Page 1

Manual

Read the safety instructions.

Page 2

Page 3

Warranty

Logosol offers a two-year

warranty against material and

manufacturing defects. The

company will replace or fix any

faulty parts or constructions

within two years of purchase.

Free technical support

Regardless of where you

bought our equipment, we

offer free technical support by

phone, fax, mail or e-mail.

Regular information

All users of Logosol

equipment receive regular

information about new

products and accessories.

Our homepage is also a

source of up-to-date information.

Those who haven’t

ordered directly

from Logosol.

Everyone who bought directly

from Logosol in Madison is

already fully registered here.

Those of you who bought the

M7 through dealers must

send in the warranty card

below within thirty days of

purchase in order to benefit

from the warranty, get good

service and receive the right

spare parts.

World service

I have the following equipment:

Sawmill M7

Woodworkers Mill

Husqvarna 395 XP

Log House Moulder

Other:

Other:

Other:

Name:

Address:

Tel:

Mobile:

E-mail:

Where bought:

When bought:

World Service

P.O.Box 660

Madison MS 39130

Page 4

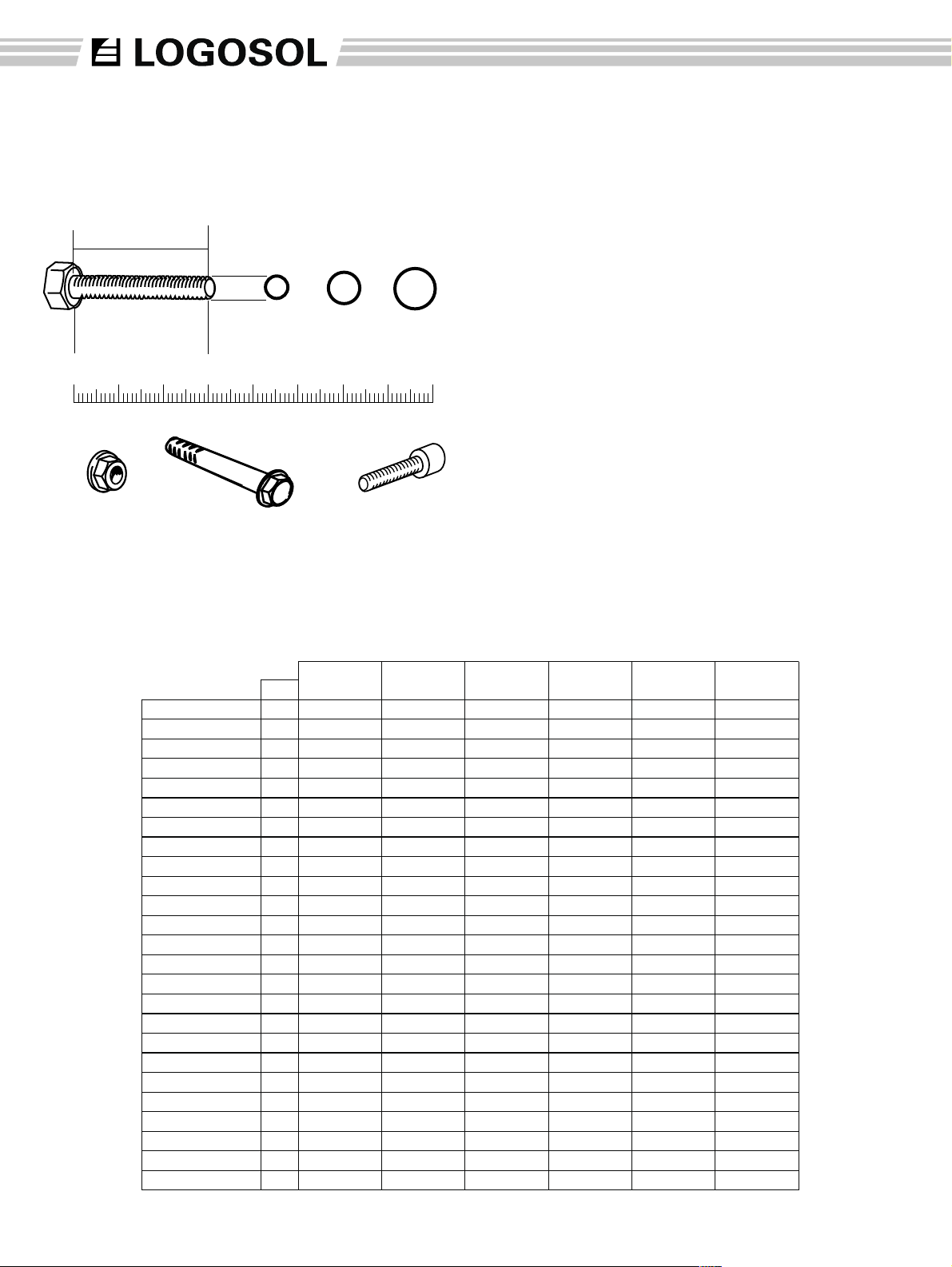

Metric Parts Sizing Chart Nut, Bolt and Washer Chart

To assist you in the assembly of this mill, we have

detailed the nuts, bolts and washers found on each

M6x30 Bolt Sawmill Bolt Sizes

30 mm

M6 M8 M10

0 1020304050607080

Metric scale in mm

Collar nut Collar bolt Allen head bolt

page in the chart below. The part name and size is

listed to the left and the total number found in the

package listed in the second column. To the right, if

a part is listed on a page in the manual, the number

of that part to be used on that page is entered in the

column for the page. Using this chart, you can lay

out the parts for each page, and work your way

through the assembly with your parts needed for

each page. If you find you are missing any parts,

please call our Toll-Free number and we will ship

them out immediately to you.

Note: You will also notice pages referenced on

the bags themselves. DO NOT USE THE PAGE

NUMBERS ON THE BAGS FOR REFERENCE.

Only use the chart below to determine what bag

is used for the assembly of which page.

You will have extra nuts and bolts after the

assembly of this mill.

BAG 71 BAG 72-73 BAG 74 BAG 75 BAG 76 BAG 77

Total for Page 10 for Page 11 for Page 12 for Page 13-14 for page 15-17 for Page 18

Collar nut M6

Collar nut M8 18 8 10

Locking nut M6 7 43

Locking nut M8 22

Locking nut M10 1 1

Square nut M6 18 6 8 4

Nut M10 22

Collar bolt M6x20 30 16 14

Collar bolt M6x40 88

Bolt M6x16 12 84

Bolt M6x20 12 8 4

Bolt M6x25 1 1

Bolt M6x40 6 42

Bolt M6x60 22

Bolt M10x40 22

Allen head bolt M6x25 44

Allen head bolt M6x30 44

Allen head bolt M8x14 22

Allen head bolt M8x25 88

Allen head bolt M8x30 88

Locking screw M6x8 66

Locking screw M6x10 44

M6 Washer 7 43

M8 Washer 88

M10 Washer 22

64 24 8 8 8

4

Page 5

Preface

You are now the owner of a

Logosol M7 WoodWorkers

Mill, the result of our collective

experience and dedicated

efforts since 1988. There are

currently more than fifteen

thousand Logosol Sawmill in

use in Sweden and the rest of

the world, making the Logosol

Portable sawmills the top

seller world-wide.

The goal for Logosol’s

development effort is to design smaller and lighter

machines that solve a task

intelligently, but without

lowering the quality of the

finished product. To top it off,

Logosol products must be

affordably priced so as to

make them available to

everyone working with wood.

Logosol produces a large

range of products, enabling a

single person to handle the

entire production chain from

forest felling to finished

product.

In addition to various sized

sawmills, the range includes

such products as a multisided planer providing

exellent profiling. For more

information on Logosol

products and accessories,

send for our catalog.

In closing, I wish you much

enjoyment and success with

your future Woodworking

projects.

Bengt-Olov Byström

Precident Logosol

Design and construction of the

M7 WoodWorkers Milll, plus

manual text and pictures:

Mattias Byström.

As LOGOSOL is constantly

developing and improving all

machines and devices, we

must reserve the right to

change the design, technical

characteristics and equipment

of our machines.

Printed on chlorine-free paper

using vegetable-oil based ink.

Manual, part. no.:

9999-000-9999

Copyright 2003 Logosol, Härnösand, Sweden

Contents

Safety Rules 6

Description 8

Technical Specifications 8

Assembly 8

Tools Needed 8

M7 Components 9

Assembly: frame 10

Assembly: guide rail 11

Assembly: cross beam 11

Assembly: guide rail strut 11

Assembly: log side-rest 12

Assembly: log bed 12

Assembly: saddle plate 13

Assembly: rachet 13

Assembly:

crank and lifting cable 14

Assembly: edge support 14

Assembly: carriage 15

Assembly: chain guard 16

Assembly: extender nuts 16

Assembly: chain-saw 17

Assembly: spiked log grip 18

Siting 19

Adjustments – log bed 20

Adjustments –guide bar 21

Step-by-step Sawing 22

Sawing Tips 23

Material Drying 24

Trouble-shooting 25

Cutting Equipment 26

Accessories 28

Parts List 29

EU Declaration 30

For us, the most important

consideration is that you are

100% satisfied with your M7

WoodWorkers Mill. If you have

any questions or thoughts

about the sawmill, please do

not hesitate to contact us.

5

Page 6

Safety rules

There are special

safety rules to

follow and dangers

to be aware of when

working with the

Logosol M7

WoodWorkers Mill.

other than the operator is 8 m

(26 feet) from all sides except

where the logs are rolled in.

The safety distance from this

side is 15 m (50 feet), due to the

danger of the chain being

thrown out if it breaks.

Always wear authorized

personal protective

clothing and equipment.

Close-fitting working overalls

are the appropriate garment –

never wear loose items,

worker’s jackets or the like.

This symbol points to

dangers. However, since

all risks are not marked,

you must read the entire

text.

This symbol calls for

additional attention to the

text.

Read through this whole

manual carefully before using

the M7. Failure to observe these

safety instructions may result in

fatal injury.

Make sure that every person

who uses the machine is well

informed of the dangers and

has read the entire manual. The

manual must also be available

to everyone using the sawmill.

This is also necessary if the

machine is sold or loaned out.

Read the manual and safety

rules for the particular sawing

unit used on the M7.

Minors under age 18 should not

be allowed to operate the M7.

Make sure that children and

animals are kept at a safe

distance.

Anyone working with the Logosol M7 WoodWorkers Mill must

be well-rested, healthy and in

good physical condition. Take

regular breaks while working

and never operate the machine

while under the influence of

alcohol, other drugs or

medicines that might cause

drowsiness or in-attention.

Work only in when the light is

good – never in darkness, fog or

the like.

Whenever you add extra

equipment to the M7 sawmill,

use products made by Logosol

or specifically approved by

Logosol for the purpose. Other

equipment can cause accidents

and thus should not be used.

Logosol will not accept liability

for personal injury or material

damage incurred while using

unauthorized attachments.

Should a sawing unit weighing

more than 15 kg (33 lbs) be

used, support legs must be

fitted under the guide rail ends in

order to avoid tipping.

Do not wear a neckerchief, tie,

jewellery or other items that can

get caught in the equipment.

Use safety shoes with

high-grip soles and

steel toecaps.

Wear a safety helmet

with hearing protection

and a face shield.

Remember that hearing can

be damaged after relatively

short exposure to the high

frequency sounds from the

motor and the cutting

equipment.

Protective goggles are also

required as a face shield used

alone will not provide sufficient

protection for the eyes.

Wear strong gloves.

There is an injury risk

whenever you handle

the chain and the

cutting equipment can be hot

after sawing .

Never reach over or under the

guide rail during operation. The

cutting equipment can cause

severe injuries.

While the Logosol

WoodWorkers Mill is a oneperson machine, be sure that

there are other persons within

hailing distance. The proper

safety distance for persons

6

Page 7

When using a petrol-driven

chain-saw:

Fire danger – Turn the

motor off before filling with

petrol. Petrol is extremely

flammable! Burns can cause

death! If you spill any fuel, clean

off any parts involved. If you get

fuel on your clothing, change

immediately.

Close the tank lid as tightly as

possible in order to reduce the

risk of it coming loose due to

vibrations during sawing.

Never operate the chain-saw

with the throttle lever locked.

Always operate the throttle

manually.

Do not use a ripping chain

for cross-cuts as this

increases the danger of

kickback.

Before using the M7:

Check the condition of the lifting

lines especially carefully,

replacing them at the slightest

sign of wear. Check that all bolts

and lock nuts on the log bed

lifting unit and the locking system are tight and that all moving

parts move freely.

Service:

The M7 sawmill must be

checked regularly and

maintained as needed.

Perform only the maintenance

and repairs specified in the

manual. Other repairs must be

done by Logosol or by

authorized Logosol dealers.

Do not make any alterations in

the construction of the sawmill

as this can increase the

accident risk. After service, the

M7 sawmill should be returned

to its original condition.

Logosol accepts no liability for

damage that occurs while

working on an improperly

modified machine.

During operation:

To avoid tipping, never

place the machine at an

angle while operating. The

M7 should be fastened directly

to the floor or be placed on a

bedding of planks in order to

increase the contact surface

(follow the manual).

Hold the crank firmly whenever

raising or lowering a log. If

released, the crank may spin

back and hit your hand.

Do not saw logs that are so

short that they do not extend

0.2 m (app. 10 “) outside each

log bed. A shorter log could fall

when the log beds are raised.

The overall max. load capacity

of the M7 is 500 kg (1100 lbs).

The 2.5 m extension increases

the capacity by 250 kg (550 lbs)

for each extension with a lifting

unit.

Always stand to the right

of the chain-saw while it is

operating. When a chain or

band breaks, it is thrown out

through the chip outlet.

Keep the worksite free of tools,

pieces of wood, chips and other

items you can trip on.

Turn the chain-saw off after

each cut. Do not leave the M7

sawmill unattended where

unauthorized persons might

start it.

To avoid tipping, check that the

M7 stands level and is well

fastened in the bedding.

To avoid chain breaks, check

that the cutting equipment is

correctly assembled.

To avoid kickbacks when starting, check that the chain-saw is

correctly positioned on the guide

rail.

Do not place your hand

inside the long leg while

raising or lowering the log.

Should the lifting line snap or the

crank spin, your hand may be

caught.

Logs must always be rolled

on to the sawmill level with the

horizontal beam. Do not lift logs

from ground level directly onto

the sawmill as this can cause

injury if the machine tips or the

log falls.

ALWAYS

REMEMBER that should

any type of problem occur,

stop sawing and turn off the

chain-saw. Most accidents

with dangerous machines

happen when something

goes wrong and the operator attempts to fix it while

the machine is still running.

A stop seldom shows up

on the finished product.

7

Page 8

Description Assembly

- Because of the high quality

and precision construction,

none of the angles need setting.

The only parts to adjust are the

guide rail and the height of log

bed, in all three bolts.

- All aluminium components are

anodized, creating a wearing

surface as tough as tempered

steel. It has a low friction

coefficient and is easy to keep

free of pitch and chips.

- Adjustable legs make it easy to

compensate for uneven sites.

- The M7 has a double rachet

mechanism enabling a simple

shift by hand between 1/4” (6.25

mm) and 1/8” (3.12 mm)

increments.

- Clear scales show the height

of the log bed. Extra measuring

rods are available as

accessories to show sawing

height settings.

- The knee joint on the front leg

has a non-slip surface that

facilitates log handling. The joint

also has a mounting hole for

ramps, log tables and the like.

- The cross beam between the

short legs is a significant

stabilization factor.

- No maintenance is needed.

The crank axle runs through

maintenance-free bronze

bearings, the slide rails use lowfriction plastic that has a

working life of several years

thanks to the superbly smooth

surface anodization.

- The settings for sawing

parallel to the grain of conical

logs are quick and simple.

- All accessories for M7 sawmill

fits the M7 WoodWorkers Mill as

well.

Technical specifications

Length: 2.75 m (9 ft)

Width: 1.25 m (4 ft)

Width of log bed:0.5 m (1ft 8 in)

Weightwithout saw:38.5 kg (85

lbs)

Max. rec. log diam.: 0.6 m (2 ft)

Max. rec. log length (standard

design): 2.35 m (8 ft)

Max.logweight: 500 kg (1 100

lbs)

The M7 is designed for simple

assembly and adjustment,

mainly because there are fewer

parts and assembly steps than

were needed in earlier models.

Most of the aluminium parts are

anodized making it easier to

force the bolts through the

profile holes. Assemble the M7

on a surface that will not

scratch the surface treatment.

Save time by reading the

entire assembly instruction

before beginning to work. Then

follow the instructions step by

step.

Whenever this symbol

appears, tighten bolt loosely

to allow some movement.

When there is no symbol,

tighten the bolts well.

Tools needed

(Tools are not supplied with

delivery of the M7

WoodWorkers Mill.)

2 x 10 mm open end wrench

1 x 13 mm open end wrench

1 x 16 mm open end wrench

1 x 17 mm open end wrench

Hexagon socket wrench/Allen

key (metric)

1 x 4 mm open end wrench

1 x 8 mm open end wrench

1 x Try square

- The Logosol M7

WoodWorkers Mill will not rust.

Springs are stainless steel and

all steel parts are thoroughly

galvanized.

8

Assembly will be facilitated with

a battery-driven drill or

screwdriver with a 10 mm

hexagon socket and a ratchet

key with 10 and 13 mm hexagon

sockets.

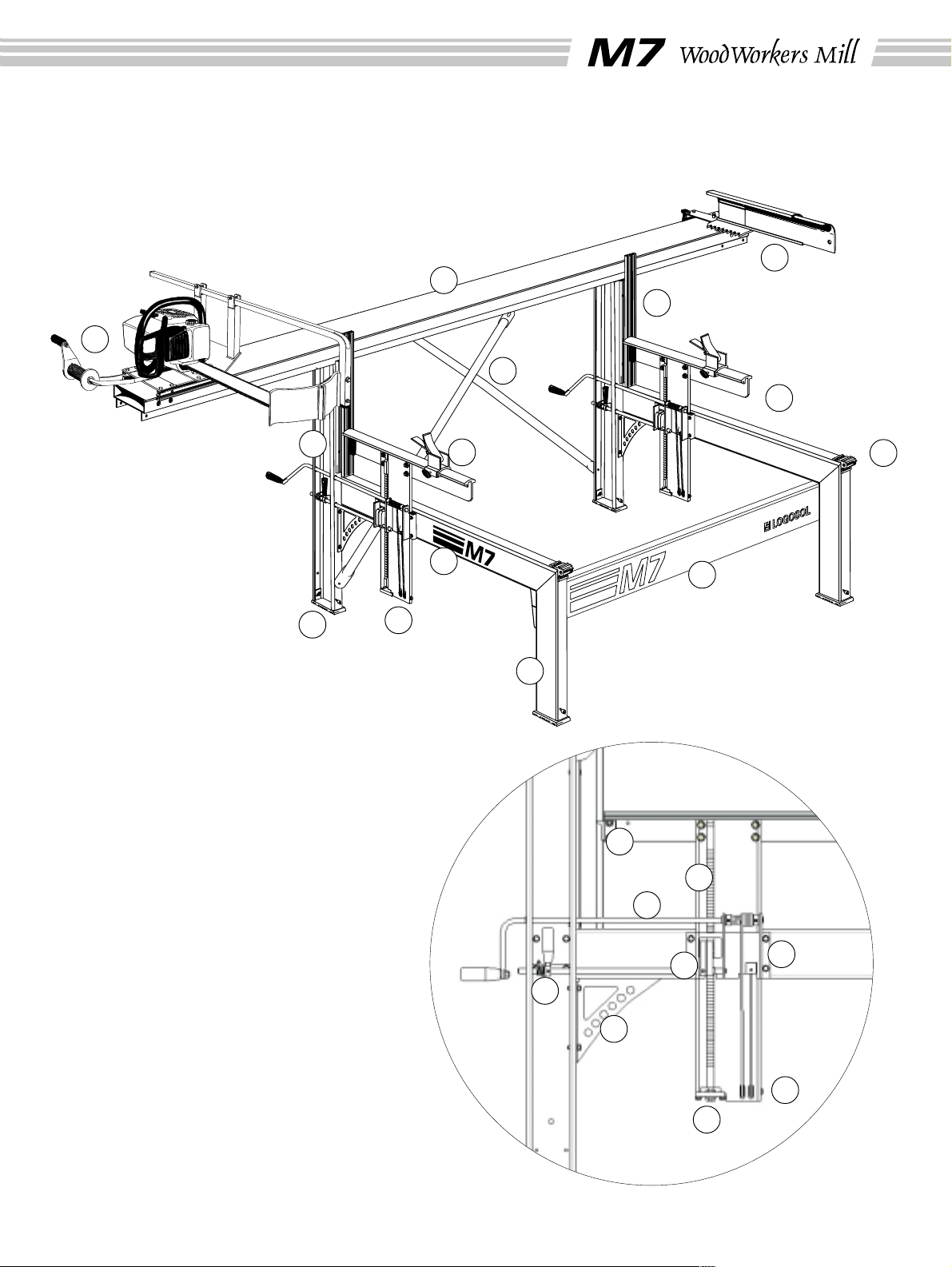

Page 9

M7 WoodWorkers Mill components

What follows is a brief description of the M7

components to assist in identifying them during

assembly. A more complete listing is found at the end

of the manual.

1

12

13

10

8

7

2

1 Guide rail

2 Long leg

3 Horizontal beam

4 Short leg

5 Cross beam

6 Edge support

7 Log bed

9

8 Guide rail strut

9 Foot

10 Log rest

11 Knee joint

12 Carriage

13 Log grip

14 Lifting beam

15 Ratchet bar

16 Ratchet bar stop plate

17 Saddle plate

18 Ratchet Cam

Cam Axle

19 Ratchet handle

Ratchet neutral plate

Turning spring

20 Crank

Lockring

Lockring with line attachment

21 Plastic slide rail on log bed

Indicator

22 Angle fitting

23 Line pulleys

14

6

11

3

5

4

21

15

20

18

17

19

22

23

16

9

Page 10

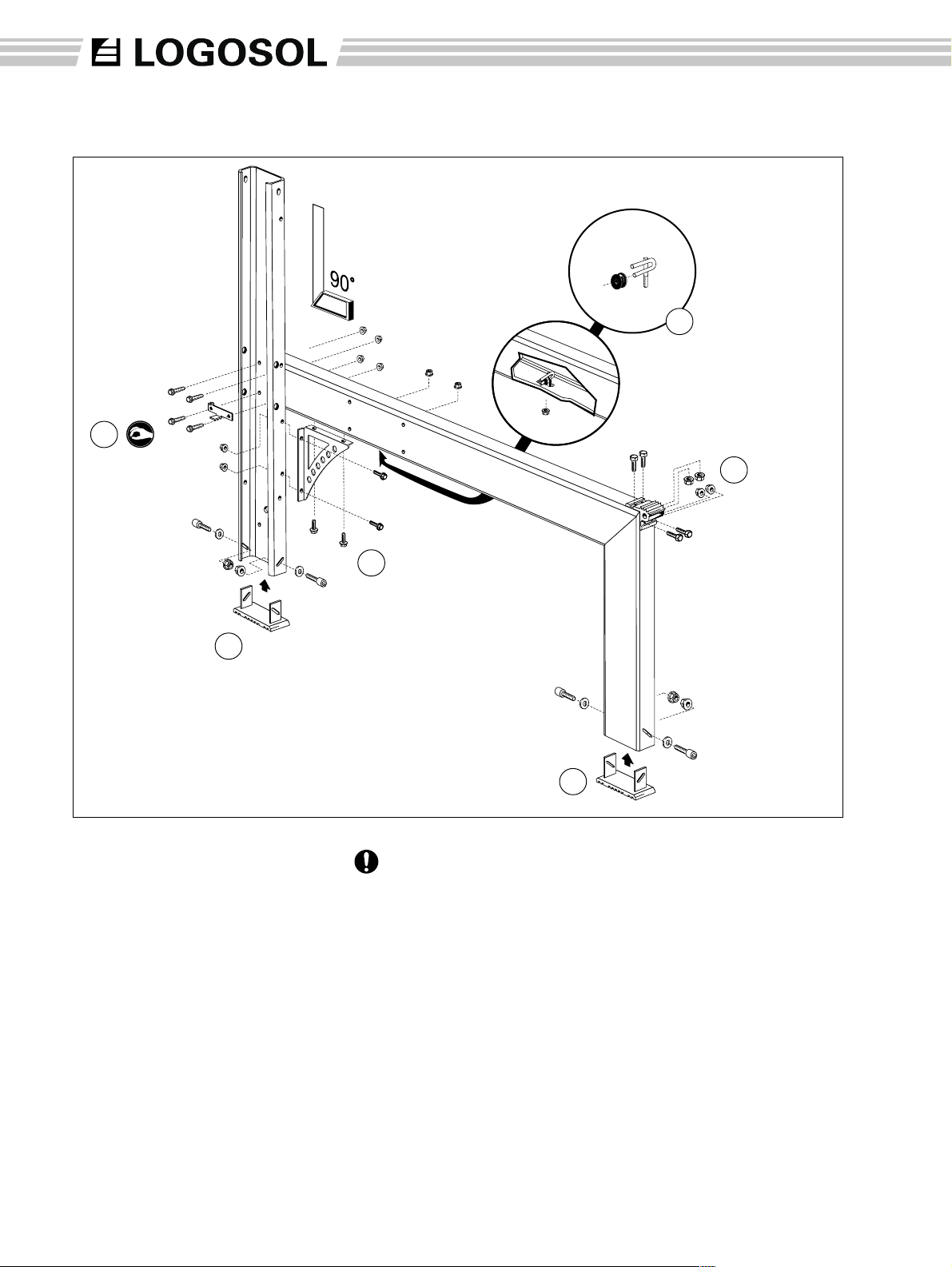

Assembly: frame

2

A

1

3

4

The right and left leg units of the

frame are assembled in the

same way. The bolts listed

below are for one leg unit.

(1) Fit the horizontal beam to

the short leg using the corner

fitting. Be careful not to damage

the bevelled faces before

assembly. (4 x M6x20 bolts, 4 x

M6 collar nuts)

(2) Fit the horizontal beam to

the long leg. The scale plate is

fitted to the long leg using the

two lower bolts.

4

Tighten all four bolts

loosely to allow the beams

to move somewhat in relation to

each other. (4 x M6x20 collar

bolts, 4 x M6 collar nuts)

(3) Fit the angle fitting to the

long leg and to the underside of

the horizontal beam. First

tighten the four bolts on the

angle fitting loosely, gradually

tightening them all the way. In

this way the frame will be set at

exactly 90°. (4 x M6x20 collar

bolts, 4 x M6 collar nuts)

Finally tighten the bolts between

the horizontal beam and the

long leg. (2)

(4) Fit the sawmill feet, turning

them so that the holes in the

foot and the leg form a cross

and that they lie correctly in the

leg tracks. (4 x M8x25 allen

head bolts, 4 x M8 nuts, 4 x M8

washers)

(A) Assemble the pulley, see

picture. (1x M6 collar nut)

10

Page 11

Assembly: guide rail, guide rail strut, cross beam

B

6

5

C

(5) Place the guide rail on the

long legs, pressing the guide rail

down while the bolts are tightened. (4 x M6x20 collar bolts, 4 x

M6 collar nuts)

Check that the angle

between the guide rail and

the long leg is 90°.

7

(6) Fit the strut to the inside (D)

of the guide rail flanges with the

oval hole up. (4 x M6x20 collar

bolts, 4 x M6 collar nuts)

(7) Fit the cross beam. In each

leg there are six holes. The

inner ones are used for the

standard M7 unit (C), while the

others are used when the M7 is

extended and an additional

cross beam is fitted on either

side. (6 x M6x20 collar bolts, 6 x

M6 square nuts)

11

Page 12

Assembly: log side-rest

Assembly: log bed

(7) Fit the log side-rest. make

sure that the measuring scales

are both facing in torwards the

center of the mill so that

operator can read both scales

from the center position.(2 x

M6x20 bolts, 2 x M6 collar nuts)

7

(8) Place the plastic slide rail on

the log bed. Fit the longer (A)

scale against the plastic rail on

the right log bed and the shorter

(B) against the side of the left

log bed. Do not tighten the bolts

all the way. (2 x M6x30 allen

head bolts, 2 x M6 collar nuts)

(9) Fit the ratchet bar stop plate

under the lifting beam. (2 x

M6x25 allen head bolts)

12

8

A

C

11

B

12

8

10

9

D

(10) Fit the line pulleys. (1 x

M6x60 self-tapping bolt) Apply

some pressure while driving it

in.

(11) Fit the log support on the

lifting beam. As the bolts will be

hard to screw through the holes,

use an Allen wrench to pull the

log support down to the lifting

beam. After app. 20 hours of

use, these bolts will need to

be retightened. (4 x M8x30

self-tapping allen head bolts, 4 x

M8 collar nuts)

(C) Fit the bolt for extra support

(M8x16 allen head bolt, 1xM8

collar nut)

(12) Fit the rachet bar by

threading the adjustment bolt

(D) through the ratchet bar stop

plate and screwing on the nut.

Do not tighten. Place the bar in

the track of the lifting beam and

tighten the adjusting nut on the

bar. (1 x M10x40 bolt, 1 x M10

nut)

Page 13

Assembly: saddle plate

(13) Thread the lifting line

through the hole in the lower

part of the saddle plate and

make the knot shown (A).

A

14

13

Assembly: rachet mechanism

15

16

B

Leave a 1 cm (3/8”) end

after the knot.

(14) Press the steel sleeves into

the holes in the plastic glides.

Place the plastic glides (B) on

each side of the lifting beam and

fit the saddle plate over these.

(4 x M6x40 collar bolts, 4 x M6

collar nuts)

B

(15) The ends of the ratchet

cam axle are different. Insert

the one that has the recess

nearest the tip through the lower

hole in the long leg.

(16) Thread the short end of the

spring through the scale

selector’s spring holder and slip

both over the cam axle inside

the long leg.

Now thread the axle through the

first flange of the sadle plate.

Thread the ratchet cam on in

front of the opening in the sadle

plate, placing an O-ring on both

sides. Turn the axle so that the

cam locking screw (M6x10)

lines up with the recess. Screw

the locking screw into the

recess.

Screw the cam axle handle

locking screw (M6x10) in the

other recess.

Use protective gloves for

the following steps (B): Pull

the long end of the spring around to fasten it in the spring

holder on the scale selector

fitting.

13

Page 14

Assembly: crank and lifting cable

17

A

(17) Thread the lifting line under

the outside pulley on the lifting

beam, straight up and around

the pulley on the cross beam

(A) and then down again to the

inner pulley on the lifting beam.

Fit the crank rod through the

upper hole in the long leg and

through the bushing on the

middle flange.

Place the lifting line in the

locking collar recess. Thread

the collar bushing with the line

and the other collar bushing, on

the crank rod.(collars facing out)

Push the crank rod through until

app. 1/8” extends beyond the

outer saddle plate bushing.

Screw the locking screw

(M6x8)on the locking collars into

the recesses on the crank rod.

Then tighten the locking screw

(M8x8) that’s holding the lifting

line.

Assembly: edge support

A

18

(18) Slide the edge support onto

the log bed.

(A) Attach crank handle to the

crank rod. Insert an allen

wrench into the end of the

threads on the handle and tight

it with an m8 locking nut.

14

Page 15

Assembly: saw carriage

21

19

20

(19) Insert bolts through the

holes along the sides of both the

chain-saw bed (pylon) and the

spool holder plate. Turn the

square nuts a few times. (8x

M6x16 bolts, 8 x M6 square

nuts)

(20) Insert the square nuts into

the slide rail track, moving the

spool holder plate and the

chain-saw bed to opposite ends

of the slide rails. Tighten the

bolts.

(21) Thread the line spool over

the spool holder arm and tighten

the nut. (1 x M10 locking nut)

15

Page 16

Assembly: chain guard

(22) Fit the chain guard on the

support and bolt. (2 x M6x40

collar bolts, 2 x M6 locking nuts)

22

Assembly: extender nuts

24

Remove the two bolts holding

the guide bar and remove the

guide bar cover.

(23) Remove the bark grips,

leaving the bolts and

retightening the nuts.

23

(24) Refit the guide bar cover,

replacing the guide bar bolts

with the two extender nuts. The

guide bar nuts will be used to

fasten the chain-saw to the

carriage.

Only CE-approved chain-

saws with two guide bar

nuts may be used with the M7

sawmill.

16

Page 17

Assembly: chain-saw

26

25

(25) Fit the Logosol extender

nuts through the chain-saw

plate using the front hole. (For

some chain-saw models the

rear hole has to be used to

(27) Push the assembled

carriage onto the guide rail with

the guide bar facing the log

beds.

Check that the carriage

moves easily on the guide

rail. If not, loosen the eight bolts

holding the sliding rails, move

the carriage back and forth and

retighten the eight bolts. If this is

insufficient, check the plastic

slide rails for damage.

ensure that the saw cover will

not extend too far. However, this

is relatively unusual.) Screw the

chain-saw’s guide bar nuts onto

the Logosol extender nuts under

the plate and tighten.

(26) Fit the chain guard support

on the two arms of the chainsaw plate so that the chain

guard sits app. 4 cm (1 1/2”)

from the tip of the guide bar. (2 x

M6x40 bolts, 2 x M6 collar nuts)

27

17

Page 18

Assembly: spiked log grip with guard

31

32

28

29

30

30

(28) Screw the handle with a

washer on the threaded rod for

the log grip carriage. (1 x M6

washer)

(29) Insert the bolts and screw

on square nuts in the same way

as when the chain-saw carriage

was assembled (see page 17).

(4 x M6x16 bolts, 4 x M6 square

nuts)

29

(30) Fit the sliding rails under

the plate so that the square nuts

fit into the slide rail tracks.

(31) Center the guard, log grip

and plastic spacer over the

holes in the plate. The spacer

should be turned so it extends

as far as possible behind the

grip. Thread the bolts through

the holes and tighten. (2 x

M6x40 bolts, 2 x M6 washers, 2

x M6 nuts)

(32) Thread the chain-saw feed

line holder bolt through the

spacer and fit on the plate. (1 x

M6x25 bolt, 1 x M6 nut)

The holder bolt can be fitted in

one of two holes depending on

whether a petrol or an electric

saw is being used. The picture

illustrates set-up for a petrol

saw. Make a loop on the feed

line and place it over the spacer.

18

Page 19

Siting

Min. 0.5 m (1.6 ft)

M

7

The M7 WoodWorkers Mill

may not tilt more than 5 °

from the horizontal in any

direction.

The saw may tip over if

the tilt is greater. The unit

may not be operated

unless the feet are faste-

ned to the floor.

The carriage may slide

off the guide rail if the tilt

is greater.

While the goal is to have the M7

WoodWorkers Mill fully level,

any tilt, however slight, must not

be away from the operator as

this can cause the logs to slide

off or lie at an angle.

When setting up the M7

directly on the ground:

The surface must firm and

level enough that driving a

normal car on it would not be a

problem.

Fit a board under each pair

of legs using two M6 bolts

for each foot. The boards must

be of good quality, at least

50x150 mm (2”x 6”) and at least

2 m (6.5 ft) long. The boards

must extend at least 0.5 m

(1.5 ft) beyond the long legs.

When bolting the M7 to a

concrete floor, asphalt

surface or similar, rigid surface,

a rubber underlay should be

placed under each foot in order

to prevent vibration damage to

the sawmill. Use a reliable

fastening system between

the feet and the surface.

19

Page 20

Adjustments – log bed

B

D

A

(A) Check that when the log bed

is cranked down, it moves

easily through the saddle plate

driven by its own weight. If this

is not the case:

- Stop the log bed in the position

that you judge to be the stickiest. If it is equally hard in all

positions, place it in its uppermost position.

Lock it using the rachet

cam to prevent it from

falling down.

- Loosen the four bolts on the

saddle plate and place it straight

in relationship to the lifting

beam.

C

- Loosen the plastic slide rail on

the log bed (D) and adjust it so

that it is straight in relation to the

log bed track.

- Lubricate the sliding surfaces

and the T-track of the lifting

beam using silicon or Teflon

spray.

(B) Check the height of the log

bed. Set the rachet in the 1/4”

position. Place the setting block

on the log bed. Move the chainsaw guide bar to right over the

log bed. Move the log bed up to

the notch where the setting

block is nearest to the underside of the guide bar.

(C) Use the bolt and inside nut

on the rachet bar to move the

log bed up until the setting block

touches the underside of the

guide bar. Should the

adjustment be insufficient or too

much, move the log bed up or

down a notch and adjust again.

Lock using the inside nut.

(D) To adjust the scale indicator,

loosen the two bolts holding it

and the plastic block on the log

bed. Set both indicators of the

scale to 2” in the position where

the setting block touches the

underside of the guide bar.

20

Page 21

Adjustments –guide bar

A

The guide bar should be

parallel to the log bed. If this

is not so, the guide bar is

probably not straight. Remove

the chain from the guide bar

without removing the guide bar

and move the sawing unit over

the log bed.

Use protective gloves!

(A) Grasp the middle of the

guide bar with both hands as

shown and bend it carefully until

it is parallel to the log bed.

Check using the setting block.

B

(B) How straight the guide bar

mounts varies between chainsaws.

It should only be necessary to

adjust a guide bar once,

provided that it is not bent during

sawing.

If after turning the guide bar you

notice that you need to bend it

again in the same direction as

before, it may be that the guide

bar mount isn’t true. This can be

compensated for by placing one

or more adjustment pieces

between the aluminium sliding

rails and the chain-saw or

electric saw plate. Adjustment

pieces can be ordered from

Logosol, part. no. 4507-001-

1305.

21

Page 22

Step-by-step sawing instructions

1.1 Roll the log onto the log

bed.

1.2 Fasten the log in place

using the edge support. Place

the edge support arms

backwards and lock the block in

place using the edge support

1

2

side.

1.3 Set the rachet cam on

either 1/4” or 1/8” increments

using the rachet handle. The

normal choice is the larger

measurement.

1.4 Raise the stock so that a

suitable slab size will be cut off.

Normally the top end of the log is

raised 1/4” or 1/2” (one or two

clicks) above the bottom end so

that the cut will parallel the grain.

1.5 Ram the spiked log grip

into the butt end of the log to

keep it from rotating. This should

be done prior to each cut.

For larger logs the log beds might

be set at 7 1/4” or 8 1/4”,

depending on whether a 1” or 2”

board is wanted.

2.3 Cut the slab and perhaps

one more board.

3.1 Rotate the cant 90° and fix

with the edge support arms. Set

the height so that a suitable slab

is sawn. Now lay the top end

somewhat higher than the bottom.

3.2 Raise both log beds the

same distance while retaining the

height differential. Saw out planks

and boards until app. 10 cm (4”)

remain. Do not forget to add 1/4”

to each desired board thickness

to compensate for the kerf.

4.1 Rotate the cant 180° and

place both log beds at the same

height. If a 1” and a 2” board are

to be sawed out at the end, place

the log beds at 3 1/4” (2+1+1/4).

22

3

4

5

1.6. Place the saw feed line on

the bolt with the spacer on the

log grip carriage (not with electric

feed).

1.7 Cut the slab off.

1.8 On larger logs it is

customary to raise the log bed to

cut off another, wane-edged

plank about 2 1/4” thick (nine

clicks) to create a 2” plank. Don’t

forget to knock out the log grip

before raising the log beds.

2.1 Make the saw cut and then

rotate the log 180°.

2.2 Should the log be small,

the block size might now be set

to 6”, for example. The log beds

would be at the same height.

4.2 Place the edge support

arms backwards and lock the

block in place using the edge

support side. Otherwise you may

saw into the arms.

4.3 Cut off the last slab.

4.4 Raise the log bed by 1 1/4”

and saw the 1” board. What you

have left is a 2” board.

5 Place the wane edged

boards on their short end. Lock

them in place with the edge

support arm and trim the wane.

As is usual, adjust the log bed

height for the fact that one edge is

still barked. When you turn the

boards so that the side down is

trimmed, set the log beds to the

same height.

Page 23

Sawing tips

In the beginning it might serve

you well to make a drawing on

the top end of how you want to

piece the log. Use a thick

marker so that the line

corresponds to the saw kerf.

Remember that:

When the log rests on a bark

surface, the log bed at the

top end is set higher than the

one at the root end.

When a sawn surface faces

down, the log beds are set at

the same height.

Through sawing

At times it can be best to slice

the log entirely into wane-edged

boards. This way it is possible

to get a bit more from each log.

The price for the gain is that it

takes a bit more time because

of the need for after-trimming. If

fine carpentry wood is the aim, it

might be best to trim one side

before drying. The last trim can

be done when you know what

the board will be used for –

everything to allow maximum

use of the wood.

When you are going to slice a

log beds, preventing movement

between cuts and ensuring

even boards.

Turn the log when you approach

the centre.

Figure out the height where you

should start and then saw.

The example shown in the

drawing calls for the first cut

after the log is turned to be at 8

1/4”, calculated as follows:

1+1+1+1+1+2= 7. For each +

add 1/4” to compensate for the

kerf. The total is (5x 1/4) + 7 = 8

1/4”.

In this way the final cut will be

correct and you will have a

minimum of wastage.

Quarter sawing

Compensate for the kerf with

one click (1/4”) whenever the

cut is above the guide bar.

Do not compensate for the

kerf when the cut is below

the guide bar.

The last board may not be

thinner than 2”.

Make sure you do not saw

into the edge support spring

arms.

Many of us here at Logosol can

share long sawing experiences.

As a new Logosoloist, if you

have any questions call us.

We’ll be happy to provide you

useful tips.

log in this way it is best to saw

off a thin slab first and then turn

that side downwards. In this

way the log will rest on an even

surface on at least one of the

Quarter sawing provides you

with the finest material. You

obtain optimal grain direction in

all boards, something that is a

great advantage for carpentry

work and the like. The price is in

time, in difficulty and in that you

obtain several different width

boards. Do not quarter saw

small logs. Begin by halving

andquartering the log. When

sawing the boards out of the

quarters, you turn the log 90°

between each cut. Sometimes it

is best to cut from below as this

allows you to raise the log beds

to the same height throughout.

23

Page 24

Material drying

Generally, once the wood is

sawn it must be dried.

It is possible to use undried

wood in some construction, but

only keeping in mind a 7%

shrinkage in width and height.

While most wood shrinks some

0.4% in length, this amount can

usually be ignored. In order to

avoid rot, you should not

enclose undried wood in a way

that makes it hard for air to

circulate. One further tip is not

to drive two nails into undried

wood next to each other as the

board will probably crack in the

middle when it dries out. Drive

one nail and wait with the

second until the wood has dried.

One example when you ought to

use undried wood is building log

structures. In such a situation, a

heavy wall is a plus, as is the

possibility that the logs still can

be shaped when they are pressed against each other.

In most cases, however, the

wood must be dried. If this is not

done, there is a danger it will be

damaged by dry or fungal rot.

The best time for outdoor drying

is in the spring. At that time the

relative humidity in the air is

comparably low meaning that

the wood will dry quicker.

Cut some supportive blocks

(5x5”) in the length that

corresponds to the width of your

pile. Place these at regular

intervals as shown below on

dry, level ground free of growth.

The spacing should not exceed

1 m (app. 1 yd) and should lie

level and in line with each other.

Cut spacers or drying sticks in

the same length as the

supportive blocks. They should

be the same thickness (1x1” or

1x2”) and dry. You can get

material for these by making an

extra cut when trimming your

boards.

Place your first row of boards

on the support logs, leaving

about an inch between them.

Then place a spacer on the

boards above each support log.

It is important to place the

spacers exactly over each other

to keep the boards from warping

or bending.

The higher you pile the boards,

the better pressure there is on

the lower boards. Place roofing

or some material over the top,

but leave the sides and ends

open. Put a weight of some sort

on top of the upper row to put

pressure on those planks as

well.

If the wood is to be used for fine

carpentry it ought to be stored in

a heated facility several weeks

before use or be dried in a kiln

or other kind of wood drier.

24

Page 25

Trouble-shooting

Reasons for wrong

measurements on an

M7 sawmill.

A. Incorrect adjustment

or set-up.

B. Cutting equipment

misfunction.

C. Tensions in the

wood.

A. Checking the M7

1. Check that all four legs

stand firmly and that the feet do

not sink into the ground when a

heavy log is loaded.

2. Sight over the log beds

and cross beam to check that

the sawmill stands straight.

Check both loaded and

unloaded.

3. Use a square to check

very carefully that the guide rail

is at an exact 90° angle to the

long legs. Even a small deviation can lead to large

measurement errors.

4. Set the distance between

log bed and guide bar so that it

is exactly the same to both log

beds. Make sure the guide bar

and the log beds are fully

parallel. Use the setting block

included with the machine.

5. Check that the guide rail

is absolutely straight by sighting

along the guide rail or by running

a line over the guide rail and

using nails or something similar

as spacers between the line

and the guide rail.

6. Check that the guide bar

is straight in relation to the

sawing direction by placing a

1.5 m (5 ft) strip of wood on the

guide bar without the chain.

Sight across the strip to make

sure it is parallel to the guide

rail.

Even factory-new guide bar

mounts can be out of true. This

is discovered if the parallel

relation to the log bed changes

when the guide bar is turned. A

bent guide bar is most easily

straightened by being pressed

up or down while the saw is

mounted on the sawmill (see

page 21). An out of true mount

is corrected for by placing

washers between the carriage

plate and the slide rail.

7. The set-up of the M7 can

be checked by placing a board

with maximum length on the log

beds. First trim off a narrow

strip from one side of the board.

Then turn it, set both log beds to

the same height and remove a

similar strip. Now measure the

width of the board carefully. If

the board is not the same width

along its entire length it can

mean that the log beds are

incorrectly set or that the guide

rail is crooked. It is also possible

that the guide rail has been

depressed by the weight of the

log. When a heavy cutting unit is

used, this problem can even

occur if the support legs are not

on a rigid surface. If a chainsaw is used the same thing can

happen if you extend the guide

rail more than 0.5 m (1.5 ft)

without adding support legs.

B. Checking the

cutting equipment

The guide bar must not cut

upwards or downwards during

sawing. This is most obvious

when the guide bar leaves the

log. If the guide bar does not

simply float out of the log but

springs up or down, problems

can arise. In such cases there

can be something wrong with

the guide bar or the chain.

Reasons for misfunction in the

cutting equipment:

1. One frequent reason for

problems when using the M7 is

that the chain is dull (see page

26).

2. The chain may be

damaged on one side, such as

by metal objects in the log. The

chain may still cut, but pulls up

or down (see page 27).

3. The chain may have been

filed wrong. The cutters may be

filed less on one side than on

the other. To get a more even

result, try to maintain the same

working position when filing the

left and the right sides of the

chain. That individual cutters are

faulty or that some are missing,

such as after sawing through

nails, usually has very small

effect on the function.

4. When precision

diminishes after a period of

fault-free sawing, it is almost

always due to wear on the guide

bar (see page 27).

Continued on the page

following.

25

Page 26

Tensions in the wood can

sometimes result in similar

symptoms as faults in the

cutting equipment.

C. Tensions in the

wood

The M7 sawmill can only saw

straight. If the wood grain twists

during sawing, precision will be

lost. Tension can cause large

variations in measurement.

Broad leaved trees have greater

tension than do evergreens, but

even the latter can have

problematic tensions. One

example is in trees that have

grown on sharp inclines. In such

cases a whole group of logs

can be hard to saw.

Tensions can also arise in

storage. If the bark and top

segment begin to dry, the whole

surface will begin to shrink. In

such a case, when one side is

trimmed, the log may bend

slightly.

It is easy to discover tension in

logs that leads to measurement

errors. Each time you pull the

saw back, you can read what is

happening in the log. As long as

the guide bar continues to lie

just above the newly sawn

surface, the log has not bent.

However, if a spaces show up

between the guide bar and the

sawn surface or if the guide bar

is pressed upwards, it is time to

plan how the next cut will go to

reduce the tensions.

When sawing from the top

towards the bottom, the wood

has a tendency to sink at the

ends pulled by its own weight.

This is especially true if there is

large root-end growth. If this is

true, then it would be best to

turn the log after passing

through the centre and saw the

rest of the material from the

other side.

Some tips for avoiding the

effects of wood tensions.

1. Cut wood with tension in

as short lengths as possible.

2. Work around the log,

sawing all sides in order.

3. Special arrangements

may be needed in order to get a

perfect measurement on the

last board of a log. One effective

way is to saw the last cuts

using a recently sawn board as

support.

Demands on precision

We are convinced that the M7

Wood Workers Mill provides as

good or better results as other

sawing methods. A large

number of users of the Logosol

sawmills have reported that they

have never had better wood

products than those they have

sawn themselves with their

Logosol mill.

However, it is natural that we

also meet customers who want

to improve on the precision. By

now we know that variations in

sawing results can have many

explanations. The choice of raw

material is vital. Cutting good

boards from short, sturdy logs

is considerably easier than

getting the same results with

thin, long ones. Tensions

caused by storage or place of

growth can cause problems.

Some tree types cause more

problems than others. The

reasons are many, including

how much time is available.

Sawyers with unlimited time

have a greater chance to

succeed than those whose time

is short.

The precision requirements also

vary. A result that is satisfactory

for someone sawing boards for

rustic fence posts may not be

good enough for someone

sawing boards to be used in

construction without being

planed.

If you have gone through the

various steps for adjusting the

M7 sawmill, checked the cutting

equipment and observed the

effects of tensions in the

wood,but still do not get the

sawing results you expect,

contact us at Logosol. We have

years of experience and can

always help you find solutions to

problems you may have.

Cutting equipment

The Logosol PMX chain provides for rapid ripping with a

narrow kerf. But it is more

sensitive than normal chains.

Still, if you keep the cutting

equipment in trim, you will get

the right measurements, the

sawing will be quicker and the

cutting equipment will last

longer.

File before it slows down

You will sense that the chain is

loosing its edge by the fact that

the sawing slows down, the

guide bar gets hot and the feed

is harder. Stop sawing at once!

At this point it’s really too late to

file. Sawing with a dull chain

exposes the sawing equipment

to great wear and tear. You

26

Page 27

must learn to file before the

chain gets dull.

File comfortably

Both hand and electrical chain

filing can give good results. The

electrical is faster and simpler.

For hand filing, we recommend

a double file with a built-in filing

gauge. (Pferd 4 mm, part. no.

9999-000-0400).

It is much easier to sharpen the

chain if you have a proper work

place. Fasten the guide bar in a

screw vice or a saw clamp.

Best is to build a table next to

the sawmill for filing and other

chain-saw maintenance. If you

have an electric saw, you will

need a file block (part. no. 9999000-0620) to hold the chain

during filing.

Avoid chain breaks

If you saw too long with a dull

chain, it can break under the

cutter where the material is

worn.

If, on the other hand, a drive link

breaks the reason can be that

the chain and the sprocket are

not matched. For best results

you should alternate five chains

on one sprocket. When the

chains are worn out, replace the

entire set, including the

sprocket. A new chain placed

on a worn down sprocket can

break during the first few minutes.

It is not good to drive a normal

3/8” chain and a PMX chain with

the same sprocket.

The guide bar can pull

askew

If the chain has been damaged

on one side or filed unevenly,

the guide bar can steer askew.

The guide bar will be pressed

up or down or jumps when it

leaves the log. This way the

chain wears more on one bar

rail and if you continue to saw,

the guide bar will be worn

lopsidedly. Even if you change

the chain, a worn down guide

bar can steer wrong and the

new chain can be worn down.

A lopsided guide bar can be

fixed. File the bar rails until they

are even, using a tool like a UKF

file (part. no. 9999-000-0450).

Another, more common reason

that the guide bar pulls askew is

that it is so worn out that the

drive link bottoms in the bar

groove and the chain looses its

support from the guide bar

walls. This can be seen on the

chain in that the tip of the drive

link becomes worn.

The best chain oil

In order for the chain oil to work

well it must be viscous and

thready. When you place a drop

between the thumb and the

index finger and then open

them, long threads should form.

Edge in the chromium layer

The cutter on a chain-saw chain

is covered with a very thin

chromium layer, giving a very

sharp and durable edge.

As long as the edge is in the

chromium layer, your chain will

have perfect sharpness.

However, after between 50 and

100 cuts with the M7, the edge

in the chromium layer will be

worn down. At that point it is

time to file the chain. If you are

really sensitive, you will notice

that the chain slows up, the

guide bar heats up and the feed

pressure must be increased. If

you file as soon as you sense

that the chain is no longer

perfectly sharp, you will need

only a few, light pulls with the

file.

If you always file before the

chain becomes dull, wear on

the guide bar and chain will be

minimal.

However, if you make 5-10 cuts

after the edge has left the

chromium layer, the chain will

be so dull it will be difficult to

saw. The sawing speed will be

low and the feed pressure high.

The guide bar and chain will

easily overheat. It is still

possible to saw, but the

equipment will wear out very

quickly.

When you file a chain, there is a

real danger that you won’t reach

the chromium layer. The chain

may feel sharp, but because it

isn’t in the chromium layer, it will

become dull again very quickly.

If you don’t file in time, you will

have to remove a lot of the

cutter to get it sharp. The

working life of the chain will be

short. And if a lot of the sawing

is done with a dull chain, you will

need a high feed pressure, with

consequent rapid guide bar

wear and a high risk for chain

breaks.

In conclusion, file before the

chain is dull so that you avoid

getting into a vicious circle

where the wear on the sawing

equipment increases and the

sawing result goes down.

Regular chain sharpening

is especially important if

you are sawing wood that

is aggressive to the chain,

such as dry material, hard

wood or wood with sand or

earth in the bark.

27

Page 28

Accessories

Logosol offers a great range of extensions, special tools and other accessories for the M7 Wood

Workers Mill. Simple extensions can be bought in 0.5 lengths (1.6 ft). It is also possible to extend the

Wood Workers mill to the M7Logosol Sawmill.

The product catalog is available at no cost. Just order it.

Cutting equipment Part number

Guide bar - 16” (40 cm), 1.3 picco 3003-000-6313

Ripping chain for guide bar above, 60 DL 3961-000-0060

Guide bar - 25” (63 cm), 1.3 picco 3003-000-5531

Ripping chain for guide bar above, 84 DL 3961-000-0084

To Stihl 064 / 066:

Chain drive sprocket, picco 1122-640-2006

To E 5000:

Star drive, picco 1207-642-1310

Filing equipment

File block to hold the chain steady while filing 9999-000-0620

Pferd file gauge, files cutter and drive link together 9999-000-0400

4 mm round file for Pferd file gauge 9999-000-0401

Extensions

End extension 0.5 m (1.6 ft) 4510-720-6602

M7 Sawmill upgade kit (9 ft) 4517-000-1020

Aids

Measuring rod to check saw height setting 4507-001-1300

Board shoe to fasten a 2x5” in the knee joint 4507-001-1304

Log steps to load logs over 20” (50 cm), 2 items 4507-001-1302

Edge support with spring-loaded arm 4507-001-1025

Loading ramp to simplify control of saw on an M7 9999-000-0920

Accessory for rounding logs, saws 16 sides 9999-000-1100

Adjustable log support, a universal tool 4510-720-6202

Log roller, to move logs sideways 9999-000-1420

Hearing protection with face shield 0000-884-0503

Stainless steel knife, Logosol 9922-140-0000

Folding rule 2 m, Logosol 9922-130-0000

Cap, Logosol 9922-120-0000

Electrical sawing unit

E 5000, high capacity 3-phase saw, incl. support leg 9999-011-0003

Feed for E 5000, stepless in both directions 6600-000-1000

Moulders

Electrical log molder, 3-phase 7600-000-0230

Logosol SH230 planer, size and profile planing 7200-000-0230

Logosol PH 260 4-side planer moulder 7502-000-0260

28

Page 29

Article list

43

53

50, 51

17

35-41

1

18

2

4

9

44-47,52

48, 49

54, 55

10

7

3

This list includes items that are not

part of the standard construction.

The items are ordered one at a time.

The number listed in the table

5

6

12-14

indicates the number usually

included.

24

28

29

32

16

15

42

27

30

31

33

No. Article number # Description

1. 4507-001-1000 2 Guide rail, 2.75 m (9 ft)

2. 4507-001-1015 2 Guide railstrut

3. 4517-001-1009 1 Cross beam

4. 4507-001-1030 2 Long leg

5. 4507-001-1035 2 Short leg

6. 4507-001-1040 4 Foot

7. 4507-001-1200 2 Horizontal beam

8. 4507-001-1045 2 Knee fitting

9. 4507-001-1050 2 Log bed

10. 4507-001-1025 2 Edge support

11. 4510-723-3900 6 Line pulley

12. 4507-001-1190 2 Setting block for log bed

13. 4507-001-1165 2 Short indicator

14. 4507-001-1170 2 Long indicator

15. 4507-001-1055 2 Rachet Cam Nuetral plate

16. 4507-001-1060 2 Angle fitting

17. 4507-001-1075 2 Log support

18. 4507-001-1070 4 Scale

19. 4507-001-1065 2 Lifting beam

20. 4507-001-1080 2 Lifting line, 2.05 m (6’9”)

21. 4507-001-1085 2 Saddle Plate, compl.

22. 4507-001-1090 4 Plastic slide rail, plate clamp

23. 4507-001-1095 8 Spacer

24. 4507-001-1101 2 Handle crank rod

25. 4507-001-1105 2 Stop ring, track

26. 4507-001-1106 2 Stop ring

27. 4507-001-1150 2 Rachet Axle

28. 4507-001-1115 2 Step chooser

29. 4507-001-1120 2 Turn spring

30. 4507-001-1125 2 Rachet Cam

31. 4507-001-1130 4 O-ring

32. 4507-001-1020 2 Rachet handle

33. 4507-001-1185 2 Rachet bar stop plate

34. 4507-001-1205 2 Line pulley holder

35. 4507-001-7600 1 Log grip, compl.

36. 4510-723-2905 2 Plastic slide rail, log grip *

37. 4510-723-2511 1 Spacer *

38. 4510-723-4806 1 Log grip guard *

39. 4510-723-5100 1 Threaded rod *

40. 4510-723-4902 1 Adjustable handle, log grip *

41. 4510-723-4403 1 Log grip spikes 9-points *

42. 4507-001-1110 2 Rachet axle

43. 6600-000-1100 1 Carriage, complete

44. 4510-723-2002 1 Chain-saw feed line *

45. 4510-723-6010 1 Electric saw feed line *

46. 6600-001-2121 1 Line for electric feed 7mm*

47. 4510-723-3402 1 Line spool *

48. 9999-000-1030 2 Carriage slide rail, complete *

49. 4510-723-2904 2 Plastic slide rail, carriage *

50. 4510-723-4809 1 Chain guard *

51. 4510-720-3000 1 Chain guard mount *

52. 4510-720-2800 1 Spool holder *

53. 4510-720-2900 1 Pylon carriage plate *

54. 4510-723-3402 2 Logosol chainsaw nut

55. 4507-001-1305 2 Adjusting plate 0.5 mm *

* Articles that are part of another article number, but can be ordered as a spare part or accessory.

8

19

21-26

20

34

11

29

Page 30

EU Declaration

Product: Logosol M7 portable sawmill

Manufacturer: Logosol KB, Industrigatan 13

SE-871 53 Härnösand

Tel. +46 (0)611 18285

The company hereby certifies that the Logosol M7 portable sawmill is manufactured in accord

with the specifications in Machine Directive 89/392/EEC, as amended, and in accord with the

following harmonised standard: EN 292.

The M7 portable sawmill may only be used in combination with Logosol’s sawing units E 5000, E

3000 and BS 320 or with a chain-saw that satisfies the specifications in Machine Directive 89/

392/EEC, as amended, and is fitted with two guide bar nuts for fastening to the carriage. In

combination with an electric saw unit, the M7 portable sawmill satisfies the specifications in EMC

Directive 89/336/EEC, as amended, and the low-tension directive 73/23/EEG.

Härnösand 950101

Bengt-Olov Byström, Managing Director

Page 31

Page 32

Loading...

Loading...