Page 1

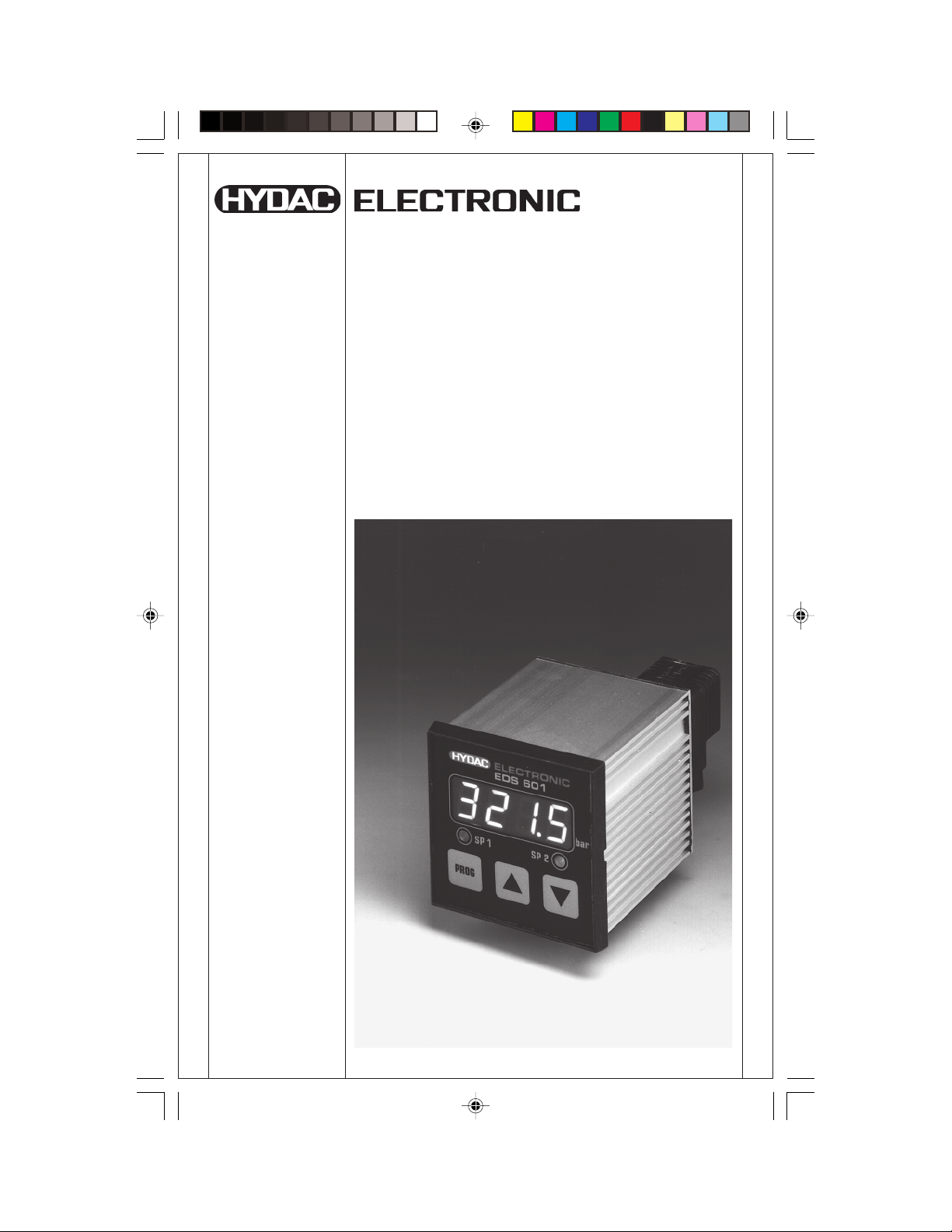

Elektronischer Druckschalter

Electronic Pressure Switch

Manocontacteur électronique

EDS 601

Benutzerhandbuch

Operating Manual

Manuel d'utilisation

Page 2

E

CONTENTS

1. General

1.1. Features

1.2. Installation options

1.3. Settings

1.4. Warranty

1.5. Queries and problems

2. Installation

2.1. Installed as pressure gauge

2.2. Installed as front panel measuring unit

2.3. Making the electrical connection

2.4. Supply voltage

2.5. Dimensions

2.6. Pin connections

2.7. Connection examples analogue output

3. Operation

3.1. Overview

3.2. Setting the switching points

3.3. Basic settings

3.4. Altering the measuring range

3.5. Altering the calibration

3.6. Disabling the programming

4. Error messages

4.1. Operating errors

4.2. Data errors

4.3. Invalid operating conditions

5. Technical data

6. Appendix A: Menu hierarchy

7. Appendix B: Parameter form sheet

8. Appendix C: Application example

Page 3

General

1.

Features

1.1.

l built-in pressure sensor with steel membrane

l 4-digit, 7-segment display to show the current pressure

l analogue output, switchable 0..10 V or 4..20 mA as current source

l two individually adjustable switching relays with change-over contacts

1.2.

Installation options

l directly into the system using a G ¼ threaded connection,

or via a mechanical adapter into a G ½ pressure gauge connection

to DIN 16288

l as a front panel unit where the connection is made via a hydraulic hose

Settings

1.3.

Switching point settings:

l Switching point and switching hysteresis relay 1 and relay 2

Basic settings:

l Switching direction relay 1 and relay 2

l Switching delay relay 1 and relay 2

l Switch-back delay relay 1 and relay 2

l Measured value filter on the display value

l Standard display value (current pressure, switching point or peak value)

l Analogue output signal (0..10 V or 4..20 mA)

Measuring range settings:

l Upper and lower measuring range limit

Calibration options:

l Re-calibration of the internal sensor for both zero and final value settings

l Re-calibration of the signal range of the analogue output

Warranty

1.4.

Both the components of the EDS 601 and the complete unit are subject to

stringent quality controls. Each EDS 601 is individually calibrated and subjected

to a final test. In this way we can guarantee that the unit is fault-free on despatch

and conforms to the given specifications. However, if there is cause for

complaint, please return the pressure switch to us outlining the fault.

Interference by anybody other than Hydac personnel will invalidate all warranty

claims.

Queries and problems

1.5.

If you have any queries regarding technical details or the suitability of the

pressure switch for your application, please contact our sales/technical

department. The EDS 601 pressure switches are maintenance-free and should

operate perfectly when used according to the specifications

(see Technical Data). If faults do nonetheless arise, please contact the

Electronics Servicenter.

E

FLUPAC LIMITED

Technical sales

Tel.: 01608 / 81 12 11

Fax: 01608 / 81 12 59

Page 4

E

Installation

2.

Installed as pressure gauge

2.1.

The EDS 601 can be installed directly into the hydraulic system via the G ¼

threaded connection or an adapter. Depending on the type of connection, the

sealing should be to DIN 3852 or DIN 16288. The torque should be within the

range 20..30 Nm. (Where adapted for G½: 45..50 Nm).

Installed as front panel measuring unit

2.2.

The unit is installed in a front panel cut-out of 68.5 x 68.5 mm. The unit is

secured with clamps from the mounting set, which can be ordered separately.

For mechanical de-coupling the hydraulic connection must be via a standard

small bore instrument hose. The sealing can be by means of an O-ring or a

metallic soft seal to DIN 3852. The torque should be within the range 20..30 Nm.

Note: When installed as a front panel unit a rigid hydraulic connection

G

Making the electrical connection

2.3.

The electrical connection should be carried out by a qualified electrician

according to the relevant regulations of the country concerned (VDE 0100 in

Germany).

The electronic pressure switches EDS 601 carry the mark. A declaration of

conformity is available on request.

The EMC-standards EN 50081-1, EN 50081-2, EN 50082-1 and EN 50082-2

apply.

The requirements of the standards are fulfilled only if the pressure switch

housing is earthed correctly by qualified personnel. If the pressure switch is

mounted inline, it is sufficient if the pipe is earthed via the hydraulic system. In

the case of hose-mounting, the housing must be earthed separately via the PE

connection of the 4-pole plug.

Additional assembly notes which, from experience, reduce the effect of

electromagnetic interference:

l Make line connections as short as possible.

l Use screened lines (e.g. LIYCY 4 x 0.5 mm

l The cable screening must be fitted by qualified personnel subject to the

l Direct proximity to connecting lines of user units or electrical or electronic

must not be used.

2

).

ambient conditions and with the aim of suppressing interference.

units causing interference must be avoided as far as possible.

Page 5

E

2.4.

Supply voltage

The EDS 601 switches on automatically as soon as sufficient supply voltage is

available. If, however, the supply voltage afterwards falls so low that reliable

operation can no longer be guaranteed, "- - - - appears in the display and the

relays and the analogue output are switched off. As soon as sufficient voltage is

once more available the unit operates again automatically. If the voltage sinks so

low that operation is no longer possible at all, the unit switches itself off

completely.

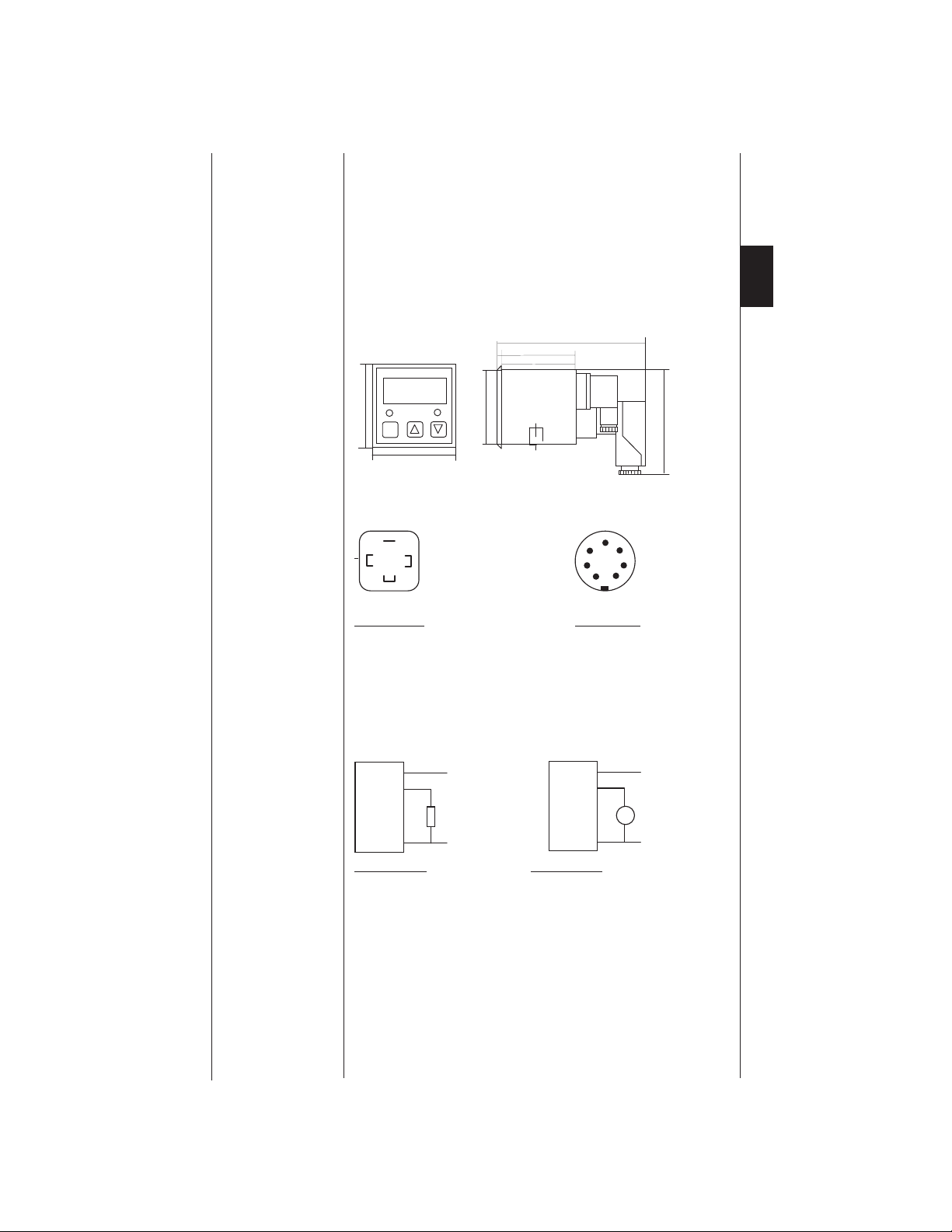

Dimensions

2.5.

164

98,7

83,5

E

2.6.

72

SP1 SP2

Prog

72

Pin connections

PE

1

2

3

67

G1/4"

PE

1

2

3

4

Voltage supply Relay outputs

Plug to DIN 43650 / IEC 4400 plug to DIN 43651

Pin 1: 24V Pin 1: relay 1 N/C contact

Pin 2: 0V Pin 2: relay 1 N/O contact

Pin 3: analogue output Pin 3: relay 1 common supply

Pin 4: relay 2 N/C contact

Pin 5: relay 2 N/O contact

Pin 6: relay 2 common supply

2.7.

Connection examples analogue output

EDS 601

1

24 V

3

Signal

R

L

2

0 V

EDS 601

1

3

2

Current output: Voltage output:

max. load resistance 400 W min. load resistance 2 kW

100,5

6

5

24 V

Signal

V

0 V

Page 6

E

3.

Operation

Overview

3.1.

The EDS 601 pressure switch is designed so that all standard applications are

covered with very little effort and the secondary operating options provide for a

high level of functionality.

When the supply voltage is switched on the unit displays the current pressure,

the relays switch in accordance with the set switching points and the analogue

signal is available. If the measured value is below the accuracy limit of 1 % the

lower measuring range limit (i.e. 0) is always displayed. If the measured value

exceeds or falls below the evaluation range of the pressure switch, either "O.P.

(Over Pressure) or "U.P. (Under Pressure) is displayed. The switching points

and switching hystereses of both relays can be set using the PROG, D and Ñ

keys. The switching hysteresis establishes by how many bar the value has to

fall below the switching point before the relay switches back again. This is the

standard use of the EDS 601.

In a secondary "Basic menu the following settings can be altered:

l To prevent switching during short-term pressure changes, the switching

delay and switch-back delay for each relay can be set within the range 0.00

to 90.00 s.

l The switching direction can be set for each relay. This allows the user to

determine whether the relay pulls in or drops when the switching point is

reached.

l The primary display can be altered to determine if the EDS 601 displays

the current pressure, either of the set switching points or the pressure

peak value. The pressure peak value is the highest pressure value that has

occurred since the unit was last reset. The unit is reset via the keyboard or

when the unit is switched on.

l In order to steady the displayed value an adjustable filter can be used to

smooth slight pressure deviations in the display.

l The analogue output signal can be converted from current to voltage. It is

switched between 4..20 mA and 0..10 V as standard.

For all applications where the measuring range is not required in bar, the

measuring range can be altered in a "Measuring range menu. This allows the

range to be displayed in bar, psi, MPa, kg, Nm, to name but a few. It is also

possible to specifically adjust the limits for an offset. (Please see point 3.4)

The EDS 601 also has a "Calibration menu. This allows the user at any time to

calibrate the built-in sensor in the zero point and the final value, the analogue

output in the zero point and the final value and to attain other output signal

ranges (e.g. 1..5 V, 0..20 mA, ...). To prevent accidental re-programming of the

settings, the programming can be disabled.

The appendix gives an overview of the menu hierarchy as well as a parameter

form sheet to assist with the setting of the EDS 601.

Page 7

3.2. Setting the switching points

To set the switching points, press the PROG key. "S.P.1 appears in the display

and shortly afterwards the value of switching point 1 begins to flash. The D and

Ñ keys increase or decrease the displayed value. If the D or Ñ key is held

down the value is automatically advanced. After 10 automatic advances the

speed is increased so that even values that are far removed from the initial

values can be reached quickly. If PROG is pressed again "HYS.1 is displayed

and shortly afterwards the value of switching hysteresis 1. This value can now

be altered in the same way as described above. Further pressing of the PROG

key then allows selection of switching point 2 and switching hysteresis 2.

Exiting the switching point setting:

If no key has been pressed for approx. 3 seconds the EDS 601 reverts to the

normal display. If any settings have been altered the new settings are

programmed into an internal memory and are saved even after the unit has

been switched off. "PROG appears for a short time in the display before the

unit reverts to the normal display.

Invalid settings:

If the switching hysteresis is larger than the corresponding switching point, the

error message "Er.01 (Error No. 1) is displayed. This error message can be

acknowledged by pressing any key. Then the invalid switching point is displayed

and can then be corrected.

The values are not saved in the memory and the unit does not revert to the

normal display (primary display) until all the settings are valid.

Notes:

l The switching points can be set from 1..100 % of the measuring range, the

switching hystereses from 0.5..99.5 % of the measuring range. The setting

is carried out in steps of 0.5 bar, on measuring ranges below 100 bar in

steps of 0.05 bar.

l While the switching points/switching hystereses are being altered the

relays are switched according to the previous settings. The unit only

operates with the altered settings after it has reverted to the normal display.

l The individual menu options (S.P.1, HYS.1, S.P.2, HYS.2) can also

be selected by pressing the D key or the Ñ key whilst holding down the

PROGkey.

Basic settings

3.3

Basic settings are settings that are altered only very rarely, usually only when

the unit is first installed. The following table shows the available settings and

the manufacturers pre-setting.

E

Settings Display Settings available Pre-setting

Switching direction relay 1 REL.1 on/off on

Switching delay relay 1 T.ON.1 0.0..90 s 0.01

Switch-back delay relay 1 T.OF.1 0.0..90 s 0,01

Switching direction relay 2 REL.2 on/off on

Switching delay relay 2 T.ON.2 0.0..90 s 0.01

Switch-back delay relay 2 T.OF.2 0.0..90 s 0.01

Primary display PRIM. act./S.P.1/S.P.2/Top act.

Display filter DISP. fast/med./slow med.

Analogue output signal OUTP. M.Amp./Volt Volt

Display of software version VERS. installed version

Exiting the basic setting END. yes/no

Page 8

E

If the manufacturers pre-settings suit your application you can skip this chapter.

Altering the basic settings:

If the EDS 601 is showing the normal display, "S.P.1 appears when the PROG

key is pressed. If the key is held down for 5 seconds the word "BASE begins

to flash in the display. If the key is now released the unit returns to normal

operation. However, if it is held down for a further 5 seconds when the PROG

key is released the flashing stops and "REL.1, the first option under the basic

settings, appears in the display. The pre-set switching direction ("ON or "OFF)

begins to flash in the display and can be altered using the D or Ñ key. The

PROG key is used to alter the other basic settings. The setting is carried out as

described under "Setting the switching points.

Exiting the basic setting:

If no key is pressed for approx. half a minute the new settings are stored in an

internal memory and are saved even after the unit has been switched off.

"PROG appears briefly in the display and the current pressure is displayed

again (or the programmed primary display value).

A faster way of exiting the basic setting is to select option "END, set it to "YES

and press the PROG key.

Notes:

l The switching direction "ON means that the relay switches to the active

condition when the switching point is reached (relay pulls in, N/O contact

closes), and switches back to the inactive condition when the value falls

below the switch-back point (switching point - switching hysteresis) (relay

drops, N/O contact opens). "OFF means that the relay switches to the

inactive condition when the switching point is reached, i.e. the reverse of

"ON.

l The switching delay "T.ON operates when the switching point is reached

and the switch-back delay "T.OFF operates when the value falls below the

switch-back point (switching point - switching hysteresis) regardless of the

set switching direction.

l The set delay times refer only to the amount of time by which the value

must exceed or fall below the particular switching point in order for a

switching operation to take place. In addition, the reaction time of the unit

(sensor, electronics and relays) of approx. 10 ms must be taken into

account.

l So that the delay times can be altered quickly the setting is carried out in

various steps:

Range Steps

0 ms ..... 100 ms 10 ms

100 ms .... 1 s 50 ms

1 s ........... 10 s 0.5 s

10 s ......... 90 s 5 s

l When setting the primary display, "ACT means current pressure, "S.P.1

means value of switching point 1, "S.P.2 means value of switching point 2

and "TOP means peak value.

l If the primary display is set to "S.P.1 or "S.P.2, during normal operation

the EDS 601 displays the value of the switching point concerned. Here, the

current pressure can be displayed using the D or Ñ key. This remains in

the display until the key is released. As an indication, the number of the

particular switching point ("S.P.1 or "S.P.2) is briefly displayed when the

unit is switched on.

l If the primary display is set to "TOP, during normal operation the EDS

601 displays the peak value. This can be reset using the D or Ñ key. Then

"RES (RESET) appears briefly in the display. If the key is held down, the

current peak value is reset to the current display value. As an indication,

"TOP appears briefly in the display when the unit is switched on and the

peak value is automatically reset.

Page 9

l Altering the setting of the display filter affects the interval in which the

displayed value is renewed.

"FAST - renews the display value every 0.2 seconds.

"MED - renews the display value every 0.33 seconds.

"SLOW - renews the display value every 0.66 seconds.

The setting of the display filter does not affect the reaction time of the relay

outputs or the analogue output, but merely serves to steady the display in

the event of rapid pressure fluctuations.

l The software version can only be viewed, not altered. The display serves

as a means of identifying the unit version in the event of queries.

Altering the measuring range

3.4.

Please note: Altering the measuring range merely means that another

G

Example: If the measuring range of an EDS 601-250-000 (nominal

To alter the measuring range follow the same procedure as for the basic

settings, but do not release the PROG key when "BASE stops flashing, only

when "RANG stops flashing.

The measuring range has three settings:

1. The number of decimal places ("POIN.)

2. The lower measuring range limit ("RAN.L.)

3. The upper measuring range limit ("RAN.H.)

To select and alter the settings and to exit the setting follow the procedure

outlined in the "Basic settings chapter. If the measuring range is changed so

much that the set switching points or switching hystereses are now outside the

new range, they are automatically set to the standard setting (switching

hysteresis: 1 %, switching point 1: 50 % and switching point 2: 75 %). The error

message "ER.04 is displayed to indicate this.

3.5.

Altering the calibration

The EDS 601 can be calibrated at any time without opening the housing.The

calibration covers 3 areas:

l the sensor input

l the analogue output for the "Volt setting

scale is selected. The nominal pressure range of the

pressure switch always remains the same and must not be

exceeded.

pressure range 250 bar) is changed to 0 ... 738, the display

value of 738 corresponds to a pressure of 250 bar.

l the analogue output for the "M.Amp. setting

Note: The calibration menu should only be used by a qualified person.

G

To access the calibration menu all 3 keys must be held down as the unit is

switched on. After approx. 5 seconds "CALI. begins to flash in the display. After

a further 5 seconds the flashing stops. If the keys are now released the

calibration menu can now be used.

Calibrating the sensor input

When the menu option "AD.L is selected the current lower calibration value is

displayed for approx. 2 seconds followed by the current value of the A/D

converter. Set the pressure to the lower limit (i.e. 0 bar) and press the D or Ñ

key. If the value is within the permitted tolerance range "NEW is displayed. The

lower limit is now calibrated. Otherwise, "FAIL is displayed and the sensor will

not be calibrated.

The same applies for "AD.H with regard to the upper calibration value.

Calibrating the analogue output

The menu option "OUTP selects whether the output should be calibrated as

current output (setting "M.AMP) or voltage output (setting "VOLT). The D or Ñ

key can be used under option "DA.L and "DA.H to change the value of the

analogue output. The value can be "DA.L 0V or 4 mA and "DA.H 10 V or

20 mA.

Exiting the calibration

This menu is not exited automatically. To exit the calibration select option

"END, set it to "YES and press the PROG key.

Improper handling can lead to a loss of accuracy of the pressure

switch.

E

Page 10

E

Notes:

l The calibration should only be altered by a qualified person.

l Calibration is possible in the following ranges:

(All details in digits, based on 10 bit values = max. 1023)

Zero point Final value

Sensor 30 .. 120

digits

Output current 0 .. 300 digits 300 .. 1020 (10 digits 0.11

850 .. 1015

V)

l The zero point always refers to the lower measuring range limit, i.e. to the

pressure value 0 bar, not to the measured value 0. (The two are only

identical if the measuring range begins at 0).

l The signal range can be made compatible by specifically changing the zero

point and the final value of the analogue output, e.g. to 0..5 V, 1..5 V,

0..20 mA, 0..10 mA

l If the measuring range is not given in bar, incorrect measuring ranges can

arise due to the conversion, e.g., a 40 bar pressure switch which is

designed to be operated in the converted unit kN has a measuring range of

5.14 kN due to the conversion. By re-calibrating the unit it can be operated

as a 5 kN unit. For this purpose, change the measuring range to 5.00 and

calibrate the final value of the sensor to this value. This is especially

sensible when making use of the analogue output, as the 10 V signal now

corresponds to a value of 5.00 kN, no longer 5.14 kN.

Disabling the programming

3.6.

To prevent accidental re-programming of the settings, the programming can be

disabled. To enable or disable the programming the D and Ñ keys must be

pressed simultaneously. After approx. 5 seconds "PROG appears in the

display. Afterwards the condition of the programme disable is displayed and can

be changed with the D and Ñ keys.

l "ON means programming enabled

l "OFF means programming disabled

Once the PROG key has been pressed the condition of the programme enable

is saved in the memory and the unit reverts to the normal display (primary

display). If the programming is disabled ("PROG = "OFF) all the settings can

still be viewed but not altered.

»

»

4.

Error messages

4.1.

Operating errors

ER 01 Error when setting the switching points and switch-back hystereses.

ER 02 Error when setting the measuring range.

ER 03 Error when setting the calibration data.

ER 04 After the measuring range was altered the switching points or

4.2.

Data errors

For these errors to be understood, the following needs to be explained:

The settings with which the unit is operated are stored in a RAM. This memory

loses its contents, however, if the unit is no longer supplied with voltage. All

settings are stored in a second memory, an EEPROM. Whenever settings are

altered the data is written into the EEPROM from the RAM. When, however,

voltage is supplied they are then read back into the RAM from the EEPROM.

The switching hysteresis is either too large for the pre-set switching

point or the measuring range was altered so much that the

switching point lies outside the measuring range.

switching hystereses lay outside the new range and were

automatically corrected to the standard value by the EDS 601.

Page 11

For safety purposes, there are several means of recognising data errors in both

types of memory. The data in the EEPROM is checked during every read and

write operation, the data in the RAM is monitored cyclically. In environments of

strong electro-magnetic fields or when there are extreme surges in the supply

voltage, a data error can occur. However, if lots of errors occur external antiinterference measures must be taken. In individual cases, there may also be a

fault in the pressure switch.

To guarantee reliable operation, in cases of error a corresponding message is

displayed and the relays and the analogue output are switched off until the error

is acknowledged by pressing any key.

ER 10 An error was discovered when the EEPROM was used. Switch the

ER 11 Errors were discovered in the RAM. Please take appropriate anti-

ER 12 The calibration data has been lost. Until the unit is re-calibrated this

Invalid operating conditions

4.3.

The displays listed below are not error messages which need to be

acknowledged. As soon as the valid operating condition re-occurs the unit

operates normally.

unit off and on again. If error 10 still appears when the unit is

switched back on the data in the EEPROM is invalid. Please check

all settings (measuring range, basic settings, switching points,

calibration) and correct them if necessary. Then check whether the

settings are saved if the unit receives no supply voltage or if an error

message is still displayed when the unit is switched off and on again.

interference measures to guarantee reliable operation.

error will be displayed every time the unit is switched on.

l The display "- - - - means that the supply voltage has fallen so low that a

reliable operation of the pressure switch is no longer guaranteed. (see

chapter 2.4.). The relays and the analogue signal have been switched off.

l The display "U.P. (under pressure) means that the pressure in the system

is too low.

l The display "O.P. (over pressure) means that the measuring range of the

pressure switch has been exceeded so much that the pressure can no

longer be correctly measured.

E

Page 12

E

Technical data

5.

General data

Dimensions approx. 72 x 72 x 110 mm (W x H x D)

Housing material aluminium, an odised

Pressure ranges 16; 40; 100; 250; 400; 600 bar

Overload pressures 24; 60; 150; 375; 600; 900 bar

Burst pressure 300 % FS

Accuracy 1 % FS

Repeatability switching point 0.25 % FS typ.

Temperature range - 25...+ 70° C (-25...+ 85° C media temperature)

Temperature drift 0.5 %/10 K; typ 0.25 %/10 K FS

Safety type IP 65

Vibration resistance 25 g/0...500 Hz

Shock absorbency 50 g/ 1 ms

mark

Connection supply voltage plug to DIN 43650/ISO 4400 (3 pol. + earth)

Connection relays plug to DIN 43651 (6 pol. + PE)

Pressure connection G¼" female thread, sealing to DIN 3852

Supply voltage DC 20...32 V

Current consumption approx. 120 mA

Starting current approx. 1.5 A (0.1 s)

Display 7-segment LED display, 4 digits, 13 mm high

Signal output 0...10 V ohmic resistance: min. 2

Limit frequency signal output 20 Hz

Relay outputs

Number/function 2 relays with change-over contacts

Switching voltage 0.1...250 V

Switching current 0.025...2 A

Switching capacity 50 W/ 400 VA

Reaction time approx. 10 ms (sens or + electronics + relays)

Life expectancy of contacts 10 m ill. without load

£

£

£

EN 50081-1, EN 50081-2,

EN 50082-1, EN 50082-2

4...20 mA ohmic resistance m ax. 400

1 mill. at nominal load

kW

W

Note: FS (Full Scale) = relative to the full measuring range

Page 13

Appendix A: Menu hierarchy6.

E

Page 14

Appendix B: Parameter form sheet

7.

E

Switching point settings

Switching point 1 S.P.1

Switching hyster esis 1 HYS.1

Switching point 2 S.P.2

Switching hyster esis 2 HYS.2

Basic settings

Switching direction relay 1 REL. 1

Switching delay relay 1 T. ON.

Switch-back delay relay 1 T. OF.

Switching direction relay 2 REL. 2

Switching delay relay 2 T. ON.

Switch-back delay relay 2 T. OF.

Primary disp lay PRIM.

Display filter DISP.

1

1

2

2

Measuring range settings

Decimal point position POIN.

Lower measur ing range limit RAN.L.

Upper meas uring range limit RAN.H.

Notes

EDS 601

Serial number:

Date:

Installation site:

Note: Take a copy of this sheet and fill in your required settings. You can

keep this form sheet near your manual so that you can refer to the

particular setting options at the same time. Do not commence

programming of the EDS 601 until you are sure about all the

settings. This is especially important in the case of complex settings.

This sheet can also be used for documentation purposes.

Page 15

Appendix C: Application example

8.

Accumulator charging circuit:

When the system pressure is reached, relay 1 switches the pump into the

bypass. If the pressure falls by the value of the switching hysteresis, the pump

begins to feed to the system again. The switching direction of relay 1 was set to

"OFF and the N/O contact was used as the switching contact. This guarantees

that the pump is not operating if the EDS 601 is switched off.

Relay 2 switches a warning light which lights up when the system pressure is

too low. As it also needs to light up if the EDS 601 is switched off, the switching

direction of relay 2 was set to "ON and the N/C contact was used. To bridge

short-term pressure surges, the switch-back delay was programmed to

2 seconds.

For documentation purposes, the analogue output is also connected to a central

data acquisition unit (DAU).

E

20 .. 36 V

to DAU

Rel 2

Rel 1

UB

6

5

4

3

2

1

warning light

pressure- min.

0V

EDS 601

1

2

0V

3

Loading...

Loading...