HUSABERG FE 400 e, FE 501 e, FE 650 e, FS 400 e, FS 650 e User Manual

...

INDEX

INTRODUCTION Page 2-

SAFETY AND PRECAUTIONS Page 4-

GENERAL INFORMATION Page 6-

MAINTENANCE SCHEDULE Page 9-

CONTROLS Page 12-

1

2

3

4

5

STARTING PROCEDURE Page 15

ENGINE Page 16-

FUEL & COOLING Page 20-

CLUTCH & DECOMPRESSION Page 22

WHEELS & BRAKES Page 23-

A LUBRICATION SYSTEM

B IGNITION

C AIR FILTER

D VALVE ADJUSTMENT

A CARBURETTOR

B FUEL

C COOLING SYSTEM

A WHEELS

B CHAIN

C BRAKES

6

7

8

9

10

SUSPENSION Page 29-

WIRING DIAGRAMS Page 33-

A SUSPENSION

B STEERING HEAD

C SWINGARM

11

12

1

1

INTRODUCTION

1

Please read and observe the following:

Warning

If the engine has to be running during any maintenance, make sure that the area is

properly ventilated. Never run the engine in a closed area though the exhaust fumes

are posionous and thus hazardous to your health and life.

Warning

Although the battery is of a sealed construction, please take care. The electrolyte contains

sulfuric acid and you must protect your eyes, skin and clothing if such fluid is assumed

to be leaking or likewise exposed. In case of contact, wash and flush thoroughly with

water and contact medical help if needed, especially if your eyes have been exposed to

the fluid.

Warning

Fuel is extremely flammable and explosive under certain conditions. Do not smoke or

expose the fuel to open fire or sparks.

SERVICE CONDITIONS:

1. Always use original Husaberg parts.

2. Use the special Husaberg tools when required.

3. Install new gaskets, o-rings, circlips etc whenever possible.

4. Always clean all parts thoroughly before assembly.

5. All screws, nuts and bolts etc. are in the metric system. Do not use incorrect tools.

PRINT & COPY RIGHTS

The material and information included in this Owner’s Manual are all of the latest editions

available at the time of the printing.

Husaberg Motor AB reserves the right to make changes regarding the products at any

time without prior notice.

This Owner’s Manual is subject to corrections without prior notice.

No part of this Owner’s Manual may be reproduced without written permission

Endurovägen, S-695 72 SWEDEN

www.husaberg.se

force@husaberg.se

2

1

INTRODUCTION

Dear client,

We feel ourselves privileged and honoured to be the supplier of your choice of motorcycle. We

know for sure that our product will give you years of fun and performance though the Husabergs

are based upon decades of experience in racing and a dedication hard to find elsewere. You’re

bound to feel this through the inborn lively spirit of your bike.

Although mainly designed and constructed for competition purposes it is still very rider-friendly

but due to the design the product needs careful and proper maintenannce. In order to get the

most out of your "beast" and before any use of the motorbike; we highly recommend you to

carefully read this Owner's Manual through. We also recommend you to pay your outmost

attention to the following page regarding safety and precautions and always remember the

fundamental base of all activities on two wheels:

- "Do not overestimate your capabilities, follow the domestic regulations and do think about

your surroundings"

Although the Owner's Manual is put together and written in a way that will make it possible for

an average mechanical experienced person to take care of the maintenance, we recommend

you to let an authorized Husaberg dealer take care of at least the parts we’ve mentioned under:

1

Also, part of the maintenance has to be performed by an authorized dealer in order to fulfill the

terms of warranty.

If you follow the advice regarding the set-up and of course also regarding the vital maintenance

of the motorcycle; the Husaberg of yours will provide a maintained level of performance (read:

joy and satisfaction - the reason to your choice of brand).

The personnel of Husaberg Motor AB Sweden

ATTENTION:

ATTENTION:

ATTENTION:

Never ride in a too low or too high gear Never let the engine run for more than one minute while stationary

It may cause severe mechanical damages

Always put the motorcycle on a stable centerstand

whenever removing either front or rear wheel.

Never ride your motorcycle under the influence of

alcohol, drugs, barbiturates or any other kind of medical

treatments hazardous to your riding performance.

WARNING:

Do not check the coolant

level while the engine is hot.

ATTENTION:

Service more frequently when

riding under hard conditions

ATTENTION:

Less clearances than the required

cause severe engine damages

ATTENTION:

Do not use a highpressure jet-cleaning

equipment on surfaces around

bearings and other fragile components.

3

2

2

SAFETY AND PRECAUTIONS

SAFETY

PROTECTION:

Always protect yourself with adequat clothing and protective apparel.

Always wear a helmet, goggles and boots.

MOTORCYCLE:

The motorcycle may become dangerous to ride if it is modified or if any other parts than

original Husaberg parts are used. The use of other parts than original makes the warranty

no longer valid.

Always keep your motorcycle in a safe state and in the best of conditions.

Regular cleaning and maintenance are extremely vital in order to avoid any mechanical

damages hazardous to you and/or your surroundings.

TRANSPORTATION:

Always transport your bike upright in order to avoid any leakages of oil and/or fuel. Such

fluids may increase the risk of fire. Always make sure that the bike is properly fastened

in a safe and firm position during transportation.

RIDING:

Always check the motorcycle for any deterioration/damages and any necessary

adjustments before you start the motorcycle (see "Pre-ride inspection").

Though the Husaberg motorcycle has a very high level of performance; always ride

with care and do not overestimate your capabilities. Get to know your Husaberg

motorcycle really well before you try to get the most out of it.

Never lend your motorcycle to any other rider unless you are sure that he/she is fully

capable of handling it.

Always obey all local and federal regulations and laws valid within the territory.

Never ride in terrain unfamiliar to you unless inspected and guaranteed by the local

authorities.

PRE-RIDE INSPECTION:

Make it a habit to give your motorcycle an inspection before and after every ride.

Always check all bolts and nuts and tighten if necessary - All for your own safety.

A clean and well lubricated bike makes for a safer ride as well as a higher value of the

machine. The Pre-ride Inspection Checklist on the next page is to be regarded as a

brief summary of the main important items to be controlled and, if necessary; to be

adjusted or replaced.

Never ride your motorcycle under the influence of

ATTENTION:

4

alcohol, drugs, barbiturates or any other kind of medical

treatments hazardous to your riding performance.

2

SAFETY AND PRECAUTIONS

PRE-RIDE INSPECTION CHECK LIST

Engine oil Check the level and fill up if necessary.

Check for any leakages in the casing.

Ignition Check the sparkplug cap/HV lead for damages.

Radiator Check the coolant level and fill up if necessary.

Check for leakages and/or damages of the cells and hoses

and attachments.

Airfilter Clean, or if necessary, replace the filter

Carburettor Check the function of the throttle/cable and adjust/replace

any damaged parts if necessary.

Adjust the idling- and/or mixture screw if necessary.

After every time the motorbike has been washed drain the

float chamber of the carburettor.

2

Clutch Check the function and for any leakages.

Decompression Check the function of the manual and the semi-automatic

decompression lever and adjust if necessary (non-electrical

starter models only).

Chain Check and adjust/replace the chain if necessary.

Check the sprockets and replace if necessary.

Suspension Check the operation of the front fork and the shock absorber

and adjust if necessary.

Check and tighten the swingarm if necessary.

Wheels Check the air pressure of the tyres and fill up if necessary.

Check the spokes and tighten if necessary.

Brakes Check the level of brakefluid and fill up if necessary.

Check for any leakages and the function of the brakes.

Adjust levers and/or replace hoses/pads if necessary.

Fuel Check the level and fill up if necessary.

Check for any leakages in the fuel lines.

Steering Check the clearance of the steering head bearings and

adjust if necessary.

Controls Check the function of the speedometer or odometer (if

incl.in equipment).

Lighting Check the functions of the front-, tail-, and brake lights

(and any occuring turn signals).

5

3

3

GENERAL INFORMATION

SPECIFICATIONS

242 lb. 243 lb. 244 lb. 247 lb. 249 lb. 233 lb. 235 lb. 228 lb. 228 lb. 229 lb. 242 lb. 242 lb. 243 lb.

Ratios 1st: 14/33 - 2,357 2nd: 17/30 - 1,765 3rd: 19/26 - 1,368 4th: 23/25 - 1,087 5th: 24/22 - 0,917 6th: 27/20 - 0,741 (6th CR: 25/21-0,840)

SUBJECT/MODEL FE 400 e FE 501 e FE 650 e FS 400 e FS 650 e FS 400 c FS 650 c FC 470/6 FC 550/4 FC 550/6 FC 470 e FX 470 e FX 650 e

Displacement 399cc 501cc 644cc 399cc 644cc 399cc 644cc 472cc 550cc 550cc 472cc 472cc 644cc

Bore x Stroke (mm) 92 x 60,1 95 x 70,7 100 x 82,0 92 x 60,1 100 x 82,0 92 x 60,1 100 x 82,0 100 x 60,1 100 x 70,0 100 x 70,7 100 x 60,1 100 x 60,1 100 x 82,0

Compression ratio 12,5:1 11,8:1 11,0:1 12,5:1 11,0:1 12,5:1 11,0:1 12,4:1 12,7:1 12,7:1 12,4.1 12,4:1 11,0:1

Start system Electrical and kick-starter Kick-starter Electrical and kick-starter

Decompression system Three separate ones; one activated by the kickstart lever, one activated by the camshaft and one activated by a lever on the handlebar

Decomp. cable clearance 2mm ± 1mm / 0,08 in ± 0,04 in.

Engine Liquid cooled single cylinder 4-stroke, SOHC-4 valves, counter balancer

Valve clearance Intake and Exhaust: 0,10mm / 0,004 in.

Lubrication system Orbit oil pump and reed valve controlled. High pressure jet spray of piston and connecting rod, pressure lubrication of connecting rod bearing and rocker arms. Oil screen and micro filter

Engine oil 1,0 Litre Synthetic SAE 5W-50 API SG/CF (minimum SAE 10W-50)

Ignition system SEM Dynamic Force Control, DFC™, Dual Ignition Curves; High & Low. A load sensitive digital system with six sensors

Spark plug - Spark plug gap NGK DCPR8E - 0,6 mm / 0,025 in.

Alternator 12 V 70 + 70 W Not available 12 V 70 + 70 W

Air intake system Single foam filter

Carburettor (DELLORTO) PHM 38 PHM 40 PHM 40 PHM 38 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40 PHM 40

Fuel RON 98 (octane), unleaded

Exhaust system Chrome plated steel pipes, 2 into 1 collector, Aluminium/steel silencer. USA versions, except FC and FSc models, equipped with spark arresters

Coolant 1,3 Litre of 50% Anti-freeze, with corrosion inhibitor, and 50% water

Clutch Hydraulic, 7 friction- and 8 mating plates in oil bath

Clutch hydraulic oil Mineral oil SAE 2-7W

Wear limit clutch discs 19,6 mm / 0,772 in.

Primary transmission Spur gears, ratio 29/78 - 2,690

Gearbox 6-speed 6-speed 6-speed 6-speed 6-speed 6-speed 6-speed 6-speed CR 4-speed 6-speed CR 6-speed CR 6-speed 6-speed

Secondary transmission D.I.D. 520 O-ring chain

Sprockets front/rear 13/48 15/48 15/42 15/42 15/42 15/42 15/42 13/42 15/42 15/48 13/48 13/48 15/42

Wear limit drive chain 272 mm - 18 chain reels (tensioned, center distance between reels)

Frame Heat treated BTR / 25CrMo4 steel

Caster 28,5°

6

Weight (dry) 109,8 kg 110,1 kg 110,9 kg 111,9 kg 113,1 kg 105,7 kg 106,8 kg 103,5 kg 103,5 kg 103,9 kg 109,6 kg 109,6 kg 110,4 kg

3

GENERAL INFORMATION

SPECIFICATIONS

3

Rear EXCEL 2.15 x 18” BEHR 4.25 x 17” EXCEL 2.15 x 19” EXCEL 2.15 x 18”

SUBJECT/MODEL FE 400 e FE 501 e FE 650 e FS 400 e FS 650 e FS 400 c FS 650 c FC 470/6 FC 550/4 FC 550/6 FC 470 e FX 470 e FX 650 e

Rims Front EXCEL 1.60 x 21” BEHR 3.50 x 17” EXCEL 1.60 x 21” EXCEL 1.60 x 21”

Rear 140/80-18” 150/60-17” 110/100-19” 130/80-18”

Tyres (MICHELIN)Front 90/90-21” 120/60-17” 80/100-21” 90/90-21”

Tyre pressure (cold)

Rear 0,8 bar / 12,0 psi 0,8 bar / 12,0 psi

Rear 1,0 bar / 14,5 psi 2,0 bar / 29,0 psi

Offroad Front 0,8 bar / 12,0 psi 0,8 bar / 12,0 psi

Tarmac Front 1,0 bar / 14,5 psi 2,2 bar / 31,9 psi

ø 260 mm Inox steel disc ø 310 mm Plated cast iron disc ø 260 mm Inox steel disc

Hydraulic twin piston floating caliper Hydraulic four piston floating caliper Hydraulic twin piston floating caliper

Rear PDS 5018-HBG E PDS 5018-HBG S PDS 5018-HBG MX

Rear 320 mm / 12,6 in. 287 mm / 11,3 in. 320 mm / 12,6 in.

Suspension (WP) Front MXMA 4860-HBG E ø 48 mm MXMA 4860-HBG S ø 48 mm MXMA 4860-HBG MX ø 48 mm

Wheel travel Front 295 mm / 11,6 in. 260 mm / 10,2 in. 295 mm / 11,6 in.

Front fork oil WP SAE 5

Brakes Front BREMBO BERINGER BREMBO

Rear BREMBO hydraulic single piston floating caliper, ø 220 mm Inox steel disc

Brake fluid DOT 4

Alt. B 12 V 45/40 W - BA20d Not applicable

Wear limit brake pads 1,5 mm / 0,06 in.

Head light Alt. A 12 V 65/50 W - P43t Not applicable

Tail / Stop light 12 V 21/5 W - BAY 15d Not applicable

Parking light 12 V 4 W - BA9s Not applicable

Turn signal lights 12 V 10 W - BA15s Not applicable

Speedometer light 12 V 2 W - BA7s Not applicable

Battery / Main fuse 12 V 8 Ah / 15 A Not applicable

Wheel base - Width 1490 mm / 58,66 in. - 810 mm / 31,89 in.

Seat height 930 mm / 36,61 in. 870 mm / 34,25 in. 930 mm / 36,61 in.

Ground clearance 380 mm / 14,96 in. 320 mm / 12,60 in. 380 mm / 14,96 in.

Overall length 2200 mm / 86,61 in. 2150 mm / 84,65 in. 2200 mm / 86,61 in.

7

3

GENERAL INFORMATION

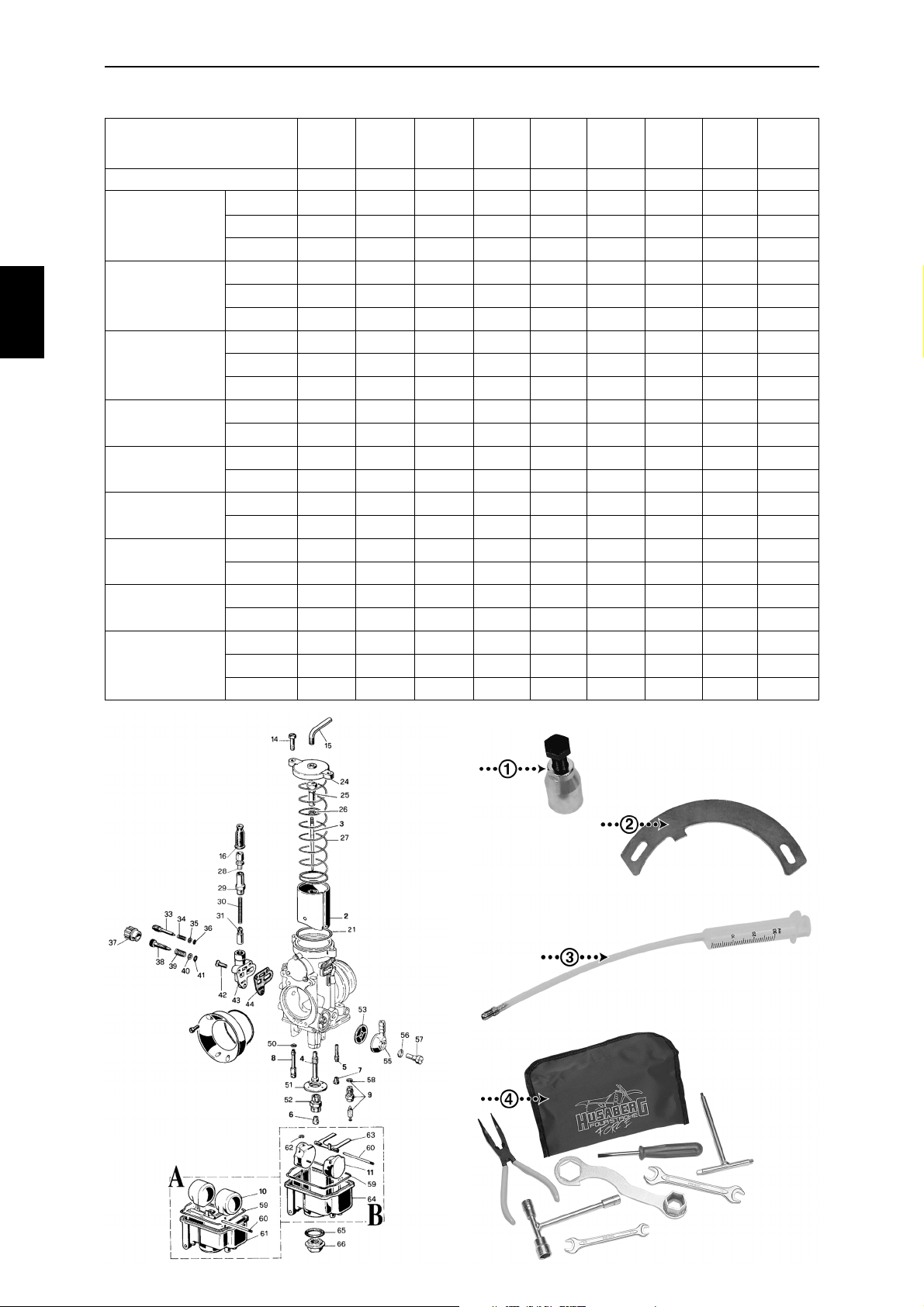

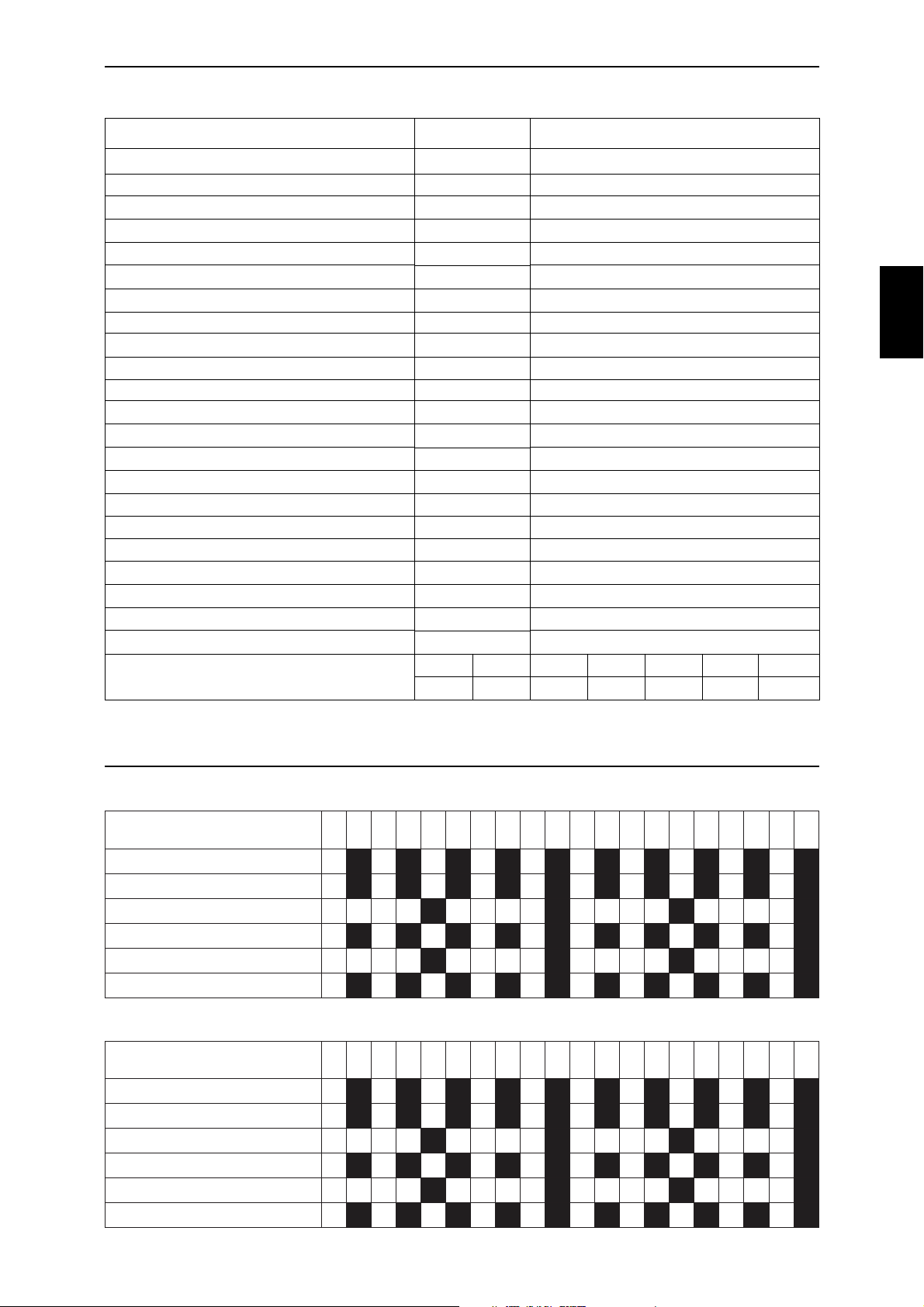

CARBURETTOR STD. JETTINGS

3

MODEL/SUBJECT

Exploded view number

Enduro

Enduro

ECE

Enduro

USA

Super Motard

Street

Super Motard

Street ECE

Super Motard

Street USA

Super Motard

Competition

Cross Country

Motocross

FE 400 e

FE 501 e

FE 650 e

FE 400 e

FE 501 e

FE 650 e

FE 400 e

FE 501 e

FE 650 e

FS 400 e

FS 650 e

FS 400 e

FS 650 e

FS 400 e

FS 650 e

FS 400 c

FS 650 c

FX 470 e

FX 650 e

FC 470

FC 550

FC 470 e

Main

Needle

jet

# 6

185 DR 270 K 51 #3 33 40 300

185 DR 272 K 51 #3 35 40 300

190 DR 272 K 51 #3 40 40 300

110 DR 266 K 51 #2 48 40 300

110 DR 264 K 35 #4 33 40 300

100 DR 266 K 51 #3 33 40 300

190 DR 270 K 51 #3 38 40 300

195 DR 268 K 35 #3 33 40 300

195 DR 270 K 35 #3 33 40 300

185 DR 270 K 51 #3 33 40 300

190 DR 272 K 51 #3 40 40 300

110 DR 266 K 51 #2 48 40 300

100 DR 266 K 51 #3 33 40 300

190 DR 270 K 51 #3 38 40 300

195 DR 270 K 35 #3 33 40 300

180 DR 272 K 35 #3 33 40 300

190 DR 272 K 51 #3 40 40 300

185 DR 266 K 35 #3 33 30 300

190 DR 270 K 51 #3 33 40 300

185 DR 266 K 35 #3 33 30 300

190 DR 272 K 51 #3 33 40 300

185 DR 266 K 35 #3 33 30 300

jet

# 4

Needle

# 3

Needle

clip pos.

# 26

Pilot

jet

# 7

Throttle

# 2

Float

valve

# 9

Start

jet

# 8

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

45

Mixture

screw

# 33

2 turns

1½ turns

1½ turns

½ turn

½ turn

½ turn

2 turns

1½ turns

1½ turns

2 turns

1½ turns

½ turn

½ turn

2 turns

1½ turns

1½ turns

1½ turns

1½ turns

1½ turns

1½ turns

1½ turns

1½ turns

1. Flywheel puller Article No. 270028-01

2. Flywheel holder Article No. 270030-01

3. Air bleeding syringe Article No. 270032-01

4. Tool kit Article No. 390029-01

8

3

GENERAL INFORMATION

TORQUE VALUES

SUBJECT

Waterpump cover screws

Exhaust pipe screws

Spark plug

Standard torque values M8 M10

TORQUE

5 NmIntake manifold screws

5 NmOil filter cover screws

5 Nm

5 NmValve inspection cover screws

5 Nm

8 NmStator screws

10 NmCrankcase screws

10 Nm

10 NmGearshift lever screw

10 Nm Apply a threadlock liquidKick start lever screw

10 NmValve cover screws

12 NmOil drain plug

12 Nm

12 NmValve adjustment lock nuts

15 NmFront fork triple clamp screws lower (M8)

20 NmFront fork triple clamp screws upper (M8)

25 Nm Apply a threadlock liquidUpper timing sprocket screws

44 NmCylinderstud nuts

50 Nm Left-hand threadFlywheel nut

80 Nm Apply a threadlock liquidIntermediate gear wheel nut

110 Nm

125 NmSwingarm shaft nuts

M4

6 Nm

8 Nm

M5

M6

10 Nm

Apply a threadlock liquidReed valve screws

Apply a threadlock liquidPrimary gear wheel nut

25 Nm 40 Nm

NOTE

M12

40 Nm

3

M16

125 Nm

4

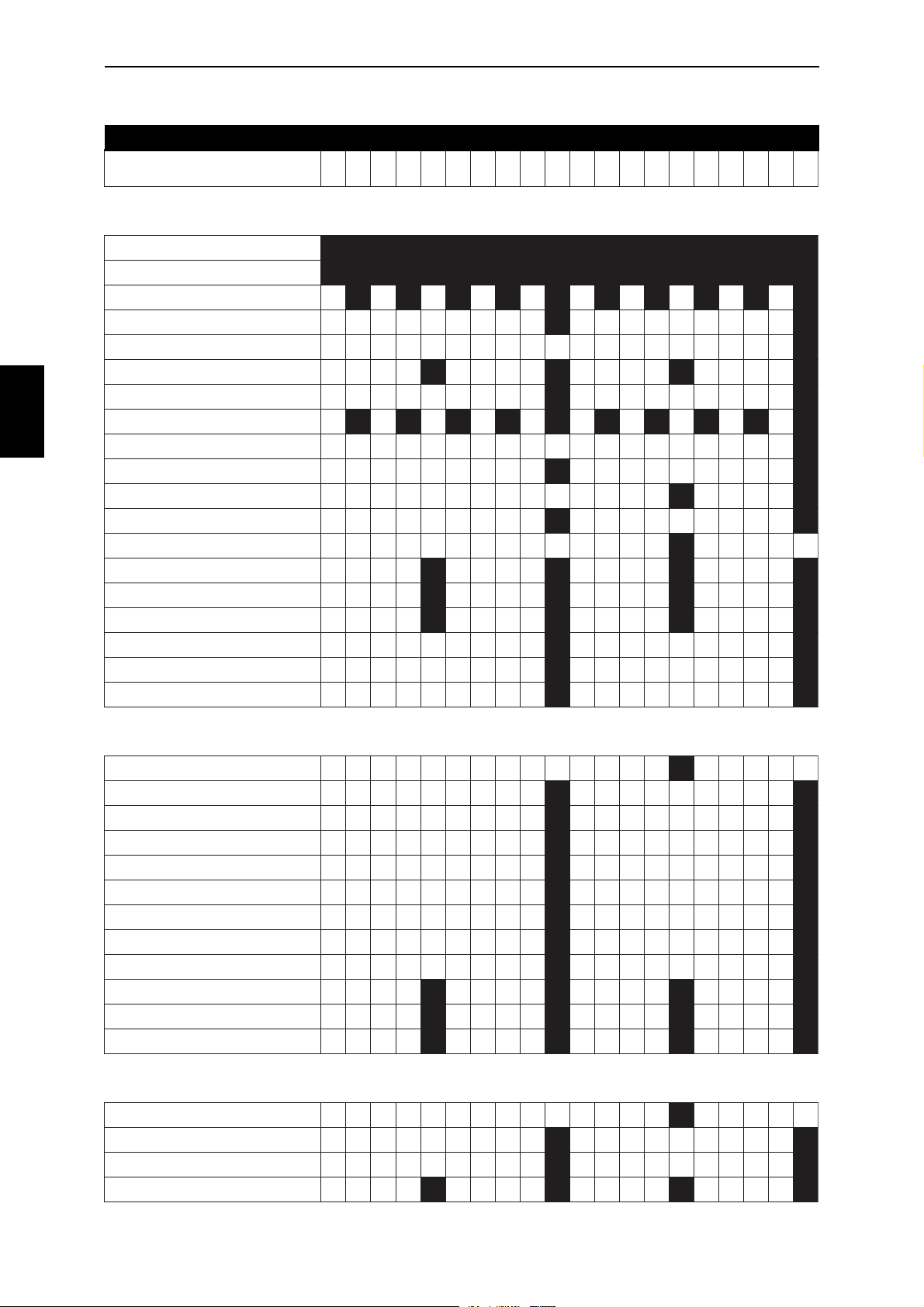

MAINTENANCE SCHEDULE

Chassis - FC, FSc and FX models

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUS

*liokroftnorF

*diulfekarB

sgnihsub/sgniraebmragniwS

sgnihsubrebrosbakcohS

sgniraebdaehgnireetS

sgniraebleehW

Chassis - FE and FSe models

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUS

*liokroftnorF

*diulfekarB

sgnihsub/sgniraebmragniwS

sgnihsubrebrosbakcohS

sgniraebdaehgnireetS

sgniraebleehW

55555010101010151515151510202020202525252525203030303035353535353040404040454545454540505050505555555555506060606065656565656070707070757575757570808080808585858585809090909095959595959001001

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII

010101010102020202020303030303040404040405050505050606060606070707070708080808080909090909001001

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII

001001011011

001

011011021021

011

021021031031

021

031031041041

031

041041051051

041

051051061061

051

061061071071

061

071071081081

071

081081091091

081

091091002002

091

001001

001

002002

002

C: Clean - I: Inspect - R: Replace - *Maximum 12 months interval

9

4

MAINTENANCE SCHEDULE

Engine - FC, FSc and FX models

Please observe: Riding under hard conditions demands more frequent maintenance

4

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUS

lioenignE

neercsliO

retliforcimliO

evlavdeer.lcnipmupliO

*diuqiltnalooC

)pac.lcni(gulpkrapS

**noitingI/rotanretlA

ecnaraelcevlaV

nip&sgnir.lcninotsiP

gninilrednilyC

dorgnitcennoC

niptfahsknarC

***/**rotterubraC

msinahcemtratskciK

msinahcemtfihsraeG

msinahcemleehweerF:LE

55555010101010151515151510202020202525252525203030303035353535353040404040454545454540505050505555555555506060606065656565656070707070757575757570808080808585858585809090909095959595959001001

RALUGERRALUGER

RALUGERRALUGER

RALUGER

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

C/IC/I

C/IC/I C/IC/I

C/I

IIIII RRRRR IIIII RRRRR

IIIII IIIII

IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII

sgnilaes&sediug.lcnisevlaV

renoisnet.lcniniahcgnimiT

IIIII RRRRR IIIII RRRRR

scsid.lcnimsinahcemhctulC

IIIII IIIII IIIII IIIII

C/IC/I

C/IC/I C/IC/I

C/I

RRRRR RRRRR

RRRRR RRRRR

IIIII IIIII

RRRRR

C/IC/I C/IC/I

C/I

IIIII IIIII

IIIII IIIII

IIIII IIIII

C/IC/I C/IC/I

C/I

001001

001

C/IC/I

C/I

RRRRR

IIIII

C/IC/I

C/I

SGNIRAEBSGNIRAEB

SGNIRAEBSGNIRAEB

SGNIRAEB

dorgnitcennoC

tfahsknarC

tfahsniamxobraeG

tfahsyradnocesxobraeG

murdtfihS

tfahsmaC

etalperusserphctulC

leehwraegtratskciK

leehwraegetaidemretnI

smrarekcoR

.labretnuoctfahsetaidemretnI

recnalabretnuoC

dorgnitcennoC

smrarekcoR

tfahstratskciK

tfahshctulC

RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR RRRRR RRRRR

SGNIHSUBSGNIHSUB

SGNIHSUBSGNIHSUB

SGNIHSUB

IIIII RRRRR IIIII RRRRR

RRRRR RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII IIIII

IIIII IIIII

RRRRR

RRRRR

10

C: Clean - I: Inspect - R: Replace

* Maximum 12 months interval - ** Clean whenever the engine has been washed - *** I(R): Especially needle and needle jet

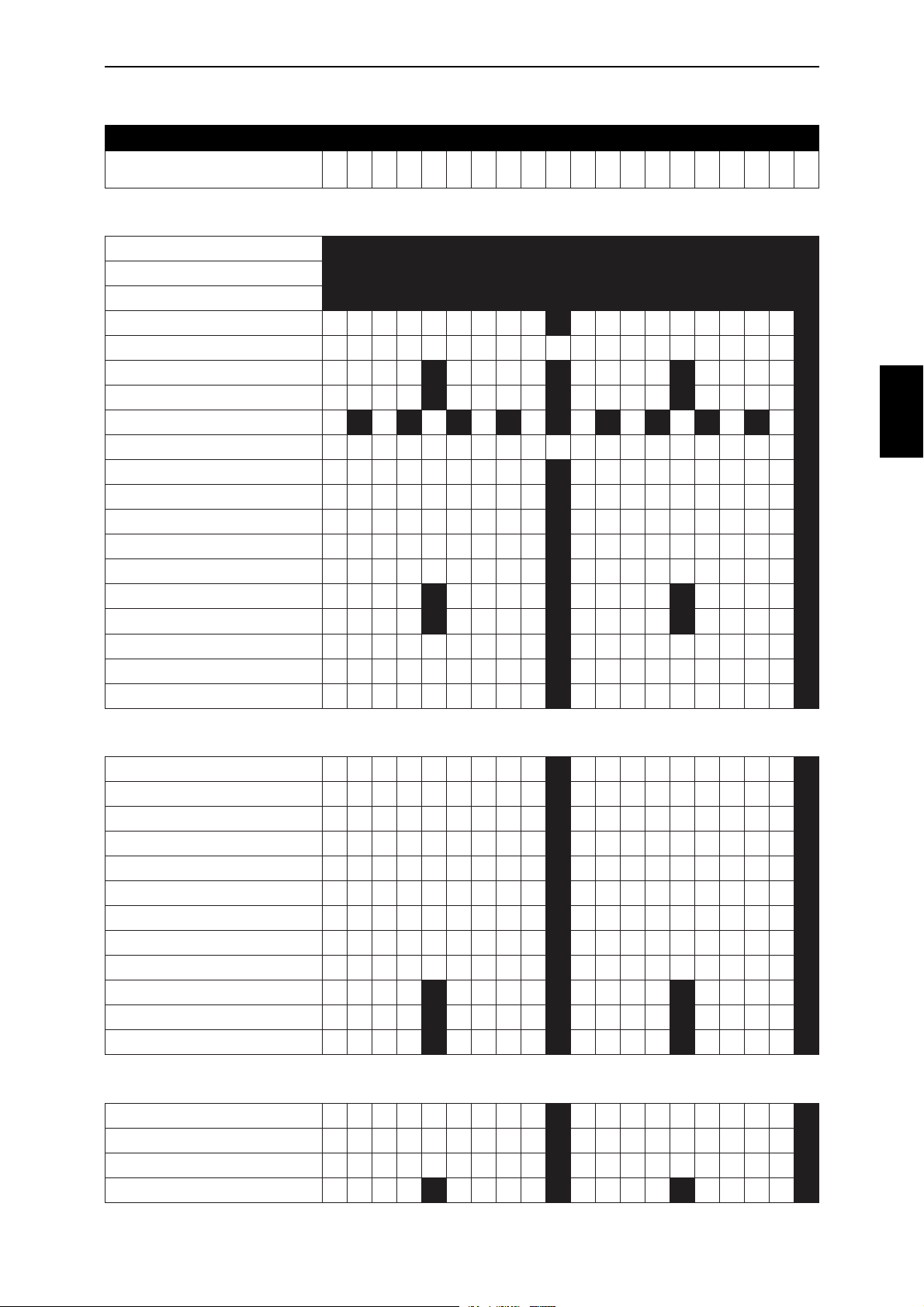

4

MAINTENANCE SCHEDULE

Engine - FE and FSe models

Please observe: Riding under hard conditions demands more frequent maintenance

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUSSRUOH/TCEJBUS

SRUOH/TCEJBUS

lioenignE

neercsliO

retliforcimliO

evlavdeer.lcnipmupliO

*diuqiltnalooC

)pac.lcni(gulpkrapS

**noitingI/rotanretlA

ecnaraelcevlaV

nip&sgnir.lcninotsiP

gninilrednilyC

dorgnitcennoC

niptfahsknarC

***/**rotterubraC

msinahcemtratskciK

msinahcemtfihsraeG

msinahcemleehweerF:LE

010101010102020202020303030303040404040405050505050606060606070707070708080808080909090909001001

RALUGERRALUGER

RALUGERRALUGER

RALUGER

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC CCCCC

RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR RRRRR

IIIII RRRRR IIIII RRRRR

IIIII IIIII IIIII IIIII

IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII IIIII

sgnilaes&sediug.lcnisevlaV

renoisnet.lcniniahcgnimiT

scsid.lcnimsinahcemhctulC

IIIII IIIII IIIII IIIII

C/IC/I

C/IC/I C/IC/I

C/I

001001011011

011011021021

021021031031

031031041041

041041051051

051051061061

061061071071

071071081081

081081091091

001

011

021

031

041

051

061

071

C/IC/I

C/IC/I C/IC/I

C/I

RRRRR RRRRR

IIIII RRRRR

IIIII IIIII

RRRRR RRRRR

RRRRR RRRRR

C/IC/I C/IC/I

C/I

IIIII IIIII

IIIII IIIII

IIIII IIIII

C/IC/I C/IC/I

C/I

091091002002

081

091

002002

002

C/IC/I

C/I

RRRRR

4

IIIII

C/IC/I

C/I

SGNIRAEBSGNIRAEB

SGNIRAEBSGNIRAEB

SGNIRAEB

dorgnitcennoC

tfahsknarC

tfahsniamxobraeG

tfahsyradnocesxobraeG

murdtfihS

tfahsmaC

etalperusserphctulC

leehwraegtratskciK

leehwraegetaidemretnI

smrarekcoR

.labretnuoctfahsetaidemretnI

recnalabretnuoC

dorgnitcennoC

smrarekcoR

tfahstratskciK

tfahshctulC

RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR RRRRR RRRRR

SGNIHSUBSGNIHSUB

SGNIHSUBSGNIHSUB

SGNIHSUB

RRRRR RRRRR RRRRR RRRRR

RRRRR RRRRR

RRRRR RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

IIIII RRRRR

RRRRR RRRRR

IIIII IIIII

IIIII IIIII

C: Clean - I: Inspect - R: Replace

* Maximum 12 months interval - ** Clean whenever the engine has been washed - *** I(R): Especially needle and needle jet

11

Loading...

Loading...