©Husqvarna

Chain saw

model 266

TECHNICAL SPECIFICATION

Displacement . .

Bore

..................

Stroke

Ignition advance. .. . 25° before t.d.c. at 8500 rpm

Sparking Plug . . . . Champion CJ 7Y, PAL P8Y

Electrode gap . . . . 0.5 mm

Carburettor . . . . . . Diaphragm type

...............

. . 66.7 cm3

. . 50 mm

. . 34 mm

Tillotson HS 163 A

Fuel tank capacity

Oil tank capacity . . . . 0.45 l

Sawing chain. . . . . .3/8” pitch

Guide Bar

Weight empty, incl. 15”

guide bar , chain . . . . 7.0 kg (SE)

and chain brake .

...........

___

0.75 l

. . . 15”

. . . 7.4 kg (SG)

Operator’s manual

101 84 00-26 B

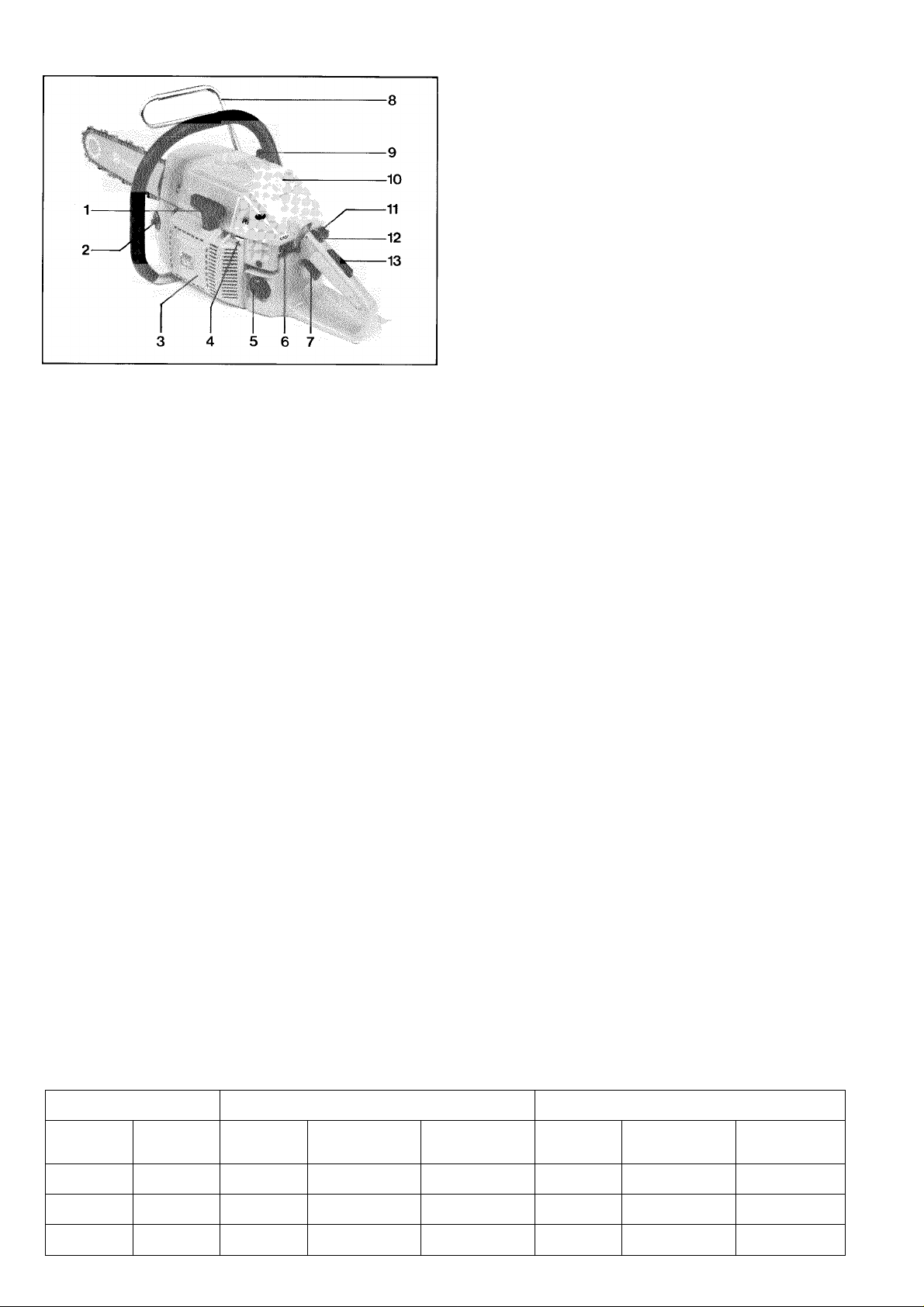

What is what on the chain saw?

1. Starter handle

2. Oil filler cap

3. Starter

4. Adjusting screws.

carburettor 11.

5. Fuel filler cap 12.

6. Ignition switch

7.

Throttle trigger

8.

Front hand guard

Chain brake activator

9.

10.

Choke

13.

Assembiing guide bar and chain

A. Undo the guide bar nuts and remove the clutch cover and

transport packing piece.

B. Place the guide bar into its rearmost position. Make sure that

the chain tensioning stud is properly in the hole in the guide

bar

E. Tension the chain while holding up the bar tip. Do not tension

the chain stronger than it can be pulled around by hand.

Tighten the guide bar nuts.

NOTE!

Do not forget to “run in” the chain and guide bar. Please see the

chain manufacturer’s recommendation.

CHECK THE CHAIN TENSION FREQUENTLY FOR OPTIMAL

PERFORMANCE AND DURABIITY.

Fuei and oii

The power plant of this chain saw is a

twostroke engine, that is run on a petroland oil mixture of certain proportions

acc. to the table.

Do not use but a twostroke oil of high

quality, e.g. Husqvarna Twostroke Oil, that

is specially developed for chain saws.

NOTE!

No extra oil is needed in the petrol during

the running-in period of the chain saw.

' For lubricating the chain and guide bar

. we recommend a chain lubricating oil

Always use quality chain oil. If not available use gear box oil type

EP 90.

with good adhesive properties.

During the wintertime at air temperatures

below 0°C (32°F) some types pf chain

lubricating oils are viscous. This can

cause overloading of the oil pump,

which can result in damage of the pump

drive and pump parts. Under cold

weather conditions it is therefore ne

cessary to use a “wintergrade” oil which

stays fluent even when cold'.

Concerning the choice of oil and its suit

ability at different air temperatures,

please refer to your Husqvarna dealer.

ALWAYS TOP UP WITH FUEL AND CHAIN LUBRICANT AT

C. Fit the chain around the drive sprocket and in the groove of the

bar. Start on the upper side of the guide bar.

Make sure that the cutting edges of the sawing teeth along the

top of the guide bar are facing towards the tip. Also check that

the drive links go down properly into the drive sprocket.

D. Tension the chain so it does not sag along the bottom of the

guide bar. Check that the chain and guide bar fit properly.

Fit the clutch cover and tighten the nut fingertight only.

Pull the chain a few turns around by hand and check that it

can move freely.

Mixing table 2%

Litres Points Litres Petrol in Petrol in Litres Petrol in Petrol in

of oil of oil of petrol

0.2

0.4 0.40 20 4.4 5.2 10 2.2 2.6

1.0 1.76 50 11.0

0.35 10

Imp. gallon US gallon

2.2

THE SAME TIME.

NOTE!

On no account waste oil should be used as this can damage the

oil pump.

Oil mixture:

Husqvarna Twostroke Oil 1:50 (2%).

Ordinary twostroke oil 1:25 (4%)

4%

of petrol

2.6 5 1.1 1.3

13.2

25 5.5 6.6

Imp. gallon US gallon

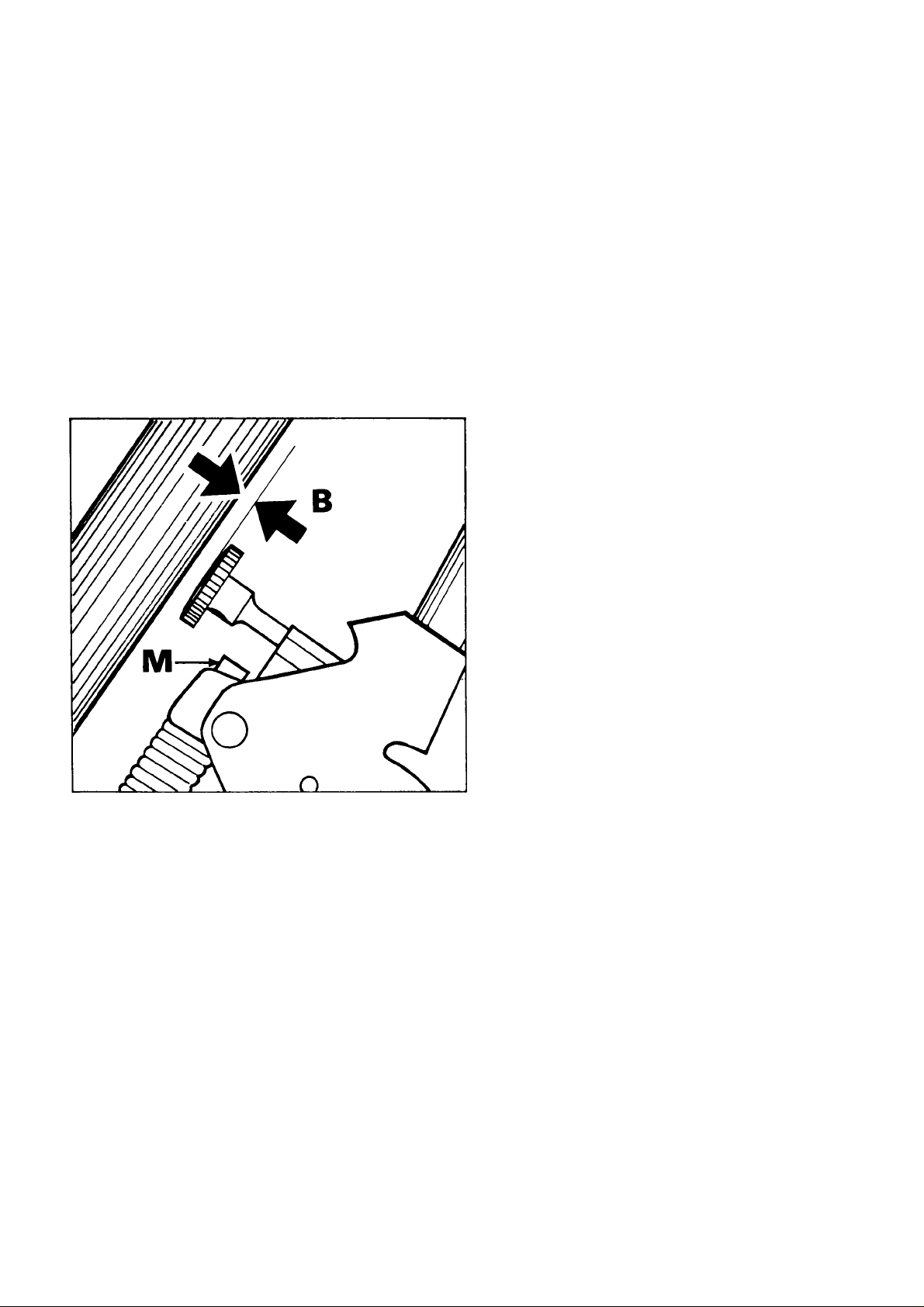

Chain brake activator “Swed-o-Matic” Maintenance of the chain brake

The Swed-o-Matic should release the chain brake at a certain load

on the guide bar tip.

Adjusting the release power

The distance between the Swed-o-Matic release screw and the

front handle (B) determines the release power. A smaller

gap means reduced release power.

The release power can be checked as follows: Push the guide bar

tip against a spring balance. With a 15" guide bar the chain brake

should be released at a load of 10-15 kp.

The forestry worker could make a rough check on the spot as follows:

Hold the saw horizontally over a trunk, at a height of abt 35 cm. As

the saw by force of its own weight swings around the rear handle

and hits the trunk, the brake should be released.

Note that during this check the engine must not be running. If the

brake is not released, contact your service workshop.

Nut M should be tightened completely.

Clean the brake band and the mechanism. Check that the band

has at least 0.75 mm thickness on the most worn part.

Lubricate the links and supports of the brake mechanism with twostroke oil. Release and lock the brake repeatedly to check that the

mechanism works smoothly.

Check the chain brake function regularly. Start the saw on clear

ground making sure that the chain runs freely. Apply full throttle

and release the chain brake. The chain should immediately stop

rotating. If not, contact your service workshop.

h

X

starting the chain saw

A. Cold engine

I

CAUTION!

Guide bar, chain and clutch cover must be assembled before

the engine is started, otherwise the clutch may come loose

and cause injuries.

Adjusting the carburettor

1. Switch on the ignition (push the switch to the left so that the 1

is visible).

2. Pull out the choke control.

3. Push down the throttle trigger lockout (A).

4. Open the throttle fully (B).

5. Push the throttle latch backwards (C).

Now all the controls are in starting position and the chain saw is

ready to be started.

6 Put your right foot on the plate beneath the rear handle.

7. Grasp the front handle with your left hand and press the saw

against the ground.

8. Grasp the starter handle with your right hand and pull out the

starting cord slowly until the starter pawl engage.

9. Give the starting cord a short sharp tug.

NOTE!

Do not pull the starting cord entirely out or release the starter

handle In pulled out position, as this can cause damages on the

chain saw.

10. Normally the engine will start after 2-3 starting attempts. Push

the choke control as soon the engine starts. Open rapidly the

throttle wide and the latch will disengage.

To stop the engine push the ignition switch to the right so that the

O is visible.

B. Warm engine

Use the same starting procedure as for cold engine but without

pulling out the choke control.

The carburettor has three adjusting screws:

L = Low speed needle

H = High speed needle

T = Throttle adjusting screw

A. Basic setting

Clean the air filter.

Check the spark plug and its electrodes.

Check that the fuel filter is not clogged.

Screw the needles H and L carefully right in.

Then screw the needles out to recommended basic position:

H = 3/4 turn out, L = 1 turn out

Start the engine and warm it up. Adjust the idling speed by means

of the throttle adjusting screw to that speed at which the chain just

starts rotating.

B. Adjustment of L-needle

1. Screw in the L-needle slowly and the speed will increase. Screw

in the needle a little further and the speed will slow down again

as the fuel supply becomes too “lean". Notice the position of the

needle at the highest speed.

2. Open the L-needle again and notice the highest position. Note

that the speed slows down at “richer” supply.

3. Adjust the L-needle to the highest speed position. Then open it

equivalent to 10 min on a clock-face to obtain a somewhat

“richer” supply to aid acceleration.

4. By means of the T-screw, adjust the idling speed to 2.300-2.500

r/min, ensuring that the chain does not rotate when engine is

idling.

5. Give full throttle a couple of times to check that the engine

“responds”. If not, open the L-needle by abt 3 min. Check again.

NOTE!

One of the most common causes of starting difficulties is that too

many starting attempts have been made with a closed choke flap.

If this is the case, remove the spark plug and wipe it dry. Open the

choke flap fully.

Before you reassemble the spark plug, we recommend you to pull

the starter handle several times to “ventilate the cylinder", the

ignition switch in 0-position.

Assemble the spark plug and make a new starting attempt with

open choke flap and full throttle.

C. Adjustment of H-needle

At correct adjustment of the H-needle the engine should be fourstroking. Screw in the H-needle slowly until there is no more fourstroking. Then screw the needle out equivalent to 10 min on a

clockface.

Check by means of a revolution counter that the high idle speed

does not exceed 11.500 r/min.

Cleaning the air filter

A clean air filter Is necessary for optimal carburettor function and

optimal engine power.

%

In order to get at the air filter, remove the cylinder cover by undoing

the retaining screws and lifting the cover off upwards-backwards.

Remove the heaviest dirt from the air filter. Undo the screw and lift

the filter off carefully to prevent dirt from falling down into the

carburettor.

Changing starter cord and return spring

Loosen the four screws that retain the starter. Remove the starter.

Pull out the cord approx. 30 cm and lift it up into the notch in the

periphery of the pulley.

Zero-set the return spring by carefully letting the pulley rotate

backwards.

Undo the screw in the centre of the pulley and remove the pulley.

■

Separate the two filter halves by means of a screwdriver or a knife.

Clean the filter halves carefully in warm soapy water.

Avoid cleaning them in chain saw petrol.

Dry the filter with compressed air

Reassemble the filter and make sure that it lies close to the

carburettor.

Use two air filters alternately.

Clean the filter each day!

In case you change the return spring as well, undo the screws that

retain the plastic cassette, which then can be removed.

Change the spring and lubricate it with engine oil.

Assemble the remaining parts in reverse order.

Lift up the starter cord into the notch on the pulley. Tension the

return spring by turning the pulley clockwise about two turns.

NOTE!

Make sure that it is possible to turn the puliey at ieast 1/4 of

a turn further when the cord is fully pulled out.

Winter use

In winter, extreme cold and powdery snow can cause running

problems.

A

The cylinder cover is prepared for extreme cold working conditions.

In the partition wall of the cover there is a hole, that is covered by a

cap (A) when operating at normal temperatures.

In case of extreme cold, this cap shall be removed so that heated

air from the cylinder can flow into the carburettor space and

prevent the air filter from being iced up.

NOTE!

Under normal temperature conditions the cap has to be

mounted. Otherwise there is a certain risk of overheating the

chain saw.

Adjusting the oil pump capacity

The oil pump is adjustable for four different capacities. Adjustment

is to be done after removal of chain, guide bar, clutch cover, centri

fugal clutch and clutch drum.

With a screwdriver the oil capacity can be adjusted by turning the

screw. The index on the screw should face the capacity wanted.

Figure shows the position for capacity 2.

Recommended positions:

Bar 15": Pos. 2.

Bar 18" and more: Pos. 3-4.

Before assembling the clutch drum check that the washer between

drum and sealing ring is not lost.

Maintenance of the chain saw

Daily maintenance

1. Clean the saw body from the outside.

2. Clean the air filter. Change if necessary.

3. Turn around the guide bar, lower edge up. Clean the bar

groove.

4. Clean the fan and air intakes in the starter cover.

5. Clean the cooling fins on the cylinder.

6. Clean the space under the clutch cover.

7. Sharpen the chain and check its tension.

8. Check the oiling system for the chain and the guide bar.

9. Clean the chain brake. Make it a habit to lock the chain

brake during pauses and transports.

Weekly maintenance

10. Check the starter, its cord and return spring.

11. Clean the spark plug from the outside and check the gap.

Adjust the gap or change the plug if necessary.

12. File off burrs if any on the sides of the guide bar.

13. Lubricate the bearings of the clutch drum.

Monthly maintenance

14. Wash out the fuel tank with petrol.

15. Wash out the oil tank with petrol.

16. Clean the carburettor.

17. Check the fire-fighting screen inside the silencer.

Clean or change if necessary.

Safety reminders

Handling

1. When transporting the saw, fit the chain protection.

2. Do not smoke when filling the fuel tank.

3. Before cutting, fix the barking support properly.

4. When using the saw, keep both hands on the handles.

5. Nobody is allowed to be within the swing area of the saw.

6. Always stop the engine before checking and adjusting the

chain tension or exchanging the chain.

Personal safety equipment

1. To protect the hearing organ, wear protective wad, plugs or

ear caps.

^HusqWna

The Chain Saw Professionals.

20. 6-83

Procedure

1. When felling, always step aside from the falling tree and watch

out for falling branches.

2. When cutting split wood, look out for ejecting wood pieces.

3. When bucking a felled tree on sloping ground, always stand

above the tree.

4. Be calm and collected when working, eliminate the risk of

injury to other persons.

2. When cutting, wear gloves of chrome leather.

3. When felling, wear a protective helmet.

4. Wear suitable clothes which do not hinder your work.

■ SWEDEN

Printed in Sweden BrattS Trycken AB, Jkpg 49034

Loading...

Loading...