Page 1

OPERATION INSTRUCTIONS

Supersedes Form 4202T, 07-05

Form 4202T, 11-05

GSP9700 Series

Road Force Measurement

System

With SmartWeight™ Balancing Technology

Software Version 5.0

Copyright 1997-2005 Hunter Engineering Company

Page 2

OWNER INFORMATION

Model Number ____________________________________________________________________

Software Version Number ___________________________________________________________

Serial Number ____________________________________________________________________

Date Installed_____________________________________________________________________

Service and Parts Representative _____________________________________________________

Phone Number____________________________________________________________________

Sales Representative_______________________________________________________________

Phone Number____________________________________________________________________

Concept and Procedure Training Checklist

Trained

Safety Precautions

Quick-Thread

Autostart

Servo-Stop

Maintenance & Calibration

Cleaning, Lubrication, and Maintenance of Adaptors, Hub, and Shaft

Calibrating the Balancer

Calibrating the Load Roller and Dataset Arms

Calibrating the Inflation Station

Mounting the Wheel/Tire Assembly

Verifying Mounting Repeatability with Centering Check® Feature

Cone Mounting

Pressure Ring and Spacers

Flange Plate and Cone Mounting

Wheel Balancing

SmartWeight™

Standard

Mixed Weights

Adhesive Weights with Auto Dataset Arms

Split-Spoke

Patch Balancing with Auto Dataset Arms (optional)

Declined

Do’s and Don’ts of Wheel Balancing

Road Force Measurement and ForceMatching™

Adjusting P/SUV/LT Limits

Assembly Measurements

Applying Previous Wheel Measurements

Applying Previous Tire Measurements

Wheel Measurement with Dataset Arms

Tire Installed

Bare Rim

Road Force Measurement First Harmonic Diagnosis Screen

“Current Runout and Force Variation”

“Diagnosis Explanation” and “Details” Screens

Match Codes

MatchMaker Procedure Explained

Do’s and Don’ts of Road Force Measurement

Page 3

Individuals and Date Trained

__________________________________ __________________________________

__________________________________ __________________________________

__________________________________ __________________________________

__________________________________ __________________________________

__________________________________ __________________________________

__________________________________ __________________________________

Page 4

Page 5

CONTENTS

1. GETTING STARTED........................................................................................1

1.1 Introduction.................................................................................................................1

1.2 For Your Safety ........................................................................................................... 1

Hazard Definitions.................................................................................................. 1

IMPORTANT SAFETY INSTRUCTIONS

Electrical.................................................................................................................3

Decal Information and Placement.......................................................................... 4

Right Side View...............................................................................................4

Left Side View..................................................................................................5

Back View........................................................................................................6

Specific Precautions/Power Source....................................................................... 7

Turning Power ON/OFF......................................................................................... 7

Equipment Installation and Service .......................................................................8

Equipment Specifications....................................................................................... 8

Electrical.......................................................................................................... 8

Air .................................................................................................................... 8

Atmospherics...................................................................................................8

Sound Pressure Level..................................................................................... 8

Safety Summary ....................................................................................................8

Explanation of Symbols...................................................................................8

1.3 Equipment Components ............................................................................................ 9

Standard Balancer Accessories........................................................................... 10

1.4 Operating the Console ............................................................................................. 11

Using Softkeys.....................................................................................................11

Primary Balancing Display................................................................................... 12

Using the Control Knob (GSP9712).....................................................................12

Using Control Knobs (GSP9702).........................................................................13

Resetting the Program......................................................................................... 13

Using the Screen Saver/Merchandising Display..................................................13

........................2

2. BALANCING OVERVIEW..............................................................................15

2.1 Balancing Modes ......................................................................................................15

SmartWeight™ Balancing Technology................................................................ 15

Balancing Theory................................................................................................. 15

Static Imbalance............................................................................................ 15

Couple Imbalance..........................................................................................16

Static and Dynamic Imbalance Sensitivity........................................................... 17

2.2 Identifying the Static Balance Weight Plane.......................................................... 18

2.3 Identifying the Dynamic Balance Weight Planes................................................... 19

2.4 SmartWeight™ Dynamic Weight Planes ................................................................ 20

3. MOUNTING WHEELS ON THE BALANCER ................................................21

3.1 Mounting the Wheel Using Wheel Lift (Optional) .................................................. 21

Raising the Tire/Wheel Assembly........................................................................21

Lowering the Tire/Wheel Assembly.....................................................................23

3.2 Mounting the Wheel (Without Wheel Lift)...............................................................23

Mounting Error Detection Features...................................................................... 24

Front/Back Cone Mounting..................................................................................24

Using Plastic Wheel Mounting Washer................................................................26

Cone/Flange Plate Mounting ............................................................................... 27

Expandable Collet Mounting................................................................................28

Using the Pressure Ring and Spacers................................................................. 28

Pressure Ring................................................................................................28

Spacers .........................................................................................................29

CenteringCheck®..................................................................................................30

3.3 On-Vehicle Wheel Mounting Methods ....................................................................33

Hub Centric..........................................................................................................33

Lug Centric........................................................................................................... 33

GSP9700 Series Road Force Measurement System Operation Contents i

Page 6

4. BALANCING A WHEEL................................................................................. 35

4.1 Balancing Procedures.............................................................................................. 35

SmartWeight™ Balancing Technology................................................................ 35

Using SmartWeight™....................................................................................35

Switching from SmartWeight™ to Traditional Dynamic Balancing Modes....37

Dynamic Balancing Selection ..............................................................................37

Static Balancing Selection ...................................................................................37

Static Balance Mode Reminder for “Dynamic Balance Importance” (Except

Patch Balance)..............................................................................................38

Selecting Weight Types and Placement Modes..................................................39

STANDARD Balancing Procedure (Using Clip-On Weights)........................39

MIXED WEIGHTS Balancing Procedure (Combination of Clip-On &

Adhesive Weights).........................................................................................41

ADHESIVE WEIGHTS Balancing Procedure (Adhesive Weights Only).......43

PATCH BALANCE® Procedure.....................................................................45

4.2 Using the Auto Dataset® Arms ................................................................................48

Automatic Weight Position Measurement............................................................48

Manual Weight Position Measurement................................................................ 48

Measuring Dimensions for Standard Clip-on Weight Balancing.......................... 49

Measuring Dimensions for Mixed Weights (Clip-on/Tape-on) Balance...............49

Measuring Dimensions for Adhesive Weights Balancing (Tape-on/Tape-on).... 50

Measuring 20 Inch or Larger Rims.......................................................................51

Adjustable Length Inner Dataset Arm ........................................................ 51

Servo-Aided Adhesive Weight Placement.....................................................51

Manual Adhesive Weight Placement.............................................................53

Rim Runout Measurements.................................................................................54

Single Arm Rim Runout External Measurement (Tire and Wheel Assembly)54

Dual Arm Rim Runout External Measurement (Tire and Wheel Assembly).54

Rim Runout Measurement (Bare Rim)..........................................................56

4.3 Primary and Popup Screens....................................................................................57

Primary Screen Selection ....................................................................................57

Balance Primary Screen......................................................................................58

4.4 Load Roller ................................................................................................................ 60

Load Roller Operation..........................................................................................60

4.5 ForceMatching™.......................................................................................................61

ForceMatching™ Procedures..............................................................................62

ForceMatching™ Using Previous Bare Rim Measurement.................................63

ForceMatching™ Using Previous Road Force™ Measurement.......................... 63

Using ForceMatch Codes Feature.......................................................................64

Dial Indicator Gauges Feature.............................................................................64

Lateral/Radial Rim High Spot Indicators Feature ................................................65

Details/Diagnosis Explanation Key......................................................................65

Encountering ForceMatching™ Prediction Errors ...............................................65

Do’s and Don’ts of Road Force Measurement.................................................. 66

4.6 QuickMatch™ Tire and Wheel Mounting................................................................ 66

QuickMatch™ Procedures...................................................................................67

QuickMatch™ Using Previous Bare Rim Measurement......................................68

QuickMatch™ Using Previous Loaded Runout Measurement............................68

Dial Indicator Gauges Feature.............................................................................68

Lateral/Radial Rim High Spot Indicators Feature ................................................69

Encountering ForceMatching™ or QuickMatching™ Prediction Errors...............69

Do’s and Don’ts of Loaded Runout Measurement............................................... 70

4.7 StraightTrak® LFM (Lateral Force Measurement) ..................................................70

Disabling StraightTrak®........................................................................................73

Vehicle Plan View ................................................................................................ 74

Net Tire Pull Arrow...............................................................................................74

Road Force Arrows...........................................................................................74

Changing Tag Numbers.......................................................................................75

Show Least Pull ................................................................................................... 76

Show Least Vibration........................................................................................... 76

Show Alternate Placements.................................................................................76

ii Contents GSP9700 Series Road Force Measurement System Operation

Page 7

Show Details........................................................................................................77

Determining Tire Conicity Outliers.................................................................77

Printout................................................................................................................. 77

Inflation Pressure................................................................................................. 78

4.8 Quick-Thread™ Feature...........................................................................................78

4.9 Motor Drive/Servo-Stop............................................................................................79

4.10 Spindle-Lok® Feature.............................................................................................. 79

4.11 Hood Autostart Feature..........................................................................................79

4.12 Loose Hub Detect Feature ..................................................................................... 79

4.13 Blinding and Rounding ..........................................................................................80

4.14 Inflation Station.......................................................................................................81

5. BALANCING FEATURES AND OPTIONS ....................................................83

5.1 SmartWeight™ Balancing Technology................................................................... 83

5.2 WeightSaver™ Wheel Balancing Feature............................................................... 84

5.3 Quick-Thread™ Feature...........................................................................................84

5.4 Motor Drive/Servo-Stop............................................................................................85

5.5 Spindle-Lok® Feature................................................................................................ 85

5.6 Hood Autostart Feature............................................................................................86

5.7 Loose Hub Detect Feature ....................................................................................... 86

5.8 Inflation Station.........................................................................................................86

5.9 Split Weight® Feature ...............................................................................................87

Split Weight® Operation.......................................................................................87

Correcting Large Imbalances...............................................................................88

5.10 Split Spoke® Feature............................................................................................... 88

Hiding Adhesive Weight behind Spoke................................................................ 88

Re-entering Similar Wheel after Split Spoke® is Enabled.................................... 90

Placing Hidden Weight Inside of Hollow Spokes................................................. 91

5.11 MatchMaker™ Tire and Wheel Mounting Procedure........................................... 93

Tires Mounted on Rims........................................................................................93

Tires Not Mounted to Rims..................................................................................94

5.12 Diagnosis Explanation Screen (Limits Disabled)................................................95

5.13 Diagnosis Explanation Screen (Limits Enabled).................................................95

5.14 Details Screen.........................................................................................................96

5.15 Print Summary ........................................................................................................97

5.16 Harmonics & T.I.R. Data/Plots ............................................................................... 98

Assembly Data Plots Screen ............................................................................... 98

Tire Data Plots Screen.........................................................................................99

5.17 Statistics................................................................................................................100

Show Statistics................................................................................................... 100

Weight Savings..................................................................................................101

Rim Data Plots Screen....................................................................................... 102

6. EQUIPMENT INFORMATION ......................................................................103

6.1 Software Identification ........................................................................................... 103

6.2 Program Cartridge Removal and Installation.......................................................103

6.3 Balancer Set Up ......................................................................................................104

GSP9700 Series Road Force Measurement System Operation Contents iii

Setting Up the Display Language......................................................................105

Setting Up the Printout Language......................................................................105

Setting Up the QuickMatch® Feature.................................................................105

Setting Up the Use Limits Feature.....................................................................106

Setting Up the Screen Saver Time-out..............................................................106

Setting Up the Hood Autostart Feature.............................................................. 107

Setting Up the Servo-Stop/Servo-Push.............................................................107

Setting Up the Quick-Thread™ Feature............................................................108

Setting Up the Balance Check Spin...................................................................108

Setting Up the Weight Units...............................................................................108

Setting Up the Inflation Station Units................................................................. 109

Setting Up the Runout Units .............................................................................. 109

Setting Up the Road Force Units.......................................................................109

Setting Up the Prompted Inflation Station..........................................................110

Setting Up the Prompted Centering Checks......................................................110

Page 8

6.4 Service Mode Setup and Features ........................................................................ 111

Setting Up the Runout & Road Force Limits...................................................111

Setting the “P” Limits...................................................................................111

Setting the “P/SUV” Limits...........................................................................111

Setting the “LT” Limits .................................................................................112

Setting the Limits to “Factory Default”......................................................... 112

Programmed Road Force Limits...............................................................112

Setting Up the Balance Limits............................................................................113

Main Selections...........................................................................................113

Setting Up the Weight Units ........................................................................113

Setting Up the Ounce Round Amount.........................................................113

Setting Up the Gram Round Amount...........................................................113

Setting the Limits Displayed........................................................................113

Non-SmartWeight Options ..........................................................................113

Setting Up the Ounce Blind Amount............................................................113

Setting Up the Gram Blind Amount.............................................................113

SmartWeight™ Options - Setting Up the Force Limits................................114

WeightSaver™ Residual Goal.....................................................................114

Setting Up the Inner Dataset Arm Type.............................................................114

Setting Up the Console Type.............................................................................115

Setting Up the Load Roller Type........................................................................ 115

7. CALIBRATION AND MAINTENANCE......................................................... 116

7.1 Calibration Procedures .......................................................................................... 116

Balancer (3 Spin Procedure)..............................................................................117

Inner Dataset® Arm (Calibration Tool, 221-672-1, Required)............................118

Outer Dataset® Arm (Calibration Tool, 221-672-1, Required) ...........................121

Load Roller (Calibration Tool, 221-672-1, Required).........................................123

Servo-Stop.........................................................................................................125

Quick Calibration Check Procedure...................................................................126

7.2 Diagnostic Procedures...........................................................................................126

Force Sensors....................................................................................................127

Rotary Encoders ................................................................................................127

Keys and Switches.............................................................................................127

Data Acquisition Circuits....................................................................................127

Dataset® Arm Sensors.......................................................................................127

Loaded Runout Sensor......................................................................................127

7.3 Printing.....................................................................................................................127

Changing Ribbon Cartridge (P/N 162-42-2): ..................................................... 128

Bottom Feed Paper Loading..............................................................................128

7.4 Cleaning the Console .............................................................................................128

7.5 Spindle Hub Face and Shaft Maintenance ........................................................... 129

7.6 Mounting Cone Maintenance.................................................................................129

8. THEORY OF OPERATION ..........................................................................131

8.1 Harmonic Vibrations...............................................................................................131

8.2 Road Force™ Measurement .................................................................................. 133

Force Variation................................................................................................... 133

Tire Radial Force Variation (Uniformity)......................................................134

8.3 Radial Force Variation (RFV) ................................................................................. 134

8.4 Radial Force Variation vs. Unloaded Run Out .....................................................135

8.5 Road Force Vibration Placed into Perspective.................................................135

8.6 StraightTrak® Lateral Force Measurement System.............................................136

StraightTrak® Lateral Force Measurement ........................................................136

Tire Pull Measurement and Correction........................................................136

Theory................................................................................................................137

Conicity........................................................................................................138

Plysteer........................................................................................................138

Net Tire Pull.................................................................................................138

9. GLOSSARY .................................................................................................139

9.1 Balancing Terms..................................................................................................... 139

iv Contents GSP9700 Series Road Force Measurement System Operation

Page 9

1.1 Introduction

The GSP9700 Series Road Force Measurement System is a wheel balancer with the

added capabilities of measuring tire/wheel Road Force, Lateral Force, Assembly, and

Wheel runout.

The GSP9700 simulates a “road test”, with a unique “load roller” which applies up to

1400 pounds of force against the rotating assembly. The roller measures the loaded

runout of the assembly (deflection while under load) and automatically recommends

corrections when needed. The GSP9700 technology eliminates many of the time

consuming, subjective, and often non-productive manual measurements previously

used to diagnose and repair ride disturbance concerns. The operation of this

diagnostic tool is discussed later in this manual.

1. Getting Started

This manual provides operation instructions and information required to operate the

GSP9700. Read and become familiar with the contents of this manual prior to

operating the GSP9700.

The owner of the GSP9700 is solely responsible for arranging technical training. The

GSP9700 is to be operated only by a qualified trained technician. Maintaining records

of personnel trained is solely the responsibility of the owner and management.

“References”

This manual assumes that you are already familiar with the basics of tire balancing.

The first section provides the basic information needed to operate the GSP9700. The

following sections contain detailed information about equipment operation and

procedures. “Italics” are used to refer to specific parts of this manual that provide

additional information or explanation. For example, Refer to “Equipment

Components,” page 9. These references should be read for additional information to

the instructions being presented.

1.2 For Your Safety

Hazard Definitions

Watch for these symbols:

CAUTION: Hazards or unsafe practices, which could result in minor

personal injury or product or property damage.

WARNING: Hazards or unsafe practices, which could result in

DANGER: Immediate hazards, which will result in severe personal

These symbols identify situations that could be detrimental to your safety and/or

cause equipment damage.

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 1

severe personal injury or death.

injury or death.

Page 10

IMPORTANT SAFETY INSTRUCTIONS

When using your garage equipment, basic safety precautions should always be

followed, including the following:

Read all instructions before operating the GSP9700.

Read and follow the instructions and warnings provided in the service, operation and

specification documents of the products with which this GSP9700 is used (i.e.,

automobile manufacturers, tire manufacturers etc.).

Do not operate equipment with a damaged cord or equipment that has been dropped

or damaged until a Hunter Service Representative has examined it.

Always unplug equipment from electrical outlet when not in use. Never use the cord

to pull the plug from the outlet. Grasp plug and pull to disconnect.

If an extension cord is necessary, a cord with a current rating equal to or more than

that of the equipment should be used. Cords rated for less current than the

equipment may overheat. Care should be taken to arrange the cord so that it will not

be tripped over or pulled.

Verify that the electrical supply circuit and the receptacle are properly grounded.

To reduce the risk of electrical shock, do not use on wet surfaces or expose to rain.

Verify the appropriate electrical supply circuit is the same voltage and amperage

ratings as marked on the balancer before operating.

WARNING: DO NOT ALTER THE ELECTRICAL PLUG. Plugging the

electrical plug into an unsuitable supply circuit will

damage the equipment and may result in personal

injury.

To reduce the risk of fire, do not operate equipment near open containers of

flammable liquids (gasoline).

Read and follow all caution and warning labels affixed to your equipment and tools.

Misuse of this equipment can cause personal injury and shorten the life of the

balancer.

Keep all instructions permanently with the unit.

Keep all decals, labels, and notices clean and visible.

To prevent accidents and/or damage to the balancer, use only Hunter GSP9700

Series Road Force MeasurementSystem recommended accessories.

Use equipment only as described in this manual.

Never stand on the balancer.

Wear non-slip safety footwear when operating the balancer.

Keep hair, loose clothing, neckties, jewelry, fingers, and all parts of body away from

all moving parts.

Do not place any tools, weights, or other objects on the safety hood while operating

the balancer.

2 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Page 11

ALWAYS WEAR OSHA APPROVED SAFETY GLASSES. Eyeglasses that have only

impact resistant lenses are NOT safety glasses.

Keep the safety hood and its safety interlock system in good working order.

Verify that the wheel is mounted properly and that the wing nut is firmly tightened

before spinning the wheel.

The safety hood must be closed before pressing the green “START” key, located on

the right front corner of the CRT assembly, to spin the wheel.

Hood Autostart will cause the balancer shaft to spin automatically upon hood closure.

For the next Autostart, the safety hood has to be lifted to the full up position and then

closed.

Raise safety hood only after wheel has come to a complete stop. If safety hood is

raised before the spin is completed, the weight values will not be displayed.

Do not let cord hang over any edge or contact fan blades or hot manifolds.

The red “STOP” key, located on the right front corner of the CRT assembly, can be

used for emergency stops.

Electrical

The GSP9700 is manufactured to operate at a specific voltage and amperage rating.

Make sure that the appropriate electrical supply circuit is of the same voltage and

amperage ratings as marked on the balancer.

Make sure that the electrical supply circuit and the appropriate receptacle is installed

with proper grounding.

To prevent the possibility of electrical shock injury or damage to the equipment when

servicing the balancer, power must be disconnected by removing the power cord

from the electrical power outlet.

After servicing, be sure the balancer ON/OFF switch is in the “O” (off) position before

plugging the power cord into the electrical power outlet.

This device is rated as Class A for radiated emissions.

DANGER: Never reach under the hood while the balancer is

performing a Road Force Measurement or balance

spin.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT ALTER THE ELECTRICAL PLUG. Plugging the

electrical plug into an unsuitable supply circuit will

damage the equipment.

In the event of radio interference, the display read out may flicker - this is normal.

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 3

Page 12

Decal Information and Placement

Right Side View

Decal 128-963-2 gives the maximum wheel diameter, maximum wheel weight, and

maximum rotational frequency for the GSP9700.

Decal 128-605-2-00 cautions the user that spindle rotation may occur with foot pedal

depression and to keep clear of clamping components during Quick-Thread™ shaft

rotation.

4 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Page 13

Left Side View

Decal 128-391-2-00 cautions that the unit may automatically start upon closing of the

hood when hood Autostart is enabled.

Decal 128-229-2 and decal 128-905-2 work in conjun ction to caution the user to not

remove the screw because of the risk of electrical shock.

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 5

Page 14

Back View

Decal 128-907-2 warns the user to place the GSP9700 at garage floor level, and not

in a recessed area, to avoid the possibility of flammable fume ignition.

Decal 128-229-2 and decal 128-905-2 work in conjun ction to caution the user to not

remove the screw because of the risk of electrical shock.

6 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Page 15

Specific Precautions/Power Source

The GSP9700 is intended to operate from a power source that will apply 230 volts

(208 - 240), 1 phase, 50/60 Hz between the supply conductors of the power cord.

The power cord supplied utilizes a twist lock connector, NEMA L6-20P. This machine

must be connected to a 20 amp branch circuit. Please refer all power source issues

to a certified electrician. Refer to “Installation Instructions for GSP9700 Series Road

Force Measurement System,” Form 4203T (for GSP9702) or “Installation

Instructions for GSP9712 Series Road Force Measurement System,” Form 4972T

(for GSP9712).

CAUTION: A protective ground connection, through the grounding

conductor in the power cord, is essential for safe operation.

Use only a power cord that is in good condition.

Turning Power ON/OFF

The ON/OFF switch is located on the back of the balancer cabinet. To turn the

balancer “ON,” press the “I” side of the ON/OFF switch. To turn the balancer “OFF,”

press the “O” side of the ON/OFF switch.

The system requires only a few seconds to “boot up.” During “boot up,” the system

will generate a high-pitched tone until the software is loaded and running.

After the GSP9700 performs a self-check, the “Logo” screen will appear indicating

the unit is ready for use.

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 7

Page 16

Equipment Installation and Service

A factory-authorized representative should perform installation.

This equipment contains no user serviceable parts. All repairs must be referred to a

qualified Hunter Service Representative.

NOTE: To replace program cartridge, refer to “Program Cartridge

Removal and Installation,” page 103.

Equipment Specifications

Electrical

Voltage: 230 volts (208 - 240), 1 phase, 50/60 Hz

Amperage: 15 amperes

Wattage: 3450 watts (peak)

Air

Air Pressure Requirements: 100-175 PSI (6.9-12.0 bar)

Approximate Air Consumption: 4 CFM (110 Liters/Minute)

Atmospherics

Temperature:

+32F to +122F (0C to +50C)

Relative Humidity: Up to 95% Non-condensing

Altitude: Up to 6000 ft. (1829 m)

Sound Pressure Level

Equivalent continuous A-weighted sound pressure at operator’s

position does not exceed 70 dB (A).

Safety Summary

Explanation of Symbols

These symbols may appear on the equipment.

Alternating current.

Earth ground terminal.

Protective conductor terminal.

l ON (supply) condition.

OFF (supply) condition.

Risk of electrical shock.

Stand-by switch.

8 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Not intended for connection to public telecommunications network.

Page 17

1.3 Equipment Components

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 9

GSP9712

Page 18

Standard Balancer Accessories

A. 106-82-2 Sleeve, Scratch Guard for Small Cup

B. 175-353-1 Polymer Cup (4.5” O.D.)

C. 76-371-3 Quick Take-Up Wing Nut with Handles

D. 221-658-2 Hammer Heads (4)

E. 46-320-2 Spacer

F. 221-589-2 Weight Hammer/Pliers

G. 20-1650-1 Rim Tags

H. 221-659-2 Adhesive Weight Scraper

I. 223-68-1 Pressure Ring

J. 65-72-2 Calibration Weight

NOTE: Hunter wheel balancers do not include a standardized set of

mounting adaptors.

For optional accessories, refer to Wheel Balancer Brochure, Form 3203T.

10 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Page 19

1.4 Operating the Console

Using Softkeys

The “softkeys,” located on the CRT support console directly beneath the CRT,

provide operator control of the balancer. The keys are identified as:

K1 key

K2 key

K3 key

K4 key

Menu shift key

Start key

Stop key

Reset key

The four menu labels that appear at the bottom of each video screen are referred to

as the “softkey labels.” Each label indicates the action that the program takes when

the corresponding K1, K2, K3, or K4 key is pressed.

The display between the “K2” and “K3” labels indicates how many rows of labels are

available. Most screens have only one or two rows, however more rows are possible.

The green box indicates the row that is currently displayed.

The menu row is changed by pressing the menu shift key,

. When this key is

pressed, the menu labels change to the next row down. If the last row is currently

displayed, the menu labels change to the first row.

Throughout this manual, the statement press “nnnnnnn” means press the softkey

with the label “nnnnnnn.” If the required label is not on the current menu, press

to

change rows until the desired label is displayed.

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 11

Page 20

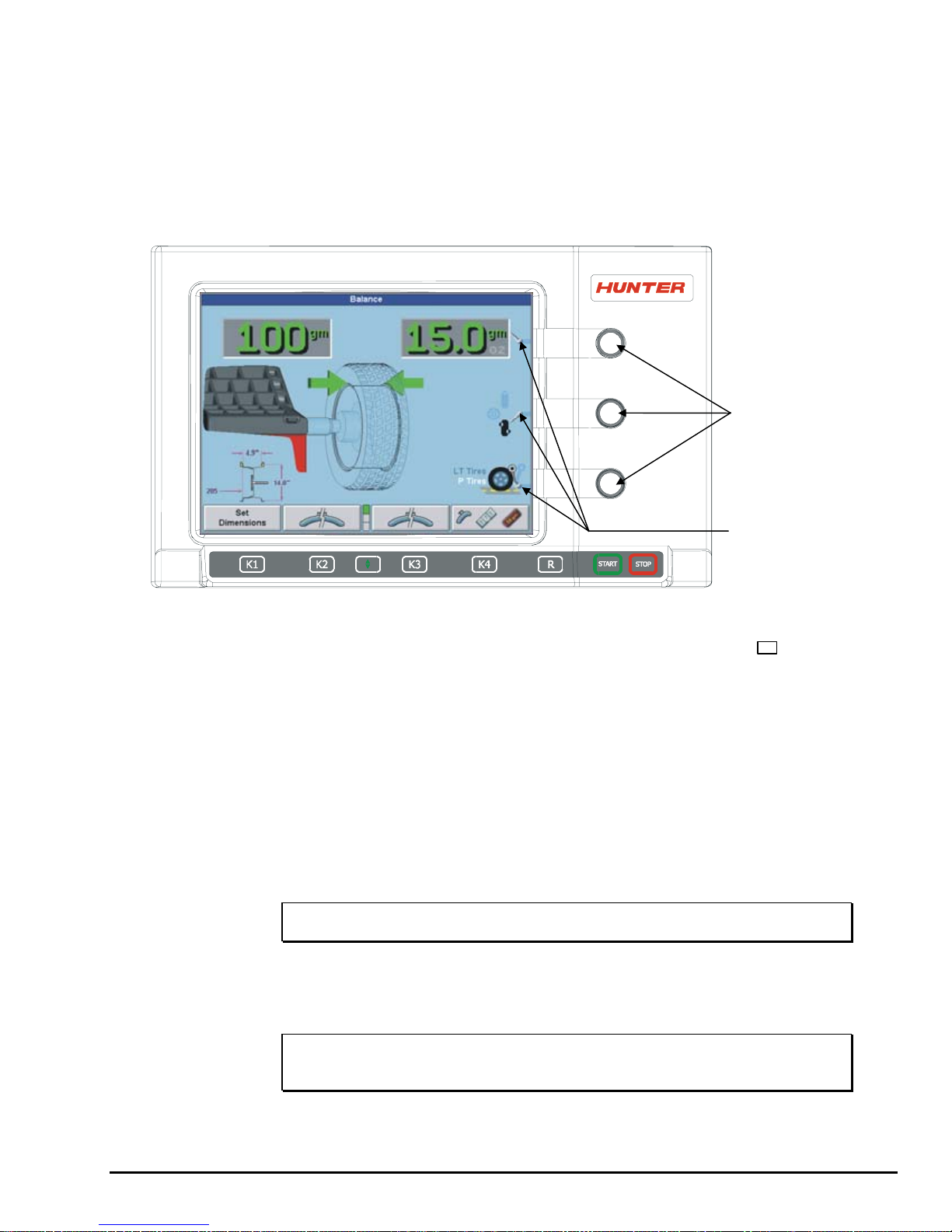

Primary Balancing Display

Using the Control Knob (GSP9712)

The control knob is located to the right of the softkeys. The control knob is used to

control the on-screen switches and manually input data. The on-screen switches that

are available are dependent upon the setup configuration of the balancer.

MENU

SHIFT

KEY

START

KEY

STOP

KEY

RESET

KEY

K1 KEY

K2 KEY

CONTROL KNOB ACCESSED ON-SCREEN SWITCHES

K3 KEY

K4 KEY

CONTROL

KNOB

Pushing in on the control knob cycles through the on-screen switches that are available

on the current primary screen. Rotating the control knob clockwise or counter-clo ckwise

changes the setting for the selected on-screen switch.

For example, in the “Balance” primary screen, pushing in on the control knob will cycle

through the grams to ounces, the static and dynamic, and the load roller on-screen

switches. After selecting an on-screen switch, the setting may be selected by rotating

the control knob. The “selected” switch is the one showing the hand.

12 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Page 21

Using Control Knobs (GSP9702)

The control knobs are located to the right of the CRT screen. The control knobs are

used to control the on-screen switches and to manually input data. The control knobs

are identified as the upper, middle, and lower control knobs. The on-screen switches

that are available are dependent upon the current mode of the balancer.

For example, in the “Balance” primary screen, the upper knob (1) controls the grams

to ounces on-screen switch. The middle knob (2) controls the static, dynamic and

non-rounding on-screen switch, and the lower knob (3) controls the load roller and

P/LT tires on-screen switch.

1

2

3

Resetting the Program

The wheel balancing program may be reset at anytime by using the “ R ” key,

located on the CRT support console directly beneath the CRT. To reset the balancer,

press the reset key twice within a four-second period without pressing any other keys

in-between. This prevents a single accidental keystroke from resetting the system.

When the balancer is reset, the information collected for the wheel balance in

progress is erased and the display returns to the “Logo” screen.

Using the Screen Saver/Merchandising Display

If the CRT displays the same image for a long time, the image may become “burned

in” and will be visible even when the display is turned “OFF.” This is a characteristic

of all computer CRT displays. Therefore, after the designated time has passed, the

screen saver will appear on the CRT if “Screen Saver” is not disabled.

CONTROL KNOBS

ON-SCREEN

SWITCHES

NOTE: The system is still running when the screen saver is enabled.

When any “softkey” is pressed or the spindle turned, the program will reappear on the

CRT. This keystroke or spindle movement is recognized only by the screen saver

program and will not affect the balancer program. After the screen is on, additional

key presses will operate the program normally.

NOTE: The screen saver is not affected by rotating the control

GSP9700 Series Road Force Measurement System Operation 1. Getting Started 13

knob(s).

Page 22

14 1. Getting Started GSP9700 Series Road Force Measurement System Operation

Page 23

2. Balancing Overview

2.1 Balancing Modes

SmartWeight™ Balancing Technology

SmartWeight™ balancing technology is a method of reducing forces on a wheel

during balancing. This results in less weight used, and less time balancing tires.

SmartWeight is not a procedure. Instead, it measures the forces of side-to-side

shimmy and up-and-down shake and computes weight to reduce these forces. This

reduces the amount of weight, reduces time, reduces chec k spins and chasing

weights, and saves the shop time and money.

SmartWeight can reduce the number of steps in the balancing process.

Balancing Theory

Static Imbalance

As the word static implies, the tire will be balanced when at rest. For example, if an

unmoving assembly was centered on a cone and was balanced, it would be statically

balanced. A “bubble balancer” is designed to statically balance a tire/wheel

assembly.

IMBALANCE

FORCE

STATIC IMBALANCE

Static imbalance is where there is one amount of weight located in the center of the

tire/wheel assembly causing an imbalance. As the weight rotates, centrifugal forces

are created causing the wheel to lift as the weight reaches top dead center. This

lifting motion causes the tire/wheel assembly to move “up and down” creating a

bounce to be felt. This static imbalance condition is evident by a “jiggle” or up-down

movement of the steering wheel. These vibrations may also be apparent in the body,

with or without steering wheel shake.

FRONT VIEW

CUPPING

A statically imbalanced tire driven for an extended period may cause “cupping” in the

tire’s tread, create vibration, and adversely effect handling.

GSP9700 Series Road Force Measurement System Operation 2. Balancing Overview 15

Page 24

Static balancing alone is a seldom-recommended procedure. For example, a single

weight is commonly placed on the inner clip weight position for cosmetic purposes.

This is not a recommended practice and usually insures the assembly is not properly

dynamically balanced. The assembly may then experience side-to-side imbalance

while in motion, causing a shimmy condition and objectionable vibration.

Couple Imbalance

In general terms, dynamic imbalance is defined as where one or more locations of

the tire/wheel assembly are heavier causing an imbalance force and/or an imbalance

wobble. Shown below is a tire/wheel assembly with two heavy spots of equal weight

which are located 180 degrees radially from each other on opposite sides. As this

assembly rotates, centrifugal forces cause a large imbalance wobble to be created,

but the imbalance force (as well as the static imbalance) will be zero. A wheel with

this condition will cause a wobble or shimmy to be felt in the steering wheel.

Excessive dynamic imbalance of this type creates a shimmy that transfers through

the suspension components to the occupants of the vehicle, especially at higher

speeds.

IMBALANCE WOBBLE

(LATERAL TWIST OR TORQUE)

ZERO STATIC IMBALANCE WITH LARGE

COUPLE IMBALANCE

FRONT VIEW

16 2. Balancing Overview GSP9700 Series Road Force Measurement System Operation

Page 25

Modern “dynamic” balancers spin the wheel in order to measure both the up and

down imbalance force and the wobble or shimmy related imbalance (side-to-side).

Dynamic balancers direct the operator to place correction weights on the inside and

outside correction locations of the rim so that both imbalance shake (static) and

imbalance wobble (couple) will be eliminated.

SmartWeight may also utilize a single weight placement to balance out shake and

shimmy forces.

Static and Dynamic Imbalance Sensitivity

As a general rule of thumb, to achieve the best balance on an average sized tire and

wheel (15x6) assembly.

Residual static imbalance should be less than 1/4 ounce.

Residual couple imbalance should be less than 3/4 ounce.

Residual couple imbalance is preferred over remaining static imbalance.

It takes much more residual couple imbalance to cause a vibration than the same

amount of static imbalance.

The larger the diameter used for weight placement, the smaller the amount of

correction weight is required.

The wider the distance between the two weight placement locations, the smaller the

amount of correction weight is required.

If static balance is the only option, always verify that the remaining couple residual

imbalance is within acceptable tolerance.

For detailed information on adjustment and setup of modes of wheel balancing

sensitivity see section 5.1 and section 6.4.

GSP9700 Series Road Force Measurement System Operation 2. Balancing Overview 17

Page 26

2.2 Identifying the Static Balance Weight Plane

In “STANDARD BALANCE” mode, using only a clip-on weight, the plane is input as

follows:

For static balancing, it is recommended that you place half of the correctional weight

value on each side of the tire to reduce residual dynamic imbalance.

In “MIXED WEIGHTS BALANCE” mode and “ADHESIVE WEIGHTS BALANCE”

mode, using an adhesive weight, the plane is input as follows:

DIAMETER

For static balancing, it is recommended that the adhesive weight be placed as close

to the center of the wheel as possible to reduce residual dynamic imbalance.

In “PATCH BALANCE” mode, using a patch weight, the plane is input as follows:

DIAMETER

For static balancing, it is recommended that the patch weight be placed as close to

the center of the tread as possible to reduce residual dynamic imbalance.

18 2. Balancing Overview GSP9700 Series Road Force Measurement System Operation

Page 27

2.3 Identifying the Dynamic Balance Weight Planes

The balancer must know the location of the two weight circle planes for placement of

correction weights on the wheel assembly.

Each plane is described by a distance from the balancer and a diameter.

MIXED WEIGHTSST ANDARD PATCHADHESIVE WEIGHTS

RIM LIP / RIM LIP RIM LIP / INNER RIM SURFACE

INNER RIM SURFAC E /

INNER RIM SURFAC E

INNER TIRE SURFACE /

INNER TIRE SURF ACE

In “STANDARD BALANCE” mode, using only clip-on weights, left and right planes

are input as follows:

In “MIXED WEIGHTS BALANCE” mode, using clip-on and adhesive weights, the left

and right planes are input as follows:

In “ADHESIVE WEIGHTS BALANCE” mode, left and right planes are input as

follows:

GSP9700 Series Road Force Measurement System Operation 2. Balancing Overview 19

Page 28

In “PATCH BALANCE” mode, using patch weights, left and right planes are input as

follows:

LEFT DISTANCE

DIAMETER

RIGHT DISTANCE

2.4 SmartWeight™ Dynamic Weight Planes

SmartWeight requires the operator to enter two weight planes. This balancing

method will automatically determine if one or both weight planes require a weight to

be added. This eliminates “blinded” static single plane balancing, which alone may

not be sufficient to solve vibration issues.

20 2. Balancing Overview GSP9700 Series Road Force Measurement System Operation

Page 29

3. Mounting Wheels on the Balancer

3.1 Mounting the Wheel Using Wheel Lift (Optional)

The Wheel Lift is an optional feature on the GSP9700 series balancer. For

instructions on mounting the tire/wheel assembly without the optional wheel lift, refer

to “Mounting the Wheel,” page 23.

Raising the Tire/Wheel Assembly

Press the lift control handle “down” until the trolley carriage is at its lowest level.

Slide the appropriate mounting cone onto the spindle.

UP

LIFT CONTROL

DOWN

HANDLE

With the trolley carriage extended all the way out to the right, roll the tire/wheel

assembly onto the trolley carriage.

TROLLEY

CARRIAGE

Raise the lift control handle “up” to move the lifting beam and trolley into a position

where the tire/wheel assembly can be installed onto the spindle.

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 21

Page 30

Slide the tire/wheel assembly onto the spindle and center on the mounting cone.

A

Verify that the tire/wheel assembly is centered vertically on the spindle. Refer to

“Mounting the Wheel,” page 23.

TIRE/WHEEL

SSEMBLY CENTERED

VERTICALLY ON

SPINDLE

SPINDLE

Install the clamping cup and wing nut on the spindle shaft against the wheel and

secure the entire assembly by firmly tightening the wing nut, while depressing the

foot pedal to hold the spindle in place.

With the tire/wheel assembly secured to the GSP9700, press the lift control handle

“down” until the trolley carriage is at its lowest level.

NOTE: The trolley carriage will also retract to its lowest level

Service the tire/wheel assembly as necessary. Refer to “Balancing a Wheel,” page 35

for specific operation instructions.

22 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

automatically when the hood is closed.

Page 31

Lowering the Tire/Wheel Assembly

Raise the hood.

Lift the lift control handle “up” to move the lifting beam and trolley into position to

support the tire/wheel assembly.

Step on the Spindle-Lok

®

/foot pedal of the GSP9700, and then loosen the wing nut

that secures the clamping cup.

With the wheel lift supporting the tire/wheel assembly, steady the tire/wheel assembly

with your left hand, and remove the wing nut and clamping cup with your right hand.

Slide the tire/wheel assembly to the right, so that it clears the spindle shaft.

Press the lift control handle “down” until the trolley carriage is at its lowest level.

Roll the tire/wheel assembly off the carriage trolley.

3.2 Mounting the Wheel (Without Wheel Lift)

CAUTION: Use only cones and accessories that are specifically

designed for the GSP9700 Series Road Force Measurement

System.

Since today’s vehicle designs are more sensitive to road feel, it is critical to achieve

the best balance. Proper balance requires that the tire/wheel assembly be centered

on the balancer. Tire/wheel assemblies can be balanced to zero, even with the

tire/wheel assembly mounted off-center. The main objective of the balancer operator

is to center the wheel on the hub and shaft, using the best available method.

Mounting the wheel off-center creates incorrect measurements of imbalance and

runout conditions.

Remove any existing wheel weights, rocks, and debris from the tire tread, and clean

the center hole of the wheel. Inspect inside of wheel for excessive accumulation of

dirt and debris. Remove if necessary before balancing.

Accurate balancing depends on accurately centering the wheel. Choose the prop er

wheel mounting cone by placing it in the center hole of the wheel to be balanced.

Refer to “CenteringCheck

®

,” page 30.

NOTE: If the basic cone and adaptors do not fit the wheel, additional

centering adaptors will be necessary. A wheel that cannot

be properly centered, cannot be properly balanced. All

balancers require additional centering adaptors to properly

center certain types of wheels. For additonal information,

refer to Form 3203T for optional accessories.

With the safety hood open, place the wheel mounting cone on the spindle shaft

against the captivated spring. Position the wheel with the inside surface facing the

balancer, centered on the cone.

Install the plastic clamping cup and wing nut on the spindle shaft against the wheel

and secure the entire assembly by firmly tightening the wing nut.

If equipped with optional Spindle-Lok

tightening the wing nut. Holding the shaft locked while tightening the wing nut

improves centering accuracy.

Slowly roll the wheel towards you while tightening the wing nut. This improves

accurate wheel centering, since the wheel is allowed to roll up the taper of the cone

as opposed to forcing it to slide up the cone.

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 23

®

foot pedal, depress and hold down while

Page 32

Mounting Error Detection Features

To verify that the tire/wheel assembly is centering, remount the tire/wheel assembly

and observe the results. Do any of the following conditions occur?

Weight amount varies excessively

Weight location changes

Runout and road force measurements vary excessively

If any of these conditions occur, the centering accuracy of the tire/wheel assembly

needs to be verified.

There are two methods using wheel runout that the GSP9700 will utilize to detect

mounting error:

Anytime the wheel runout is measured, the displayed diagnostic

message may caution the operator to check wheel mounting if

runout on inner and outer bead seats move up and down or side

to side together.

From the balance screen, the operator can choose to perform a

CenteringCheck

®

. The CenteringCheck® feature will automatically

confirm if the wheel is centered for the operator on the balancer

(preventing improper measurement from occurring).

See page 30, CenteringCheck

Front/Back Cone Mounting

®

, for a detailed description of the feature.

Cone mounting is one of the most common and reliable ways to mount wheels on

balancers. Select the proper wheel mounting cone by placing it in the center bore of

the wheel to be balanced. Select the cone that contacts the wheel nearest the center

of the cone.

Place the wheel mounting cone on the spindle against the spring plate. Mount the

wheel with the inner rim facing the balancer and centered on the cone.

Install the clamping cup and wing nut on the spindle shaft against the wheel and

secure the entire assembly by firmly tightening the wing nut, while depressing the

foot pedal to hold the spindle in place.

24 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

Page 33

NOTE: If equipped with optional Spindle-Lok® foot pedal, depress

and hold down while tightening the wing nut. Holding the

shaft locked while tightening the wing nut improves centering

accuracy.

Slowly roll the wheel toward you during the initial tightening

of the wing nut. This aids in accurate wheel centering and

increased repeatability, since the wheel is allowed to roll up

the taper of the cone as opposed to forcing it to slide up the

cone.

WHEEL

MOUNTING

CONE

CAPTIVATED

SPRING

SURFACE

INSIDE

STANDARD

WHEEL

SPINDLE

SHAFT

WING NUT

PLASTIC

CLAMPING

CUP

Wheels with center holes over 3 9/16 inch diameter require the light truck cone. The

light truck cone can be installed from the outside of the wheel. (When using the light

truck cone, the plastic clamping cup is not used.)

LIGHT TRUCK

WHEEL

LIGHT

TRUCK CONE

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 25

CAPTIVATED

SPRING

PLASTIC

CLAMPING

CUP

NOT USED

Page 34

Using Plastic Wheel Mounting Washer

The plastic wheel mounting washer, 46-320-2, is used to prevent scratches on

wheels where the standard plastic cup and scratch guard cannot be used. The plastic

wheel mounting washer can also be used when mounting a wheel with a large offset

that is between cone sizes. Use of the washer as shown below can improve

centering ability by increasing cone pressure against the wheel.

For example: One cone size is too small because the captivated spring is not

pressing the cone against the inner wheel opening, but the next larger cone size is

too big and will not fit the opening. Use the smaller cone size with the plastic wheel

mounting washer to “extend” the captivated spring to hold the mounting cone against

the wheel opening with greater pressure.

PLASTIC

WASHER

LARGE OFFSET

MOUNTING

CONE

WHEEL

SPINDLE

SHAFT

CAPTIVATED

SPRING

WING NUT

PLASTIC

CUP

The scratch guard may be installed on the clamping cup to protect aluminum rims

from being marred, but should not be used on steel wheels.

NOTE: Use only the wing nut supplied with the GSP9700.

In some cases, the mounting pad of the wheel may be extremely wide, and the

standard clamp cup will not properly contact the wheel hub area. In these cases, the

optional nine-inch alloy wheel pressure cup may be used in place of the clamping cup.

26 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

Page 35

Wheels with center bores over 3 9/16 inch diameter require one of the light truck

cones. The light truck cones must be mounted from the outside of the wheel.

NOTE: When using the light truck cones, the pressure ring is used

in place of the clamping cup.

This procedure utilizes a tapered cone inserted from the front side of the wheel

instead of the backside as previously described.

Select the proper wheel mounting cone by placing it in the center bore of the wheel to

be balanced. Choose the cone that contacts the wheel nearest the center of the

cone.

Mount the wheel with the inner rim facing the balancer. Place the wheel mounting

cone on the spindle with the small end of the cone facing the front of the wheel.

Install the wing nut and pressure ring assembly onto the spindle shaft against the

wheel and secure the entire assembly by firmly tightening the wing nut.

Heavy wheel centering may benefit by (1) pulling the tire away from the hub face at

top dead center while tightening the wing nut or (2) use of optional wheel lift to

position heavy wheel onto shaft and cone. This helps the wheel to overcome gravity

against the hub or spacer.

Cone/Flange Plate Mounting

Wheels may be centered using the lugholes and center bore with a flange plate and

centering cone. It is important that a back mounted cone be used to support and

center the wheel when using flange plates.

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 27

Page 36

The correct flange adaptor setup is determined by:

Measure and set the bolt circle diameter and number of studs to use

against the lug holes.

Set the number of lugholes as follows:

A three-lug wheel uses three studs.

A four-lug wheel uses four studs.

A five-lug wheel uses five studs.

A six-lug wheel uses three studs.

A seven-lug wheel uses seven studs.

An eight-lug wheel uses four studs.

Choose the correct taper design of flange studs to fit the wheel lug seats.

The mounting area of the flange stud must match the design of the

wheel’s lughole seat or depression.

The flange plate must be able to apply pressure to the center of the wheel while

maintaining perpendicularity to the shaft.

NOTE: If the lug seats are unevenly machined or worn, an optional

universal flange adaptor with compressible studs or bolt on

lugs may be used to more accurately mount the wheel with

the cone.

Flange plates are useful when the wheel cannot be properly centered off the hub

bore with a tapered cone alone because of improper fit, interference, or lack of a

center hole.

A flange plate in many cases adds value because it aids in more effective centering

than a tapered cone alone. This statement is true for many wheels including hub

centric wheels. That is why a flange plate and back cone may be more accurate and

repeatable, regardless of whether the wheel is lug centric or hub centric.

Expandable Collet Mounting

An expandable collet should NOT be used with the GSP9700 due to the amount of

force applied by the load roller.

Using the Pressure Ring and Spacers

Pressure Ring

The pressure ring clips on to the wing nut. It is used in lieu of the clamping cup.

It may also be used in place of a clamping cup if space is limited between the wheel

and the end of the spindle.

28 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

Page 37

The pressure ring should be used to prevent the wing nut from directly contacting an

adaptor or a cone. It will act as a bearing to enable higher clamping forces.

Spacers

Hub Ring Spacers

These light truck spacers are designed to build a larger pocket when using extra

large truck cones. It also provides a location for the centering pins found on some

dual wheel configurations.

Shaft Spacers

The shaft spacer can be used to make the cone contact the hub bore more firmly.

For example, one cone size is too small because the captivated spring is not

pressing the cone against the inner wheel opening, but the next larger cone size is

too large and will not fit the opening. Use the smaller cone size, with the spacer, to

extend the captivated spring and hold the smaller mounting cone against the wheel

opening with greater pressure.

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 29

Page 38

CenteringCheck®

The CenteringCheck® feature can be used to inspect each mounting to identify

possible centering errors, thus preventing improper measurements from occurring.

The inner Dataset

mounting repeatability.

CenteringCheck

On-screen prompts lead you through the procedure as follows:

Select “Perform Centering Check” from the menu.

®

arm, is used to measure wheel runout which is an indication of

®

may be used with either a “bare rim” or a “rim with tire assembly.”

Place the inner Dataset® arm against the rim at a location that will maintain

unobstructed contact for a complete revolution. Refer to “Using the Auto Dataset

Arms,” page 48.

Press the outer Dataset® arm button or “Start” when ready to take readings.

30 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

Page 39

Position the valve stem at 12 o’clock, and then press “Enter Valve Stem.”

After measuring rim runout, you will be prompted to loosen the wheel and re-clamp at

one half turn (approximately 180 degrees) from the current position.

Place the inner arm against the rim as shown.

Press the outer arm button or “Start” when ready to take readings.

Once more, position the valve stem at 12 o’clock, and then press “Enter Valve Stem.”

If the rim is centered properly, the following screen will appear briefly.

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 31

Page 40

The GSP9700 will then proceed to the “Balance” screen.

If a centering problem is detected, the following screen will appear.

The procedure will repeat the re-centering check up to four times and always

compare the previous measurement to the next check. If centering is not achieved

after four attempts, the following screen will appear.

Check for:

Correct mounting cone/adaptor for this wheel design.

Wheel defect such as a metal burr interfering with the

Dirt or debris interfering with the cone/adaptor.

Follow the on-screen prompts, and then press “Restart Procedure.”

32 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

cone/adaptor.

Page 41

3.3 On-Vehicle Wheel Mounting Methods

Hub Centric

A hub centric wheel is aligned to the hub by the center bore of the wheel. The vehicle

weight rests on the hub bore. The clearance between the hub bore and the hub on a

hub centric wheel is between 0.003 and 0.004 of an inch. A hub centric wheel is

identified by removing the lug nuts (or bolts) and moving the wheel up, down, and

side-to-side. If there is little or no movement, the wheel is centered by the hub.

To verify if the wheel is hub centric:

Lug Centric

A lug centric wheel is identified by removing the lug nuts (or bolts) and moving the

wheel up, down, and side-to-side. If movement around the hub is apparent, the wheel

is centered on the vehicle by the lugs or studs of the axle flange.

Remove the lug nuts (or bolts) and try to move the wheel up/down and

side/side on the hub.

If the wheel has no appreciable movement around or about the

centerline of the hub, it should be considered hub centric.

A hub centric wheel will have very little (0.003 – 0.004”) clearance or a

slip fit to the hub.

GSP9700 Series Road Force Measurement System Operation 3. Mounting Wheels on the Balancer 33

Page 42

To verify if the wheel is lug centric:

Remove the lug nuts (or bolts) and try to move the wheel up/down and

side/side on the hub.

A lug centric wheel will display noticeable movement.

TIP: When mounting a lug centric wheel to a vehicle, extreme

centering care must be taken by ensuring the lug nuts (bolts)

are tightened equally, while rotating the wheel.

“Step-torque” star pattern to proper torque specification.

34 3. Mounting Wheels on the Balancer GSP9700 Series Road Force Measurement System Operation

Page 43

4. Balancing a Wheel

4.1 Balancing Procedures

The GSP series balancer offers two primary ways to balance tires:

1. SmartWeight™ balancing technology

2. Traditional balancing technology

Both of these methods can balance tires dynamically. The main difference is

SmartWeight will reduce the amount of corrective weight and possibly limit the

number of steps in a basic wheel balancing situation.

SmartWeight™ Balancing Technology

SmartWeight™ balancing technology is a method of reducing forces on a wheel

during balancing. SmartWeight is not a procedure. Instead, it measures the forces of

side-to-side movement and up-and-down shake and computes weight to redu ce

these forces. This reduces the amount of weight, reduces time, reduces check spins

and chasing weights. SmartWeight saves the shop time and money.

Using SmartWeight™

The SmartWeight enabled balancing display varies slightly from the standard

balancing display. The primary difference between the displays is the SmartWeight

tire graphs that display the static and couple forces within a tire/wheel assembly.

The red-dotted line represents the acceptable amount of force the tire can have that

will not result in a ride problem. Any forces below that line will be shown in green.

Any forces that are above that level will be shown in red and indicate an excessive

amount of force.

The traditional “static” and “dynamic” modes are eliminated. The traditional non-round

off mode is eliminated. These modes are no longer necessary with SmartWeight

balancing.

GSP9700 Series Road Force Measurement System Operation 4. Balancing a Wheel 35

Page 44

Install the tire/wheel assembly as normal. Rim measurements are not required.

Lower the hood and spin.

If SmartWeight requires correction weights wheel dimensions will be required.

Enter the dimensions using the dataset arms. The SmartWeight tire graphs will

display red for excessive forces and green for acceptable amounts of force. Prior to

measurement the tire graphs will display no color.

The screen will display the amount and location of corrective weight necessary.

Install the weights in the appropriate manner using the correct type of weight and

lower the hood to re-spin and check the balance.

Instead of displaying zeros in the weight display, SmartWeight displays “OK,”

indicating that the force levels are reduced to within the acceptable tolerances.

36 4. Balancing a Wheel GSP9700 Series Road Force Measurement System Operation

Page 45

Switching from SmartWeight™ to Traditional Dynamic Balancing Modes

At any time, SmartWeight can be switched to standard balancing as long as both

standard and SmartWeight modes are enabled in setup.

On units with a control knob, press the knob until SmartWeight is highlighted. Once

highlighted, press and hold the knob till the standard balance icons appear. Cycle

back the same way.

On units without the control knob select the “Disable SmartWeight” button on the

balance screen.

Dynamic Balancing Selection

Dynamic balancing is selected by pointing the indicator to while rotating the

control knob. Dynamic will always display two weight planes.

Dynamic balancing provides a more complete balance than static balancing.

Dynamic balancing should be selected whenever possible to minimize vehicle

vibration. Refer to “Dynamic Imbalance,” page 16.

Static Balancing Selection

Static balancing is selected by pointing the indicator to while using the control

knob. Static balancing provides a less desirable balance than dynamic bala ncing.

Dynamic balancing should be selected whenever possible to minimize vehicle

vibration. Refer to “Static Balance,” page 15.

GSP9700 Series Road Force Measurement System Operation 4. Balancing a Wheel 37

Page 46

Static Balance Mode Reminder for “Dynamic Balance Importance”

(Except Patch Balance)

Two reminder pop-up text messages appear on the balance screen dialog box when

you first select static mode.

The first screen gives the warning: Avoid STATIC single-plane balancing.

The second screen suggests: DYNAMIC dual-plane balancing recommended (even

for hidden weights).

If STATIC is selected, the reminders show up again at the end of the spin, and if in

clip-on weight mode, the dynamic weights are shown momentarily, and then the

static weight is displayed.

38 4. Balancing a Wheel GSP9700 Series Road Force Measurement System Operation

Page 47

A

Selecting Weight Types and Placement Modes

Press “ ” to change the weight types and placement. The GSP970 0 offers

Standard Balance, Mixed Weights Balance, Adhesive Weights Balance, and Patch

Balance

for dynamic and static modes.

With these four selections, a correction weight can be placed at an infinite number of

locations, based upon the choice of the operator.

DYNAMIC

STATIC

STANDARD

BALANCE

MIXED

WEIGHTS

BALANCE

PATCH

BALANCE

DHESIVE

WEIGHTS

BALANCE

STANDARD BALANCE should be selected when clip-on weights can be used for

both rim flanges.

MIXED WEIGHTS BALANCE should be selected when a clip-on weight can be used