Hunter Industries Golf Irrigation User Manual

Golf Irrigation Product Catalogue

GOLF IRRIGATION

|

Built on Innovation

®

VOLUME 37

hunterindustries.com/golf

HUNTER FAMILY

of Products

Founded in 1981, Hunter Industries is

a family-owned, global

of best-in-class solutions for residential,

commercial, municipal, agricultural,

and golf course irrigation systems, as

well as the outdoor lighting industry.

Headed by CEO Greg Hunter, our

Global Operations team provides

leadership for the entire company.

The core mission of Hunter Industries

will always remain the same: to deliver

valued products and services backed

by unwavering customer support,

grow the company conscientiously,

and remain true to the culture that

makes our employees proud to work

at Hunter. Learn more at

hunterindustries.com.

manufacturer

GOLF IRRIGATION

Hunter has been on the leading edge

of golf course irrigation for more than

three decades. We build performance,

reliability, and serviceability into every

product. From our industry-best rotors

to our robust Pilot

system, we take pride in providing

golf experts and professionals with

the tools and support they need to

conceptualise, create, and manage

world-class golf courses. Learn more

at hunterindustries.com/golf.

irrigation control

From rotors and valves to weather sensors and

smart controllers, our philosophy is to produce

products that allow landscape professionals to create

optimal functionality and ambience while promoting

sustainable resource use. We are committed to

pushing the boundaries of technology and customer

experience in every product and project we undertake.

Learn more at hunterindustries.com/products.

COMMERCIAL IRRIGATION

FX Luminaire is an industry-leading manufacturer

of landscape and architectural lighting products. We

focus on the advancement of LED technology and

digital lighting control with zoning, dimming, and

colour adjustment capabilities. In addition, we oer a

full spectrum of highly ecient lighting xtures that

can be utilised to create elegant landscape lighting

systems for a range of golf course applications, from

clubhouses to pathways. Learn more at fxl.com.

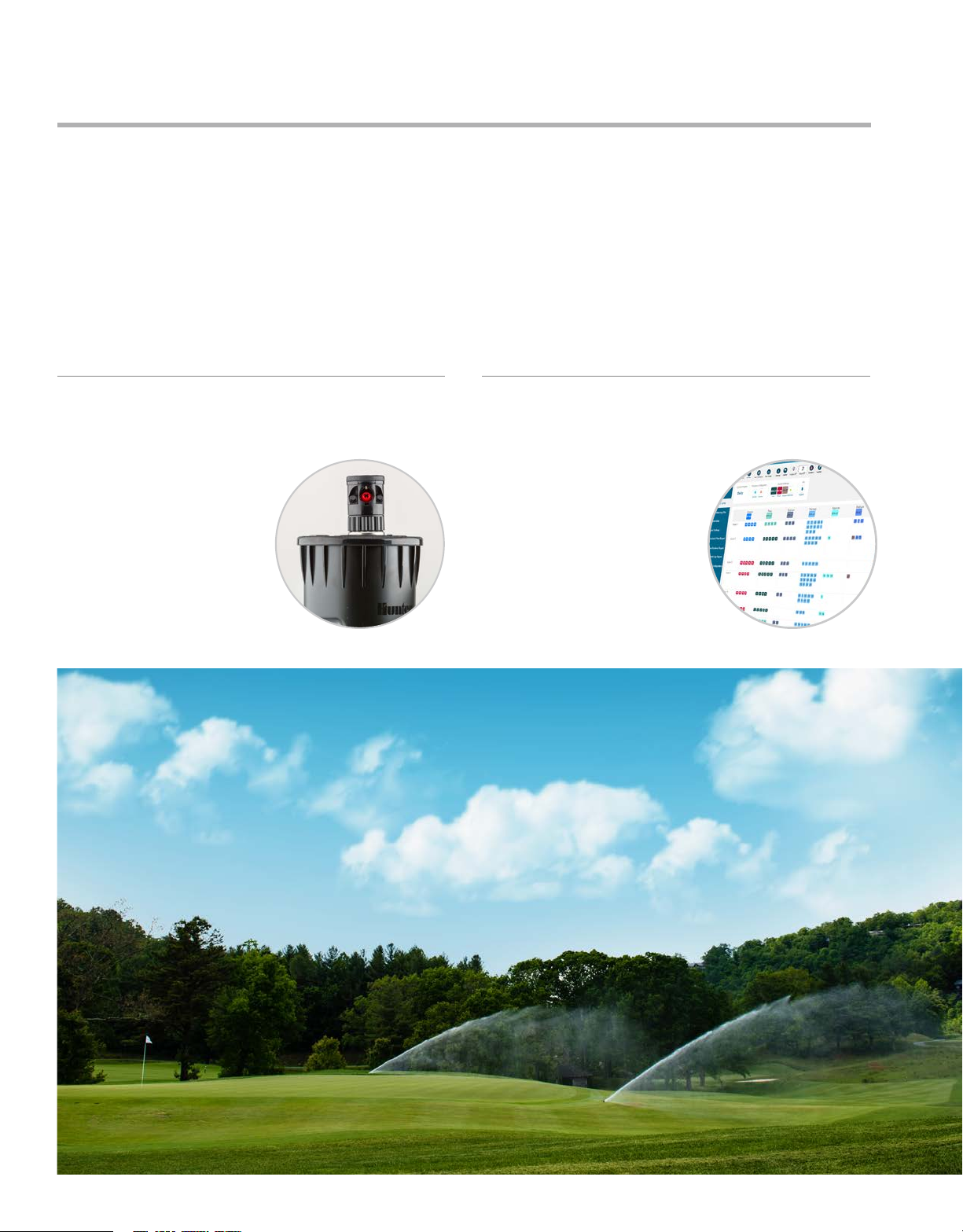

What’s New IN VOLUME 37

AT HUNTER INDUSTRIES, WE KNOW THAT THE NEEDS OF GOLF COURSE SUPERINTENDENTS CONTINUE TO EVOLVE.

Irrigation simply must become more ecient. Today’s professionals are calling for more than just high-performance products —

they expect unwavering partnership from manufacturers, from conception to installation and beyond.

That’s why we have redoubled our eorts to bring you solutions that meet and exceed golf course irrigation requirements. We’ve enhanced

our world-class Pilot irrigation management platform and invested in groundbreaking rotor technology. All our products remain backed by

industry-leading training and technical support.

TTS-800 Series Rotors

TTS-800 Series rotors provide maximum uniformity and

longevity in the eld. The high-torque gear drives are the

strongest in the industry, so the challenges of reclaimed water

use or poor water quality are mitigated.

An extra-large, fast-access

ange compartment comfortably

accommodates wire connections

and other components.

Convenient, no-dig Total Top

Serviceability means routine

maintenance is a breeze.

See page 20 for more details.

Pilot Command Center Soware

With newly enhanced Pilot Command Center soware,

superintendents can create hydraulically safe and ecient daily

golf course watering plans faster than ever before. Pilot allows

you to operate thousands of individually

controlled sprinklers in seconds —

right from the Command Center.

From here, all watering changes

can be performed from one

easy-to-navigate screen.

See page 8 for more details.

Table of CONTENTS

PILOT NETWORK

7 Pilot Network

8 Pilot CCS

10 Pilot Field Controller Systems

12 Pilot Integrated Hub Systems

14 Weather Station

15 Maintenance Radio

15 ICD-HP

GOLF ROTORS

20 TTS-800 Series

32 G-800 Series

40 B Series

48 G-900 Series

SWING JOINTS AND ACCESSORIES

50 HSJ Swing Joints

53 Accessories

54 To ols

LANDSCAPE SOLUTIONS

55 Landscape Solutions

LANDSCAPE AND ARCHITECTURAL LIGHTING

93 FX Luminaire

TECHNICAL INFORMATION

95 Technical Services

97 Hunter University

98 Precipitation Rates

99 Conversion Factors

100 Symbols and Constants

101 Electrical Specifications

102 Current Requirement Charts

103 Wire Sizing

104 Wire Data

105 Additional Data

STATEMENT OF WARRANTY

106 Statement of Warranty

ROTORS

57 PGP Ultra

58 PGP Ultra PRB

58 I-20 PRB

62 I-2 5

65 I-40

68 I-80

70 I-90

MP ROTATOR

73 MP Rotator

78 MP Rotator 800 Series

SPRAY BODIES

81 Pro-Spray PRS40

VALVES

85 ICV

87 IBV

89 Accu Sync

90 Quick Couplers

PILOT NETWORK

PILOT® NETWORK

6

PILOT NETWORK

TOTAL IRRIGATION CONTROL

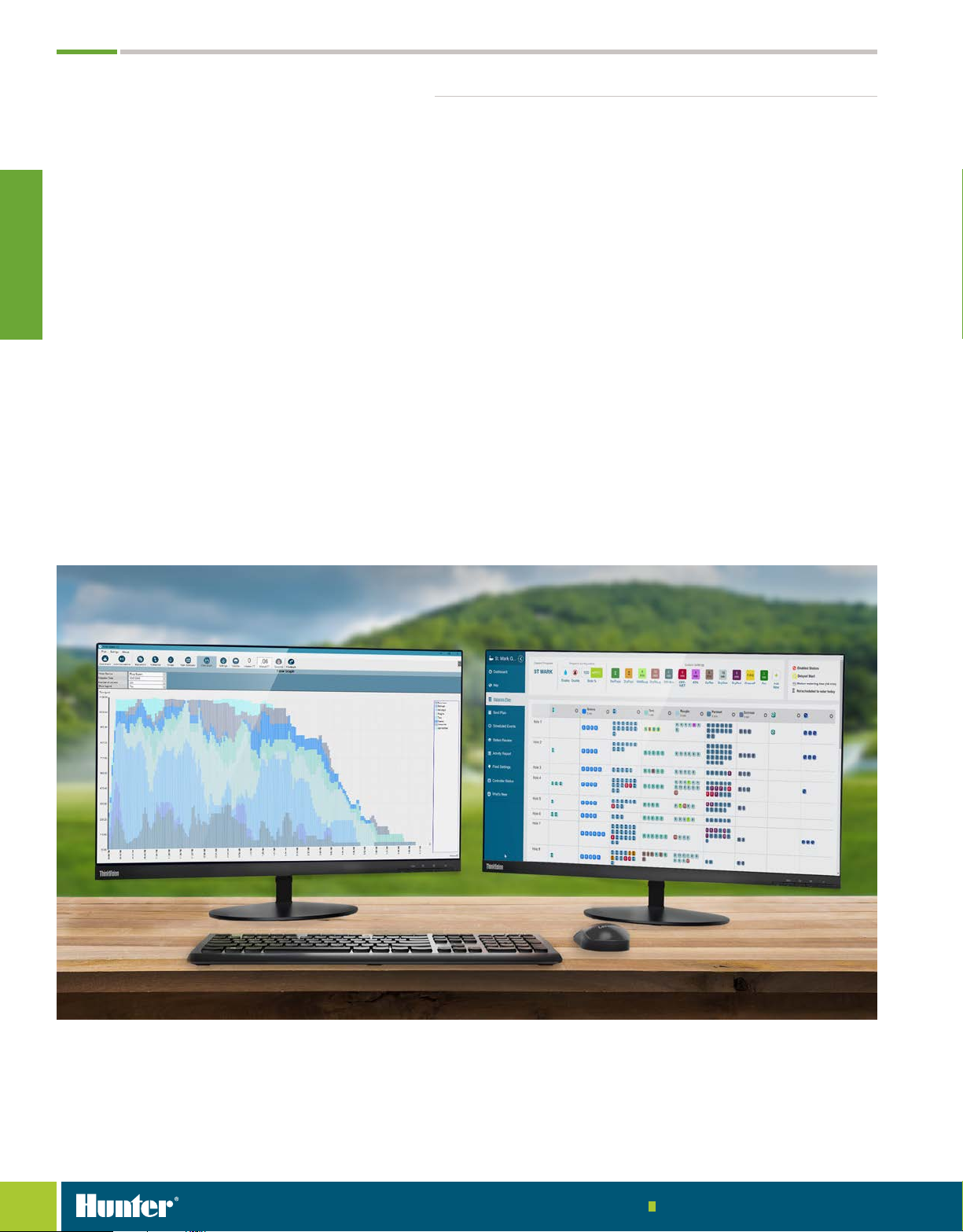

PILOT COMMAND CENTER SOFTWARE

With industry-leading Pilot Command

Center soware (CCS), you can create

a daily watering plan for thousands of

individually controlled sprinklers in just

minutes, right from an easy-to-navigate

central screen. Pilot CCS allows you to

safely balance sprinkler demand with water

and electrical supply for the most ecient

irrigation cycles possible.

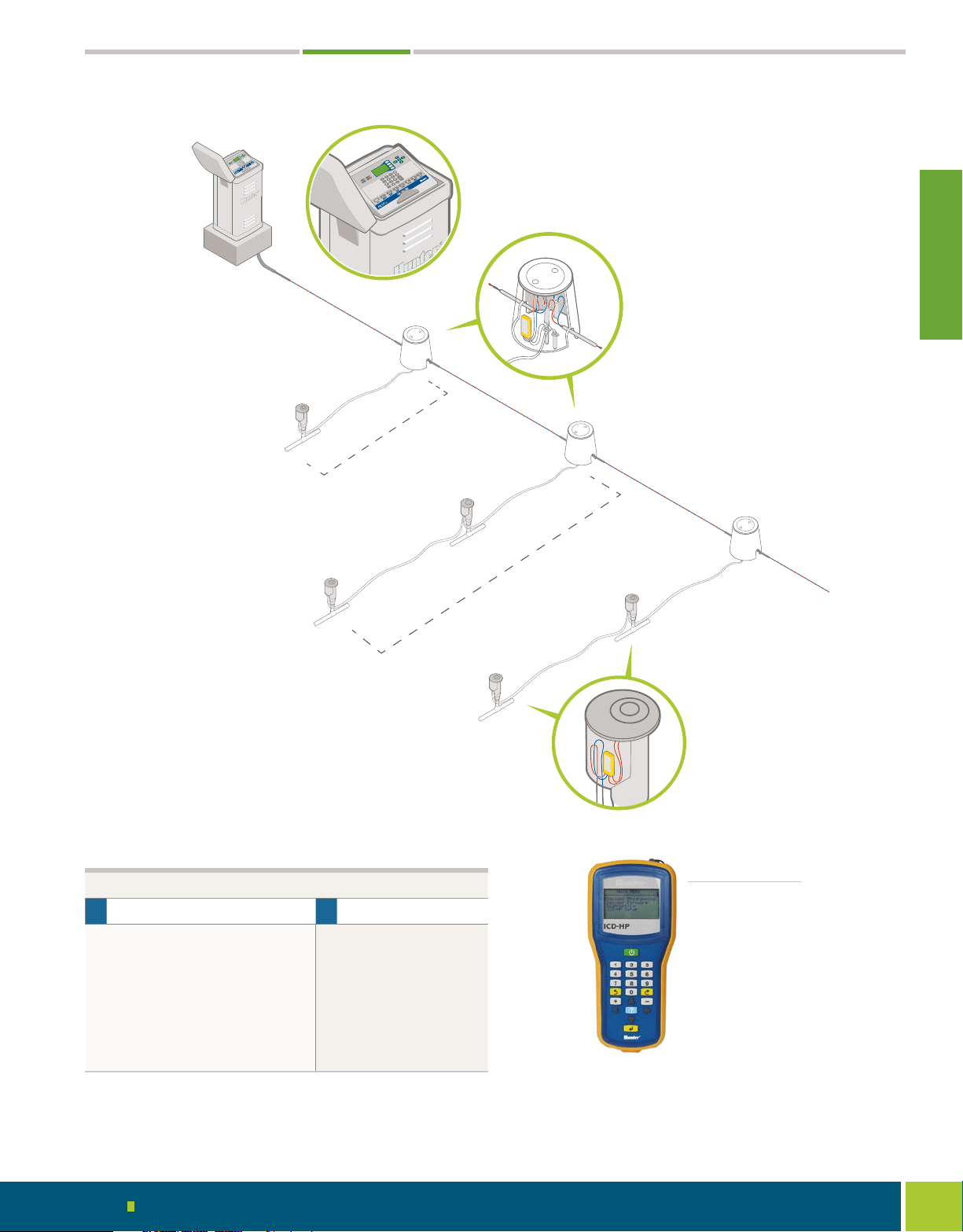

PILOT INTEGRATED HUB SYSTEM

Thanks to integrated two-way modules, Pilot hub systems have a

999-station capacity and can run up to 120 stations simultaneously. Each

hub has a plastic enclosure with a full-featured control panel. It can be used

as a standalone device or connected to Pilot CCS as part of a Pilot network

for ow-optimised irrigation management. Communication options within

the Pilot network include wired, UHF radio, spread spectrum radio, or a

mixture of all three.

PILOT NETWORK

PILOT FIELD CONTROLLER SYSTEM

The eld controller has an 80-station capacity, so you can do more with less.

Because each controller can run up to 20 stations at a time, they shorten

your overall watering window. The full-featured controller has everything

you need in a standalone eld controller. For a fully automated, owoptimised system, network all your controllers together with Pilot CCS.

Communication options within the Pilot network include wired, UHF radio,

spread spectrum radio, or a mixture of all three.

EASY TO PROGRAM AND MAINTAIN

Pilot CCS is an advanced soware package designed to centrally manage

all decision-making in a Pilot network. The heart of Pilot CCS is the

Command Center. This convenient view allows you to quickly create

and manage daily watering plans, tune the system to match your local

environment, and produce hydraulically balanced watering instructions.

7

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

PILOT COMMAND

CENTER SOFTWARE

PILOT NETWORK

Pilot Command Center soware (CCS) is easy to use and has all the features

you need to reliably and automatically water your course.

adjusted manually or determined automatically using ET. You create watering

plans directly in the Command Center — a powerful irrigation planning tool

that shows you every sprinkler on the course organised according to your

management style.

PILOT SPECIFICATIONS

• Operating system: 64-bit Windows

• Maximum controllers or hubs: about 1,000

• Maximum two-way module stations: about 1 million

• Sprinkler run time options: minutes, millimetres, inches, or ET

• Hydraulic management: fully customisable down to individual stations

• Mapping: interactive and based on scalable vector graphics (SVG)

Run times can be

Windows is a trademark of Microsoft Corporation in the United States and/or other countries.

Lenovo and ThinkVision are trademarks of Lenovo in the United States, other countries, or both.

8

Visit hunterindustries.com/golf

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

SPEND LESS TIME RUNNING YOUR PUMP

Pilot CCS uses your electrical and hydraulic data to eciently balance sprinkler

demand while maintaining ow at safe velocities. To protect your pump station

and maintain optimal sprinkler uniformity, you can gradually step up irrigation

in safe increments.

Flow Optimisation

PILOT NETWORK

COMMAND CENTER

Planning daily watering for your course has never been simpler. The Command

Center shows every sprinkler on the course, logically arranged according to your

personal management requirements. You can easily make daily adjustments with

just a few clicks of the mouse.

MAPPING YOUR COURSE

Although having a map is not required, adding one allows you to run

water by simply clicking the station symbols on the map. With this helpful

feature, you can also monitor stations as they are running.

Command Center

Visit hunterindustries.com/golf

Maps

GOLF IRRIGATION | Built on Innovation

®

9

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

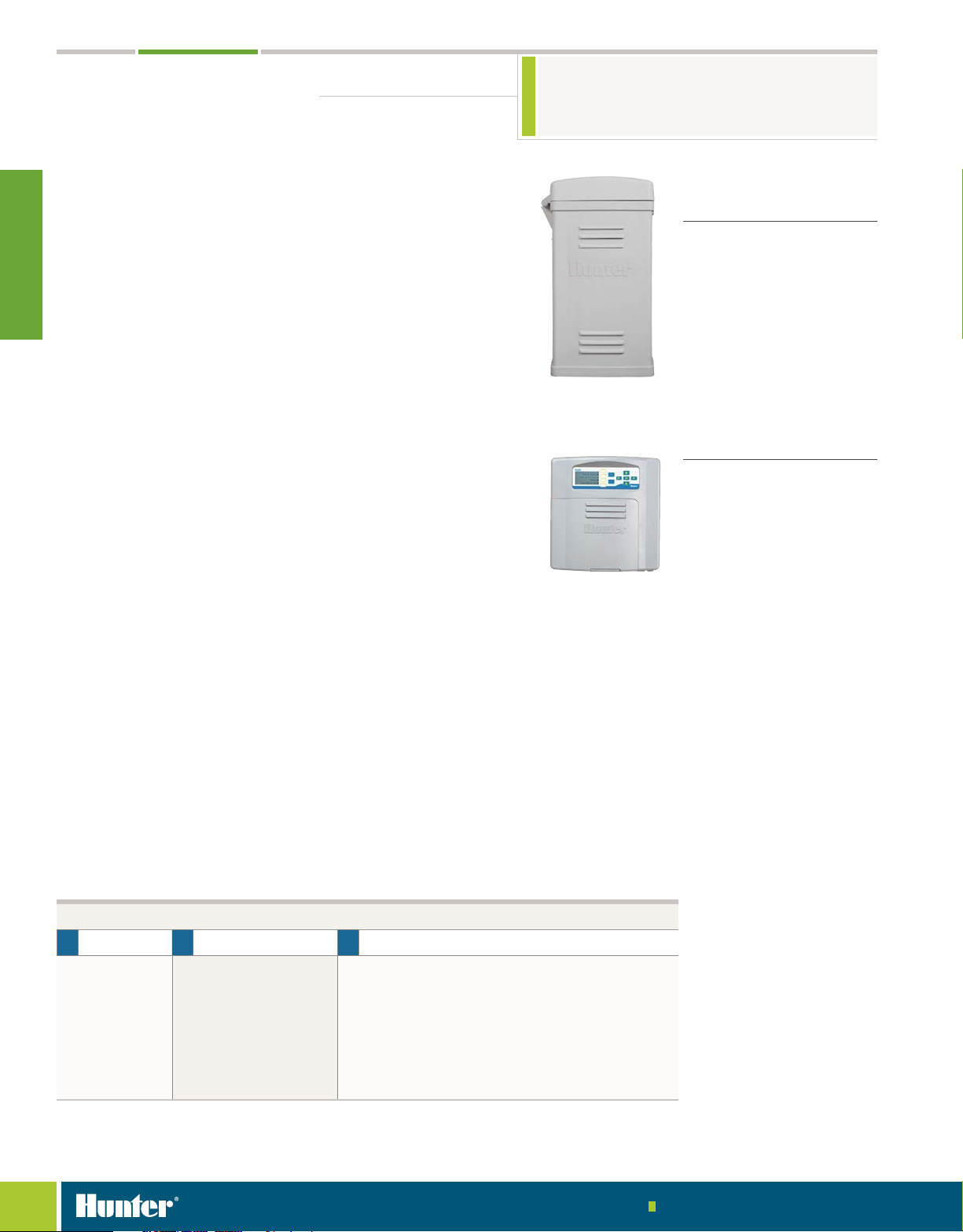

Number of Stations: 80

PILOT FIELD

Typ e: Field Controller

CONTROLLER SYSTEMS

PILOT NETWORK

FEATURES

• Five languages

• Up to 80 station outputs in

10-station increments

• Up to three Hunter golf valve-in-head

rotors per station output

• Up to 20 simultaneous Hunter

golf valve-in-head rotors active

per controller

• 32 automatic schedules with

eight start times per schedule

• Exclusive Safe-Toggle™ mechanical

on-o-auto station switches

POWER SUPPLY INPUT

Two voltage settings:

• 120 VAC nominal voltage at 60/50 Hz (100 to 132 VAC)

• 230 VAC nominal voltage at 50/60 Hz (200 to 260 VAC)

Current requirement:

• 1 amp under load at 110 VAC

• 0.7 amp under load at 230 VAC

For additional information, see electrical data on page 101.

OUTPUT VOLTAGE

• Station: 1 A at 24 VAC

• Hot post: 0.4 A at 24 VAC

• Capacity: Three standard 24 VAC Hunter golf rotors per output;

20 maximum simultaneously running stations

• 1–31 day skip-day scheduling

• One-touch rain shutdown up

to 30 days or indenitely

• One-touch Safe-Pause™ with

30 minute safety timer

• 1–300% run time seasonal

adjustment

• Seasonal start time adjustment

is used to quickly change all start

times plus or minus 30 minutes

Pilot-FC Plastic Pedestal

Height: 100 cm

Width: 60 cm

Depth: 44 cm

Weight: 32 kg

Pilot-FI Field Interface

One is required with any Pilot

network system. It is used to link

the central computer to the eld

equipment. For indoor locations only.

Height: 30 cm

Width: 30 cm

Depth: 11 cm

Weight: 2 kg

RADIO SYSTEMS

• UHF radio: 450-490 MHz; other UHF frequencies

available for selected markets

• Spread spectrum radio: 915 MHz

WIRED SYSTEMS

• GCBL: Shielded two twisted pairs, 0.82 mm²

• GCBLA: Armoured, shielded two twisted pairs, 0.82 mm²

PILOTFI SPECIFICATION BUILDER ORDER 1 + 2 + 3

1

Model

Pilot-FI

Examples:

Pilot-FI-HWR

Pilot-FI-UHF

= Field interface with hardwire communications

= Field interface with UHF radio communications

Standard Features

2

Plastic pedestal (grey)

Communication Options

3

HWR

Hardwire communications

UHF

UHF radio communications

(licence required)

UHFA

UHF radio (licence required, Australia only)

LF

915 MHz spread-spectrum radio communications

(no licence needed)

10

Visit hunterindustries.com/golf

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

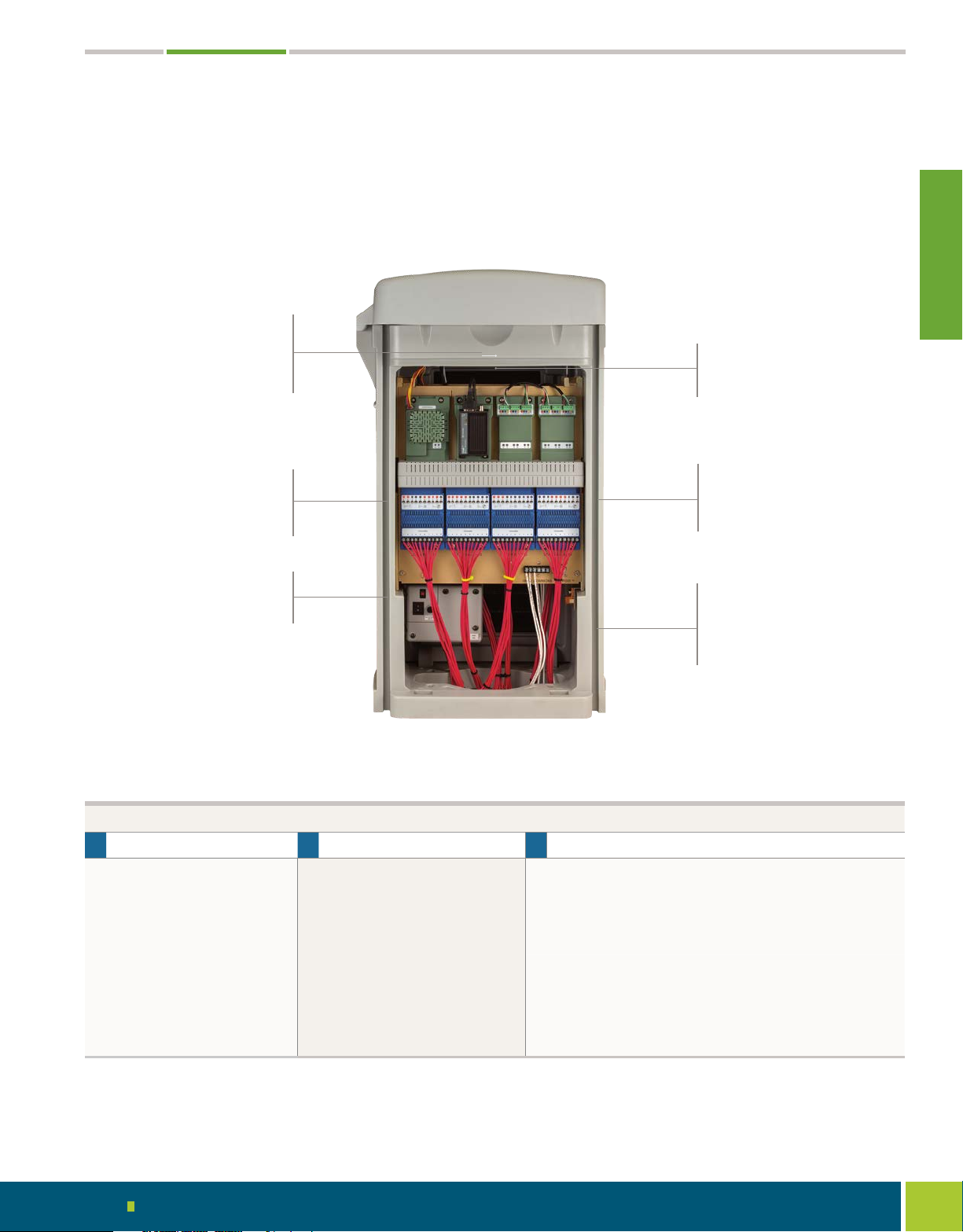

THE PILOT FIELD CONTROLLER IS ENGINEERED EXCLUSIVELY

FOR GOLF COURSE IRRIGATION MANAGEMENT.

Large backlit display with convenient

Water-Resistant Keypad

function buttons for the most

commonly used features. Built-in

system diagnostics make

troubleshooting your system a breeze.

Safe-Toggle Station Switches and

Diagnostic LED Indicators

Standard for all station outputs,

these features provide quick

troubleshooting and watering tools.

Conveniently Located Dual-Voltage

(120/230 VAC) Junction Box

Features heavy-duty surge protection

and even includes a spare fuse.

PILOT NETWORK

Easy to Service

The only tool required is a Phillips

screwdriver, which is included with

every controller.

Modular 10-Station Expansion Boards

Colour-coded modular components

have captured screws. This means no

more lost screws, which simplies

assembly and troubleshooting.

Spacious Wiring Area

No exposed circuitry or loose wires.

All circuit boards are encapsulated in

polyurethane to protect them from

moisture, insects, and temperature

extremes.

PILOTFC SPECIFICATION BUILDER ORDER 1 + 2 + 3

1

Model

Pilot-FC20

Pilot-FC30

Pilot-FC40

Pilot-FC50

Pilot-FC60

Pilot-FC70

Pilot-FC80

Examples:

Pilot-FC40-S

Pilot-FC70-HWR

(20-station)

(30-station)

(40-station)

(50-station) Plastic pedestal (grey)

(60-station)

(70-station)

(80-station)

= 40-station, standalone eld controller with no central communications

= 70-station eld controller with wired communications

Standard Features

2

120/230 VAC 60/50 Hz

dual-voltage transformer

Visit hunterindustries.com/golf

Communication Options

3

S

Standalone eld controller with no central communications

HWR

Wired communications

UHF

UHF radio (licence required)

UHFA

UHF radio (licence required, Australia only)

LF

915 MHz spread-spectrum radio

(no licence needed)

GOLF IRRIGATION | Built on Innovation

®

11

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

Number of Stations: 999

PILOT INTEGRATED

Typ e: Integrated Hub

HUB SYSTEMS

PILOT NETWORK

Integrated hub systems are one of the fastest growing forms of technology

in irrigation control. A key advantage over eld controller systems is that

integrated hub systems use signicantly less wire. This means lower

costs, faster installation, and easier system diagnosis and repair if needed.

Systems can be easily expanded — with minimal digging and disruption of

landscaping — by adding more two-way modules (TWMs) instead of

running additional wires.

Pilot embraces this cost-ecient approach. Pilot two-way modules are

available with 1-, 2-, 4-, and 6-station outputs, making it possible to run each

head on an entire green with a single device. In all, TWMs let you operate about

1,000 stations up to 2.5 km from a single hub.

Pilot two-way modules include built-in surge suppression, colour-coded

wire connections, true independent station control, programmable station

addresses, and two-way feedback to the hub with conrmation and status

indication. Pilot-SG surge suppressors are required when the system is

designed and installed with golf rotors containing integrated TWMs.

TWM Hub

Water-Resistant Keypad

The backlit display and illuminated control panel

mean you can easily access the hub, day or night

Diagnostic LED Indicators

For all functions on 250-station output modules

250-Station Output Modules

Enable your integrated hub system to expand

with your course; start with 250 and grow to 999

Pilot TWMs

1- and 2-station:

Height: 9 cm

Width: 4 cm

Depth: 2.5 cm

Weight: 150 g

4- and 6-station:

Height: 9 cm

Width: 4.5 cm

Depth: 4 cm

Weight: 250 g

The distinct yellow design makes it much easier to nd the modules in dark valve

boxes or buried in the soil.

PILOTDH SPECIFICATION BUILDER ORDER 1 + 2 + 3

1

Model

Pilot-DH250

Pilot-DH500

Pilot-DH750

(250-station)

(500-station)

(750-station)

Standard Features

2

Plastic pedestal (grey)

Communication Options

3

S

HWR

UHF

UHFA

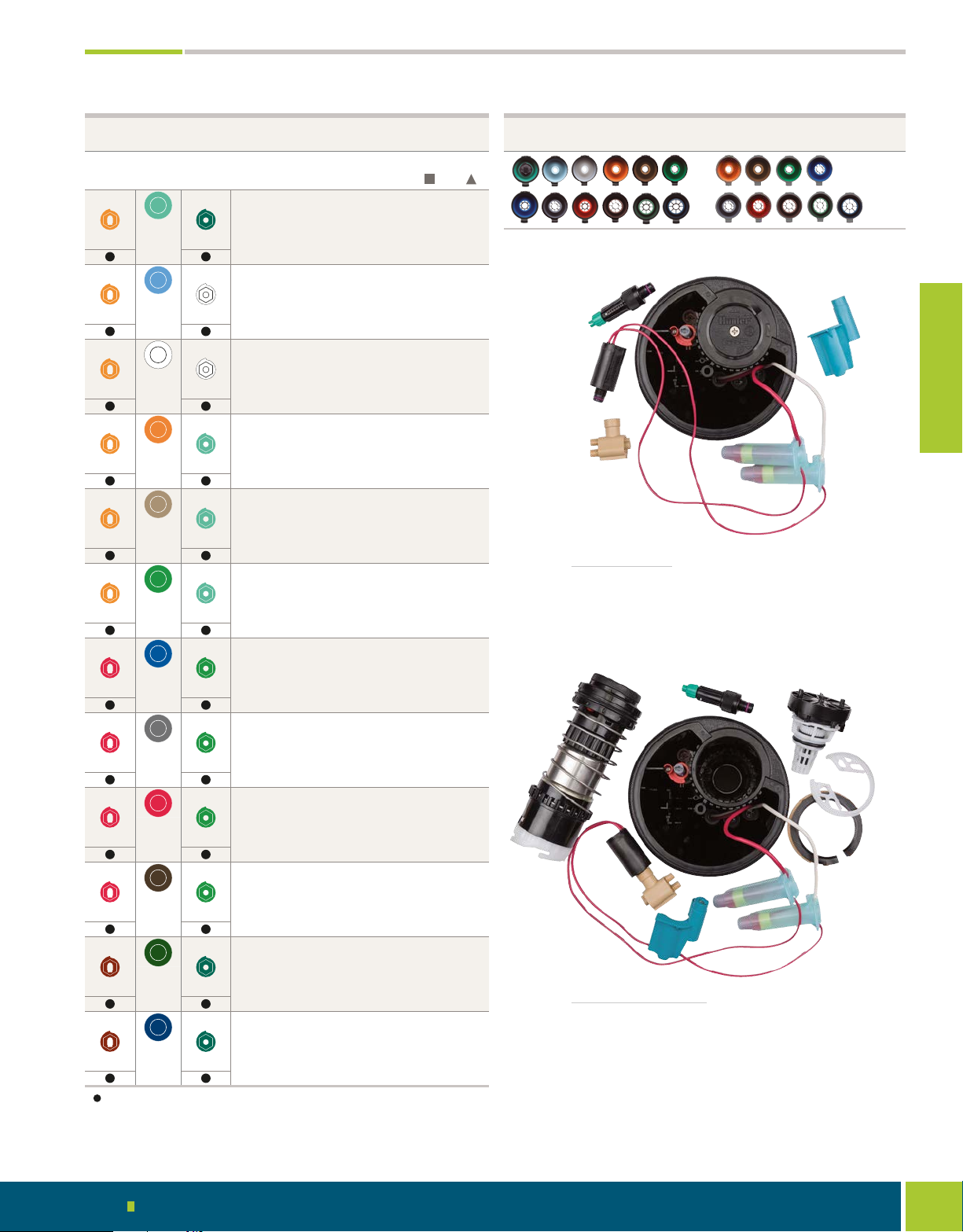

PILOT-SG Surge Suppressor

All integrated TWM rotors include two

3M DBRY-6 splices for connection to

the two-wire path. Integrated TWM

systems require grounding with

Pilot-SG surge suppressors coupled

to an appropriate grounding plate or

rod. Hunter recommends a minimum

of one Pilot-SG for every 12 installed

rotors or as per project specication.

Standalone TWM hub with no central communications

Wired communications

UHF radio (licence required)

UHF radio (licence required, Australia only)

12

Pilot-DH999

Examples:

Pilot-DH250-S

Pilot-DH999-HWR

(999-station)

= 250-station, standalone TWM hub with no central communications

LF

= 999-station TWM hub with wired communications

915 MHz spread-spectrum radio

(no licence required)

Visit hunterindustries.com/golf

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

Extended Control

Control system components up

to 2,500 m away with single pair of wires.

Pilot Integrated Hub

The hub provides independent station

control of 999 TWMs with up to 120

running simultaneously.

Surge Protection

Integrated TWM systems require

approximately one Pilot surge

suppressor for every 12 rotors.

The actual number will vary by

system design.

Up to 70 m

Up to 70 m

TWM in Valve Box

Sprinkler solenoids can

be up to 70 m from

the TWM.

Expansion Options

More than 999 stations,

you can use up to 999 TWM

hubs for nearly 100,000

TWM devices.

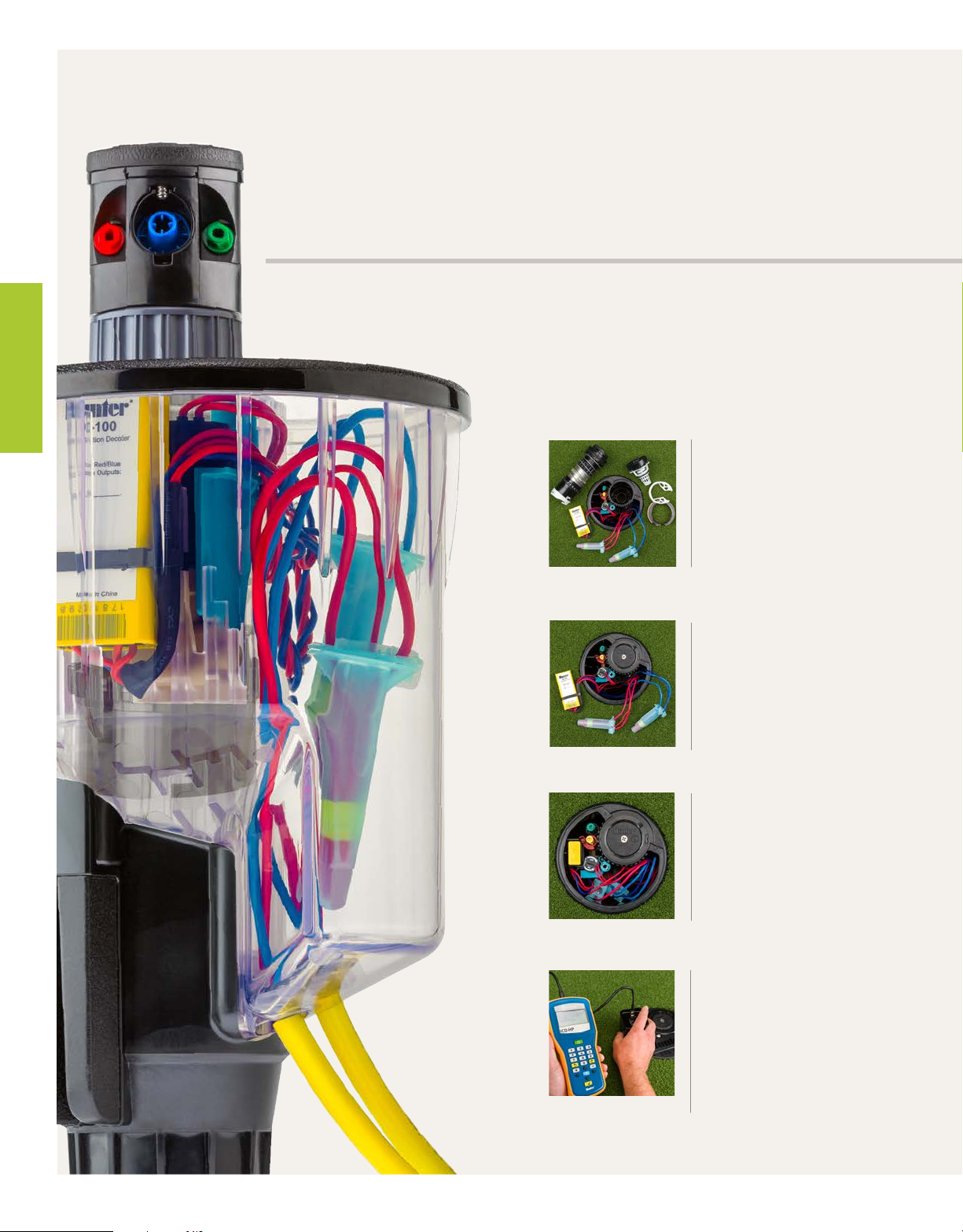

Integrated TWM

Hunter’s exclusive integrated

TWM module within TTS rotors

minimises valve box covers on

playing surfaces. See page 22

for more information.

PILOT NETWORK

TWM SPECIFICATION BUILDER ORDER 1

1

Model

Pilot-100

Pilot-200

Pilot-400

Pilot-600

Pilot-SG

Example:

Pilot-100

1-station TWM

2-station TWM

4-station TWM

6-station TWM

Inline surge suppression

(for integrated TWM

rotor systems)

= 1-station TWM

2

Built-in surge suppressor

DBRY-6 waterproof connectors

included

Visit hunterindustries.com/golf

Standard Features

Wireless Programming

This device is used to test, troubleshoot,

and program integrated TWMs. It allows

you to wirelessly link directly to TWMs

without removing the TTS cover. You can

also use it to update the coding inside the

TWM's microprocessor.

See the ICD-HP on page 15

GOLF IRRIGATION | Built on Innovation

®

13

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

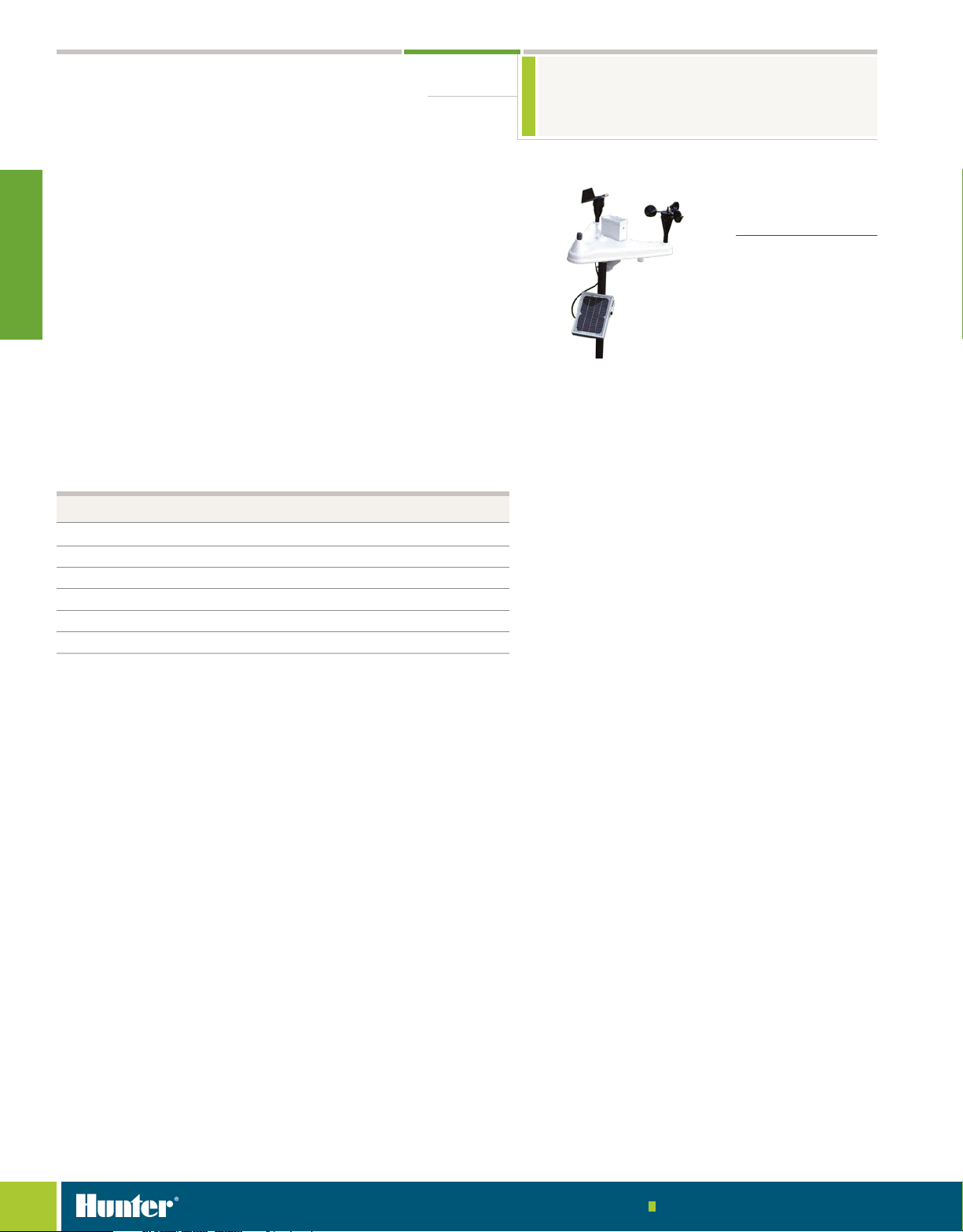

Range: Wireless, 1 km

WEATHER STATION

PILOT NETWORK

FEATURES

• Includes built-in 60-day data logger: With onboard evapotranspiration (ET)

calculation (modied Penman-Monteith equation for turf grass)

• Wireless package uses 2.4 GHz licence-free technology

- 2.4 GHz radio systems can reach up to 3 km

- In rural areas, try the licence-free, 900 MHz radio for links up to 800 m

• Wired systems use Hunter GCBL, direct-bury cable with a range of 1.25 km

(dedicated nine-pin serial computer port required)

• Optional solar panel kit provides wireless power

- Simple installation and versatile mounting with onboard 800 mAh

rechargeable gel cell battery with 18 VDC transformer and

7 m power cable

• Weatherproof construction: With UV-stabilised enclosure, weatherproof

external connectors and long-life coated circuit boards

• UL, c-UL and CE certications

Typ e: Weather Station

TurfWeather Station

Height: 61 cm

Width: 40.5 cm

Depth: 38 cm

Weight: 6 kg

COMPLETE PACKAGES INCLUDE HUNTER WEATHER SOFTWARE

Model Description

TWHW Wired communications to central computer (GCBL cable required)

TW24 2.4 GHz licence-free radio communication to central computer

TW916 916 MHz licence-free radio communication to central computer

TW922A 922 MHz licence-free radio communication to central computer

TWSUN Optional solar power kit for all TurfWeather models

14

Visit hunterindustries.com/golf

PILOT CCS FIELD CONTROLLER INTEGRATED HUB WEATHER STATION MAINTENANCE RADIO ICDHP

Range: Up to 3.5 km

MAINTENANCE RADIO

Typ e: Remote Control

FEATURES

• Hunter’s famous StraightTalk™ technology enables wireless

remote control at ranges up to 3.5 km whether or not the

central computer is turned on

• Instant control of stations, blocks, and programs

• Instant audio conrmation of commands

• Easy commands that show in display before sending

• Compact size, industrial construction

• Suitable for two-way voice communication with crews and oce

• High signal output: 2 watts, UHF (450–490 MHz)*

* Licence required

TRNR Radio

Height: 10.25 cm

Width: 5.25 cm

Depth: 3 cm

Weight: 200 g

PILOT NETWORK

ICDHP

FEATURES

• Wirelessly program TWM addresses

• Program TWM station numbers in any order, or skip stations for

future expansion

• Turn stations on and view solenoid status, current in milliamps,

and more

• Built-in voltmeter for testing communication path

• Communicates with TWMs directly through plastic case; wireless

electromagnetic induction saves waterproof connectors

• Communicates through the top of integrated TWM rotor

cases; no cover removal required

ICD-HP

Typ e: Two-Way Module Programmer

ICD-HP

Height: 21 cm

Width: 9 cm

Depth: 5 cm

Packaged in an outdoor carrying case, this complete kit

includes probes, an induction cup, cable, a USB power cable

for bench use, and four AA batteries for eldwork.

Visit hunterindustries.com/golf

GOLF IRRIGATION | Built on Innovation

®

15

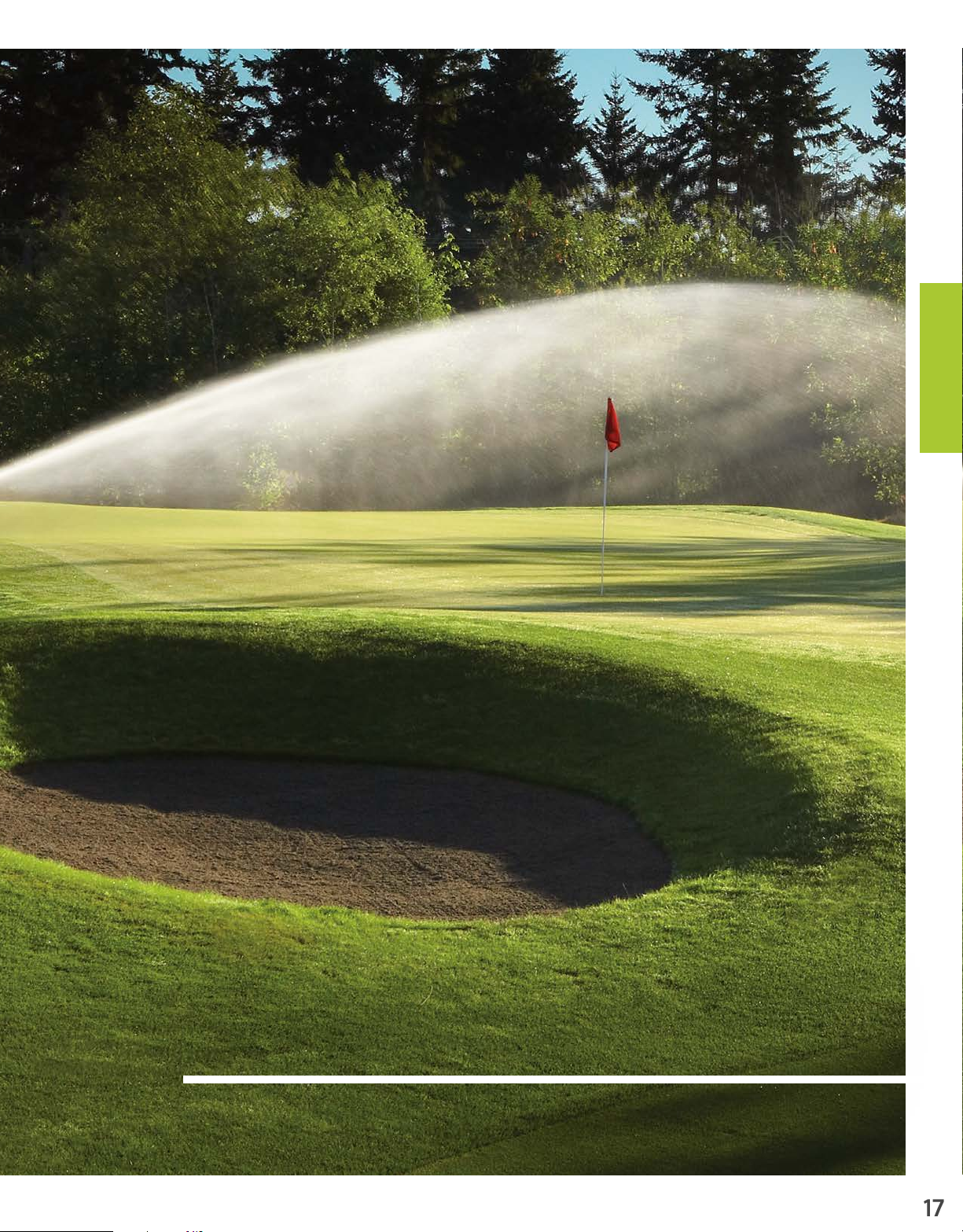

GOLF ROTORS

ROTOR SOLUTIONS

FOR EVERY GOLF COURSE

INTRODUCING THE TTS800 SERIES: THE MOST ADVANCED

ROTORS IN THE GOLF INDUSTRY

Over the last three decades, Hunter Industries has built a

longstanding reputation for innovation in the golf industry.

Introductions such as the rst Windows-based central control

system, the rst Total-Top-Service (TTS) rotors, the rst

Decoder-in-Head (DIH) rotors with integrated two-way modules,

and the powerful and water-ecient G85 gear-drives are among

these revolutionary innovations.

Now, we are proud to advance our legacy of rsts with our all-new

TTS-800 Series rotors — the most innovative and technologically

advanced rotors in the industry. TTS-800 Series rotors provide

maximum uniformity and longevity in the eld. The high-torque gear

drives are the strongest in the industry, so the potential challenges

of reclaimed water use or poor water quality are mitigated. The

fast-access ange compartment is the largest in the industry and can

accommodate full-sized DBRY-6 splice connectors. And with no-dig

Total Top Serviceability, the TTS-800 provides solenoid and pressure

regulator servicing without mainline depressurisation, making routine

maintenance a breeze.

16

So, whether your irrigation requirements fall into our budgetconscious B-Series category, the advanced G-800 Series rotors,

or our top-of-the-line TTS-800 Series rotors, Hunter Industries

oers total solutions that will exceed your expectations and ensure

beautiful, playable courses for years to come.

GOLF ROTORS

GOLF ROTORS

17

GOLF ROTORS

18

UNIFORMITY

YOU CAN COUNT ON

Playability and water eciency go hand-in-hand when

it comes to golf course management. This means great

distribution uniformity and proper irrigation scheduling

are crucial to ensuring world-class performance and

beautiful results.

Healthy, playable turf starts with a well-designed

irrigation system and top-level golf rotors — like

Hunter’s ultra-reliable TTS-880 and TTS-885, with

their superior distribution uniformity. Couple this with

the best support team in the business, and Hunter's

golf solutions are second to none.

At Hunter Golf, we pride ourselves in providing products

that set the standard in eciency. Each year, we work

directly with golf course superintendents worldwide to

conduct comprehensive irrigation system audits that

maximise water savings, reduce operating costs, and

enhance the golf experience for players and course

managers alike.

Choose Hunter Golf products for best-in-class

performance and enhanced playability.

GEAR DRIVES

POWER, PERFORMANCE,

AND VERSATILITY

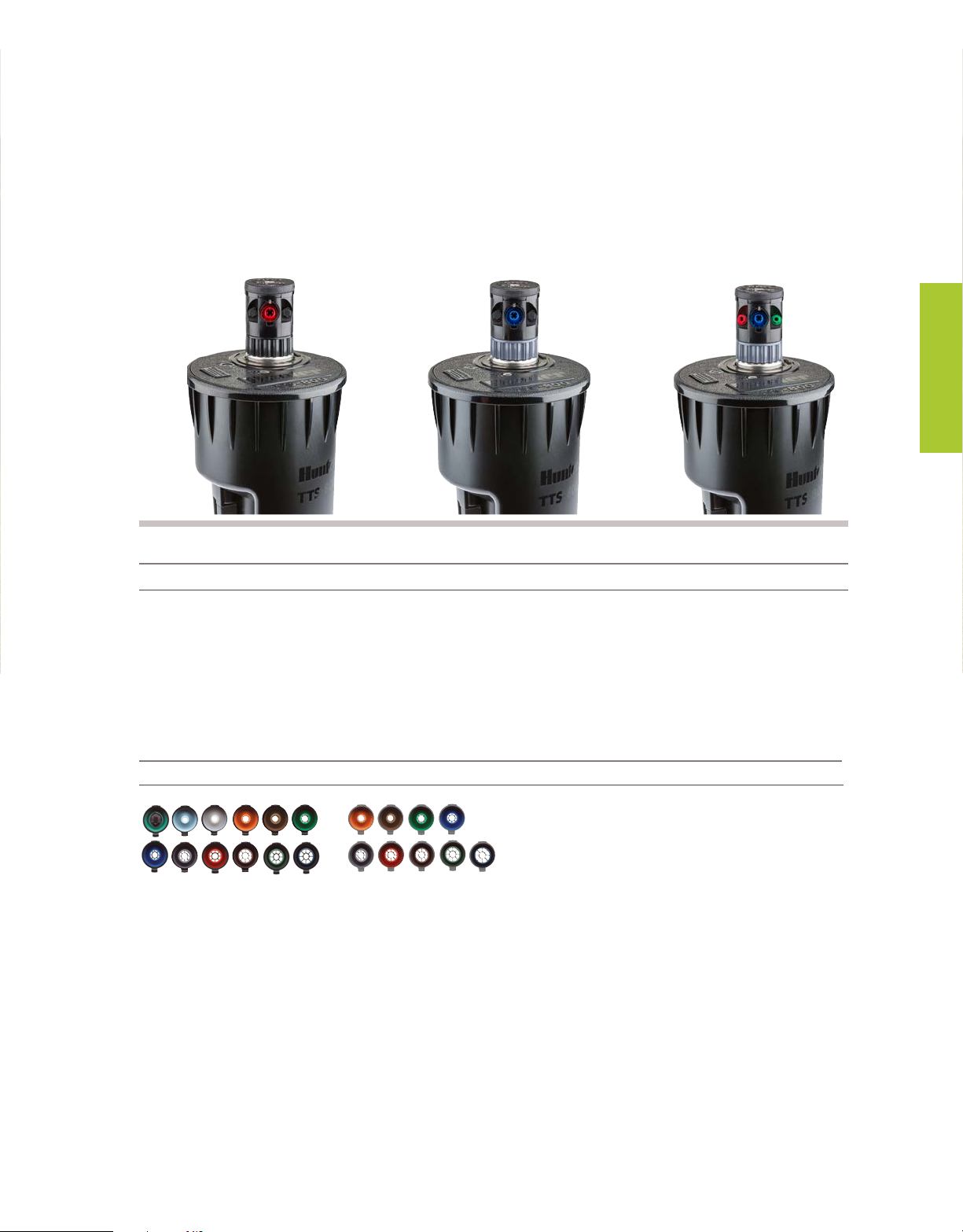

TTS-880 TTS-884 TTS-885

POWERFUL GEAR DRIVES

GOLF ROTORS

MEET THE G80 FULLCIRCLE DIRECTDRIVE DYNAMO

In 2013, Hunter introduced the revolutionary G-85 gear-drive, the most powerful in the golf industry. Since then, the G-85’s

reputation for power, performance, and versatility have earned the respect of professionals industry-wide. While the G-85 has an

adjustable arc drive with triple forward-facing nozzles, it can also be adjusted to non-reversing full-circle rotation. In addition,

the G-85 can be congured at the factory as a G-84 in an opposing-nozzle full-circle conguration.

Now, in 2019, Hunter completes the trilog y with the introduction of the new direct-drive G-80 full-circle dynamo — with power to

spare. The dedicated full-circle G-80 melds the tried and proven 2006 to 2018 G-80 gearbox with the G-85’s outstanding platform

to create the best full-circle gear drive in the golf industry.

DUALTRAJECTORY FLEXIBILITY

The G-80 and the G-84/G-85 gear drives share the same

primary nozzle sets. Each gear drive has dedicated short and

mid-range nozzles that when combined with the primary

nozzles create the uniformity you can count on. Choose from

a wide assortment of ecient wind-ghting 22.5° standard

Standard Nozzles Low-Angle Nozzles

trajectory nozzles, or 15° low-angle trajectory nozzles.

Either way, there is a perfect match for your unique course

conditions and problem-solving needs. Regardless of the

version you choose, changing nozzles is fast and easy with

Hunter’s exclusive QuickChange technology.

19

GOLF ROTORS

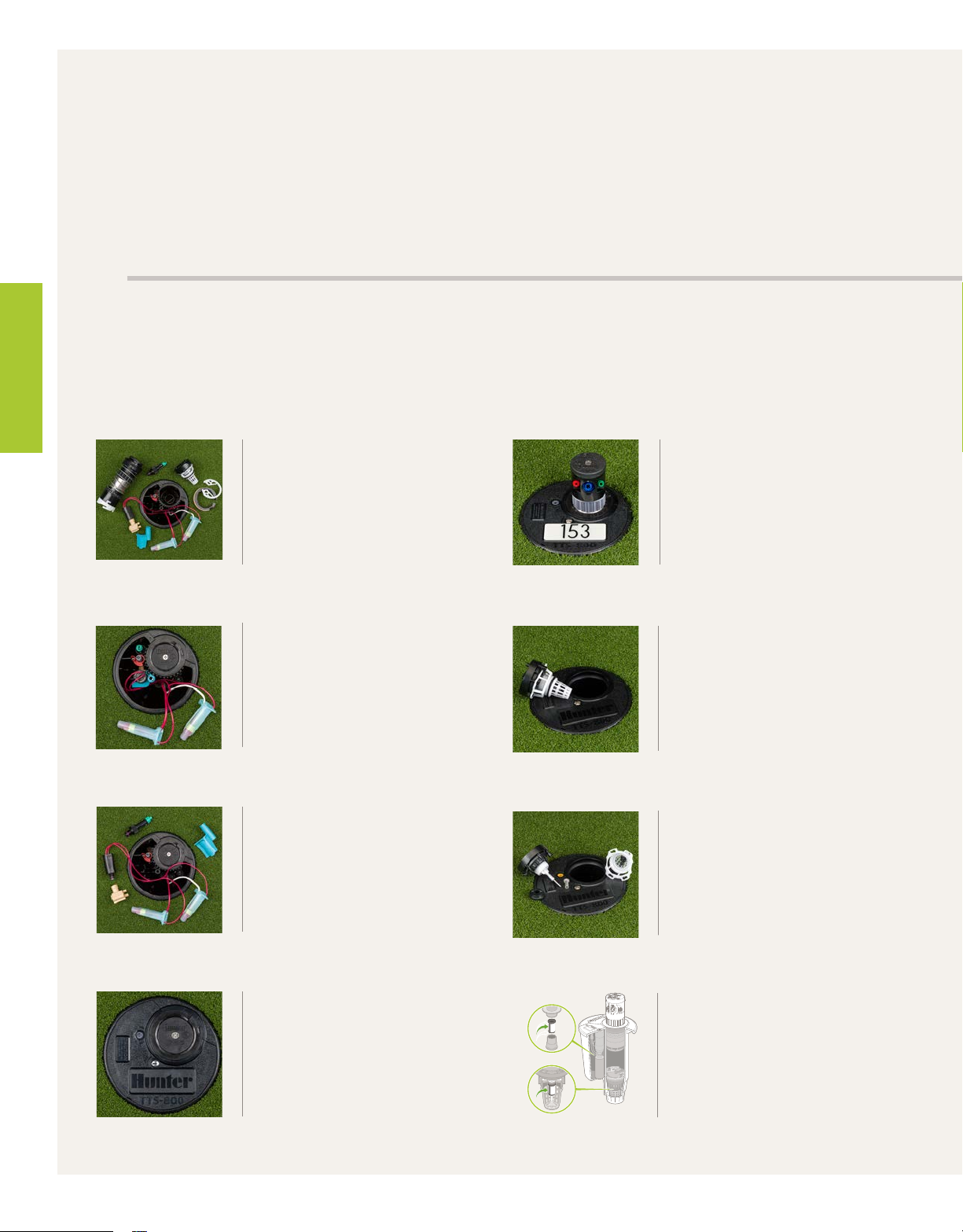

TTS-800 VIH GOLF ROTORS

ADVANCED FEATURES

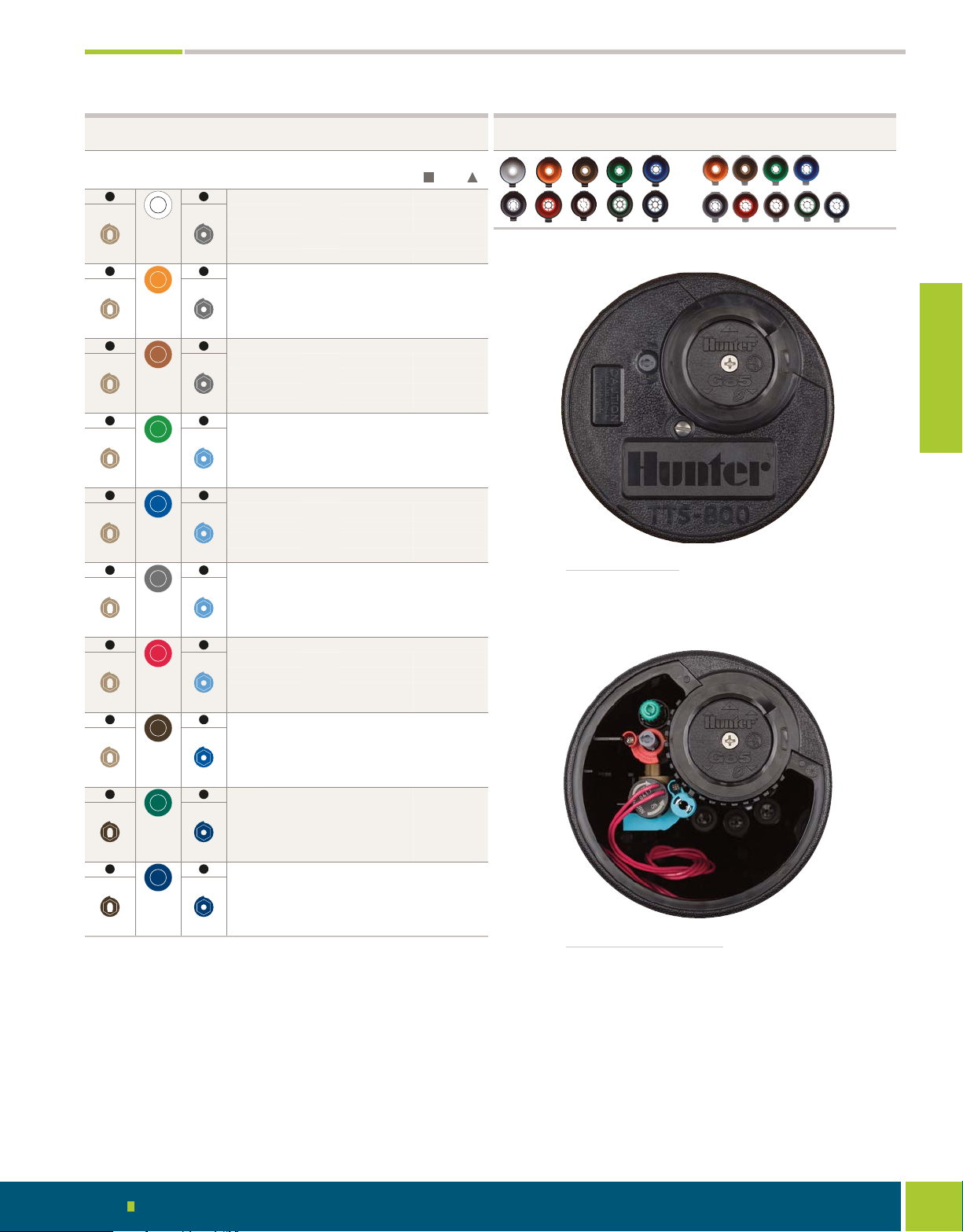

Total-Top-Service (TTS)

Access Everything

Through the Top

This no-dig solution is

appreciated by golfers,

management, and especially

the superintendent

Largest Flange

Compartment in

the Industry

Spacious cavity with enough

room for full-sized 3M

DBRY-6 splice connectors

Easy Access and

Servicing of Solenoid

and Pressure Regulators

Colour-coded components are

removed and replaced without

mainline depressurisation

Large and Flexible Yardage

Marker Capabilities

Oversized marker plates with

standard black or red, white,

blue, and purple options

Unitized Inlet Valve

Design Includes

Serviceable Components

Contamination damage is

quickly resolved with replaceable

valve seat and seat-seal

Exclusive Inlet Valve

Includes Self-Cleaning

Capabilities

Filter Sentry technology wipes

debris from the stainless-steel

screen with every activation

20

Single-Point Fast-Access

to Flange Compartment

Extra-thick compartment lid

is retained with stainless-steel

¼-turn fastener

Stage 2 Filtration

Stage 1 Filtration

Two-Stage Serviceable

Filtration in Valve Circuitry

Oversize stainless-steel

screens at inlet valve and

pilot valve are easily cleaned

or replaced

Heavy-Duty Flanged and

Ribbed Body Design

Impact-resistant and

ultra-durable design

includes extra-strength

PVC Acme inlet

Three Cable Entry Ports

at Base of Flange

Compartment

Makes splice and cable

connections fast, easy,

and organised

Low-Bounce Rubber

Cover Kit

Impact-absorbing design

reduces ball ricochet around

the greens

GOLF ROTORS

No-Bounce Turf Cup Kit

Recessed turf cup design

is aesthetically clean and

eliminates ball ricochet

21

GOLF ROTORS

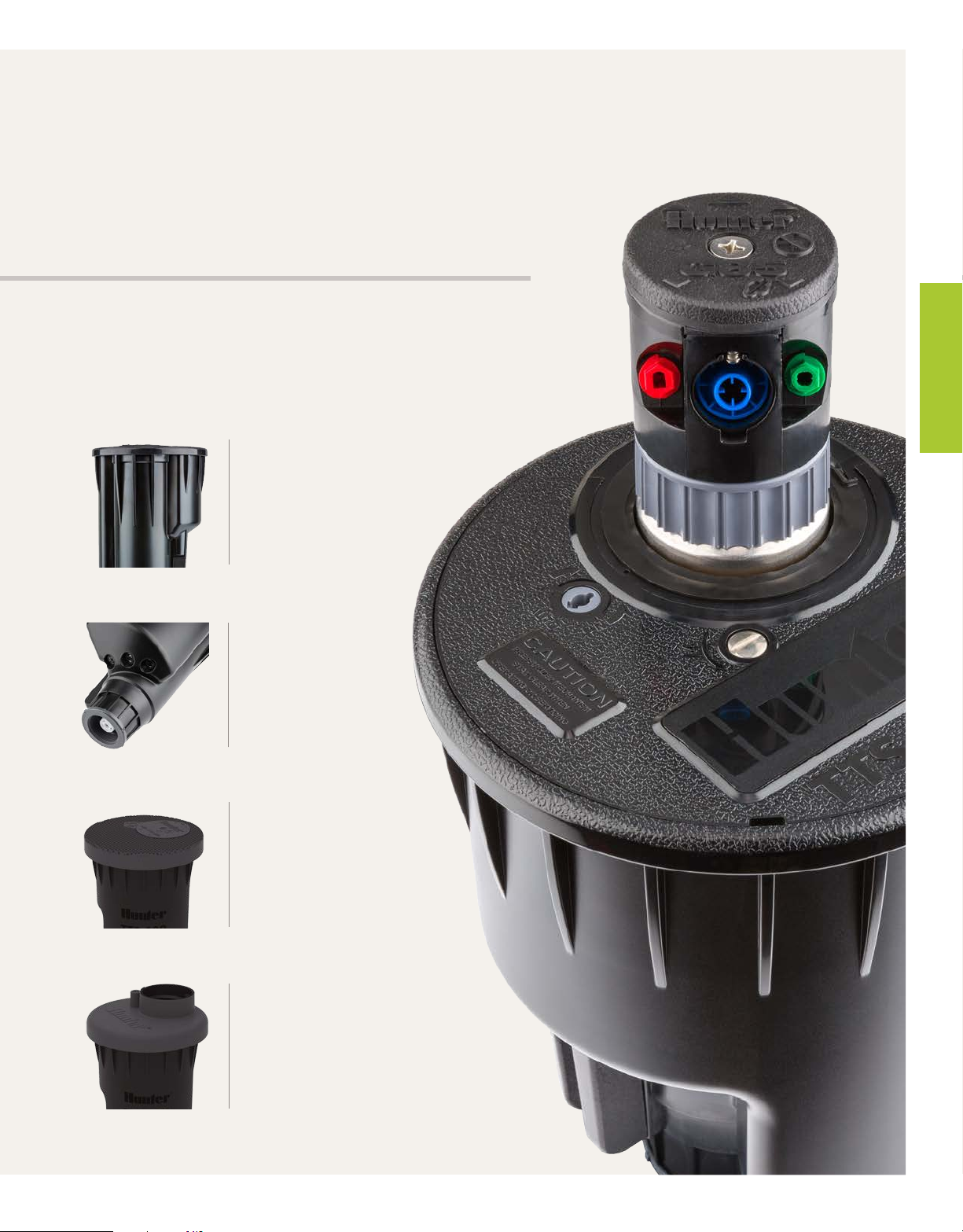

TTS-800 DIH GOLF ROTORS

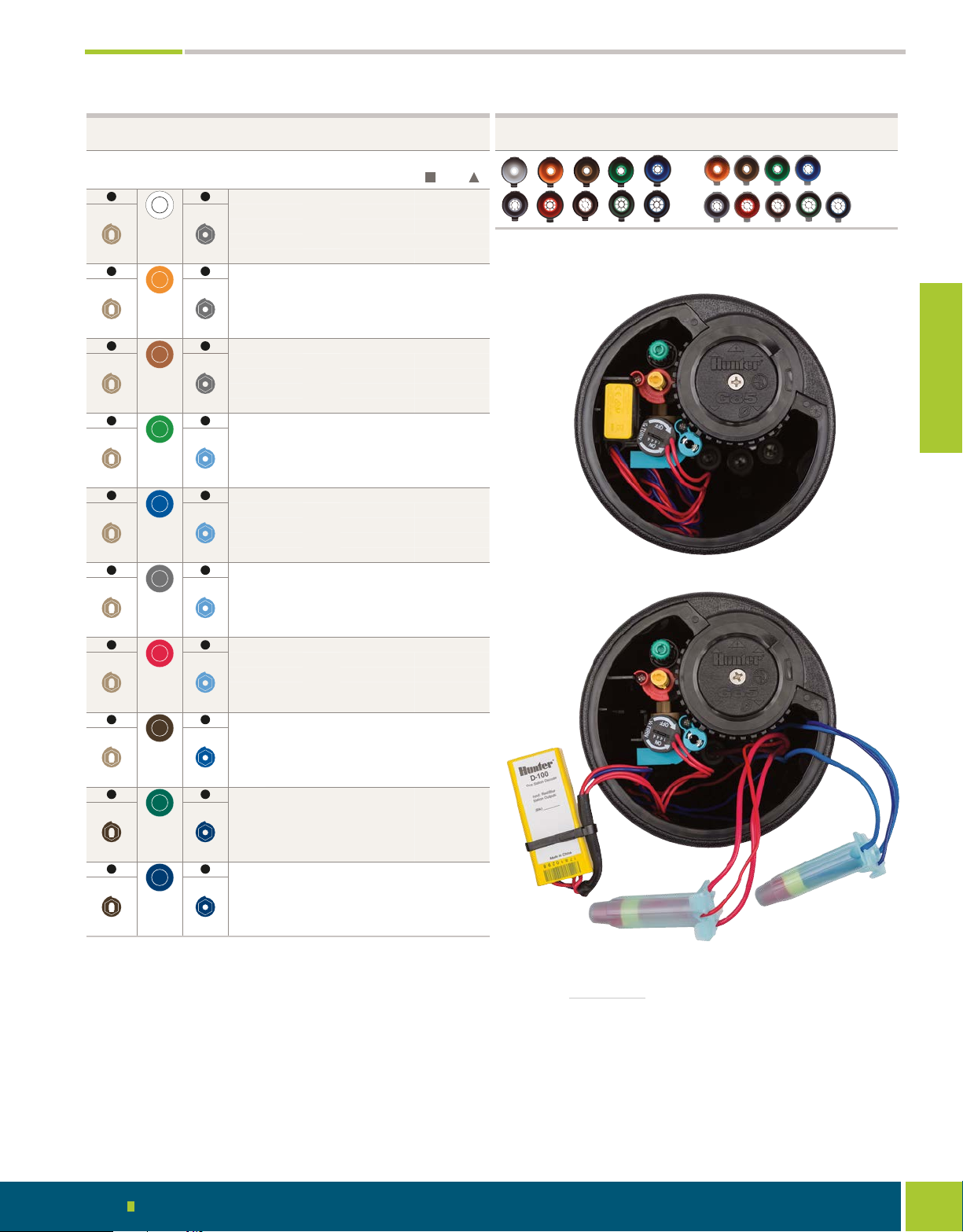

ADVANCED FEATURES

Access Everything,

Including Two-Way

Modules, Through the Top

This no-dig solution is

appreciated by golfers,

management, and especially

the superintendent

Largest Flange DIH

Compartment in

the Industry

Spacious cavity with enough

room for two-way modules

and full-sized 3M DBRY-6

splice connectors

Two-Way Modules

Are Housed in the

DIH Rotor’s Spacious

Flange Compartment

Improves playability and

eliminates unsightly enclosures

around the course

Programming Two-Way

Modules Wirelessly

From the Surface with

No Disassmbly

Quick and easy to program and

perform diagnostics before or

aer installation with ICD-HP

22

GOLF ROTORS

Individual Two-Way

Module and Solenoid

Components Within

Flange Compartment

Isolated/separated

conguration minimises

yearly maintenance costs

State-of-the-Art Surge

Suppression

Earth grounding is easily

added with the Pilot-SG

surge protector

Seamless No-Splice

Connection Between

Two-Way Module and

Solenoid

With no connectors, maintains

ongoing electrical continuity

Two-Station DIH Rotor

Option

Perfect cost-eective

solution for back-to-back

heads around greens

DIH Rotors Include All

the Unique Features and

Benets of TTS Rotors

Makes splice and cable

connections fast, easy,

and clean

Durability, Eciency, and

Reliability from the Makers

of the Industry's First TTS

and DIH Rotors

Peace of mind from the

world's leading producer

of gear-driven rotors

23

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS800 SERIES

FEATURES

• Model: TTS-880 – Full-circle

• Dual-trajectory, color-coded nozzles:

- 10 standard trajectory (22.5°)

- 9 low-angle trajectory (15°)

• Nozzle range: #15 to #53

• Exclusive PressurePort™ nozzle technology

GOLF ROTORS

• Stainless-steel riser

• Water-lubricated gear drive

► All TTS-800 VIH advanced features

► All TTS-800 DIH advanced features

OPERATING SPECIFICATIONS

• Radius: 14.9 to 29.6 m

• Flow: 3.23 to 13.29 m/hr; 53.8 to 221.4 l/min

• Pressure range: 3.4 to 6.9 bar; 340 to 690 kPa

• All TTS rotors are pressure rated at 10 bar; 1,000 kPa

Model: TTS-880

Radius: 14.9 to 29.6 m

Flow: 3.23 to 13.29 m/hr; 53.8 to 221.4 l/min

TTS-800

Pop-up height: 9.5 cm

Overall height: 30 cm

Flange diameter: 18 cm

Female inlet: 1½" Acme

OPTIONS

• C – Check-O-Matic checks up to 8 m in elevation change and readily

converts to Normally Open Hydraulic with through-the-top connections

• D – Decoder Valve-in-Head with all “E” specications below*

• DD – Two-station Decoder Valve-in-Head with all “E” specications below*

• E – Electric Valve-in-Head with adjustable pressure regulation, on-o-auto

selector, 210 mA (370 mA inrush) 50 Hz; 190 mA (350 mA inrush) 60 Hz

solenoid with captive plunger and internal downstream bleed

* All DIH rotors include two 3M DBRY-6 splices for connection to the two-wire

path. See page 13 for critical recommendations on grounding DIH rotors.

► = TTS and DIH Advanced Features detailed on pages 20 and 22

TTS880 SPECIFICATION BUILDER: ORDER 1 + 2 + 3 + 4 + 5

1

Model

GT-880 = Full-Circle

Valve Options

2

C = Check-O-Matic*

D = Decoder Valve-in-Head P6 = 65 PSI (nozzles 18 to 25)

DD = Two-station Decoder Valve-in-Head P8 = 80 PSI (nozzles 25 to 53)

E = Electric Valve-in-Head

* Converts to N.O. Hydraulic Valve-In-Head

Nozzle

3

15 to 53 = Installed G-880 Nozzle*

* SSU = #18, #23, #25, or #48

Regulation*

4

P5 = 50 PSI (nozzles 15 to 18)

* SSU = P5/#18, P6/#23

P8/#25, P8/#48

Options

5

S = SSU*

* Standard

Stocking Unit

24

Example:

GT-880 - E - 48 - P8 - S =

GT- full-circle electric valve-in-head, installed # nozzle, PSI regulation, standard stocking unit model

Visit hunterindustries.com/golf

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS880 NOZZLE PERFORMANCE DATA*

Nozzle Set

Tan Grey

15

White

803611

Tan Grey

315317 5.5 551 16.8 4.13 68.9 14.7 17.0

18

Orange

803611

Tan Grey

315317 5.5 551 18.6 4.82 80.3 13.9 16.1

20

Brown

803611

Tan Lt. Blue

315317 5.5 551 19.5 5.16 85.9 13.5 15.6

23

Green

803611

Tan Lt. Blue

315311 5.5 551 20.7 6.04 100.7 14.1 16.2

25

Blue

803611

Tan Lt. Blue

315311 6.9 689 23.5 8.12 135.3 14.7 17.0

33

Grey

803611

Tan Lt. Blue

315311 6.9 689 24.7 8.68 144.6 14.2 16.4

38

Red

803611

Tan Blue

315311 6.9 689 26.5 9.90 165.0 14.1 16.3

43

Dk. Brown

803611

Dk. Brown Dk. Blue

315300 6.9 689 27.1 11.09 184.7 15.1 17.4

48

Dk. Green

803610

Dk. Brown Dk. Blue

833500 6.9 689 29.3 12.15 202.5 14.2 16.4

53

Dk. Blue

803610

* Preliminary performance data. Complies to ASAE standard. All

precipitation rates calculated for 360° operation. All triangular rates are

equilateral. To calculate precipitation rates for 180° operation, multiply by 2.

833500 6.9 689 29.6 13.29 221.4 15.2 17.6

Pressure

bar kPa m3/hr l/min

3.4 344 14.9 3.23 53.8 14.5 16.7

4.1 413 15.5 3.57 59.4 14.8 17.0

4.5 450 15.9 3.73 62.1 14.8 17.1

4.8 482 16.2 3.86 64.4 14.8 17.1

3.4 344 17.1 3.91 65.1 13.4 15.5

4.1 413 17.7 4.28 71.3 13.7 15.8

4.5 450 18.0 4.48 74.6 13.8 16.0

4.8 482 18.3 4.54 75.7 13.6 15.7

3.4 344 17.4 4.18 69.7 13.8 16.0

4.1 413 18.0 4.61 76.8 14.3 16.5

4.5 450 18.6 4.86 81.0 14.1 16.2

4.8 482 19.2 4.91 81.8 13.3 15.4

3.4 344 19.2 4.91 81.8 13.3 15.4

4.1 413 19.8 5.22 87.1 13.3 15.4

4.5 450 20.1 5.45 90.8 13.5 15.6

4.8 482 20.4 5.66 94.3 13.6 15.7

4.5 450 21.6 6.50 108.3 13.9 16.0

4.8 482 22.3 6.75 112.5 13.6 15.7

5.5 551 22.6 7.19 119.8 14.1 16.3

6.2 620 22.9 7.65 127.5 14.6 16.9

4.5 450 22.6 7.02 117.0 13.8 15.9

4.8 482 22.9 7.27 121.1 13.9 16.1

5.5 551 23.5 7.77 129.5 14.1 16.3

6.2 620 24.1 8.22 137.0 14.2 16.4

4.5 450 23.5 7.97 132.9 14.5 16.7

4.8 482 24.1 8.31 138.5 14.3 16.6

5.5 551 25.0 8.84 147.3 14.1 16.3

6.2 620 25.6 9.38 156.3 14.3 16.5

- - - - - - -

4.8 482 25.3 9.38 156.3 14.7 16.9

5.5 551 25.9 9.90 165.0 14.8 17.0

6.2 620 26.5 10.52 175.3 15.0 17.3

- - - - - - -

4.8 482 27.4 10.65 177.5 14.2 16.3

5.5 551 28.0 11.11 185.1 14.1 16.3

6.2 620 28.7 11.46 191.0 14.0 16.1

- - - - - - -

4.8 482 27.7 11.31 188.5 14.7 17.0

5.5 551 28.3 11.86 197.7 14.8 17.0

6.2 620 29.0 12.61 210.1 15.0 17.4

Radius

m

Flow

Precip mm/hr

TTS880 STANDARD NOZZLES TTS880 LOWANGLE NOZZLES**

** Low-angle nozzles reduce radius by 15%

GOLF ROTORS

Easy-Access Servicing

An extra-thick compartment lid is retained with

a ⁄-turn, stainless-steel, single-point fastener.

Spacious Flange Compartment

The largest and deepest compartment in the industry

offers plenty of room for full-sized DBRY-6 splice

connectors.

Visit hunterindustries.com/golf

GOLF IRRIGATION | Built on Innovation

®

25

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS800 SERIES

FEATURES

• Model: TTS-884 – Full-circle

• Dual-trajectory, colour-coded nozzles:

- 10 standard trajectory (22.5°)

- 9 low-angle trajectory (15°)

• Nozzle range: #15 to #53

• Exclusive PressurePort™ nozzle technology

GOLF ROTORS

• Stainless-steel riser

• Water-lubricated gear drive

► All TTS-800 VIH advanced features

► All TTS-800 DIH advanced features

OPERATING SPECIFICATIONS

• Radius: 14.9 to 29.6 m

• Flow: 3.23 to 13.29 m

• Pressure range: 3.4 to 6.9 bar; 340 to 690 kPa

• All TTS rotors are pressure rated at 10 bar; 1,000 kPa

3

/hr; 53.8 to 221.4 l/min

Model: TTS-884

Radius: 14.9 to 29.6 m

Flow: 3.23 to 13.29 m

3

/hr; 53.8 to 221.4 l/min

TTS-884

Pop-up height: 9.5 cm

Overall height: 30 cm

Flange diameter: 18 cm

Female inlet: 1½" Acme

OPTIONS

• C – Check-O-Matic checks up to 8 m in elevation change and readily

converts to Normally Open Hydraulic with through-the-top connections

• D – Decoder Valve-in-Head with all “E” specications below*

• DD – Two-station Decoder Valve-in-Head with all “E” specications below*

• E – Electric Valve-in-Head with adjustable pressure regulation, on-o-auto

selector, 210 mA (370 mA inrush) 50 Hz; 190 mA (350 mA inrush) 60 Hz

solenoid with captive plunger and internal downstream bleed

* All DIH rotors include two 3M DBRY-6 splices for connection to the two-wire

path. See page 13 for critical recommendations on grounding DIH rotors.

► = TTS and DIH Advanced Features detailed on pages 20 and 22

TTS884 SPECIFICATION BUILDER: ORDER 1 + 2 + 3 + 4 + 5

1

Model

GT-884 = Full-Circle

(convertible to forward-

facing adjustable arc rotor)

Valve Options

2

C = Check-O-Matic*

D = Decoder Valve-in-Head P6 = 65 PSI (nozzles 18 to 25)

DD = Two-station Decoder Valve-in-Head P8 = 80 PSI (nozzles 25 to 53)

E = Electric Valve-in-Head

* Converts to N.O. Hydraulic Valve-in-Head

Nozzle

3

15 to 53 = Installed G-880 Nozzle*

* SSU = #18, #23, #25, or #48

Regulation*

4

P5 = 50 PSI (nozzles 15 to 18)

* SSU = P5/#18, P6/#23

P8/#25, P8/#48

Options

5

S = SSU*

* Standard

Stocking Unit

26

Example:

GT-884 - E - 48 - P8 - S =

GT- full-circle electric valve-in-head, installed # nozzle, PSI regulation, standard stocking unit model

Visit hunterindustries.com/golf

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS884 NOZZLE PERFORMANCE DATA*

Nozzle Set

Tan Grey

15

White

803611

Tan Grey

315317 5.5 551 16.8 4.13 68.9 14.7 17.0

18

Orange

803611

Tan Grey

315317 5.5 551 18.6 4.82 80.3 13.9 16.1

20

Brown

803611

Tan Lt. Blue

315317 5.5 551 19.5 5.16 85.9 13.5 15.6

23

Green

803611

Tan Lt. Blue

315311 5.5 551 20.7 6.04 100.7 14.1 16.2

25

Blue

803611

Tan Lt. Blue

315311 6.9 689 23.5 8.12 135.3 14.7 17.0

33

Grey

803611

Tan Lt. Blue

315311 6.9 689 24.7 8.68 144.6 14.2 16.4

38

Red

803611

Tan Blue

315311 6.9 689 26.5 9.90 165.0 14.1 16.3

43

Dk. Brown

803611

Dk. Brown Dk. Blue

315300 6.9 689 27.1 11.09 184.7 15.1 17.4

48

Dk. Green

803610

Dk. Brown Dk. Blue

833500 6.9 689 29.3 12.15 202.5 14.2 16.4

53

Dk. Blue

803610

* Preliminary performance data. Complies to ASAE standard. All

precipitation rates calculated for 360° operation. All triangular rates are

equilateral. To calculate precipitation rates for 180° operation, multiply by 2.

833500 6.9 689 29.6 13.29 221.4 15.2 17.6

Pressure

bar kPa m3/hr l/min

3.4 344 14.9 3.23 53.8 14.5 16.7

4.1 413 15.5 3.57 59.4 14.8 17.0

4.5 450 15.9 3.73 62.1 14.8 17.1

4.8 482 16.2 3.86 64.4 14.8 17.1

3.4 344 17.1 3.91 65.1 13.4 15.5

4.1 413 17.7 4.28 71.3 13.7 15.8

4.5 450 18.0 4.48 74.6 13.8 16.0

4.8 482 18.3 4.54 75.7 13.6 15.7

3.4 344 17.4 4.18 69.7 13.8 16.0

4.1 413 18.0 4.61 76.8 14.3 16.5

4.5 450 18.6 4.86 81.0 14.1 16.2

4.8 482 19.2 4.91 81.8 13.3 15.4

3.4 344 19.2 4.91 81.8 13.3 15.4

4.1 413 19.8 5.22 87.1 13.3 15.4

4.5 450 20.1 5.45 90.8 13.5 15.6

4.8 482 20.4 5.66 94.3 13.6 15.7

4.5 450 21.6 6.50 108.3 13.9 16.0

4.8 482 22.3 6.75 112.5 13.6 15.7

5.5 551 22.6 7.19 119.8 14.1 16.3

6.2 620 22.9 7.65 127.5 14.6 16.9

4.5 450 22.6 7.02 117.0 13.8 15.9

4.8 482 22.9 7.27 121.1 13.9 16.1

5.5 551 23.5 7.77 129.5 14.1 16.3

6.2 620 24.1 8.22 137.0 14.2 16.4

4.5 450 23.5 7.97 132.9 14.5 16.7

4.8 482 24.1 8.31 138.5 14.3 16.6

5.5 551 25.0 8.84 147.3 14.1 16.3

6.2 620 25.6 9.38 156.3 14.3 16.5

- - - - - - -

4.8 482 25.3 9.38 156.3 14.7 16.9

5.5 551 25.9 9.90 165.0 14.8 17.0

6.2 620 26.5 10.52 175.3 15.0 17.3

- - - - - - -

4.8 482 27.4 10.65 177.5 14.2 16.3

5.5 551 28.0 11.11 185.1 14.1 16.3

6.2 620 28.7 11.46 191.0 14.0 16.1

- - - - - - -

4.8 482 27.7 11.31 188.5 14.7 17.0

5.5 551 28.3 11.86 197.7 14.8 17.0

6.2 620 29.0 12.61 210.1 15.0 17.4

Radius

m

Flow

Precip mm/hr

TTS884 STANDARD NOZZLES TTS884 LOWANGLE NOZZLES**

** Low-angle nozzles reduce radius by 15%

GOLF ROTORS

Room to Spare

Adding a two-way module does not reduce flange

compartment space. The exclusive configuration

provides extra room for full-sized DBRY-6 splice

connectors and multiple cables.

Visit hunterindustries.com/golf

GOLF IRRIGATION | Built on Innovation

®

27

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS800 SERIES

FEATURES

• Model: TTS-885 – True full-circle/adjustable part-circle (60° to 360°)

• QuickCheck™ arc mechanism

• QuickSet-360 arc mechanism

• Dual-trajectory, colour-coded nozzles:

- 12 standard trajectory (22.5°)

GOLF ROTORS

- 9 low-angle trajectory (15°)

• Nozzle range: #10 to #53

• Exclusive PressurePort™ nozzle technology

• Contour “Back-Nozzle” capabilities

• Ratcheting stainless-steel riser

• Water-lubricated gear drive

► All TTS-800 VIH advanced features

► All TTS-800 DIH advanced features

OPERATING SPECIFICATIONS

• Radius: 11.3 to 28.7 m

• Flow: 2.02 to 13.54 m

• Pressure range: 3.4 to 6.9 bar; 340 to 690 kPa

• All TTS rotors are pressure rated at 10 bar; 1,000 kPa

3

/hr; 33.7 to 225.6 l/min

Model: TTS-885

Radius: 11.3 to 28.7 m

Flow: 2.02 to 13.54 m

3

/hr; 33.7 to 225.6 l/min

TTS-885

Pop-up height: 9.5 cm

Overall height: 30 cm

Flange diameter: 18 cm

Female inlet: 1½" Acme

OPTIONS

• C – Check-O-Matic checks up to 8 m in elevation change and readily

converts to Normally Open Hydraulic with through-the-top connections

• D – Decoder Valve-in-Head with all “E” specications below*

• DD – Two-station Decoder Valve-in-Head with all “E” specications below*

• E – Electric Valve-in-Head with adjustable pressure regulation, on-o-auto

selector, 210 mA (370 mA inrush) 50 Hz; 190 mA (350 mA inrush) 60 Hz

solenoid with captive plunger and internal downstream bleed

* All DIH rotors include two 3M DBRY-6 splices for connection to the two-wire path.

See page 13 for critical recommendations on grounding DIH rotors.

► = TTS and DIH Advanced Features detailed on pages 20 and 22

TTS885 SPECIFICATION BUILDER: ORDER 1 + 2 + 3 + 4 + 5

1

Model

GT-885 = Full/Part-Circle

60º-360º Arc Range

Example:

GT-885 - E - 48 - P8 - S =

Valve Options

2

C = Check-O-Matic*

D = Decoder Valve-in-Head P6 = 65 PSI (nozzles 18 to 25)

DD = Two-station Decoder Valve-in-Head P8 = 80 PSI (nozzles 25 to 53)

E = Electric Valve-in-Head

* Converts to N.O. Hydraulic Valve-in-Head

GT- full/part circle electric valve-in-head, installed # nozzle, PSI regulation, standard stocking unit model

Nozzle

3

10 to 53 = Installed G-885 Nozzle*

* SSU = #18, #23, #25, or #48

Regulation*

4

P5 = 50 PSI (nozzles 10 to 18)

* SSU = P5/#18, P6/#23

P8/#25, P8/#48

Options

5

S = SSU*

* Standard Stocking

Unit

28

Visit hunterindustries.com/golf

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS885 NOZZLE PERFORMANCE DATA*

Nozzle Set

Orange Dk. Green 3.4 344 11.3 2.02 33.7 15.9 18.4

803603 315312

Orange

803603 315314

Orange

803603 315314

Orange

803603 315313

Orange

803603 315313

Orange

803603 315313

Red

803602 315310

Red

803602 315310

Red

803602 315310

Red

803602 315310

Dk. Red

803601 315312

Dk. Red

803601 315312

= Nozzle plug P/N 315300 installed in the back side of the nozzle housing.

10

Lt. Green

White 3.4 344 14.3 2.59 43.2 12.6 14.6

13

Lt. Blue

White 3.4 344 15.9 2.93 48.8 11.7 13.5

15

White

Lt. Green 3.4 344 17.4 3.77 62.8 12.5 14.4

18

Orange

Lt. Green 3.4 344 18.0 4.07 67.8 12.6 14.5

20

Tan

Lt. Green 3.4 344 19.8 4.59 76.5 11.7 13.5

23

Green

Green 4.5 450 21.6 6.43 107.1 13.7 15.8

25

Blue

Green 4.5 450 21.9 6.95 115.8 14.4 16.7

33

Grey

Green 4.5 450 23.2 7.93 132.1 14.8 17.1

38

Red

Green - - - - - - -

43

Dk. Brown

Dk. Green - - - - - - -

48

Dk. Green

Dk. Green - - - - - - -

53

Dk. Blue

Pressure

bar kPa m3/hr l/min

4.1 413 11.9 2.23 37.1 15.8 18.2

4.5 450 12.5 2.32 38.6 14.8 17.1

- - - - - - -

- - - - - - -

4.1 413 14.6 2.79 46.6 13.1 15.1

4.5 450 14.9 2.93 48.8 13.1 15.2

- - - - - - -

- - - - - - -

4.1 413 15.9 3.29 54.9 13.1 15.1

4.5 450 16.2 3.38 56.4 13.0 15.0

4.8 482 16.2 3.52 58.7 13.5 15.6

5.5 551 16.5 3.75 62.5 13.8 16.0

4.1 413 17.7 4.04 67.4 12.9 14.9

4.5 450 18.0 4.23 70.4 13.1 15.1

4.8 482 18.3 4.41 73.4 13.2 15.2

5.5 551 18.6 4.66 77.6 13.5 15.6

4.1 413 18.6 4.43 73.8 12.8 14.8

4.5 450 18.9 4.50 75.0 12.6 14.5

4.8 482 19.2 4.68 78.0 12.7 14.7

5.5 551 19.5 5.02 83.7 13.2 15.2

4.1 413 20.1 5.02 83.7 12.4 14.3

4.5 450 20.4 5.43 90.5 13.0 15.0

4.8 482 20.4 5.50 91.6 13.2 15.2

5.5 551 21.0 5.88 98.0 13.3 15.4

4.8 482 21.9 6.66 110.9 13.8 16.0

5.5 551 22.3 7.16 119.2 14.5 16.7

6.2 620 22.6 7.59 126.4 14.9 17.2

6.9 689 22.9 8.04 134.0 15.4 17.8

4.8 482 22.3 7.18 119.6 14.5 16.7

5.5 551 22.9 7.70 128.3 14.7 17.0

6.2 620 23.5 8.13 135.5 14.8 17.0

6.9 689 24.1 8.61 143.5 14.8 17.1

4.8 482 23.8 8.22 137.0 14.5 16.8

5.5 551 24.4 8.88 148.0 14.9 17.2

6.2 620 25.0 9.36 156.0 15.0 17.3

6.9 689 25.6 9.88 164.7 15.1 17.4

4.8 482 24.7 9.36 156.0 15.4 17.7

5.5 551 25.3 9.88 164.7 15.4 17.8

6.2 620 26.2 10.49 174.9 15.3 17.6

6.9 689 27.1 11.06 184.3 15.0 17.4

4.8 482 25.3 10.52 175.3 16.4 19.0

5.5 551 25.9 10.99 183.2 16.4 18.9

6.2 620 27.1 11.74 195.7 16.0 18.4

6.9 689 27.7 12.38 206.3 16.1 18.6

4.8 482 26.5 11.52 191.9 16.4 18.9

5.5 551 27.1 12.06 201.0 16.4 18.9

6.2 620 28.0 12.81 213.5 16.3 18.8

6.9 689 28.7 13.54 225.6 16.5 19.0

Radius

m

Flow

Precip mm/hr

TTS885 STANDARD NOZZLES TTS885 LOWANGLE NOZZLES**

** Low-angle nozzles reduce radius by 15%

GOLF ROTORS

Reduced Downtime

There is no need to depressurise the mainline for

solenoid and pressure regulator servicing.

Total-Top-Service Solution

From the originators of TTS technology, Hunter's

no-dig TTS-800 rotors provide total-top-servicing

of every serviceable component.

* Complies to ASAE standard. All precipitation rates calculated for 360°

operation. All triangular rates are equilateral. To calculate precipitation

rates for 180° operation, multiply by 2.

Visit hunterindustries.com/golf

GOLF IRRIGATION | Built on Innovation

®

29

TTS800 SERIES G800 SERIES B SERIES G900 SERIES

TTS800 SERIES

FEATURES

• Model: TTS-835: Full/Part circle (50º to 360°)

• QuickCheck™ arc mechanism

• QuickSet-360 arc mechanism

• Nozzle choices: 8 multi-trajectory (15° to 25°)

• Nozzle range: #2 to #12

GOLF ROTORS

• Water-lubricated gear drive

► All TTS-800 VIH advanced features

► All TTS-800 DIH advanced features

Model: TTS-835

Radius: 5.5 to 15.2 m

Flow: 0.43 to 2.91 m

3

/hr; 7.2 to 48.5 l/min

OPERATING SPECIFICATIONS

• Radius: 5.5 to 15.2 m

• Flow: 0.43 to 2.91 m

• Pressure range: 2.8 to 4.5 bar; 280 to 450 kPa

• All TTS rotors are pressure rated at 10 bar; 1,000 kPa

3

/hr; 7.2 to 48.5 l/min

OPTIONS

• C – Check-O-Matic checks up to 8 m in elevation change and readily

converts to Normally Open Hydraulic with through-the-top connections

• D – Decoder Valve-in-Head with all “E” specications below*

• DD – Two-station Decoder Valve-in-Head with all “E” specications below*

• E – Electric Valve-in-Head with adjustable pressure regulation, on-o-auto

selector, 210 mA (370 mA inrush) 50 Hz; 190 mA (350 mA inrush) 60 Hz

solenoid with captive plunger and internal downstream bleed

* All DIH rotors include two 3M DBRY-6 splices for connection to the two-wire

path. See page 13 for critical recommendations on grounding DIH rotors.

► = TTS and DIH Advanced Features detailed on pages 20 and 22

TTS835 SPECIFICATION BUILDER: ORDER 1 + 2 + 3 + 4 + 5

1

Model

GT-835 = Full/Part Circle 50

to 360°

Valve Options

2

C = Check-O-Matic * 6 = Installed G-835 Nozzle *

D = Decoder Valve-in-Head

E = Electric Valve-in-Head

* Converts to N.O. Hydraulic

Valve-in-Head

Nozzle

3

includes 8-nozzle rack

* SSU = #6 * SSU = P5

Regulation*

4

P5 = 50 PSI

P6 = 65 PSI

TTS-835

Pop-up height: 8 cm

Overall height: 30 cm

Flange diameter: 18 cm

Female inlet: 1½" Acme

Options

5

S = SSU *

* Standard Stocking Unit

30

Examples:

GT-835 - 6 - P5 - S =

GT- full/part-circle electric valve-in-head, installed # nozzle, PSI regulation, standard stocking unit model

Visit hunterindustries.com/golf

Loading...

Loading...