Page 1

UJAbSflH

-L

Page 2

CONGRATULATIONS

A

CHOOSING

HUSKYLOCK!

ON

Your

machine

enjoy

that

If

Huskylock,

service.

Enjoy

you

all

you

need

Yourself!

the

study

your

is

a

features

this

more

Husqvarna

high

quality,

incorporated,

booklet.

information

easy-to-use

regarding

dealer

however,

is

always

product.

we

the

use

happy

To

fully

suggest

of

your

to

be

of

Page 3

TABLE

OF

CONThNTS

NAMES

ELECTRONIC

ACCESSORIES

NEEDLE

MOTOR

SElliNG

THREADING

SEWING

STITCH

RATIO

THREAD

CHART

STITCH

STITCH

MECHANISM

DIFFERENTIAL

PRESSER

STITCH

PERFORMANCE

CHANGING

RETRACTING

MAINTENANCE

MACHINE

OF

UP

Before

Threading_overlooper

Threading_underlooper

Threading

To

start

Operation

To

remove

Chaining-off

If

threads

CHART

TENSION

Thread

OF

LENGTH

Stitch

Stitch

WIDTH

FOOT

SPECIFICATION

PARTS_AND

NOTE]

I

FUNCTIONS

TE

YOUR

NOTE

threading...

NOTE

I

[NOTE

NOTE

I

needles

sewing

the

break

NOT1

OF

SEWING

tension

[NOTE

THREAD

AND

length

width

AND

FEED

PRESSURE

[NOTE

PROBLEMS

THE

LIGHT

THE

BLADE

THEIR

Turning

Two-needle

MACHINE

How

to

I

Threading

If

overlooper

I

If

underlooper

I

work

during

Optional

control

Order

TENSION

STITCH

CUTrING

MECHANISM

Don’t

I

sewing

MATERIAL,

levers

of

touch

FAULT-FINDING

BULB

FUNCTIONS

direction

use

order

stitches

thread

ADJUSTMENT

WIDTH

WIDTH

models

the

thread

thread

the

of

thread

THREAD

tension

FINE

stitch

motor

spool

breaks

during

breaks

tongue

during

AND

adjustment

ADJUSTMENT

cap

and

NEEDLE

changing

the

sewing

sewing

1-2

3

4

5

6

7

net

8-11

12

13-14

15

16

17-20

21

22

23

25

25

knob

26

28

28

29

30

Page 4

CAUTION!

THREADING,

WHEN

SWITCH

WHEN

OF

THE

THE

MACHINE

DISCONNECTED

REPLACING

MACHINE.

IS

FROM

THE

NOT

NEEDLE

IN

WALL

USE,

SOCKET

LIGHT

OR

IS

RECOMMENDED

IT

TO

BULB,

AVOID

BE

ANY

TO

SURE

THAT

POSSIBLE

TURN

THE

ELECTRIC

HAZARDS.

OFF

THE

SUPPLY

MAIN

POWER

PLUG

IS

Page 5

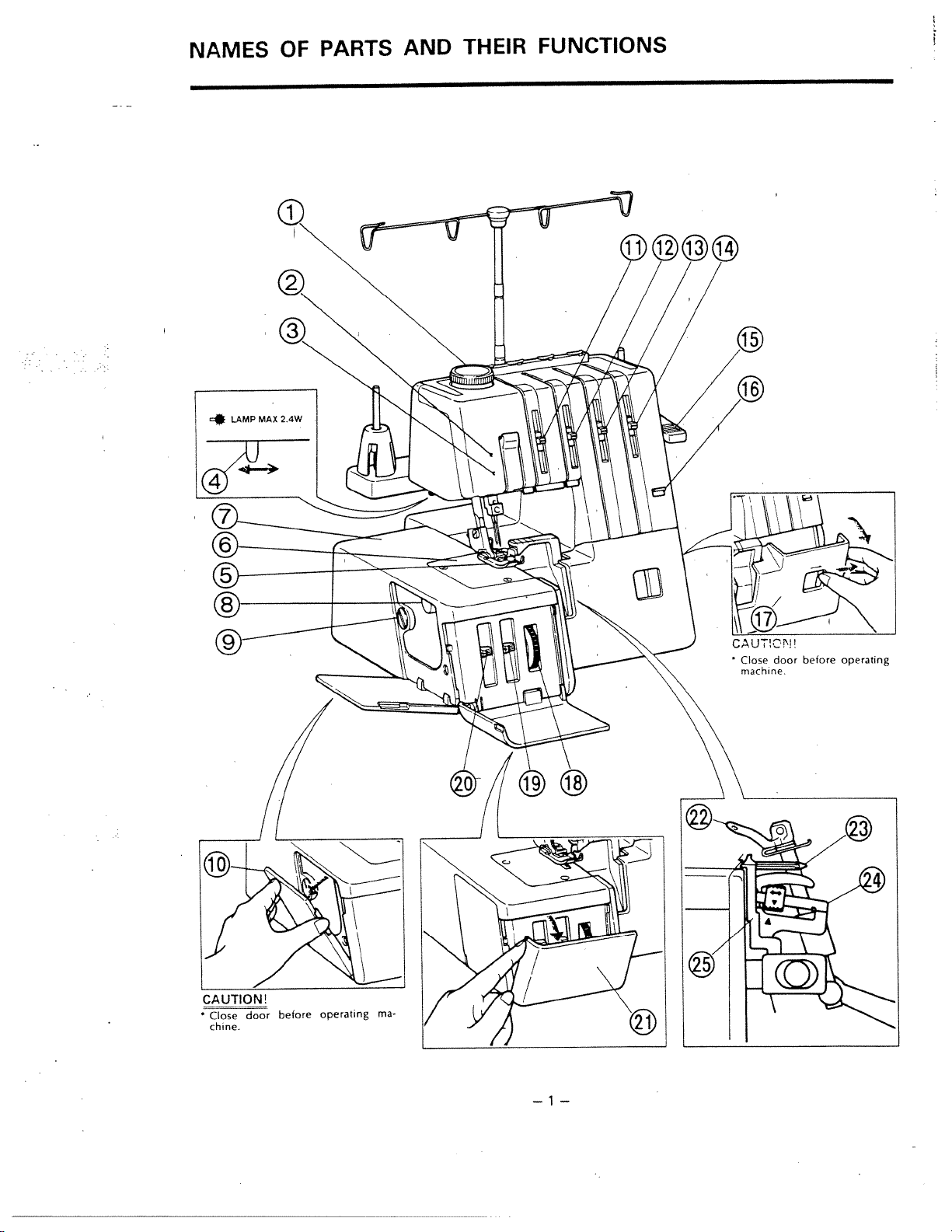

NAMES

OF

PARTS

AND

THEIR

FUNCTIONS

CAUT!CN’

door

*

Close

rnachioe.

before

operatiog

—1—

Page 6

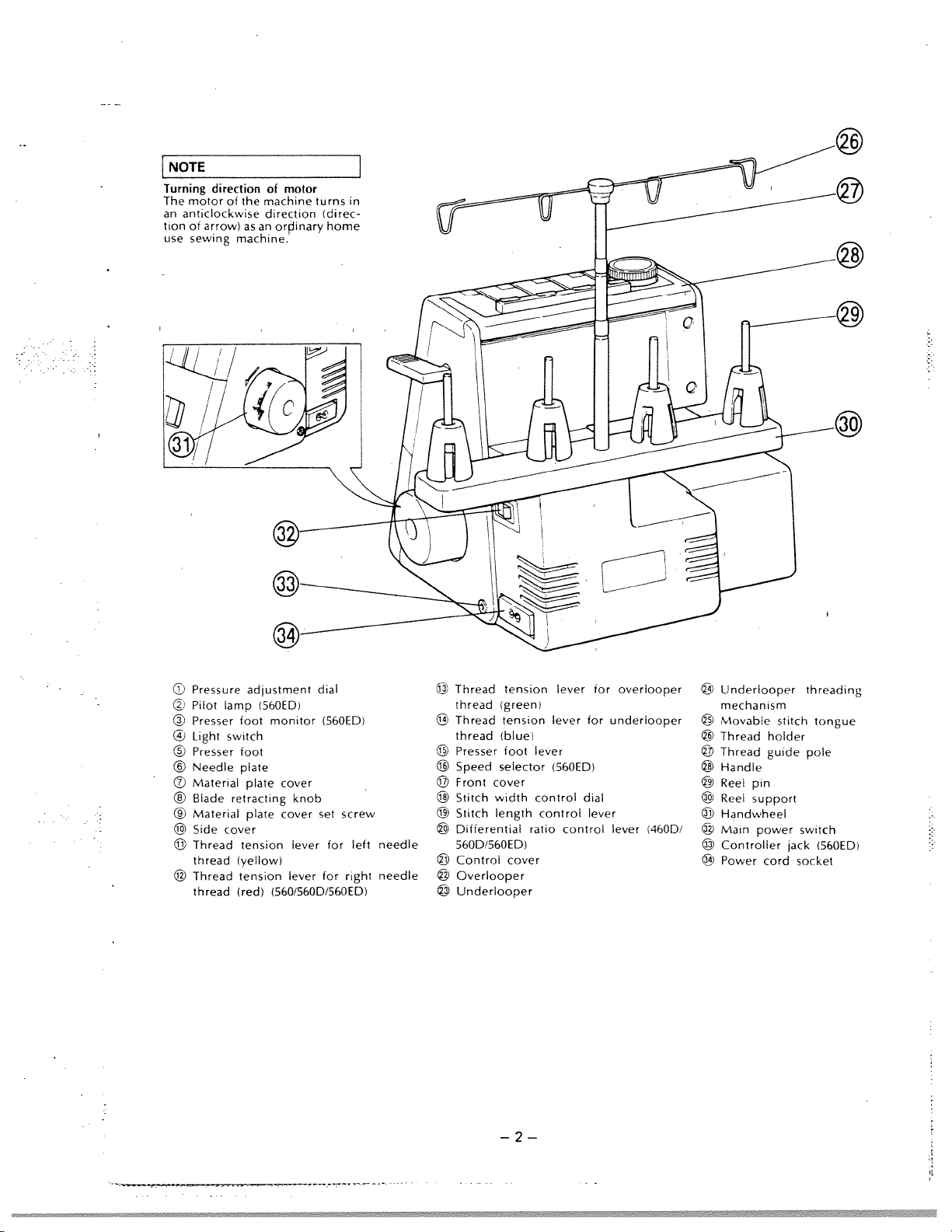

Turning

The

motorofthe

an

anticlocksvise

tion

ot

use

sewing

direction

arrow)

machine.

as

of

machine

direction

an

orØinary

motor

turns

(direc

home

in

(J

©

®

®

©

®

®

©

©

©

©

Pressure

Pilot

Presser

Light

Presser

Needle

Material

Blade

Material

Side

Thread

thread

Thread

thread

adjustment

lamp

foot

switch

foot

plate

plate

retracting

plate

cover

tension

(yellow

tension

(red)

(360E0,

monitor

cover

knob

cover

lever

lever

(

560

/560D/S6OED(

dial

1560ED)

set

screw

for

for

right

left

needle

needle

Thread

©

thread

Thread

®

thread

Presser

®

Speed

®

Front

©

Stitch

®

Stitch

©

Difterenjj

©

5

600/569W)

Control

©

©

Overlooper

@

Underlooper

tension

(green;

tension

(blue;

foot

selector

cover

width

length

cover

—2—

lever

control

control

ratio

lever

lever

(560ED)

control

for

for

dial

lever

overlooper

underlooper

lever

1460D’

©

Underloop

mechanism

©

Movable

Thread

®

Thread

©

Handle

@

Reel

©

Reel

©

Handwh

Main

©

Controller

©

Power

©

holder

guide

pin

support

power

cord

stitch

lack

threading

tongue

pole

switch

(560ED)

socket

Page 7

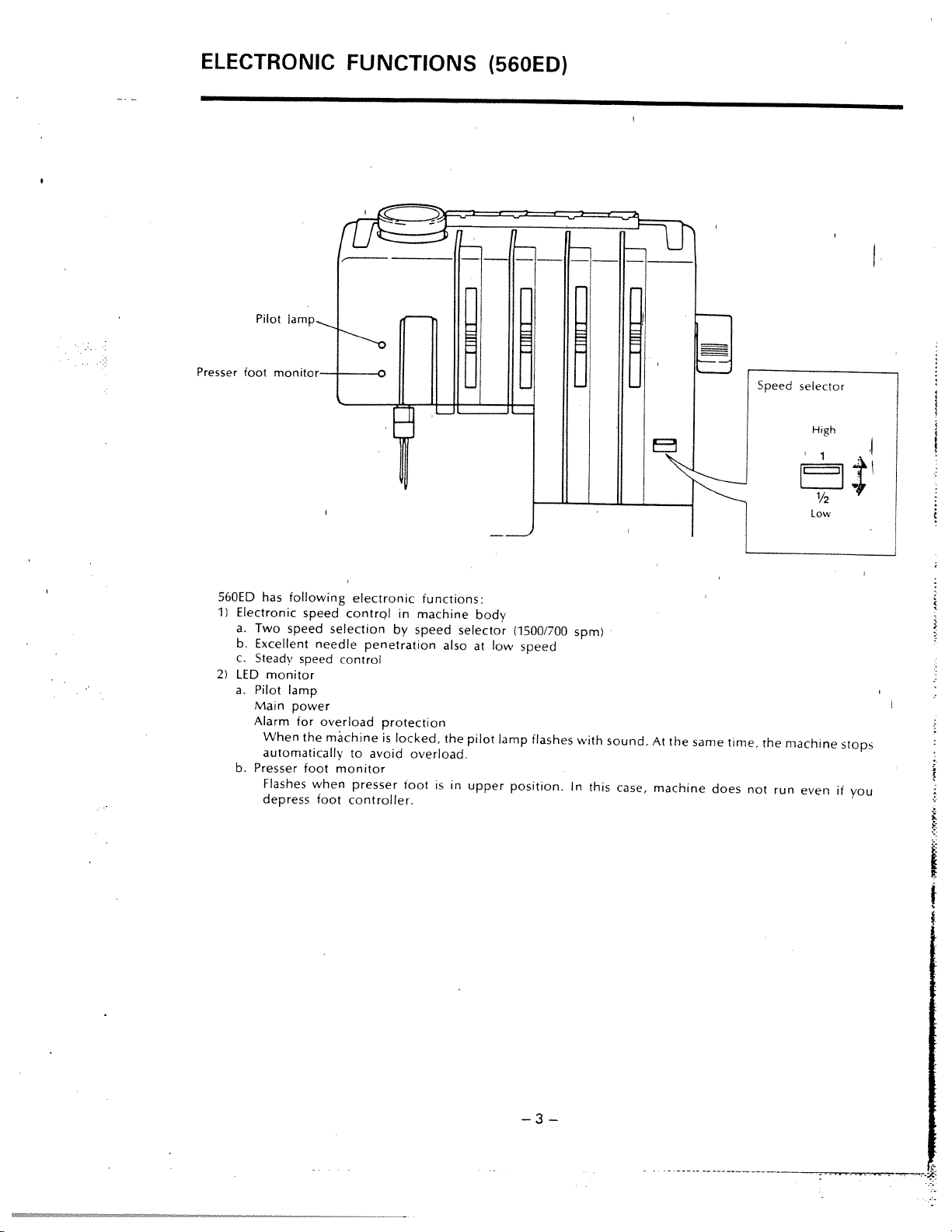

ELECTRONIC

Pilot

lamp.

FUNCTIONS

(560ED)

Presser

560ED

1)

2)

foot

monitor—

has

Electronic

a.

Two

Excellent

b.

C.

Steady

monitor

LED

a.

Pilot

Main

Alarm

When

automatically

b.

Presser

Flashes

depress

following

speed

speed

needle

speed

lamp

power

for

overload

the

foot

when

foot

electronic

control

selection

control

machine

to

monitor

presser

controller.

in

by

penetration

protection

is

locked,

avoid

overload.

toot

functions:

machine

speed

also

s

the

in

body

selector

at

pilot

upper

E

(1500/700

ow

speed

lamp

flashes

position.

spm)

with

In

this

sound.

case,

At

the

machine

same

does

time,

not

Speed

the

run

selector

High

Low

machine

even

1/2

stops

if

you

—3—

Page 8

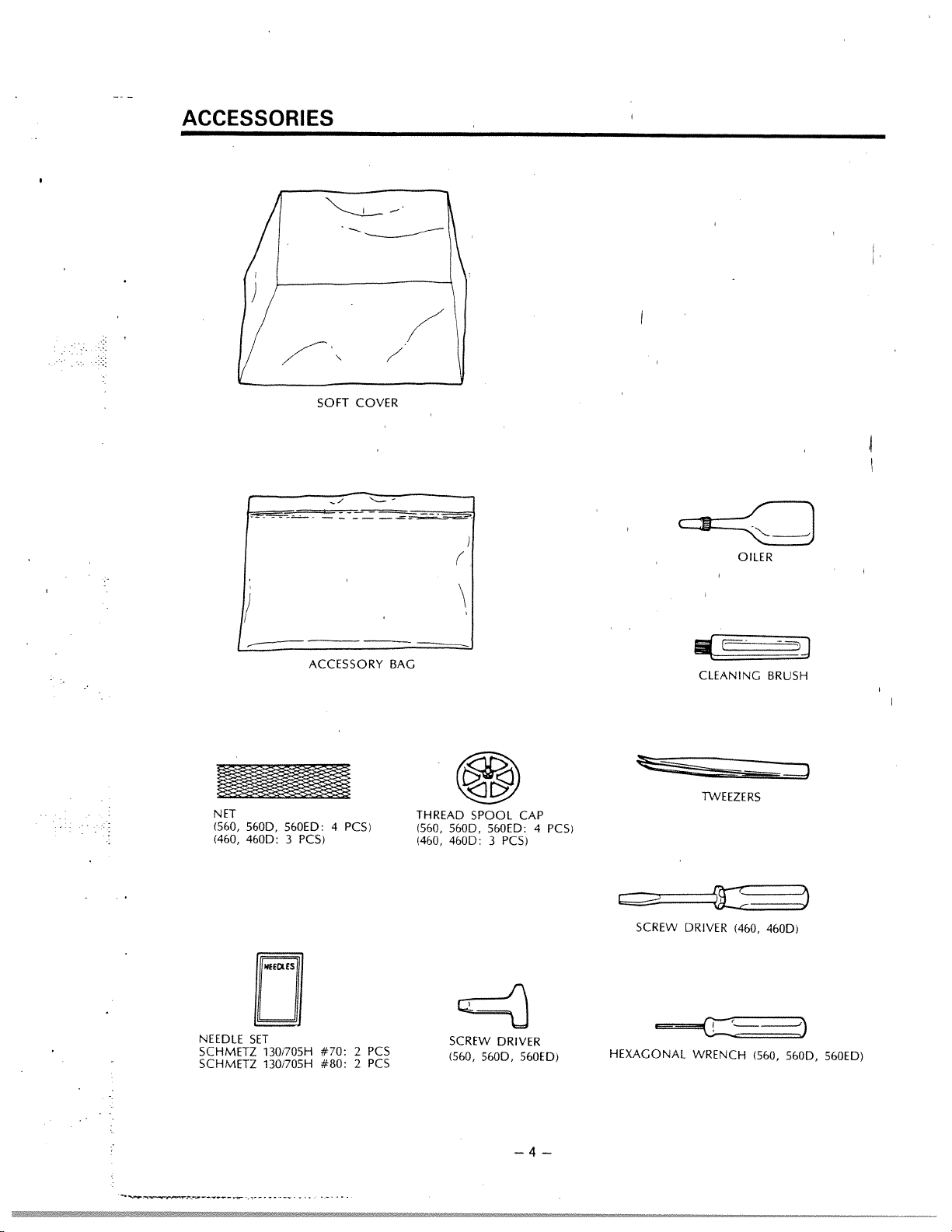

C,

0

m

Cl)

-

fi

0

rn

fill

0

jJ

:zU:_J

cJwz

fifirn

I

I

I

>

fi

fi

I

0

Q

m

(‘

rn

N

rfl

N

41

iEEi

-<

>

0

Ix

fi

c-I,

fin

c-fcc-I,

00

rn

4-c1,>

00

-v

fi

II

fl

Iii

Im><

>

z

9

0

II

ii

a

rnf

rn

z

liii

mIj

m

N

IIl

Q

z

I

niIi

01111

:1lIII

c-ri

ijI!

lI’J

C

I

0

9

ai

U,

0

c-ri

rn

-Q

9

Page 9

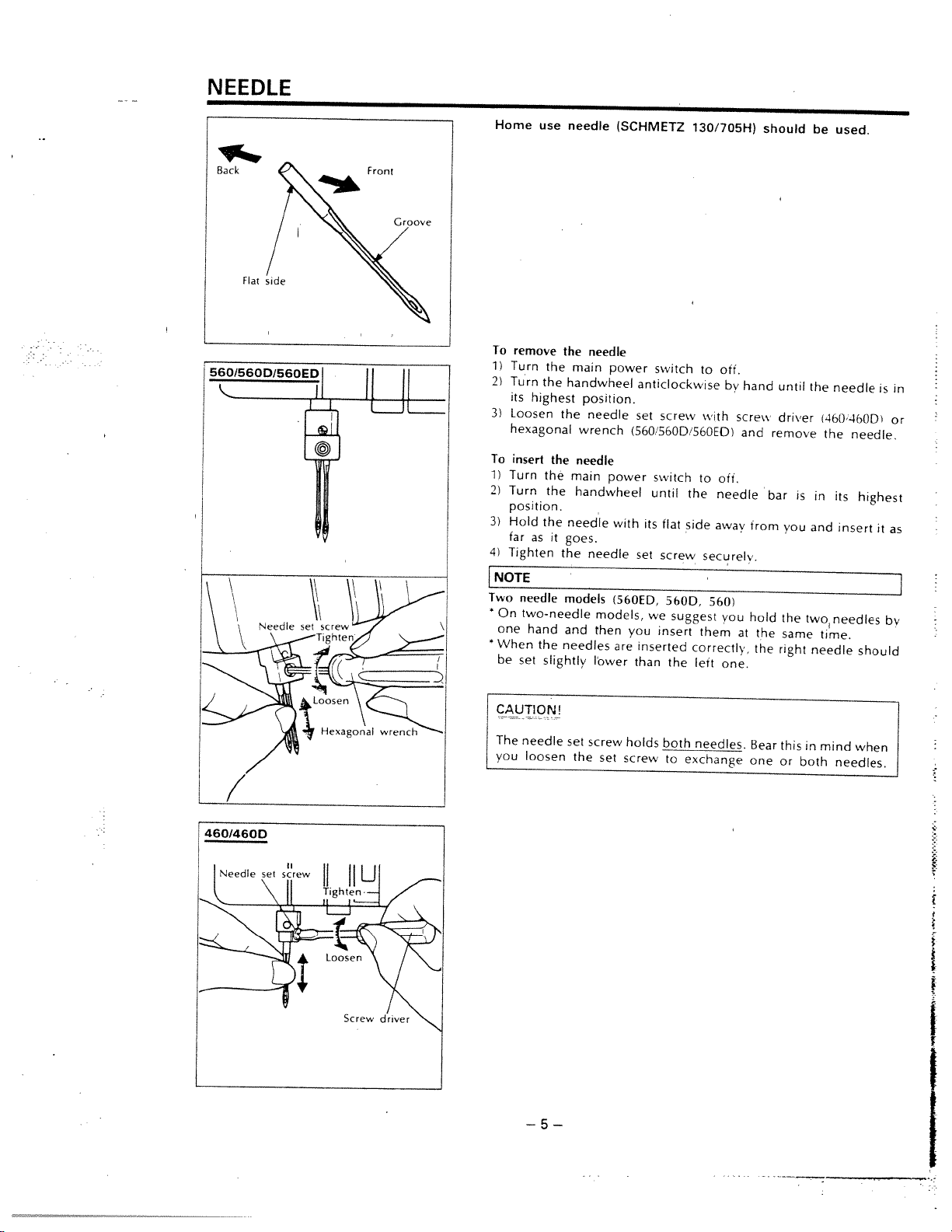

NEEDLE

Back

Flat

Home

To

11

2)

3)

To

1)

2)

3)

4)

NOTE

j

Two

On

one

When

be

use

remove

Turn

the

Turn

the

its

highest

Loosen

hexagonal

insert

Turn

the

Turn

the

position.

Hold

the

far

as

Tighten

needle

two-needle

hand

the

set

slightly

needle

the

main

handwheel

the

the

needle

main

handwheel

needle

it

goes.

the

models

and

needles

needle

position.

needle

wrench

needle

models,

then

lbwer

(SCHMETZ

power

switch

anticlockwise

set

screw

(56056ODi56OED)

power

switch

until

with

its

flat

set

screw

(560W,

are

you

inserted

than

we

5600,

suggest

insert

the

130/705H)

to

off.

with

off.

to

the

needle

side

away

securely

560)

them

correctl’,

left

by

you

one.

hand

screw

and

from

hold

at

should

bar

the

the

until

driver

remove

you

the

same

right

is

two

be

the

needle

46D460D

the

in

and

needles

time.

needle

used.

its

insert

needle.

highest

should

is

in

or

it

as

by

CAUTION

The

needle

you

loosen

—5—

set

the

screw

set

holds

screw

both

to

needles.

exchange

Bear

one

this

or

in

both

mind

when

needles.

Page 10

MOTOR

The

maximum

to

the

operating

noted

that

machine.

*

The

bearings

withstand

Continuous

controller,

The

motor

paper

during

When

the

opposite

significance.

Satety

Article

When

disconnected

8V/2

The

and

the

regulation

7.1”.

the

.4W.

machine

C.l.S.P.R.

operating

the

motor

in

long

operation

but

and

use.

motor

handwheel.

machine

from

has

speed

the

hours

tiis

will

foot

controller

is

running,

for

domestic

is

the

an

interference

of

of

this

motor

of

of

not

power

speed

600

to

sewing

are

continuous

the

sewing

in

no

sparks

These

sewing

in

use,

supply

of

this

sewing

800

stitches

machine

made

of

operation.

way

affect

are

equipped

may

sparks

machines

or

when

by

suppressor

turns

special,

machine

the

be

seen

are

produced

threading,

removing

for

machine

per

minute

in

the

sintered

will

slightly

performance.

with

ventilating

through

by

in

conformity

the

radio

and

is

1,500

for

same

oil-impregnated

increase

the

the

carbon

replacing

plug

from

television,

stitches

the

ordinary

direction

holes,

ventilating

brushes

with

“CEE

needle

the

complying

per

as

the

which

wall

minute,

home

the

motor

alloy

temperature

must

hole

in

and

he

Publication

or

light

socket.

with

which

sewing

in

mounted

not

be

the

motor

commutator,

No.10,

bulb,

Use

birective

machine.

an

ordinary

of

covered

the

bulbs

quite

is

in

the

bracket

fast

home

oil-soaked

motor

with

and

Part

II,

machine

designed

No.82/499

compared

It

should

and

cloth

on

the

are

Section

must

for

sewing

felt

foot

side

of

no

C,

be

max

E.E.C.

be

to

or

—6—

Page 11

SETTING

UP

YOUR

MACHINE

Raise

the

positioning

and

lower

thread

support.

thread

stopper

holders

Connect

power

guide

sections.

are

supply.

pole

at

the

Make

right

the

machine

and

joint

above

sure

to

the

set

tiv

the

that

the

the

tipper

the

reel

of

NOTE

HI

How

to

Thread

When

you

the

use

trated.

Net

If

you

are

nylon

thread,

you

cover

supplied

slipping

the

to

illustration.

use

spool

thread

to

off

shape

thread

cap

use

a

sewing

we

the

prevent

the

of

spool

wooden

spool

with

recommend

spool

the

spool.

the spool,

—7—

cap

thread

cap

loosely

with

thread

Adapt

and

as

the

the

as

net

reel,

illus

spun

that

net

from

net

per

Place

thread

reels

on

reel

suppdrt

1

Page 12

THREADING

Before

1)

Turn

Raise

2)

When

discs

thread

tension

threading...

off

the

main

the

presser

the

presser

in

the

thread

runs

clearly

cannot

food

tension

between

be

power

by

foot

is

obtained.

switch

means

raised,

control

them.

for

safety.

of

the

the

panel

Otherwise

presser

two

are

foot

thread

released

correct

lever.

tension

so

that

thread

NOTE

Threading

Thread

Overlooper

1)

2)

Right

3)

4)

Left

order

in

the

Underlooper

needle

(560/5600/560ED>

needle

following

thread

thread

thread

thread

3

Set

handwheel

In

overlooper,

order:

(green)

(blue)

(red)

(yellow)

—8—

this

the

needle

toward

position,

right

bar

you

you.

and

in

can

its

left

highest

thread

needle,

all

position

parts,

easily.

by

i.e.

underlooper,

turning

the

Page 13

Threading

Run

the

thread

overlooper

in

the

sequence

illustrated.

4601460D

—9—

If

overlooper

Underlooper

on

overlooper.

overlooper

and

take

from

overlooper.

overlooper.

thread

by

the

breaks

thread

In

such

turning

underlooper

Then

during

sometimes

a

case,

the

handwheel

re-thread

lower

thread

sewing

hangs

the

ott

the

Page 14

Threading

--

-

Run

ihe

thread

underlooper

in

the

sequence

illustrated.

Easy

threading

a

Pull

b

Thread

hook

c

Push

basic

CAUTION!

When

always

meet

each

out

the

of

the

the

position

pushing

make

rechanism

the

undertooper

underlooper

underlooper

underlooper

while

the

sure

that

other

as

threading

and

threading

threading

holding

underlooper

the

two

per

illustration.

position

the

end

threading

red

lever.

the

lever.

lever

of

triangle

back

the

thread

thread.

lever,

marks

to

on

.ts

—10—

Page 15

Threading

CAUTION

needles

Thread

underlooper

1)

Right

needle

1560156001560ED)

the

needles

and

thread

after

overlooper.

threading

of

2)

Left

needle

(5601560D1560E0

thread

AND

4601460D)

—11—

Page 16

SEWING

To

start

*

Thread

from

*

Place

foot

hand.

*

Check

re-check

Operation

Turn

When

and

as

With

presser

On

model

upper

flashes

lowered.

sewing

the

you

a

spare

and

sew

the

on

the

the

it

is

the

spare

foot

560ED

position

with

machine

behind

a

stitch

that

main

pedal

depressed

and

even

sound

piece

few

the

is

piece

the

and

the

of

the

stitches

formation

threading

power

lightly

of

test-sew

machine

if

you

telling

pull

prser

fabric

by

switch

depressed

further

fabric

at

depress

you

the

threads

foot.

you

turning

produced

has

been

and

the

under

low

speed.

does

not

that

intend

the

lamp

the

machine

run

the

foot

the

about

handwheel

to

see

carried

machine

the

it

presser

15

to

use

if

it

out

switch.

runs

will

increase

presser

the

presser

controller.

cm

(6

under

towards

is

uniforrt.

correctly.

foo,

The

foot

inches)

at

foot

should

the

low

speed

lower

is

monitor

away

presser

you

If

npt,

speed

t[e

in

its

be

by

To

remove

*

After

to

scissors.

you

obtain

the

work

reach

the

chaining-off.

end

of

Then

the

fabric

trim

continue

off

the

sewing

stitches

for

with

about

a

pair

5

cm

of

Chaining-off

‘After

sewing,

(chaining-off).

be

•

fed

enough,

If

threads

*

Remove

“Threading”).

cm

over

forward

pull

break

the

fabric

Put

the

previous

hold

the

The

threads

automatically.

the

thread

during

and

the

foot

sewing

fabric

stitches.

control

will

gently.

re-thread

back

entwine

If

feeding

correctly

under

depressed

themselves

the

presser

slightly

for

chaining-off

(refer

into

foot

for

a

while

a

chain

and

is

not

to

page

8—11,

and

sew

3—5

—12—

Page 17

STITCH

SELECTION

560!560D1560E0

*These

follows:

machines

1.

Four-thread

Use

overlock

knitted

Use:

2.

Three-thread

Use

which

Remove

Use:

all

three

For

Ideal

will

right

can

four

stitches,

ones.

for

overlock

threads

fit

all

needle

overlock

form

overlock

threads

which

sewing

and

kinds

stitching

three

and

stitch

left

of

when

stitch

will

knitted

needle,

materials.

and

kinds

two

neatly

(5.

sewing

of

(5,

6,

needles

fit

garments

6,7

producing

this

sewing

stitches

7

all

kinds

mm)

overlocL

suits,

mm)

for

in

producing

of

materials,

5.

6.

or

stitch.

blouses,

simple

7

mm

slacks,

steps

four-thread

especialls’

seams.

etc.

as

3.

Three-thread

Use

seams.

Remove

three

threads

left

overlock

needle

and

when

right

stitch

needle,

sewing

(2.8,

this

3.8,

producing

overlock

4.8

mm)

2.8.

3.8

stitch.

and

4.8

mm

—

13

—

Page 18

46014600

NOTE

j

OptonaI

stitches

Three-thread

Use

three

will

fit

Use:

all

For

overlock

threads

kinds

overlock

and

of

stitching

Optional

t

those

stitch

one

materials.

stitches.

(3—5

needle,

and

special

mm)

producing

sewing

presser

suits,

3—5

blouses,

feet

mm

are

seams,

slacks,

necessary

which

etc.

I

for

Narrow/Rolled

Blind

stitch

Overlock

stitch

hemming

with

elastic

stitches

tape

—

14

—

Page 19

RATIO

CHART

OF

SEWING

MATERIAL

THREAD

AND

NEEDLE

Light

material

Medium

material

Heavy

material

Materials

Georgette

Crepe

Lawn

Organdie

Tricot

Poplin

Gingham

Sucker

Gabardine

Serge

Knitted

Cashmere

Tweed

Denim

Jersey

de

(Broadi

chine

Overiock

lOptiona0

Narrow

Rolled

Overlock

Overlock

Stitch

hem

NEEDLE

Overlock

LOOPER

Overlock

Textured

NEEDLE

Overlock

LOOPER

Overlock

Textured

NEEDLE

Overlock

LOOPER

Overlock

Textured

NEEDLE

Sewing

Overlock

LOOPER

Overiock

Thread

THREAD

thread

THREAD

thread

thread

THREAD

thread

THREAD

thread

thread

THREAD

thread

THREAD

thread

thread

THREAD

thread

thread

THREAD

thread

120—150

120—150

120—150

120—150

120—150

120—150

80—100

120—150

120—150

Stitch

2.0—3.0

Less

2.5—3.5

3.0—4.0

than

length

2.0

nim

SCHMETZ

130/705

SCHMETZ

13H705

SCHMETZ

130705

Ball

point

accessories

SCHMETZ

130-705

Needle

H

H

H

H

70

80

needle

90

70

r

CAUTION!

When

you

please

push

and

wind

carry

the

threads

the

spool

machine

down

on

each

with

at

spool.

threads

the

lowest

threaded,

position

—15—

Page 20

THREAD

Thread

tension

For

left

TENSION

control

levers

For

right

(except

needle

nedle

460/460D)

thread

(red)

For

overIoopr

For

thread

underlooper

(green)

thread

(blue)

I

Tension

Sewing

circumstances.

ing

Order

When

following

1)

2)

3)

4)

This

control

is

to

the

The

thread

the

thread

needle

underlooper

with

the

Adjust

the

lar

case.

and

downwards

Whenever

be

sure

“Chart

NOTE

of

you

Left

needle

Right

Overlooper

Underlooper

is

the

thread(s),

kind

Move

to

of

thread

order;

needle

easiest

possible

If

drawing.

tension

tension

thread.

of

thread

you

adjust

Thread

adjust

thread

thread

you

fabric,

tension

slide

to

change

the

tension

thread

thread

way

at

position

find

it

of

this

adjustment

the

overlooper

The

correct

the

lever

upwards

decrease

fabric,

thread

Tension

adjustment.

the

thread

(except

to

obtain

“5”

impossible,

machine

levers

thread

thickness

as

required

it.

thread

tension.

Adjustment”.

tension,

430/430D)

correct

under

can

of

to

adjust

be

for

the

thread

tension

the

in

each

increase

or

stitch

See

do

thread

almost

accord

adjusted

two

and

thread

particu

tension

width,

Page

in

it

tension.

any

by

(one)

the

varies

etc.

17—20

the

.

-I

.4

16—

—

Page 21

CHART

560/560D/560ED

OF

THREAD

TENSION

ADJUSTMENT

Lett

Right

needle

needle

keit

L.

thread

needle

thread

is

thread

is

slack.

slack

is

tlZhL

I

Page 22

I

III

1

III

I

III

I

I

III

I

IIII

I

I

I

I

III’

I

I

ii

III

ii

III

ii

III

ii

÷—III

II

I

j

III

II

III

I

I

III

II

I

I

i

III

I

I

III

III

I

I

III

III

E

I

III—

II

III

I

I

III—’

I

a,

III——*

1

I

III

I

J

4—III

I

I

III———’

I

Page 23

CHART

4601460D

OF

THREAD

TENSION

ADJUSTMENT

Needle

Fabric

Overlooper

Underlooper

thread

puckers

thread

thread

is

slackf

is

is

tight.

slack.

Overlooper

Underlooper

Overooper

Underlooper

thread

thread

s

s

thread

thread

tJack.

slack.

is

is

slack.

tight.

I

—19--

.

Page 24

I

III

____________

I

I

I

_1

III

_________

.—III

I

III

I

F

I

1

n

0

(D

n

(t

C

0

0

0

0

III

_________

1

1

III

I

I

III

I

III

+—fj

III

I

I

III-—

I

1

III

liii

I

1II

L

I

III

F

I

I

I

I4t.

I

lII—

I

0

N)

I

Page 25

STITCH

Stitch

Stitch

Width

LENGTH

AND

STITCH

WIDTH

Stitch

Open

control

Minimum

Maximum

1—2

Stitch

The

stitch

stitch

CAUTION!

When

always

(ength

the

lever

mm

Width

width

adjusting

raise

control

1

5

for

width

control

mm

mm

cover,

in

the

proper

(position

(position

narrow/rolled

can

be

dial

the

the

presser

then

RI

5)

adjusted

inside

sutch

foot

set

position.

hem

through

the

width

lever.

the

stitch

(optional)

turning

control

control

CO\

length

the

e

dial.

REMARK

L

I

560/5600!560ED

4

thread-stoch

thread-stch

3

needle

thread-stitch

3

right

needle

Narrow/Rolled

Position

rolled

optional

attachment

left

by

by

hemming

hemming

Narrowa

Rolled

hemming

—

with

“R”

special

is

necessary.

is

5

5

2.8

optional

used

stitclt.

5

mm

mm

mm

for

In

presser

mm

6

mm

6

3.8

mm

foot

narrow:

this

4.8

7

7

case.

toot/

mm

mm

mm

—21

460/460D

Mm.

3

mm—Max

Narrow/Rolled

—

mm

5

hemming

with

optional

foot

and

needle

plate

..

Page 26

STITCH

Stitch

width

Cutting

width

Stitch

width

Cutting

width

Standard

positioni

WIDTH

5

mm

5—6

mm

5

mm

5

mm

AND

CUTTING

When

sometimes

because

you

control

width.

result

How

When

at

5,

6

mm.

when

within

elastic

WIDTH

you

of

contraction

can

eliminate

dial

through

This

unique

also

on

to

adjust?

you

turn

or

7

mm

If

you

want

sewing

elastic

“A”

area

materials.

sew

will

the

while

as

FINE

elastic

find

the

Homelock

knitted

stitch

the

to

sew

materials,

illusrated.

ADJUSTMENT

that

of

problem

keeping

materials.

width

cutting

5

materials

the

the

mm

This

material

by

the

feature

control

width

stitch

you

like

garments

fine

stitch

is

width

only

will

e.g.

after

adjustment

width

will

ensure

dial,

the

increased

but

set

the

result

MECHANISM

are

cutting.

and

stitch

stitch

in

knitted

not

5,5

correct

properly

When

of

the

increasing

a

satisfactory

width

gradually

mm

cutting

width

overcasting

garments,

control

this

stitch

the

can

from

you

overcast

occurs

width

cutting

sewing

be

set

5

to

width

dial

in

7

a

—

22

—

Page 27

DIFFERENTiAL

FEED

MECHANISM

What

The

machine

one

(the

less

in

It

is

adjustable

dependent

stitch

length

the

more

How

to

1)

Open

2)

Adjust

ratio

3)

Close

is

“differential

difterential

relation

on

also

material

adjust

the

control

the

feed

control

the

control

is

equipped

to

between

the

affects

th

ratio

lever.

feed

feeder)

the

rear

thickness

the

is

being

differential

cover.

as

required

cover.

ratio”?

with

two

can

one

0.7—2.0.

and

adjustment.

fed

feed

feeders,

be

adjusted

(the

main

The

elasticity

forwards.

ratio

by

means

exact

of

The

of

which

to

feeder).

the

longer

of

the

the

feed

more

adjustment

material.

the

differential

front

or

is

The

stitch

I

Adjustment

.

:

‘

:

L4_.__J

M

example

:\

D

ll°

Stretch

material

Ad1ustment

REMARK

j

M

Main

D

—

“.

Ieeder

Diftereritial

Direction

of

feeder

feeding

J

Adjustment

stretching

Non-stretch

Adjustment

Ad1ustment

to

to

material

to

0.7

to

2.0

0.7

2.0

result

prevents

results

results

in

in

in

a

stretched

the

a

straight

puckering

edge

edge

edge

trom

-

—

23

—

:-

Page 28

N)

Page 29

PRESSER

FOOT

PRESSURE

*

The

the

Since

suitable

is

and

pressure

pressure

the

for

necessary

elastic

of

adjustment

machine

light

except

material.

the

and

presser

has

medium

when

dial.

already

sewing

toot

fabrics,

can

been

be

adjusted

vçry

adjusted

no

heavy

further

b’

to

a

pressure

adjustment

or

very

turning

light

tcmr

Heavy

material

Standard

STITCH

NOTE

560/560D!560ED

-

position

TONGUE

Decrease

Increase

DON’T

KNOB.

You

can

knob.

However

narrow/rolled

don’t

touch

operation.

In

case

you

cannot

TOUCH

(560,

retract

this

the

overlooper

THE

560D,

the

stitch

mechanism

hemming

the

changing

push

the

STITCH

560ED

stitch

is

safety

tongue

is

not

TONGUE

using

used

optional).

knob

in

its

guard.

the

only

during

lowest

CHANGING

changing

for

the

Therefore

normal

position,

—

25

—

Page 30

—

Page 31

CHANGING

THE

LIGHT

BULB

CHANGING

Remove

the

Use

Maximum

Recording

the

new

correct

cover

bulb

Rated

#:

LIGHT

THE

as

and

bulb.

light

input

X50228001

BULB

illustrated.

replace

of

the

bulb:

Pull

cover.

8V,

out

the

2.4W

light

bulb,

insert

RETRACTING

THE

BLADE

In

case

needle

the

knob.

CAUTION

Make

than

reasonisthatifthe

and

*

Close

28

—

you

sure

the

needle

door

—

wishtosew

plate

that

width

stitch

can

before

and

the

seam

be

without

the

retract

allowance

have

you

seam

allowanceiswider

damaged.

operating

cutting,

blade

on

chosen

machine.

set

the

needle

of

means

by

materialisnot

machine.

on

the

the

above

retracting

wider

The

overlooper

Page 32

MAINTENANCE

Oiling

smooth

For

machine

the

illustration.)

REMARKS:

ONCE

OIL

1.

IS

USED

MORE

HIGH

After

2.

Wipe

avoid

Cleaning

front

Open

mechanical

cally.

and

silent

should

OR

NORMALLY.

OFTEN,

QUALITY

oiling,

excess

off

stains.

oil

cover

parts

TWICE

OIL

SEWING

run

oil

(see

inside

operation

be

MONTH

A

IF

ONCE

machine

the

with

page

the

moving

the

oiled

periodically.

IF

MACHINE

THE

WEEK.

A

MACHINE

without

scrap

a

pieceofcloth

1.

©(

coverbybrush

parts

THE

MACHIN

IS

ALWAYS

OIL.

and

clean

periodi

of

(See

USED

USE

thread.

to

up

REMARKS

for

one

service

losening

off

cover

can

itisnecessary

but

plate

Cloth

screw

at

—

29

—

per

dealers.

illustration,

taken

be

by

Page 33

PERFORMANCE

FAULT-FINDING

PROBLEMS

1.

2.

3.

4.

not

Does

Needle breaks.

Thread

Skipped

Problem

fed.

breaks.

stitches

Probable

Preser

weak.

(1)

(2)

(3)

(1)

(2)

(3)

(4)

(5)

(1)

(2)

(3)

foot

Needle

blunt.

Needles

Fabric

Improper threading

Thread

Thread

Needle

wrong

Needle

blunt.

Needle

Wrong

bent,orneedle

incorrectly

has

tangled.

tension

incorrectly

needle

bent,orneedle

incorrectly

needle

cause

pressure

been

pulled.

too

used.

used.

set.

tight.

set.

set.

too

tip

tip

Turn

pressure

increase

Insert

new

Re-set

needle.

not

Do

Re-thread

Check

remove

See

page

Re-set

needle.

Usesewing

SCHMETZ

Insert

new

Re-set

sewing

Use

SCHMETZ

presser

needle.

press or

machine

spool

tangled

l6—2O

l30!705H

needle.

130/705H

Possible

adjustment

foot

(See

pin,,

thread.

(See

machine

needle.

(See

machine

correction

pressure.

(See

page

pull

fabric—guide

(See

thread

“Thread

page

ned(es—

(See

page

needles—

dial

page

5)

page

holders,

tension”

5)

page

5)

clockwise

page

(See

5)

it

8—il)

etc.

5)

to

25)

gently.

and

I

•11

Stitches

5.

Fabric

6.

Machine

(Monitor

not

puckers.

does

flashes,

uniform.

not

S6OED)

work.

(4)

Improper

Presser

(5)

weak.

Thread

properly.

Thread

(1>

Improper

(2)

thread

Presser

(1)

position

Machine

(2)

thread

foot

tension

tension

tangled.

foot

(560ED).

tangle.

threading

pressure

not

too

threading

is

is

locked

adjusted

tight.

in

upper

too

or

by

Re-thread

Turn

pressure

increase

See

page

Decrease

weight

Re-thread

Lower

page

(See

Remove

Check

(See

page

presser

or

the

tangled

and

machine.

adjustment

16—20

thread

fine

machine.

presser

3)

re-thread

8—li)

foot

“Thread

tension

fabric.

thread.

(See

pressure.

(See

(See

foot

machine.

page

dial

tension”.

when

page

page

(560ED).

8—il)

clockwise

(See

page

sewing

16—20)

8—li)

to

25)

light

Loading...

Loading...