Page 1

Hustler 3500/3700 Catcher

Owner’s Manual

111782_0910

•••••

P.O. Box 7000

•••

Hesston, Kansas

•

67062-2097

Page 2

t-2 109686_0910

Page 3

TABLE OF CONTENTS

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Assembly Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parts Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

111782_0910 t-1

Page 4

t-2 111782_0910

Page 5

GENERAL INFORMATION

This manual applies to the following equipment:

Catcher, 929455

60” Blower, 929430

72” Blower, 929448

To the new owner

The purpose of this manual is to assist owners and operators

in maintaining and operating the catcher for the 3500/3700

tractors and decks. Please read it carefully; information and

instructions furnished can help you achieve years of

dependable performance.

Using this manual

General operation, adjustment and maintenance guidance is

outlined for both the experienced and novice Hustler user.

Operating conditions vary considerably and cannot all be

addressed individually. Through experience, however,

operators should find no difficulty in developing good

operating skills suitable to most conditions.

Directions used in this manual, for example RIGHT or

LEFT, refer to directions when seated on tractor facing

forward, unless otherwise stated.

Photographs and illustrations used were current at the time

of printing, but subsequent production changes may cause

your machine to vary slightly in detail. Hustler Turf

Equipment reserves the right to redesign and change the

machine as deemed necessary, without notification. If a

change has been made to your machine which is not reflected

in this owner’s manual, or the parts manual, see your Hustler

dealer for current information and parts.

Warranty registration

The Delivery and Warranty Registration form must be

completed and signed to validate your warranty protection.

As the new equipment owner, you are expected to see that the

card is completed and forwarded to Hustler Turf Equipment at

time of delivery.

Be sure to register the tractor plus each attachment that

displays a model and serial identification number plate with

Hustler Turf Equipment.

IMPORTANT: Any unauthorized modification, altera-

tion, or use of non-approved attachments voids the warranty

and releases Hustler Turf Equipment from any liability arising

from subsequent use of this equipment.

Parts and service

Use original Hustler replacement parts only. These parts

are available through your local Hustler dealer. To obtain

prompt, efficient service, always provide the following

information when ordering parts:

1. Correct part description and number, as given in the

parts manual supplied with your owner’s packet.

2. Correct model number.

All warranty repair and service must be handled through an

authorized Hustler dealer. Arrangements should be made

through your local service center.

111782_0910 1-1

Page 6

1-2 111782_0910

Page 7

SAFETY PRECAUTIONS

This safety alert symbol is used to call attention to a

message intended to provide a reasonable degree of

PERSONAL SAFETY for operators and other persons

during the normal operation and servicing of this equipment.

DANGER – Denotes immediate hazards which WILL

result in severe personal injury or death.

WARNING – denotes a potential hazard or unsafe practice

which COULD result in severe personal injury or death.

All operators should read this manual and be instructed

about safe operating and maintenance procedures. This is the

owner’s responsibility.

Incorrect usage of this machine may result in severe

injury. It is the owner’s responsibility that all operators

read this manual thoroughly and be properly trained in

operation and maintenance before attempting to set-up,

adjust, or service this machine. This owner’s manual

contains many safety precautions that must be followed to

avoid injury.

V Park the machine on level ground. Place park brake

lever in the brake engaged position, place the PTO

lever in the “OFF” position, lower the attachment, shut

off engine and remove ignition key before leaving

operator’s seat for any reason including unclogging the

chute.

V Always be aware of any obstructions, especially small

children, when backing or when unloading the catcher.

V Always keep safety shields and covers in place while

operating machine.

V Stop the engine before removing any part of the grass

catcher or unclogging the discharge chute. Never clear

teh discharge chute with the engine running. Turn off

the engine and be sure the blades have stopped before

cleaning. Use a stick to clear a plugged discharge area.

Never use your hands!

V Grass collection system components are subject to

wear, damage, and deterioration, which could expose

moving parts or allow objects to be thrown. Frequently

check components and replace with manufacturer’s

recommended parts, as necessary.

V Never work on blower assembly or mower deck when

the tractor engine is running.

V Never operate machine with catcher in the dump

position.

V Never attempt high speed maneuvering in crowded or

congested areas.

V Always operate with complete catcher system or side

discharge chute in place.

Whirling blades! Keep hands

and feet away.

Beware of thrown objects.

Stop tractor engine, remove ignition key.

Engage park brake.

Use a probe to clean debris from

spout.

Never engage mower deck

unless hose is clamped in place

on blower outlet.

Never operate the mower deck

with the deflector removed or in

a raised position, except when

the grass catching att achment is

being used.

111782_0910 2-1

Page 8

2-2 111782_0910

Page 9

ASSEMBLY INSTRUCTION

These instructions apply to the assembly of the Hustler

Catcher to a Hustler 3500/3700 tractor equipped with a 60” or

72” side discharge deck.

It is intended that these units be installed by trained Hustler

service personnel. If additional assistance is required, contact

the Hustler Customer Service Department.

Directions given in these instructions, for example left and

right, refer to direction while seated on the tractor.

Before proceeding, read thru the following instructions to

familiarize yourself, while at the same time identify and

inventory kit parts supplied.

Unpack and inspect all parts. Notify carrier of any shipping

damages immediately.

Packing list - 929455 Catcher

PART NO. DESCRIPTION QTY.

PECA1089 BOX ASSEMBLY 1

PECB0212 FRAME SUPPORT BRACE 1

PECA0578 REAR SUPPORT FRAME 1

PECA1001 PIVOT HANDLE 2

PECK1231 1/2”-13x 1” HHCS 2

PECK0364 3/4”-10 x 1-1/2” HHCS 2

PECK1433 3/4”-10 NYLOC NUT 2

PECK1432 3/8”-16 U-BOLT 2

PECK1215 3/8”-16 FLANGE NUT 4

PECK0331 1/2”-13 U-BOLT 2

PECK1247 1/2”-13 NYLOC NUT 4

PECK0055 1/2” FLAT WASHER 4

Packing list - 929430 60” Blower

INDEX NO. PART NO. DESCRIPTION QTY.

1 704916 CS .250-20X1.250 HX G5 3

2 768515 FW .281X.625X.051/.080H 6

3 111901 BOX PLATE SUPPORT 1

4 111915 CHUTE SUPPORT 1

5 111902 THICK GUIDE SPACER 1

6 111903 THIN GUIDE SPACER 1

7 111904 CHUTE GUIDE 1

8 024927 NT .250-20 HX GR.5 ZNYC 3

9 111638 CATCHER WEIGHT FULL 2

10 111639 CATCHER WEIGHT HALF 1

11 111448 PULLEY COVER 1

12 078949 CS .500-13X2.000 G5 ZNY 1

13 752386 CW .515X 2.25X .204 BLK 1

14 787986 BELT, B 46" EL 1

15 524785 PULLEY, DOUBLE 6.0 1.0 1

602244 PULLEY, DBL 5.02/6.87EOD (NOT

SHOWN)

16 023036 HP .148 X2.690 ZN 1

17 019471 CE .380X1.75 .150X1.60 1

18 103036 CHUTE MOUNT 1

19 086660 NT .375-16 HXZY NL 4

20 767954 FW .406X .812 X.060 SAE 4

21 109716 HOOK, BLOWER TUBE 1

22 036236 CS .312-18X1.000 HX G5 2

23 768523 FW .343X.687X.051/.080H 4

24 025395 CB .375-16X 1.00 STD CD 3

1

INDEX NO. PART NO. DESCRIPTION QTY.

25 710194 CB .375-16X 1.50 STD G5 1

26 107045 60" XR7 BLOWER SPACER 1

27 058766 NT .312-18 HXZY NL 2

28 111445 BLOWER GUARD 60" 1

29 102913 BLOWER PIVOT MOUNT 1

30 111920 PECO ELBOW 1

31 111849 TUBE SUPPORT 2

32 111852 LOWER TUBE W/A/ 1

33 601229 TRANSITION TUBE, LOWER 1

34 601640 BUNGEE STRAP 1

35 056077 CS .250-20 X 1.00 HX G5 ZN 1

36 068551 NT .250-20 HX NL ZN 1

37 768523 FW .343X.687X.051/080 HD ZN/YL 8

38 064014 CS .312-18 X .875 HS G5 ZN 2

39 064006 CS .312-18 X .625 HX G5 ZN 4

40 058776 NT .312-18 HX NL ZN 2

41 760306 FLEXIBLE TRANSFER TUBE 1

42 022608 HOSE CLAMP 2

43 544501 BLOWER ASSEMBLY 1

Packing list - 929448 72” Blower

INDEX NO. PART NO. DESCRIPTION QTY.

1 704916 CS .250-20X1.250 HX G5 3

2 768515 FW .281X.625X.051/.080H 6

3 111901 BOX PLATE SUPPORT 1

4 111915 CHUTE SUPPORT 1

5 111902 THICK GUIDE SPACER 1

6 111903 THIN GUIDE SPACER 1

7 111904 CHUTE GUIDE 1

8 024927 NT .250-20 HX GR.5 ZNYC 3

9 111638 CATCHER WEIGHT FULL 2

10 111639 CATCHER WEIGHT HALF 1

11 111452 PULLEY COVER 1

12 078949 CS .500-13X2.000 G5 ZNY 1

13 752386 CW .515X 2.25X .204 BLK 1

14 787986 BELT, B 46" EL 1

15 524785 PULLEY, DOUBLE 6.0 1.0 1

602244 PULLEY, DBL 5.02/6.87EOD (NOT

SHOWN)

16 023036 HP .148 X2.690 ZN 1

17 019471 CE .380X1.75 .150X1.60 1

18 103036 CHUTE MOUNT 1

19 086660 NT .375-16 HXZY NL 4

20 767954 FW .406X .812 X.060 SAE 4

21 109716 HOOK, BLOWER TUBE 1

22 036236 CS .312-18X1.000 HX G5 2

23 768523 FW .343X.687X.051/.080H 4

24 025395 CB .375-16X 1.00 STD CD 3

25 710194 CB .375-16X 1.50 STD G5 1

26 058766 NT .312-18 HXZY NL 2

27 111449 BLOWER GUARD 72" 1

28 102913 BLOWER PIVOT MOUNT 1

30 111920 PECO ELBOW 1

31 111849 TUBE SUPPORT 2

32 111852 LOWER TUBE W/A/ 1

33 601229 TRANSITION TUBE, LOWER 1

34 601640 BUNGEE STRAP 1

1

111782_0910 3-1

Page 10

INDEX NO. PART NO. DESCRIPTION QTY.

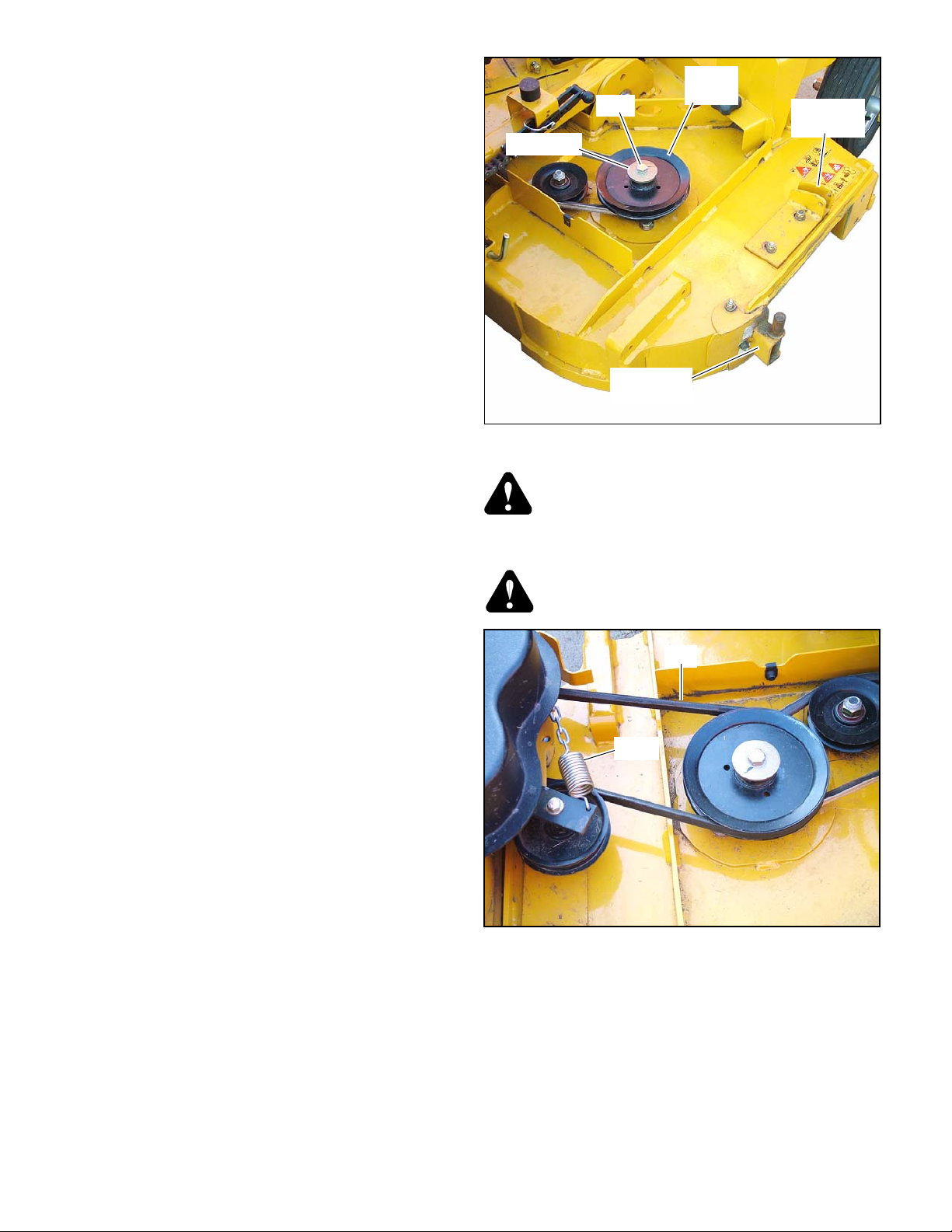

Cup washer

Bolt

Blower pivot

mount

Chute

mount w/a

Double

pulley

Spring

Belt

35 056077 CS .250-20 X 1.00 HX G5 ZN 1

36 068551 NT .250-20 HX NL ZN 1

37 768523 FW .343X.687X.051/080 HD ZN/YL 8

38 064014 CS .312-18 X .875 HS G5 ZN 2

39 064006 CS .312-18 X .625 HX G5 ZN 4

40 058776 NT .312-18 HX NL ZN 2

41 760306 FLEXIBLE TRANSFER TUBE 1

42 022608 HOSE CLAMP 2

43 544501 BLOWER ASSEMBLY 1

Mower deck preparation

1. Park the tractor on a flat surface and place the park brake

lever in the brake engaged position, place the PTO lever

in the “OFF” position and lower the attachment. Shut off

the ignition switch and remove the key from the switch.

Disconnect the negative battery cable.

2. Remove the right side pulley cover, discharge chute and

discharge chute bracket.

NOTE: Retain these parts as they will be re-installed

when the catcher is removed.

3. Release the deck belt tension. Remove the existing

spindle bolt and pulley from the right side blade spindle.

Replace the pulley with the double pulley and place the

existing cup washer between the head of the new bolt and

the drive pulley. Torque the bolt into the pulley before

threading the bolt into the spindle shaft. Torque top

spindle bolt to 118 ft.-lbs. Thread the pulley, cup washer

and bolt assembly into the right hand spindle shaft.

Torque bol t to 118 ft.-lbs. Figure 3-1

NOTE: There are two double pul leys shipped with this

catcher. Two different deck gearboxes have been used on

these decks.

Decks built prior to serial number 09080000 – The

gearbox is painted black and the pulley is held onto the

drive shaft with set screws. Use pulley, 602244, on these

decks.

Decks built with serial number 09080000 and later –

The gearbox on these decks is painted gray. The pulley is

held onto the drive shaft with a cap screw. Use pulley,

524785, on these decks.

CE Decks regardless of serial number – The gearbox is

painted black and the pulley is held onto the drive shaft

with set screws. Use pulley, 602244, on these decks.

4. Attach the blower mount to the top of the deck. Figure 3-

1

5. Attach the blower assembly to the deck mount. Figure 3-

6. Re-adjust the blower pivot mount, if necessary, to

1

minimize the gap between the deck opening and blower

housing. Tighten all hardware.

7. Install and route the blower belt to the deck. Tension the

belt using the chain and spring. Pull the chain until the

spring extension is 6” hook to hook. Figure 3-2 & Figure

3-3

8. Re-tension the deck drive belt.

9. Attach the pulley cover.

10. Swing the housing so that it is tight against the deck and

insert the clevis pin and hair pin thru the latch..

Figure 3-1

WARNING: Do not operate deck without discharge

chute or complete catcher system in place.

Tractor Preparation

WARNING: Allow engine and muffler to cool before

assembling the unit to the tractor.

Figure 3-2

1. Position the rear support frame and the weights (centered

side to side) to the rear of the tractor . Make sure the upper

holes in the rear support frame are positioned as shown.

Attach with the hardware shown. Figure 3-10

NOTE: It is recommended that 3 people assist when

attaching the box assembly to the rear support frame.

2. Locate the box assembly onto the rear support frame and

attach to the rear support frame with the hardware shown.

Figure 3-10

3-2 111782_0910

Page 11

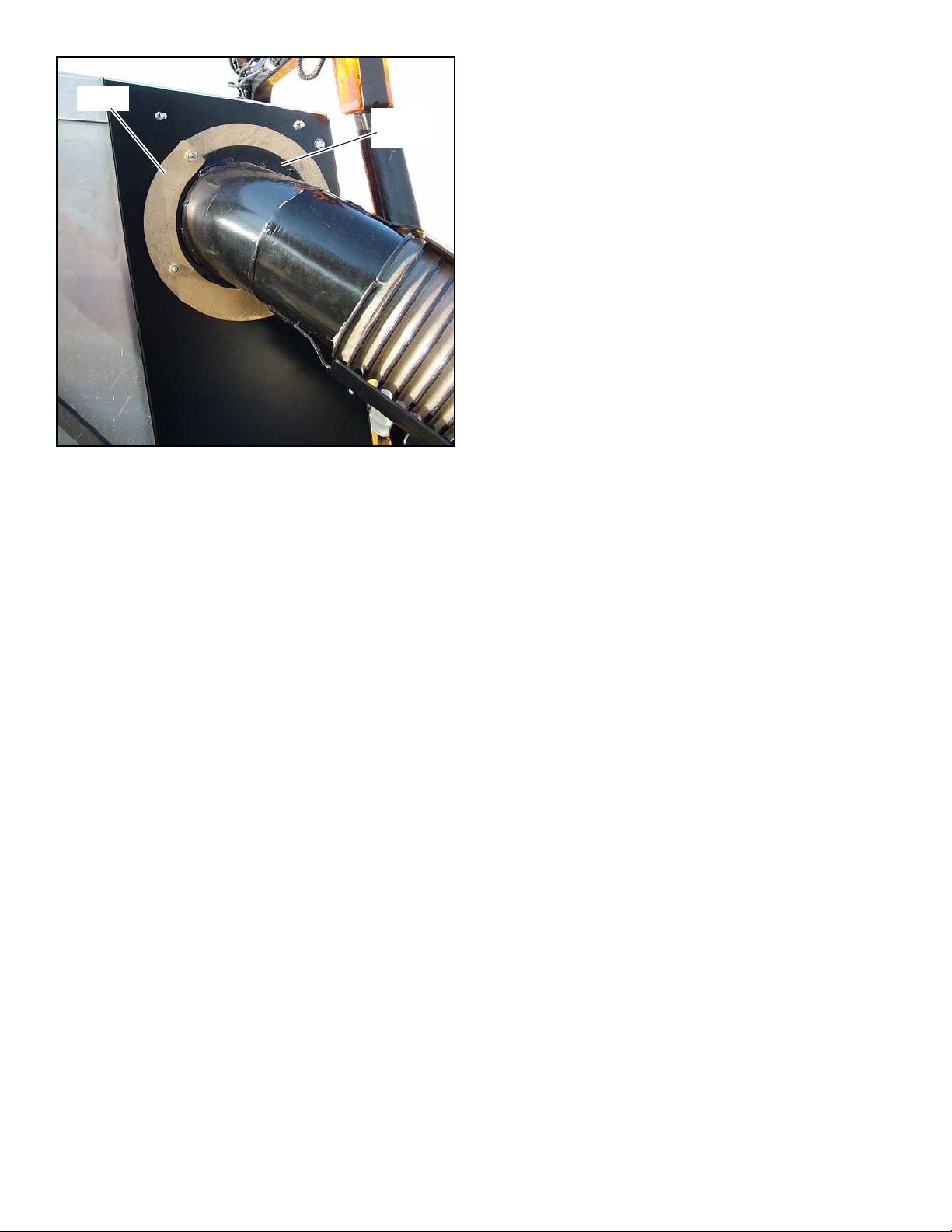

Figure 3-3

Chain

Remove these nuts

and flat washers

Bungee

strap

109716

Blower

housing

tube

Lower

tube

Tube assembly

3. Locate the frame support brace onto the tractor’s ROPS

with the short end of the bend facing upwards and to the

rear of the tractor. Figure 3-11

Raise the support brace until the pins from the box

support frame rest inside the notches in the support brace.

Secure in place using the hardware shown. Tighten all

nuts and bolts.

4. Test to make sure the dump mechanism is working

properly. Pull the lift handle towards the operator’s seat

and lift upward. The container’s door should open and the

box should pivot towards the ground. If the dump

mechanism needs adjusted, refer to the Adjusting dump

mechanism section found elsewhere in this manual for

detailed information.

5. Attach the bungee cord, located on the lower tube, to the

blower tube hook. Figure 3-4

6. Reconnect the negative battery cable. NOTE: Refer to

the Accessing the engine compartment section, found

elsewhere in this manual, for detailed information.

Figure 3-4

Catcher Box Preparation

1. Install the box plate support, chute support, thick guide

spacer, thin guide spacer and chute guide to the side of

the box assembly per Figure 3-7 or Figure 3-8

Final Connection

1. Assemble the blower tube per Figure 3-9.

2. Remove the top two nuts and flat washers that attach the

blower housing tube to the blower housing. Slide the

blower tube hook (109716) onto these bolts and secure in

place with the nuts and flat washers. Figure 3-4

3. Slide the lower tube onto the blower housing tube. Figure

3-4

4. Adjust the length of the blower tube assembly until the

top tube flange can slide into the box assembly’s inlet

mount. Secure in place with the chute guide (111904).

Tighten chute guide hardware. Figure 3-6

Figure 3-5

111782_0910 3-3

Page 12

111904

Top tube

flange

Figure 3-6

3-4 111782_0910

Page 13

929430 – 60” Deck

1

2

3

4

5

6

7

2

8

11

12

13

14

15

16

17

20

21

22

23

25

27

23

28

29

19

19

18

19

24

20

EXISTING

HARDWARE

EXISTING

HARDWARE

EXISTING

HARDWARE

26

43

Figure 3-7

111782_0910 3-5

Page 14

929448 – 72” Deck

1

2

3

4

5

6

7

2

8

11

12

13

14

15

16

17

20

21

22

23

25

26

23

27

28

20

20

18

19

24

19

EXISTING

HARDWARE

EXISTING

HARDWARE

EXISTING

HARDWARE

43

Figure 3-8

3-6 111782_0910

Page 15

40

37

30

42

41

38

37

31

31

39

37

39

37

42

32

33

36

34

35

Transfer Tube Assembly

NOTE: Assembly is included with 929430 and 929448

111782_0910 3-7

Figure 3-9

Page 16

929455 – Catcher

PECA1001

PECK1231

PECK0364

PECK1433

10

9

PECK0331

PECK1247

PECK0055

Box Assembly

PECA1089

PECA0578

These items included in 929430 and 929448.

111

Figure 3-10

3-8 111782_0910

Page 17

929455 – Catcher continued

PECK1432

PECK1215

PECB0212

PECK1432

ROPS

PECK1215

Figure 3-11

111782_0910 3-9

Page 18

3-10 111782_0910

Page 19

OPERATION

Dump

handle

Catcher shown in

dumping position

Vacuum pickup and collection

Follow normal tractor and mower deck start-up and operating

procedures as described in the tractor and deck owner's manuals.

NOTE: Refer to the Accessing the engine compartment section

for more detailed information.

The blower assembly for the catcher is directly belt driven by

the right-hand deck spindle, therefore, the deck and blower

assembly will operate when the mower deck lever is engaged

into the mow position. To stop the deck and blower assembly,

place the PTO lever in the disengaged (OFF) position.

Proceed to mow in the normal manner. The tube is made of a

clear material which allows the operator to see when grass is

starting to clog the tube. When this occurs either the hopper is

full and needs dumped or the tube is clogged and needs cleaned

out.

When the box is full, move the PTO lever to the disengaged

(OFF) position. Then drive the machine to the unloading area.

It is best that the catcher box be unloaded before the blower

and tube areas become clogged. If clogging occurs, it will be

necessary to clean the blower and tube areas of all material

before starting to mow again.

WARNING: Make certain the engine is turned off, the

park brake is engaged and the ignition key is removed

from the ignition switch before cleaning the blower

and chute areas.

NOTE: If you do not hold the handle towards the mower

as you pull the handle downward, the latc h will not lock

and the box can unexpectedly release the clippings.

Figure 4-1

WARNING: Ne ver place hands or feet into the blower

housing spout. There is an impeller located inside the

housing that will cause severe injury. Use a probe to

clean debris from spout.

WARNING: Never engage mower deck unless the

catcher box is installed and the door is closed. Also,

the transfer tube assembly must be in place on the

blower outlet and the box assembly and the bungee

cord is connected. Figure 3-4 and Figure 3-5

Unloading

WARNING: Make certain the PTO lever is in the dis-

engaged (OFF) position before unloading.

Use the following procedure to operate the dumping

mechanism:

1. Park the unit on a level surface, shut the engine off and

place the park brake lever in the park brake position.

2. Pull the dump handle towards the operator’s seat. While

holding the handle, move the handle upward. The catcher

box door will swing upward and the box will rotate

downward. The box will dump it’s contents.

3. Once the box is empty, return the box to the catching

position. With the handle in the “open” position, pull the

handle downward until it stops. Move the handle to the

“closed” position. Figure 4-3 and Figure 4-4

111782_0910 4-1

Figure 4-2

Page 20

Figure 4-3

Dump handle shown

in closed position

Dump handle shown

in open position

Pivot handle

Catcher box

and frame

Dump handle

Figure 4-4

Accessing the engine compartment

Use the following procedure to access the engine

compartment:

1. Park the unit on a level surface, shut the engine off and

place the park brake lever in the park brake position.

2. Loosen the pivot handle on each side. Figure 4-5

3. Keeping the dump handle in the closed position (Figure

4-3), lift up on the dump handle and rotate the complet

catcher box and frame back until the assembly comes to a

stop. Be sure to maintain a secure gri p on the handle and

slowly rotate the assembly back. Figure 4-6

4. Unhook the engine compartment latch. Figure 4-7

5. Using the lift handles on the side of the hood, slowly lift

and rotate the hood back to access the engine

compartment.

6. Using the lift handles on the engine compartment hood,

slowly raise and pivot the catcher and hood back. Figure

4-8

IMPORTANT: When raising or lowering the hood maintain a firm hold on the lift handle. Allowing the hoo d to

make hard contact with the catcher frame may cause

damage to the hood.

Figure 4-5

Figure 4-6

4-2 111782_0910

Page 21

Figure 4-7

Hood latch

Hood

Lift handle

Figure 4-8

111782_0910 4-3

Page 22

MAINTENANCE

Blower

assembly

Tube assembly

Belt

Spring

Blower housing and transfer tube

WARNING: Never work on the blower assembly or

mower deck when the tractor engine is running.

WARNING: Clean flammable material from machine.

Prevent fires by keeping engine compartment, top of

deck, exhaust area, battery, hydraulic lin es, fuel line,

fuel tank and operator’s station clean of accumulated

trash, grass clippings, and other debris. Always clean

up spilled fuel and oil.

The blower and tube assembly (Figure 5-1) should be kept

clean and free of any accumulation of matted clippings or other

obstructions. Occasional clogging may also occur when

working in heavy, wet or matted grass.

WARNING: Never place hands or feet into the blower

housing spout. There is an impeller located inside the

housing that will cause severe injury. Use a probe to

clean debris from spout.

WARNING: Never engage mower deck unless the

catcher box is installed and the door is closed. Also,

the transfer tube assembly must be in place on the

blower outlet and the box assembly and the bungee

cord is connected.

To service the blower housing: remove the clevis pin and

swing the housing away from the deck.

To service the transfer tubes, remove the tube assembly from

the unit. The tube assembly can be cleaned by using soapy

water and washing the inside of the tubes with a pressure

washer. Rinse with water.

To clean the catcher box, use a power washer.

Blower drive belt

The blower drive belt (Figure 5-2) is located under the belt

shield. This belt is spring tensioned and should not need

adjustment. When replacing the belt the spring extension

should be 6” hook to hook.

To inspect or replace, remove the clevis pin and swing the

housing open. This loosens the belt and allows it to be

removed.

When belt replacement becomes necessary, check the

condition of the pulleys. Clean the grooves and check for

excessive wear . A new belt should not run against the bottom of

groove. If it does bottom out, the the pulley needs replacing.

Figure 5-1

Figure 5-2

Blower spindle jack shaft

The blower spindle jack shaft assembly requires lubrication

after every 500 hours of use or annually, whichever occurs first.

The spindle is equipped with two grease zerks (Figure 5-3).

They are accessible by unlatching the blower housing from the

deck and pivoting it outward. Use SAE multi-purpose grease,

fill until grease flows from side of zerk (one or two ounces

maximum).

111782_0910 5-1

Page 23

Figure 5-3

Grease zerk

5-2 111782_0910

Page 24

STORAGE

When your mower is to set idle for a period of time, scrape

and remove the matted grass material from inside the catcher

box. Clean the discharge area in the blower assembly

likewise. A light coating of oil applied to these surfaces will

help retard rusting.

Check for loose or missing hardware, tighten or replace.

Also check for badly worn or damaged parts, consider

replacing them at this time. Touch up chipped paint areas,

your Hustler dealer has aerosol spray paint available.

111782_0910 6-1

Page 25

6-2 111782_0910

Page 26

929455 Parts List

Peco Catcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Blower Assembly (544510) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Transition Chute Assembly (544510) . . . . . . . . . . . . . . . . . . . . . . . 7-10

Spindle Housing Assembly (520627). . . . . . . . . . . . . . . . . . . . . . . . 7-12

_0910 7-1

Page 27

Peco Catcher

1

2

3

4

5

6

8

7

11

13

9

10

15

16

17

12

14

Base

18

14

7-2 _0910

Page 28

Peco Catcher

INDEX NO. PART NO. QTY. DESCRIPTION

1 PECC0041 1 BOX TOP

2 PECC0039 1 SCREEN SUPPORT

3 PECB8001 1 SCREEN

4 PECC0043 1 BOX RIGHT SIDE

5 PECC0045 1 BOX BACK

6 PECC1184 1 FILL GAUGE

7 PECC0044 1 BOX LEFT SIDE

8 PECC0042 1 BOX BOTTOM

9 PECA0331 1 BOX OPENING FRAME

10 PECK1435 2 ADJUSTING SCREW

11 PECK1422 2 ADJUSTING NUT

12 PECB1596 2 DOOR LINKAGE

13 PECK1418 2 LINKAGE PIN

14 PECK1437 4 RUE_RING COTTER PIN

15 PECV1154 1 PLASTIC DOOR

16 PECB1834 1 UPPER DOOR MEMBER

17 PECA0330 1 DOOR FRAME ASSEMBLY

18 602210 1 DECAL SERIAL NUMBER

NOTES:

_0910 7-3

Page 29

Peco Catcher

19

20

21

25

23

24

26

28

29

Hopper

22

30

31

32

27

7-4 _0910

Page 30

Peco Catcher

INDEX NO. PART NO. QTY. DESCRIPTION

19 PECB1833 1 BOX BASE FRAME

20 PECB0007 1 HANDLE MOUNT

21 PECJ0552 1 HANDLE GRIP

22 PECA0329 1 HANDLE ASSEMBLY

23 PECB0006 1 HANDLE SLIDE BRACKET

24 PECB1835 1 PIVOT PLATE

25 PECB1832 2 PIVOT BRACKETS

26 PECB1840 1 LATCH ROD

27 PECJ0255 1 LATCH SPRING

28 PECJ0234 1 3/8" BALL JOINT

29 PECB1804 1 LATCH HOOK

30 PECK1410 1 3/8" NUT

31 PECS0155 1 PIVOT BUSHING

32 PECB1805 1 LATCH HOOK PIVOT PLATE

NOTES:

_0910 7-5

Page 31

Peco Catcher

33

34

38

37

39

36

40

35

41

42

43

44

45

46

47

7-6 _0910

Page 32

Peco Catcher

INDEX NO. PART NO. QTY. DESCRIPTION

33 PECK1432 2 3/8"-16 U-BOLT

34 PECB0212 1 FRAME SUPPORT BRACE

35 PECK1215 4 3/8"-16 FLANGE NUT

36 PECA0579 1 BOX SUPPORT FRAME

37 PECK0088 2 5/32" X 2-5/8" HAIR PIN

38 PECK0058 2 5/8" FLAT WASHER

39 PECK1231 2 1/2"-13" X 1" HHGS

40 PECK1437 4 RUE_RING COTTER PIN

41 PECK0172 2 CLEVIS PIN

42 PECA0578 1 REAR SUPPORT FRAME

43 PECK1247 4 1/2"-13 N YLOC NUT

44 PECK0055 4 1/2" FLAT WASHER

45 PECK1433 2 3/4"-10 N YLOC NUT

46 PECK0364 2 3/4"-10 X 1-1/2" HHCS

47 PECA1001 2 PIVOT HANDLEVR

NOTES:

_0910 7-7

Page 33

Blower Assembly (544510)

1

1

10

9

3

1

2

15

35

36

11

10

26

2

27

20

11

28

3

2

1

16

19

17

30

25

24

22

29

22

32

31

23

33

34

1

3

2

4

12

2

13

14

5

6

16

7

6

8

11

19

20

21

22

22

23

17

24

25

1

2

3

4

18

7-8 _0910

Page 34

Blower Assembly (544510)

INDEX

NO.

PART NO. QTY. DESCRIPTION

1 078378 4 CS .50-20 X 1.50 HX G5 ZN

2 017046 12 LW .50 MEDIUM SPRING ZN

3 078386 4 FW .510 X 1.750 X .180 ZN

4 301267 2 DRIVE PULLEY

5 324327 1 BLOWER TOP

6 077123 2 BEARING W/O COLLAR

7 022582 1 CAST SPINDLE HOUSING

8 758565 1 IMPELLER 11”

9 758730 1 JACK SHAFT

10 212472 4 KEY

11 045765 5 FW 1.030 X 1.50 X .134 ZN

12 705194 4 CS .50-13 X .750 HX G5 ZN

13 034272 6 NT .312-18 HX G5 ZN

14 768523 6 FW .343 X .687 X .051/.080 HD ZN

15 324319 1 BLOWER HOUSING

16 074252 2 CS .50-13 X 1.50 HX G5 ZN

17 263517 2 BEARING DISK

18 324343 1 UPPER IDLER ARM

19 068759 6 CW .560 X 1.340 X .050 PN

20 023317 2 NT .50-13 UNT LK G5 ZN

21 705178 1 CS .375-16 X 1.750 HX G5 ZN

22 767954 7 FW .406 X .812 X .060 SAE HRD ZN

23 022772 2 FLAT IDLER PULLEY

24 036384 2 SPRING 1/4 COIL PL 1.23

25 259812 2 DECK LIFT SPRING CHAIN

26 520627 1 SPINDLE HOUSING ASSEMBLY

27 016527 4 CS .50-13 X 1.00 HX G5 ZN

28 301317 1 PULLEY

29 324293 1 LOWER IDLER ARM

30 705731 1 CS .375-16 X 2.750 G5 ZN

31 324350 1 IDLER SPACER

32 054502 1 NT .375-16 HX G5 ZN

33 079194 6 MS .25-20 X .750 TH CR ZN

34 324335 1 BLOWER INLET

35 768515 6 FW .281 X .625 X .051/.080 HD ZN

36 024927 6 NT .25-20 HX G5 ZN

NOTES:

1. Assemble bearings in spindle housing with extended race to the inside.

_0910 7-9

Page 35

Transition Chute Assembly (544510)

BLOWER

ASSEMBLY

1

2

3

4

5

6

2

7

9

8

10

11

7-10 _0910

Page 36

Transition Chute Assembly (544510)

INDEX

NO.

10 727453 1 BELT & PULLEY DECAL

11 727438 1 WHIRLING BLADES DECAL

PART NO. QTY. DESCRIPTION

1 064329 4 CS .25-20 X .625 HX G5 ZN

2 768515 10 FW .281 X .627 X .051/.080 HD ZN

3 770180 1 PULLEY COVER

4 770404 1 UPPER BLOWER BELT

5 024927 6 NT .25-20 HX G5 ZN

6 017038 6 LW .25 MEDIUM SPRING ZN

7 757245 1 TRANSITION CHUTE

8 079194 6 MS .25-20 X .750 TH CR ZN

9 767012 1 DANGER BLOWER DECAL

NOTES:

_0910 7-11

Page 37

Spindle Housing Assembly (520627)

1

1

1

2

1

3

4

7-12 _0910

Page 38

Spindle Housing Assembly (520627)

INDEX

NO.

PART NO. QTY DESCRIPTION

1 077123 2 BEARING W/O COLLAR

2 034843 1 CAST SPINDLE HOUSING

3 008805 1 SPINDLE SHAFT

4 012005 1 GREASE FITTING

NOTES:

1. Install upper bearing with extended inner race up and lower bearing with

extended inner race down.

_0910 7-13

Page 39

7-14 _0910

Page 40

Index

Page

No.

Page

No.

Page

No.

Numeric

019471 3-1

022608 3-1, 3-2

023036 3-1

024927 3-1

025395 3-1

036236 3-1

056077 3-1, 3-2

058766 3-1

058776 3-1, 3-2

064006 3-1, 3-2

064014 3-1, 3-2

068551 3-1, 3-2

078949 3-1

086660 3-1

102913 3-1

103036 3-1

107045 3-1

109716 3-1

111445 3-1

111448 3-1

111449 3-1

111452 3-1

111638 3-1

111639 3-1

111849 3-1

111852 3-1

111901 3-1

111902 3-1

111903 3-1

111904 3-1

111915 3-1

111920 3-1

524785 3-1

544501 3-1, 3-2

601229 3-1

601640 3-1

602210 7-3

602244 3-1

704916 3-1

710194 3-1

752386 3-1

760306 3-1, 3-2

767954 3-1

768515 3-1

768523 3-1, 3-2

787986 3-1

Alphabetical

Accessing the engine compartment 4-2

Assembly Instruction 3-1

Blower drive belt 5-1

Blower housing and transfer tube 5-1

Blower spindle jack shaft 5-1

Catcher Box Preparation 3-3

Final Connection 3-3

General Information 1-1

Maintenance 5-1

Mower deck preparation 3-2

Operation 4-1

Packing list - 929430 60” Blower 3-1

Packing list - 929448 72” Blower 3-1

Packing list - 929455 Catcher 3-1

Parts and service 1-1

peca0329 7-5

peca0330 7-3

peca0331 7-3

peca0578 3-1, 7-7

peca0579 7-7

peca1001 3-1, 7-7

peca1089 3-1

pecb0006 7-5

pecb0007 7-5

pecb0212 3-1, 7-7

pecb1596 7-3

pecb1804 7-5

pecb1805 7-5

pecb1832 7-5

pecb1833 7-5

pecb1834 7-3

pecb1835 7-5

pecb1840 7-5

pecb8001 7-3

pecc0039 7-3

pecc0041 7-3

pecc0042 7-3

pecc0043 7-3

pecc0044 7-3

pecc0045 7-3

pecc1184 7-3

pecj0234 7-5

pecj0255 7-5

pecj0552 7-5

peck0055 3-1, 7-7

peck0058 7-7

peck0088 7-7

peck0172 7-7

peck0331 3-1

peck0364 3-1, 7-7

peck1215 7-7

peck1231 3-1, 7-7

peck1247 3-1, 7-7

peck1410 7-5

peck1418 7-3

peck1422 7-3

peck1432 3-1, 7-7

peck1433 3-1, 7-7

peck1435 7-3

peck1437 7-3, 7-7

pecs0155 7-5

pecv1154 7-3

Safety Precautions 2-1

Storage 6-1

To the new owner 1-1

Tractor Preparation 3-2

Unloading 4-1

Using this manual 1-1

Vacuum pickup and collection 4-1

Warranty registration 1-1

111782_0910 i-1

Loading...

Loading...