Husqvarna 326P5X, 326P4X Owner’s Manual

Operator's manual (CARB II) /r _

326P4 326P4x.SER, ES

326P5x.SER, ES

Please read these instructions carefully and make

sure you understand them before using the machine. English

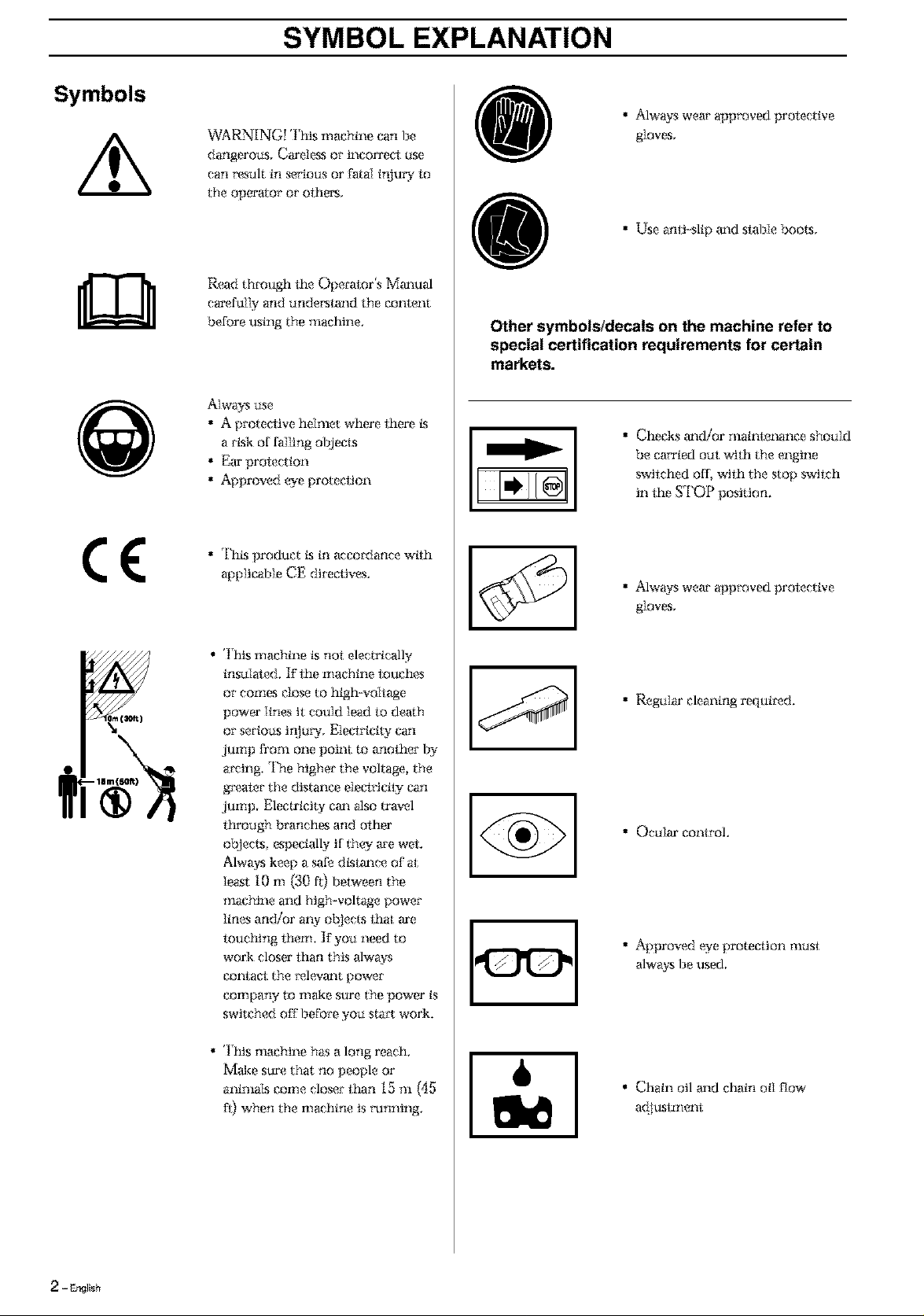

Symbols

SYMBOL EXPLANATION

WARNING! Tiffs nlachine can be

dangerous. Cra'eless or incorrect use

can _x_sultin serious or Fatal inlury lo

the operator or others,

Read through the Operaior's Mramal

can_thlly and under.lined the con*ent

before uMng the machine.

Always use

• A protective hehnet where there Ls

a rLsk of falling ol_jecis

• Era' protection

• Approved eye proteciion

• Alwws wear approved protective

gloves,

• Use anti-slip ra_d siable boots,

Other symbols!decals on the machine refer to

special certification requirements for certain

markets.

• Checks ra_dior rnainlenance should

be carried out with the engine

swiiched off, with the stop swilch

in the STOP position.

• ]'hks product ksin accordance wtth

applicable CE direciives.

• This machine Lsnot electrically

insulated, If the machine louches

or conies close to high-voltage

powra' lines it could lead to death

or serious irlluW, Eleciricity can

.jump Dom one point to another by

arcing. The higher the voltage, the

g*xmterthe distance electdctty can

.jump Electricity cra_also travel

itu'ough branches and other

oblects, especially if th W are wet.

Alwayskeepa safedLstm_eeoFat

least I0 ni ('30 It) between the

machine and high-voltage power

lines and/or aW ot_ieelsthat are

iouct_ng them. If you need to

wo*Ckcloser than this alwws

coniact the *xd_'m_tpower

company to make sure the power is

switched oFFbefore you stra_ wo*¢k.

• Alwws wear approved protective

gloves,

• Regulra' cleaning required.

• Oculra' comroL

• Approved we protec{ion mus{

always be u_sed.

- Ee<41sh

• Tiffs n_tchine has a long reach.

Make sure that no people or

animals come closer limn 15 m (45

FI)when the machine is running.

• Chain oil ra_dchain off flow

adJtLstnlem

CONTENTS

Husqvarna AB has a policy of continuous product dev*dopment

zmd therefotx_ reserves the right to modify the design and

appe_'ance of products wit}tout prior notice,

List of contents

Maintenance, replacement, or repair of the emission control

de_ices and systems may be performed by any nonroad

engine repair establishment or individual

IMPORTA_f ENGINE INFORMATI01_

']'iris decal certifies that the product has been approved in

accordance wtth American exhaust emissions tx_qui*x_ments

EPA Ph [I and CARB Tier II,

The Emissiom Compliance Period referred to on the

Emkssioos Compiiance label indicates the nvnibet's of opera-

ling hou*'sfor which the engine has been shown to meet

Federal and California emkssion requiremems.

Category C = 50 hours, B = 125 hour, and A = 300 hours,

SYMBOL EXPLANATION

Symbols ............................................................................... 2

CONTENTS

L_st of contents ................................................................... 3

SAFETY INSTRUCTIONS

Personal protec_ve equipment ............................................. fl

The machine's safety equipment .......................................... 4

Comroi maintenance and service of fhe nlachine's safety

equipment ................................................................. (_

Specification of blade and chain ......................................... 7

Sharpening you*' chain and adjusting rakes clearance ........... 8

*I_nsiontng the saw chain ................................................... 10

Lubricating cutting equipment ......................................... 10

Checktng wear on cutting equipment ................................ ] 1

General safety tnsu'uctions ................................................. 12

Safety JnsI_ctioI'IS _ghen tLstng the machine ........................ 13

Bastc worktng techniques ................................................... 14

WHAT IS WHAT?

What is what on the machin_ ........................................... 16

ASSEMBLY

[qtting the cutting head ...................................................... 17

Mounting guide 13_'mad chain ........................................... 17

A({}usting the tmrness ......................................................... 17

Filling wtlh oil ................................................................ 17

_'-g'mMing and dtsmantlirg the t_vo-p_ sl_fl (326P5)........... 18

FUEL HANDLING

Fuel mlxtur_ .................................................................... 19

Fueliing ............................................................................. 19

START AND STOP

ContmI b_fotx_ starting ....................................................... 20

St_'t and stop ..................................................................... 20

MAINTENANCE

Carbu*x_tor......................................................................... 21

_uffler ............................................................................ 23

Cooling system .................................................................. 23

Spark plug .......................................................................... 23

Air filter ............................................................................. 24

Matntenance schedule ........................................................ 24

TECHNICAL DATA

326P4 .............................................................................. 25

326P4 ................................................................................ 25

326P5 ................................................................................ 25

FEDERAL AND CALIFORNIA EMISSION CONTROL

WARRANTY STATEMENT

Your warranty t'tghts and obltgattons .................................. 27

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, bh'th

defects or other reproductive harm.

English - 3

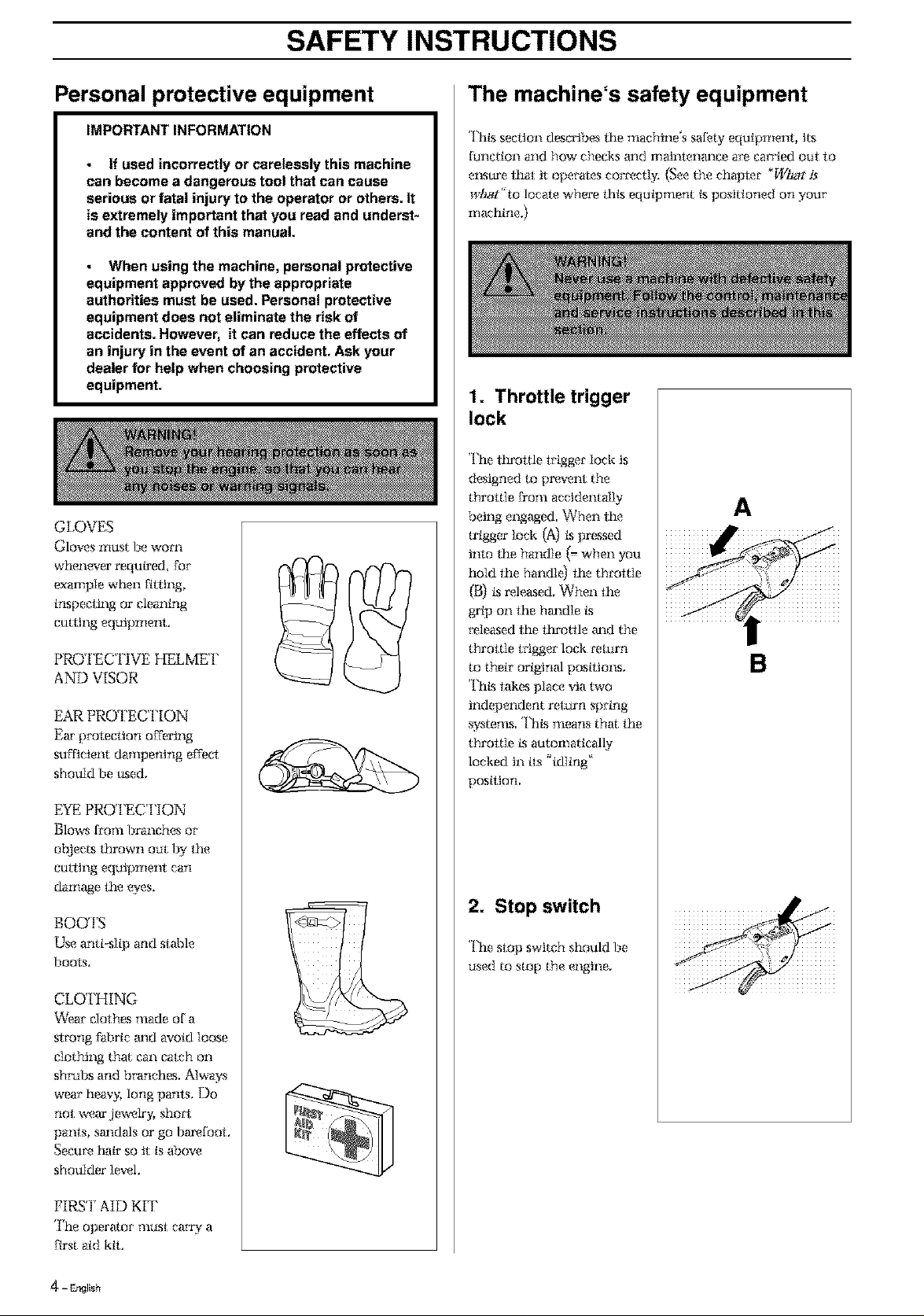

SAFETY INSTRUCTIONS

Personal protective equipment

IMPORTANT INFORMATION

If used incorrectly or carelessly this machine

can become a dangerous tool that can cause

serious or fatal injury to the operator or others. It

is extremely important that you read and underst-

and the content of this manual.

When using the machine, personal protective

equipment approved by the appropriate

authorities must be used. Personal protective

equipment does not eliminate the risk of

accidents. However, it can reduce the effects of

an injury in the event of an accident. Ask your

dealer for help when choosing protective

equipment.

GLOVES

Gloves must lie worn

whenemer required, for

example when fitltng,

inspeciing or cleaning

culling equipment,

PRO FEC FIVE HELME 1'

AND VISOR

EAR PROTEC I'[ON

Ear protecllon offering

sufficient dampening elfeel

should be used,

EYE PRO FEC ]'ION

Blmvs from branches or

oblects thrown out by the

culling equipmeni can

damage the eyes.

BOOTS

Use anti-slip and siable

boots,

The machine's safety equipment

Thks seeiton desca'ibes the machine's safety equipment, Its

function and how checks m_d mainlenm_ee m_ em_'ied o_t to

e1_.surethai; tt operatvs corr_ctI 5 (See the chaplet "WDat is

wDat"to locate where thks equipment ks positioned on your

machine,)

1. Throttle trigger

lock

The throttle lrigger lock ts

designed to pr_,ent the

throttle Dora accidental]>,

being engaged When lhe

trigger loci{ (A) ks pressed

hlto the handle (=when you

hold the handl_t the throltle

(B) ksreleased, When the

grip on the hm_dle ks

*_leesed the ttu'otlle m_d the

throttle trigger lock celurn

to their original postties_s,

<['titstakes place via two

independent relm'n spring

systems Thks means tha the

throttle ks automatically

locked tn its _idling'

position,

2. Stop switch

The stop switch should be

used to stop the engine,

A

B

CLOTHING

Wear clothes made of a

sirong fabric mid avoid loose

clothing that can ealch on

shrubs and branches, Always

wear heavy, long pants. Do

not werw jewelry, sho_9

paros, sandals or go bmx_fooh

Secure hair so tt is above

shoulder level.

FIRS']' AID KIT

The operator musl carry a

first aid kiL

4 - EP,gllsh

SAFETY INSTRUCTIONS

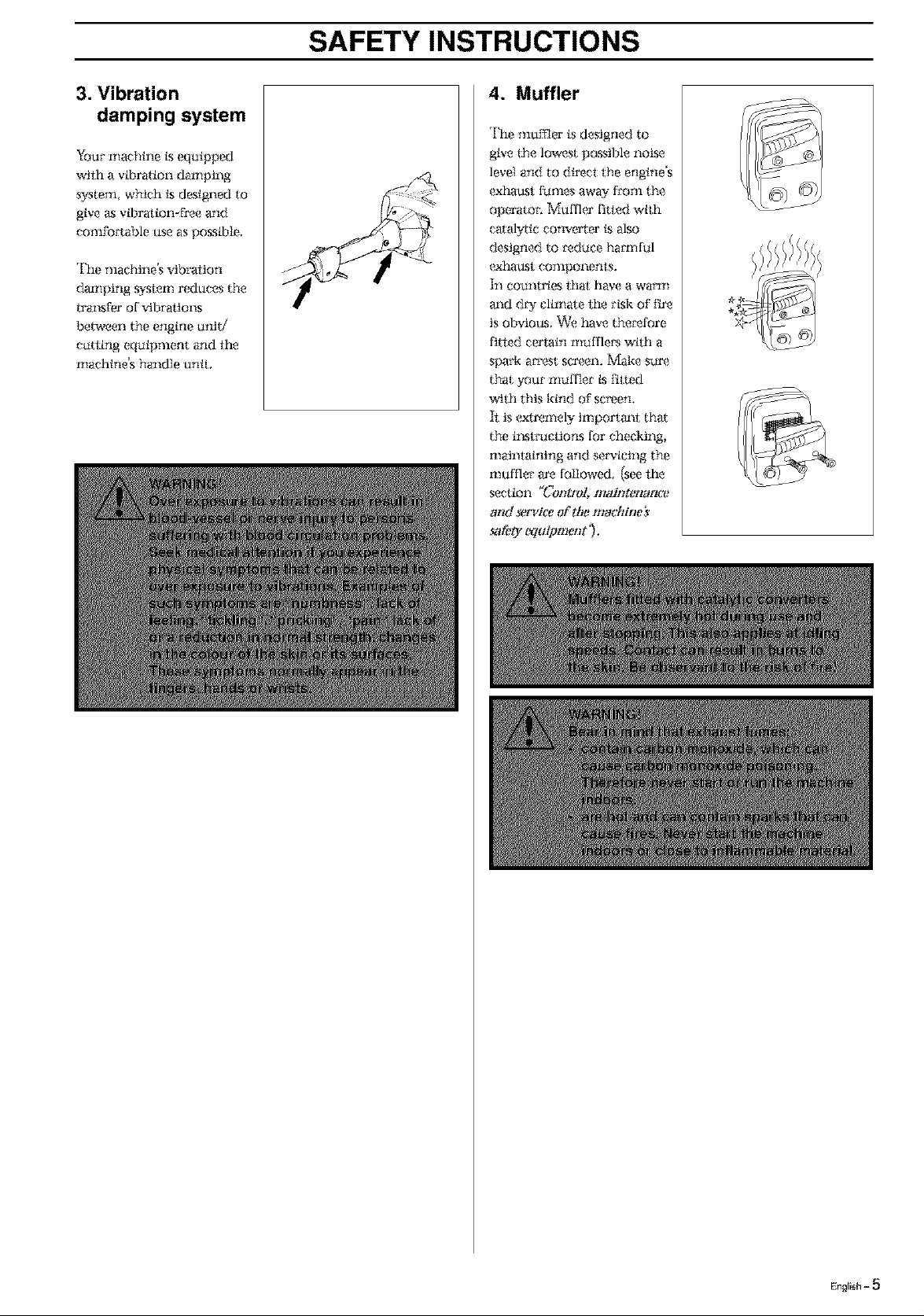

3. Vibration

damping system

Your nlachine ksequipped

wtlh a vibration damping

system, which ksdesigned to

give as vii)ration-free and

comfoaable use as posstble,

The machine's vibraiton

daznping _'slem reduces the

traP.sfer of vtbi'atioP.s

between the engine unit/

catting equipment and the

nlaehine's handle untL

4. Muffler

The mumer is designed to

give the lowest possible noise

level and to direct the engine's

exhat_st fumes away from the

operator: Muffk,' fitted wtth

catalytic converter ksalso

designed to *_duee hamfful

(_haust components.

In countries lhat have a warm

and d W climate lhe risk of fire

is obvious. _'e t_lve the_'efore

fitted certain nmffle*_ with a

spark arrest sca_,_en.Make s_r_

that your hi,If fief ks fitted

with this kind of screen,

h: is (_tremely importm_i tha

the i1_stcoctions for checking,

mainlaining and servicing the

nmffler am followed (see lhe

section _Control, maintenantv

and *t,rvice of the machine}

_1_'0" WuiP merit '},

.1111111111

English = 5

SAFETY INSTRUCTIONS

Inspecting, maintaining and

servicing machine safety equipment

IMPORTANT INFORMATION

All service and repairs to the machine require

special training.

This applies especially to the machine's safety

equipment. If the machine does not meet any

of the controls listed below you should

contact your service workshop.

The purchase of one of our products

guarantees that professional repair and

servicing will be carried out on it. If the point

of purchase is not one of our servicing

dealers, please ask for details of the closest

service workshop.

1. Throttle trigger

lock

Check t_l: the ttn'o/tle is

locked in the 'idling

position' when the

throttle trigger lock is in

its original postlion,

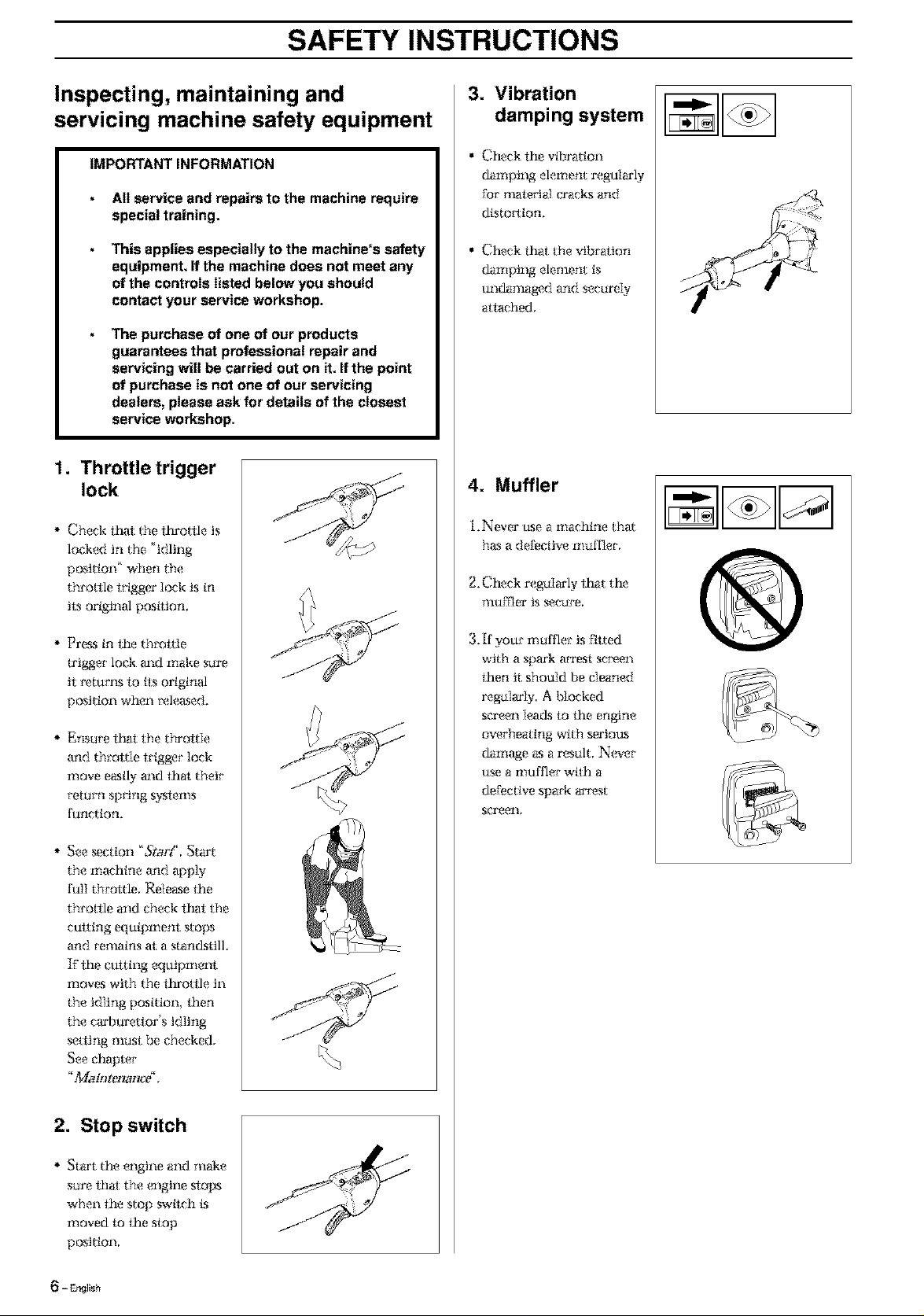

3. Vibration

damping system

• Check the vfl)ration

damping element regularly

for illatelJal cx'acks and

distortion,

• Check that the vibration

damptog elenlent is

undamaged and securely

attached,

4. Muffler

i.Never use a nlachine that

has a defective muffler,

2. Check regaIarly lhat the

muffler is secure,

Press in the throttle

u'igger lock m_d make sure

it i_turl_,slo its original

position when _xdeased.

Ensure t_t the throttle

and throl:tle trigger lock

move easily and thai; their

return spring systems

function.

* See section 'StorY, Start

the machine and apply

full throttle, Release the

throAle and check that the

cutting equipment stops

and remains at a stan_kstilL

If lhe cutting equipment

nloves with the fhrottle in

the idling position then

the craq]urettor's idling

setting must be checked,

See chapter

_+%.Ioh)ten_nag,

3. If your muffler is ftlted

with a spark arrest sc_x_en

then it should be cleaned

regularly A Socked

screen lea(ks to the engine

overheating with sertou_s

damage as a result. N(wer

use a muffler wtlh a

defective spark ar_x_st

screell,

J

2. Stop switch

Start the engine and make

sure thai; the engine ,slops

when the stop switch ks

moved to the stop

position,

- EP4_Ish

SAFETY INSTRUCTIONS

5. Cutting equipment

ThLs section describes how f_ough corix_et maintenance and

through using the _Jght t91)e of cutting equipment you can:

• Obtain maximum curling capacity.

• Increase the service life of the cutting equipment.

i Check the cutting

equipment with regard lo

damage m_d era(k

formaion. Damaged

cutting equipment should

always be replaced.

2 Only use cutting

equipment recommended

by us_ See the "l'echnical

data" secllon,

3 Keep the chain cutting

teeth properly sha_ened!

Follow our instructiol_s

and use the

recommended file gauge,

A damaged or badly

sharpened chain inc*x_ases

the *'isk of accidenls.

4 Maintain the correct

*'ake*"elearancd Follmv

our instructim_,sand use

the *'eeommended raker

gauge, Too ]arge a

c]earance increases ihe

rLgkof kickback,

5 Keep the chain properly

tesioned! If the chain is

slack it Ls mo_x_ likely to

Jump off m_d lead to

increased wear on i_e

bar chain m_d drive

sprocket.

8 Keep cutting equipment

wd] lubricated and

propeiqy nmintained! A

poor{y iubricated chain is

nlore ]ikely to b*x_akand

lead to increased wear on

the bar chain and drive

sprocket,

© ©

© ©

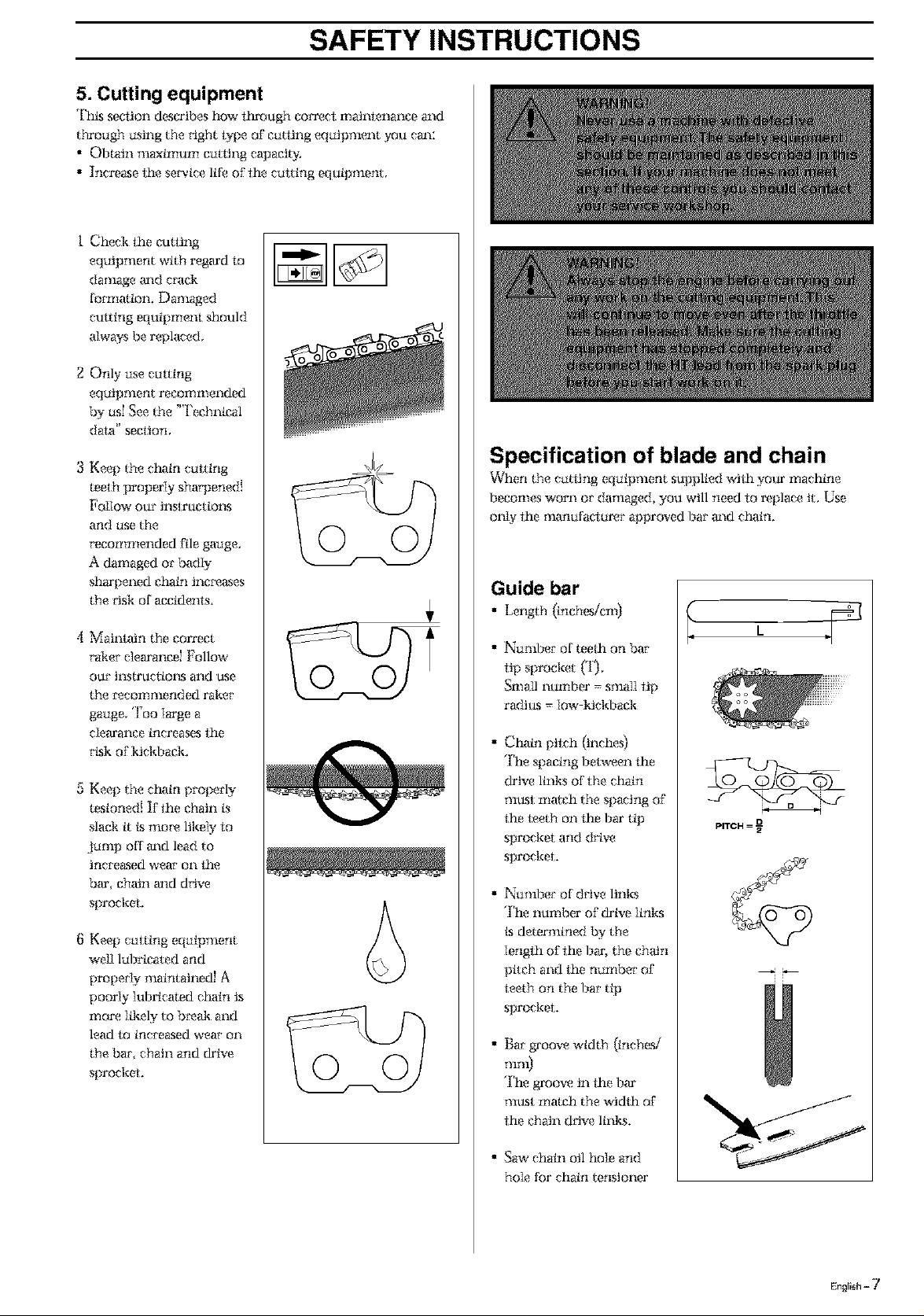

Specification of blade and chain

Vv'her the cattir g equipnient supplied with your nlaehine

becomes worn or damaged, you will need to replace it. Use

only the manufactar<_r approved bar and chain.

Guide bar

• Length (inchesicni)

• Number of teeth on bar

tip sprocket (*1).

Small number = small tip

radius = low-kickback

• Chain pilch (inches)

The spacing between lhe

drive links of the chain

must nlatch the spacing of

the leeth on the bar tip

sprocket and drive

sprocket,

• Number of drive links

The number of drive ]inks

Lsdetermined by the

]engfh of ihe bar, the chain

pitch and the number of

leeth on the bar tip

sprocket,

• Bar g*'oovewidth (inches/

TlllI1)

The groove in the bar

must match the width of

the chain d*Jve links.

PITCH = D

• Saw chain oil hole and

hole for chain tensioner

English - 7

SAFETY INSTRUCTIONS

Saw chain

Saw c_in pitch {inches}

Spacing between drive

links,

PITCH = D

Drive link width (ram/

inch_.

Namber of drive links.

Level of kickbak _duciJon

The level of kickback

_'educlion offered by a

chain is indicated by its

r! iodeI nu;llbec

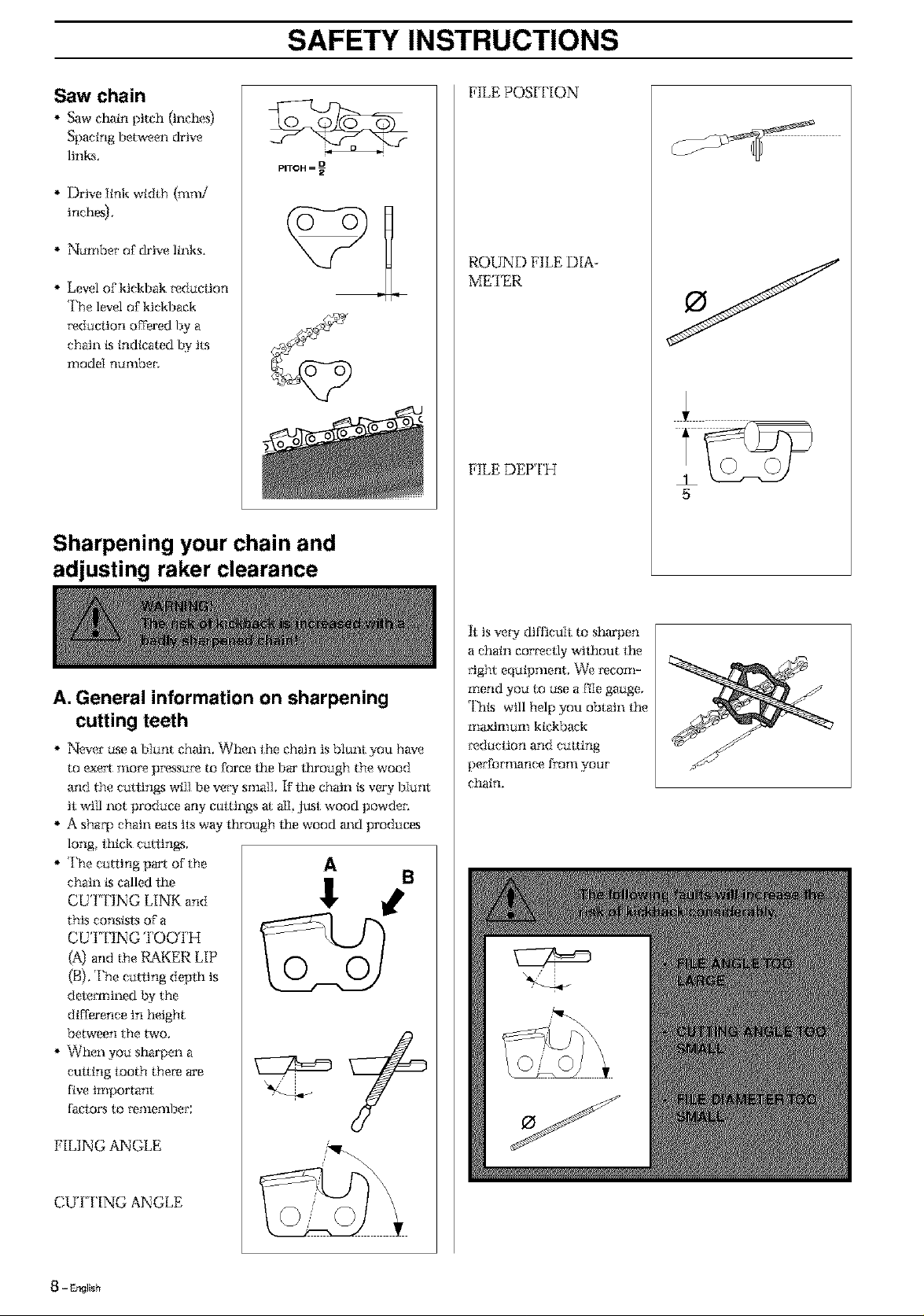

Sharpening your chain and

adjusting raker clearance

FILE POSI I'ION

ROUND FILE DIA-

METER

FILE DEP I'H

5

A. General information on sharpening

cutting teeth

* Nexer use a bIunt chain. When lhe chrdn is blunt you have

to (_e_ rno_ p_?ssure to force the bar lhrough the wood

and the cutiin_s will be vec¢ sinai1, F the chain ks very bIunt

it will not produce any cm:tings a all just wood powden

A shaq) chain eats ils way through the wood a_d produces

long, lhick cutiings.

The curling part of the

chain ks called lhe

CUTTING LINK and

this consists of a

CUT'IING TOOTH

(A) and the RAKER LIP

(B). The curling depfli is

determined by the

difference in height

between the two.

When you sharpen a

culting looth there are

five important

faciors to _a_llellfl)er;

0 0

h is veW difficult to sharpen

a chain corr_ctly without the

_'ight equipment, _e recom-

mend you to use a file gauge,

This will help you obtain lhe

maximum kickback

_duction and culting

perfomlance froTll yOUI"

chain.

FILING ANGLE

CUT I'ING ANGLE

8 - DNIsb

SAFETY INSTRUCTIONS

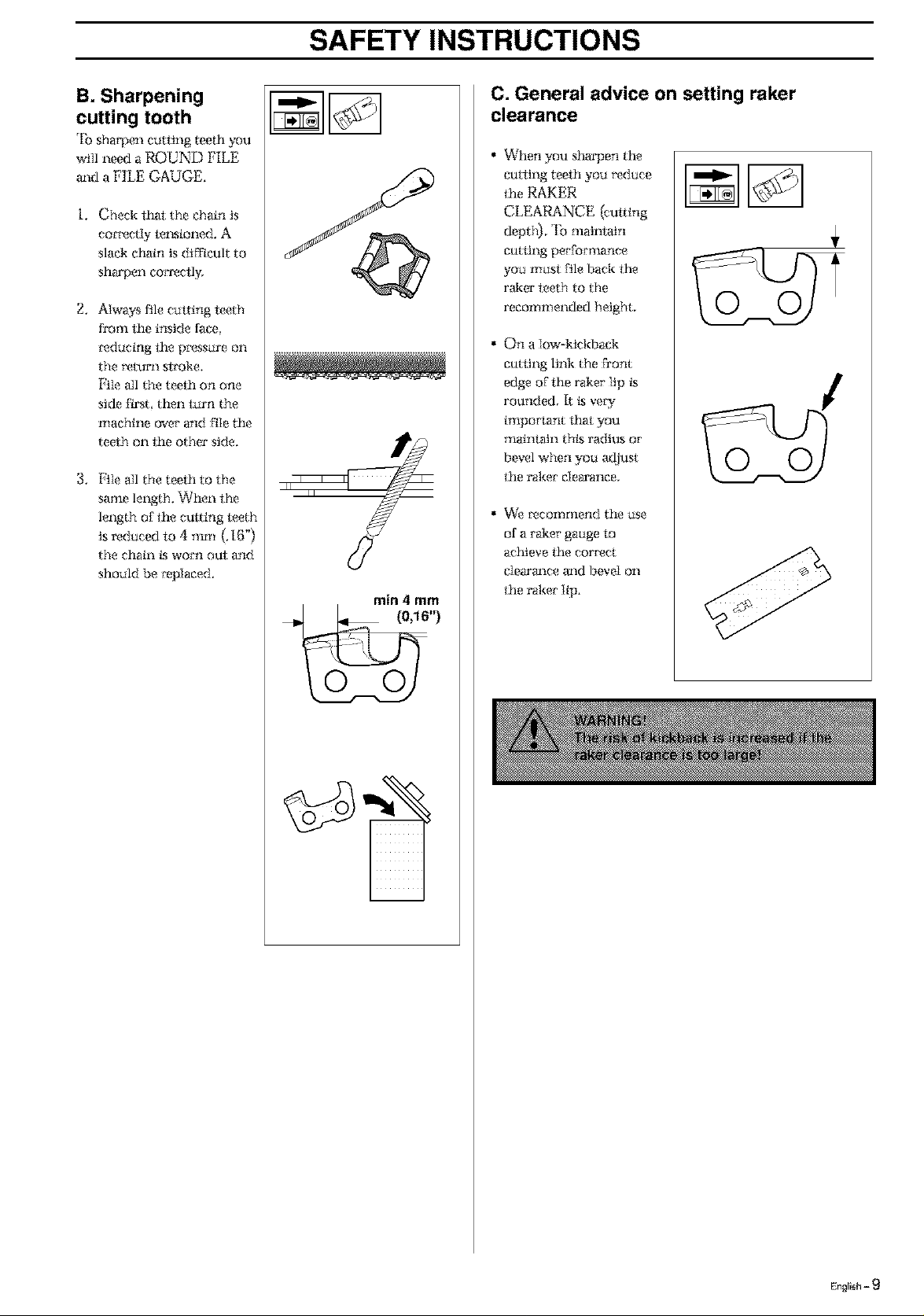

B. Sharpening

cutting tooth

'lb shaq)en catting teeth you

wiIl need a ROUND FILE

and a FILE GAUGE.

i. Check t_l: the chain is

correctly le1_aioned. A

slack ctmin is difficult to

sharpen cora'eclly.

2, Always file ctltting leeth

from the inside Nee

*'educing the pressure on ............................................................................

the i_turn sl:_'oke.

File all the teeth on one

side First then turn the

machine over and file the

teeth on the other side.

3. File all the teeth to the

same length. When the

length of the culting leeth

is reduced m 4 mm (.16")

the chain ksworn out and

should be repIaced.

min 4 mm

C. General advice on setting raker

clearance

When you stmrpen the

curling teeth you reduce

the RAKER

CLEARANCE (crating

depth), *lbmaintain

cutting perFornmnce

you musl file back the

raker leeth to the

recommended height,

On a Iow-ktcM)ack

curling link the Front

edge of the raker iip ks

rounded, It ksveW

important f_t you

mainIatn thLs radius or

bevel when you adjust

the raker clearance,

We recommend the use

of a taker gauge m

act_eve the cors_ct

clearm_ce m_d bevel on

the taker Iip,

0

i

English - 9

Loading...

Loading...