suitable hitching materials.

Train/truck

During transport, the FAMs that have castors must be placed that on supports that

are high enough to ensure that there is no load on the castors.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 16 / 80

Page 17

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Scope of Delivery

Scope of Delivery

Upon receiving the FAM check it for any damage in transit. The FAM may not be set

up and installed unless it is in perfect order. Any damage in transit is to be reported

to the forwarding agent or the department in charge immediately; the unit may not

be commissioned until this damage is properly remedied.

The following items are supplied:

Qty Description

1

FluidAqua Mobil FAM, ready for connection with suction and pressure hose

1 Tool, square 6 mm for switch box

1 Operating and maintenance instructions FAM

1 Operating and maintenance instructions Busch vacuum pump

1 Supplementary operating instructions (depending on FAM design)

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 17 / 80

Page 18

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Description

FAM Description

The FluidAqua Mobil FAM was developed for the dewatering, filtration and degassing of hydraulic and lubricating oils. It removes free water, emulsified water and

a large percentage of the water to be found in solution. The fluid filter that is installed

provides efficient filtering-out of solid materials.

The degassing of the medium is achieved by the vacuum set up in the vacuum container.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 18 / 80

Page 19

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Description

FAM components

Item Description

1 control cabinet with control panel consisting of:

2 Regulating valve to regulate the necessary vacuum in the vacuum

3 Vacuum gauge

4 Motor pump unit with fluid filter for the separation of solid particles

5 Vacuum chamber

6 3/2-directional control valve

7 Suction strainer

8 Vacuum pump

9 Evacuation pump

10 Air filter and dryer

11 Heater mounted in vacuum chamber (Option)

12 AS1000 (Optional)

13 CS1000 (Optional)

14 Motor-pump assembly for CS1000 (Optional)

- main switch

- alarm signal lamp

- control panel with display

- component diagram

chamber

(OLF-5)

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 19 / 80

Page 20

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Description

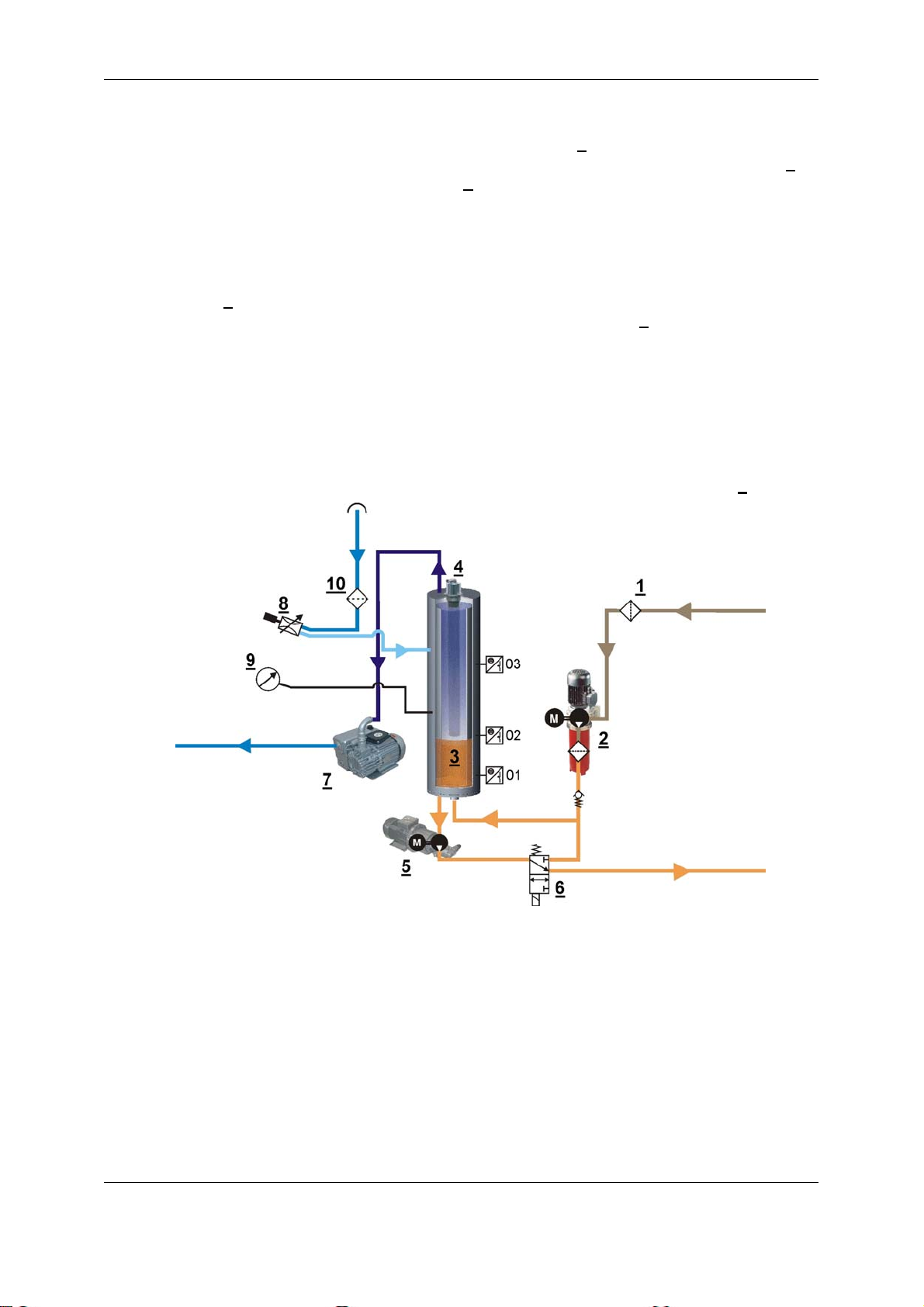

Hydraulic schematic

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 20 / 80

Page 21

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Description

Technical specifications

The FAM is able to dewater authorized fluids down to a water content of less than

100 PPM.

FAM 10/10 ≈ 0.8 l/h

FAM 10/15 ≈ 1.0 l/h

The dewatering speed is dependent on:

Water content

Fluid temperature

Detergent additives

Volumetric flow of the FAM

The fluid temperature must be at least 40°C in order to ensure an effective water

separation speed.

The sample for the determination of the water content must be extracted from the

system to be cleaned during operation.

Typical dewatering rates:

Dewatering rate

Free water on the floor of the tank influences the overall water content. This is to be

drained before starting.

Suitable Fluids

The FAM may only be used only in connection with lubrication and mineral oils

or with mineral oil-based media or with biological fluids that can be broken down

quickly - on the basis of synthetic esters (HEES).

Please contact us if you want to use other fluids.

Operation with other media could destroy the FAM.

The FluidAqua Mobil can only be utilised in connection with the following hydraulic

fluids:

Mineral oils acc. DIN 50524

Gear oils acc. DIN 51517 and DIN 51524

NOTE

Synthetic esters (HEES) acc. to DIN 51524/2

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 21 / 80

Page 22

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Description

FAM Function description

After the FAM has been switched on, filter pump unit 1 begins to suction fluid out of

the tank to be cleaned out and to pump it through the filter into vacuum chamber 3

at a speed of 10 l/min. Vacuum pump 7

begins at the same time to build up the necessary vacuum. The fluid to be cleaned trickles downward through special filling materials. These filling materials are responsible for forming a thing fluid film and reducing the speed of the trickle. At the same time, a stream of air flowing upward from

below against this current takes up the fluid and conveys the to the outside by

means of the vacuum pump. Once level 02 is reached on the level switch, emptying

pump 5

level falls until level 01 is reached, after which solenoid valve 6

is switched on in order to convey around 15 l/min to the outlet. The filling

switches on and the

two pumps convey into the vacuum chamber. The filling level continues to rise until

level 02 is reached, after which the solenoid valve shuts back off again, the filling

level falls again, etc.

After actuating the stop switch, the filter-pump unit stops and the evacuation pump

empties the vacuum chamber.

Switching the main switch to "OFF" renders all engines and valves voltage-free.

The vacuum in the vacuum chamber is regulated with the regulating valve 8

.

Possible Applications

The electric control supports several operation modes e.g.,

• the FAM is switched On/Off at a control room.

• the general malfunction message can be transmitted to a control room

• the operating status can be queried

• the FAM can be switched on/off by a level sensor in the transfer by pumping

operation mode.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 22 / 80

Page 23

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Description

Better cleaning results can be obtained through permanent operation of the FAM in

bypass flow.

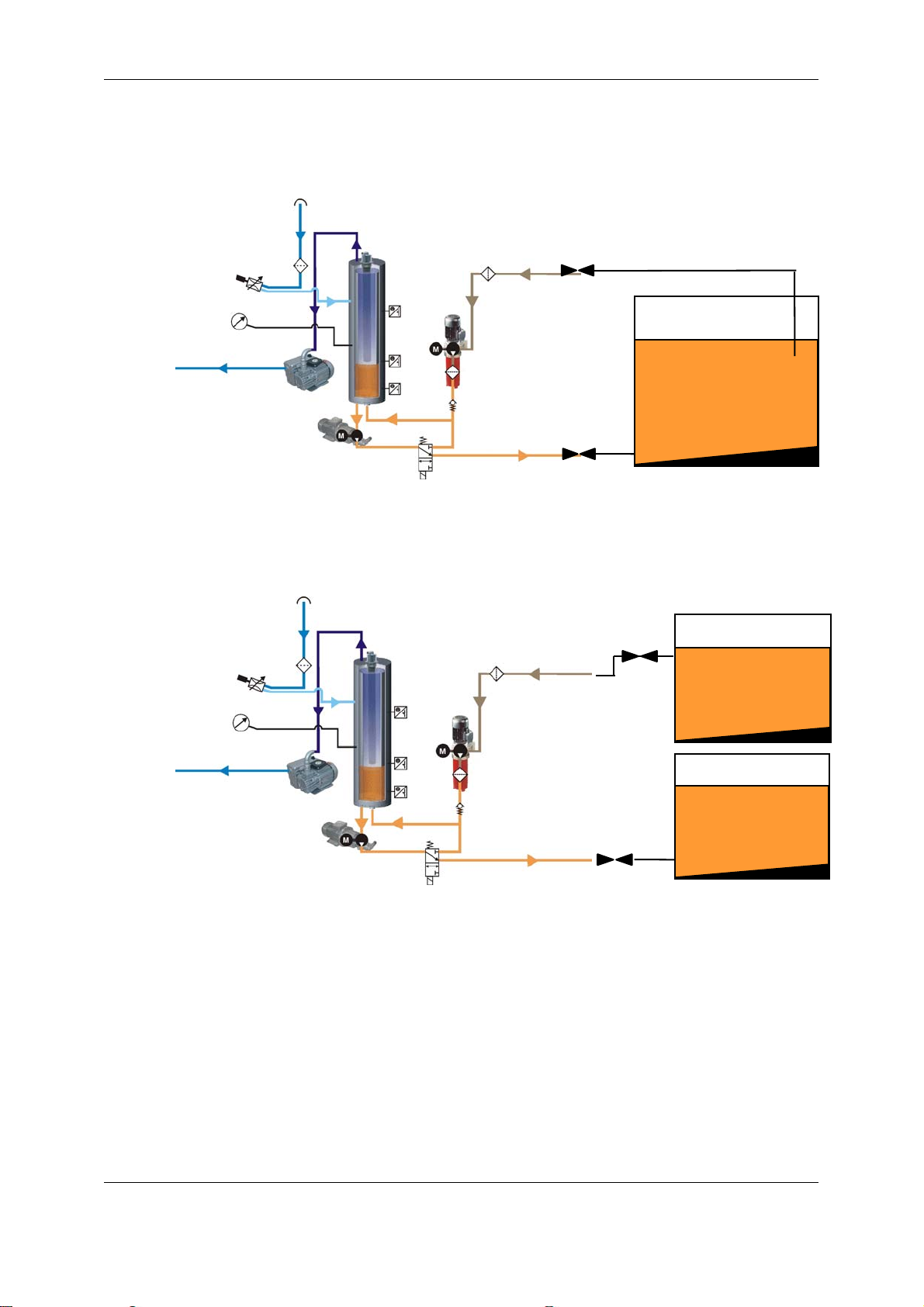

Bypass purification (dewatering, filtration and degassing).

The FAM is connected with suction and pressure lines to the tank and cleans the

medium in continuous operation.

Transfer by pumping (dewatering, filtration and degassing)

The FAM is connected to a contaminated oil tank by means of a suction line and

pumps the fluid into the clean oil tank.

The filling level in the clean oil tank must be monitored permanently during this operating mode in order to exclude the possibility of overfilling.

Contaminated

oil

Clean oil

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 23 / 80

Page 24

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Set-up and Connection

FAM Set-up and Connection

Setting up the FAM

The following points are to be observed when setting up the FAM:

• The unit has to be set up in a horizontal position on a level surface.

Special mounting is not required.

• The immobilization brakes on the wheels must be locked to avoid unintended

movement of the unit.

• Place the FAM near the tank to be cleaned (length of the hoses max. 5 m, height

difference max. 2 m).

• The ambient temperature may not be below 10°C and may not exceed 40°C.

• Access to the main switch has to be unimpeded at all times.

• An area of at least 0.8 m must be kept free for maintenance purposes on both

the left hand and right hand sides of the FAM.

Hydraulic Connection of the FAM

Connecting the suction port connection (IN)

Make the suction-side connection with a flexible hose that is resistant to negative

pressure or with pipelines. The nominal size of the connecting lines must be at least

as large as the cross-section of the unit in order to prevent excessively high pressure loss.

Permissible suction pressure: -0.3 to 1 bar.

Connection to the tank must be done in a manner so that it is always below the oil

level.

NOTE

The medium may not be suctioned directly from the bottom of the tank.

The greatest amount of impurities in the fluid is to be found at the bottom of

the tank.

High levels of contamination in the fluid can cause damage to the FAM.

Connecting the return port connection (OUT)

The return-flow line or the return-flow hose must be installed below the level of the

oil in order to prevent air from entering the medium.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 24 / 80

Page 25

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Set-up and Connection

Preparing the Vacuum Pump

As a basic rule, the rotary vane vacuum pump is not filled with oil at the time the

FAM is delivered.

NOTE

Operating the FAM without oil in the vacuum pump will cause irreparable

damage to the pump.

The rotary vane vacuum pump must be checked for sufficient filling be-

fore commissioning.

To fill the rotary vane vacuum pump, the

oil is filled in through the filling screw plug

(1) until the oil filling has risen above the

MIN marking in the viewing glass (2).

Exceeding the MAX marking will lead to

fault messages on the control panel.

1

2

The oil quantity between the MIN/MAX markings is ≈ 0.3 liters

The water level is monitored automatically by the integrated float switch while the

FAM is in operation. A message will appear on the control panel when the MIN filling

level has been reached.

Synthetic vacuum pump oil in accordance with DIN 51506, Group VDL, ISO VG100

must be used for topping up.

This can be ordered from HYDAC under the part. no.:

Description Part no.:

Vacuum pump oil VE101

DIN 51506, Group VDL, ISO VG100, synthetic

1 liters 06018128

Vacuum pump oil VE101

DIN 51506, Group VDL, ISO VG100, synthetic

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

5 liters 06018129

Page 25 / 80

Page 26

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Set-up and Connection

Checking the settings on the heater (optional)

If the FAM-is equipped with an internal heater, the temperature can now be set to

the desired value.

For this, the upper cover of the heater must be opened with appropriate equipment

and the desired operating temperature set. (The working temperature is preset to

55°C; if 80°C is exceeded, then the safety thermostat will shut the device off.)

(A) Fluid temperature 55°C

(B) Safety thermostat 80°C

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 26 / 80

Page 27

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 FAM Set-up and Connection

Electrical Connection of the FAM

DANGER

Electric shock

Any work involving the electrical system may

only be done by a properly trained, certified

electrician.

The voltage and frequency indicated on the rating plate must coincide with the voltage supply present.

If a plug is present on the FAM or if a plug is mounted, then the FAM is to be operated from a correspondingly fused socket.

The direction of rotation of the motor is checked by means of a phase sequence relay. If the phase sequence at the socket is recognized as being incorrect, then a

message will appear on the display.

Any reversal of the direction of rotation that may be

required is accomplished by switching two phases in

the terminal box of the engine or, in the event that the

device is equipped with an electric plug with phase

switcher, by rotating two phases in the plug. No dismantling of the plug is required.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 27 / 80

Page 28

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Starting up the FAM

Switching on the FAM

Move main switch to the "ON" position and wait until the "Fault" lamp lights up briefly

(lamp test) and the following message will appear in the display.

The most recently selected operating mode will be shown in the display.

Operating mode: Dewater + Filter

Ready for operation, please press Start

START

F1

Press "START" key. The system now begins with the starting phase:

• The vacuum pump starts up, the feed pump conveys and the vacuum column is

filled.

• The controller switches to the RH+P Menu

• The evacuation pump is started up and the starting period is finished when the

vacuum chamber is filled to the MAX filling level.

• The FAM controller switches over to automatic operation.

Now regulate the vacuum pressure with the regulating valve on the right of the vacuum gauge depending upon the operating viscosity:

Operating viscosity Vacuum pressure (absolute pressure)

50 mm2/s Hydraulic oil 300 mbar / 30 kPa

F2

F3

MENU1

F4

F1 = Start FAM

F2 = Stop

F3 = Reset (after malfunction)

F4 = Switch to MENU1

300 mm2/s Lubrication oil 400 mbar / 40 kPa

50 mm2/s Ester oil 400 mbar / 40 kPa

If a foaming of the medium is noticed in the standpipe, then increase the pressure

by 50 ... 100 mbar (e.g. from 300 mbar to 400 mbar).

The FAM will not start up again automatically when voltage is restored after a voltage failure; it must be restarted instead.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 28 / 80

Page 29

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Shutting off the FAM

Operating mode: Dewater + Filter

Automatic mode

STOP

MENU1

F1 = Start FAM

F1

F2

F3

F4

F2 = Stop

F3 = Reset (after malfunction)

F4 = Switch to MENU1

Press the "STOP" key. Now the unit starts the run-down phase:

• the vacuum pump and all filling pumps are switched off.

Exception: When the heater is switched on, a 60-second cooling phase intervenes during which only the heater is switched off.

It is not until this has run its course that the filling pumps are switched off. The

respective current operating status will be shown in the display.

• The evacuation pump runs until the vacuum column is empty.

The run-down phase status is shown in the display

• If the main screen from Section 0 appears on the display, then the after-running

phase has been completed and the FAM is ready for operation again.

• Now the FAM can be switched off via the main switch.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 29 / 80

Page 30

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Control Panel - SIMATIC PANEL

INSDEL

TAB

HELP

ESC

+/-

F1

F2

F3

F4

SHIFT

ACK

ENTER

Unintended actions could be triggered if several keys are pushed at once.

Caution

Unintended actions

Pressing more than two keys at once during the "Online" operating

mode could lead to unintended actions in the system.

Never press more than two keys simultaneously

Operating the FAM from the Control Panel

Only those buttons are described below whose operation may be required.

The selected operating mode is shown in the upper line, the middle line shows the

current operating status, and the key assignment is displayed in the lower line.

Operating mode: Dewater + Filter

Ready for operation, please press Start

MENU1

F4

START

F1

F2

F3

-> Mode

-> Operating status

-> Key assignment

-> Function keys

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 30 / 80

Page 31

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Start screen

Operating mode: Dewater + Filter

Ready for operation, please press Start

START

MENU1

F1 = Start FAM

F1

F2

F3

F4

F2 = Stop

F3 = Reset (after malfunction)

F4 = Switch to MENU1

START = Is displayed only in the operating status "Ready for op-

eration".

After this key has been pressed, the current operating

status on the display switches to "Starting phase" and

the "RF+D" screen appears.

STOP = Is shown during the starting phase and during automatic

operation.

RESET = Is displayed only when there is a fault

The most recently selected operating mode will always be shown in the start screen.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 31 / 80

Page 32

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Menu1

Start

image

OM

F1

Measured values:

RH

MAN.

F2

LANGUAGE

F3

Cont.

MENU1

MENU2

F4

F1 = Select operating mode

2 = Switch on manual operation

F3 = Change languages

F4 = Switch to MENU2

INS

or by means of

The buttons illustrated can be selected with the keys

+

TAB

, which is marked by framing made up of a line of

SHIFT

the key combination

DEL

dashes.

The changeover to the selected menu is achieved with the key

Start

= Back to the start screen

.

screen

RH = "Relative humidity" menu screen

Menu2

Cont. = "Contamination" menu screen

MENU2

INTER-

F1

OHM

F2

CONFIG.

F3

MENU1

F4

F1 = INTERVALS

F2 = Operating hours meter

F3 = CONFIGURATION

F4 = Switch to MENU1

INTERVALS

= Times for the recurrent inspection interval for the "Cleaning until"

and/or "Dewatering to" operating mode

OHM = Display operating hours meter

CONFIG. = FAM Configuration – Access password-protected

(For HYDAC Service only)

MENU1 = Switch to MENU1

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 32 / 80

Page 33

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Operating Mode (OM)

Operating mode: Dewater + Filter

F1 = EW+FT

DW+FT

DWT+

FT

EW+H

+FT

NEXT

F2 = DWT+FT

F3 = EW+H+FT

F1

F2

F3

F4

F4 = CONTINUE

= Switch to MENU1

DW+FT = Dewatering + Filtration

DWT+FT = Dewatering until + Filtration

EW+H+FT = Dewatering + Heating + Filtration

NEXT = Other operating modes

Only operating modes that can be selected are displayed.

A change of operating modes is possible at any time during the automatic operation

of the ready for operation status. Operating modes are active as soon as they are

selected.

Operating mode: Dewater + Filter

F1 = DWT+H+FT

DWT+

H+FT

FT

FT+H

NEXT

F2 = FT

F3 = FT+H

F1

F2

F3

F4

F4 = CONTINUE

= Switch to MENU1

DWT+H+FT = Dewatering until + Heating + Filtration

FT = Filtration only

FT+H = Filtration + Heating

NEXT = Other operating modes

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 33 / 80

Page 34

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Operating mode: Dewater + Filter

EW+

FTB

F1

EW+FTB = Dewatering + Filtration until

EW+H+FTB = Dewatering + Heating + Filtration until

FTT = Filtration until

NEXT = Other operating modes

Operating mode: Dewater + Filter

FTT+

H

F1

DW+H

+FTT

F2

F2

F3

F3

FTT

NEXT

F4

MENU1

F4

F1 = EW+FTB

F2 = EW+H+FTB

F3 = FTB

F4 = CONTINUE

= Switch to MENU1

FTT+H = Filtration until + Heating

MENU1 = Back to MENU1

Manual Menu (MANUAL)

OPERA-

TOR

F1

OPERATOR = Manual operation for operator

SERVICE = Manual operation for HYDAC Service (password-protected)

SERVICE

F2

F3

Selection

Manual

MENU1

F4

F1 = FTB+H

F4 = Switch to MENU1

F1 = OPERATOR

F2 = SERVICE

F4 = MENU1

MENU1 = Back to MENU1

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 34 / 80

Page 35

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

OPERATOR (MANUAL1)

Manual

operation

ON

F1

Manual Operation

FP = Switch filling pump On/Off

DP = Switch evacuation pump On/Off

The ON/OFF operating status of each component is shown on the display.

FP

OFF

F2

= Switching manual operation on/off

The ON displayed below Manual operation indicates that

manual operation is switched on.

If individual components are switched on beforehand, then

these components can now all be switched On or Off vai

manual operation F1.

DP

OFF

F3

Manual1

Back

NEXT

F4

F1 = Manual operation

F2 = FP (Filling pump)

F3 = EP (Evacuation pump)

F4 = CONTINUE in Manual2

Menu

= return to the screen "Se-

lection manual operation"

Components that are not installed will not be displayed.

OPERATOR (MANUAL2)

VP

OFF

F1

VP = Switching vacuum pump on/off

RV = Switching return valve on/off

RV

OFF

F2

F3

Manual2

Back

END

F4

F1 = VP (Vacuum pump)

F2 = RV (return valve)

F4 = END

= back to "Manual1" Menu

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 35 / 80

Page 36

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

LANGUAGE

Language selected:

SELECT

LAN-

F1

SELECT

LANGUAGE

Language

ENGLISH

MENU1

F2

F3

F4

F1 = Select language

F4 = back to "MENU1"

= Press the F1 key repeatedly until the desired language ap-

pears.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 36 / 80

Page 37

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

RH+P (Relative Humidity + Pressure)

Rel. humidity: Nominal: 30% Actual:

33%

°

Ready for operation. Please press Start

START

F1

STOP

F2

RESET

F3

MENU1

F4

START = Start FAM

is displayed only in the operating status "Ready for operation"

STOP = Stop FAM

is displayed only in the operating status "Starting phase" and

"Automatic operation"

RESET = Reset error messages

Is displayed only in the presence of faults

Display:

Rel. humidity: Nominal:

= The nominal value can be changed from 0 ... 99% (see

chapter 0).

RH

+P

F1 = START

F2 = STOP

F3 = RESET

F4 = back to "MENU1"

Factory setting: 30%

Rel. humidity: Actual: = Display of the current moisture at the FAM inlet.

A display of 0 ... 100% is possible.

Temp. = Medium temperature at inlet to the FAM.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 37 / 80

Page 38

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Contamination (Selection Contamination)

Selection

ISO

YES

F1

ISO = Display cleanliness code in accordance with ISO

SAE = Display cleanliness code in accordance with SAE

SAE = Display cleanliness code in accordance with NAS

Only the cleanliness code marked with "YES" can be selected.

SAE

NO

F2

NAS

NO

F3

Contami-

nation

BACK

F4

F1 = ISO

F2 = SAE

F3 = NAS

F4 = back to "MENU1"

ISO

tgt:

av:

Ready for operation. Please press Start

18

20

START

F1

START = Start FAM

STOP = Stop FAM

RESET = Reset error messages

Display:

16

4µ

4µ

18

STOP RESET

F2

is displayed only in the operating status "Ready for operation"

is displayed only in the operating status "Starting phase" and

"Automatic operation"

Is displayed only in the presence of faults

6µ

6µ

F3

14

15

14µ

14µ

MENU1

F4

ISO

F1 = START

F2 = STOP

F3 = RESET

F4 = back to "MENU1"

ISO: Nominal: = The nominal value can be changed from 0 ... 25% (see

chapter 0).

ISO: Actual: = Display of the current contamination at the FAM inlet.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 38 / 80

Page 39

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Intervals

Messwiederholintervall:

Intervals

3 Sollminuten

0 Abgelaufene Minuten

MENU2

F1

F2

F3

F4

F4 = back to "MENU2"

Display:

TRG MIN: = Recurrent measurement interval:

Adjustable from 2 – 360 minutes

Factory setting: 60 minutes

Elapsed minutes

= Display of the repeat testing interval minutes that have already

elapsed

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 39 / 80

Page 40

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

an operating-hours counter, and

Operating hours

18 hours 43 minutes

MENU2

F1

F2

F3

Display:

Operating hours = Display of the FAM operating hours

Operating Mode "Cleaning until"

The operating mode "Cleaning until" is possible only after a water saturation of

<90%. In cases of >90% or free water, the measurements of the ContaminationSensor will be falsified to such an extent that the CS will issue a fault message.

This fault message is ignored by the SPS. The most recently saved measured value

remains saved there until a restart is required.

The following message is output when the contamination is selected:

"Oil saturation >90%. Measurement with CS not possible!"

This display can be minimized by pressing the ESC key, so that the screen can be

exited again by selecting Menu1.

F4

F4 = back to "MENU2"

If a water saturation level of 90% occurs during automatic operation, then the operating mode switches automatically in accordance with the following table:

Selected operating mode: changes automatically after:

FTT => FT

EW+FTB => DW+FT

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 40 / 80

Page 41

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

General Operating Instructions - SIEMENS PANEL

System Keys

The system keys are used for making entries on the operating device. Overview of

the control keys

Functioning Effect

Moving the cursor

,

,

INS

+/-

DEL

TAB

Activate field

TAB

SHIFT

+

SHIFT

Display Help text

HELP

+

ESC

SHIFT

The next field in horizontal direction is activated with

Fields.

The next field in vertical direction is activated with

Fields.

The next field is activated - in the sequence that has

been defined in the project (Tab sequence).

The second function of an additional system key is

enabled.

Displays a window with Help text for the selected object.

Pressing makes it possible to switch back and

forth between screen Help text and the object Help

text, i.e. for an EA field.

Cancel action

HELP

ESC

Acknowledge message

ACK

Undo

An entry can be undone as long as that entry has not

yet been confirmed with .

• Closing the message window – if present

• Cancelling the display of a Help text in order to return

to the previous display.

Acknowledges the currently displayed or highlighted

message or all messages of an acknowledgement

group - depending on the project planning.

Calling up the Edit mode – redirects the entry via

TAB

and

+/-

ends the Edit mode and confirms the

entry

Navigating in the list

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 41 / 80

Page 42

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Table 8-2 Keys for navigating in lists

Key Effect of actuation

Moving the cursor

TAB

or

Entries and Help

You enter values in the Entry fields. The values are transferred from the entry fields

to the controller.

Proceed as follows:

1. Select the desired entry field within the image.

Depending on the field type, you can enter values of the following type in the

entry field:

– Numerical

– Alphanumerical

– Symbolic

– Date/Time

2. Enter the value.

3. Confirm your entry with

Marks the previous or the following list entry

+/-

HELP

ESC

or cancel the entry with

.

Numerical Values

Numerical values are entered one character at a time via the system keyboard. If

has been pressed, then you can modify the value one character at a time with

the aid of the cursor keys.

If a field already contains a value, then this will be deleted completely from the field

SHIFT

by pressing

Alphanumerical Values

Alphanumerical values, numbers and letters are entered one character at a time via

the system keyboard. If

character at a time with the aid of the cursor keys.

If a field already contains a value, then this will be deleted completely from the field

SHIFT

by pressing

+

+

DEL

.

has been pressed, then you can modify the value one

DEL

.

The expanded character set is available in fields that have the "String" format.

Date and Time

Values for date and time are entered in accordance with the alphanumerical values.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 42 / 80

Page 43

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Entering and Modifying Numerical and Alphanumerical Values

TAB

SHIFT

One entry field was activated with

+

or with the cursor keys.

Key Effect

Moving the cursor

DEL

or

INS

Marks the previous or the following list entry

Control buttons for entering characters

Functioning Effect

SHIFT

+

+/-

The algebraic sign of a numerical value is changed.

Pressing

tween the two signs.

TAB

,

+/-

All available characters from the expanded character

set will be called up one after the other.

The entry becomes valid

HELP

ESC

The entry is deleted

The original value becomes valid again.

SHIFT

+

+/-

switches back and forth be-

The following approaches are possible for entering numerical and alphanumerical

characters:

• Entering a value, which causes the existing value to be replaced completely

• Modifying the character of an existing value

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 43 / 80

Page 44

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Enter Value

If you wish to enter a new value - and not only a single character - then you can delete the entire contents of the field.

Proceed as follows:

DEL

SHIFT

1. Actuate

+

TAB

+/-

2. Enter value with

3. Press

The entry is confirmed. You can abort the entry with

Partial Value Changes

Proceed as follows:

1. Press

2. Select character to be changed with

3. Modify character with

4. Press

The entry is confirmed. You can abort the entry with

or with

HELP

ESC

.

TAB

or with

INS

or with

+/-

DEL

HELP

ESC

.

Character Call-up Sequence

When you enter a value in an alphanumerical field for the first time,

INS

The letter "A" will be called up after pressing

or

. This also applies when

a character is added to ones that have already been entered.

The following applies for further entries:

TAB

Press

when letters of the alphabet are to be entered.

All of the upper and lower case letters will be displayed first, and afterwards the

special characters and numerals.

+/-

Press

when characters are to be entered.

First a few special characters are displayed, and then the numerals.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 44 / 80

Page 45

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

If a value has already been entered, then the next following value will be displayed

TAB

+/-

with

or with

.

Example for numeric entry

To enter "–12.34", activate the entry field. Hold one of the cursor keys

+/-

with

pressed down for as long as it takes for the desired character to appear.

Press the following keys:

+00.00

5x

DEL

+00.00

+/-

-00.00

INS

-00.00

TAB

-10.00

TAB

or

INS

-10.00

TAB

-12.00

2x

INS

-12.00

TAB

-12.30

INS

-12.30

TAB

-12.34

-12.34

You can begin the entry at any given position in the entry field. The

algebraic sign can also be modified during the entry at any position in the entry field

+/-

SHIFT

with

+

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

.

en

Page 45 / 80

Page 46

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Entering and Changing Date and Time

TAB

SHIFT

A Date/Time field was activated with

+

or with the cursor keys.

Entering date and time

Use numerical and alphanumerical characters for entering date and time.

Safety Queries

The manual operation of the FAM is protected by a safety system.

If you are operating one operating object with password protection in the project,

then you must first register on the operating device.

A registration dialog is displayed for this purpose in which you enter a password.

User:

Password:

OK

F1

F2

Admin

F3

Cancel

F4

Registration dialog

You enter the password in the "Password" field in the registration dialog.

Proceed as follows:

1. Press

2. Hold one of the keys

+

TAB

pressed down for as long as it takes for

SHIFT

the desired character to appear.

INS

3. If you need additional characters, press

TAB

or with

+/-

4. If the password is complete, activate the "OK" button with

press

. You can abort the process with "Cancel".

and select the character with

TAB

SHIFT

+

and

After logging in, you can operate the operating objects that have password protection.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 46 / 80

Page 47

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Starting up the FAM

Once you log out, you can no longer operate the objects that have password protection, but instead you must also register yourself once again as necessary.

Sign-off time

A log-out time is entered in the system for the user. The user is automatically logged

out if the time that elapses between any two given actions on the part of the user,

e.g. entering a value or changing screens, is longer than the log-out time. He will

then have to log in again in order to operate objects under password protection.

Password

The password and the log-out time are encoded in a list and stored on the operating

device in a manner that is not affected by network power outages.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 47 / 80

Page 48

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Error messages

Error messages

NOTE

The switch cabinet door may not be opened unless the main switch is at "Off", because otherwise the main switch would be damaged.

The fault messages are not displayed in all of the menus but rather only in the following screens:

- Start screen

- RH

- CS

The fault messages that are relevant to the CS will only be displayed on the CS

screen.

The device comes to a stop and the fault indicator lamp flashes when fault messages occur. The device can not be started any more.

The operator can however jump into the different menus and operate a component

in the Manual Menu necessary for the elimination of the fault.

If several errors occur, then the most recently occurring message will be displayed

first. One can used the arrow keys to scroll through the individual fault messages.

In order to restart the device, first the error must be eliminated and then acknowledged afterwards. It is only then that automatic operation is possible again.

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 48 / 80

Page 49

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Error messages

Displayed

Cause Remedy see

fault message

CS1xxx + CS conveyor

pump switched Off,

CS1xxx malfunction.

Start 10 new attempts

with Reset!

10x errors on the CS in

sequence

acknowledge the first

time this occurs and

restart, inform Service

Department if this occurs again with a

week's time

flow at the FAM inlet

too low for 5 minutes

already. Please check

insufficient oil in the

vacuum column after

switch-on

check and open inlet

FAM inlet.

FAM outlet blocked. Min. is not reached

Error, float switch of

rotary vane vacuum

Float switch or cable

defective

Determine error and

replace defective part

pump at fill level Min/fill

level Overflow.

Error, float switch of

vacuum tower at fill

Float switch or cable

defective

Determine error and

replace defective part

level Min. and/or fill

level Max.

Error, float switch of

water ring vacuum

Float switch or cable

defective

Determine error and

replace defective part

pump at fill level Min/fill

level Overflow.

Cable break, AS 1000

temperature

Cable break, AS 1000

water content

Cable break or AS is

defective

Cable break or AS is

defective

Cable break, CS. Cable break or CS is

defective

No defined value from

CS.

For details, see Operating and Maintenance

Instructions for the

ContaminationSensor.

No measured value

from CS. Check flow.

For details, see Operating and Maintenance

Instructions for the

ContaminationSensor.

Malfunction CS flow too

low.

For details, see Operating and Maintenance

Instructions for the

ContaminationSensor.

Fault, CS device error For details, see Operat-

Determine error and

replace defective part

Determine error and

replace defective part

Determine error and

replace defective part

For details, see Operat-

ing and Maintenance

Instructions for the

ContaminationSensor.

For details, see Operat-

ing and Maintenance

Instructions for the

ContaminationSensor.

For details, see Operat-

ing and Maintenance

Instructions for the

ContaminationSensor.

For details, see Operat-

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 49 / 80

Page 50

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Error messages

Displayed

Cause Remedy see

fault message

Motor protection switch

Q2, drain pump,

tripped.

Motor protection switch

Q3, vacuum pump,

tripped.

Motor protection switch

Q4, filling pump,

tripped.

Motor protection switch

Q5, CS pump, tripped.

Oil filter contaminated.

Please replace oil filter.

Instructions for the

ContaminationSensor.

Electric motor of

evacuation pump overloaded

Electric motor of vacuum pump overloaded

Electric motor of filling

pump overloaded

Electric motor of CS

pump overloaded

Maximum differential

pressure at the filter

reached

Instructions for the

ContaminationSensor.

Switch on engine pro-

tection in the electric

control, check operat-

ing viscosity

Drain the fluid in the

tank, clean the tank,

refill

Switch on engine pro-

tection in the electric

control, check operat-

ing viscosity

Switch on engine pro-

tection in the electric

control, check operat-

ing viscosity

Changing the Filter

Element

0

Oil tank of rotary vane

vacuum pump empty.

Top up oil.

Oil tank of rotary vane

vacuum pump too full.

Please drain off oil.

Heater safety thermostat triggered.

Oil level in the tank of

the rotary vane vacuum

pump too low

Oil level in the tank of

the rotary vane vacuum

pump too high

Oil temperature heater

too large, oil diffusion

too low through the

heater

Top up oil

Open ball faucet and

drain oil

Reset thermostat in the

head of the heater.

Remove the cover of

the heater to do so.

Check filling pump for

proper functioning

Fuse element, heater Fuse has tripped Call in an electrician

Supply voltage to FAM:

wrong phase sequence. Change phase

incorrect phase sequence or phase sequence relay defective

Call in an electrician

sequence.

Dry-running Evacuation

Pump.

too little medium is being pumped into the

vacuum column

check suction filter and

clean it if necessary,

check filling pump for

proper functioning,

check viscosity

Vacuum chamber over- Emergency Off Max Check pressure in vac-

HYDAC Filtertechnik GmbH

BEWA FAM10 3417360 en.doc 2008-06-06

en

Page 50 / 80

Page 51

FluidAqua Mobil – FAM 10/15 +CS1000 +AS1000 Error messages

Displayed

Cause Remedy see

fault message

flow. Please empty the

vacuum chamber and

determine the cause.

FAM tray too full. Drain

and seal leaky site of

FAM.

filling level exceeded,

possible foam formation, evacuation pump

cavitation

uum column, check

evacuation pump for

proper functioning, in-

crease pressure in the

vacuum column in the

event of foaming (e.g.

from 300 mbar abso-

lute to 400 mbar ab-

soute)

FAM oil pan too full Drain oil pan, check the

FAM for leaks

HYDAC Filtertechnik GmbH