Page 1

®

IIMMPPOORRTTAANNTT

Keep in store for

future reference!

Installation &

Operation Manual

Shipped With Case Data Sheets

P/N 0387183_D

Impact Series

October 2007

Reach-in Merchandisers

Medium and Low Temperature Cases

Merchandisers

Page 2

Page 3

iii

P/N 0387183_D

Table of Contents

INSTALLATION

NSF Certification . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Exterior Loading . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Merchandisers Shipped With End Installed . . . . 1-2

Shipping Braces . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Remove Front Panel . . . . . . . . . . . . . . . . . . . . . . 1-2

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Door Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Joining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Installing Splashguard Brackets . . . . . . . . . . . . . 1-4

Installing Bumpers . . . . . . . . . . . . . . . . . . . . . . . . 1-5

REFRIGERATION / ELECTRICAL

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Branch Line Piping . . . . . . . . . . . . . . . . . . . . . . . 2-2

Expansion Valve Adjustment . . . . . . . . . . . . . . . 2-3

Refrigeration Thermostat . . . . . . . . . . . . . . . . . . . 2-3

Defrost Termination Thermostat . . . . . . . . . . . . . 2-5

Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Merchandiser Electrical Data . . . . . . . . . . . . . . . 2-8

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Electrical Connections . . . . . . . . . . . . . . . . . . . . 2-8

Identification of Wiring . . . . . . . . . . . . . . . . . . . 2-8

Wiring Color Code . . . . . . . . . . . . . . . . . . . . . . . 2-8

DRIP PIPING AND SPLASHGUARDS

Waste Outlet and Water Seal . . . . . . . . . . . . . . . . 3-1

Installing Drip Piping . . . . . . . . . . . . . . . . . . . . . 3-1

Installing Splashguards . . . . . . . . . . . . . . . . . . . . 3-2

Sealing Splashguard to Floor . . . . . . . . . . . . . . . 3-3

START UP / OPERATION

Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Stocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Load Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Load Limit Profiles . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installing FDA/NSF Required Thermometer . . .4-2

MAINTENANCE

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Cleaning Honeycomb Assemblies . . . . . . . . . . . . 5-2

Cleaning Under Merchandisers . . . . . . . . . . . . . 5-2

Removing Scratches from Bumper . . . . . . . . . . . 5-2

SERVICE

Replacing Fan Motors and Blades . . . . . . . . . . . 6-1

Replacing Electric Defrost Heaters . . . . . . . . . . 6-3

Replacing Drain Pan Heater . . . . . . . . . . . . . . . . 6-5

RLT with Gas Defrost Only: Replacing

Slave Plate Heater . . . . . . . . . . . . . . . . . . . . . . 6-6

Removing RLT Return Air Bracket . . . . . . . . . . 6-7

Replacing Lamp Ballast (other than RLT) . . . . . 6-8

Replacing RLT Lamp Ballast . . . . . . . . . . . . . . . 6-9

Servicing Vertical Lighting . . . . . . . . . . . . . . . 6-10

Servicing Doors and Frames . . . . . . . . . . . . . . 6-10

Replacing Door or Door Frame Parts . . . . . . . 6-10

Replacing Damaged Drain Fitting . . . . . . . . . . . 6-11

Repairing Aluminum Coils . . . . . . . . . . . . . . . 6-12

WARRANTY

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

www.hussmann.com

© 2007 Hussmann Corporation

®

®

Page 4

INSTALLATION

TOOL LIST

Unloading From Trailer:

Lever Bar (also know as a Mule,

Johnson Bar, J-bar, Lever Dolly, and pry lever)

Moving Dolly

Setting Case Line-Up:

Level, 4 ft suggested

Ratchet

1

/

4 in. Socket

5

/16 in. Socket

1

/2 in. Socket

Battery Drill/Screw Gun

Caulking Gun

10 in. Adjustable Crescent Wrench

REVISION D — SEPTEMBER 2007

1. Added front panel text and illustration, Page 1-2.

2. Clarified shimming directions, page 1-3.

3. Added RLT information throughout.

4. Added note to remove bumper protective film, Page 1-6.

5. Added information on Always*Clear™ glass, page 5-1.

6. Removed reference to Anthony doors, Page 6-5.

7. Added repairing aluminum coil, Page 6-12.

8. Changed warranty page.

9. Added Installation Tool List, page iv.

10. Added revision history, page iv.

REVISION C — JUNE 2002

1. Added NSF information,pages 1-1,4-2 through 4-4.

2. Sections 2 through 6 are completely rewritten.

3. Changed warranty to March 15,2002.

P/N 0387183_D

iv CONTENTS

Page 5

NSF CERTIFICATION

These merchandisers are manufactured to meet

ANSI / National Sanitation Foundation (NSF®)

Standard #7 requirements. Proper installation is

required to maintain certification. Near the serial

plate, each case carries a label identifying the

type of application for which the case was certified.

ANSI/NSF-7 Type I – Display Refrigerator / Freezer

Intended for 75°F / 55%RH Ambient Application

ANSI/NSF-7 Type II – Display Refrigerator / Freezer

Intended for 80°F / 55%RH Ambient Application

ANSI/NSF-7 – Display Refrigerator

Intended for Bulk Produce

LOCATION

These merchandisers are designed for displaying

products in air conditioned stores where temperature is maintained at or below the ANSI/NSF-7

specified level and relative humidity is maintained

at or below 55%.

Placing refrigerated merchandisers in direct sunlight, near hot tables or near other heat sources

could impair their efficiency.

Like other merchandisers, these are sensitive to air

disturbances. Air currents passing around merchandisers will seriously impair their operation.

Do NOT allow air conditioning, electric fans,

open doors or windows, etc. to create air currents

around the merchandisers.

To prevent sweating on the exterior surfaces

of merchandisers, there must be

A MINIMUM

CLEARANCE OF

4 INCHES (102 MM) between the

merchandisers and other fixtures or walls.

Product should always be maintained at proper

temperature. This means that from the time the

product is received, through storage, preparation

and display, the temperature of the product must

be controlled to maximize the life of the product.

SHIPPING DAMAGE

All equipment should be thoroughly examined

for shipping damage before and during unloading.

This equipment has been carefully inspected at

our factory. Any claim for loss or damage must be

made to the carrier. The carrier will provide any

necessary inspection reports and/or claim forms.

Apparent Loss Or Damage

If there is an obvious loss or damage, it must be

noted on the freight bill or express receipt and

signed by the carrier’s agent; otherwise, carrier

may refuse claim. The carrier will supply necessary forms.

Concealed Loss Or Damage

When loss or damage is not apparent until after

equipment is uncrated, a claim for concealed

damage is made. Upon discovering damage,

make request in writing to carrier for inspection

within 15 days and retain all packing. The carrier

will supply inspection report and required claim

forms.

Reach-In

P/N 0387183_D 1-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

INSTALLATION

Do not walk or put heavy objects on case.

CAUTION

!

Page 6

EXTERIOR LOADING

Do NOT walk on top of merchandisers or dam-

age to the merchandisers and serious personal

injury could occur. T

HEY ARE NOT STRUCTURALLY

DESIGNED TO SUPPORT EXCESSIVE EXTERNAL

LOADING

such as the weight of a person. Do not

place heavy objects on the merchandiser.

MERCHANDISERS SHIPPED WITH END INSTALLED

If the case was shipped with the end installed,

two long bolts were used to hold the shipping

brace to the end. If the shipping bolts are

reinserted after removing the brace, they will

extend into the product area and may damage

the coil. T

HEREFORE, BE SURE TO REPLACE

THESE BOLTS WITH THE SHORTER BOLTS

PROVIDED

.

Be careful not to damage the factory-installed

end while moving the merchandiser. Make sure

that tools are positioned past the end and beneath

the merchandiser’s support bar.

SHIPPING BRACES

Move the merchandiser as close as possible to its

permanent location and then remove all packaging. Check for damage before discarding packaging. Remove all separately packed accessories

such as kits and shelves.

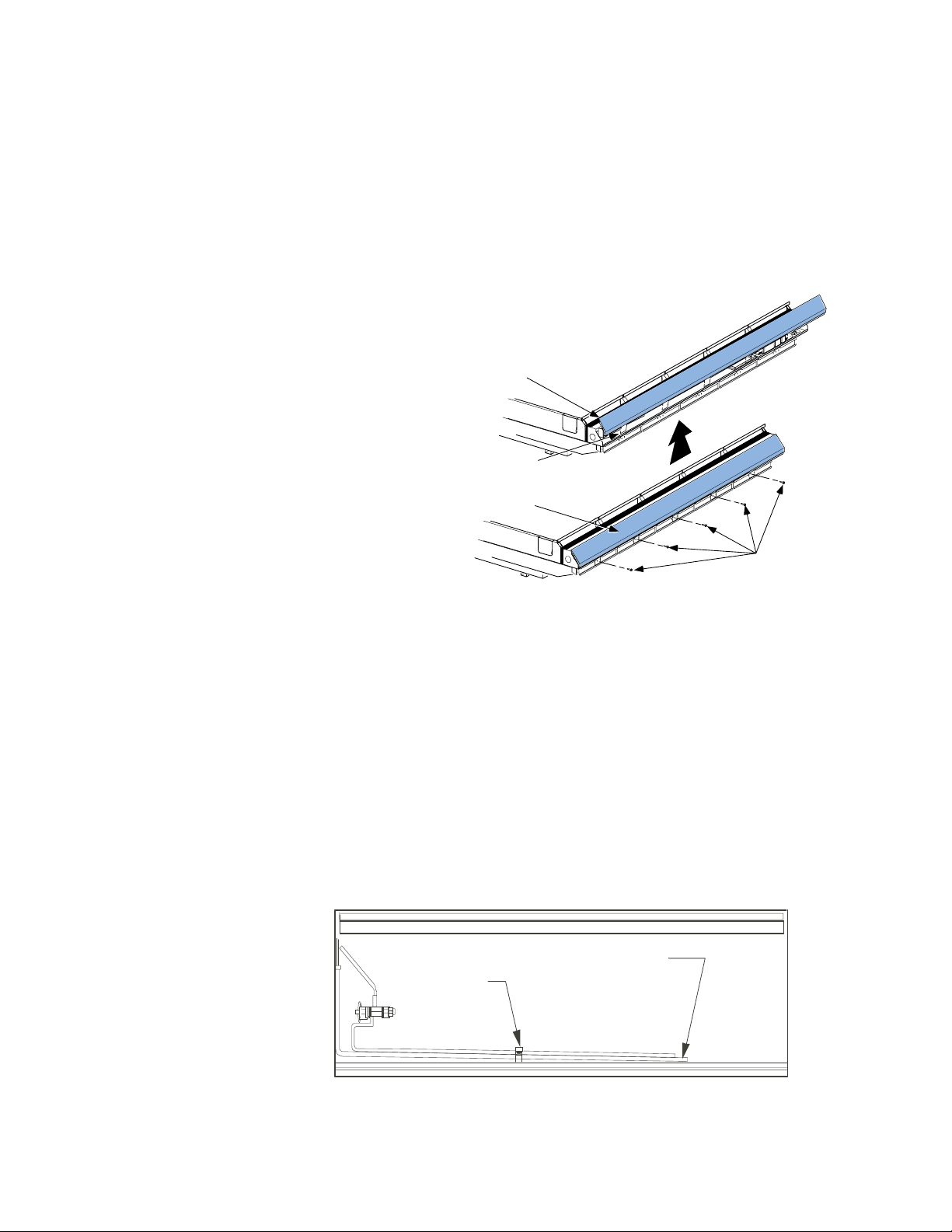

Locate the shipping block in the

center of the heat exchanger (see

illustration), and remove it before

piping the merchandiser. This

block was installed to minimize

shipping vibration.

REMOVE FRONT PANEL

(D

OES NOT APPLY TO RLT)

Before setting case, remove the front panel as

follows: remove screws from front panel tabs,

then lift the front panel. Refer to the illustration

below. Set panel and screws aside to reinstall

once all electrical work is complete.

At completion of all electrical work, installation

contractor shall re-install the panels using care to

ensure all panels are centered and properly

fastened.

1-2 INSTALLATION

P/N 0387183_D WWW

.HUSSMANN.COM

Shipping

Block

Heat Exchanger

Top View of Merchandiser

Edge Fits Over Raceway

Tabs Fit in

Retainer Slots

Front Panel

Remove Screws

Page 7

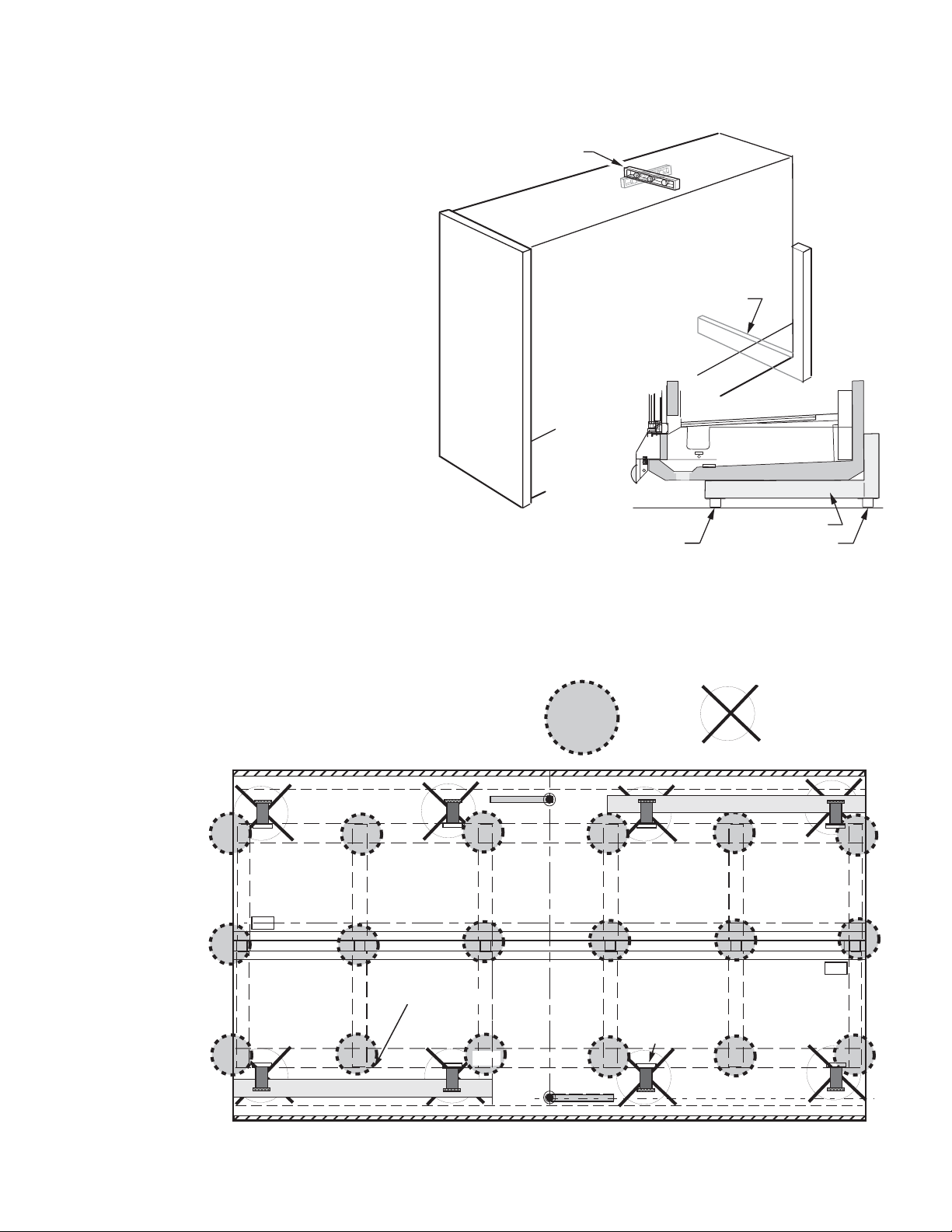

LEVELING

Merchandisers must be installed level

to ensure proper operation of the

refrigeration system and to ensure

proper drainage of defrost water.

When leveling merchandisers, use a

carpenter’s level as shown.

Metal leveling shims or wedges are

provided with each merchandiser for

use if needed.

NOTE: B

EGIN LINEUP LEVELING

FROM THE HIGHEST POINT OF THE

STORE FLOOR

.

Place shims under the rail and make

sure that they are positioned at a base

component (crossbar). This transfers

the weight directly from the loaded

case through to the floor. Placing shims

at other locations will cause uneven

distribution of weight leading to piping

leaks, as well as sagging or wracked

doors.

Reach-In

P/N 0387183_D 1-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

5-Door Island Shown

Bottom Front

Support

Skid/External Base

Electrical Wireway

Electrical Wireway

Shim

Here

NO SHIM

HERE

Approximately

Centered

Rear of Reach-in

Shim Here

Base

Component

Base Component

Shim Here

Page 8

DOOR ADJUSTMENT

After leveling and joining the merchandisers,

adjust and level doors according to manufacturer’s

instructions shipped with each product. Factory

settings are lost due to vibration during shipment.

JOINING

Sectional construction means that two or more

merchandisers may be joined in line yielding one

long continuous display requiring only one pair

of ends. Joining kits and instructions are

shipped with each merchandiser.

To join like fixtures, a joining kit is required.

To join unlike fixtures, or like fixtures operating

at different temperatures, a 1

1

/

2 inch (38 mm)

partition kit is required. To join same

temperature fixtures on different defrost cycles,

a plexiglass partition kit is required.

A

LL JOINTS MUST BE AIR-TIGHT TO PREVENT

FORMATION OF ICE OR CONDENSATION

.

Refer to separate joining instruction shipped

with each case

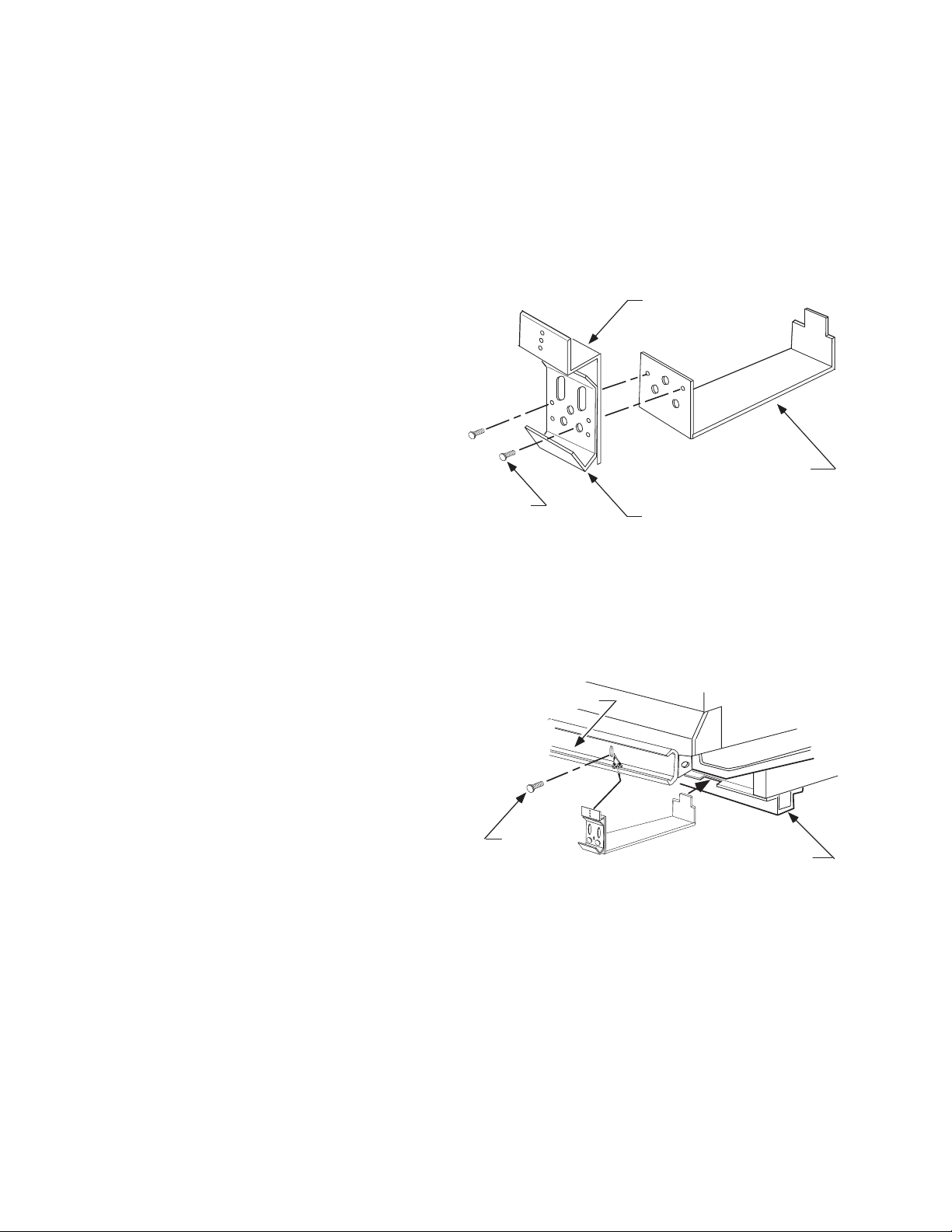

INSTALLING SPLASHGUARD BRACKETS

1. Attach splashguard retainer and splashguard

retainer support to splashguard support bracket using two screws per bracket.

2. I

NSTALL SPLASHGUARD SUPPORT BRACKETS

BEFORE PIPING CASE. The leveling brackets

have a maximum extension of one (1) inch

(25 mm) for uneven floors.

DO NOT

PLACE SHIMS UNDER SPLASHGUARD

BRACKETS

.

1-4 INSTALLATION

P/N 0387183_D WWW

.HUSSMANN.COM

Splashguard

Retainer Support

Splashguard

Support Bracket

Screw

Splashguard Retainer

Bumper Retainer

Screw

Base Rail

Page 9

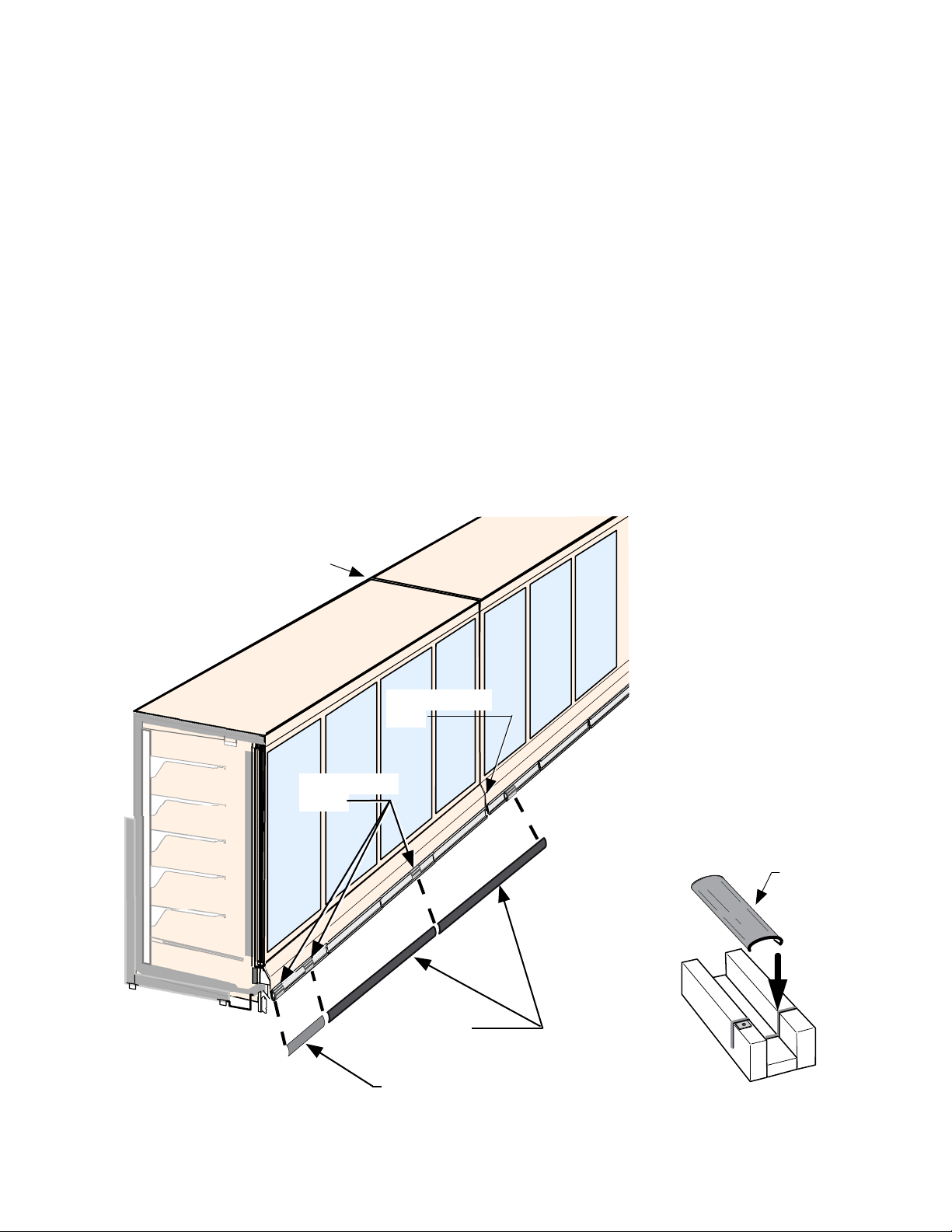

INSTALLING BUMPERS

Offsetting the bumpers and top rails helps to

disguise the joint locations, giving the lineup a

smoother look.

Begin at the left end of the line-up. A starter

bumper is factory-installed with end kits. Insert

the internal joint trim, then add the full-length

bumper.

Align each bumper section with its retainer and

push into place, working from the end of the lineup. Install full length bumpers and internal joint

trims offset across joints. Make sure that no gaps

exist between sections. Continue installing

bumpers the length of the line up.

Do NOT install the last bumper sections at this

time. These sections will be installed in the last

step.

Once all except the last section of bumper have

been installed, refrigerate the case line-up for

at least six (6) hours. The last sections of

bumper should be kept inside a refrigerated

case or cooler during this time to allow the

bumpers to contract.

Before installing the last full-length section,

measure the remaining space. Use a miter box

and fine-tooth saw to cut last bumper to length.

Install the last section.

Reach-In

P/N 0387183_D 1-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Merchandiser

Joint

Full Length

Bumpers

Starter

Bumper

Merchandiser

Joint

Internal Joint

Trims

Bumper

Miter Box

Page 10

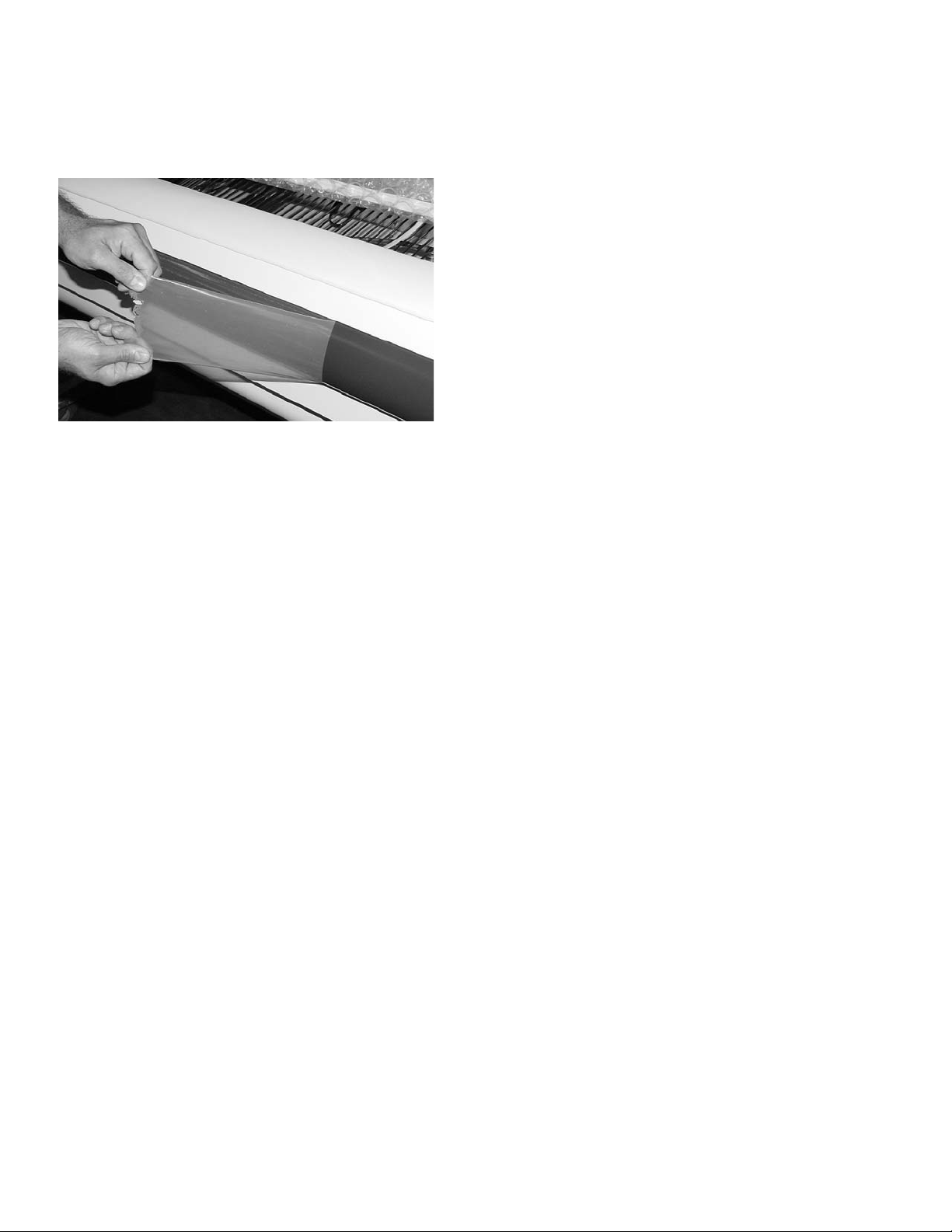

Remove protective film from bumpers once

installation is complete.

Optional end bumpers are factory-installed.

1-6 INSTALLATION

P/N 0387183_D WWW

.HUSSMANN.COM

Page 11

Reach-In

REFRIGERANT

The correct type of refrigerant will be stamped on

each merchandiser’s serial plate which is located

on the left-hand end of the interior top liner.

REFRIGERANT PIPING

Connection Location

The refrigerant line connections are at the righthand end of the merchandiser (as viewed from

the front) beneath the display pans.

After connections have been made, seal this outlet thoroughly. Seal both the inside and the outside. We recommend using an expanding

polyurethane foam insulation.

Multiplexing

Piping of merchandisers operating on the same

refrigeration system may be run from merchandiser to merchandiser through the end frame

saddles provided for this purpose. D

O NOT

RUN

REFRIGERANT LINES THROUGH MERCHANDISERS

THAT ARE

NOT ON THE SAME REFRIGERATION

SYSTEM

as this may result in poor refrigeration

control and compressor failure.

NOTE: If Gas defrost is used, the liquid line

will need to be increased two sizes larger inside

the merchandiser area. This is necessary to ensure

even liquid drainage from all evaporators during

defrost.

Line Sizing

Refrigerant lines should be sized as shown on the

refrigeration legend that is furnished for the store

or according to ASHRAE guidelines.

Oil Traps

P-traps (oil traps) must be installed at the base of

all suction line vertical risers.

Pressure Drop

Pressure drop can rob the system of capacity. To

keep the pressure drop to a minimum, keep the

refrigerant line run as short as possible using a

minimum number of elbows. Where elbows are

required,

USE LONG RADIUS ELBOWS ONLY.

INSULATION

With GAS Defrost

The suction and liquid lines should NOT contact

each other and should be insulated separately

for a minimum of 30 ft (9144 mm) from the

merchandiser.

With OTHER Than Gas Defrost

The suction and liquid lines should be clamped or

taped together and insulated for a minimum of

30 ft (9144 mm) from the merchandiser.

With All Defrost

Additional insulation for the balance of the liquid

and suction lines is recommended wherever

condensation drippage is objectionable or the

lines are exposed to ambient conditions.

P/N 0387183_D 2-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

REFRIGERATION / ELECTRICAL

When brazing pipes be sure to use the

insulation blanket shipped with the

merchandiser to prevent damage to

the plastic case bottom.

Refrigeration lines are under pressure and

should be depressurized before attempting

to make any connections.

!

WARNING

CAUTION

!

Page 12

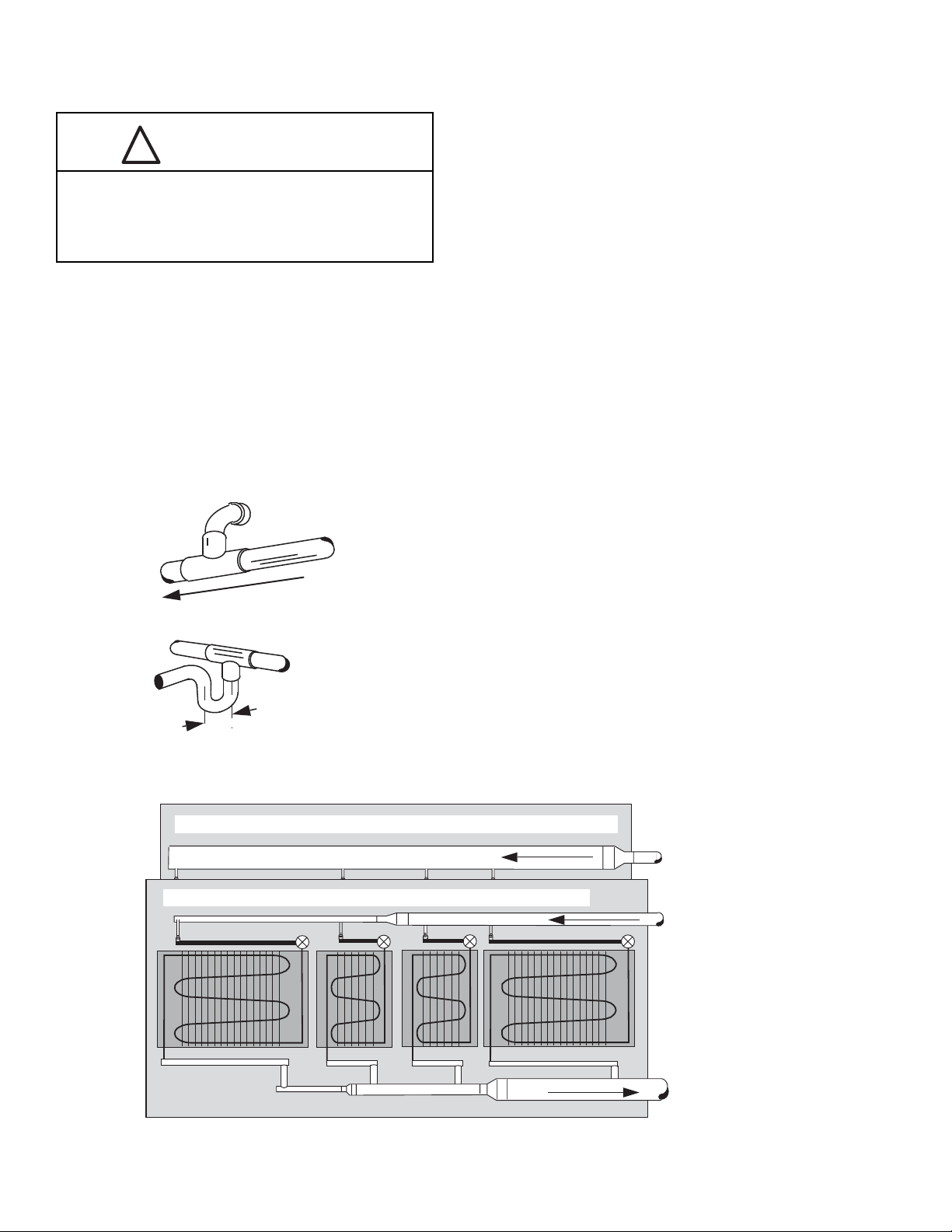

BRANCH LINE PIPING

Suction Line – All Defrosts

• Pitch in direction of flow.

• May be reduced by one size at one third of case

run load and again after the second third. Do

NOT reduce below evaporator connection size.

• Suction returns from evaporators enter at the

top of the branch line.

Liquid Line – Off-time and Electric Defrost

• May be reduced by one size after one half the

case load run. Do not reduce below evaporator

connection size.

• Take-offs to evaporators exit the bottom of the

liquid line. Provide an expansion loop for each

evaporator take-off (minimum 3 in. (76 mm)

diameter).

Liquid Line – Koolgas Defrost

• Maximum of 6 evaporators per Branch System.

• Increase the liquid line size inside the case by

two sizes over the branch size.

Branch Size In Case Size

1

/2

7

/8

5

/8 11/8

7

/

8 1

3

/

8

11/81

5

/8

13/8 21/8

• Take-offs to evaporators exit the bottom of the

liquid line. Provide an expansion loop for each

evaporator take-off (minimum 3 in. (76 mm)

diameter).

2-2 REFRIGERATION / ELECTRICAL

P/N 0387183_D WWW

.HUSSMANN.COM

The following information is applicable only

for piping Hussmann merchandisers to

Hussmann refrigeration equipment.

CAUTION

!

Suction Line Return

3-In. Loop (76 mm)

Liquid Line Take Off

Koolgas Defrost Liquid Line Two Sizes Larger in Merchandiser

Electric or Offtime Defrost Liquid Line

From

Liquid

Manifold

To

Suction

Manifold

Page 13

Reach-In

EXPANSION VALVE ADJUSTMENT

Expansion valves must be adjusted to fully feed

the evaporator. Before attempting to adjust

valves, make sure the evaporator is either clear or

only lightly covered with frost, and that the

merchandiser is within 10 deg F (6.5 deg C) of

its expected operating temperature. Adjust valves

as follows:

Attach two sensing probes

(either thermocouple or

thermistor) to the evaporator.

Position one under the clamp

holding the expansion valve

bulb; securely tape the other

to the coil inlet line.

Some “hunting

”

of the

expansion valve is normal.

The valve should be adjusted

so that during the hunting

THE GREATEST DIFFERENCE

BETWEEN THE TWO PROBES IS

3–5 deg F (1.7–2.8 deg C).

With this adjustment, during

a portion of the hunting the

temperature difference

between the probes will be

less than 3 deg F (1.7 deg C)

and at times 0.

Make adjustments of no more

than 1/

4 turn for Balanced

Port TEV and

1

/

2 turn at a

time for other valve models.

Wait at least 15 minutes

before rechecking the probe

temperature or making further

adjustments.

REFRIGERATION THERMOSTAT

The thermostat body is located in the electrical

raceway near the right-hand end of the merchandiser. Its sensing bulb is located behind the right

end interior back panel.

P/N 0387183_D 2-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Heat

Exchanger

body

Expansion

Valve

Expansion Valve

Bulb

Check Valve

Optional

Gas Bypass

Manifold

Thermostat

Component Location in

RL / RM / RLN / RLNI Models

Page 14

2-4 REFRIGERATION / ELECTRICAL

P/N 0387183_D WWW

.HUSSMANN.COM

Component Location in RLT Models

Distributor

Assembly

TEV Bulb

Mounted

on Side of

Suction Tube

TEV

Heat Exchanger

Assembly

RLT Coil

Optional

Gas Bypass

Check Valve

Page 15

DEFROST TERMINATION THERMOSTAT

The standard disc type defrost termination thermostat is not adjustable.

On low-temperature merchandisers, the defrost

termination thermostat or optional termination

sensor is located on the right end of the coil at

the bottom center return bend. If an optional

adjustable thermostat is used, the bulb will be

clamped to the suction line on the left end of the

case.

Reach-In

P/N 0387183_D 2-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

RLT

5 Door

&

4 Door

RL

RLN

RLNI

RLNIE

3 Door

RL

RLN

RLNI

RLNIE

ELECTRIC

ELECTRIC DEFROST ONLY

2 Door

RL

RLN

RLNI

RLNIE

Defrost Termination

Thermostat Location

.

Page 16

CONTROL SETTINGS

MEDIUM TEMPERATURE

Conventional Single Compressor

Measure Discharge Air Temperature

at the center of the case

at the discharge honeycomb.

Merchandiser temperature must be controlled by

a thermostat or other device with a 3–6 deg F

(1.7–3.3 deg C) differential. It will be wired to

control the compressor motor contactor.

Standard Off Time defrost is temperature terminated. The defrost termination thermostats for all

the merchandisers on one compressor are wired

in series. On outdoor units the defrost timer will

control a liquid line solenoid beginning a defrost

pumpdown 4 minutes before defrost.

The defrost frequency and lengths listed may

require adjustment for specific store conditions.

Factors include:

Store temperature and humidity

Low head pressure

Long refrigerant line runs

Seasonal changes

Merchandiser temperature lower than

recommended

When practical, defrost when store is closed.

Low pressure control settings are applicable to

outdoor condensing units where ambient does not

fall below 0 deg F.

CONTROL SETTINGS

LOW TEMPERATURE

Conventional Single Compressor

Measure Discharge Air Temperature

at the center of the case

at the discharge honeycomb.

Merchandiser temperature must be controlled by

a thermostat or other device with a 3–6 deg F

(1.7–3.3 deg C) differential. It will be wired to

control the compressor motor contactor.

Standard Electric defrost is temperature terminated. The defrost termination thermostats for all

the merchandisers on one compressor are wired

in series. Failsafe must not control defrost cycle

length, especially when less than 208V power

supply is used for defrost heaters, or if frost

build up is heavy from shopping demands.

On outdoor units the defrost timer will control a

liquid line solenoid beginning a defrost pumpdown 4 minutes before defrost.

Optional Gas defrost is time terminated and has

fan cycling thermostat. The defrost frequency and

lengths listed may require adjustment for specific

store conditions. Factors include:

Store temperature and humidity

Low head pressure

Long refrigerant line runs

Seasonal changes

Merchandiser temperature lower than

recommended

When practical, defrost when store is closed.

Low pressure control settings are applicable to

outdoor condensing units where ambient does not

fall below 0 deg F.

2-6 REFRIGERATION / ELECTRICAL

P/N 0387183_D WWW

.HUSSMANN.COM

Page 17

Reach-In

CONTROL SETTINGS

MEDIUM TEMPERATURE

Parallel Compressor Rack

Measure Discharge Air Temperature

at the center of the case

at the discharge honeycomb.

Merchandiser temperature must be controlled by

a mechanical or electronic pressure regulator or

thermostat that will be mounted on the rack.

Standard Off Time defrost is temperature terminated. The defrost frequency and lengths listed

may require adjustment for specific store conditions. Factors include:

Store temperature and humidity

Low head pressure

Long refrigerant line runs

Seasonal changes

Merchandiser temperature lower than

recommended

Stagger defrosts to maintain stable compressor

loading and sufficient defrost gas. When practical, defrost when store is closed.

CONTROL SETTINGS

LOW TEMPERATURE

Parallel Compressor Rack

Measure Discharge Air Temperature

at the center of the case

at the discharge honeycomb.

Merchandiser temperature must be controlled by

a mechanical or electronic pressure regulator or

thermostat that will be mounted on the rack.

Standard Electric defrost is temperature terminated. Failsafe must not control defrost cycle length,

especially when less than 208V power supply is

used for defrost heaters, or if frost build up is

heavy from shopping demands.

Optional Gas defrost is time terminated and has

fan cycling thermostat. The defrost frequency and

lengths listed may require adjustment for specific

store conditions. Factors include:

Store temperature and humidity

Low head pressure

Long refrigerant line runs

Seasonal changes

Merchandiser temperature lower

than recommended

Stagger defrosts to maintain stable compressor

loading and sufficient defrost gas. When practical, defrost when store is closed.

P/N 0387183_D 2-7

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Page 18

MERCHANDISER ELECTRICAL DATA

Merchandiser data sheets for specific models are

shipped with this manual. The data sheets provide

merchandiser electrical data, standard electrical

schematics, parts lists and performance data.

Refer to the merchandiser data sheets and case

serial plate for electrical information. Refer to

the separate wiring diagrams shipped with the

case for specific information about the case and

any optional wiring kits that may have been

applied.

FIELD WIRING

Field wiring must be sized for component amperes

stamped on the serial plate. Actual ampere draw

may be less than specified. Field wiring from the

refrigeration control panel to the merchandisers is

required for defrost termination thermostats and for

optional refrigeration thermostats. When multiple

merchandisers are on the same defrost circuit, the

defrost termination thermostats are wired in series.

ALWAYS CHECK THE SERIAL PLATE FOR

COMPONENT AMPERES

.

Electric Defrost is standard for low temperature

merchandisers and requires temperature termination. Gas defrost is optional

Off Time Defrost is standard for medium temperature merchandisers and is time terminated.

When two or more merchandisers with full length

raceways are installed in line, remove the splashguards, end caps and raceway covers, and install

the nipple and nuts (supplied) providing electrical

passage from one merchandiser to the next.

Following NEC and local codes is the

responsibility of the electrical contractor.

ELECTRICAL CONNECTIONS

All wiring must be in compliance with NEC and

local codes. All electrical connections are to be

made to the terminal blocks in the electrical raceway behind the lower front panel at the righthand end of the merchandiser (facing front).

IDENTIFICATION OF WIRING

Leads for all electrical circuits are identified by

colored plastic bands. These bands correspond to

the color code sticker (shown below) located

inside the merchandiser raceway.

2-8 REFRIGERATION / ELECTRICAL

P/N 0387183_D WWW

.HUSSMANN.COM

WIRING COLOR CODE

Leads for all electrical circuits are identified by a colored plastic band: neutral wire for each

circuit has either White insulation or a White plastic sleeve in addition to the color band.

P

INK ............REFRIG.THERMOSTAT LOW TEMP.ORANGE OR

LIGHT BLUE .REFRIG.THERMOSTAT NORM TEMP.TAN ..........LIGHTS

DARK BLUE..DEFROST TERM.THERMOSTAT MAROON ..RECEPTACLES

P

URPLE .......ANTI-SWEAT HEATERS YELLOW*..DEFROST HEATERS, 120V

B

ROWN ........FAN MOTORS RED*........DEFROST HEATERS, 208V

G

REEN* .......GROUND

*E

ITHER COLORED SLEEVE OR COLORED INSULATION

ELECTRICIAN NOTE: Use copper conductor wire only.

CASE MUST BE GROUNDED

Terminal block NOT for case-to-case wire

connection.

!

WARNING

Page 19

WASTE OUTLET AND WATER SEAL

The waste outlet location varies for each of the 1,

2, 3, 4, and 5 door merchandisers. Drip piping is

located between the front case base and the

splashguard fixture and runs parallel to the case

(see Data Sheet for exact locations).

INSTALLING DRIP PIPING

Poorly or improperly installed drip pipes can

seriously interfere with the merchandiser's operation and result in costly maintenance and product

losses. Please follow the recommendations listed

below when installing drip pipes to ensure proper

installation.

1. Never use drip piping smaller than the nominal diameter of the pipe or water seal supplied with the merchandiser.

2. When connecting drip piping, the water seal

must be used as part of the drip piping to prevent air leakage or insect entrance. Never use

two water seals in series in any one drip pipe.

D

OUBLE WATER SEALS IN SERIES WILL CAUSE

AN AIR LOCK AND PREVENT DRAINING

.

3. Pitch the drip piping in the direction of flow.

There should be a minimum pitch of

1

/8 inch

per foot (1 mm per 100 mm).

4. Avoid long runs of drip piping. Long runs

make it impossible to provide the pitch necessary for good drainage.

5. Provide a suitable air break between

flood rim of the floor drain and outlet

of drip pipe. To meet code on low base

merchandisers, it may be necessary

to install a field-supplied drip pipe

reducer. An alternative is to cut the

last section of drip pipe at an angle.

6. Prevent drip pipes from freezing:

A. Do NOT install drip pipes in contact with

uninsulated suction lines. Suction lines should

be insulated with a non-absorbent insulation

material.

B. Where drip pipes are located in dead air

spaces, such as between merchandisers or

between a merchandiser and a store wall,

provide means to prevent freezing.

Reach-In

P/N 0387183_D 3-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

DRIP PIPING AND SPLASHGUARDS

Splashguard

brackets

MUST be installed

before piping case.

(See Page 1-3)

CAUTION

!

Field Installed

Drip Piping

This End MUST Be

Above Tee Fitting

Field-Installed

Coupling

Case Bottom

Field-Installed

Water Seal

TEE-SIDE

Tee

Fitting

Waste Outlet

Plug

Adapter

Page 20

INSTALLING SPLASHGUARDS

The splashguard is shipped inside each merchandiser. AFTER merchandisers have been leveled and joined, and all drip piping, electrical

and refrigeration work has been completed,

re-install the front color panel, then install the

splashguards.

First, position top of splashguard over the top

edge of the bracket; second, push the lower edge

of the splashguard toward the bottom of the

bracket until it snaps into place.

Splashguards are joined with a galvanized

metal splice connector that comes with the

joint kit. Join the splashguards before

installing on case.

3-2 DRIP PIPING AND SPLASHGUARDS

P/N 0387183_D WWW

.HUSSMANN.COM

1

2

Splashguard

Joint

Splashguard

Retaining

Bracket

Splashguard

Side

Detail

Splice Connector

Page 21

SEALING SPLASHGUARD TO FLOOR

I

F REQUIRED by local sanitation codes, or if

desired by the customer, plastic splashguards may

be sealed to the floor using silicone type sealer.

The amount needed will depend on how much

the floor is out of level.

• Remove all dirt, wax and grease from the area of

the splashguard where adhesion will be necessary.

This is to ensure a good and secure installation.

• Apply a good silicone type sealer along the

bottom of the splashguard. Sealant must be

removed and replaced when servicing.

O

PTIONAL Stainless steel splashguards may be

sealed to the floor using a vinyl cove base trim.

The size of trim needed will depend on how

much the floor is out of level.

To install the trim to the splashguard:

• Remove all dirt, wax and grease from the area

of the splashguard where adhesion will be necessary. This is to ensure a good and secure installation.

• Apply a good contact cement to the cove trim

and allow proper drying time according to the

directions supplied with the cement.

• Install the trim to the splashguard so that it is

lying flush with the floor. D

O NOT SEAL THE TRIM

TO THE FLOOR

.

• If required by local health codes Cove Trim

may be sealed to the floor using a silicone type

sealer. Sealant must be removed and replaced

when servicing.

Reach-In

P/N 0387183_D 3-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Splashguard

Silicone-type

Sealer

Splashguard

Cement

Cove Trim

Page 22

NOTES

3-4 DRIP PIPING AND SPLASHGUARDS

P/N 0387183_D WWW

.HUSSMANN.COM

Page 23

P/N 0387183_D 4-1

STARTUP

See the merchandiser's Data Sheet Set for

refrigerant settings and defrost requirements.

Bring merchandisers down to the operating

temperatures listed on the data sheet.

STOCKING

Product should NOT be placed in merchandisers

until all refrigeration controls have been adjusted

and merchandisers are at proper operating

temperature.

All shelves and the lower deck are intended to

display product. Shelf height is adjustable in one

inch increments. Spacing of 12 inches is

recommended for most applications. Maximum

load per shelf is 170 pounds. Merchandisers may

be ordered with optional “L” shaped wire

shelves.

Proper rotation of product during stocking is

necessary to prevent product loss. Always bring

the oldest product to the front and set the newest

to the back.

A

IR DISCHARGE AND RETURN FLUES MUST REMAIN

OPEN AND FREE OF OBSTRUCTION AT ALL TIMES

to

provide proper refrigeration and air curtain

performance. Do not allow product, packages,

signs, etc. to block these grilles. Do not use nonapproved shelving, baskets, display racks, or any

accessory that could hamper air curtain

performance.

Do not prop doors open while stocking. And keep

the doors closed as much as possible to prevent

coil frosting and high merchandiser temperature.

LOAD LIMITS

Shelf life of perishables will be short if load limit

is violated. A

T NO TIME SHOULD MERCHANDISERS

BE STOCKED BEYOND THE LOAD LIMITS INDICATED

.

DO NOT BLOCK HONEYCOMB

.

LOAD LIMIT PROFILES

Reach-In

HUSSMANN CORPORATION, BRIDGETON, MO 63044-2483 U.S.A.

START UP / OPERATION

RL / RM / RMF

FAN

COIL

Page 24

INSTALLING FDA/NSF REQUIRED

THERMOMETER

The following pages provide the same

information that ships with the thermometer.

This requirement does not apply to display

refrigerators intended for bulk produce (refer

to page 1-1).

Please note that the tape cannot be exposed after

installation.

4-2 START UP / OPERATION

P/N 0387183_D WWW.HUSSMANN.COM

RMN

Load

Limits

FAN

RLN

or

COIL

Limits

FAN

RLNI

Load

COIL

COIL

RLNI

Load

Limits

FAN

RLT

Load

Limits

C

O

I

L

FAN

Page 25

Reach-In

P/N 0387183_D 4-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Suggested Mounting Locations

in Single Deck Glass Front

Impact Merchandisers

Package Guard,

Facing Out

Double Stick Tape

Flexible Plastic

Fits in Price Tag

Moldings

This is an NSF-7 &

US FDA Food Code

Required

Thermometer

Thermometer — Hussmann Part TM.4911251

Hussmann Corporation • 12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900 • www.hussmann.com

© 2007 Hussmann Corporation

End Panel

Price Tag

Molding

Hussmann P/N 0429971_C 10/2007

Suggested Mounting Locations

in Multi-deck Merchandisers

Page 26

4-4 START UP / OPERATION

P/N 0387183_D WWW.HUSSMANN.COM

Important – Please read!

This thermometer is provided in response to United States

Food and Drug Administration (US FDA) Food Code [ http://www.fda.gov/ ]

National Sanitation Foundation (NSF / ANSI) Standard 7 [ http://www.nsf.org/ ]

and

Each installation will be different

depending on how the unit is

stocked, shopping patterns in the

department and ambient conditions

of the store. The suggested loca-

tions provided herein are possible

locations. It is the responsibility of

the purchaser / user to determine

the location within the food storage

area of the unit that best meets the

code requirements above.

The thermometer may need to be

moved several times to find the

warmest location. Mounting options

include flexible plastic for price tag

molding application, magnet

applied to back of flexible plastic for

steel end wall, and double stick

tape. Tape must not be exposed

after installation.

Questions about either code should

be addressed to local agencies or

other appropriate officials.

Keep with merchandiser

or give to store manager.

DO NOT DESTROY.

Page 27

CARE AND CLEANING

Long life and satisfactory performance of any

equipment is dependent upon the care it receives.

To ensure long life, proper sanitation and minimum maintenance costs, these merchandisers

should be thoroughly cleaned, all debris removed

and the interiors washed down, weekly.

Fan Plenum

To facilitate cleaning, the fan plenum is hinged

and also fastened with screws at each end. After

cleaning be sure the plenum is properly lowered

into position and that screws are reinstalled

OR PRODUCT LOSS WILL RESULT

due to improper

refrigeration.

Exterior Surfaces

The exterior surfaces should be cleaned with a

mild detergent and warm water to protect and

maintain their attractive finish. N

EVER USE

ABRASIVE CLEANSERS OR SCOURING PADS

.

Always*Clear™ Glass

Wipe inside of glass with isopropyl alcohol and

a soft cloth. Allow surface to dry before closing

door. Use of other cleaners or abrasives may

damage the Always*Clear surface, and/or void

the warranty. Refer to manual that ships with

doors.

Interior Surfaces

The interior surfaces may be cleaned with most

domestic detergents, ammonia based cleaners and

sanitizing solutions with no harm to the surface.

D

O

NOT USE:

• Abrasive cleansers and scouring pads, as

these will mar the finish.

• Solvent, oil or acidic based cleaners on any

interior surfaces.

• Ammonia based cleaners on acrylic surfaces.

D

O:

• Remove the product and all loose debris to

avoid clogging the waste outlet.

• Store product in a refrigerated area such as a

freezer. Remove only as much product as can

be taken to the freezer in a timely manner.

• First turn off refrigeration, then disconnect

electrical power.

• Thoroughly clean all surfaces with soap and

hot water. D

O NOT USE STEAM OR HIGH

WATER

PRESSURE HOSES TO WASH THE INTERIOR

.

T

HESE WILL DESTROY THE MERCHANDISERS’

SEALING CAUSING LEAKS AND POOR PERFOR-

MANCE.

• Remove screws and lift hinged fan plenum

for cleaning. B

E SURE TO REPOSITION THE FAN

PLENUM AFTER CLEANING MERCHANDISER

.

• Take care to minimize direct contact between

fan motors and cleaning or rinse water.

• Rinse with hot water, but do NOT flood.

N

EVER INTRODUCE WATER FASTER THAN THE

WASTE OUTLET CAN REMOVE IT

.

• Allow merchandisers to dry before resuming

operation.

• After cleaning is completed, turn on power

and refrigerant to the merchandiser.

• Verify that merchandiser is working properly.

Reach-In

P/N 0501904_A 5-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

MAINTENANCE

Do NOT use HOT water on COLD glass surfaces.

This can cause the glass to shatter and could

result in personal injury. Allow glass fronts,

ends and service doors to warm

before applying hot water.

SHUT FANS OFF DURING CLEANING

PROCESS.

!

WARNING

!

WARNING

Page 28

CLEANING HONEYCOMB ASSEMBLIES

Honeycombs should be cleaned every six months.

Dirty honeycombs will cause merchandisers to

perform poorly. The honeycombs may be cleaned

with a vacuum cleaner. Soap and water may be

used if all water is removed from the honeycomb

cells before reassembling. Be careful not to

damage the honeycombs.

1. Remove the sheet metal screws located in the

front metal retainer which holds the honeycomb assembly in place.

2. Lift the honeycomb assembly out of the

L-bracket to remove it.

3. Clean and dry the honeycomb.

4. After cleaning, reassemble in reverse order of

removal.

CLEANING UNDER MERCHANDISERS

Remove splashguards not sealed to floor. Use a

vacuum with a long wand attachment to remove

accumulated dust and debris from under the

merchandiser.

REMOVING SCRATCHES FROM BUMPER

Most scratches and dings can be removed using

the following procedure.

1. Use steel wool to smooth out the surface area

of the bumper or top rail.

2. Clean area.

3. Apply vinyl or car wax and polish surface for

a smooth glossy finish.

5-2 MAINTENANCE

P/N 0387183_D WWW.HUSSMANN.COM

Do NOT allow product to sit in a

non-refrigerated area.

Internal

Frame

Interior

Top Panel

SIDE VIEW

!

WARNING

Honeycomb

Top Panel

Adhesive

Honeycomb

Retainer

Screw

Page 29

REPLACING FAN MOTORS AND BLADES

See cross section for location of evaporator

fans. Should it ever be necessary to service or

replace the fan motors or blades be certain that

the fan blades are re-installed correctly.

For access to RL / RM / RLN / RMN / RLNI /

RLNIE fans:

1. Turn off power.

2. Remove bottom display pans.

3. Disconnect fan from wiring harness.

4. Remove fan blade.

5. Remove screws holding fan motor/bracket

assembly to plenum and remove assembly.

6. Replace fan motor/bracket assembly and

reinstall screws.

7. Reinstall fan blade.

8. Reconnect fan to wiring harness.

9. Turn on power.

10. Verify that motor is working and blade is

turning in the correct direction.

11. Close air gaps under fan plenum. Warmer air

moving into refrigerated air reduces effective

cooling. If the plenum does not rest against

the case bottom without gaps, apply foam

tape to the bottom of the fan plenum to

reduce improper air movement. Use silicone

sealant to close other gaps.

12. Replace display pans. Bring merchandiser to

operating temperature before restocking.

Reach-In

P/N 0387183_D 6-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Always disconnect the electrical power at

the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

SERVICE

Hussmann recommends against frame heater

cycling with

Innovator

doors to prevent door

seals from freezing to the frames and tearing.

!

WARNING

Fan Assembly

Servi c e

# MO.XXXXXXX

XXXXXXX

Screws

Speed-Nut

Fan Blade

Airflow

Direction

Bracket

Plenum

Motor

Page 30

RLT ONLY

For access to these fans:

1. Turn off power.

2. Remove bottom display pans.

3. Disconnect fan from wiring harness.

4. Remove fan blade.

5. Lift fan plenum and remove screws holding

bottom of motor to fan basket.

6. Replace fan motor and blade.

7. Lower fan plenum.

8. Reconnect fan to wiring harness.

9. Turn on power.

10. Verify that motor is working and blade is

turning in the correct direction.

11. Close air gaps under fan plenum. Warmer air

moving into refrigerated air reduces effective

cooling. If the plenum does not rest against

the case bottom without gaps, apply foam

tape to the bottom of the fan plenum to

reduce improper air movement. Use silicone

sealant to close other gaps.

12. Replace display pans. Bring merchandiser to

operating temperature before restocking.

6-2 SERVICE

P/N 0387183_D WWW

.HUSSMANN.COM

Always disconnect the electrical power at

the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

Motor

Lock Nut

Tool

Nut

Fan Blade

Gasket

Bracket

!

Screws

Tape

Motor

WARNING

Page 31

REPLACING ELECTRIC DEFROST

HEATERS (RL / RLN / RLNI / RLNIE

Only)

Electric defrost requires a heater on the front

and rear of the coil as shown. The heaters are

held in place by tabs in the coil brackets.

Front Defrost Heater

1. Disconnect Power.

2. Lift fan plenum up and back to access the

heater.

3. Bend tabs holding heater to horizontal.

4. Remove heater from coil bracket.

5. Position new heater in bracket.

6. Bend tabs back to vertical to hold heater in

bracket.

7. Replace the coil cover and lower fan plenum.

8. Turn on power.

9. Verify that heater is working correctly.

10. Close air gaps under fan plenum. Warmer air

moving into refrigerated air reduces effective

cooling. If the plenum does not rest against

the case bottom without gaps, apply foam

tape to the bottom of the fan plenum to

reduce improper air movement. Use silicone

sealant to close other gaps.

11. Replace display pans. Bring merchandiser to

operating temperature before restocking.

Rear Defrost Heater

1. Disconnect Power.

2. Remove coil cover.

3. Remove clips holding heater to coil tube.

4. Remove heater from slots in coil bracket.

5. Position new heater in slots.

6. Replace clips.

7. Replace the coil cover.

8. Turn on power.

9. Verify that heater is working correctly.

10. Replace display pans. Bring merchandiser to

operating temperature before restocking.

Reach-In

P/N 0387183_D 6-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Electric Defrost

Bend Tabs

on Each

Bracket

to Release

or Secure

Heaters

Page 32

REPLACING ELECTRIC DEFROST

HEATERS (RLT Only)

RLT electric defrost heaters are located under

the coil as shown in the photo below. Mounting

brackets and supports are attached to plenum

brackets.

1. Disconnect Power.

2. Remove lower back panels to access the

heater.

3. Lift fan plenum up and back to access the

heater.

4. Remove heater from bracket.

5. Position new heater in bracket.

6. Close the bracket with the element support

7. Turn on power.

8. Verify that heater is working correctly.

6-4 SERVICE

P/N 0387183_D WWW

.HUSSMANN.COM

RLT Defrost Heater Location

Defrost Heater

Heating Element Support

LH Plenum Mounting Bracket

This view shows one bracket assembly, typical on 2-door case;

two assemblies are used on 3-door case,

three on 4-door, four on 5-door case.

RLT Defrost Heater

RH Plenum Mounting Bracket

Heating Element Support

Page 33

REPLACING DRAIN PAN HEATER —

ELECTRIC AND GAS DEFROST

(Low Temperature Only )

The drain pan heater is located as shown

below.

Remove Drain Pan Heater

1. Disconnect power.

2. Pull heater out from under jiffy clips.

3. Position new heater under jiffy clips. Be

sure offset is properly positioned around

the drain. If jiffy clips are removed, make

certain sealer is replaced.

4. Reconnect power.

5. Verify that heater is working correctly.

Reach-In

P/N 0387183_D 6-5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Drain Heater

Sealer

Screw

Jiffy Clip

Detail

Drain Heater Offset

Jiffy Clip

Drain

Heater

Sealer

Screw

Jiffy Clip

Side View

Always disconnect the electrical power at

the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

!

WARNING

Page 34

RLT with GAS DEFROST ONLY: REPLACING SECONDARY PLATE HEATER

The secondary plate heater is located as

shown below.

Remove Secondary Plate Heater

1. Disconnect power.

2. Pull heater out from under jiffy clips.

3. Position new heater under jiffy clips. Be sure

offset is properly positioned around the

drain. If jiffy clips are removed, make cer-

tain sealer is replaced.

4. Reconnect power.

5. Verify that heater is working correctly.

6-6 SERVICE

P/N 0387183_D WWW

.HUSSMANN.COM

Always disconnect the electrical power at

the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

Rear Secondary

Plate and Heater

Front

Secondary

Plate and

Heater

Interlock

Plates

Strap together

and Attach to

Harness

Together

Slide Rod Heater

Under Tabs.

Lightly Press

Down on Tabs.

!

WARNING

Page 35

REPLACING LAMP BALLAST

(O

THER THAN RLT MODELS)

The lamp ballasts are located in the electrical

raceway, in the left-hand end of the merchandiser.

To gain access:

1. Disconnect the electrical power to the light

fixture.

2. Remove the front panel.

A. Pull off the bumper.

B. Remove screws from bumper retainer.

NOTE: The front panel is attached by

(2) screws (two-door),

(3) screws (three -door),

(4) screws (four-door),

(5) screws (five door), to the front panel

C. Lift the front panel up and out from the

front of the case. Tabs on front panel must

clear slots on bumper retainer.

3. Service or replace ballasts as required.

4. Reinstall front panel by sliding it into bumper

retainer slots, then reinstall screws.

5. Install bumper.

6. Restore power to merchandiser.

Reach-In

P/N 0387183_D 6-7

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Bumper

Lift-up on

Front

Panel

Screws

Raceway

Area

Ballas

Bumper

Retainer

Ballasts

Page 36

REPLACING RLT LAMP BALLAST

The lamp ballasts are located in the electrical

raceway, in the left-hand end of the merchandiser.

To gain access:

1. Disconnect the electrical power to the light

fixture.

2. Remove the front panel. Lift the front panel

up and out from the front of the case.

3. Service or replace ballasts as required.

4. Reinstall front panel

5. Restore power to merchandiser.

6-8 SERVICE

P/N 0387183_D WWW

.HUSSMANN.COM

RLT Wiring Routed Up Through Top Panel to

Wireway on Top

Always disconnect the electrical power at

the main disconnect when servicing or

replacing any electrical component. This

includes, but is not limited to, such items

as fans, heaters, thermostats and lights.

Hussmann recommends against frame heater

cycling with

Innovator

doors to prevent door

seals from freezing to the frames and tearing.

Door Frame and Door Heater

Wiring Routed Through

Ballast Tray into Wireway

Field

Connection

Knock-outs

Wireway Cover

Wireway

Top Foam

Assembly

Fan and Heater Wiring

Routed Through Top Foam Assembly

Ballast

Tray

Door Frame

Assembly

!

WARNING

Page 37

SERVICING VERTICAL LIGHTING

Refer to door manufacturer’s manual for servicing of vertical lamps.

SERVICING DOORS AND FRAMES

See door manufacturer’s service manual for

servicing information. One manual is shipped

with each merchandiser.

REPLACING DOOR OR DOOR FRAME PARTS

Parts for Reach-in doors and door frame

assemblies must be ordered direct from the door

manufacturer This includes the glass doors, door

frame assemblies, lamps, ballasts, door handles,

hold open slides, and power cords.

Refer to specific warranty supplied with the

door. The manufacturers have a warranty

against moisture penetration, a warranty against

tempered glass breakage, and a warranty on

ballasts. Lamps are not covered by Hussmann

or the door manufacturer.

REPLACING DAMAGED DRAIN FITTING

The following procedure is for the field repair of

a broken drain fitting.

1. Use a drill with a 1

7

/8-inch (48 mm) hole saw

to drill out the bottom of the drain fitting. Be sure

to drill completely through fitting and bottom

liner.

2. Apply teflon tape to threaded end of adapter

and screw into threaded end of tee.

3. Apply an ABS and PVC compatible primer

and sealer to adapter and inside of drain. Insert

adapter into drain fitting.

Reach-In

P/N 0387183_D 6-9

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Drain Fitting Viewed from Inside Case

End Section View

Foam Bottom

Assembly

Modified

Drain Fitting

PVC Adapter

1

1

/2 x 11/4 in.

(38 x 32 mm)

(obtained at local

building supply store)

Tee

1

1

/4 in. TxSxS

(32 mm)

Page 38

REPAIRING ALUMINUM COIL

The aluminum coils used in Hussmann merchandisers may be easily repaired in the field.

Materials are available from local refrigeration

wholesalers.

Hussmann recommends the following solders and

technique:

Solders

Aladdin Welding Products Inc.

P.O. Box 7188

1300 Burton St.

Grand Rapids, MI 49507

Phone: 1-800-645-3413

Fax: 1-800-645-3414

X-Ergon

1570 E. Northgate

P.O. Box 2102

Irving, TX 75062

Phone: 1-800-527-9916

NOTE:

Hussmann Aluminum melts at 1125°F (607°C)

Aladdin 3-in-1 rod at 732°F (389°C)

X-Ergon Acid core at 455°F (235°C)

Technique:

1. Locate Leak.

2. REMOVE ALL PRESSURE.

3. Brush area UNDER HEAT.

4. Use PRESTOLITE TORCH ONLY.

Number 6 tip.

5. Maintain separate set of stainless steel

brushes and USE ONLY ON ALUMINUM.

6. Tin surface around area.

7. Brush tinned surface UNDER HEAT,

thoroughly filling the open pores around leak.

8. Repair leak. Let aluminum melt solder, NOT

the torch.

9. Don't repair for looks. Go for thickness.

10. Perform a leak check.

11. Wash with water.

12. Cover with a good flexible sealant.

6-10 SERVICE

P/N 0387183_D WWW

.HUSSMANN.COM

Page 39

To obtain warranty information

or other support, contact your

Hussmann representative.

Please include the model and

serial number of the product.

Hussmann Corporation, Corporate Headquarters: Bridgeton, Missouri, U.S.A. 63044-2483 01 July 2005

®

Page 40

Loading...

Loading...