Page 1

Gasoline containing up to 10% ethanol (E10) is acceptable for use in this machine. The use of any gasoline exceeding 10% ethanol (E10) will void the product warranty.

Esta máquina puede utilizar gasolina con un contenido

de hasta el 10% de etanol (E10). El uso de una gasolina

que supere el 10% de etanol (E10) anulará la garantía

del producto. the product warranty.

586 24 20-49

Operator’s Manual

Manual de Operario

GT48XLSi

Please read the operator's manual carefully and make sure

you understand the instructions before using the machine.

Por favor lea cuidadosamente y comprenda

estas intrucciones antes de usar esta maquina.

English/Spanish

Page 2

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

DANGER: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROW ING OBJECTS. FAILURE

TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING: In order to prevent ac ci den tal

starting when setting up, trans port ing,

ad just ing or making repairs, al ways dis con nect spark plug wire and place wire where

it can not contact spark plug.

WARNING: Do not coast down a hill in neutral, you may lose control of the tractor.

WARNING: Tow only the attachments that

are rec om mend ed by and comply with

spec i fi ca tions of the man u fac tur er of your

tractor. Use common sense when towing.

Operate only at the low est possible speed

when on a slope. Too heavy of a load, while

on a slope, is dan ger ous. Tires can lose

trac tion with the ground and cause you to

lose control of your tractor.

WARNING

Engine exhaust, some of its con stit u ents, and cer tain

vehicle com po nents contain or emit chem i cals

known to the State of Cal i for nia to cause can cer

and birth de fects or oth er re pro duc tive harm.

• Never leave a running machine unattended. Always turn

off blades, set parking brake, and stop engine before

dismounting. Manually lock ignition switch. (See “MANUALLY LOCKING THE S

Op er a tion section of this manual).

• Disengage blades when not mowing. Shut off engine

and wait for all parts to come to a complete stop before

cleaning the machine, removing the grass catcher, or

unclogging the discharge chute.

• Operate machine only in daylight or good artificial light.

• Do not operate the machine while under the influence of

alcohol or drugs.

• Watch for traffic when operating near or crossing road ways.

• Use extra care when loading or unloading the machine

into a trailer or truck.

• Always wear eye protection when operating machine.

• Data indicates that operators, age 60 years and above,

are involved in a large percentage of riding mower-related

injuries. These operators should evaluate their ability to

operate the riding mower safely enough to protect them selves and others from serious injury.

• Follow the manufacturer's recommendation for wheel

weights or counterweights.

• Keep machine free of grass, leaves or other debris buildup

which can touch hot exhaust / engine parts and burn. Do

not allow the mower deck to plow leaves or other debris

which can cause build-up to occur. Clean any oil or fuel

spillage before operating or storing the machine. Allow

machine to cool before storage.

MARTSWITCH™ IGNITION” in the

WARNING

Battery posts, terminals and related ac ces so ries

contain lead and lead compounds, chem i cals known

to the State of Cal i for nia to cause can cer and birth

defects or oth er re pro duc tive harm. Wash hands

after handling.

I. GENERAL OPERATION

• Read, understand, and follow all instructions on the machine and in the manual before starting.

• Do not put hands or feet near rotating parts or under the

machine. Keep clear of the discharge opening at all times.

• Only allow responsible adults, who are familiar with the

in struc tions, to operate the machine.

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown by the blades.

• Ensure the area is clear of bystanders before operating.

Stop machine if anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while back ing.

• Never direct discharged material toward anyone. Avoid

discharging material against a wall or obstruction. Material

may ricochet back toward the operator. Stop the blades

when crossing gravel surfaces.

• Do not operate machine without the entire grass catcher, discharge chute, or other safety devices in place and working.

• Slow down before turning.

II. SLOPE OPERATION

Slopes are a major factor related to loss of control and tipover accidents, which can result in severe injury or death.

Operation on all slopes requires extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not mow it.

• Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven terrain could overturn the machine. Tall

grass can hide obstacles.

• Choose a low ground speed so that you will not have to

stop or shift while on the slope.

• Do not mow on wet grass. Tires may lose traction.

Always keep the machine in gear when going down slopes.

Do not shift to neutral and coast downhill.

• Avoid starting, stopping, or turning on a slope. If the tires

lose traction, disengage the blades and proceed slowly

straight down the slope.

• Keep all movement on the slopes slow and gradual. Do

not make sudden changes in speed or direction, which

could cause the

• Use extra care while operating machine with grass catchers or other at tach ments; they can affect the stability of

the machine. Do no use on steep slopes.

• Do not try to stabilize the machine by putting your foot

on the ground.

• Do not m

machine could suddenly roll over if a wheel is over the edge

or if the edge caves in.

ow near drop-offs, ditches, or embankments. The

machine to roll over.

2

Page 3

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

III. CHILDREN

WARNING. CHILDREN CAN BE INJURED BY

THIS EQUIPMENT. The American Academy

of Pediatrics recommends that children be a

minimum of 12 year of age before operating

a pedestrian controlled lawn mower and a

minimum of 16 years of age before operating

a riding lawn mower.

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the machine and the mowing activity. Never assume that children

will remain where you last saw them.

• Keep children out of the mowing area and in the watchful

care of a responsible adult other than the operator.

• Be alert and turn machine off if a child enters the area.

• Before and while backing, look behind and down for small

children.

• Never carry children, even with the blades shut off. They

may fall off and be seriously injured or interfere with safe

machine operation. Children who have been given rides

in the past may suddenly appear in the mowing area for

another ride and be run over or backed over by the machine.

• Never allow children to operate the machine.

• Use extra care when approaching blind corners, shrubs,

trees, or other objects that may block your view of a child.

• If fuel is spilled on clothing, change clothing immediately.

• Never overfill fuel tank. Replace gas cap and tighten

securely.

GENERAL SERVICE

• Never operate machine in a closed area.

• Keep all nuts and bolts tight to ensure the equipment is

in safe working condition.

• Never tamper with safety devices. Check their proper

operation regularly.

• Keep machine free of grass, leaves, or other debris buildup. Clean oil or fuel spillage and remove any fuel-soaked

debris. Allow machine to cool before storing.

• If you strike a foreign object, stop and inspect the machine.

Repair, if necessary, before restarting.

• Never make any adjustments or repairs with the engine

run ning.

• Check grass catcher components and the discharge chute

frequently and replace with manufacturer's recommended

parts, when necessary.

• Mower blades are sharp. Wrap the blade or wear gloves,

and use extra caution when servicing them.

• Check brake operation frequently. Adjust and service as

required.

• Maintain or replace safety and instruction labels, as necessary.

IV. TOWING

• Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the hitch

point.

• Follow the manufacturer's recommendation for weight

limits for towed equipment and towing on slopes.

• Never allow children or others in or on towed equipment.

• On slopes, the weight of the towed equipment may cause

loss of traction and loss of control.

• Travel slowly and allow extra distance to stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage, use extreme

care in handling gasoline. Gasoline is extremely flammable

and the vapors are explosive.

• Extinguish all cigarettes, cigars, pipes, and other sources

of ignition.

• Use only approved gasoline container.

• Never remove gas cap or add fuel with the engine running.

Allow engine to cool before refueling.

• Never fuel the machine indoors.

• Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as on a water

heater or other appliances.

• Never fill containers inside a vehicle or on a truck or

trailer bed with plastic liner. Always place containers on

the ground away from your vehicle when filling.

• Remove gas-powered equipment from the truck or trailer

and refuel it on the ground. If this is not possible, then

refuel such equipment with a portable container, rather

than from a gasoline dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

• Ensure the area is clear of bystanders before operating.

Stop machine if anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary.

Al ways look down and behind before and while backing.

• Never carry children, even with the blades shut off. They

may fall off and be seriously injured or interfere with safe

machine operation. Children who have been given rides

in the past may suddenly appear in the mowing area

for another ride and be run over or backed over by the

machine.

• Keep children out of the mowing area and in the watchful

care of a responsible adult other than the operator.

• Be alert and turn machine off if a child enters the area.

• Before and while backing, look behind and down for small

children.

• Mow up and down slopes (15° Max), not across.

• Choose a low ground speed so that you will not have to

stop or shift while on the slope.

• Avoid starting, stopping, or turning on a slope. If the tires

lose traction, disengage the blades and proceed slowly

straight down the slope.

• If machine stops while going uphill, disengage blades,

shift into reverse and back down slowly.

• Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

• When loading or unloading this machine, do not exceed

the maximum recommended operation angle of 15°.

3

Page 4

PRODUCT SPECIFICATIONS

Gasoline Capacity

and type:

Oil Type:

(API: SG-SL)

Oil Capacity: W/Filter: 64 Oz./1,65 L

Spark Plug:

Charging System: 16 Amps @ 3600 RPM

Battery: Amp/Hr: 28

Blade Bolt Torque: 45-55 Ft. Lbs./62-75 Nm

4 Gallons/15,14 L

Regular Unleaded

SAE 30 (above 32°F/0°C)

SAE 5W30 (below 32°F/0°C)

W/out Filter: 60 Oz./1,4 L

Champion 795135

(Gap: .030"/ 0,76 mm)

Min. CCA: 230

Case size: U1R

CONGRATULATIONS on your purchase of a new tractor.

It has been designed, engineered and manu fac tured to

give you the best possible dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest authorized service

center/department. We have com pe tent, well-trained tech ni cians and the proper tools to ser vice or repair this tractor.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your tractor prop erly.

Always observe the “SAFETY RULES”.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your tractor.

• Follow the instructions under “Maintenance” and “Stor age” sec tions of this manual.

• Wear proper Personal Protective Equipment (PPE)

while operating this machine, including (at a minimum)

sturdy footwear, eye protection, and hearing protection.

Do not mow in short and/or, open toed footwear.

• Always let someone know you are outside mowing.

WARNING: This tractor is equipped with an internal com bus tion engine and should not be used on or near any un im proved forest-covered, brush-covered or grass-cov ered

land unless the engine’s exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

A spark arrester for the muffler is available through your

nearest authorized service center/department.

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply

on federal lands.

TABLE OF CONTENTS

SAFETY RULES ................................................................... 2-3

PRODUCT SPECIFICATIONS ................................................. 4

CUSTOMER RESPONSIBILITIES ........................................... 4

ASSEMBLY ........................................................................... 5-6

OPERATION .......................................................................7-15

MAINTENANCE SCHEDULE ................................................ 16

MAINTENANCE ............................................................... 16-20

SERVICE AND AD JUST MENTS ...................................... 21-27

STORAGE .............................................................................. 28

TROU BLE SHOOT ING ...................................................... 29-30

WARRANTY ...................................................................... 31-34

ESPAÑOL .............................................................................. 36

4

Page 5

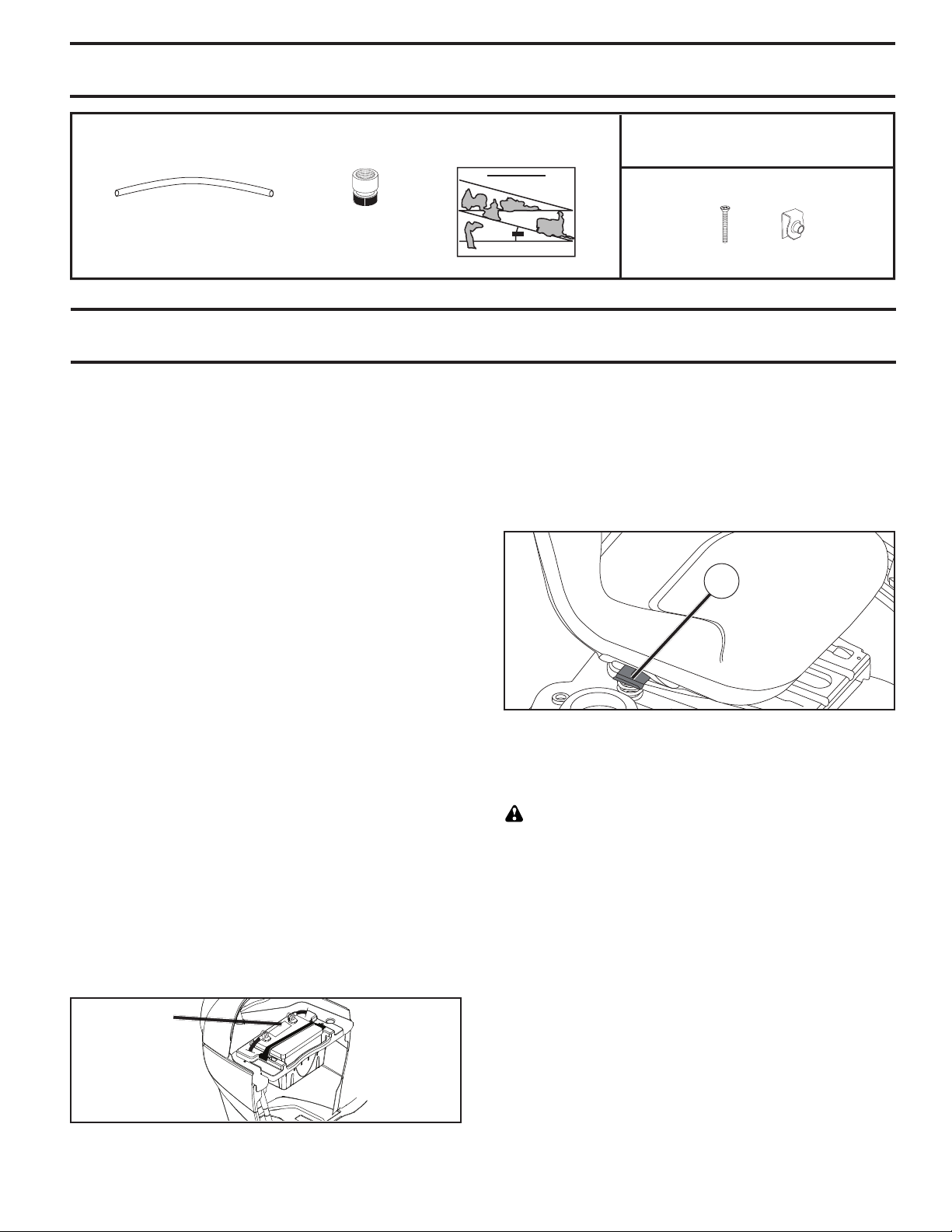

UNASSEMBLED PARTS

Slope Sheet

*Installed by Dealer

*Brush Guard Kit

*Pedal

(1) Quick Connect(1) Oil Drain Tube

(2) Screw (2) Nut

U-Channel

ASSEMBLY

Your new tractor has been assembled at the factory with the exception of those parts left unassembled for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Stan dard

wrench sizes are listed.

(1) 1/2" wrench Tire pressure gauge

(2) 7/16" wrenches Utility knife Pliers

When right or left hand is mentioned in this man ual, it means

when you are in the operating po si tion (seated be hind the

steer ing wheel).

TO REMOVE TRACTOR FROM CARTON

ADJUST SEAT (See Fig. 2)

• Sit in seat.

• Lift up adjustment lever (A) and slide seat until a comfortable position is reached which allows you to press

clutch/brake pedal all the way down.

• Release lever to lock seat in position.

A

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton.

• Remove end panels and lay side panels flat.

• Check for any additional loose parts or cartons and

remove.

BEFORE REMOVING TRACTOR FROM

SKID

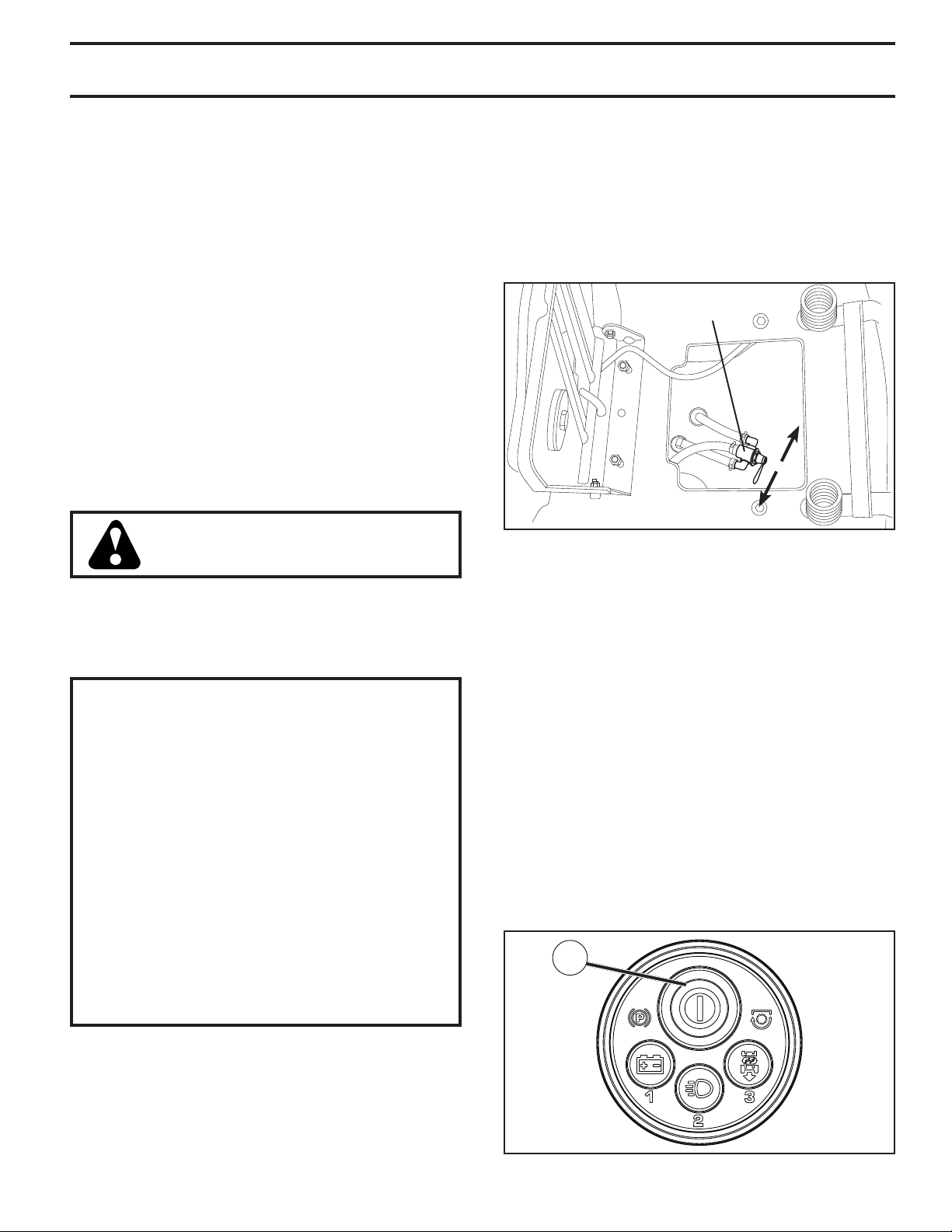

TO CHECK BATTERY (See Fig. 1)

• Lift hood to raised position.

NOTE: If this battery is put into service after month and

year indicated on label (label is located between terminals)

charge battery for minimum of one hour at 6-10 amps.

(See "BATTERY" in Maintenance section of this manual

for charging instructions).

• For battery and battery cable installation see "REPLACING BATTERY" in the "Service and Adjustments"

section in this manual.

LABEL

Fig. 2

NOTE: You may now roll your tractor off the skid. Continue

using the instructions that follow to remove the tractor from

the skid.

WARNING: Before start ing, read, un der stand and fol low all in struc tions in the Op er a tion section of this man u al.

Ensure tractor is in a well-ventilated area. Ensure the area

in front of tractor is clear of other peo ple and objects.

TO ROLL TRACTOR OFF SKID (See

Op er a tion section for location and function

of con trols)

• Raise attachment lift lever to its highest po si tion.

• Release parking brake by de press ing brake ped al.

• Place freewheel control in dis en gaged po si tion to

dis en gage trans mis sion (See “TO TRANS PORT” in

the Op er a tion section of this manual).

• Roll tractor forward off skid.

Continue with the in struc tions that follow.

Fig. 1

5

Page 6

ASSEMBLY

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory

for shipping purposes. Correct tire pressure is important

for best cutting performance.

• Reduce tire pressure to PSI shown on tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly leveled. See “TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

sec tion of this manual. Verify that the belts are routed

cor rect ly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see that

the brake is operating properly. See “TO CHECK BRAKE”

in the Service and Adjustments section of this manual.

✓CHECKLIST

BEFORE YOU OPERATE YOUR NEW TRAC TOR, WE

WISH TO ASSURE THAT YOU RECEIVE THE BEST

PERFORMANCE AND SATISFACTION FROM THIS

QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

✓ All assembly instructions have been com plet ed.

✓ No remaining loose parts in carton.

✓ Battery is properly prepared and charged.

✓ Seat is adjusted comfortably and tightened securely.

✓ All tires are properly inflated. (For shipping purposes,

the tires were overinflated at the factory).

✓ Ensure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

✓ Check mower and drive belts. Ensure they are routed

properly around pulleys and inside all belt keepers.

✓ Check wiring. See that all connections are still secure

and wires are properly clamped.

✓ Before driving tractor, ensure free wheel control is in

“transmission engaged” position (see “TO TRANS PORT” in the Operation section of this man u al).

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

✓ Engine oil is at proper level.

✓ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

✓ Become familiar with all controls, their location and

function. Operate them before you start the engine.

✓ Ensure brake system is in safe operating condition.

✓ Ensure Operator Presence System and Reverse Op-

eration System (ROS) are working properly (See the

Operation and Maintenance sections in this manual).

✓ It is important to purge the transmission before op er at-

ing your tractor for the first time. Follow proper starting and transmission purging instructions (See “TO

START EN GINE” and “PURGE TRANSMISSION” in

the Op er a tion section of this manual).

6

Page 7

OPERATION

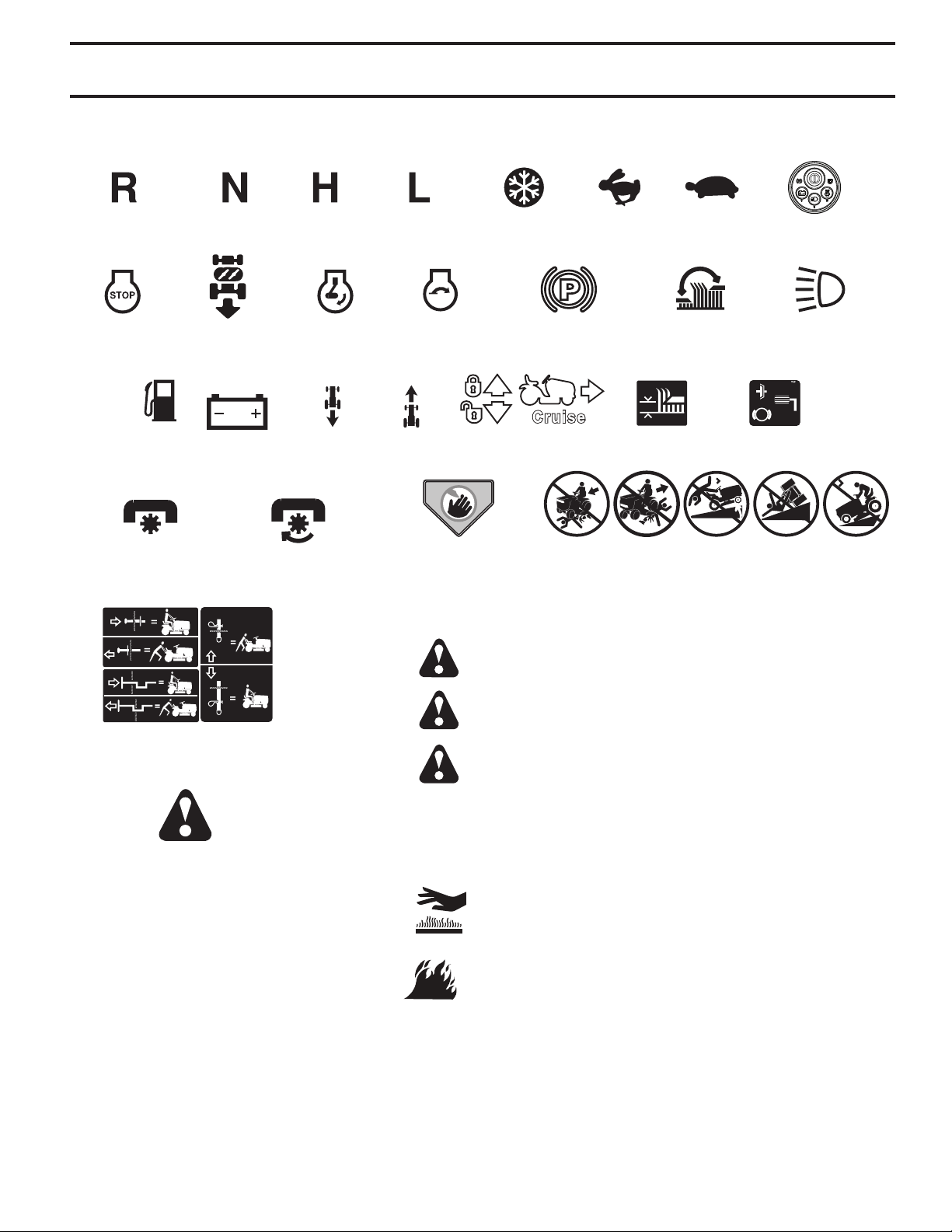

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

REVERSE NEUTRAL HIGH LOW

ENGINE OFF

FUEL

ATTACHMENT

CLUTCH DISENGAGED

REVERSE

OPERATION

SYSTEM (ROS)

BATTERY

CLUTCH ENGAGED

ENGINE ON

REVERSE

ATTACHMENT

FORWARD

COLD WEATHER

STARTING POSITION

ENGINE START

DANGER, KEEP HANDS

AND FEET AWAY

PARKING BRAKE

CRUISE CONTROL

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

FAST SLOW

MOWER HEIGHT

MOWER LIFT

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

CLUTCH/BRAKE

15

S

MARTSWITCH™

IGNITION

LIGHTS ON

PEDAL

15

FREE WHEEL

(Automatic Models only)

Failure to follow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safety information about hazards which can

result in death, serious injury

and/or property damage.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION when used without the alert symbol,

indicates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious injury

and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage.

7

Page 8

OPERATION

KNOW YOUR TRACTOR

READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of various controls and ad just ments.

Save this manual for future reference.

P

Z

S

Y

F

D

E

CC EE

B

K

Q

M

A

C

J

I

H

L

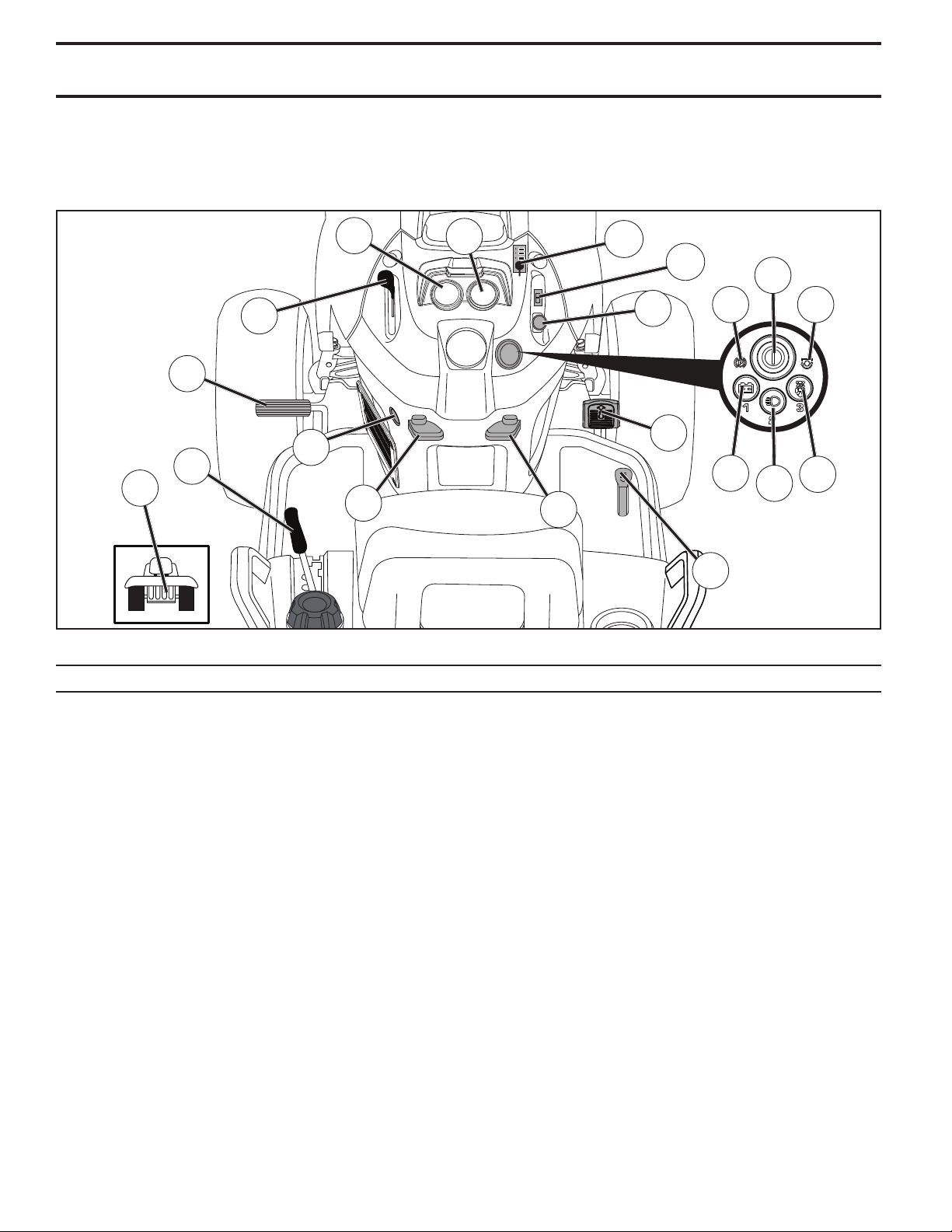

Fig. 3

Our tractors conform to the applicable safety standards of the American National Standards Institute.

G

(A) ATTACHMENT LIFT LEVER - Used to raise and

lower mower or other attachments mounted to tractor.

(B) BRAKE PEDAL - Used for braking the tractor and

starting the engine.

(C) PARKING BRAKE - Locks clutch/brake pedal into the

brake position.

(CC) PARKING BRAKE SYMBOL - Indicates a starting

fault when the parking brake is disengaged.

(D) THROTTLE CONTROL - Used to control engine speed.

(E) ATTACHMENT CLUTCH SWITCH - Used to engage

mower blades or other attachments mounted to tractor.

(EE) BLADE SWITCH SYMBOL - Indicates a fault when

the attachment clutch switch is engaged.

(F) S

MARTSWITCH IGNITION (SSI) BUTTON - Used for

starting/stopping engine and communicating status updates.

(G)* REVERSE OPERATION SYSTEM (ROS) - Allows

operation of mower deck or other powered attachment

while in reverse.

(H)* HEADLIGHT BUTTON - Turns the headlights on/off.

(I)* BATTERY INDICATOR BUTTON - Used to indicate

low battery voltage or a charging system fault.

(J) CRUISE CONTROL LEVER - Used to set forward

movement of tractor at desired speed without holding the

forward drive pedal.

(K) FORWARD DRIVE PEDAL - Used for forward movement of tractor.

(L) REVERSE DRIVE PEDAL - Used for reverse movement of tractor.

(M) FREEWHEEL CONTROL - Disengages transmission

for pushing or slowly tow ing the trac tor with the engine off.

(P) HOURMETER - Indicates hours of operation.

(Q) 12-VOLT POWER PORT - Used for 12 volt accessories.

(S) BATTERY INDICATOR/CHARGING PLUG - Indi-

cates the status of the battery.

(Y) DIFFERENTIAL LOCK SWITCH - Used to engage

and disengage the differential lock on transaxle.

(Z) AMMETER - Indicates charging (+) or discharging (-)

of battery.

NOTE: G, H, and I are also used as the numerical input buttons

*

for entering the passcode.

8

Page 9

OPERATION

The operation of any tractor can result in foreign objects thrown into the eyes, which can result

in severe eye dam age. Always wear safety glass es or eye shields while operating your tractor

or per form ing any ad just ments or repairs. We rec om mend standard safety glasses or a wide

vision safety mask worn over spectacles.

HOW TO USE YOUR TRAC TOR

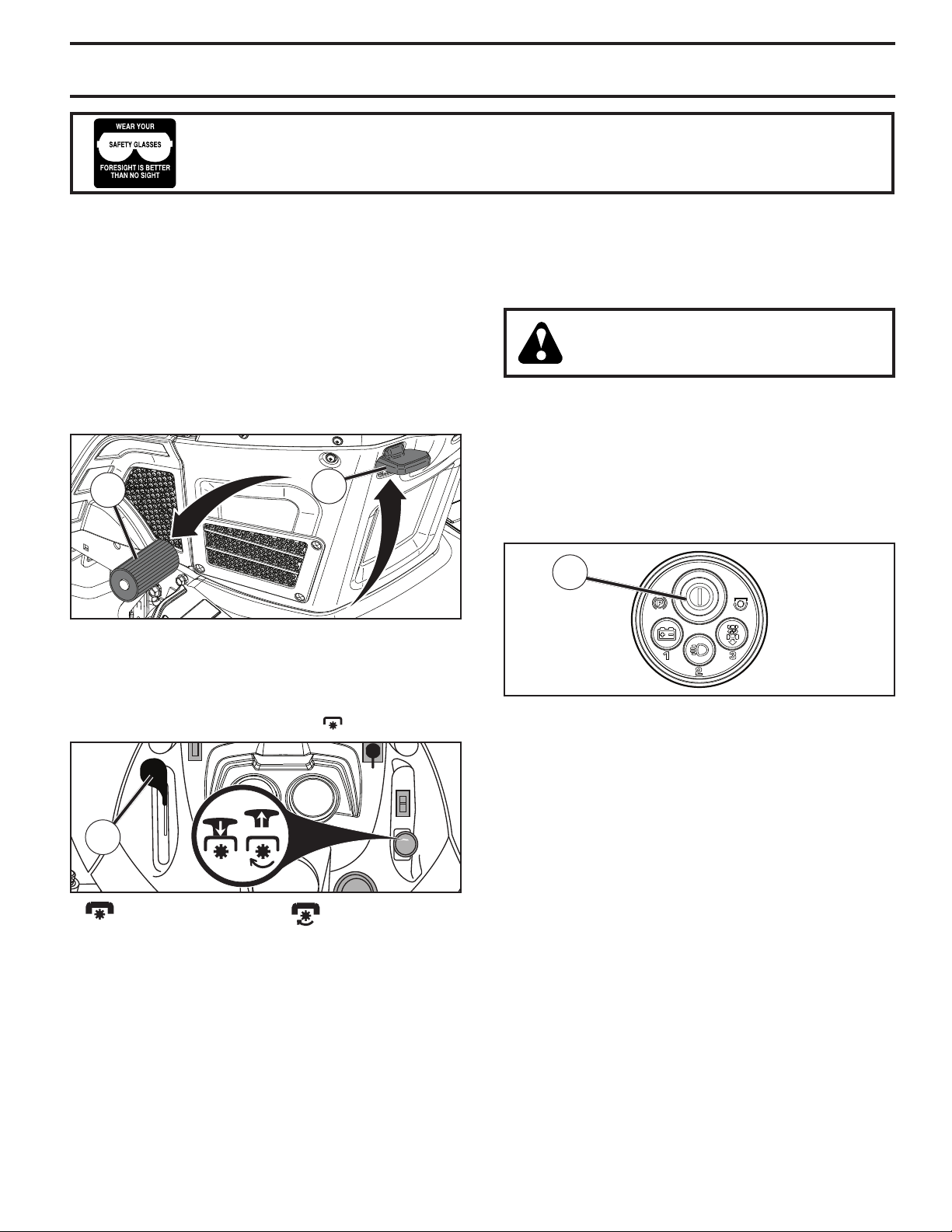

TO SET PARKING BRAKE (See Fig. 4)

Your tractor is equipped with an operator presence sens ing switch. When engine is running, any attempt by the

op er a tor to leave the seat without first setting the parking

brake will shut off the engine.

• Depress brake pedal (B) all the way down and hold.

• Pull parking brake lever (C) up and hold, re lease pres sure from brake pedal (B), then release parking brake

lever. Pedal should re main in brake position. Ensure

parking brake will hold tractor secure.

B

Fig. 4

STOPPING (See Fig. 5)

MOWER BLADES -

• To stop mower blades, place attachment clutch control

in the “DIS EN GAGED” position ( ).

D

( ) ATTACHMENT

CLUTCH SWITCH

“DIS EN GAGED”

Fig. 5

GROUND DRIVE -

• To stop ground drive, depress brake pedal into full

“BRAKE” position.

IMPORTANT: FORWARD AND REVERSE DRIVE PEDALS

RETURN TO NEUTRAL POSITION WHEN NOT DEPRESSED.

ENGINE -

• Move throttle control (D) to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine

to “back fire”.

C

( ) ATTACHMENT

CLUTCH SWITCH

“ENGAGED”

• Press SSI button (F) once to stop engine.

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot en gine exhaust gases

may cause “browning” of grass. To eliminate this possibility,

al ways stop engine when stopping tractor on grass areas.

CAUTION: Always stop tractor com plete ly,

as described above, and set parking brake

before leav ing the op er a tor's position.

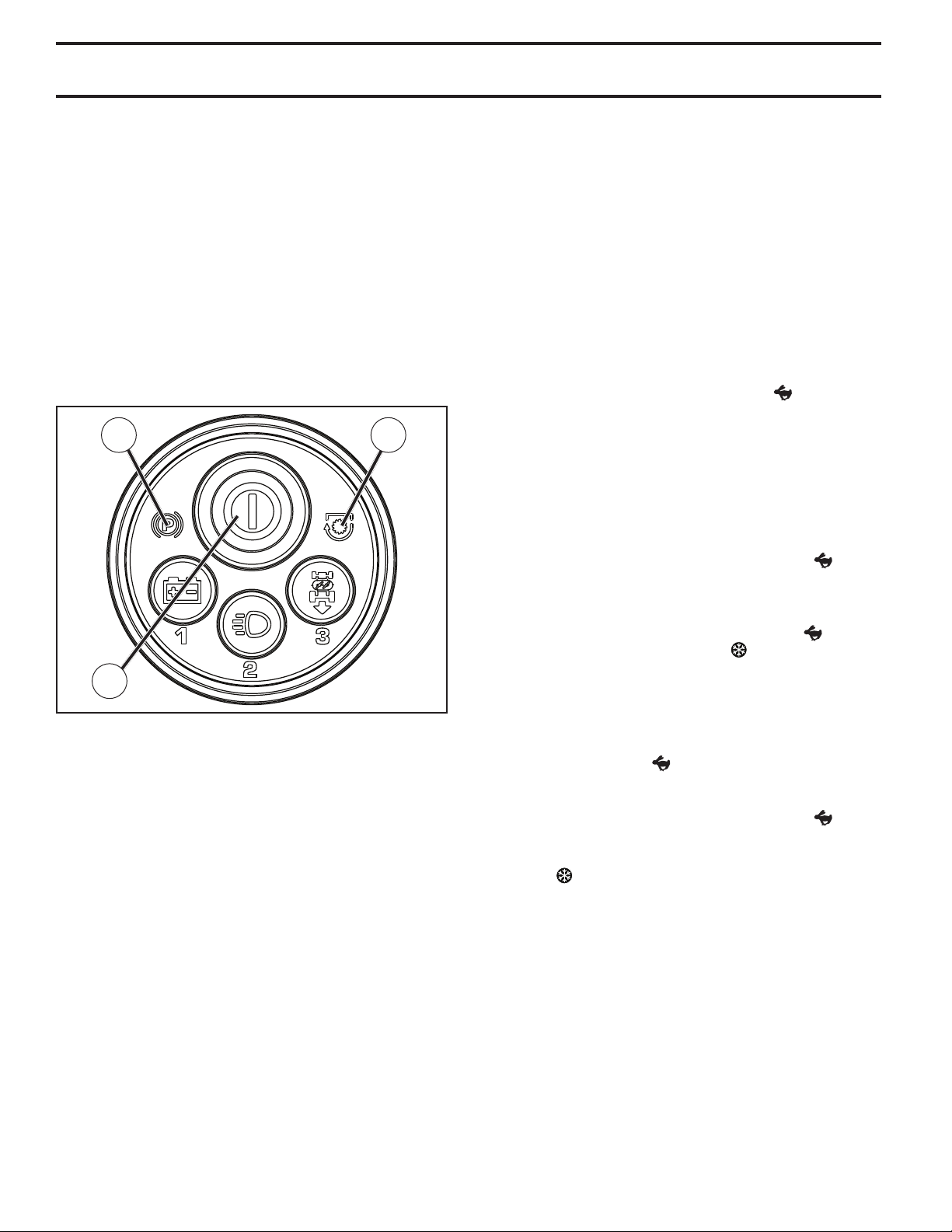

MANUALLY LOCKING THE SMARTSWITCH IGNITION

(See Fig. 6)

With the engine completely stopped and the SmartSwitch

Ignition (SSI) button (F) blinking green, the SSI button can

be manually locked by pressing buttons "1" and "3" at the

same time for approximately two seconds.

NOTE: The tractor is already locked if asleep or if SSI

button is blinking blue.

F

Fig. 6

SMARTSWITCH SAFETY SYSTEM

Your tractor is equipped with an operator presence sens ing

switch. If the parking brake has not been engaged before

the operator leaves the seat, the engine will shut off. To

continue mowing, the tractor will need to be restarted. See

"TO START ENGINE" in this section of the manual.

TO STOP MOWING

• While seated in operating position, depress brake pedal

and set parking brake.

After setting the parking brake, any attempt by the operator

to leave the seat will stop the mower blades. The engine

will continue to run for approximately five minutes before

shutting off. This allows an operator to momentarily leave

the seat to remove obstacles without having to restart the

tractor.

TO CONTINUE MOWING

• Return to seat.

• Place attachment clutch switch first in "DISENGAGED"

position and then in "ENGAGED" position.

NOTE: Any attempt to place attachment clutch switch in

the "ENGAGED" position without the operator first being

in the seat will immediately shut off engine.

9

Page 10

OPERATION

TO USE THROTTLE CONTROL (D) (See Fig.7)

Always operate engine at full speed (fast).

• Operating engine at less than full speed (fast) reduces

the engine's operating efficiency.

• Full speed (fast) of fers the best mower per for mance.

D

Fig. 7

TO MOVE FORWARD AND BACKWARD

(See Fig. 8)

The direction and speed of movement is controlled by the

forward and reverse drive pedals.

• Start tractor and release parking brake.

• Slowly depress forward (K) or reverse (L) drive pedal to

begin movement. Ground speed increases the further

down the pedal is depressed.

TO USE CRUISE CONTROL (J) (See Fig. 8)

The cruise control feature can be used for forward travel only.

K

TO USE DIFFERENTIAL LOCK CONTROL (Y)

(See Fig. 9)

• To engage differential lock, stop the tractor and push

the differential lock switch to the "ON" position.

NOTE: Driving for long periods of time with the differential

lock engaged is not detrimental or abusive to the system.

CAUTION: To minimize the risk of damage, avoid engaging differential lock while

vehicle is in motion.

Y

Fig. 9

• Drive tractor forward. As the rear tires rotate the

differential lock will engage.

NOTE: Operators may notice displacement or turfing of

grass in turns with differential lock engaged.

• To disengage differential lock, push differential lock

switch to the "OFF" position. If the differential lock

does not disengage, steering the vehicle from side to

side will assist.

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 10)

The position of the attachment lift lever (A) determines the

cutting height.

J

L

Fig. 8

SYSTEM CHARACTERISTICS

The cruise control should only be used while mowing or

transporting on relatively smooth, straight surfaces. Other

con di tions such as trimming at slow speeds may cause the

cruise control to dis en gage. Do not use the cruise control

on slopes, rough terrain or while trimming or turning.

• With forward drive pedal depressed to desired speed,

pull cruise control lever (J) up and hold while lifting

your foot off the pedal, then release the lever.

To disengage the cruise control, depress the brake pedal

or tap on forward drive pedal.

A

Fig. 10

• Put attachment lift lever in desired cutting height slot.

The cutting height range is ap prox i mate ly 1 to 4" (25,4 to

101,6 mm). The heights are measured from the ground to

the blade tip with the engine not running. These heights are

approximate and may vary depending upon soil conditions,

height of grass and types of grass being mowed.

• The average lawn should be cut to approximately

2-1/2" (63,5 mm) during the cool season and to over 3"

(76,2 mm) during hot months. For healthier and better

looking lawns, mow often and after moderate growth.

• For best cutting performance, grass over 6" (152,4 mm)

in height should be mowed twice. Make the first cut

relatively high; the second to de sired height.

10

Page 11

OPERATION

TO ADJUST GAUGE WHEELS (See Fig. 11)

Gauge wheels are properly adjusted when they are slightly

off the ground when mower is at the desired cutting height

in operating position. Gauge wheels then keep the deck

in proper position to help prevent scalping in most terrain

conditions.

NOTE:Adjust gauge wheels with tractor on a flat level

surface.

• Adjust mower to desired cutting height. (See “TO AD JUST MOWER CUT TING HEIGHT” in the Operation

sec tion of this manual.)

• With mower in desired height of cut po si tion, gauge

wheels should be assembled so they are slightly off

the ground. In stall gauge wheel in appropriate hole as

shown and tighten se cure ly.

• Repeat for opposite side installing gauge wheel in same

adjustment hole.

9/16”

3/4”

Fig. 11

TO OPERATE MOWER

Your tractor is equipped with an operator presence sensing switch. While engine is running, any attempt by the

op er a tor to leave the seat without first setting the parking

brake will shut off the engine. You must remain fully and

centrally positioned in the seat to prevent the engine from

hesitating or cutting off when operating your equipment on

rough, rolling terrain or hills.

• Select desired height of cut. (See "TO ADJUST MOWER

CUTTING HEIGHT".)

• Start mower blades by engaging at tach ment clutch

control.

TO STOP MOWER BLADES

Disengage at tach ment clutch con trol.

REVERSE OPERATION SYSTEM (ROS)

(See Fig. 13)

Your tractor is equipped with a Reverse Operation System

(ROS). Any attempt by the operator to mow in the reverse

direction without first pressing the ROS button (G) will stop

mower blades. Ensure the transmission is in the neutral

position, move the attachment clutch control to the disengaged position, and then back into the engaged position

before continuing with ROS operation.

WARNING: Backing up with the attachment clutch engaged while mowing is strongly discouraged. Allowing reverse operation with the attachment clutch engaged should

only be done when the operator decides it is necessary

to reposition the machine with the attachment engaged.

Do not mow in reverse unless absolutely necessary.

USING THE REVERSE OPERATION SYSTEM Only use if you are certain no children or other bystanders

will enter the mowing area.

• With engine running, depress brake pedal all the way

down.

• Press ROS button (G) and ensure the ROS button is lit.

• Look down and behind before and while backing.

• Release brake pedal and depress reverse drive pedal

to start movement.

• When use of the ROS is no longer needed, press the

ROS button to return to normal operation. The ROS

button should no longer be lit.

G

Fig. 13

TO OPERATE ON HILLS

CAUTION: Do not operate the mower without

either the en tire grass catcher, on mowers

so equipped, or the deflector chute in place

(See Fig. 12).

Fig. 12

CAUTION: Do not drive up or down

hills with slopes greater than 15° and

do not drive across any slope.

• Choose the slowest speed before starting up or down

hills.

• Avoid stopping or changing speed on hills.

• If stopping is absolutely necessary, push brake pedal

quickly to brake position and engage parking brake.

• To restart movement, slowly release parking brake and

brake pedal.

• Slowly depress appropriate drive pedal to slowest set ting.

• Make all turns slowly.

11

Page 12

OPERATION

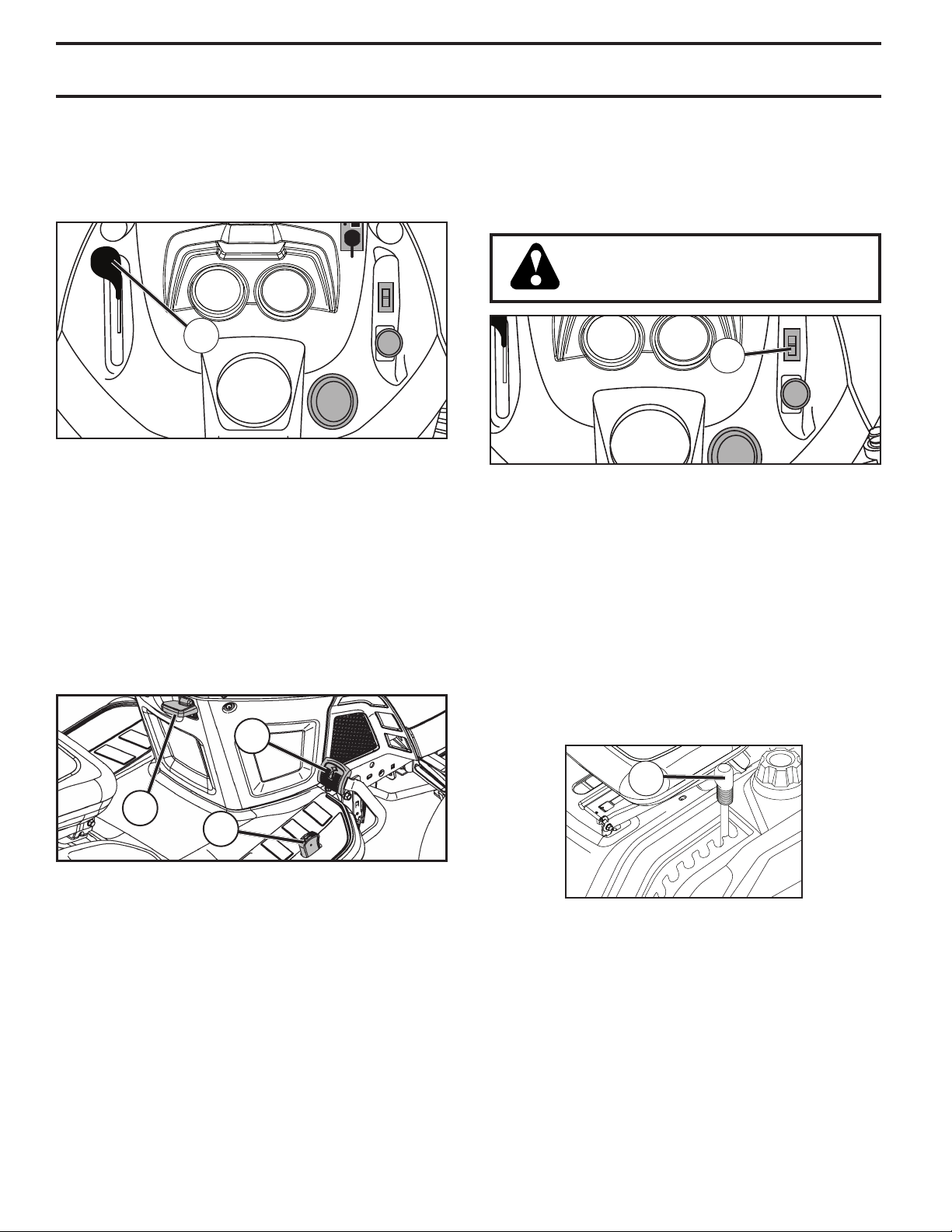

TO TRANSPORT (See Fig. 14)

When push ing or tow ing your trac tor, ensure transmission

is disengaged by placing freewheel control in free wheel ing po si tion. Free wheel control is located under the seat.

• Raise attachment lift to highest position with at tach ment

lift control.

• Raise seat and pull freewheel control up and back into

the slot and release so it is held in the disengaged

position.

• Do not push or tow tractor at more than two (2) mph

(3,2 km/h).

• To reengage transmission, reverse above procedure.

TRANSMISSION ENGAGED

TRANSMISSION DISENGAGED

Fig. 14

NOTE: To protect hood from damage when transporting

your tractor on a truck or a trailer, ensure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc.).

TOWING CARTS AND OTHER AT TACH MENTS

Tow only the attachments that are recommended by and

comply with specifications of the manufacturer of your tractor. Use common sense when towing. Too heavy of a load,

while on a slope, is dangerous. Tires can lose traction with

the ground and cause you to lose control of your tractor.

HEADLIGHTS

Headlights can be used without your passcode and with

the engine off.

WITH ENGINE OFF:

• Press headlight button (H) once to turn headlights on

for one minute.

• Press and hold headlight button (H) until headlights

blink twice to turn headlights on for five minutes.

NOTE: If the engine is running and shuts off for any reason,

the headlights will also shut off.

RED

YELLOW

GREEN

Fig. 15

NOTE: Wait 30 minutes after battery use for accurate

charge indication.

For charging, the battery can be charged through the

Charging Plug.

WARNING: The Charging Plug only fits

CTEK's 12 volt chargers between 0.8 - 10

Amps and must only be used with these

chargers.

See your local dealer for an available charger.

CHARGING

PLUG

BATTERY INDICATOR BUTTON (See Fig. 16)

The battery indicator button (I) is located on the SmartSwitch

Ignition module and is used to display the status of the

battery. The indicator will only work after the passcode

has been entered and is blinking green.

• Press and hold battery indicator button (I) for three (3)

seconds.

• The SmartSwitch Ignition Button (F) will light up and

indicate the battery status as follows:

RED Charge necessary

RED AND GREEN Charge recommended

GREEN Charge not necessary

• Press the battery indicator button (I) once to stop

viewing the battery status.

NOTE: When the battery is too low and after the first unsuccessful start attempt, the battery indicator button will

blink for two (2) seconds and then stay lit until battery is

charged or until approximately five (5) minutes since last

attempted start.

BATTERY INDICATOR/CHARGING PLUG

(See Fig. 15)

The Battery Indicator displays the status of the battery.

There are three different indicator lights:

1. RED Charge necessary

2. YELLOW Charge recommended

3. GREEN Charge not necessary

F

I

Fig. 16

12

Page 13

PRIMARY

RESERVE

RESERVE

FUEL VALVE

OPERATION

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine in your tractor has been shipped from the factory already filled with sum mer weight oil.

• Check engine oil with tractor on level ground.

• Remove oil fill cap/dipstick and wipe clean, reinsert the

dipstick and screw cap tight, wait for a few seconds,

remove and read oil level. If necessary, add oil until

“FULL” mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for

easier starting. (See “OIL VISCOSITY CHART” in the

Maintenance sec tion of this manual.)

• To change engine oil, see the Maintenance section in

this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do not overfill.

Use fresh, clean, regular gasoline with a minimum of

87 octane. Do not mix oil with gasoline. Purchase fuel

in quantities that can be used within 30 days to ensure

fuel freshness.

CAUTION: Wipe off any spilled oil or

fuel. Do not store, spill or use gasoline

near an open flame.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F (0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP ENSURE GOOD COLD WEATHER

STARTING.

CAUTION: Alcohol blended fuels (called gasohol

or using ethanol or methanol) can attract moisture

which leads to sep a ra tion and for ma tion of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid

engine problems, the fuel system should be emptied

before stor age of 30 days or longer. Drain the gas

tank, start the engine and let it run until the fuel

lines and carburetor are empty. Use fresh fuel next

season. See Storage In struc tions for additional

information. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may

occur. Fuel stabilizer is an acceptable alternative

in minimizing the formation of fuel gum deposits

during stor age. Add stabilizer to gasoline in fuel

tank or storage container. Always follow the mix

ratio found on stabilizer container. Run engine at

least 10 minutes after adding stabilizer to allow the

stabilizer to reach the carburetor. Do not empty

the gas tank and carburetor if using fuel stabilizer.

RESERVE FUEL VALVE OPERATION

(See Fig. 17)

1. Raise seat to access reserve fuel valve.

2. In normal operation, valve should be set to primary (as

shown in view)

3. If tractor runs out of fuel, rotate valve handle to reserve.

4. Drive tractor to be refueled.

5. After refueling, return valve to primary position.

RESERVE

FUEL VALVE

RESERVE

PRIMARY

Fig. 17

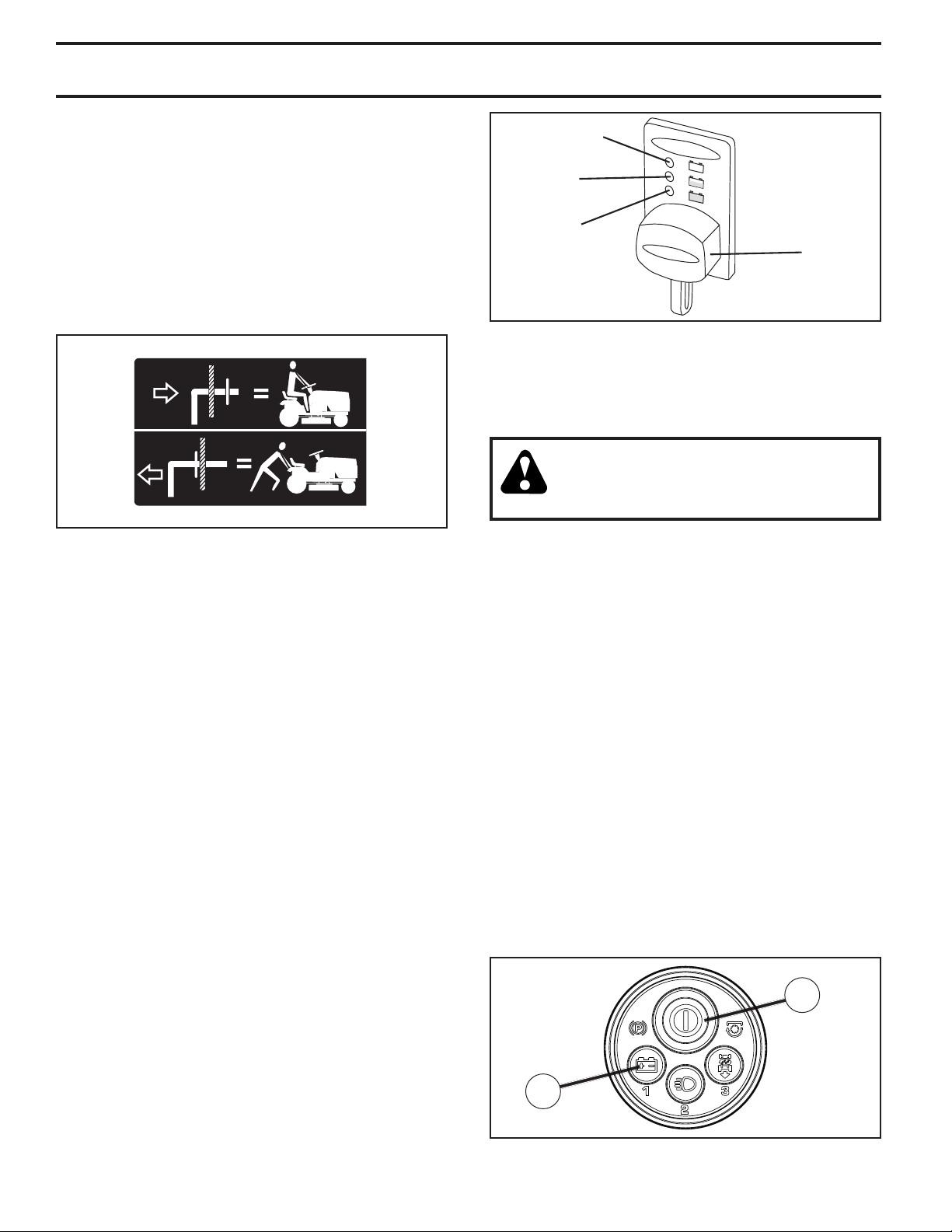

RESETTING IGNITION SYSTEM PASSCODE

(See Fig. 18)

The SmartSwitch Ignition is preset at the factory with the

default code "321". To reset or change the passcode, the

operator does not have to be seated on the tractor.

1. Press the SmartSwitch Ignition (SSI) button (F) once (or

sit on the seat). Ensure the indicator is blinking blue.

2. Press and hold the (1) and (3) buttons simultaneously

for approximately three (3) seconds until the SSI button

changes to solid blue.

3. Using the numbered buttons, enter the desired passcode. The passcode may be anywhere from one to

five digits in length.

4. After the desired passcode has been entered, press

the SSI button (F) once.

NOTE: When the indicator flashes green, the passcode has

been accepted. If the indicator blinks red, the passcode has

not been accepted. Wait until the indicator returns to blinking blue and repeat this procedure starting from step two.

F

13

Fig. 18

Page 14

OPERATION

TO START ENGINE

NOTE: The default passcode "321" is preset at the factory

and should be changed prior to first use. (See "RESETTING IGNITION SYSTEM PASSCODE" in this section of

the manual.)

S

MARTSWITCH WARNING LIGHTS (See Fig. 19)

The SmartSwitch Ignition is programmed with warning lights

to indicate when any part of the safety system is not being

followed. The engine will not start until all the following

ignition system faults are resolved:

• The park brake symbol (CC) will be lit if the parking

brake has not been engaged during a start attempt.

• The blade switch symbol (EE) will blink if the attachment

clutch control is not in the "DISENGAGED" position

during a start attempt.

CC EE

STARTING

The Briggs & Stratton Endurance engine equipped with

your tractor features a Ready-Start automatic choke system

to provide simplified starting in normal conditions. Please

read the following starting instruction carefully.

NOTE: For the first time starting after your tractor has sat

for an extended period of time, or after running out of gas,

the engine may require an extended start attempt to reprime

the fuel system. For an extended start, press and hold

SSI button for three seconds before releasing. This will

prompt the engine to attempt starting for up to ten seconds

(instead of the normal five seconds), allowing time for fuel

to be pulled into the engine.

NORMAL STARTING (32°F/0°C and above)

1. Move throttle control to fast position (

2. Perform procedures outlined in "SMARTSWITCH IGNITION UNLOCK" as previously described.

3. While the SSI button (F) is flashing green, press and

release the SSI button once more to start the engine.

• Once engine starts, the attachments and ground

drive can now be used. If the engine does not accept

the load, restart the engine and allow it to warm up

for one minute.

• Leave throttle control in fast position ( ) while

mowing.

).

F

Fig. 19

PRE-START

• Ensure freewheel control is in the transmission en gaged

position.

• Ensure transmission is in the neutral position

• Move attachment clutch control to the “DISENGAGED”

position.

• Sit on seat in operating position, depress brake pedal

and set parking brake.

S

MARTSWITCH IGNITION UNLOCK

1. Press the SmartSwitch Ignition (SSI) button (F) once (or

sit on the seat). Ensure the indicator is blinking blue.

2. Enter passcode and press the SSI button. If passcode

is not accepted, the SSI button will blink red. Wait until

the SSI button returns to blinking blue before attempting

to re-enter passcode. Once accepted, the SSI button

will flash green.

3. Ensure that the SmartSwitch Safety System warning

lights are not showing any faults present. If any warning

lights do indicate faults present, resolve those faults

before continuing with STARTING.

COLD WEATHER STARTING (32°F/0°C and below)

1. Move throttle control beyond fast position ( ) into the

cold weather starting position ( ).

2. Perform procedures outlined in "SMARTSWITCH IGNITION UNLOCK" as previously described.

3. While the SSI button is flashing green, press the SSI

button once more to start the engine.

• Once engine starts, move the throttle control back to

the fast position ( ) to warm-up. The time required

for warm-up will vary from a few seconds to a minute

depending upon conditions and temperature.

• Leave throttle control in fast position ( ) while

mowing.

NOTE: Failure to move throttle from cold weather starting

position ( ) will result in poor engine performance and

spark plug fouling.

AUTOMATIC TRANSMISSION WARM UP

• Before driving the unit in cold weather, the trans mis sion

should be warmed up as follows:

• Ensure the tractor is on level ground.

• Release the parking brake and let the brake slowly

return to operating position.

• Allow one minute for transmission to warm up. This

can be done during the engine warm up period.

• The attachments can also be used during the engine

warm-up period after the transmission has been warmed

up.

14

Page 15

OPERATION

PURGE TRANSMISSION

CAUTION: Never engage or disengage freewheel lever while the engine is run ning.

To ensure proper operation and performance, it is rec om mend ed that the transmission be purged before operating

tractor for the first time. This procedure will remove any

trapped air inside the transmission which may have de vel oped during shipping of your tractor.

IMPORTANT: SHOULD YOUR TRANSMISSION RE QUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT SHOULD

BE PURGED AFTER REINSTALLATION BEFORE OPERATING

THE TRACTOR.

1. Place tractor safely on a level surface - that is clear

and open - with engine off and parking brake set.

2. Disengage transmission by placing freewheel control

in disengaged position. (See “TO TRANSPORT” in

this section of manual.)

3. Sitting in the tractor seat, start engine. After the engine is running, move throttle control to slow position.

Dis en gage parking brake

CAUTION: At any time, during step 4, there

may be movement of the drive wheels.

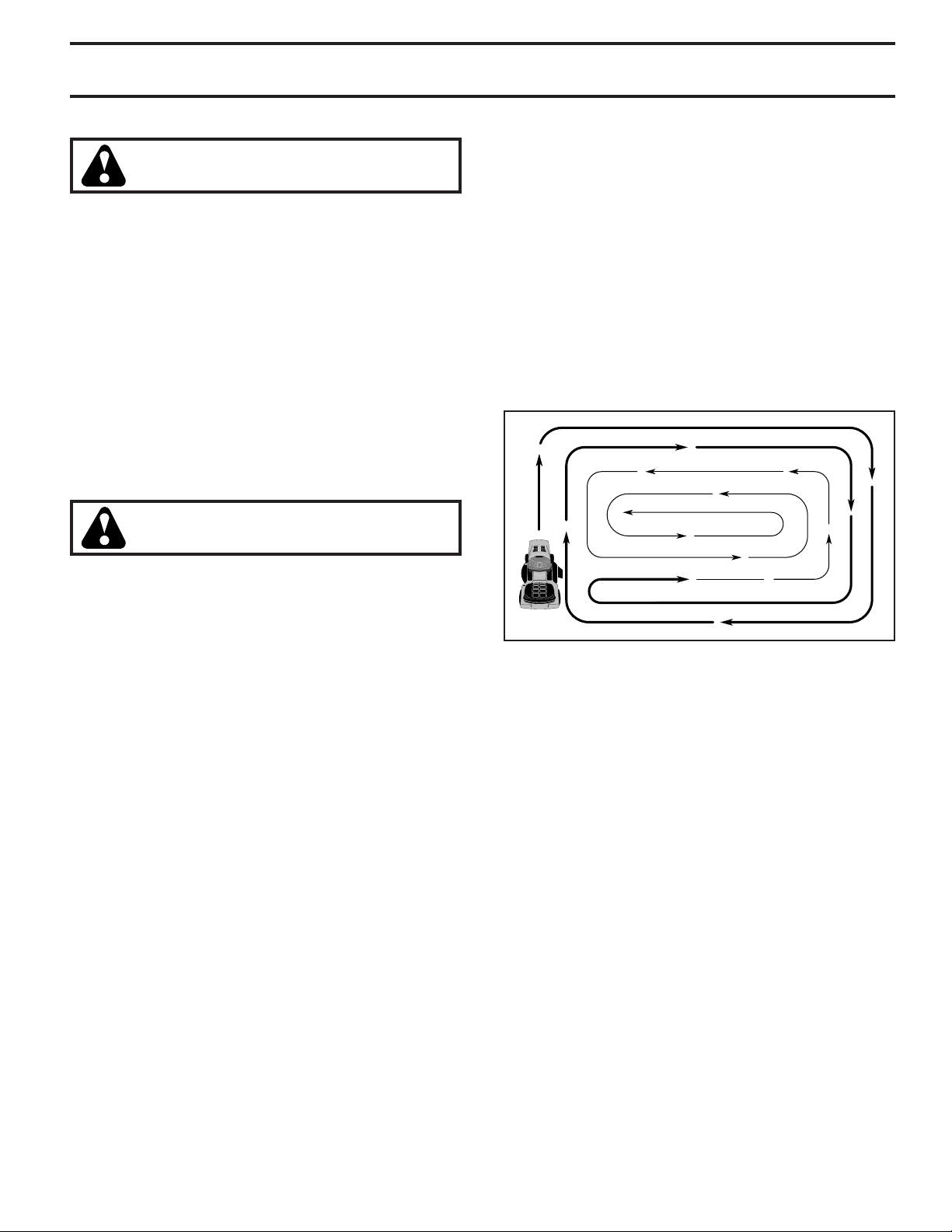

MOWING TIPS

• DO NOT use tire chains when the mower hous ing is

attached to tractor.

• Mower should be properly leveled for best mowing

performance. See “TO LEVEL MOWER HOUSING”

in the Service and Adjustments section of this manual.

• The left hand side of mower should be used for trim ming.

• Drive so that clippings are discharged onto the area

that has been cut. Have the cut area to the right of

the tractor. This will result in a more even dis tri bu tion

of clippings and more uniform cutting.

• When mowing large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

in the opposite direction making left hand turns until

finished (See Fig. 20).

4. Depress forward drive pedal to full forward position,

hold for five (5) seconds and release pedal. Depress

reverse drive pedal to full reverse position, hold for five

(5) seconds and release pedal. Repeat this procedure

three (3) times.

5. Shut- off engine and set parking brake.

6. Engage transmission by placing freewheel control

in engaged position. (See “TO TRANSPORT” in this

sec tion of manual.)

7. Sitting in the tractor seat, start engine. After the engine

is running, move throttle control to half (1/2) speed.

Disengage parking brake.

8. Drive tractor forward for approximately 5 feet (1,5 m)

then backwards for 5 feet (1,5 m). Repeat this driving

procedure three times.

Your transmission is now purged and now ready for normal

op er a tion.

HOUR METER

The hourmeter shows the total number of hours the engine

has run. To service engine and mower, see the Maintenance

section of this manual.

Fig. 20

• If grass is extremely tall, it should be mowed twice to

reduce load and possible fire hazard from dried clip pings. Make first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

• Always operate engine at full throttle when mow-

ing to ensure better mowing performance and proper

dis charge of material. Regulate ground speed by

se lect ing a low enough gear to give the mower cut ting

per for mance as well as the quality of cut desired.

• When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the at tach ment being used.

15

Page 16

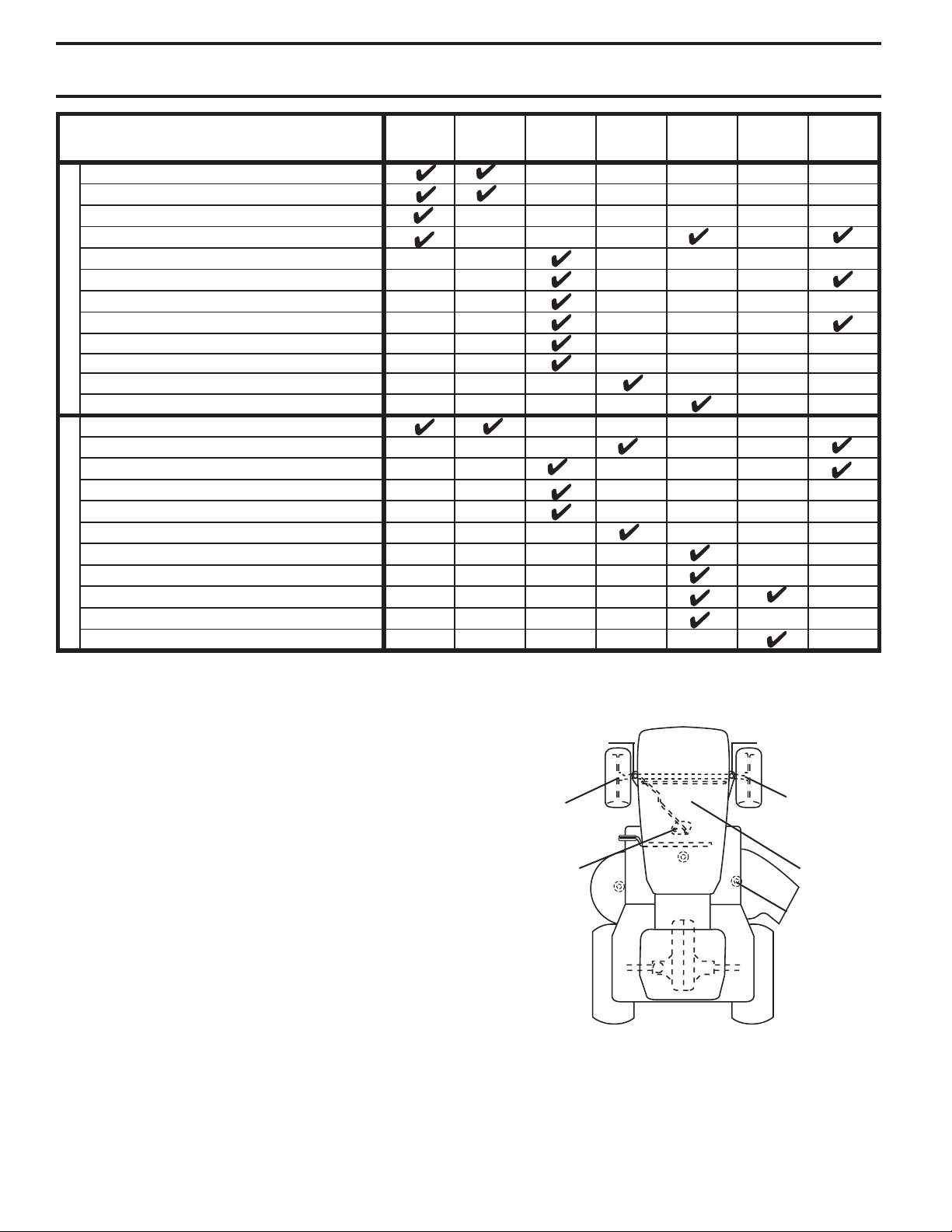

MAINTENANCE

MAINTENANCE

SCHEDULE

Check Brake Operation

Check Tire Pressure

T

Check Operator Presence & ROS Systems

R

Check for Loose Fasteners

A

Check/Replace Mower Blades

C

T

Lubrication Chart

0

Check Battery Level

R

Clean Battery and Terminals

Clean Debris Off Steering Plate

Che

ck Transaxle Cooling

Check Mower Levelness

Che

ck V-Belts

Check Engine Oil Level

Change Engine Oil (models with oil filter)

Change Engine Oil (

E

Clean Air Filter

N

Clean Air Screen

G

Inspect Muffler/Spark Arrester

I

Replace Oil Filter (If equipped)

N

E

Clean Engine Cooling Fins

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

1 - Change more often when operating under a heavy load or in high ambient temperatures

2 - Service more often when operating in dirty or dusty conditions.

models

without oil filter)

BEFORE

EACH

USE

EVERY

8

HOURS

3 - Replace blades more often when mowing in sandy soil.

4 - Not required if equipped with maintenance-free battery.

EVERY

25

HOURS

EVERY

50

HOURS

3

4

5

1,2

1,2

2

2

EVERY

100

HOURS

1

5 - See Cleaning in Maintenance Section.

EVERY

SEASON

,

2

2

2

BEFORE

STORAGE

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, operator must main tain tractor

as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tractor.

At least once a season, check to see if you should make

any of the adjustments described in the Service and

Adjustments section of this manual.

• At least once a year you should replace the spark plug,

clean or replace air filter, and check blades and belts

for wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check operator presence and ROS systems for proper

operation.

• Check for loose fasteners.

LUBRICATION CHART

SPINDLE ZERK

➀

FRONT

➀

WHEEL

BEARING

ZERK

STEERING

➀

SECTOR

GEAR

TEETH

02501

General Purpose Grease

➀

Refer to Maintenance “ENGINE” Section

➁

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS

LU BRI CANTS WILL ATTRACT DUST AND DIRT THAT WILL

SHORT EN THE LIFE OF THE SELF-LU BRI CAT ING BEARINGS.

IF YOU FEEL THEY MUST BE LU BRI CAT ED, USE ONLY A

DRY, POW DERED GRAPHITE TYPE LU BRI CANT SPARINGLY.

SPINDLE ZERK

➀

FRONT

➀

WHEEL

BEARING

ZERK

➁

MANDREL

➀

ZERKS

16

ENGINE

Page 17

MAINTENANCE

TRACTOR

Always observe safety rules when per form ing any

main te nance.

BRAKE OPERATION

If tractor requires more than five (5) feet (1,5 m) to stop at

highest speed in high est gear on a level, dry concrete or

paved surface, then brake must be checked and ad just ed.

(See “TO CHECK BRAKE” in the Ser vice and Ad just ments

section of this manual.)

TIRES

• Maintain proper air pressure in all tires. (See the sides

of tires for proper PSI.)

• Keep tires free of gasoline, oil, or insect control

chemi cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and pre vent flat tires due

to slow leaks, tire sealant may be purchased from your

local parts dealer. Tire sealant also pre vents tire dry rot

and corrosion.

OPERATOR PRESENCE SYS TEM AND REVERSE

OPERATION SYSTEM (ROS) (See Fig. 21)

Ensure operator presence and reverse operation sys tems

are work ing properly. If your tractor does not function as

described, repair the problem immediately.

• The engine should not start unless the parking brake

is engaged, and the attachment clutch con trol is in the

dis en gaged position.

CHECK OPERATOR PRESENCE SYSTEM

• While the engine is running, any attempt by the op er a tor

to leave the seat without first setting the parking brake

should shut off the engine.

• With the engine running, the parking brake engaged,

and the at tach ment clutch engaged, any attempt by the

operator to leave the seat should shut off the attachment

clutch.

• The attachment clutch should never operate unless

the operator is in the seat.

CHECK REVERSE OPERATION (ROS) SYSTEM

• With the engine running, the SmartSwitch Ignition

(SSI) button (F) solid green, and the attachment clutch

engaged any attempt by the operator to shift in reverse

will disengage the attachment clutch.

• With the engine running, the SmartSwitch Ignition (SSI)

button (F) solid green, and the Reverse Operation System

(ROS) button (G) lit, any attempt by the operator to shift

in reverse should NOT disengage the attachment clutch.

F

G

Fig. 21

BLADE CARE

For best results mower blades must be kept sharp. Re place

bent or damaged blades.

CAUTION: Use only a replacement blade approved by the manufacturer of your tractor.

Using a blade not approved by the manufacturer of your tractor is hazardous, could

damage your tractor and void your warranty.

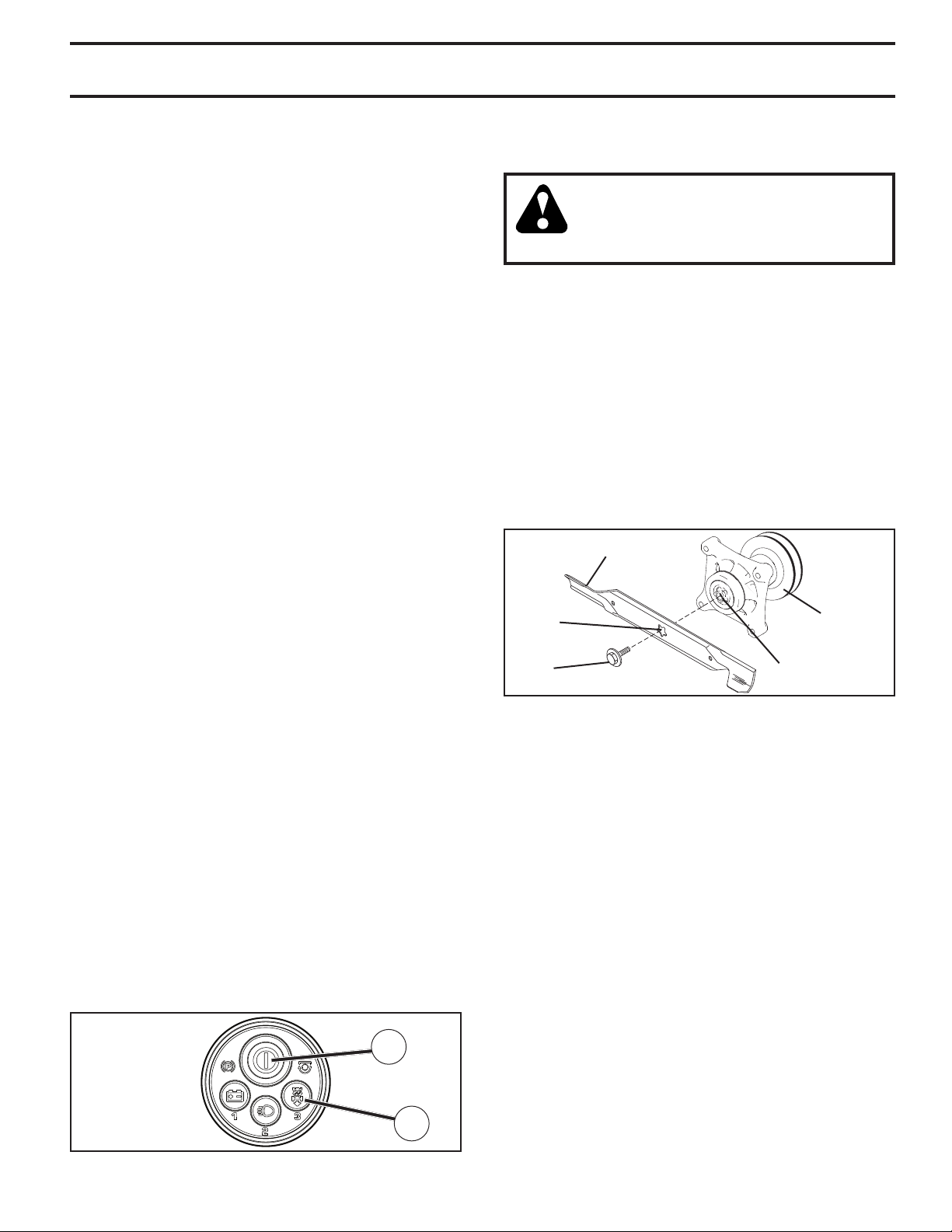

BLADE REMOVAL (See Fig. 22)

• Raise mower to highest position to allow access to

blades.

NOTE: Protect your hands with gloves and/or wrap blade

with heavy cloth.

• Remove blade bolt by turning counterclockwise.

• Install new or resharpened blade with stamped "THIS

SIDE UP" facing deck and mandrel assembly.

IMPORTANT: To ensure proper assembly, center hole in

blade must align with star on mandrel assembly.

• Install and tighten blade bolt securely (45-55 Ft. Lbs./

62-75 Nm).

IMPORTANT: SPECIAL BLADE BOLT IS HEAT TREATED.

BLADE

CENTER

HOLE

BLADE

BOLT

(SPECIAL)

Fig. 22

MANDREL

ASSEMBLY

STAR

BATTERY

Your tractor has a battery charging system which is suf fi cient

for normal use. However, periodic charging of the battery

with an automotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on your tractor is

maintenance free. Do not attempt to open or remove caps

or covers. Adding or checking level of electrolyte is not

necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak” power.

• Remove terminal guard.

• Disconnect BL ACK battery cable first then RED bat tery

cable and remove battery from tractor.

• Rinse the battery with plain water and dry.

• Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery. (See “REPLACING BATTERY" in the

Service and Adjustments section of this manual.)

17

Page 18

MAINTENANCE

TRANSAXLE MAINTENANCE

The transmission fan and cooling fins should be kept clean

to ensure proper cooling.

Do not attempt to clean fan or transmission while engine

is running or while the transmission is hot. To prevent pos si ble damage to seals, do not use high pressure water or

steam to clean transmission.

• Inspect cooling fan to ensure fan blades are intact and

clean.

• Inspect cooling fins for dirt, grass clippings and other

materials. To prevent damage to seals, do not use compressed air or high pressure sprayer to clean cool ing fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fluid main te nance is not required for the life of the transaxle. Should

the transaxle ever leak or require servicing, contact your

near est au tho rized ser vice center/department.

V-BELTS

Check V-belts for deterioration and wear after 100 hours

of operation and replace if necessary. The belts are not

ad just able. Re place belts if they begin to slip from wear.

ENGINE

LUBRICATION

Only use high quality detergent oil rated with API service

classification SG-SL. Select the oil’s SAE viscosity grade

according to your expected operating temperature.

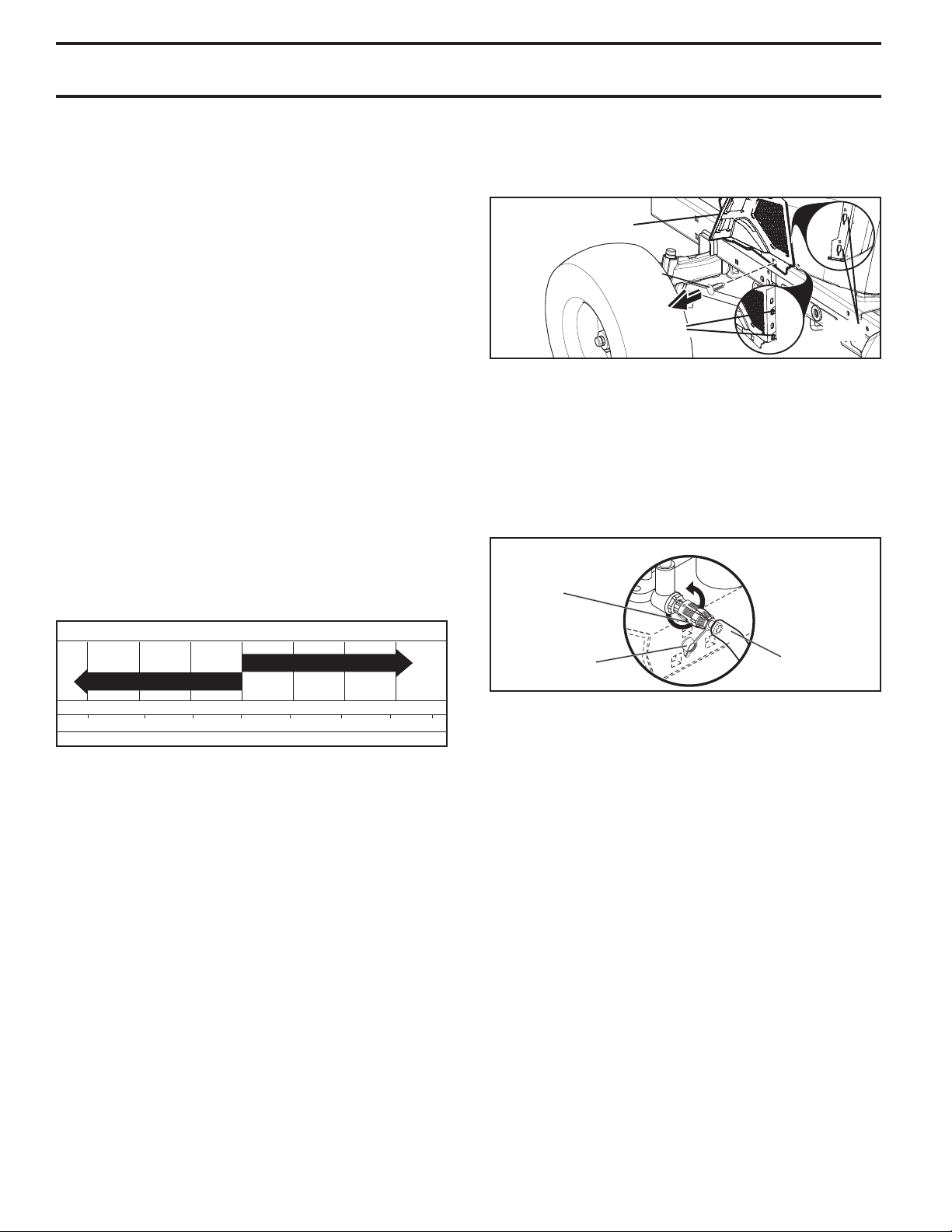

SAE VISCOSITY GRADES

SAE 30

5W-30

-20 0 30 40

F

C

-30

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

-20 0

-10

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, they will result in increased

oil consumption when used above 32°F/0°C. Check your

engine oil level more frequently to avoid possible engine

damage from running low on oil.

Change the oil after every 50 hours of operation or at least

once a year if the tractor is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

32

Fig. 23

10

60

80

20 30 40

100

CAUTION: Remove lower dash cover carefully to ensure

cover tabs are not broken.

• Slide lower dash cover up to release cover tabs from

tapered slots in lower dash and remove.

LOWER DASH COVER

FASTENER

TABS

SLOTS

Fig. 24

• Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

• Remove yellow cap from end of drain valve and install

the drain tube onto the fitting.

• Unlock drain valve by pushing inward and turning

coun ter clock wise.

• To open, pull out on the drain valve.

OIL DRAIN VALVE

CLOSED

AND

LOCKED

POSITION

YEL LOW CAP

02463

DRAIN

TUBE

Fig. 25

• After oil has drained completely, close and lock the

drain valve by pushing inward and turning clockwise

until the pin is in the locked position as shown.

• Remove the drain tube and replace the cap onto to the

bottom fitting of the drain valve.

• Refill engine with oil through oil fill dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

“PRODUCT SPECIFICATIONS” section of this man u al.

• Use gauge on oil fill cap/dipstick for checking level.

Ensure dipstick cap is tightened securely for accurate

reading. Keep oil at “FULL” line on dipstick. Tighten

cap onto the tube securely when finished.

TO CHANGE ENGINE OIL (See Fig. 23 - 25)

Determine temperature range expected before oil change.

All oil must meet API service classification SG-SL.

• Ensure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

LOWER DASH COVER REMOVAL

• Raise hood.

• Remove fastener from lower dash cover.

ENGINE OIL FILTER

Replace the engine oil filter every season or every other

oil change if the tractor is used more than 100 hours in

one year.

NOTE: If needed, remove lower dash covers using steps

from "Lower dash cover removal" section of this manual.

18

Page 19

MAINTENANCE

AIR FILTER

Your engine will not run properly using a dirty air filter.

Service air cleaner more often under dusty conditions.

CLEAN AIR SCREEN

The air screen is over the air intake blower located on top

of engine. The air screen must be kept free of dirt and

chaff to prevent engine dam age from overheating. Clean

with a wire brush or compressed air to re move dirt and

stubborn dried gum fibers.

ENGINE COOLING SYSTEM

To ensure proper cooling, make sure the grass screen,

cooling fins, and other external surfaces of the engine are

kept clean at all times.

Every 100 hours of operation (more often under extremely

dusty, dirty conditions), remove the blower housing and other

cooling shrouds. Clean cooling fins and external surfaces

as necessary. Ensure the cooling shrouds are reinstalled.

NOTE: Operating the engine with a blocked grass screen,

dirty or plugged cooling fins, and/or cooling shrouds re moved

will cause engine damage due to overheating.

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of each mowing

season or after every 100 hours of operation, whichever

occurs first. Spark plug type and gap setting are shown

in “PROD UCT SPECIFICATIONS” section of this manual.

IN-LINE FUEL FILTER (See Fig. 26)

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, ob struct ing fuel flow to car bu re tor,

re place ment is re quired.

• With engine cool, remove filter and plug fuel line sec tions.

• Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Ensure there are no fuel line leaks and clamps are

properly positioned.

• Immediately wipe up any spilled gasoline.

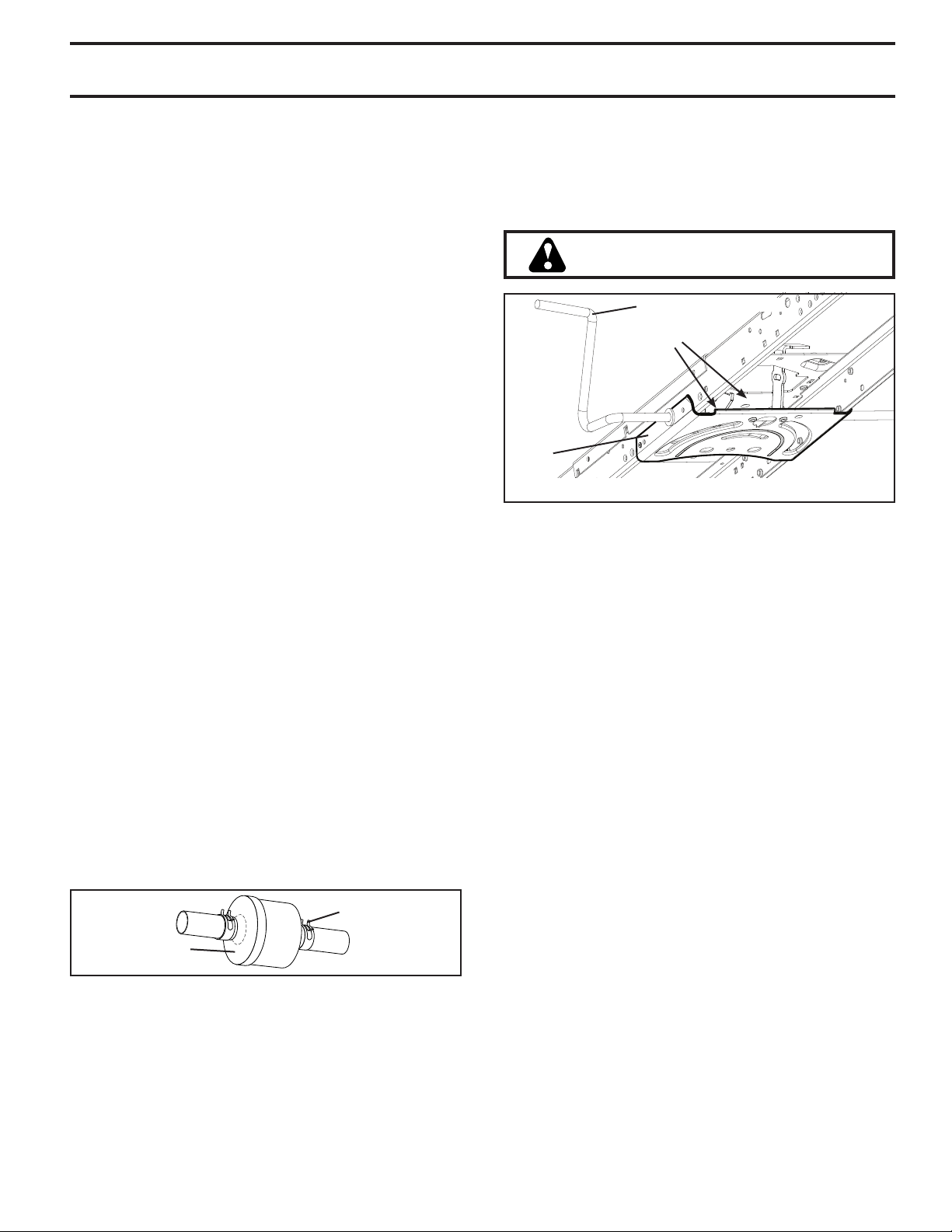

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Clean debris from steering plate. Debris can restrict

clutch/brake pedal shaft movement, causing belt slip

and loss of drive. (See Fig. 27.)

CAUTION: Avoid all pinch points and

movable parts.

CLUTCH/BRAKE PEDAL

CLEAN

TOP SIDE

STEERING

PLATE

STEERING SYSTEM, DASH, FENDER AND MOWER NOT SHOWN

Fig. 27

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

Except for the washout port (if equipped), we do not

recommend using a garden hose or pressure washer to

clean the outside of your tractor unless the engine and

transmission are covered to keep water out. Water in

engine or transmission will shorten the useful life of your

tractor. Use compressed air or a leaf blower to remove

grass, leaves and trash from outside tractor and mower.

FUEL FILTER

CLAMP

Fig. 26

19

Page 20

MAINTENANCE

DECK WASHOUT PORT (See Fig. 28)

Your tractor’s deck is equipped with a washout port as part

of its deck wash system. It should be utilized after each use.

1. Drive the tractor to a level, clear spot on your lawn, near

enough to a water spigot for your garden hose to reach.

IMPORTANT: Ensure the tractor’s discharge chute is directed AWAY from your house, garage, parked cars, etc.

Remove bagger chute or mulch cover if attached.

2. Ensure the attachment clutch control is in the

“DIS EN GAGED” position, set the parking brake, and

stop the engine.

3. Thread the nozzle adapter (packaged with your tractor’s

Operator’s Manual) onto the end of your garden hose.

4. Pull back the lock collar of the nozzle adapter and push

the adapter onto the deck washout port at the left end

of the mower deck. Release the lock collar to lock the

adapter on the nozzle.

HOSE

NOZZLE ADAPTER

WASHOUT

PORT

Fig. 28

IMPORTANT: Tug hose ensuring connection is secure.

5. Turn the water on.

6. While sitting in the operator’s position on the tractor,

re-start the engine and place the throttle lever in the

Fast " " position.

IMPORTANT: Recheck the area to ensure the area is clear.

Ensure no children are in the area while cleaning the deck.

7. Move attachment clutch control to the “ENGAGED” position. Remain in the operator’s position with the cutting

deck engaged until the deck is cleaned.

8. Ensure attachment clutch control is in the “DIS EN GAGED” position. Shut engine off. Turn the water off.

9. Pull back the lock collar of the nozzle adapter to disconnect the adapter from the nozzle washout port.

10. Move the tractor to a dry area, preferably a concrete or

paved area. Place the attachment clutch control in the

“ENGAGED” position to remove excess water and to

help dry before putting the tractor away.

WARNING: A broken or missing washout

fitting could expose you or others to

thrown objects from contact with the blade.

• Replace broken or missing washout fitting

immediately, prior to using mower again.

20

Page 21

SERVICE AND ADJUSTMENTS

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY SER VICE OR AD JUST MENTS:

• Depress brake pedal fully and set parking brake.

• Place attachment clutch in “DISENGAGED” position.

• Shut engine off and lock the SmartSwitch Ignition.

• Make sure the blades and all moving parts have completely stopped.

• Disconnect spark plug wire from spark plug and place wire where it cannot come in contact with plug.

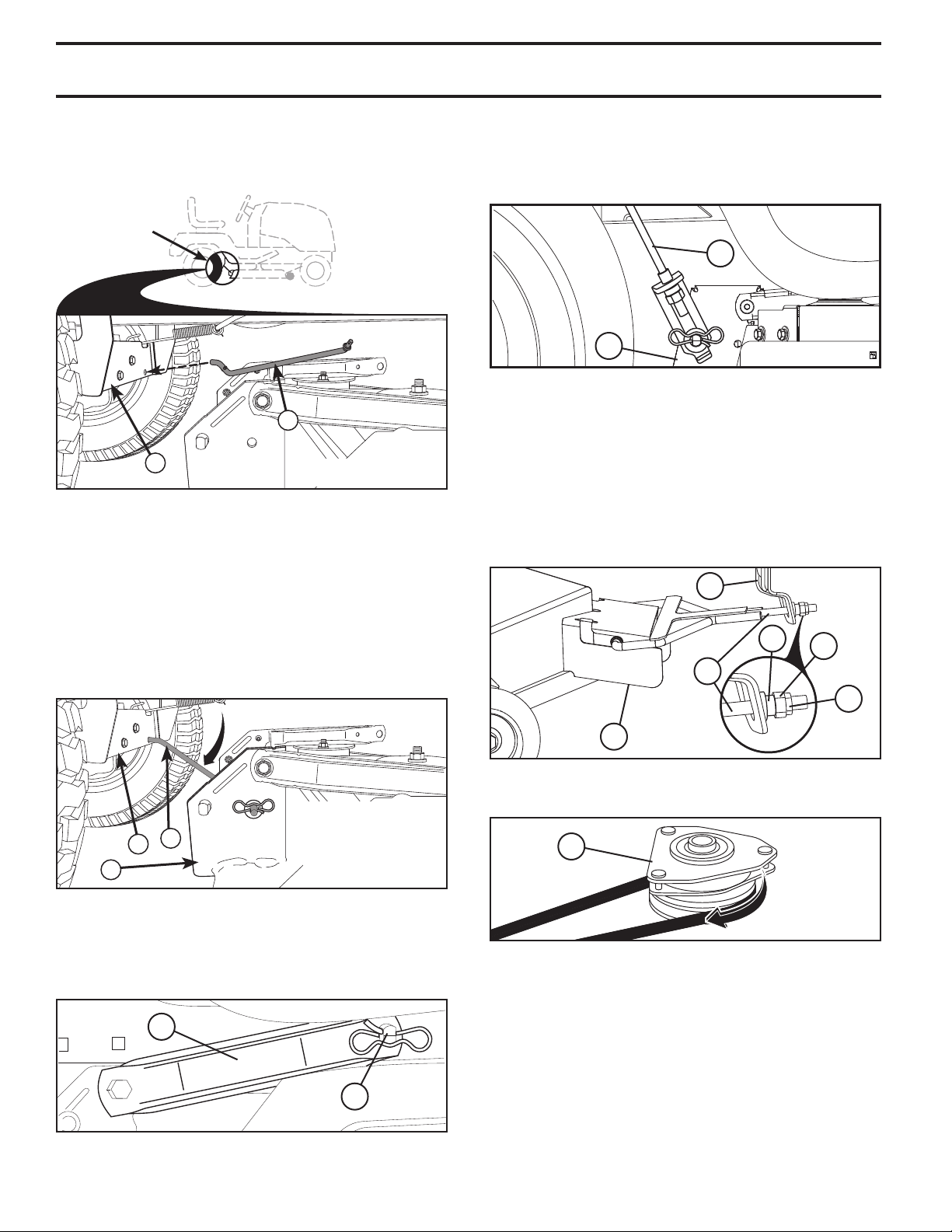

TO REMOVE MOWER (See Fig. 29)

• Place attachment clutch in “DIS EN GAGED” position.

• Lower attachment lift lever to its lowest position.

• Remove mower belt from electric clutch pulley (M). See

Mower Drive Belt Removal in "TO REPLACE MOWER

BLADE DRIVE BELT" in this section.

• Disconnect front link (E) from mower - remove retainer

spring and washer.

• Go to either side of mower and disconnect mower

suspension arm (A) from chassis and rear lift link (C)

from rear mower bracket (D) - remove retainer springs

and washers.

• Go to other side of mower and disconnect the suspension arm and rear lift link.

CAUTION: After rear lift links are disconnected, the attachment lift lever will be

spring loaded. Have a tight grip on lift

lever when changing position of the lever.

• Slide mower out from under right side of tractor.

A

TO INSTALL MOWER (See Fig. 29 - 36)

Ensure tractor is on level surface and engage park ing brake.

• Lower attachment lift lever to its lowest position.

CAUTION: Lift lever is spring loaded.

Have a tight grip on lift lever, lower it

slowly and engage in lowest position.

NOTE: Ensure mower side suspension arms (A) are point-

ing forward before sliding mower under tractor.

• Slide mower under tractor until it is centered under

tractor.

INSTALL ANTI-SWAY BAR (S) (IF EQUIPPED)

ANTI-SWAY BAR (S)

TOWARDS TOWARDS

TRANSAXLE MOWER DECK

90° END INTEGRATED WASHER END

Fig. 30

M

F

O

P

Q

C

E

H

D

S

B

D

Fig. 29

21

Page 22

SERVICE AND ADJUSTMENTS

PLACE 90° END INTO HOLE

• From right side of mower, first insert 90° end of anti-sway

bar (S) into hole in transaxle bracket (T), located near

left rear tire in front of transaxle.

NOTE: Flashlight may be helpful.

ATTACH REAR LIFT LINKS (C) - Lift rear corner of

•

mower and position slot in link assembly over pin on

rear mower bracket (D) and secure with washer and

retainer spring.

• Repeat on opposite side of tractor.

ANTI-SWAY BAR

(S) LOCATION

PLACE 90° END INTO HOLE

T

S

S. ANTI-SWAY BAR

T. TRANSAXLE BRACKET

TRANSAXLE

BRACKET (T)

LOCATED

BETWEEN REAR

TIRES

Fig. 31

NOTE: Depending on model, bracket (T) may be differ-

ent than shown but hole for anti-sway bar will be in same

position/location.

• Pivot the integrated washer end of anti-sway bar (S)

towards mower deck bracket on right side of mower.

Insert integrated washer end of bar into hole in rear

mower bracket (D). Move mower as needed to insert

integrated washer end of bar into rear mower bracket (D).

• Secure with small washer and small retainer spring as

shown.

C

D

Fig. 34

• ATTACH FRONT LINK (E) - Work from left side of tractor. Insert threaded rod end of link assembly through

front hole in tractor suspension bracket (F).

• Install bushing (O) and loosely install nut (P) and jam

nut (Q).

• Insert flared ends of link (E) into slots in front mower

bracket (H).

• Check Front-To-Back Adjustment in "TO LEVEL

MOWER" in this section.

F

O

P

E

Q

D. RIGHT SIDE

REAR MOWER

S

T

D

BRACKET

S. ANTI-SWAY BAR

T. TRANSAXLE

BRACKET

Fig. 32

• ATTACH MOWER SIDE SUSPENSION ARMS (A) TO

CHASSIS - Position hole in arm over pin (B) on outside

of tractor chassis and secure with retainer spring.

• Repeat on opposite side of tractor.

A

B

Fig. 33

H

Fig. 35

• Install belt onto electric clutch pulley (M).

M

Fig. 36

IMPORTANT: CHECK BELT FOR PROPER ROUTING

IN ALL MOWER PULLEY GROOVES.

• Raise attachment lift lever to highest position.

• If necessary, adjust gauge wheels before op er at ing

mower as shown in the Operation section of this manual.

See Mower Drive Belt Installation in "TO REPLACE MOWER

BLADE DRIVE BELT" in this section of the manual.

22

Page 23

SERVICE AND ADJUSTMENTS

TO LEVEL MOWER

Ensure tires are properly inflated to the PSI shown on tires.

If tires are over or under inflated, it may affect the appearance of your lawn and lead you to think the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT (See Fig. 37)

• With all tires properly inflated and if your lawn appears

unevenly cut, determine which side of mower is cutting

lower.

NOTE: As desired, you can raise the low side of mower

or lower the high side.

• Go to side of mower you wish to adjust.

• With a 3/4" or adjustable wrench, turn lift link adjustment

nut (A) to the left to lower the mower, or, to the right to

raise the mower.

A

TURN NUT RIGHT

TO RAISE MOWER

Fig. 37

NOTE: Each full turn of adjustment nut will change mower

height about 3/16" (4,7 mm).

• Test your adjustment by mowing some uncut grass and

visually checking the appearance. Readjust, if necessary, until you are satisfied with the results.

TURN NUT LEFT

TO LOWER MOWER

FRONT-TO-BACK ADJUSTMENT (See Figs. 39 & 40)

IMPORTANT: Deck must be level side-to-side.

To obtain the best cutting re sults, the mower blades should

be adjusted so the front tip is 1/8" to 1/2" (3,1 to 12,7 mm)

lower than the rear tip when the mower is in its highest

position.

CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap

blade with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing straight forward.

Measure distance (B) to the ground at front and rear tip

of the blade.

B

B

Fig. 39

• If front tip of blade is not 1/8" to 1/2" (3,1 to 12,7 mm)

lower than the rear tip, go to the front of tractor.

• With an 11/16" or adjustable wrench, loosen jam nut A

several turns to clear adjustment nut B.

• With a 3/4" or adjustable wrench, turn front link adjustment nut (B) clockwise

( ) (tighten) to raise the front of

mower, or, counterclockwise ( ) (loosen) to lower the

front mower.

A

PRECISION SIDE-TO-SIDE ADJUSTMENT (See Fig. 38)

• With all tires properly inflated, park tractor on level

ground or driveway.

CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap

blade with heavy cloth.

• Raise mower to its highest position.

• At both sides of mower, position blade at side and measure the distance (A) from bottom edge of blade to the

ground. The distance should be the same on both sides.

• If adjustment is necessary, see steps in Visual Adjustment instructions above.

• Recheck measurements, adjust if necessary until both

sides are equal.

AA

Fig. 38

B

TIGHTEN

ADJUST

B

NUT

TO RAISE

MOWER

NUT B TO

LOOSEN JAM

NUT A FIRST

Fig. 40

NOTE: Each full turn of the adjustment nut will change

mower height about 1/8" (3,1 mm).

• Recheck measurements, adjust if necessary until front

tip of blade is 1/8" to 1/2" (3,1 to 12,7 mm) lower than

the rear tip.

• Hold adjustment nut in position with wrench and tighten

jam nut securely against adjustment nut.

23

LOOSEN

ADJUST

LOWER

MOWER

Page 24

SERVICE AND ADJUSTMENTS

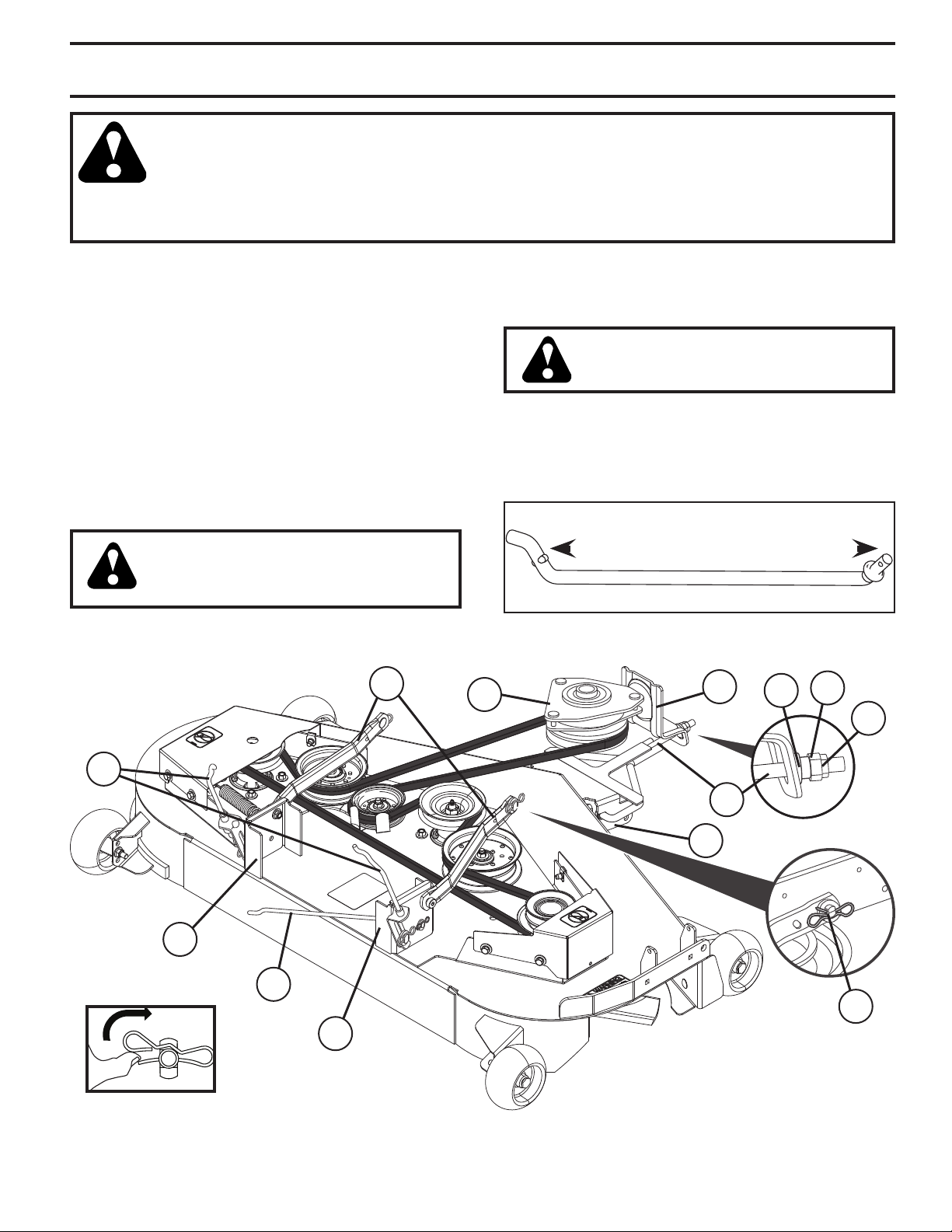

TO REPLACE MOWER BLADE DRIVE BELT

MOWER DRIVE BELT REMOVAL (See Fig. 41)

• Park tractor on a level surface. En gage parking brake.

• Lower attachment lift lever to its lowest position.

• Remove mandrel covers.

• Remove any dirt or grass clippings which may have

accumulated around mandrels and entire upper deck

surface.

• With a 3/8" breaker bar and using the square opening

in the idler arm, shift the arm counterclockwise (

relieve the tension on the belt.

• Carefully roll the belt over the top of the cutter housing

pulleys.

IDLER ARM

Fig. 41