Page 1

Oper

ator′s manual

Manual de instrucciones

Instruções para o uso

уководство по эксплуатации

143AE15

Please r

ead the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Leia as instruções para o uso com toda a atenção e compreenda o seu conteúdo antes de fazer uso da máquina.

режде чем приступить к работе с машиной внимательно прочитайте инструкцию и

убедитесь, что ‚ам все понЯтно.

GGGGBBBB ((((2222----11119999))

EEEESSSS ((((22220000----33337777))

PPPPTTTT ((((33338888----55555555))

RRRRUUUU ((((55556666----77774444))

))

))

))

))

Page 2

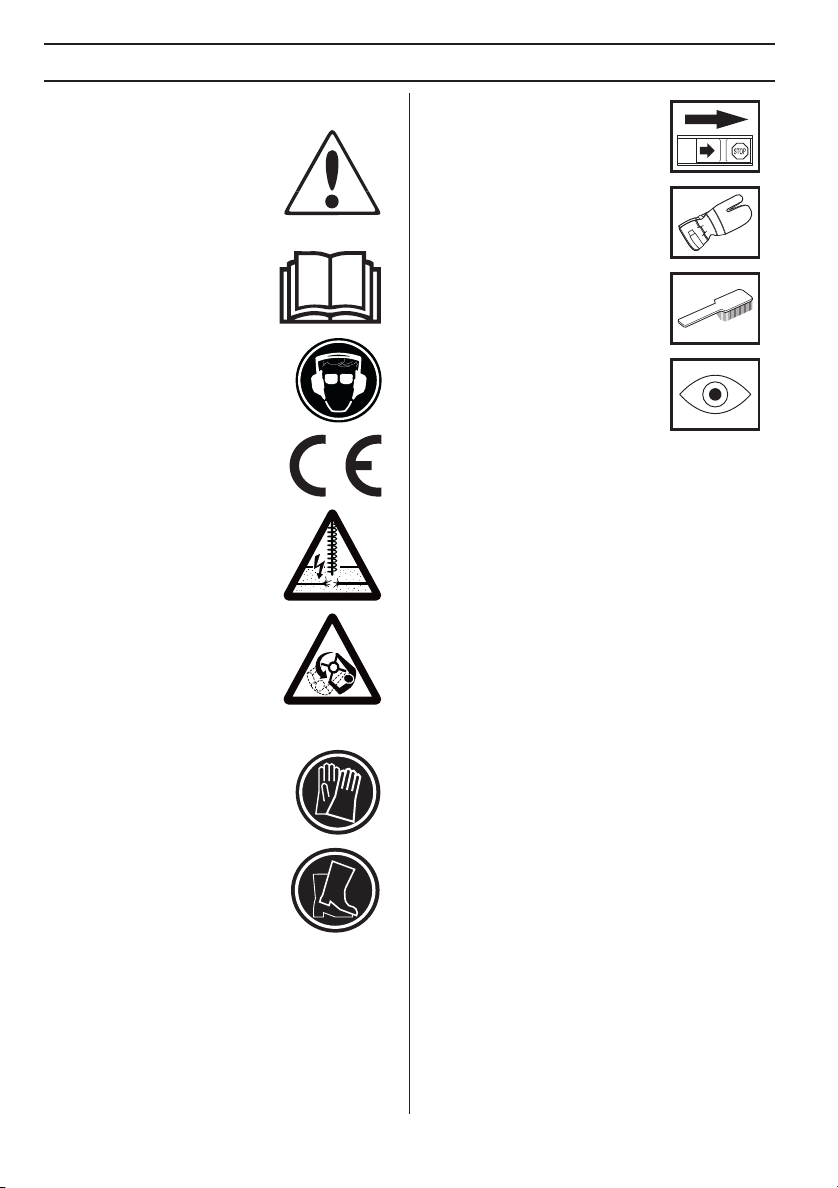

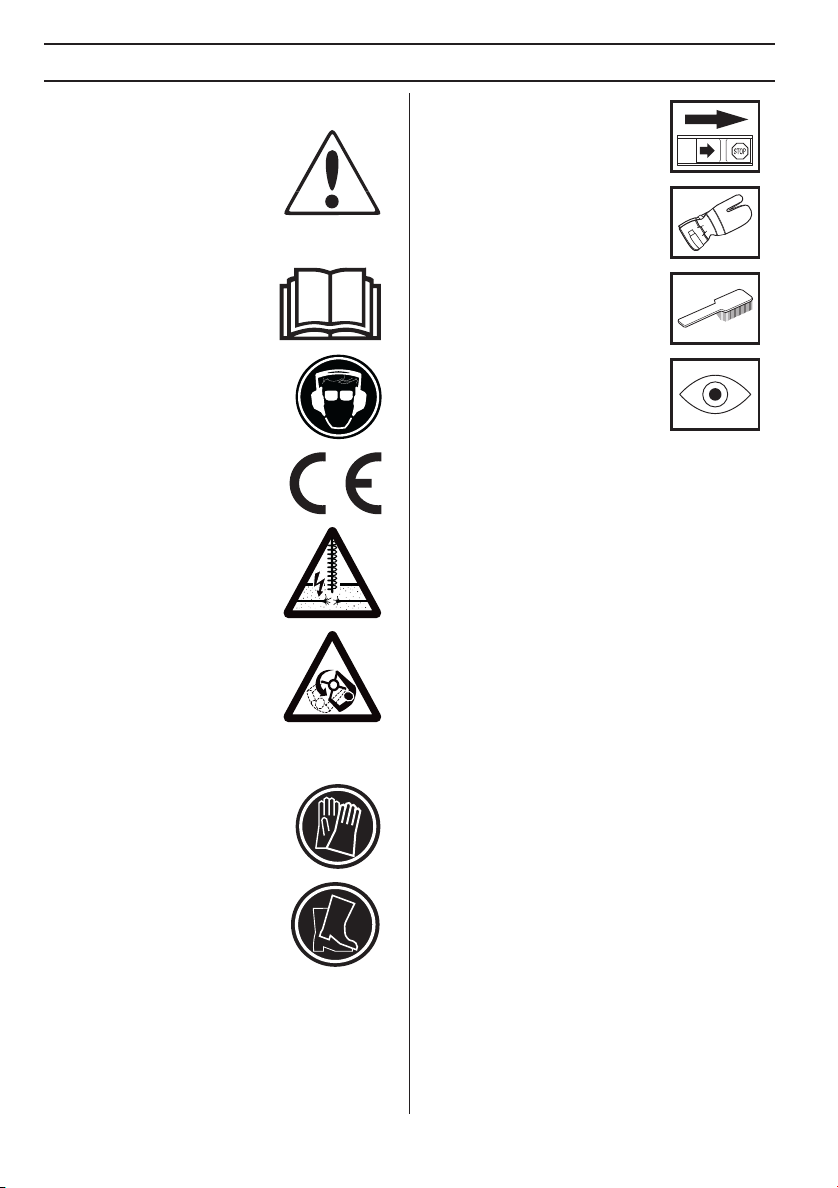

Symbols

W

ARNING! An earth auger is a

dangerous tool if used carelessly or

incorrectly and can cause serious,

even fatal injuries. It is extremely

important that you read and

understand the contents of this

Operator’s Manual.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Always wear:

• Approved hearing protection

• Approved eye protection

KEY TO SYMBOLS

The engine is switched off by moving

the stop switch to the stop position.

Always wear approved protective

gloves.

Regular cleaning is required.

Visual check.

This product is in accordance with

applicable EC directives.

Drilling into or contact with electrical

cables or wires can lead to death or

serious bodily injury. The machine is

not electrically insulated.

Striking something hard in the earth,

such as rocks or tree roots, may

cause the drill to come to a sudden

stop. This can lead to a reacting

motion on the auger, which can

cause the operator to lose control of

the machine or throw him to the

ground, resulting in serious injury.

Always wear approved protective

gloves.

Wear sturdy, non-slip boots or shoes.

Other symbols/decals on the mac

certification requirements for certain markets.

hine refer to special

2

–

English

Page 3

CONTENTS

!

!

!

Contents

KEY

TO SYMBOLS

Symbols

................................................................ 2

CONTENTS

Contents

............................................................... 3

Note the following before starting: ........................ 3

INTR

ODUCTION

Dear Customer

WHA

T IS WHAT?

What is what?

GENERAL SAFETY PRECA

Impor

Personal protective equipment ............................. 6

Machine′s safety equipment ................................. 7

ASSEMBL

Fitting the handle

Fitting the auger ................................................... 9

FUEL HANDLING

Fuel saf

Fuel ...................................................................... 10

Fuelling ................................................................. 11

ST

ARTING AND STOPPING

Chec

k before starting ........................................... 12

Starting and stopping ........................................... 12

W

ORKING TECHNIQUES

Gener

MAINTENANCE

Carb

urettor ........................................................... 16

Muffler .................................................................. 16

Cooling system ..................................................... 16

Air filter ................................................................. 16

Gear ..................................................................... 17

Fuel filter ............................................................... 17

Spark plug ............................................................ 17

Maintenance schedule ......................................... 18

TECHNICAL D

T

echnical data ...................................................... 19

, .................................................... 4

....................................................... 5

UTIONS

tant .............................................................. 6

Y

.................................................. 9

ety ............................................................ 10

al working instructions ................................ 14

ATA

Note the f

ollowing before

starting:

Please read the oper

W

ARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection.

W

ARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use genuine

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

W

ARNING! An earth auger is a

dangerous tool if used carelessly or

incorrectly and can cause serious, even

fatal injuries. It is extremely important

that you read and understand the

contents of this Operator’s Manual.

ator’s manual carefully.

English –

3

Page 4

INTR

ODUCTION

Dear Customer

Cong

ratulations on your choice to buy a Husqvarna product! Husqvarna is based on a tradition that dates back to 1689,

when the Swedish King Karl XI ordered the construction of a factory on the banks of the Husqvarna River, for production

of muskets. The location was logical, since water power was harnessed from the Huskvarna River to create the waterpowered plant. During the more than 300 years of beeing, the Husqvarna factory has produced a lot of different products,

from wood stoves to modern kitchen appliances, sewing machines, bicycles, motorcycles etc. In 1956, the first motor

driven lawn mowers appeared, followed by chain saws in 1959, and it is within this area Husqvarna is working today.

Today Husqvarna is one of the leading manufacturers in the world of forest and garden products, with quality as our

highest priority. The business concept is to develop, manufacture and market motor driven products for forestry and

gardening as well as for building and construction industry. Husqvarna

ergonomics, usability, security and environmental protection. That is the reason why we have developed many different

features to provide our products within these areas.

We are convinced that you will appreciate with great satisfaction the quality and performance of our product for a very

long time to come. The purchase of one of our products gives you access to professional help with repairs and service

whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask for the

address of your nearest service workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this

operator

′

s manual as a valuable document. By following its′ content (using, service, maintenance etc) the life span and

the second-hand value of the machine can be extended. If you will sell this machine, make sure that the buyer will get

the operator

Thank you for using a Husqvarna product.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice.

′

s manual.

,

′

s aim is also to be in the front edge according to

4

–

English

Page 5

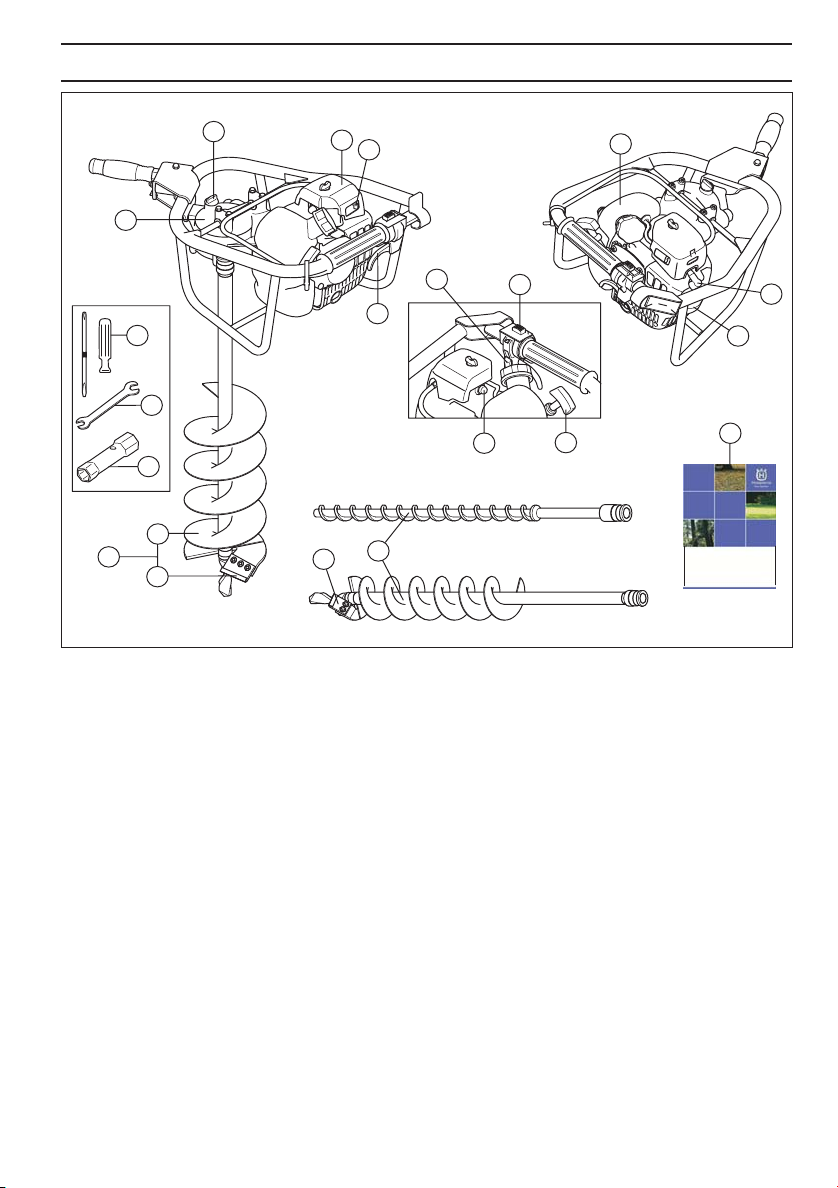

WHA

T IS

WHA

T?

1

5

17

18

19

6

8

7

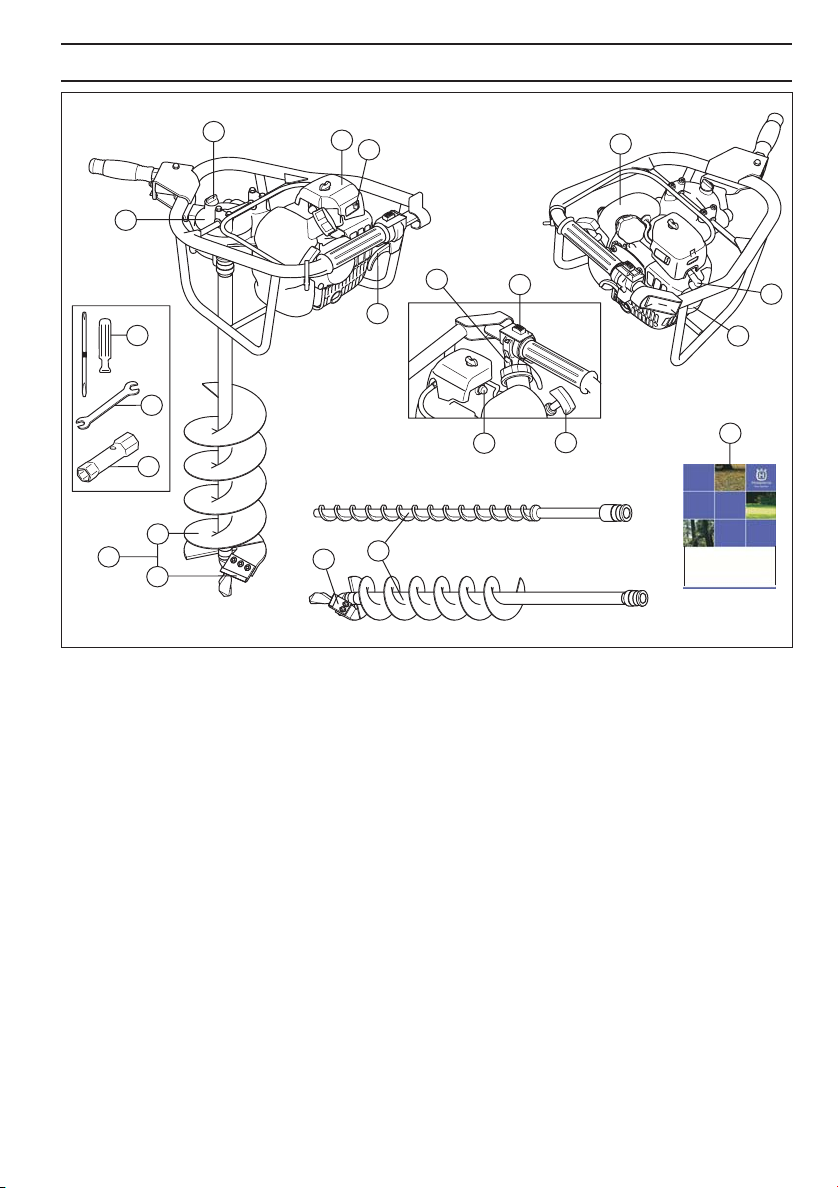

What is what?

1

Filling with oil

2 Air filter cover

3 Choke control

4 Throttle control

5 Gear

6 Drill (Available as an accessory.)

7 Cutters (Available as an accessory.)

8 Cutting equipment

9 Start throttle button

10 Stop switch

2

3

9

4

6

7

11 Starter handle

12 Air purge

13 Fuel tank

14 Spark plug cap and spark plug

15 Cylinder cover

16 Operator′s manual

17 Screwdriver

18 Combination spanner

19 Spanner

10

12

13

14

15

11

16

English

–

5

Page 6

GENERAL SAFETY PRECA

!

UTIONS

Impor

tant Personal protective equipment

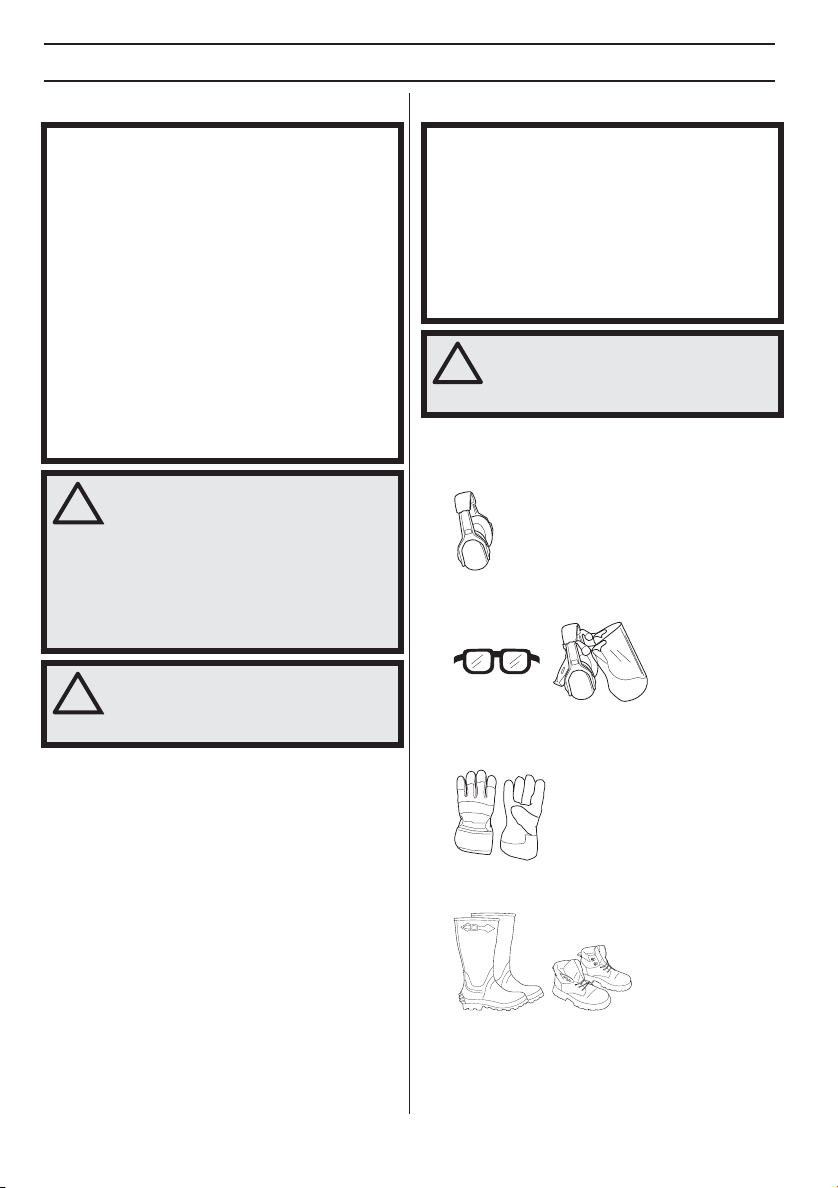

IMPORTANT!

The machine is solely designed for drilling in earth.

Never use a machine that has been modified in any way

from its original specification.

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the heading Maintenance.

All covers and guards must be fitted before starting.

Ensure that the spark plug cap and ignition lead are

undamaged to avoid the risk of electric shock.

W

ARNING! This machine produces an

electromagnetic field during operation.

!

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

W

ARNING! Running an engine in a

confined or badly ventilated area can

!

result in death due to asphyxiation or

carbon monoxide poisoning.

IMPOR

TANT!

An earth auger is a dangerous tool if used carelessly or

incorrectly and can cause serious, even fatal injuries. It

is extremely important that you read and understand the

contents of this Operator’s Manual.

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

W

ARNING! Listen out for warning signals

or shouts when you are wearing hearing

protection. Always remove your hearing

protection as soon as the engine stops.

HEARING PR

Wear hearing protection that provides adequate noise

reduction.

EYE PROTECTION

Protective goggles or a visor must be worn.

GLOVES

Gloves should be worn when necessary, e.g., when fitting

cutting attachments.

OTECTION

BOOTS

Wear sturdy, non-slip boots or shoes.

CLOTHING

Never wear loose-fitting clothes, scarves, jewellery or

similar items that could get caught in the auger. Make

sure your hair does not hang below shoulder level.

6

–

English

Page 7

GENERAL SAFETY PRECA

!

!

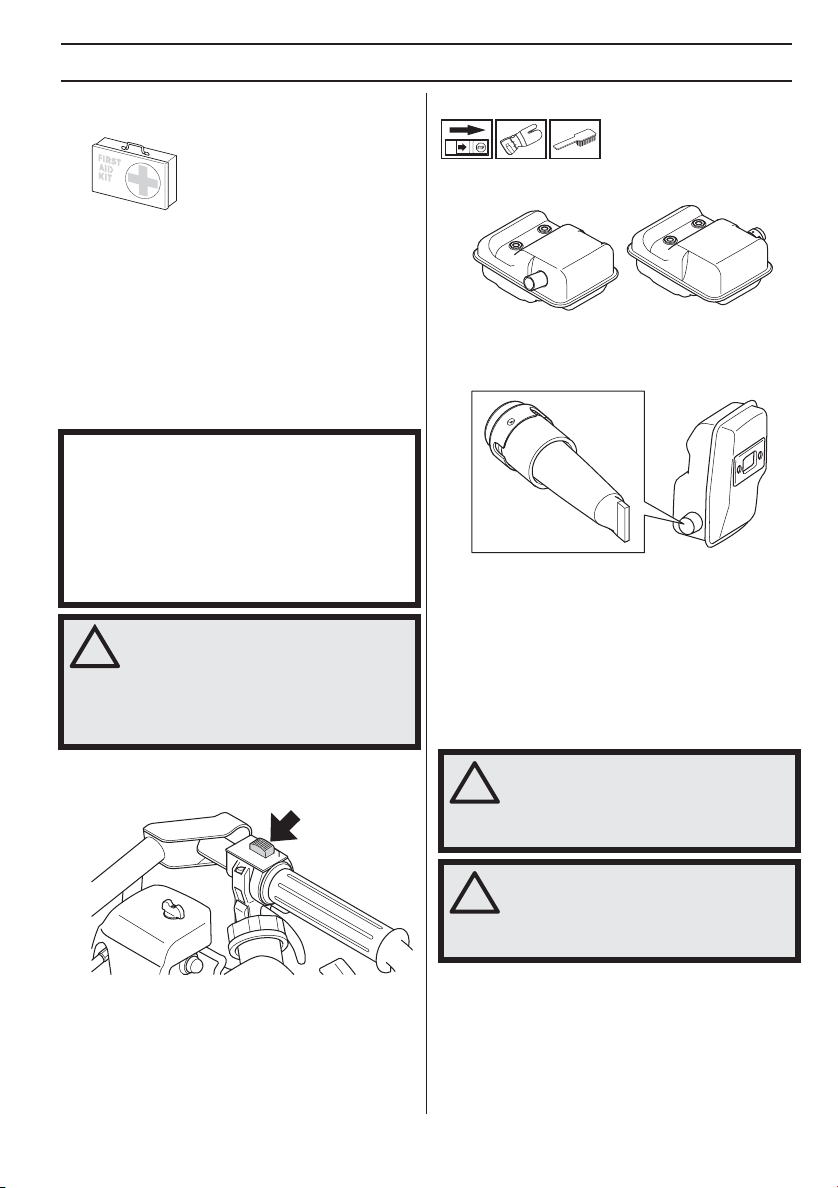

FIRST AID KIT

Alw

ays have a first aid kit nearby.

Mac

hine′s safety equipment

This section descr

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest service workshop.

IMPORTANT!

All servicing and repair work on the machine requires

special training. This is especially true of the machine

safety equipment. If your machine fails any of the

checks described below you must contact your service

agent. When you buy any of our products we guarantee

the availability of professional repairs and service. If the

retailer who sells your machine is not a servicing dealer,

ask him for the address of your nearest service agent.

!

ibes the machine′s safety equipment,

W

ARNING! Never use a machine with

faulty safety equipment. The machine’s

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

UTIONS

Muffl

er

The m

uffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

In countries that have a warm and dry climate there is a

significant risk of fire. We therefore fit certain mufflers with

a spark arrestor mesh. Check whether the muffler on your

machine is fitted with this kind of mesh.

′

s

For mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine.

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to

the machine.

If the muffler on your machine is fitted with a spark

arrestor mesh this must be cleaned regularly. A blocked

mesh will cause the engine to overheat and may lead to

serious damage.

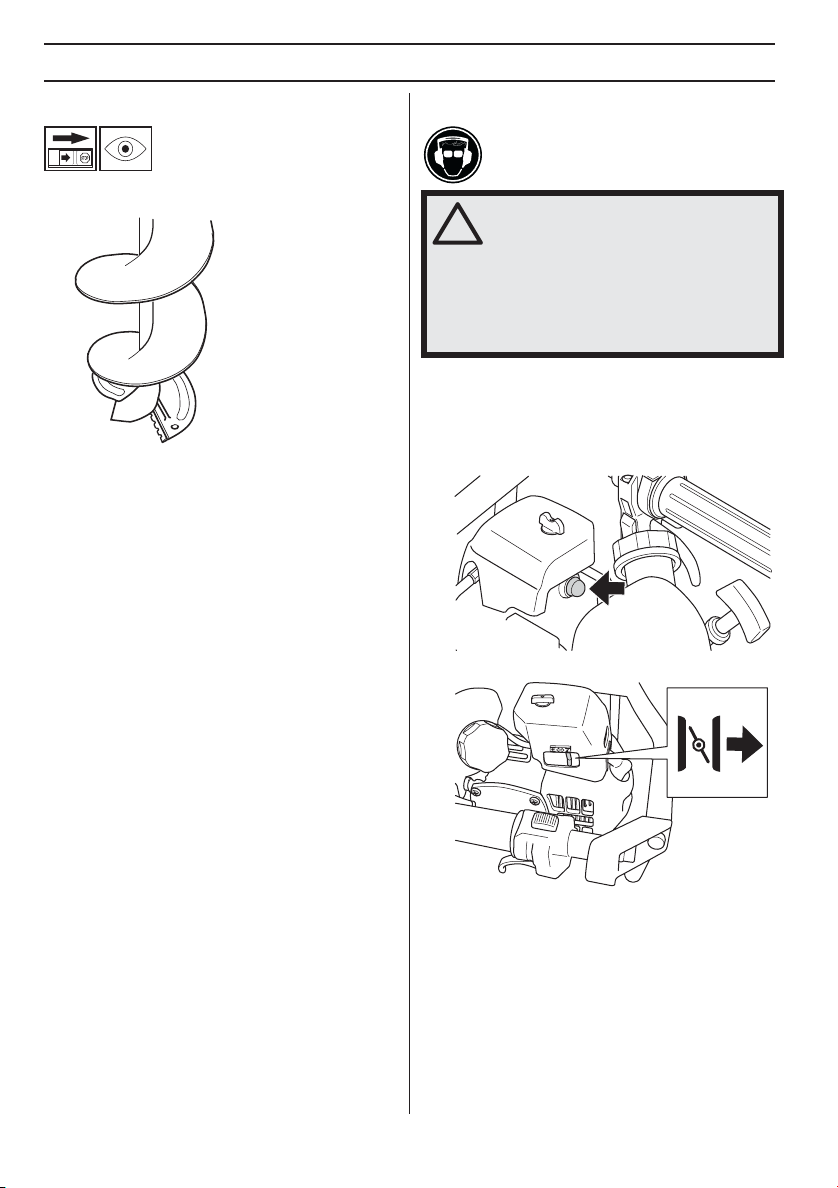

Stop s

witch

Use the stop s

Start the engine and make sure the engine stops when

you move the stop switch to the stop setting.

witch to switch off the engine.

W

ARNING! The inside of the muffler

contain chemicals that may be

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

W

ARNING! Bear in mind that: The

exhaust fumes from the engine are hot

and may contain sparks which can start

a fire. Never start the machine indoors or

near combustible material!

English –

7

Page 8

GENERAL SAFETY PRECA

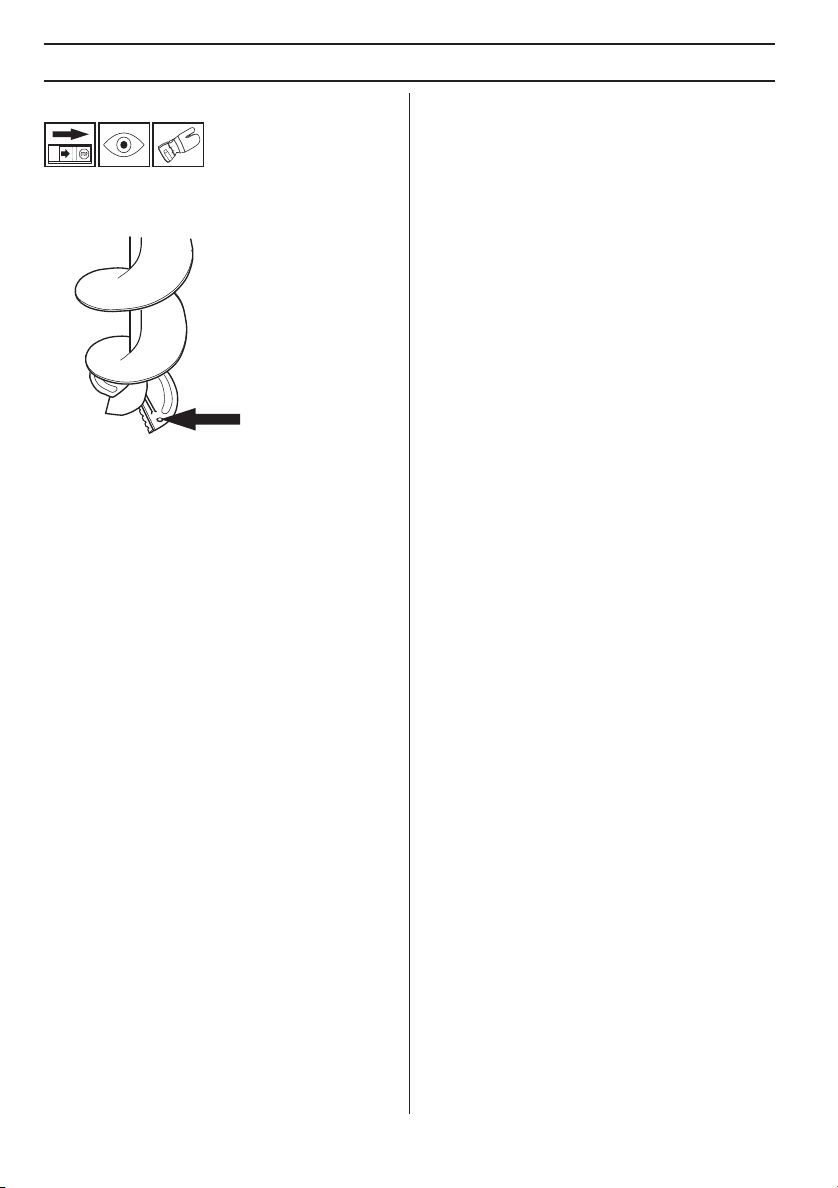

Cutter

s

Chec

k the cutters. Never use cutters that are blunt,

cracked or damaged.

Ensure that the cutters are securely attached.

When the blade is manufactured it is sharpened using an

advanced method. This means that the blade cannot be

re-sharpened using conventional methods. Worn blades

must be replaced with new ones to ensure your machine

works satisfactorily.

UTIONS

8

–

English

Page 9

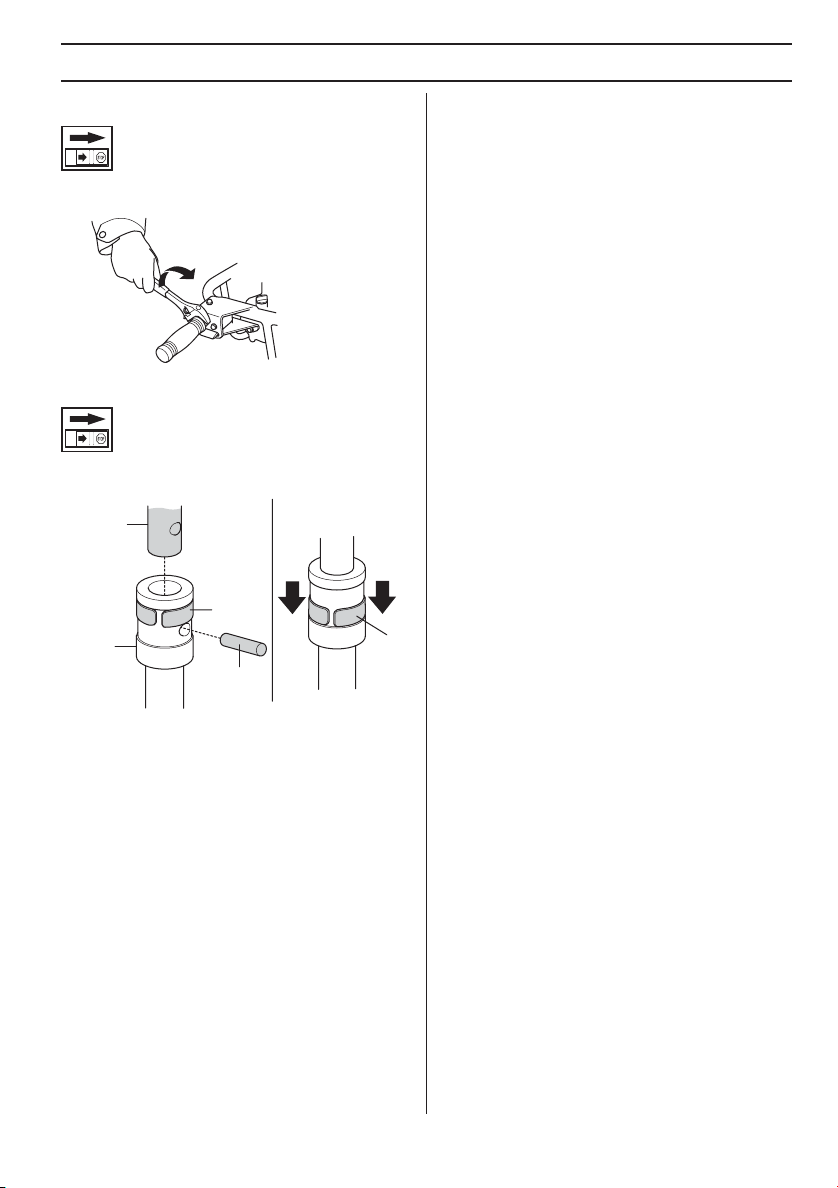

Fitting the handle

•

Screw in the left grip to the bracket provided on the

frame and tighten securely.

ASSEMBL

Y

Fitting the aug

•

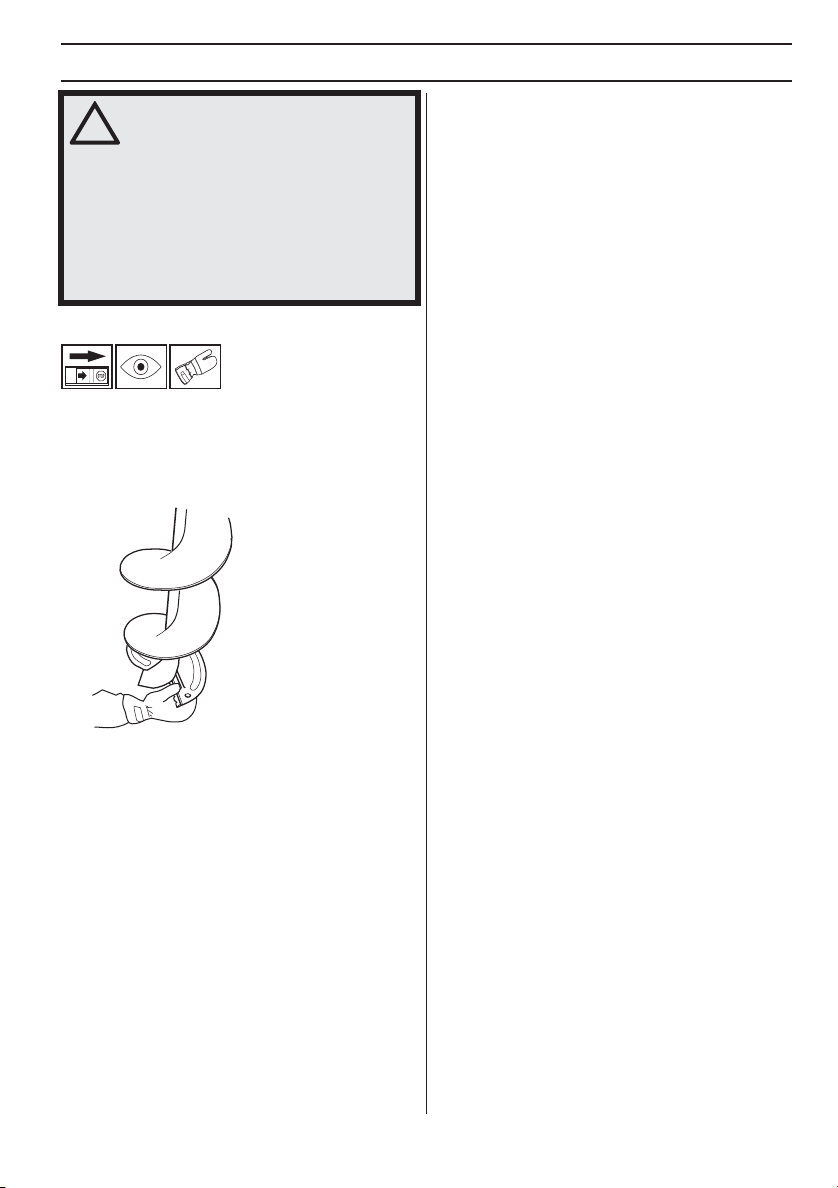

Slide the ring clip (A) and remove the locking pin (B)

from the auger.

er

D

A

C

B

• Fit the auger (C) to the output shaft (D).

• Fit the locking pin and slide the ring clip so that it

covers the locking pin.

A

English –

9

Page 10

FUEL HANDLING

Fuel safety

Never start the machine:

1 If you have spilt fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

2 If you have spilt fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines.

Transport and storage

• Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or naked flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

approved containers intended for this purpose.

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local petrol

station to find out where to dispose of excess fuel.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• The transport guard must always be fitted to the

cutting attachment when the machine is being

transported or in storage.

• In order to prevent unintentional starting of the engine,

the spark plug cap must always be removed during

long-term storage, if the machine is not under close

supervision and when performing all service

measures.

WARNING! Take care when handling fuel.

Bear in mind the risk of fire, explosion

!

and inhaling fumes.

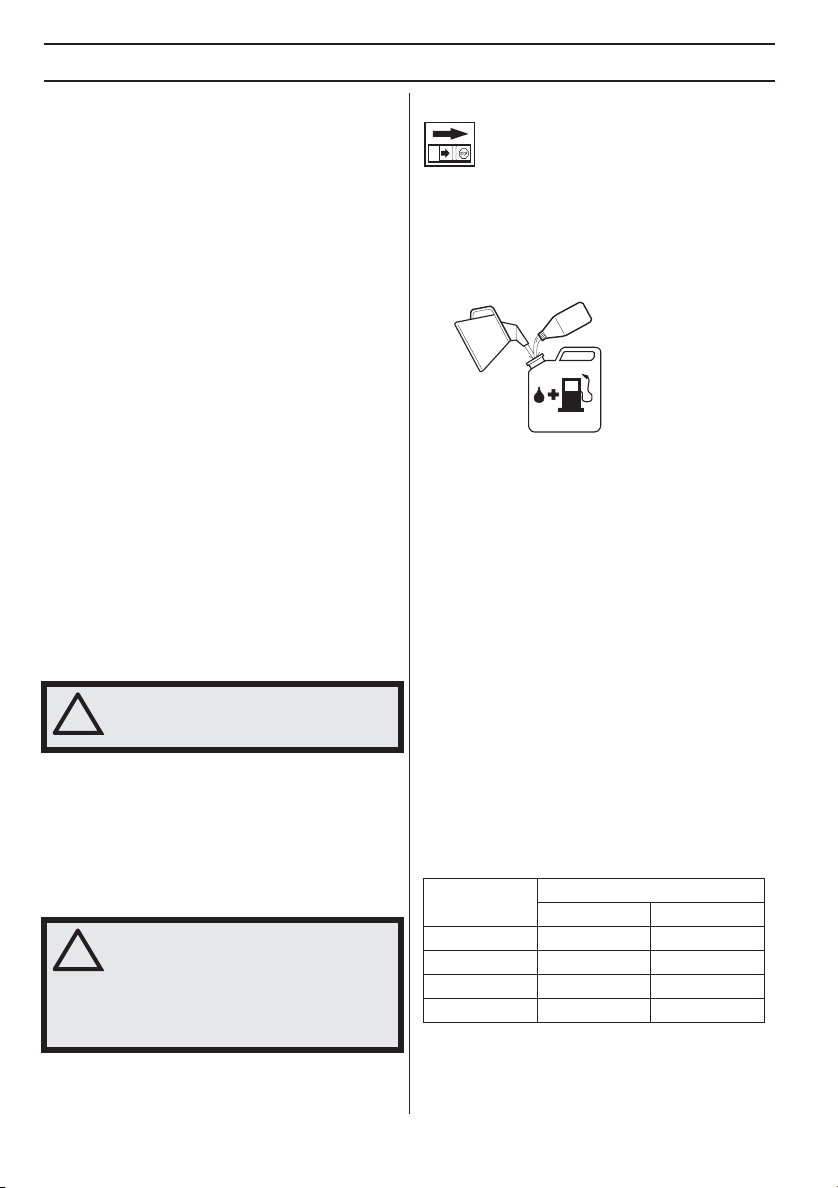

Fuel

CAUTION! The machine is equipped with a two-stroke

engine and must always been run using a mixture of

petrol and two-stroke oil. It is important to accurately

measure the amount of oil to be mixed to ensure that the

correct mixture is obtained. When mixing small amounts

of fuel, even small inaccuracies can drastically affect the

ratio of the mixture.

WARNING! Fuel and fuel fumes are

highly inflammable and can cause

!

serious injury when inhaled or allowed to

come in contact with the skin. For this

reason observe caution when handling

fuel and make sure there is adequate

ventilation.

Petrol

CAUTION! Always use a quality petrol/oil mixture at least

90 octane (RON). If your machine is equipped with a

catalytic converter (see chapter on Technical data) always

use a good quality unleaded petrol/oil mixture. Leaded

petrol will destroy the catalytic converter.

Use low-emission petrol, also known as alkylate petrol, if

it is available.

• The lowest octane recommended is 90 (RON). If you

run the engine on a lower octane grade than 90 socalled knocking can occur. This gives rise to a high

engine temperature, which can result in serious

engine damage.

• When working at continuous high revs a higher octane

rating is recommended.

Two-stroke oil

• For best results and performance use HUSQVARNA

two-stroke engine oil, which is specially formulated for

our air-cooled two-stroke engines.

• Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

• A poor oil quality and/or too high oil/fuel ratio may

jeopardise function and decrease the life time of

catalytic converters.

• Mixing ratio

1:50 (2%) with HUSQVARNA two-stroke oil.

1:33 (3%) with oils class JASO FB or ISO EGB

formulated for air-cooled, two-stroke engines.

Petrol, litre

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Two-stroke oil, litre

2% (1:50) 3% (1:33)

10 – English

Page 11

FUEL HANDLING

!

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

Fuelling

WARNING! Taking the following

precautions, will lessen the risk of fire:

Do not smoke or place hot objects near

fuel.

Always shut off the engine before

refuelling.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine away from the

refuelling area before starting.

• Always use a fuel container with an anti-spill valve.

• Clean the area around the fuel cap. Contamination in

the tank can cause operating problems.

• Ensure that the fuel is well mixed by shaking the

container before filling the tank.

English – 11

Page 12

STARTING AND STOPPING

!

Check before starting

• Check the cutters. Never use cutters that are blunt,

cracked or damaged.

• Check that the machine is in perfect working order.

Check that all nuts and screws are tight.

• Check that the cutting attachment always stops when

the engine is idling.

• Only use the machine for the purpose it was intended

for.

• Make sure that the handle and safety features are in

good working order. Never use a machine that lacks a

part or has been modified outside its specifications.

• All covers must be correctly fitted and undamaged

before you start the machine.

Starting and stopping

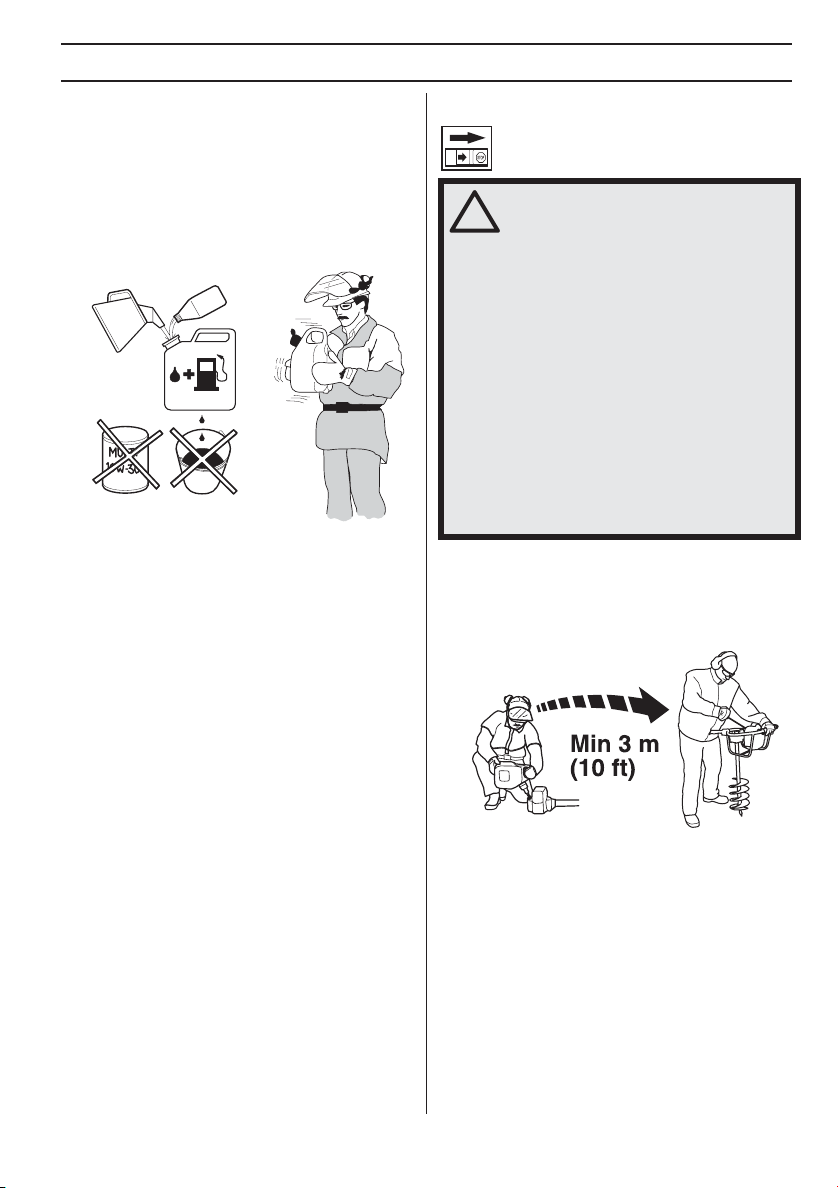

WARNING! Always move the machine

about 3 metres from the refuelling

position before starting. Place the

machine on a flat surface. Ensure the

cutting attachment cannot come into

contact with any object. Make sure no

unauthorised persons are in the working

area, otherwise there is a risk of serious

personal injury.

Cold engine

Ignition: Set the stop switch to the start position.

Primer bulb: Press the air purge repeatedly until fuel

begins to fill the bulb. The bulb need not be completely

filled.

Choke: Set the choke control in the choke position.

12 – English

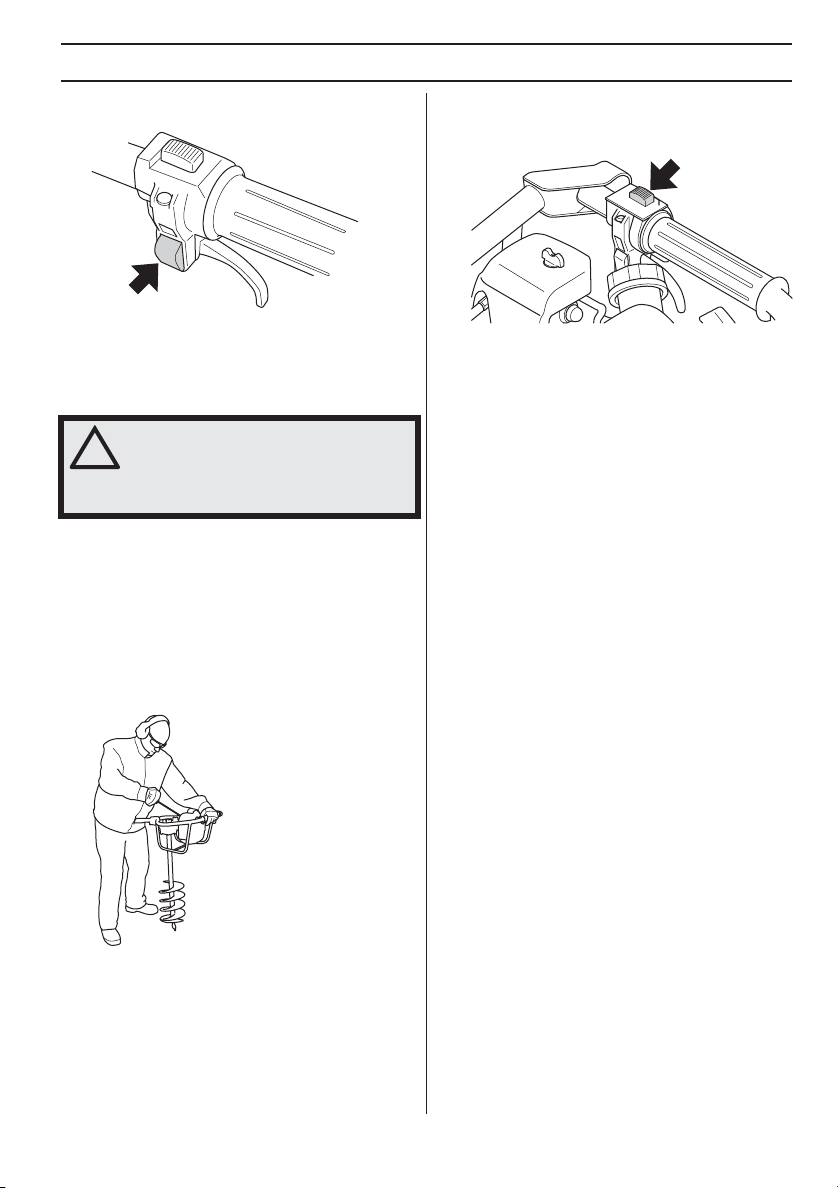

Start throttle:

Set the throttle to the start position by first pressing the

throttle trigger, then pressing the start throttle button (A).

Then release the throttle trigger, followed by the start

Page 13

STARTING AND STOPPING

throttle button. The throttle function is now activated. To

return the engine to idle, press the throttle trigger again.

Warm engine

Use the same starting procedure as for a cold engine but

without setting the choke control in the choke position.

Starting

WARNING! When the engine is started

with the choke in either the choke or

!

start throttle positions the cutting

attachment will start to rotate

immediately.

Hold the machine upright with your left hand. Grip the

starter handle, slowly pull out the cord with your right hand

until you feel some resistance (the starter pawls grip),

now quickly and powerfully pull the cord.

Push the choke control back to its original position as

soon as the engine fires, and continue trying to start until

the engine starts.

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Stopping

The engine is switched off by moving the stop switch to

the stop position.

English – 13

Page 14

WORKING TECHNIQUES

!

!

General working instructions

IMPORTANT!

This section takes up the basic safety precautions for

working with an earth auger.

If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact your

dealer or your service workshop.

Avoid all usage which you consider to be beyond your

capability.

WARNING! The machine can cause

serious personal injury. Read the safety

!

instructions carefully. Learn how to use

the machine.

WARNING! Cutting tool. Do not touch the

tool without first switching off the

!

engine.

Safety instructions regarding the surroundings

• Never allow children to use the machine.

• Ensure that no-one comes closer than 5 m while you

are working.

• Never allow anyone else to use the machine without

first ensuring that they have understood the contents

of the operator’s manual.

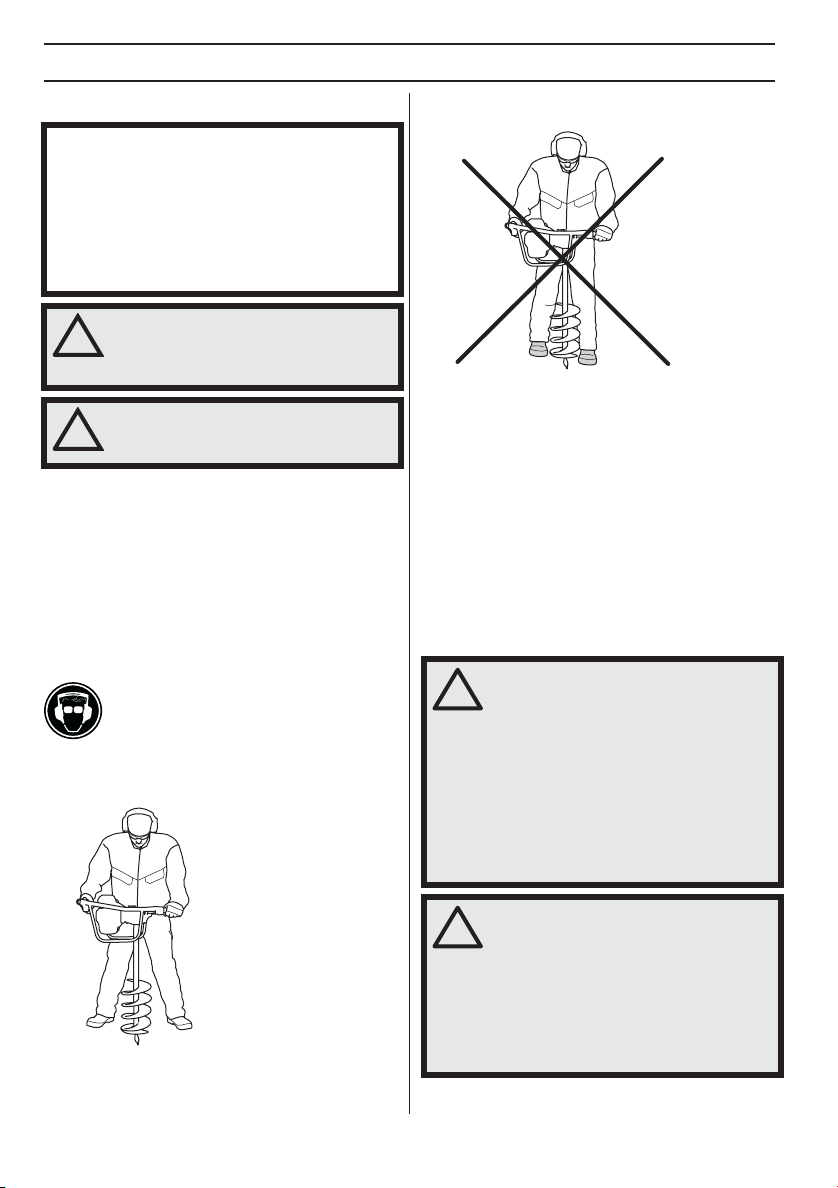

Safety instructions while working

• Always ensure you have a safe and stable working

position.

• Always hold the machine with both hands.

• Make sure that your hands and feet do not come near

the cutting attachment when the engine is running.

• Start drilling with half-throttle, and gradually increase

the engine speed so that the drill may get into the

ground smoothly.

• If the drill has been caught in the ground and cannot

be pulled out, stop the engine and rotate the auger

counter-clockwise.

• Always turn off the engine when you have finished

drilling.

• When the engine is switched off, keep your hands and

feet away from the cutting attachment until it has

stopped completely.

• If any foreign object is hit or if vibrations occur stop the

machine immediately. Disconnect the HT lead from

the spark plug. Check that the machine is not

damaged. Repair any damage.

WARNING! Drilling into or contact with

electrical cables or wires can lead to

death or serious bodily injury. The

machine is not electrically insulated. To

reduce the risk of electrocution, always

check for underground pipes, cables and

wires before drilling. Contact your local

utility company or locator service for

information regarding cable and pipe

locations. If necessary, confirm the

actual locations by use of devices such

as cable detectors and by carefully

digging trenches.

• Use your right hand to control the throttle setting.

14 – English

WARNING! Striking something hard in

the earth, such as rocks or tree roots,

may cause the drill to come to a sudden

stop. This can lead to a reacting motion

on the auger, which can cause the

operator to lose control of the machine

or throw him to the ground, resulting in

serious injury. To reduce the risk of

injury, always hold the auger securely to

control such motion.

Page 15

WORKING TECHNIQUES

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. The risk

increases at low temperatures.

Safety instructions after completing work

• Make sure the cutting attachment has stopped before

cleaning, carrying out repairs or an inspection.

Disconnect the HT lead from the spark plug.

• Always wear heavy gloves when replacing the cutters.

The cutters are extremely sharp and can easily cause

cuts.

• Store the machine out of reach of children.

• Use only original spare parts for repairs.

English – 15

Page 16

MAINTENANCE

!

Carburettor

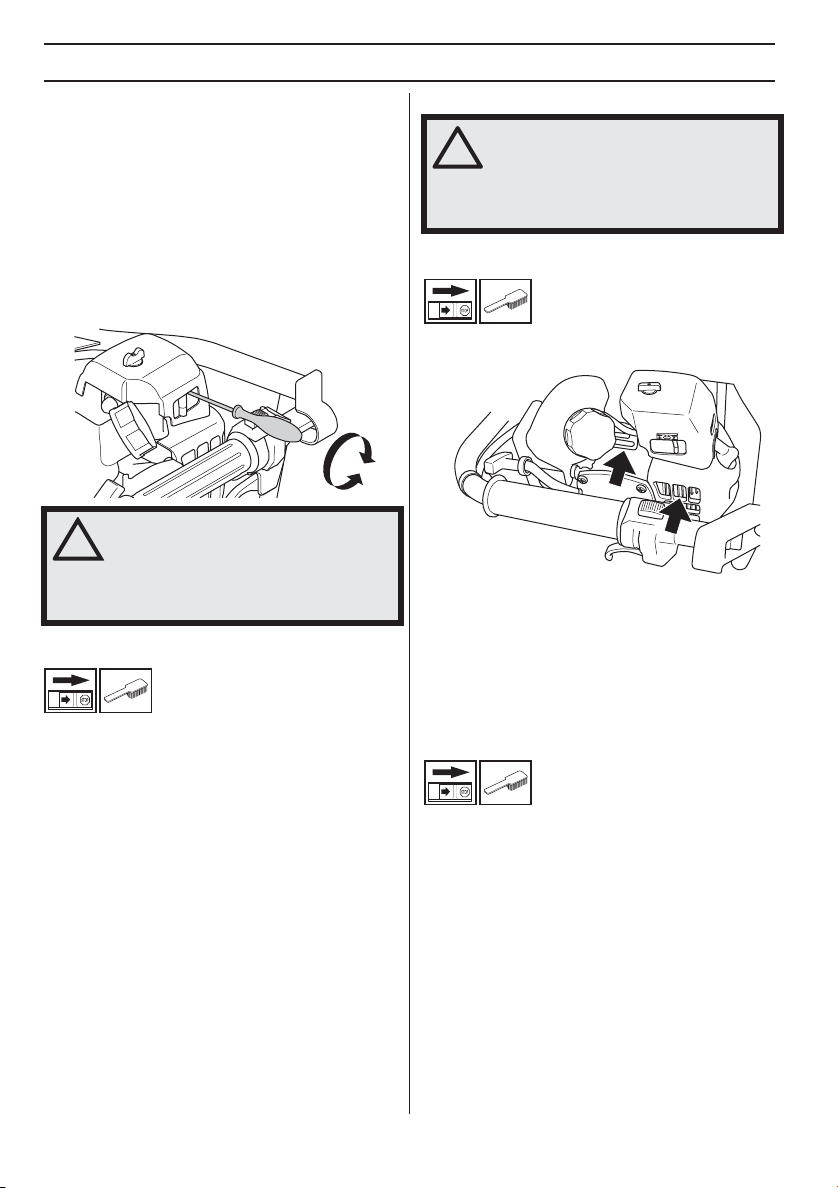

Adjusting the idle speed (T)

Check that the air filter is clean. When the idle speed is

correct, the cutting attachment should not rotate. If

adjustment is required, close (turn clockwise) the idle

adjustment screw T, with the engine running, until the

cutting attachment starts to rotate. Open (turn

anticlockwise) the screw until the cutting attachment

stops. The idle speed is correctly set when the engine

runs smoothly in all positions, and there is a clear margin

to the speed at which the cutting attachment starts to

rotate.

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

!

stops, contact your dealer/service

workshop. Do not use the machine until

it has been correctly adjusted or

repaired.

Muffler

NB! Some mufflers are fitted with a catalytic converter.

See chapter on Technical data to see whether your

machine is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

Some mufflers are equipped with a special spark arrestor

mesh. If your machine has this type of muffler, you should

clean the mesh at least once a week. This is best done

with a wire brush.

On mufflers without a catalytic converter the mesh should

be cleaned weekly, or replaced if necessary. On mufflers

fitted with a catalytic converter the mesh should be

checked, and if necessary cleaned, monthly.

is damaged it should be replaced.

If the mesh is frequently blocked, this can be a sign that

the performance of the catalytic converter is impaired.

Contact your dealer to inspect the muffler. A blocked

mesh will cause the machine to overheat and result in

damage to the cylinder and piston.

If the mesh

CAUTION! Never use a machine with a defective muffler.

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping.

This also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fire!

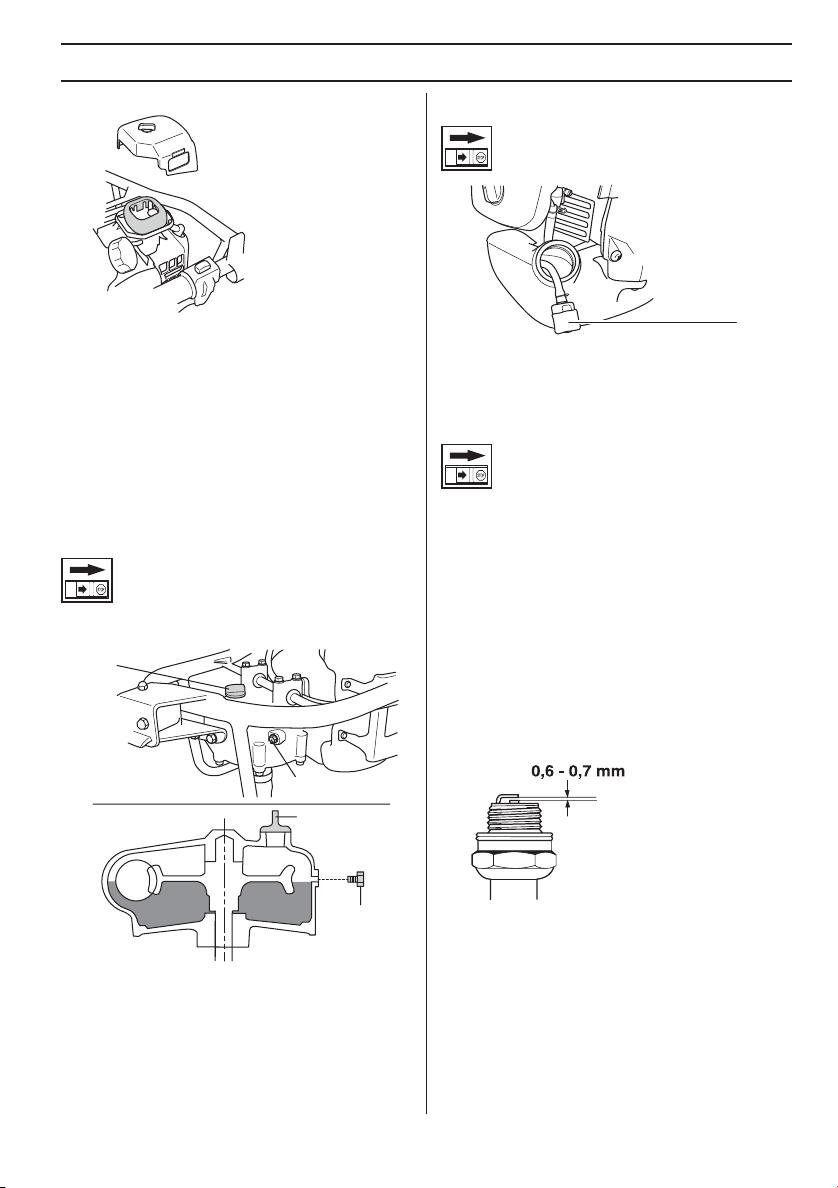

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Cooling fins on the cylinder.

2 Air intake.

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts.

16 – English

Page 17

• Excessive fuel consumption.

MAINTENANCE

Fuel filter

Clean the filter every 25 hours, or more regularly if

conditions are exceptionally dusty.

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals.

must always be replaced.

A damaged air filter

Gear

Check the oil level of the gear box every 50 hours of use

and change with new oil as necessary (SAE 80-90).

A

B

A

1

1 Fuel filter

When the engine runs short of fuel supply, check the fuel

cap and the fuel filter for blockage.

Spark plug

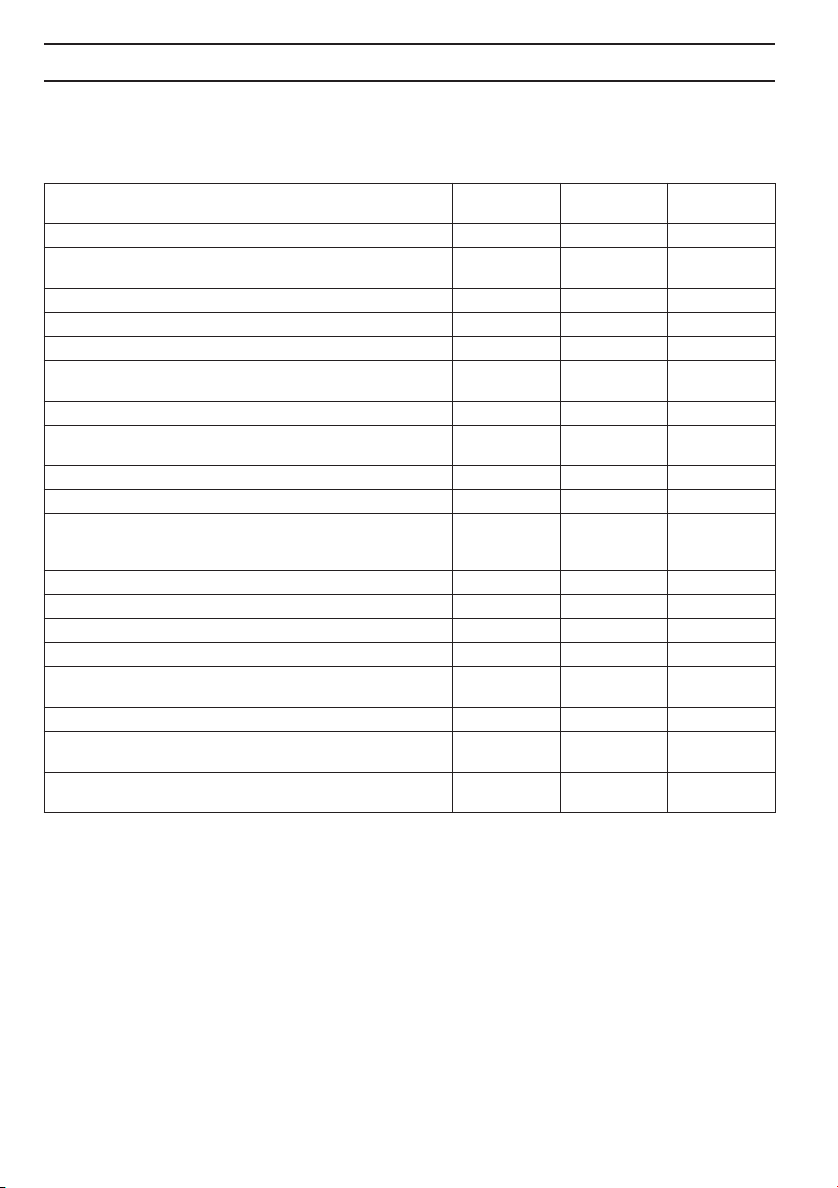

The spark plug condition is influenced by:

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0,6-0,7 mm.

The spark plug should be replaced after about a month in

operation or earlier if necessary.

B

• Make sure that the auger is standing in an upright

position.

• Open the oil filler cap A and the screw B.

• Fill the gear box with oil. The correct level of oil is

reached when you can see a drop of oil come out of

the hole for the screw B.

• Fit the screw B and close the oil filler cap A.

CAUTION! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder. Check that the spark plug is fitted with a

suppressor.

English – 17

Page 18

MAINTENANCE

Maintenance schedule

The following is a list of the maintenance that must be performed on the machine. Most of the items are described in the

Maintenance section. The user must only carry out the maintenance and service work described in this Operator’s

Manual. More extensive work must be carried out by an authorized service workshop.

Maintenance

Clean the outside of the machine. X

Check that the handle and handlebar are undamaged and

secured correctly.

Check that the stop switch works correctly. X

Check that the cutting attachment does not rotate at idle. X

Clean the air filter. Replace if necessary. X

Check the cutters. Never use cutters that are blunt, cracked or

damaged.

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or fuel

lines.

Check the starter and starter cord. X

Check that the vibration damping elements are not damaged. X

Clean the outside of the spark plug. Remove it and check the

electrode gap. Adjust the gap to 0,6-0,7 mm or replace the spark

plug. Check that the spark plug is fitted with a suppressor.

Clean the machine’s cooling system. X

Clean the outside of the carburettor and the space around it. X

Check the oil level of the gear box, and top up if necessary. X

Clean the muffler. X

Check the fuel filter from contamination and the fuel hose from

cracks or other defects. Replace if necessary.

Check all cables and connections. X

Check the clutch, clutch springs and the clutch drum for wear.

Replace if necessary by an autorized service workshop.

Replace the spark plug. Check that the spark plug is fitted with a

suppressor.

Daily

maintenance

X

X

X

Weekly

maintenance

X

Monthly

maintenance

X

X

X

18 – English

Page 19

TECHNICAL DATA

Technical data

143AE15

Engine

Cylinder displacement, cm

Cylinder bore, mm 40,0

Stroke, mm 33

Idle speed, rpm 2500

Recommended max. speed, rpm 12000

Max. engine output, acc. to ISO 8893, kW/ rpm 1,47/7500

Catalytic converter muffler No

Speed-regulated ignition system No

Ignition system

Manufacturer/type of ignition system TCI

Spark plug NGK BPMR 7A

Electrode gap, mm 0,6-0,7

Fuel and lubrication system

Manufacturer/type of carburettor Walbro WYK

Fuel tank capacity, litre 0,94

Weight

Weight, without fuel and cutting tool, kg 8,9

Sound levels

(see note 1)

Equivalent sound pressure level at the operator’s ear,

measured according to EN ISO 22868, dB(A):

Equivalent noise power level, measured according to

ISO 3744, dB(A)

Vibration levels

Equivalent vibration levels (a

according to EN ISO 22867, m/s

left/right handles: 6,0/9,3

Note 1: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard

deviation) of 1 dB (A).

Note 2: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

3

) at handles, measured

hv,eq

2

41,5

103

110

2

English – 19

Page 20

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos

¡ATENCIÓN! Una barrena para

tierra empleada de forma errónea o

negligente puede ser una

herramienta peligrosa que puede

causar daños graves e incluso la

muerte. Es muy importante que lea

y comprenda el contenido de este

manual de instrucciones.

Lea detenidamente el manual de

instrucciones y asegúrese de

entender su contenido antes de

utilizar la máquina.

Utilice siempre:

• Protectores auriculares

homologados

• Protección ocular homologada

Este producto cumple con la directiva

CE vigente.

El motor se para poniendo el

contacto de parada en la posición de

parada.

Utilice siempre guantes protectores

homologados.

La máquina debe limpiarse

regularmente.

Control visual.

Si al taladrar la máquina toca o

perfora cables eléctricos, puede

provocar la muerte o lesiones

graves. La máquina no tiene

aislamiento eléctrico.

Si llega a golpear algo duro en la

tierra, como rocas o las raíces de un

árbol, el taladro puede detenerse

repentinamente. Esto puede

conllevar un movimiento de

reacción en la barrena, lo que haría

que el usuario perdiese el control de

la máquina o cayese al suelo, con lo que podría sufrir

daños graves.

Utilice siempre guantes protectores

homologados.

Utilice botas o zapatos

antirresbalantes y fuertes.

Los demás símbolos/etiquetas que aparecen en la

máquina corresponden a requisitos de

homologación específicos en determinados

mercados.

20 – Spanish

Page 21

ÍNDICE

!

!

!

Índice Antes de arrancar, observe lo

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos .............................................................. 20

ÍNDICE

Índice .................................................................... 21

Antes de arrancar, observe lo siguiente: .............. 21

INTRODUCCIÓN

Apreciado cliente: ................................................. 22

¿QUÉ ES QUÉ?

¿Qué es qué? ....................................................... 23

INSTRUCCIONES GENERALES DE

SEGURIDAD

Importante ............................................................ 24

Equipo de protección personal ............................. 24

Equipo de seguridad de la máquina ..................... 25

MONTAJE

Montaje de la empuñadura ................................... 27

Montaje de la barrena .......................................... 27

MANIPULACION DEL COMBUSTIBLE

Seguridad en el uso del combustible ................... 28

Carburante ............................................................ 28

Repostaje ............................................................. 29

ARRANQUE Y PARADA

Control antes de arrancar ..................................... 30

Arranque y parada ................................................ 30

TÉCNICA DE TRABAJO

Instrucciones generales de trabajo ...................... 32

MANTENIMIENTO

Carburador ........................................................... 34

Silenciador ............................................................ 34

Sistema refrigerante ............................................. 34

Filtro de aire ......................................................... 34

Engranaje ............................................................. 35

Filtro de combustible ............................................ 35

Bujía ..................................................................... 35

Programa de mantenimiento ................................ 36

DATOS TECNICOS

Datos técnicos ...................................................... 37

siguiente:

Lea detenidamente el manual de instrucciones.

¡ATENCIÓN! La exposición prolongada al

ruido puede causar daños crónicos en el

oído Por consiguiente, use siempre

protectores auriculares homologados.

¡ATENCIÓN! Bajo ninguna circunstancia

debe modificarse la configuración

original de la máquina sin autorización

del fabricante. Utilizar siempre

recambios originales. Las

modificaciones y/o la utilización de

accesorios no autorizadas pueden

ocasionar accidentes graves o incluso la

muerte del operador o de terceros.

¡ATENCIÓN! Una barrena para tierra

empleada de forma errónea o negligente

puede ser una herramienta peligrosa que

puede causar daños graves e incluso la

muerte. Es muy importante que lea y

comprenda el contenido de este manual

de instrucciones.

Spanish – 21

Page 22

INTRODUCCIÓN

Apreciado cliente:

¡Felicidades por haber adquirido un producto Husqvarna! La historia de Husqvarna data del año 1689, cuando el Rey

Karl XI encargó la construcción de una fábrica en la ribera del río Huskvarna para la fabricación de mosquetes. La

ubicación junto al río Huskvarna era lógica dado que el río se utilizaba para generar energía hidráulica. Durante los más

de 300 años de existencia de la fábrica Husqvarna, se han fabricado productos innumerables; desde estufas de leña

hasta modernas máquinas de cocina, máquinas de coser, bicicletas, motocicletas, etc. En 1956 se introdujo el primer

cortacésped motorizado, seguido de la motosierra en 1959; y es en este segmento en el que actualmente trabaja

Husqvarna.

Husqvarna es hoy uno de los principales fabricantes del mundo de productos de bosque y jardín, con la calidad y las

prestaciones como principal prioridad. La idea de negocio es desarrollar, fabricar y comercializar productos motorizados

para silvicultura y jardinería, así como para las industrias de construcción y obras públicas. Husqvarna tiene como

objetivo estar en la vanguardia por lo que respecta a ergonomía, facilidad de empleo, seguridad y consideración

ambiental; motivo por el cual ha desarrollado una serie de detalles para mejorar los productos en estas áreas.

Estamos convencidos de que usted apreciará con satisfacción la calidad y prestaciones de nuestro producto por mucho

tiempo en adelante. Con la adquisición de alguno de nuestros productos, usted dispone de asistencia profesional con

reparaciones y servicio en caso de ocurrir algo. Si ha adquirido el producto en un punto de compra que no es uno de

nuestros concesionarios autorizados, pregúnteles por el taller de servicio más cercano.

Esperamos que su máquina le proporcione plena satisfacción y le sirva de ayuda por mucho tiempo en adelante. Tenga

en cuenta que este manual de instrucciones es un documento de valor. Siguiendo sus instrucciones (de uso, servicio,

mantenimiento, etcétera) puede alargar considerablemente la vida útil de la máquina e incrementar su valor de reventa.

Si vende su máquina, entregue el manual de instrucciones al nuevo propietario.

¡Gracias por utilizar un producto Husqvarna!

Husqvarna AB trabaja constantemente para perfeccionar sus productos y se reserva, por lo tanto, el derecho a introducir

modificaciones en la construcción y el diseño sin previo aviso.

22 – Spanish

Page 23

¿QUÉ ES QUÉ?

1

5

17

18

19

6

8

7

¿Qué es qué?

1 Repostado de aceite

2 Cubierta del filtro de aire

3 Estrangulador

4 Acelerador

5 Engranaje

6 Taladro (Disponible como accesorio.)

7 Cuchillas (Disponible como accesorio.)

8 Equipo de corte

9 Botón de aceleración de arranque

10 Botón de parada

2

3

9

4

6

7

10

12

13

14

15

11

16

11 Empuñadura de arranque

12 Bomba de combustible

13 Depósito de combustible

14 Capuchón de encendido y bujía

15 Cubierta del cilindro

16 Manual de instrucciones

17 Destornillador

18 Llave combinada

19 Llave de boca

Spanish – 23

Page 24

INSTRUCCIONES GENERALES DE SEGURIDAD

!

Importante Equipo de protección personal

¡IMPORTANTE!

La máquina está diseñada para taladrar únicamente en

tierra.

No utilice nunca una máquina que haya sido modificada

de modo que ya no coincida con la configuración

original.

Nunca utilice la máquina si está cansado, si ha ingerido

alcohol o si toma medicamentos que puedan afectarle

la vista, su capacidad de discernimiento o el control del

cuerpo.

Utilice el equipo de protección personal. Vea las

instrucciones bajo el título ”Equipo de protección

personal”.

No utilice nunca una máquina defectuosa. Siga las

instrucciones de mantenimiento, control y servicio de

este manual. Algunas medidas de mantenimiento y

servicio deben ser efectuadas por especialistas

formados y cualificados. Vea las instrucciones bajo el

título Mantenimiento.

Todas las cubiertas y protecciones deben estar

montadas antes de arrancar la máquina. Compruebe

que el capuchón y el cable de encendido estén intactos

para evitar sacudidas eléctricas.

¡ATENCIÓN! Esta máquina genera un

campo electromagnético durante el

!

funcionamiento. Este campo magnético

puede, en determinadas circunstancias,

interferir con implantes médicos activos

o pasivos. Para reducir el riesgo de

lesiones graves o letales, las personas

que utilizan implantes médicos deben

consultar a su médico y al fabricante del

implante antes de emplear esta máquina.

¡ATENCIÓN! Si se hace funcionar el

motor en un local cerrado o mal

!

ventilado, se corre riesgo de muerte por

asfixia o intoxicación con monóxido de

carbono.

¡IMPORTANTE!

Una barrena para tierra empleada de forma err nea o

negligente puede ser una herramienta peligrosa que

puede causar da os graves e incluso la muerte. Es muy

importante que lea y comprenda el contenido de este

manual de instrucciones.

Para trabajar con la máquina debe utilizarse un equipo

de protección personal homologado. El equipo de

protección personal no elimina el riesgo de lesiones,

pero reduce su efecto en caso de accidente. Pida a su

distribuidor que le asesore en la elección del equipo.

¡ATENCIÓN! Cuando use protección

auditiva preste siempre atención a las

señales o llamados de advertencia.

Sáquese siempre la protección auditiva

inmediatamente después de parar el

motor.

PROTECCIÓN AUDITIVA

Se debe utilizar protección auditiva con suficiente

capacidad de reducción sonora.

PROTECCIÓN OCULAR

Debe utilizarse gafas protectoras o visor.

GUANTES

Se deben utilizar guantes cuando sea necesario, por

ejemplo al montar el equipo de corte.

24 – Spanish

BOTAS

Utilice botas o zapatos antirresbalantes y fuertes.

Page 25

INSTRUCCIONES GENERALES DE SEGURIDAD

VESTIMENTA

No utilice nunca ropa amplia, bufandas, joyas o artículos

semejantes que podrían engancharse en la barrena.

Compruebe que el cabello no esté suelto por debajo de

los hombros.

PRIMEROS AUXILIOS

Tenga siempre a mano el equipo de primeros auxilios.

Botón de parada

El botón de parada se utiliza para parar el motor.

Equipo de seguridad de la máquina

En este capítulo se describen los componentes de

seguridad de la máquina, su función y el modo de

efectuar el control y el mantenimiento para garantizar un

funcionamiento óptimo. En cuanto a la ubicación de estos

componentes en su máquina, vea el capítulo Qué es qué.

La vida útil de la máquina puede acortarse y el riesgo de

accidentes puede aumentar si el mantenimiento de la

máquina no se hace de forma adecuada y si los trabajos

de servicio y/o reparación no se efectúan de forma

profesional. Para más información, consulte con el taller

de servicio oficial más cercano.

¡IMPORTANTE!

Todos los trabajos de servicio y reparación de la

máquina requieren una formación especial. Esto es

especialmente importante para el equipo de seguridad

de la máquina. Si la máquina no pasa alguno de los

controles indicados a continuación, acuda a su taller de

servicio local. La compra de alguno de nuestros

productos le garantiza que puede recibir un

mantenimiento y servicio profesional. Si no ha adquirido

la máquina en una de nuestras tiendas especializadas

con servicio, solicite información sobre el taller de

servicio más cercano.

¡ATENCIÓN! Nunca utilice una máquina

que tenga un equipo de seguridad

!

defectuoso. Efectúe el control y

mantenimiento del equipo de seguridad

de la máquina como se describió en este

capítulo. Si su máquina no pasa todos

los controles, entréguela a un taller de

servicio para su reparación.

Arranque el motor y compruebe que se pare cuando se

mueve el botón de parada a la posición de parada.

Silenciador

El silenciador está diseñado para reducir al máximo

posible el nivel sonoro y para apartar los gases de escape

del usuario.

En países con clima cálido y seco, puede ser grande el

riesgo de incendio. Por eso, hemos equipado a ciertos

silenciadores con cortafuegos. Controle si el silenciador

de su máquina lo tiene.

Para el silenciador, es sumamente importante seguir las

instrucciones de control, mantenimiento y servicio.

Nunca utilice una máquina que tenga un silenciador

defectuoso.

Compruebe regularmente que el silenciador esté

firmemente montado en la máquina.

Si el silenciador de su máquina lleva rejilla apagachispas,

límpiela a intervalos regulares. La obturación de la rejilla

Spanish – 25

Page 26

INSTRUCCIONES GENERALES DE SEGURIDAD

produce el sobrecalentamiento del motor, con el riesgo

consiguiente de averías graves.

¡ATENCIÓN! En el interior del silenciador

hay sustancias químicas que pueden ser

!

cancerígenas. Evitar el contacto con

estas sustancias si se daña el

silenciador.

¡ATENCIÓN! Recuerde que: Los gases de

escape del motor están calientes y

!

pueden contener chispas que pueden

provocar incendio. Por esa razón, ¡nunca

arranque la máquina en interiores o

cerca de material inflamable!

Cuchillas

Compruebe las cuchillas. No utilice nunca cuchillas

romas, agrietadas o dañadas.

Compruebe que las cuchillas estén firmemente

montadas.

Durante el proceso de fabricación, las cuchillas se afilan

siguiendo un método avanzado. Esto significa que no

pueden volver a afilarse con métodos convencionales.

Las cuchillas gastadas deben sustituirse por cuchillas

nuevas para asegurarse de que la máquina funciona

satisfactoriamente.

26 – Spanish

Page 27

MONTAJE

Montaje de la empuñadura

• Atornille el mango izquierdo al soporte incluido en el

bastidor y apriételo con firmeza.

Montaje de la barrena

• Deslice la abrazadera de anillo (A) y retire el pasador

de bloqueo (B) de la barrena.

D

A

C

A

B

• Coloque la barrena (C) en el eje de salida (D).

• Coloque el pasador de bloqueo y deslice la

abrazadera de anillo de forma que lo cubra.

Spanish – 27

Page 28

MANIPULACION DEL COMBUSTIBLE

!

Seguridad en el uso del combustible

Nunca arranque la máquina:

1 Si derramó combustible sobre la máquina. Seque

cualquier residuo y espere a que se evaporen los

restos de combustible.

2 Si se salpicó el cuerpo o las ropas, cambie de ropas.

Lave las partes del cuerpo que han entrado en

contacto con el combustible. Use agua y jabón.

3 Si hay fugas de combustible en la máquina.

Compruebe regularmente si hay fugas en la tapa del

depósito o en los conductos de combustible.

Transporte y almacenamiento

• Almacene y transporte la máquina y el combustible de

manera que eventuales fugas o vapores no puedan

entrar en contacto con chispas o llamas, por ejemplo,

máquinas eléctricas, motores eléctricos, contactos

eléctricos/interruptores de corriente o calderas.

• Para almacenar y transportar combustible se deben

utilizar recipientes diseñados y homologados para tal

efecto.

• Si la máquina se va a almacenar por un período largo,

se debe vaciar el depósito de combustible. Pregunte

en la estación de servicio más cercana qué hacer con

el combustible sobrante.

• Antes del almacenaje prolongado, limpie bien la

máquina y haga el servicio completo.

• La protección para transportes del equipo de corte

siempre debe estar montada durante el transporte o

almacenamiento de la máquina.

• Para evitar el arranque imprevisto del motor, se debe

quitar siempre el capuchón de encendido para el

almacenaje prolongado de la máquina, si se va a

dejar la máquina sin vigilar y para efectuar todas las

medidas de servicio previstas.

¡ATENCIÓN! Sea cuidadoso al manejar el

combustible. Piense en los riesgos de

!

incendio, explosión e intoxicación

respiratoria.

Carburante

¡NOTA! La máquina tiene un motor de dos tiempos, por

lo que debe utilizarse siempre una mezcla de gasolina

con aceite para motores de dos tiempos. Para obtener

una mezcla con las proporciones correctas, debe

medirse con precisión la cantidad de aceite que se

mezclará. En la mezcla de pequeñas cantidades de

combustible, los errores más insignificantes en la

medición del aceite influyen considerablemente en las

proporciones de la mezcla.

¡ATENCIÓN! El combustible y los

vapores de combustible son muy

inflamables y pueden causar daños

graves por inhalación y contacto con la

piel. Por consiguiente, al manipular

combustible proceda con cuidado y

procure que haya buena ventilación.

Gasolina

¡NOTA! Use siempre gasolina de buena calidad

mezclada con aceite de como mínimo 90 octanos (RON).

Si su máquina está equipada con catalizador (vea el

capítulo Datos técnicos), debe usarse siempre gasolina

sin plomo de buena calidad mezclada con aceite. La

gasolina con plomo avería el catalizador.

Si hay disponible gasolina menos nociva para el medio

ambiente, denominada gasolina de alquilato, se debe

usar este tipo de gasolina.

• El octanaje mínimo recomendado es 90 (RON). Si se

hace funcionar el motor con gasolina de octanaje

inferior a 90, puede producirse clavazón. Esto

aumenta la temperatura del motor, con el

consiguiente riesgo de averías.

• Para trabajar durante mucho tiempo en altas

revoluciones se recomienda el uso de gasolina con

más octanos.

Aceite para motores de dos tiempos

• Para un resultado y prestaciones óptimos, utilice

aceite para motores de dos tiempos HUSQVARNA,

especialmente fabricado para motores de dos

tiempos refrigerados por aire.

• No utilice nunca aceite para motores de dos tiempos

fuera borda refrigerados por agua (llamado outboard

oil), con designación TCW.

• No utilice nunca aceite para motores de cuatro

tiempos.

• Un aceite de calidad deficiente o una mezcla de

aceite/combustible demasiado rica puede perjudicar

el funcionamiento del catalizador y reducir su vida útil.

28 – Spanish

Page 29

MANIPULACION DEL COMBUSTIBLE

!

• Mezcla

1:50 (2%) con aceite para motores de dos tiempos

HUSQVARNA.

1:33 (3 %) con otros aceites para motores de dos

tiempos refrigerados por aire y clasificados para

JASO FB/ISO EGB.

Aceite para motores de dos

Gasolina, litros

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Mezcla

• Siempre haga la mezcla de gasolina y aceite en un

recipiente limpio, homologado para gasolina.

• Primero, ponga la mitad de la gasolina que se va a

mezclar. Luego, añada todo el aceite y agite la

mezcla. A continuación, añada el resto de la gasolina.

• Agite bien la mezcla de combustible antes de ponerla

en el depósito de combustible de la máquina.

tiempos, litros

2% (1:50) 3% (1:33)

Repostaje

¡ATENCIÓN! Las siguientes medidas

preventivas reducen el riesgo de

incendio:

No fume ni ponga objetos calientes

cerca del combustible.

No haga nunca el repostaje con el motor

en marcha.

Apague el motor y deje que se enfríe

unos minutos antes de repostar.

Para repostar, abra despacio la tapa del

depósito de combustible para evacuar

lentamente la eventual sobrepresión.

Después de repostar, apriete bien la tapa

del depósito de combustible.

Antes de arrancar, aparte siempre la

máquina del lugar de repostaje.

• Utilice un recipiente de combustible con protección

antirebose.

• Limpie alrededor de la tapa del depósito. Los residuos

en el depósito ocasionan problemas de

funcionamiento.

• Asegúrese de que el combustible esté bien mezclado

sacudiendo el recipiente antes de llenar el depósito.

• No mezcle más combustible que el necesario para

utilizar un mes como máximo.

• Si no se ha utilizado la máquina por un tiempo

prolongado, vacíe el depósito de combustible y

límpielo.

Spanish – 29

Page 30

ARRANQUE Y PARADA

Control antes de arrancar

• Compruebe las cuchillas. No utilice nunca cuchillas

romas, agrietadas o dañadas.

• Controle que la máquina esté en excelentes

condiciones de funcionamiento. Verifique que todas

las tuercas y tornillos estén apretados.

• Compruebe que el equipo de corte siempre se

detenga en ralentí.

• Utilice la máquina solamente para el uso al que está

destinada.

• Controle que los mangos y las funciones de

seguridad estén en buenas condiciones. No utilice

nunca una máquina que carece de una pieza o que ha

sido modificada fuera de las especificaciones.

• Todas las cubiertas deben estar correctamente

montadas y en buenas condiciones antes de arrancar

la máquina.

Arranque y parada

comience a llenarse de combustible. No es necesario

llenarla totalmente.

Estrangulador: Ponga el estrangulador en la posición de

estrangulamiento.

Aceleración de arranque:

Para obtener la posición de aceleración de arranque,

presione primero el acelerador y después el botón de

aceleración de arranque (A). A continuación, suelte el

acelerador y después el botón de aceleración de

arranque. Ahora está activada la función de aceleración

de arranque. Para reponer el motor en ralentí, presione

de nuevo el acelerador.

¡ATENCIÓN! Aparte siempre la máquina

unos 3 metros del lugar donde cargó de

!

combustible antes de arrancar. Coloque

la máquina sobre una base firme.

Controle que el equipo de corte no pueda

atascarse en algún objeto. Asegúrese de

que no haya personas desautorizadas en

la zona de trabajo, de lo contrario se

corre el riesgo de ocasionar graves

daños personales.

Motor frío

Encendido: Coloque el mando de detención en posición

de arranque.

Bomba de combustible: Presione varias veces la

burbuja de goma de la bomba de combustible hasta que

30 – Spanish

Motor caliente

Siga el mismo procedimiento de arranque que para el

motor frío, pero sin poner el estrangulador en la posición

de estrangulamiento.

Page 31

ARRANQUE Y PARADA

Arranque

¡ATENCIÓN! Cuando el motor es

arrancado con el estrangulador en la

!

posición activada o de aceleración de

arranque, el equipo de corte comienza a

girar inmediatamente.

Mantenga la máquina en posición vertical con la mano

izquierda. Agarre la empuñadura de arranque y tire

despacio de la cuerda con la mano derecha, hasta sentir

una resistencia (los dientes de arranque engranan), y

después tire rápido y con fuerza.

Al encender el motor, vuelva a colocar rápidamente el

mando del estrangulador en su posición inicial y repita el

intento de arranque hasta que el motor arranque.

¡NOTA! No extraiga el cordón de arranque al máximo, y

no suelte la empuñadura de arranque si ha extraido todo

el cordón. Ello puede ocasionar averías en la máquina.

Parada

El motor se para poniendo el contacto de parada en la

posición de parada.

Spanish – 31

Page 32

TÉCNICA DE TRABAJO

Instrucciones generales de trabajo

¡IMPORTANTE!

Este apartado contiene las precauciones de seguridad

básicas para utilizar una barrena para tierra.

Cuando se vea en una situación insegura para

continuar el trabajo, debe consultar a un experto.

Póngase en contacto con su distribuidor o taller de

servicio.

Evite todo uso para el cual no se sienta suficientemente

calificado.

¡ATENCIÓN! La máquina puede

ocasionar lesiones graves. Lea

!

atentamente las instrucciones de

seguridad. Aprenda a utilizar la máquina.

¡ATENCIÓN! Herramienta cortante. No

toque la herramienta sin apagar antes el

!

motor.

Instrucciones de seguridad durante el trabajo

• Cerciórese siempre de tener una posición de trabajo

segura y firme.

• Utilice siempre ambas manos para sujetar la

máquina.

Instrucciones de seguridad para el entorno

• No permita nunca que los niños utilicen la máquina.

• Controle que nadie se acerque a menos de 5 metros

durante el trabajo.

• Nunca deje que terceros utilicen la máquina sin

asegurarse primero de que hayan entendido el

contenido de este manual de instrucciones.

• Utilice la mano derecha para manejar el acelerador.

• Cerciórese de mantener las manos y los pies alejados

del equipo de corte mientras el motor está en marcha.

• Comience taladrando con una aceleración media y

aumente el régimen del motor gradualmente para que

el taladro penetre en la tierra sin dificultad.

• Si el taladro se ha enganchado en la tierra y no puede

extraerlo, detenga el motor y gire la barrena en

sentido contrario a las agujas del reloj.

• Apague siempre el motor cuando haya acabado de

taladrar.

• Al apagar el motor, mantenga las manos y los pies

alejados del equipo de corte hasta que el motor se

detenga por completo.

• Si choca con algún objeto o si se producen

vibraciones fuertes, pare la máquina. Desconecte el

32 – Spanish

Page 33

TÉCNICA DE TRABAJO

cable de encendido de la bujía. Controle que la

máquina no esté dañada. Repare posibles averías.

¡ATENCIÓN! Si al taladrar la máquina

toca o perfora cables eléctricos, puede

!

provocar la muerte o lesiones graves. La

máquina no tiene aislamiento eléctrico.

Para evitar el riesgo de electrocución,

compruebe siempre antes de taladrar

que no haya tuberías o cables

subterráneos. Póngase en contacto con

la empresa local de servicios públicos

para obtener más información sobre la

ubicación de las tuberías y los cables. Si

es necesario, confirme su ubicación real

utilizando aparatos como detectores de

cables o excavando con cuidado.

¡ATENCIÓN! Si llega a golpear algo duro

en la tierra, como rocas o las raíces de

!

un árbol, el taladro puede detenerse

repentinamente. Esto puede conllevar

un movimiento de reacción en la

barrena, lo que haría que el usuario

perdiese el control de la máquina o

cayese al suelo, con lo que podría sufrir

daños graves. Sujete la barrena con

firmeza para controlar dicho movimiento

y reducir el riesgo de lesiones.

¡ATENCIÓN! La sobreexposición a las

vibraciones puede producir lesiones

!

vasculares o nerviosas en personas que

padecen de trastornos circulatorios. Si

advierte síntomas que puedan

relacionarse con la sobreexposición a

las vibraciones, consulte a un médico.

Ejemplos de estos síntomas son

entumecimiento, falta de sensibilidad,

”hormigueo”, ”puntadas”, dolor, pérdida

o reducción de la fuerza normal, cambios

en el color o la superficie de la piel.

Generalmente, estos síntomas se

presentan en los dedos, las manos y las

muñecas. El riesgo puede ser mayor a

bajas temperaturas.

Instrucciones de seguridad después del trabajo

• Antes de la limpieza, reparación o inspección,

cerciórese de que el equipo de corte se haya

detenido. Desconecte el cable de encendido de la

bujía.

• Utilice siempre guantes protectores al sustituir las

cuchillas. Las cuchillas están muy afiladas y puede

cortarse con facilidad.

• Guarde la máquina fuera del alcance de los niños.

• Para las reparaciones, utilice solamente repuestos

originales.

Spanish – 33

Page 34

MANTENIMIENTO

!

Carburador

Regulación de la marcha en ralentí (T)

Controle que el filtro de aire esté limpio. Cuando la

marcha en ralentí está correctamente regulada, el equipo

de corte no debe rotar. Si es necesario ajustar, cierre

(sentido horario) el tornillo T con el motor en marcha

hasta que el equipo de corte comience a girar. Abra

(sentido antihorario) el tornillo hasta que el equipo de

corte se detenga. Se ha logrado el régimen correcto de

marcha en ralentí cuando la marcha del motor sea

uniforme en todas las posiciones, con un amplio margen

hasta el régimen en que el equipo de corte comienza a

girar.

¡ATENCIÓN! Si no puede regular el

régimen en ralentí para que el equipo de

!

corte deje de girar, consulte a su

distribuidor/taller de servicio. No utilice

la máquina hasta que no esté

correctamente regulada o reparada.

Si el apagachispas se obstruye, la máquina se recalienta

y se dañan el cilindro y el pistón.

¡NOTA! No utilice nunca la máquina con un silenciador

en mal estado.

¡ATENCIÓN! El silenciador con

catalizador se calienta mucho durante el

uso y permanece caliente aún luego de

apagado el motor. Lo mismo rige para la

marcha en ralentí. Su contacto puede

quemar la piel. ¡Tenga en cuenta el

peligro de incendio!

Sistema refrigerante

Para lograr una temperatura de funcionamiento lo más

baja posible, la máquina incorpora un sistema

refrigerante.

Silenciador

¡NOTA! Algunos silenciadores tienen catalizador.

Consulte el capítulo Datos técnicos para ver si su

máquina tiene catalizador.

El silenciador está diseñado para amortiguar el ruido y

para apartar del usuario los gases de escape. Los gases

de escape están calientes y pueden contener chispas

que pueden ocasionar incendios si se dirigen los gases a

materiales secos e inflamables.

Algunos silenciadores incorporan una rejilla

apagachispas. Si el silenciador de su máquina lleva rejilla

apagachispas, límpiela cada semana. Lo mejor es utilizar

un cepillo de acero.

En silenciadores sin catalizador, el apagachispas se debe

limpiar y cambiar una vez por semana, si es necesario.

En silenciadores con catalizador, se debe controlar el

apagachispas y limpiarlo, si es necesario, una vez por

mes.

Si el apagachispas presenta daños, se debe

cambiar el apagachispas.

Si el apagachispas se obstruye con frecuencia, esto

puede ser señal de que el catalizador no funciona

correctamente. Consulte a su distribuidor para un control.

34 – Spanish

El sistema refrigerante está compuesto por:

1 Aletas de enfriamiento en el cilindro.

2 Entrada de aire.

Limpie el sistema refrigerante con un cepillo una vez por

semana (en condiciones difíciles, con mayor frecuencia).

Un sistema refrigerante sucio u obturado produce

sobrecalentemiento de la máquina, con las consiguientes

averías del cilindro y el pistón.

Filtro de aire

El filtro de aire debe limpiarse regularmente de polvo y

suciedad para evitar:

• Fallos del carburador

• Problemas de arranque

• Reducción de la potencia

• Desgaste innecesario de las piezas del motor.

Page 35

MANTENIMIENTO

• Un consumo de combustible excesivo.

Limpie el filtro cada 25 horas de funcionamiento o más

seguido si trabaja en un entorno muy polvoriento.

Limpieza del filtro de aire

Desmonte la cubierta del filtro de aire y retire el filtro.

Lávelo en agua jabonosa caliente. Controle que el filtro

esté seco antes de volver a montarlo.

Un filtro utilizado durante mucho tiempo no puede

limpiarse del todo. Por tanto, hay que cambiarlo a

intervalos regulares.

cambiarse.

Un filtro de aire averiado debe

Engranaje

Compruebe el nivel de aceite de la caja de engranajes

cada 50 horas de uso y cámbielo por aceite nuevo

cuando sea necesario (SAE 80-90).

A

B

A

• Apriete el tornillo B y cierre el tapón para la recarga

de aceite A.

Filtro de combustible

1

1 Filtro de combustible

Cuando el motor se quede sin suministro de combustible,

compruebe la tapa y el filtro del combustible para verificar

si están obstruidos.

Bujía

Los factores siguientes afectan al estado de la bujía:

• Carburador mal regulado.

• Mezcla de aceite inadecuada en el combustible

(demasiado aceite o aceite inadecuado).

• Filtro de aire sucio.

Estos factores producen revestimientos en los electrodos

de la bujía que pueden ocasionar perturbaciones del

funcionamiento y dificultades de arranque.

Si la potencia de la máquina es demasiado baja, si es

difícil arrancar la máquina o si el ralentí es irregular:

revise primero la bujía antes de tomar otras medidas. Si

la bujía está muy sucia, límpiela y compruebe que la

separación de los electrodos sea de 0,6-0,7 mm. La bujía

debe cambiarse aproximadamente después de un mes

de funcionamiento o más a menudo si es necesario.

B

• Asegúrese de que la barrena está en posición

vertical.

• Quite el tapón para la recarga de aceite A y el tornillo

B.

• Recargue el aceite de la caja de engranajes. Se

habrá alcanzado el nivel de aceite correcto cuando

vea que sale una gota de aceite por el orificio del

tornillo B.

¡NOTA! ¡Utilice siempre el tipo de bujía recomendado!

Una bujía incorrecta puede arruinar el pistón y el cilindro.

Asegúrese de que la bujía tenga supresión de

perturbaciones radioeléctricas.

Spanish – 35

Page 36

MANTENIMIENTO

Programa de mantenimiento

A continuación incluimos una lista con los puntos de mantenimiento a efectuar en la máquina. La mayoría de los puntos

se describen en el capítulo “Mantenimiento”. El usuario sólo puede efectuar los trabajos de mantenimiento y servicio

descritos en este manual. Los trabajos de mayor envergadura debe efectuarlos un taller de servicio oficial.

Mantenimiento

Limpie la parte exterior de la máquina. X

Compruebe que la empuñadura y el manillar estén intactos y

bien fijos.

Controle que el mando de detención funcione. X

Controle que el equipo de corte no gire en ralentí. X

Limpie el filtro de aire. Cámbielo si es necesario. X

Compruebe las cuchillas. No utilice nunca cuchillas romas,

agrietadas o dañadas.

Compruebe que los tornillos y las tuercas estén apretados. X

Controle que no haya fugas de combustible del motor, del

depósito o de los conductos de combustible.

Controle el mecanismo de arranque y la cuerda del mismo. X

Compruebe que estén intactos los aisladores de vibraciones. X

Limpie la bujía por fuera. Quítela y controle la distancia entre

los electrodos. Ajuste la distancia a 0,6-0,7 mm o cambie la

bujía. Controle que la bujía tenga supresión de perturbaciones

radioeléctricas.

Limpie el sistema de refrigeración de la máquina. X

Limpie el exterior del carburador y la zona alrededor del mismo. X

Compruebe el nivel de aceite de la caja de engranajes y llénelo,

en caso necesario.

Limpie el silenciador. X

Compruebe que el filtro de combustible no está sucio y que la

manguera de combustible no tiene grietas ni otros defectos.

Cambie el componente que sea necesario.

Revise todos los cables y conexiones. X

Compruebe si están desgastados el embrague, los muelles de

embrague y el tambor embrague. Cambie los componentes

que sea necesario en un taller de servicio oficial.

Cambie la bujía. Controle que la bujía tenga supresión de

perturbaciones radioeléctricas.

Mantenimiento

diario

X

X

X

Mantenimiento

semanal

X

X

Mantenimiento

mensual

X

X

X

36 – Spanish

Page 37

DATOS TECNICOS

Datos técnicos

143AE15

Motor

Cilindrada, cm

Diámetro del cilindro, mm 40,0

Carrera, mm 33

Régimen de ralentí, r.p.m. 2500

Régimen máximo de embalamiento recomendado, r.p.m. 12000

Potencia máxima del motor según ISO 8893, kW/ r.p.m. 1,47/7500

Silenciador con catalizador No

Sist. de encendido con reg. de veloc. No

Sistema de encendido

Fabricante/tipo de sist. de encendido TCI

Bujía NGK BPMR 7A

Distancia de electrodos, mm 0,6-0,7

Sistema de combustible y lubricación

Fabricante/tipo de carburador Walbro WYK

Capacidad del depósito de gasolina, litros 0,94

Peso

Peso sin combustible y herramienta de corte, kg 8,9

Niveles acústicos

(ver la nota 1)

Nivel de presión sonora equivalente en la oreja del usuario, medido

según EN ISO 22868, dB(A):

Nivel de efecto sonoro equivalente, medido según ISO 3744, dB(A) 110

Niveles de vibraciones

Niveles de vibración equivalentes (a

medidos según la norma EN ISO 22867, m/s

mango izquierdo/derecho: 6,0/9,3

Nota 1: Los datos referidos del nivel de presión sonora equivalente de la máquina tienen una dispersión estadística

habitual (desviación típica) de 1 dB (A).

Nota 2: Los datos referidos del nivel de vibración equivalente poseen una dispersión estadística habitual (desviación

típica) de 1 m/s

3

) en las empuñaduras,

hv, eq

2

.

2

.

41,5

103

Spanish – 37

Page 38

EXPLICAÇÃO DOS SÍMBOLOS

Símbolos

ATENÇÃO! Um perfurador de solo,

se utilizado inadvertida ou

erradamente, pode tornar-se num

instrumento perigoso, causando

sérias lesões, até mesmo mortais.

É extremamente importante que

leia e compreenda o conteúdo

deste Manual do Operador.

Leia as instruções para o uso com

toda a atenção e compreenda o

seu conteúdo antes de fazer uso da

máquina.

Use sempre:

• Protectores acústicos aprovados

• Protecção ocular aprovada

O motor é desligado deslocando o

contacto de paragem para a posição

de paragem.

Use sempre luvas de protecção

aprovadas.

Limpeza periódica obrigatória.

Inspecção ocular.

Este produto está conforme as

directivas em validade da CE.

Perfurar ou entrar em contacto com

cabos ou fios eléctricos pode

provocar a morte ou ferimentos

graves. A máquina não está

electricamente isolada.

Bater em algo duro no solo, como

pedras ou raízes de árvores pode

fazer com que a broca pare de

repente. Isto pode provocar um

movimento reactivo no perfurador e

fazer com que o operador perca o

controlo da máquina e seja atirado

para o chão, levando a ferimentos graves.

Use sempre luvas de protecção

aprovadas.

Use botas ou sapatos

antideslizantes e estáveis.

Os restantes símbolos e autocolantes existentes na

máquina dizem respeito a exigências específicas

para homologação em alguns países.

38 – Portuguese

Page 39

ÍNDICE

!

!

!

Índice Antes de arrancar, observe o

EXPLICAÇÃO DOS SÍMBOLOS

Símbolos .............................................................. 38

ÍNDICE