Page 1

P/N 374511B

March, 1997

Page 2

P/N 374511B

PROTOCOL

™

Hand Held Device

TABLE OF CONTENTS

Key Pad Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Select Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Protocol™ Main Menus . . . . . . . . . . . . . . . . . . . . . . . .4

Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Defrost Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Alarm Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483 USA • (314) 291-2000 •FAX (314) 298-6485

Page 3

P/N 374511B

Page 1

PROTOCOL

™

Hand Held Device

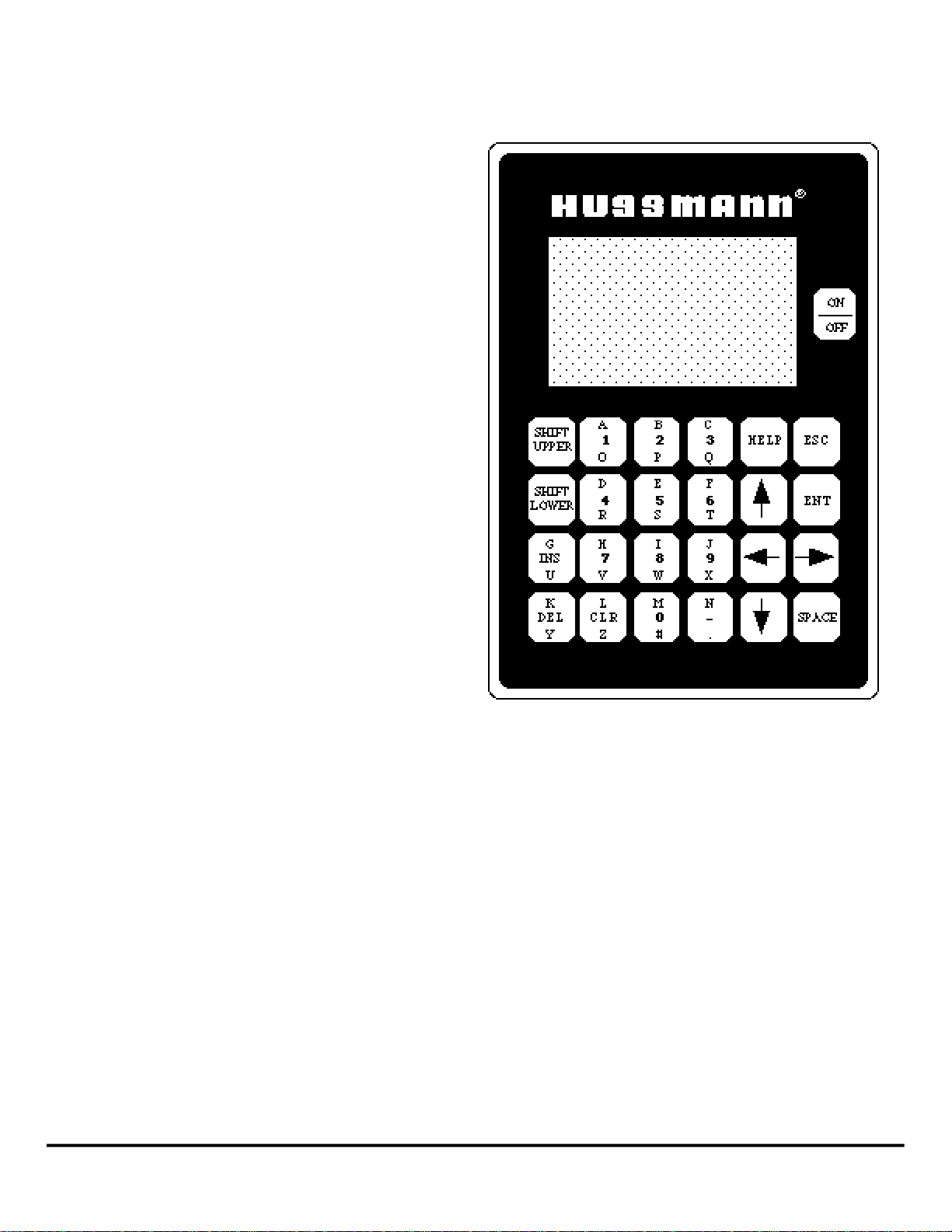

KEY PAD INSTRUCTIONS

Shift Upper – This key is used to key in the top

(red) letters.

Shift Lower – This key is used to key in the

bottom (blue) letters.

NOTE: If either of the above keys is pressed

accidentally, simply press it again to deactivate

it.

INS & DEL – The screen will prompt you

when you need to use these keys.

CLR – Clears last entry

Help – There are no help screens on the current

software.

ESC – Escape; returns you to the previous

menu.

ENT – Enter; you will be prompted as to when

to use this key.

Space – enters a space between letters.

Arrows – These keys move the cursor in the

direction shown. The Right Arrow key is also

used to toggle between functions such as

enable/disable and press/temp.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 4

P/N 374511B

Page 2

PROTOCOL

™

Hand Held Device

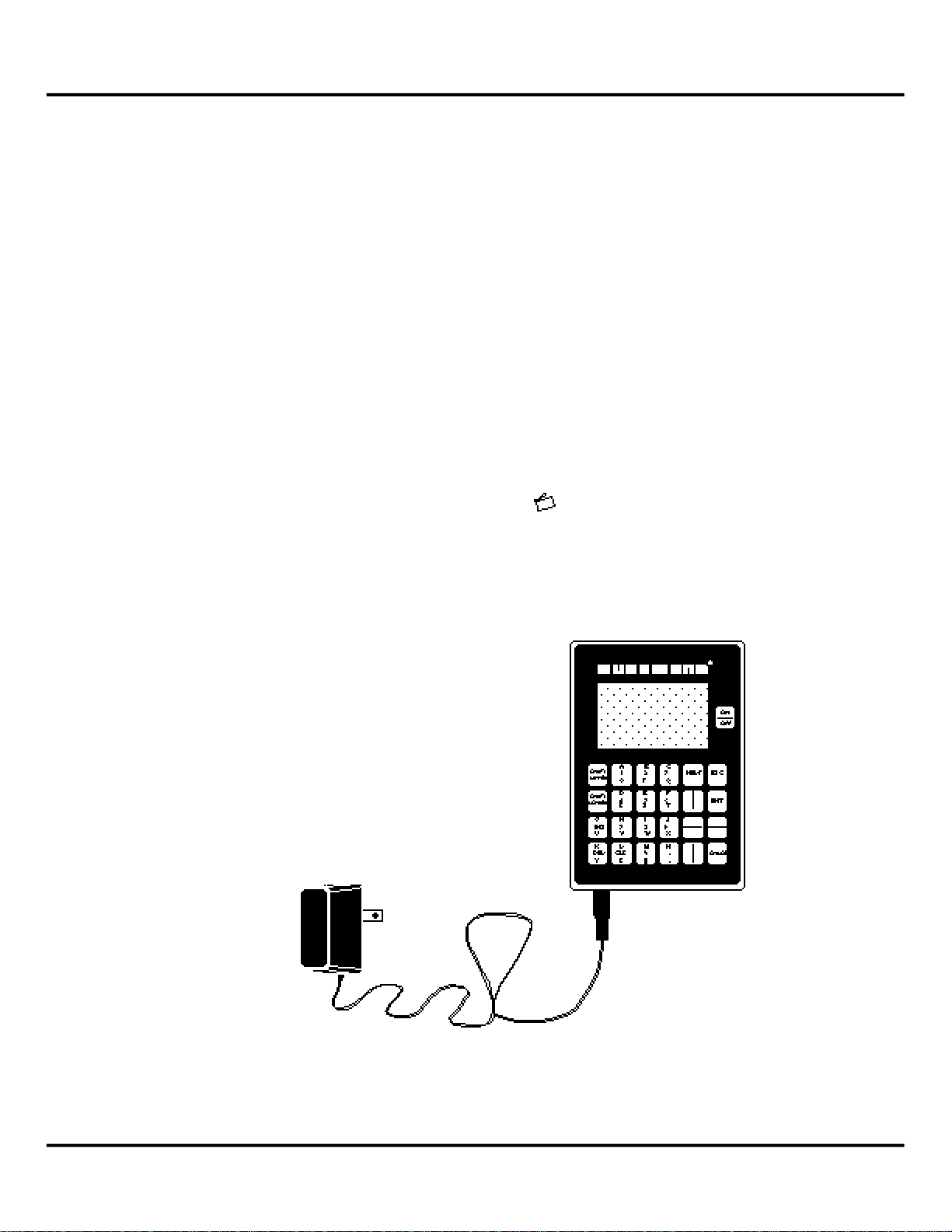

The Hussmann Interface Module may be operated

from either battery power or from a 120V/12VDC

transformer. When using the transformer, connect

Module before plugging in the transformer. The

startup screen will automatically appear.

HUSSMANN

INTERFACE MODULE

(C) 1991 HUSSMANN

CORPORATION

VER 1.30

When battery operated, the Module will shut down

if the key pad has not been used for three minutes.

When a transformer is used, the hand held module

will beep and remain on.

If the battery is too weak to function, the menu

screen will become faint or not come up at all. If

the battery is completely without power, the hand

held module will beep and show an alarm

message. There is also a Low Battery message

that appears at the Main Menu for Protocol™.

Regardless of the power source, if Protocol™ is

not communicating with the hand held module, a

beep will sound and a

appear. If the Protocol™ system is without power,

the hand held module will beep and show an

ALARM message.

COMM ERROR message will

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 5

P/N 374511B

Page 3

PROTOCOL

™

Hand Held Device

SELECT EQU I P M E N T

1 - P ROTO C O L

2-CASE CONTRO L

3-PUMPING STAT I O N

4-FLUID COOLER

P ROTOCOL MAIN MENU

1 - S TATUS MENU

2-CONFIG MENU

3 - D E F ROST MENU

4-MAINT MENU

5-ALARM MENU

L OW BAT T E RY

Following the startup screen, the

SELECT EQUIPMENT screen will appear.

SELECT EQUIPMENT

1-PROTOCOL

2-CASE CONTROL

3-PUMPING STATION

4-FLUID COOLER

Press 1 on the key pad.

The PROTOCOL™ MAIN MENU will appear. This

screen has 5 submenus each of which has its own

submenu(s), see page 4.

Any time a numbered list appears on the menu

screen, pressing the key pad number will take you

to that submenu or function.

Notes:

1) If Case Control is accidentally selected, the

only way to escape is to disconnect power to the

Interface Module.

2) Neither Pumping Station nor Fluid Cooler

information is contained in this manual.

3) L

OW BATTERY appears only if battery voltage

is below normal levels

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 6

P/N 374511B

Page 4

PROTOCOL

™

Hand Held Device

P ROTOCOL MAIN MENU

( _ _) = P

A G E N U M B E RF O RM O R E I N F O R M AT I O N

1- STATUS MENU (07) MAIN STATUS MENU

2- CONFIG MENU (10) CONFIG MENU 1-PRESSURES (07)

3- DEFROST MENU (23) DEFROST MENU 2 - D E F R O S T / T E M PC K T ( 0 8 )

4- MAINT MENU (28) MAINT MENU 1 - S E T THE CLOCK (10) 3 - T E M P E R ATURE MENU (09)

5- ALARM MENU (30) 1 - V I E W / S E T ITEMS (23) 2-SENSOR SETUP ( 11 ) 4 - C O M P RUN METERS (09)

1-FORCE A C O M P O N 2 - C O P Y SCHEDULE (25) 3 - P R O TO C O LS E T U P( 1 5 )

ALARM MENU 2-CLEAR FORCE FLAG 3-ASSIGN OUTPUTS (26) 4-COMM SETUP ( 2 0 ) PRESSURE STAT U S

3-FORCE A C O M P O F F *4-ASSIGN CIRCUITS 5 - L I G H TC O N T R O L( 2 1 ) P 1 P 2

A01- LO SUCTION PRESS 4-FORCE A DEFR ON FOR SPLIT S U C T( 2 7 ) 6 - T E M PC O N T R O L( 2 2 ) S U C T I O N 4 2 0

TIME 01:56 01/21 5-FORCE A DEFR OFF S E T P O I N T 4 0 0

END OF A L A R M S PRESS ENT FOR MORE #COMPS - 1 2 3 4 5 6

6-CLEAR RUN METER ON (X) X X X X

7-FORCE LIGHT O N *This item only appears when unit is configured

8-FORCE LIGHT O F F for split suction option. T E M P E R ATURE STAT U S

**9-CLEAR ALM TA B L E ( F ) S P

* * 0 - R E S E TC O N T R O L T 1 - 4 0 0

T 2 - 4 0 0

T 3 - 4 0 0

* * These options only available with Software Version 2.30 or greater. PRESS ENT FOR MORE

Protocol Control must also be V1.30 or greater T E M P E R ATURE STATUS (CONT)

( F ) S P

T 4 0 0

T 5 0 0

T 6 0 0

T E M P / CIRCUIT #1 T 7 0 0

NAME – CIRCUIT #1 NAME T 8 0 0

S TATUS – REFR

T E M PC T R L – ENABLED A U X I L I A RY S TATUS (EXPA N D E D )

(F) SETPT A7 - 0

AUX #1 22 20 A8 - 0

REFRIG: ON REF 18 A9 - 0

A10 - 0

A 11 - 0

A12 - 0

COMPRESSOR RUN METER

C O M P 1 5 6 H O U R S

C O M P 2 5 7 H O U R S

C O M P 3 5 6 H O U R S

C O M P 4 5 3 H O U R S

C O M P 5 0 H O U R S

C O M P 6 0 H O U R S

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 7

P/N 374511B

Page 5

PROTOCOL

™

Hand Held Device

CONFIG MENU

( _ _) = P

A G EN U M B E R F O RM O R E I N F O R M AT I O N

1- SET THE CLOCK (10) CLOCK SETUP M E N U

2- SENSOR SETUP ( 11 ) SENSOR SETUP M E N U

3- PROTO C O LS E T U P( 1 5 ) P R O TO C O LS E T U PM E N U T I M E - 2 2 : 2 3

4- COMM SETUP ( 2 0 ) COMM SETUP M E N U 1-PRESSURE # 1 (11 ) D AT E - 0 2 : 2 3

5- LIGHT C O N T R O L( 2 1 ) 1-REFR SETUP ( 1 5 ) 2-PRESSURE #2 (12) Y E A R - 9 6

6 - T E M PC O N T R O L( 2 2 ) S TATION NUMBER - 99 2-DEFR SETUP ( 1 8 ) 3 - T E M P # 1 (13) D AY L I G H T- E N A B L E D

BAUD RATE - 19200 3-DESCRIPTION (19) 4 - T E M P # 2 (13) S P R I N G - 02:00 04/27

4-ALARM OUTPUT ( 1 9 ) 5 - T E M P # 3 (13) FA L L - 02:00 10/28

T E M P E R ATURE CONTROL

1-REFR CIRCUIT #1 (22) 1 - T E M P # 4 (13)

2-REFR CIRCUIT #2 (22) LIGHT MENU 2 - T E M P # 5 (13)

3-REFR CIRCUIT #3 (22) 1 - C I R C U I T #1 (21) ALARM OUTPUT 3 - T E M P # 6 (13)

4-REFR CIRCUIT #4 (22) 2 - C I R C U I T #2 (21) O U T P U T NUMBER - X 4 - T E M P # 7 (13)

5-REFR CIRCUIT #5 (22) 5 - T E M P # 8 (13)

6-REFR CIRCUIT #6 (22) LIGHT CIRCUIT #1 6-AUX SENSORS (14)

7-REFR CIRCUIT #7 (22) S TAT U S - E N A B L E D

8-REFR CIRCUIT #8 (22) S TAT U S - E N A B L E D

N A M E - CASE LT S D E S C R I P T I O N CONFIG - REFRIGERAT I O N

REFR CIRCUIT #1 ON T I M E - 0 4 : 0 0 NAME – PROTO C O LN A M E COMPS (TO TAL) - 4

T E M PC N T L - E N A B L E D OFF T I M E - 2 2 : 0 0 CYCLING - ROUND ROBIN

S E T P O I N T - 15 F O U T P U T - 0 8 SUCTION SP - 15 PSI

R AT E - 3 F S P L I T SUCTION - DISABLED

O U T P U TR E L AY - 1 CONFIG DEFROST # COMPRS - 0

# OF CIRCUITS - 3 S P L I TS P - 0 PSI

INTERLOCK - DISABLED

D R I P CYCLE - 0 S AT C O N T R O L - D I S A B L E D

S AT S E T P T - 0 F

S AT D I F F - 0 F

C O N T R O L - T E M P

SPR CONTROL - D I S A B L E D

SPR SP - 0 F

M I X M ATCH SETUP

C O M P R E S S O R S

S T E P 1 2 3 4

1 - 0 1 = X 0 0 0

2 - 0 3 = X X 0 0

3 - 0 6 = 0 X X 0

4 - 1 4 = 0 X X X

:

:

1 6 - 0 0 = 0 0 0

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 8

P/N 374511B

Page 6

PROTOCOL

™

Hand Held Device

DEFROST MENU

( _ _) = P

A G EN U M B E R F O RM O R EI N F O R M AT I O N

1- VIEW/SET ITEMS (23) DEFROST MENU DEFROST CIRCUIT #X

2- COPY SCHEDULE (25)

3- ASSIGN OUTPUTS (26) DEFROST BOARD #1 C I R C U I T N A M E S TAT U S T Y P E O F T I M

*4-ASSIGN CIRCUITS O U T P U T C I R C U I T 1 C I R C U I T #1 NAME D E F R N U M B E R 0 3

FOR SPLIT S U C T( 2 7 ) 1 1 2 C I R C U I T #2 NAME R E F R L E N G T H 1 5

2 2 3 C I R C U I T #3 NAME D AT V S TA RT 0 0 : 0 0

SUCTION A S S I G N M E N T ( 2 7 ) 3 3 4 C I R C U I T #4 NAME N / A A M P E R A G E 0 0

C I R C U I T S U C T I O N 4 4 5 C I R C U I T #5 NAME N / A

1 01 6 C I R C U I T #6 NAME N / A DEFR T E R M E N A B L E D

2 01 DEFROST BOARD #2 7 C I R C U I T #7 NAME N / A 2ND DEFR 0 8 : 1 5

3 01 O U T P U T C I R C U I T 8 C I R C U I T #8 NAME N / A 3RD DEFR 1 6 : 0 0

4 01 5 5

5 01 6 6

6 01 7 7

7 01 8 8 C O P Y DEFROST SCHEDULE

8 01

E X PANSION BOARD C O P Y FROM CIRCUIT - 00

O U T P U T C I R C U I T C O P Y TO CIRCUIT - -

9 0 0

1 0 0 0

11 0 0

1 2 0 0

E X PANSION BOARD DEFROST BOARD #3 DEFROST BOARD #4

O U T P U T C I R C U I T O U T P U T C I R C U I T O U T P U T C I R C U I T

1 3 0 0 1 7 0 0 2 1 0 0

1 4 0 0 1 8 0 0 2 2 0 0

1 5 0 0 1 9 0 0 2 3 0 0

1 6 0 0 2 0 0 0 2 4 0 0

*This item only appears when unit is configured for split suction option.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 9

P/N 374511B

Page 7

PROTOCOL

™

Hand Held Device

1

2

3

4

5

6

1 2 3 4 5 6

P ROTOCOL MAIN MENU

1 - S TATUS MENU

2-CONFIG MENU

3 - D E F ROST MENU

4-MAINT MENU

5-ALARM MENU

S TATUS MENU

1 - P R E S S U R E S

2 - D E F ROST / TEMP CKT

3 - T E M P E R AT U R E S

4-COMPR RUN METER

PRESSURE STAT U S

P1 P2

SUCTION 0 0

SETPOINT 0 0

# COMPS - 1 2 3 4

ON(X) X X

PRESS ENT FOR MORE

STATUS MENU

1-STATUS MENU

This is a read only menu. It gives you current

operating conditions.

P1 gives the present pressure for the suction manifold.

P2 gives the second suction pressure input.*

Press ESC Key.

SETPOINT is the Suction Set Point for the control

board. The board turns compressors ON and OFF

to maintain this suction pressure.

# COMPS - 1 2 3 4

ON(X) X X

lists the compressor numbers, and indicates

which are running.

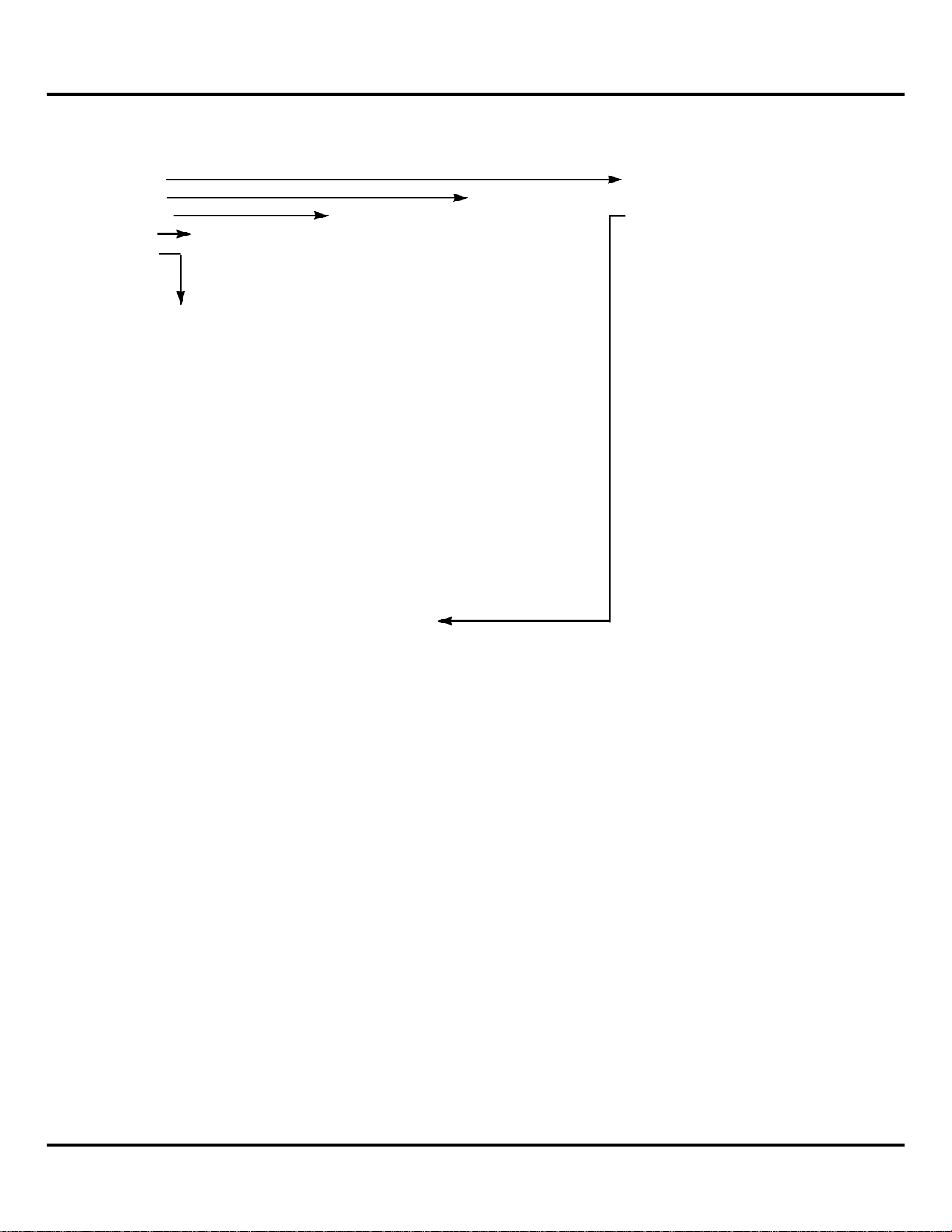

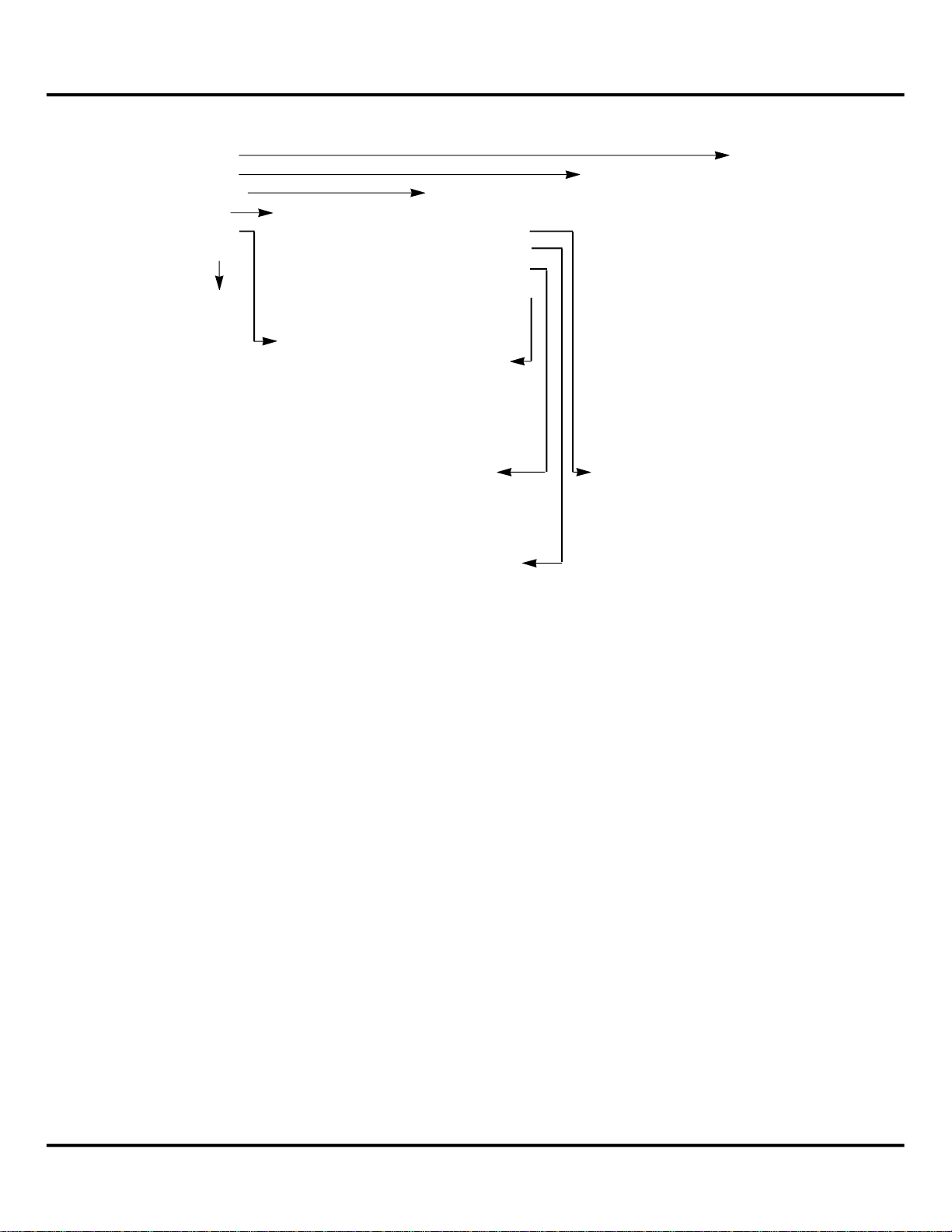

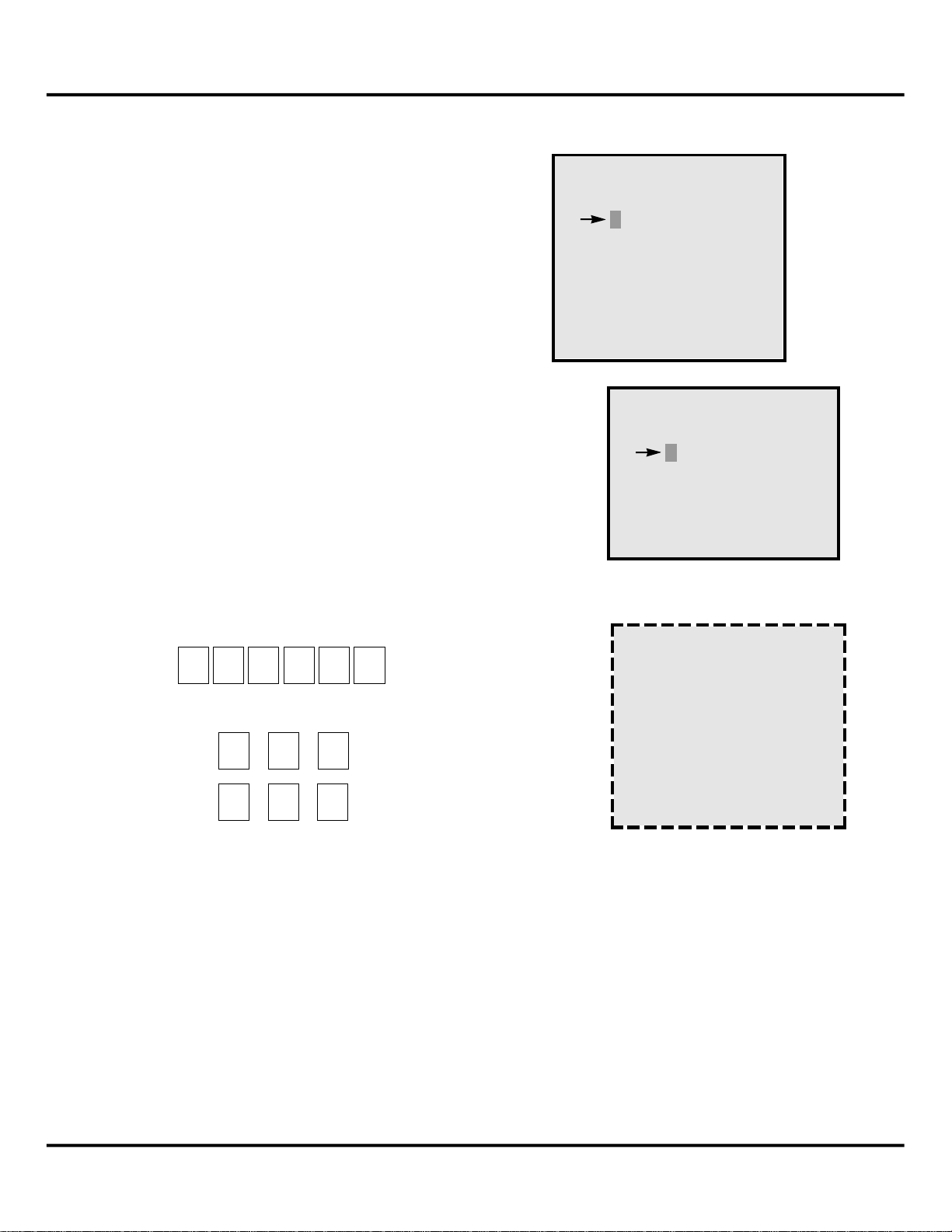

Note: Compressors are configured as follows:

Horizontal Protocols

Vertical Protocols

*When Split Suction is installed or when Satellite

compressor is controlled by pressure, P2 can also

be used to monitor high side discharge pressures.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 10

P/N 374511B

Page 8

PROTOCOL

™

Hand Held Device

S TATUS MENU

1 - P R E S S U R E S

2 - D E F ROST / TEMP CKT

3 - T E M P E R AT U R E S

4-COMPR RUN METER

TEMP CIRCUIT #1

N A M E – CIRCUIT #1 NAME

S TAT U S – R E F R

TEMP CTRL – E N A B L E D

( F ) S E T P O I N T

AUX #1 2 2 20

REFRG – ON REF 7

STATUS MENU (Continued)

2-DEFROST / TEMPCKT

This is a read-only menu. This screen shows the

current operational status of Defrost Circuits and

associated temperatures as provided by Auxiliary

inputs.

NAME gives a description of the case loads for this

defrost circuit.

STATUS indicates whether the defrost circuit is in

defrost (DEFR), refrigeration (REFR), or a

Manually Forced condition (F-DEFR, F-REFR).

T

EMP-CTRL indicates whether temperature control

is available for this circuit. This control feature

allows the refrigeration solenoid to be operated ON

and OFF to maintain a temperature setpoint.

AUX #X provides the actual temperature reading

of the circuit. Note that X will be a number

between 1 and 8 depending upon the Temp/Circuit

number you are currently accessing.

REFRIG is the status of the defrost/refrigeration

relay. ON indicates that power is being fed to the

solenoid. OFF indicates that the solenoid is deenergized.

R

EF is an internal setpoint used by the Temp

Control algorithm. This number will increase up /

decrease down dependent upon the relationship of

the temperature reading (AUX #) and the circuit

setpoint.

Press ENT to view additional circuit information.

Note: Temperature Control is available on Hand

Held Devices V2.40 or greater.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 11

P/N 374511B

Page 9

PROTOCOL

™

Hand Held Device

AU X I L I A RY MENU

A7 - O P E N

A8 - C L O S E D

A9 - O P E N

A10 - - 40

A11 - 6 0

A12 - - 40

COMPRESSOR RUN METER

C O M P 1 5 6 H O U R S

C O M P 2 5 7 H O U R S

C O M P 3 5 6 H O U R S

C O M P 4 5 5 H O U R S

C O M P 5 0 H O U R S

C O M P 6 0 H O U R S

T E M P E R ATURE MENU

F S P

T1 - - 40 0

T2 - - 40 0

T3 - - 40 0

PRESS ENT FOR MORE

T E M P E R ATURE MENU

F S P

T4 - 0 0

T5 - 0 0

T6 - 0 0

T7 - 0 0

T 8 0 0

PRESS ENT FOR MORE

STATUS MENU (Continued)

3-TEMPERATURE MENU

T1 temperature reading for suction pressure reset

or optional temperature input.

T2 temperature reading for satellite or optional

temperature input.

T3 If split suction is installed, T3 may be factory

set to read head pressure instead of temperature.

Screen will show T3- ___PSI.

If split suction is not installed, T3 is a designated

temperature input; but if you prefer, it can be configured as a pressure input (See page12).

Press ESC Key.

A7

thru

A 1 2

are additional temperature inputs.

These readings may be established by the user as

either ANALOG or DIGITAL under the CONFIGURATION MENU. When set on DIGITAL the read

out will be either OPEN or CLOSED. The digital

setting is applicable to thermostats or auxiliary

contactors.

When the ANALOG setting is used a thermistor is

used to retrieve temperature readings between – 40

and + 120˚F.

When not used the menu will read

DIGITAL. Set on ANALOG, an unused input will

OPEN if set on

produce a – 40.

Press ESC Key.

4-COMPRESSOR RUN METER

COMPRESSOR RUN METER submenu appears.

This menu shows the total number of hours that

each compressor has been operating.

Press ESC to return to S

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

TATUS MENU.

Page 12

P/N 374511B

Page 10

PROTOCOL

™

Hand Held Device

P ROTOCOL MAIN MENU

1 - S TATUS MENU

2-CONFIG MENU

3 - D E F ROST MENU

4-MAINT MENU

5-ALARM MENU

CONFIG MENU

1-SET THE CLOCK

2-SENSOR SETUP

3 - P ROTOCOL SETUP

4-COMM SETUP

5-LIGHT CONTRO L

6-TEMP CONTRO L

CLOCK SETUP MENU

T I M E – 22: 2 3

DAT E – 0 1/ 02

Y E A R – 9 6

DAY L I G H T – E N A B L E D

S P R I N G – 02:00 04/28

FA L L – 02:00 10/27

CONFIG MENU

2-CONFIG MENU

This set of menus is used to make changes in the

Protocol’s configuration. Press 2 on the Keypad

to enter the CONFIG submenu.

1- SET THE CLOCK

Press 1 on the Keypad to enter the CLOCK SETUP

submenu. This screen has 5 fields used to set the

correct time/date.

Hour

2 2

(24-hr clock only)

Minute

Month date

Day date

2 3

0 1

0 2

Year date

9 6

(Last two digits only)

The screen appears with the cursor indicating the

hour field.

22

CURSOR

Press the CLR button. This will change the field

to 00. Then input the correct hour and press ENT.

The cursor will move to the next field. Repeat the

process through each field.

Press ESC to return to the CONFIG MENU.

When enabled, the DAYLIGHT function will auto-

matically adjust the time and year (in case of leap

years) corresponding to changes in TIME and DATE.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 13

P/N 374511B

Page 11

PROTOCOL

™

Hand Held Device

PRESSURE #1

HI ALARM 40 PSI

LO ALARM 20 PSI

XDCR RANGE - 100 PSI

OFFSET 0 PSI

CONFIG MENU

1-SET THE CLOCK

2-SENSOR SETUP

3 - P ROTOCOL SETUP

4-COMM SETUP

5-LIGHT CONTRO L

6-TEMP CONTRO L

SENSOR SETUP MENU

1-PRESSURE #1

2-PRESSURE #2

3-TEMP #1

4-TEMP #2

5-TEMP #3

CONFIG MENU (continued)

2- SENSOR SETUP

Press 2 on the Keypad to enter the Sensor Setup

Submenu. This screen has 6 menus.

1- PRESSURE #1

Press 1 on the Keypad to enter the Pressure #1

Submenu.

PRESSURE #1 controls the suction pressure for

the Protocol Control. Press the CLR key. Key in

the applicable suction pressure in psig for

ALARM and press ENT. Repeat for LO ALARM.

HI

Pressure Transducers are supplied in one of three

ranges:

0 to 100

0 to 200

0 to 500

Using the key, toggle to the range of the transducer used. Press ENT.

O ffset allows manual calibration for the pressure

t r a n s d u c e r. Manual calibration is achieved by

entering a number between -5 and +5. This number

will then be used to offset the pressure reading by

the entered amount.

WA R N I N G: Impro p e r calibration of the

t r a n s d u c e r could lead to unpre d i c t a b l e

operation of the control. Verify the accuracy of the transducer reading with a

minimum of two gauges.

N o t e : Manual calibration is available on Hand

Held version V2.40 or greater.

Press ESC to return to S

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

E N S O R SE T U P ME N U.

Page 14

P/N 374511B

Page 12

PROTOCOL

™

Hand Held Device

PRESSURE #2

HI ALARM 0 PSI

LO ALARM 0 PSI

XDCR RANGE - 100 PSI

ALARM ENABLED

OFFSET 0 PSI

SENSOR SETUP MENU

1-PRESSURE #1

2-PRESSURE #2

3-TEMP #1

4-TEMP #2

5-TEMP #3

CONFIG MENU (continued)

2- PRESSURE #2

Press 2 on the Keypad to enter the Pressure #2

Submenu.

PRESSURE #2 controls the suction pressure or

Split Suction on the Protocol Control. Press the

C L R k e y. Key in the applicable suction pressure in psig for

Repeat for

L O A L A R M.

H I A L A R M and press E N T.

Pressure Transducers are supplied in one of three

ranges:

0 to 100

0 to 200

0 to 500

Using the key, toggle to the range of the transducer used. Press ENT.

Using the key, move down to the Alarm status

selection. Using the key, toggle

DISABLED. Press ENT.

ENABLED or

O ffset allows manual calibration for the pressure

t r a n s d u c e r. Manual calibration is achieved by

entering a number between -5 and +5. This number

will then be used to offset the pressure reading by

the entered amount.

WA R N I N G: Impro p e r calibration of the

t r a n s d u c e r could lead to unpre d i c t a b l e

operation of the control. Verify the accuracy of the transducer reading with a

minimum of two gauges.

N o t e : Manual calibration is available on Hand

Held version V2.40 or greater.

Press ESC to return to S

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

E N S O R SE T U P ME N U.

Page 15

P/N 374511B

Page 13

PROTOCOL

™

Hand Held Device

TEMPERATURE # 1

SET PT - XX F

HI ALARM - XX F

LO ALARM - XX F

ALARM - ENABLE

ALM DELAY - 30 MIN

CIRCUIT - X

TEMPERATURE # 2

SET PT - XX F

HI ALARM - XX F

LO ALARM - XX F

ALARM - ENABLE

ALM DELAY - 30 MIN

CIRCUIT - X

TEMPERATURE # 3

INPUT MODE - TEMP

SET PT - XX F

HI ALARM - XX F

LO ALARM - XX F

ALARM - ENABLE

ALM DELAY - 30 MIN

CIRCUIT - X

SENSOR SETUP MENU

1-PRESSURE #1

2-PRESSURE #2

3-TEMP #1

4-TEMP #2

5-TEMP #3

CONFIG MENU (continued)

3- TEMP #1

3 - T E M P # 1

allows you to establish set point

and alarm levels for the first temperature

i n p u t .

Press 3 on the Keypad to enter the TEMP #1

Submenu.

The

ALM DELAY is a programmable time delay.

This sets the time it will take before the control

log’s the alarm.

The CIRCUIT - X allows you to attach a defrost

circuit to the temperature input (or vice versa).

When the circuit is in defrost, the HI ALARM will be

ignored.

Press CLR. Key in your selection and

press ENT.

Using the key, toggle ENABLED or DISABLED.

Press ENT.

Press ESC to return to S

E N S O R SE T U P ME N U.

3

4- TEMP #2

Press 4 on the Keypad to enter the TEMP #2

Submenu. Follow instructions above.

5- TEMP #3

Press 5 on the Keypad to enter the

TEMP #3

Submenu.

If split suction is installed, TEMP #3 may be

f a c t o ry set to read head pressure instead of

temperature. This is accomplished by changing

the input mode to Pressure.

If split suction is not installed, TEMP #3 is a

designated temperature input; but if you prefer it

can be factory set as a pressure input.

Using the key, toggle

TEMP or PRESS. Press

ENT.

Press ESC to return to SE N S O R SE T U P ME N U.

4

5

Note: When using T3 for a pressure reading,

remember to place the hardware switch on the

main control board in the pressure position.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 16

P/N 374511B

Page 14

PROTOCOL

™

Hand Held Device

AUX SENSOR #1

M O D E – D I G I TA L

NAME –

T E R M . S P – C L O S E D

HI ALARM – 0 F

LO ALARM – -40 F

A L A R M – E N A B L E D

SENSOR SETUP MENU

1-TEMP #4

2-TEMP #5

3-TEMP #6

4-TEMP #7

5-TEMP #8

6 - AUX SENSORS

AU X I L I A RY SENSORS

1-AUX SENSOR #1

2-AUX SENSOR #2

3-AUX SENSOR #3

4-AUX SENSOR #4

5-AUX SENSOR #5

6-AUX SENSOR #6

MORE ON NEXT PAGE

AU X I L I A RY SENSORS

1-AUX SENSOR #7

2-AUX SENSOR #8

3-AUX SENSOR #9

4-AUX SENSOR #10

5-AUX SENSOR #11

6-AUX SENSOR #12

CONFIG MENU (continued)

6- AUX SENSORS

Press 6 on the Keypad to enter the Auxiliary

Sensors Submenu.

AUXILIARY SENSORSprovide six temperature

inputs—analog or digital.

Analog for thermistors

Digital for thermostats.

ANALOG SETTING

A N A L O G accommodates temperature readings

between – 40 and + 120˚F. Set on

ANALOG, an

unused input will produce a – 40.

DIGITALSETTING

When set on

OPEN (not in use) or CLOSED.

DIGITAL the read out will be either

Use the key to toggle between ANALOG and

DIGITAL.

Using the ENT key, move down the selections.

Press CLR. Key in your selection and press ENT.

The cursor will move down to the next sensor.

Press ESC to return to AUXILIARY SENSORS MENU.

Press ESC again to return to SENSOR SETUP MENU.

Press ESC again to return to CONFIG MENU.

Note: Aux Sensors 7 through 12 are available

only on Expansion Module.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 17

P/N 374511B

Page 15

PROTOCOL

™

Hand Held Device

P ROTOCOL SETUP

1-REFR SETUP

2-DEFR SETUP

3 - D E S C R I P T I O N

4-ALARM OUTPUT

C O N F I G - R E F R I G E R AT I O N

COMPS (TOTAL) – 4

CYCLING – ROUND ROBIN

SUCTION SP – 30 PSI

SPLIT SUCT – ENABLED

# COMPRS – 0

SPLIT SP – 0 PSI

C O N F I G - R E F R I G E R AT I O N

SAT CONTROL – DISABLED

SAT SETPT – 0 F

SAT DIFF – 0 F

CONTROL – TEMP

SPR CONTROL – DISABLED

SPR SP – 0 F

CONFIG MENU

1-SET THE CLOCK

2-SENSOR SETUP

3 - P ROTOCOL SETUP

4-COMM SETUP

5-LIGHT CONTRO L

6-TEMP CONTRO L

CONFIG MENU (continued)

3- PROTOCOL SETUP

Press 3 on the Keypad to enter the Protocol Setup

Submenu.

1- REFR SETUP

Press 1 on the Keypad to enter the REFR SETUP

submenu.

This screen programs the Control Board for the

refrigeration parameters:

Number of compressors controlled

Compressor Cycling Algorithm*

Suction Pressure Set Point

Split Suction Control—

E

NABLED/DISABLED

Number of compressors controlled

Split Suction Reset Set Point

To change numeric fields, press the CLR key.

Key in the applicable number. Press ENT. Use

the key, toggle between ENABLED/DISABLED.

Press ENT.

Use the down arrow to get to the next screen

which programs the satellite and Suction Pressure

Reset controls.

Satellite Control — E

N A B L E D/ DI S A B L E D

Satellite Set Point

Satellite Differential

Sat. Control Status — TEMP/PRESS**

**When configured for pressure, the P2 input

serves as the connection point for the transducer.

Suction Pressure Reset status —

ENABLED/DISABLED

Suction Pressure Reset Set Point

To change numeric fields, press the CLR key.

Key in the applicable number. Press ENT. Use

the key, toggle between E

NABLED/DISABLED

and TEMP/PRESS. Press ENT.

Press ESC to return to enter the MixMatch Setup.

Press ESC again to return to P

R O TO C O L SE T U P

ME N U.

*Algorithm options are Round Robin or MixMatch.

NO T E:

C O M P S(TO TA L) is the total number of compressors on the

Protocol units

# C O M P R S is the number of compressors (total) assigned to

split suction

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 18

P/N 374511B

Page 16

PROTOCOL

™

Hand Held Device

M I X M ATCH SETUP

C O M P R S S O R S

S E T U P 1 2 3 4

1 – 0 1 – X 0 0 0

2 – 0 2 – 0 X 0 0

3 – 0 3 – 0 0 X 0

4 – 0 4 – 0 0 0 X

CONFIG MENU (continued)

MixMatch compressor cycling is used when compressors of varying horsepowers have been

installed. This algorithm allows the compressor

horse power to be more closely matched with the

evaporator load

There are 16 available steps for MixMatch

cycling. The additional steps are accessible by

pressing the arrow to view additional screens.

Each step can be programmed by entering anumber between 1 and 63 of the step number. The

Hand Held Device will use this number to display

the compressors selected with an ‘X’and those not

selected with a ‘0.’

The number entered and used by the Hand Held

Device is a binary number. The following example

describes the relationship of the number to compressors. Causion: If you have concerns over this

programming, consult Bridgeton Refrigeration

Engineering.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 19

P/N 374511B

Page 17

PROTOCOL

™

Hand Held Device

Mixmatch Programming Worksheet

Compr # 1 2 3 4 5 6 Total

HP 4 4 5 6 Total Column

Column Value 1 2 4 8 16 32 HP Value

1 0 0

2 X 4 1

3 X 5 4

4 X 6 8

5 X X 8 3

6 X X 9 6

7 X 10 10

8 X X 11 12

9 X X X 14 11

10 X X X 15 13

11 X X X X 19 14

12 0

13 0

14 0

15 0

16 0

CONFIG MENU (continued)

MIXMATCH PROGRAMMING EXAMPLE

1. Start by making a column for each compressor.

2. The first row must be all 0’s.

A programming worksheet is available at the back

of this manual.

3. Each row will be a step. Each step should

increase rack capacity by the smallest increase in

capacity possible.

4. Use an X in the column for a compressor being

on, and a 0 in the column for a compressor being

Any unused steps must have a zero inserted for the

numbers to prevent unwanted compressors from

running.

o ff. It may help to write the capacity in horsepower

to the right of each row.

5. For each row, add the value of each column

with an X in it and put it on the right of each row.

These are the numbers you enter in for each step.

6. Adjust the X’s and the 0’x for equal runtime on

each compressor.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 20

P/N 374511B

Page 18

PROTOCOL

™

Hand Held Device

CONFIG - DEFR O S T

# OF CIRCUITS – 7

INTERLOCK – DISABLED

DRIP CYCLE – 0

P ROTOCOL SETUP

1-REFR SETUP

2-DEFR SETUP

3 - D E S C R I P T I O N

4-ALARM OUTPUT

*

CONFIG MENU (continued)

2- DEFR SETUP

Press 2 on the Keypad to enter the Defrost Setup

Submenu.

This screen programs the Control Board for the

defrost parameters:

Number of defrost circuits controlled

Interlock status—

ENABLED/DISABLED

To change numeric fields, press the CLR key.

Key in the applicable number. Press ENT. Use

the key, toggle between E

Press ENT.

Press ESC to return to PROTOCOL SETUP MENU.

Interlock is used when there is only one defrost

circuit programmed into the control. If that one

defrost circuit is electric, all compressors will turn

on during the duration of the defrost. If the single

defrost circuit is gas, the reverse cycle algorithm

will be activated.

NABLED/DISABLED.

*This drip cycle is only used for reverse cycle gas

defrost units.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 21

P/N 374511B

Page 19

PROTOCOL

™

Hand Held Device

CONFIG - DESCRIPTION

NAME -

P ROTOCOL SETUP

1-REFR SETUP

2-DEFR SETUP

3 - D E S C R I P T I O N

4-ALARM OUTPUT

ALARM OUTPUT

OUTPUT NUMBER – X

P ROTOCOL SETUP

1-REFR SETUP

2-DEFR SETUP

3 - D E S C R I P T I O N

4-ALARM OUTPUT

CONFIG MENU (continued)

3- DESCRIPTION

Press 3 on the Keypad to enter the Description

Submenu.

This screen provides for a 16 character description

of the Protocol unit for user identification on

Hussnet™.

Press the CLR key.

Key in the description . Press Shift Upper to use

the red (upper) letters and Shift Lower to use the

blue (lower) letters.

Press ENT.

Press ESC to return to PROTOCOL SETUP MENU.

Press ESC again to return to CONFIG MENU.

4- ALARM OUTPUT

Press 4 on the Keypad to enter the Alarm Output

Submenu.

The alarm output feature allows one of the 24

available outputs to be energized during the

occurance of any alarm (High/Low Pressure,

High/Low Temp, etc.)

The output number refers to a relay which is wired

into the main Protocol Alarm Relay (AR).

Key in the number (between 1 and 24). Make sure

that the output is available and not being used by

another function (defrost, lighting or temperature

control).

Press ENT.

Press ESC to return to PROTOCOL SETUP MENU.

Press ESC again to return to CONFIG MENU.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 22

P/N 374511B

Page 20

PROTOCOL

™

Hand Held Device

COMM SETUP MENU

STATION NUMBER – 00

BAUD RATE – 19200

CONFIG MENU

1-SET THE CLOCK

2-SENSOR SETUP

3 - P ROTOCOL SETUP

4-COMM SETUP

5-LIGHT CONTRO L

6-TEMP CONTRO L

CONFIG MENU (continued)

4- COMM SETUP

Press 4 on the Keypad to enter the Communication

Setup Submenu.

This screen provides for assigning each Protocol a

station number for computer identification on

Hussnet™. It also provides baud rate assignment.

The baud rate is the rate at which a computer can

receive data from Protocol. All Protocols must

have the same baud rate in order to communicate.

A baud rate of 19200 is suggested.

Press the CLR key. Key in the number. Press

ENT.

Press ESC to return to CONFIG MENU.

Note: All baud rates will be the same for all

Protocols in a given store. However, the station

numbers must be different.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 23

P/N 374511B

Page 21

PROTOCOL

™

Hand Held Device

CONFIG MENU

1-SET THE CLOCK

2-SENSOR SETUP

3 - P ROTOCOL SETUP

4-COMM SETUP

5-LIGHT CONTRO L

6-TEMP CONTRO L

LIGHT MENU

1-CIRCUIT #1

2-CIRCUIT #2

LIGHT CIRCUIT #1

S TAT U S – E N A B L E D

N A M E – CASE LT S

O N T I M E – 0 4 : 0 0

O F F T I M E – - 2 2 : 0 0

O U T P U T – - 0 8

CONFIG MENU (continued)

5- LIGHT CONTROL

Press 5 on the Keypad to enter the Light Control

Submenu.

1-CIRCUIT #1

Press 1 or 2 on the Keypad to enter the Circuit #

Submenu.

This screen programs lighting controls on one circuit.

Use the key to toggle between

D I S A B L E D to activate the lighting function. Press

E N A B L E D /

E N T.

Using the ENT key, move down the selections.

Press CLR. Key in your selection and press ENT.

The cursor will move down to the next sensor.

NAME identifies the lights on this circuit.

ONTIME controls when the lights turn on.

OFFTIME controls when the lights turn off.

O

U T P U T controls the relay used by these

PowerLinks™ (lighting circuit breakers).

Press ESC to return to LIGHT MENU.

Press ESC again to return to CONFIG MENU.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 24

P/N 374511B

Page 22

PROTOCOL

™

Hand Held Device

CONFIG MENU

1-SET THE CLOCK

2-SENSOR SETUP

3 - P ROTOCOL SETUP

4-COMM SETUP

5-LIGHT CONTRO L

6-TEMP CONTRO L

T E M P E R ATURE CONTRO L

1-REFR CIRCUIT #1

2-REFR CIRCUIT #2

3-REFR CIRCUIT #3

4-REFR CIRCUIT #4

MORE ON NEXT PAG E

T E M P E R ATURE CONTRO L

1-REFR CIRCUIT #5

2-REFR CIRCUIT #6

3-REFR CIRCUIT #7

4-REFR CIRCUIT #8

MORE ON NEXT PAG E

REFR CIRCUIT #1

TEMP CONTRO L – E N A B L E D

S E T P O I N T – 15 F

R AT E – 3 F

O U T P U T – - 1

CONFIG MENU (continued)

6- TEMPERATURE CONTROL

Press 6 on the Keypad to enter the Temperature

Control Submenu.

Note: Temperature Control is available on HAND

HELD DEVICE V2.40 or greater.

Press the number of the Temp Refr Circuit you

wish to view or use the and to move to the

appropriate entry and press ENT.

1-REFR CIRCUIT #1

This screen allows configuration for temperature

control of a given circuit.

Use the key to toggle between

D I S A B L E D to activate the control function. Press

E N A B L E D /

E N T.

SETPOINT will be the setting the control will try to

achieve for this circuit.

R

AT E is a number from 1 to 3 which allows the

algorithm to be adjusted for different evaporators.

Arate of 1 establishes a 30 second cycle rate for the

output; 2 establishes a 60 second cycle rate; and

3 establishes a 90 second cycle rate. You may need

to experiment with the rate adjustment in order to

achieve the optimum level of performance.

OUTPUT controls the relay used by the corresponding Defrost Circuit.

Important – Verify the output number between

this temperature circuit and the connected

defrost circuit to ensure proper energizing and

de-energizing of solenoids. Make sure that in

the case of electric defrosts, you haven’t selected the output that operates defrost heaters.

Press ESC to return to T

EMP CONTROL MENU.

Press ESC again to return to CONFIG MENU.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 25

P/N 374511B

Page 23

PROTOCOL

™

Hand Held Device

D E F ROST MENU

1-VIEW/SET ITEMS

2-COPY SCHEDULE

3-ASSIGN OUTPUTS

4-ASSIGN CIRCUITS

FOR SPLIT SUCT

D E F ROST MENU

C I R C U I T N A M E S TAT U S

1 CIRCUIT #1 NAME R E F R

2 CIRCUIT #2 NAME D E F R

3 CIRCUIT #3 NAME DAT V

4 CIRCUIT #4 NAME R E F R

PRESS ENT TO SET

P ROTOCOL MAIN MENU

1 - S TATUS MENU

2-CONFIG MENU

3 - D E F ROST MENU

4-MAINT MENU

5-ALARM MENU

DEFROST MENU

3-DEFROST MENU

Press 3 on the Keypad to enter the Defrost submenu.

1- VIEW/SET ITEMS

Press 1 on the Keypad to enter the V

IEW/SET ITEMS

Submenu.

This screen shows three columns:

C I R C U I T lists the defrost circuit within the

Protocol. The numbers 1 through 8 are fixed.

NAME refers to the description used to identify

the defrost circuit.

STATUS lists the status of each defrost circuit.

REFR = In refrigeration

DEFR = In defrost

DATV = DE-activated, will not defrost.

TERM = Defrost terminated by temp.

N/A = Not Available or Not Installed

The horizontal arrows are used to activate or deactivate a circuit for defrost control, to force a circuit

in or out of refrigeration or defrost go to the

M

AINTENANCE MENU. Note that the DATV status

permanently disables the defrost function.

Use the vertical arrows to move up and down the

circuit list.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 26

P/N 374511B

Page 24

PROTOCOL

™

Hand Held Device

D E F ROST MENU

C I R C U I T S Y S T E M S TAT U S

5 0 0 N / A

6 0 0 N / A

7 0 0 N / A

8 0 0 N / A

PRESS ENT TO SET

CIRCUIT #6 - REFR

N A M E DEFR T Y P E - O F T I M

N U M B E R / DAY - 0 3

DEFR LENGTH - 1 5

1ST DEFR - 0 0 : 0 0

A M P E R AG E - 0 0

CIRCUIT #6 - REFR

DEFR T E R M - E N A B L E D

2ND DEFR - 0 8 : 1 5

3ND DEFR - 1 6 : 0 0

END OF DEFRO S T S

DEFROST MENU (continued)

WITH THE CURSOR ON A CIRCUIT NUMBER, press the

ENT key to open that circuit submenu.

CIRCUIT #6 - REFR

Press the CLR key. Key in the applicable Lineup

name. Press ENT. Repeat for NAME, NUMBER/DAY,

DEFR LENGTH and 1ST DEFR HOUR:MINUTES.

Note: To key in name, press Shift Upper to use

the red (upper) letters and Shift Lower to use the

blue (lower) letters.

Three different types of defrost may be used:

Offtime

Gas

Electric

Using the key, toggle to the desired defrost

type. Press ENT.

The amperage number is used for electric

defrosts to turn off compressors and reduce overall amp draw.

Using the key, toggle between

D I S A B L E D for defrost termination. Press E N T.

E N A B L E D /

Note: the termination signal is provided by the

appropriate Auxiliary input (i.e., A

U X1 for CK T1,

AU X2 for CK T2, …).

The remaining defrosts are listed. The control

panel spaces the number of defrosts evenly

across a 24 hour day. To customize the defrost

schedule, press the C L R k e y. Key in the applicable hour for defrost start. (Defrost times can be

entered on the quarter hour – :00, :15, :30 or

:45.) Press E N T. Press the C L R k e y. Key in

the applicable minute for defrost start. Press

E N T.

Press ESC to return to previous screen and to

return to V

IEW / SET ITEMS MENU.

Press ESC again to return to DEFROST MENU.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 27

P/N 374511B

Page 25

PROTOCOL

™

Hand Held Device

D E F ROST MENU

1-VIEW/SET ITEMS

2-COPY SCHEDULE

3-ASSIGN OUTPUTS

4-ASSIGN CIRCUITS

FOR SPLIT SUCT

COPY DEFROST SCHEDULE

COPY FROM CIRCUIT - 0 0

COPY TO CIRCUIT -

DEFROST MENU (continued)

2- COPY SCHEDULE

Press 2 on the Keypad to enter the Copy Schedule

Submenu.

Press the CLR key. Key in the applicable Circuit

# for Copy From. Press ENT.

Press the CLR key. Key in the applicable Circuit

# for Copy to. Press ENT.

Press ESC to return to D

EFROST MENU.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 28

P/N 374511B

Page 26

PROTOCOL

™

Hand Held Device

D E F ROST BOARD #1

O U T P U T C I R C U I T

1 0 0

2 0 0

3 0 0

4 0 0

D E F ROST BOARD #2

O U T P U T C I R C U I T

5 0 0

6 0 0

7 0 0

8 0 0

E X PANSION BOA R D

O U T P U T C I R C U I T

9 0 0

1 0 0 0

1 1 0 0

1 2 0 0

E X PANSION BOA R D

O U T P U T C I R C U I T

1 3 0 0

1 4 0 0

1 5 0 0

1 6 0 0

D E F ROST BOARD #3

O U T P U T C I R C U I T

1 7 0 0

1 8 0 0

1 9 0 0

2 0 0 0

D E F ROST BOARD #4

O U T P U T C I R C U I T

2 1 0 0

2 2 0 0

2 3 0 0

2 4 0 0

D E F ROST MENU

1-VIEW/SET ITEMS

2-COPY SCHEDULE

3-ASSIGN OUTPUTS

4-ASSIGN CIRCUITS

FOR SPLIT SUCT

DEFROST MENU (continued)

3- ASSIGN OUTPUTS

Press 3 on the Keypad to enter the Assign Outputs

Submenu.

Press ENT to move the cursor to the value to be

changed. Press the CLR key.

Key in the applicable Circuit #. Press ENT.

Electric defrost circuits will typically require two

outputs (one for solenoid and one for heater control); while offtime and gas defrost circuits require

only one.

Press ESC to return to D

EFROST MENU.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 29

P/N 374511B

Page 27

PROTOCOL

™

Hand Held Device

D E F ROST MENU

1-VIEW/SET ITEMS

2-COPY SCHEDULE

3-ASSIGN OUTPUTS

4-ASSIGN CIRCUITS

FOR SPLIT SUCT

SUCTION ASSIGNMENT

C I R C U I T S U C T I O N

1 0 0

2 0 0

3 0 0

4 0 0

SUCTION ASSIGNMENT

C I R C U I T S U C T I O N

5 0 0

6 0 0

7 0 0

8 0 0

DEFROST MENU (continued)

4- ASSIGN CIRCUITS

FOR SPLIT SUCTION

NOTE: This item only appears when the unit is

configured for the split suction option.

Press 4 on the Keypad to enter the Assign Circuits

For Split Suction Submenu.

Press ENT to move the cursor to the value to be

changed. Press the CLR key.

Press the left and right arrow keys to toggle

between suctions #1 and #2.

Press ESC to return to D

EFROST MENU.

Press ESC again to return to PROTOCOL MAIN

MENU.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 30

P/N 374511B

Page 28

PROTOCOL

™

Hand Held Device

P ROTOCOL MAIN MENU

1 - S TATUS MENU

2-CONFIG MENU

3 - D E F ROST MENU

4-MAINT MENU

5-ALARM MENU

MAINT MENU

1-FORCE A COMP ON

2-CLEAR FORCE FLAG

3-FORCE A COMP OFF

4-FORCE A DEFR ON

5-FORCE A DEFR OFF

PRESS ENT FOR MORE

FORCE A COMP ON

ENTER NUMBER - 0

FORCE A COMP OFF

ENTER NUMBER - 0

FORCE A DEFR ON

ENTER NUMBER - 0

FORCE A DEFR OFF

ENTER NUMBER - 0

1

3

4

5

MAINT MENU

4- MAINT MENU

Press 4 on the Keypad to enter the Maintenance

Menu Submenu. This screen has one function,

four menus, and a second page.

The functions is: 2-CLEAR FORCE FLAG

Simply press 2 to activate clear function.

Press Numbers 1, 3, 4, 5 on the Keypad to enter

the Submenu. Key in compressor or defrost

circuit #. Press ENT.

The time limit on C

OMPRESSORS forced on/off is

20 minutes. After time limit expires, compressors

return to normal operation.

The time limit for DEFROST CIRCUITS forced on is

a function of the defrost length programmed for

that circuit. For circuits forced out of defrost, operation is suspended for the current defrost only.

Normal operation resumes at the next scheduled

defrost.

Press ESC to return to M

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

AIN MENU.

Page 31

P/N 374511B

Page 29

PROTOCOL

™

Hand Held Device

MAINT MENU

6-CLEAR RUN METER

7-FORCE LIGHT ON

8-FORCE LIGHT OFF

9-CLEAR ALM TABLE

0-RESET CONTROL

FORCE A LIGHT ON

ENTER NUMBER - 0

FORCE A LIGHT OFF

ENTER NUMBER - 0

RESET CONTRO L

ENTER NUMBER - 0

7

8

0

4- MAINT MENU

Press 4 on the Keypad to enter the Maintenance

Menu Submenu.

Press ENT to move to the second page.

This screen has two functions and three menus.

The two functions are:

6-CLEAR RUN METER

9-CLEAR ALARM TABLE

Simply press 6 or 9 to activate clear function.

Press Numbers 7, 8, 0 on the Keypad to enter the

Submenu. Key in compressor or defrost circuit #.

Press ENT.

Press ESC to return to M

Options 9 and 0 are available with Software Version 2.30 or greater. Protocol™ Control

must be V1.30 or greater

AIN MENU.

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 32

P/N 374511B

Page 30

PROTOCOL

™

Hand Held Device

P ROTOCOL MAIN MENU

1 - S TATUS MENU

2-CONFIG MENU

3 - D E F ROST MENU

4-MAINT MENU

5-ALARM MENU

ALARM MENU

A01 - LO SUCTION PRES

TIME 01:56 01/21

END OF ALARMS

ALARM MENU

5-ALARM MENU

Press 5 on the Keypad to enter the A l a r m

Submenu.

This screen lists the last 16 alarms giving the type,

time (24 hour clock) and date of each. Alarms

may be continued on the next screen. To read continued alarms, Press ENT.

The screen will read END OF ALARMS after last

alarm reading.

Press ESC to return to MAIN MENU. When exiting

the menu, you will be prompted whether to clear

the alarms. Press the CLR Key to remove the current alarm.

Types of Alarms

•POWER DOWN

•POWER RESET

•HI TEMPALARM – AUXILIARYINPUT

•MODULES IN BACKUP MODE

•HIGH SUCTION PRESSURE*

•LOW SUCTION PRESSURE*

•HIGH HEAD PRESSURE

•LOW HEAD PRESSURE

•ALL COMPRESSORS OFF ALARM*

•LO TEMPALARM – AUXILIARY INPUT

•HI ALARM T1

•LO ALARM T1

•HI ALARM T2

•LO ALARM T2

•HI ALARM T3

•LO ALARM T3

•MEMORYCHECK ERROR

•DEFROST MEMORY CHECK ERROR

•HI ALARM T4

•LO ALARM T4

•HI ALARM T5

•LO ALARM T5

•HI ALARM T6

•LO ALARM T6

•HI ALARM T7

•LO ALARM T7

•HI ALARM T8

•LO ALARM T8

*Denotes switchback. Control operated by mechanical low pressure switch. No defrosts occur during

s w i t c h b a c k .

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.) 970307

Page 33

P/N 374511B

Page 31

PROTOCOL

™

Hand Held Device

Mixmatch Programming Worksheet

Compr # 1 2 3 4 5 6 Total

HP Total Column

Column Value 1 2 4 8 16 32 HP Value

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Mixmatch Programming Worksheet

Compr # 1 2 3 4 5 6 Total

HP Total Column

Column Value 1 2 4 8 16 32 HP Value

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

970307 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

Page 34

®

CORPORATION

CONDENSING UNITS AND REFRIGERATION SYSTEMS

This wa r ranty is made to the original purchaser user and is N OT T R A N S F E R A B L E.

ONE YEAR LIMITED WA R R A N T Y

1 . Hussmann Cor p o ration wa r rants the new Hussmann Equipment, and all parts thereof, to be free of defects in mate-

rial and wo rkmanship at time of purchase.

2 . Hussmann's obligation under this w a r ranty shall be limited to repairing or exchanging free of charge any part or

p a rts of the system or unit, supplied by Hussmann Corp o ration, Bridgeton, Missouri, F. O. B. fa c t o ry or the nearest

a u t h o ri zed parts depot, which may prove to be defe c t i ve within one year from date of original installation (not to

exceed fifteen months from date of shipment from fa c t o ry) and which is proven to the satisfaction of Hussmann to

be thus defe c t i ve.

3 . THIS WARRANTY TO REPAIR OR REPLACE ABOVE RECITED, IS THE ONLY WARRANTY EXPRESSED, IMPLIED,

OR STAT U TO RY MADE BY HUSSMANN WITH RESPECT TO THE EQUIPMENT ABOVE LISTED, AND IT NEITHER

ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT, ANY OTHER OBLIGATION OR LIABILITY IN

CONNECTION WITH THE SALE OF SAID EQUIPMENT OR ANY PA RT T H E R E O F.

E X C L U S I O N S

1 . THIS WARRANTY SHALL NOT APPLY TO LOSS OF FOOD DUE TO FAILURE FOR ANY REASON.

2 . HUSSMANN SHALL NOT BE LIABLE:

a . For any repairs or replacements made by bu yer without written consent of Hussmann, or when equipment is

installed or operated in a manner contra ry to printed instructions cove ring installation and service which accompanied or was supplied for such equipment.

b. For any damages, dela y s, losses, direct or consequential, caused by def e c t s, nor for damages caused by short

or reduced supply of material, fire, flood, str i ke s, acts of God or circumstances beyond its control.

c . When the failure or defect of any part or parts is incident to ordinary w e a r, accident, abuse or misuse, or when

the serial number of the equipment has been removed, defaced, altered or tampered with.

d . When equipment is operated on low or improper vo l t a g e s, or put to use other than normally recommended by

H u s s m a n n .

e. For payment of any removal or installation charges of w a r ranted part s.

f. For payment of refri g e rant losses for any reasons.

g . When equipment is moved to an address other than the original installation.

ADDITIONAL FOUR YEAR PROTECTION PLAN FOR MOTOR/COMPRESSOR ASSEMBLY ONLY

(OPTIONAL – MUST BE PURCHASED PRIOR TO SHIPMENT

OF CONDENSING UNIT OR REFRIGERATION SYSTEM)

In addition to the above One Year Wa r ranty on said Condensing Unit or Refri g e ration System, Hussmann Corp o ra t i o n ,

a grees to repair or replace the motor compressor only, with a motor compressor of like or author i zed similar capacity

( F. O. B. Fa c t o ry or nearest Vendor author i zed parts depot), at any time during this four year period immediately fo l l owing the ex p i ration of the above one year w a r ra n t y, if proven to the satisfaction of Hussmann,

that the compressor is inoper a t i ve due to defects in f a c t o ry w o rkmanship or material under normal use and

s e rv i c e. Hussmann reserves the right to inspect the job site, installation and reason for f a i l u r e.

The Four Year Protection Plan does not include controls, relay, capacitor, ov e rload protector, va l ve plates, oil

p u m p s, gaskets or any e x t e rnal part on the motor compressor replaceable in the field, or any other part of the

r e f ri g e ration system.

GENERAL CONDITIONS

No service or labor charges incidental to the replacement of parts during the First Year Wa r ranty and the succeeding

four years under the protection plan will be allowed under the terms thereof.

All claims must be presented and completed within six months from date of fa i l u r e. Claims must be accompanied by

the vendor invoice and credit showing model and serial number of compressor that failed and the new replacement

c o m p r e s s o r. Records should be maintained with copies of above documents to show any inwa r ranty replacements within the One Year Wa r ranty and should be submitted along with claim to show original compressor model and serial n u mb e r.

HUSSMANN CORPORAT I O N

8/92

B r i d ge t o n , Missouri 63044 – U. S . A .

Loading...

Loading...