Page 1

7iy

‘(

/

I

Page 2

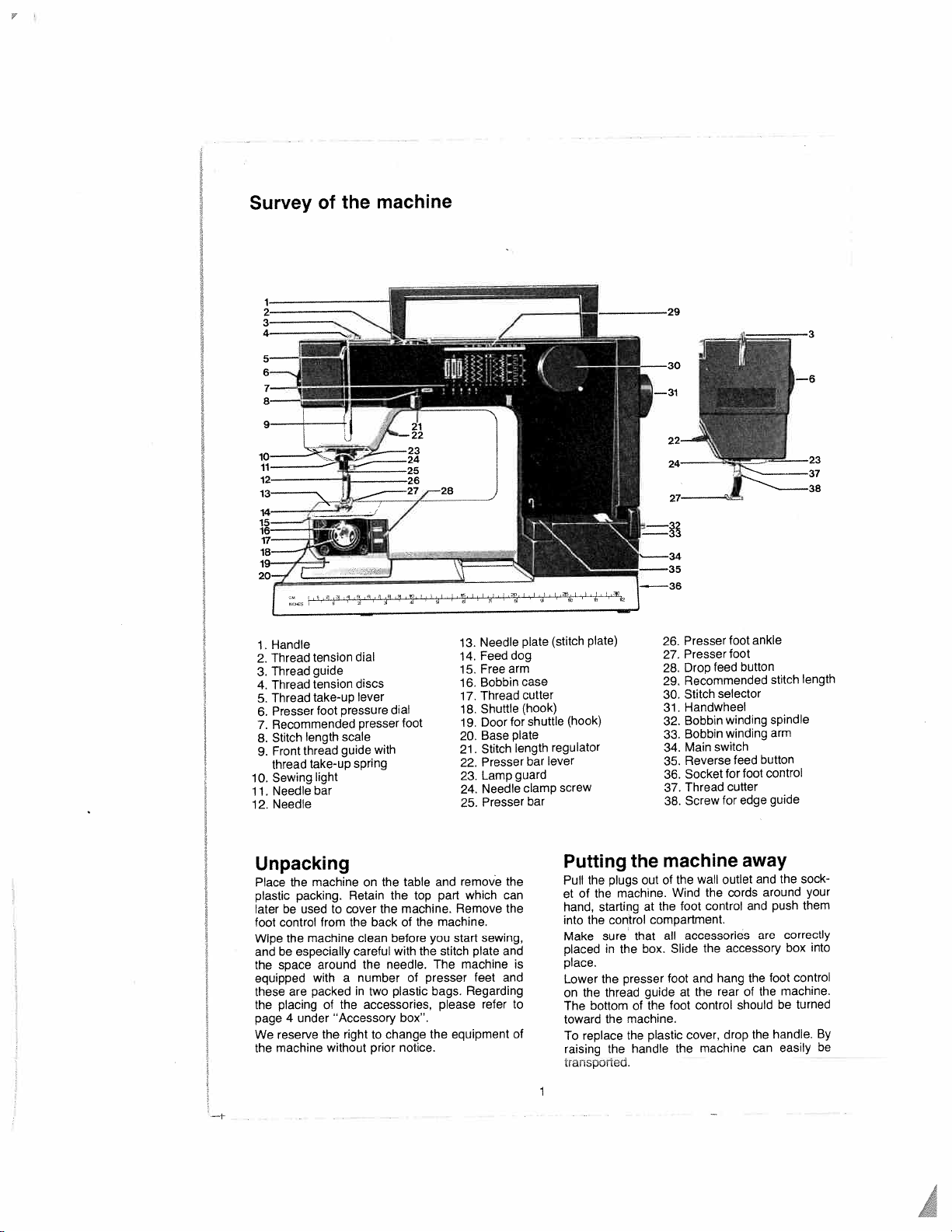

Survey

of

the

machine

Handle

1

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

tension

Thread

guide

Thread

tension

Thread

take-up

Thread

foot

Presser

Recommended

length

Stitch

thread

Front

take-up

thread

light

Sewing

bar

Needle

Needle

Unpacking

Place

plastic

laterbeused

foot

Wipe

and

the

equipped

these

the

page

We

the

the

packing.

control

the

especially

be

space

are

placing

4

under

reserve

machine

machine

machine

around

with

packed

pressure

scale

guide

cover

to

from

a

the

of

‘Accessory

right

the

without

dial

discs

lever

presser

with

spring

on

Retain

the

backofthe

the

clean

careful

the

number

two

in

accessories,

to

prior

dial

the

the

before

with

needle.

plastic

box”.

change

notice.

foot

table

top

machine.

you

the

The

presser

of

bags.

the

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

remove

and

part

Remove

machine.

start

stitch

machine

please

equipment

Needle

Feed

Free

Bobbin

Thread

Shuttle

Door

Base

Stitch

Presser

Lamp

Needle

Presser

which

sewing,

plate

feet

Regarding

refer

arm

the

can

the

and

and

plate

dog

case

cutter

(hook)

for

plate

length

guard

clamp

is

to

of

shuttle

lever

bar

bar

(stitch

(hook)

regulator

screw

Putting

Pull

of

et

hand,

into

Make

placed

place.

Lower

the

on

The

toward

replace

To

raising

transportea.

plate)

the

the

starting

the

sure

in

the

thread

bottom

the

the

plugs

machine.

control

the

presser

machine.

the

the

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

machine

of

out

Wind

the

at

compartment.

all

that

Slide

box.

foot

guideatthe

foot

the

of

plastic

handle

foot

Presser

foot

Presser

feed

Drop

Recommended

selector

Stitch

Handwheel

winding

Bobbin

winding

Bobbin

switch

Main

Reverse

for

Socket

cutter

Thread

for

Screw

outlet

wall

the

the

cords

control

foot

accessories

accessory

the

hang

and

rear

control

drop

cover,

machine

the

button

feed

foot

edge

away

and

the

of

should

ankle

button

control

and

around

are

the

the

can

stitch

spindle

arm

guide

the

push

correctly

box

foot

machine.

be

handle,

easily

length

sock

your

them

into

control

turned

By

be

Page 3

Connecting

Remove

control

marking

side

of

the

under

‘UP”

the

cord

the

machine.

Connnecting

The

the

spond

the

voltage

base

machine.

to

of

those

(V)

the

the

from

table.

upward

and

machine.

of

the

foot

the

Insert

into

to

the

frequency

Check

electricity

foot

the

the

control

control

foot

socket

wall

(Hz)

that

source

control

on

outlet

are

indicated

these

before

and

plug

the

values

connecting

place

the

with

the

right-hand

under

corre

ii

I

I—

Working

The

working

of

the

machine

Retain

require

the

left

Pant

legs

making

The

free

and

cuffs

and

stockings

Main

The

light

inner

part

Reverse

As

long

the

machine

sewing

off.

Presser

means

By

machine,

When

position,

pushing

position.

with

thick

The

presser

Presser

The

presser

a

marked

pressure

The

higher

setting

By

pressure

used

when

darning,

quilting.

If

you

turn

the

lowest

A.

Lower

the

ward

and

surface

surface

upper

side

itself,

the

accessory

larger

a

and

remove

and

sleeves

it

easytosew,

arm

also

well

as

on

switch

and

the

of

the

feed

as

you

will

soon

as

bar

of

the

the

presser

raising,

the

but

the

the

presser

This

is

seams

foot

foot

foot

dial

on

is

obtained

the

number,

the

dial

is

completely

free-hand

monogramming,

the

graded

number,

feed

dog

sideways

of

i.e.

the

working

it

makes

as

sew

the

machine

main

keep

sew

as

you

lever

presser

presser

height

bar

useful

under

should

pressure

pressure

the

by

at

dial

it

is

and

by

around

the

accessory

free

box

surface.

if

you

can

mend

it

children’s

machine.

are

switch.

button

the

reverse

in

reverse

release

foot

foot

can

lever

when

the

presser

lowered

be

can

left

side

setting

the

greater

the

symbol

released.

sewing

for

possible

move

hand.

the

arm.

on

wish

drawn

be

or

much

turned

but

it.

lever

bar

can

will

be

upward

you

be

of

the

with

machine

the

pressure

to

the

stitch

plate

box

the

machine

Pull

the

to

use

patch

easier

clothes,

onbypressing

feed

will

Excellent

at

be

raised

remain

increased

and

want

foot.

while

adjusted

the

dial

the

This

the

darn

fabric

consists

and

partly

accessory

the

free

onto

the

these

parts.

attach

to

or

button

revert

for

the

rear

and

in

by

holding

to

put

sewing.

with

machine.

the

at

pressure.

the

presser

setting

darning

embroidery

pressure

foot

with

presser

forward,

when

box

arm.

free

collars

darn

socks

depressed

ordinary

to

fastening

of

lowered.

raised

the

mm

3

it

in

garments

the

aid

Normal

white

should

foot,

back

partly

of

you

arm,

the

the

this

dot.

foot

be

i.e.

and

to

foot

the

to

LZ

by

of

2

Page 4

Lowering

You

lower

push-button.

the

lower

feed

thick

dog

part.

and

garments

are

The

darning

get

feed

Removing

Open

the

on

the

the

bobbin

door

the

bobbin

latch

recess

Grip

that

The

depressed.

released.

the

In

dog

when

not

is

will

When

the

feed

order

should

sewing

under

above

the

in

front

left

side.

case

depressed

remain

you

feed

dog

by

to

be

the

bobbin

of

the

with

in

release

pushing

raise

lowered

on

the

the

and

the

dog

the

buttons.

presser

level

shuttle

thumb

pull

case

the

in

feed

of

case

by

the

as

latch,

for

foot

the

and

the

dog

a

It

stitch

means

bobbin

long

the

upper

certain

is

also

if

the

index

as

bobbin

again

teeth

plate.

of

the

part

easier

the

finger

case

latch

push

type

of

small

will

of

out.

be

the

so

the

is

__—

in

of

to

I

L.

-

‘‘

-_

-

‘

-—

‘

Bobbin

Turn

side

is

Slide

on

the

Grip

the

hand

the

presser

by

the

the

thread

from

underneath.

allow

the

under

the

eye

the

risk

lightly

depress

you

can

Threading

When

the

beside

should

case

without

Slide

the

case.

Pull

that

the

wise)

when

The

thread

otherwise

Insertion

Slide

the

and

to

the

bobbin

case

thread

cutter

the

thread

up

toward

cut

oft

and

Thread

On

the

back

thread

cutter,

threads

when

the

outward.

the

right

lower

side

needle

thread

the

of

of

release

its

run

thread

the

bobbin

the

thread

right.

end

the

kept

cutter

winding

empty

bobbin

side

part

of

the

foot

clamp

around

presser

the

needle

bending

the

bobbin

case

as

shown

turning

thread

rotates

the

thread

must

spring

of

behind

Put

until

it

is

located

and

thread

in

of

the

by

means

you

have

bobbin

onto

of

the

of

machine

and

the

If

to

go

foot.

the

foot

the

thread

the

winding

with

it

into

the

be

pulled

will

the

the

clicks

draw

cutter.

place.

presser

until

the

machine.

the

pull

the

through

bobbin

you

are

through

Never

to

the

needle.

control.

lower

the

in

the

around.

slot

in

under

in

the

is

pulled.

be

bobbin

the

bobbin

to

ensure

to

the

the

By

Shut

bar

of

which

finished

the

small

bobbin

bobbin

winding

and

turn

thread

the

groove

a

couple

using

the

run

bobbin

Hold

As

soon

end.

thread

is

finished,

marking

figure.

Place

on

the

the

tension

direction

in

the

direction

overloaded.

case

projection

case

into

that

left

of

the

thread

from

doing

so

the

door.

you

will

you

can

sewing.

round

winding

it

out

from

of

a

metal

eye

of

the

thread

because

the

as

place

upward.

the

edge

of

the

of

the

place.

it

fits

bobbin

underneath

the

find

easily

spindle

arm

to

the

the

thread

on

the

times,

presser

the

you

thread

winding

the

The

bobbin

of

the

spring.

arrow

of

the

bobbin

Press

properly.

case.

thread

a

notch,

cut

mark

on

the

side.

arm.

beginning

needle

direct

will

end

bobbin

thread

bobbin

Check

(clock

spring,

case

The

Hold

and

will

the

off

the

on

one

located

rightRaise

guide

Wind

foot,

and

from

run

and

starts

in

its

the

be

Page 5

Threading

the

Raise

highest

pin

Slide

draw

the

Continue

into

the

Thread

the

the

under

presser

position.

thread

and

the

thread

it

upward.

tension

threading

slotonthread take-up

the

needle, ensuring

the

presser

threading

the

presser

discs

needle

foot

of

the

Place

the

into

Then

ankle

foot.

machine

thread

3

by

from

the

foot

upper

Check

spool

the

for

guide

the

draw

down

and

drawing

thatitgoes

the

front.

the

needle-eye

needle,

about

thread

lever

7,

15

sewing.

the

is

thread

the

that

of

thread

on

2

to

around

thread

and

5

through

to

Due

is

easier.

cm

(6”)

the

the

thread

the

clearly

toward

needle

on

upper

front

from

draw

thread

white

Pull

the

is

left

arm

between

guide

the

it

down

guide

color

seen

the

the

at

spool

and

right

and

thread

rear.

its

4.

to

6.

of

Tension

The

thread

higher the

tension

may

thickness

There

tension

stitching,

is

be

necessary

of

is

also

that

topstitching,

number,

obtained

Correct

tension

In

order

to

tension,

thread

on

sewing

loose

thread

neath

number,

The

the

Please

thickness.

sometimes

tension,

lies

the

thread

middle

note

a

fabric.

the

of

When

Accessory

Store

the

accessories

as

the

the

doing.

foot

for

when

the

in

allowance

of

the

at

the

footEcan

edging

joining

or

illustrated,

correct

straight

This

center

them

replace

Select

are

Presser

used

stitches.

guides

dle

seam

edge

(/32”)

Zipper

the needle,

The

zag

of

the

tension

the

is

and

easily

scrapoffabric.

straight

opposite

tension

that

be

thread

mark

a

suitable

you

i.e.

If,

both

even

visible.

dial

the

by

to

embroidering,

incorrect

understand

can

set

the

and

however,

will

is

correct

layers

the

sewing

box

it

foot

sewing.

if

4

fine,

will

presser

stitching,

has notches

When

position,

guide

you

mm

attached

be

foot.Isused

slippery

box.

Aisfitted

foot;

innermost

makingiteasy

presser

upper thread

is

graduated

tension.

the

tighter

the

the

the

type

the thread

making

dial

thread

of

tension

buttonholes,

etc.

setting

adapt

and

on

for

thread

importance

the

different

try

Beginbyusing

tension

the upper

you

occur,

when

of

fabric.

best

in

the

in

easier

be

foot

the

on

straight

you

the

at

(3A6”)

notch.

to

sew

fabrics

dial

thread

set

or

the

the

quality

fabrics,

fine

accessory

for

the

for

machine

zig-zag

which

will

fabric

the

the

to

both

for

with

thread

near

the

typeofsewing

stitching

have

inner

right

overcasting

from

Normal

white

at the

tension

fabric.

dial

tensions

an

excessively

0”.

is

drawn

dial

at

the

may

seam

threads

thread

may

the

box.

to

remove and

you

delivery

at

and

other

canbeused

with

7

a

even

with

edge

ortothe

of

sides

overcast

0—b.

thread

dot.

to

for

for

of

correct

The

lower

under

highest

pucker.

interlock

vary

knot

placing

By

and

utility

the

mm

outer

the

and

2

left

zipper.

the

with

stitch.

4

The

the

the

satin

may

you

nee

(¼’)

mm

zig

It

LX

by

in

in

is

as

of

N/’

Page 6

Needle

The

machine

can

which

Mercerized

For

buttonholes,

No.

30—50

Always

use

machine

the

Two

needles

specially

and

is

be

used

cotton

is

recommended.

needles

is

No.

for

designed

thread

delivered

for

all

can

also

topstitching

coded

80.

sewing

for

the

with

spool

a

typesoffabrics

used.

be

and

darning

1

30,705

H.

in

stretch

purpose.

fabric

of

synthetic

and

embroidery

The

needle

and

most

denim

thread,

seams.

fitted

silk

in

are

Changing

Even

if

the

tions

which

high

quality

Only

a

completely

sewing

results.

the

slightest

point

is

screw

away

socket

screwdriver.

damaged.

in

the

from

as

Stitch

The

pattern

machine

with

between

widths

The

at

needle

hems

fabric

needle

The

selector

indicator

the

to

straight

the

and

is

hole.

required

indicates

machine.

0

choose

center

position

well

to

linesupwith

the

needles

affect

can

needles.

Therefore,

reason

needle

insert

you,

far

it

as

selection

scale

located

which

The

and

5mmand

from.

stitch

canbesewn

left

or

is

suitable

when

sewinginlight

supported

stitch

the

left

or

needle

look

alike

the

sewing

undamaged

change

to

believe

To

remove

clamp.

With

the

will

go.

on

stitches

stitch

length

there

needle

when

the

in

is

set

by

to

the

stitch

the

there

that

the

new

Tighten

the

are

with

position.

sewing

fabrics

outer

turning

right

symbol.

can

be

result.

Be

needle

will

the

needle

it

is

bent

the

needle,

flat

side

needle

into

the

screw

front

of

you

can

canbevaried

three

zig-zag

the

needle

The

narrow

where

edgeofthe

stitch

the

until

the

of

the

sew

left

the

red

slight

sure

give

if

you

or

loosen

the

the

varia

to

perfect

have

that

shank

needle

with

There

stitch.

foot.

use

the

the

the

Choice

are

There

indicate

sewing

Set

the

regulator.

for

sewing

Always

with

start

exact

stitch

doing.

Presser

are

indicate

The

of

figures

the

most

normal

stitch

lengthbymeans

under

indicates

buttonholes.

use

the

experiment

but

length

foot

letters

the

most

letter

stitch

above

suitable

fabrics.

the

symbols.

the

stitch

recommended

for

the

under

the

suitable

is

also

length

the

stitch

stitch

length

until

actual

stitch

presser

marked

of

you

work

symbols

length

the

stitch

The

which

stitch

arrive

symbols

foot

on

the

length

you

which

when

length

symbol

is

at

will

which

each

for

presser

best

to

the

be

5

Page 7

General

The

lightly

of

the

Do

and

When

the

seam.

the

the

Lower

increase

When

of

mm

being

extend

few

reverse

presser

Fasten

ton

and

When

the

work

least

Straight

Check

stitch

Set

the

setting

stitch

length

Increase

It

is

even

in

the

left

step

to

fabrics.

best

on

fabric

not

pull

let

the

you

needle

When

overcast

left

edge

the

the

sewing

(l/s”)

pulled

the

foot

off

sew

the

seam

from

15

cm

that

selector

stitch

2.5

the

possible

needle

the

hints

way

to

the

work

at

B

the

fabric—just

machine

wish

to

goes

down

sewing

stitch

of

the

presser

speed

fine

from

the

down

seam

out

stitches

when

the

seam

a

few

is

finished,

behind

(6”)

of

stitching

the

needle

to

the

length

but

experiment

for

the

stitch

length

to

position

left.

This

hold

at

A

with

do

straight

zig-zag

place

needle

foot,

gradually.

and

soft

edge

into

to

and

sewing

by

reverse

and

thread.

is

straight

regulator

actual

do

straight

is

the

fabric

and

guide

your

right

guide

the

feeding.

stitch,

in

the

center

and

the

hole.

start

fabrics,

of

the

the

needle

the

very

then

hold

forward

depressing

stitches.

raise

cut

in

the

stitch

to

until

work

when

basting

by

turning

very

useful

is

to

it

hand

it

toward

place

other

marking

the

start

fabric,

edge

the

again.

the

the

presser

off

the

highest

symbol.

the

recommended

you

you

will

stitching

the

when

let

your

forward.

and

the

of

the

wide

for

machine

the

to

hole.

of

the

threads

reverse

threads

position.

arrive

be

doing.

and

with

stitch

left

hand

Hold

the

guide

the

the

presser

work

so

marking

stitches,

the

seam

gently

seam

a

couple

prevent

it

If

you

wish

fabric,

sew

behind

feed

foot,

remove

leaving

Turn

basic

at

the

exact

topstitching.

the

needle

selector

sewing

one

light

edge

work.

for

along

and

from

the

but

the

rest

foot

that

the

e.g.

to

at

B

a

Zig-zag

Check

that

the

choice

Turn

the

Recommended

Zig-zag

edging,

Three-step

binds

is

appliqués,

better

Three-step

Check

that

stitch

selector

length

1.

Three-step

rics,

especially

rics.

It

has

zag.

It

is

fabric.

darning

more

It

is

ideal

and

the

needle

of

three

stitch

stitch

used

zig-zag

and

the

needle

to

zig-zag

stretch,

many

elastic

for

mending.

is

zig-zag

selector

length

for

sewing

etc.

is

recommended

is

more

zig-zag

is

symbol

is

suitable

lightweight

advantages

and

sewing

in

the

widths,

to

the

1.5—2.5.

on

attractive.

in

the

,..,,.\.\.‘.

for

compared

will

not

terry

highest

1.5,

required

lace,

for

highest

Recommended

overcasting

or

loosely

pucker

cloth

and

position.

3

and

5

zig-zag

gathering,

overcasting,

position.

most

woven

to

ordinary

the

edge

is

also

You

mm.

symbol.

Turn

of

used

have

bound

as

the

stitch

fab

fab

zig

the

for

it

Oil

Page 8

Blindstitching

Blindstitching

and

knitted

right

side.

Check

stitch

stitch

The

thicker

stitches

is

unavoidable

side.

Fold

the

the

presser

edge

guide

thickness

Be

sure

underneath

Sew

a

catch

just

reach

the

too

far

that

selecter

length

will

fabric

of

that

few

inches

one

fold,

in

on

is

fabrics

the

1.5.

and

be.

foot

1

underneath

the

the

the

thread

turn

the

used

without

needle

at

the

softer

When

that

illustrated.

as

0

fabric.

folded

presser

and

the

fabric

for

symbol

sewing

small

a

can

check

of

the

red

fold,

hemming

the

is

in

the

be

may

edge

foot.

folded

roller

turn

the

stitch

shifted

that

skirts

stitches

being

highest

will

fabrics

sideways

be

set

large

edge.

roller

position.

the

show

vary

according

the

If

the

toward

Recommended

fabric,

lightweight

As

follows

the

slightly

the

made

visible

less

woven

on

in

edge

zig-zag

stitches

+.

toward

of

visible

fabrics,

the

thickness

so

that

guide

stitches

If

they

—.

woven

on

Set

right

to

fail

the

the

the

it

the

the

1

to

are

Overcast

Check

that

stitch

The

ing

Join

(/ie’)

seam

close

the

selector

overcast

lightweight

and

overcast

seam

is

allowance,

to

the

stitching.

Double-action

Check

that

selector

the

elastic

under

that

selector

the

edges.

would

(without

Use

around

bridging

the

double-action

seams

with

does

the

seams

stitch

the

to

like

sewing

each

other

stitch

the

its

stitch

Use

overlapped

gathering

the

freely

Overlapped

leather.

Bridging

Check

stitch

Use

folded

If

you

edges

ters

from

The

bridging

elastic.

elastic

stitch

needle

to

the

stitch

can

woven

directly

allowed,

sew

needle

to

the

symbol

in

narrow,

not

get

stitching.

are

needle

the

symbol

stitch

a

decorative

and

is

also

buttonhole

heel”.

is

in

symbol

be

and

or

cut

with

stitch

in

is

stitch

tricot

flat

stitched

also

is

in

for

joining

them

join

useful

the

highest

vVV.

used

elastic

on

the

out

overcast

the

highest

for

and

soft

elastic

in

recommended

the

highest

two

seam,

together

with

for

foot

C

for

joining

fabrics.

edge

the

garment

stitch

hemming

material

or

elastic

by

mistake

position.

pieces

first)

bridging

gathering

and

place

position.

where

and

position.

cord.

of

place

a

few

stitch.

with

and

and

and

the

with

but

for

Turn

fabric

the

millime

Turn

overcast

a

5

wider

a

then

Turn

sewing

also

Be

sure

can

sewing

the

with

folded

shirring

shirring

the

mm

trim

the

for

run

7

Page 9

Buttonholes

When

sewing

C.

This

foot

buttonholes

tension

symbol.

Set

buttonhole

attractive

the

Always

setting.

bering

ii

0

the

fabric

that

turning

by

stitch

and

where

test

Insert

the

Set

The

reverse.

rect

Turn

Now

Sew

buttonholes,

has

graduated

the

same

selector

symbol.

even

you

sew

a

the

machine

the

stitch

machine

Stop

column

to

symbol

the

machine

three

length.

the

thread

and

The

finer

buttonhole

the

wish

buttonhole

fabric

under

will

selector

sews

when

length.

2—4.

or

four

change

markings

Decrease

tension

stitch

thread

to

begin

and

begin

to

the

you

will

form

stitches.

length

will

the

adjust

the

to

symbol

first

reach

the

to

the

to

help

dial

you

be.

buttonhole.

presser

sew

column

the

bar

buttonhole

you

the

upper

to

the

regulator

use,

Make

the

stitch

foot,

in

reverse.

1.

in

cor-

tack.

foot

make

the

thread

buttonhole

at

the

the

more

a

mark

length

remem

on

_________

Turn

to

symbol

Sew

the

the

as

first

2

Turn

back

will

form

four

stitches.

the

threads

other

to

the

one.

final

in

3.

column

symbol

bar

Turn

the

to

first

the

2—4.

tack.

symbol

column.

same

The

Sew

machine

three

1

and

length

or

lock

Corded

A

small

material,

around

shown

normal

In

heavy

sewing

time.

Cutting

The

buttonhole

box,

is

can

be

handle.

When

you

must

be

Pierce

edge

reaches

With

the

forward,

buttonhole.

buttonhole

other

direction.

Sewing

Lower

the

button

in

selector

handwheel

enters

the

six

stitches.

needle

fasten

the

When

a

trated.

buttonholes

cord

in

order

the

projection

in

the

way,

garments

the

columns

the

equipped

pushed

have

cut

open

the

fabric

down

knife

taking

The

to

the

on

feed

place

at

the

toward

first

Move

to

straight

threads

shank”

can

be

usedtosew

to

keep

at

illustration

you

twice

buttonhole

knife

which

with

a

onto

the

finished

as

follows:

at

right

a

to

the

more

or

care

not

small

red

middle

buttons

dog.

Remove

and

lower

widest

or

you

and

to

stitch

with

is

required,

and

the

a

hole

the

shape

the

heel

and

can

sew

and

you

safety

cap

back

of

sewing

angle

buttonhole.

less

parallel

to

bead

and

then

presser

the

intermediate

test

then

the

other

in

the

few

stitches.

use

of

sew

reinforced

the

will

which,

the

knife,

all

until

cut

the

serves

repeat

the

presser

carefully

other

holes

left

the

buttonholes

better.

Attach

the

buttonhole

the

buttonhole

buttonholes

bar

tacks

find

in

the

when

providing

buttonholes,

the

the

curved

to

the

columns

guide.

as

a

the

foot,

bar.

Set

zig-zag.

that

hole.

and

repeat.

needle

button

reedasillus

in

the

accessory

taken

fabric,

cut

from

the

Turn

the

Sew

position

elastic

the

foot

in

second

a

good

blade

push

of

Cut

put

stitch

needle

five

Set

cord

as

the

by

off,

Er

they

the

the

the

the

the

or

the

and

Page 10

Changing

The

lamp

the

lamp

recess

leverage,

To

in

push

the

The

machine.

Care

If

and

to

straight

Clean

you

When

the

small

place.

guard.

at

you

remove,

direction

the

it

upward

arrow.

wattage

of

want

you

lower

the

right

up

between

will

find

replacing

recessinthe

pin

and

Belts

Belt

adjustment

Why

haven’t

expected?

start

Always

An

important

from

time

to

new

needle

a

seam

is

thread

machine

3.

needle

may

the

upper

the

in

needle

thread,

upper

much

thread

hole

sharp

thread

bobbin

bobbin

may be

not

inserted.

threading

upper

as

wrongly

have

the

any

tension.

in

See

thread

correctly

Unattractive

The

The

correct

Wrong

thickness

Bobbin

page

The

You

pulling

against

The

Check

caught

The

the

The

too

The

The

have

Lower

The

inserted.

The

Uneven

This

the

located

is

the

the

to

the

and backward

left

can

press

of

and

of

clean

feed

above

the

in

the

the

continue

is

to

By

inserting

edge

slide

the

the

turn

the

bulb

machine

the

dog.

the

teeth

accessory

stitch

arm.

not

I

by

checking

which

part

time

is

the

as

soon

what

you

stitches

tension

is

may

be

is

shown

thread.

the

lower

inserted

breaks

helped

fabric.

The

needle

plate

thread

breaks

thread

spool

way.

eye

may

change

so,

is

See

knotted.

needle

Replace

breaks

case

page

3.

overwound.

tension

due

to

have

incorrectly

is

poor

If

thread

is

the

edges.

is

light

left

the

and

the guard

light

bulb

arrow.

it

a

is

machine,

There

hook

at

of

plate,

Ease

push

to

required.

got

the

the

needs

needle.

as

you

expected.

not

correct.

incorrectly

on

It

should

thread.

in

the

the

machine

needle

and

to

sharp

the

needle.

page

may

plate

the

incorrectly

quality

bulb

of

the

the

applying

upward.

To

insert

quarter

indicated

isarecess

cover.

the

same

the

feed

box.

insert

the

it

forward

results

needle

to

Always

discover

Check

See

threaded.

pages

be

bobbin

can

break.

see

that

edges

threaded

4.

be

needle

thread.

needle.

small

down

turn

remove

Push

time

dog

front

be

page

3

of

the

case.

to

easily

it

which

See

chipped

threaded

First

screwdriver

slight

the

to

stitch

turn

quarter

a

the

new

in

the

on

the

the

presser

in

the

the

until

with

it

from

behind

edge

up

until

it

I

changed

start

with

that

that

it

4.

The

and

4.

same

See

feed

by

strike

has

not

cut

page

5.

or

has

and

plate.

or

remove

in

downward

plate.

bulb,

light

direction

rear

of

free

stitch

plate

it

loosens.

the

brush

onto

snaps

a

is

9

the

turn

of

the

foot

arm

into

the

into

Irregular

The

The

winding.

The

The upper

for

The

The

length

The

pressing

See

The

page

The

the

Machine

Dirt

Loosen

tween

See

Dirt

bobbin

See

We

equipment

sories

in

Such

benefit

bobbin

bobbin

machine

See

fabric

thread

thread

correct

machine

stitch

regulator

feed

dog

the

page

3.

presser

2.

feed

dog

brush.

See

runs

or

lint

has

the

the

teeth

instructions

or

lint

has

case

instructions

reserve

and

without

the

designorappearance

modifications

of

the

winding

not

placed

is

is

not

page

puckers

does

length

to

may

lower

foot

is

instructions

sluggishly

fastened

needle

of

fastened

and

the

the

prior

user

full

above.

clean

above.

correctly.

correctly

3.

tension

is

tension.

feed

not

short,

is

too

higher

a

be

part

of

pressureisdisengaged.

of

dust

under

plate

the

feed

in

the

with

right

to

assortment

notice,

however

the

and

threaded

too

tight.

the

number.

lowered.

the

feed

and

above.

the

and

brush

dog.

hook.

the

brush.

change

make

or

of

will

always

product.

page

See

for

See

fabric

Shift

the

Raise

dog

dirt.

Clean

needle

clean

Remove

machine

the

of

extra

modifications

machine.

the

be

bobbin

page

stitch

it

button.

See

with

plate.

be

the

acces

to

the

3.

by

4

>

o

C

0

0

C?

Cd

0)

N

Loading...

Loading...