BEDIENUNGSANLEITUNG

OWNERS MANUAL

MANUEL D’UTILISATION

"

06

Edition 2006

TABLE OF CONTENTS

- 1 -

ENGLISH

Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important LIMITED warranty and LIMITED guarantee

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . 5

Chassis number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine-Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATION INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . 6

Clutch lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hand decompression lever. . . . . . . . . . . . . . . . . . . . . . . . 6

Hand brake lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Short circuit button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Combination switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Flasher switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Headlamp switch (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Starter button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Emergency OFF switch (Australia). . . . . . . . . . . . . . . . . . 8

Electronic speedometer . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Kilometers or miles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Filler cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fuel Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Choke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hot start device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shift lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Kickstarter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Foot brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Side stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Compression damping of fork . . . . . . . . . . . . . . . . . . . . 16

Rebound damping of fork . . . . . . . . . . . . . . . . . . . . . . . . 16

Damping action during compression of shock absorber

. 17

Rebound damping of shock absorber . . . . . . . . . . . . . . 18

Steering lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Instructions for initial operation. . . . . . . . . . . . . . . . . . . . 19

Running in the Husaberg models . . . . . . . . . . . . . . . . . . 19

TIPS AND WARNINGS FOR STARTING THE

MOTORCYCLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DRIVING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check the following before each start . . . . . . . . . . . . . . 20

Starting when the engine is cold. . . . . . . . . . . . . . . . . . . 21

Starting when the engine is warm . . . . . . . . . . . . . . . . . 21

What to do when the engine is “flooded” . . . . . . . . . . . . 21

Starting off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Shifting/Riding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stopping and parking . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PERIODIC MAINTENANCE SCHEDULE. . . . . . . . . . . . . . 24

MAINTENANCE WORK ON CHASSIS AND ENGINE . . . . 27

Checking and adjusting the steering head bearing . . . . 27

Breather plug front fork. . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cleaning the dust sleeves of the telescopic fork . . . . . . 28

Basic suspension setup for the weight of the driver . . . . 29

Checking the shock absorber and spring . . . . . . . . . . . . 29

Determining the static sag of the shock absorber . . . . . 29

Determining the riding sag of the shock absorber . . . . . 29

Checking the basic setup of the telescopic fork . . . . . . . 30

Changing the spring preload on the telescopic fork . . . 30

Replacing fork springs . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page

Changing the fork offset (caster) (FS) . . . . . . . . . . . . . . 31

How to change the handlebar position . . . . . . . . . . . . . . 33

Changing the spring preloading of the shock absorber . 33

Check chain tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Correct chain tension . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chain maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chain wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

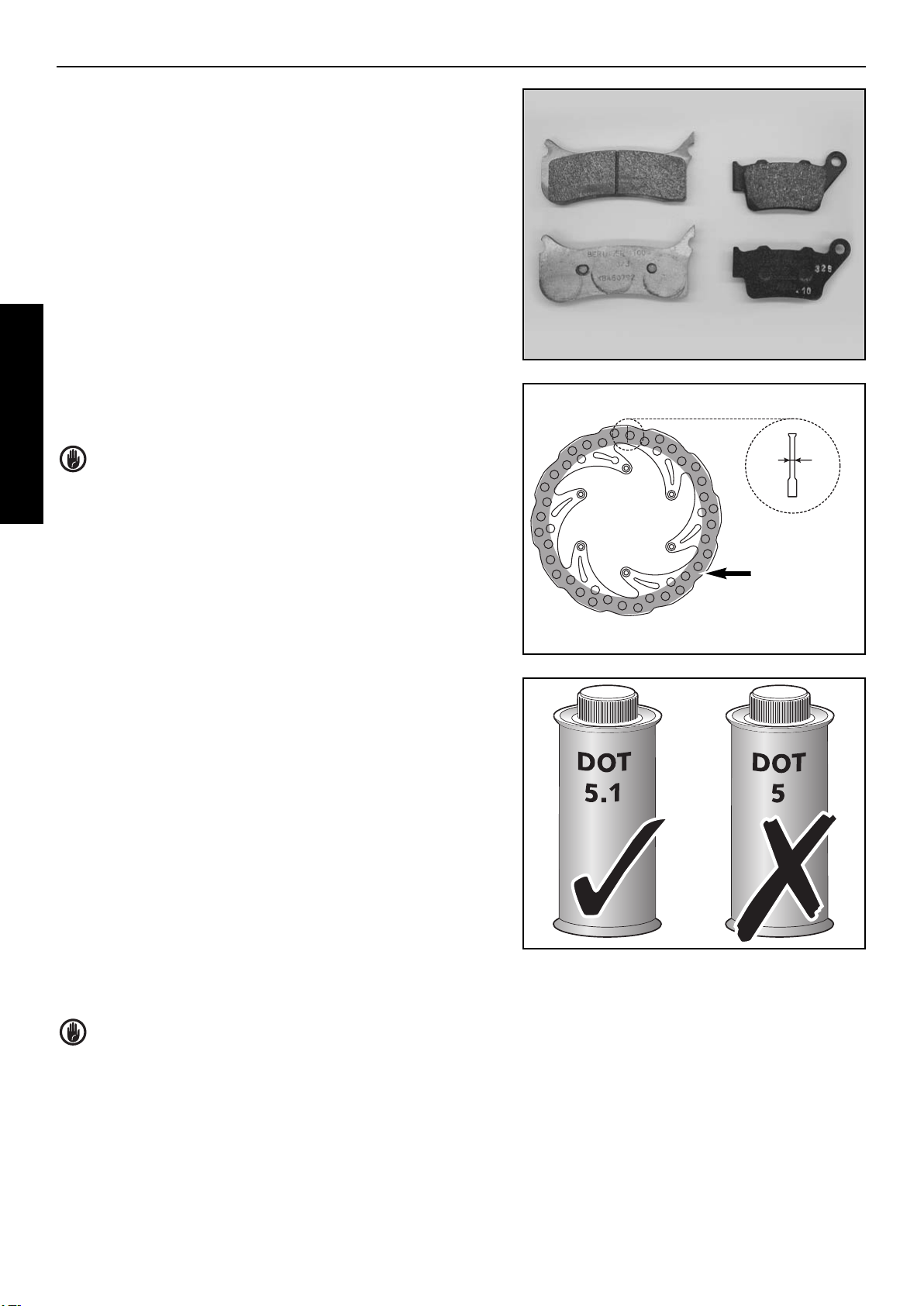

General information about Husaberg disc brakes . . . . . 36

Changing the basic position the hand brake lever (FE) . . . .

37

Changing the basic position the hand brake lever (FS) . 37

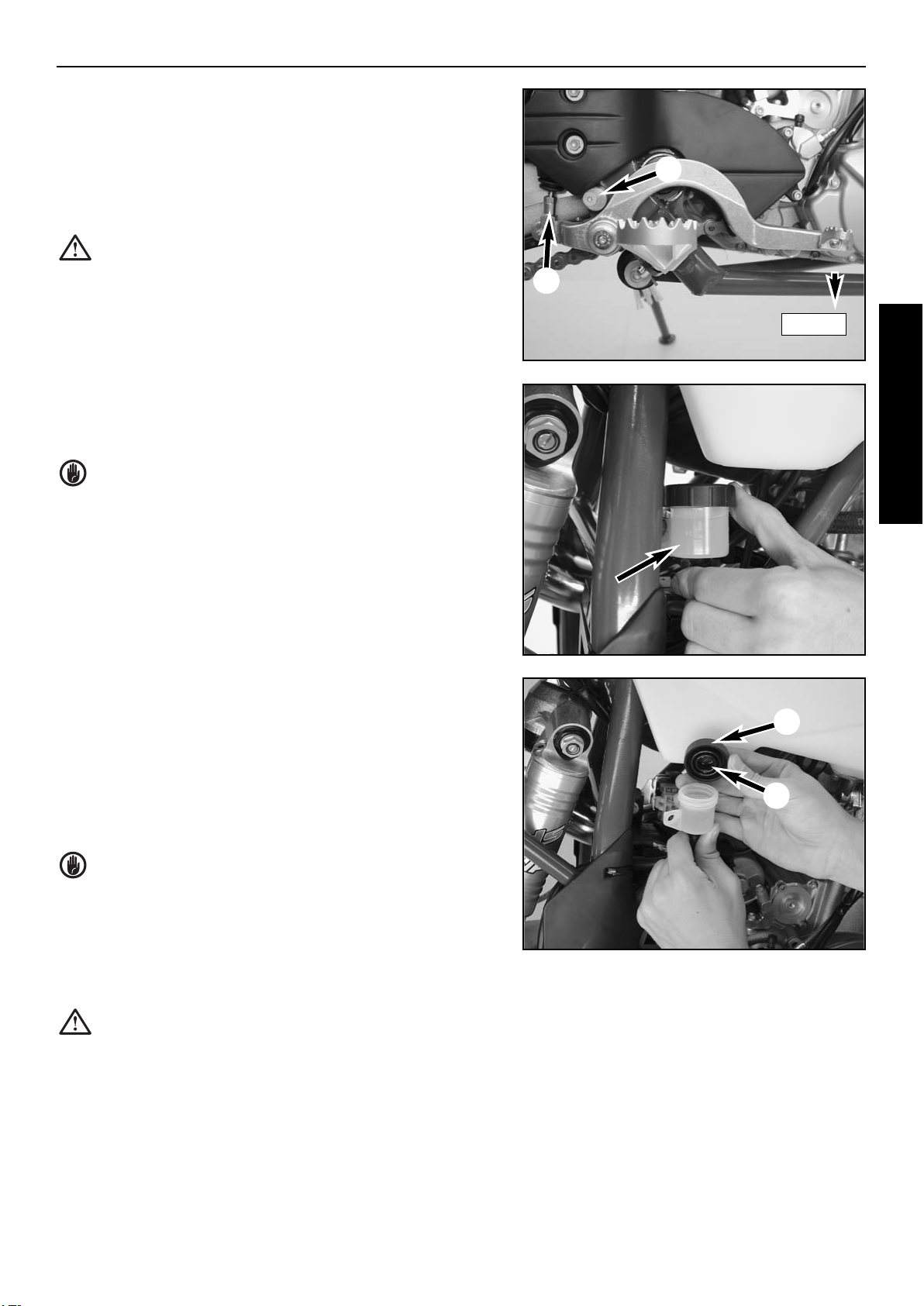

Checking the brake fluid level - front brake . . . . . . . . . . 37

Refilling the front brake fluid reservoir . . . . . . . . . . . . . . 37

Checking the front brake pads . . . . . . . . . . . . . . . . . . . . 38

Replacing the front brake pads (FE) . . . . . . . . . . . . . . . 38

Replacing the front brake pads (FS) . . . . . . . . . . . . . . . 38

Changing the basic position of the foot brake pedal . . . 39

Check the rear brake fluid level . . . . . . . . . . . . . . . . . . . 39

Refilling the rear brake fluid reservoir. . . . . . . . . . . . . . . 39

Checking the rear brake pads . . . . . . . . . . . . . . . . . . . . 40

Replacing the rear brake pads . . . . . . . . . . . . . . . . . . . . 40

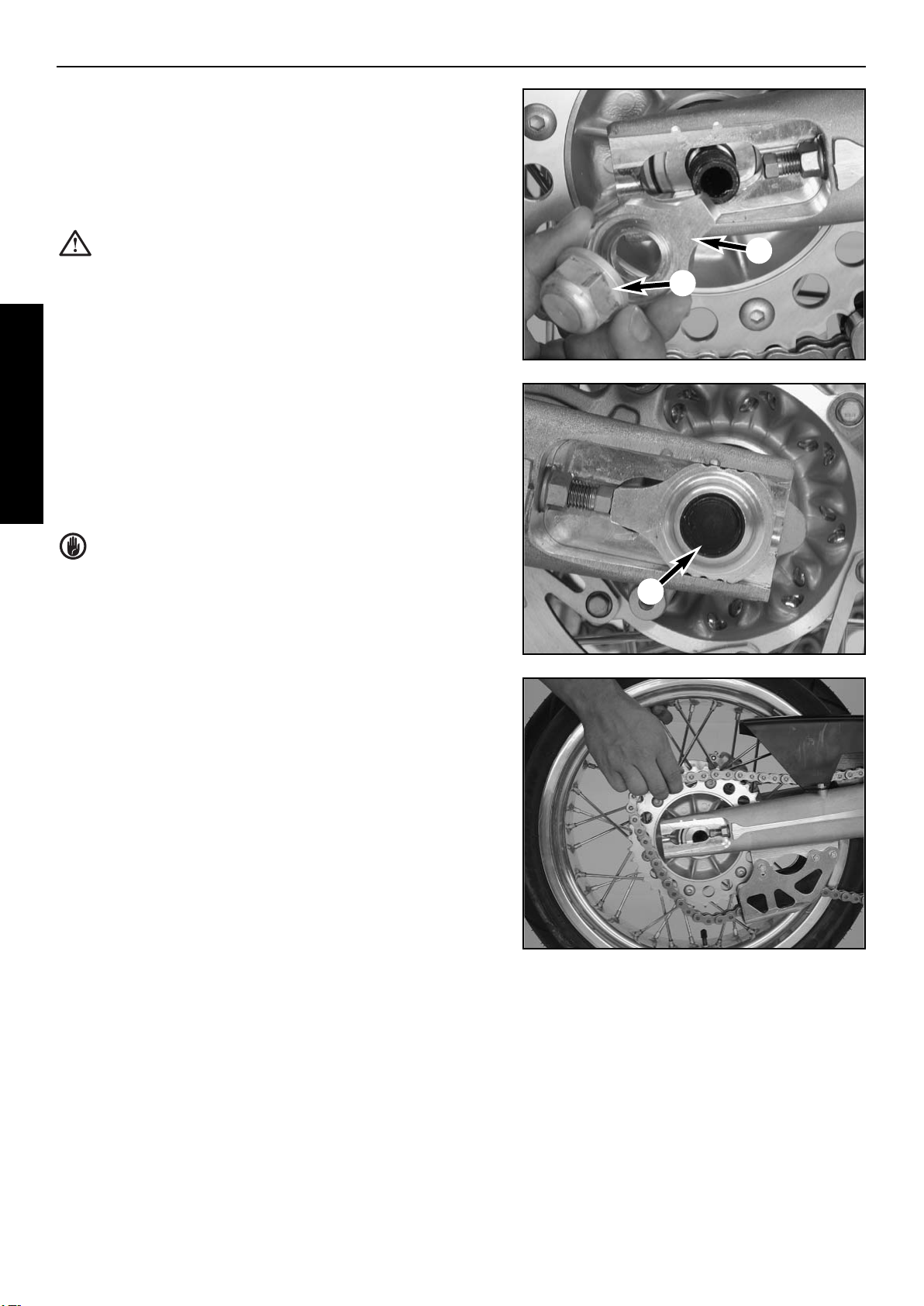

Dismounting and mounting the front wheel . . . . . . . . . . 41

Dismounting and mounting the rear wheel. . . . . . . . . . . 42

Checking the shock absorption rubbers in the rear hub. 43

Checking spoke tension . . . . . . . . . . . . . . . . . . . . . . . . . 43

Tires, air pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Check/set distance of the magnetic sensor . . . . . . . . . . 44

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Charging the battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fuse (FE/FS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replacing headlight lamp/parking light lamp . . . . . . . . . 46

Cooling system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Checking the coolant level . . . . . . . . . . . . . . . . . . . . . . . 47

Bleeding the cooling system. . . . . . . . . . . . . . . . . . . . . . 48

Replacing the glassfiber yarn packing of the silencer . . 48

Cleaning the spark arrester . . . . . . . . . . . . . . . . . . . . . . 48

Cleaning the air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Checking the adjustment of the hand decompression

release cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Adjusting the throttle cables . . . . . . . . . . . . . . . . . . . . . . 49

Changing the original position of the clutch lever. . . . . . 50

Checking the oil level of the hydraulic clutch . . . . . . . . . 50

Bleeding of the hydraulic clutch . . . . . . . . . . . . . . . . . . . 50

Carburetor – Adjust idling. . . . . . . . . . . . . . . . . . . . . . . . 51

Basic information on carburetor wear. . . . . . . . . . . . . . . 51

Adjusting the mixture control screw . . . . . . . . . . . . . . . . 51

Checking the float level (float height) . . . . . . . . . . . . . . . 52

Draining the float chamber of the carburetor . . . . . . . . . 52

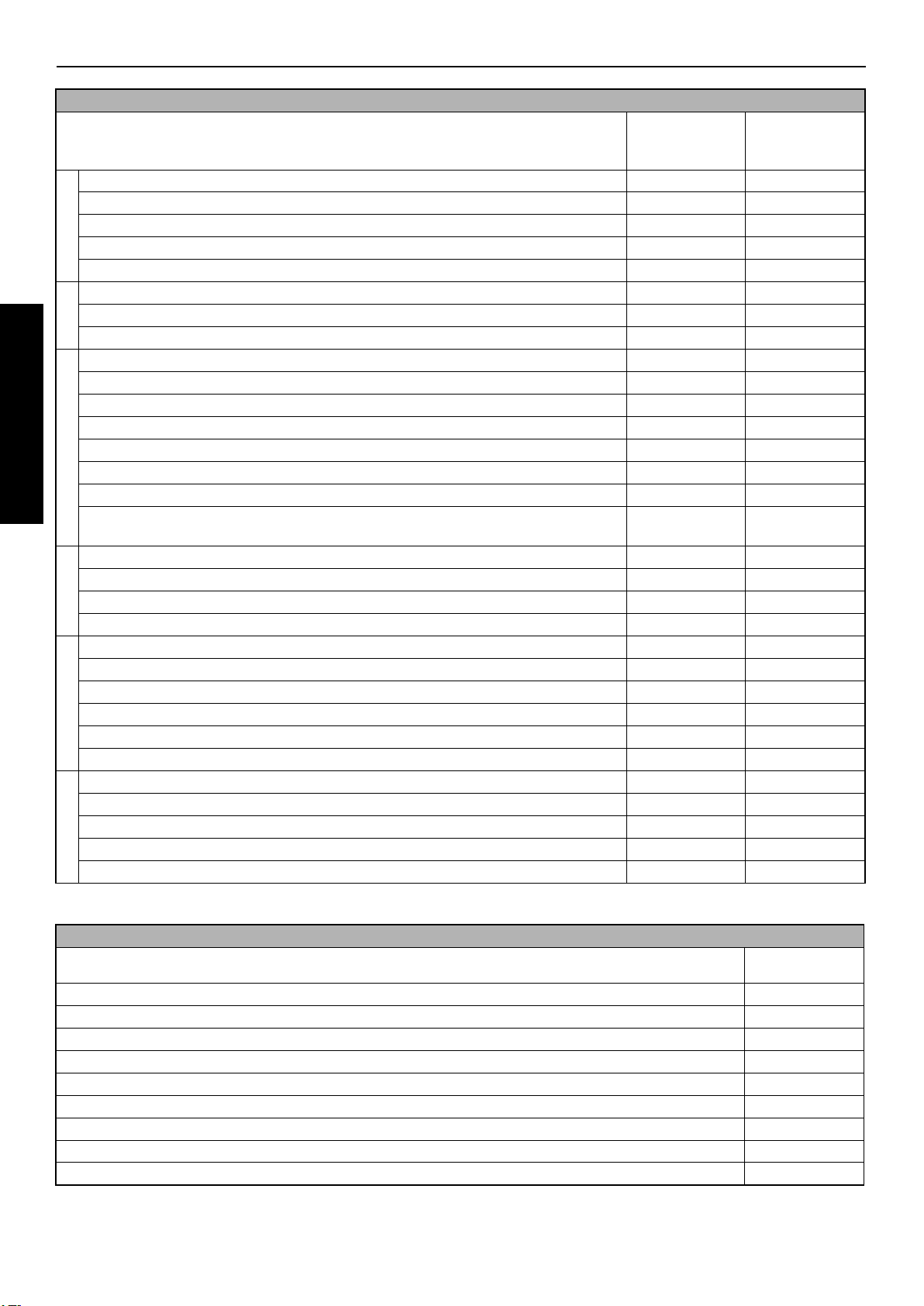

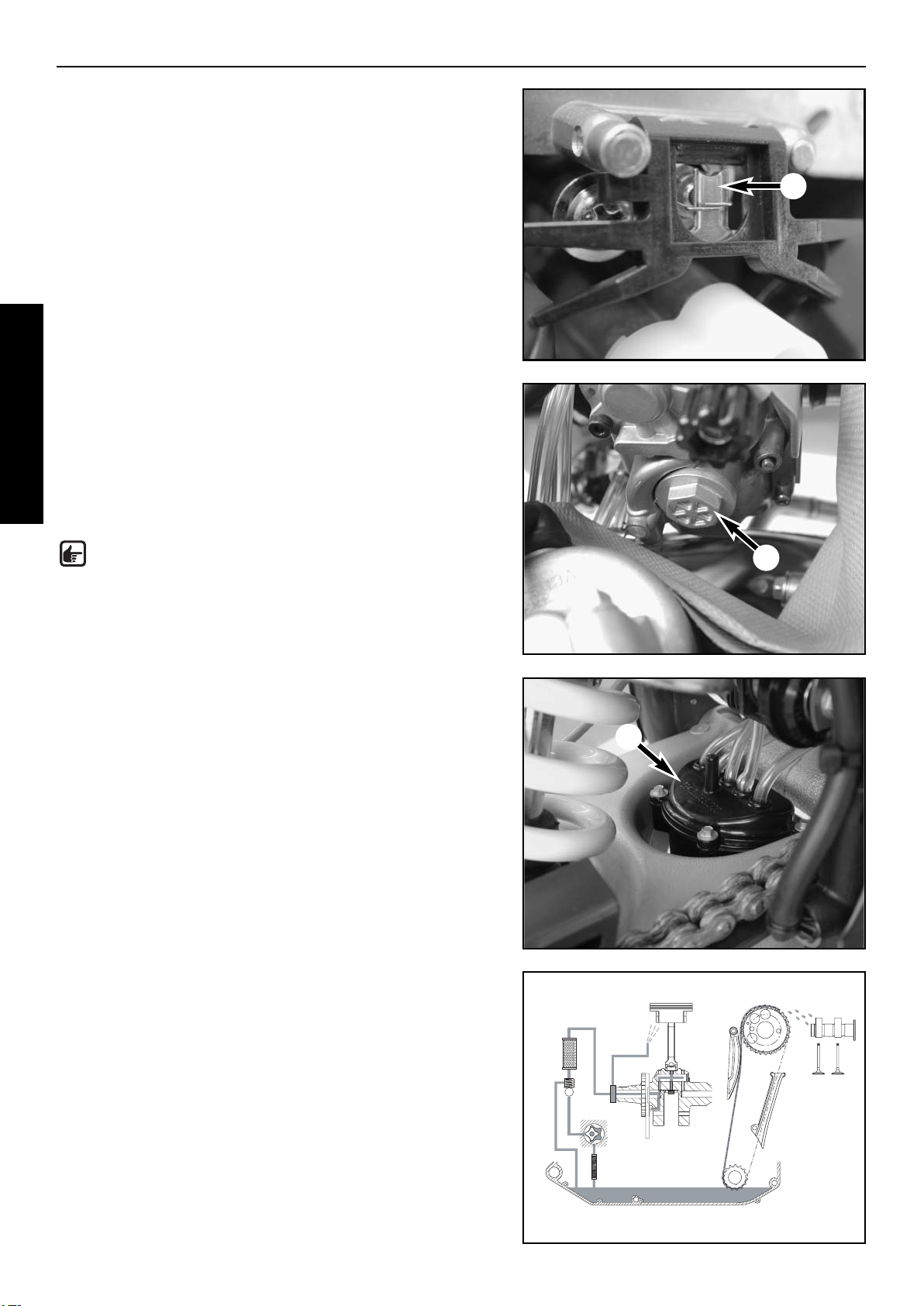

Oil Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

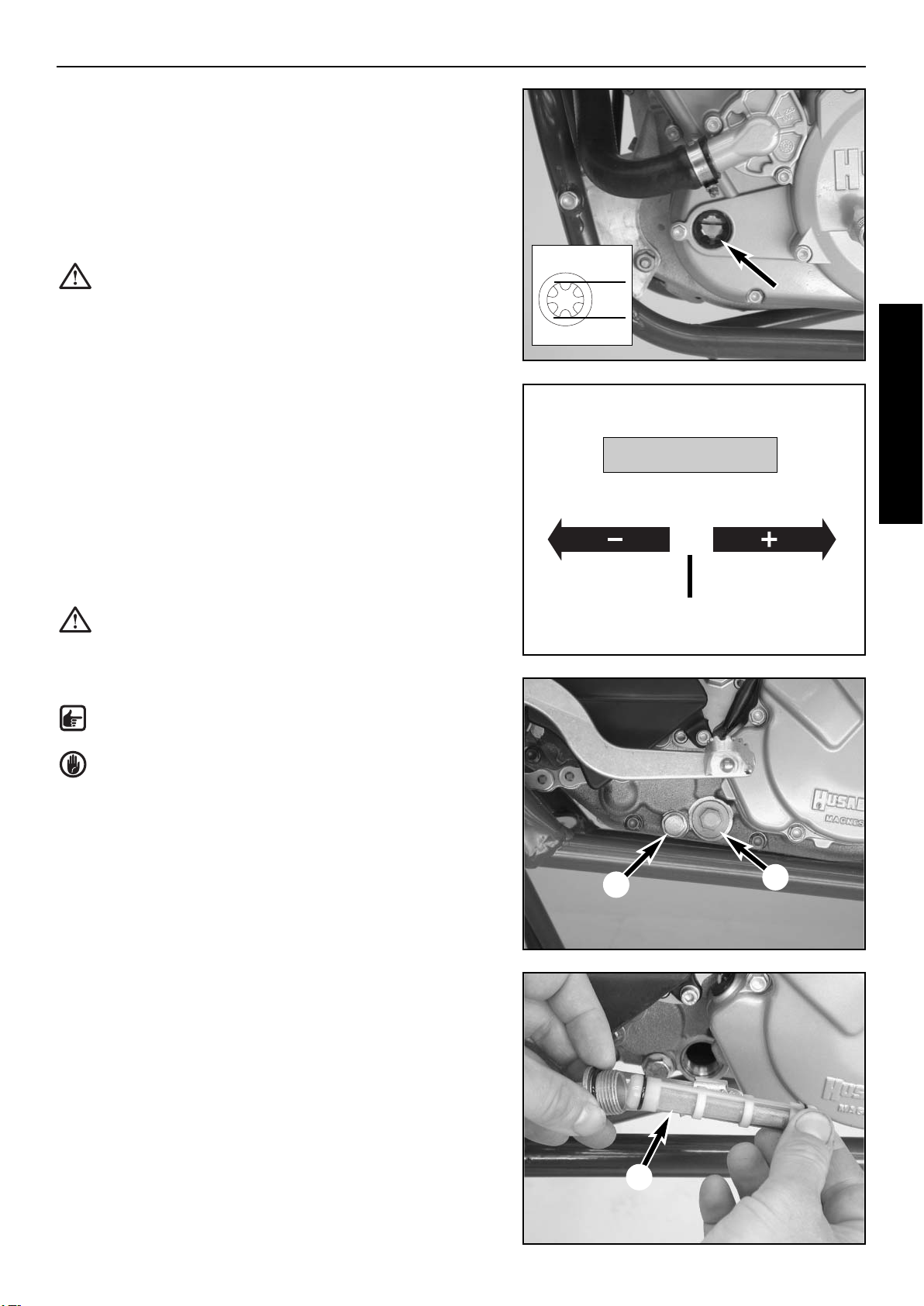

Checking the engine oil level . . . . . . . . . . . . . . . . . . . . . 53

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Changing the engine oil . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cleaning the oil screen . . . . . . . . . . . . . . . . . . . . . . . . . 53

Changing the oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

CLEANING, CONSERVATION, STORAGE . . . . . . . . . . . . 57

TECHNICAL DATA - ENGINE . . . . . . . . . . . . . . . . . . . . . . . 58

TECHNICAL DATA - CHASSIS . . . . . . . . . . . . . . . . . . . . . . 61

HEAD WORD INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

WIRING DIAGRAMM. . . . . . . . . . . . . . . . . . . . . . . . Appendix

INTRODUCTION

- 2 -

ENGLISH

IMPORTANT

WE STRONGLY SUGGEST THAT YOU READ THIS MANUAL CAREFULLY AND COMPLETELY BEFORE GOING ON YOUR FIRST RIDE. IT CONTAINS A GREAT DEAL OF INFORMATION AND ADVICE WHICH WILL HELP YOU USE AND HANDLE YOUR BIKE PROPERLY.

IN YOUR OWN INTEREST, PLEASE PAY PARTICULAR ATTENTION TO NOTICES THAT

ARE MARKED AS FOLLOWS:

WARNING: IGNORING THESE INSTRUCTIONS, CAN ENDANGER YOUR BODY

AND YOUR LIFE.

CAUTION: IGNORING THESE INSTRUCTIONS COULD CAUSE DAMAGE TO

PARTS OF YOUR MOTORCYCLE OR THAT THE MOTOR-CYCLE IS NOT ROADSAFE ANYMORE.

NOTE: USEFUL INFORMATION ON HANDLING AND SERVICING YOUR

MOTORCYCLE.

Please insert the serial numbers of your motorcycle in the boxes below

Frame number:

Motor number:

Stamp of dealer:

H

USABERG RESERVES THE RIGHT TO MODIFY ANY EQUIPMENT, TECHNICAL SPECIFICATIONS, COLORS, MATERIALS

,

SERVICES OFFERED AND RENDERED, AND THE LIKE SO AS TO ADAPT THEM TO LOCAL CONDITIONS WITHOUT PREVIOUS ANNOUNCE

-

MENT AND WITHOUT GIVING REASONS, OR TO CANCEL ANY OF THE ABOVE ITEMS WITHOUT SUBSTITUTING THEM WITH OTHERS

. I

T

SHALL BE ACCEPTABLE TO STOP MANUFACTURING A CERTAIN MODEL WITHOUT PREVIOUS ANNOUNCEMENT

.

The exhaust system on this vehicle has no owner serviceable parts. Should there be an

increase in noise or damage to any component relating to the noise reduction system, replacement parts should be fitted by an Authorised dealer.

Tampering with noise control system prohibited

Owners are warned that the law may prohibit:

(a)The removal or rendering inoperative by any person other than for purposes of

maintenance, repair or replacement, of any device or element of design incorporated into

any new vehicle for the purpose of noise control prior to its sale or delivery to the ultimate

purchaser or while it is in use; and

(b)the use of the vehicle after such device or element of design has been removed or rende-

red inoperative by any person.

COMSUMER INFORMATION FOR AUSTRALIA ONLY

INTRODUCTION

- 3 -

ENGLISH

We would like to congratulate you on your purchase of a Husaberg motorcycle.

You are now the owner of a state-of-the-art sport motorcycle that guarantees to bring you lots

of fun and enjoyment, provided that you clean and maintain it appropriately. Before you go

for your first ride, be sure to read this manual carefully and thoroughly in order to familiarize yourself with how to operate your new motorcycle and with its characteristics,

even if this means that you will have to dedicate some of your valuable time to this

task. Only by doing so will you learn how to tune your motorcycle to your specific

needs and how to protect yourself against injury. Besides, this manual contains important information on motorcycle maintenance. At the time this manual was typeset, it was

up-to-date with the latest state of this production series. Please note that motorcycle features

may vary according to the effective legal provisions. It cannot be completely ruled out, however, that minor discrepancies may exist resulting from further design upgrades of these

motorcycles.This manual is an important part of your motorcycle and should be passed on to

any subsequent owner in case you decide to sell it.

The work marked with an * in the chapter "Servicing the chassis and engine" must be performed by an authorized Husaberg dealer. If such service work becomes necessary during a

competition, it must be performed by a trained mechanic.

For your own safety, use Husaberg-approved parts and accessories only. Husaberg

is not liable for damage that arises in connection with the use of other products.

Take special care to follow the recommended run in, inspection, and maintenance intervals.

Heeding these guidelines will significantly increase the life of your motorcycle. Be sure to

have your motorcycle serviced by an authorized Husaberg dealer to maintain the validity of

your warranty.

Off-road / Supermoto motorcycle driving is a wonderful sport and we hope that you will be

able to enjoy it to the full. It may, however, involve potential problems for the environment or

lead to conflicts with others. These problems or conflicts can be avoided if the motorcycle is

used responsibly. To safeguard the future of motorcycle sports, make sure that you use the

motorcycle in accordance with the law, show that you are environmentally conscious and respect the rights of others.

We wish you a lot of fun when driving !

HUSABERG

5230 MATTIGHOFEN, AUSTRIA

A

LL RIGHTS RESERVED TO MAKE ALTERATIONS TO DESIGN AND MODEL.

© by HUSABERG Alle Rechte vorbehalten

INTRODUCTION

- 4 -

ENGLISH

IMPORTANT LIMITED WARRANTY AND LIMITED GUARANTEE

INFORMATION

Husaberg sports motorcycles are designed and constructed to resist the usual wear and tear

of normal use in competitions.

The motorcycles comply with the regulations and categories currently in effect with the leading

international motorcycle associations.

Observance of the service, maintenance and tuning instructions for the engine and chassis

specified in the Owner's Manual is a prerequisite for faultless operation and the avoidance of

premature wear. An improperly tuned chassis can lead to damage and breakage of the chassis components (see chapter on checking the basic chassis setting).

The service work described in the "Lubrication and maintenance chart" must be carried out

and confirmed by an authorized Husaberg dealer, otherwise your warranty will become void.

The fuels and lubricants specified in the Owner's Manual or fluids with equivalent specifications must be used in accordance with the maintenance schedule.

No claims can be filed under the warranty for damage or consequential damage caused by

manipulations or conversions to the motorcycle.

The use of the motorcycle under extreme conditions, e.g. on extremely muddy and wet terrain, can lead to higher than average wear on components such as the drive train or the brakes. In this case it may become necessary to service or replace wear parts before the service

limit specified in the maintenance schedule has been reached.

MODELS FE

“On the road“ approved models are only allowed on public roads in the original homologated

(throttled) version. Without this performance restriction (i.e. de-throttled), these models

are only allowed to be driven off-road and not on public roads.The FE models are designed for off-road sports endurance competitions(enduro) and not suitable for predominant

motocross use.

MODELS FS

The FS models are only allowed on public roads in the original homologated (throttled) version. Without this performance restriction (i.e. dethrottled), these models are only allo-

wed to be driven in Supermoto competitions but not on public roads.

No warranty will be assumed if the bike is used in races or competitions.

In accordance with the international quality management ISO 9001 standard, Husaberg uses quality assurance processes that lead to the highest possible product quality.

SERIAL NUMBER LOCATIONS

- 5 -

ENGLISH

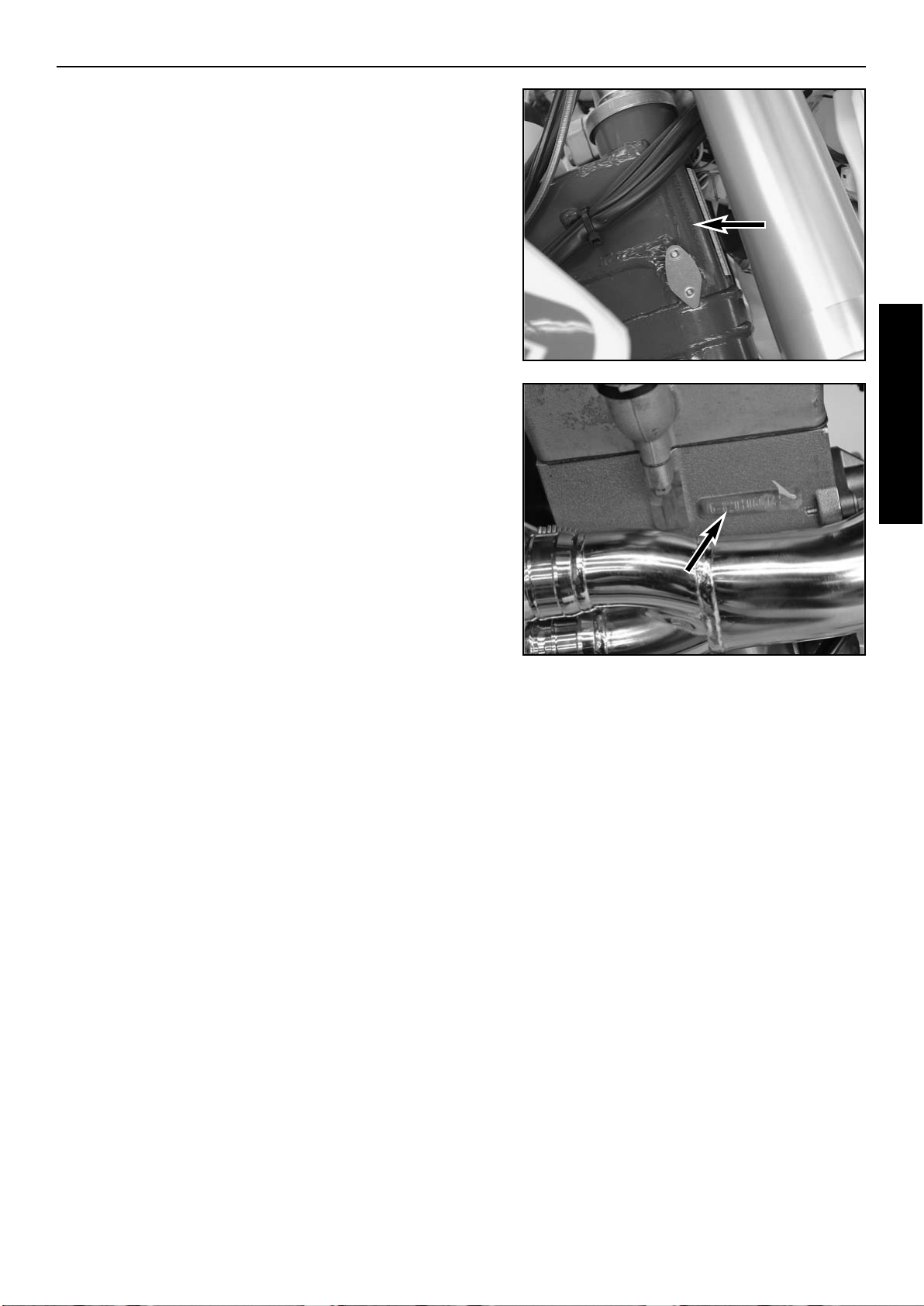

CHASSIS NUMBER

The chassis number is stamped on the right side of the steering head

tube. Enter this number in the field on page no 2.

ENGINE-NUMBER

The engine number is embossed in the engine case on the left side of

the engine under the radiator hose.

OPERATION INSTRUMENTS

- 6 -

ENGLISH

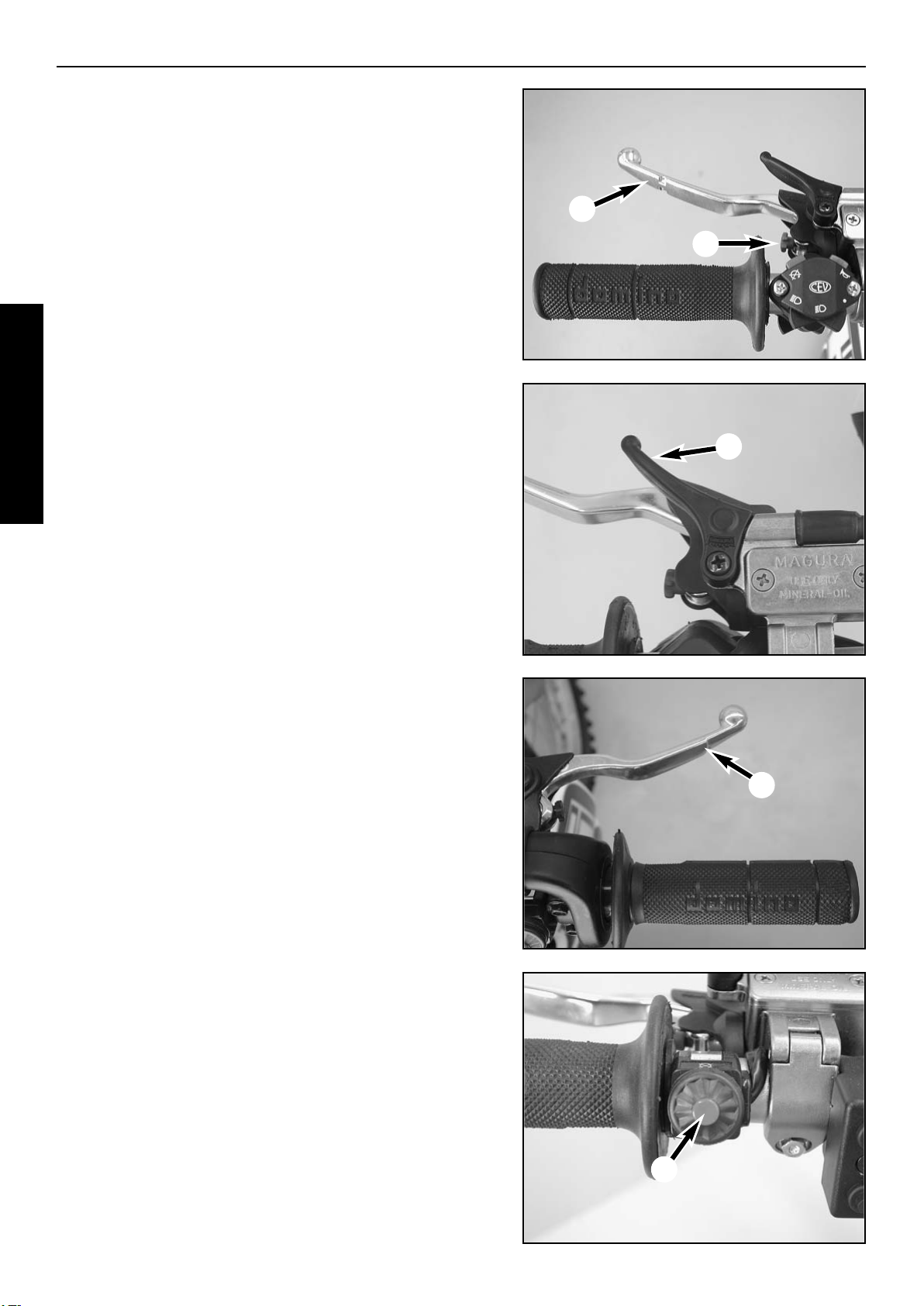

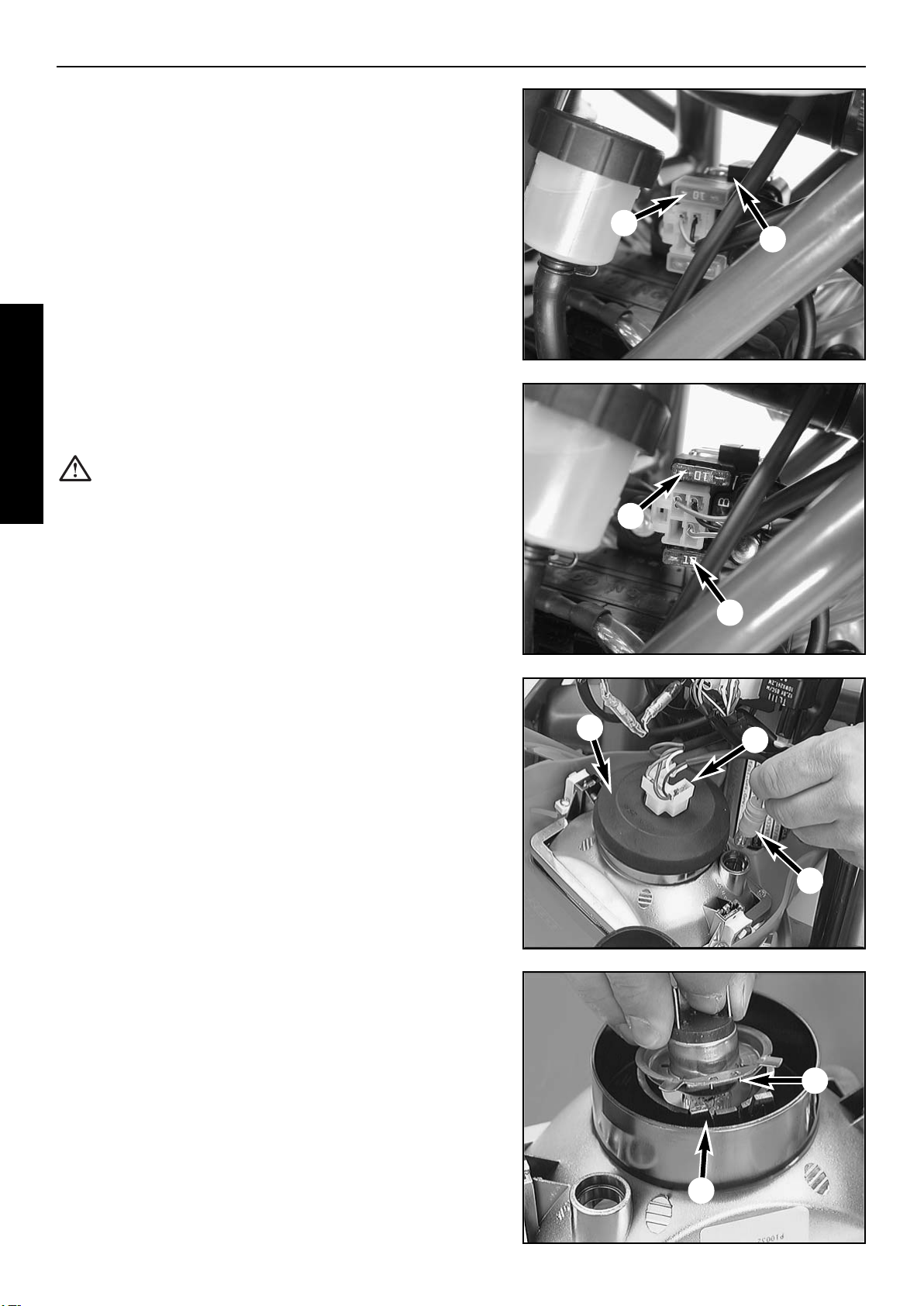

CLUTCH LEVER

The clutch lever (1) is located on the left side of the handlebar. The adjusting screw (A) is used to change the original position of the clutch lever

(see maintenance work on chassis and engine).

HAND DECOMPRESSION LEVER

The hand decompression lever (2) is needed only if the carburetor overflows after a fall. To "pump the engine free", pull the hand decompression

lever during the starting procedure.

The outer end of the lever must provide for a backlash of approx. 10 mm

(0.4 in) at all times. Only thereafter may it cause valve motion (to be recognized by the stronger resistance which the hand decompression lever

encounters).

HAND BRAKE LEVER

The hand brake lever (3) is located on the right side of the handlebar and

actuates the front brake. The basic setting of the hand brake lever can

be adjusted (see maintenance work).

A

1

2

3

SHORT CIRCUIT BUTTON

The short circuit button (4) turns off the engine. When pressing this button, the ignition circuit is short-circuited.

4

OPERATION INSTRUMENTS

- 7 -

ENGLISH

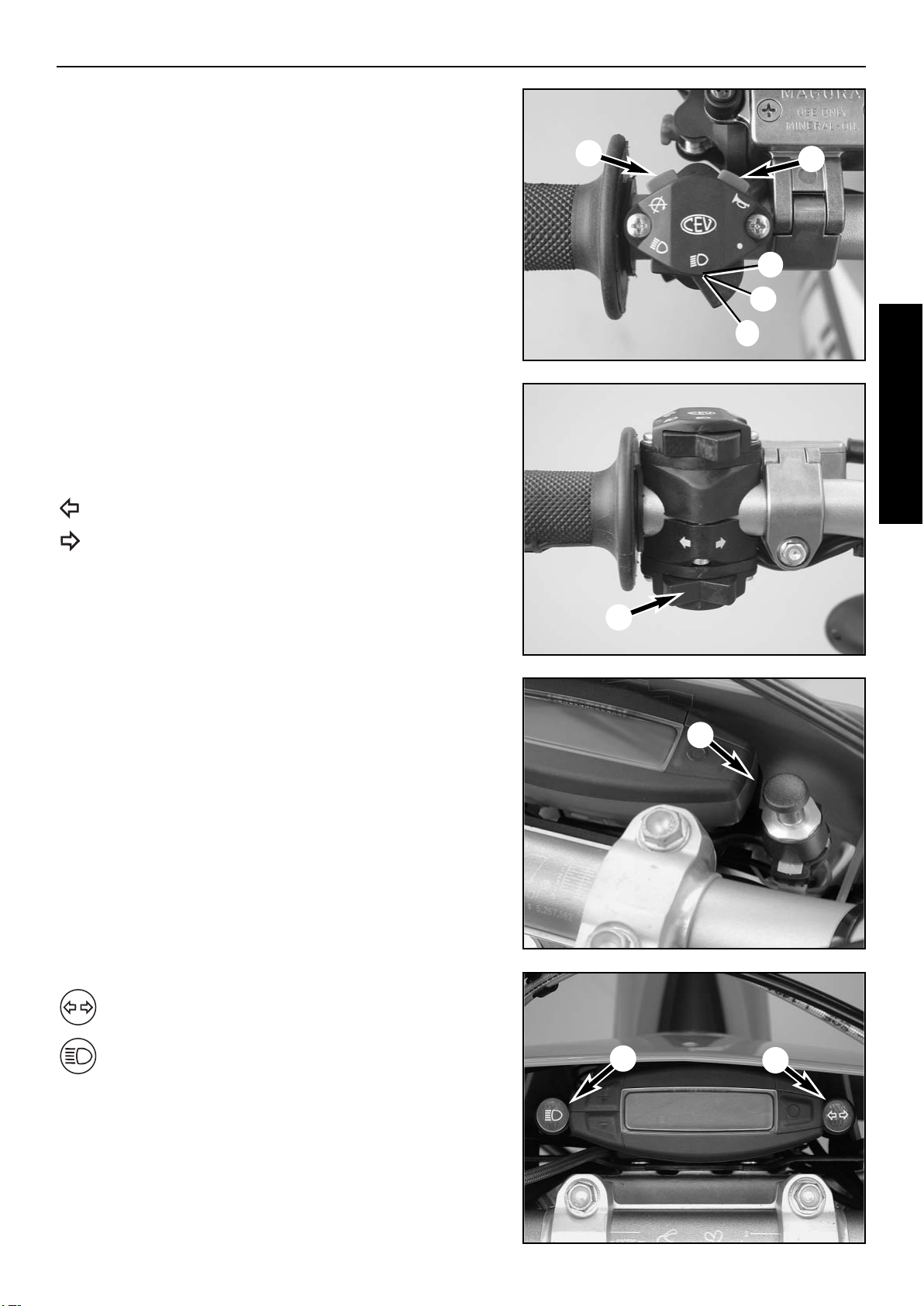

COMBINATION SWITCH

The light switch has 2, respectively 3 switch positions.

(A) = Light off (this function is not available in all models)

(B) = Low beam on

(C) = High beam on

You may use button (1) to actuate the horn.

The red short circuit button (2) serves to switch off the engine. Leave the

switch pressed until the engine stops.

FLASHER SWITCH

The flasher switch (3) is a separate unit and is mounted on the left portion of the handlebar.

The wire harness is designed in a way that whenever you want to use

your bike off-road, you can dismount the entire turn indicator system

without affecting the function of the remaining electrical system.

Flasher left

Flasher right

HEADLAMP SWITCH (USA)

In this model the headlamp is switched on with the pull switch (4).

1

2

A

C

B

3

INDICATOR LAMPS

The green control lamp (5) flashes in the same rhythm as

the flashing indicator when the indicator is working.

The blue control lamp (6) lights up when the high beam

is on.

4

6

5

OPERATION INSTRUMENTS

- 8 -

ENGLISH

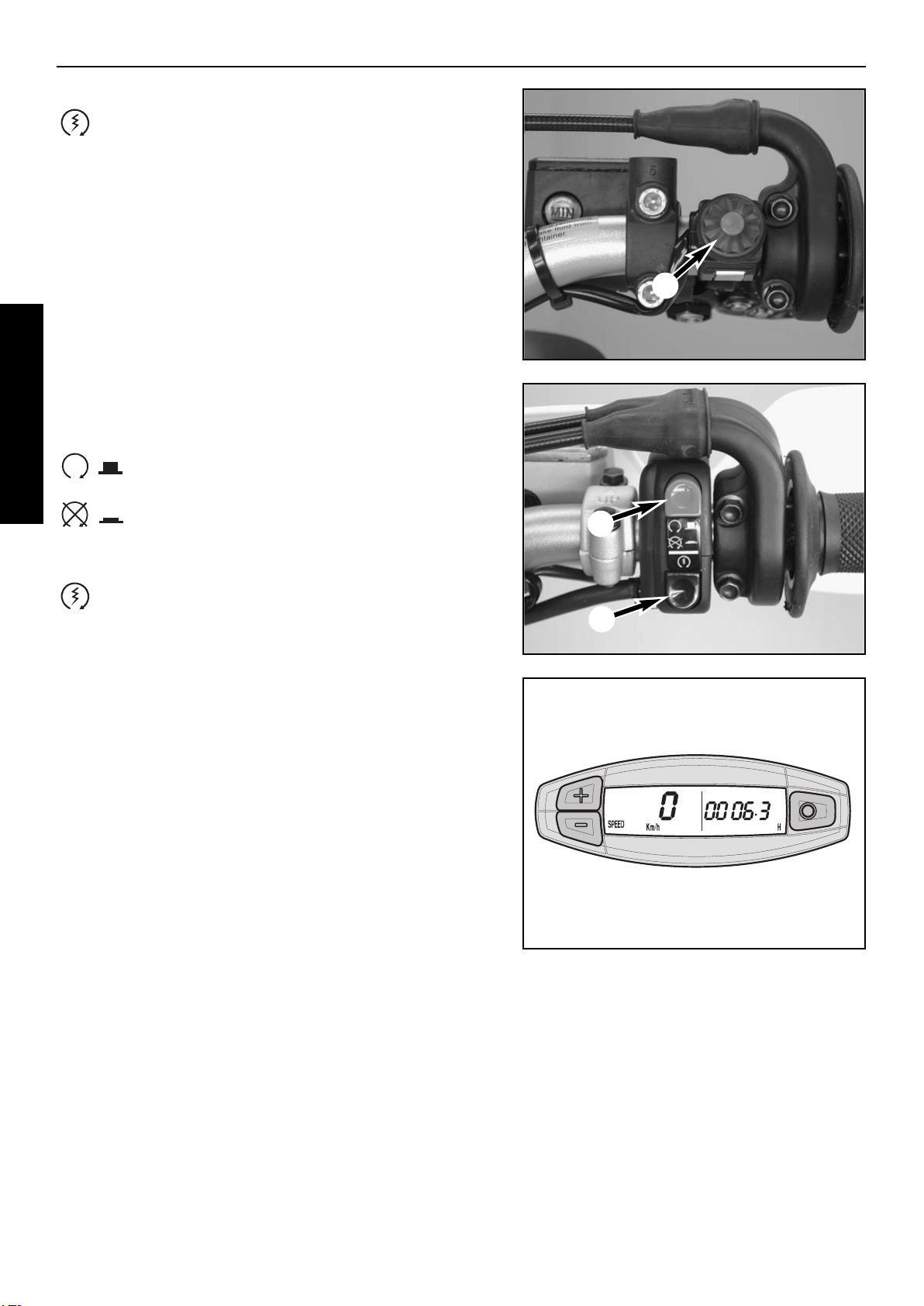

STARTER BUTTON

Pushing the black starter button (1) will actuate the E-starter

EMERGENCY OFF SWITCH (AUSTRALIA)

The red emergency-OFF switch (2) is arranged adjacent to the throttle

grip.

In this position, the E-starter is operational and the engine

can be started.

In this position, the E-starter and ignition circuits are

interrupted. The E-starter cannot be actuated, and the engine

will not start, not even if you attempt to start it with the

kickstarter.

Pushing the black starter button (3) will actuate the E-starter.

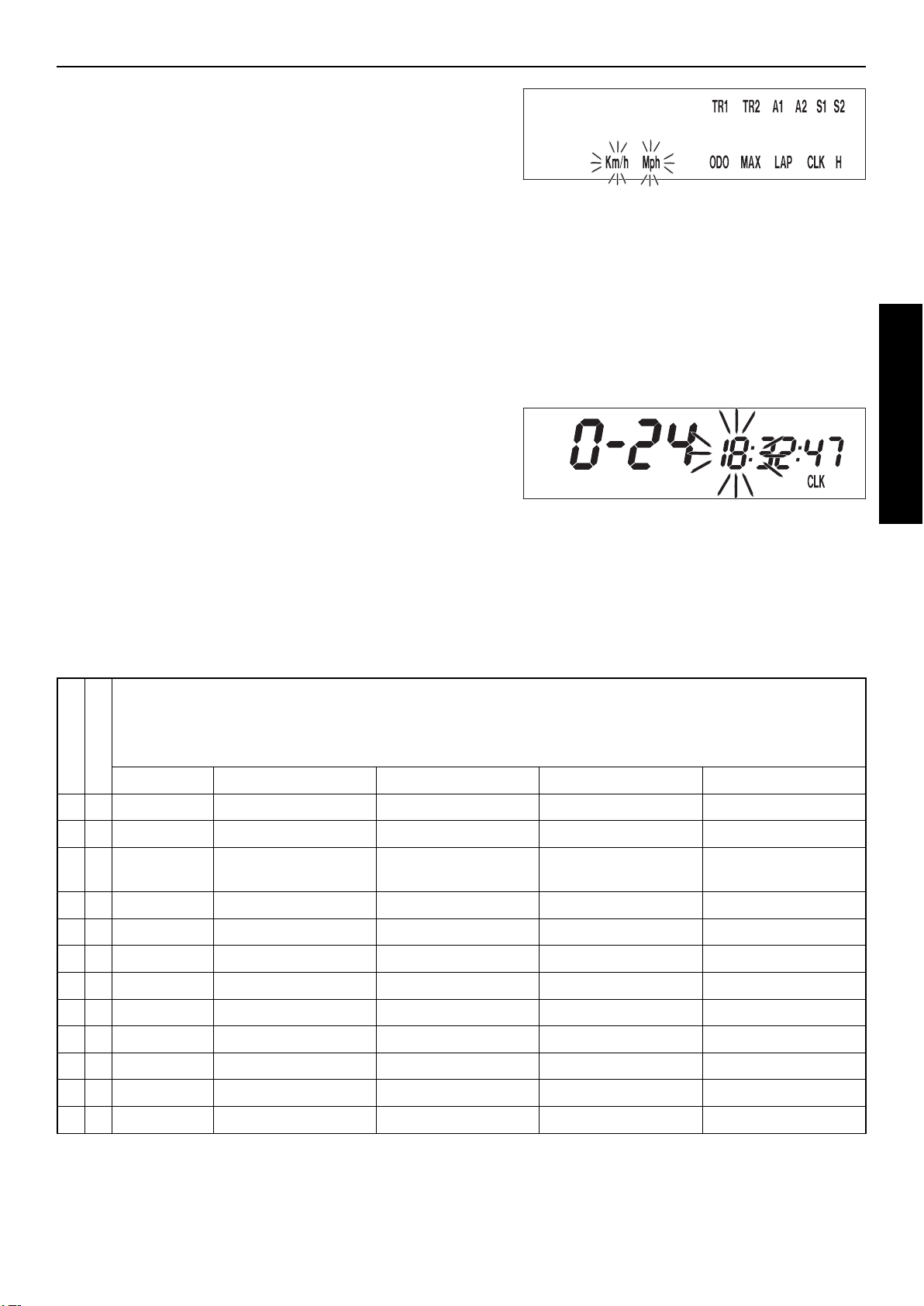

ELECTRONIC SPEEDOMETER

The display in the electronic speedometer is activated as soon as you

press a button on the speedometer or an impulse is received from the

wheel sensor. The display lights up when the engine is running.

The display is cleared if no button is pressed for 1 minute or no impulse

is received from the wheel sensor.

The | button is used to change between display modes.

The + and – buttons are used to control various functions.

3

1

2

OPERATION INSTRUMENTS

- 9 -

ENGLISH

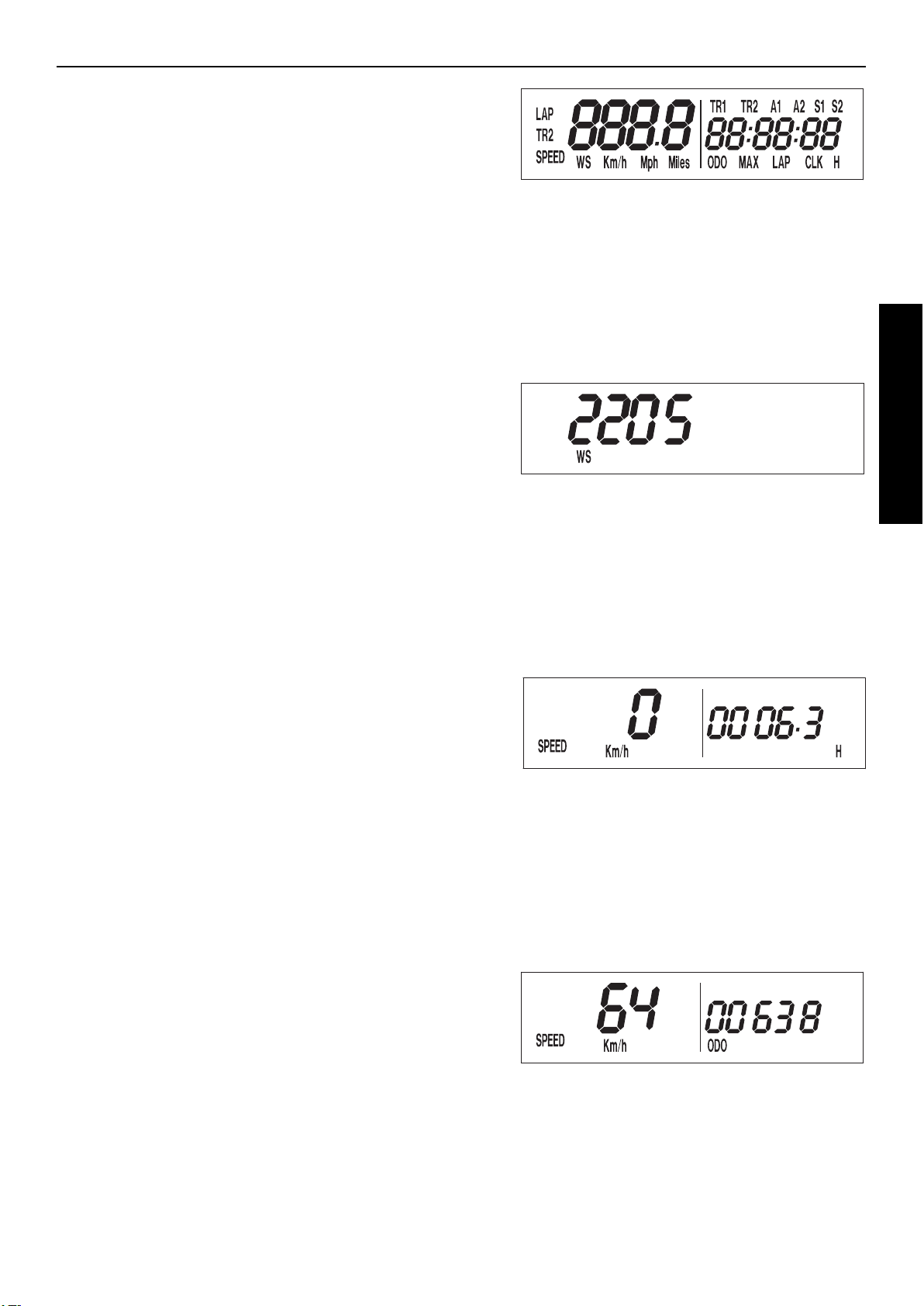

TEST

All of the display segments briefly light up for the display function test.

WS (WHEEL SIZE)

The display changes and the circumference of the front wheel is briefly

displayed in millimeters (2205 mm corresponds to a front wheel circumference of 21" with production tires).

Afterwards the display will return to the previous display mode.

SPEED DISPLAY MODE / H (SERVICE HOURS)

Only the SPEED / H and SPEED / ODO display modes are activated in

the condition at delivery. SPEED/H is displayed whenever the display is

activated and the front wheel is not turning. It automatically changes to

the SPEED/ODO display mode as soon as the front wheel starts turning.

SPEED displays the speed.

H displays the engine's service hours. The service hour counter starts to

count as soon as you start the engine. The displayed figure cannot be

changed.

Service intervals are indicated in service hours for some Husaberg offroad

motorcycles, making the service hour counter a very practical function.

SPEED / ODO DISPLAY MODE (ODOMETER)

The SPEED/ODO mode displays the speed and the total distance traveled. The display automatically changes to the SPEED/H display mode when

the front wheel stops turning.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. changes to the next display mode

The electronic speedometer has a number of display modes (functions)

that you can also activate (reveal) (see: Activating and deactivating display modes).

OPERATION INSTRUMENTS

- 10 -

ENGLISH

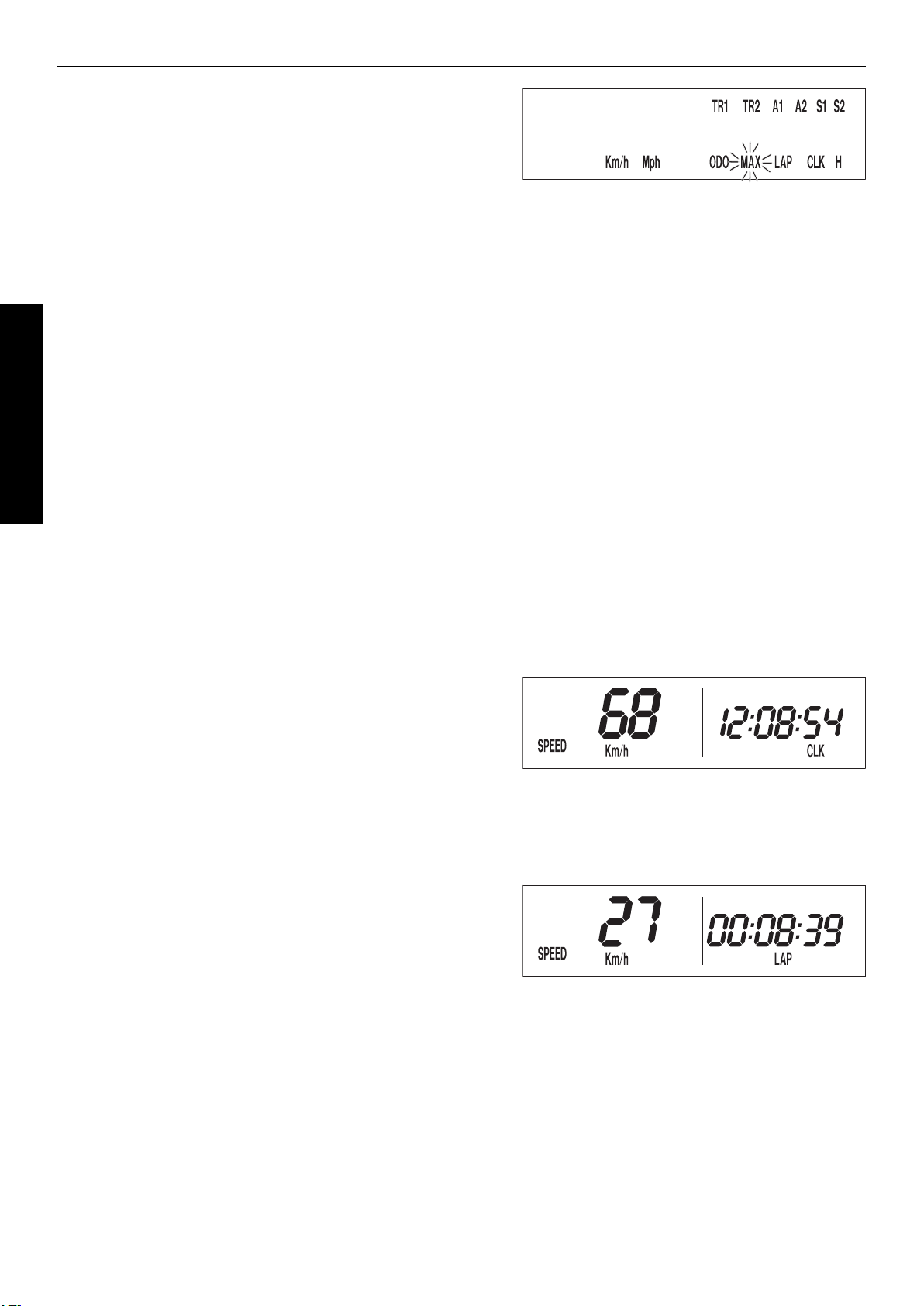

ACTIVATING AND DEACTIVATING DISPLAY MODES

In the display mode SPEED/H, press and hold the | button for 3 seconds

to access the SETUP menu. The active functions will be displayed. The

blinking function can be activated by pressing the + button and deactivated by pressing the – button.

Press and hold the | button 3 seconds to store the settings.

If no button is pressed for 20 seconds, the setting will be stored automatically and the display will return to the SPEED/H mode.

+ button activates the blinking display

– button deactivates the blinking display

briefly press | button changes to the next display without changing

any settings

hold | button 3 secs. starts the SETUP

stores the settings and changes to the SPEED/H

mode

The following display modes can be activated:

TR1 tripmaster 1

TR2 tripmaster 2

A1 average speed 1

A2 average speed 2

S1 stop watch 1

S2 stop watch 2

CLK clock

LAP lap time

MAX maximum speed

KMH/MPH display in kilometers or miles (see: Kilometers or miles)

If you have activated all of the display modes, they will be displayed in

the following order:

SPEED/H, SPEED/CLK, SPEED/LAP, LAP/LAP, SPEED/MAX,

SPEED/ODO, SPEED/TR1, SPEED/TR2, SPEED/A1, SPEED/A2,

SPEED/S1, SPEED/S2

SPEED / CLK (TIME) DISPLAY MODE

CLK displays the time in hours, minutes and seconds.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. set the clock menu

To set the clock, see „Setting the clock“.

SPEED / LAP (LAP TIME) DISPLAY MODE

You can use the manual stop watch to stop and store up to 10 lap times,

which you can view in the LAP/LAP display mode (see below).

LAP displays the lap times in hours, minutes and seconds.

+ button Starts and stops the stop watch, lap time is not

reset to 0

– button Stops the stop watch, stores the lap time and

restarts the stop watch again. The time is reset

to 0. Atotal of 10 lap times can be stored. If the

lap time continues to run after you press the button, all 10 memory locations are occupied.To

clear all of the stored lap times, hold the | but

ton for 3 seconds in the SPEED/LAP mode.Up

to 10 lap times can be stored in this way.

briefly press | button Changes to the next display mode.If no lap time

is stored or the motorcycle is driving, the

LAP/LAP mode will be skipped.

hold | button 3 secs. Clears all LAP figures

OPERATION INSTRUMENTS

- 11 -

ENGLISH

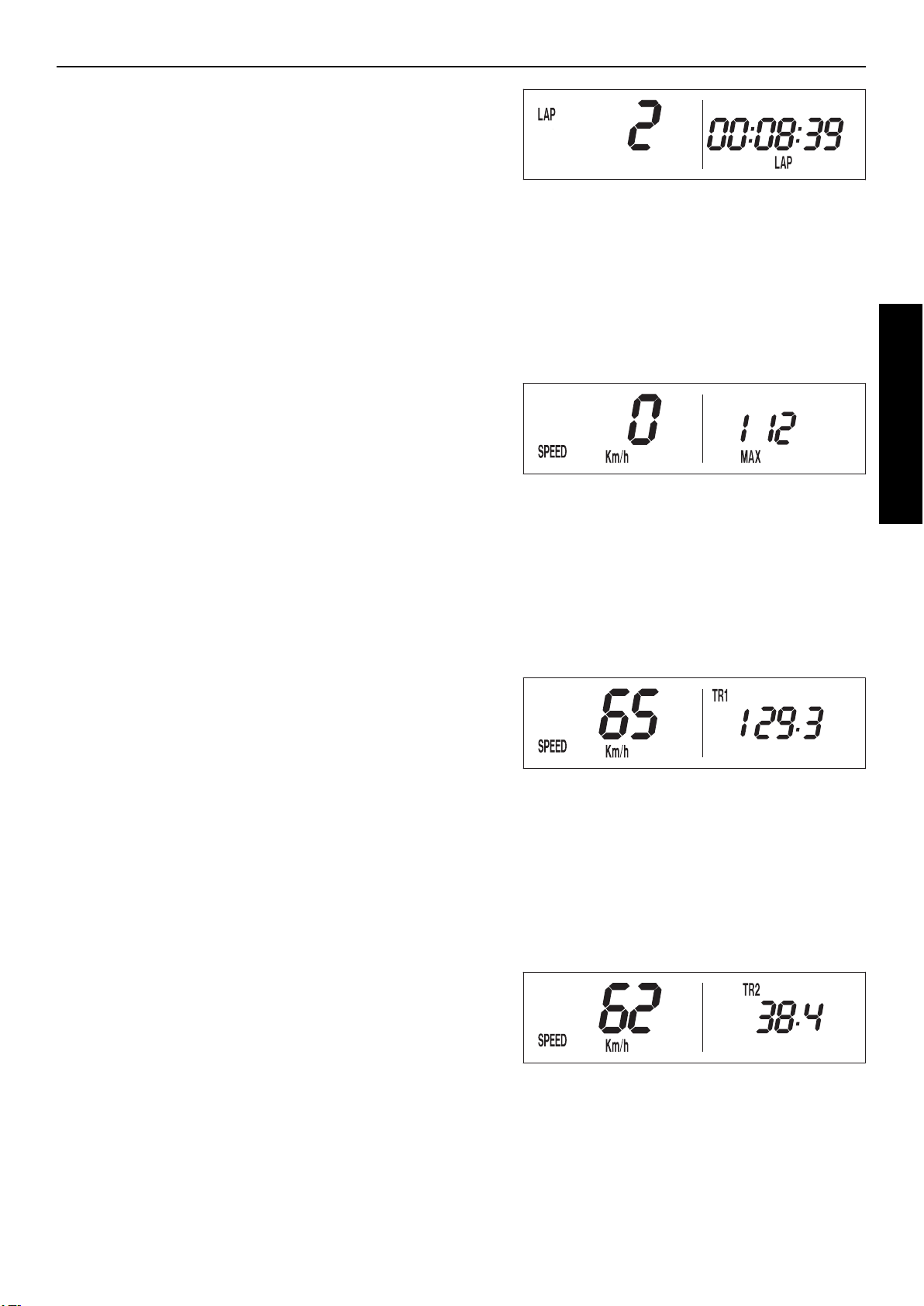

LAP / LAP DISPLAY MODE (TO VIEW LAP TIMES)

The LAP/LAP display mode will only be shown if lap times have been stored and the front wheel has stopped. It will display the lap number and

the stopped lap time in hours, minutes and seconds. Press the + button

to access the next lap time.

To clear all of the stored lap times, hold the | button for 3 seconds in the

SPEED/LAP mode.

+ button changes to the next lap time

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. changes to the next display mode

SPEED / MAX DISPLAY MODE (MAXIMUM SPEED)

MAX displays the maximum speed traveled and is always active.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. clears the MAX figure

SPEED / TR1 DISPLAY MODE (TRIPMASTER 1)

The TR1 tripmaster is always active and counts to 999.9. It is used to

measure the length of a trip or the distance between 2 refueling stops.

TR1 is linked to A1 (average speed 1). The calculation of these figures

is activated by the first impulse received from the wheel sensor (when

the front wheel starts to turn) and stops 3 seconds after the last impulse

is received (when the front wheel has stopped).

The TR1, A1 and S1 figures are automatically cleared after passing 999.9.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. clears the TR1, S1, A1 figures

SPEED / TR2 DISPLAY MODE (TRIPMASTER 2)

The tripmaster 2 is always active and counts to 999.9. Contrary to TR1,

the displayed figure can be changed using the + and – buttons. This is a

very useful function for trips taken according to a roadbook.

+ button increases the TR2 figure

– button decreases the TR2 figure

briefly press | button changes to the next display mode

hold | button 3 secs. clears the TR2 figure

OPERATION INSTRUMENTS

- 12 -

ENGLISH

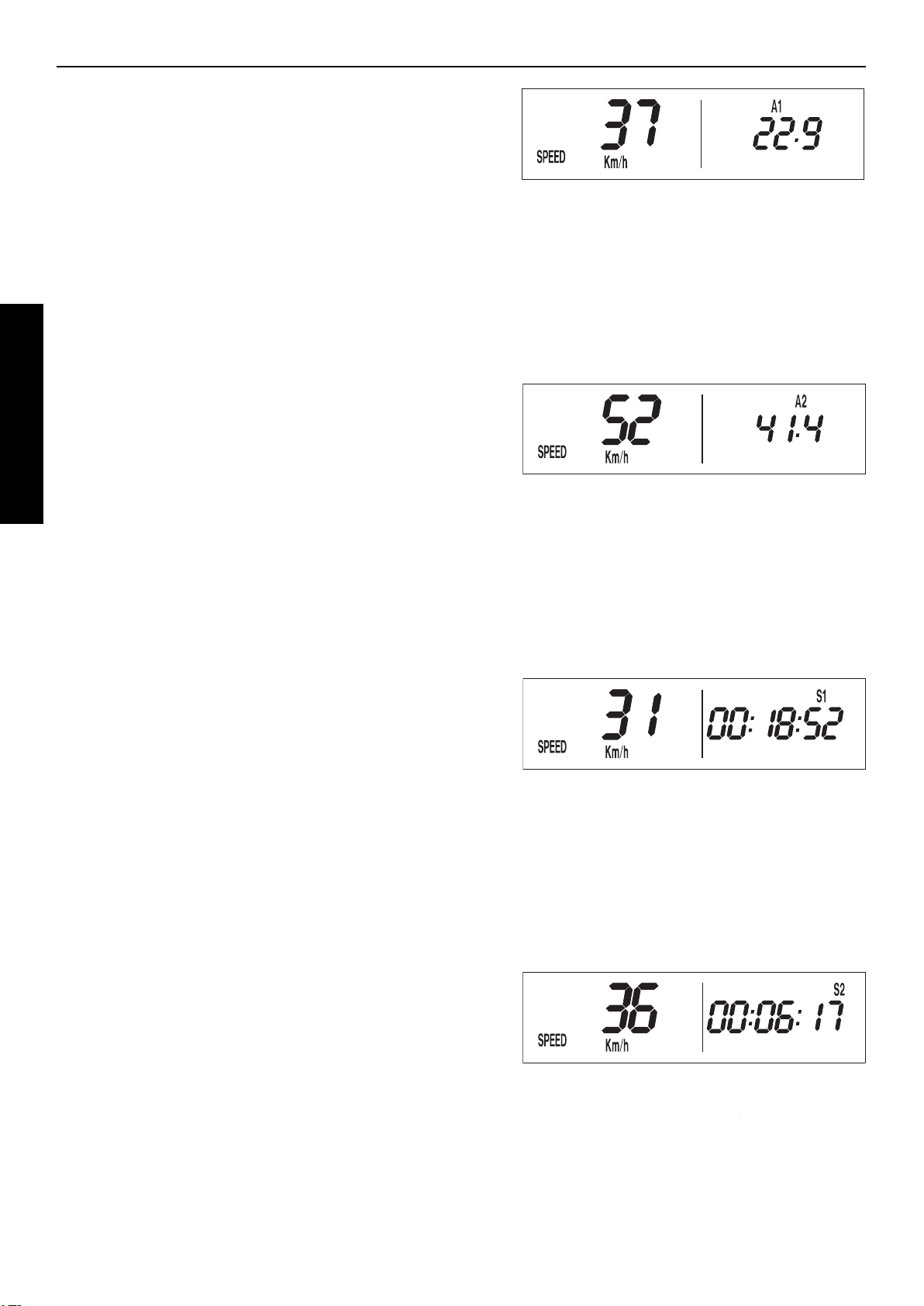

SPEED / A1 DISPLAY MODE (AVERAGE SPEED 1)

A1 shows the average speed based on the TR1 (tripmaster 1) and S1

(stop watch 1) figures. The calculation of this figure is activated by the

first impulse received from the wheel sensor and stops 3 seconds after

the last impulse is received.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. clears the TR1, S1, A1 figures

SPEED / A2 DISPLAY MODE (AVERAGE SPEED 2)

A2 shows the average speed based on the TR2 (tripmaster 2) and S2

(stop watch 2) figures.

The displayed figure can deviate from the actual average speed if the TR2

figure was changed manually or if S2 was not stopped after the trip.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. changes to the next display mode

SPEED / S1 DISPLAY MODE (STOP WATCH 1)

S1 shows the traveling time based on TR1 and continues to run whenever it receives impulses from the wheel sensor. The calculation of this figure

is activated by the first impulse received from the wheel sensor and stops

3 seconds after the last impulse is received.

+ button no function

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. clears the TR1, S1, A1 figures

SPEED / S2 DISPLAY MODE (STOP WATCH 2)

S2 is a manual stop watch. Start the stop watch by pressing the + button, press again to hold. Press again to continue timing.

Press the | button to change to the next mode. The S2 display will blink

in the other modes if S2 continues to run in the background. To stop S2,

return to the SPEED/S2 mode and press the + button.

+ button starts and stops the stop watch

– button no function

briefly press | button changes to the next display mode

hold | button 3 secs. clears the S2 figure

OPERATION INSTRUMENTS

- 13 -

ENGLISH

KILOMETERS OR MILES

The unit (kilometers or miles) can also be changed. The ODO figure will

be retained and converted accordingly. The TR1, A1, S1, TR2 and A2 figures will be cleared.

To select the unit, select the SPEED/H mode and hold the | button for

3 seconds to access the SETUP menu. Press the | button until the

KMH/MPH function blinks. Press the + button briefly to move to the

options. Press the + button for KMH or the – button for MPH.

To set, briefly press the | button 1 x and hold for 3 seconds until the display returns to the SPEED/H mode.

If no button is pressed for 20 seconds, the setting will be stored automatically and the display will return to the SPEED/H mode.

+ button to access the menu

to activate the KMH display

– button to activate the MPH display

briefly press | button changes to the next mode

changes from the menu to the SETUP menu

hold | button 3 secs. stores and closes the SETUP menu

SETTING THE CLOCK

To set the clock, switch the ignition off and select the SPEED/CLK mode.

Press and hold the | button for 3 seconds. The blinking digits can be

changed using the + and - buttons. Press the | button to move to the

next digit. 0-12 will show the time in the 12-hour mode, 0-24 in the 24hour mode.

Press and hold the | button for 3 seconds to store the settings.

If no button is pressed for 20 seconds, the settings will be stored automatically and the display will return to the SPEED/CLK mode.

+ button time +

– button time briefly press | button changes to the next digit

hold | button 3 secs. starts the SETUP menu

stores the time and changes to the SPEED/CLK

display mode

If the CLK, LAP, MAX, TR1, TR2 A1, A2, S1 and S2 figures are suddenly cleared, the battery in the electronic speedometer is empty

and must be replaced (see: Replacing the battery in the electronic speedometer).

A tripmaster switch is available as an accessory that lets you control the electronic speedometer functions from the handlebar.

Motorcycle is standing

Motorcycle is driving

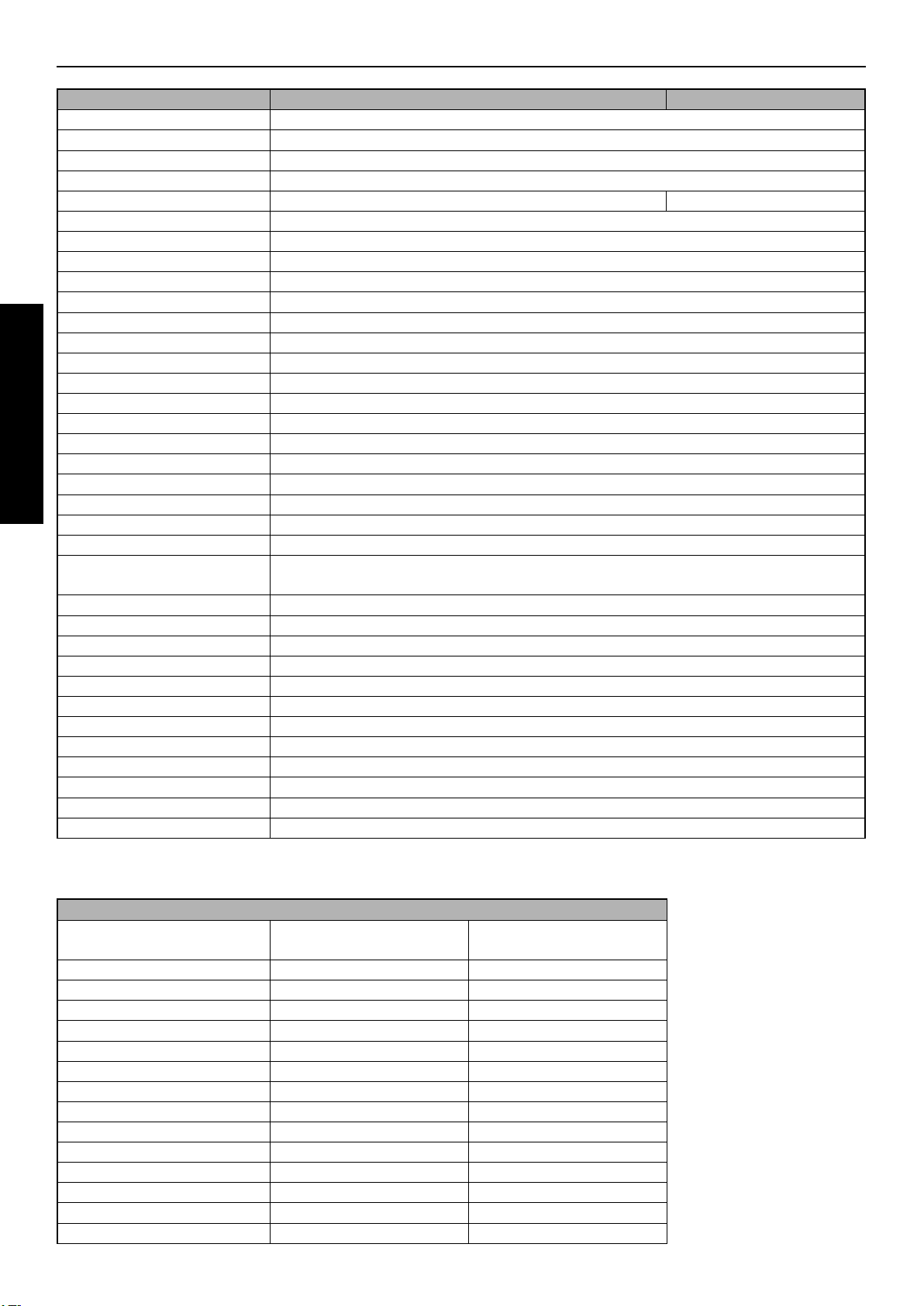

OVERVIEW OF THE ELECTRONIC SPEEDOMETER FUNCTIONS

display briefly press + button briefly press – button

briefly press |button hold |button 3 secs.

X

SPEED / H no function no function next display mode

displays the SETUP menu

X X

SPEED / CLK

no function no function next display mode Setting the clock menu

X X

SPEED /

LAP

starts/stops LAP without

clearing LAP figure

stops LAP, stores LAP

figure, resets LAP to 0

next display mode clears all LAP figures

X

LAP / LAP next figure no function next display mode next display mode

X X

SPEED / MAX

no function no function next display mode clears MAX

X

SPEED / ODO

no function no function next display mode next display mode

X X

SPEED / TR1

no function no function next display mode clears TR1, S1, A1

X X

SPEED / TR2

increases the TR2 figure

reduces the TR2 figure next display mode clears TR2

X X

SPEED / A1 no function no function next display mode clears TR1, S1, A1

X X

SPEED / A2 no function no function next display mode next display mode

X X

SPEED / S1 no function no function next display mode clears TR1, S1, A1

X X

SPEED / S2 starts - stops S2 no function next display mode clears S2

OPERATION INSTRUMENTS

- 14 -

ENGLISH

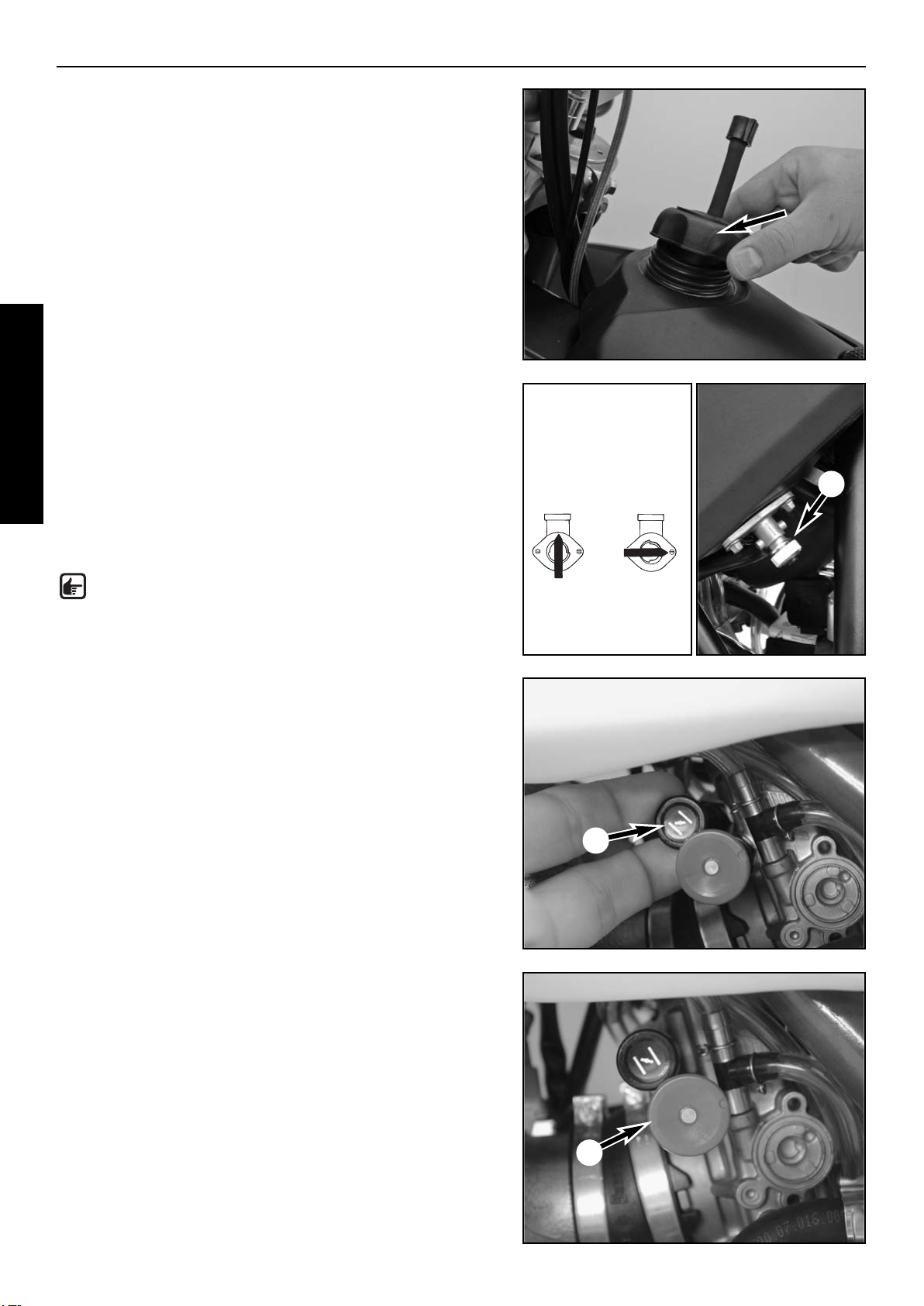

FILLER CAP

To open the filler cap: Turn the filler cap counter-clockwise.

To close the filler cap: Put the filler cap on and tighten it by turning

it clockwise.

Install the tank breather hose (1) without kinks.

FUEL TAPS

OFF The fuel tap is closed in this position. No fuel can flow to the

carburetor.

ON Turn the twist grip in the ON position to operate the motorcycle.

Now fuel can flow to the carburetor. The tank will drain

completely in this position.

A threaded fuel tap (1) is also located on the left side. No fuel can flow to

the carburetor if it is screwed-in. Fuel will flow to the carburetor if the fuel

tap is screwed-out.

NOTE: No RES function is available.

CHOKE

If you pull the choke button (2) out as far as possible, a bore in the

carburetor will be opened through which the engine may take in additional fuel. The result is a „fat“ fuel-air mixture of the type needed for cold

starts. To deactivate the choke, push the choke button back into its basic

position.

HOT START DEVICE

If you pull the hot start device (3) out as far as possible, a bore in the

carburetor will be opened through which the engine may take in additional air. The result is a „lean“ fuel-air mixture of the type needed for hot

starts.

To deactivate the hot start device, push the hot start button back into its

basic position.

3

2

ON

OFF

1

OPERATION INSTRUMENTS

- 15 -

ENGLISH

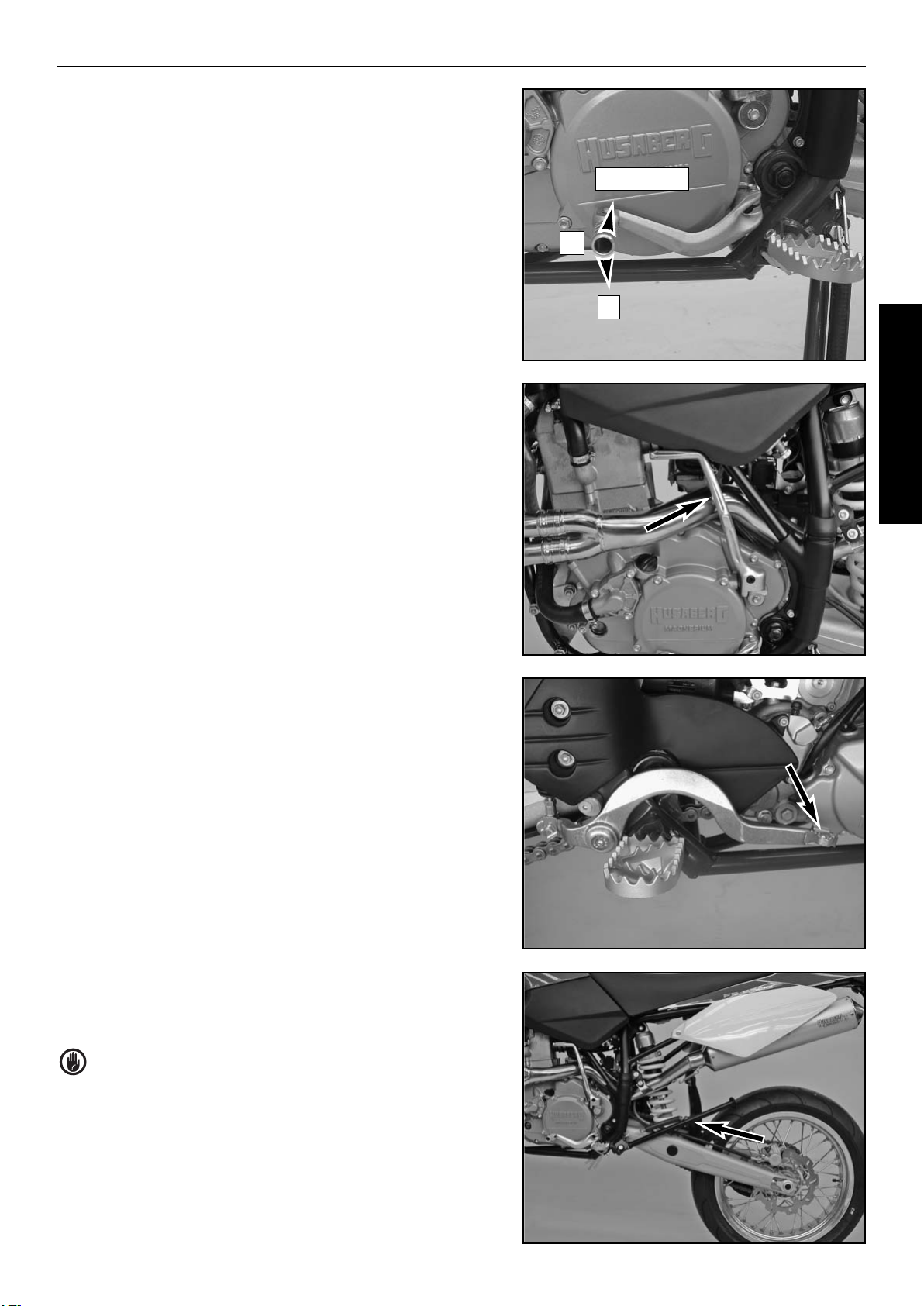

SHIFT LEVER

The shift lever is mounted on the left side of the engine. The

position of the gears is shown in the illustration. Neutral, or the idle speed,

is located between first and second gear.

KICKSTARTER

The kickstarter is located on the left side of the engine. The upper part is

tiltable.

FOOT BRAKE PEDAL

The foot brake pedal is located in front of the right footrest. Its basic position

can be adjusted to your seat position (see maintenance work).

SIDE STAND

Push the side stand to the ground with your foot and load it with the motorcycle. Make sure that you put your bike on solid ground and in a secure

position.

WARNING: The side stand swings up rapidly when the load

is released. Make sure you are not standing in the way.

2,3,4,5,6

1

N

OPERATION INSTRUMENTS

- 16 -

ENGLISH

COMPRESSION DAMPING OF FORK

Hydraulic compression damping determines the reaction when the fork

is compressed. The degree of compression can be adjusted with adjusting screws at the bottom of the fork legs.Remove the protecting cap (1).

Turn the adjusting screws (2) clockwise to increase damping, turn it counterclockwise to reduce damping during compression.

STANDARD ADJUSTMENT

– turn adjusting screw clockwise as far as it will go

– turn it back by as many clicks as are specified for the relevant type of

fork

Typ WP Suspension 14457B02...........21 clicks

Typ WP Suspension 14457B03...........15 clicks

REBOUND DAMPING OF FORK

Hydraulic rebound damping determines the reaction when the fork is

rebound. By turning the adjusting screw (3) (REB), the degree of

damping of the rebound can be adjusted. Turn the knob clockwise to

increase damping, turn it counterclockwise to reduce damping during

rebounding.

STANDARD ADJUSTMENT

– turn adjusting screw clockwise as far as it will go

– turn it back by as many clicks as are specified for the relevant type of

fork

Typ WP Suspension 14457B02...........20 clicks

Typ WP Suspension 14457B03...........12 clicks

1

2

2

3

3

OPERATION INSTRUMENTS

- 17 -

ENGLISH

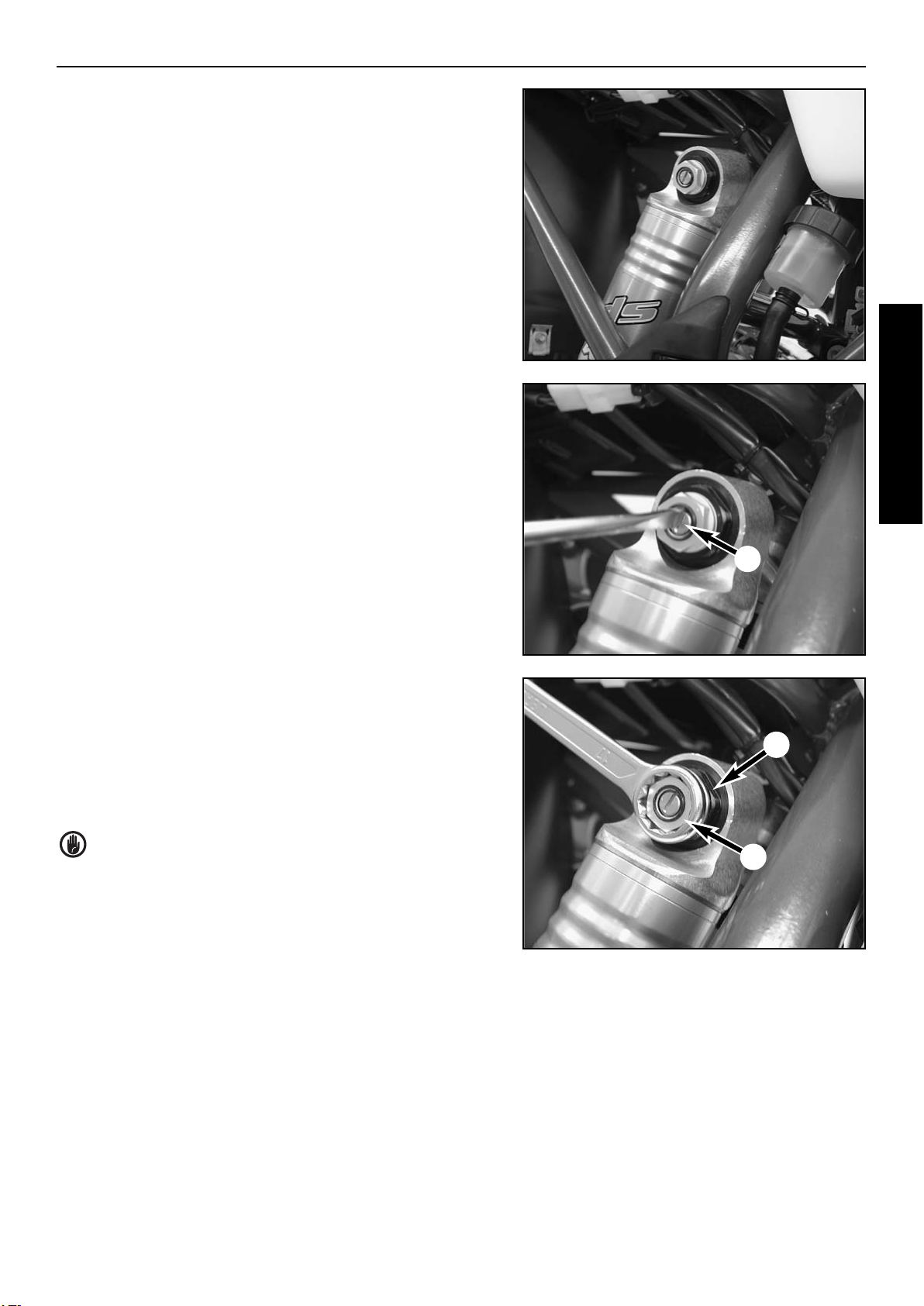

DAMPING ACTION DURING COMPRESSION OF

SHOCK ABSORBER

The shock absorber can synchronize the compression

damping in the low and high-speed range separately (Dual Compression

Control).

Low and high speed refers to the movement of the shock absorber during

compression and not to the speed of the motorcycle.

The low and high-speed technology overlaps.

The low-speed setting is primarily for slow to normal shock absorber

compression rates.

The high-speed setting is effective at fast compression rates.

Turning in a clockwise direction will increase the damping, turning

counterclockwise will decrease the damping.

STANDARD LOW-SPEED SETTING:

– turn the adjusting screw (1) to the limit in a clockwise direction using

a screwdriver .

– unscrew the respective number of clicks for the specific type of shock

absorber in a counterclockwise direction.

Typ WP Suspension 12457B02 ..........22 clicks

Typ WP Suspension 12457B03 ..........12 clicks

STANDARD HIGH-SPEED SETTING:

– turn the adjusting screw (2) to the limit in a clockwise direction using

a box wrench.

– unscrew the respective number of turns for the specific type of shock

absorber in a counterclockwise direction.

Typ WP Suspension 12457B02...........2 turns

Typ WP Suspension 12457B03...........2 turns

WARNING: The damping unit of the shock absorber is

filled with high-compression nitrogen. Never try to take the

shock absorber apart or to do any maintenance work yourself. Severe injuries could be the result. Never unscrew the black

screw connection (3) (24mm).

1

2

3

OPERATION INSTRUMENTS

- 18 -

ENGLISH

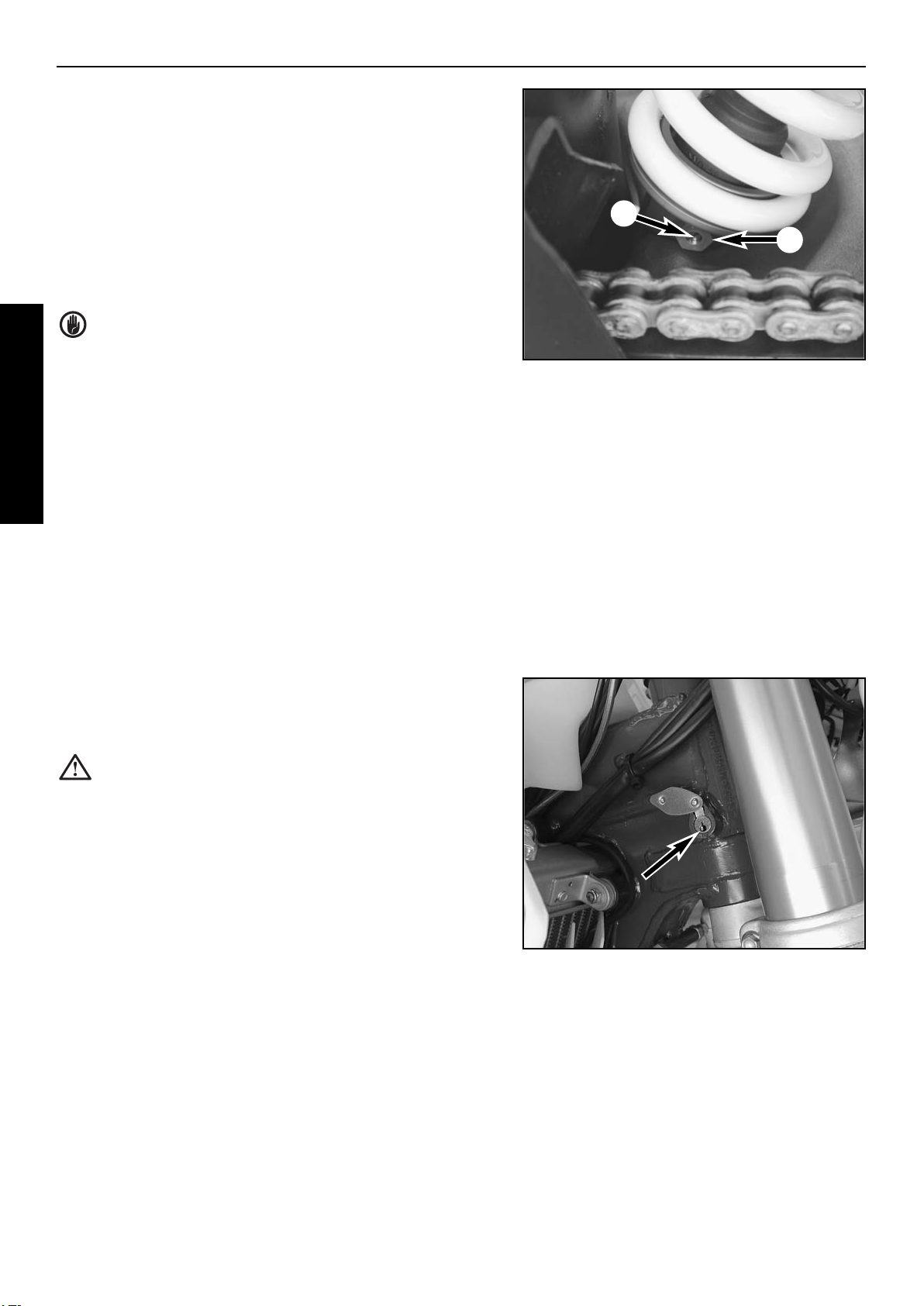

REBOUND DAMPING OF SHOCK ABSORBER

By using the adjusting screw (1), the degree of damping of the rebound

can be adjusted. Turn the knob clockwise to increase damping, turn it counterclockwise to reduce damping during rebounding.

STANDARD ADJUSTMENT:

– turn the adjusting screw clockwise to the stop.

– then turn the adjusting screw counterclockwise, counting the number

of clicks that corresponds to the respective type of shock absorber.

Typ WP Suspension 12457B02...........15 clicks

Typ WP Suspension 12457B03...........10 clicks

WARNING: The damping unit of the shock absorber is filled

with high-compression nitrogen. Never try to take the shock

absorber apart or to do any maintenance work yourself.

Severe injuries could be the result. Never unscrew the black

screw connection (2) (15mm).

STEERING LOCK

The lock mounted on the steering head locks the steering system. To lock,

turn the handlebar all the way to the left, insert the key, turn to the left,

press in, turn to the right and pull off the key.

CAUTION: Never leave the key inserted in the steering lock.

If you turn the handlebar to the right the key could get

damaged.

1

2

TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE

- 19 -

ENGLISH

INSTRUCTIONS FOR INITIAL OPERATION

– Verify that your Husaberg dealer performed the PREPARATION

OF VEHICLE jobs (see Customer Service Manual).

– Read these operating instructions carefully before your first ride.

– Familiarize yourself with the operating elements.

– Set the clutch lever, the handbrake lever, and the footbrake

pedal to the positions that are most convenient for you.

– Get used to handling the motorcycle on an empty parking lot

or open space, before starting on a longer drive. Also try to

drive as slowly as possible and in a standing position, to

improve your feeling for the vehicle.

– Do not drive along off-road tracks which go beyond your abitily

and experience.

– Hold the handlebars with both hands and leave your feet on

the foot rests while driving.

– Remove your foot from the foot brake lever when you are not

braking. If the foot brake lever is not released the brake pads

rub continuously and the braking system is over-heated.

– Do not make any alterations to the motorcycle and always use

ORIGINAL Husaberg SPARE PARTS. Spare parts from other

manufacturers can impair the safety of the motorcycle.

– Motorcycles are sensitive to alterations in the distribution of

weight. If you are taking luggage with you, this should be secu-

red as close as possible to the middle of the vehicle; distribute

the weight evenly between the front and rear wheel. Never

exceed the maximum permissible laden weight and the axle

weights. The maximum permissible laden weight is comprised

of the following components:

– Motorcycle ready for operation and tank full

– Luggage

– Driver with protective clothing and helmet.

– Pay attention to the running-in procedure.

RUNNING IN THE HUSABERG MODELS

Even very precisely machined sections of engine components

have rougher surfaces than components which have been sliding

across one another for quite some time. Therefore, every engine

needs to be broken in.

For this reason, do not load the engine more than 50% of its capacity during the first 3 operating hours. Besides, the engine speed

must not exceed 7000 rpm. Avoid going full-throttle!

In the following 12 operating hours, you may load the engine up

to 75% of its capacity. Use the motorcycle on various types of terrain (road, easy off-road trails).

CAUTION: The Husaberg models were uncompromi-

singly designed for off-road competition purposes

only. “On the road“ approved models FE/FS are only

allowed on public roads in the original homologated

(throttled) version. Avoid extended on-road rides at full

throttle.

WARNING: Wear suitable clothing when driving a

motorcycle. Clever Husaberg drivers always wear a helmet, boots, gloves and a jacket, regardless of whether

driving all day or just for a short trip. The protective

clothing should be brightly colored so that other

vehicles can see you as early as possible.

Always turn on the light to make sure that other drivers become aware of you as early as possible.

Do not drive after having consumed alcohol.

Only use accessories recommended by Husaberg. For

example, front panelling can impair the driving properties of the motorcycle. Cases, extra tanks, etc. can

alter the weight distribution and thus also impair the

vehicles driving properties.

The front and rear wheel may only be fitted with tires

that have the same profile type.

The Husaberg models are designed and dimensioned

for 1 person only. Never take another rider along.

Observe the traffic regulations, drive defensively and

try to look ahead as far as possible so that any hazards

can be recognized as early as possible.

Adjust your driving speed according to the conditions

and your driving skills.

Drive carefully on unknown roads or on unfamiliar

trials.

When driving off-road, always have a friend on a second

motorcycle to keep you company, so that you can help

each other should difficulties arise.

Replace the helmet visor or goggle lens when scratched or damaged. if bright light shines through a scratched visor or lens, the operator will be blinded.

Never leave your motorcycle without supervision if the

engine is running.

When riding your motorcycle, please bear in mind that

other people may feel molested by excessive noise.

DRIVING INSTRUCTIONS

- 20 -

ENGLISH

CHECK THE FOLLOWING BEFORE EACH START

When you start off, the motorcycle must be in perfect technical

condition. For safety reasons, you should make a habit of performing an

overall check of your motorcycle before each start.

The following checks should be performed:

1 CHECK THE OIL LEVEL

Insufficient oil results in premature wear and consequently to engine

damage. Too much engine oil will lead to higher oil consumption and

will clog the carburetor.

2 FUEL

Check that there is sufficient fuel in the tank; when closing the

filler cap, check that the tank venting hose is free of kinks.

3 CHAIN

A loose chain can fall from the chain wheels; an extremely worn chain

can tear, and insufficient lubrication can result in unnecessary wear

to the chain and chain wheels. Excessive tensioning of the chain will

put additional load on the components of the secondary drivetrain (chain,

bearings of transmission and rear wheel). Aside from resulting in premature wear, if worst comes to worst the chain may rupture or the countershaft of the transmission may break.

4 TIRES

Check for damaged tires. Tires showing cuts or dents must be replaced. The tread depth must comply with the legal regulations. Also check

the air pressure. Insufficient tread and incorrect air pressure deteriorate the driving performance.

5 BRAKES

Check correct functioning of the braking system. Check for

sufficient brake fluid in the reservoir. The reservoirs have been designed in such a way that brake fluid does not need to be refilled even

when the brake pads are worn. If the level of brake fluid falls below

the minimum value, this indicates a leak in the braking system or completely worn out brake pads. Arrange for the braking system to be checked by a Husaberg specialist, as complete failure of the braking system can be avoided.

Also check the state of the brake hose and the thickness of the brake

linings.

Check free travel at the hand brake lever and foot brake lever.

6 CABLES

Check correct setting and easy running of all control cables.

7 COOLING FLUID

Check the level of the cooling fluid when the engine is cold.

8 ELECTRICAL SYSTEM

Check correct functioning of headlamps, tail-lights, brake lights,

indicators, control lamps and horn while the engine is running.

9 LUGGAGE

If you are taking luggage with you, check that this is securely fastened.

10 REAR MIRROR

Checking the rear mirror setting.

DRIVING INSTRUCTIONS

- 21 -

ENGLISH

STARTING WHEN THE ENGINE IS COLD

1 Open the fuel taps (1).

2 Swing up the side stand or center stand.

3 Put the gear in neutral.

4 Operate the choke (2).

5 Leave throttle closed and kick the kickstarter briskly ALL THE WAY or

actuate the E-starter.

WARNING: If you want to start the engine, make sure that you

always put on sturdy motorcycle boots in order to avoid injuries. You might slip off the kickstarter, or the engine may kick

back and propel your foot upward with great force.

Always kick the kickstarter briskly all the way without opening the throttle. If you do not Kick hard enought, with an open

throttle grip, the kick-back hazard will be higher.

Do not start the engine and allow it to idle in a closed area.

Exhaust fumes are poisonous and can cause loss of consciousness and death. Always provide adequate ventilation

while the engine is running.

Always verify that the transmission has been set to idle (neutral) before actuating the starter button. If you start the

motorcycle with a gear engaged, the motorcycle will move

forward.

CAUTION: Be sure to kick up the side stand before you start

the engine to avoid any damage.

Maximal period for continuous starting: 5 seconds. Wait at

least 5 seconds before trying again.

Don’t ride your motorcycle with full load and don’t rev up the

engine when cold because the piston is warming up faster

than the water cooled cylinder and can cause engine damage.

NOTE: If it is difficult to start the engine, this could be due

to old fuel in the float chamber. The highly inflammable constituents in the new fuel volatilize if left standing over longer

periods of time. If the motorcycle was not used for over 1 week,

drain the old fuel from the float chamber. The engine will start

immediately after the float chamber is filled with fresh ignitable fuel.

STARTING WHEN THE ENGINE IS WARM

1 Open the fuel tap (1).

2 Swing up the side stand.

3 Put the gear in neutral.

4 Leave throttle closed and kick the kickstarter briskly ALL THE WAY or

actuate the E-starter.

NOTE: Pull the hot start knob if the engine won't start.

WHAT TO DO WHEN THE ENGINE IS “FLOODED”

In the event of a fall, more fuel than necessary may get into the engine.

In order to "pump the engine free", pull the hand decompression lever,

fully rev up the engine, actuate the kickstarter 5 to 10 times or actuate

the E-starter 2 times for 5 seconds each. Then, start the engine as described above.

If the engine fails to start, unscrew the spark plug and dry it.

NOTE: The carburetor has an accelerator pump. Every time

you open the throttle, fuel will be injected into the intake passage. When starting, be sure that you open the throttle completely only once.

2

1

1

DRIVING INSTRUCTIONS

- 22 -

ENGLISH

BRAKING

Close the throttle and apply the hand and foot brake simultaneously. Be especially careful when applying the brakes on sandy,

wet or slippery surfaces. Always brake with feeling, locked wheels

will cause the motorcycle to skid or crash. Always shift down the

gears in accordance with the speed. Always finish braking before

you enter a curve.

When driving down hill, use the braking effect of the engine.

Change down one or two gears but do not overspeed the engine.

In this way, you will not need to brake so much and the brakes will

not overheat.

WARNING: In case of rain, after washing the motorcy-

cle, after rides through water and in case of rides on

wet off-road tracks, humid or dirty brake discs can delay

the braking effect. The brakes must be pulled until

they are dry or clean.

Rides on salt-strewed or dirty roads can also delay the

braking effect. The brakes must be pulled until they

are clean.

Dirty brake discs cause increased tear of brake pads

and brake discs.

When you brake, the brake discs, brake pads, brake

caliper and brake fluid heat up. The hotter these parts

get, the weaker the breaking effect. In extreme cases,

the entire braking system can fail.

If the resistance in the hand brake lever or foot brake

pedal feels “spongy” (too much play), this is an indication that something is wrong with the brake system.

Don’t ride your motorcycle anymore without first having

the brake system looked over by a Husaberg dealer.

STARTING OFF

Pull the clutch lever, engage 1st gear, slowly release the clutch

lever while you open the throttle.

WARNING: Always make sure the side stand is folded

all the way up before driving off. The motorcycle can

go out of control if the side stand touches the ground.

SHIFTING/RIDING

You are now in first gear, refered to as the drive or uphill gear. Depending on the conditions (traffic, hill size, etc.), you can shift to a higher gear. Close throttle, at the same time pull clutch lever in and

shift to the next higher gear. Let clutch lever go again and accelerate. If you turned on the choke, make sure you turn it off again

as soon as engine is warm.

When you reach full speed through opening the throttle all the way,

turn throttle back to 3/4; the speed hardly decreases although the

engine will use less gas. Only give as much gas as the engine

can handle. Through quick and high revving of the throttle, the fuel

usage increases.

By shifting down, use the brakes if necessary and close the throttle

at the same time. Pull the clutch lever and shift down to the next

gear. Let clutch lever go slowly and open the throttle or shift down

again

NOTE: Dedicated to nothing but offroad racing, Hus-

aberg models make no compromises in their design.

As such, they do not include any radiator fan, and the

size of the radiator is dimensioned for optimum ergonomics. In normal racing, the cooling system is sufficient. If you use your motorbike in other conditions,

please note that: the E-starter allows you to start FS

models again at any time. Therefore, turn off the engine

if you intend to run your motorcycle in idle or at a standstill for longer periods of time (more than 2 minutes).

Avoid letting the clutch slip frequently and for extended periods. This would cause the engine oil to heat

up, thereby heating up the cooling system. You should

drive at low speeds (4-stroke style - letting the engine

pull you) and not at high speeds not by letting the clutch

slip (2-stroke style).

WARNING: After falling with the motorcycle, check all

functions thoroughly before starting up operations

again.

A twisted handlebar must always be replaced. Do not

adjust the handlebar, it will lose stability.

CAUTION: High rpm rates when the engine is cold

have an adverse effect on the life of your engine. We

recommend you run the engine in a moderate rpm

range for a few miles giving it a chance to warm up.

After that no further precautions in this respect need

to be taken. The engine has reached its operating temperature as soon as the radiators become warm.

Never have the throttle wide open when changing

down to a lower gear. The engine will over-rev, damaging the valves. In addition, the rear wheel locks so

that the motorcycle can easily get out of control.

If any abnormal vibrations occur while driving, check

that the engine fastening bolts are tight.

In the event that, while riding on your motorcycle, you

notice any unusual operation-related noise, stop immediately, turn the engine off, and contact an authorized

Husaberg dealer.

DRIVING INSTRUCTIONS

- 23 -

ENGLISH

STOPPING AND PARKING

Decelerate and switch the engine into neutral. To switch off the engine at

idling speed, press the short-circuit switch or the emergency off switch

until the engine is off. Close the fuel taps, park the motorcycle on a firm

surface and lock.

WARNING: Motorcycle engines produce a great amount of heat

while running. The engine, exhaust pipe, muffler, brake rotors,

and shock absorbers can become very hot. Do not touch any

of these parts after operating the motorcycle, and take care

to park it where pedestrians are not likely to touch it and get

burned.

CAUTION: Do not use the hand decompressor lever to switch

off the engine. Always use the short-circuit switch, the emergency off switch.

Close the fuel tap when leaving your vehicle.Otherwise the

carburettor can flood and fuel will enter the engine.

Never park your motorcycle in places where there are fire

hazards due to dry grass or other easily flammable

materials.

NOTE REGARDING THE SIDE STAND: Use your foot to kick

side stand forward up to the stop and lean the motorcycle

sideways. Make sure that the ground is solid and that your

motorcycle is standing securely. Just in case, you can shift

into first gear.For off-road riding, you can use the rubber

band to additionally secure the center stand in its folded-up

position

CAUTION: The side stand is designed to bear only the load

of the motorcycle. The side stand and/or the frame can be

damaged and the motorcycle can fall over if you mount the

motor-cycle, thus putting an additional load on the side stand.

FUEL

The engine needs unleaded fuel with at least RON 95 (USA = Premium

RON 91).

CAUTION: Use leaded or unleaded premium grade gasoline

(95 octanes). Never use gasoline having less than 95 octanes because it may damage the engine.

WARNING: Gasoline is highly flammable and poisonous.

Extreme caution should be used when handling gasoline. Do

not refuel the motorcycle near open flames or burning cigarettes. Always switch off the engine before refuelling. Be

careful not to spill gasoline on the engine or exhaust pipe while

the engine is hot. Wipe up spills promptly. If gasoline is swallowed or splashed in the eyes, seek a doctor’s advice immediately.

Fuel expands when its temperature rises. Therefore do not fill the tank to

the top (see fig.).

35 mm

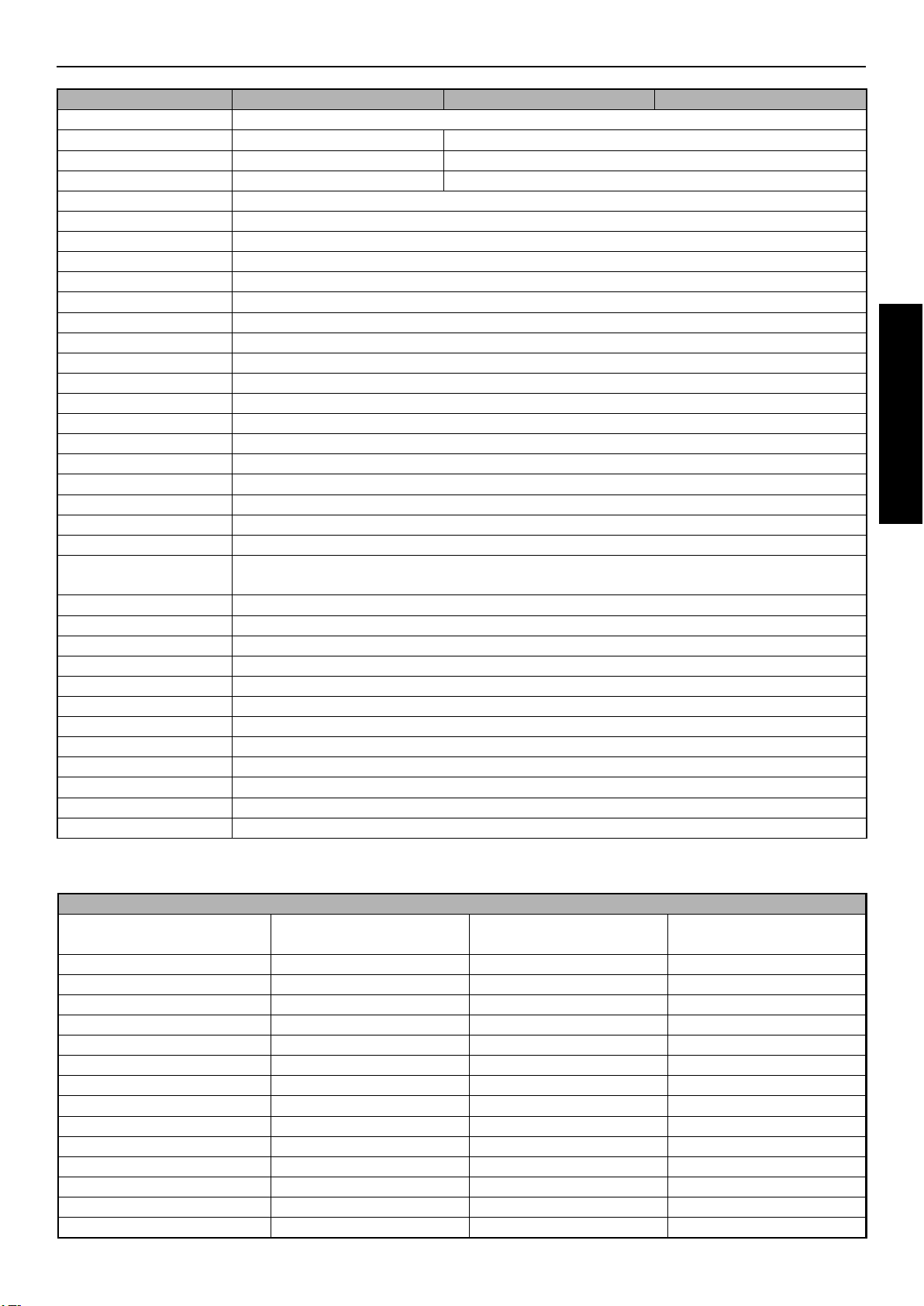

PERIODIC MAINTENANCE SCHEDULE

- 24 -

ENGLISH

FE 450,550,650 e/6, FS 450,650 e/6

A clean motorcycle can be checked more quickly which saves money!

1. service after

3 hours or

20 l fuel

after/every

15 hours or

100 l fuel

ENGINE

Change engine oil and oil filter

z z

Clean oil screen and drain plug magnet

z z

Replace spark plug (after 30 hours)

Check and adjust valve clearance

z z

Check engine mounting bolts for tightness

z z

CARBURETOR

Check carburetor connection boot for cracks and leaks

z

Check idle speed setting

z z

Check vent hoses for damage or bends

z z

ADD-ON-PARTS

Check cooling system for leaks, check quantity of antifreeze

z z

Check exhaust system for leaks and fitment

z

Check cables for damage, smooth operation and bends adjust and lubricate

z z

Check fluid level of the clutch master cylinder

z z

Clean air filter and filter box

z

Check electric wires for damage and bends

z

Check headlamp setting

z

Check function of electric systems (low high beam, brake light, indicator lamps,

speedometer illumination, horn, emergency OFF switch or button

z z

BRAKES

Check brake fluid level, lining thickness, brake discs

z z

Check brake lines for damage and leaks

z z

Check function and smooth operation and adjust free travel of handbrake/foot brake lever

z z

Check tightness of brake system screws

z z

CHASSIS

Check shock absorber and fork for leaks and function

z z

Clean fork dust bellows

z

Bleed fork legs

z

Check swing arm bearings

z

Check/adjust steering head bearings

z z

Check tightness of chassis screws (triple clamps, fork leg axle passage)

z z

WHEELS

Check spoke tension and rim joint

z z

Check tires and air pressure

z z

Check chain, chain joint, rear sprockets and chain guides for wear, fit and tension

z z

Lubricate chain

z z

Check clearance of wheel bearings

z z

IMPORTANT RECOMMENDED MAINTENANCE WORK THAT CAN BE CARRIED OUT BY EXTRA ORDER

at least

once a year

Complete maintenance of fork

z

Complete maintenance of shock absorber

z

Clean and grease steering head bearings and gasket elements

z

Clean and adjust carburetor

z

Replace glass fibre yarn filling of the exhaust main silencer

z

Treat electric contacts and switches with contact spray

z

Treat battery connections with contact grease

z

Change hydraulic clutch fluid

z

Change brake fluid

z

IF MOTORCYCLE IS USED FOR COMPETITION 15 HOURS SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE.

Service intervalls should never be exceeded by more than 2 hours or 15 liters of fuel.

Maintenance work done by Husaberg authorised workshops is not a substitute for care and checks done by the rider.

PERIODIC MAINTENANCE SCHEDULE

- 25 -

ENGLISH

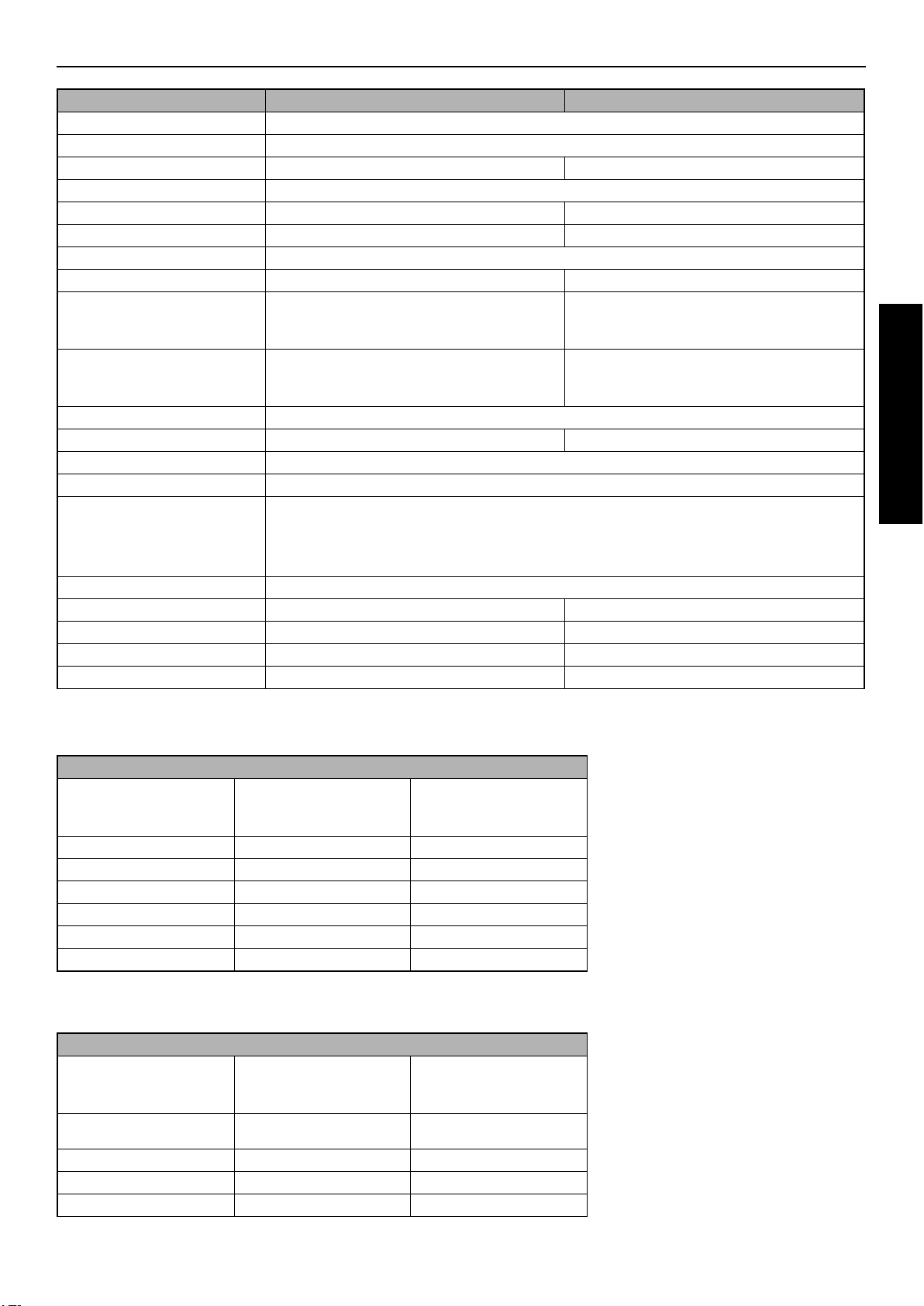

IMPORTANT CHECKS AND MAINTENANCE TO BE CARRIED OUT BY THE RIDER

Before each

start

After every

cleaning

For cross-

country use

Check oil level

z

Check brake fluid level

z

Check brake pads for wear

z

Check lights for function

z

Check horn for function

z

Lubricate and adjust cables and nipples

z

Bleed fork legs regularly

z

Remove and clean fork dust bellows regularly

z

Clean and lubricate chain, check tension and adjust if necessary

z z

Clean air filter and filter box

z

Check tires for pressure and wear

z

Check cooling fluid level

z

Check fuel lines for leaks

z

Drain and clean float chamber

z

Check all control elements for smooth operation

z

Check brake performance

z z

Treat blank metal parts (with the exception of brake and exhaust system) with

wax-based anti corrosion agent

z

Treat ignition and steering locks and light switches with contact spray

z

Check tightness of screws, nuts and hose clamps regularly

z

RECOMMENDED INSPECTION OF THE HUSABERG - ENGINES USED FOR HOBBY-ENDURO COMPETITIONS BY YOUR

HUSABERG WORKSHOP (ADDITIONAL ORDER FOR THE HUSABERG WORKSHOP)

a 100 liter fuel consumption is equivalent to approx.

15 operating hours

30

hours

200

liter

60

hours

400

liter

90

hours

600

liter

120

hours

800

liter

180

hours

1200

liter

240

hours

1600

liter

270

hours

1800

liter

Check the clutch disks for wear

z z z z z z z

Check the length of the clutch springs

z z z z z z

Check the cylinder and piston for wear

z z z

Check the groove on the piston pin retainer for wear

(visual check)

z z z

Check the camshaft for wear (visual check)

z z z

Check the camshaft bearings

z z z

Check the length of the valve springs

z z z

Check the spring cap for wear

z z z

Check the eccentricity of the valve disk

z z z

Check the valve guides for wear

z z z

Check the radial clearance of the rocker arm rollers

z z z

Check the elongation of the timing chain

z z z

Check the chain tensioner tooting for damage

(visual check)

z z z z z z

Check the eccentricity of the crankshaft journal

z z z

Replace the conrod bearings

z z z

Check piston pin bearing

z z z

Replace the balancer shaft bearings

z z z

Replace the crankshaft main bearings

z z z

Check the entire transmission including the roller

and bearings for wear

z z z

PERIODIC MAINTENANCE SCHEDULE

- 26 -

ENGLISH

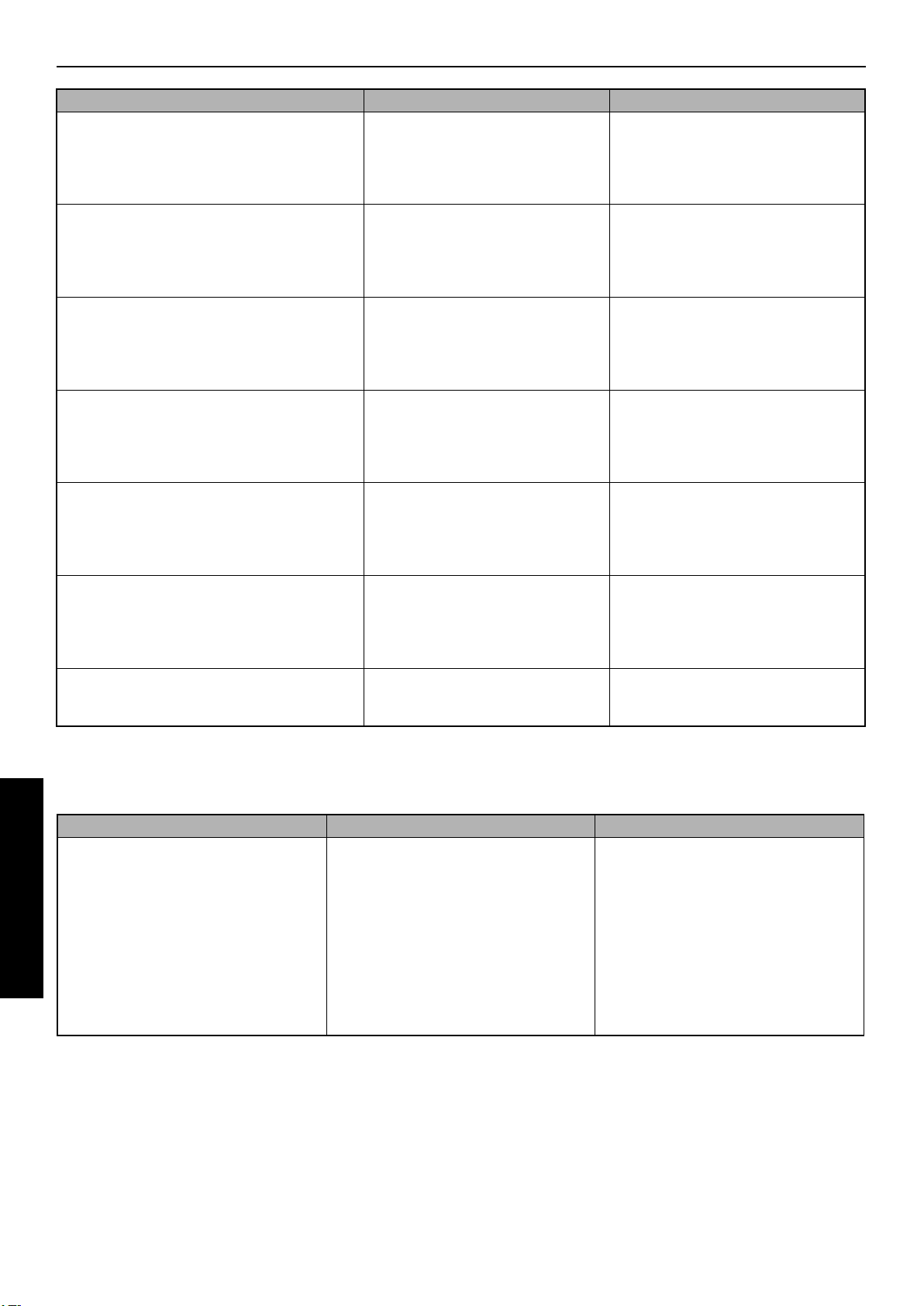

RECOMMENDED INSPECTION OF THE HUSABERG - ENGINES USED FOR ENDURO COMPETITIONS BY YOUR HUSABERG WORKSHOP (ADDITIONAL ORDER FOR THE HUSABERG WORKSHOP)

a 100 liter fuel consumption is equivalent to approx.

15 operating hours

15

hours

100 liter

30

hours

200 liter

45

hours

300 liter

60

hours

400 liter

90

hours

600 liter

120

hours

800 liter

135

hours

900 liter

Check the clutch disks for wear

z z z z z z z

Check the length of the clutch springs

z z z z z z

Check the cylinder and piston for wear

z z z

Check the groove on the piston pin retainer for wear

(visual check)

z z z

Check the camshaft for wear (visual check)

z z z

Check the camshaft bearings

z z z

Check the length of the valve springs

z z z

Check the spring cap for wear

z z z

Check the eccentricity of the valve disk

z z z

Check the valve guides for wear

z z z

Check the radial clearance of the rocker arm rollers

z z z

Check the elongation of the timing chain

z z z

Check the chain tensioner tooting for damage

(visual check)

z z z z z z

Check the eccentricity of the crankshaft journal

z z z

Replace the conrod bearings

z z z

Check piston pin bearing

z z z

Replace the balancer shaft bearings

z z z

Replace the crankshaft main bearings

z z z

Check the entire transmission including the roller and

bearings for wear

z z z

PERIODIC MAINTENANCE SCHEDULE

- 27 -

ENGLISH

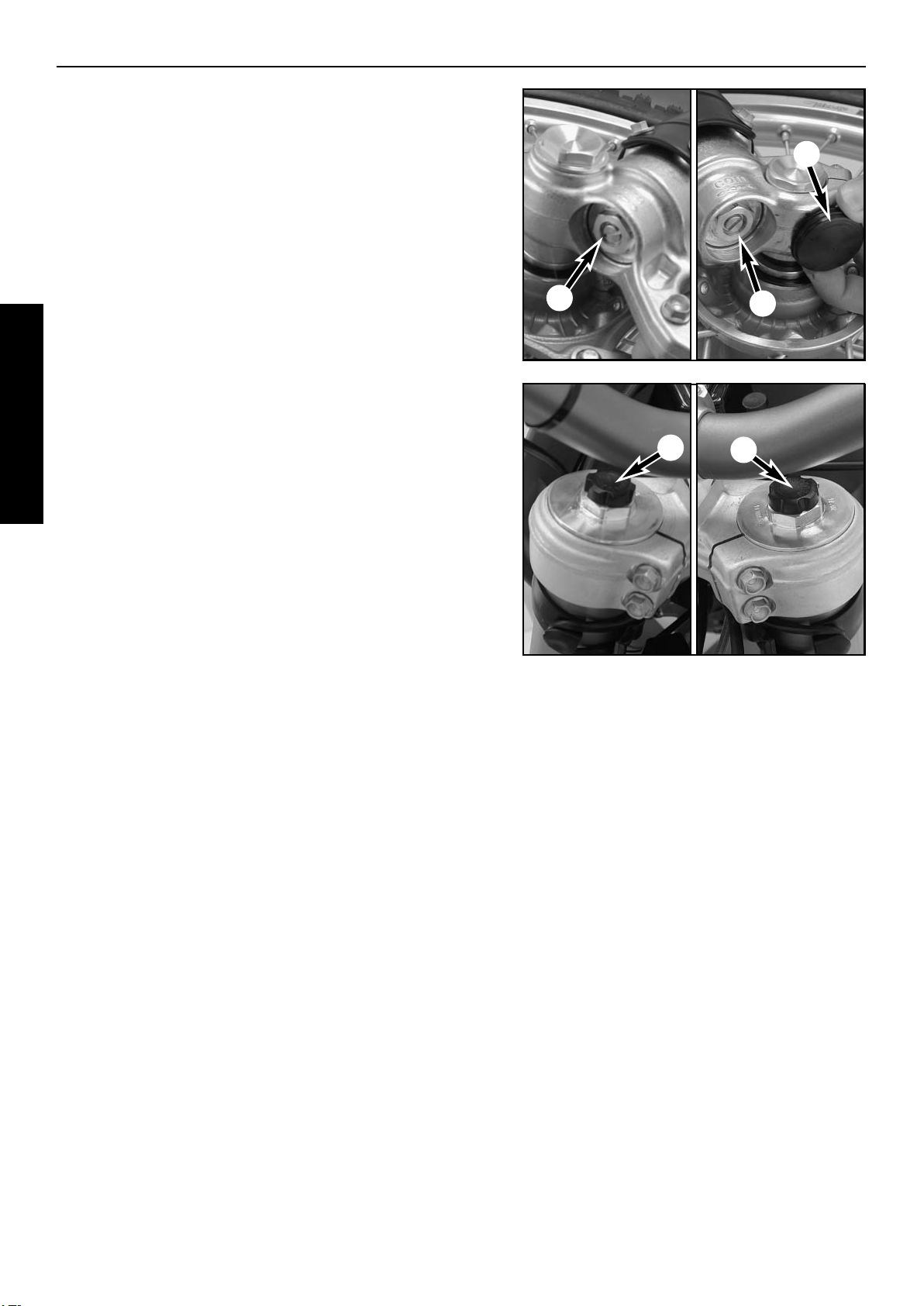

CHECKING AND ADJUSTING THE STEERING HEAD

BEARING *

The steering head bearing should be checked regularly for play. For this

purpose, jack up the motorcycle by the frame so that the front wheel is in

the air. Now try to move the fork forward and backward. There should be

no clearance. For readjustment, release the 4 clamp screws (1) of the

top triple clamp and the steering head nut (2). Turn the adjusting nut (3)

until almost no play is left. Do not tighten the adjusting nut! Tightening the

adjusting nut can damage the bearings! Keep in mind that tightening the

steering head nut (2) reduces the play of the bearing. Slightly tap the top

triple clamp with a rubber hammer to prevent jamming. Then tighten the

4 clamp screws with 20 Nm(FE)/ 17 Nm(FS).

WARNING: If the steering head bearing is not adjusted to be

free of play, the motorcycle will exhibit unsteady

driving characteristics and can get out of control.

CAUTION: If you drive with play in the steering head

bearing for longer periods, the bearings and subsequently

the bearing seats in the frame will be destroyed.

The steering head bearings should be regreased at least once a year (e.g.

Motorex Long Term 2000).

WARNING: MAINTENANCE AND ADJUSTING WORK MARKED WITH AN ASTERISK (*) REQUIRES EXPERT SKILLS

AND TECHNICAL KNOW-HOW. FOR YOUR OWN SAFETY, ALWAYS HAVE SUCH WORK PERFORMED BY A SPECIALIZED HUSABERG DEALER WHERE YOUR MOTORCYCLE WILL BE OPTIMALLY SERVICED BYAPPROPRIATELY QUALIFIED, SKILLED STAFF.

CAUTION: When cleaning the motorcycle, do not use a high pressure cleaning unit if possible, otherwise water will

penetrate the bearings, carburetor, electric connectors, etc.

When transporting your Husaberg, ensure that it is held upright with restraining straps or other mechanical fastening

devices and that the fuel tap is in the OFF position - if the motorcycle should fall over, no fuel can leak from the carburetor or fuel tank

Do not use toothed washers or spring rings with the engine fastening screws, as these work into the frame parts and

keep working loose. Instead, use self-locking nuts.

Let your motorcycle cool down before beginning any maintenance work in order to avoid getting burned.

Dispose oils, fatty matters, filters, fuels, washing detergents etc. properly.

Under no circumstances may used oil be disposed of in the sewage system or in the open countryside.

1 liter of used oil contaminates 1,000,000 liters of water.

1

2

3

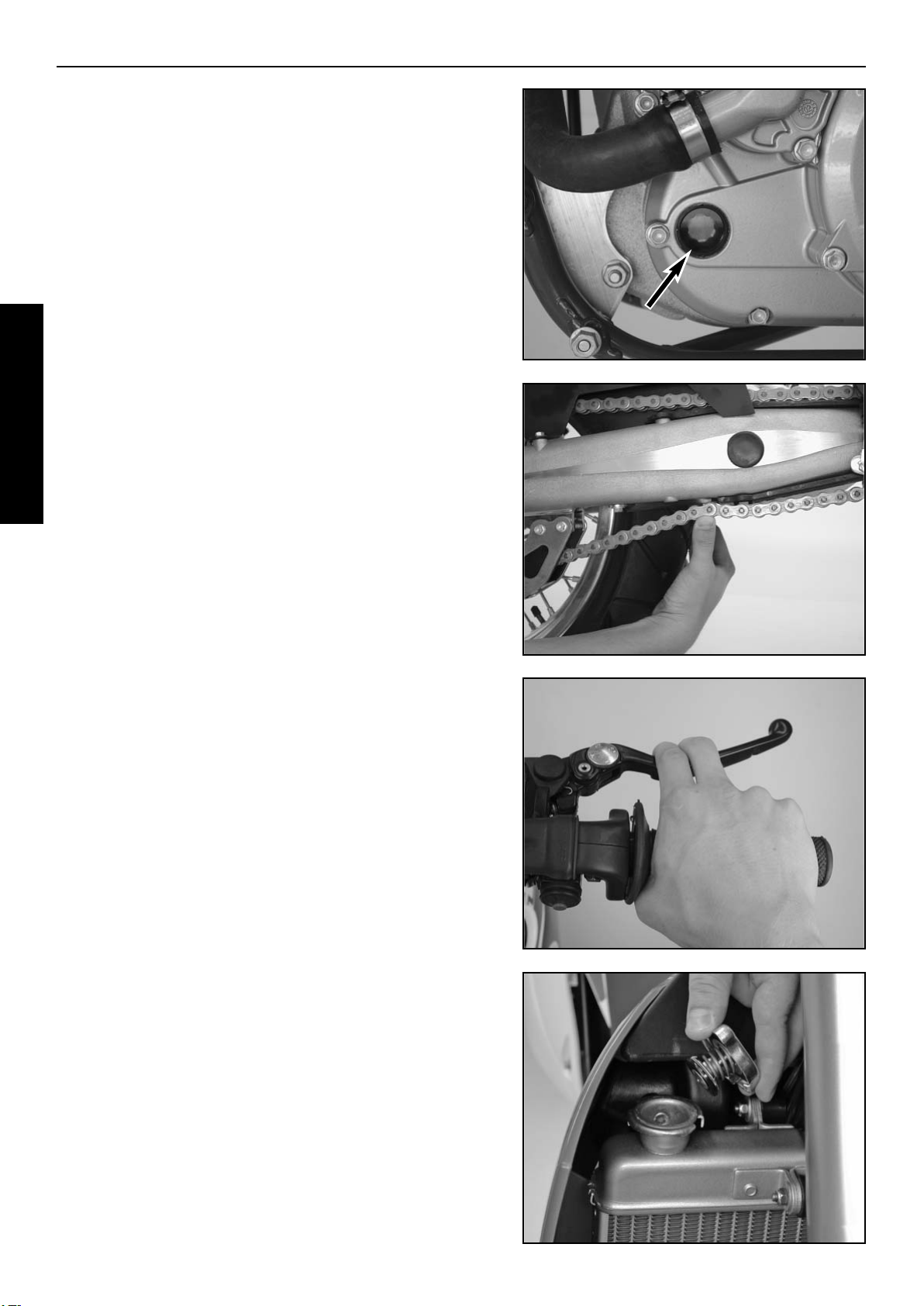

BREATHER PLUG FRONT FORK

After every 5 hours of use for competitive racing, slacken the breather

plugs (1) a few turns in order to relieve excess pressure from the inside

of the fork. To do this, place the motorcycle on a stand with the front wheel

lifted off the ground. When riding the motorcycle mainly on the road, it will

suffice to have this job performed in the course of the periodical maintenance service.

CAUTION: Excessive pressure in the interior of the fork can

cause leaks in the fork. If your fork is leaking, it is recommended

to open the breather plugs before having the seals replaced.

CLEANING THE DUST SLEEVES OF THE TELESCOPIC FORK

The dust-protection bellows (2) are to remove dust and coarse dirt particles from the fork tube. However, after some time, dirt may also get in

behind the dust-protection bellows. If this dirt is not removed, the oil sealing rings located behind it may start to leak.

Use a screwdriver to lift the dust-protection bellows out of the outer tubes

and slide them downward.

Pry the dust boots out of the outer pipes with a screwdriver and slide down.

Clean dust boots, outer pipes and fork tubes thoroughly. Oil generously

with Universal oil spray (Motorex Joker 440) or engine oil. Press the dust

boots into the outer pipes by hand.

WARNING: No oil may reach the front tire or the brake disk

since this would considerably reduce the tire's road grip and

the braking effect of the front brake.

MAINTENANCE WORK ON CHASSIS AND ENGINE

- 28 -

ENGLISH

1

2

MAINTENANCE WORK ON CHASSIS AND ENGINE

- 29 -

ENGLISH

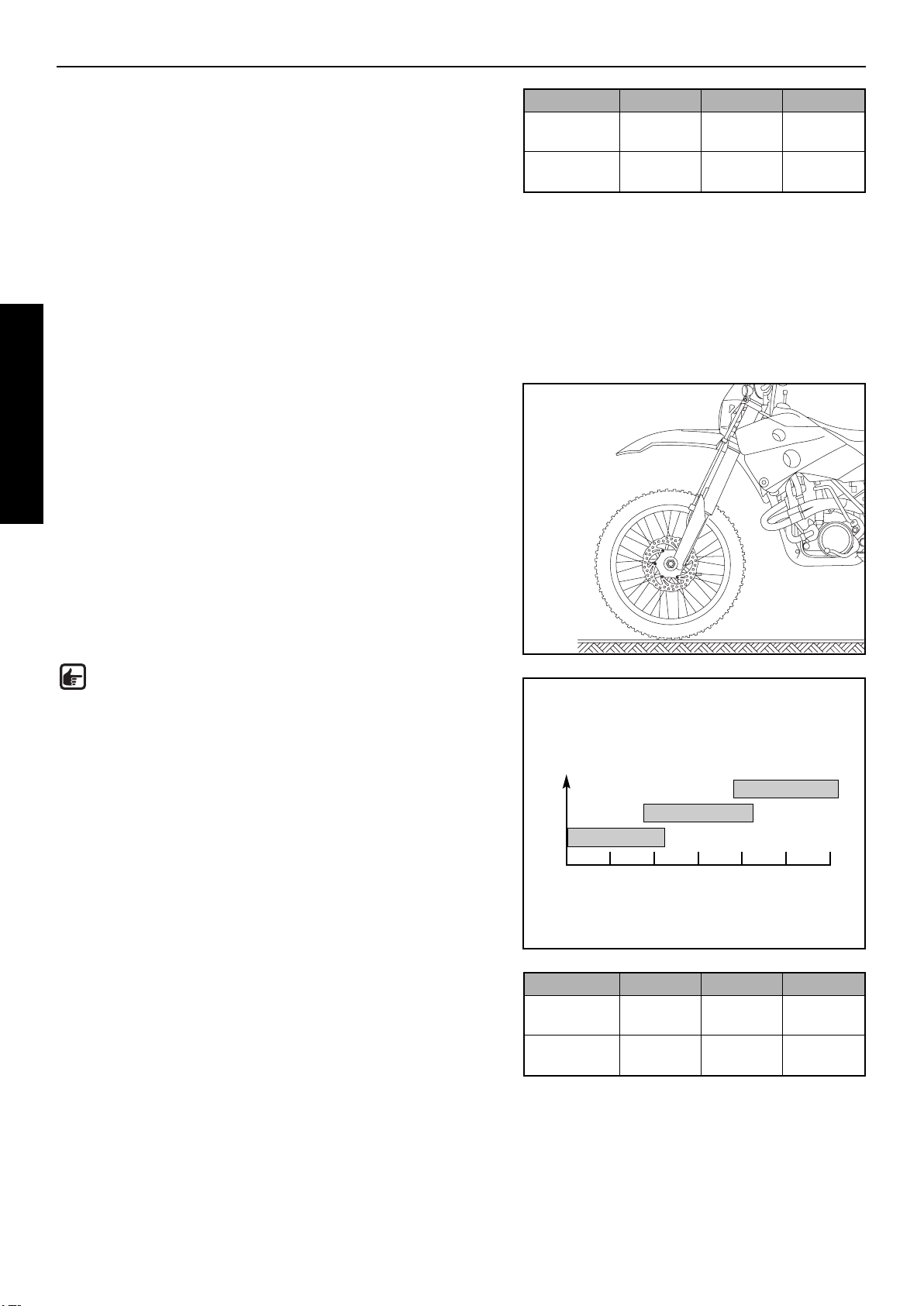

BASIC SUSPENSION SETUP FOR THE WEIGHT OF

THE DRIVER

To achieve maximum handling performance and to prevent the fork, shock

absorber, swing arm and frame from being damaged, the basic setup of

the suspension components must be suitable for your weight. At delivery,

Husaberg's offroad motorcycles are set to accommodate a driver weighing 70 - 80 kg (wearing full protective clothing). If your weight exceeds

or falls short of this range, you will need to adjust the basic setup for the

suspension components accordingly. Minor deviations in weight can be

compensated by adjusting the spring preload. Different springs must be

installed for larger deviations.

CHECKING THE SHOCK ABSORBER AND SPRING

You can establish whether or not the shock absorber spring is

suitable for your weight by checking the riding sag. The static slag must

be correctly adjusted before the riding sag can be determined.

DETERMINING THE STATIC SAG OF THE SHOCK

ABSORBER

The static sag should be as close as possible to 35 mm. Deviations of

more than 2 mm can strongly influence the motorcycle's performance.

Procedure:

– Jack up the motorcycle until the rear wheel no longer touches the ground.

– Measure the vertical distance between the rear wheel axle and a

fixed point (e.g. a mark on the side cover) and write it down as

dimension A.

– Place the motorcycle on the ground again.

– Ask a helper to hold the motorcycle in vertical position.

– Measure the distance between the rear axle and the fixed point again

to establish dimension B.

– The static sag is the difference between dimensions A and B.

EXAMPLE:

Motorcycle jacked up (dimension A) . . . . . . . . . . . . . . . . . . . . .600 mm

Motorcycle on ground, unloaded (dimension B)

. . . . . . . . . . .– 565 mm

Static sag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 mm

If the static sag is lower, the spring preload of the shock absorber must

be reduced, if the static sag is higher, the spring preload must be increased. See chapter "Changing the spring preload of the shock absorber."

DETERMINING THE RIDING SAG OF THE SHOCK

ABSORBER

– Have a helper hold the motorcycle while you sit on the bike in a

normal seating position (feet on the footrests) wearing full protective

clothing and bounce up and down a few times to allow the rear wheel

suspension to become level.

– Stay on the bike and have another person measure the distance bet-

ween the same two points and write it down as dimension C.

– The riding sag is the difference between dimensions A and C.

EXAMPLE:

Motorcycle jacked up (dimension A) . . . . . . . . . . . . . . . . . . . . .600 mm

Motorcycle on ground, loaded (dimension C)

. . . . . . . . . . . . .– 510 mm

Riding sag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 mm

B

60

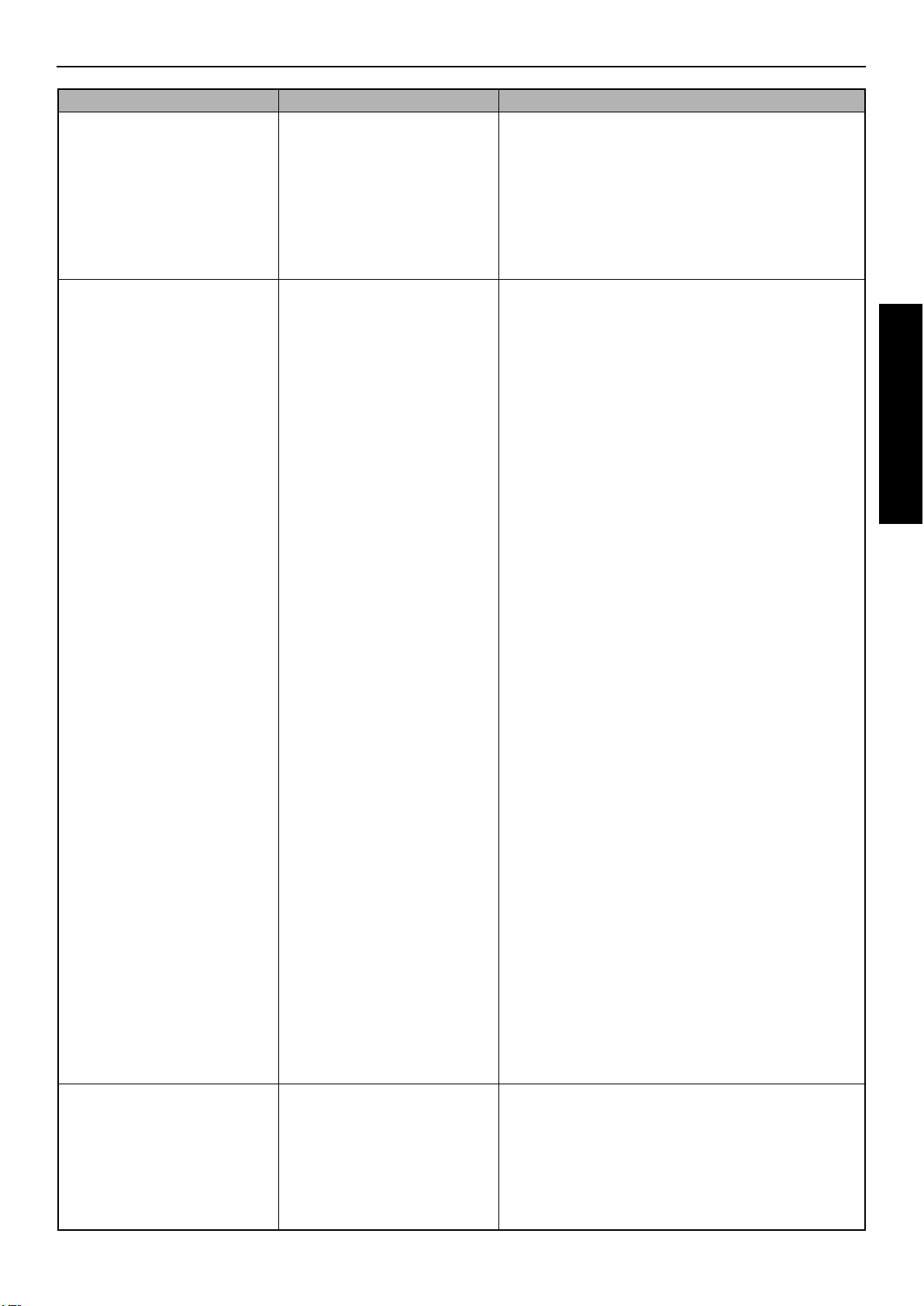

SPRING RATE

65 70 75 80 85 90

RIDERS WEIGHT INCLUSIVE GEARS IN KILOGRAM

80/250

84/250

76/250

for example FE 450, 550

A

B

C

The riding sag should lie between 90 and 105 mm.

If the riding sag is less than 90 mm, the spring is too hard (the spring rate

is too high). If the riding sag is more than 105 mm, the spring is too soft

(the spring rate is too low).

The spring rate is written on the outside of the spring (e.g. 88/250). The

type number of the shock absorber is embossed on the bottom of the tank.

The illustrations show which spring should be installed. The standard spring

is shown in bold print. After installing a different spring, readjust the static sag to 35 mm (± 2 mm).According to our experience, the damping rate

of the compression stage can remain unchanged. The damping rate of

the rebound stage can be reduced by a few clicks for a softer spring or

increased by a few clicks for a harder spring.

CHECKING THE BASIC SETUP OF THE TELESCOPIC

FORK

The precise riding sag of the telescopic fork cannot be determined for

various reasons. Similar to the shock absorber, smaller deviations in your

weight can be compensated by adjusting the spring preload. However, if

your telescopic fork bumps frequently (hard end stop during compression),

you should install harder fork springs to avoid damaging the telescopic

fork and frame.

CHANGING THE SPRING PRELOAD ON THE TELESCOPIC FORK

The telescopic forks for these models must be partly disassembled to adjust

the spring preload (see WP manual). Pretension spacers are available in

heights of 1.5, 2.5 and 5 mm (see spare parts catalog). The fork springs

may not be pretensioned by more than 20 mm.

NOTE: WP precisely adjusts the spring pressure by

inserting pretension spacers. Fluctuations in production are

compensated with pretension spacers in various heights.

This can cause the fork springs in the fork legs to have

different degrees of pretension. Fork springs and pretension

spacers should always stay together.

REPLACING FORK SPRINGS

If you weigh less than 70 kg or more than 80 kg, you should install the

respective fork springs. The correct spring rate is shown in the illustrations. The standard spring is shown in bold print. The type number of the

telescopic fork is embossed on the caps on the top of the telescopic fork.

If you are uncertain which spring to use, contact your Husaberg

workshop.

According to our experience, the damping rate of the compression stage

can remain unchanged. The damping rate of the rebound stage can be

reduced by a few clicks for a softer spring or increased by a few clicks for

a harder spring.

MAINTENANCE WORK ON CHASSIS AND ENGINE

ENGLISH

MODELL SOFTER

STANDARD

HARDER

12457B02

FE 450,550,650

76/250 80/250

84/250

12457B03

FS 450,650

84/250 88/250 92/250

MODELL SOFTER

STANDARD

HARDER

14457B02

FE 450,550,650

4,2 N/mm 4,4 N/mm 4,6 N/mm

14457B03

FS 450,650

4,6 N/mm 4,8 N/mm –

60

SPRING RATE

65 70 75 80 85 90

RIDERS WEIGHT INCLUSIVE GEARS IN KILOGRAM

4,4 N/mm

4,6 N/mm

4,2 N/mm

for example FE 450, 550

MAINTENANCE WORK ON CHASSIS AND ENGINE

- 31 -

ENGLISH

CHANGING THE FORK OFFSET (CASTER) (FS) *

The fork offset (A) in the FS models (center fork legs - center steering

head angle) can be set to either 16 or 18 mm. This allows you to optimize

the handling to match the race course.

You can see which offset is preset when you remove the end screw (1).

If the flat area (B) is in the rear, the offset is 16 mm. This setting will improve

driving stability on fast race courses.

If the flat area (B) is in the front, the offset is 18 mm. This setting will improve

the handling in curves.

The offset is set to 16 mm in the condition at delivery.

To adjust the offset, dismount the front wheel and remove the front wheel

fender.

Remove the headlight mask and disconnect the plug connector from the

brake light switch and speedometer sensor.

Remove the clamp screws on the hand brake cylinder and fasten the hand

brake cylinder to the left fork leg with a cable tie to keep the brake line

from kinking (see illustration).

Loosen the clamp screws and take the fork legs out of the triple clamps.

Loosen the collar screw (2) on the lower triple clamp 2 turns.

Remove the end screw (1) from the upper triple clamp and rest the upper

triple clamp on the tank. Remove the adjusting nut (3) and protection

ring (4).

Tap gently on the lower triple clamp with a rubber hammer to loosen the

steering stem (5) out of the bearing seat. Take the lower triple clamp with

the steering stem out of the steering head.

A

B

3

4

2

1

5

Remove the collar screw from the lower triple clamp and pull out the steering stem. Thoroughly clean all parts. Turn the steering stem 180° and

insert it in the triple clamp, tighten the collar screw all the way to the stop.

WARNING:A plastic insert in the collar screw thread makes

the collar screw self-locking. Replace if the collar screw can

be screwed in by hand.

Do not confuse the collar screw with the blind screw. The collar

screw is self-locking.

Grease the steering head bearing and sealing elements.