Page 1

Manual

Installation

& Operation

REV. 0608

/CHINO

RHR-HEX, RHR-HEX2, RHR 1/2, RHR-SQ

ISLAND HOT FOOD CASE

RHR-HEX, RHR2-HEX, RHR 1/2 HEX

ISLAND HOT FOOD CASE

P/N IGHT-RHR-HEX, RHR2HEX2, RHR 1/2 HEX, RHR SQUARE-0608

INSTALLATION & OPERATION GUIDE

Page 2

General Instructions

This equipment is to be installed

to comply with the applicable

NEC, Federal, State , and Local

Plumbing and Construction

Code h a ving j u risdict i o n .

IGHT-RHR, RHR2-HEX-0608

Table of Contents

General Instructions.....................................................2

Cut and Plan Views ......................................................3

Installation .....................................................................3

Leveling .....................................................................................3

Bumper Installation Instructions................................................. 4

Electrical........................................................................8

Wiring Color Code ..................................................................... 8

Electrical Circuit Identication ....................................................8

Field Wiring and Serial Plate Amperage ....................................8

Ballast Location .........................................................................8

User Information ........................................................... 9

Food Handling ...........................................................................9

Important Operation Tips: .......................................................... 9

Controls .....................................................................................9

Overhead Heating System......................................................... 9

Care and Cleaning .....................................................................9

General Cleaning Rules............................................................. 9

Cleaning Instructions ............................................................... 10

Plexiglass and Acrylic Care ..................................................... 10

Antistatic Coatings ................................................................... 10

Cleaning Precautions............................................................... 10

Maintenance ................................................................ 11

Replacing Overhead Heat Lamps............................................ 11

Electrical Wiring Diagrams ........................................12

Wiring Diagrams .........................................................13

Appendices .................................................................21

Appendix A. - Temperature Guidelines .................................... 21

Appendix B. - Application Recommendations .......................... 21

Appendix C. - Field Recommendations ................................... 21

Appendix D. - Recommendations to User ............................... 21

This Booklet Contains Information on:

The RHR-HEX is a self-service Hot Food Hexagon-shaped

Island Stand, available in 4 and 6 foot sizes.

The RHR2-HEX is a similar unit, with the addition of a

second shelf: Both feature surface and overhead food

warmers, but both are also available with an overhead

Radiant Heat option.

Shipping Damage

All equipment should be thoroughly examined for shipping

damage before and during unloading.

This equipment has been carefully inspected at our factory

and the carrier has assumed responsibility for safe arrival.

If damaged, either apparent or concealed, claim must be

made to the carrier.

Apparent Loss or Damage

If there is an obvious loss or damage, it must be noted on

the freight bill or express receipt and signed by the carrier’s

agent; otherwise, carrier may refuse claim. The carrier will

supply necessary claim forms.

Concealed Loss or Damage

When loss or damage is not apparent until after all

equipment is uncrated, a claim for concealed damage

is made. Make request in writing to carrier for inspection

within 15 days, and retain all packaging. The carrier will

supply inspection report and required claim forms.

Shortages

Check your shipment for any possible shortages of

material. If a shortage should exist and is found to be the

responsibility of Hussmann Chino, notify Hussmann Chino.

If such a shortage involves the carrier, notify the carrier

immediately, and request an inspection. Hussmann Chino

will acknowledge shortages within ten days from receipt

of equipment.

Hussmann Chino Product Control

The serial number and shipping date of all equipment

has been recorded in Hussmann’s les for warranty and

replacement part purposes. All correspondence pertaining

to warranty or parts ordering must include the serial number

of each piece of equipment involved, in order to provide

the customer with the correct parts.

Keep this booklet with the case at all times for future reference.

/CHINO

A publication of HUSSMANN® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

2

Page 3

Rev. 0608

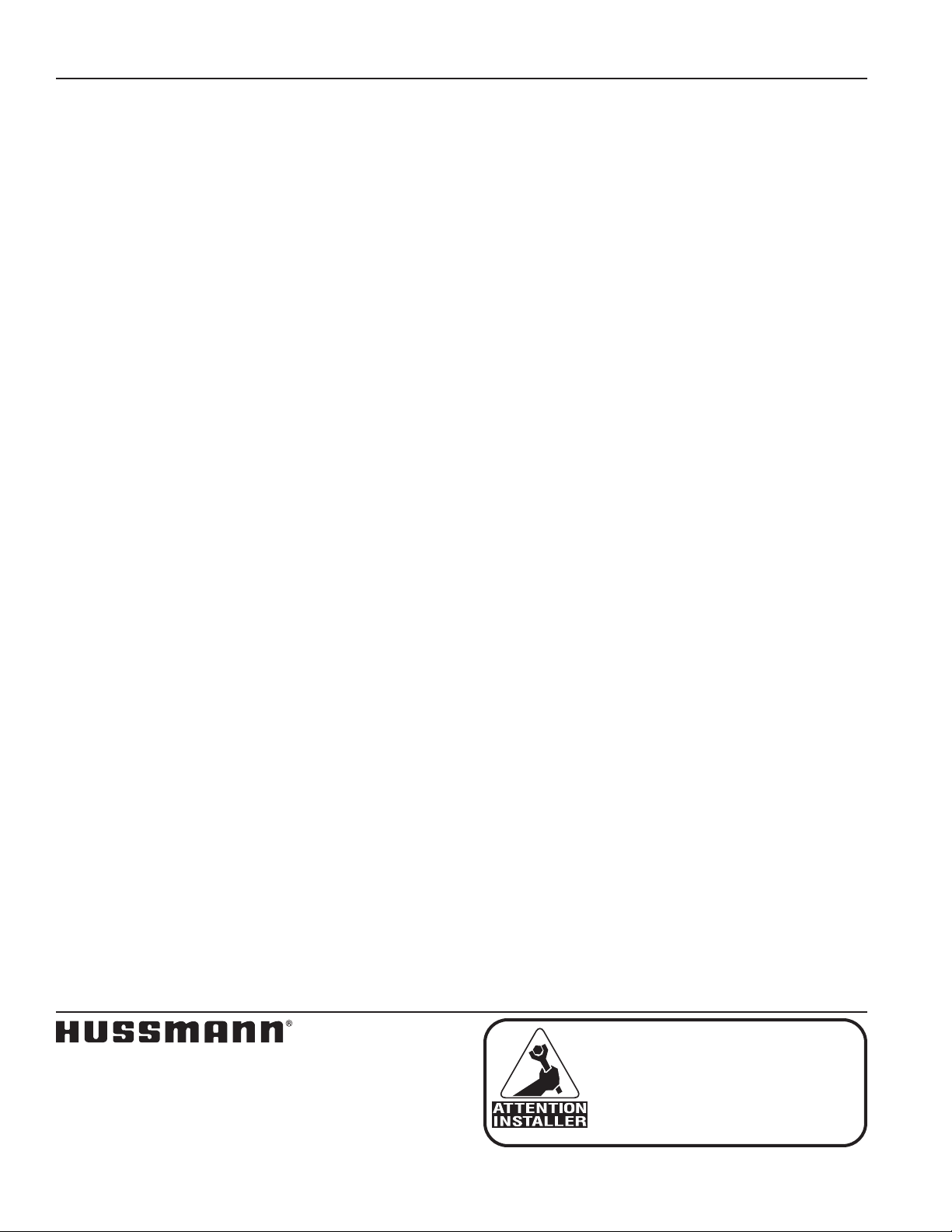

RHR2-HEX 6' & (4')

Self-Service Hot

Scale = 1/2"

431/4" (251/8")

Control

Panel

541/4" (473/8")

W

ar

m

in

g

G

ri

d

d

le

58"

21

1

/

16

"

32

9

/

16

"

101/2"

10

1

/2"

28

1

/2" (191/2")

Food

Warmer

12"

183/4"

13"

12

1

/4"

RHR SQUARE

Self Service Hot Food

20

11

/

16

"

47

3

/

8

"

27"

ELEC.

MECHANICAL

STUB UP AREA

4" X 6"

23

11

/

16

" (33

3

/

8

")

4'-67/16" (6'-53/

8

"

)

RHR-HALF-HEX-4' (6')

Self-Service Hot

14

1

/

8

" (24

5

/

8

")

2'-21/2" (3'-11/

2

"

)

RHR-HEX 6' & (4')

Self-Service Hot

431/4" (251/8")

Control Panel

641/4" (471/8")

Wa

rm

in

g

Gr

iddle

50

1

/

4

"

21

1

/

16

"

32

9

/

16

"

101/2"

Light

Food

Warmer

10

1

/2"

18"

281/2" (191/2")

Light

Food

Warmer

773/8"

371/2"

65

3

/

8

"

(47

3

/

8

")

48

3

/

4

"

(27

5

/

8

")

(261/2")

(547/16")

RHR-HEX 6' & (4')

PLAN VIEW

IMPORTANT: It is imperative that cases

be leveled front to back and side to

side prior to joining.A level case is

necessary to ensure proper operation.

Cut and Plan Views

Installation

Leveling

1. Check oor where cases are to be set to see if it’s

3

level. Determine where the highest part of the oor

Cases will be shimmed off this point Using case

blueprints, measure off and mark on oor the exact

dimensions of the case footprint Snap chalk line for

front and back position of base rail. Mark location

of each joint front and back. Use a transit to nd the

highest point along both lines. Mark the difference,

and place the appropriate number of shims required

to maintain high-point level.

Page 4

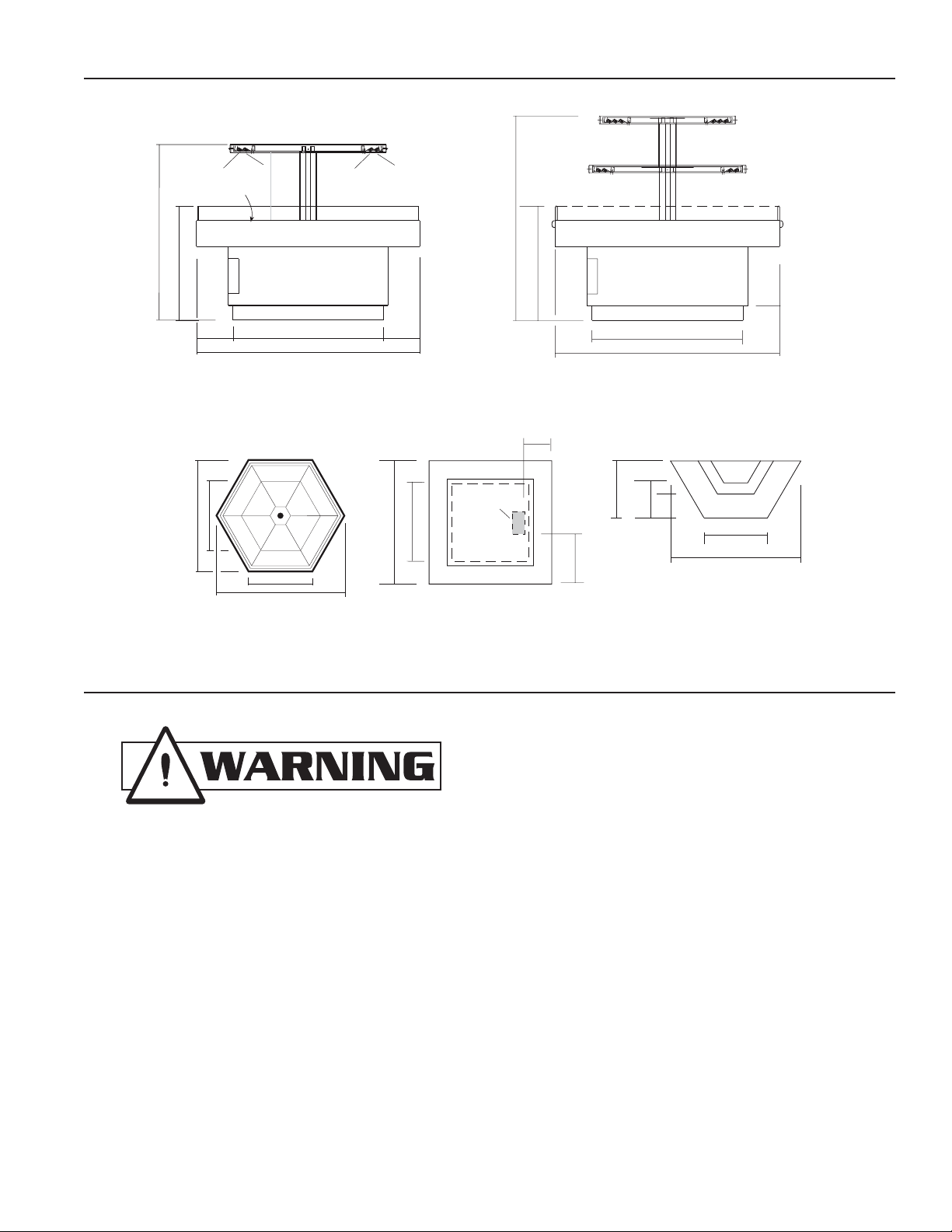

Bumper Installation Instructions

IGHT-RHR, RHR2-HEX-0608

Installation (Cont'd)

Step 1: Make sure the aluminum channel and end caps

are installed.

Step 3: Starting on one end: while inserting the bumper,

push it up against the end cap to prevent

the bumper from shrinking after installation

(when it gets cold).

Step 2: Use silicone lubricant to help the

bumper slide into the channel.

Step 4: As you insert the bumper into the channel with

one hand, pull the bumper toward you with

the other to open the inside lips. Slowly

apply pressure by rolling the bumper into

the track.

4

Page 5

Rev. 0608

Installation (Cont'd)

Boston Series 2000

NOTE: Flexible top: Over cut vinyl 1/8" for every 4' section for the exible top to ensure a proper t.

NOTE: Rigid Top: Do not over cut.

1. Attach the base and end/corner cap to the desired surface by inserting #8 pan head screws through the pre-slotted

holes in both the end cap and the base. Insert screws through the two holes of end cap and tighten.

2a. Flexible Top: Butt end of the vinyl top against end/corner cap. While applying pressure, bend back vinyl top so that

vinyl legs are positioned within the base grooves. Roll vinyl top over full length of base, then tap with rubber mallet

to ensure vinyl is securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature 24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or silicone before installing.

● Over cut the flexible vinyl and compression fit. Adding the additional materials will compensate for stretching which

occurs during installation.

5

Page 6

IGHT-RHR, RHR2-HEX-0608

Installation (Cont'd)

Boston 2000 Eco Series

1. Attach the base and end/corner cap to the desired surface by inserting #8 pan head screws through the pre-slotted

holes in both the end cap and the base. Insert screws through the two holes of end cap and tighten.

2a. Flexible Top: Butt end of the vinyl top against end/corner cap. While applying pressure, bend back vinyl top so that

vinyl legs are positioned within the base grooves. Roll vinyl top over full length of base, then tap with rubber mallet

to ensure vinyl is securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature 24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or silicone before installing.

● Over cut the flexible vinyl and compression fit. Adding the additional materials will compensate for stretching which

occurs during installation.

6

Page 7

Rev. 0608

Installation (Cont'd)

Boston 1000 Series

NOTE: Flexible top: Over cut vinyl 1/8" for every 4' section for the exible top to ensure a proper t.

NOTE: Rigid Top: Do not over cut.

Installation

1. Attach the base and end/corner cap to the desired surface by inserting #8 pan head screws through the pre-slotted

holes in both the end cap and the base. Insert screws through the two holes of end cap and tighten.

2a. Flexible Top: Butt end of the vinyl top against end/corner cap. While applying pressure, bend back vinyl top so that

vinyl legs are positioned within the base grooves. Roll vinyl top over full length of base, then tap with rubber mallet

to ensure vinyl is securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature 24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or silicone before installing.

● Over cut the flexible vinyl and compression fit. Adding the additional materials will compensate for stretching which

occurs during installation.

7

Page 8

Electrical

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters

Thermostats, and Lights.

RHR-HEX 6' & (4')

Self-Service Hot

Control Panel

Ballast

Ballast

(one for each light)

RHR2-HEX 6' & (4')

Self-Service Hot

Scale = 1/2"

Control

Panel

Ballast

Ballast

(one for each light)

Ballast for shelves

IGHT-RHR, RHR2-HEX-0608

Wiring Color Code

Electrical Circuit Identication

Standard lighting for all models will be uorescent lamps

located within the case at the top.

The switch controlling the lights and heaters are located

within an access panel on the side of the case.

Field Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate.Actual ampere draw may be less than

specied. Case amperes are listed on the wiring diagram,

but due to parts availability they may vary slightly. Always

check the serial plate for the actual loads.

Ballast Location

8

Page 9

Rev. 0608

User Information

Food Handling

These hot tables are for short-term holding and display of

precooked hot foods. They are not intended to cool or reheat

food. The temperature of the food should be approximately

160°F when rst put into the hot table. Any attempt to use

the hot table to display large amounts of food for long

periods of time will result in dehydrated, overcooked and

unsafe food. The quality of food will progressively worsen

as the length of time increases. The deterioration of product

quality is a function of time and temperature. All products

are affected even though in a gravy or other liquid. They

may appear to withstand the temperature better than “dry”

foods such as fried chicken but this is not necessarily

true. ALL foods will continue to be affected by prolonged

exposure to elevated temperatures.

The following guidelines are provided only as a general

guide for the use of this equipment. The local health

agency for your area can provide specic temperature

requirements.

Critical attention must be given to the heat controls for

these hot tables. Both the upper and lower heat controls

must be adjusted to maintain proper food temperatures. Hot

foods should be held at a minimum temperature of at least

140°F (60°C) according to 1993 FDA Food Code. However,

increasing the temperature too high will also cause the

food to overcook, dry out, lose its avor, texture and color.

Food held for prolonged periods at high temperatures will

also lose some of their nutritional value.

All griddle type units are designed to maintain temperatures

above the FDA guideline of 140°F. This is product

temperature, not air or griddle temperature. Due to the open

design of these units, they must be loaded with product for

proper operation. When units are empty, they experience

rapid rise of heated air from air outside the case. This action

gives empty units a false, lower than desired, temperature

reading. Loading the case traps the air at the griddle,

raising temperatures to the 165°F to 185°F range, keeping

product well above the FDA guidelines. Remember, these

units must be loaded with product to maintain safe product

temperature.

Different foods will require different control settings. The

type of food, the quantities of food and length of time that

it is to remain in the hot table must be considered when

establishing control settings. Therefore, it must be the

user’s responsibility to establish the correct control settings

to maintain the food at the safest, tastiest and most saleable

condition.

FOOD TEMPERATURES CAN BE

ACCURATELY DETERMINED ONLY

THROUGH THE USE OF FOOD

THERMOMETERS!

Important Operation Tips:

• Preheat case 30 minutes before loading product

using higher settings.

• Using thermometer, check product before loading

in case (150°F-160°F).

• At start, set lamps to “3”.After loading, recheck

temperature every 1/2 hour to see that unit is

operating properly.Adjust the thermostat (a higher

number for hotter and a lower number for cooler)

to maintain product temperature of 140°F (60°C)

minimum. The setting will depend on the type of

product being displayed Be sure to test product

temperature with a thermometer frequently for good

product maintenance.

• Food should maintain contact directly with the

“griddle” at all times.

Controls

There are three sets of controls for the hex case, each

behind its own access panel located on the side of the

case. The dial with the numbered settings is for the griddle.

The other dials/switches are for the overhead lights and

heating components.

Overhead Heating System

Cal rod units are located above the griddles to provide

top heat. To obtain the proper food temperatures, they

must be adjusted. Settings may vary depending on

food composition. Maximum limits should be avoided

to prevent overcooking or drying out food.

Care and Cleaning

Long life and satisfactory performance of any equipment

is dependent upon the care it receives. With this in mind,

all of the exposed work surfaces of these hot tables have

been made entirely of easy to clean stainless steel.

Stainless steel is one of the easiest materials to clean and

keep clean. Normally it is just a matter of wiping spills off the

surface when they happen followed by a thorough cleaning

with soap and water at the end of the day. Frequent and

regular cleaning will prevent the buildup of baked on difcult

to remove spills. Many types of cleansers are available and

safe to use on stainless steel. However, ordinary steel wool

and steel brushes should not be used. Small particles of

the steel may become imbedded into the stainless steel

surfaces that will eventually rust and stain.

General Cleaning Rules

1. ALLOW SURFACES TO COOL BEFORE

HANDLING.

2. Clean frequently and regularly.

3. Rinse thoroughly after cleaning.

4. Remove surface spills immediately with a damp

cloth.

9

Page 10

User Information (Cont'd)

IGHT-RHR, RHR2-HEX-0608

Cleaning Instructions

1 . Turn temperature control knobs to OFF position.

2. Allow unit to cool completely.

3. Wipe entire unit with clean cloth and mild detergent.

The EXTERIOR surfaces of these hot tables must be

cleaned with a mild detergent and warm water to protect

and maintain their attractive nish. Never use abrasive

cleaners or scouring pads.

TO REMOVE “BAKED-ON” SPLATTER, GREASE OR

LIGHT DISCOLORATION TO STAINLESS STEEL.

CLEANSING AGENT APPLICATION

Grade F Italian Pumice........Scour or rub with damp cloth

Liquid NuSteel.....................Scour with small amount on

dry cloth

Paste NuSteel

Household Cleansers...........Rub with damp cloth

TO REMOVE HEAT TINT OR HEAVY

DISCOLORATION

CLEANSING AGENT APPLICATION

Allen Stainless Steel Polish........Small amount on damp

cloth

Birdsall “Staybright” ...................Rub with damp cloth

Wyandotte

Bab-O

Nusteel.......................................Rub with stainless steel

wool

Plexiglass and Acrylic Care

Cleaning

Clean with plenty of nonabrasive soap (or detergent) and

lukewarm water, using the bare hand to feel and dislodge

any caked-on dirt. A soft, grit-free cloth, sponge, or chamois

may be used, but only as a means of carrying the water to

the plastic. Dry with a clean damp chamois or clean soft

cloth such as cotton annel. Hard, rough cloths or paper

towels will scratch the acrylic and should not be used.

Waxing

If after removing dirt and grease, the acrylic can be waxed

with a good grade commercial wax. This will improve

the appearance of the surface by lling in most minor

scratches. Wax should be applied in a thin even coat, and

brought to a high polish by rubbing lightly with a dry clean

soft cloth, such as a cotton annel. Excessive rubbing may

cause scratching and/or buildup an electrostatic charge,

which attracts dust and dirt to the surface. Blotting with a

clean damp cloth is recommended to remove charge.

Antistatic Coatings

For acrylic used indoors, antistatic coatings successfully

prevent the accumulation of electrostatic charge for periods

of several months, if the surface is not washed or wiped

down with a wet cloth. Between applications of the antistatic

coatings, the parts need only be dusted with a soft clean

cloth to maintain a good appearance. In use, liquid antistatic

coatings should be applied in a very thin even coat. If beads

appear as it is applied, the coat is too thick and the excess

should be removed with another cloth. Allow the coating to

dry, then bring to a high gloss with a soft cloth.

Cleaning Precautions

To preserve the attractive nish, use warm water and a mild

detergent to wash the exterior of the cases. DO NOT USE

ABRASIVE CLEANERS OR STEEL WOOL SCOURING

PADS as these will mar the surface.

10

Page 11

Rev. 0608

ALWAYS DISCONNECT ELECTRICAL POWER

AT THE MAIN DISCONNECT WHEN SERVICING

OR REPLACING ANY ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters,

Thermostats, and Lights.

The Heat lamps used in these cases get

EXTREMELY HOT! NEVER touch a lamp

until the case has had ample time to cool

down! It is also highly recommended to handle

lamps with gloves or use a cloth rag - not just

for the heat factor, but also the oils in your

fingers will drastically shorten the life of the lamp.

Maintenance

Replacing Overhead Heat Lamps

Overhead Halogen and Merco lamps are designed to

last through many hours of use. Should there be a need

to replace one, it is as simple as replacing a standard

uorescent light bulb.

1. Turn light switch to OFF before replacing any

lighting components.

2. Disconnect light xture by removing power cord

from socket in the right rear interior corner of the

merchandiser.

3. Place the shelf on a at surface to remove the clear

plastic protective shield from the xture. Carefully

insert one nger between the xture socket and

the protective shield. Use other hand to “pinch”

lens cover (and simultaneously hold the xture in

place) while lifting with inserted nger.When shield

separates from xture at one end, remove it by

SLOWLY pulling remainder of shield away from

xture.

4. Remove lamp by depressing spring loaded socket

at end of xture, and swinging opposite end of lamp

from it’s former position.

5. Using gloves or covering for lamp, insert new lamp

into spring loaded socket, depressing socket until

opposite end of lamp properly enters stationary light

socket.

6. Return lamp to original position by lightly pinching it

in from each side, and inserting shield anges into

xture channel. Continue process along length of

lamp shield until it is in it’s nal proper position.

7. Return lamp to original position by lightly pinching it

in from each side, and inserting shield anges into

xture channel. Continue process along length of

lamp shield until it is in it’s nal proper position.

11

Page 12

IGHT-RHR, RHR2-HEX-0608

Electrical Wiring Diagrams

RHR-HEX RHR-HEX 4’ W6100012

5’ 6” W6100002

RHR-HEX-2 (w/shelf) OLD► 4’ W6100003

NEW ► 4’ W6100020

6’ W6100015

RHR-Square 4’ W6100005

RHR-1/2-HEX 4’ W6100007

6’ W6100008

12

Page 13

Rev. 0608

Sheet 1 of 1

final

D.QUAN

Date:

Project Title:

Drawing No.:

Drawn By:

Next Assembly:

Drawing Title:

Date:

Hussmann Corporation

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910

Lic.#: 644406

Revisions:

No. Description:

Checked By:

By:

7

3

P1

5

1 2 4

6

P

H2

L2

L1

H1

L

White

White

Red

White

White

Red

White

White

Red

White

White

Red

White

White

Red

White

White

Red

L

Griddle

(6) 206W/220VAC Flexible Heater Pad #225-01-6770/-6770T

Overhead Heating Element

HE-04-68" #125-01-3235

2700 W / 240 VAC

Bulb Sensor

Pilot Light

Pilot Light

Electronic

T-Stat

s

L1

L2

N

G

POWER

#125-01-0311

L3

Contactor

#125-001-1001

(2) F14T5/TL830

WH2-120-135

(2) F14T5/TL830

WH2-120-135

(2) F14T5/TL830

WH2-120-135

Ledge Lights-optional

Overhead Lighting

INCANDESCENT LAMPS

GE APPLIANCE BULB PC15206-100A15-CD1-100 WATT - 115V

(6) 125-03-1206 100WATT INCANDESCENT LAMP

(6) 125-01-0287 LIGHT SOCKET

L

SWITCH

125-01-0311

15 AMP

FUSE 125-01-3282

FUSE HOLDER

125-01-3283

L

L

SWITCH

125-01-0311

~208 / 240V - 1 Ø - 60Hz

M

COOLING

FAN

MOTOR

SAFETY T-STAT

CLOSE ON RISE

NGT # 11S31T4444

225-01-0076

ON: 98.6°F

OFF: 80.6°F

(LOCATED IN COLUMN)

Note: Case MUST be grounded

RHR-Hex-4' basic

RHR Hex 4' Case Wiring

W6100012

06.12.2000

Loads, amp

208 V 240 V

L1

L2

L3

19.7

14.2

0.0

22.8

16.4

0.0

1 DELETED (1) 225-01-3301 08/05/05 D.Q.

®

Wiring Diagrams

13

Page 14

IGHT-RHR, RHR2-HEX-0608

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

Boris Kasrel

PAGE OF

®

1

1

2/1/00

B Updated dwg; added 2 limiters and 1 t-stat 2/15/08 JR

RHR-Hex-5'6"

W6100002

RHR Hex 5'6"

GRIDDLE

HEATING PADS - 451W 1.88A @ 240 VAC - EA.

(6) 225-01-6771

OVERHEAD CANOPY INSTALLATION

TUBULAR HEATER

125-01-3247A

2250W 9.4A @ 240 VAC

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

6

421 5

P1

3 7

L

P

H2

L2

L1

H1

L

L1

L2L3N

G

L

MAIN POWER

~208 / ~240 VAC 50/60 HZ

125-01-0002

SQUARE -D

CONTACTOR

8910DPA43V02

INFINITE

CONTROL

125-01-1663

LIGHT SWITCH

125-01-0311

COOLING

FAN MOTOR

.18A @ 120VAC

125-01-2012-A

SAFETY T-STAT

CLOSE ON RISE

NGT # 11S31T4444

225-01-0076

ON: 98.6°F

OFF: 80.6°F

(LOCATED IN COLUMN)

INCANDESCENT LAMP

BULB 60W 115V

(6) 125-03-1206

RED # 12

GREEN # 12

BLACK # 12

BLUE # 12

WHITE # 14

M

SWITCH

125-01-0311

PILOT LIGHT

175-01-1102C

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

15A

20A

15A

15A

(2) 15 AMP FUSE

125-01-8604

FUSE HOLDER

125-01-8610

15 AMP FUSE

125-01-8604

FUSE HOLDER

125-01-8605

20 AMP FUSE

125-01-8537

FUSE HOLDER

125-01-8612

LOADING

208 V 240 V

L1

L2

L3

21.1

9.8

8.2

23.9

11.3

9.4

6180W @ 240VAC

4695W @ 208VAC

Wiring Diagrams (Cont'd)

14

Page 15

Rev. 0608

Sheet 1 of 1

final

BK

Boris Kasrel

Date:

Project Title:

Drawing No.:

Drawn By:

Next Assembly:

Drawing Title:

Date:

Hussmann Corporation

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910

Lic.#: 644406

Revisions:

No. Description:

Checked By:

By:

73

P1

51 2 4 6

P

H2

L2

L1

H1

L L

Griddle

(2) sets of 3 pads - 206 W / 220 VAC

Bulb

Sensor

Temp. Control

Pilot Light

Pilot Light

Electronic T-Stat

Shelf Installation

(6) F13DBX23T4/SPX35

Fluorescent Double Biax Lamps

(6) Ballast 4111F2RP

Control Box Installation

W

hite

W

hite

Red

White

White

Red

W

hite

White

Red

White

W

hite

Red

White

W

hite

Red

W

hite

White

Red

Cal-Rod 980W /~240V

Cal-Rod 1200W / ~240V

Infinite

Control

P

H2

L2

L1

H1

L

Pilot Light

Overhead (crown) Installation

(3) F13DBX23T4/SPX35

Fluorescent Double Biax Lamps

Ballast 4111F2RP

Infinite

Control

M

Overhead

Ballast Cooling

POW

ER

#12

5-0

1-031

1

s

L1L2L3

N

G

LIGH

TS

#12

5-0

1-031

1

#225-01-3301A

NGT 11S11T444

Safety T-Stat

ON: 183°F

OFF:210°F

#225-01-0076

NGT 11S31T444

Column Heat Limit

ON: 98.6°F

OFF: 80.6°F

Note: Case MUST be grounded

RHR - Hex 4' w/shelf Case Wiring

RHR - Hex 4' Shelf Unit

LOADING

208 V 240 V

L1L2L3

16.0

13.1

18.1

14.6

10/22/99

W6100003

®

Wiring Diagrams (Cont'd)

15

Page 16

IGHT-RHR, RHR2-HEX-0608

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

D.QUAN

PAGE OF

®

1

1

B Updated dwg; add limit switches and t-stats 2/15/08 JR

C Remove inf switch ctrls;add packtronics ctrls 2/21/08 JR

08/05/05

RHR-HEX-2 HEX CASES

W6100020

RHR-HEX-2-4' CASE W/ SHELF UNIT

GRIDDLE

HEATING PADS - 206W .86A @ 240 VAC - EA.

(6) 225-01-6770

SHELF INSTALLATION

TUBULAR HEATER

125-01-0478A

1200W 5A @ 240VAC

OVERHEAD CANOPY INSTALLATION

TUBULAR HEATER

125-01-1006A

1800W 7.5A 240 VAC

L

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

64

2

1 5

P1

3 7

L

L1

L2L3N

G

L

MAIN POWER

~208 / ~240 VAC 50/60 HZ

125-01-0002

SQUARE -D

CONTACTOR

8910DPA43V02

LIGHT SWITCH

125-01-0311

LIGHT SWITCH

125-01-0311

COOLING

FAN MOTOR

.18A @ 120VAC

125-01-2012-A

SAFETY T-STAT

CLOSE ON RISE

NGT # 11S31T4444

225-01-0076

ON: 98.6°F

OFF: 80.6°F

(LOCATED IN COLUMN)

RED # 12

GREEN # 12

BLACK # 12

WHITE # 14

M

INCANDESCENT LAMP

BULB 60W 115V

(3) 125-03-1206

PILOT LIGHT

175-01-1102C

INCANDESCENT LAMP

BULB 60W 115V

(6) 125-03-1206

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

15A

(2) 15 AMP FUSE

125-01-8604

FUSE HOLDER

125-01-8610

15A

15A

(2) 15 AMP FUSE

125-01-8604

FUSE HOLDER

125-01-8610

15A

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

6

4

21 5

P1

3 7

SENSOR

225-01-3228

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

6

4

2

1 5

P1

3 7

SENSOR

225-01-3228

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

NOTE: CASE MUST

BE GROUNDED

LOADING

208 V 240 V

L1

L2

19.8

15.3

22.2

17.7

5328W @ 240VAC

4118W @ 208VAC

Wiring Diagrams (Cont'd)

16

Page 17

Rev. 0608

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

D.QUAN

---

PAGE OF1 1

06/08/01

1 UPDATED CASE TOTAL LOADING 06/27/01 AEC

2 DELETED (1) 225-01-3301 08/05/05 D.Q.

GRIDDLE

(2) SETS OF 3 FLEXIBLE HEATING PA DS - 451W / ~240 VAC - EA.

SHELF INSTALLATION

TUBULAR HEATER

125-01-3247A

2250W / ~240VAC

(OUTER UNIT)

TUBULAR HEATER

125-01-1006A

980W / ~240 VAC

(INNER UNIT)

OVERHEAD CANOPY INSTALLATION

TUBULAR HEATER

125-01-3246A

1850W / ~240 VAC

L

P

H2

L2

L1

H1

L

M

PACKTRONICS

CONTROLLER

225-01-3229

PILOT

LIGHT

L

TEMP. CONTROL

SENSOR

225-01-3228

6

42

1 5

P1

3 7

CAP EACH RED LEAD

ON EACH HEATER

L

P

H2

L2

L1

H1

L

L1

L2

L3

N

G

L

MAIN POWER

~208 / ~240 VAC - 3Ø - 50/60 HZ - 5W

125-01-0002

SQUARE -D

CONTACTOR

8910DPA43V02

INFINITE CONTROL

125-01-1663

INFINITE CONTROL

125-01-1663

PILOT

LIGHT

PILOT

LIGHT

LIGHT SWITCH

125-01-0311

LIGHT SWITCH

125-01-0311

COOLING

FAN MOTOR

SAFETY T-STAT

CLOSE ON RISE

NGT # 11S31T4444

225-01-0076

ON: 98.6°F

OFF: 80.6°F

(LOCATED IN COLUMN)

INCANDESCENT LAMPS

GE APPLIANCE BULB PC15206-100A15-CD1-100 WATT- 115V

(6) 125-03-1206 100WATT INCANDESCENT LAMP

(6) 125-01-0287 LIGHT SOCKET

INCANDESCENT LAMPS

GE APPLIANCE BULB PC15206-100A15-CD1-100 W

TT- 1

(6) 125-03-1206 100WATT INCANDESCENT LAMP

(6) 125-01-0287 LIGHT SOCKET

RHR HEX CASES

W6100015

RHR HEX 5'-6" - (1) SHELF UNIT

H:\WIRESCHEMATICS\NEWWIRING

NOTE:

CASE MUST BE

GROUNDED

28.3

21.4

18.6

24.5

18.6

16.1

L1

L2

L3

208 V 240 V

LOADING

®

Wiring Diagrams (Cont'd)

17

Page 18

IGHT-RHR, RHR2-HEX-0608

DATE:

:# GWD:ELTIT TCEJORPDRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

REVISIONS:

:YB

DEKCE

HC:

N

OI

TPI

RCSED :#

BY:

FILE LOCATION:

ADRIAN E. CRISCI

AEC

PAGE OF

HUSSMANN CORPORATION

13770 RAMONA AVENUE

CHINO, CA.91710

(909) 590-4910 LIC.#: 644406

1

2

3

1 1

10/22/99

H:\WIRESCHEMATICS\NEW-WIRING

RHR CASES

W6100005

4' x 4' SQUARE CASE MODEL

REPLACE CONTACTOR FOR RELAY 02/22/02 AEC

BROUGHT TO SPEC FROM ORIGINAL BY AEC 10/22/99 02/22/02 AEC

RELAY OMRON

G7L-2A-TUBJ-CB

125-01-3182

LIGHT SWITCH

TIPPETTE

125-01-0311

L

SWITCH

125-01-0311

MAIN

POWER

L

L1

L2L3N

G

~208 / 240 VAC - 1Ø - 50/60 Hz. - 4W

BALLAST MAGNETEK

4111F2RP

(8) 125-01-3240

INFINITE

CONTROL

125-01-1663

PILOT

LIGHT

BALLAST

SAFETY T-STAT

NGT CONTROLS™

11S11T444

ON: 183°F / OFF: 210°F

225-01-3301A

OVERHEAD LIGHTS

FLUORESCENT DOUBLE

BIAX LAMPS

(8) F13DBX23T4/SPX35

OVERHEAD HEATER

WATLOW™ HE-08

(1) 3550W @ ~ 240 VAC

125-01-3243

GRIDDLE HEATERS - THERMOFLEX™

(4) 364W @ ~240 VAC

225-01-6790T

PACKTRONICS

CONTROLLER

225-01-3229

PILOT

LIGHT

L

TEMP. CONTROL

SENSOR

225-01-3228

6421 5

P1

3 7

L

P

H2

L2

L1

H1

M

OVERHEAD COOLING

AXIAL FAN -

COMAIR™

MX2B1-E1

125-01-2012

NOTE: CASE MUST

BE GROUNDED

26.5

23.9

~

20.6

18.1

~

L1L2L3

208 V 240 V

LOADING

Wiring Diagrams (Cont'd)

18

Page 19

Rev. 0608

Sheet 1 of 1

X

Boris Kasrel

Date:

Project Title:

Drawing No.:

Drawn By:

Next Assembly:

Drawing Title:

Date:

Hussmann Corporation

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910

Lic.#: 644406

Revisions:

No. Description:

Checked By:

By:

BK

73

P1

51 2 4 6

P

H2

L2

L1

H1

L

W

hite

W

hite

Red

W

hite

White

Red

White

W

hite

Red

BBB

Pilot

Light

Temp Control

Bulb

(3) Heater Pad 206 W / 220

VAC 225-01-6770 / ...-6770T

Griddle

HE-07 #125-01-3242

Overhead Installation

(3) Compact Double Biax Lamps

F13DBX23T4/SPX35

Infinite

Control

Pilot

Light

L

Electronic

T-Stat

Ballast

4111F2RP

208 / 240 VAC - 1 Ø - 50 / 60 Hz

Overhead

Ballast Cooling

M

L1

L2

N

G

L3

Power

125-01-0311

Light

s

125-01

-0311

Cal-Rod Htr 1250 W / 240 VAC

DPSTRelay, 25A

125-01-3182

#225-01-3301A

NGT 11S11T444

Safety Limit

ON: 183°F

OFF: 210°F

RHR HEX - 4'/ Half Case

Flr Lamps, Contactor

Note: Case MUST be grounded

LOADING

208 V 240 V

L1L2L3

9.0

7.2

10.2

8.3

10/22/99

W6100007

®

Wiring Diagrams (Cont'd)

19

Page 20

Sheet 1 of 1

final

Boris Kasre

Date:

Project Title:

Drawing No.:

Drawn By:

Next Assembly:

Drawing Title:

Date:

Hussmann Corporation

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910

Lic.#: 644406

Revisions:

No. Description:

Checked By:

By:

BK

73

P1

51 2 4 6

P

H2

L2

L1

H1

L L

Griddle Heaters Pads

(2) sets of 3 pads - 451 W / 220 VAC

Overhead Heating

Element

Bulb

Sensor

Temp. Control

Pilot Light

Pilot Light

Electronic T-Stat

Light

s

1

25-01-0311

Overhead Lights

(6) F13DBX23T4/SPX35

Fluorescent Double Biax Lamps

(6) Ballast 4111F2RP

Overhead

Ballast Cooling

(2) 2500 W / 240 VAC

M

s

L1L2L3

N

G

Power Switc

h

1

25-01-0311

W

hite

W

hite

Red

White

W

hite

Red

W

hite

White

Red

#225-01-3301A

NGT 11S11T444

Safety Limit

ON:183°F

OFF: 210°F

208 / 240 VAC - 1Ø - 50 / 60z.

RHR Hex 5'6" 1/2 Case Wiring

RHR-Hex-5'6" 1/2 Case

LOADING

208 V 240 V

L1L2L3

14.8

16.5

17.1

18.8

10/22/99

W6100008

Note: Case must be grounded

®

Wiring Diagrams (Cont'd)

IGHT-RHR, RHR2-HEX-0608

20

Page 21

Rev. 0608

Appendices

Appendix A. - Temperature Guidelines

1.0 Hot cases are tested to maintain all hot food at

140°F - 150°F. These cases are not designed to

heat up or cook food. It is the user’s responsibility

to stock the hot food cases immediately after the

cooking of the food with a pulp temperature of at

least 150°F to 160°F.

All griddle type units are designed to maintain

temperatures above the FDA guideline of

140°F. This is product temperature, not air or

griddle temperature. Due to the open design

of these units, they must be loaded with

product for proper operation. When units are

empty, they experience rapid rise of heated

air from air outside the case. This action

gives empty units a false, lower than desired,

temperature reading. Loading the case traps

the air at the griddle, raising temperatures to

the 165°F to 185°F range, keeping product well

above the FDA guidelines. Remember, these

units must be loaded with product to maintain

safe product temperature.

Appendix B. - Application Recommendations

1.0 The installer should perform a complete start-up

evaluation prior to the loading of food into the hot

food case, which includes such items as:

a) Initial temperature performance, Griddles and

Hot Wells.

b) Observation of outside inuences such

as drafts, radiant heating from the ceiling

and from lamps. Such inuence should be

properly corrected or compensated for.

c) Complete start-up procedures should include

1. Heat/display lamps are lighting.

2. Indicator lamps on control panel(s) are

working

3. Auto-ll is functioning properly (Service

cases)

4. Hot Griddles are functioning.

Appendix C. - Field Recommendations

1.0 The most consistent indicator of display hot case

performance is temperature of the product itself.

NOTE: Public Health will use the temperature of the product

in determining if the hot case will be allowed to display

potentially hazardous food. For the purpose of this

evaluation, product temperature above the FDA Food

Code 1993 temperature for potentially hazardous food

will be the rst indication that an evaluation should be

performed. It is expected that all hot case will keep food

at the FDA Food Code 1993 temperature for potentially

hazardous food.

1.1 The following recommendations are made

for the purpose of arriving at easily taken and

understood data which, coupled with other

observations, may be used to determine whether

a hot case is working as intended:

a) INSTRUMENT - A stainless steel stem-type

thermometer is recommended and it should

have a dial a minimum of 1 inch internal

diameter. A test thermometer scaled only

in Celsius or dually scaled in Celsius and

Fahrenheit shall be accurate to 1°C (1.8°F).

Temperature measuring devices that are

scaled only in Fahrenheit shall be accurate to

2°F. The thermometer should be checked for

proper calibration. (It should read 32°F when

the stem is immersed in an ice water bath).

b) LOCATION - The thermometer must be

inserted into the food itself to acquire proper

food pulp temperature.

c) READING - The thermometer reading should

be made only after it has been allowed to

stabilize, i.e., maintain a constant reading.

Loading Product: Cases should be allowed

to heat up for one hour before product is

loaded.

Temperature adjustments: Allow 4 hours after

adjustment has been made before testing

pulp temperature of product.

d) OTHER OBSERVATIONS - Other

observations should be made which may

indicate operating problems, such as

unsatisfactory product, feel/appearance.

Appendix D. - Recommendations to User

1.0 The manufacturer should provide instructions and

recommendations for proper periodic cleaning.

The user will be responsible for such cleaning,

including the cleaning of equipment within the

compartment and the hot area(s). Cleaning

practices, particularly with respect to proper

refrigerator unloading and warm-up, must be in

accordance with applicable recommendations.

1. Allow the case to preheat for one hour prior

to loading.

2. Hot foods should enter the case directly after

cooking or no lower than 150° - 160°F. The

Hot Cases are not designed to heat up or

cook food.

3. Self Service - be sure to display product in

single layer in direct contact with heating

surface.

21

Page 22

Appendices (Cont'd)

IGHT-RHR, RHR2-HEX-0608

4. All griddle type units are designed to maintain

temperatures above the FDA guideline of

140°F. This is product temperature, not air or

griddle temperature. Due to the open design

of these units, they must be loaded with

product for proper operation. When units are

empty, they experience rapid rise of heated

air from air outside the case. This action

gives empty units a false, lower than desired,

temperature reading. Loading the case traps

the air at the griddle, raising temperatures to

the 165°F to 185°F range, keeping product

well above the FDA guidelines. Remember,

these units must be loaded with product to

maintain safe product temperature.

5. Check the food pulp temperature frequently

with a thermometer to make sure it is at

the proper holding temperature. Hot foods

should be at 140°F. The thermometer must

be inserted into the food itself for the proper

temperature.

6. Do not display more food than will be sold

within a 4 hour period.

7. When restocking, bring older food to the

front, and stock fresher food on top.

8. Clean spills as soon as they happen.

9. Fingerprints and food splatter will drastically

shorten bulb life. Clean splatter off the bulbs

immediately with a soft cloth. When handling

bulbs, wear cotton gloves or use a cotton

rag/towel.

10. When “freshening” foods such as macaroni

and cheese with added water, heat the water

in a clean container until it is 10°F to 20°F

above the desired holding temperature of the

food. This will keep the food at a safe serving

temperature. Depending on the amount of

water, the temperature can drop 100°F to

20°F in as little as ve minutes.

11. When transferring hot foods in the heated

merchandiser to clean pans, preheat the

clean pan. Transferring hot foods to room

temperature pans can cause the temperature

of the food to drop 20°F or more thus causing

food to be at an unsafe serving temperature.

12. Clean spills as they happen simply by wiping

with a cloth. Be sure to use a dry cloth on

very hot surfaces to prevent steam burns.

13. Turn the equipment off and allow to cool

before cleaning.

14. To remove “baked-on” splatter from Stainless

Steel, the following may be used

Grade F Italian Pumice Scour or rub

with a damp cloth

Liquid NuSteel Scour with a small

amount of a dry cloth

Paste NuSteel

Household Cleaners Rub with a damp cloth

Coopers Stainless Steel Cleaner

Allen Stainless Steel Polish

For further technical information, please log on to http://www.hussmann.com/products//RHR_HEX.htm

22

Page 23

IGHT-RHR, RHR2-HEX-0608

Service Record

Last service date: By:

_______________ __________________________________________________________________________________________________

_______________ __________________________________________________________________________________________________

_______________ __________________________________________________________________________________________________

_______________ __________________________________________________________________________________________________

_______________ __________________________________________________________________________________________________

_______________ __________________________________________________________________________________________________

_______________ __________________________________________________________________________________________________

/Chino

Additional copies of this publication may be obtained by contacting:

Hussmann® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

The MODEL NAME and SERIAL NUMBER is required in order to provide

you with the correct parts and information for your particular unit.

They can be found on a small metal plate on the unit.

Please note them below for future reference.

MODEL:

SERIAL NUMBER:

Loading...

Loading...