Page 1

EN

Operator´s manual p.3

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

DE

NL

IT

Bedienungsanweisung p. 21

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie

sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Gebruiksaanwijzing p. 39

Neem de gebruiksaanwijzing grondig door en gebruik de machine

niet voor u alles duidelijk heeft begrepen.

Istruzioni per l’uso p. 61

Prima di usare la macchina, leggere per intero le istruzioni per l’uso

e accertarsi di averne compreso il contenuto.

FS 700 EX

EN DE NL IT

HUSQVARNA CONSTRUCTION PRODUCTS

Page 2

Page 3

11

14

16

17

Operator’s Manual

Contents

English

Contents

Key to symbols

Safety Instructions

Introduction

Technical data

Operation

........................................................................

Before cutting

Assembling/Replacing the blade

Connecting the machine

Sawing

...........................................................................

Stop cutting

Transport

........................................................................

Maintenance

..............................................................

......................................................

......................................................................

.............................................................

..............................................................

.......................................

..................................................................

.................................................................

.......................

5

6

7

10

11

11

12

13

15

Trouble shooting

.......................................................

EU declaration of conformity

.............................

English - 3

19

Page 4

Contents

Operator’s Manual

4 - English

Page 5

Operator’s Manual FS 700EX

CE

Key to symbols

The symbols below are used on the machine and in this

Operator's Manual. It is important that the user

understands the significance of these in order to work with

the machine safely.

Manual

Please read the Operator's Manual carefully and

understand the contents before the machine is started.

Protective equipment

Always wear:

• Approved protective helmet.

• Approved hearing protection.

• Approved protective glasses or a visor, and other

essential safety equipment.

Attention

A hand with a raised index finger with the text “Attention”

signifies that a described element demands extra

attention.

This symbol indicates that the machine conforms to

applicable EU directives.

Electrical Warning

This symbol warns that there is high voltage present

Warning

A large warning triangle with the text “Warning” signifies

that there is a risk of serious personal injury or even

death.

Note

A smaller warning triangle with the text “Note” signifies

that there is a risk of minor personal injury or damage to

the machine.

Environmental Information

The symbol on the product or on its packaging indicates

that this product may not be treated as household waste.

Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic

equipment.

By ensuring this product is disposed of correctly, you will

help prevent potential negative consequences for the

environment and human health, which could otherwise be

caused by inappropriate waste handling of this product.

For more detailed information about recycling of this

product, please contact your local council office, your

household waste disposal service or the shop where you

purchased the product.

English -

5

Page 6

Safety Instructions

During the design and production of Husqvarna products,

great importance is placed on safety, as well as

effectiveness and ease of use. To ensure that the

machine remains safe you must pay attention to the

following points:

• Note that under no circumstances may the machine be

started without following the safety instructions. Should

the user fail to comply with these, Husqvarna Construction Products Sweden AB or its representatives

are free from all liability both directly and indirectly.

Read through these operating instructions and make

sure that you understand the contents before starting

to use the machine. Should you, after reading these

safety instructions, still feel uncertain about the safety

risks involved you must not use the machine

Please contact your dealer for more information.

• Check that all couplings, connections and the blade

guard are in full working order.

• Make sure that all hoses and electrical cables are

connected to the machine correctly before you start the

machine.

• The safety distance is 4 metres in front of and to the

side of the saw.

Operator’s Manual FS 700EX

• People that need to be in close proximity of the

machine must wear hearing protection.

• The machine must not be turned, swung or moved

laterally with the blade rotating.

• Only use blades recommended by the manufacturer.

• Never saw without a blade guard.

• Never saw without coolant. A poorly cooled blade can

cause segments to come loose from the blade. The

water coolant also binds concrete dust.

• Never use a damaged or worn blade.

• Do not use the machine if it is not working properly.

• Regulations for the prevention of accidents, and other

general safety and occupational health regulations,

must always be followed.

• Store the machine in a locked space away from

children and adults untrained in use of the machine.

• Firmly secure or anchor concrete blocks that have

been cut loose. The heavy weight of cut material can

cause extensive damage if it is not moved under

controlled conditions.

• Make sure that there is always another person close at

hand when you use the machines, so that you can call

for help if an accident should occur.

• Make sure that there are no persons or animals in the

working area.

• Check that the blade guard and blade flange guard are

fitted correctly.

• Always saw in a manner that permits easy access to

the emergency stop.

• Never leave the machine unsupervised with the engine

running.

• Clearly mark out all cuts to be made on the floor before

you start sawing, plan these so they can be carried out

without danger to persons or the machine.

• Check with the construction drawings whether there

are electrical cables, water mains, gas pipes or

drainage pipes within the working area.

• Check that electrical cables within the working area are

not live.

• Observe care when lifting. You are handling heavy

parts, which implies the risk of crush injuries or other

injuries.

• Personal protective equipment according to the

Operator's Manual must always be used and you

should use protective clothing too. Never wear loose

fitting clothes that can catch in moving parts.

WARNING!

Always use approved protective clothing

and approved protective equipment when

using the machine. Protective clothing and

protective equipment cannot eliminate

accident risks, but by using the right

clothes and equipment you can reduce the

seriousness if an accident should occur.

Ask your dealer about approved and

recommended protective clothing and

protective equipment.

6 - English

Page 7

Operator’s Manual FS 700EX

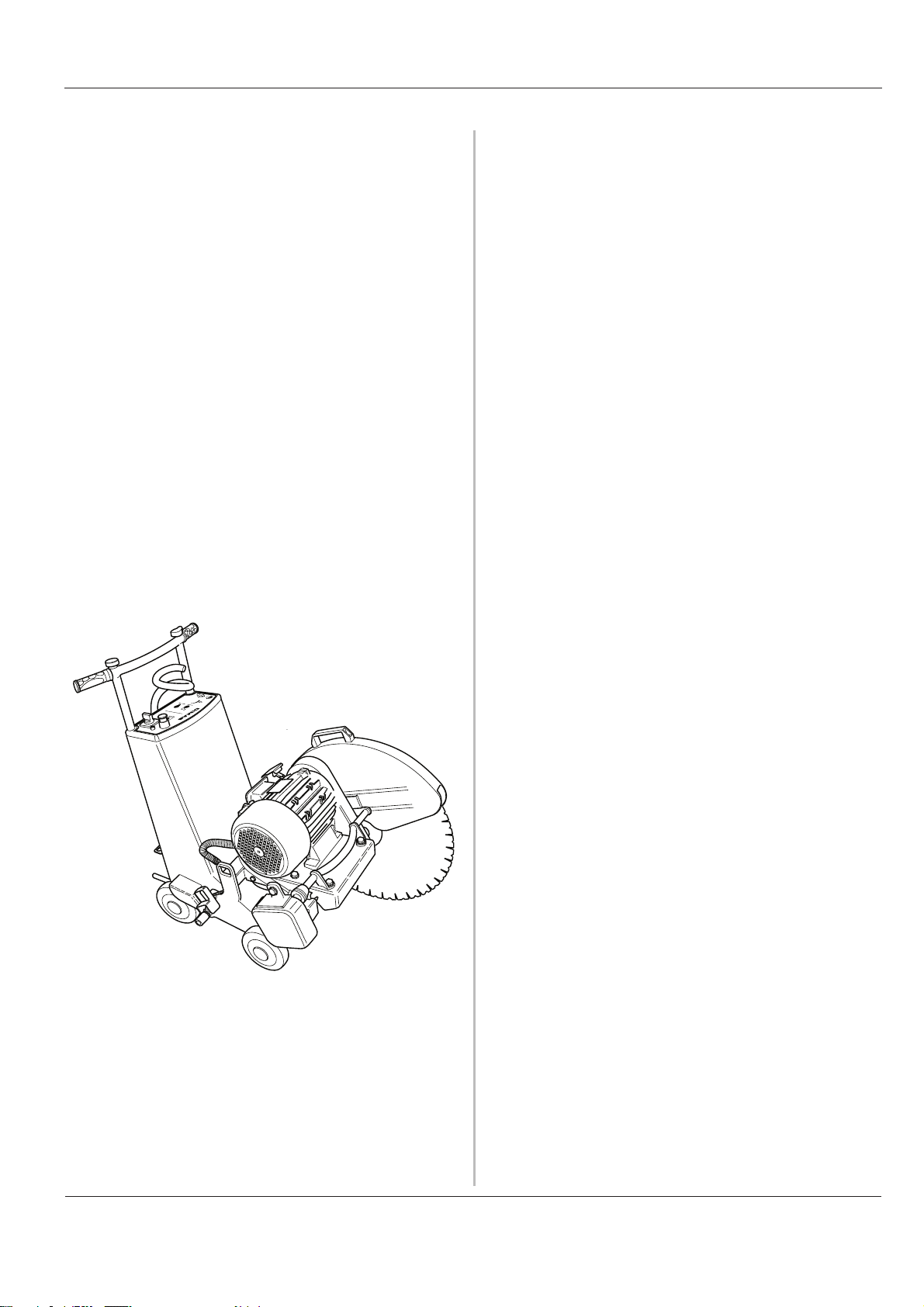

Introduction

The FS series is a new series of electrically powered floor

saws from Husqvarna. The aim during development has

been to create a powerful, yet easy to handle machine for

cutting reinforced concrete, brick and other stone material.

The machine should also be easy to use for one person.

The FS series features electrical trolley feed and blade

feed. These are both controlled by a lever fitted on the

adjustable handle.

The handle can be folded down into the saw and the

cutting bridge can easily be removed to facilitate transport.

This means it is easier to lift the saw, and it takes up less

space.

A saw is supplied with a flange and blade guard. A flush

cutting blade flange and a flush cutting blade guard are

available as accessories.

In order to use this machine as effectively as possible, it is

important that as the user you read through this Manual

carefully. In the event of uncertainty concerning any

details these should be discussed with your dealer before

you start to use the machine.

English -

7

Page 8

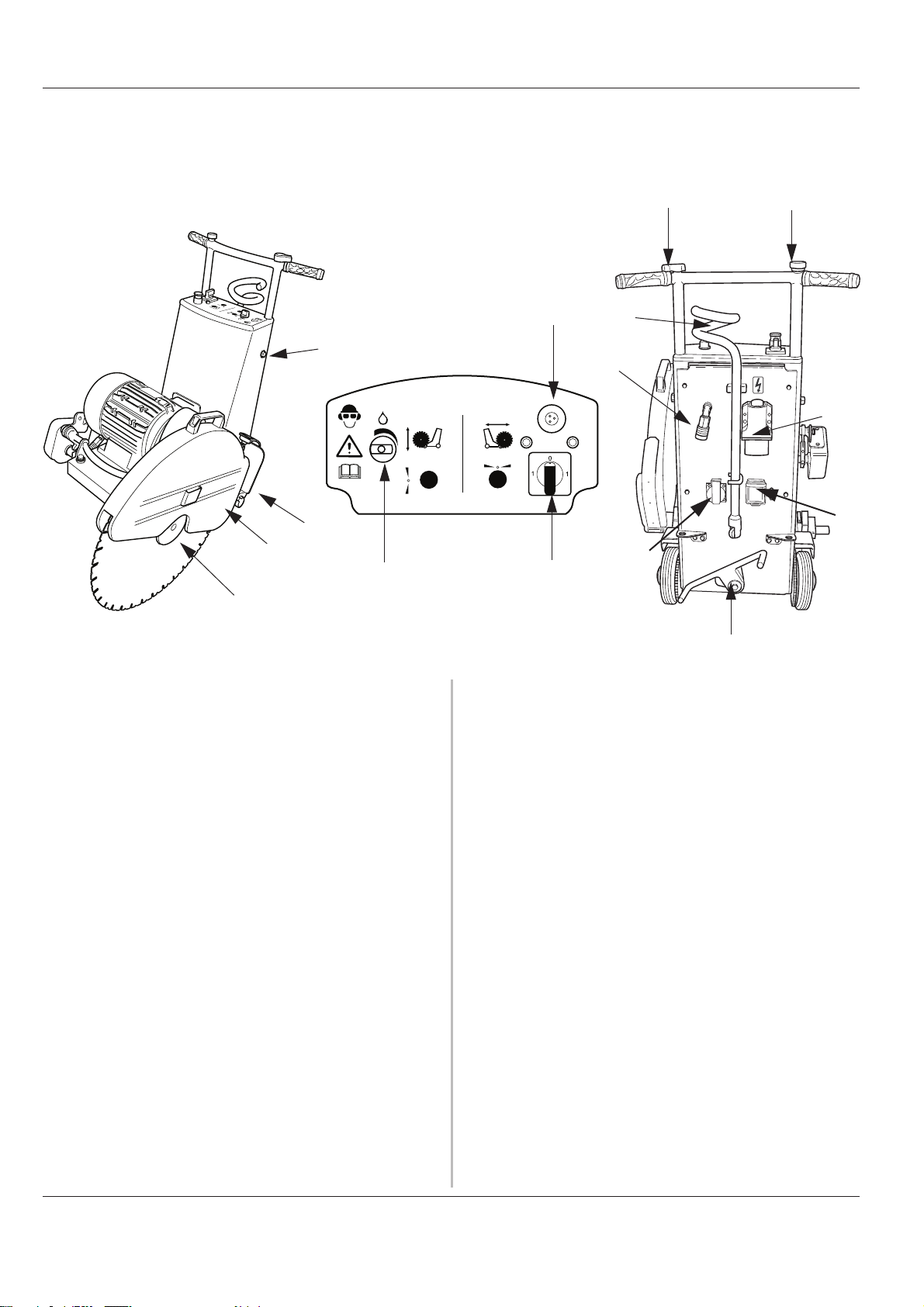

What is what

12

10

11

13

Operator’s Manual FS 700EX

12

5

3

4

11

7

6

9

8

1. Trolley feed lever

The machine's propulsion is controlled using this lever.

The machine is driven forwards by turning the lever

clockwise. When the lever is turned anticlockwise, the

machine reverses. When lever is in the neutral position

the machine stands still. This function works as soon

as the machine is connected to the power and the

machine's propulsion is engaged.

2. Blade feed lever

This lever is used to raise and lower the cutting bridge.

The blade is fed downwards when the lever is turned

anticlockwise. When the required cutting depth is

achieved the lever is turned to the neutral position.

The blade is raised by turning the lever clockwise.

This function works as soon as the machine is

connected to the power.

3. Water selector

Turn this knob anticlockwise to open the water valve.

Water is led through the blade spindle and out to the

blade flange, where the water cools the blade and

prevents dust build-up.

10

5. Emergency stop

Cuts all power to the machine. No functions can be

activated until the emergency stop has been reset. The

emergency stop is reset by pulling out the button.

6. Power supply

For connecting an electrical connector of the type:

5-way 400 V/16A

4-way 480V/16 A.

4-way 600V/16A

7. Water connector

Water coolant is connected to the machine here.

8. 1-Phase 230V outlet Socket

To connect a 230V tool to the machine.

9. Personel protection

Will cut the power to the 1-phase outlet socket at 30

mA earth fault.

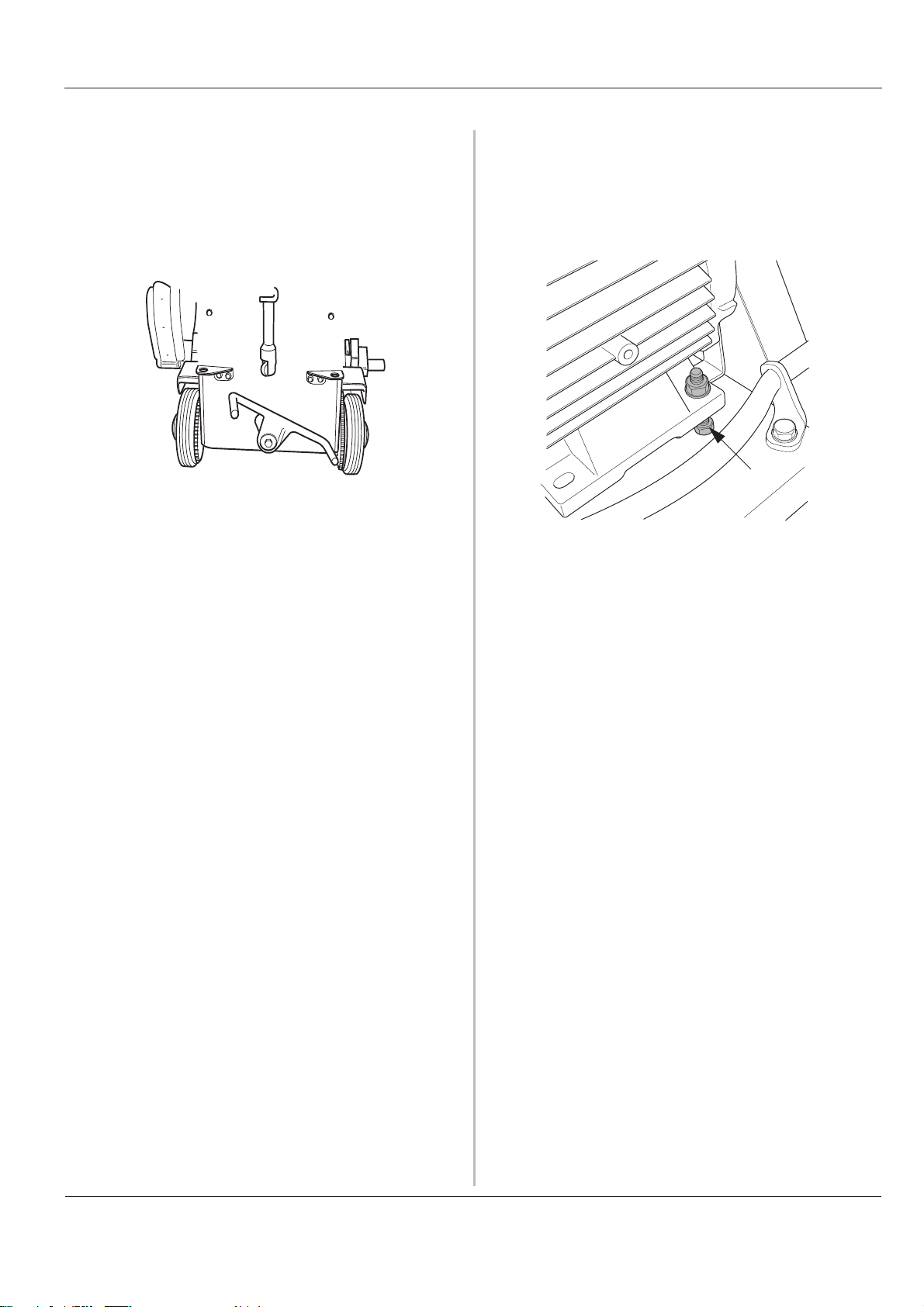

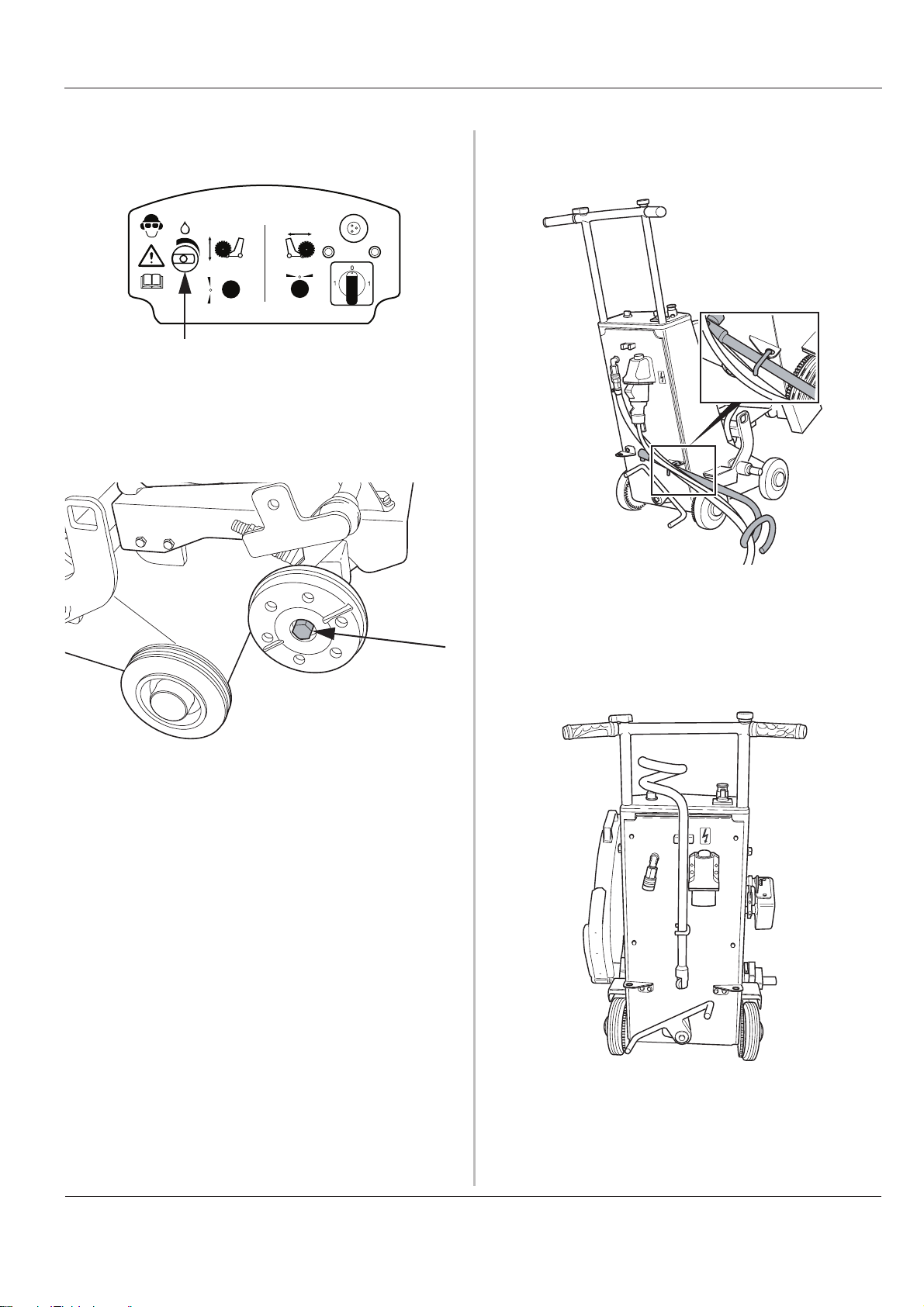

10.Propulsion/Parking brake

4. Start knob

Used to start the blade.

8 - English

When the foot lever is in the illustrated position the

drive is engaged. When the foot lever is in this position

Page 9

Operator’s Manual FS 700EX

and the trolley feed lever is in the neutral position or

the machine is not voltage fed, this position acts as a

parking brake.

If the foot lever is switched to the other position no

gear is engaged and the machine is easy to move. Use

this position when the machine needs to be

transported over long distances.

11.Hose holder

15.Handle setting

The height of the handle can be adjusted by loosening

these two screws to the most suitable height.

16.Adjuster screw

Adjust this screw to tension the drive belt.

14

The user can use the hose holder to prevent hoses

and cables trailing behind the machine. These will lie

to the side of the machine instead.

12.Blade guard

Can be fitted on either the right or left-hand side of the

machine as required. The guard can be secured in the

upright position by using the lever on the rear edge of

the guard.

13.Splash guard

The machine is equipped with a folding splash guard to

minimise water spray and dirtying. When the machine

is transported over long distances the splash guard

should be folded up and secured using the spring on

the blade guard. The splash guard should always be

folded down when cutting.

14.Blade flange

The blade flange fits on either side of the machine to

allow the blade to be easily fitted on both sides of the

machine

The blade flange should be covered with the blade

flange guard when a blade is not fitted The blade

flange guard is fitted on the right-hand side on delivery.

The machine is supplied with a standard blade flange.

A flush cutting blade flange can be purchased as an

option. Fit the blade on the flush cutting blade flange

when the cut is to be made next to a wall. A special

flush cutting blade guard must be used when cutting

flush.

English -

9

Page 10

Technical data

Operator’s Manual FS 700EX

Max. cutting depth:

600 mm (23") blade diameter__________ 235 mm (9.25")

625 mm (24") blade diameter__________ 248 mm (9.76")

700 mm (28.6") blade diameter ________ 285 mm (11.2")

725 mm (29") blade diameter__________ 298 mm (11.7")

We recommend that Husqvarna W1100 series blades are

used together with the machine

Weight (excl. blade): _____________ 155 kg

Weight (incl. blade):______________

Power: ___________________________ 7.5 kW

Voltage: __________________________ 400V/3 phase/50 Hz

Type of current _____________________ 16 A

Max. speed drive shaft: ______________ 1780 rpm

Periphery speed, saw blade___________ 56 m/s

Maximum blade diameter_____________ 725 mm

max. cutting depth __________________ 298 mm

150 kg

480V/3 phase/60 Hz

600V/3 phase/60 Hz

NOTE

When unsure about the significance of the

technical specifications or when ordering

spare parts please contact your dealer.

WARNING!

Under no circumstance may the machine

be modified without written permission

from Husqvarna Construction Products

Sweden AB. Non approved modifications

put you and others at risk of serious or

fatal injuries. Husqvarna Construction

Products Sweden AB bears no

responsibility for operations or measures

that do not follow these instructions.

10 - English

Page 11

Operator’s Manual FS 700EX

Operation

Before cutting

NOTE!

Follow the safety precautions.

Check that the correct power cable is connected to the

saw.

Check that the coolant water coupling on the hose is the

same as the type fitted on the machine.

Enclose the area to be cut so that unauthorised persons

can not be injured or disturb the operator while working.

Clearly mark out all cuts to be made on the floor before

you start sawing, plan these so they can be carried out

without danger to persons or the machine.

In order to prevent stoppages and sources of irritation

while cutting, plan the work so that you fit the blade to the

most appropriate side of the machine from the outset.

Check that you have the right saw blade for the machine

and the material to be cut. See the technical data.

WARNING!

Carefully check that all electrical power

cables, water pipes and gas pipes are

marked out within the cutting area. To cut

into a gas pipe that has not been emptied

is directly associated with mortal danger.

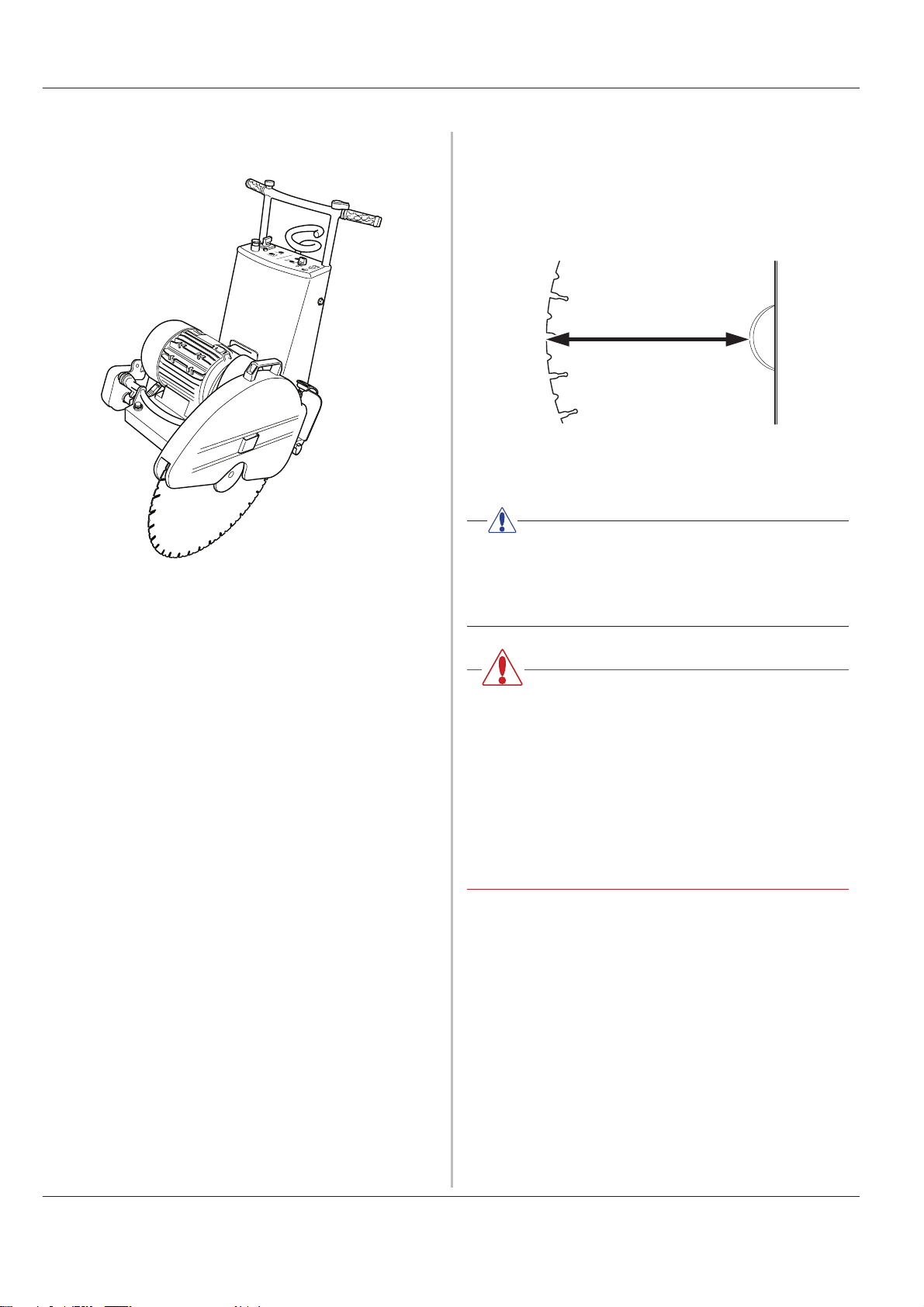

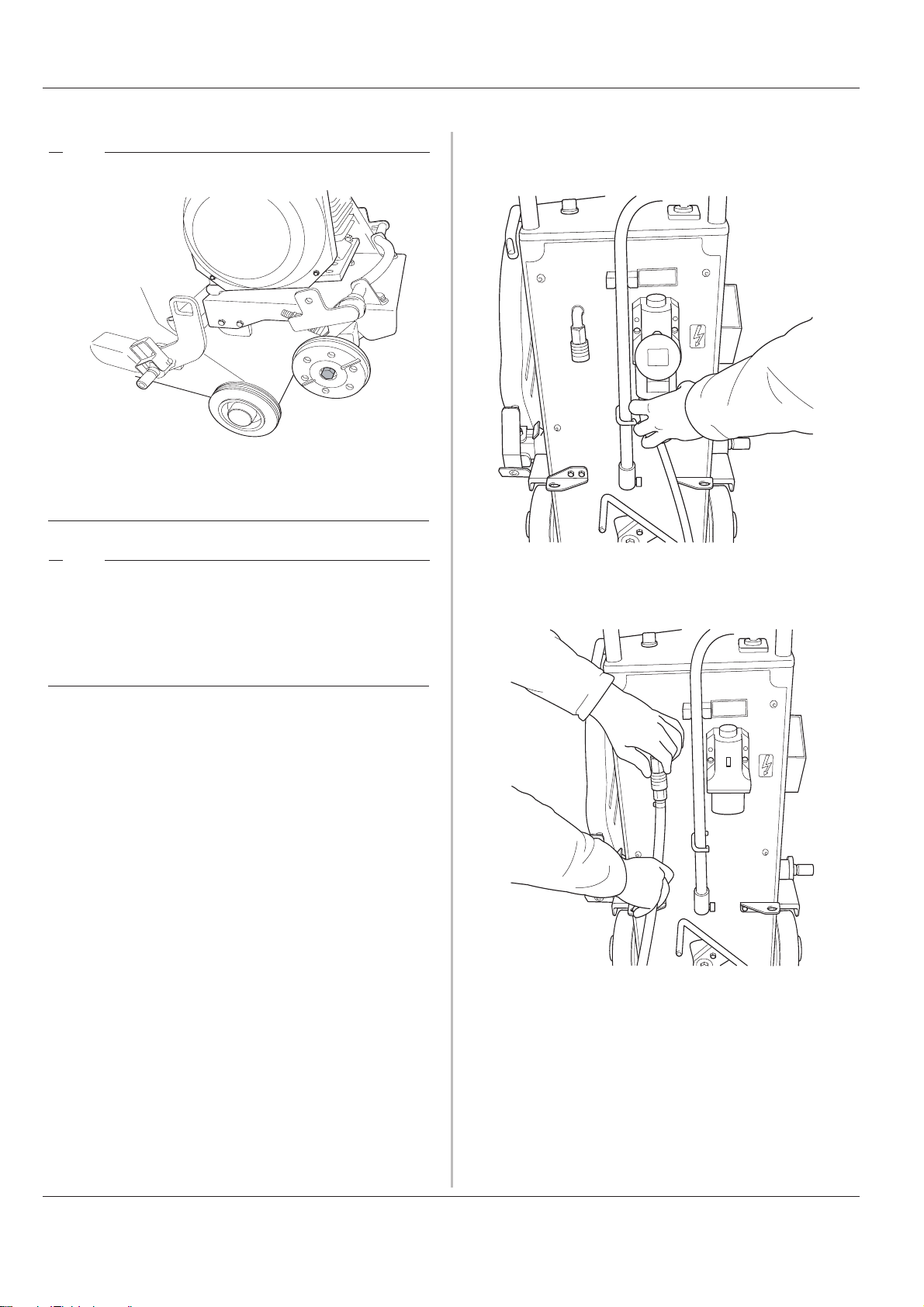

Assembling/Replacing the blade

• Lift up the cutting bridge to its highest position.

• Disconnect the incoming electrical connection.

• Engage the machine's propulsion by moving the foot

lever as illustrated below.

Check that the saw blade is not worn. The blade is worn

when only a few millimetres of the diamond segment

remains or when the diamond segment is not wider than

the body of the blade.

Check that the blade guard is not damaged or broken. A

broken or damaged blade guard must never be used.

Ensure you are fully conversant with how machine's

control levers work before starting the machine.

Make sure that the emergency stop is not blocked. The

emergency stop must not be blocked or covered while

working.

Check that the trolley feed, and blade feed levers are in

the neutral position.

Remove all foreign objects in the path of the machine that

can damage the machine or the surroundings.

Check that there are no unauthorised persons within the

safety zone, i.e. 4 metres in front of or to the side of the

machine.

Make sure that persons in the vicinity of the machine wear

hearing protection and protective glasses.

Move the machine so the blade follows the pre-drawn

cutting line.

• Fold up the blade guard and secure it in the raised

position by using the blade guard holder.

• Clean the blade flanges and check that they are not

damaged.

• Assemble the saw blade and check that the direction

of rotation corresponds with the arrow on the blade

guard. If the direction of rotation is not marked on the

body of the blade, the blade's direction of rotation must

be determined with the help of the wear on the

diamond segments, the exposed part of the diamond

should then be in the direction of rotation.

• Tighten the blade flange using the supplied spanner so

hard that it is well secured. At least 70 Nm.

• Fold down the blade guard.

• Check that the saw blade rotates freely and easily by

turning it by hand, and that no abnormal noise occurs

when the saw blade is rotated. Also check that the saw

blade is straight. Never cut with a damaged saw blade.

Check your safety equipment and any protective clothing.

English -

11

Page 12

Operator’s Manual FS 700EX

Connecting the machine

Attention

Remember that the screw securing the righthand blade flange has a left-hand thread.

Connect the power cable to the electrical socket.

3 x 380-420 V

A 50 Hz

16

Attention

The blade should be assembled on the

machine's left-hand side when possible. This

is because assembly on the right-hand side

affects motor cooling.

Connect the coolant hose to the right coupling.

3 x 380-420 V

A 50 Hz

16

12 - English

Page 13

Operator’s Manual FS 700EX

Turn on the water coolant so that sufficient cooling is

obtained and dust build-up is prevented.

Check that the water supply is ample and that the nozzles

are not clogged. Also check that the set screw is fitted in

the end of the blade spindle where no blade is fitted

.

Make sure that the machine's power cable and water

supply can not end up under the machine or are in the

way by using the hose holder.

Make sure that the saw blade rotates freely before starting

the machine.

Sawing

Activate the propulsion by moving the foot lever as

illustrated with your foot. The machine will not start to

move until the trolley feed lever is moved from the neutral

position.

English - 13

Page 14

Operator’s Manual FS 700EX

Start blade rotation by turning the switch towards the lamp

that is on. If the switch is turned in the opposite direction

the blade will rotate in the wrong direction.

0

1

Feed the saw blade by turning the blade feed lever

towards you, so that a cutting depth adapted to the floor

material, however at least 20 mm, is realized.

Make a pilot cut at an even speed at this depth along the

pre-drawn line. When the complete pilot cut has been made,

raise the blade, shut off the water coolant and stop the blade

rotating. Reverse the machine to the starting point.

1

Stop cutting

Lift up the cutting bridge to its highest position.

Shut down blade rotation by turning the switch the neutral

position.

Turn both the travel feed and blade feed to their neutral

positions.

Shut off the water coolant.

NOTE!

The protective devices are for your own

safety, consequently, it is extremely important

to check all safety equipment regularly. Should

a fault be discovered, please contact your

dealer.

Align the machine with the pilot cut again and start the

machine as above.

Lower the saw blade to a suitable cutting depth (5-10 cm).

A suitable cutting depth varies depending on the floor

material and the speed.

A simple rule is if the machine tends to “climb up” out of

the pilot cut the cutting depth is too large and/or the speed

too high.

The machine must not be driven faster than that it cuts

without “climbing” i.e. that the machine's front wheels lift

off from the ground. If the machine “climbs”, decrease the

trolley feed by turning the lever for the travel feed

anticlockwise or raise the blade by turning the blade feed

lever clockwise

NOTE!

The operator must always be behind the

machine when cutting and within reach of the

levers and stop.

WARNING!

Contact with the rotating saw blade can

result in serious, physical injury or even

death.

14 - English

Page 15

Operator’s Manual FS 700EX

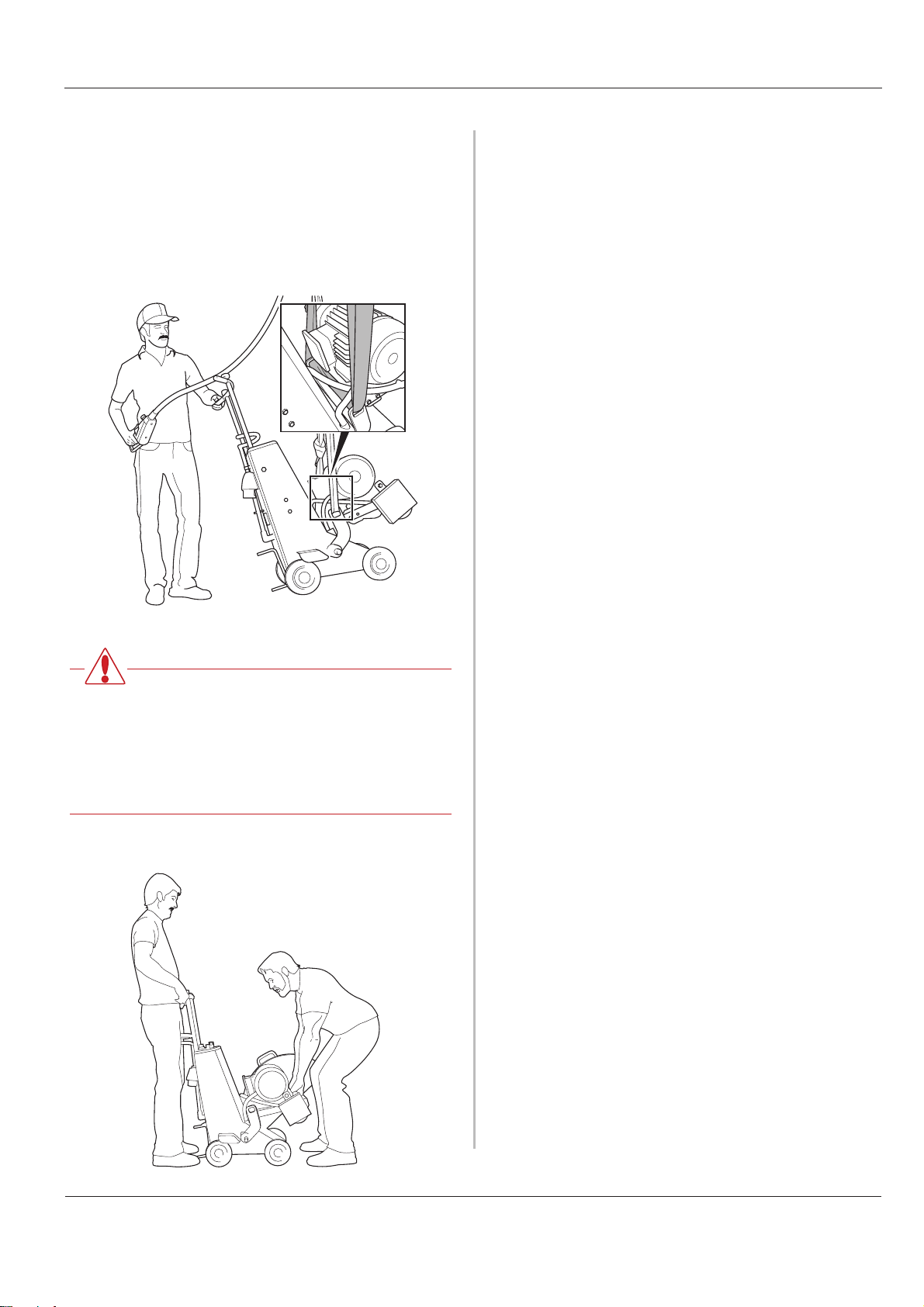

Transport

The blade must be removed from the saw during all

transport and lifting. If the blade is not removed, there is a

risk it will be damaged.

The saw can be lifted in several different ways during

transport. When the saw is lifted using a crane, secure the

lifting strap in the lifting eyes.

WARNING!

Pay attention to ensure that you or anyone

else never stands under a free hanging

machine. Should you be hit by a falling

machine, this can result in death or serious

physical injury.

When the saw is only lifted a little, it can be lifted from the

handles and the front lifting stay.

English - 15

Page 16

Operator’s Manual FS 700EX

Maintenance

Once cutting has been completed the machine should be

cleaned. Make sure that the electrical connection has

been disconnected before washing. Avoid spraying water

against the electric motor and electrical connections. Use

a dish-brush or sponge to clean the machine.

Attention

Avoid cleaning the machine with a high

pressure washer.

Check the condition of the saw blade regularly for signs of

wear or damage. When segments are worn or the width of

the segments is nearly the same as the body of the blade,

it should be replaced.

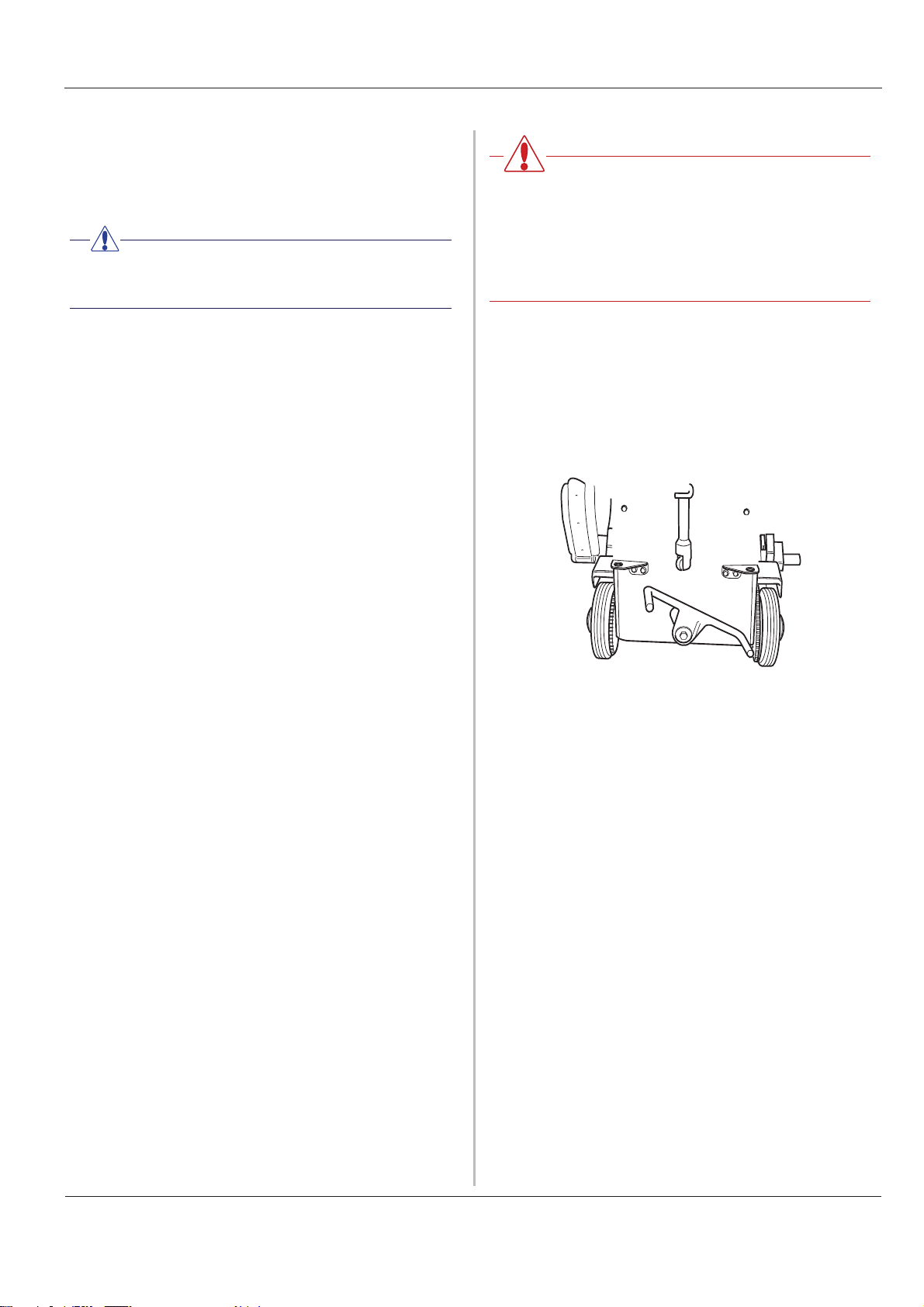

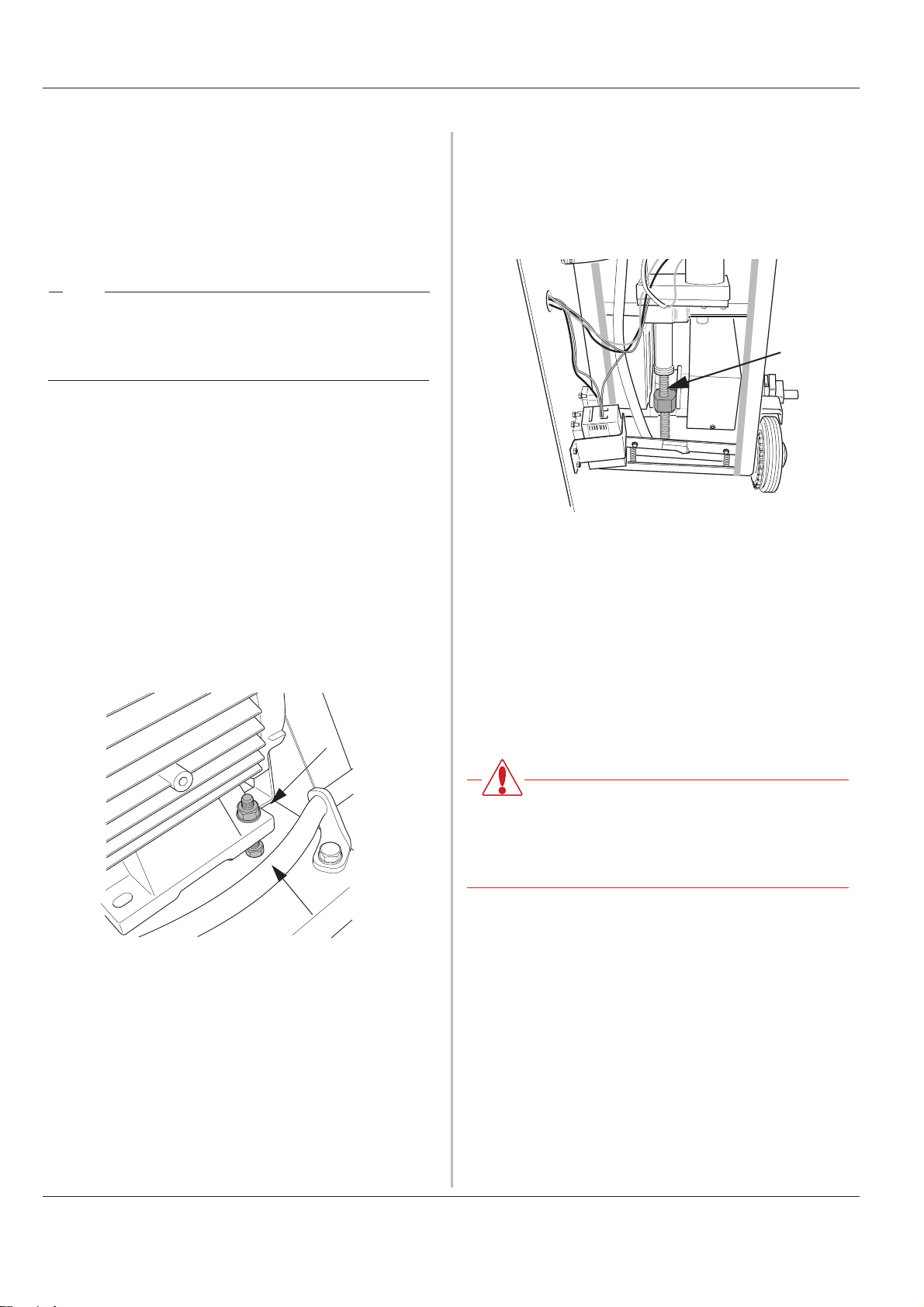

Check regularly that electrical cables, couplings, drive belt

and screw joints are not damaged.

Check regularly that the drive belt and couplings are not

dirty and that the drive belt is not tensioned too little or too

much. The guard around the drive belt must be removed

in order to check the drive belt tension.

Tension the drive belt, if necessary, by first loosening the

nut (a), hold the nut under the base with a spanner and

then turn the bolt (b) until the belt is tensioned. When the

belt is tensioned, lock by screwing back the nut.

Periodically lubricate the nut for the blade feed. The rear

of the machine must be dismantled first to gain access to

the nut.

Once the rear has been removed, grease the feed screw

a few centimetres above and under the nut.

Refit the rear as follows:

1. Hang the cover from the top edge.

2. Pull a part the cogs that drive the saw forwards by

inserting a screwdriver between the cogs and carefully

pressing the screwdriver downwards.

At the same time press the rear against the saw's

chassis.

a

b

When storing the machine for long periods it must be

cleaned carefully and the water tank emptied.

3. Refit the screws that hold the rear in position.

WARNING!

The electrical connection must be

disconnected before carrying out

maintenance repairs and service-work

16 - English

Page 17

Operator’s Manual FS 700EX

Trouble shooting

If a fault occurs, first check whether it coincides with any of

the possible faults in the trouble shooting guide below.

If the fault coincides with one of the fault possibilities in the

NOTE

trouble shooting guide, contact your dealer for further

information.

Before rectifying a fault, check that all

electrical connections are disconnected to

prevent the machine from starting during the

course of the work.

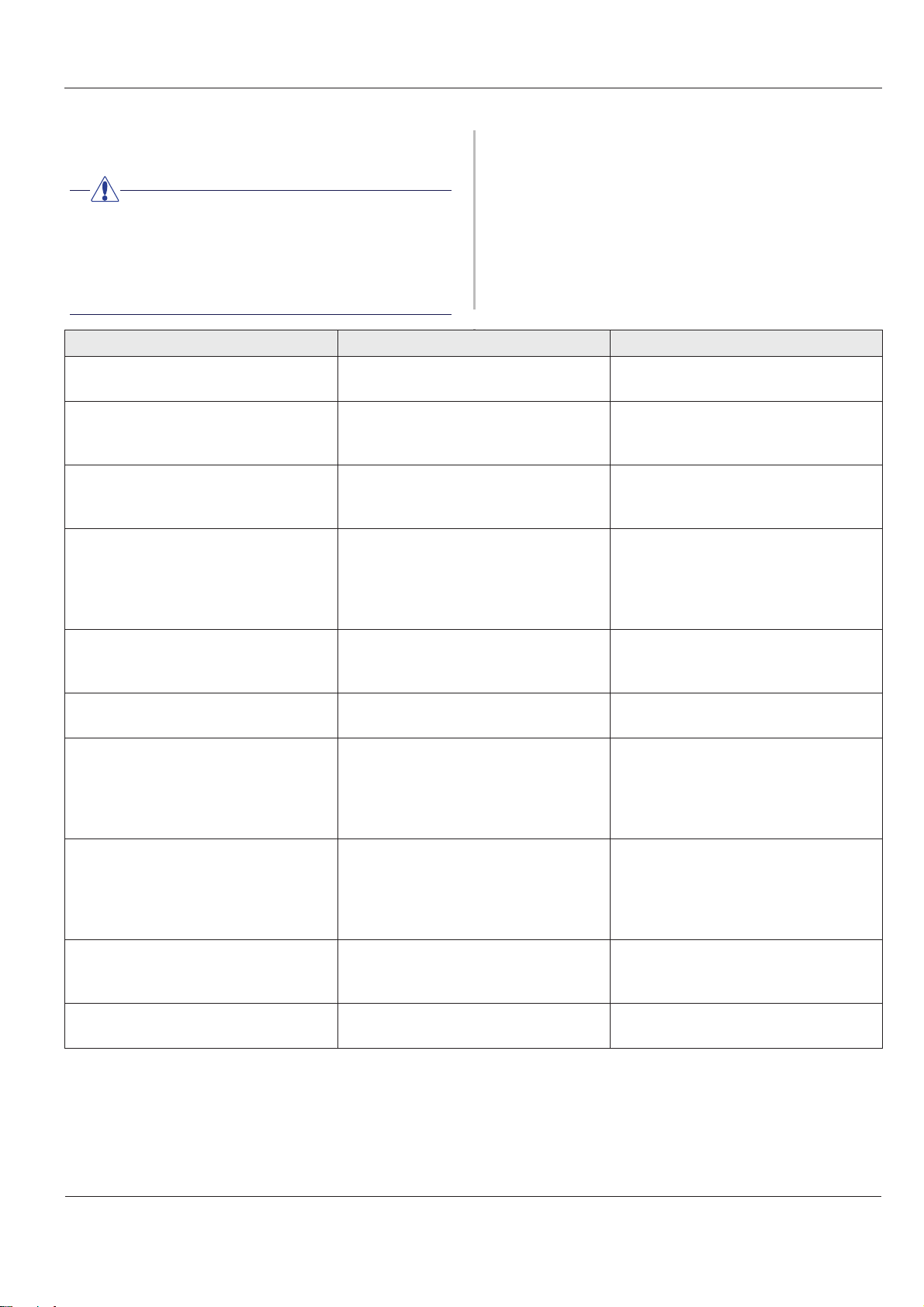

Fault Cause Action

The blade rotates in the wrong direction. The starter knob is defective. Turn the starter knob in the direction

indicated by the lit lamp.

The blade jams. Drive belt slips.

Drive belt dirty.

Drive belt worn.

No water is produced or too little water

reaches the blade.

The blade jams. The blade is worn.

The blade flange is dirty Clean the blade flange.

The saw blade is clamped.

The saw has been fed too hard.

Tension the drive belt.

Clean the drive belt.

Replace the drive belt.

Increase the water pressure by opening

the water tap a little more.

Replace the blade.

Support the saw block with braces or a

jack.

Run with either a lower feed rate or

shallower cutting depth.

The motor does not start. The emergency stop has been switched

on.

Electrical fault.

There is no trolley feed. The drive shaft is not engaged. Change the foot lever for propulsion so

There is no trolley feed/blade feed. The feed levers were not reset when the

power was connected.

There is no blade feed up or down. The feeder nut has jammed at the end

position.

The feed nut is dry.

The machine cuts out / does not start

blade rotation.

Both status lamps for blade rotation are

on.

The thermal cut-out on the motor has

tripped.

A phase is down. Check the fuses and electrical power

Reset the emergency stop.

Contact your dealer.

that the drive shaft is engaged.

Reset the machine by turning off the

blade rotation, pressing down the

emergency stop and turning the levers to

the neutral position. Wait 3 seconds and

then reset the emergency stop button.

Remove the rear cover and carefully

loosen the feed nut by turning the nut at

the bottom of the feed screw.

Grease the feed axle.

Wait until the motor has cooled. Once the

temperature of the motor has dropped

the saw is started again as normal.

cable.

English - 17

Page 18

Operator’s Manual FS 700EX

18 - English

Page 19

Operator’s Manual FS 700EX

EU declaration of conformity

Husqvarna Construction Products Sweden AB, Box 2098, 550 02 Jönköping, Sweden, tel:

036-570 60 00, hereby declares that its FS 700E floor saw, from serial number 01001

onwards, is manufactured in compliance with the Council's machinery directive 98/37/EC,

low-voltage directive 73/23/EEC and EMC directive 89/336/EEC, including subsequent

amendments, and that the following standards have been used for guidance: EN 55 014-1,

EN 55 014-2, EN 61 000-3-2, EN 50 144-1, EN 13 862.

Jönköping 2005-01-01

Christer Carlberg

Managing Director

English - 19

Page 20

Operator’s Manual FS 700EX

20 - English

Page 21

Bedienungsanleitung FS 700EX

Inhalt

Deutsch

Inhalt

Erklärung der Symbole.......................................... 23

Sicherheitsvorschriften

Einleitung

Was ist was?

....................................................................... 25

................................................................ 26

Technische Daten

Bedienung

Vor dem Sägen

...................................................................... 29

.......................................................... 29

Einbau/Austausch der Trennscheibe

Maschine anschließen

Schneiden

.................................................................... 31

Schneiden beenden

Transport

Wartung

........................................................................ 33

........................................................................... 34

......................................... 24

..................................................... 28

.............. 29

........................................... 30

................................................ 32

Fehlersuche

EU-Erklärung

................................................................. 35

................................................................ 38

Deutsch - 21

Page 22

Inhalt Bedienungsanleitung FS 700EX

22 - Deutsch

Page 23

Bedienungsanleitung FS 700EX

Erklärung der Symbole

Diese Symbole sind auf der Maschine und in der

Bedienungsanleitung angegeben. Um sicher mit der

Maschine arbeiten zu können, muss der Bediener ihre

Bedeutung verstehen.

Anleitung

Vor der Inbetriebnahme der Maschine lesen Sie die

Bedienungsanleitung aufmerksam durch und machen Sie

sich mit dem Inhalt vertraut.

Schutzausrüstung

Stets verwenden:

• Zugelassener Schutzhelm

• Zugelassener Gehörschutz

• Zugelassene Schutzbrille oder Gesichtsschutz sowie

sonstige erforderliche Schutzausrüstung.

Anmerkung

Eine Hand mit erhobenem Zeigefinger mit dem Zusatz

"Anmerkung" bedeutet, dass ein beschriebener Vorgang

zusätzliche Aufmerksamkeit erfordert.

CE

Dieses Symbol weißt darauf hin, dass die Maschine den

geltenden EG-Richtlinien entspricht.

Stromwarnung

Dieses Symbol warnt vor Hochspannung.

Warnung

Ein großes Warndreieck mit dem Zusatz "Warnung"

bedeutet, dass die Gefahr von schweren, sogar

lebensgefährlichen Verletzungen besteht..

Achtung

Ein kleines Warndreieck mit dem Zusatz "Achtung"

bedeutet, dass die Gefahr von leichteren Verletzungen

oder Maschinenschäden besteht.

Umweltinformation

Das Symbol auf dem Produkt bzw. auf der

Produktverpackung gibt an, dass dieses Produkt nicht als

Hausmüll behandelt werden darf. Zur Entsorgung ist es

an einen entsprechenden Recycling-Punkt für elektrische

und elektronische Geräte zu bringen.

Durch die umweltgerechte Entsorgung dieses Produkts

tragen Sie dazu bei, potentielle Folgeschäden an der

Umwelt und Gesundheitsschäden zu verhindern.

Ausführlichere Informationen über das Recycling dieses

Produkts erhalten Sie auf Wunsch von Ihrem Stadt- oder

Gemeinderat, den für die Hausmüllentsorgung

zuständigen Behörden oder dem Geschäft, in dem Sie

dieses Produkt gekauft haben.

Deutsch - 23

Page 24

Bedienungsanleitung FS 700EX

Sicherheitsvorschriften

Bei der Konstruktion und Herstellung von HusqvarnaProdukten wurde neben der Leistungsfähigkeit und

Benutzerfreundlichkeit größtes Gewicht auf die Sicherheit

gelegt. Folgende Punkte sind zu beachten, um einen

sicheren Maschinenbetrieb zu gewährleisten:

• Die Maschine darf ausschließlich unter Befolgung der

Sicherheitsvorschriften gestartet werden. Bei

Missachtung der Vorschriften seitens des Bedieners

haftet Husqvarna Construction Products Sweden AB

oder ihre Vertreter weder direkt noch indirekt.

Lesen Sie die Bedienungsanleitung aufmerksam durch

und machen Sie sich mit dem Inhalt vertraut, bevor Sie

die Maschine benutzen. Sollten Sie sich auch nach

Lektüre der Sicherheitsvorschriften nicht über die

vorliegenden Sicherheitsrisiken im Klaren sein, dürfen

Sie die Maschine nicht benutzen.

Ihr Fachhändler erteilt auf Anfrage gerne weitere

Informationen.

• Sicherstellen, dass alle Verbindungen, Anschlüsse und

der Trennscheibenschutz unbeschädigt sind.

arbeiten. Keine Kleidung tragen, die sich in den

beweglichen Teilen der Maschine verfangen kann.

• Personen, die sich in der Umgebung aufhalten,

müssen einen Gehörschutz tragen.

• Mit rotierender Trennscheibe darf die Maschine nicht

gedreht, gewendet oder seitlich bewegt werden.

• Nur vom Hersteller empfohlene Trennscheiben

verwenden.

• Niemals ohne Trennscheibenschutz schneiden.

• Niemals ohne Kühlwasser schneiden. Von einer

unzureichend gekühlten Trennscheibe können sich

Segmente lösen. Das Kühlwasser bindet darüber

hinaus Betonstaub.

• Niemals beschädigte oder verschlissene

Trennscheiben verwenden.

• Die Maschine nur verwenden, wenn sie einwandfrei

funktioniert.

• Unfallverhütungsvorschriften, sonstige Sicherheitsund arbeitsmedizinische Vorschriften sind jederzeit zu

beachten.

• Vor der Inbetriebnahme sicherstellen, dass alle

Schläuche und Stromkabel korrekt an der Maschine

angeschlossen sind.

• Vor und seitlich der Trennscheibe muss ein

Sicherheitsabstand von 4 m eingehalten werden.

• Sicherstellen, dass sich im Arbeitsbereich keine

Personen oder Tiere aufhalten.

• Sicherstellen, dass Trennscheibenschutz bzw.

Trennscheiben-Flanschschutz korrekt montiert sind.

• Stets so arbeiten, dass der Nothalt schnell und einfach

zu erreichen ist.

• Niemals die Maschine unbeaufsichtigt mit laufendem

Motor stehen lassen.

• Vor dem Schneiden sind alle auszuführenden Schnitte

deutlich auf dem Boden zu markieren und zu planen,

sodass sie ohne Gefahr für Mensch oder Maschine

durchgeführt werden können.

• Anhand von Bauzeichnungen prüfen, ob Stromkabel,

Wasser-, Gas- oder Abflussleitungen im Arbeitsbereich

verlegt sind.

• Sicherstellen, dass die Stromkabel im Arbeitsbereich

nicht stromführend sind.

• Vorsicht beim Heben. Schweres Gerät bedeutet

Klemmgefahr und Gefahr für andere Verletzungen.

• Die Maschine in einem verschlossenen Raum

abstellen, der für Kinder sowie für Erwachsene ohne

besondere Ausbildung für die Verwendung der

Maschine unzugänglich ist.

• Abgesägte Betonblöcke ausreichend sichern oder

verankern. Freigesägte Materialien mit hohem Gewicht

können schwere Schäden verursachen, wenn sie nicht

kontrolliert bewegt werden können.

• Beim Arbeiten mit den Maschinen muss stets eine

weitere Person anwesend sein, die bei Unfällen

Hilfestellung leisten kann.

WARNUNG!

Bei Benutzung der Maschine stets zugelas-

sene Schutzkleidung und zugelassene

Schutzausrüstung tragen. Schutzkleidung

und Schutzausrüstung können die Verletzungsgefahr nicht völlig eliminieren, doch

lässt sich im Unglücksfall der Ernst eventueller Verletzungen durch die richtige Kleidung und angemessene Ausrüstung

reduzieren. Ihr Händler informiert Sie über

empfehlenswerte, zugelassene Schutzausrüstung und -kleidung.

• Niemals ohne eine persönliche Schutzausrüstung

(siehe Bedienungsanleitung) und Schutzkleidung

24 - Deutsch

Page 25

Bedienungsanleitung FS 700EX

Einleitung

Die FS-Serie ist eine neue Reihe mit elektrischen BodenTrennschleifern von Husqvarna. Wir wollten eine

leistungsfähige, handliche Maschine für das Schneiden in

armiertem Beton, Backstein und anderen Steinmaterialien

entwickeln. Die Maschine sollte für eine Person leicht zu

bedienen sein.

Die FS-Serie ist mit elektrischem Längs- und

Tiefenvorschub ausgerüstet. Beide werden mit Reglern

bedient, die sich am einstellbaren Handgriff befinden.

Um den Transport des Trennschneiders zu erleichtern,

kann der Handgriff heruntergeklappt und die

Schneideinheit auf einfache Art abgenommen werden. So

lässt sich das Gerät leichter heben und nimmt beim

Transport weniger Platz in Anspruch.

Zum Lieferumfang des Trennschleifers gehören ein

Flansch und ein Trennscheibenschutz. Als Zubehör sind

ein Flachschneideflansch und ein Flachschneideschutz

erhältlich.

Diese Bedienungsanleitung ist aufmerksam

durchzulesen, nur so lässt sich die Maschine so effektiv

wie möglich einsetzen. Bei Unklarheiten oder Fragen

wenden Sie sich bitte an Ihren Händler, bevor Sie die

Maschine in Gebrauch nehmen.

Deutsch - 25

Page 26

Bedienungsanleitung FS 700EX

Was ist was?

12

15

13

12

3

14

1. Längsvorschubregler

Mit diesem Regler wird der Vorwärtsantrieb geändert.

Regler im Uhrzeigersinn drehen, um vorwärts zu

fahren. Regler im Gegenuhrzeigersinn drehen, um

rückwärts zu fahren. Mit dem Regler in der Nullstellung

steht die Maschine still. Diese Funktion ist bereit,

sobald die Maschine mit Strom versorgt und der

Vorwärtsantrieb aktiviert ist.

2. Tiefenvorschubregler

Mit diesem Regler wird die Schneideinheit angehoben

und gesenkt. Der Tiefenvorschub der Trennscheibe

erfolgt durch Drehen des Reglers im

Gegenuhrzeigersinn. Ist die gewünschte Schnitttiefe

erreicht, wird der Regler in die Nullstellung

zurückgestellt. Regler im Uhrzeigersinn drehen, um die

Trennscheibe anzuheben. Diese Funktion ist bereit,

sobald die Maschine mit Strom versorgt ist.

3. Wasserregler

Regler im Gegenuhrzeigersinn drehen, um das

Wasserventil zu öffnen. Das Wasser wird durch die

Trennscheibenachse und zum Trennscheibenflansch

geleitet, wo es die Trennscheibe kühlt und eine

Staubbildung verhindert.

5

4

4. Startschalter

Wird für den Start der Trennscheibenrotation verwendet.

5. Nothalt

Unterbricht die gesamte Stromzufuhr zur Maschine.

Sämtliche Funktionen können erst aktiviert werden,

wenn der Nothalt zurückgestellt wird. Der Nothalt wird

durch Herausziehen des Knopfs zurückgestellt.

6. Stromanschluss

Für folgenden Stromanschlusstyp:

5-polig, 400 V/16 A

7. Wasseranschluss

Hier wird Kühlwasser an die Maschine angeschlossen.

8. 1-Phasen 230-V-Anschluss

Um 230-V-Werkzeug an die Maschine anzuschließen.

9. Personenschutz

Unterbricht den Strom zum 1-Phasen-Anschluss bei

30 mA Stromverlust.

10.Vorwärtsantrieb/Feststellbremse

Befindet sich der Arm in der abgebildeten Position, ist

der Antrieb aktiviert. Befindet sich der Arm in dieser

Position und der Längsvorschubregler ist nullgestellt

11

7

8

10

6

9

26 - Deutsch

Page 27

Bedienungsanleitung FS 700EX

oder die Maschine ist stromlos, fungiert die Stellung

als Feststellbremse.

Wird der Arm in die andere Position bewegt, ist kein

Gang eingelegt und die Maschine lässt sich leicht

bewegen. Diese Stellung wählen, wenn die Maschine

über längere Strecken bewegt werden soll.

11.Schlauchhalter

Durch Verwendung des Schlauchhalters wird

vermieden, dass Schläuche und Kabel hinter der

Maschine hergezogen werden. Sie befinden sich

stattdessen seitlich von der Maschine

12.Trennscheibenschutz

Kann je nach Wunsch auf der rechten oder linken

Seite der Maschine angebracht werden. Der Schutz

kann in aufrechter Lage mit dem Hebel an der hinteren

Kante gesichert werden.

13.Spritzschutz

Um Wasserspritzer und Verschmutzung zu minimieren,

ist die Maschine mit einem klappbaren Spritzschutz

ausgestattet. Soll der Trennschleifer über längere Strekken transportiert werden, muss der Spritzschutz nach

oben geklappt und mit der Feder am Trennscheibenschutz befestigt werden. Beim Schneiden muss der

Spritzschutz stets nach unten geklappt sein.

14.Trennscheibenflansch

Um auf einfache Weise die Trennscheibe auf der

gewünschten Seite der Maschine montieren zu können, passt der Trennscheibenflansch an beide Seiten.

Der Trennscheibenflansch ohne montierte Scheibe ist

mit dem Trennscheibenflanschschutz zu bedecken,

der sich bei Lieferung auf der rechten Seite befindet.

Die Maschine wird mit einem herkömmlichen Trennscheibenflansch geliefert. Ein Flachschneideflansch ist

als Zubehör erhältlich. Die Trennscheibe am Flachschneideflansch anbringen, wenn der Schnitt an einer

Wand liegen soll. Beim Flachschneiden muss der spezielle Flachschneideschutz verwendet werden.

15.Handgriffeinstellung

Durch Lösen dieser beiden Schrauben kann der

Handgriff auf die gewünschte Höhe eingestellt werden.

16.Stellschraube

Diese Schraube justieren, um den Antriebsriemen zu

spannen.

16

17.Motorhalterung

Durch Lösen dieser beiden Schrauben kann die

Schneideinheit mit Motor abgehoben werden, um das

Maschinengewicht zu reduzieren.

17

Deutsch - 27

Page 28

Bedienungsanleitung FS 700EX

Technische Daten

Gewicht ohne Trennscheibe: _______ 155 kg

Gewicht mit Trennscheibe: ________

Motorleistung:______________________ 7,5 kW

Spannung: ________________________ 400 V/3 Phasen/50

Strom:____________________________ 16 A

Max. Drehzahl Antriebsachse: _________ 1780 U/min

Umfangsgeschwindigkeit, Trennscheibe: _ 56 m/s

Max. Trennscheibendurchmesser: ______ 725 mm

Max. Schnitttiefe: ___________________ 298 mm

150 kg

Hz

Max. Schnitttiefe:

600 mm (23") Trennscheibendurchmesser 235 mm (9,25")

625 mm (24") Trennscheibendurchmesser 248 mm (9,76")

700 mm (28,6") Trennscheibendurchmesser285 mm (11,2")

725 mm (29") Trennscheibendurchmesser 298 mm (11,7")

Wir empfehlen, Trennscheiben der Serie Dimas W1100

zusammen mit der Maschine zu verwenden.

ACHTUNG

Bei Unsicherheiten bezüglich der Bedeutung

der technischen Daten oder bei der Bestellung

von Ersatzteilen sprechen Sie bitte mit Ihrem

Händler.

WARNUNG!

Ohne die schriftliche Genehmigung von

Husqvarna Construction Products Sweden AB dürfen unter keinen Umständen

Veränderungen an der Maschine vorgenommen werden. Unzulässige Änderungen

bringen die Gefahr von schweren oder

lebensgefährlichen Verletzungen für Sie

und andere mit sich. Husqvarna Construction Products Sweden AB haftet nicht für

den Umgang mit oder Maßnahmen an der

Maschine, die diesen Anweisungen nicht

folgen.

28 - Deutsch

Page 29

Bedienungsanleitung FS 700EX

Bedienung

Vor dem Sägen

ACHTUNG!

Sicherheitsvorschriften beachten.

Sicherstellen, dass das richtige Anschlusskabel für den

Trennschleifer zur Verfügung steht.

Sicherstellen, dass der Kühlwasseranschluss des

Schlauchs mit dem an der Maschine übereinstimmt.

Den zu schneidenden Bereich einzäunen, damit keine

unbeteiligten Personen zu Schaden kommen oder den

Bediener bei der Arbeit stören können.

Vor dem Schneiden sind alle auszuführenden Schnitte

deutlich auf dem Boden zu markieren und zu planen,

sodass sie ohne Gefahr für Mensch oder Maschine

durchgeführt werden können.

Um Unterbrechungen und kritische Momente beim

Schneiden zu vermeiden, ist die Arbeit so zu planen, dass

die Trennscheibe von Anfang an auf der am besten

geeigneten Seite angebracht wird.

Sicherstellen, dass die korrekte Trennscheibe für die

Maschine und für den zu sägenden Untergrund verwendet

wird. Siehe Technische Daten.

Sicherstellen, dass Personen, die sich in der Umgebung

der Maschine aufhalten, Gehörschutz und Schutzbrille

tragen.

Die Maschine so bewegen, dass die Trennscheibe der

zuvor markierten Schnittlinie folgt.

Schutzausrüstung und Schutzkleidung müssen intakt

sein.

WARNUNG!

Genau prüfen, dass alle Strom-, Wasser-

und Gasleitungen im Schnittbereich

markiert sind. Sollte beim Schneiden eine

volle Gasleitung getroffen werden, ist dies

absolut lebensgefährlich.

Einbau/Austausch der

Trennscheibe

• Schneideinheit in die höchste Position bringen.

• Stromzufuhr unterbrechen.

• Vorwärtsantrieb der Maschine aktivieren, dazu den

Arm in die abgebildete Stellung bringen.

Sicherstellen, dass die Trennscheibe nicht verschlissen

ist. Eine verschlissene Trennscheibe ist daran zu

erkennen, dass die Resthöhe des Diamantsegments nur

2-3 mm beträgt oder das Segment nicht breiter ist als das

Stammblatt.

Sicherstellen, dass der Trennscheibenschutz nicht defekt

ist. Ein schadhafter Trennscheibenschutz darf niemals

verwendet werden.

Erst wenn Sie sich über die Funktion der Bedienelemente

der Maschine im Klaren sind, dürfen Sie die Maschine

starten.

Darauf achten, dass der Nothalt nicht blockiert wird. Der

Nothalt darf beim Betrieb nicht blockiert oder überdeckt

werden.

Sicherstellen, dass Längs- und Tiefenvorschubregler in

Nullstellung sind.

Alle fremden Gegenstände entfernen, die Maschine oder

Umgebung beschädigen können und im Weg sind.

Sicherstellen, dass sich keine Unbefugten innerhalb der

Sicherheitszone befinden, d. h. 4 m vor oder seitlich von

der Maschine.

• Trennscheibenschutz hochklappen und in dieser

Position mit dem Trennscheibenschutzhalter sichern.

• Trennscheibenflansche säubern und sicherstellen,

dass sie unbeschädigt sind.

• Trennscheibe einbauen und darauf achten, dass die

Drehrichtung mit dem Pfeil auf dem Trennscheibenschutz übereinstimmt. Ist die Drehrichtung nicht auf

dem Stammblatt angegeben, wird die Drehrichtung der

Trennscheibe mithilfe des Verschleißes der Diamantsegmente bestimmt, wobei der freigelegte Teil des Diamanten in Drehrichtung liegt.

• Trennscheibenflansch mit dem beiliegenden Schlüssel

fest anziehen, sodass er richtig fest sitzt. Mindestens

70 Nm.

Deutsch - 29

Page 30

Bedienungsanleitung FS 700EX

• Trennscheibenschutz herunterklappen.

• Trennscheibe von Hand drehen und sicherstellen,

dass sie sich frei und leicht drehen lässt und keine

ungewöhnlichen Geräusche auftreten. Auch darauf

achten, dass die Trennscheibe gerade sitzt. Niemals

mit einer defekten Trennscheibe arbeiten.

Anmerkung

Maschine anschließen

Stromkabel (400 V/16 A/3 Phasen/50 Hz) anschließen.

3 x 380-420 V

16 A 50 Hz

Daran denken, dass die Schraube, die den

rechten Trennscheibenflansch hält, ein

Linksgewinde hat.

Anmerkung

Die Trennscheibe sollte primär auf der linken

Maschinenseite montiert werden. Die

Montage auf der rechten Seite führt zu einer

Beeinträchtigung der Motorkühlung.

Kühlwasserschlauch mit dem vorgesehenen Anschluss

verbinden.

3 x 380-420 V

16 A 50 Hz

30 - Deutsch

Page 31

Bedienungsanleitung FS 700EX

Kühlwasser aufdrehen, sodass eine ausreichende

Kühlung erzielt und die Staubbildung vermieden wird.

Für eine reichliche Wasserzufuhr sorgen und darauf

achten, dass die Düsen nicht verstopft sind. Auch

sicherstellen, dass sich die Stoppschraube an dem Ende

der Trennscheibenachse befindet, an dem keine

Trennscheibe angeschraubt ist.

.

Sicherstellen, dass Stromkabel und Wasserversorgung

nicht unter die Maschine geraten oder im Weg sein

können; dazu den Schlauchhalter verwenden.

Die Trennscheibe muss sich frei drehen können, bevor die

Maschine gestartet wird.

Schneiden

Vorwärtsantrieb aktivieren, dazu den Arm mit dem Fuß in

die abgebildete Stellung bringen. Die Maschine bewegt

sich erst wieder, wenn der Regler für den Längsvorschub

aus der Nullstellung bewegt wird.

Deutsch - 31

Page 32

Bedienungsanleitung FS 700EX

Den Schalter in Richtung der leuchtenden Lampe drehen,

dann setzt die Rotation der Trennscheibe ein. Wird der

Schalter in die falsche Richtung gedreht, dreht sich auch

die Trennscheibe in der falschen Richtung.

WARNUNG!

Ein Kontakt mit der sich drehenden

Trennscheibe kann zu schweren

Verletzungen und sogar zum Tod führen.

0

Schneiden beenden

1

Regler für den Tiefenvorschub in Richtung Bediener

drehen und die Trennscheibe so einführen, dass eine dem

Bodenmaterial entsprechende Tiefe erreicht wird, jedoch

mindestens 20 mm.

Mit gleichmäßiger Geschwindigkeit eine Führungsnut in

dieser Tiefe und entlang der gesamten zuvor markierten

Linie schneiden. Ist die komplette Führungsnut

geschnitten, Trennscheibe anheben, Kühlwasser

abschalten und Trennscheibenrotation anhalten.

Maschine zum Startpunkt zurückfahren.

1

Schneideinheit in die höchste Position bringen.

Den Schalter in die Nullstellung drehen, um die

Trennscheibenrotation auszuschalten.

Längs- und Tiefenvorschub auf Null stellen.

Kühlwasser abschalten.

ACHTUNG!

Die Schutzvorrichtungen dienen Ihrer

Sicherheit, sie sollten daher regelmäßig

kontrolliert werden. Bei Störungen den

Händler kontaktieren.

Maschine nach der Führungsnut neu einstellen und wie

oben beschrieben starten.

Trennscheibe auf eine geeignete Schnitttiefe senken (510 cm). Die Schnitttiefe richtet sich nach dem

Bodenmaterial und der Geschwindigkeit.

Faustregel: Neigt die Maschine zum "Klettern" aus der

Führungsnut, ist die Schnitttiefe zu groß und/oder die

Geschwindigkeit zu hoch.

Die Maschine darf nicht schneller gefahren werden, als

sie ohne zu "Klettern" schneidet, d. h. die Vorderräder

heben sich vom Boden ab. Wenn die Maschine "klettert",

den Regler für den Längsvorschub im

Gegenuhrzeigersinn drehen, um den Längsvorschub zu

senken, oder den Regler für den Tiefenvorschub im

Uhrzeigersinn drehen, um die Trennscheibe anzuheben.

ACHTUNG!

Beim Schneiden muss sich der Bediener die

gesamte Zeit über hinter der Maschine und in

Reichweite von Bedienelementen und Nothalt

befinden.

32 - Deutsch

Page 33

Bedienungsanleitung FS 700EX

Transport

Beim Transport und beim Heben muss die Trennscheibe

stets ausgebaut sein. Wird die Trennscheibe nicht entfernt, ist sie der Gefahr von Beschädigungen ausgesetzt.

Beim Transport kann der Trennschleifer auf mehrere Arten

angehoben werden. Soll der Trennschleifer mithilfe eines

Krans bewegt werden, sind die Hebebänder an den

Hebeösen zu befestigen.

Um das Gewicht der Maschine zu reduzieren, kann die

Schneideinheit mit montiertem Elektromotor

abgenommen werden.

1. Sicherstellen, dass die Trennscheibe nicht montiert ist.

2. Schneideinheit in die tiefste Position bringen.

3. Wasserschlauch (a) und Stromanschluss (b) von der

Schneideinheit lösen.

4. Die beiden Schrauben (c) der Schneideinheit lösen

und die Einheit abheben.

b

c

WARNUNG!

Es dürfen sich niemals Personen unter

einer frei hängenden Maschine befinden.

Eine fallende Maschine kann tödliche oder

schwere Verletzungen zur Folge haben.

Soll der Trennschleifer nur über eine kürzere Strecke

gehoben werden, kann er am Handgriff und an der

vorderen Hubstange angehoben werden.

a

ACHTUNG

Daran denken, dass die falsche Hebetechnik

Ihrem Rücken schaden kann. Deshalb auf

eine korrekte Hebetechnik achten.

Wenn die Schneideinheit wieder angebracht werden soll,

die Einheit auf den Sägewagen stellen und in die

Schraublöcher einpassen. Um das Einpassen zu

erleichtern, sind an der Unterseite der Schneideinheit

zwei Kunststoffklötze angebracht.

Deutsch - 33

Page 34

Bedienungsanleitung FS 700EX

Wartung

Nach dem Schneidvorgang ist die Maschine zu reinigen.

Vor der Reinigung ist der Stromanschluss zu trennen.

Elektromotor und elektrische Anschlüsse dürfen nicht mit

Wasser in Kontakt kommen. Zum Reinigen der Maschine

eine Spülbürste oder einen Schwamm verwenden.

Anmerkung

Die Maschine nicht mit Hochdruck reinigen.

Den Zustand der Trennscheibe regelmäßig kontrollieren,

sie darf nicht verschlissen oder beschädigt sein. Bei

verschlissenen Segmenten oder wenn sich die

Segmentbreite der Stammblattbreite annähert, ist sie

auszutauschen.

Regelmäßig Stromkabel, Anschlüsse, Antriebsriemen und

Schraubverbindungen auf Unversehrtheit überprüfen.

Regelmäßig dafür sorgen, dass Antriebsriemen und

Anschlüsse nicht verschmutzt sind und der

Antriebsriemen die korrekte Spannung hat. Für die

Kontrolle der Antriebsriemenspannung muss der Schutz

um den Riemen zuerst ausgebaut werden.

Antriebsriemen bei Bedarf wie folgt spannen: Mutter (a)

lösen, Mutter unter dem Sockel mit einem Schlüssel

festhalten und dann die Schraube (b) drehen, bis der

Riemen gespannt ist. Die korrekte Riemenspannung

anschließend durch Aufschrauben der Mutter sichern.

Die Vorschubmutter muss in regelmäßigen Abständen

geschmiert werden. Die Mutter wird zugänglich, nachdem

die Maschinenrückseite entfernt wurde.

Bei ausgebauter Rückseite die Vorschubschraube ein

paar Zentimeter über und unter der Mutter einfetten.

Die Rückseite wie folgt wieder anbringen:

1. Klappe an der Oberkante einhängen.

2. Die Zahnräder für den Vorwärtsantrieb

auseinanderdrücken, dazu einen Meißel zwischen die

Zahnräder stecken und vorsichtig nach unten drücken.

Gleichzeitig die Rückseite an das Gestell des

Trennschleifers drücken.

3. Die Befestigungsschrauben der Rückseite wieder

anbringen.

a

WARNUNG!

BEI ALLEN WARTUNGS-, REPARATUR-

UND SERVICEARBEITEN MUSS DER

STROMANSCHLUSS GETRENNT SEIN.

b

Bei einer längeren Aufbewahrung muss die Maschine

sorgfältig gereinigt und das Wasser abgelassen werden.

34 - Deutsch

Page 35

Bedienungsanleitung FS 700EX

Fehlersuche

Bei Störungen ist in erster Hand zu untersuchen, ob der

Fehler einer der u. a. ist.

Ist der Fehler nicht im nachstehenden Schema aufgelistet,

ACHTUNG

wenden Sie sich bitte an Ihren Händler für weitere

Informationen.

Vor fehlerbehebenden Maßnahmen sicherstellen, dass alle Stromanschlüsse getrennt sind,

um ein versehentliches Starten der Maschine

während der Arbeit zu vermeiden.

Fehler Ursache Maßnahme

Trennscheibe dreht sich in die falsche

Richtung.

Trennscheibe festgefahren. Antriebsriemen rutscht durch.

Kein/zu wenig Wasser zur Trennscheibe. Schmutz im Trennscheibenflansch. Trennscheibenflansch reinigen.

Trennscheibe festgefahren. Trennscheibe verschlissen.

Startschalter steht falsch. Startschalter in die Richtung drehen, die

von der leuchtenden Lampe angezeigt

wird.

Antriebsriemen spannen.

Antriebsriemen schmutzig.

Antriebsriemen verschlissen.

Trennscheibe klemmt.

Trennschleifer zu hart gefahren.

Antriebsriemen reinigen.

Antriebsriemen austauschen.

Wasserdruck durch Aufdrehen der

Wasserventile erhöhen.

Trennscheibe austauschen.

Sägeblock mit Stützen oder Winde

unterstützen.

Mit geringerem Längsvorschub oder

geringerer Schnitttiefe arbeiten.

Motor startet nicht. Nothalt aktiviert.

Stromfehler.

Vorwärtsantrieb funktioniert nicht. Vorwärtsgang nicht eingelegt. Arm für den Vorwärtsantrieb umlegen,

Vorwärtsantrieb/Tiefenvorschub

funktioniert nicht.

Höhen-/Tiefenvorschub funktioniert nicht. Vorschubmutter in Endstellung

Die Maschine unterbricht/startet die

Trennscheibenrotation nicht.

Beide Anzeigelampen für die

Trennscheibenrotation leuchten.

Vorschubregler beim Einschalten des

Stroms nicht nullgestellt.

verklemmt.

Vorschubmutter trocken.

Temperatursensor im Motor hat

ausgelöst.

Eine Phase fehlt. Sicherungen und Kabel überprüfen.

Nothalt rückstellen.

Händler kontaktieren.

um den Vorwärtsgang zu aktivieren.

Trennscheibenrotation ausschalten und

Maschine nullstellen, Nothalt drücken

und Regler in Nullstellung drehen. 3 sek

warten und Nothaltknopf wieder

rückstellen.

Hintere Klappe abnehmen und

Vorschubmutter vorsichtig lösen, dazu

die Mutter ganz unten an der

Vorschubschraube drehen.

Vorschubachse einfetten.

Dem Motor Zeit zum Abkühlen geben.

Nach dem Abkühlen des Motors wird der

Trennschleifer wie üblich gestartet.

Deutsch - 35

Page 36

Bedienungsanleitung FS 700EX

36 - Deutsch

Page 37

Bedienungsanleitung FS 700EX

Deutsch - 37

Page 38

Bedienungsanleitung FS 700EX

EU-Erklärung

Husqvarna Construction Products Sweden AB, Box 2098, SE-550 02 Jönköping,

Schweden, Tel.: + 46 (0)36 570 60 00 bescheinigt hiermit, dass die Herstellung des

Trennschleifers FS 700E ab dem 1. Januar 2001 folgenden Richtlinien des Rates

einschließlich aller Änderungen entspricht: 98/37/EG über Maschinen, 73/23/EWG

„Niederspannungsrichtlinie“ und 89/336/EWG über elektromagnetische Verträglichkeit.

Folgende Standards dienten als Grundlage: EN 55 014-1, EN 55 014-2, EN 61 000-3-2,

EN 50 144-1, EN 13 862.

Jönköping, den 01.01.2005

Christer Carlberg

Geschäftsführer

38 - Deutsch

Page 39

Gebruiksaanwijzing FS 700EX

Inhoudsopgave

Nederlands

Inhoudsopgave

Verklaring van de symbolen....................... 41

Veiligheidsinstructies ................................. 43

Inleiding ........................................................ 45

Wat is wat .....................................................47

Technische gegevens ................................. 49

Gebruik ......................................................... 51

Voor het zagen ............................................ 51

Monteren/Vervangen van schijf ..................51

De machine aansluiten ...............................52

Zagen .......................................................... 53

Zagen beëindigen ....................................... 54

Transport ...................................................... 55

Onderhoud ................................................... 56

Opsporen van storingen .............................. 57

EU-verklaring ............................................... 59

Nederlands - 39

Page 40

Inhoudsopgave Gebruiksaanwijzing FS 700EX

40 - Nederlands

Page 41

Gebruiksaanwijzing FS 700EX

Verklaring van de symbolen

Onderstaande symbolen komen voor op de machine en in

het handboek voor de machine. Om op een veilige manier

met de machine te kunnen werken is het belangrijk dat de

gebruiker hun betekenis begrijpt.

Boek

Neem de gebruiksaanwijzing grondig door en start de

machine niet voor u alles duidelijk hebt begrepen.

Beschermingsuitrusting

Draag altijd:

• Goedgekeurde veiligheidshelm.

• Goedgekeurde gehoorbescherming.

• Goedgekeurde veiligheidsbril of vizier, en andere

noodzakelijke beschermingsuitrusting.

Opmerking

Een hand met uitgestoken wijsvinger en daarbij

”Opmerking” betekent dat een beschreven moment extra

aandacht vereist.

CE

Dit symbool geeft aan dat de machine overeenstemt met

geldende EG-richtlijnen.

ELEKTRICITEITS-waarschuwing

Dit symbool waarschuwt voor de aanwezigheid van hoge

spanning.

Waarschuwing

Een grotere waarschuwingsdriehoek met daarop

”Waarschuwing” betekent dat het risico bestaat van

ernstig persoonlijk letsel of zelfs overlijden.

Opgelet

Een kleinere waarschuwingsdriehoek met daarop

”Opgelet” betekent dat het risico bestaat van minder

ernstig persoonlijk letsel of beschadigingen aan de

machine.

Informatie met betrekking tot het milieu

Het symbool op het product of de verpakking betekent dat

dit product niet mag worden behandeld als gewoon

huishoudelijk afval, maar in plaats daarvan moet worden

ingeleverd bij het punt voor recycling van elektrische en

elektronische apparatuur.

Door dit product correct te verwijderen helpt u om de

negatieve gevolgen die een verkeerde verwerking van dit

product kan hebben voor het milieu en de gezondheid te

voorkomen.

Voor verdere informatie over recycling van dit product kunt

u contact opnemen met uw gemeente, de relevante dienst

voor de verwerking van huishoudelijk afval of de winkel

waar u het product hebt gekocht.

Nederlands - 41

Page 42

Gebruiksaanwijzing FS 700EX

42 - Nederlands

Page 43

Gebruiksaanwijzing FS 700EX

Veiligheidsinstructies

Bij de constructie en productie van Husqvarna producten

hebben we veel aandacht geschonken aan het feit dat ze,

naast efficiënt en eenvoudig te hanteren, ook veilig

moeten zijn. Opdat de machine veilig blijft, moeten

onderstaande zaken in acht worden genomen:

• Let op dat de machine absoluut niet mag worden

gestart zonder dat de veiligheidsinstructies worden

gevolgd. Indien de gebruiker dit niet doet, draagt

Husqvarna Construction Products Sweden AB of diens

vertegenwoordiging geen enkele aansprakelijkheid,

direct of indirect.

Lees deze gebruiksaanwijzing door en zorg ervoor dat

u de inhoud begrijpt voor u de machine gaat

gebruiken. Wanneer u, nadat u deze

veiligheidsinstructies hebt gelezen, nog niet zeker bent

over de veiligheidsrisico’s die er zijn, moet u de

machine niet gebruiken.

Neem contact op met uw dealer wanneer u meer

informatie nodig hebt.

• Controleer of alle koppelingen, aansluitingen en de

schijfbeschermer heel zijn.

• Zorg ervoor dat alle slangen en elektriciteitsleidingen

op de juiste manier op de machine zijn aangesloten

voor u de machine start.

• De veiligheidsafstand is 4 m voor en naast de zaag.

• Zorg ervoor dat er geen personen of dieren binnen het

werkgebied aanwezig zijn.

• Controleer of de schijfbescherming resp. kap voor de

zaagflens goed zijn gemonteerd.

• Zaag nooit zo dat u niet op eenvoudige wijze bij de

noodstop kunt komen.

de bewegende delen van de machine, mag niet

worden gebruikt.

• Mensen die zich in de omgeving ophouden, dienen

gehoorbescherming te dragen.

• De machine mag niet worden gedraaid, gezwaaid of

naar de zijkant worden verplaatst wanneer de schijf

draait.

• Gebruik alleen schijven die door de producent worden

aangeraden.

• Zaag nooit zonder schijfbeschermer.

• Zaag nooit zonder koelwater. Een slecht gekoelde

schijf kan ertoe leiden dat segmenten van de schijf

losraken. Het koelwater bindt zelfs betonstof.

• Gebruik nooit een beschadigde of versleten schijf.

• Gebruik de machine niet als deze niet naar behoren

functioneert.

• Bepalingen ter voorkoming van ongelukken, andere

veiligheidsbepalingen en beroepsmedische richtlijnen

moeten altijd worden gevolgd.

• Bewaar de machine in een afgesloten ruimte, waar

deze niet toegankelijk is voor kinderen en

volwassenen die niet hebben geleerd hoe ze met de

machine moeten omgaan.

• Zeker of veranker losgezaagde betonblokken goed.

Het grote gewicht van het materiaal dat wordt

losgezaagd kan tot groot letsel leiden als het niet

gecontroleerd wordt verplaatst.

• Zorg er altijd voor dat er nog iemand aanwezig is

wanneer u de machine gebruikt, zodat u om hulp kunt

roepen mocht een ongeluk plaatsvinden.

• Laat de machine nooit zonder toezicht achter met

draaiende motor.

• Voor het zagen moeten alle sneden, die moeten

worden gemaakt, duidelijk op de vloer worden

aangegeven en gepland, zodat dit zonder gevaar voor

mens of machine kan worden uitgevoerd.

• Controleer aan de hand van de bouwtekeningen of er

elektrische leidingen, waterleidingen, gasleidingen of

afvoerleidingen binnen het werkgebied liggen.

• Controleer of de elektrische leidingen binnen het

werkgebied stroomloos zijn.

• Wees voorzichtig met tillen. U gaat om met zware

delen wat risico van beknelling en ander letsel inhoudt.

• Persoonlijke beschermingsuitrusting volgens de

gebruiksaanwijzing en veiligheidskleding moeten altijd

worden gebruikt. Kleding, die vast kan komen zitten in

WAARSCHUWING!

Gebruik altijd goedgekeurde bescher-

mingskleding en goedgekeurde beschermingsuitrusting wanneer u de machine

gebruikt. Beschermingskleding en beschermingsuitrusting kunnen het risico van ongelukken niet geheel uitsluiten, maar door

het dragen van de juiste kleding en de

juiste uitrusting kunt u wellicht de ernst van

eventuele verwondingen reduceren, mocht

een ongeluk plaatsvinden. Vraag uw dealer

welke goedgekeurde beschermingskleding

en welke goedgekeurde beschermingsuitrusting hij aanraadt.

Nederlands - 43

Page 44

Gebruiksaanwijzing FS 700EX

44 - Nederlands

Page 45

Gebruiksaanwijzing FS 700EX

Inleiding

De FS-serie is een nieuwe serie elektrische vloerzagen

van Husqvarna. Met deze ontwikkeling hadden wij voor

ogen een krachtige, maar toch gemakkelijk te hanteren

machine te maken om in gewapend beton, baksteen en

ander steenmateriaal te zagen. De machine moet ook

gemakkelijk te hanteren zijn voor één persoon.

De FS-serie heeft zowel elektrische langsbeweging als

invoer. Deze worden beide gestuurd door hendels die op

de verstelbare handgreep zijn gemonteerd.

Om transport van de vloerzaag te vergemakkelijken kan

de handgreep ingeklapt worden en het zaagplatform kan

op een eenvoudige manier losgehaald worden. Hierdoor

wordt het tillen lichter en neemt de zaag minder ruimte in

tijdens transport.

Een zaag wordt geleverd met een flens en een

schijfbeschermer. Als accessoire zijn een vlakzaagflens

en een vlakzaagschijfbeschermer verkrijgbaar.

Om deze machine zo efficiënt mogelijk te kunnen

gebruiken, is het belangrijk dat u als gebruiker deze

handleiding zorgvuldig doorleest. Mochten er op een

bepaald punt onduidelijkheden bestaan, moet u dit met

uw leverancier opnemen voor u de machine in gebruik

neemt.

Nederlands - 45

Page 46

Gebruiksaanwijzing FS 700EX

46 - Nederlands

Page 47

Gebruiksaanwijzing FS 700EX

Wat is wat

12

15

13

12

3

14

1. Hendel voor langsbeweging

Met deze hendel wijzigt u de aandrijving van de

machine. De machine gaat naar voren door de hendel

met de klok mee te draaien. Als de hendel tegen de

klok in wordt gedraaid, gaat de machine achteruit.

Wanneer de hendel in de nulstand staat, staat de

machine stil. Deze functie werkt zodra de machine op

stroom is aangesloten en de aandrijving van de

machine is ingeschakeld.

2. Invoerhendel

Met deze hendel verhoogt of verlaagt u het

zaagplatform. De schijf gaat naar beneden door de

hendel tegen de klok in te draaien. Wanneer u de

gewenste zaagdiepte hebt verkregen, zet u de hendel

weer in nulstand. U brengt de schijf omhoog door de

hendel met de klok mee te draaien. Deze functie werkt

zodra u de machine op stroom hebt aangesloten.

3. Waterhendel

Door deze hendel tegen de klok in te draaien opent u

de waterklep. Het water gaat door de as van de schijf

naar de zaagflens waar het water de schijf koelt en

stofvorming voorkomt.

4. Startknop

Wordt gebruikt om het draaien van de schijf te starten.

5

4

5. Noodstop

Onderbreekt alle stroom naar de machine. Geen

enkele functie werkt voordat u de noodstop weer reset.

U reset de noodstop door de knop uit te trekken.

6. Elektrische aansluiting

Voor het aansluiten van elektrische schakelingen van

het type:

5-polig 400 V/16 A.

7. Wateraansluiting

Hier sluit u het koelwater op de machine aan.

8. Een-fase 230 V uitgang

Om 230 V gereedschap op de machine aan te sluiten.

9. Persoonlijke bescherming

Onderbreekt de stroom naar de een-fase uitgang bij 30

mA aardefout.

10.Aandrijving/Parkeerrem

Wanneer de arm in de stand staat, die op de

afbeelding te zien is, is de aandrijving ingeschakeld.

Als de arm in deze stand staat en de hendel voor

langsbeweging staat op nul of als er geen stroom

ingeschakeld is, werkt deze stand als parkeerrem.

11

7

8

10

6

9

Nederlands - 47

Page 48

Gebruiksaanwijzing FS 700EX

Als de arm in de andere stand wordt gezet, is er geen

versnelling ingeschakeld en kunt u de machine

gemakkelijk verplaatsen. Gebruik deze stand als u de

machines over langere afstanden moet verplaatsen.

11.Slanghouder

Door het gebruik van de slanghouder voorkomt de

gebruiker dat slangen en kabels achter de machine

aan slepen. In plaats daarvan zullen ze naast de

machine liggen.

12.Schijfbeschermer

Kan naar wens zowel aan de rechter- als de linkerkant

van de machine worden gemonteerd. De

schijfbeschermer kan rechtop worden vastgezet door

de hendel aan de achterkant van de kap te gebruiken.

13.Spatbescherming

Om waterspatten en vies worden van de machine te

minimaliseren, is de machine uitgerust met een

opklapbare spatbescherming. Als u de zaag over

langere afstanden wilt verplaatsen, moet u de

spatbescherming opklappen en met de veer op de

schijfbeschermer vastmaken. Tijdens het zagen moet

de spatbescherming altijd ingeklapt zijn.

14.Zaagflens

Om de schijf gemakkelijk te kunnen monteren aan de

machinekant naar keuze, past de zaagflens op beide

kanten van de machine.

De zaagflens, waarop geen schijf is gemonteerd, moet

u afdekken met de flenskap, die bij levering aan de

rechterkant is gemonteerd.

De machine wordt geleverd met een normale zaagflens. Een flens om vlak te zagen is verkrijgbaar als

optie. Monteer de schijf op de vlakzaagflens, wanneer

de snede vlakbij een muur moet liggen. Bij vlakzagen

moet u speciale schijfbeschermers gebruiken.

15.Handgreepinstelling

Door deze twee schroeven los te draaien kan de

hoogte van de handgreep worden ingesteld op de

meeste geschikte hoogte.

16.Stelschroef

Stel deze schroef af om de aandrijfriem op te spannen.

16

17.Motorsteun

Door deze schroeven los te draaien kunt u het

zaagplatform met motor wegtillen om een lichtere

machine te krijgen.

17

48 - Nederlands

Page 49

Gebruiksaanwijzing FS 700EX

Technische gegevens

Gewicht (excl. schijf): _____________ 155 kg

Gewicht (incl. schijf):______________

Motorvermogen: ____________________ 7,5 kW

Spanning: _________________________ 400 V/3 fase/50 Hz

Stroomsoort _______________________ 16 A

Max. toeren aandrijfas: _______________ 1780 rpm

Randsnelheid, schijf _________________ 56 m/s

Maximale schijfdiameter______________ 725 mm

Max. zaagdiepte ____________________ 298 mm

150 kg

Max. zaagdiepte:

600 mm (23") schijfdiameter___________ 235 mm (9,25")

625 mm (24") schijfdiameter___________ 248 mm (9,76")

700mm (28,6") schijfdiameter__________ 285 mm (11,2")

725mm (29") schijfdiameter ___________ 298 mm (11,7")

Wij raden aan Husqvarna W1100 schijven in combinatie

met deze machine te gebruiken.

OPGELET

Wanneer u onzeker bent over de betekenis

van de technische specificaties of wanneer

u reserveonderdelen bestelt, moet u contact

opnemen met uw dealer.

WAARSCHUWING!

Onder geen enkele omstandigheid mogen

wijzigen aan de machine worden uitgevoerd

zonder schriftelijke toestemming van Husqvarna Construction Produkts Sweden AB.

Met niet-goedgekeurde wijzigingen lopen

u en anderen risico op ernstig of levensbedreigend letsel. Husqvarna Construction

Products Sweden AB is niet verantwoordelijk voor onderhoud of maatregelen die deze

instructies niet volgen.

Nederlands - 49

Page 50

Gebruiksaanwijzing FS 700EX

50 - Nederlands

Page 51

Gebruiksaanwijzing FS 700EX

Gebruik

Voor het zagen

N.B.!

Volg de veiligheidsvoorschriften.

Controleer of u de juiste aansluitkabel voor de zaag hebt.

Controleer of de koelwaterkoppeling op de slang hetzelfde

type is als de koppeling die op de machine zit.

Omkader het terrein dat gezaagd moet worden, zodat

onbevoegden niet verwond kunnen raken of de operator

tijdens het werk kunnen storen.

Voor het zagen moeten alle zaagsneden die moeten

worden gemaakt, duidelijk op de vloer worden

aangegeven en gepland, zodat dit zonder gevaar voor

mens of machine kan worden uitgevoerd.

Om onderbrekingen en irritatiemomenten tijdens het

zagen te voorkomen, moet u het werk zo plannen dat u de

schijf gelijk op de meest geschikte kant monteert.

zaaglijn volgt.

Controleer uw beschermingsuitrusting en evt.

beschermingskleding.

WAARSCHUWING!

Controleer zorgvuldig of alle elektrische

leidingen, waterleidingen en gasleidingen

binnen het zaaggebied aangegeven zijn. In

een niet lege gasleiding zagen is direct

verbonden met levensgevaar.

Monteren/Vervangen van schijf

• Hijs het zaagplatform naar de hoogste stand.

• Schakel de inkomende elektrische aansluiting uit.

• Schakel de aandrijving van de machine in, door de arm

te plaatsen zoals hieronder aangegeven.

Controleer of u de juiste schijf hebt voor de machine en

voor de ondergrond die moet worden doorgezaagd. Zie

technische gegevens.

Controleer of de schijf niet versleten is. De schijf is

versleten wanneer nog slechts enkele millimeters van het

diamantsegment over zijn of wanneer het

diamantsegment niet breder is dan de stamschijf.

Controleer of de schijfbeschermer niet beschadigd of

kapot is. Een kapotte of beschadigde schijfbeschermer

mag nooit worden gebruikt.

Vergewis u ervan dat u goed begrijpt hoe de bedieningen

van de machine werken, voor u de machine start.

Zorg ervoor dat de noodstop niet is geblokkeerd. De

noodstop mag tijdens gebruik niet worden geblokkeerd of

afgedekt.

Controleer of de langsinvoer- en hendel voor invoer

omlaag in de nulstand staan.

Verwijder alle vreemde voorwerpen die de machine of de

omgeving kunnen beschadigen en die in de weg liggen

voor de machine.

Controleer of er geen onbevoegden binnen de

veiligheidsafstand aanwezig zijn, d.w.z. 4 meter voor of

naast de machine.

Zorg ervoor dat personen in de buurt van de machine

gehoorbescherming en een veiligheidsbril dragen.

Verplaats de machine zo dat de schijf de voorgetrokken

• Klap de schijfbeschermer omhoog en bevestig deze in

opgeklapte stand door de houder van de

schijfbeschermer te gebruiken.

• Maak de zaagflenzen schoon en controleer of ze niet

beschadigd zijn.

• Monteer de schijf en controleer of de rotatierichting

klopt met de pijl op de schijfbeschermer. Indien de

rotatierichting niet op de stamschijf is aangegeven,

moet u de rotatierichting van de schijf bepalen aan de

hand van de slijtage van de diamantsegmenten, de

vrijgekomen deel van het diamant moet dan in de

rotatierichting liggen.

• Draai de zaagflens met de meegeleverde sleutel hard

aan, zodat deze goed vastzit. Ten minste 70 Nm.

• Klap de schijfbeschermer omlaag.

• Controleer of de schijf vrij en gemakkelijk draait, door

deze met de hand te bewegen, en controleer of er

geen rare geluiden te horen zijn wanneer u de schijf

draait. Controleer ook of de schijf recht gemonteerd is.

Nederlands - 51

Page 52

Gebruiksaanwijzing FS 700EX

Zaag nooit met een beschadigde schijf.

Opmerking