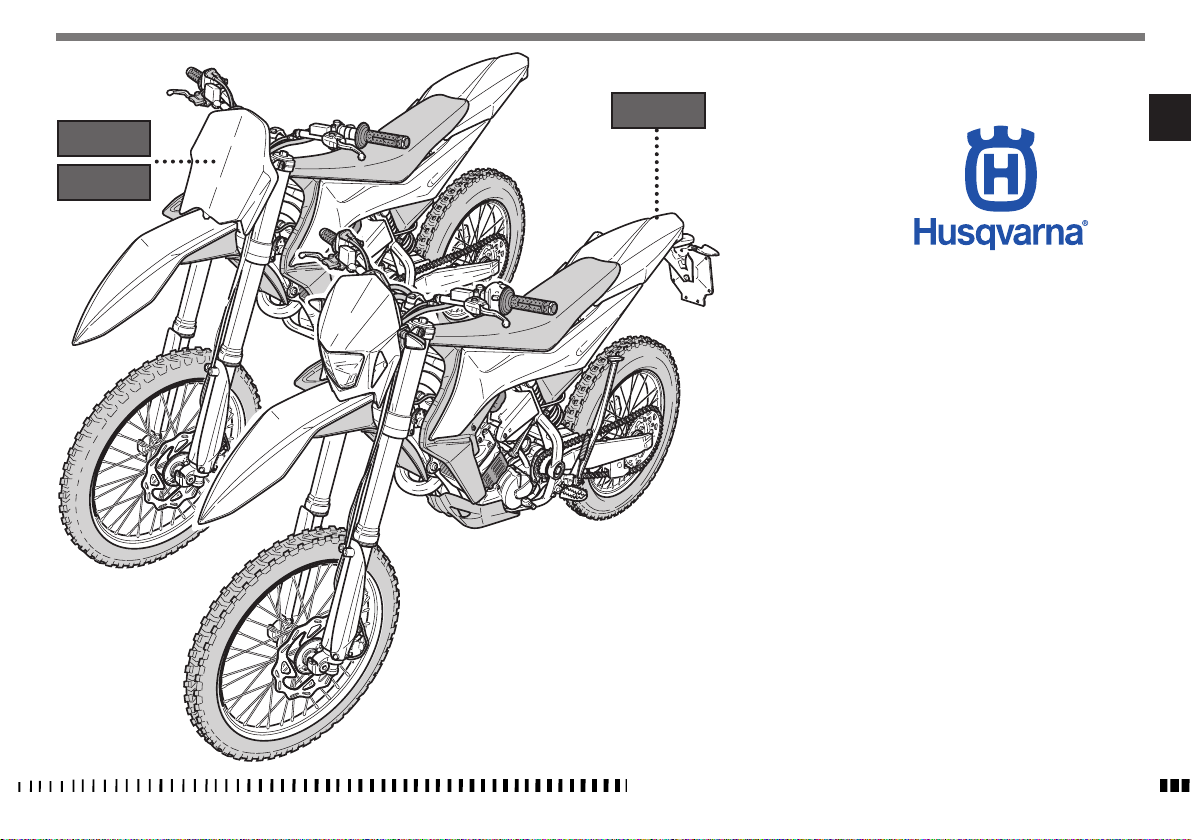

TXC

TC

TE

EN

TC - TE 449 2013 I.E.

TE - TXC 511 2013 I. E.

Ed. 03-2012 - Rev. 00

Unless specified, data and prescription are referred to all the models.

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 1

EN - 2

SPECIFICATIONS - OPERATION - MAINTENANCE

SUMMARY Page

PRESENTATION ............................................................3

IMPORTANT NOTICES....................................................3

INTENDED USE .............................................................4

IDENTIFICATION DATA ..................................................5

TECHNICAL DATA ..........................................................6

TABLE FOR LUBRICATION, SUPPLIES ..............................7

MOTORCYCLE OVERALL VIEW - TE ..................................8

MOTORCYCLE OVERALL VIEW - TC - TXC ........................10

CONTROLS .................................................................12

RIDING

.......................................................................19

APPENDIX ..................................................................51

PRE-DELIVERY INSPECTION .........................................52

ALPHABETICAL INDEX ................................................. 53

SCHEDULED MAINTENANCE ..........................APPENDIX A

Note

lReferences to the “left” or “right” of the motorcycle are

considered from the point of view of a person facing forward.

lZ: number of teeth

l A: Austria

AUS: Australia

B: Belgium

BR: Brazil

CDN: Canada

CH: Switzerland

D: Germany

E: Spain

F: France

FIN: Finland

GB: Great Britain

I: Italy

J: Japan

USA: United States of America

lUnless otherwise specified, all the data and the instructions

are referred to any and all Countries.

EN - 3

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

PRESENTATION

Welcome to the Husqvarna motorcycling Family!

Your new Husqvarna motorcycle is designed and manufactured to be the best in its field. The instructions in

this book have been prepared to provide a simple and

understandable guide for your motorcycle’s operation

and care. Follow the instructions carefully to obtain

maximum performance and your personal motorcycling pleasure. Your owner’s manual contains instructions for owner care and maintenance. The main repair

or maintenance work requires the attention of a skilled

mechanic and the use of special tools and equipment.

Your Husqvarna Dealer has the facilities, experience

and original parts necessary to properly render this

valuable service.

This “Owner’s Manual” is part and

parcel of the motorcycle, hence, it shall

remain with the motorcycle even when

sold to another user.

This motorcycle uses components designed thanks to

systems and state-of-the-art technologies which are

thereafter tested in competitions.

In racing motorcycles, every detail is verified after each

race in order to always guarantee better performance.

To ensure trouble-free operation of the vehicle, it is necessary to follow the maintenance and inspection table

found under Appendix A.

IMPORTANT NOTICES

1) TC - TXC models are designed for RACING use, and guar-

anteed free from operating faults; the recommended maintenance table for racing use can be found in Appendix A.

2) TE models are designed for ROAD use, guaranteed

free from faults, and covered by legal warranty provided

that NO CHANGE IS MADE TO THE STANDARD SETTING and

that the intervals specified on maintenance table of Appendix A are complied with.

TXC

TC

3) All the motorcycles and any of their

parts used in competitions of any type

are excluded from the warranty.

TE

EN - 4

SPECIFICATIONS - OPERATION - MAINTENANCE

IMPORTANT

In order to maintain the vehicle’s “Guarantee of Functionality”, the client must

follow the maintenance programme indicated in the user’s manual by carrying

out maintenance inspections at authorised HUSQVARNA dealers.

The cost for changing parts and for the

labour necessary in order to comply

with the maintenance plan is charged to

the Client.

NOTE: the warranty is NULL AND VOID if

the motorcycle is rented.

Important Notice

Read this manual carefully and pay special attention to

statements preceded by the following words:

WARNING*: Indicates the possibility of severe

personal injury or death if instructions are not

followed.

CAUTION*: Indicates the possibility of personal

injury or vehicle damage if instructions are not

followed.

Note*: Gives helpful information.

WARNING*: Never attempt to start or operate

your motorcycle unless you are wearing appropriate protective clothing. Always wear a

motorcycle helmet, boots, gloves, goggles and

other appropriate protective clothing.

PRECAUTIONS FOR CHILDREN

WARNING

l Park the vehicle where it is unlikely to be

bumped into or damaged.

Even slight or involuntary bumps can cause

the vehicle to tip over, with subsequent risk

of serious harm to people or children.

l To prevent the vehicle from tipping over, nev-

er park it on soft or uneven ground, nor on

asphalt strongly heated by the sun.

l Engine and exhaust pipes become very hot

during riding. Always park your motorcycle

where people or children can not easily reach

these parts, in order to avoid serious scalds.

INTENDED USE

This motorcycle has been manufactured so as to withstand the standard Offroad stresses.

Nevertheless, it is not suitable for use under the following conditions:

- prolonged use at a steady speed;

- prolonged use with fully-opened throttles;

- use with luggage;

WARNING* riding the motorcycle for

more than two consecutive minutes

with fully-opened throttles could cause

engine damage, with consequent faults

storage inside memory. Any warranty

claim for engine damage caused by

too high engine revs will be rejected

HUSQVARNA MOTORCYCLES S.R.L.

by

When parts replacement is required, use only Husqvarna

Parts Replacement

ORIGINAL parts.

WARNING*: After a crash, inspect the motorcycle

carefully. Make sure that the throttle, brake,

clutch and all other systems are undamaged.

Riding with a damaged motorcycle can lead to

a serious accident.

EN - 5

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

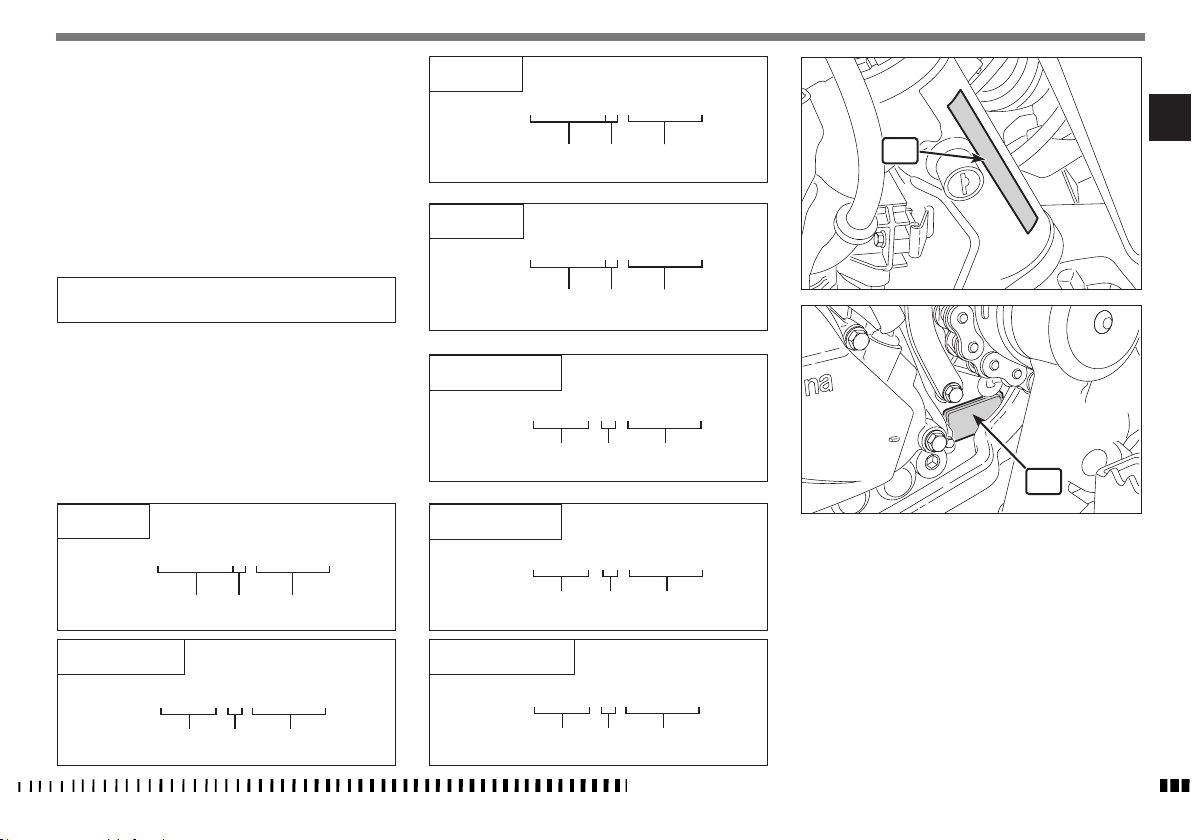

IDENTIFICATION DATA

The engine identification number is stamped at the top of

the crankcase, while vehicle serial number is stamped on

the frame steering tube.

Always quote the number stamped on the

frame when ordering spare parts or requesting further

details about your vehicle and note it on this booklet.

CHASSIS NUMBER

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17-digit serial, or Vehicle Identification Number, is

stamped on the steering tube (R.H. side).

(

l

) = Model designation

(▲) = Model Year (2013)

(♦) = Progressive no.

TE 449

ZKHA600AADV000001

(l) (▲)

TE 511

ZKHA601AADV000001

(l) (▲)

TE 449 USA

ZKHKEEFM#DV000001

(l) (▲) (♦)

(

♦

)

(

♦

)

1

2

TC 449

ZKHA600AADV050001

(l) (▲)

TC 449 USA

ZKHTC443#DV000001

(l) (▲) (♦)

TE 511 USA

1. Chassis serial number

2. Engine serial number

ZKHKEEGM#DV000001

(

♦

)

(l) (▲) (♦)

TXC 511 USA

ZKHTX510#DV000001

(l) (▲) (♦)

EN - 6

SPECIFICATIONS - OPERATION - MAINTENANCE

TECHNICAL DATA

ENGINE

Type . . . . . . . . . . . . . . . . . . . . single cylinder, 4 stroke

(TE - TXC)

Liquid cooling with double radiator and electric fan

(TC)

Liquid cooling with double radiator

TC-TE 449

Bore . . . . . . . . . . . . . . . . . . . . . . . . . .3.86 in (98 mm)

Stroke .......................2.35 in (59,6 mm)

Displacement . . . . . . . . . . . . .27.44 cu. in (449,6 cm3)

(TC) Compression ratio . . . . . . . . . . . . . . . . . . . . . 13:1

(TE-TXC) Compression ratio . . . . . . . . . . . . . . . . . . 12:1

TE-TXC 511

Bore . . . . . . . . . . . . . . . . . . . . . . . . .3.98 in (101 mm)

Stroke .......................2.35 in (59,6 mm)

Displacement . . . . . . . . . . . . . 29.14 cu.in (477,5 cm3)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . 12:1

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . electric

Type of fuel .............unleaded fuel 95ROZ/RON

TIMING SYSTEM

Type . . .

double overhead camshaft chain operated; 4 valve

Valve clearance (with engine cold)

Intake ...........0.008 ÷ 0.01 in (0,20 ÷ 0,25 mm)

Exhaust .........0.011 ÷ 0.013 in (0,30 ÷ 0,35 mm)

LUBRICATION

Type . . . . . . . . . . . . . . . wet sump with two lobe pumps

and cartridge filter

IGNITION

Type . . . . . . . . . .Capacitive discharge electronic system

with adjustable advance (digital control)

Spark plug type . . . . . . . . . . . . . . . . . .“NGK” CR 9EKB

Spark plug electrode gap . . . . . . . . 0.028 in (0,7 mm)

FUEL SYSTEM

Type . . . . . . . . . . . . . . . . . . . . .Electronic injection feed

PRIMARY DRIVE

Drive pinion gear . . . . . . . . . . . . . . . . . . . . . . . . . Z 32

Clutch ring gear ..........................Z 22

Transmission ratio . . . . . . . . . . . . . . . . . . . . . . . 2.618

CLUTCH

Type . . . . oil bath multiple disc clutch, hydraulic control

TRANSMISSION

Type . . . . . . . . . . . . . . . . . . . . constant mesh gear type

Transmission ratio

(TC)

1st gear . . . . . . . . . . . . . . . . . . . . . . . . 2.286 (32/14)

2nd gear ........................1.875 (30/16)

3rd gear ........................1.533 (23/15)

4th gear . . . . . . . . . . . . . . . . . . . . . . . . 1.260 (29/23)

5th gear . . . . . . . . . . . . . . . . . . . . . . . . 1.043 (24/23)

(TE - TXC)

1st gear . . . . . . . . . . . . . . . . . . . . . . . . 2.286 (32/14)

2nd gear ........................1.875 (30/16)

3rd gear ........................1.533 (23/15)

4th gear . . . . . . . . . . . . . . . . . . . . . . . . 1.250 (25/20)

5th gear . . . . . . . . . . . . . . . . . . . . . . . . 1.043 (24/23)

6th gear . . . . . . . . . . . . . . . . . . . . . . . . 0.917 (22/24)

SECONDARY DRIVE

Transmission sprocket . . . . . . . . . . . . . . . . . . . . . Z 15

Wheel sprocket (TC) . . . . . . . . . . . . . . . . . . . . . . . Z 53

Wheel sprocket (TE - TXC) . . . . . . . . . . . . . . . . . . . Z 51

Transmission ratio (TC) . . . . . . . . . . . . . . . . . . . . 3.530

Transmission ratio (TE - TXC) . . . . . . . . . . . . . . . . . 3.40

Transmission chain dimensions . . . . . . . . . .5/8”x1/4”

FINAL RATIOS

(TC)

1st gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.126

2nd gear ..............................17.327

3rd gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.167

4th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.644

5th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.639

(TE - TXC)

1st gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.348

2nd gear ..............................16.689

3rd gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.645

4th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.126

5th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.283

6th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.162

CHASSIS

Type . . . . . . . . . . . . . . . . . . . . . . . twin beam and twin

cradle steel chassis with round and elliptic cross-section,

rear subframe in aluminium alloy.

FRONT SUSPENSION

Fork type . . .Upside-down hydraulic fork and advanced

stanchion (adjustable compression and rebound); tubes

ø 1.89 in (ø 48 mm)

Travel .......................11.81 in (300 mm)

REAR SUSPENSION

Type . .progressive with hydraulic single shock absorber

(preload regulation of spring and hydraulic brake in

compression and extension)

Wheel travel . . . . . . . . . . . . . . . . . .11.81 in (300 mm)

EN - 7

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

FRONT BRAKE

Fixed disc type . . . . . “WAVE” Ø 10.23 in (Ø 260 mm)

with hydraulic control and floating calliper.

REAR BRAKE

Fixed disc type . . . . . . . “WAVE” Ø 9.45 in (Ø240 mm)

with hydraulic control and floating calliper

RIMS

Front .....................in light alloy: 1.6”x21”

(TC) Rear . . . . . . . . . . . . . . . .in light alloy: 2.15”x19”

(TE-TXC) Rear . . . . . . . . . . . . .in light alloy: 2.15”x18”

TYRES

(TC)

Front ............................ 80/100x21”

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110/90x19”

(TXC)

Front ............................ 80/100x21”

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . 110/100x18”

(TE)

Front ............................. 90/90x21”

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140/80x18”

Cold tyre pressure

Front

TC ............12.8 ÷ 14.22 psi (0,9 ÷ 1,0 Kg/cm

TE - TXC (*) ......12.8 ÷ 14.22 psi (0,9 ÷ 1,0 Kg/cm2)

TE (%) . . . . . . . . . . . . . . . . . 15.64 psi () 1,1 Kg/cm

Rear

TC .............11.37 ÷ 12.8 psi (0,8 ÷ 0,9 Kg/cm

TE - TXC (*) ......11.37 ÷ 12.8 psi (0,8 ÷ 0,9 Kg/cm2)

TE (%) ....................14.22 psi (1,0 Kg/cm

(*) - In case of racing use

(%) - Road use

DIMENSION, WEIGHT, CAPACITY

(TC-TXC)

Wheelbase ..................58.66 in (1490 mm)

Overall length ................86.92 in (2208 mm)

Overall width .................32.28 in (820 mm)

Max. height . . . . . . . . . . . . . . . . .49.60 in (1260 mm)

Saddle height . . . . . . . . . . . . . . . . .37.71 in (958 mm)

Min. ground clearance ...........13.19 in (335 mm)

(TE)

Wheelbase ..................58.66 in (1490 mm)

Overall length ................86.92 in (2280 mm)

Overall width .................32.28 in (820 mm)

Max. height . . . . . . . . . . . . . . . . .49.60 in (1260 mm)

Saddle height . . . . . . . . . . . . . . . . .37.91 in (963 mm)

Min. ground clearance ...........13.19 in (335 mm)

Kerb weight, without fuel.

(TE) . . . . . . . . . . . . . . . . . . . . . . . .249.12 lb (113 kg)

(TC) . . . . . . . . . . . . . . . . . . . . . . . .238.10 lb (108 kg)

(TXC) . . . . . . . . . . . . . . . . . . . . . . .242.50 lb (110 kg)

Fuel tank capacity, reserve included

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.87 Imp. Gall

2.25 U.S. Gall

8,5 l

2

)

(TE 499/511) .................... 1.87 Imp. Gall

2.25 U.S. Gall

2

)

8,5 l

2

)

(TE 499/511 USA) . . . . . . . . . . . . . . . . 2.09 Imp. Gall

2.51 U.S. Gall

2

)

9,5 l

(TXC) . . . . . . . . . . . . . . . . . . . . . . . . . . .2.09 Imp. Gall

2.51 U.S. Gall

9,5 l

Fuel reserve (warning light coming on - TE)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.44 Imp. Gall

0.53 U.S. Gall

2 l

Coolant capacity . . . . . . . . . . . . . . . . . . . .0.2 Imp. Gall

0.24 U.S. Gall

0,9 l

Transmission oil

Oil and filter replacement . . . . . . . .Max 0.25 Imp. Gall

0.3 U.S. Gall

Max. 1,15 l

Oil replacement ....................0.22 Imp. Gall

0.26 U.S. Gall

1 l

TABLE FOR LUBRICATION, SUPPLIES

Engine, gearbox and primary drive lubricating oil .......

. . . . . . . . . . . . . . . . . . . . . . . . .

CASTROL GPS SAE 10W-40

Engine coolant . . . . . . . . .CASTROL MOTORCYCLE COOLANT

Brake system fluid . . . . .CASTROL RESPONSE SUPER DOT 4

Clutch fluid ...........CASTROL RESPONSE SUPER DOT 4

Grease lubrication ...........

Final drive chain lubrication

CASTROL PASTE TA GREASE

. . CASTROL CHAIN LUBE RACING

Front fork oil ...........CASTROL SYNTHETIC FORK OIL 5W

Oil for rear shock absorber . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

CASTROL SYNTHETIC FORK OIL 5W

Electric contact protection . CASTROL METAL PARTS CLEANER

Fillers for radiator ........AREXONS TURAFALLE LIQUIDO

EN - 8

SPECIFICATIONS - OPERATION - MAINTENANCE

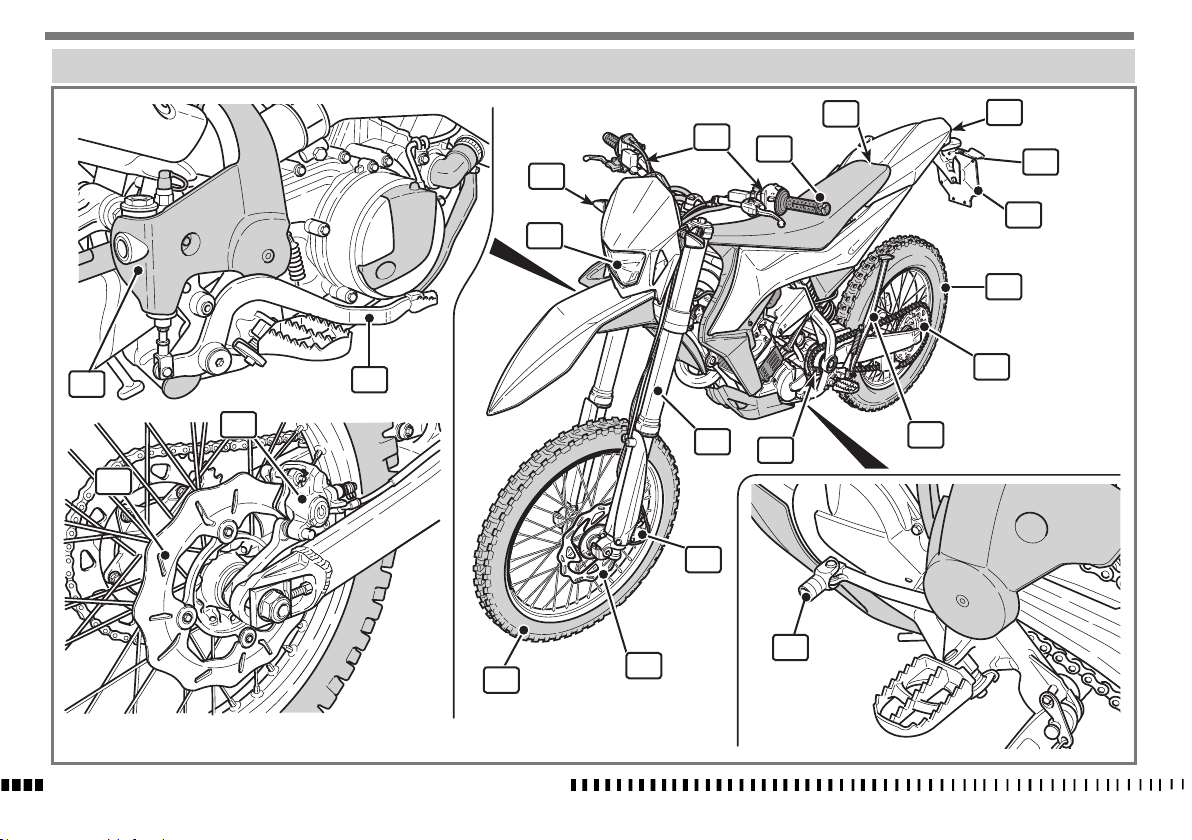

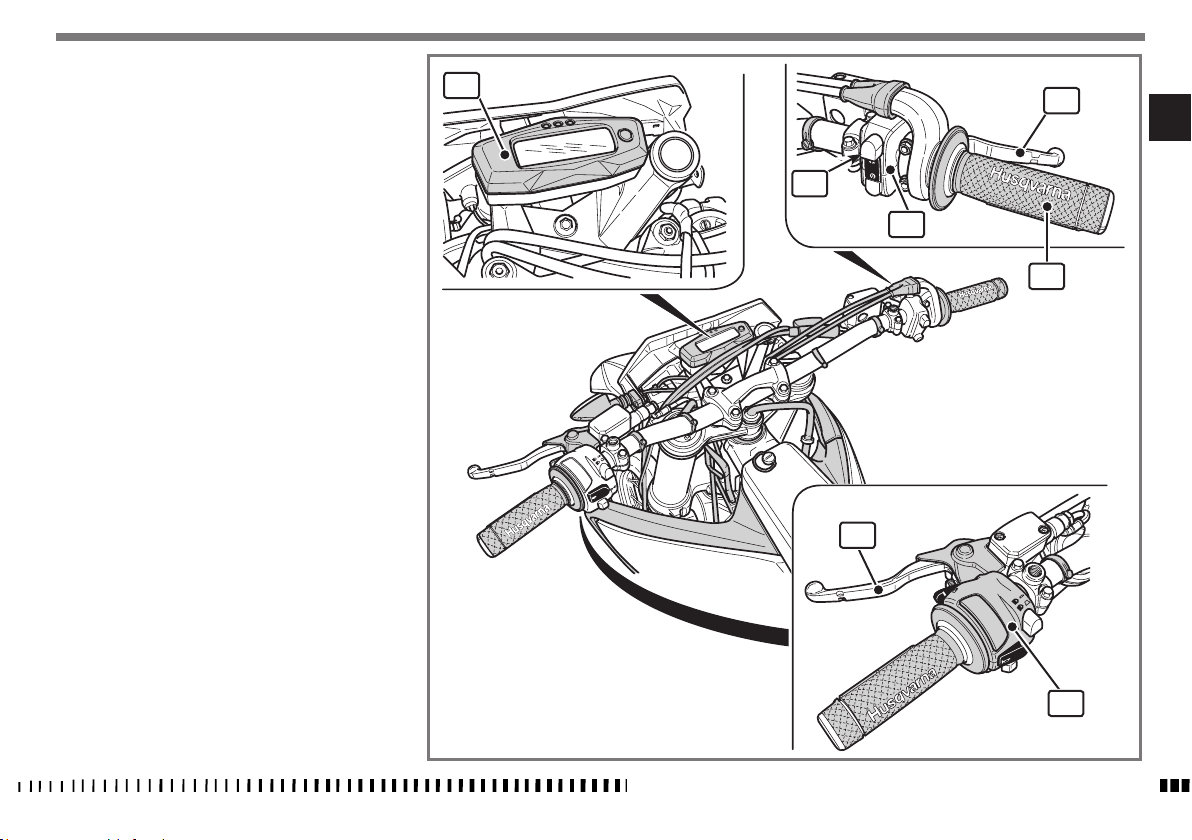

MOTORCYCLE OVERALL VIEW - TE

19

20

21

18

13

15

16

17

3

1

2

14

4

6

5

7

12

11

10

9

8

EN - 9

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

LEGEND

1. Front wheel

2. Front brake disc

3. Front brake calliper

4. Front fork

5. Gear shift pedal (the first gear is engaged by

pushing lever downwards; for other gears push

it upwards. The neutral gear is between the first

and second gear)

6. Front sprocket

7. Side stand

8. Rear sprocket

9. Rear wheel

10. Number plate holder

11. Rear turning indicators

12. Tail light

13. Fuel tank filler cap

14. Saddle

15. Handlebar controls

16. Front turning indicators

17. Headlight

18. Rear brake control pedal

19. Rear brake master cylinder

20. Rear brake disc

21. Rear brake calliper

22. Instrument

23. L.H. switch

24. ENGINE STOP button

25. R.H. switch

26. Front brake control lever

27. Throttle control twistgrip

28. Clutch control lever

22

26

24

25

27

28

23

EN - 10

SPECIFICATIONS - OPERATION - MAINTENANCE

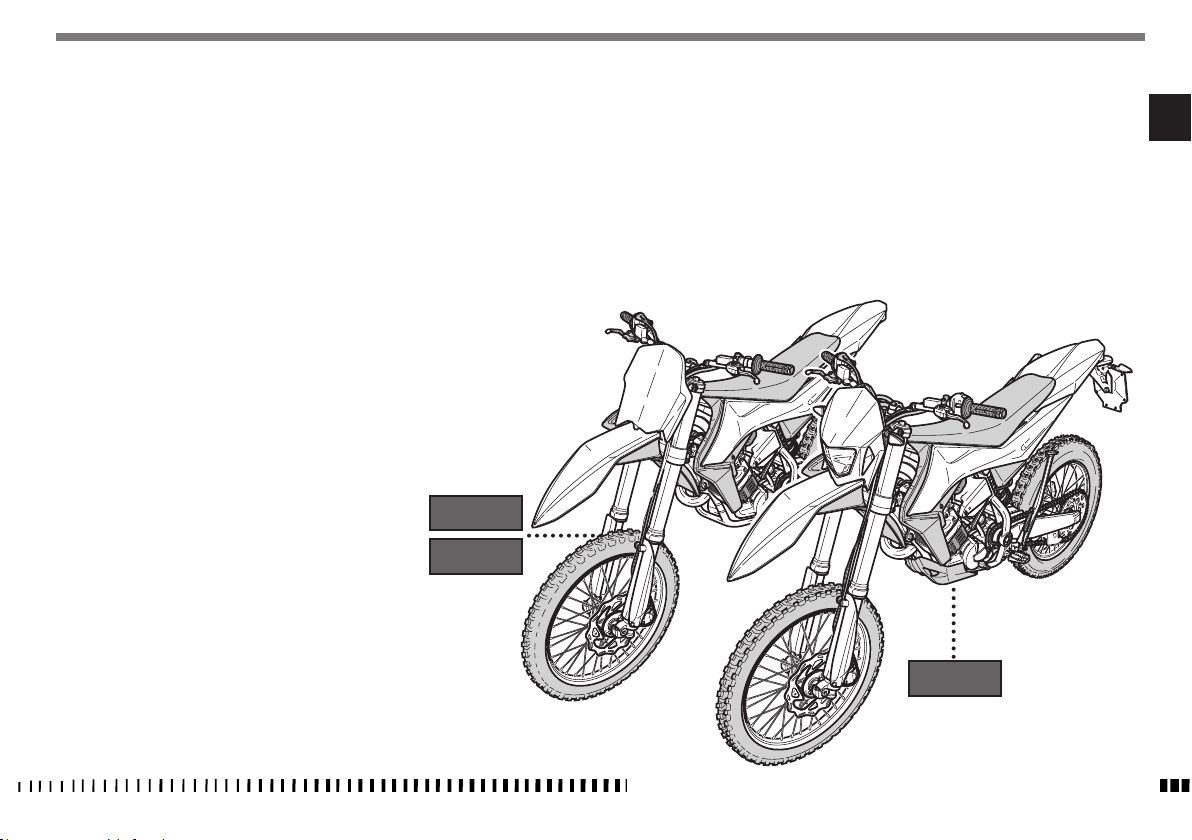

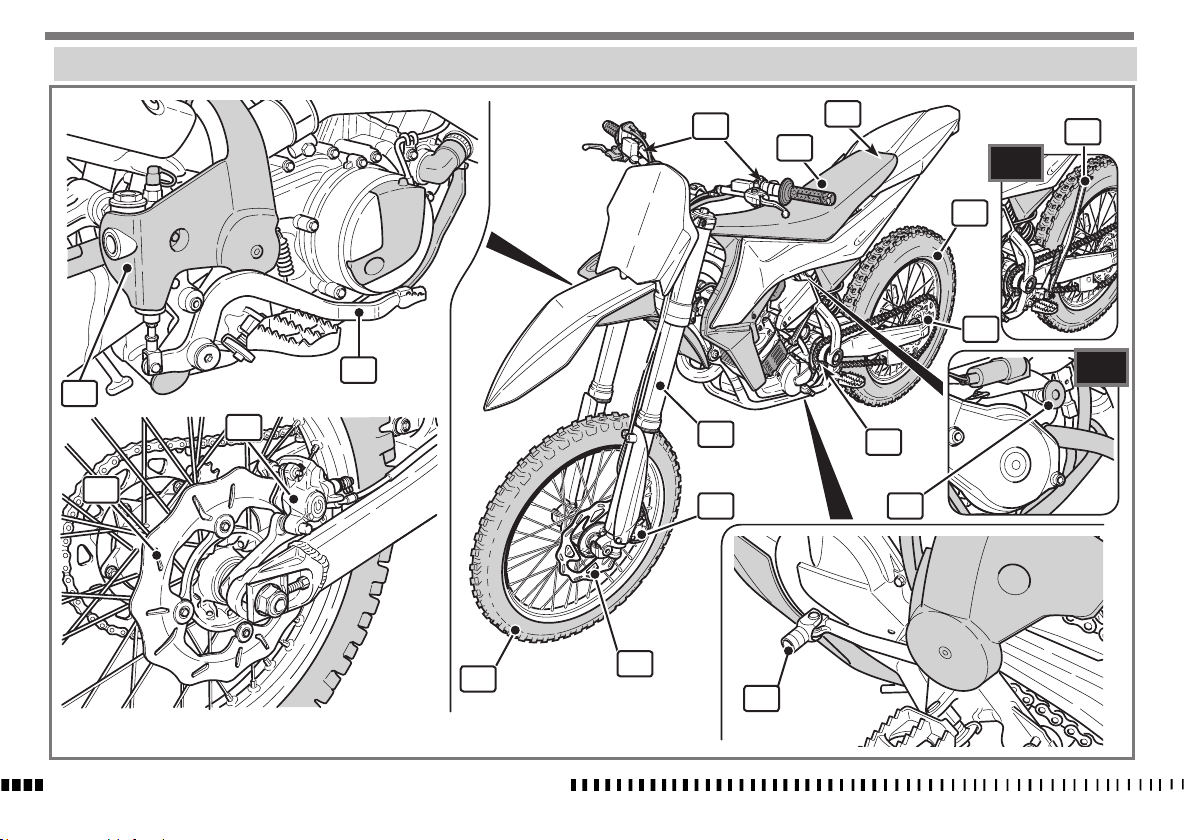

MOTORCYCLE OVERALL VIEW - TC - TXC

14

15

16

13

11

10

7

TXC

9

8

12

TC

4

3

1

2

5

6

23

EN - 11

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

LEGEND

1. Front wheel

2. Front brake disc

3. Front brake calliper

4. Front fork

5. Gear shift pedal (the first gear is engaged by

pushing lever downwards; for other gears push

it upwards. The neutral gear is between the first

and second gear)

6. Front sprocket

7. Side stand (TXC)

8. Rear sprocket

9. Rear wheel

10. Fuel tank filler cap

11. Saddle

12. Handlebar controls

13. Rear brake control pedal

14. Rear brake master cylinder

15. Rear brake disc

16. Rear brake calliper

17. DOUBLE MAP push-button (TC)

18. R.H. switch

19. Front brake control lever

20. Throttle control twistgrip

21. Clutch control lever

22. ENGINE STOP button (TXC)

23. Starter device (TC)

TXC

17

TC

19

20

18

21

22

TC

EN - 12

SPECIFICATIONS - OPERATION - MAINTENANCE

CONTROLS

FUEL TAPS

The two screw taps (1) positioned on tanks left rear side,

shall always be left in fully OPEN position.

TE: The reserve warning is indicated on the digital instrument panel by the relevant warning light (See paragraph

“Digital instrument, warning lights”).

FUEL

Recommended fuel: premium grade UNLEADED petrol with octane rating of 95 or

higher.

WARNING*: Do not overfill the tank. Refer to the lower mark on filler. After

refuelling, make sure the tank cap (2)

is closed securely.

Note*: If the engine "knocks", change

fuel brand or use a higher octane rating fuel.

WARNING*: Do not continue operation if

the engine pings or knocks. The engine

will be damaged and could seize.

WARNING*: Fuel is extremely flammable and can be explosive under certain

conditions. Always stop the engine and

do not smoke or allow flames or sparks

in the area where the motorcycle is refuelled or fuel is stored.

TC TE - TXC

1

2

2

EN - 13

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

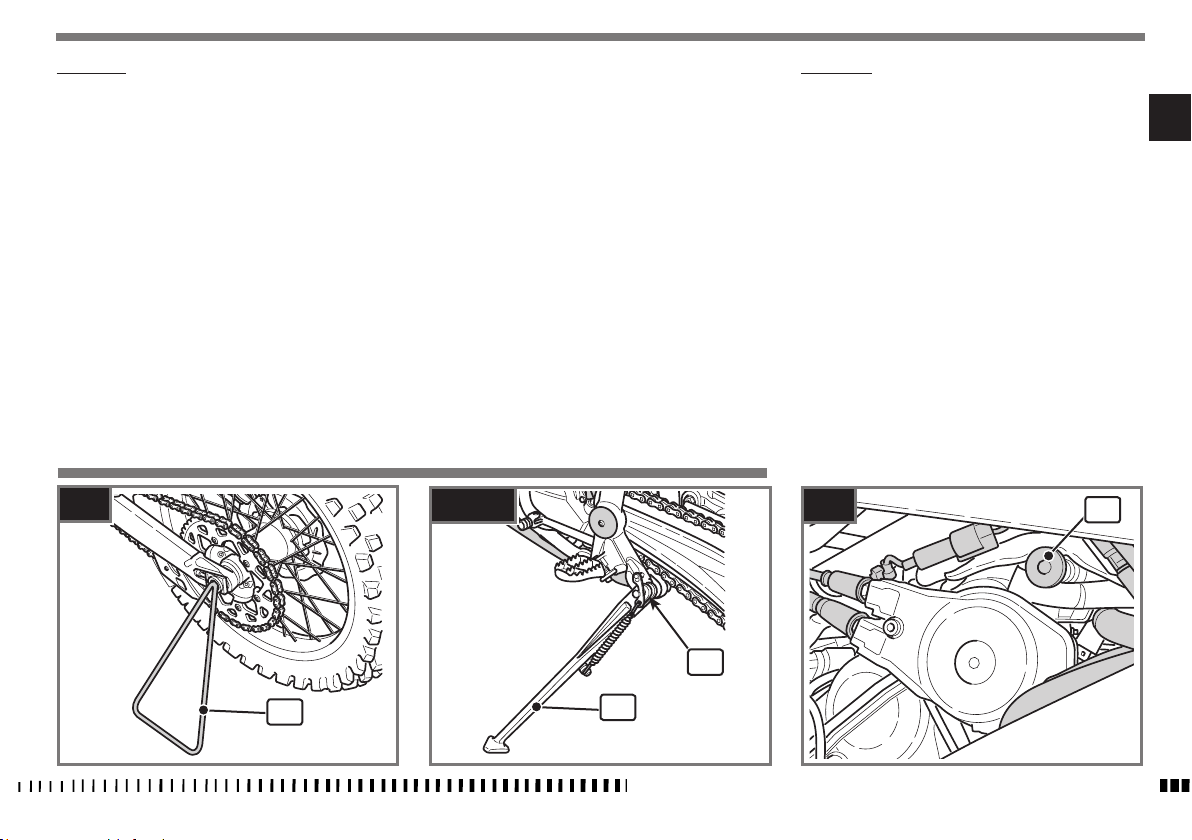

SIDE STAND

A side stand (1) is supplied with every motorcycle.

WARNING*: The stand is designed to

support the WEIGHT of the MOTORCYCLE ONLY. Do not sit astride the motorcycle using the stand for support this could

cause structural failure to the stand resulting in serious injury.

WARNING*: The motorcycle MUST be set

on the side stand ONLY AFTER the rider

has got off the vehicle. Stand AUTOMATICALLY folds back to rest position once

the vehicle is vertical, no longer resting

on the ground.

TE-TXC:

Periodically check the side stand (see “Scheduled Maintenance Chart”); make sure that the springs are not damaged and the side stand freely moves. If the side stand is

noisy, lubricate the fastening pivot (A).

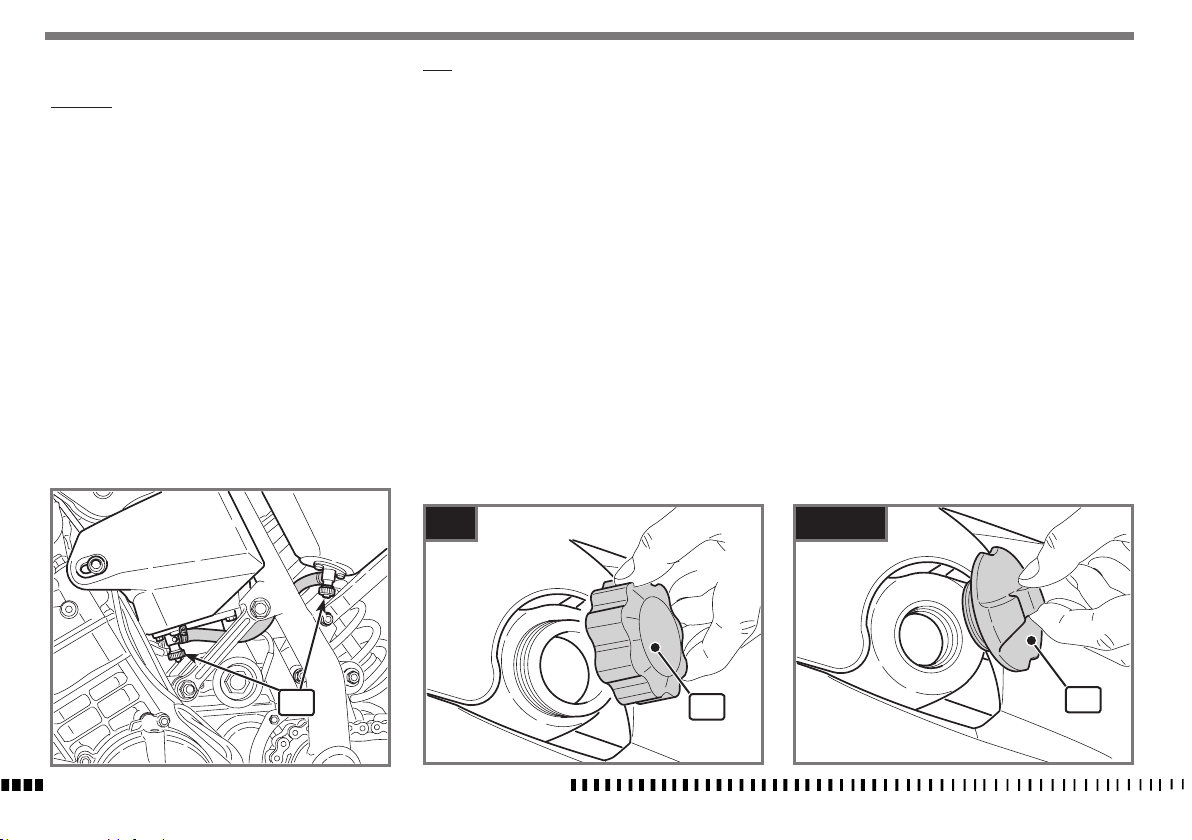

COLD START

TE-TXC:

These models feature an automatic starter positioned

onto throttle body that is automatically enabled based

on external temperature and engine temperature.

TC:

For cold start, motorcycle is equipped with a knob (1)

positioned on throttle body left side. Pull knob to enable

starter, push it to close it.

TC

TE-TXC

A

1

1

TC

1

EN - 14

SPECIFICATIONS - OPERATION - MAINTENANCE

DIGITAL DASHBOARD, WARNING LIGHTS (TE)

The motorcycle is fitted with a digital dashboard on which

3 warning lights are also available: high beam, turning

indicators and fuel reserve.

1- BLUE warning light “High beam”

2- GREEN warning light “Turning indicators”

3- ORANGE warning light “Fuel reserve”

When the ignition key is turned to the IGNITION position,

the dashboard display lights up (amber colour).

NOTES

- At every connection with the battery, the dashboard

shows the version of the test SW for the first 2 seconds;

after the check routine, the dashboard shows the last

planned function.

- When the engine is turned off, the dashboard does not

show any functions.

- To select dashboard functions and reset functions, use

the SCROLL button (A).

- The functions, which can be selected in this sequence,

are as follows:

1- SPEED / ODO (figure 1)

2- SPEED / CLOCK (figure 2)

3- SPEED / TRIP (figure 3)

4- SPEED / LAP TIMER (figure 4)

5- SPEED (figure 5)

1- SPEED / ODO (figure 1)

.................

IMPORTANT: In the event of a FUEL INJECTION SYSTEM MALFUNCTION, the word FAIL appears on the right

side of the dashboard display: When this is the

case, contact your HUSQVARNA dealer.

1- SPEED (Km/h or mph) / ODO (figure 1)

- SPEED: vehicle speed - maximum value: 299 Km/h or

299 mph;

- ODO: odometer- maximum value: 99999 km or

62136.50 mi;

To change unit from kilometres to miles or miles to kilometres, proceed as follows:

1) set to figure 1, turn the key to OFF and push SCROLL (A).

2) place the ignition key in the IGNITION position and

hold down the SCROLL button (A) until the word

“Km/h” is displayed.

3) the display will now alternate between “Km/h” and

“Mph Miles”, push the SCROLL button (A) again while

the desired unit is displayed.

2

1

3

A

A

EN - 15

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

2- SPEED / CLOCK (figure 2)

- SPEED: speed - maximum value: 299 Km/h or 299 mph;

- CLOCK: clock - reading from 0:00 to 23:59:59.

To reset the clock, push the SCROLL button (A) and hold

for more than 3 seconds in order to increase the hour

value; release the button then, after 3 seconds, it is possible to increase the minutes value;

4- SPEED / LAP TIMER (STP)

(figure 4)

- SPEED: speed - maximum value: 299 Km/h or 299 mph;

- STP 1: miles/kilometres covered time

- Reading from 0:00 to 99:59:59 (data will be lost after

disconnecting the battery).

To activate the function STP, push the SCROLL button (A)

and hold for more than 3 seconds.

5- SPEED (figure 5)

- SPEED: speed - maximum value: 299 Km/h or 299 mph

A

3- SPEED / TRIP 1 (figure 3)

- SPEED: speed - maximum value: 299 Km/h or 299 mph

- TRIP 1: distance- maximum value: 999.9 Km or 621.31

mi (data will be lost after disconnecting the battery).

To reset TRIP, push the SCROLL button (A) and hold for

more than 3 seconds.

A

- 1st step: activate function;

- 2nd step: stop counters

- 3rd step: reset STP;

- 4th step: activate function;

- 5th step: stop counters;

.............................

and so on

The display also provides a Neutral” and a fuel injection

system “Malfunction” indication; the latter takes

priority over any other indication.

MALFUNCTION: a "FUEL INJECTION SYSTEM MALFUNCTION" indicated by the word "FAIL" appearing in the

right-hand portion of the dashboard display.

A

EN - 16

SPECIFICATIONS - OPERATION - MAINTENANCE

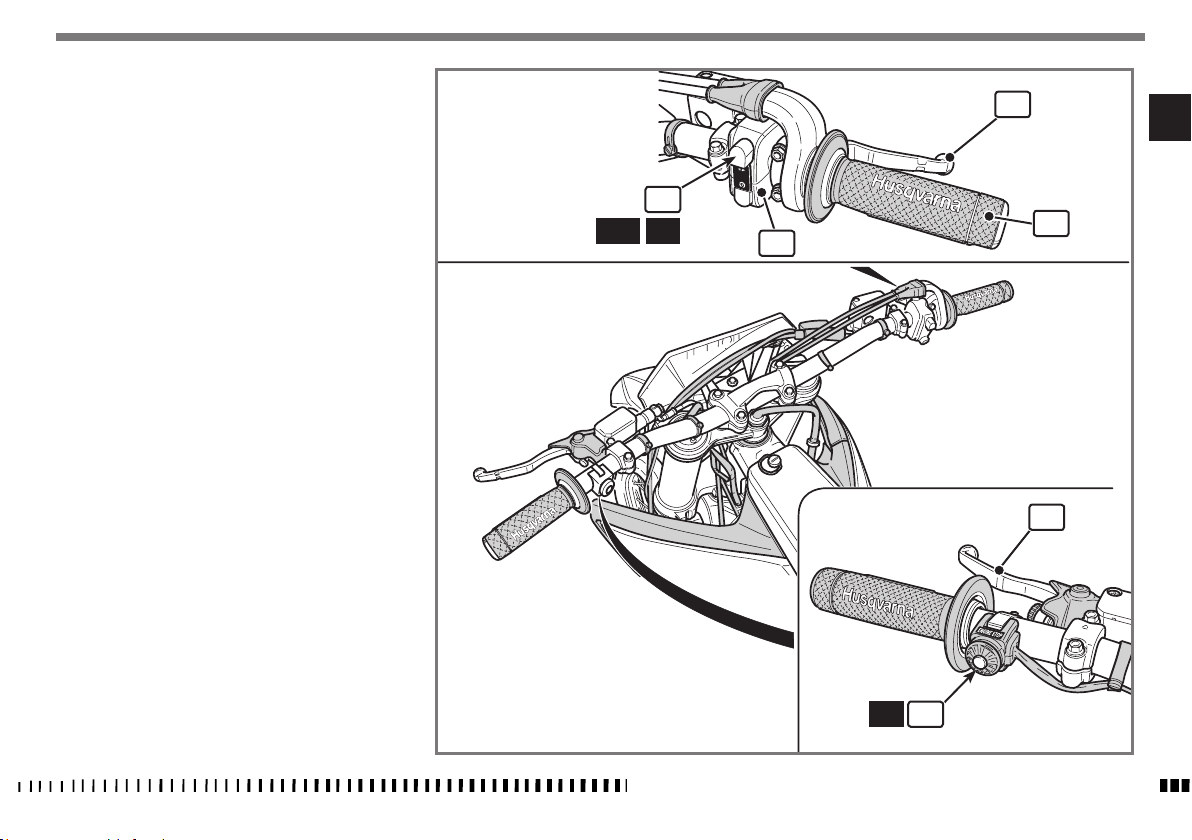

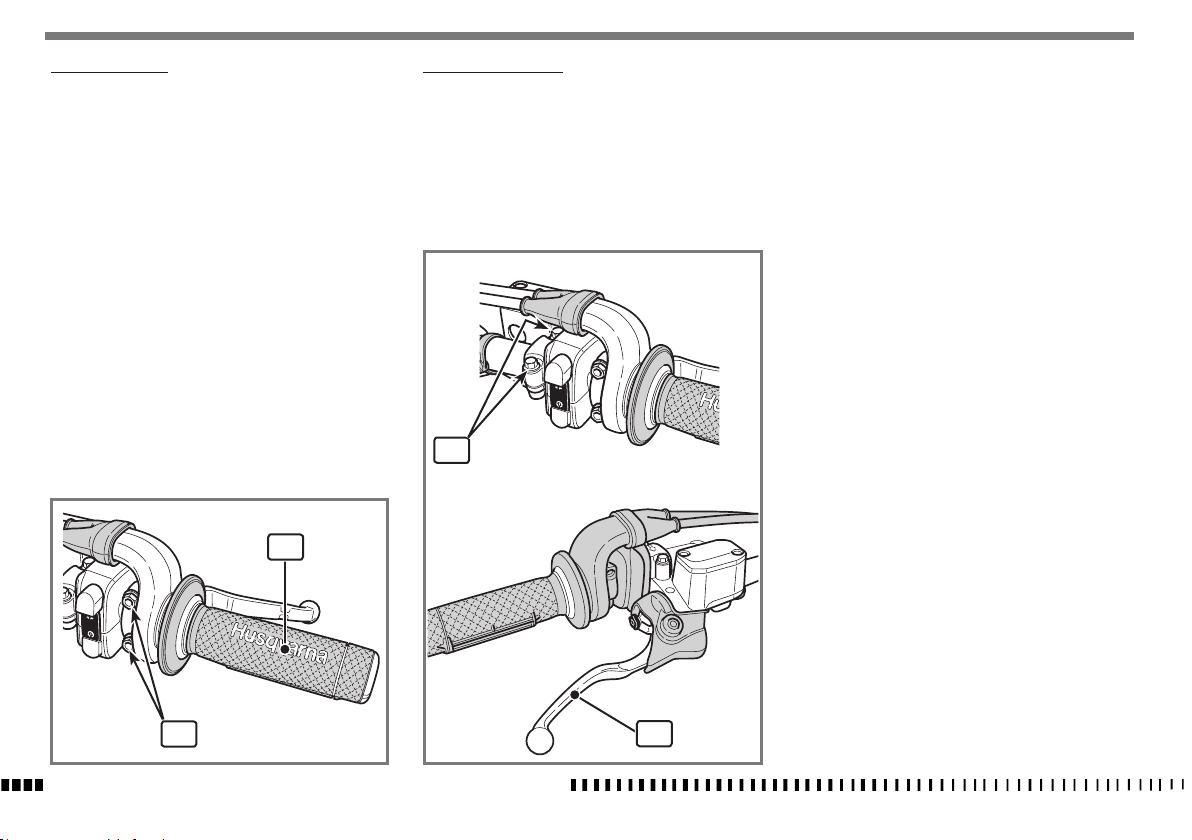

THROTTLE CONTROL

The throttle twistgrip (1) is located on the right-hand side

of the handlebar. The position of the throttle control can

be adjusted by loosening the two retaining screws.

CAUTION*

Do not forget to tighten the screws (A)

after the adjustment.

1

FRONT BRAKE CONTROL

The brake control lever (2) is located on the right-hand

side of the handlebar. The position of the control on handlebar can be adjusted by loosening the two retaining

screws (B).

CAUTION*

Do not forget to tighten the screws (B)

after the adjustment.

B

A

2

HARD

SOFT

EN - 17

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

STEERING LOCK (TE)

The motorcycle is equipped with a steering lock (1) on

the R.H. side of the steering head tube.

To lock it, proceed as follows:

Turn the handlebar to the left, place the key in the switch

and turn counter clockwise. Push the key in (if necessary,

turn handlebar in both directions). Turn the key clockwise and remove it from the switch.

To unlock the steering, reverse the above procedure.

RIGHT-HAND HANDLEBAR SWITCH

The right-hand switch features the following controls:

(TE-TXC)

1) Engine start button

2) ENGINE STOP button

(TC)

1) Engine start button

2) Double map push-button

pressed for motorcycle SOFT performance;

released for motorcycle HARD performance.

to change the map from HARD to SOFT and vice versa

you shall stop the vehicle, and then, with engine

idling, press button (2).

LEFT-HAND HANDLEBAR SWITCH (TE)

The left-hand handlebar switch contains the following

commands:

High beam flasher (self-cancelling)

1)

2)

High beam

Low beam

3)

Left-hand turning indicators (self-cancelling)

Right-hand turning indicators (self-cancelling)

To deactivate the turning indicators, press the control

lever after it is returned to the centre.

Warning horn

4)

1

TE-TXCTC

1

2

1

4

3

2

EN - 18

SPECIFICATIONS - OPERATION - MAINTENANCE

ENGINE STOP BUTTON (TC)

Engine stop push-button (1) is located on handlebar left-

hand side. Press it to cut the engine electric supply circuit,

switching it off.

CAUTION*:

Do not inadvertently press push-button

(1) when riding the vehicle.

CLUTCH CONTROL

The hydraulic clutch control lever (1) is located on the lefthand side of the handlebar and is protected against dirt.

The position of the clutch control on handlebar can be

adjusted by loosening the retaining screws (A).

CAUTION*

Do not forget to tighten the screws after

the adjustment.

TE

1

A

REAR BRAKE CONTROL

The rear brake control (1) is placed on the right-hand

side of the motorcycle.

TE:

A stop switch, during the braking action, causes the stop

light on the tail light to come on.

1

TC-TXC

A

1

1

EN - 19

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

GEAR SHIFT CONTROL

The lever (1) is placed on the left-hand side of the en-

gine. The operator must release the lever after each gear

change to allow it to return to its central position. Neutral

position (N) is between the first and second gears.

First gear is engaged by pushing the lever downwards;

for other gears push it upwards.

The position of the gear shift lever on the shaft can be

varied as follows: loosen the screw, pull the lever out,

and place the lever in a new position on the shaft.

Tighten the screw once operation is completed.

CAUTION*: Do not shift gears without

disengaging the clutch and closing the

throttle. The engine could be damaged

by overspeed.

WARNING*: Do not downshift when travelling at a speed that would force the engine to overrev in the next lower gear,

or cause the rear wheel to lose grip.

TE-

TE-

TXC

TXC

6

5

4

3

2

TC

TC

N

1

1

INSTRUCTIONS FOR USING THE MOTORCYCLE

NOTE*: If you are not familiar with the

motorcycle operation, read paragraphs

on “CONTROLS” before riding this motorcycle.

PRE-RIDE CHECKS

Any time you ride your motorcycle, make a general in-

spection rst and proceed to check the following:

- check fuel level and engine oil level;

- check the brake and clutch fluids level;

- check the steering by turning the handlebar both ways,

fully home;

- check the tyre pressure;

- check the chain tension;

- check the throttle twistgrip and adjust it, if necessary;

- The two screw taps positioned on tanks left rear side,

shall always be left in fully OPEN position.

- TE: turn the key in the ignition switch to ON: check

dashboard display lighting;

- TE: check that parking lights, low beam, and high beam

come on, as well as the relevant warning light;

- TE: operate turning indicators, and check that the relevant warning light comes on;

- TE: check that the rear stop light comes on.

INSTRUCTIONS FOR RUNNING-IN

The exclusivity of the design, coupled to the high quality

of the materials used and the accuracy of the assembly,

guarantee the higher comfort right from the start. Nevertheless, during the rst 4 hours, you will have to THOROUGHLY respect the following rules. FAILURE TO COMPLY

WITH THEM COULD SERIOUSLY AFFECT MOTORCYCLE LIFE

AND PERFORMANCE.

- warm up the engine by running at low revs before using the motorcycle;

- avoid quick starts and never rev up the engine when in

low gear;

- ride at low speed until the engine is warmed up;

- apply both brakes several times to settle the pads and

the discs;

- do not maintain the same speed for a long time;

- do not ride for a long time without stopping;

- NEVER drive downhill with GEARBOX IN NEUTRAL, but

shift into gear to brake with the engine if necessary,

thus preventing the fast wear of the brake pads.

- Max. speed during running-in period: 80 Km/h in 5

gear (TC) or 6th gear (TE-TXC).

- Have the first inspection be carried out after the first 4

hours of operation.

th

EN - 20

SPECIFICATIONS - OPERATION - MAINTENANCE

TROUBLESHOOTING

The following list is used for troubleshooting and to nd

the necessary remedies.

The engine does not start

- the starting procedures are not correctly followed: follow the instructions given on paragraph “Starting the

engine”

- dirty spark plug: clean

- the spark plug does not spark: adjust the electrodes gap

- faulty starter motor: repair or replace

- faulty start button: replace the switch

The engine has starting troubles

- dirty or worn out spark plug: clean or replace

The engine starts, but it is erratic

- dirty or worn out spark plug: clean or replace

- faulty spark plug electrode gap: adjust

The spark plug gets easily dirt:

- unfit spark plug: replace

The engine overheats

- the air flow on the radiators is blocked: clean

- Faulty cooling fan (TE - TXC): replace thermal switch

- insufficient quantity of oil: top up

The engine lacks power

- dirty air filter: clean

- the spark plug electrode gap is too large: adjust

- incorrect valve clearance: adjust

- insufficient compression: check for the cause

The engine knocks

- excessive carbon deposit on the piston crown, or in the

combustion chamber: clean

- faulty spark plug or wrong heat rating: replace

The alternator fails to charge, or its charge is insufficient

- the cables on the voltage regulator are badly connected, or in short-circuit: correctly connect, or replace

- faulty alternator coil: replace

- demagnetised alternator rotor: replace

- faulty voltage regulator: replace

The battery overheats

- faulty voltage regulator: replace

Difficulty in shifting gears

- engine oil with too high viscosity rating: replace with

the recommended oil

The clutch slips

- insufficient spring load: replace

- worn-out clutch plates: replace

Faulty brakes

- worn-out pads: replace

EN - 21

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

ENGINE STARTING (TE-TXC)

With cold engine, i.e., after the motorcycle has not

been used for a while or in low ambient temperatures,

operate in the following manner:

1) pull clutch lever (1) and hold it in place;

2) shift gear pedal (2) to neutral position;

3) press the starter button (3), then release clutch lever (1).

When a cold engine has just been started, do not

increase revs, to ensure an adequate oil warm-up

and circulation.

Note*:

A safety switch allowing to start engine ONLY when

the clutch lever is pulled is assembled onto clutch lever

mount.

IMPORTANT

NEVER START ENGINE WITH BATTERY DISCONNECTED FROM CIRCUIT.

IMPORTANT

DO NOT OPERATE THE THROTTLE CONTROL WHILE STARTING-UP.

TE

TXC

1

N

2

1

3

EN - 22

SPECIFICATIONS - OPERATION - MAINTENANCE

ENGINE STARTING (TC)

With cold engine, i.e., after the motorcycle has not

been used for a while or in low ambient temperatures,

operate in the following manner:

1) Pull starter knob (1);

2) Pull clutch lever (2) and hold it in place;

3) Shift gear pedal (3) to neutral position;

4) Press the starter button (4), then release clutch lever (1).

Take starter knob (1) back to its initial position as

soon as engine stays idle. When starting with an

already warmed up engine DO NOT USE the starter.

When a cold engine has just been started, do not

increase revs, to ensure an adequate oil warm-up

and circulation.

Note*:

A safety switch allowing to start engine ONLY when

the clutch lever is pulled is assembled onto clutch

lever mount.

IMPORTANT

NEVER START ENGINE WITH BATTERY DISCONNECTED FROM CIRCUIT.

IMPORTANT

DO NOT OPERATE THE THROTTLE CONTROL WHILE STARTING-UP.

1

4

IMPORTANT NOTE IN CASE OF COLD START AT LOW TEM-

2

PERATURES

It is recommended to briefly warm up the engine at idle

until, after having turned off the starting device, the engine response when opening the throttle is normal.

This allows oil reaching all points that need lubricating and

coolant to warm up to regular operating temperature.

Avoid warming up the engine for too long.

N

3

EN - 23

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

STOPPING THE MOTORCYCLE AND THE ENGINE

- Close the throttle (1) completely in order to slow

down the motorcycle.

- Apply both front (2) and rear (3) brakes while downshifting (for fast deceleration, press firmly on both

brake pedal and lever).

- When stopped, pull the clutch lever (4) and shift

gear lever (5) into the neutral position.

TE

4

5

1

- To turn vehicle off, press push-button (6).

TC

4

2

TC

6

TE - TXC

TXC

3

4

6

EN - 24

SPECIFICATIONS - OPERATION - MAINTENANCE

ENGINE EMERGENCY STOP (TE)

- Press the red button (6) to stop the engine.

TC

6

6

TE - TXC

OIL LEVEL CHECK

WARNING

Oil level depends on oil temperature.

The higher the temperature, the higher the

oil level inside oil sump. Should oil level

be checked with the engine cold or after

short runs, wrong readings may be taken,

with consequent wrong topping-up.

- Start vehicle as described in the relevant section, let it run

for approx. 3 to 5 minutes so as to warm engine up.

- Stop the engine.

With the vehicle on a flat ground and in vertical posi-

-

tion, check oil level through the inspection sight glass

(1) positioned on engine right-hand crankcase.

Make sure the level is in between the MIN and MAX

notches.

- To top up, remove filler cap (2).

WARNING*: Independent use of the front

or rear brake may be advantageous under certain conditions. Be careful when

using the front brake, especially on

slippery surfaces. Improper use of the

brakes can lead to a serious crash.

WARNING*: In the event of stuck throttle

or other malfunction which causes the engine to run uncontrollably, IMMEDIATELY

depress the engine kill switch (7). Control the motorcycle by normal use of the

brakes and steering while pressing the

engine kill switch.

WARNING

To check that the oil quantity does not

exceed the “MAX” level notch, set

the motorcycle on the side stand and

check that in this position the level

goes below the “MAX” notch by looking through the inspection sight glass

(1).

1

2

EN - 25

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

ENGINE OIL REPLACEMENT AND MESH FILTERS-FILTER

CARTRIDGE CLEANING OR REPLACEMENT

WARNING*: Be careful not to touch hot

engine oil.

Drain the oil with WARM ENGINE; proceed as follows:

- Remove oil filler cap (2);

- put a drip pan under engine;

- remove oil drainage plug (3);

- evacuate the exhausted oil, and clean magnet on plug (3);

1

- loosen the two caps (4), and remove the two mesh

filters (5) and (6);

- check for O-rings (7) conditions. If worn, change them.

Then clean filters (5) and (6) using gasoline;

- reassembly is a reverse of removal.

- undo cap (8) and remove cartridge filter (9);

- replace filter (9), lubricate O-ring (10), and screw cap

(8);

- once filter has been replaced, refit oil drainage plug

(3), and pour the recommended quantity of oil.

5

4

7

WARNING

Start the engine to allow the oil to reach

all the points of the engine and check

the level as described in the relevant

paragraph.

To check that the oil quantity does not

exceed the “MAX” level notch, set

the motorcycle on the side stand and

check that in this position the level

goes below the “MAX” notch by looking through the inspection sight glass

(1).

8

2

4

3

7

7

7

9

6

7

4

7

10

8

EN - 26

SPECIFICATIONS - OPERATION - MAINTENANCE

COOLANT LEVEL CHECK

Check level (1) inside left radiator, with the engine cold

and the vehicle in vertical position. The coolant should

be approximately 10 mm (0.39 in) above the cells.

1

*:

Note

Difficulties may arise in eliminating coolant from painted

surfaces. If this occurs, wash off with water.

COOLANT REPLACEMENT

WARNING*: Coolant shall be replaced

with cold engine and coolant.

- Place a container on cylinder right side, under coolant

drainage screw (1). FIRST remove the screw (1) then

SLOWLY open the L.H. radiator cap (2); slope the motorcycle on the right side to drain the coolant easily in

the vessel. Reassemble the screw (1).

The radiator cap (2) features two locking positions, the

first being for the previous pressure discharge of the

cooling system.

CAUTION*:

Avoid removing radiator cap (2) when

engine is hot, as coolant may spout

out and cause scalding.

2

1

2

EN - 27

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

- Pour the necessary quantity of coolant in the radiator

then warm up the engine in order to eliminate any

possible air bubbles.

- Allow the coolant to cool down then remove cap (2)

and check the level as explained under “Coolant level

check”.

- Periodically check the connecting hoses (see “Scheduled Maintenance Chart”): this will avoid coolant

leakage and consequent engine seizure: If hoses (A)

show cracks, swelling or hardening due to sheaths

desiccation, their replacement shall be advisable.

- Check the correct tightening of the clamps (B).

A

B

WARNING

To fill in the system, set motorcycle on

a central stand, or in any case keep

the bike in a vertical position (not on

the side stand).

A

B

B

A

B

A

B

EN - 28

SPECIFICATIONS - OPERATION - MAINTENANCE

THROTTLE CONTROL CABLE ADJUSTMENT

To check the correct adjustment of the throttle control

cable, operate as follows:

- loosen screws (1) and remove protective cap (2);

- turn throttle twistgrip (3) and make sure that there is

a clearance of approx. 2 mm (0.08 in);

- should this not be the case, loosen check nuts (4) and (5);

- turn and keep twistgrip (3) in the fully closed position;

- loosen upper "return" cable (6) using adjuster screw (7);

- keeping twistgrip (3) fully closed, reset cable (6)

clearance by turning adjuster screw (7);

- tighten check nut (4);

- turn adjuster screw (8) until reaching an opening

clearance of approx. 2 mm (0.08 in);

- tighten check nut (5);

- reassemble all parts, in the reverse order compared

to disassembly.

TC

1

2

TE-TXC

2 mm

(0,08 in)

TC

WARNING*: Operation with damaged

throttle control cable could result in an

unsafe riding condition.

3

7

8

5

7

4

4

6

TE-TXC

6

2

1

8

5

EN - 29

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

IDLE ADJUSTMENT

Adjust the carburettor with warm engine and with the

throttle control in closed position. Proceed as follows:

TC

- Turn knob (1) clockwise until fully closed position,

then turn anticlockwise through 33 clicks until obtaining an idle speed of 1,850 - 1,950 rpm, which can be

read using the suitable diagnosis instrument.

TC

1

TE - TXC

- turn adjuster screw (2) with a screwdriver until reaching an idle speed of 1,850 - 1,950 rpm, to be detected

by the special diagnosis tester.

WARNING*: Exhaust gas contains poisonous carbon monoxide. Never run the

engine indoors.

TE-TXC

2

TE-TXC

SPARK PLUG CHECK

Spark plug electrodes gap shall be 0.7 - 0.8 mm (0.028

÷ 0.031 in).

A wider gap may cause difficulties in starting the engine

and overload the coil.

A gap that is too narrow may cause difficulties when accelerating, when idling or poor performance at low speed.

Clean off any dirt around spark plug base before removing the spark plug.

It is very useful to examine the state of the spark plug

just after it has been removed from the engine since the

scale deposits on the plug and the colour of the insulator

provide useful indications.

Correct heat rating:

The tip of the insulator should be dry and the colour

should be light brown or grey.

High heat rating:

In this case, the insulator tip is dry and covered with dark

deposits.

Low heat rating:

In this case, the spark plug has overheated and insulator

tip is vitrified (glazed), white or grey in colour.

0,7 ÷ 0,8 mm (0,028 ÷ 0,031 in)

EN - 30

SPECIFICATIONS - OPERATION - MAINTENANCE

To remove spark plug, proceed as follows:

- remove the air lter cover;

- disconnect connector (1) on engine left side;

- on engine right side, undo screw (2) using an 8 mm

wrench;

- turn spark plug cap (3) complete with coil through

90° and lift it to remove it; then remove spark plug.

1

2

CAUTION*: Carefully change the spark

plug, if necessary, using one having the

same rating.

Before refitting the plug, thoroughly

clean the electrodes and the insulator

using a metal brush. Apply graphitised

grease on spark plug thread, screw it

by hand all the way down, then tighten

it to the torque of 10 ÷ 12 Nm (7.38

÷ 8.85 ft-Ib). Loosen spark plug and

tighten it again to 10÷12 Nm (7.38 ÷

8.85 ft-Ib).

Spark plugs which have cracked insulators or corroded electrodes should be

replaced.

3

EN - 31

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

AIR FILTER CHECK

- Turn pin (1) counter clockwise and remove saddle

from central retaining screw;

1

- remove right-hand side panel (2) by loosening the

ve screws (3) using an 8 mm wrench;

3

2

- release retaining clips (4), and slide lter (5) out of

vehicle right side, taking special care not to damage

the two retaining hooks;

4

5

3

EN - 32

SPECIFICATIONS - OPERATION - MAINTENANCE

- widen the two retaining tabs (6) and remove subframe (7) with sponge (8);

8

7

6

- remove sponge (8) from subframe (7) and check if it

needs cleaning or replacing;

8

- ret all the disassembled parts in reverse order, mak-

ing sure to position lter sponge (8) with the "TOP"

wording facing up. Ret lter (5) inside guides, push

it all the way down and lock it using the clip-on fasteners (4).

AIR FILTER CLEANING

Wash the filter with a specific detergent (CASTROL FOAM

AIR FILTER CLEANER or similar) then dry it fully (wash

filter with gasoline only in case of need). Plunge the filter

in special oil for filters (CASTROL FOAM AIR FILTER OIL or

similar), then wring it to drain superfluous oil.

WARNING*: Do not use fuel or a low

flash-point solvent to clean the filtering

element. A fire or explosion could result.

WARNING*: Clean the filtering element

in a well ventilated area and do not allow sparks or flames anywhere near

the working area.

STEERING ANGLE ADJUSTMENT

To modify steering angle, turn the adjuster screws posi-

tioned on steering tube sides, as follows:

- loosen check nut (1) and turn adjuster screw (2) until

reaching the desired angle, then tighten check nut (1)

again. Adjust angle evenly on both sides.

1

2

EN - 33

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

ADJUSTMENT OF THE CONTROL LEVER AND FRONT BRAKE

FLUID LEVEL CHECK

The adjuster (1) located on the control lever, allows adjusting

of the free play (a). Free play (a) shall be of at least 3 mm

(0.118 in).

The level of the fluid in master cylinder reservoir must

never be below the minimum value (2), which can be

checked from the inspection window on the rear of the

master cylinder body.

A decrease of the fluid level will let air into the system,

hence an extension of the lever stroke.

A: to increase clearance

B: to decrease clearance

1

A

+

WARNING*: If the brake lever feels

mushy when pulled, there may be air in

the brake lines or the brake may be defective. Since it is dangerous to operate

the motorcycle under such conditions,

have the brake system immediately

checked by the Husqvarna Dealer.

CAUTION*: Do not spill brake fluid onto

any painted surface or light lens.

CAUTION*: Do not mix two brands of fluid. Completely change the brake fluid in

the brake system if you wish to switch

to another fluid brand.

CAUTION*: Brake fluid may cause irritation. Avoid contact with skin or eyes. In

case of contact, flush thoroughly with

water and call a doctor if your eyes

were exposed.

2

B

-

a

EN - 34

SPECIFICATIONS - OPERATION - MAINTENANCE

REAR BRAKE PEDAL POSITION ADJUSTMENT

The position of the rear brake pedal with respect to the

footrest may be adjusted according to individual needs.

For adjusting, proceed as follows:

- loosen the screw (1);

- turn the cam (2) in order to raise or lower the brake

pedal (3) within the range available (A);

- the operation done, tighten the screw (1). Once this

adjustment is completed, adjust the free play of the

pedal as follows.

REAR BRAKE PEDAL FREE PLAY ADJUSTMENT

Before staring the braking action, rear brake pedal (3)

shall have a free play (B) of 5 mm (0.196 in).

Should this not happen, operate as follows:

- loosen nut (4);

- operate the pump rod (5) to increase or decrease the

free play;

- tighten nut (4) at the end of the operation.

WARNING*:

When the free play requirement is not

met, the brake pads will be subjected

to an early wear that may lead to TOTAL

BRAKE INEFFECTIVENESS.

2

1

A

3

5

4

B

3

EN - 35

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

REAR BRAKE FLUID LEVEL CHECK

Fluid level inside master cylinder shall never be below

the min. level indicated on reservoir (1).

A decrease of the fluid level will let air into the system,

hence an extension of the lever stroke.

WARNING*: If the brake pedal feels

mushy when pulled, there may be air in

the brake lines or the brake may be defective. Since it is dangerous to operate

the motorcycle under such conditions,

have the brake system immediately

checked by the Husqvarna Dealer.

CAUTION*: Do not spill brake fluid onto

any painted surface or light lens.

CAUTION*: Do not mix two brands of fluid. Completely change the brake fluid in

the brake system if you wish to switch

to another fluid brand.

CAUTION*: Brake fluid may cause irritation. Avoid contact with skin or eyes. In

case of contact, flush thoroughly with

water and call a doctor if your eyes

were exposed.

ADJUSTMENT OF THE HYDRAULIC CLUTCH CONTROL LEVER

Free play (A) shall be of at least 3 mm (0.118 in).

Lever (1) position on handlebar could be modified, based

on rider's hand size.

To decrease the lever distance from the handgrip, rotate

the adjuster (B) CLOCKWISE.

To increase the lever distance from the handgrip, rotate

the adjuster (B) COUNTER CLOCKWISE.

1

A

B

1

EN - 36

SPECIFICATIONS - OPERATION - MAINTENANCE

SUSPENSION

Hereinafter is a general guide for suspension adjustment,

based on the type of ground or use of the motorcycle.

Always start from the suspension standard setting before

making any change. Afterwards, increase or decrease the

adjusting clicks, one at a time.

HARD GROUND

Front fork: softer compression setting.

Shock absorber: softer compression setting.

For fast tracks, a softer compression and rebound setting

both front and rear will give more grip.

SANDY GROUND

Front fork: set compression harder, or replace the standard spring with a harder spring and set the compression

softer and the rebound harder.

Shock absorber: harder compression, and especially

harder rebound settings. Work on the spring preload to

lower the motorcycle riding height (rear end).

MUDDY GROUND

Front fork: harder compression setting, or replacement of

standard spring with a harder one;

Shock absorber: harder compression and rebound setting, or replacement of standard spring with a harder

one; Work on the spring preload to lift the motorcycle

riding height (rear end). Changing the springs front and

rear is advised in order to compensate for increased motorcycle weight due to caked-on mud.

NOTES

Should the fork be too soft or too hard under all adjustment conditions, check oil level inside fork leg as it could

be too low or too high; Remember that the more oil you

add, the more frequently you will need to bleed the forks.

Should suspension not react to calibration changes, check

adjuster units, as they could be stuck.

WARNING*:

ALWAYS remember that all the motorcycles and their parts used in competitions of any type are excluded from the

warranty and that all modications to

standard conguration cause THE VE-

HICLE NON COMPLIANCE WITH TYPE-AP-

PROVAL REQUIREMENTS and it is hence

unsuitable for circulating on public

roads: consequently it may be used only

in “CLOSED CIRCUITS” by authorised subjects holding the relevant driving licence

or authorisation.

EN - 37

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

ADJUSTING THE FRONT FORK

a) COMPRESSION (TC-TXC: TOP ADJUSTER; TE: LOWER

ADJUSTER)

Standard setting: -11 clicks (TC - TXC);

Standard setting: -10 clicks (TE)

To reset standard calibration, turn adjuster screw (A)

clockwise to reach the fully closed position; then turn it

back by the mentioned clicks. In order to obtain a smooth

braking action, turn the adjuster counter clockwise. Vice

versa to obtain a harder braking action.

b) REBOUND (TC-TXC): LOWER ADJUSTER; TE: TOP ADJUSTER)

Standard setting: -14 clicks (TC - TXC);

Standard setting: -14 clicks (TE).

To reset standard calibration, turn adjuster (C) clockwise

to reach the fully closed position; then, turn it back by

the mentioned clicks. In order to obtain a smooth braking

action, turn the adjuster counter clockwise. Vice versa to

obtain a harder braking action.

c) BLEEDING (to carry out after each competition, or monthly).

Set the motorcycle on a central stand, release the fork

fully extended and loosen the air vent valve (D). Once

this operation is over, tighten the valve.

WARNING*: Never force the adjusting screws

beyond the maximum open and closed posi-

.

tions

TC-TXC

D

A

TE

TE

C

A

TC-TXC

C

D

EN - 38

SPECIFICATIONS - OPERATION - MAINTENANCE

FORK OIL LEVEL

For regular fork operation, both legs must be provided

with the necessary oil quantity.

TE: Remove the fork legs from the fork to check the oil

level. Work as follows:

- remove the damper rod caps;

- remove springs from the legs letting the oil drain into

the legs;

- bring fork to stroke end;

- TE: check that level is at the distance (A) of 118 mm

(4.65 in.) from rod upper limit.

OIL QUANTITY IN EACH FORK LEG

- TC - TXC: 566 cu.cm (34.54 cu.in)

Cartridge: 196 cu.cm (11.96 cu.in)

Fork sleeve: 370 cu.cm (22.58 cu.in)

- TE: 670 cu.cm (40.89 cu.in)

ADJUSTING THE SHOCK ABSORBER

Shock absorber is adjusted for vehicle running with rider

and a light luggage only; by varying spring preload it

can nevertheless be adjusted based on rider's weight.

WARNING*: The shock absorber adjustment affects both the stability and

the handling of the motorcycle. After

changing the standard suspension setting, ride with care. Before making any

change, it is recommended to measure

the "A" reference dimension with the

motorcycle resting on central stand, and

the rear wheel raised off the ground.

B: rear mudguard top height

C: rear wheel axle height

B

- Have motorcycle resting on ground without rider;

Measure dimension "A";

The difference between dimension "A" with the wheel

raised off the ground and dimension "A" with the wheel

on the ground shall be 40÷45 mm (1.57 ÷ 1.77 in).

- Have motorcycle resting on the ground with rider sitting on it;

Measure dimension "A";

The difference between dimension "A" with the wheel

raised off the ground and dimension "A" with the

wheel on the ground and rider sitting on it shall be

100÷105 mm (3.93 ÷ 4.13 in).

WARNING*: Never disassemble the shock

absorber, which contains compressed

gas. Contact your Husqvarna Dealer for

any major service.

A

A

C

EN - 39

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

ADJUSTING THE SHOCK ABSORBER SPRING PRELOAD

- Turn pin (1) counter clockwise and remove saddle

from central retaining screw;

1

- remove right-hand side panel (2) by loosening the

ve screws (3) using an 8 mm wrench;

3

- Clean spring (6) lock ring nut (4), and adjuster ring

nut (5).

- Loosen lock ring nut using a hook wrench or an aluminium drift.

- Turn adjuster ring nut until reaching the desired position.

- After having adjusted the suspension based on your

weight and riding style, tighten lock ring nut (tightening torque 10 Nm; 1 Kgm; 7.38 ft-lb).

- Refit the right-hand side panel and the saddle.

WARNING*: Be careful not to touch hot

exhaust pipe while adjusting the shock

absorber.

2

5

6

3

4

EN - 40

SPECIFICATIONS - OPERATION - MAINTENANCE

ADJUSTING THE SHOCK ABSORBER HYDRAULIC DAMPING

Adjustment of the compression stroke is independent

from the rebound stroke.

A) COMPRESSION - Standard setting:

1) Low damping speed:

- TC - TXC: 13 +1/-2 clicks

- TE: 16 + 1/-2 clicks

(adjuster screw 1)

2) High damping speed:

- TC - TXC: 1 ± 1/2 turns

- TE: 1 ± 1/2 turns

(adjuster screw 2)

To reset the standard setting, turn upper adjusters (1)

and (2) clockwise until reaching fully closed position.

Then turn them back to the above-mentioned positions.

In order to obtain a smooth braking action, turn the adjusters counter clockwise. Vice versa to obtain a harder

braking action.

B) REBOUND - Standard setting:

- TC - TXC: 13 +1/-2 clicks

- TE: 16 + 1/-2 clicks

To reset the standard setting, turn lower adjuster (3)

clockwise until reaching fully closed position. Then turn it

back by the mentioned clicks.

In order to obtain a smooth braking action, turn the adjuster counter clockwise. Vice versa to obtain a harder

braking action.

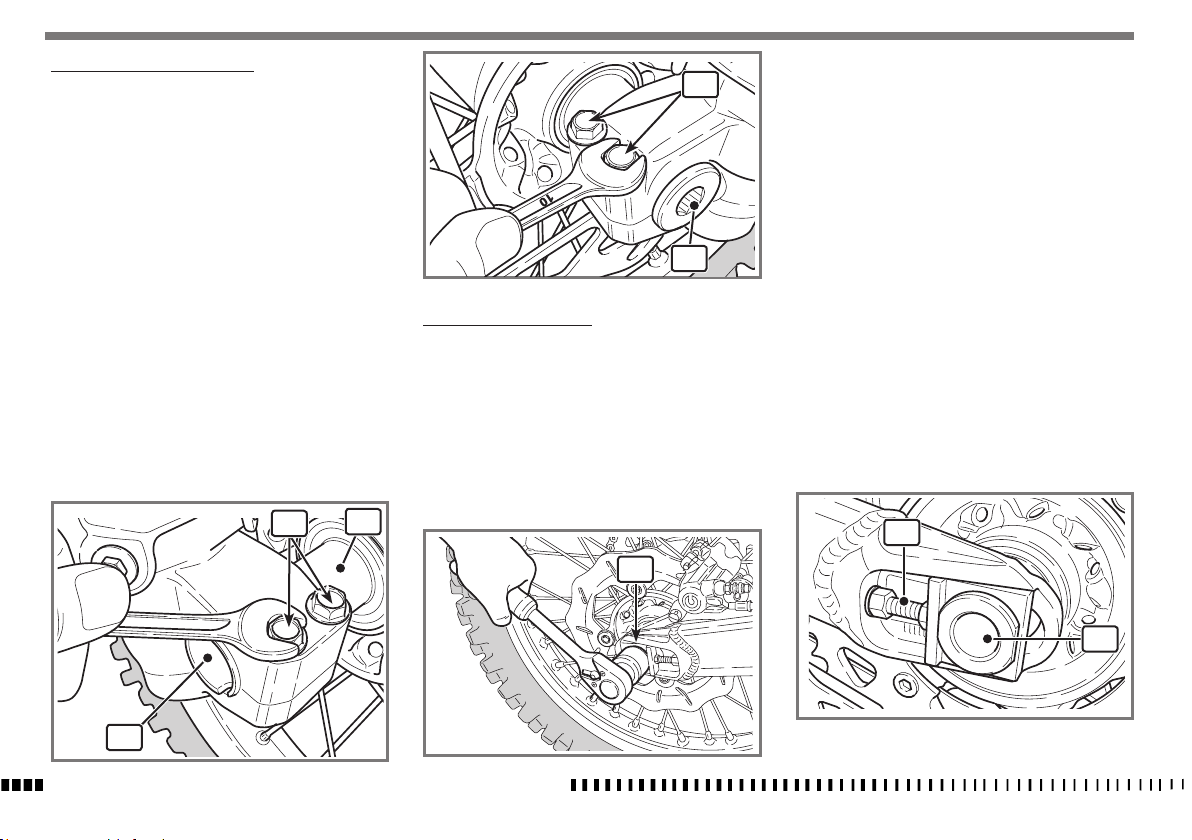

CHAIN ADJUSTMENT

Chain should be checked, adjusted and lubricated as

per the Maintenance Chart to ensure safety and prevent

excessive wear. If the chain becomes badly worn or is

poorly adjusted (i.e., if it is too loose or too taut), it could

escape from sprocket or break.

Check that chain has a max. 5 mm (0.2 in.) gap (A).

WARNING*: Incorrect chain tension involves excessive and early wear of the

chain slider lower part; Periodically check

for wear and replace it, if worn out.

A

+

2

1

-

+

3

EN - 41

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

If it is not, proceed as follows:

- on the right side, with a 27 mm Allen wrench, loosen

the locking nut (2) of the wheel axle;

- loosen the check nuts (3) on both chain tensioners with

a 12 mm wrench and work on the screws (4) with a 10

mm wrench to achieve the right tension;

- when the adjustment is completed, tighten the check

nuts (3) and the wheel axle nut (2).

Once adjustment is over, always check that chain has a

max. 5 mm (0.2 in.) gap.

2

LUBRICATING THE CHAIN

Lubricate the chain following these instructions.

CAUTION*: Never use grease to lubricate

the chain. Grease helps to accumulate

dust and mud, which act as abrasive

and help to rapidly wear out the chain,

the front and rear sprockets.

Disassembling and cleaning

When particularly dirty, remove and clean the chain before lubrication. Proceed as follows.

- Set a stand or a block under the engine and see that

the rear wheel is lifted from the ground.

- Remove clip (1), master link (2), then remove chain (3).

To reassemble, follow the disassembly procedure in

reverse order, taking care to correctly position clip

(1), master link (2), and the corresponding O-rings

(TE-TXC).

- Make sure that chain is neither worn nor damaged. If

the rollers or the links are damaged, replace the chain

by following the instructions given in the Scheduled

Maintenance Chart.

- Check front and rear sprockets for damage.

- Wash and lubricate chain as described in the relevant

paragraph.

- If the chain has been cut, refit it using the master link.

- Fit master link clip (1) so that the closed part is facing

chain direction of rotation, as shown in the figure below.

Note*:The master link is the most critical safety part

in the drive chain. Even if the master links are reusable when in good conditions, for safety purposes we

advise using a new master link when reassembling

the chain.

- Correctly adjust chain, as described in the relevant

paragraph.

4

3

3

2

1

EN - 42

SPECIFICATIONS - OPERATION - MAINTENANCE

Washing chain without O-rings (TC)

Wash using petroleum or naphtha. If you use fuel or especially trichloroethylene, dry and lubricate the chain to

avoid oxidisation.

Washing chain with O-rings (TE - TXC)

Wash using petroleum, naphtha or paraffin oil. Never

use fuel, trichloroethylene or solvents, as the O-rings

may get damaged.

Use instead special sprays for chains with O-rings.

Lubrication of chain without O-rings (TC)

After drying, dip the chain in Molybdenum Disulphide

chain lubricant, if possible, or in warm high-viscosity engine oil (if warmed up, oil will be more fluid).

Note * : As an alternative, you can use suitable spray

lubricants.

Lubricating the chain with O-rings

(TE - TXC)

Lubricate all metallic and rubber (O-ring) elements using

a brush and engine oil with SAE 80-90 viscosity, inside

and outside parts.

Note * : As an alternative, you can use suitable spray

lubricants.

CAUTION*: The chain lubricant shall NEVER get in contact with the tyres or the

rear brake disc.

1 - Chain guide eye

2 - Chain slider

Chain guide slot, chain slider

Check the wear of the above-mentioned elements and

replace them when necessary.

CAUTION*: Check the chain guide alignment, and remember that a bent element

can cause chain early wear. In this case,

chain might unwrap from the sprocket.

2

1

EN - 43

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

REMOVING THE FRONT WHEEL

Set a stand or a block under the engine and see that the

front wheel is lifted from the ground.

- Loosen screws (1) securing wheel axle (2) onto fork

leg mounts.

- Hold wheel axle head and, at the same time, loosen

screw (3) on the opposite side; draw the wheel axle out.

Note*:

Do not operate the front brake lever when the wheel has

been removed; this causes the calliper pistons to move

outwards. After removal, lay down the wheel with brake

disc on top.

1

1

2

1

3

EN - 44

SPECIFICATIONS - OPERATION - MAINTENANCE

REASSEMBLING THE FRONT WHEEL

- Fit wheel hub left spacer (D).

- Insert wheel between fork legs, so as to couple brake

disc with calliper.

- working on right side, drive the previously-greased

wheel axle (2) all the way down, tapping it on left fork

leg; during this operation, the wheel should be turned.

- Fasten the screw (3) on fork left-hand side into its

thread, but DO NOT tighten it.

- Pump on handlebar a few times, by pushing it downwards

until you are sure about fork legs perfect alignment.

- Tighten: screws (1) on right fork leg (20 Nm/ 2 Kgm/

14.75 ft-lb), screw (3) on left-hand side (51.45 Nm/

5.25 Kgm/ 38 ft-lb), and screws (1) on left fork leg

(20 Nm/ 2 Kgm/ 14.75 ft-lb).

Note*:

After reassembly, pull the brake control lever until the

pads are against the brake disc.

1

3

REMOVING THE REAR WHEEL

Unscrew the nut (1) of the wheel axle (3) and extract it.

It is not necessary to loosen the chain tensioners (2); in

this way, the chain tension will remain unchanged after

reassembly. Extract the complete rear wheel, keeping the

spacers located at the hub sides.

To reassemble, reverse the above procedure remembering to insert the brake disc into the calliper.

Note*:

Do not operate the rear brake pedal when the wheel has

been removed; this causes the calliper pistons to move

outwards.

After removal, lay down the wheel with brake disc on top.

After reassembly, depress the brake pedal until the pads

are against the brake disc.

1

2

D

2

1

3

EN - 45

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

TYRES

Care should be taken to keep the tyres properly inflated.

See "Technical data" chart at the beginning of the manual for correct tyre inflation pressure.

Replace the tyre if its wear exceeds reference values on

the table below.

MINIMUM HEIGHT

OF THE TREAD

FRONT 3 mm (0.118 in)

REAR 3 mm (0.118 in)

BRAKES

The key components of the braking systems are: brake

master cylinder with its lever (front) or pedal (rear),

brake lines, calliper assembly and disc.

LEGEND

1. Front brake lever

2. Front brake master cylinder with fluid reservoir

3. Front brake line

4. Front brake calliper

5. Front brake disc

6. Rear brake fluid reservoir

7. Rear brake line

8. Rear brake calliper

9. Rear brake disc

10. Rear brake master cylinder

11. Rear brake control pedal

7

8

5

3

4

2

1

6

10

9

11

EN - 46

SPECIFICATIONS - OPERATION - MAINTENANCE

BRAKE PADS REMOVAL

- Remove clips (1).

- Slide out pin (2).

- Remove pads.

WARNING

*:

Do not work the brake lever or pedal

while removing the pads.

PADS WEAR

Check brake pad wear.

Service limit “ A” is: 3.8 mm (0.15 in).

If service limit is exceeded, always replace the pads in pairs.

FRONT REAR

PADS CLEANING

Be careful that no brake fluid or any oil gets on brake

pads or discs. Clean off with alcohol any fluid or oil that

inadvertently gets on the pads or disc. Replace the pads

with new ones if they cannot be cleaned satisfactorily.

PADS INSTALLATION

- Install new brake pads.

- Reassemble the two pins (2) and the clips (1).

WARNING*:

Do not attempt to ride the motorcycle

until the brake lever or pedal are fully

effective. "Pump" with the brake lever

or pedal until the pads are against the

discs. The brake will not function on the

first application of the lever or pedal.

1

2

1

1

1

2

FRONT

REAR

EN - 47

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

BATTERY

The sealed battery does not require any maintenance.

When electrolyte leaks, or other failure of the electrical

system is detected, apply to the HUSQVARNA Dealer.

If the vehicle remains unused for long periods, it is recommended to disconnect the battery from the electrical

system and store it in a dry place.

- After extensive use, battery should be allowed to run

a slow charging cycle

TE - TXC = 0.6A for 10 hours for 12V-6Ah battery.

TC = 0.4A for 10 hours for 12V-3Ah battery.

- Battery quick charging is only recommended under

extremely urgent conditions, as lead elements life

will be greatly reduced.

TE - TXC = 3A for 1 hour for 12V-6Ah battery.

TC = 4A for 3 hours for 12V-3Ah battery.

BATTERY CHARGER

To gain access to the battery (1):

- Turn pin (2) counter clockwise, and remove saddle (3)

from central retaining screw;

- release battery elastic band (4);

- rst remove the BLACK or BLUE negative cable, then

2

the RED positive cable (when reassembling, rst connect the RED positive cable, then the BLACK or BLUE

negative cable);

- remove the battery (1) from its housing.

Check, using a voltmeter, that battery voltage is not less

than 12.5 V.

If it is not so, the battery needs to be charged.

Using a battery charger with a constant voltage, first connect the RED positive cable to the battery positive terminal then the BLACK or BLUE negative cable to the battery

negative terminal.

The voltage reaches a constant value only after a few

hours, therefore it is suggested NOT to measure it immediately after having charged or discharged the battery.

Always check the battery charge before reinstalling it on

the vehicle.

Battery shall be kept clean, with greased terminals.

4

1

WARNING*: The battery contains sulphuric acid. Avoid contact with skin,

eyes or clothing.

Antidote:

EXTERNAL - Flush with water.

INTERNAL - Drink large quantities of water or milk. After milk, take magnesia,

beaten eggs or vegetable oil. Immediately call a doctor. Eyes: Flush with water for no less than 15 minutes and get

prompt medical attention.

WARNING*: Even if not used, battery shall

nevertheless be recharged with a slow

charging cycle at least every 3 weeks.

WARNING*: Batteries produce explosive

gas, ventilate when charging or using

indoors. When using a battery charger,

always connect the battery before turning on the charger. This procedure prevents sparks at the battery terminals

which could ignite any battery gases.

3

EN - 48

SPECIFICATIONS - OPERATION - MAINTENANCE

HEADLAMP BULB REPLACEMENT (TE)

Proceed as follows to reach the headlamp bulbs:

- Loosen upper screw (1) using an 8 mm wrench;

- loosen the two lower screws (2) using a Phillips screwdriver;

- move headlight unit (3) aside;

- release connector (4);

- slide off the rubber gaiter (5);

- release the bulb holder clips (6) and take out bulb (7);

Note*:

Headlamp bulb (7) is of the halogen type; be careful when replacing it since the glass part shall not be

touched with bare hands.

5

2

3

6

1

4

7

EN - 49

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

To replace the parking light bulb (8) extract it from the

inside cover.

Once the bulb has been replaced, reverse the above procedure to reassemble.

8

TURNING INDICATOR BULB REPLACEMENT (TE)

- Loosen screw (1) using a Phillips screwdriver;

- remove lens (2) and replace bulb (3) pushing it inside,

and turning it to remove it;

Once the bulb has been replaced, reverse the above procedure to reassemble.

1

TAIL LIGHT (TE)

The tail light (1) is a LED light; Replace it when it does

not function.

1

2

3

EN - 50

SPECIFICATIONS - OPERATION - MAINTENANCE

REPLACING THE NUMBER PLATE BULB (TE)

HEADLIGHT ADJUSTMENT (TE)

Beam height can be adjusted as follows:

- loosen screw (1) and remove the number plate bulb

(2) from the mudguard;

- take bulb holder (3) and bulb (4) out of the support;

- pull the bulb (4) to detach it from bulb holder.

Once the bulb has been replaced, reverse the above procedure to reassemble.

2

1

3

4

When checking the proper aiming of the headlight beam:

inflate tyres at the right pressure, have a person sit

astride the motorcycle and set the motorcycle perpendicular to its longitudinal axis

In front of a wall or a screen positioned at a distance of

10 metres (32.8 ft), draw a horizontal line corresponding to headlight centre height, and a vertical line aligned

with vehicle longitudinal axis.

If possible, execute this operation in a shaded place.

When the low beam is on, the upper edge between dark

and lit zone should be at 9/10th of headlight centre

from ground.

1

- Work adjuster screw (1);

tighten to lower the beam,

loosen to raise the beam.

Once set, reverse the above procedure to reassemble.

EN - 51

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

APPENDIX

LONG PERIOD OF INACTIVITY

When the motorcycle is to be stored for a certain period,

it should be prepared for storage as follows:

- Clean the entire motorcycle thoroughly.

- Drain all fuel from the tank.

- Fill the tank with fuel added with a stabiliser.

WARNING*:

Never release fuel into the environment

or let the engine run indoors.

- Lubricate the final drive chain and all the cables.

- Spray oil on all unpainted metal surfaces to prevent

rusting. Avoid getting oil on rubber parts or brakes.

- Set the motorcycle on a support or stand so that both

wheels are raised off the ground (if this cannot be

done, put boards under the wheels to keep moisture

away from the tyres).

- Tie a plastic bag over the exhaust pipe to prevent moisture from entering.

- Put a cover over the motorcycle to keep dust and dirt

from collecting on it.

To set the motorcycle back ready for use after storage:

- Make sure the spark plug is tight.

- Fill the fuel tank.

- Run the engine to warm the oil up then drain the oil.

- Refill with fresh oil.

- Check all the points listed under the inspection and

Adjustment Section (Appendix A).

- Lubricate all the points listed under the "Lubrication"

Section (Appendix A).

CLEANING

Before washing the motorcycle, it is necessary to:

- remove the chassis lower caps (4);

- duly protect the following parts from water:

a) Rear opening of the muffler;

b) Air filter intake;

AVOID AIMING HIGH-PRESSURE WATER OR

AIR JETS FOR TOO LONG on ELECTRICAL

COMPONENTS and on INJECTION SUPPLY

SYSTEM, mainly on electronic control unit

(1), dashboard (2), and throttle body (3).

After washing:

- Lubricate the points listed in the "Maintenance Chart"

(Appendix A).

- Refit the caps (4) after having dried the interior from

water.

- Briefly warm up the engine.

WARNING*: Never wax or lubricate the

brake discs. Loss of braking efficiency

and an accident could result. Clean the

disc with a solvent such as acetone.

TC

3

1

2

TE-TXC

3

4

EN - 52

SPECIFICATIONS - OPERATION - MAINTENANCE

Olio motore Controllo livello

Olio miscela benzina Controllo livello

Liquido di raffreddamento Controllo / Ripristino livello

Impianto raffreddamento Controllo perdite

Elettroventole Controllo funzionamento

Candele Controllo / Sostituzione

Corpo farfallato / Carburatore Controllo e Regolazione

Fluido freni e frizione Controllo livello