Page 1

®

FLOW-CLIK

Flow Sensor

Owner’s Manual and

Installation Instructions

Version for use with any standard 24 volt controllers

®

Page 2

Page 3

TABLE OF CONTENTS .....................................................................................

Introduction .............................................................................................................................. .....................................1

Flow-Clik Components ....................................................................................................................................................2

Flow-Clik Sensor ........................................................................................................................................................2

Flow-Clik Sensor Body ................................................................................................................................................ 2

Flow-Clik Inter face Box ...............................................................................................................................................3

System Status Indicator .............................................................................................................................. ................4

System Overview and Flow-Clik Operation .......................................................................................................................5

Installing the Flow-Clik Sensor Body ...............................................................................................................................9

Installing the Flow-Clik Sensor .............................................................................................................................. ........ 10

Mounting the Flow-Clik Interface Box ............................................................... ............................................................. 11

Wiring the Flow-Clik Interface Box to the Controller ....................................................................................................... 12

Wiring When Using Multiple Sensors ............................................................................................................................14

System Considerations ................................................................................................................................................. 15

Programming the Flow-Clik Interface Box ......................................................................................................................16

Setting the Startup Delay ............................................................... ...............................................................................20

Setting the Interrupt Period ..........................................................................................................................................21

Troubleshooting Guide .............................................................................................................................. .................... 22

Frequently Asked Questions .......................................................................................................................................... 25

Specifications............................................................... ................................................................................................ 27

Page 4

1

Page 5

INTRODUCTION ...............................................................................................

Shutting down an irrigation system when excess flow occurs provides the benefits of reduced liability, water conservation,

erosion prevention and overall reduction in repair costs. Typical causes for over-flow conditions can stem from problems

due to ruptures in the main or lateral lines, when heads are broken or removed from the system, or when valves do not

shut off automatically.

The Hunter Flow-Clik flow sensor monitors flow to an entire irrigation system or through an individual valve. In the case of

an overflow condition, the Flow-Clik will automatically shut down the irrigation system at the controller. The Flow-Clik acts

as a switch to break the electrical circuit to the solenoid valves as soon as it registers a flow exceeding a calibrated set

limit. This allows the timer to advance as scheduled, but keeps the valve(s) with a “high flow” condition from activating.

As a result, of installing the flow sensor in a system, the user gains the benefit of substantially reducing the amount of

water loss during an occurrence of an over-flow condition.

1

Page 6

3

3

2

1

4

6

5

7

8

FLOW-CLIK COMPONENTS............................................................................

This section will give you a brief overview of some of the

components of the Flow-Clik system. Each item will be

discussed in further detail later, however, this section can

be helpful in getting acquainted with the different options

available.

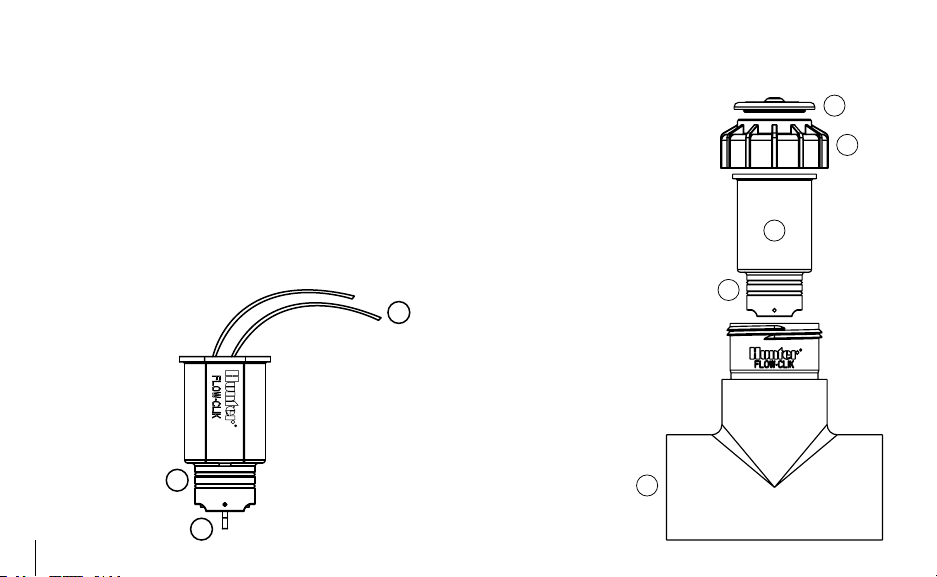

A. Flow-Clik Sensor

1. Impeller – rotates when flow is occurring

2. O-rings – provides sealing of sensor in sensor body

3. Wires – black and red wires connect sensor to

Flow-Clik Inter face Box

2

B. Flow-Clik Sensor Body (FCT Series)

4. Flow-Clik Tee – the Tee

is installed into the irrigation system and houses the

Flow-Clik sensor

5. Plug – used to seal the

body when the sensor is not

installed in the sensor body

6. O-rings – provides sealing of

plug in sensor body

7. Cap – retains plug or sensor

in sensor body

8. Cover – snaps over the top of

the sensor

Note: Flow-Clik sensor bodies

ordered separately.

Page 7

10

11

12

9

13

14

Black

Red

To Sensor

To 24 VAC Terminals in Controller

To Sensor Terminals in Controller

Yellow

White

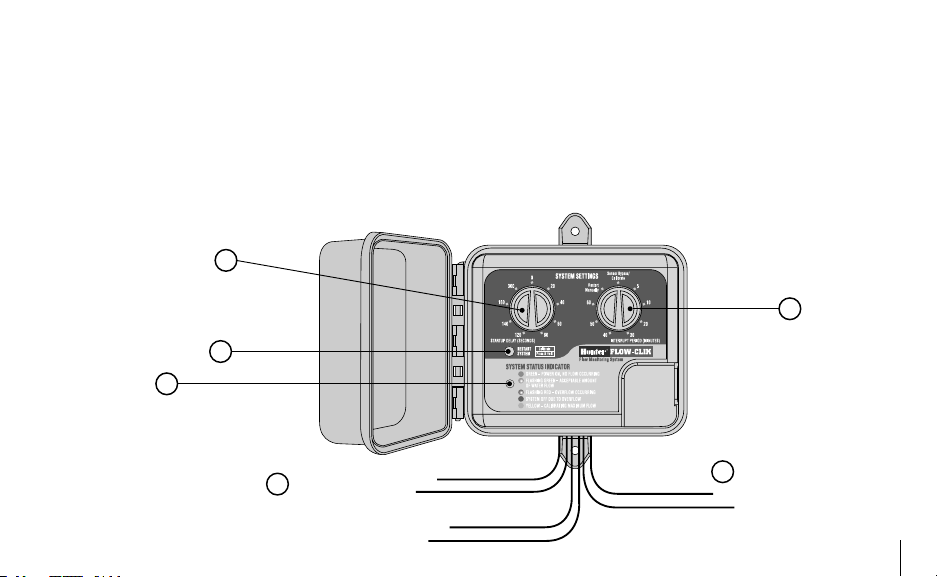

C. Flow-Clik Interface Box

9. Startup Delay Rotary Dial – used to set startup delay

and calibrate sensor

10. Interrupt Period Rotary Dial – used to set interrupt

period and calibrate sensor

11. Restart/Calibrate Button – used to restart system

(when using the “Restart Manually” setting) and calibrate sensor during setup

12. System Status Indicator – provides a visual indication

of the Flow-Clik status

13. Wires – black and red wires to Flow-Clik Sensor

14. Wires – yellow wires to AC power terminals at Control-

ler, white wires to sensor or common terminals at

controller

3

Page 8

5

FLOW-CLIK COMPONENTS (continued) ......................................................

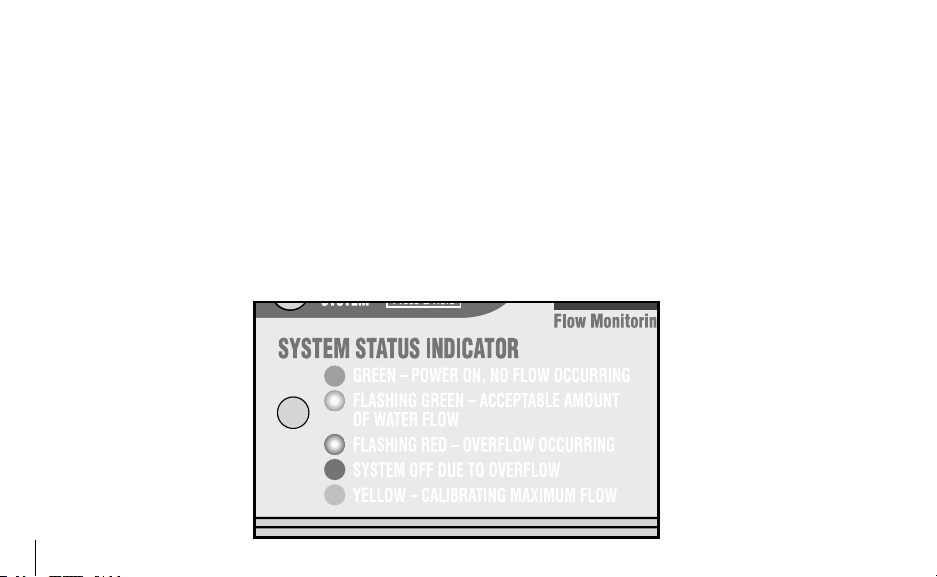

D. System Status Indicator

The Flow-Clik Interface Box has a System Status indicator

LED that provides information on the current status of the

Flow-Clik system.

GREEN indicates power is applied to the sensor, but no

flow is occurring

FLASHING GREEN indicates an acceptable amount of water

is flowing (below the flow sensor calibrated maximum)

FLASHING RED indicates that overflow is occurring (Water

flow in excess of the calibrated maximum)

RED indicates an unacceptable amount of water was flow-

ing and the system has been shut down. (Water flow

exceeded the calibrated maximum for a time period

longer than the startup delay).

YELLOW indicates that the Flow-Clik is calibrating the

sensor to the system flow.

4

Page 9

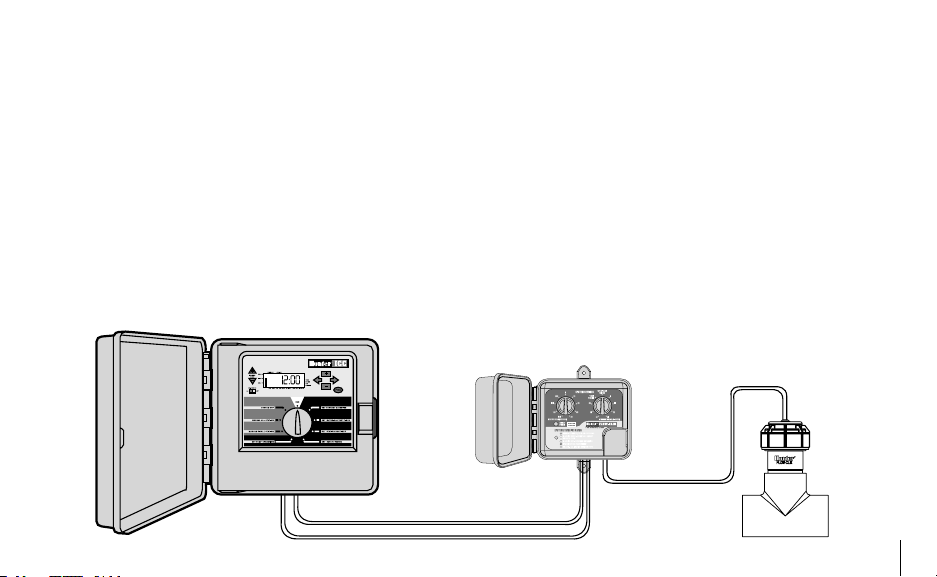

SYSTEM OVERVIEW AND FLOW-CLIK OPERATION .................................

Standard 24 Volt Controller

Flow-Clik Interface Box

Flow-Clik Sensor

4 Wires

The Flow-Clik System can be installed simply and easily

to most standard 24 volt irrigation control systems. The

Flow-Clik System consists of the Flow-Clik flow sensor that

is installed in the main line or lateral line of an irrigation

system, and the Inter face Box mounted near the controller to control the operation of the irrigation system. The

flow sensor, wired directly to the Interface Box, continually

monitors flow occurring within the system and transmits

this data to the Interface Box. The programmable Flow

Sensor Inter face Box allows the Flow-Clik to function with

all Hunter controllers and makes the Flow-Clik compatible

with most common irrigation controllers on the market. The

controller provides the power for the Interface Box, allowing it to send signals continuously to the controller telling

it to shut down or start up based upon flow conditions.

5

Page 10

7

SYSTEM OVERVIEW AND FLOW-CLIK OPERATION (continued) ............

ICC Controller

®

® ®

®

®

®

®

®

Flow-Clik Sensor

Master Valve

Back Flow Preventer

Point of Connection

Flow-Clik

Interface

Valve 4 has been

determined to have the

highest flow

Wire

Mainline Pipe

Flow-Clik is located on

mainline to shut down

the system if the

mainline is ruptured

Valve 4

(18.9 GPM)

Valve 6

(17.0 GPM)

Valve 1

(13.0 GPM)

Valve 7

(16.0 GPM)

Valve 2

(14.0 GPM)

Valve 3

(15.0 GPM)

Valve 5

(16.0 GPM)

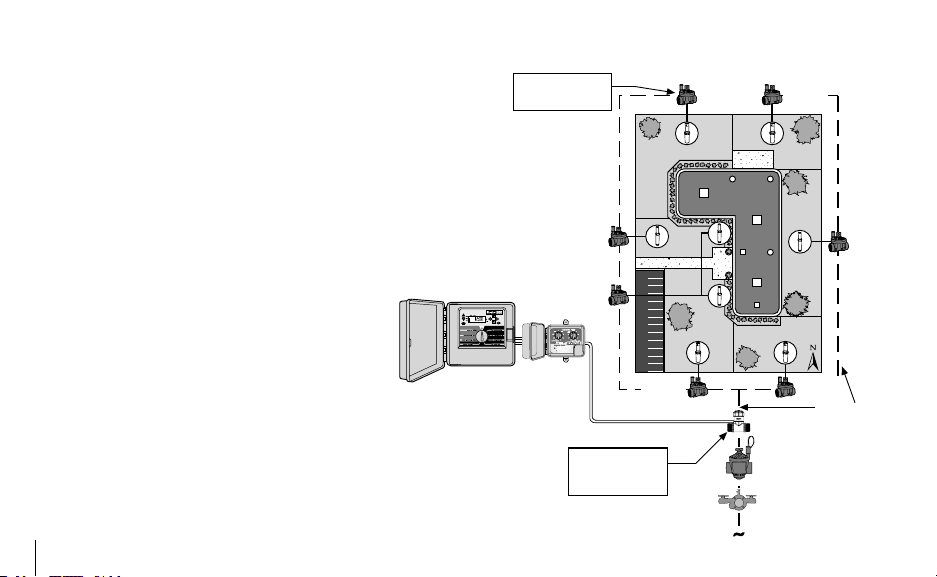

Example of System Operation

In this illustrative example of a small commercial site, the

Flow-Clik sensor is connected to the mainline pipe that

provides water to the system control valves. Because it

is installed immediately down stream of the master valve,

it will provide the added protection of shutting down the

irrigation system if a mainline break should occur.

The Flow-Clik can be set to automatically shut off the

system whenever actual flow within the system exceeds the

flow of the system’s highest flow zone. During installation

of the Flow-Clik, a calibration procedure (see Calibrating the Flow-Clik) is used to set the Flow-Clik

at a level of flow dictated by the highest flow zone.

If the system flow exceeds the “calibrated” flow by

a pre-determined amount, the Interface Box will

signal an overflow condition is occurring.

The figure to the right shows an example of an application

using the Flow-Clik sensor. In this example, the valve that

commands the highest flow is valve number 4, which has a

total flow rate of 18.9 gallons per minute (GPM). The user

would turn this valve on and calibrate the Flow-Clik to this

zone. If flow exceeds 18.9 gpm, a signal will be sent to the

Interface Box which would communicate to the controller

6

Page 11

to interrupt the system for a prescribed period of time set

by the interrupt delay position on the dial.

The system startup delay and interrupt period can be

adjusted by moving the dials on the Flow-Clik Interface Box

to the desired settings. The system startup delay allows

for system stabilization to occur prior to the Flow-Clik

sensing for an overflow condition. The startup delay can be

adjusted from 0 to 300 seconds.

The interrupt period setting allows the user to program the

Flow-Clik to shut the system off for a prescribed amount of

time. The interrupt period can be adjusted by moving the

dial to a specified setting from 5 to 60 minutes. There is

also a Restart Manually position on the dial that shuts the

system off until it is manually restarted at the Interface Box.

In the following example, the startup delay is set for 20

seconds and the interrupt period is set to 10 minutes.

High-Flow Scenario 1 – Valve 3 Lateral Line Breaks

If a lateral line break should occur on valve number 3, the

Flow-Clik would sense a “high flow” condition and would

shut the system down after a sustained 20 second over

flow condition. Once the system has been shut off, the

Flow-Clik will continue to keep the system off for the 10

minutes programmed into the interrupt period. After 10

minutes have passed, the Flow-Clik will turn the system

back on and begin to monitor for an over flow condition.

If the run time for zone 3 is 19 minutes and is scheduled

to come on at 6:00 am, then the following chain of events

would occur:

6:00 AM – Valve 3 is activated and the Flow-Clik senses an

over flow condition. After a 20 second delay the system is

shut off for 10 minutes.

6:10 AM – Valve 3 is reactivated (it still has 9 minutes of

run time left) and after a 20 second delay, a “high flow”

condition is again identified and the system is interrupted

for another 10 minutes.

6:18 AM – Valve 4 is scheduled to be activated by the

irrigation controller, however, the Flow-Clik continues to

interrupt system operation due to the 1 minute left on the

interrupt delay.

6:20 AM – Valve 4 is activated and the Flow-Clik begins to

monitor the flow of valve 4 which is below the “high flow”

trigger point enabling the controller to continue to irrigate

as it normally would.

7

Page 12

9

SYSTEM OVERVIEW AND FLOW-CLIK OPERATION (continued) ............

Post 6:20 AM – For the balance of the irrigation cycle flow

is monitored by the Flow-Clik without exceeding the maximum and the total irrigation schedule is completed.

The Flow-Clik will continue to shut the system off during

automatic operation of valve 3 until the lateral line break is

repaired.

High Flow Scenario 2 – Mainline Ruptures

If a mainline ruptures, the Flow-Clik would identify a “high

flow” condition approximately 20 seconds after the first

valve is activated based upon the irrigation schedule and

the master valve would be shut down. Flow would continue

to be monitored every 10 minutes and after a sustained 20

second “high flow” condition, the system would be shut

off. Each time the system is deactivated by the Flow-Clik

the System Status Indicator will show a steady red light.

This will occur until the mainline pipe is repaired.

In both of the above scenarios, the “high flow” shut down

capability of the Flow-Clik sensor would eliminate the water

waste and associated damage to the site that would be

caused by the breaks in the irrigation system. In the lateral

break scenario, the Flow-Clik halts irrigation of the effected

valve while continuing to allow the controller to irrigate the

rest of the zones throughout the system.

8

Page 13

turn in system

Minimum 5

pipe diameter

from nearest

x

from nearest turn in system

Minimum 10 x pipe diameter

Water Flow

MAIN LINE OR LATERAL LINE

INSTALLING THE FLOW-CLIK SENSOR BODY ...........................................

The Flow-Clik sensor body is designed in diameters from

1" to 3". It is installed into the mainline or lateral pipe of

the irrigation system. It is important to install the Flow-Clik

Sensor Body downstream of the master valve (for mainline

installations) or the zone valve (for lateral line installations). Also, it is necessary to install the Sensor Body in

an area of low turbulence within the system. Areas of high

turbulence will cause erratic readings from the Flow-Clik.

The figure below represents a recommended sensor body

installation. There must be at least 10 times the pipe diameter of straight pipe upstream of the Sensor Body inlet and

at least 5 times the pipe diameter in length of straight pipe

downstream of the Sensor Body outlet. This will assure

that the Flow-Clik sensor be placed in the optimum position

within the irrigation system.

NOTE: For maximum protection against overflow conditions, it is required that a master

valve be installed.

9

Page 14

11

INSTALLING THE FLOW-CLIK SENSOR INTO THE SENSOR BODY .......

Figure 1

Figure 2

The Flow-Clik Sensor Body comes with a plug that allows

for installation of the Sensor Body into the irrigation

system prior to installing the Sensor. This allows the

sensor body to be installed separate of the sensor and prevents damage to the sensor during installation of the body.

NOTE: Do not attempt to remove the sensor

plug or sensor while the system is under

pressure

To install the sensor into the body:

1. Turn the system pressure is off.

2. Unscrew the cap from the top of the

body (figure 1).

3. Use pliers or a screwdriver and carefully pry the plug from the body.

4. Insert the sensor into the sensor

body (Check to make sure the two

o-rings provided with the sensor

are installed in the grooves at

the lower end of the sensor). The

sensor has a flat side that engages

with a flat on the inside of the

sensor body (figure 2).

5. Replace the cap on the sensor body

(hand tighten only).

6. Feed the two sensor wires through

the hole in the cover and snap the

cover on the cap.

10

Page 15

MOUNTING THE FLOW-CLIK INTERFACE BOX .........................................

The Flow-Clik Interface Box is designed to mount next to

the irrigation controller. A door is provided to keep water

and debris from entering the inside of the Interface Box. A

lock is also provided to prevent unauthorized changes in

Flow-Clik settings. There are two mounting tabs on the top

and bottom of the Interface Box to provide an easy means

to secure it on the wall next to the controller. Using the

hardware included, mount the Interface Box to the wall (use

screw anchors if needed). Make sure to place the Interface

Box close to the controller (check that the controller door

and Inter face Box door to not inter fere with one another).

11

Page 16

13

WIRING THE FLOW-CLIK TO THE IRRIGATION SYSTEM ........................

Flow-Clik Interface Box Flow-Clik Sensor

Hunter Controller

Power Module (Typical)

Yellow

Yellow

Sensor Loop

24 VAC Power

White

White

WARNING! This unit is designed to be installed in conjunc -

tion with 24 VAC circuits only. Do not use with 110 or 220

VAC circuits.

Wiring the Sensor to the Interface Box

The red and black leads from the Flow-Clik sensor are

connected to the red and black leads on the Interface Box.

A minimum wire size of 18-gauge wire can be used to connect the leads from the sensor to the Interface Box. Secure

all wire connections with waterproof connectors.

12

Note: The Flow-Clik Sensor can be installed

up to a maximum of 1,000 ft. from the Interface Box when installed with #18 gauge or

larger copper wire.

Page 17

Wiring the Interface Box to the Controller

White

White

Yellow

Yellow

AC AC R RS C MV 1 2 3 4 5 6

WhiteYellow

The Flow-Clik Interface Box is designed to operate similar

to most micro-switch type sensors. Hunter controllers

have provisions for sensor installations that allow for easy

wiring of the Flow-Clik to the controller. The two yellow

wires from the Interface Box are attached to the sensor

terminals inside the controller and the two white wires are

attached directly to a constant 24-volt source.

To wire the Flow-Clik Interface Box on Hunter controllers:

Pro-C and ICC Controller Installations

1. Attach the two yellow wires to

the AC terminals on the controller (polarity does not matter).

2. Attach the two white wires to

the SEN terminals on the controller.

SRC Controller Installations

1. The two yellow wires are connected to the AC terminals

on the controller (polarity does not matter).

2. Attach one of the two white wires to the RS terminal on

the controller.

3. Attach the other white wire to the “C” terminal.

4. Attach the valve common and pump relay common (if

used) to the RS terminal.

13

Page 18

15

WIRING THE FLOW-CLIK TO THE IRRIGATION SYSTEM (continued)...

Interface Box

Common Wire

to All Valves

Y

W

Y

W

1 2 3 4

Controller

CAC AC

Hunter Controllers

Mini-Clik

AC

AC

SEN

Interface Box

SEN

Y

Y

W

W

1 2 3

Interface Box

C

Common Wire

to All Valves

AC AC

Y

W

Mini-Clik

Y

W

Other Controllers

Other Controllers

1. Attach the two yellow wires to the AC terminals on the

controller (polarity does not matter).

2. Some controllers do not have terminals dedicated for

sensor installations. Locate the common wire to the

solenoid valves and disconnect it from the common

terminal (usually marked “C” on the controller). Attach

one white wire from the Flow-Clik Interface Box to the

common terminal. Attach the other white wire to the

common wire leading to the valve.

WIRING WHEN USING MULTIPLE SENSORS ............................................

The Flow-Clik can be wired to a controller already using

another Hunter sensor (i.e. Rain-Clik™, Wind-Clik®,

Freeze-Clik®, etc.) or other micro-switch type sensors. It is

14

important to make sure that, when using multiple sensors,

they are connected in series.

Page 19

SYSTEM CONSIDERATIONS ..........................................................................

Proper irrigation system design and operation assures optimum performance of the Flow-Clik in monitoring for poten tial high flow conditions. It is important to understand that

the Flow-Clik is primarily designed to shut off the irrigation

system in the event of a catastrophic system failure such as

a main line or lateral line break. However, depending upon

the design of the irrigation system, the Flow-Clik can offer

increased protection when components such as sprays

or rotors are damaged or removed due to vandalism. The

following may be helpful in making your Flow-Clik System

operate at its optimum level.

Proper Irrigation System Design

Generally, the Flow-Clik is designed to shut off the irrigation system when a high flow condition is identified. A high

flow occurs when the actual flow rate through the system

exceeds the “learned” flow of the highest flow zone. If a

wide variation in flow rates exist between the highest flow

zone and the lowest flow zone, the Flow-Clik may not sense

an over flow condition if damage occurs within the low

flow zone(s). For example, if an irrigation system has a

rotor zone that operates at 18.9 GPM, and a drip zone that

flows at 5 GPM; any damage to the drip zone components

may not result in high enough flow rate for the Flow-Clik to

sense an over flow condition.

The more balanced the irrigation system is designed, the

more protection will be provided by the Flow-Clik. Zones

should be designed so that they operate at similar flow

rates.

Mainline Pressure Fluctuation

Some water sources may have varying pressure depending

upon the demand for water upstream of the point of connection. During times of heavy demand, system pressure

through the mainline may drop. A decrease in mainline

pressure will result in a decrease in flow rates throughout

the system. If the Flow-Clik calibration procedure takes

place during a period of time which pressure is at its lowest

point, an increase in pressure at the point of connection

may result in system flow rates that exceed the calibrated

“high flow”. As a result, the Flow-Clik may shut the system

down prematurely even though the system is functioning

normally.

15

Page 20

17

SYSTEM CONSIDERATIONS (continued).....................................................

Note: If pressure fluctuations at the point of

connection in excess of 10 psi are expected,

it is recommended that a pressure regulator

be installed on the mainline or at the master

valve.

Proper System Maintenance and Operation

It is important that your irrigation system be maintained

and is functioning properly for optimum performance.

Check your irrigation system for any broken components

or leaks also, make sure that all sprinklers are operating

within the pressure ranges recommended by the manufacturer.

PROGRAMMING THE FLOW-CLIK INTERFACE BOX.................................

Calibrating the Flow-Clik to the Irrigation System

Note: Before calibrating the Flow-Clik to your

system, it is very important that the irrigation

system be in good working condition. Irrigation system leaks, broken sprinklers, zones

operating outside specified pressure ranges,

will have a negative effect on the performance

of the Flow-Clik.

Using the Flow-Clik’s Interface Box, the sensor is calibrated

by pressing the Calibrate button while the highest flow

zone is operating. While the system is “learning” the flow,

the System Status Indicator light will be yellow. After a 10

16

second period of “learning” it will begin to monitor system

flow.

If you already know the hig hest flow zone within the

system:

1. Turn the Startup Delay dial to the 0 second position.

2. Turn the Interrupt Period dial to the Sensor Bypass/

Calibrate position.

3. Manually activate the zone with the highest flow.

4. While the zone is operating, press and hold the Calibrate button on the Interface Box. The System Status

Indicator light will change to yellow during the calibra-

Page 21

tion process. Once the Flow-Clik has finished “learning” the system’s high flow zone, the light will turn to

flashing green which means that the calibration process

is complete and flow is occurring.

5. Turn the irrigation system off and set the Startup Delay

and Interrupt Period settings on the Interface Box (see

Setting the Startup Delay and Interrupt Period).

If you do not know the highest flow zone within the

system:

Flow Estimate Calibration Method

In some cases, you may not know the zone with the highest flow. A guideline that will help you easily determine

which zone valve has the highest flow (GPM) is to count

the number of sprinklers on each zone. If there are zones

with both sprays and rotors operating in the irrigation

system, you can multiply each spray head by 2.0 GPM,

each medium range rotor by 4.0 GPM, and each large range

rotor by 15.0 GPM for a general estimate of total flow for

each zone.

For a more accurate determination of total flow for each

zone, it is recommended that you measure the nozzle pressure at each sprinkler zone and then look up the nozzle flow

at that specific pressure in the nozzle performance data

section of the manufacturer product catalog. Once a determination is made of the highest flow zone, you can use the

procedure above to calibrate the Flow-Clik to the system.

For example, Figure 1 (on the following page) shows a

typical zone using I-20 rotors. To estimate the total flow

of the zone:

1. Determine the approximate water pressure at the base

of the sprinklers in each zone while the system is operating. In the illustrative example it has been determined

that the sprinkler pressure in zone 4 is 50 psi.

2. Identify the model of sprinkler and its associated nozzle

for each valve. Valve 4 has Hunter I-20 rotors that have

various nozzles based on the distance of throw and the

arc of coverage needed. For reference, the quantities of

each type of sprinkler and nozzle configuration for zone

4 is identified in the attached irrigation legend.

3. Determine the flow rate for each sprinkler and nozzle

configuration. Based upon information found in the

Hunter Catalog the associated flows for each Hunter

I-20 sprinkler and nozzle configuration is listed in the

attached irrigation legend.

17

Page 22

19

PROGRAMMING THE FLOW-CLIK INTERFACE BOX (continued) ...........

Figure 1

Valve 4 (18.9 GPM)

Operating pressure = 50 psi

4. Determine the total flow of all sprinklers on the zone.

The total flow of zone 4 in this example is 18.9 GPM as

identified in the irrigation legend.

Manual Cycle Method

You can also use your controller to help calibrate the FlowClik in a system with unknown flow rates among zones.

This method is easy, accurate and prevents the user from

having to count and estimate system zone flows. Simply

operate your controller manually and sequentially “learn”

as you cycle through each of the zones.

To calibrate the Flow-Clik with the Manual Cycle Method:

1. Turn the Startup Delay dial to the 0 second position.

Symbol Sprinkler Descri ption *Flow

Hunter I-20-ADS – 1.5 1.6 x 3 = 4.8

Hunter I-20-ADS – 3.0 2.7 x 2 = 5.4

Hunter I-20-ADS – 4.0 4.2 x 1 = 4.20

Hunter I-20-ADS – .75SR .75 x 2 = 1.50

Hunter I-20-ADS – 1.5SR 1.5 x 2 = 3.0

*Inf ormation obtained from pg. 17 o f th e Hu nter cat alog

18

Figure 1 Legend

@ 50 psi

Total Flow = 18.9 G PM

Qty Total

Flow

Page 23

2. Turn the Interrupt Period dial to the Sensor Bypass/

Calibrate position.

3. Start a manual cycle on the controller beginning with

the first zone (for Hunter controllers, use the One

Touch Manual Advance feature).

4. Press and hold the Flow-Clik Calibrate button on the

Interface Box for 5 seconds. The System Status Indica tor will change to yellow indicating that the Flow-Clik

is “learning” the flow of the zone. Release the button

when the yellow light appears. When finished calibrating, the System Status Indicator will begin to flash

green.

5. Advance the controller sequentially to the next zone.

Wait a few seconds for a change in the System Status

Indicator. If the indicator begins flashing red, repeat

Step 4. If the indicator continues to flash green,

advance the controller to the next zone.

6. Repeat until all zones have been checked.

7. Set the Startup Delay and Interrupt Period settings on

the Inter face Box (see Setting the Startup Delay and

Interrupt Period).

Note: If your controller is programmed to

operate more than one zone at a time, those

zones will have to be activated together to

calibrate the Flow-Clik to total system flow.

19

Page 24

21

SETTING THE STARTUP DELAY....................................................................

The high velocities that are common

during initial activation of an irrigation cycle could cause the Flow-Clik

to sense a “high flow” situation (primarily due to air trapped within the

system) and subsequently shut down

the irrigation system at the beginning of ever y cycle. The Flow-Clik

addresses the problem by providing a

programmable Startup Delay to allow the system to stabilize

prior to the Flow-Clik monitoring for high flow conditions.

To program the Startup Delay, turn the dial on the left side

of the Inter face Box to one of the eight preset delay positions from 20 seconds to 300 seconds.

Note: The 0 second delay position is used

for calibration of the Flow-Clik during initial

installation only.

Note: The startup delay required may vary

between zones. Select the largest start up

delay required for all zones.

20

Page 25

SETTING THE INTERRUPT PERIOD.............................................................

The Flow-Clik monitors for a high flow condition, shutting

down the system or individual zone when overflow occurs.

Once the system has been shut off due to a high flow

condition, the Flow-Clik turns the system back on automatically after a pre-selected amount of time has passed. By

waiting out a selected amount of time allows for the system

to resume watering areas that may not be affected by the

“problem.”

The Inter face Box offers nine preselected off times from 5 to 60

minutes that are programmable by a

single rotar y switch. To set the Interrupt Period, turn the dial on the right

of the Inter face Box to the desired

period of time you would like the

Flow-Clik to keep the system off after

a high flow condition has occurred

before continuing to irrigate.

Example: A system that is mostly spray zones set for 10

minute run times could select a delay of 10 minutes so the

system is only off during the operation if a single zone.

A manual restart feature is also provided. If the dial is set

to the Restart Manually position, and an over flow condition

is detected by the Flow-Clik, irrigation will not resume until

the system has been manually reset.

To manually restart the system after an overflow condition has occurred:

Press the Restart System button once on the Interface Box.

The System Status indicator light will change from red to

green or flashing green (if flow is occurring).

Sensor Bypass

The Sensor Bypass setting allows the user to manually

override the Flow-Clik sensor. This is helpful during situations that require the system to operate at higher than

“learned” flow rates (i.e. system winterization, running a

hose bib, or operating multiple valves).

21

Page 26

23

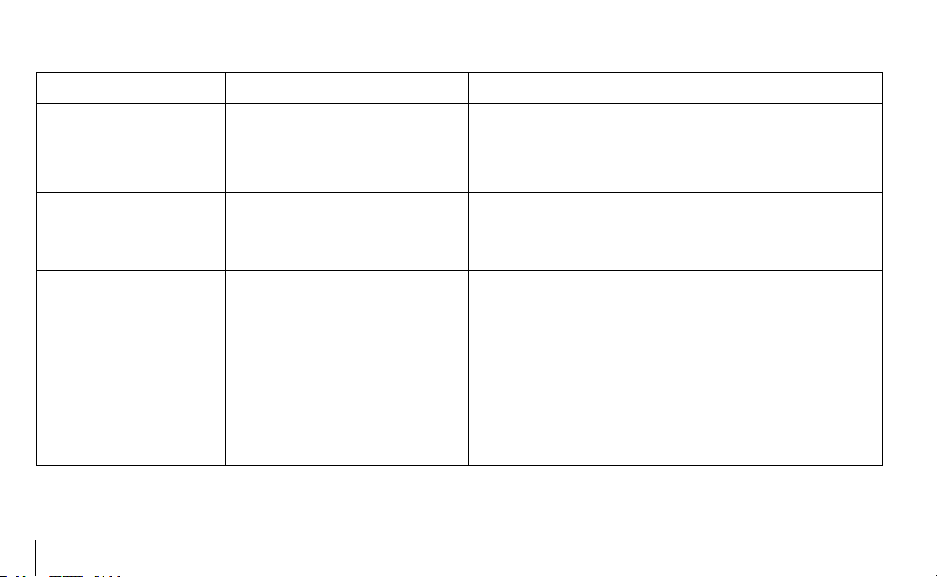

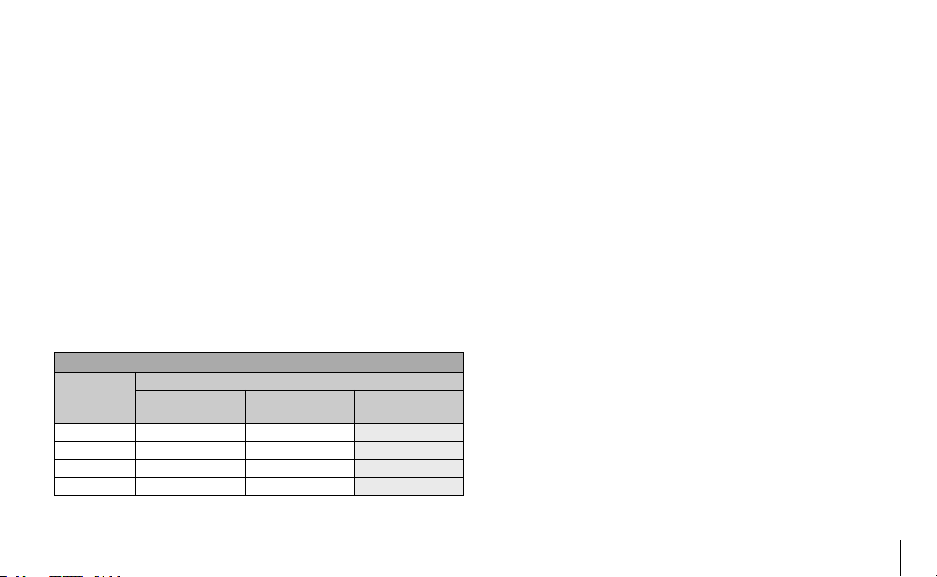

TROUBLESHOOTING GUIDE ..........................................................................

PROBLEM CAUSE SOLUTION

System Status Indicator

light is off

System Status Indicator

light is ashing red

System Status Indicator is

steady red

No AC power to the Flow-Clik

Interface Box

Irrigation system is in an overow

condition

Irrigation system is in an overow

condition

A) Check that the Interface Box power leads (yellow wires) are

attached to the 24 VAC terminals on the controller.

B) Verify that the power to the controller is on.

Normal operation during an overow condition. The Flow-Clik has

identied overow condition and is waiting the pre-set startup

delay period before shutting the system off.

Normal operation during an overow condition.

A) The Flow-Clik has identied an overow condition and is

waiting the predetermined amount of time set as the Interrupt

Period before restarting the irrigation cycle.

B) The Interrupt Period setting is in the Manual Restart position

requiring that the Flow-Clik be reset before irrigation can resume.

Press the Restart System button to reactivate the Flow-Clik.

22

Page 27

Flow-Clik will not shut the

irrigation system off

No power to Flow-Clik

Check System Status Indicator light is on (if light is off, see

above).

Flow-Clik continually shuts

off a zone with no known

problems

Faulty wire connections from the

Flow-Clik sensor to the Interface Box

System has not reached an overow

condition

System is in the Startup Delay mode

Flow-Clik is improperly calibrated

High uctuations in system pressure

Check Flow-Clik sensor wires (red and black wires) are properly

connected.

A) Normal operation.

B) System is not balanced. Too much variation between ow rates

of the zones may prevent the Flow-Clik from sensing an overow

condition on the lower ow zone(s). Flow-Clik can only sense

ows above the system maximum.

Wait for start up delay period to end.

Reset the Flow-Clik to the highest ow zone.

It is recommended that the Flow-Clik be set at the time of day

that the irrigation system will be run. Note: If too much pressure

uctuation occurs, it may be necessary to add pressure regulation

to the system.

23

Page 28

25

TROUBLESHOOTING GUIDE (continued) .....................................................

System Status Indicator

light is not Flashing Green

when the system is running

24

Faulty wiring connections from the

Flow-Clik sensor to the Interface Box

AC power not being supplied to the

Interface Box

Debris is stuck in the impeller of the

Flow-Clik sensor

Check Flow-Clik sensor wires (red and black wires) are properly

connected.

Check the wiring connections from the controller to the Interface

Box.

Conrm that system pressure is off. Remove cap and pull sensor

out of the sensor body and inspect for debris or damage.

Page 29

FREQUENTLY ASKED QUESTIONS ...............................................................

What is the ideal location for a Flow-Clik sensor in my

irrigation system?

If your system is balanced (similar flow rates among all

zones), the best position for the Flow-Clik sensor would be

just downstream of the master valve in your system. Make

sure the sensor is at least 10 times the pipe diameter in

distance away from the outlet of the master valve.

Do I need a master valve to use the Flow-Clik?

The use of a master valve is preferred when installing a

Flow-Clik in your system. The Flow-Clik is designed to prevent water loss due to catastrophic failure of your irrigation

system. If a master valve is used at the beginning of the

mainline, the Flow-Clik can provide maximum protection in

shutting off the system when mainline ruptures occur.

My controller is running two valves at one time. Is this a

problem?

No. The Flow-Clik is designed to be calibrated to your highest flow zone(s). If you are operating more than one valve

with your controller, both valves need to be operating at the

same time during Flow-Clik calibration and setup.

Should I be concerned about winterization with the

Flow-Clik?

Typically, systems are winterized using compressed air to

“blow out” the water in a system. Depending upon the location of the Flow-Clik sensor in the irrigation system, it may

sense a “high flow” condition due to air moving the sensor

at a very high rate. It is recommend that the Flow-Clik be

shut off before winterization by using the sensor bypass

switch at the controller to deactivate the sensor.

Can I use one Flow-Clik sensor with two irrigation controllers on the same system?

No. The Flow-Clik is designed so that each sensor has an

Interface Box that attaches to each specific controllers.

Controllers cannot share the Interface Box.

Can I use multiple Flow-Clik sensors on the same

system?

Yes. Flow-Clik sensors can be installed on multiple lateral

lines within your irrigation system for a higher level of

overflow protection. However, each sensor would require

its own Interface Box at the controller and would need to be

wired in series with one another.

25

Page 30

27

FREQUENTLY ASKED QUESTIONS ...............................................................

How long will the Flow-Clik keep my system off if an

overflow condition occurs?

The Flow-Clik Interface Box allows the user to customize

the Flow-Clik operation based upon the specific system.

The Flow-Clik Interface Box provides for 9 pre-set Interrupt

delay positions from 5 to 60 minutes that are set by the

user. There is also a manual re-start position that requires

the user to manually re-start the irrigation system at the

Interface Box if an overflow condition has shut the system

off.

How do I know my Flow-Clik is working?

The Flow-Clik Interface Box has a System Status Indicator

that provides information on the status of your Flow-Clik.

Reference page 4 of this manual.

Will I lose my controller settings if the Mini-Clik shuts

my system off due to rain?

No, the Flow-Clik switches off the solenoid valves of the

irrigation system when it senses an overflow condition This

prevents flow of water to the sprinklers without affecting

the operation of the timer. Once the Flow-Clik has reached

the end of the Interrupt Period programmed into the Interface Box, the valves resume normal operation.

26

Page 31

SPECIFICATIONS .............................................................................................

Models

Operating Specications

Temperature: 0 to 150 degrees F

Pressures: up to 200 psi

Humidity: up to 100%

Additional Features

Programmable Start Up Delay (0 to 300 seconds)

Programmable Interrupt Period (5 to 60 minutes)

System Status Indicator Light

One Button System Calibration

F L O W R A N G E

FLOW

SENSOR

DIAMETER

1" 6 17 50

1" 13 35 100

2" 20 55 200

3" 50 120 300

* Minimum recommended ow for the highest ow zone for your system

** Good design practice dictates the maximum ow not to exceed 5ft/sec.

Suggested maximum ow is based upon Class 200 IPS plastic pipe

MINIMUM*

OPERATING RANGE (GPM)

SUGGESTED MAXI-

MUM**

MAXIMUM

Electrical Specications

Current Draw: (@ 24 VAC) .025 amps

Switching Current: 2.0 amps

Maximum Distance between Inter face Box and Sensor =

1,000 ft.

Dimensions

Flow-Clik Inter face Box (4.5"H x 5.5"W x 1.5"D)

Flow-Clik Sensor Body

Model 100 (4.8"H x 2.3"W x 4.5"L)

Model 150 (5.4"H x 2.3"W x 4.6"L)

Model 158 (5.4"H x 2.3"W x 5.1"L)

Model 200 (5.9"H x 2.7"W x 4.7"L)

Model 208 (6.0"H x 2.9"W x 5.4"L)

Model 300 (7.0"H x 4.0"W x 6.2"L)

Model 308 (7.0"H x 4.2"W x 6.4"L)

27

Page 32

Hunter Industries Incorporated • The Irrigation Innovators © 2003 Hunter Industries Incorporated

1940 Diamond Street • San Marcos, California 92069

www.HunterIndustries.com

P/N 700973 LIT-366 1/03

Loading...

Loading...