Page 1

EN

Operator´s manual p. 3

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

DE

NL

IT

Bedienungsanweisung p. 19

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie

sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Gebruiksaanwijzing p. 35

Neem de gebruiksaanwijzing grondig door en gebruik de machine

niet voor u alles duidelijk heeft begrepen.

Istruzioni per l’uso p. 51

Prima di usare la macchina, leggere per intero le istruzioni per l’uso

e accertarsi di averne compreso il contenuto.

CS 2512

EN DE NL IT

HUSQVARNA CONSTRUCTION PRODUCTS

Page 2

Page 3

5

6

7

8

10

11

12

12

13

14

14

14

15

15

Operator's Manual CS 2512

Contents

English

Contents

Key to symbols

Safety Instructions

Introduction

What is what

Technical data

Assembling/Installing equipment

Connection to the hydraulic unit

Threading the wire

Placement of the cooling water

Operation

Sawing

........................................................................

...............................................................................

Finishing sawing

..............................................................

......................................................

......................................................................

....................................................................

.............................................................

...........................

.......................................................

.............................

...........................................................

...................

Cleaning

Maintenance

............................................................................

...................................................................

EU declaration of conformity

.............................

English - 3

17

Page 4

4

Contents

Operator's Manual CS 2512

- English

Page 5

Pr

W

CE

Operator's Manual CS 2512

Key to symbols

The symbols belo w are used on the machine and in this

Operator's Manual. It is important that the user

understands the significance of these in order to work with

the machine safely.

Man ual

Please read the Oper ator's Manual carefully and

understand the contents before the machine is started.

otective equipment

Alw ays wear:

• Approved protective helmet.

• Approved hearing protection.

Key to symbols

Remark

A hand with a r aised index finger with the text “Attention”

signifies that a described element demands extra

attention.

This symbol indicates that the machine conf orms to

applicable EU directives.

• Approved protective glasses or a visor, and other

essential safety equipment.

arning

A large w arning triangle with the text “Warning” signifies

that there is a risk of serious personal injury or even

death.

Caution

A smaller w arning triangle with the text “Note” signifies

that there is a risk of minor personal injury or damage to

the machine.

English -

5

Page 6

6

W

Sw

y

Safety Instructions

Safety Instructions

Dur ing the design and production of Husqvarna products,

great importance is placed on safety, as well as effectiveness and ease of use. To ensure that the machine remains

safe you must pay attention to the following points:

ARNING!

This mac hine is onl y intended f or use

tog ether with a Husqv arna PP 455E or a

unit connected to Husqv arna RC 455. All

other use is f orbid den.

CAUTION

Under no circumstances ma y the machine be

star ted without obser ving the saf ety

instr uctions . Should the user f ail to comply

with these , Husqv ar na Constr uction Products

eden AB or its representativ es are free

from all liability both directly and indirectly .

Read through these oper ating instr uctions and

mak e sure that y ou understand the contents

bef ore star ting to use the machine . Should

ou, after reading these saf ety instr uctions,

still feel uncertain about the safety risks

involved you must not use the machine Please

contact your dealer for more information.

Operator's Manual CS 2512

• Do not misuse hoses.

• Do not use hoses that are distorted, worn, or

damaged.

• Check that the hoses are connected correctly to the

machine and that the hydraulic couplings lock as

intended before pressurising the hydraulic system. The

couplings are locked by turning the outer sleeve on the

female coupling so that the slot moves away from the

ball.

• Keep the hydraulic hoses and couplings free from dirt.

• Always switch off the power to the hydraulic unit before

moving equipment.

• Always saw in a manner that permits easy access to

the emergency stop.

• Never leave the machine unsupervised with the motor

running.

• Clearly mark out all cuts to be made before you start

sawing, plan these so they can be carried out without

danger to persons or the machine.

• Check with building drawings whether electrical cables,

water pipes, gas pipes or sewage pipes have been

routed within the working area.

• Always check and mark out where gas pipes are

routed. Cutting close to gas pipes always entails

danger. Make sure that sparks are not caused when

cutting in view of the risk of explosion. Remain

concentrated and focused on the task. Carelessness

can result in serious personal injury or death.

• Check that all couplings, connections and hydraulic

hoses are in full working order.

• Make sure that all hoses are connected to the machine

correctly before you start the machine.

• Make sure that there are no persons or animals in the

working area.

• Check that the guard is not broken and that it is fitted

correctly.

• Never cut without using the guard.

• Never disconnect the hydraulic hoses without first

shutting off the hydraulic unit and ensuring the motor

has stopped completely.

• Check the machine, couplings and hydraulic hoses

daily for leakage. A rupture or leak can cause a

”hydraulic fluid injection” in the body or result in other

serious physical injury.

• Do not exceed the specified hydraulic fluid flow or

pressure for the tool being used. Too high pressure can

result in rupturing.

• Check that electrical cables within the working area are

not live.

• Hoses that are marked and approved as electrically

non conductive must be used when using hydraulic

tools on or in the vicinity of electrical cables. The use of

other types of hoses can result in serious physical

injury or even death.

• Observe care when lifting. You are handling heavy

parts, which implies the risk of pinch injuries or other

injuries.

• Personal protective equipment and protective clothing

as set out in the Operator's manual must always be

worn. Never wear loose fitting clothes that can catch in

moving parts.

• Only use wire recommended by the manufacturer.

• Never cut without using the cooling water. A poorly

cooled wire can result in the segments overheating,

which results in greater wear. In the worst case

scenario, segments can come loose from the wire and

injure persons close to the saw.

- English

Page 7

Introduction

Husqvarna CS 2512 is designed for use together with the

hydraulic unit PP 455 E or Husqvarna RC 455. Husqvarna

CS 2512 is a powerful and easy to use wire saw with a

capacity for really large work, yet at the same time

sufficiently compact and mobile for small work. It can be

used in many different ways, both on the ground and fitted

to the wall.

The well thought-out design of the CS 2512, where the

drive wheel is placed on the machine's output side means

that the wire is always under tension even when the feed

force is low. Combined with the adjustable pressure valve

this gives exact control of cutting and unbeatable

performance.

The machine can be rigged both vertically and horizontally

and many cuts can be made directly without external idler

wheels.

Complete saw equipment consists of:

IntroductionOperator's Manual CS 2512

1 x saw unit

1 x accessory box

1 x 18 mm wrench

1 x pressure reduction block

1 x extra wear rubber for the magazine wheel

1 x cleaning brush

English - 7

Page 8

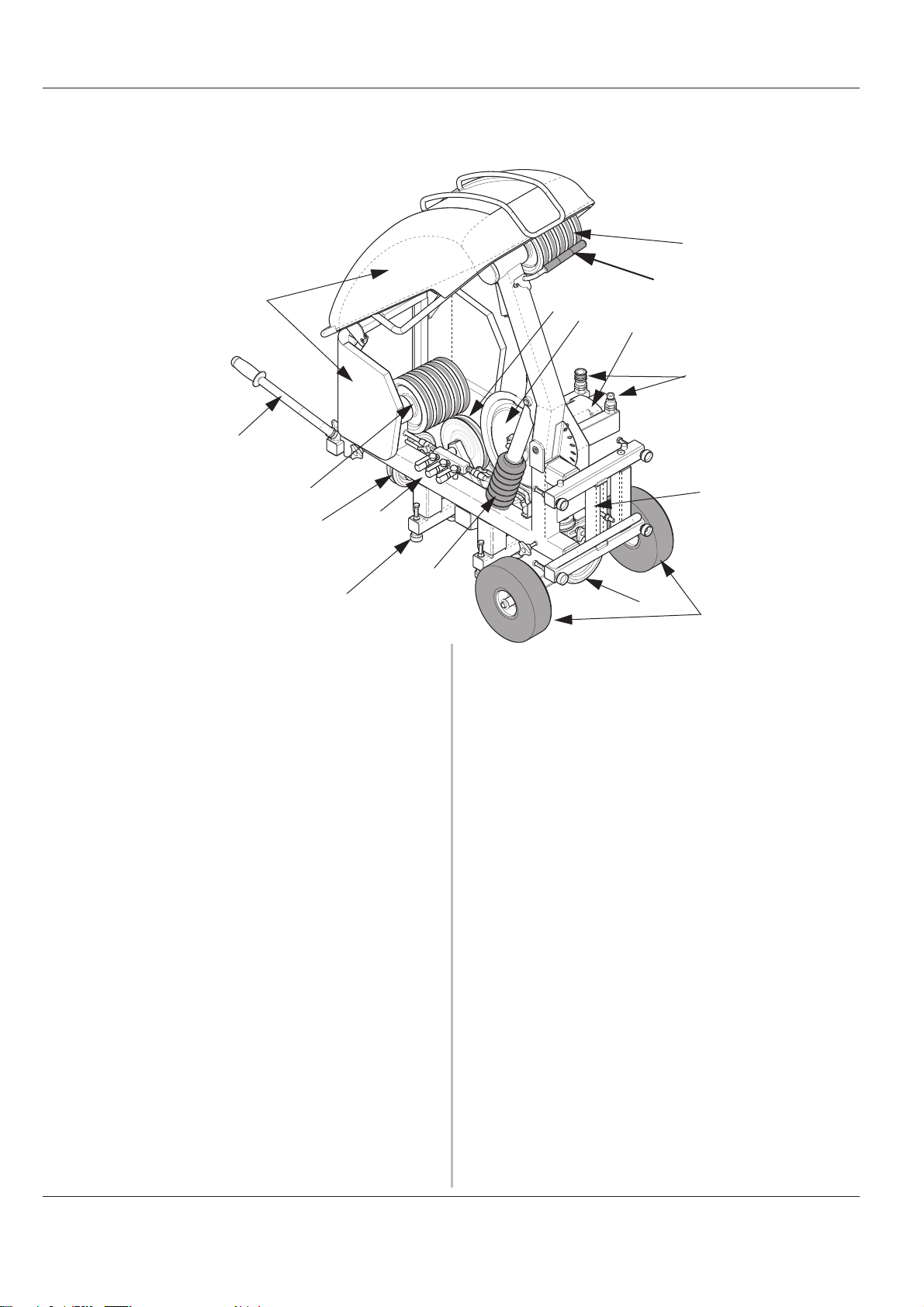

What is what Operator's Manual CS 2512

What is what

4

6

7

4

14

The saw consists of the following component parts:

1. Hydraulic motor

The machine is powered by a 60 cubic centimetre

motor. The motor has two parts, one of 50 cubic

centimetres and a smaller part of 10. Two gears are

obtained by using either just the large motor or both

the large and small motors together. The two gears

give different speeds, yet the same power.

2. Hydraulic hose connections

9

8

5

4. Wire magazine

Tensions the wire and stores recovered wire. The wire

magazine has a capacity to store a maximum of 12

metres of wire (2.4 metres per wheel set).

5. Magazine cylinder

The magazine cylinder tensions the wire in the

magazine and with that governs cutting. The pressure

in the cylinder is adjusted by means of the pressure

reduction block fitted on PP 455E or RC 455.

15

11

3

1

2

12

14

10

The hydraulic flow in the two large hoses drives the

machine's motor and with that the wire. The flow in the

two smaller hoses drives the magazine cylinder.

3. Drive wheel

Transfers the motive force from the motor to the wire.

The drive wheel is 400 mm in diameter and is covered

with replaceable rubber to give as good grip as

possible between the drive wheel and wire.

The drive wheel forms together with the hydraulic

motor and the hydraulic connections the drive wheel

unit. The drive wheel unit is adjusted depending on

how many wheel sets are used in the magazine. These

can easily be dismantled to give a lighter machine

during transporting.

8 - English

6. Guard

The machine has a two-piece guard. A fixed part made

of sheet metal and a folding cover made of plastic and

metal. The guard is easy to remove, e.g. when the wire

is threaded, it should always be fitted in position when

cutting.

7. Lifting handle

The folding handle is the perfect aid when transporting

the machine.

8. Adjustable feet

Adjusted so the saw stands firmly. In total, the saw

features 10 feet, six for horizontal cutting and four for

the vertical position.

Page 9

What is whatOperator's Manual CS 2512

9. Cooling water connections

There are two connections on the machine for water

spears and one for the incoming water. Besides

cooling the wire with these, the wire is also rinsed

when it returns to the machine and when it leaves the

machine by small nozzles.

10.Rubber wheels

To facilitate transport. The wheels can be dismantled in

some situations to facilitate access on certain jobs.

This is done by removing the split pins that lock the

wheels on the wheel axle.

11.Wire boom

Holds the wire in against the magazine when the magazine is run in. This prevents the wire tangling when

not tensioned, e.g. when changing the wire or when

changing the number of wheels used in the magazine.

12.Anchor beam

Adjustable beam with a longitudinal slot. By moving

this beam sideways, you can position the anchor bolt in

a suitable position without the need of moving the

entire saw when anchoring the saw before cutting.

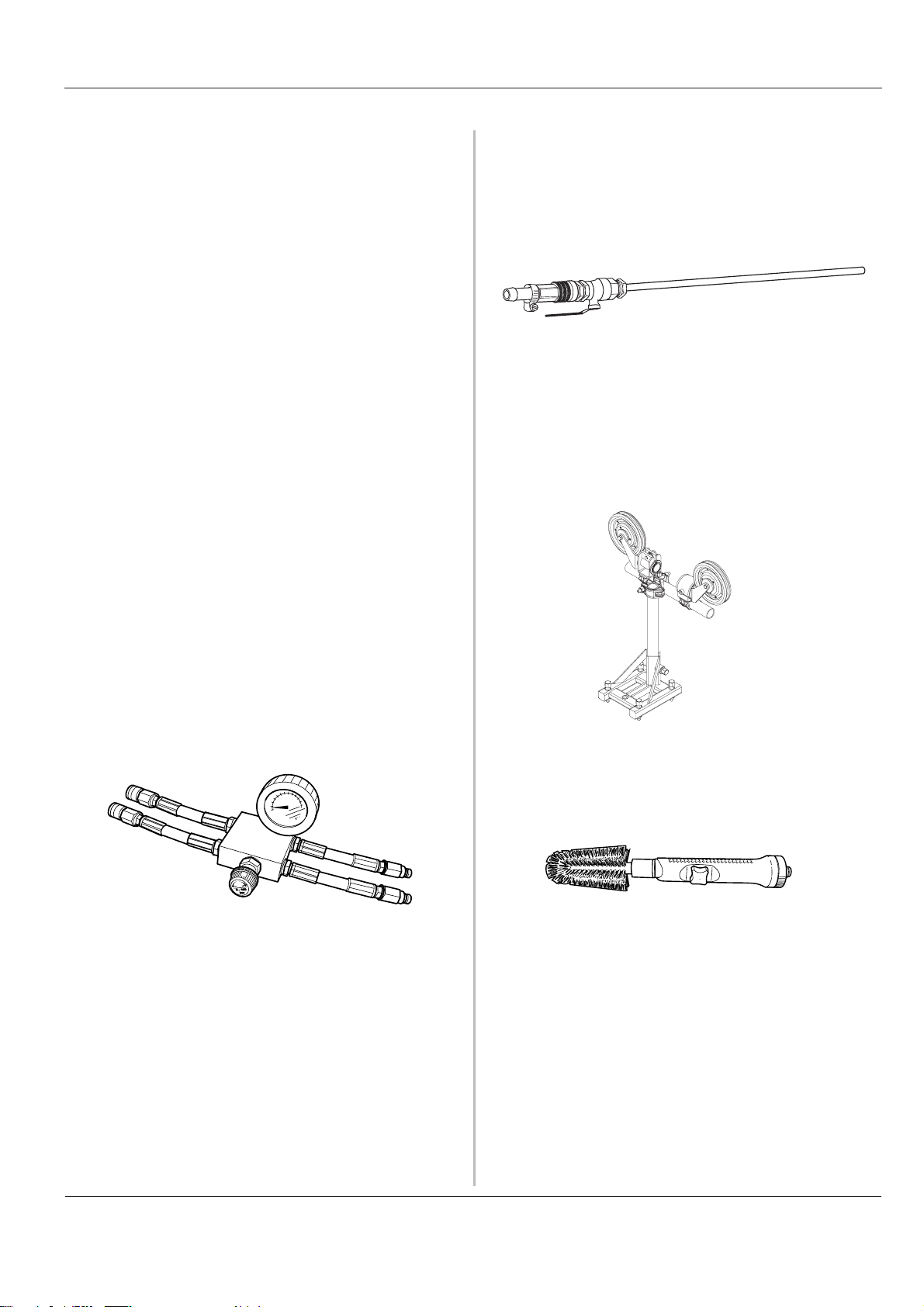

Accessories

1. Water spear

Connected to the water connections on the saw and

used to guide cooling water into the cut to cool the wire

and to bind the concrete dust.

2. Idler wheels

Husqvarna idler wheels are designed to smoothly

guide the wire as efficiently as possible. By using idler

wheels the number of sharp corners to cut around can

be reduced, which means that more of the cutting

capacity is used for material removal.

An additional anchor beam is placed under the saw.

The anchor bolt is secured in this beam when

horizontal cutting.

13.Pressure reduction block

The pressure reduction block is fitted between the

hydraulic unit and the hydraulic hoses for the input supply. There is a valve located on the pressure reduction

block, this is used to control the magazine tension.

14.Swivel wheels

The swivel wheels supported on bearings are located

where the wire enters the saw and out through the

saw. The swivel wheels help to guide the wire so it is

positioned correctly in the saw and can either be

locked in a fixed position or used in the unlock position

so that the wheels follow the wire.

3. Cleaning brush

Can be connected to the water hose and then used to

clean the machine after use.

15.Guide wheel

Guides the wire from the magazine to the drive wheel.

When the drive wheel unit is adjusted, the guide wheel

is set automatically depending on the number of

magazine wheels used.

English - 9

Page 10

Technical data Operator's Manual CS 2512

Technical data

Power on drive wheel (with PP 455): ____ 20 kW

Hydraulic oil flow: ___________________ 65l/min (17 gal/min)

Max permitted hydraulic pressure ______ 230 bar (3400 psi)

Max recommended hydraulic

pressure

Maximal wire length in the magazine: ___ 12 m

Dimensions, handle folded in and

the

Weight:___________________________ 150 kg ( 330lbs)

Wire speed gear 1 __________________ 20 m/s (66 ft/s)

Wire speed gear 2 __________________ 25 m/s (82 ft/s)

when cutting:_______________ 130 bar (1900 psi)

(2.4 m/wheel set)

guard folded down (L x W x H) ______ 1150x750x980 mm

Recommended wires:

Husqvarna recommends that the following wires are used:

• Husqvarna C710C

Husqvarna C710C is a galvanised wire developed for

use when cutting concrete with a great deal of

reinforcement. The segments have a great number of

diamonds and a smaller diameter (9.5mm) which

means the wire cuts very efficiently. The smaller

diameter also means that C710C can be used to finish

difficult cuts.

• Husqvarna C750C

Husqvarna C750C is an all round wire developed for

use when cutting reinforced concrete. The wire has

been designed for use with saws with an output power

between 10 and 25 kW.

• Husqvarna C760C

This is the Husqvarna premium wire: long life, high

cutting rate and high power resistance characterize

this wire. Husqvarna C760C can be used to cut all

types of reinforced concrete, even when the work

places high demands on the wire, for example when

cutting bridges.

• Husqvarna C790C

The segment strength on this wire makes Husqvarna

C790C the best choice when cutting soft materials

such as mortar, and lightly reinforced limestone

concrete.

• Husqvarna C575J

Husqvarna C575J is a wire with galvanised 15 mm

segments.

Husqvarna C1200M

HusqvarnaC1200M is a wire developed for use when

cutting steel. The wire has been designed for use in

WARNING

Under no circumstances may

modifications be made to the machine

without written permission from

Husqvarna Construction Products Sweden

AB. Non approved modifications put you

extremely demanding situations. The use of the latest

sintering technique has given enormous advantages

with regard to cutting rates and life span. The wire can

be supplied with either joined or loose ends.

For further information about different tools from

Husqvarna, contact your Husqvarna dealer.

and others at risk of serious or fatal

injuries. Husqvarna Construction Products

Sweden AB bears no responsibility for

operations that do not conform to these

instructions.

10 - English

Page 11

Operator's Manual CS 2512

English - 11

Page 12

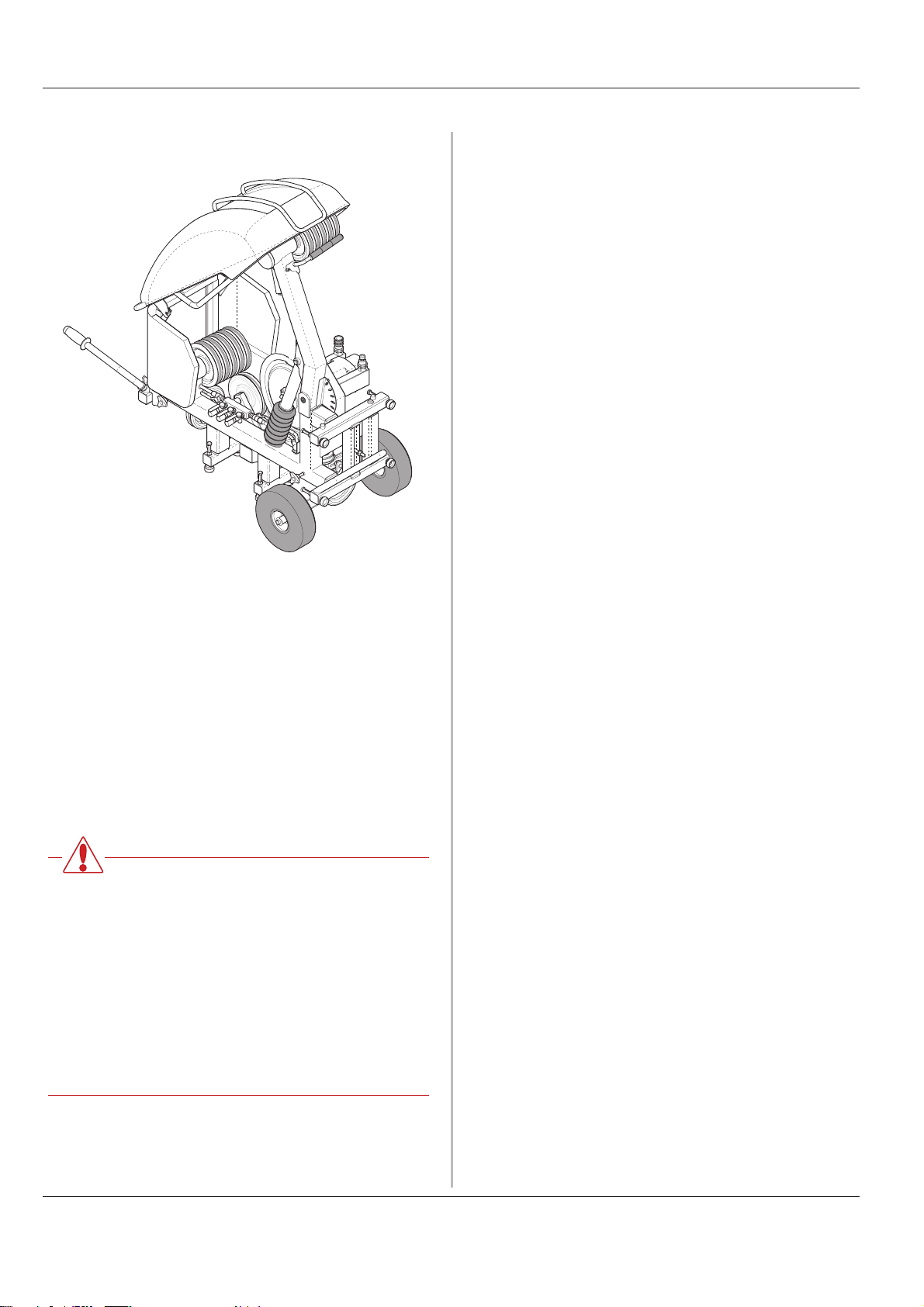

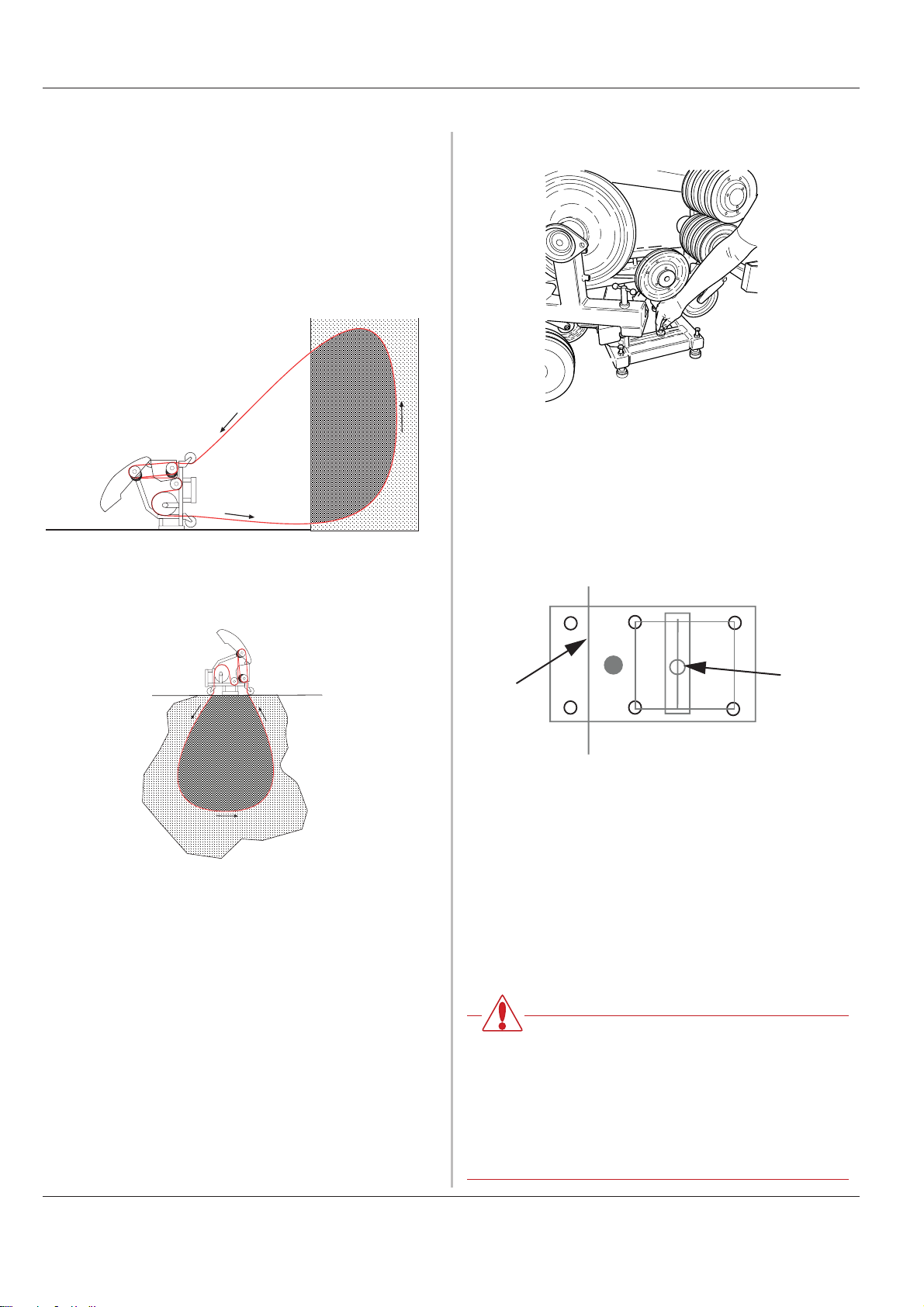

Assembling/Installing equipment Operator's Manual CS 2512

Assembling/Installing

equipment

Cutting needs to be planned carefully before assembling

the saw so that it can be performed as easily as possible.

Husqvarna CS 2512 can be assembled to make either

horizontal or vertical cuts. The saw is assembled standing

when you wish to make vertical cuts.

The saw is assembled horizontally when the cut is to be

made at floor height and when the cut is made in the floor.

When the saw is anchored to the floor, screw down the

adjuster feet so that the saw stands firmly.

Remember that the machine's centre of gravity (the grey

circle) is positioned between the first and second pairs of

adjuster feet (the adjuster feet pairs are marked 1-3) with a

horizontal cut (A). When cutting under the machine, it is

important that the saw is anchored well with the anchor

bolt (b) as the adjuster feet pairs 2 and 3 must be used.

(Adjuster feet pair 1 may rest on the sawn off section.) If

the saw is not anchored well it will overturn when the material supporting adjuster feet pair 1 has been cut through.

It may be necessary to drill holes to thread the wire

through the material to be cut.

Position the saw in an appropriate position in front of the

planned cut. When the saw is in position, secure it by

screwing down the anchor bolt.

A

1

If necessary, fit idler wheels to assist the cutting process.

Using the idler wheels allows the number of sharp corners

that the wire must be pulled around can be reduced,

which results in less wear to the wire at the same time as

cutting is made easier. Using the idler wheels also lets the

wire be guided in different directions without the need of

moving the saw unit.

Also, use the idler wheels to capture the wire when

finishing the cut.

WARNING!

Always position the saw so that you can

stand without the risk of being hit by a

broken wire. Ensure that no unauthorised

persons can access the working area while

cutting. Being hit by a broken wire can

result in death or serious personal injury.

2

3

B

12 - English

Page 13

Assembling/Installing equipmentOperator's Manual CS 2512

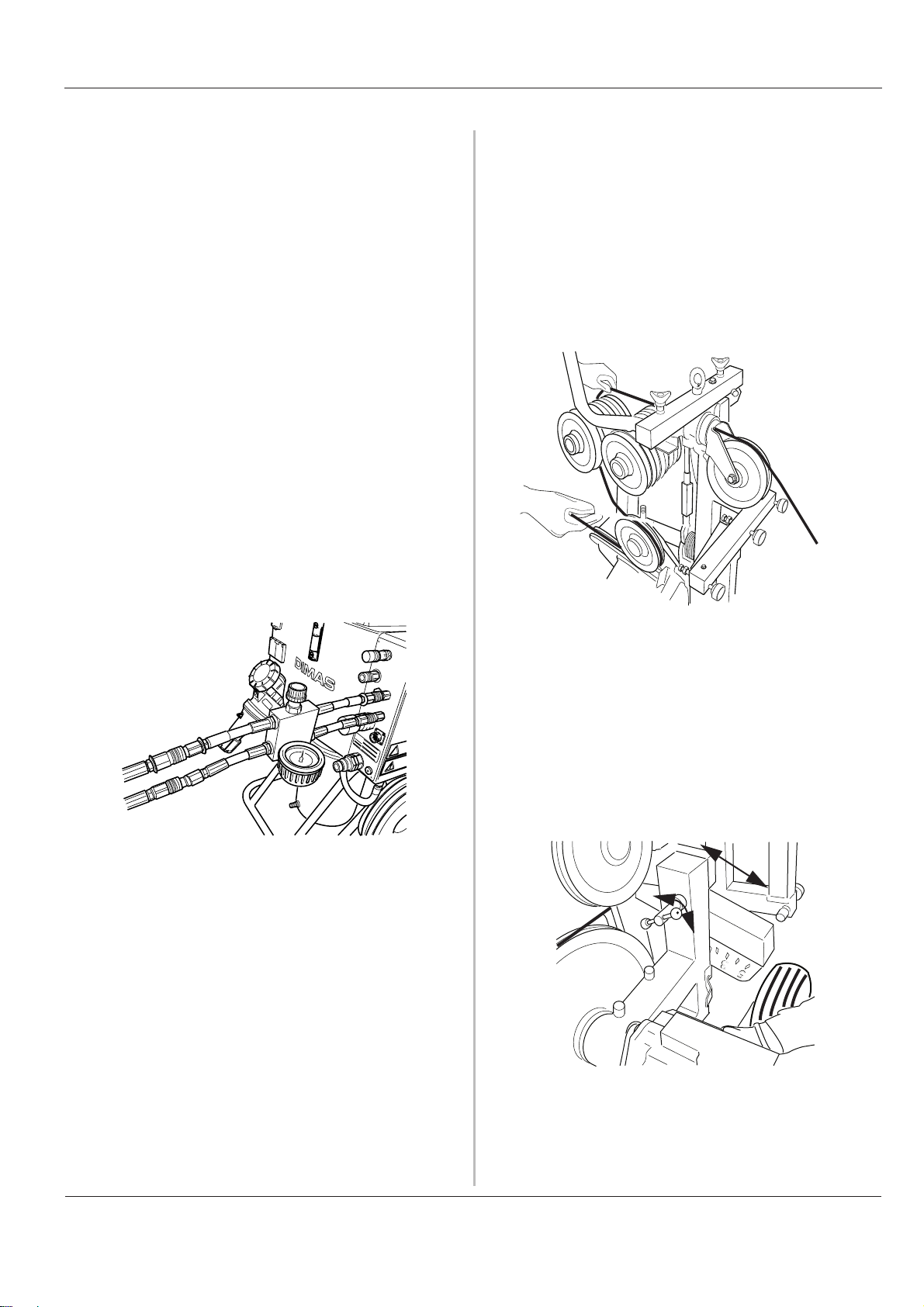

Connection to the hydraulic unit

When the saw is assembled appropriately, it should be

connected to a hydraulic unit. Husqvarna CS 2512 is

designed for use with Husqvarna PP 455 or Husqvarna

RC 455.

1. Check that the hydraulic unit is connected to the power.

2. Connect the cooling water to the motor on the

hydraulic unit.

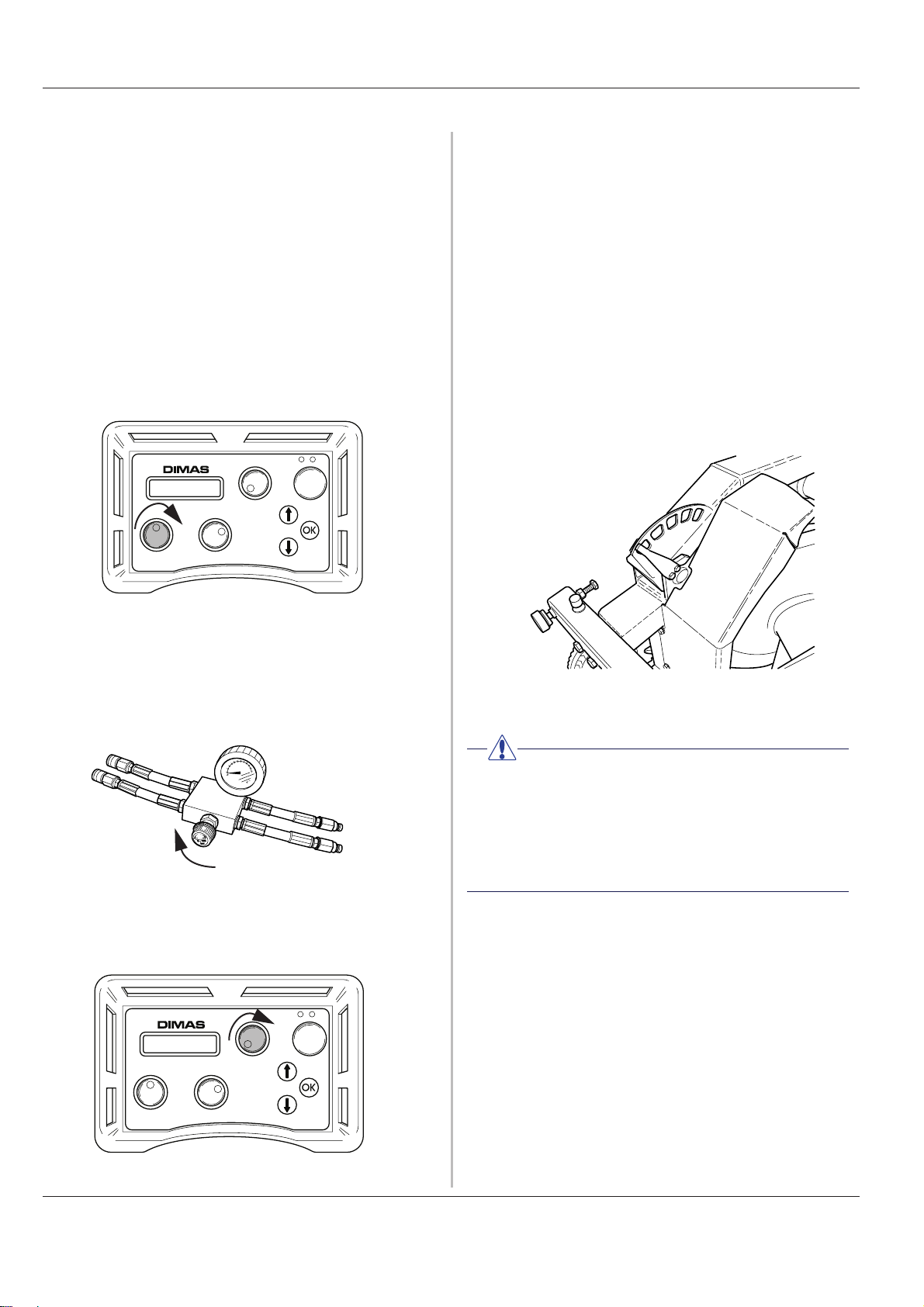

3. Check that the display on the remote control shows

“CONNECT HOSE BUNDLE”. If not follow the instructions in the Operator's manuals for PP 455E or RC 455.

4. Fit the two large hydraulic hoses on the unit first and

then to the saw motor connections. Lock the couplings

by turning the sleeve on the coupling so that the slot

moves away from the ball.

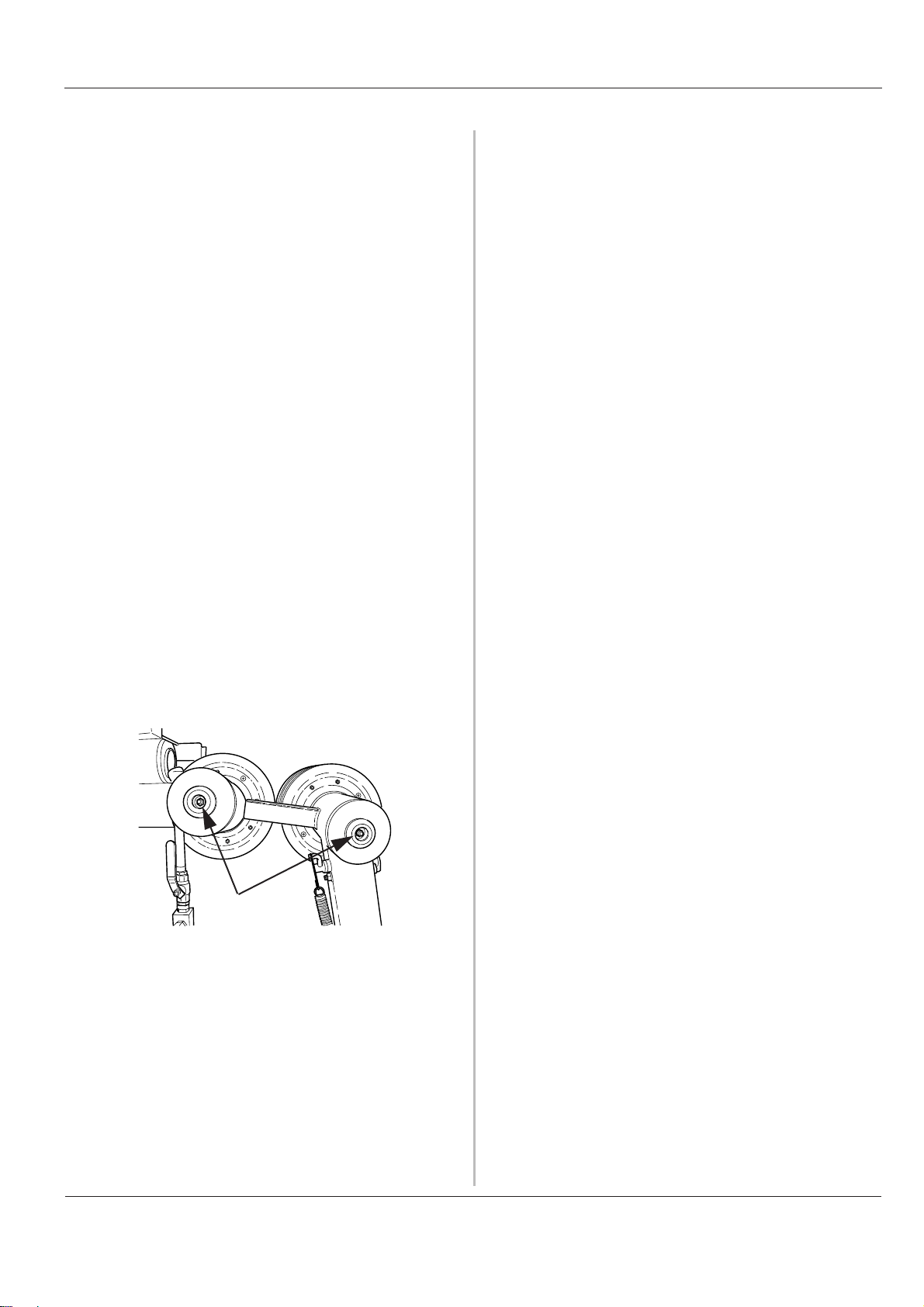

5. Fit the pressure reduction block on the hydraulic unit as

set out in the instructions on the block.

6. Connect the two smaller hydraulic hoses to the

pressure reduction block. The hoses in the hose

bundle marked with a red disc by the coupling shall be

connected to the hose on the pressure reduction block

that is also fitted with a disc.

Threading the wire

The guard can easily be lifted off to facilitate fitting wire.

Now thread the wire as follows:

1. Make sure the magazine is in the min position.

2. Place the wire around the work piece, possibly through

the predrilled holes and back to the saw.

3. Thread the wire through the hole by the swivel wheel

and around a suitable number of wheel sets in the

magazine.

Lock the couplings by turning the sleeve on the

coupling so that the slot moves away from the ball.

7. Fit the two hoses connected on the pressure reduction

block to the hoses to the feed cylinder on the saw. The

hoses in the hose bundle marked with a red disc by the

coupling shall be connected to the hose on the saw

that is also fitted with a disc.

8. Connect the water hose to the incoming water on the

saw.

If the couplings jam when assembling, they should be

removed completely before being refitted.

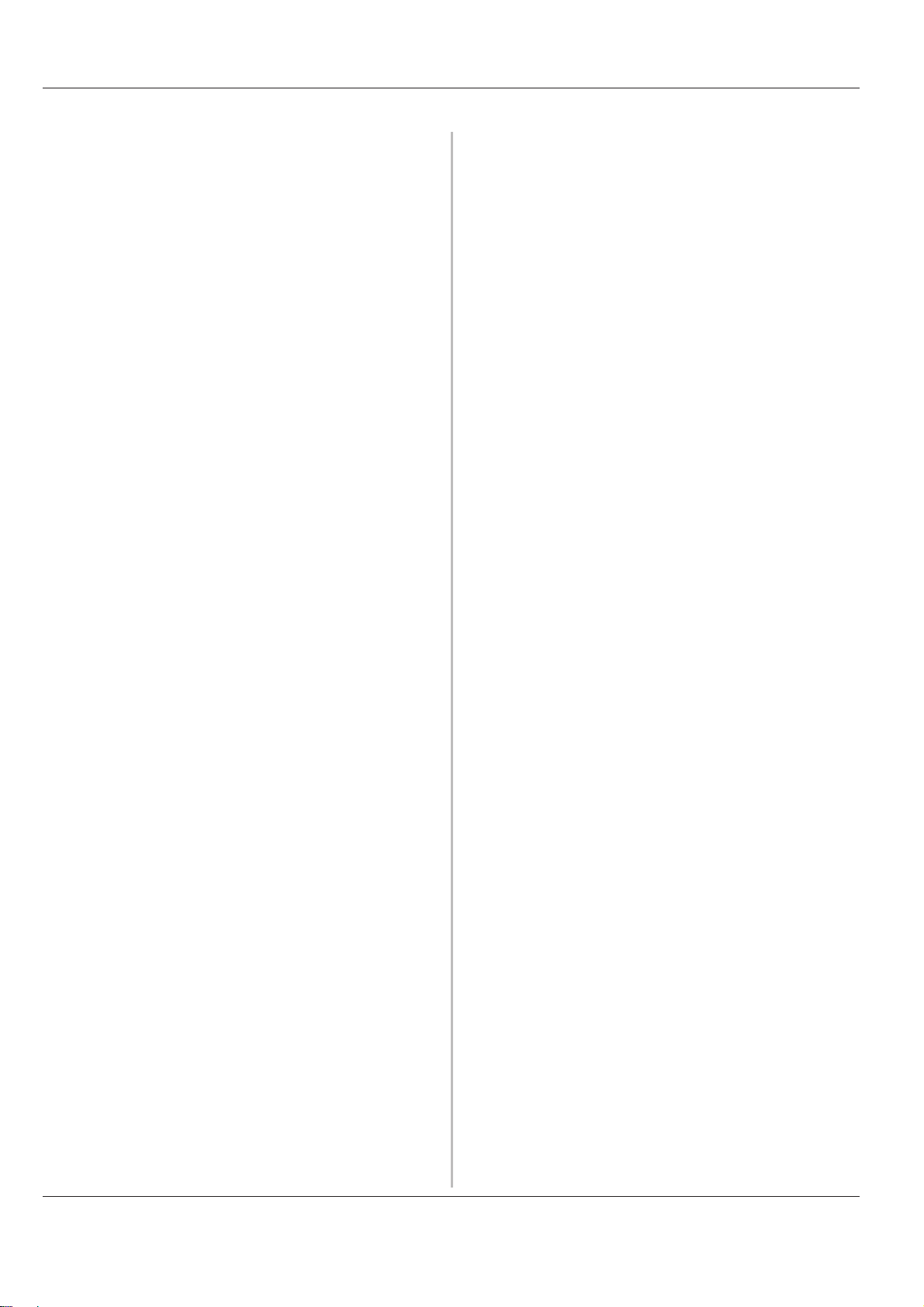

4. Adjust the drive wheel unit according to the number of

wheel sets used in the magazine:

Loosen the arm by screwing out the knob anticlockwise. Now turn the drive wheel unit so that the

arm is aligned with the markings on the saw. Lock the

drive wheel unit by turning back the knob.

Usually only one wheel set is used in the first stage of

cutting.

Make sure that the couplings on the hoses not in use do

not lie directly on the ground.

Always keep the couplings as clean as possible. A clean

coupling lasts longer.

English - 13

Page 14

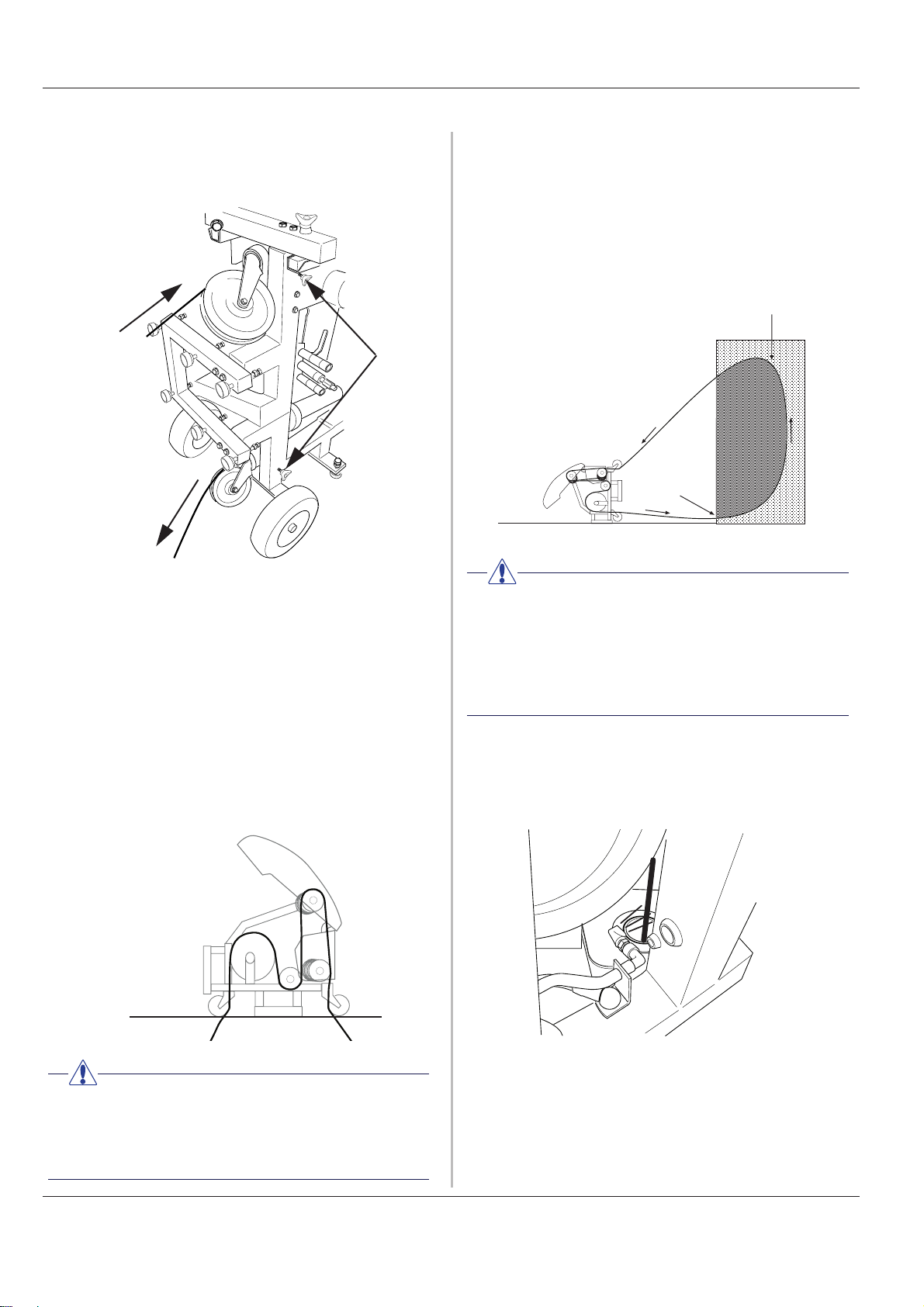

Assembling/Installing equipment Operator's Manual CS 2512

5. Thread the wire around the drive wheel and out

through the hole by the second swivel wheel. The

swivel wheel can rotate and be locked in the required

position by turning the marked (A) knobs.

a

6. Before the joints on the wire are connected, the wire

should be twisted 1 to 2 turns per metre wire used. It is

important to twist the wire in the same direction as it is

spun. This is to give as even wear as possible on the

wire’s diamond segments.

7. Lock the wire with a pin. If there are no end sleeves on

the wire, these must be spliced on to the wire. A

special pair of wire pliers must be used. If you are

unsure about which model you should use, contact

your DIMAS dealer.

8. When the wire is routed correctly it should run through

the machine as in the figure below:

Placement of the cooling water

Husqvarna CS 2512 is equipped with two outlets for the

cooling water. Ideally, Husqvarna water spears can be

connected to these. The water spears are then placed

where the wire enters the concrete. In this way the wire

takes water with it into the cut, which results in the

concrete dust binding and that the wire is cooled

efficiently.

WATER

WATER

CAUTION

In order for the water to cool the wire as

intended during cutting, it is essential to adjust

the position of the cooling water as the

material is cut. Remember to always stop the

machine when you do this.

In addition to the cooling water from the water spear, the

wire is rinsed by the two swivel wheels on the machine.

This is to keep the wire as clean as possible, which means

that the saw can work with less friction losses and greater

efficiency as the wire becomes cleaner.

CAUTION

A used wire must always be run in the same

direction, as it was previously run in order to

prevent unnecessary wear.

14 - English

Page 15

Assembling/Installing equipmentOperator's Manual CS 2512

English - 15

Page 16

Operation Operator's Manual CS 2512

Operation

Sawing

When all the equipment has been assembled cutting can

start. In order for the saw to cut as efficiently as possible it

should be started as follows:

1. Close the valve on the pressure reduction block by

turning the knob anti-clockwise until it stops and then

two turns back.

2. Start the hydraulic unit.

3. Set the feeding flow on the unit to max by turning the

control on the remote control clockwise.

6. Carefully increase the motor speed by turning the

control for motor rotation. A suitable working pressure

when cutting usually lies between 100 and 130 bar, but

varies depending on how many wheel sets are used in

the magazine, how much wire is in use and the

hardness of the material to be cut.

7. As the material is cut away the working pressure

drops, which is shown on the display, and the

magazine must then be tensioned. Do this by turning

the knob on the pressure reduction block clockwise.

8. The output tension on the magazine is shown by an

indicator on the machine (shown in the min position).

When the magazine cylinder is fully tensioned, the

machine must be stopped and the wire must be wound

around a new wheel set. Then continue to cut as

above.

4. Tension the wire by carefully turning the knob on the

pressure reduction block clockwise until the wire is

tensioned sufficiently. Make sure to always check that

the wire is seated correctly in all the wheels on the

saw.

5. Start the motor's rotation by turning the control for

motor rotation on the remote control clockwise.

CAUTION

In order for the water to cool the wire as

intended during cutting, it is essential to adjust

the position of the cooling water as the

material is cut. Remember to always stop the

machine when you do this.

Finishing sawing

1. Lower the speed on the wire and allow the motor to

stop completely.

2. Fold up the magazine arm.

3. Disconnect the incoming mains cable from the

hydraulic unit.

4. Disconnect the hydraulic hoses and the water hose

from the saw unit.

5. Other steps are done in the reverse order.

14 - English

Page 17

Cleaning

The saw should be cleaned once cutting is finished. It is

important to clean all the saw equipment. It is a good idea

to disconnect the water hose from the pivot arm and use

this to wash down the saw unit. If necessary, you can also

use the supplied cleaning brush or the like to clean the

equipment. Do not use a high pressure washer to clean

the saw.

Maintenance

In addition to the daily maintenance such as cleaning and

lubrication, the machine must be serviced. After 50 hours

of cutting, the machine should be serviced at an

accredited Husqvarna workshop. The saw should then be

serviced after every 100 hours of operation. The service is

important so that as the user you have a machine that

works as effectively as possible for a long time.

OperationOperator's Manual CS 2512

Lubrication

In order for the wire to run as friction free as possible, the

magazine axles must be filled with grease. Fill with grease

after every 5 -10 hours of operation. Use Canadian

Petroleum OG2 or similar grease.

The bearings on the magazine axles also need to be

lubricated regularly, but not as often as the magazine

axles.

English - 15

Page 18

Operation Operator's Manual CS 2512

16 - English

Page 19

EU declaration of conformityOperator's Manual CS 2512

EU declaration of conformity

Husqvarna Construction Products Sweden AB, Box 2098, 550 02 Jönköping, Sweden, tel:

036-570 60 00, hereby declares that the wire saw CS 2512, from serial number 01001

onwards, is manufactured in compliance with the Council's machinery directive 98/37/EC,

low-voltage directive 73/23/EEC and EMC directive 89/336/EEC, including subsequent

amendments, and that the following standards have been used for guidance: EN 55 014-1,

EN 55 014-2, EN 61 000-3-2, EN 50 144-1, EN 13 862.

Jönköping 2005-01-01

Christer Carlberg

Managing Director

English - 67

Page 20

EU declaration of conformity Operator's Manual CS 2512

68 - English

Page 21

Bedienungsanleitung CS 2512

Inhalt

Deutsch

Inhalt

Symbolerklärung ....................................................... 21

Sicherheitsvorschriften......................................... 22

Einleitung ....................................................................... 23

Komponentenerklärung ........................................ 24

Technische Daten ..................................................... 26

Ausrüstung montieren/installieren ................ 27

An Hydraulikaggregat anschließen..................... 28

Seil einlegen................................................................... 28

Kühlwasserpositionierung........................................ 29

Bedienung...................................................................... 30

Sägen................................................................................. 30

Schneidvorgang beenden........................................ 30

Reinigung......................................................................... 31

Wartung ............................................................................ 31

Konformitätserklärung........................................... 33

Deutsch - 19

Page 22

Inhalt Bedienungsanleitung CS 2512

20 - Deutsch

Page 23

SymbolerklärungBedienungsanleitung CS 2512

Symbolerklärung

Diese Symbole sind auf der Maschine und in der

Bedienungsanleitung angegeben. Um sicher mit der

Maschine arbeiten zu können, muss der Bediener ihre

Bedeutung verstehen.

Anleitung

Lesen Sie vor der Inbetriebnahme der Maschine die

Bedienungsanleitung aufmerksam durch und machen Sie

sich mit dem Inhalt vertraut.

Schutzausrüstung

Verwenden Sie stets:

• einen zugelassenen Schutzhelm,

• einen zugelassenen Gehörschutz,

• eine zugelassene Schutzbrille oder einen

Gesichtsschutz sowie sonstige erforderliche

Schutzausrüstung.

Bemerkung

Eine Hand mit erhobenem Zeigefinger mit dem Zusatz

„Anmerkung“ bedeutet, dass ein beschriebener Vorgang

zusätzliche Aufmerksamkeit erfordert.

CE

Dieses Symbol weist darauf hin, dass die Maschine den

geltenden EU-Richtlinien entspricht.

Warnung

Ein großes Warndreieck mit dem Zusatz „Warnung“

bedeutet, dass die Gefahr von schweren, sogar

lebensgefährlichen Verletzungen besteht.

Achtung

Ein kleines Warndreieck mit dem Zusatz „Achtung“

bedeutet, dass die Gefahr von leichteren Verletzungen

oder Maschinenschäden besteht.

Deutsch - 21

Page 24

Sicherheitsvorschriften Bedienungsanleitung CS 2512

Sicherheitsvorschriften

Bei der Konstruktion und Herstellung von HusqvarnaProdukten wurde neben der Leistungsfähigkeit und

Benutzerfreundlichkeit größtes Gewicht auf die Sicherheit

gelegt. Folgende Punkte sind zu beachten, um einen

sicheren Maschinenbetrieb zu gewährleisten:

WARNUNG!

Diese Maschine darf nur zusammen mit

Husqvarna PP 455E oder einem Aggregat

genutzt werden, das an Husqvarna RC 455

angeschlossen ist. Jegliche andere

Verwendung ist unzulässig.

ACHTUNG

Die Maschine darf ausschließlich unter Befolgung der Sicherheitsvorschriften gestartet

werden. Bei Missachtung der Vorschriften seitens des Bedieners haftet Husqvarna Construction Products Sweden AB oder ihre

Vertreter weder direkt noch indirekt. Lesen Sie

die Bedienungsanleitung aufmerksam durch

und machen Sie sich mit dem Inhalt vertraut,

bevor Sie die Maschine benutzen. Sollten Sie

sich auch nach Lektüre der Sicherheitsvorschriften nicht über die vorliegenden Sicherheitsrisiken im Klaren sein, dürfen Sie die

Maschine nicht benutzen. Ihr Fachhändler

erteilt auf Anfrage gern weitere Informationen.

• Stellen Sie sicher, dass alle Verbindungen, Anschlüsse

und Hydraulikschläuche unbeschädigt sind.

• Kontrollieren Sie vor der Inbetriebnahme, ob alle

Schläuche korrekt an der Maschine angeschlossen sind.

• Vergewissern Sie sich, dass sich im Arbeitsbereich

keine Personen oder Tiere aufhalten.

• Überprüfen Sie, ob alle Schutzvorrichtungen

unbeschädigt und korrekt montiert sind.

• Schneiden Sie niemals ohne Schutzvorrichtungen.

• Hydraulikschläuche dürfen erst abgenommen werden,

nachdem das Hydraulikaggregat abgeschaltet wurde

und der Motor zum Stillstand gekommen ist.

• Überprüfen Sie täglich die Maschine sowie alle

Verbindungen und Hydraulikschläuche auf

Undichtigkeiten. Lecks oder ein Bersten von

Schläuchen können zu einem Eindringen von Öl in den

Körper oder zu anderen schweren Verletzungen führen.

• Die für das jeweilige Werkzeug angegebenen Werte

für den Öldurchfluss oder Öldruck dürfen nicht

überschritten werden. Ein zu hoher Druck kann zu

einem Bersten der Schläuche führen.

• Achten Sie stets auf die Unversehrtheit der

verwendeten Schläuche.

• Benutzen Sie keine deformierten, verschlissenen oder

beschädigten Schläuche.

• Stellen Sie sicher, dass die Schläuche korrekt an die

Maschine angeschlossen sind und die

Hydraulikkupplungen ordnungsgemäß verriegelt

wurden, bevor das Hydrauliksystem unter Druck

gesetzt wird. Um die Kupplungen zu verriegeln, drehen

Sie die Außenhülse der Buchsenkupplung, wodurch

sich die Nut von der Kugel entfernt.

• Halten Sie Hydraulikschläuche und Verbindungen

sauber.

• Schalten Sie den Hauptschalter für das Hydraulikaggregat stets aus, bevor die Ausrüstung bewegt wird.

• Arbeiten Sie stets so, dass der Nothalt schnell und

einfach zu erreichen ist.

• Lassen Sie die Maschine niemals unbeaufsichtigt mit

laufendem Motor stehen.

• Vor dem Schneiden sind alle auszuführenden Schnitte

deutlich zu markieren und zu planen, sodass sie ohne

Gefahr für Mensch oder Maschine durchgeführt

werden können.

• Kontrollieren Sie in den Bauzeichnungen, ob

elektrische Kabel, Wasserleitungen, Gasleitungen

oder Abflussrohre im Arbeitsbereich verlegt sind.

• Überprüfen Sie den Arbeitsbereich stets auf das Vorhandensein von Gasleitungen und kennzeichnen Sie deren

Verlauf. Das Schneiden in der Nähe von Gasleitungen

stellt eine potenzielle Gefahrensituation dar. Vermeiden

Sie eine Funkenbildung beim Schneiden, andernfalls

besteht Explosionsgefahr. Konzentrieren Sie sich vollständig auf Ihre Arbeitsaufgabe. Unachtsamkeit kann zu

schweren Verletzungen bis hin zum Tod führen.

• Stellen Sie sicher, dass die Stromkabel im

Arbeitsbereich nicht stromführend sind.

• Beim Einsatz von Hydraulikwerkzeugen an oder bei

elektrischen Leitungen sind Schläuche zu verwenden,

die als „nicht elektrisch leitend“ eingestuft und gekennzeichnet wurden. Die Verwendung anderer Schläuche

kann zu schweren Verletzungen bis hin zum Tod führen.

• Gehen Sie beim Heben vorsichtig vor. Schweres Gerät

bedeutet Klemmgefahr und Gefahr für andere

Verletzungen.

• Arbeiten Sie niemals ohne eine persönliche

Schutzausrüstung und Schutzkleidung. Tragen Sie

keine Kleidung, die sich in den beweglichen Teilen der

Maschine verfangen kann.

• Verwenden Sie ausschließlich vom Hersteller

empfohlene Seile.

• Schneiden Sie niemals ohne Kühlwasser. An einem

unzureichend gekühlten Seil können sich Segmente

erhitzen, was einen beschleunigten Verschleiß bewirkt.

Im schlimmsten Fall können sich Segmente vom Seil

lösen und Personen in der Nähe der Säge verletzen.

22 - Deutsch

Page 25

Einleitung

Husqvarna CS 2512 ist für die gemeinsame Verwendung

mit dem Hydraulikaggregat PP 455 E oder Husqvarna RC

455 vorgesehen. Husqvarna CS 2512 ist eine

leistungsstarke und einfach bedienbare Seilsäge, die

anspruchsvollen Aufgaben gewachsen ist. Gleichzeitig

besticht das Modell durch seine kompakten

Abmessungen, die eine mobile Nutzung für kleinere

Aufgaben ermöglichen. Die Säge ist auf unterschiedliche

Arten einsetzbar: auf dem Boden oder montiert an der

Wand.

Dank der durchdachten Konstruktion des Modells CS

2512 mit dem Antriebsrad auf der Ausgangsseite der

Maschine ist das Seil auch bei niedriger Vorschubkraft

stets gespannt. Diese Bauweise sowie das regelbare

Druckventil erlauben eine präzise Sägesteuerung und

eine überlegene Leistung.

Die Maschine lässt sich vertikal und horizontal anbringen.

Viele Schnitte können direkt und ohne externe

Umlenkräder ausgeführt werden.

EinleitungBedienungsanleitung CS 2512

Zu einer kompletten Sägeausrüstung gehören:

1 x Sägeeinheit

1 x Zubehörkoffer

1 x 18-mm-Schlüssel

1 x Druckreduzierblock

1 x zusätzlicher Verschleißgummi für das Magazinrad

1 x Reinigungsbürste

Deutsch - 23

Page 26

Komponentenerklärung Bedienungsanleitung CS 2512

Komponentenerklärung

4

6

7

4

14

Der Trennschleifer besteht aus folgenden Komponenten:

1. Hydraulikmotor

Die Maschine wird von einem 60-cm3-Motor

angetrieben. Der Motor besteht aus zwei Bereichen:

mit 50 bzw. 10 cm3. Wird nur der große Motorbereich

verwendet bzw. werden beide Motorbereiche

kombiniert, ist das Arbeiten mit zwei Leistungsstufen

(Gängen) möglich. Die beiden Gänge weisen eine

unterschiedliche Drehzahl bei identischer Leistung auf.

2. Hydraulikschlauchanschlüsse

Der Hydraulikölfluss in den beiden dickeren

Schläuchen treibt den Motor und somit das Seil an.

Der Durchfluss in den beiden schmalen Schläuchen

treibt den Magazinzylinder an.

3. Antriebsrad

Das Antriebsrad überträgt die Antriebskraft vom Motor

zum Seil. Der Antriebsraddurchmesser beträgt 400

mm. Ein austauschbarer Gummibelag gewährleistet

ein optimales Reibungsverhältnis zwischen

Antriebsrad und Seil.

Gemeinsam mit dem Hydraulikmotor und den Hydraulikanschlüssen bildet das Antriebsrad die Antriebsrad-

einheit.Die Antriebsradeinheit wird je nach Anzahl der

Radpaare im Magazin justiert. Sie lässt sich auf einfache Weise demontieren, um zu Transportzwecken ein

leichteres Maschinengewicht zu erreichen.

9

8

15

5

4. Seilmagazin

Im Seilmagazin wird das Seil gestreckt und

eingefahrenes Seil aufgewickelt. Das Seilmagazin

kann bis zu 12 m Seil (2,4 m je Radpaar) aufnehmen.

5. Magazinzylinder

Der Magazinzylinder streckt das Seil im Magazin. Auf

diese Weise wird der Schnittvorgang kontrolliert. Die

Druckregelung im Zylinder erfolgt mithilfe eines

Druckreduzierblocks, der an Modell PP 455E oder RC

455 montiert wird.

6. Schutzvorrichtung

Die Schutzvorrichtung an der Maschine ist zweigeteilt.

Ein fester Teil besteht aus Blech, eine klappbare

Haube ist aus Kunststoff und Metall gefertigt. Die

Schutzvorrichtung lässt sich einfach entfernen (z.B.

zum Seileinzug), beim Sägen muss sie jedoch stets

vorgeklappt sein.

7. Hebegriff

Der einklappbare Handgriff leistet eine ideale

Unterstützung beim Umsetzen der Maschine.

8. Verstellbarer Fuß

Der Fuß wird so justiert, dass die Säge stabil steht. Die

Säge verfügt über insgesamt zehn verstellbare Füße:

sechs für horizontale und vier für vertikale Schnitte.

9. Kühlwasseranschlüsse

11

3

1

2

12

14

10

24 - Deutsch

Page 27

KomponentenerklärungBedienungsanleitung CS 2512

An der Maschine befinden sich zwei Wasserlanzenanschlüsse sowie ein Wassereingangsanschluss. Mithilfe

dieser Anschlüsse wird das Seil gekühlt sowie beim

Einziehen in die Maschine und beim Verlassen der

Maschine über zwei kleine Düsen gespült.

10.Gummiräder

Diese Räder erleichtern den Transport. Um bei

bestimmten Arbeiten die Zugänglichkeit zu

verbessern, lassen sich die Räder auf einfache Weise

abnehmen. Dazu wird der Stift herausgezogen, der die

Räder an der Radachse fixiert.

11.Seilstrebe

Diese Strebe drückt das Seil an das Magazin an, wenn

dieses eingerollt wird. So liegt das Seil stets optimal,

selbst wenn es nicht gespannt ist, z.B. bei einem

Seilwechsel oder wenn die Radanzahl im Magazin

geändert wird.

12.Ankerbalken

Dieser justierbare Balken weist eine Längsnut auf.

Durch ein seitliches Verschieben des Balkens kann

der Ankerbolzen beim Fixieren der Säge vor einem

Schnitt an der passenden Stelle positioniert werden,

ohne dass die gesamte Säge bewegt werden muss.

Ein weiterer Ankerbalken ist unter der Säge angebracht.

An ihm wird der Ankerbolzen bei horizontalen Schnitten

befestigt.

13.Druckreduzierblock

Der Druckreduzierblock wird zwischen dem

Hydraulikaggregat und den Hydraulikschläuchen für

die Eingangsversorgung angebracht. Am

Druckreduzierblock befindet sich ein Ventil, mit dem

sich die Magazinspannung regeln lässt.

Zubehör

1. Wasserlanze

Diese Komponente wird mit dem Wasseranschlüssen

an der Säge verbunden und leitet Kühlwasser zum

Schnitt, um das Seil zu kühlen und Betonstaub zu

binden.

2. Umlenkräder

Mit Husqvarna-Umlenkrädern lässt sich der Seilverlauf

einfach und effektiv festlegen. Durch den Einsatz von

Umlenkrädern lässt sich die Anzahl spitzer Kanten

beim Sägen verringern, wodurch eine höhere Sägekraft

für die Materialabtragung verwendet werden kann.

14.Lenkrollen

Die kugelgelagerten Lenkrollen sind dort platziert, wo

das Seil in die und aus der Säge läuft. Die Lenkrollen

dienen als Seilführung, damit das Seil korrekt in die

Säge läuft. Sie können entweder fixiert oder lose

eingesetzt werden, damit die Rollen dem Seil flexibel

folgen können.

15.Führungsrad

Dieses Rad führt das Seil vom Magazin zum Antriebsrad.

Bei der Justierung der Antriebsradeinheit wird das

Führungsrad automatisch gemäß der verwendeten

Radanzahl im Magazin eingestellt.

3. Reinigungsbürste

Die Bürste kann am Wasserschlauch angebracht

werden. Sie wird vorzugsweise zur Reinigung der

Maschine nach der Nutzung eingesetzt.

Deutsch - 25

Page 28

Technische Daten Bedienungsanleitung CS 2512

Technische Daten

Leistung des Antriebsrads (mit PP 455): _ 20 kW

Hydraulikölfluss:____________________ 65 l/min (17 gal/min)

Max. zulässiger Hydraulikdruck ________ 230 Bar (3400 psi)

Max. empfohlener Hydraulikdruck beim

Sägen: ___________________________

Maximale Seillänge im Magazin: _______ 12 m (2,4 m/Radpaar)

Abmessungen, Handgriff eingeklappt

und

Schutzvorrichtung herabgeklappt

(L

x B x H) ________________________ 1150 x 750 x 980 mm

Gewicht: __________________________ 150 kg (330 lbs)

Seilgeschwindigkeit im 1. Gang ________ 20 m/s (66 ft/s)

Seilgeschwindigkeit im 2. Gang ________ 25 m/s (82 ft/s)

130 Bar (1900 psi)

Empfohlene Seile:

Husqvarna empfiehlt die Verwendung folgender Seile:

• Husqvarna C710C

HusqvarnaC710C ist ein galvanisiertes Drahtseil, das

für das Sägen von hartem Stahlbeton entwickelt

wurde. Die Segmente weisen einen hohen

Diamantanteil sowie einen geringen Durchmesser (9,5

mm) auf. Dadurch wird ein überaus effektives Sägen

ermöglicht. Dank des geringen Durchmessers kann

C710C ebenfalls für den Schnittabschluss eingesetzt

werden.

• Husqvarna C750C

Husqvarna C750C ist ein Allzweck-Drahtseil, das für

das Sägen von hartem Stahlbeton entwickelt wurde.

Dieses Drahtseil ist für die Verwendung mit Sägen

konzipiert, deren Leistung im Bereich 10-25 kW liegt.

• Husqvarna C760C

Dieses Drahtseil ist die Toplösung von Husqvarna. Er

zeichnet sich durch lange Lebensdauer, hohe Schnittgeschwindigkeit und Leistungsbeständigkeit aus.

HusqvarnaC760C ist für das Sägen aller Stahlbetonarten geeignet, selbst bei Anwendungen, die hohe Anforderungen an das Seil stellen (z.B.

Brückensägearbeiten).

• Husqvarna C790C

Die Härte der Segmente in diesem Drahtseil macht

Husqvarna C790C zur idealen Wahl, wenn weiche

Materialien wie Mauerwerk und leicht armierter

Kalksteinbeton geschnitten werden sollen.

• Husqvarna C575J

Der Drahtseiltyp Husqvarna C575J verfügt über

galvanisierte 15-mm-Segmente.

• Husqvarna C1200M

WARNUNG

Ohne die schriftliche Genehmigung von

Husqvarna Construction Products Sweden

AB dürfen unter keinen Umständen Veränderungen an der Maschine vorgenommen

werden. Nicht genehmigte Änderungen

können Ihnen und anderen Personen

schwerwiegende oder lebensgefährliche

Verletzungen zufügen. Husqvarna Con-

Der Drahtseiltyp Husqvarna C1200M wurde für das

Sägen von Stahl entwickelt. Er eignet sich für besonders anspruchsvolle Arbeiten. Dank modernster Sintertechnologie ergeben sich überragende Vorteile bei

Schnittgeschwindigkeit und Lebensdauer. Das Drahtseil ist mit zusammengefügten oder losen Enden lieferbar.

Weitere Informationen zu Dimas-Produkten erhalten Sie

von Ihrem Dimas-Händler.

struction Products Sweden AB haftet nicht

für einen Umgang mit der Maschine, der

diesen Anweisungen nicht folgt.

26 - Deutsch

Page 29

Ausrüstung montieren/installierenBedienungsanleitung CS 2512

Ausrüstung montieren/

installieren

Vor der Sägenmontage ist der Schneidvorgang exakt zu

planen, damit die Arbeiten möglichst reibungslos ablaufen

können.

Dimas CS 2512 kann für die Ausführung horizontaler oder

vertikaler Schnitte montiert werden. Bei vertikalen

Schnitten wird die Säge stehend montiert.

Bei Schnitten auf Bodenhöhe oder im Boden wird die

Säge liegend montiert.

Wenn die Säge im Boden verschraubt ist, justieren Sie die

verstellbaren Füße, um einen stabilen Stand zu ermöglichen.

Beachten Sie, dass der Schwerpunkt der Maschine (grauer

Kreis) bei horizontalen Schnitten (a) zwischen dem ersten

und zweiten verstellbaren Fußpaar liegt. (Die Fußpaare

sind mit 1-3 gekennzeichnet.) Bei Schnitten unter der

Maschine ist es wichtig, die Säge sicher per Ankerbolzen

(b) zu befestigen, da die verstellbaren Fußpaare 2 und 3

verwendet werden müssen. (Das verstellbare Fußpaar 1

kann evtl. als Stütze für den entfernten Bereich dienen.) Ist

die Säge nicht ausreichend verankert, kippt sie um, wenn

sich das Material löst, das das verstellbare Fußpaar 1 hält.

Falls erforderlich, bohren Sie Löcher, um das Seil durch

das zu schneidende Material zu verlegen.

Platzieren Sie die Säge vor dem geplanten Schnitt.

Sichern Sie die positionierte Säge, indem Sie sie mit

einem Ankerbolzen festschrauben.

a

1

Falls erforderlich, montieren Sie Umlenkräder, um den

Schneidvorgang zu erleichtern. Durch den Einsatz von

Umlenkrädern lässt sich die Anzahl spitzer Kanten beim

Sägen verringern, wodurch ein geringerer Seilverschleiß

erreicht und ein leichteres Starten der Säge ermöglicht

wird. Durch die Verwendung von Umlenkrädern lässt sich

das Seil ebenfalls in unterschiedliche Richtungen verlegen, ohne dass die Sägeeinheit umgesetzt werden muss.

Benutzen Sie ebenfalls Umlenkräder, um das Seil nach

dem Sägen zu führen.

WARNUNG!

Positionieren Sie die Säge stets so, dass Sie

an Ihrer Arbeitsposition nicht von einem

gerissenen Seil getroffen werden können.

Vergewissern Sie sich außerdem, dass während des Schneidens keine Unbefugten den

Arbeitsbereich betreten können. Gerissene

Seile können Personen treffen und tödliche

oder schwere Verletzungen zur Folge haben.

2

3

b

Deutsch - 27

Page 30

Ausrüstung montieren/installieren Bedienungsanleitung CS 2512

An Hydraulikaggregat anschließen

Nachdem die Säge ordnungsgemäß platziert wurde, ist

die Verbindung mit einem Hydraulikaggregat herzustellen.

DIMAS CS 2512 ist für die gemeinsame Verwendung mit

DIMAS PP 455 oder DIMAS RC 455 vorgesehen.

1. Kontrollieren Sie, ob das Hydraulikaggregat an die

Stromversorgung angeschlossen ist.

2. Verbinden Sie das Kühlwasser mit dem Motor am

Hydraulikaggregat.

3. Stellen Sie sicher, dass auf der Fernsteuerung die Mel-

dung zum Anschließen des Schlauchpakets erscheint.

Ist dies nicht der Fall, befolgen Sie die Vorgaben in der

Bedienungsanleitung für PP 455E oder RC 455.

4. Montieren Sie die beiden dickeren Hydraulikschläuche

zuerst am Aggregat und anschließend an den

Anschlüssen des Sägemotors. Verriegeln Sie die

Kupplungen, indem Sie die Hülse an der Kupplung

drehen, sodass sich die Nut von der Kugel entfernt.

5. Montieren Sie den Druckreduzierblock am Hydraulik-

aggregat gemäß den Anweisungen auf dem Block.

6. Verbinden Sie zwei der dünneren Hydraulikschläuche

mit dem Druckreduzierblock. Der Schlauch im

Schlauchpaket, der mit einer roten Kennzeichnung am

Anschluss versehen ist, muss mit dem Schlauch am

Druckreduzierblock verbunden werden, der ebenfalls

über eine Kennzeichnung verfügt.

Achten Sie darauf, dass die Kupplungen an nicht

verwendeten Schläuchen nicht auf dem Boden liegen.

Halten Sie die Kupplungen stets so sauber wie möglich.

Eine saubere Kupplung besitzt eine längere Lebensdauer.

Seil einlegen

Um die Seilmontage zu vereinfachen, lässt sich die

Schutzvorrichtung einfach abnehmen. Legen Sie

anschließend das Seil wie folgt ein:

1. Stellen Sie sicher, dass sich das Magazin in der

minimalen Stellung befindet.

2. Legen Sie das Seil um das Arbeitsobjekt, evtl. durch

vorgebohrte Löcher und zurück zur Säge.

3. Führen Sie das Seil durch die Öffnung an der Lenkrolle

und um die erforderliche Anzahl von Radpaaren im

Magazin.

Verriegeln Sie die Kupplungen, indem Sie die Hülse an

der Kupplung drehen, sodass sich die Nut von der

Kugel entfernt.

7. Montieren Sie die beiden mit dem Druckreduzierblock

verbundenen Schläuche an den Schläuchen, die zum

Versorgungszylindern an der Säge führen. Der

Schlauch im Schlauchpaket, der mit einer roten

Kennzeichnung am Anschluss versehen ist, muss mit

dem Schlauch an der Säge verbunden werden, der

ebenfalls über eine Kennzeichnung verfügt.

8. Verbinden Sie den Wasserschlauch mit dem

Wassereingang an der Säge.

Wenn sich die Kupplungen bei der Montage nur schwer

verbinden lassen, sind sie vor einer erneuten Montage

komplett zu lösen.

4. Justieren Sie die Antriebsradeinheit entsprechend der

verwendeten Radpaaranzahl im Magazin:

Lösen Sie den Arm, indem Sie den Knauf gegen den

Uhrzeigersinn drehen. Drehen Sie danach die

Antriebsradeinheit so, dass der Arm parallel zu den

Markierungen auf der Säge ausgerichtet ist. Arretieren

Sie nun die Antriebsradeinheit, indem Sie den Knauf

im Uhrzeigersinn drehen.

Zum Beginn eines Schneidvorgangs wird meist nur ein

Radpaar verwendet.

28 - Deutsch

Page 31

Ausrüstung montieren/installierenBedienungsanleitung CS 2512

5. Führen Sie das Seil um das Antriebsrad und durch die

Öffnung an der zweiten Lenkrolle. Die Lenkrollen können

gedreht und in der gewünschten Stellung fixiert werden,

indem Sie die gekennzeichneten Knäufe (a) festziehen.

a

6. Bevor die Seilverbindungen zusammengesetzt werden,

ist es um 1-2 Umdrehungen pro verwendetem Meter zu

verdrehen. Das Seil muss dabei in Faserrichtung verdreht

werden. Auf diese Weise wird eine möglichst gleichmäßige Abnutzung der Diamantsegmente im Seil erreicht.

7. Verbinden Sie die Seilenden mit einem Splint. Wenn

sich am Seil keine Endhülsen befinden, müssen diese

angebracht werden. Verwenden Sie dazu eine

spezielle Drahtseilzange. Wenn Sie sich nicht sicher

sind, welches Modell sie nutzen sollen, wenden Sie

sich an Ihren DIMAS-Händler.

8. Ein korrekt verlegtes Seil muss wie auf der folgenden

Abbildung durch die Maschine laufen:

Kühlwasserpositionierung

DIMAS CS 2512 verfügt über zwei Kühlwasseranschlüsse. Diese eignen sich für eine Bestückung mit

Dimas-Wasserlanzen. Die Wasserlanzen werden dort

positioniert, wo das Seil in den Beton läuft. Dadurch führt

das Seil das Wasser mit sich in den Schnitt. Auf diese

Weise wird Betonstaub gebunden und eine nachhaltige

Seilkühlung erzielt.

ACHTUNG

Damit das Wasser das Seil beim Schneiden

wie vorgesehen kühlen kann, muss die

Kühlwasserposition mit fortschreitendem

Schneidvorgang justiert werden. Halten Sie

dazu stets die Maschine an.

Neben dem Kühlwasser von den Wasserlanzen wird das

Seil an den beiden Lenkrollen in der Maschine gespült. So

bleibt das Seil möglichst sauber und die Säge kann mit

geringeren Reibungsverlusten sowie höherer Effektivität

arbeiten.

ACHTUNG

Ein bereits benutztes Seil muss stets in der

zuvor eingesetzten Richtung durch die

Maschine laufen, damit kein unnötiger

Verschleiß auftritt.

Deutsch - 29

Page 32

Bedienung Bedienungsanleitung CS 2512

Bedienung

Sägen

Nach der Montage aller Ausrüstungskomponenten

können Schneidarbeiten ausgeführt werden. Um die Säge

so effektiv wie möglich einzusetzen, ist sie wie folgt zu

starten:

1. Schließen Sie das Ventil am Druckreduzierblock an,

indem Sie den Knauf bis zu Anschlag gegen den

Uhrzeigersinn und danach zwei Umdrehungen

zurückdrehen.

2. Starten Sie das Hydraulikaggregat.

3. Stellen Sie den Versorgungsdurchfluss am Aggregat

auf maximal, indem Sie den Regler an der

Fernsteuerung im Uhrzeigersinn drehen.

6. Steigern Sie vorsichtig die Motordrehzahl, indem Sie

den entsprechenden Regler drehen. Der geeignete

Betriebsdruck beim Schneiden liegt üblicherweise

zwischen 100 und 130 Bar. Er variiert jedoch je nach

Anzahl der Radpaare im Magazin, der vorliegenden

Seilmenge, der Härte des bearbeiteten Materials usw.

7. Beim Schneiden des Materials sinkt der Betriebsdruck

nach und nach. Dies wird auf dem Display angezeigt.

Dementsprechend muss das Seil im Magazin

gespannt werden. Drehen Sie dazu den Knauf am

Druckreduzierblock im Uhrzeigersinn.

8. Die Ausgangsspannung vom Magazin wird an der

Maschine angezeigt (auf der Abbildung in minimaler

Stellung). Steht der Magazinzylinder unter maximaler

Spannung, muss die Maschine angehalten und das

Seil um ein neues Radpaar gelegt werden. Fahren Sie

anschließend wie oben beschrieben fort.

4. Spannen Sie das Seil, indem Sie den Knauf am

Druckreduzierblock vorsichtig im Uhrzeigersinn

drehen, bis das Seil eine mittlere Spannung aufweist.

Kontrollieren Sie stets sorgfältig, dass das Seil korrekt

in allen Führungen in der Säge liegt.

5. Starten Sie die Motordrehung, indem Sie den

entsprechenden Regler an der Fernsteuerung im

Uhrzeigersinn drehen.

ACHTUNG

Damit das Wasser das Seil beim Schneiden

wie vorgesehen kühlen kann, muss die

Kühlwasserposition mit fortschreitendem

Schneidvorgang justiert werden. Halten Sie

dazu stets die Maschine an.

Schneidvorgang beenden

1. Verringern Sie die Seilgeschwindigkeit und lassen Sie

den Motor gänzlich zum Stillstand kommen.

2. Klappen Sie die Magazinarme zusammen.

3. Lösen Sie das Stromversorgungskabel vom

Hydraulikaggregat.

4. Trennen Sie Hydraulikschläuche und Wasserschlauch

von der Schneideinheit.

5. Alle weiteren Schritte werden in umgekehrter

Reihenfolge vorgenommen.

30 - Deutsch

Page 33

Reinigung

Nach dem Schneidvorgang ist der Trennschleifer zu reinigen. Eine Reinigung der gesamten Schneidausrüstung ist

äußerst wichtig. Für die Reinigung der Säge wird empfohlen, den Wasserschlauch vom Schwenkarm abzunehmen

und zum Spülen der Schneideinheit zu verwenden. Bei

Bedarf lässt sich auch die beiliegende Reinigungsbürste

o.ä. zum Reinigen der Ausrüstung benutzen. Hochdruckreiniger dürfen für die Reinigung der Schneideinheit nicht

verwendet werden.

Wartung

Neben der täglichen Pflege wie Reinigung und

Schmierung muss die Maschine gewartet werden. Nach

50 Betriebsstunden ist die Maschine einer autorisierten

Dimas-Werkstatt für den Service zu überlassen. Danach

ist die Säge alle 100 Betriebsstunden zu warten. Die

Wartung ist eine Voraussetzung für die optimale,

langfristige Leistungsfähigkeit der Maschine.

BedienungBedienungsanleitung CS 2512

Schmierung

Damit das Seil möglichst reibungsfrei läuft, müssen die

Magazinwellen mit Fett gefüllt sein. Befüllen Sie die

Wellen alle 5-10 Betriebsstunden mit Fett. Verwenden Sie

dazu Canadian Petrolium OG2 oder ein entsprechendes

Fett.

Auch die Lager der Magazinwellen müssen regelmäßig

geschmiert werden, jedoch nicht so häufig wie die

Magazinwellen.

Deutsch - 31

Page 34

Bedienung Bedienungsanleitung CS 2512

32 - Deutsch

Page 35

KonformitätserklärungBedienungsanleitung CS 2512

Konformitätserklärung

Husqvarna Construction Products Sweden AB, Box 2098, S-550 02 Jönköping, Schweden,

Tel.: +46 (0)36 570 60 00 bescheinigt hiermit, dass die Herstellung der Seilsäge CS 2512

ab dem 1. Januar 2001 folgenden Richtlinien des Rates einschließlich aller Änderungen

entspricht: 98/37/EG (Maschinenrichtlinie), 73/23/EWG (Niederspannungsrichtlinie) und

89/336/EWG (EMV-Richtlinie). Folgende Standards dienten als Grundlage: EN 55 014-1,

EN 55 014-2, EN 61 000-3-2, EN 50 144-1, EN 13 862.

Jönköping, den 01.01.2005

Christer Carlberg

Geschäftsführer

Deutsch - 33

Page 36

Konformitätserklärung Bedienungsanleitung CS 2512

34 - Deutsch

Page 37

Istruzioni per l’uso CS 2512

Indice

Italiano

Indice

Legenda........................................................................... 37

Disposizioni di sicurezza...................................... 38

Introduzione.................................................................. 39

Identificazione delle parti ..................................... 40

Dati tecnici..................................................................... 42

Montaggio/installazione dell’attrezzatura .. 43

Collegamento al gruppo idraulico ........................ 44

Inserimento del filo ...................................................... 44

Posizione del getto dell’acqua di raffreddamento

45

Funzionamento........................................................... 46

Taglio ................................................................................. 46

Conclusione del taglio................................................ 46

Pulizia ................................................................................ 47

Manutenzione ................................................................ 47

Dichiarazione di conformità CE........................ 49

Italiano - 35

Page 38

Indice Istruzioni per l’uso CS 2512

36 - Italiano

Page 39

LegendaIstruzioni per l’uso CS 2512

Legenda

Sulla macchina e nel relativo manuale sono utilizzati i

seguenti simboli. Per un utilizzo sicuro della macchina, è

importante che l’operatore conosca il loro significato.

Manuale

Leggere attentamente le istruzioni per l’uso e

comprenderne il contenuto prima di utilizzare la

macchina.

Dispositivi di protezione individuale

Utilizzare sempre:

• un elmetto protettivo approvato;

• protezioni acustiche approvate;

• occhiali protettivi o una visiera approvati e gli altri

dispositivi di protezione individuale necessari.

Nota

Una mano con l’indice sollevato accompagnata dal testo

“Nota” indica che occorre prestare particolare attenzione

durante l’esecuzione delle operazioni descritte.

CE

Questo simbolo indica che la macchina è conforme alle

direttive CE vigenti.

Avvertenza

Un grande triangolo di avvertenza accompagnato dal

testo “Avvertenza” indica che sussiste il rischio di lesioni

personali gravi o mortali.

Attenzione

Un piccolo triangolo di avvertenza accompagnato dal

testo “Attenzione” indica che sussiste il rischio di lesioni

personali o danni alla macchina.

Italiano - 37

Page 40

Disposizioni di sicurezza Istruzioni per l’uso CS 2512

Disposizioni di sicurezza

Efficienza e semplicità, unite a sicurezza d’uso, sono criteri di massima priorità nella progettazione e produzione

dei prodotti Husqvarna. Per garantire la massima sicurezza della macchina, attenersi sempre ai seguenti punti.

AVVERTENZA

Questa macchina deve essere utilizzata

esclusivamente con Husqvarna PP 455E o

un gruppo collegato a Husqvarna RC 455.

Non utilizzare la macchina per altri scopi.

ATTENZIONE

Prima di avviare la macchina, accertarsi sempre che siano rispettate le norme di sicurezza.

In caso contrario, la Husqvarna Construction

Products Sweden AB o i suoi rappresentanti

declinano ogni responsabilità per danni sia

diretti che indiretti. Leggere le presenti istru-

zioni per l’uso e accertarsi di averne compreso

il contenuto prima di utilizzare la macchina. Se

dopo aver letto le presenti disposizioni di sicurezza sussistono dubbi, non utilizzare la macchina. Per maggiori informazioni, contattare il

proprio rivenditore.

• Controllare che tutti i raccordi, i connettori e i flessibili

idraulici siano integri.

• Accertarsi che tutti i flessibili siano collegati

correttamente alla macchina prima di avviarla.

• Accertarsi che non vi siano persone o animali nell’area

di lavoro.

• Controllare che le protezioni siano integre e montate

correttamente.

• Non tagliare mai se le protezioni non sono in

posizione.

• Prima di staccare i flessibili idraulici, accertarsi sempre

di aver spento il gruppo idraulico e che il motore sia

completamente fermo.

• Controllare quotidianamente che la macchina, i raccordi e i flessibili idraulici non presentino perdite. Una

perdita o un cedimento possono causare la “penetrazione di olio” nel corpo o altre gravi lesioni personali.

• Non superare mai il flusso di olio specificato o la

pressione prevista per l’attrezzo utilizzato. Una

pressione eccessiva può causare cedimenti.

• Maneggiare i flessibili con cura.

• Non utilizzare flessibili ritorti, usurati o danneggiati.

• Controllare che i flessibili siano collegati correttamente

alla macchina e i raccordi idraulici siano bloccati prima

di mettere in pressione l’impianto idraulico. I raccordi si

bloccano girando il manicotto esterno sul raccordo

femmina, in modo da allontanare la scanalatura dalla

sfera.

• Tenere puliti flessibili idraulici e raccordi.

• Scollegare sempre la corrente al gruppo idraulico

prima di spostare l’attrezzatura.

• Durante il taglio, accertarsi di avere sempre facile

accesso al pulsante di arresto di emergenza.

• Non lasciare mai la macchina incustodita a motore

acceso.

• Prima del taglio, pianificare e segnare chiaramente tutti

i tagli necessari, in modo che la loro esecuzione non

metta a repentaglio la sicurezza delle persone e

l’integrità della macchina.

• Controllare sulle planimetrie se sono presenti cavi

elettrici oppure condutture idriche, del gas o di scarico

nell’area di lavoro.

• Controllare sempre e tracciare la posizione delle

condutture del gas. Il taglio in prossimità di condutture

del gas è estremamente pericoloso. Accertarsi che

durante il taglio non si generino scintille per evitare il

rischio di esplosione. Rimanere concentrati sul proprio

lavoro. Eventuali distrazioni possono causare lesioni

personali gravi o mortali.

• Controllare che i cavi elettrici nell’area di lavoro non

siano sotto tensione.

• Durante l’utilizzo degli attrezzi idraulici in corrispondenza o in prossimità di condutture elettriche, utilizzare

flessibili omologati come non elettroconduttori. Se si

utilizzano altri flessibili sussiste il rischio di lesioni personali gravi o mortali.

• Prestare attenzione durante le operazioni di sollevamento. In sede di movimentazione di pezzi pesanti

sussiste il rischio di schiacciamento e altri danni.

• Utilizzare sempre i dispositivi e gli indumenti di

protezione individuale come indicato nelle istruzioni

per l’uso. Non utilizzare indumenti che possono

rimanere impigliati nelle parti in movimento.

• Utilizzare esclusivamente il filo raccomandato dal

produttore.

• Non tagliare mai se l’acqua di raffreddamento non è

collegata. Un filo raffreddato in modo insufficiente può

causare il surriscaldamento dei segmenti

aumentandone l’usura. Nel peggiore dei casi, i

segmenti possono staccarsi dal filo causando lesioni

alle persone nelle vicinanze della mototroncatrice.

38 - Italiano

Page 41

Introduzione

La mototroncatrice Husqvarna CS 2512 deve essere

utilizzata insieme al gruppo idraulico PP 455 E o

Husqvarna RC 455. Husqvarna CS 2512 è una

mototroncatrice a filo potente e versatile, ideale per i lavori

più pesanti ma sufficientemente compatta e maneggevole

per svolgere anche i lavori meno impegnativi. Può essere

utilizzata in diversi modi, sia appoggiata sul terreno che

montata a parete.

Il design intelligente della mototroncatrice CS 2512, con la

ruota motrice collocata sul lato di uscita della macchina,

garantisce una tensione continua del filo anche se la forza

di movimento è ridotta. Questa caratteristica, in

combinazione alla valvola di pressione regolabile, offre un

ottimo controllo del taglio e prestazioni imbattibili.

La macchina può essere attrezzata sia in verticale che in

orizzontale ed è possibile eseguire diversi tagli senza

utilizzare galoppini esterni.

Un’attrezzatura di taglio completa comprende:

IntroduzioneIstruzioni per l’uso CS 2512

1 gruppo di taglio

1 cassetta portattrezzi

1 chiave da 18 mm

1 gruppo di riduzione della pressione

1 elemento antiusura in gomma supplementare per le

ruote del magazzino

1 spazzola per la pulizia

Italiano - 39

Page 42

Identificazione delle parti Istruzioni per l’uso CS 2512

Identificazione delle parti

4

6

7

4

14

La mototroncatrice comprende i seguenti componenti:

1. Motore idraulico

La macchina è azionata da un motore da 60 cc. Il

motore è costituito da due parti: una da 50 cc e l’altra,

più piccola, da 10 cc. Utilizzando solo il motore grande

oppure sia quello grande che quello piccolo, si

ottengono due rapporti. Questi due rapporti offrono

regimi diversi ma la stessa potenza.

2. Raccordi per flessibili idraulici

9

8

15

5

4. Magazzino del filo

Tende il filo e contiene il filo avanzato. Il magazzino del

filo contiene max 12 metri di filo (2,4 metri per ogni

coppia di ruote).

5. Cilindro del magazzino

Il cilindro del magazzino ha il compito di tendere il filo nel

magazzino, consentendo il controllo del taglio. La pressione nel cilindro si regola per mezzo del gruppo di riduzione della pressione montato su PP 455E o RC 455.

11

3

1

2

12

14

10

Il flusso di olio idraulico nei due flessibili grandi aziona

il motore della macchina e, con esso, il filo. Il flusso nei

due flessibili piccoli aziona il cilindro del magazzino.

3. Ruota motrice

Trasferisce la forza motrice dal motore al filo. La ruota

motrice ha un diametro di 400 mm e presenta un

rivestimento in gomma sostituibile per una presa

ottimale del filo.

La ruota motrice, il motore idraulico e i raccordi idraulici

costituiscono il gruppo ruota motrice. Il gruppo ruota

motrice si regola in base alle coppie di ruote utilizzate

nel magazzino e può essere smontato facilmente, ad

es. per alleggerire la macchina per il trasporto.

40 - Italiano

6. Protezione

La macchina presenta una protezione in due parti: una

parte fissa in lamiera e un carter ripiegabile in plastica

e metallo. La protezione si rimuove facilmente, ad es.

per infilare il filo, ma deve sempre essere in posizione

durante il taglio.

7. Impugnatura di trasporto

L’impugnatura ripiegabile è molto pratica per spostare

la macchina.

8. Piedini di regolazione

Si regolano per garantire la stabilità della mototroncatrice. La mototroncatrice presenta in tutto 10 piedini

regolabili: 6 per il taglio orizzontale e 4 per il taglio

verticale.

Page 43

Identificazione delle partiIstruzioni per l’uso CS 2512

9. Raccordi per l’acqua di raffreddamento

Sulla macchina sono presenti due raccordi per le lance

dell’acqua e uno per l’acqua in entrata. Oltre a raffreddare il filo, per mezzo di piccoli ugelli consentono di

lavare il filo quando entra ed esce dalla macchina.

10.Ruote di gomma

Per agevolare il trasporto. Per semplificare lo spostamento durante determinati lavori, le ruote possono

essere facilmente smontate. È sufficiente staccare le

coppiglie che bloccano le ruote al semiasse.

11.Barra reggifilo

Mantiene il filo contro il magazzino durante il

ripiegamento di quest’ultimo. In tal modo si evita che il

filo si intrecci quando non è teso, ad es. durante la sua

sostituzione o quando si cambia il numero di ruote

utilizzate nel magazzino.

12.Traversa di ancoraggio

Traversa regolabile con una scanalatura longitudinale.

Spostando la traversa lateralmente, si può sistemare il

bullone di ancoraggio nel punto desiderato senza

spostare l’intera mototroncatrice per bloccarla prima

del taglio.

Un’altra traversa di ancoraggio è collocata sotto la

mototroncatrice. In questa traversa si fissa il bullone di

ancoraggio per i tagli orizzontali.

13.Gruppo di riduzione della pressione

Il gruppo di riduzione della pressione si monta fra il

gruppo idraulico e i flessibili idraulici per il movimento

in profondità. Sul gruppo di riduzione della pressione si

trova una valvola che consente di controllare la

tensione del magazzino.

Accessori

1. Lance dell’acqua

Si collegano ai raccordi dell’acqua della

mototroncatrice e sono utilizzate per far giungere

l’acqua di raffreddamento nel taglio per raffreddare il

filo e legare la polvere di calcestruzzo.

2. Galoppini

I galoppini Husqvarna sono realizzati per guidare il filo

nel modo più efficiente possibile. Utilizzando i

galoppini, si può ridurre il numero di angoli appuntiti

intorno a cui si deve effettuare il taglio. In tal modo, è

disponibile una maggiore potenza per il taglio del

materiale.

14.Ruote di articolazione

Le ruote di articolazione con cuscinetti a sfere sono

collocate nei punti in cui il filo entra ed esce dalla

mototroncatrice. Le ruote di articolazione aiutano a

guidare il filo in modo da sistemarlo correttamente

nella mototroncatrice e possono essere utilizzate sia

bloccate che sbloccate, se si desidera che seguano

meglio il filo.

15.Ruota guida

Guida il filo dal magazzino alla ruota motrice.

Quando si regola il gruppo ruota motrice, la ruota

guida si posiziona automaticamente in base al numero

di ruote utilizzate nel magazzino.

3. Spazzola per la pulizia

Può essere collegata al flessibile dell’acqua per pulire

la macchina dopo l’uso.

Italiano - 41

Page 44

Dati tecnici Istruzioni per l’uso CS 2512

Dati tecnici

Potenza della ruota motrice (con PP 455): 20 kW

Flusso di olio idraulico:_______________ 65 l/min (17 gal/min)

Pressione idraulica max consentita:_____ 230 bar (3400 psi)

Pressione idraulica max

raccomandata

Lunghezza max del filo nel magazzino: __ 12 m (2,4 m/coppia

Dimensioni con impugnatura ripiegata e

protezione abbassata (Lung.xLargh.xAlt.)

Peso: ____________________________ 150 kg (330 lbs)

Velocità del filo in 1a: ________________ 20 m/s (66 ft/s)

Velocità del filo in 2a: ________________ 25 m/s (82 ft/s)

durante il taglio: ________ 130 bar (1900 psi)

di ruote)

1150x750x980 mm

Fili raccomandati:

Husqvarna raccomanda di utilizzare i seguenti fili:

• Husqvarna C710C

Husqvarna C710C è un filo zincato progettato per il

taglio di cemento armato rinforzato. I segmenti

presentano una percentuale di diamanti elevata e un

diametro ridotto (9,5 mm), quindi il filo è

particolarmente efficace. Grazie al diametro ridotto, il

filo C710C può essere utilizzato anche per concludere

i tagli più impegnativi.

• Husqvarna C750C

Husqvarna C750C è un filo universale progettato per il

taglio di cemento armato. Il filo è progettato per le

mototroncatrici che presentano una potenza di 1025 kW.

• Husqvarna C760C

È il filo Husqvarna migliore: le sue caratteristiche sono

lunga durata, elevata velocità di taglio e resistenza a

potenze elevate. Husqvarna C760C è ideale per il

taglio in tutti i tipi di cemento armato, anche per i lavori

che richiedono fili particolarmente efficaci, ad es. il

taglio di ponti.

• Husqvarna C790C

Grazie alla durezza dei segmenti, il filo Husqvarna

C790C è la scelta ideale per il taglio in materiali

morbidi quali calcina e cemento armato leggero.

• Husqvarna C575J

Husqvarna C575J è un filo con segmenti zincati da 15

mm.

• Husqvarna C1200M

Husqvarna C1200M è un filo progettato per il taglio

dell’acciaio. Questo filo è ideale per le condizioni di

lavoro più impegnative. L’utilizzo dell’innovativa tecnica

AVVERTENZA

Non apportare mai modifiche alla

macchina senza il consenso scritto della

Husqvarna Construction Products Sweden

AB. Eventuali modifiche non autorizzate

di sinterizzazione offre notevoli vantaggi in termini di

velocità di taglio e durata. Il filo può essere fornito con

elementi terminali applicati o a parte.

Per maggiori informazioni sulle attrezzature Husqvarna,

contattare il proprio rivenditore Husqvarna.

possono comportare il rischio di lesioni

personali gravi o mortali. La Husqvarna

Construction Products Sweden AB declina

ogni responsabilità in caso di utilizzo non

conforme alle presenti istruzioni.

42 - Italiano

Page 45

Montaggio/installazione dell’attrezzaturaIstruzioni per l’uso CS 2512

Montaggio/installazione

dell’attrezzatura

Prima di montare la mototroncatrice, programmare con

cura il taglio in modo da eseguirlo nel modo più facile

possibile.

La mototroncatrice Husqvarna CS 2512 può essere

montata per eseguire sia tagli orizzontali che verticali. Per

eseguire tagli verticali, occorre montare la mototroncatrice

in verticale.

Il montaggio in orizzontale si utilizza invece per i tagli

all’altezza del pavimento o nel pavimento stesso.

Quando la mototroncatrice è fissata al pavimento, agire sui

piedini di regolazione per garantire la massima stabilità.

Ricordare che il baricentro della macchina (cerchietto grigio) si trova fra la prima e la seconda coppia di piedini di

regolazione (le coppie di piedini di regolazione sono contrassegnate con 1-3) in caso di taglio orizzontale (a). Per il

taglio sotto la macchina, è importante ancorare la mototroncatrice adeguatamente con il bullone di ancoraggio (b)