Page 1

®

P/N 0425683F

September 2006

INNOVATOR

AND

INNOVATOR II

REACH-IN

GLASS DOOR

INSTALLATION

& SERVICE

MANUAL

Page 2

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

www.hussmann.com

© 2006 Hussmann Corporation

HUSSMANN CORPORATION, BRIDGETON, MO 63044-2483 U.S.A.

Table of Contents

General . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Always

*Clear

™

Glass . . . . . . . . . . . . . . . . 1

Shipping Damage . . . . . . . . . . . . . . . . . . . 1

New Installations . . . . . . . . . . . . . . . . . . . 1

Adjusting Closing Torque . . . . . . . . . . . . . 1

Adjusting Door Sag . . . . . . . . . . . . . . . . . 2

Conditioning Gasket . . . . . . . . . . . . . . . . . 2

Replacing Doors . . . . . . . . . . . . . . . . . . . . 3

Replacing Door Hinge Spring . . . . . . . . . 5

Replacing Magnetic Gasket . . . . . . . . . . . 5

Restoring Gasket Seal . . . . . . . . . . . . . . . .6

Door Handle Replacement . . . . . . . . . . . . 8

Frame Heater Replacement . . . . . . . . . . . 9

Lamp Replacement (Center Mullion) . . . 11

Lamp Replacement (End Mullion) . . . . . 13

Ballast Replacement . . . . . . . . . . . . . . . . 13

Heater Harnesses . . . . . . . . . . . . . . . . . . 14

Wiring Diagrams . . . . . . . . . . . . . . . . . . 15

Replacement Parts Chart . . . . . . . . . . . . 17

Replacement Parts List . . . . . . . . . . . . . . 18

WARRANTY

Revision E

1. Added Always*Clear cleaning information, page 1.

2. Revised text for diffuser removal, pages 11 & 12.

3. Revised wiring diagrams, pages 15 & 16.

4. Added ballast change-out direction, page 24.

REVISION F

1. Added instruction for conditioning gaskets during

initial case installation, page 2.

2. Revised wiring diagrams, pages 15 & 16.

3. Added Aftermarket part numbers, pages 18 through 23.

®

®

Innovator Door Installation and

Service Instruction

P/N 0425683F

iii

Page 3

GENERAL

Be sure merchandisers have been leveled according to the installation instructions shipped with

the merchandiser.

The door nameplate is attached to the top of the

door, handle side, behind the magnetic gasket.

The frame nameplate is located on the top left

near the switch.

ALWAYS*CLEAR™GLASS

Hussmann recommends using a soft cloth with

isopropyl (rubbing) alcohol to clean the inside

(coated) glass surface. Isopropyl alcohol does not

freeze and evaporates without leaving residue.

Always allow the surface to dry before closing

the door. Use of abrasives may damage the

coated surface and void the warranty. Labels

(stickers) applied to the coated surface will cause

damage and void the warranty.

SHIPPING DAMAGE

All equipment should be thoroughly examined for

shipping damage before and during unloading.

This equipment has been carefully inspected at

our factory. Any claim for loss or damage must be

made to the carrier. The carrier will provide any

necessary inspection reports and/or claim forms.

NEW INSTALLATIONS

Untape the doors and remove the shipping braces

located at top and bottom of the doors.

Doors are not fine adjusted at the factory since

they will go out of adjustment during shipment.

This is normal.

ADJUSTING CLOSING TORQUE

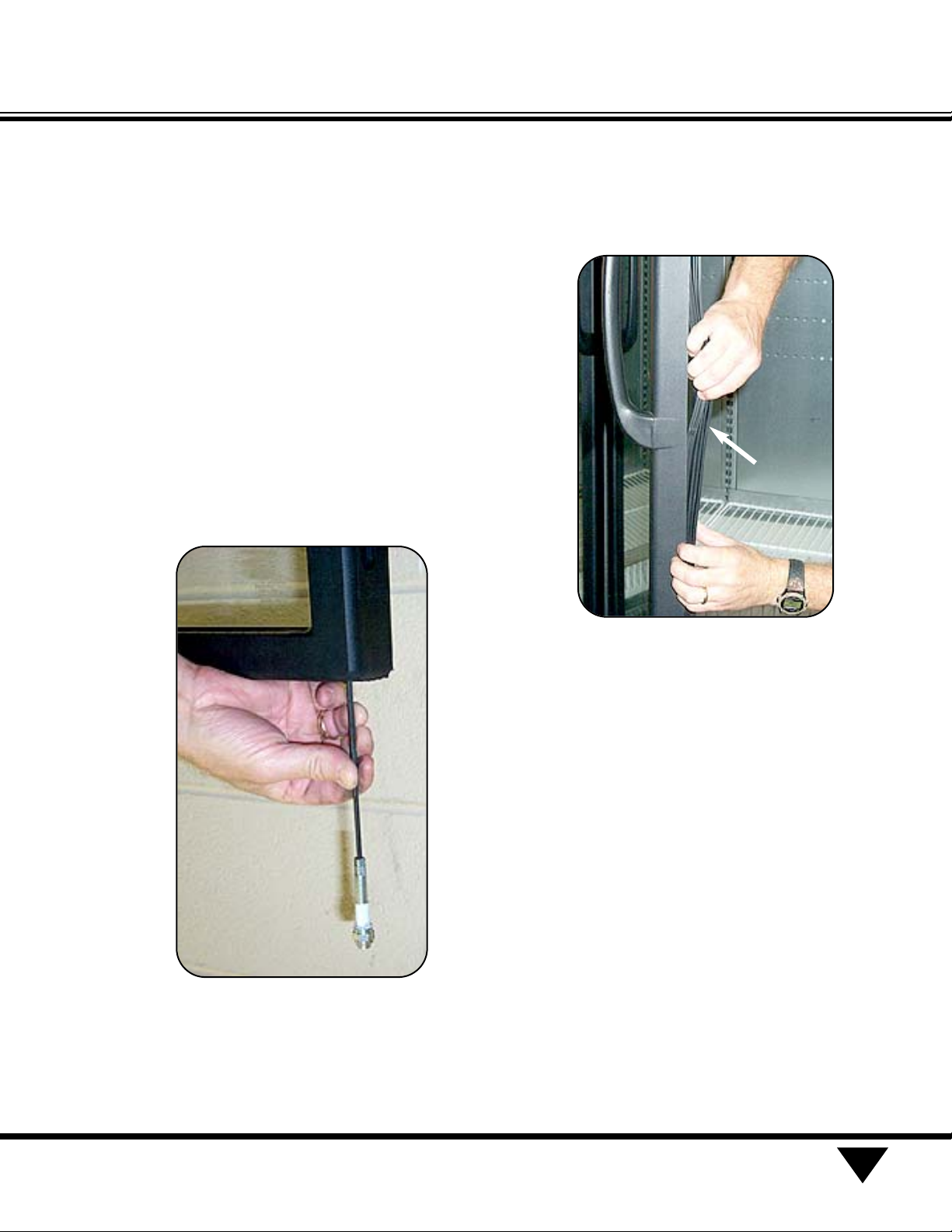

Adjust closing torque by turning the bottom

hinge pin in the direction the door closes. Use a

1

/2 in. (13 mm) wrench. Turn the hinge pin until

the door closes on its own, usually 3 to 4 clicks or

3

/4 turn. See Figure 1.

DO NOT over-torque the hinge spring assembly.

Excessive torque (over 1 full turn) will result in

damage to the spring assembly and/or door. If

door does not close on its own after one full turn

(5 clicks), look for obstructions causing the door

to hang up.

Figure 1. Adjusting Closing Torque

Innovator Door Installation and

Service Instruction

P/N 0425683F

1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Page 4

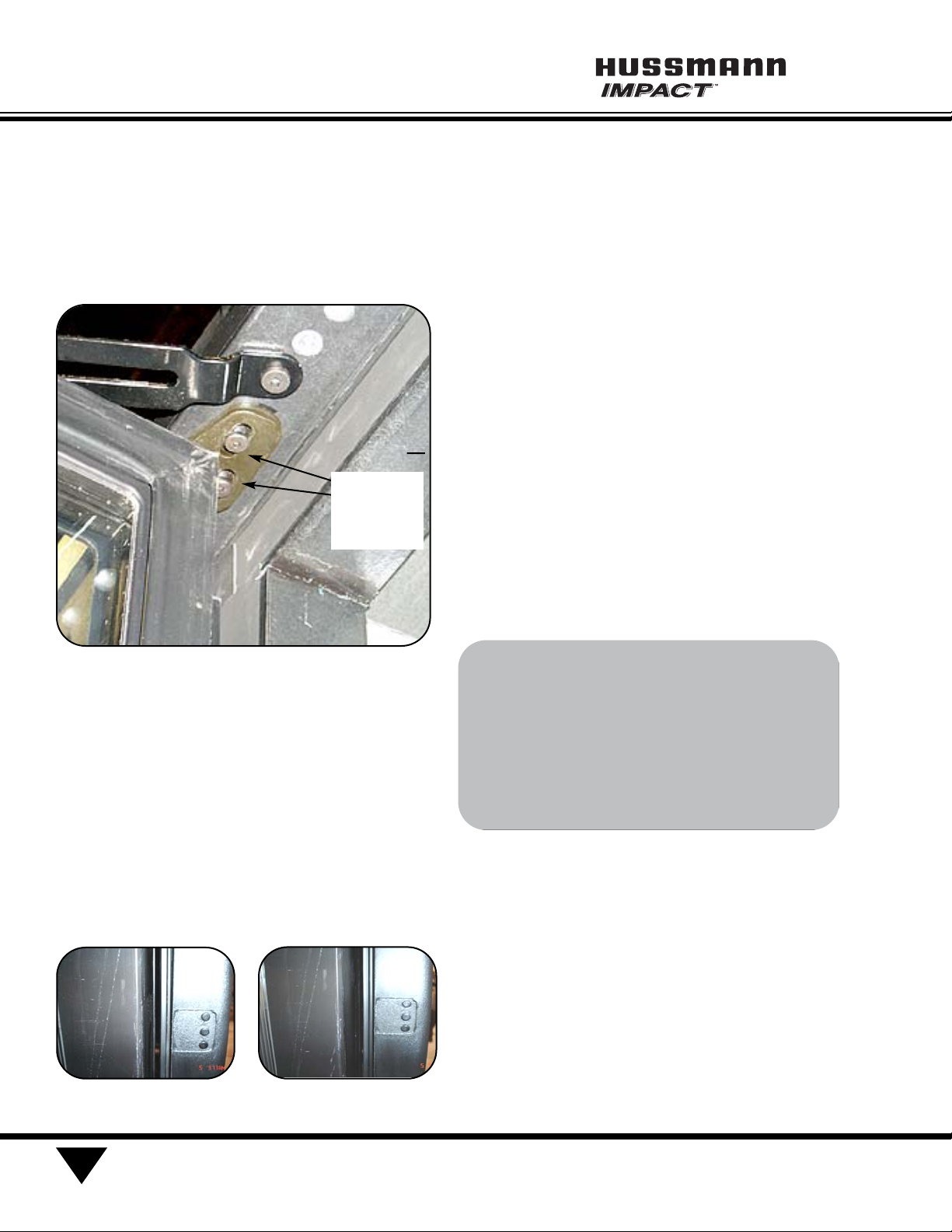

ADJUSTING DOOR SAG

To adjust door sag (saw-tooth effect from door to

door), loosen the two hinge plate mounting

screws using a Torx Plus no. 27 bit. Adjust hinge

plate as needed, then tighten the screws. See

Figure 2.

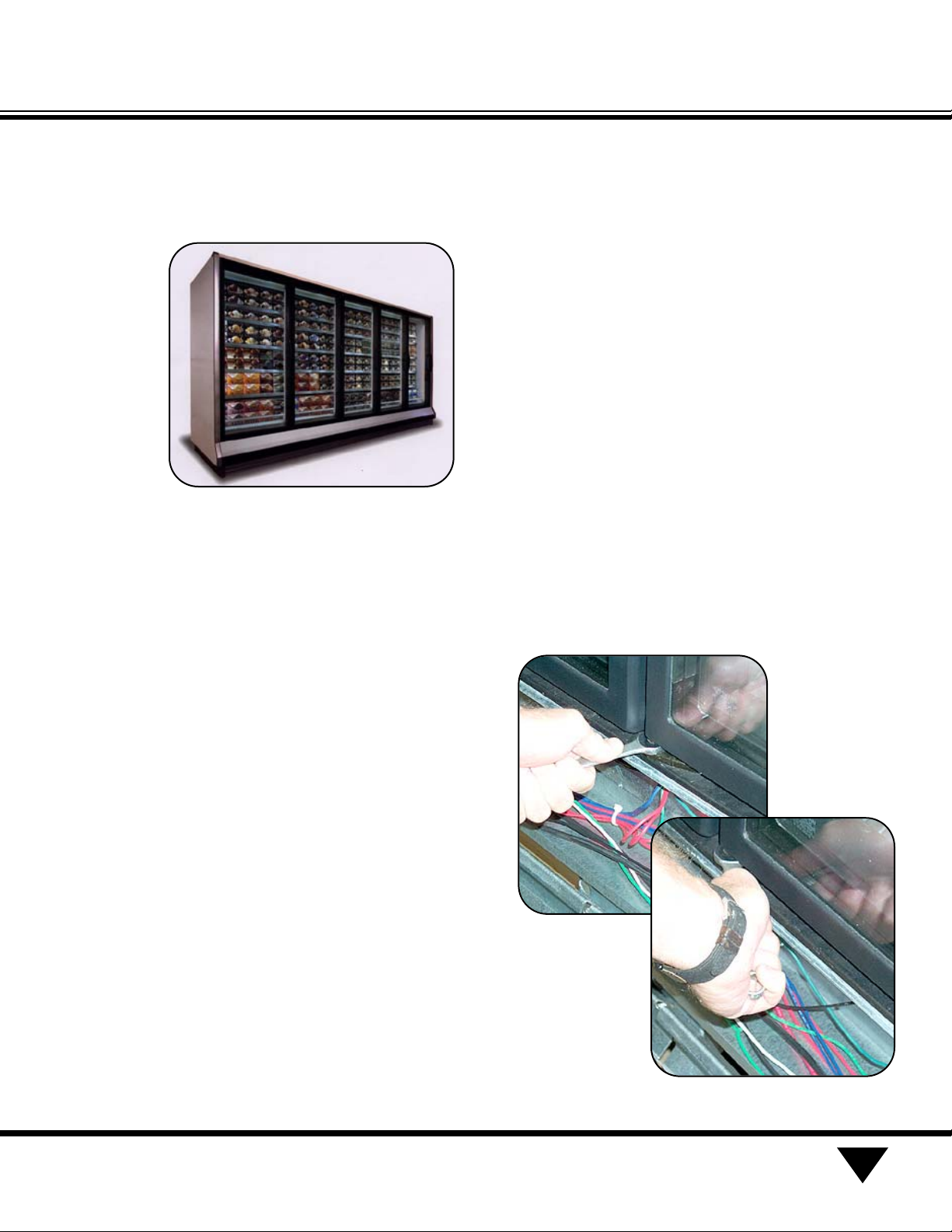

CONDITIONING GASKETS

The manufacturer cannot control the environment

surrounding cases during shipment. Temperature

and humidity fluctuations during shipment, as

well as excessive vibration, may promote gaps

between gasket and frame. These gaps prevent

gaskets from sealing even when correctly fitted at

the factory. This is not a warranty issue or defect.

Follow this procedure to ensure gaps close and

gaskets seal properly:

1. Remove all shipping retainers and packing

material.

2. Close each door. Use a flashlight to identify

any gaps between frame and gasket.

3. Energize all anti-sweat, fan and light circuits

for at least two hours, but not more than four

hours, prior to initiating the refrigeration cycle.

4. Monitor all gaps. If gaps remain at the end of

four hours, follow the procedure for Restoring

Gasket Seal, beginning on page 6 of this manual.

5. Initiate cooling sequence once gaps disappear.

Do not exceed 8 hours of energized circuits

without refrigeration. Doing so may cause

damage to the case and will void the warranty.

P/N 0425683F

®

2

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Figure 2. Adjusting Door Sag

Loosen both

hinge plate

mounting

screws.

ATTENTION

TO ENSURE PROPER DOOR GASKET SEAL – REMOVE ALL SHIPPING

RETAINERS AND ENERGIZE ALL ANTI-SWEAT, FAN & LIGHT CIRCUITS 2

TO 4 HOURS PRIOR TO INITITATING REFRIGERATION CYCLE.

DO NOT EXCEED 8 HOURS OF ENERGIZED CIRCUITS WITHOUT

REFRIGERATION. DAMAGE OR PRODUCT FAILURE MAY OCCUR AND VOID

THE WARRANTY. DO NOT REMOVE THIS LABEL UNTIL REFRIGERATION IS

INITIATED.

Before and After Gasket Conditioning

Page 5

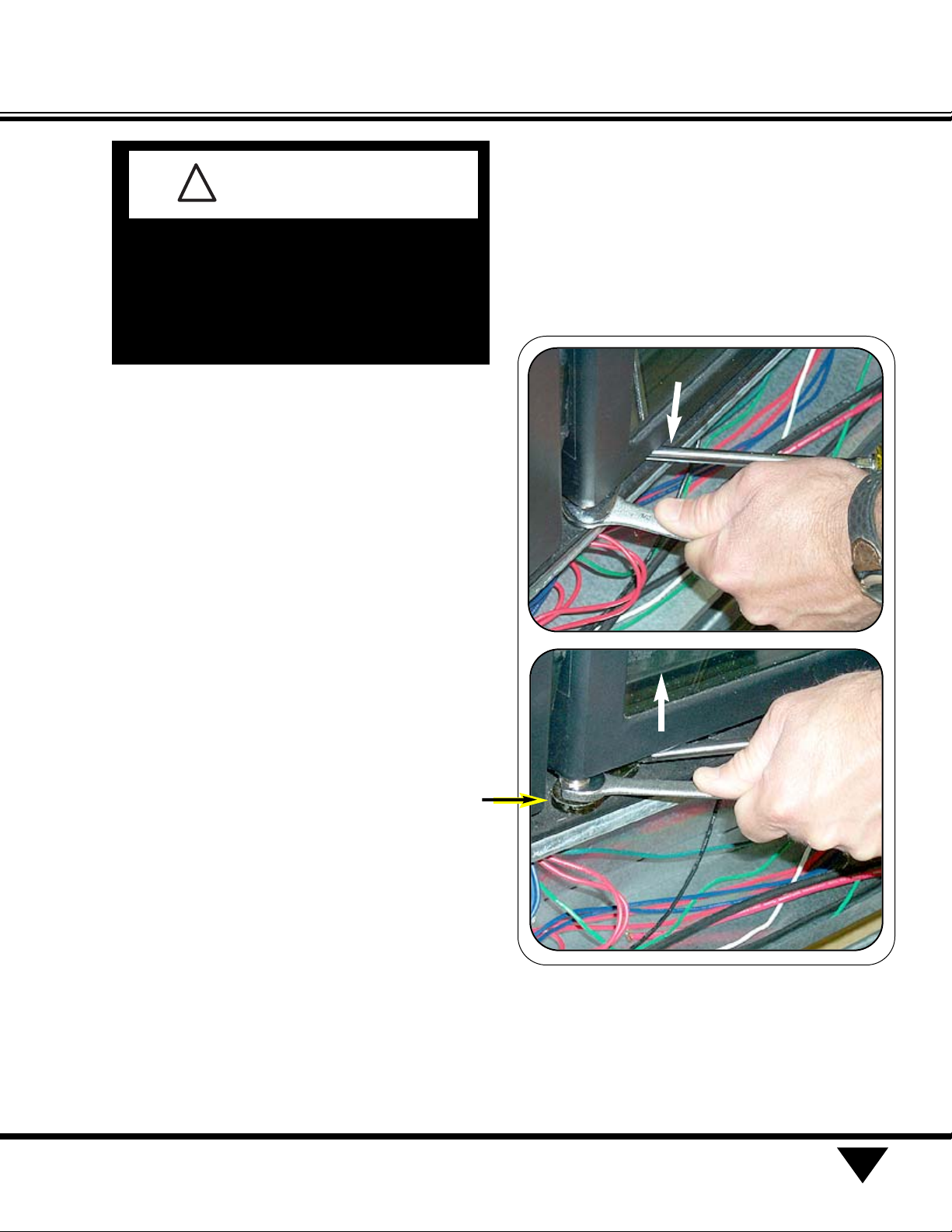

REPLACING DOORS

1. Loosen torque on door before removing the

door. Wedge a screwdriver between the bottom of

the door and the hinge socket, then lift the door

up. This will lift the bottom hinge pin up and out

of the bottom hinge socket. Hold the hinge pin

with a 1/2 in. (13 mm) open end wrench to keep

it from spinning out and stripping the socket. See

Figure 3.

Innovator Door Installation and

Service Instruction

P/N 0425683F

3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Always disconnect the electrical power at the

main disconnect when servicing or replacing

any electrical component. This includes, but is

not limited to, such items as doors, lights,

fans, heaters, and thermostats.

Lift up

Screwdriver

Figure 3. Loosening Torque on the Door

!

WARNING

Page 6

2. Unscrew the two #6 Phillips screws that hold

the black plug into the side of the door as shown

in Figure 4. Remove the plug from the door.

3. Grasp the strain relief just below the cord and

pull until the heater terminal plug comes out. See

Figure 5. Note that the left end door must be

opened more than 90 degrees to access the

screws.

4. Use a flat blade screwdriver as shown in

Figure 6 to lift the door retainer over the shoulder

screw.

5. Push down the top hinge pin until it clears the

top socket using a flat blade screwdriver as

shown in Figure 7. With finger, hold the hinge

pin in the door to keep it from popping out. Tape

may be used to temporarily hold the hinge pin

once door is removed.

P/N 0425683F

®

4

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Figure 4. Removing Screws to Plug

Figure 5.

Removing the Heater Terminal Plug

Remove Screws

Figure 6. Removing the Door Retainer

Door Retainer

Figure 7.

Removing the Door from the Top Hinge Pin

Top

Hinge

Pin

Page 7

6. Rock the door out and pull the bottom hinge

pin out from the bottom socket.

7. Install the new door in reverse order.

8. Adjust the torque on the new door. If needed,

adjust sag.

REPLACING DOOR HINGE SPRING

The door must be removed before replacing the

door hinge spring.

Pull the hinge spring assembly out of the bottom

of the door and replace with a new assembly. See

Figure 8. Note that there are right-hand and lefthand hinge spring assemblies.

REPLACING MAGNETIC GASKET

Carefully remove the old gasket from the groove

in the back of the door, Figure 9.

The new gasket will be easier to work with if it is

at ambient temperature. Begin by lubricating the

new gasket with a mild soap and water solution.

Innovator Door Installation and

Service Instruction

P/N 0425683F

5

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Figure 8. Replacing Door Hinge

Spring Assembly

Figure 9. Removing Door Gasket

Gasket

Page 8

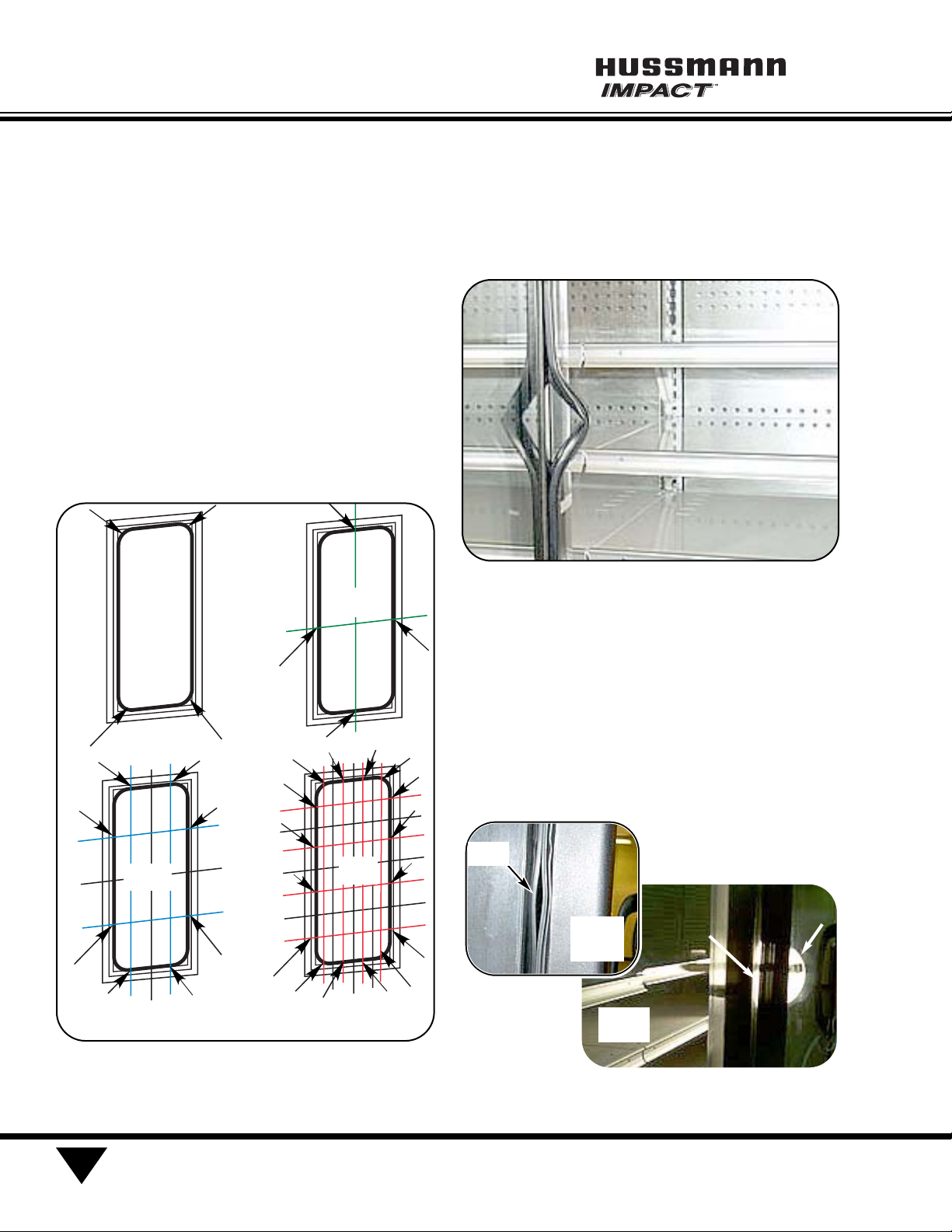

Work from the corners to the centers of each side,

top and bottom. Carefully push the new gasket

into the groove at each corner, refer to Figure

10(A). Then, push the gasket into the channel at the

center of the top, bottom and each side, Figure

10(B). Avoid stretching the gasket.

Sub-divide remaining areas and push the gasket

in at those points, Figure 10(C).

Sub-divide once again and repeat pushing the

gasket in until all of the gasket is evenly seated in

the groove, Figure 10(D).

Use a soft cloth or paper towels to dry the gasket

before closing door on clean door frame.

RESTORING GASKET SEAL

Occasionally, a crimped or damaged gasket can

cause gaps in the seal (Figure 11), leading to frost

formation on the doors. Use this procedure to

close gaps and end frost formation on doors.

Locate Gaps

Normally, interior case lighting will provide

enough light to see gaps. In some cases, the only

way to see gaps is to provide a backlight as

shown in Figure 12(A). Backlight the door

mullion and look for places the light shines

between the door and gasket, Figure 12(B).

P/N 0425683F

®

6

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Corners first

Middle of Door

Sub-divide Middle Locations

Sub-divide again

Figure 10.

Sequence for Installing New Gasket

(A)

(B)

(C)

(D)

Figure 11.

Improperly Installed or Damaged Gasket

Figure 12. Back-Lighting Gaps in Gasket

Back-Light

Gap

(A)

(B)

Gap

Page 9

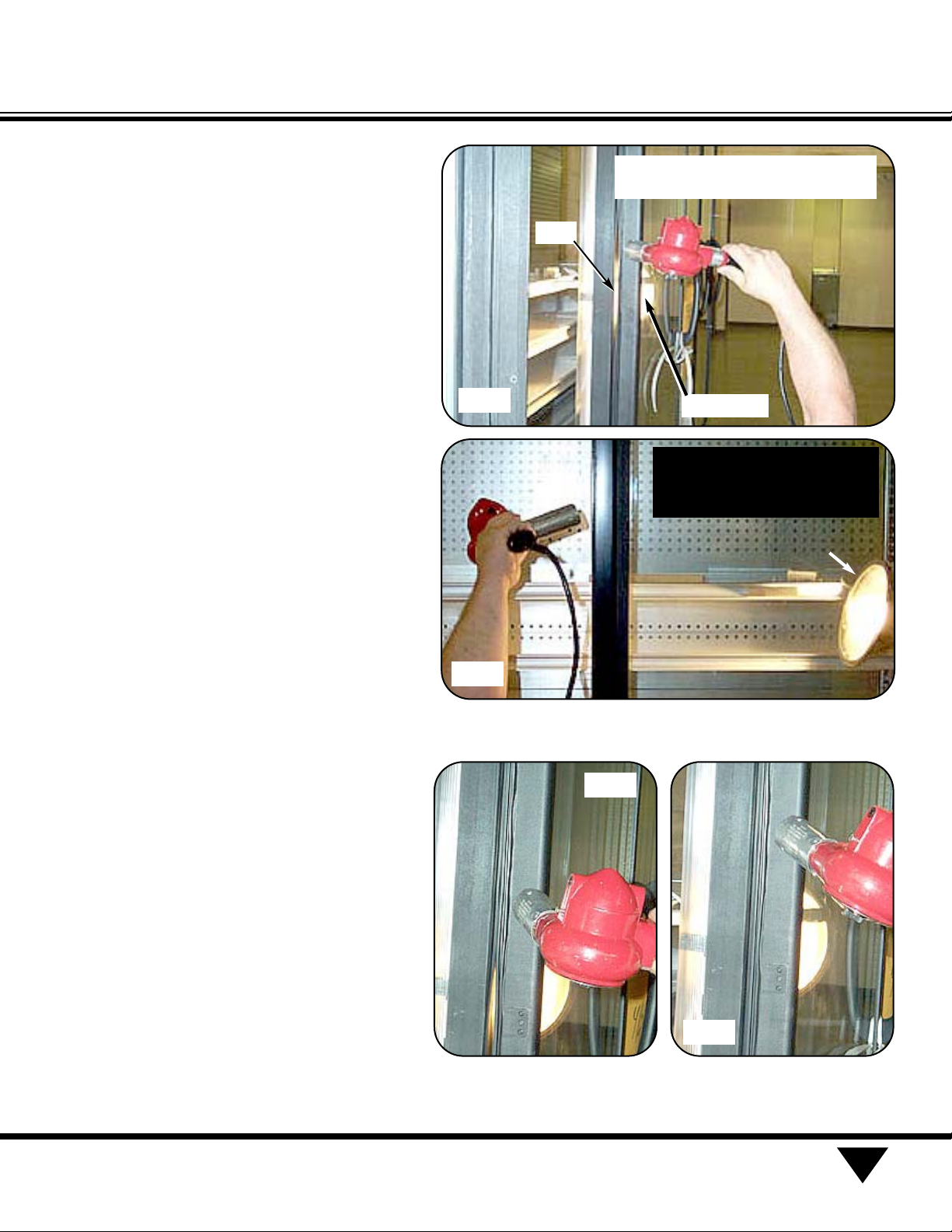

Heat the Gasket

Make sure the door is closed.

Beginning at the top of the gap,

use a heat gun or electric hair

dryer (1500-1600 watt) to heat

the gasket with a constant up

and down motion.

IMPORTANT: If a gap runs

the entire length of the door,

heat the area 4 in. (100 mm)

above and 8 in. (200 mm)

below the top-most point where

the gap starts and work in

12 in. (300 mm) increments.

If the gasket becomes shiny,

remove heat immediately as

this is an indication that the

gasket is near the melting

point.

If possible, direct the hot air

onto the gasket and also

through the gap between the

gasket and mullion. This will

help to heat both sides of the

gasket. Refer to Figure 13(A)

and (B).

As the gasket softens and

becomes pliable, the magnet in

the gasket should pull it across

the gap. As the gap closes,

move heat down to create a

zippering effect as shown in

Figure14.

If the gasket is not pulled

across the gap by the magnet,

reach around the mullion (from

the inside) and pull the gasket

skirt toward the mullion.

Innovator Door Installation and

Service Instruction

P/N 0425683F

7

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Gap

Back-Light

Direct the hot air through the gap

between the gasket and mullion.

Back-Light

Remember to use a constant

up and down motion when

applying heat.

Figure 13. Applying Heat to Gasket

(A)

(B)

Figure 14. Zipper Effect

(A)

(B)

Page 10

As shown in Figure 15, this can also be accomplished by pushing the magnet across the gap from

the outside with a pencil or other non-heat conducting material.

On doors where the gap is against an end, top, or

bottom mullion, this process can still be done;

however, the heat will need to be directed

between the lip of the mullion and the edge of the

door. It will work in the same fashion but the

back-light shining through and showing on the

mullion will have to be a guide as to the position

of the gasket.

Cool the Gasket

Once the gap is closed, remove the heat and

allow the gasket to cool, undisturbed, for 3 to

5 minutes. As the gasket cools, it will set

permanently in this new shape.

Once the gasket is cool to the touch, open the and

close the door. Verify that the gasket seals. If not,

repeat the process. If the gasket rolls it must be

replaced.

Use a soft cloth or paper towels, and a mild soap

and water solution to thoroughly clean the gasket.

Dry the gasket completely with a fresh cloth or

paper towels before closing the door on a clean

door frame.

DOOR HANDLE REPLACEMENT

Carefully pull the

magnetic gasket out

of the groove nearest

the handle to expose

the mounting screws

as shown in

Figure 16. Remove

the screws and

replace the handle.

After reinstalling

screws, carefully

push gasket back

into groove. If needed, use a mild soap

and water solution to

lubricate the gasket.

Clean and dry the

gasket to complete

the door handle

replacement.

P/N 0425683F

®

8

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Figure 16. Replacing Door Handle

Mounting Screws

Figure 15. Pulling Gasket Into Place

With a Pencil

Page 11

FRAME HEATER REPLACEMENT

Always turn off power to the case before working

on any electrical components. The old wireway

covers must be removed to access the door frame

heaters. Begin by inserting a putty knife into the

groove between the wireway cover and fiberglass

frame, about an inch (25 mm) away from joints in

the frame as shown in Figure 17(A). Carefully

begin to pry off the cover.

As shown in Figure 17(B), use a second putty

knife or flat head screwdriver to hold up the cover.

Pry the remainder of the section up, using putty

knife only, until the entire cover is off and the

frame heater inside the door frame is exposed.

Door frame heaters shown in Figure 18 may now

be replaced.

Innovator Door Installation and

Service Instruction

P/N 0425683F

9

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Hussmann recommends against frame heater

cycling with

Innovator

doors to prevent door

seals from freezing to the frames and tearing.

Always disconnect the electrical power at the

main disconnect when servicing or replacing

any electrical component. This includes, but is

not limited to, such items as doors, lights,

fans, heaters, and thermostats.

Figure 17. Removing Door Wireway Covers

(B)

(A)

!

WARNING

Page 12

During installation, the white portion of the

heater should not come in contact with itself. The

heater should be installed so that only one white

portion of the wire enters the raceway. The other

portion entering the raceway will be the black

lead wire.

Once the heater wire is connected, check resistance (ohm reading) before replacing wireway

covers. This will ensure that heater wire was not

broken during installation.

After covers are reinstalled, turn power on and

verify that heaters are working properly.

P/N 0425683F

®

10

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Figure 18. Replacing Door Frame Heaters

Page 13

LAMP (CENTER MULLION) REPLACEMENT

Note: No additional parts need to be removed to

change out the lamps

1. Turn off lights at switch.

2. Disengage the diffuser clips from the mullion

by squeezing the diffuser cover at the clips. Two

hands may be required as shown in Figure 19.

3. Raise the diffuser slightly upward and out of

the bottom filler. Twist the bottom of the diffuser

toward the shelf and center of the door while

lowering slightly to clear the honeycomb

retainer. Pull the top of the diffuser toward the

Innovator Door Installation and

Service Instruction

P/N 0425683F

11

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Reach-in models manufactured with Innovator

or Innovator II doors have anti-arc ballast.

When re-starting lamps, turn power off then on.

Figure 19. Disengaging Diffuser Clips

Squeeze

Here

Diffuser Clip

Always disconnect the electrical power at the

main disconnect when servicing or replacing

any electrical component. This includes, but is

not limited to, such items as doors, lights,

fans, heaters, and thermostats.

WARNING

!

Light

Switch

Page 14

shelf and over the lamp tube and wires. The top

part of the diffuser must be below the honeycomb

retainer and above the lamp tube. The bottom

filler need not be removed. See Figure 20.

4. Pull the top lamp-holder out of the lampholder bracket as shown below.

5. Next, remove the lamp-holder from the lamp

and pull the lamp out of the bottom lamp-holder.

6. Remove the tube guard from old lamp and

place it on the new lamp.

7. Install the new lamp in reverse order. Ensure

lamp pins line up with lamp-holder holes as

shown below, and that lamp-holder is fully

engaged in lamp-holder bracket.

P/N 0425683F

®

12

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Pull

lamp-holder

Bracket

lamp-holder

Lamp

Remove

lamp-holder

Remove

Lamp

from

Bottom

lamp-holder

Figure 20.

Removing Diffuser from Center Mullion Lamp

Diffuser

Bottom Filler

Page 15

LAMP (END MULLION ) REPLACEMENT

1. Turn off lights at switch.

2. Pry the diffuser away from the end reflector,

using a flat blade screwdriver. Pull the diffuser

slightly upward and out of the bottom filler. The

bottom filler does not have to be removed to

replace the lamps. See Figure 21.

3. Pull the top lamp-holder out of the lamp-holder

bracket.

4. Next, pull the lamp-holder off the lamp and

pull the lamp out of the bottom lamp-holder.

5. Remove the tube guard from old lamp and

place it on the new lamp.

6. Replace lamp by reversing the procedure.

Ensure lamp pins line up with lamp-holder holes,

and that lamp-holder is fully engaged in lampholder bracket.

BALLAST REPLACEMENT

Ballasts are located in the raceway below the

door frame as shown in Figure 22. To access the

raceway, remove the bumper, then remove the #8

hex head screws that hold on the front painted

panel.

Innovator Door Installation and

Service Instruction

P/N 0425683F

13

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Figure 22. Ballast Location

Ballast

Always disconnect the electrical power at the

main disconnect when servicing or replacing

any electrical component. This includes, but is

not limited to, such items as doors, lights,

fans, heaters, and thermostats.

Figure 21.

Removing Diffuser from End Mullion Lamp

End Mullion

Lamp

Switch

!

WARNING

Page 16

P/N 0425683F

®

14

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Frame Heater

Terminal Block

Door Heater Harness

Typical Low Temperature Frames

Terminal Block

Frame Heater

Typical Medium Temperature Frames

Heater Harnesses

Page 17

Innovator Door Installation and

Service Instruction

P/N 0425683F

15

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Two lamp wiring has a

red wire from each lamp

spliced together and

returning to the ballast.

Two blue wires and one

red wire go to the ballast

as a group from each lamp.

Note that one lamp goes to

top 3 pins, second lamp

goes to bottom 3 pins, with a

common connection between.

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

Page 18

P/N 0425683F

®

16

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

F58 T8 Lamp

Two lamp wiring has a

red wire from each lamp

spliced together and

returning to the ballast.

Two blue wires and one

red wire go to the ballast

as a group from each lamp.

Note that one lamp goes to

top 3 pins, second lamp

goes to bottom 3 pins, with a

common connection between.

Page 19

Innovator Door Installation and

Service Instruction

P/N 0425683F

17

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Washer,

Flat

Torsion

Assembly

Screw,

Handle

Handle, Standard

Spring,

Top

Hinge Pin

Socket, Top Hinge

Screw,#6x5/8

Oval Head SMB

Bushing,

Top

Hinge Pin

Screw,

Binder Post

Cover,

Wireway

Bushing,

Bottom

Hinge Pin

Socket, Bottom Hinge

Pin, Top Hinge

Clip, SPN 5

Strain Relief

Screw,

Socket

Retainer

Screw,

Hold-open

Shoulder

Lamp

Holder,

To p

NOTE: TOP LAMP HOLDER HAS

TWO LEADS, BOTTOM LAMP

HOLDER HAS THREE LEADS.

Lamp

Holder,

Bottom

Screw,

Case End

Shoulder

Lamp

Harness,

Female

Receptacle

(not used with

medium

temperature

or Innovator II)

Closer, Door

Molding,

Joint

Molding,

End

Innovator and Innovator II

Door and Frame

Part Identification Chart

Retainer, Door

Ballast

Heater, Frame Wire

Page 20

Ballast–One Lamp 1/F58/120v 0430329 BA.4480341 4480341

Ballast–Two Lamp 2/F58/120v 0430330 BA.4480342 4480342

Ballast–Three Lamp 3/F58/120V 0454319 BA.4480601 4480601

Ballast 1-3/F58/105-250V 0424649 BA.0424649 4480110

Bushing–Bottom Hinge Pin 0428547 DO.4550122 4550122

Bushing–Top Hinge Pin 0428548 HH.4550123 4550123

Clip–Mullion Diffuser 0428595 HH.0428595 4550105

Clip–SPN 5 Strain Relief 0432602 TP.4550113 4550113

Closer–Door Lh — Standard 65-inch Door 0428627 HH.4550125 4550125

Closer–Door Rh — Standard 65-inch Door 0428628 HH.4550126 4550126

Closer–Door Lh — RLT 75-inch Door 0454328 HH.4550307 4550307

Closer–Door Rh — RLT 75-inch Door 0454329 HH.4550308 4550308

Cover–Wireway 2 Door Top Lh Black (Bottom Rh) 0428566 TP.0428566 4910108

Cover–Wireway 2 Door Top Lh Gray (Bottom Rh) 0428575 TP.0428575 4910116

Cover–Wireway 2 Door Top Lh 311 Pearl (Bottom Rh) 0442048 TP.0442048 4910275

Cover–Wireway 2 Door Top Rh Black (Bottom Lh) 0428567 TP.0428567 4910109

Cover–Wireway 2 Door Top Rh Gray (Bottom Lh) 0428576 TP.0428576 4910117

Cover–Wireway 2 Door Top Rh 311 Pearl (Bottom Lh) 0442049 TP.0442049 4910276

Cover–Wireway 3 Door Top Lh Black (Bottom Rh) 0428568 TP.0428568 4910110

Cover–Wireway 3 Door Top Lh Gray (Bottom Rh) 0428577 TP.0428577 4910118

Cover–Wireway 3 Door Top Lh 311 Pearl (Bottom Rh) 0442088 TP.0442088 4910277

Cover–Wireway 3 Door Top Rh Black (Bottom Lh) 0428569 TP.0428569 4910111

Cover–Wireway 3 Door Top Rh Gray (Bottom Lh) 0428578 TP.0428578 4910119

Cover–Wireway 3 Door Top Rh 311 Pearl (Bottom Lh) 0442089 TP.0442089 4910278

Cover–Wireway 4 & 5 Door Top Lh Black (Bottom Rh) 0428570 TP.0428570 4910112

Cover–Wireway 4 & 5 Door Top Lh Gray (Bottom Rh) 0428579 TP.0428579 4910120

Cover–Wireway 4 & 5 Door Top Lh 311 Pearl (Bottom Rh) 0442094 TP.0442094 4910279

Cover–Wireway 4 & 5 Door Top Rh Black (Bottom Lh) 0428571 TP.0428571 4910113

Cover–Wireway 4 & 5 Door Top Rh Gray (Bottom Lh) 0428580 TP.0428580 4910121

Cover–Wireway 4 & 5 Door Top Rh 311 Pearl (Bottom Lh) 0442095 TP.0442095 4910280

P/N 0425683F

®

18

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Parts List

Description Mfg Aftermarket Service

Part No. Part No. Part No.

Page 21

Cover–Wireway 5 Door Center Black 0428572 TP.0428572 4910114

Cover–Wireway 5 Door Center Gray 0428581 TP.0428581 4910122

Cover–Wireway 5 Door Center 311 Pearl 0442100 TP.0442100 4910281

Cover–Wireway End Black — Standard 0428565 TP.0428565 4910125

Cover–Wireway End Gray — Standard 0428574 TP.0428574 4910123

Cover–Wireway End 311 Pearl — Standard 0442047 TP.0442047 4910282

Cover–Wireway End Black — RLT 0304949 TP.4978787 4978787

Cover–Wireway End Gray — RLT 0305004 TP.4978788 4978788

Cover–Wireway End 311 Pearl — RLT N/A N/A N/A

Cover–Wireway Mullion Black — Standard 0428564 TP.0428564 4910115

Cover–Wireway Mullion Gray — Standard 0428573 TP.0428573 4910124

Cover–Wireway Mullion 311 Pearl — Standard 0442046 TP.0442046 4910283

Cover–Wireway Mullion Black — RLT 0304948 TP.4978791 4978791

Cover–Wireway Mullion Gray — RLT 0305003 TP.4978792 4978792

Cover–Wireway Mullion 311 Pearl — RLT N/A N/A N/A

Diffuser Assembly–Left 0428592 BU.0428592 4910127

Diffuser Assembly–Mullion 0428594 BU.0428594 4910126

Diffuser Assembly–Right 0428593 BU.0428593 4910128

Door–Innovator Med Temp Black Lh 0425617 DO.0425617 4980180

Door–Innovator Med Temp Black Rh 0425618 DO.0425618 4980102

Door–Innovator Med Temp Gray Lh 0425619 DO.0425619 4980103

Door–Innovator Med Temp Gray Rh 0425620 DO.0425620 4980104

Door–Innovator Med Temp 311 Pearl Lh N/A N/A N/A

Door–Innovator Med Temp 311 Pearl Rh N/A N/A N/A

Door–Innovator Low Temp Black Lh — Standard 0415937 DO.4980105 4980105

Door–Innovator Low Temp Black Rh — Standard 0415938 DO.0415938 4980176

Door–Innovator Low Temp Gray Lh — Standard 0415947 DO.0415947 4980179

Door–Innovator Low Temp Gray Rh — Standard 0415948 DO.0415948 4980108

Door–Innovator Low Temp 311 Pearl Lh — Standard 0441633 DO.0441633 4980332

Door–Innovator Low Temp 311 Pearl Rh — Standard 0441634 DO.0441634 4980333

Innovator Door Installation and

Service Instruction

P/N 0425683F

19

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Parts List (Continued)

Description Mfg Aftermarket Service

Part No. Part No. Part No.

Page 22

Door–Innovator Low Temp Black Lh — RLT 0456167 DO.4981150 4981150

Door–Innovator Low Temp Black Rh — RLT 0445379 DO.4980999 4980999

Door–Innovator Low Temp Gray Lh — RLT 0445382 DO.4980978 4980978

Door–Innovator Low Temp Gray Rh — RLT 0445383 DO.4981000 4981000

Door–Innovator Low Temp 311 Pearl Lh — RLT N/A N/A N/A

Door–Innovator Low Temp 311 Pearl Rh — RLT N/A N/A N/A

Door–Innovator II Black Lh 0440469 DO.0440469 4980109

Door–Innovator II Black Rh 0440470 DO.0440470 4980110

Door–Innovator II Gray Lh 0440471 DO.0440471 4980111

Door–Innovator II Gray Rh 0440472 DO.0440472 4980112

Door–Innovator II 311 Pearl Lh 0441635 DO.0441635 4980334

Door–Innovator II 311 Pearl Rh 0441636 DO.0441636 4980335

Note: Innovator II Doors are not available for RLT

Door–Innovator No*Fog Black Lh — Standard 0458381 DO.4982571 4982571

Door–Innovator No*Fog Black Rh — Standard 0458382 DO.4982572 4982572

Door–Innovator No*Fog Gray Lh — Standard 0458455 DO.4982574 4982574

Door–Innovator No*Fog Gray Rh — Standard 0458456 DO.4978782 4978782

Door–Innovator No*Fog Black Lh — RLT 0461549 DO.4982578 4982578

Door–Innovator No*Fog Black Rh — RLT 0461550 DO.4978783 4978783

Door–Innovator No*Fog Gray Lh — RLT 0461551 DO.4978784 4978784

Door–Innovator No*Fog Gray Rh — RLT 0461552 DO.4978785 4978785

Door–Innovator II No*Fog Black Lh — Standard 0458383 DO.4982573 4982573

Door–Innovator II No*Fog Black Rh — Standard 0458384 DO.4978028 4978028

Door–Innovator II No*Fog Gray Lh — Standard 0458457 DO.4987587 4987587

Door–Innovator II No*Fog Gray Rh — Standard 0458458 DO.4978786 4978786

Filler–Diffuser Lh 0421028 TP.0421028 4910129

Filler–Diffuser Mullion 0421030 TP.4914216 4914216

Filler–Diffuser Rh 0421029 TP.4914291 4914291

P/N 0425683F

®

20

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Parts List

(Continued)

Description Mfg Aftermarket Service

Part No. Part No. Part No.

Page 23

Innovator Door Installation and

Service Instruction

P/N 0425683F

21

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Parts List

(Concluded)

Description Mfg Aftermarket Service

Part No. Part No. Part No.

Gasket–Black Magnetic — Standard 0428562 GA.4330101 4330101

Gasket–Gray Magnetic — Standard 0428563 GA.4330102 4330102

Gasket–Black Magnetic — RLT 0461957 GA.4330208 4330208

Gasket–Gray Magnetic — RLT 0461958 GA.4330207 4330207

Handle–Standard Black Door 0428559 HH.0428559 4910106

Handle–Standard Gray Door 0428561 HH.4910107 4910107

Handle–Standard 311 Pearl Door 0441686 HH.4914279 4914279

Harness–Ballast Supply 2 Door 0430293 ES.0430293 4440112

Harness–Ballast Supply 3 Door 0430294 ES.0430294 4440113

Harness–Ballast Supply 4 Door 0430295 ES.0430295 4440114

Harness–Ballast Supply 5 Door 0430296 ES.0430296 4440115

Harness–Door Heater 2 Door 0432596 ES.0432596 4440108

Harness–Door Heater 3 Door 0432597 ES.0432597 4440109

Harness–Door Heater 4 Door 0432598 ES.0432598 4440110

Harness–Door Heater 5 Door 0432599 ES.0432599 4440111

Harness–Female Receptacle Black 0432600 ES.0432600 4440104

Harness–Female Receptacle Gray 0432601 ES.0432601 4440105

Harness–Female Receptacle 311 Pearl N/A N/A N/A

Harness–Opposite Swing Black 0432612 ES.0432612 4440106

Harness–Opposite Swing Gray 0432613 ES.0432613 4440107

Harness–Opposite Swing 311 Pearl N/A N/A N/A

Heater–Frame Wire 2 Door Innovator Low Temp — Standard 0428601 HE.4480101 4480101

Heater–Frame Wire 3 Door Innovator Low Temp — Standard 0428602 HE.4480102 4480102

Heater–Frame Wire 4 Door Innovator Low Temp — Standard 0428603 HE.4480103 4480103

Heater–Frame Wire 5 Door Innovator Low Temp — Standard 0428604 HE.4480104 4480104

Heater–Frame Wire 2 Door Innovator — RLT 0458438 HE.4850651 4850651

Heater–Frame Wire 3 Door Innovator — RLT 0458439 HE.4850610 4850610

Heater–Frame Wire 4 Door Innovator — RLT 0458440 HE.4850652 4850652

Heater–Frame Wire 5 Door Innovator — RLT 0458441 HE.4850611 4850611

Page 24

P/N 0425683F

22

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

®

Parts List

(Continued)

Description Mfg Aftermarket Service

Part No. Part No. Part No.

Heater–Frame Wire 2 Door Innovator II & Med Temp 0440150 HA.440150 4480113

Heater–Frame Wire 3 Door Innovator II & Med Temp 0440151 HA.440151 4480114

Heater–Frame Wire 4 Door Innovator II & Med Temp 0440152 HA.440152 4480115

Heater–Frame Wire 5 Door Innovator II & Med Temp 0440153 HA.0440153 4480116

Lamp–Fluorescent F58/T8 4100K, Standard 0428614 BU.4480339 4480339

Lamp–Fluorescent F58/T8 3500K, 0425687 BU.0425687 4480340

Lamp–Fluorescent F58/T8 3500K, GE 0425694 BU.0425694 4480105

lamp-holder–Bottom 0428582 BU.4440116 4440116

lamp-holder–Top 0428583 BU.4440117 4440117

Molding–End Black — Standard 0425607 TP.0425607 4980336

Molding–End Gray — Standard 0425609 TP.0425609 4980337

Molding–End 311 Pearl — Standard 0442338 TP.0442338 4980338

Molding–End Black — RLT 0456200 TP.4987550 4987550

Molding–End Gray — RLT 0456201 TP.4912879 4912879

Molding–End 311 Pearl — RLT N/A N/A N/A

Molding–Joint Black — Standard 0425608 TP.0425608 4980340

Molding–Joint Gray — Standard 0425610 TP.0425610 4980341

Molding–Joint 311 Pearl — Standard 0442337 TP.0442337 4980339

Molding–Joint Black — RLT 0456200 TP.4987550 4987550

Molding–Joint Gray — RLT 0456201 TP.4912879 4912879

Molding–Joint 311 Pearl — RLT N/A N/A N/A

Pin–Top Hinge 0428546 HH.4550121 4550121

Plug – 1/4 Button Black 0428597 HH.0428597 4550115

Plug – 1/4 Button Gray 0428599 HH.0428599 4550117

Plug – 1/4 Button 311 Pearl 0441687 TP.0441687 4910285

Plug – 3/4 Button Black 0428596 HH.0428596 4550116

Plug – 3/4 Button Gray 0428598 HH.0428598 4550118

Plug – 3/4 Button 311 Pearl 0442937 TP.4987257 4987257

Page 25

Retainer–Door Black 0458446 TP.4913201 4913201

Retainer–Door Silver 0458447 TP.4978039 4978039

Screw–Handle 0428558 XX.0428558 4550108

Screw–Harness 0428652 BA.4480897 4480897

Screw–Hold-open Shoulder Black 0442731 DO.4550301 4550301

Screw–Hold-open Shoulder Silver 0442732 DO.4550303 4550303

Screw–Case End Shoulder Black 0428616 XX.0428616 4550128

Screw–Case End Shoulder Silver 0428617 XX.0428617 4550129

Screw–Socket Retainer Black 0430364 XX.0430364 4550111

Screw–Socket Retainer Silver 0430365 XX.0430365 4550112

Screw–Oval Head Sheet Metal 0425647 XX.0425647 4550107

Shield–Lamp 0428600 BU.0428600 4550106

Socket–Bottom Hinge Black 0428586 HH.4550104 4550104

Socket–Bottom Hinge Silver 0428590 HH.4550102 4550102

Socket–Top Hinge Black 0428585 HH.4550101 4550101

Socket–Top Hinge Silver 0428589 HH.4550103 4550103

Spring–Top Hinge Pin 0428549 HH.4550114 4550114

Switch–Ballast Supply Power 0428613 SW.4440103 4440103

Washer–Flat Torsion Assembly 0428629 XX.0428629 4550124

Innovator Door Installation and

Service Instruction

P/N 0425683F

23

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Parts List

(Continued)

Description Mfg Aftermarket Service

Part No. Part No. Part No.

Page 26

APPENDIX A –

REPLACEMENT BALLAST

WIRING

The diagrams below may be of

assistance when changing from

one ballast type to another. All

wiring must be done in accordance with NEC and local

codes.

P/N 0425683F

®

24

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

g

Please note that line side is on top

Black

Single lamp wiring

same as old.

White

Red

Red

Blue

Blue

Two lamp wiring has a red wire from each lamp spliced together.

Two blues and one red go to the ballast as a group.

Black

White

Blue

Blue

Blue

Red

Red

Blue

Red

Red

HUSSMANN / SYL - QT 2X54/120PHC P/N 0425671

Blue

Blue

Blue

Blue

Red

Red

Red

Red

L

N

HUSSMANN / Jamicon 2/F58/120V P/N 0430330

Note that one lamp goes to top 3 pins other lamp to bottom 3 pins with a common connection between them.

N

L

G

Please note:

Neutral on top

Power / Line middle

Ground bottom

Blue

Blue

Blue

Blue

Red

Red

Red

Two lamp wiring has a red wire from each lamp

spliced together and returning to the ballast.

Two blues and one red go to the ballast as a group from each lamp.

Page 27

To obtain warranty information

or other support, contact your

Hussmann representative.

Please include the model and

serial number of the product.

Hussmann Corporation, Corporate Headquarters: Bridgeton, Missouri, U.S.A. 63044-2483 01 July 2005

®

Loading...

Loading...