Page 1

ET System

Evapotranspiration Sensor and

Module for Hunter Controllers

®

with SmartPort

Owner’s Manual and Programming Instructions

Page 2

TABLE OF CONTENTS .............................................................................................................................

Introduction ...........................................................................1

ET System Components .........................................................3

System Overview and ET System Operation ..........................3

Installing the ET Sensor .........................................................4

Additional Tools and Materials ........................................4

Choose the Location .......................................................4

ET Sensor Wiring ............................................................5

Prevailing Wind Compensation .......................................5

Metal Fence Pole .............................................................6

Wooden Post ..................................................................6

Wall or Eave ....................................................................6

Installing the ET Module ........................................................7

ET Module Wiring ...........................................................7

SRC or SRC Plus Controller Connection .........................8

Pro-C Controller Connection ...........................................8

ICC Controller Connection ..............................................8

Remote Control Connection ............................................9

ACC Controller Connection .............................................9

Test ...............................................................................11

Maintaining the ET Sensor ...................................................11

Programming and Operating the ET Module ........................12

General Operating Tips .................................................12

Setup Overview .............................................................13

Global % Setting ...........................................................13

Initial Soil Deficit ...........................................................13

International Users – Metric Setting .............................13

Controller Type .............................................................14

Prepare the Controller ...................................................14

Set Time/Date ...............................................................15

Set Daylight Savings .....................................................16

Plant Type .....................................................................16

Maturity ........................................................................17

Type ..............................................................................17

Variety...........................................................................17

Site Info ........................................................................19

Slope ............................................................................19

Soil ...............................................................................19

Sun ...............................................................................20

Sprinkler Type ...............................................................20

Precip ...........................................................................20

Water Days ...................................................................21

Daily Start Time ............................................................22

WiltGard™ .....................................................................22

Rain Setting ..................................................................24

ET Setup .......................................................................25

Automatic .....................................................................26

Watering History ...........................................................27

View Sensor Date ..........................................................29

Reset ............................................................................29

Troubleshooting ............................................................30

Specifications .......................................................................34

ET System Compatibility List ...............................................34

Dimensions ..........................................................................34

FCC Notice ...........................................................................34

Page 3

INTrOduCTION .......................................................................................................................................

The Hunter ET System allows an irrigation program to be created automatically, based on local climate conditions. The program is then operated

via a compatible irrigation controller’s Program A (except ACC controllers, see page 14) and runs automatically, on water days and at start times

set by the system operator. Compatible controllers are Hunter Models SRC/SRC Plus, Pro-C, ICC, and ACC with SmartPort

ET System uses sensors to determine the local “evapotranspiration” (ET) rate of turf and plants. This is a formula which calculates how much water the plants have lost, or consumed, due to local atmospheric conditions. Each ET System can be customized by station (or “zone”) for specific

plant, soil, and sprinkler types.

The result is a new, water-efficient irrigation program every water day, based on local weather conditions.

Once installed, the ET-controlled zones are programmed from the ET Module, rather than the controller itself. The ET Module will display the new

program data for the climate-based irrigation.

The ET System allows manual station starts from the controller, and will also permit connection of an ICR or SRR remote control receiver.

This product is intended for turf and landscaping applications only, not intended for agricultural or scientific use.

Use the ET System Worksheet. One is included with each ET System, and this can also be downloaded free of charge from the Hunter Industries

web site (www.hunterindustries.com at the ET System product page). The ET System Worksheet will help you organize and record your station

settings. This will also help to determine and track any adjustments you may make to the watering settings. If you need Technical Support, the

Hunter technician will also need this information.

®

technology.

1

Page 4

C.

A.

D.

E.

B.

2

Page 5

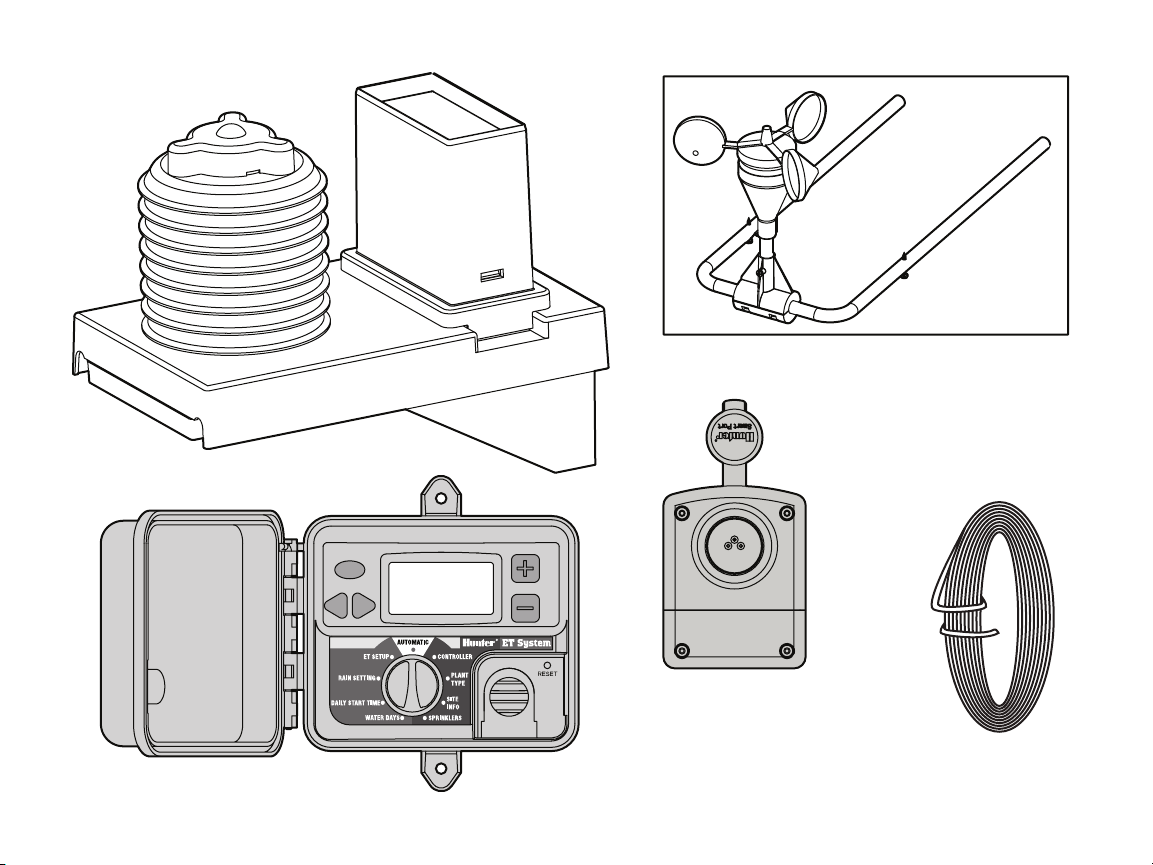

ET SySTEm COmpONENTS ...................................................................................................................

ET System has two major components, and one optional accessory. All

ET System components are low voltage (24 VAC or less).

A. ET Sensor

Sensor platform wired to the ET Module, which senses local

conditions. For external mounting up to 100 ft/33m from the Module. Pole adapters included (requires other hardware for various

mounting options).

B. ET Module

Electronic control and user interface for the ET System.

C. ET Wind (Optional)

Optional anemometer which senses wind speed. Provides more

sensitive ET measurement, especially in arid climates.

D. ET/ACC Adapter (Included)

For connection with ACC series controllers. The adapter is not

required for use with Hunter ICC, Pro-C, and SRC family

controllers.

E. ET Wire

100' (33mm) two-conductor direct burial for connection to ET

Sensor

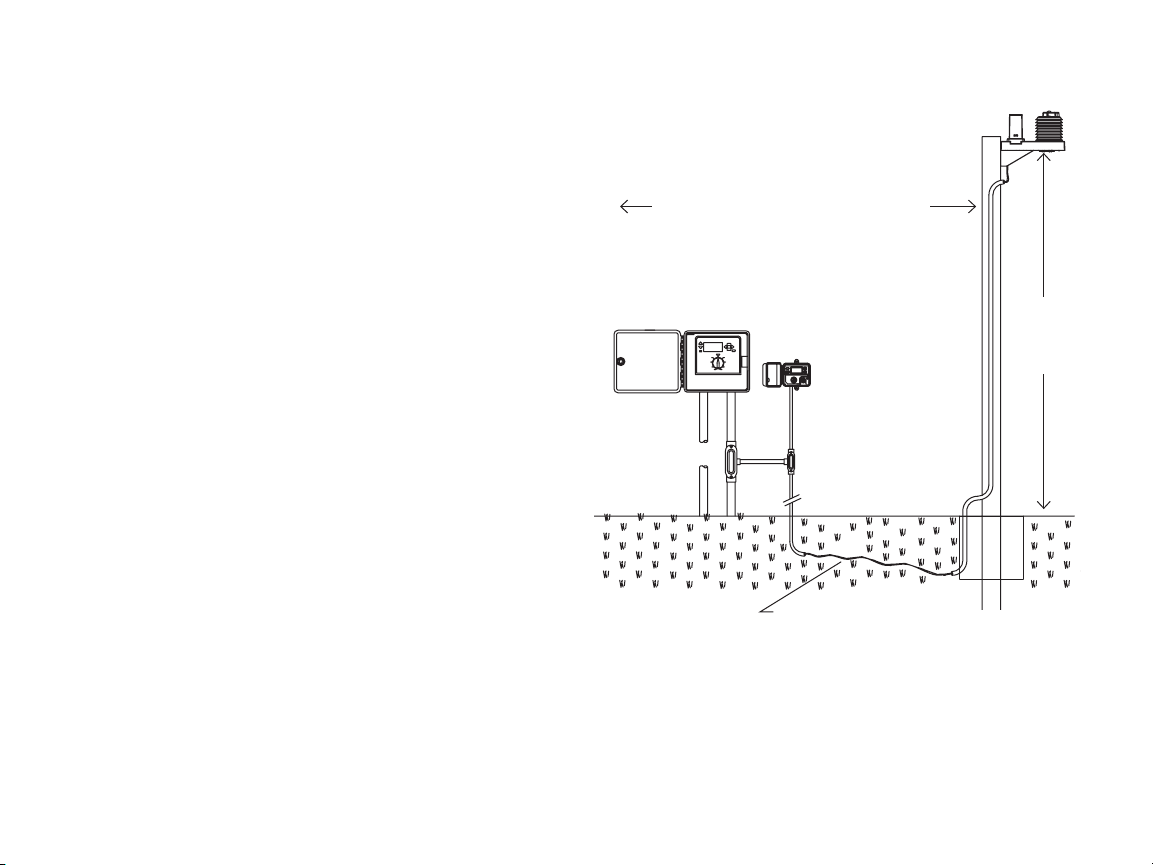

SySTEm OvErvIEw ANd ET SySTEm OpErATION .........................................................................

The ET System can be simply and easily installed with any Hunter

SmartPort®-equipped irrigation controller. The System consists of the

ET Sensor, installed in an area typical of the irrigated plants, and the

ET Module interface enclosure, installed next to the irrigation controller.

The ET Sensor measures solar radiation, air temperature, and relative

humidity, and calculates the daily Evapotranspiration factor (ET) for

the irrigation zones. This represents the amount of water lost by the

plants to local climatic conditions, which needs to be replaced by

irrigation.

The optional ET Wind sensor will add evapotranspiration loss due to

wind, along with automatic wind shutdown capability.

The ET Sensor also includes a Rain Gauge, which measures rainfall in

either hundredths of an inch, or in millimeters.

Rainfall will stop automatic ET irrigation that may be in progress. A

percentage of the rainfall itself will be added to the soil and subtracted

automatically from the automatic irrigation, to prevent waste.

The ET Module receives the data from the ET Sensor, and applies it

to the individual zones of irrigation. The ET Module has settings to

customize each zone’s plant, soil, and sprinkler types, so that ET data

can be applied proportionately for each unique irrigation requirement.

The ET Module is wired into the controller’s SmartPort and creates

irrigation run times to only replace the amount of water the plants

have lost.

ET Module works by running stations through the local controller. It

will clear Program A in the local controller (except in ACC controllers),

and it will then run the ET run times with manual commands. Program

A is no longer available for "traditional" irrigation scheduling.

How ET System Decides to Water: Using the local ET Sensor readings

and the ET Module’s database of station information, ET System predicts the Management Allowable Depletion of water (MAD) available to

each plant type.

Each day, ET System looks at the current depletion level, ET rate,

plant type (crop coefficient and root zone), and whether the next day

is an allowable watering day. The decision to start a specific station

is also based upon a minimum irrigation amount, to prevent shallow

watering. Deeper watering events encourage healthy root systems and

plant growth. The calculation for minimum sprinkler runtime is based

upon the soil type and capacity, where typically the MAD is above

30-50%. For the worst-case scenario, sandy soil with spray heads, the

minimum runtime would then be approximately 7 minutes.

3

Page 6

INSTALLINg ThE ET SENSOr................................................................................................................

ET Sensor

Additional Tools and Materials

The ET system is supplied with 100’/33m of wire for connection of the

ET Sensor. This wire has been specially tested for ET installations and

is approved to 100’/33m max.

If any other wire is to be used, Hunter recommends 2 x 18 AWG/1mm

wire rated for direct burial, color-coded or other wise marked to

identify the separate conductors. The ET signal is a low-voltage DC

and the conductors must be distinguished from each other to maintain

polarity. Either stranded or solid wire is acceptable (stranded is more

flexible and resists breakage). The ET signal is rated to 100’/33m max

and is not tested or approved to any greater distance.

Choose the Location

ET Sensor should be placed in an area representative of the plants it is

designed to irrigate.

The ET Sensor should be post or pole-mounted in a full-sun turf

grass area, approximately 6 ft./2m above the grass, with approximately 6 ft./2m of turf grass surrounding it on all sides. The ET

Sensor weighs approximately 6 lbs./2.5kg.

This may not always be practical, so choose the actual location

according to the following guidelines:

a) ET Sensor must be mounted within 100 ft./33m of the ET Module

and the controller.

b) Avoid positioning ET Sensor over large areas of concrete, asphalt,

roof tile, or shingles. These surfaces will cause the sensors to

read much higher levels of ET than plants.

c) Choose a sunny location between 6 and 20 feet (2 and 7m) above

the ground.

d) Do not mount the sensor where it will be hit by sprinkler spray or

other irrigation!

4

15 ft/5m Clearance From Any Structure

ICC Controller

ET Module

ET Sensor Wire (Included with ET

System) 100 ft./30m, maximum

e) Do not mount the ET Sensor under a ledge or overhang, and avoid

placing it directly under tree canopies. ET Sensor needs un-

blocked sun and rain to function correctly!

f) Do not mount the ET Sensor within falling distance of power

lines! High voltage shocks can injure and kill.

6 ft/2m

Above

Turf,

Minimum

Page 7

g) Position the ET Sensor where it can be reached for occasional ser-

vice. The rain gauge should be checked and cleaned once a month

during the warmer months, to ensure that it is free of debris.

h) Avoid mounting sensor near any high intensity light, heat or infra-

red sources as this may add excess ET amounts over time.

The ET Sensor is designed to adapt to steel fence poles (mounting

adapters included, requires 2 x 2"/50mm

2

U-bolts), 4x4"/100mm2 (or

larger) posts, or eaves or walls.

Metal poles or weather-treated wooden posts are preferred, since

ET measurements will be somewhat less accurate if the sensor is

wall or eave-mounted.

ET Sensor Wiring

Locate the screw terminal strip. Connect the two long conductors

(green and black) to the appropriately labeled terminals.

If an ET Wind Sensor is to be installed, this is also the time to connect the wires.

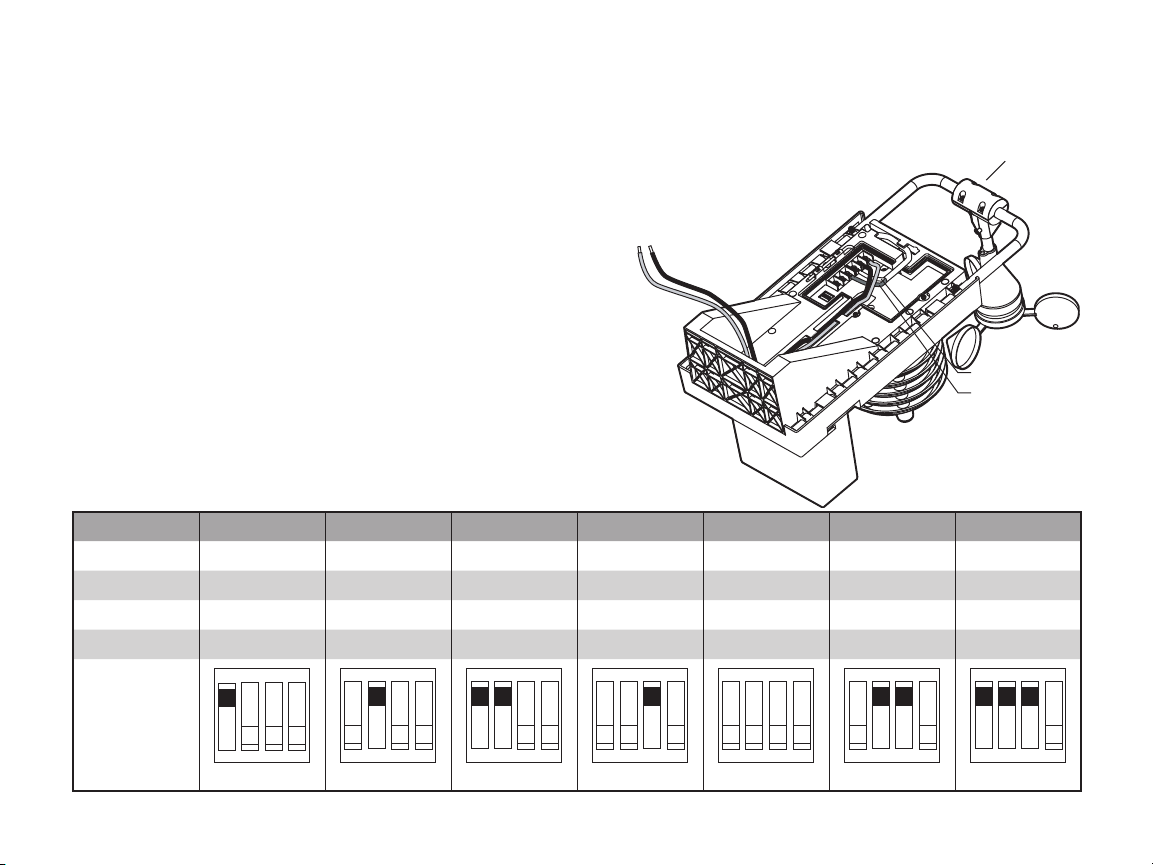

Prevailing Wind Compensation

If ET Wind will not be connected,

a factor for average prevailing

Green and

Black Wires

(ET Module)

Before mounting the ET Sensor, connect the wires to the terminal

strip. This operation is much easier on the ground, prior to mounting

the sensor.

Locate the wiring compartment cover on the bottom of the ET Sensor.

This is a trap door, secured with 2 screws. Remove the wiring com-

White Wire

Blue Wire

(ET Wind only)

partment door screws and set in a safe place, and remove the wiring

compartment door.

Average Wind Factor Settings. Switch #4 is not used, and position does not matter.

Avg. Wind 1mph 2mph 3mph 4mph 5mph 6mph 7mph

DIP setting 1.6kph 3.2kph 4.8kph 6.4kph 8kph 9.6kph 11.2kph

SW 1 On Off On Off Off Off On

SW 2 Off On On Off Off On On

SW 3 Off Off Off On Off On On

ET Wind

ON

OFF

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

5

Page 8

winds in the installation area can be entered while the wiring door is

removed. The factory default setting is 5 mph (8 kph). With the wiring

cover removed, a DIP switch is visible allowing other prevailing

average wind speeds to be set, according to the Table 1 (note

that Switch 4 is not used).

If the optional ET Wind sensor is installed, mount

the ET Wind sensor according to its instructions,

and connect the blue and white conductors from

the ET Sensor to the appropriately labeled terminals and secure their screws. Do not reverse the

blue and white wire connections from ET Wind…

connect as shown!

Replace the wiring compartment door and secure

with the screws.

Metal Fence Pole

Steel adapters are supplied for most popular sizes

of galvanized steel fence posts, 2" diameter and

smaller.

Additional materials (not supplied): 2 x 2" galvanized or stainless steel U-bolts, 3" long or greater

4 nuts and washers for U-bolts

Bag of concrete

If pole is new construction for specific purpose

of mounting ET Sensor, dig approximately 12" x

12" hole and fill with approximately one 90 lb. bag

of concrete, or place as required by local code.

Insert pole, check with level and straighten, and

brace until concrete is firmly set.

Insert U-bolts around pole through steel pole

adaptors, and through mating holes in ET Sensor

back plane. Add washers, thread nuts onto U-bolt,

and tighten. Do not overtighten.

Route ET Sensor wire to ground surface or burial trench, and run back

to ET Module.

6

External mounting in outdoor low voltage conduit

(for the above-ground exposed portion of the wire

run) is recommended for protection from the elements.

Wooden Post

Additional materials (not supplied): 4x4"/100mm

pressure-treated, outdoor, direct-burial grade

4x4"/100mm

2

or larger post.

100mm x 6mm dia. x 3,8cm long galvanized or

stainless steel lag bolts and washers

Nut driver for lag bolts

Bag of concrete

Dig approximately 12" x 12"/30cm x 30cm hole (or greater, as

local code dictates) and fill with approximately one bag of concrete.

Insert post, check with level and straighten, and brace until concrete

is firmly set.

Level, mark, and drill pilot holes for 4 lag screws through back of ET

Sensor holes. Insert lag bolts and washers through mounting hole in

backplane of ET Sensor and tighten. Do not overtighten.

Route ET Sensor wire to ground surface or burial trench, and run back

to ET Module.

External mounting in outdoor low voltage conduit (for the aboveground exposed portion of the wire run) is recommended for protection from the elements.

Wall or Eave

Additional materials (not supplied): 4 x ¼" dia. x 1.5" (100mm x 6mm

x 40mm) long galvanized or stainless steel lag bolts and washers.

Nut driver for lag bolts.

Level, mark, and drill pilot holes for 4 lag screws through back of ET

Sensor holes. Insert lag bolts and washers through mounting hole in

backplane of ET Sensor and tighten. Do not overtighten.

Route ET Sensor wire to ground surface or burial trench, and run back

2

Page 9

Orange, or Blue-And-White-Striped

in some versions

Controller Connections

(ET System Only)

Blue: REM

White: AC2

Red: AC1

To ET Sensor

Green

Black

to ET Module. External mounting in outdoor low voltage conduit (for

the above-ground exposed portion of the wire run) is recommended

for protection from the elements.

In all cases, ensure that any exposed wire loop from the ET Sensor to

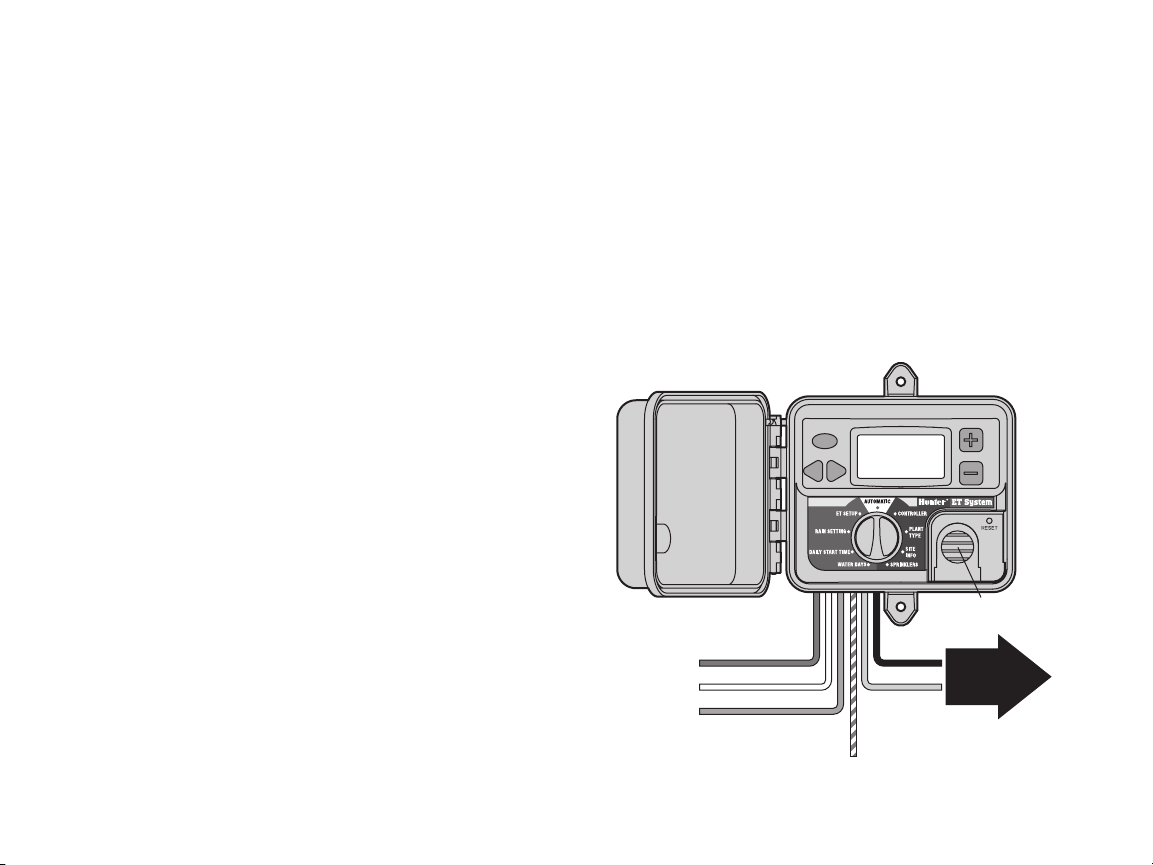

INSTALLINg ThE ET mOduLE ..............................................................................................................

immediately next (6 ft./2m) to the Hunter SmartPort-equipped irrigation controller (including models SRC, Pro-C, ICC, and ACC). The ET

Module is low-voltage only and does not require a separate highvoltage power connection.

The ET Module is connected to the ET Sensor via the two conductor

sheathed wires supplied with the ET System (up to 100 ft./30m away),

and then wired into the SmartPort wiring terminals inside the controller.

To wall mount the ET Module, choose a location within 6 ft./2m of the

controller. Avoid direct sunlight when possible (to enhance visibility of

the LCD display). Verify that the wallboard construction is of sufficient

strength to securely mount the small, lightweight enclosure.

The 6-conductor umbilical cord extends through the shielded hole in

the bottom of the enclosure. Verify that it remains clear and accessible

when securing the enclosure to the wall.

Use two anchors or self-tapping screws of minimum #12 (5.5mm)

diameter to secure the ET Module enclosure to the wall.

Turn off AC power to the irrigation controller, before connecting the

ET Module to the controller! The ET System receives its power from

the SmartPort connection to the Hunter controller. Do not connect the

ET Module to the controller while AC power is turned on.

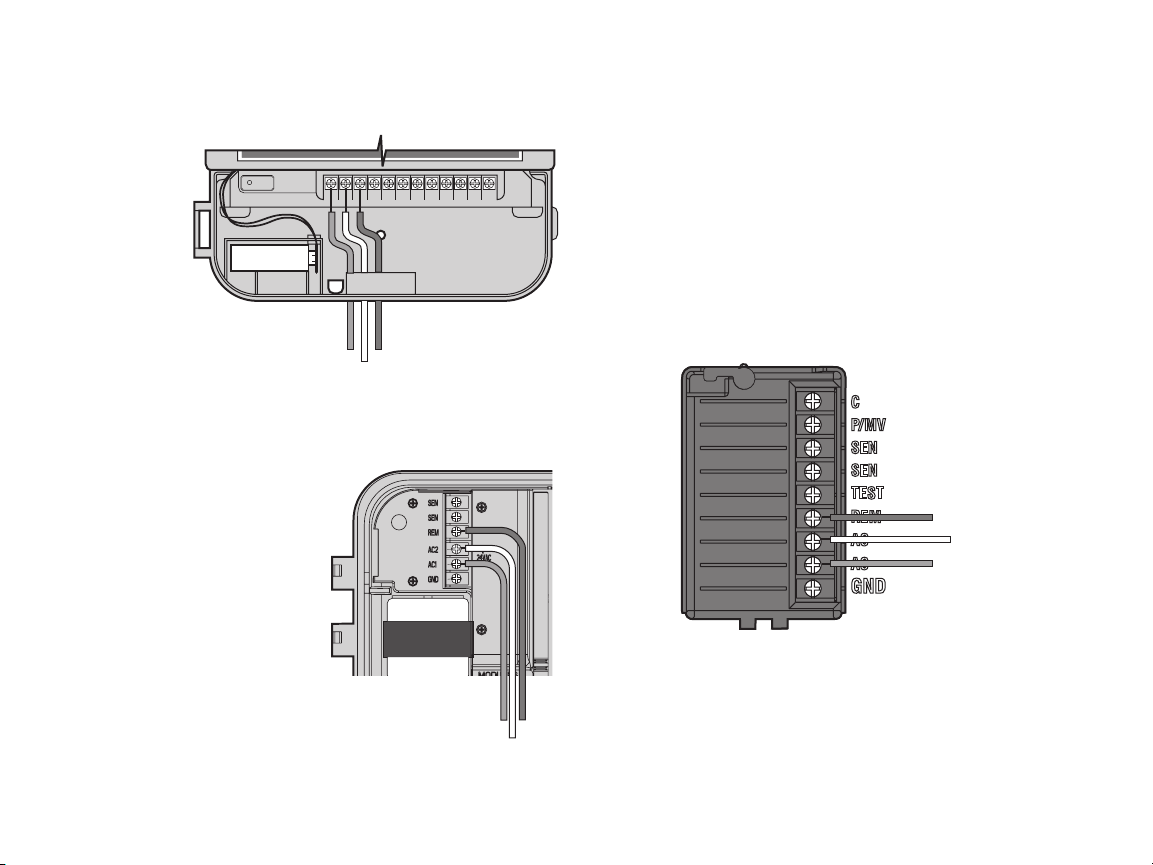

ET Module Wiring

The 6-conductor umbilical cord from the ET Module is color-coded to

simplify connections.

Do NOT connect 110/230V high-voltage power to the ET System!

Make all wiring connections with approved butt splices or wire nuts

for the ET wire, and place the splices in a suitable junction box. Conduit is recommended for both indoor and outdoor installations.

the wire routing conduit does not swing freely in the wind, as this will

shorten its life.

The ET Module is designed to be wall-mounted, either in or outdoor,

Install CR2032 backup battery for date/time backup in event of power

failure (battery included with mounting hardware). Batter y must be

installed with + visible, facing toward the installer.

If connecting the ET System to an ACC series controller, see ACC

section for special installation instructions.

ICC, Pro-C, and SRC controllers (ACC special instructions in next

section): Connect the supplied wires from the ET Module to the ET

Install CR2032 lithium batter y (included)

under cover for time/date backup.

Install CR2032 battery

7

Page 10

AC AC RRSCMV 123456

9 V Battery

RESET

BlueRed

White

BlueRed

White

Blue

Red

White

Sensor with appropriately sized butt splices or wire nuts. These two

wires may be extended up to 100 ft./30m to reach the sensor.

SRC or SRC

Plus Controller

Connection

If no wireless

remote control

receiver will be

installed, the

Orange wire

(or Blue-AndWhite-Striped

wire in some

versions) from

the ET Module

is not used.

Connect the red wire from the ET Module to the bottom left of the two

terminals on the power module labeled “24VAC” (or just AC, on older

units).

Connect the white wire from the

ET Module to the second to the

right of the two terminals on the

power module labeled “24VAC” (or

just AC, on older units)..

Connect the blue wire from the

ET Module to the terminal in the

controller labeled “R”.

If no wireless remote control

receiver will be installed, the blueand-white striped wire from the ET

Module is not used.

Pro-C Controller Connection

Connect the red wire from the ET

Module to the terminal in the controller labeled AC1.

8

Connect the white wire from the ET Module to the terminal in the

controller labeled AC2.

Connect the blue wire from the ET Module to the terminal in the controller labeled REM.

ICC Controller Connection

Connect the red wire from the ET Module to the bottommost of the

terminals on the power module labeled “AC”.

Connect the white wire from the ET Module to the upper of the two

terminals on the power module labeled “AC”.

Connect the blue wire from the ET Module to the terminal in the controller labeled REM.

Page 11

SmartPort

for ICR Receiver

Blue: REM

Connect orange

(or blue-and-white-striped)

wire from module,

to blue wire from SmartPort

White: AC2

Red: AC1

To ET Sensor

Green

Black

Controller Connections

(SmartPort with ET and ICR)

Remote Control Connection

If a remote control (either Hunter ICR or SRR) receiver is to be connected, connect the Orange wire (or Blue-And-White-Striped wire in

some versions) from the ET Module, to the blue ICR/SRR receiver

wire. The SmartPort wiring that connects ET Module to the controller

will complete the connection for the remote receiver.

ACC Controller Connection

The ET System is shipped with a special adapter for use with the ACC

series of controllers.

The ACC controllers have an integrated SmartPort for remote receivers

(such as the Hunter ICR remote control) on the side of the cabinet in

the metal cabinet configurations, and inside the pedestal in the plastic

pedestal configurations.

All ET System connections are made within the enclosed ET/ACC

adapter, which is then plugged into the SmartPort. The adapter allows

both ICR remote receivers and the ET System to be connected to the

ACC controller at the same time.

When installing ET System with an ACC controller, the ET Sensor connections are also made at the terminal strip inside the adapter, NOT to

the ET Module cable directly. This is only true for ACC connections.

9

Page 12

To ET Sensor

To

ET Module

Wiring

Harness

Blue

Orange (or Blue-AndWhite-Striped)

Red

White

Green

Black

Green

Black

Installation

Remove the screws holding the terminal strip cover on ET/ACC

adapter.

Connect the red, white, and blue wires from the ET Module (in that

order) from left to right, on the first three terminals, as shown.

Connect the Orange wire, (or Blue-And-White-Striped wire in some

versions) from the Module to the terminal as marked.

Twist the ends of the green wires from the ET Sensor and the ET Module together, and connect them together to the terminal as marked.

Twist the ends of the black wires from the ET Sensor and the ET

Module together, and connect them together to the last terminal as

marked.

10

Plug the male pin side of the ET/ACC Adapter into the SmartPort

receptacle on the ACC controller. ET connections are now made.

To use an ICR receiver with the ACC through the adapter, it is only

necessary to plug the ICR receiver into the receptacle on the adapter,

and issue commands normally.

If ICR commands are sent while ET

System is irrigating automatically,

and other programs are already running, it is possible that the ICR command will be ignored (if it violates

the ACC maximum of 6 simultaneous

stations). Likewise, if 6 events are

already running in the ACC when

the ET Start Time is reached, the ET

events may be missed. Avoid overlapping the ET Start Time with multiple

stations.

Leave enough slack in all wires to

allow for expansion and contraction in temperature extremes. Secure

the wire splice points to the inside of the junction box or controller, to

create a strain relief.

Reapply AC power to the irrigation controller, and observe the display

in the ET Module. The display should illuminate and show a welcoming screen, followed by information about the ET System.

The ET System will sense rain and freezing automatically with its own

sensors, and will terminate irrigation when necessar y. If this occurs,

the display will show “RAIN PAUSE” or “FREEZE PAUSE”.

ET System will shutdown irrigation when the temperature drops to

37°F/2.7°C. This is not programmable. Temperature shutdowns are

a “pause” mode, and the system will resume watering when the temperature rises back above the shutdown amount.

If existing Clik sensors are removed, the Clik sensor inputs should

have the original jumper replaced, or the sensor connection should be

jumpered with a short piece of wire.

Page 13

If ET WIND is connected, ET System will also detect windy conditions

and shutdown automatically at preset wind levels. If this occurs, the

display will show “WIND PAUSE”.

The ET Wind will shutdown irrigation when the hourly average exceeds

15 mph/24kph. This is not programmable. Wind shutdowns are a

“pause” mode, and the system will resume watering when the average

wind speed falls below 15 mph/24kph again.

The Sensor Bypass switch on Hunter controllers will have no effect

on the ET System, or any of its Pause modes. This switch only affects

external “Clik” sensors for other programs.

Installing other sensors to the controller.

The ET Sensors can stop ET-based irrigation, which is run through

controller program A (except ACC controllers).

ET Sensors will NOT stop irrigation running in the controller’s B, C, or

other programs.

Hunter Industries model Mini-Clik and Rain-Clik, or other sensors, can

be used to stop irrigation in programs B, C, etc. and are required if

those programs are used, and need to stop watering on sensor input.

The ET System does not sense flow, but may not per form correctly

with Flow-Clik installations, unless the Flow-Clik is wired into the

common ground to the valve connections (instead of to the controller’s sensor input). Contact Hunter Technical Services if it is necessary

to use a Flow-Clik together with the ET System.

Troubleshooting: If the ET Module screen does not illuminate,

check all wiring connections. Verify that the red wire from the ET

Module goes to AC1, and that the white wire goes to AC2, in a

Pro-C controller.

In the SRC controllers, the red wire is the left-most of the two AC

connections.

In the ICC controller, the red wire must be the bottommost of the two

AC connections.

Warning: The use of toners and line voltage testers on field wiring may

damage the ET System if it is connected to the controller. It does not

matter if the power is off to the controller. If any device is connected

to the valve wiring which produces voltage, the ET System must be

physically disconnected from the host controller.

Sensor Fault: If the ET Module display shows Sensor Fault, check

connection between ET Module and ET Sensor (green and black wires

or equivalents). Solid conductor wire is prone to breakage from rough

handling. If wires appear correctly installed and Sensor Fault persists,

check the Sensor wiring with a DC voltmeter – the voltage reading at

the black and green terminals on the sensor should be between 9 to

15VDC.

Test: The ET Module can run a test with the host controller to check

the SmartPort wiring from ET System to the controller. This will

cause Station 1 to run for up to two minutes if successful.

Press and hold the recessed Reset button with a ballpoint pen tip or

similar item.

Press the left 3 buttons on the ET Module (STA plus left and right arrows) at once, and hold them.

Release the Reset button.

Release the left 3 buttons.

This should cause Station 1 on the controller to activate for approximately 2 minutes.

The test will be visible in the ET Module display.

If the test is successful, Station 1 will also appear active in the controller display. This verifies that the SmartPort wiring connection from

the ET Module to the controller is correct.

If station does not activate in controller display (but appears in ET

Module), check SmartPort wiring, in particular the red, white and blue

wire connections.

mAINTAININg ThE ET SENSOr .....................

The ET Sensor is designed for outdoor use, but must be kept clean to

function correctly. Wiping the platform and sensors down with a clean cloth

every 30 days is recommended.

11

Page 14

Do not use harsh chemicals or abrasives, particularly on the clear plastic solar radiation lens. It is very important that this sensor be kept clean

and dust-free to record sunlight accurately.

The rain gauge may gather dust and debris, and should also be cleaned out every 30 days.

Solar Radiation

Sensor

Rain Gauge

prOgrAmmINg ANd OpErATINg ThE ET mOduLE ......................................................................

Station Advance Button

Left/Right Navigation Buttons

Dial

General Operating Tips

ET is reactive. You do not set the minutes (as in traditional controllers). ET looks at the weather, and calculates the minutes for you. You

see what it did after the fact (Station Histories).

If you want more or less water, change either:

1. Global % Adjustment (ET Setup dial position). This will change the

amount of watering for all stations, by a percentage.

Plus/Minus Buttons

Reset Button

Lithium Battery Cover

(CR2032, in box)

12

Page 15

2. Station settings (Plant, Site Info, and Sprinkler dial positions).

This information controls how each station is calculated to water.

Individual stations can have their settings changed to produce the

desired results.

It can take several weeks to dial in a new system for desired performance. Make your best effort at the original setup information, but

observe the results. It is common for adjustments to be made in the

start up period.

Enter all settings and track your changes on the ET System Worksheet.

The ET Module has a backlit LCD display, a dial, and 5 buttons. There

is also a recessed Reset button, and a removable lithium

battery cover.

The display is backlit whenever the 24V power (from the SmartPort)

is present.

When power is initially turned on with the dial in the Automatic position, the display will momentarily show a welcome screen, and will

then show the Date and Time and the Current ET. Initially, this may

be 0.00 until the sensor has accumulated enough data to generate an

automatic ET (this may take up to one hour).

11:00AM 00SEP05

DAILY ET: 0.10 IN

Setup Overview

Setup is simplified by following the dial clockwise all the way around,

and entering data for each station until setup is complete.

First, select the controller type and station size (international users,

select Metric measurement first, at the ET Setup dial position).

Then, each station will receive its own data for Plant, Soil, and Sprinkler types.

Other options related to automatic operation are set, and finally the

dial is returned to the Automatic position (straight up, or 12 o’clock

position). The module will now be ready to run ET-based automatic

irrigation.

The ET Module dial must be left in the Automatic position, or the ET

program will not irrigate! If the ET System is watering, moving the

dial from the Automatic position will cause it to stop.

Global ET % Setting

The ET System uses the modified Penman-Monteith equation to

determine moisture loss from evapo-transpiration. The %of actual ET

used is now adjustable. This allows irrigation to be adjusted based on

a percentage of measured ET, and allows the system to run “wetter” or

“drier” to customize performance for specific landscapes.

ET System is preset to operate with 80% of ET. However, this can be

adjusted (in 1% increments) from 10% to 150%. The higher the %,

the "wetter" the system will run. The adjustment is applied equally to

all stations, which are further modified by their individual settings

(Plant, Site Info, and Sprinkler types). This factor may compensate

for non-ideal mounting conditions, where the sensor cannot be placed

according to ideal specifications.

Hunter recommends obser ving performance carefully over the first

weeks of operation and adjusting the percentage to tweak system

performance.

Initial Soil Deficit

ET System assumes an initial soil deficit of .1” of water, meaning the

soil is neither saturated nor dry. This relatively neutral value prevents

excessive watering after initial installation.

If soil is very dry when the system is installed, it may be desirable to

run all stations from the host controller first, with Manual Program

starts, for a “normal” watering. Do not over water, but bring the soil to

a naturally moist state before beginning ET operations.

International Users – Metric Setting

ET System is set to Inches-style measurement, but can be quickly set

to Metric. Turn the dial to the ET Setup position, before entering the

other setup screens.

13

Page 16

ENABLE ET: YES

UNITS: INCHES

ET SOURCE: SENSOR

ET ADJUST: 80%

Use the right arrow key to advance to the UNITS: INCHES position.

Use the +/- keys to change the display to METRIC.

Turn the dial to save the setting. For initial setup, turn the dial to

the Controller Type dial position. Millimeters will now be used in the

displays in other dial positions.

Controller Type

Use the +/- keys to enter the number of stations you will be controlling with ET. Press and hold either key to accelerate the setting.

At the Controller Type dial position, select the type of Hunter controller to which the ET Module is connected. Use the +/- keys to cycle

through the valid selections: SRC, Pro-C, ICC or ACC.

When the correct controller is displayed, use the Left/Right arrow keys

to advance to the station size.

The ET Module will not allow a number greater than the maximum size

for the selected controller.

NOTE: Enter only the number of stations you wish to control with

ET–they will all run through Program A (except in the ACC controller).

It is possible to allow other stations to run in the controller’s other

programs (B, C, or higher in some models) with traditional programs.

These other programs will always run for the set Run Time in hours:

minutes.

Note that these other programs will not “stack,” and their Start Times

must be set to a safe time, after all ET stations will have completed.

The ET System Start Time will cancel any other programs that may

be running, and will prevent any new programs from beginning, until

the ET watering is complete (except in the ACC controller). The best

practice is to calculate the longest likely run times for the ET adjusted

14

stations, and add the total to the ET System Start Time. Set the Start

Times for any other programs after this longest possible ET water

window, or set them to complete before the ET Start Time.

Prepare the Controller

The ET System connects to any Hunter SmartPort®-equipped irrigation

controller. The controller must be properly prepared to work with ET

prior to use.

ICC, Pro-C, SRC (or SRC Plus) Controllers

• Program A will be erased. ET System will use the controller’s

Program A as a storage area for its ET-based run time information. Any information in the controller for Program A will be lost,

after ET System communicates with it. If the Program A information was valuable, it is a good idea to write the day/start/run time

information down before connecting ET System.

ET System will not begin to water immediately, and Program A

will not be cleared until ET System decides to water. The system

begins with an initial soil deficit of .1"/2.54mm. This means it assumes the soil is fairly moist, and that plants and soil are in good

condition.

The local ET will then begin to build up, meaning the soil will

become drier. When the moisture level is low enough, ET System

will schedule irrigation and then Program A will be erased. This

may take several days

• Adjust other Program Start Times. Programs B, C, and (in ICC

only) D can still be used when ET System is connected, but not at

the same time as the ET station program coming from the ET System. If it is still necessary to use the other programs, adjust their

start times so that they will never overlap the longest program that

ET System is likely to create. When ET starts running stations, it

will automatically cancel all other programs (including D in the

ICC) that may be running at that time, and will prevent any other

programs from starting.

• Move the Station wires (if necessary). ET System will control

the number of stations it is told to control, but does not know

Page 17

where they are in the host controller. It will assume it controls

from station 1, to the highest numbered station it knows about, in

consecutive order. If there are stations for which ET control is not

desired, their wires should be moved to the highest-numbered station positions. Be sure to change the Pump/Master Valve settings

for those stations if applicable (Pro-C and ICC only).

Example: A 9-station Pro-C controller has two stations, 3 and 5, for

which ET control is not desired. At the Controller dial position, ET

System is told that it is a 7-station system. Since ET System will assume control of the first 7 stations, move the valve wires for stations

3 and 5 to stations 8 and 9, and move the former stations 8 and 9 to

the 3 and 5 positions. ET System cannot skip stations. It will accept

any number of stations, from 1 to xx, regardless of the controller

type selected.

ACC Controllers

The Hunter ACC controller is compatible with ET System, but setup

is somewhat different. See installation section for use of the ET/ACC

adapter.

• Program A is not erased: ET System will not affect controller

Program A directly. It will issue its run commands directly from

the ET Module.

• Overlapping (with other Programs): ET System stations may

overlap other ACC controller programs which happen to be running (within the controller’s or user-program’s maximum number

of overlapping stations), which is not possible in ICC, Pro-C, or

SRC. However, if ET System and the ACC controller try to run

more than 6 stations (or the user programmed maximum) at once,

ACC will cancel any irrigation over the maximum, and watering

may be postponed or lost. Avoid overlapping ET with other programs unless absolutely necessary, to prevent confusion.

• Flow: ACC controllers may also be equipped with flow meters, and

high or low flow shutdowns will not be known to the ET System (it

will think it has watered correctly). Compensate for any lost irrigation by manual watering, after the flow condition has been fixed.

• Move the Station wires (if necessar y). This applies to ACC as it

does to the other controllers: all stations for the ET control should

be first, in consecutive order from station 1 to the highest number

to be controlled by ET, followed by any non-ET stations that the

ACC will run in other programs.

Set Time/Date

The ET Module keeps its own time, separately from the irrigation

controller, and the current date/time must be set at the Controller Type

dial position.

After the station size has been set correctly, use the right arrow key to

advance to the hour position.

Use the +/- buttons to enter the correct hour. Press and hold either

key to accelerate the setting.

Use the right arrow key to advance to the minute position, and use

+/- to enter the minute.

Use the right arrow key to advance to the AM/PM setting, and use +/to finish the time setting.

AM/PM International Time definitions (in 24-hour clock terms):

0000 – 1200 = AM (Latin Ante Meridiem, before noon)

1201 – 2359 = PM (Post Meridiem, after noon)

Midnight = 12 AM

Noon = 12 PM

Continue to set the date with the right arrow key. Set the date, month,

and year separately, using the +/- at each position, and the right arrow

to move positions (dd/mm/yy).

Set Daylight Savings

ET Module can automatically adjust for Daylight Savings time

changes.

After the time and date are set, use the right arrow key to advance to

the Daylight Savings position.

Use the +/- keys to select either USE or DO NOT USE.

15

Page 18

If Daylight Savings is set to USE, the time will change forward one

hour at 2 AM on the last Sunday in March, and will change backward

one hour at 2 AM on the last Sunday in October.

When the Controller Type settings are complete, turn the dial to

save the information. For initial setup, proceed to the Plant Type

dial position.

Individual Zone Setup

Once the general setup settings have been made, it is necessary to

enter the characteristics of each station, or zone, of irrigation in the

ET Module.

The 3 dial positions Plant Type, Site Info, and Sprinkler Type need to

be completed for each zone. This may be done one of two ways:

1) Go to each dial position and advance through all stations. Enter

the Plant Types for each station, turn to Site Info and advance

through all stations again, and finally turn to the Sprinkler Type

position and repeat for all stations.

2) It is easier for some to set all characteristics for each zone, one at

a time. ET System will stay on the same selected station through

all 3 dial positions, so you can select a station and choose the

Plant Type, turn to Site Info and enter the slope, soil, and sun

data, then turn to Sprinkler Type and set the precipitation rate.

Select the next station and repeat, until all stations have all data.

Multiple Plant Types Per Zone:

Occasionally a single zone of irrigation will water several different

types of plants. This is not ideal, but the correct approach in this

case is to set all characteristics for the most sensitive (to watering)

plant species in the zone. If one of the species is highly susceptible

to under- or over watering, use that plant’s characteristics for all zone

setup information.

The “zone” is the minimum level at which automatic irrigation control

is possible. If damage to valuable landscaping or specimen plantings

is feared, do not include the station in the ET setup at all, or physically

add an additional zone to the system.

16

Plant Type

At the Plant Type dial position, select and customize the actual plants

irrigated by each zone of irrigation. There is one screen for each zone

(if there is more than one plant type within a zone, select the type

most sensitive to watering).

STATION 01

MATURITY: ESTABLISHED

TYPE: GRASS

VARIETY: FESCUE

Set all information for one zone (or station), then advance to the next

station with the Station button on the ET Module.

Use the right arrow key to advance through the fields, and the +/- buttons to scroll through all possible selections.

Maturity

There are only two maturity settings for all plant types, NEW or

ESTABLISHED.

Established indicates normal watering requirements for turf or plants.

New indicates adjusted watering for the higher needs of growing

plants which do not yet have established root zones. The New setting

will automatically change to “Established” after a preset period of

days, depending on the Plant Type selected.

If a plant type is entered as “New”, the starting crop coefficient will

“mature” over time to an established plant crop coefficient based on

the plant type:

• Grass: 42 days (6 weeks)

• Shrub: 3 months

• Tree: 7 months

• Annual/Perennial/Biennial: 30 days

• Native/Desert: 6 weeks

The setting can also be changed manually at any time.

Page 19

Type

Selects the general plant type, from a table of choices.

The Type setting chooses the general category of plant, based on groups defined in WUCOLS (Water Use Classification of Landscape Species).

This important setting will tell the system the plant's characteristics including the depth of the root zone, and the sensitivity of the species to

watering. It combines with the Variety setting to create a crop coefficient (Kc) as well as root depth and other factors.

Variety

Selects the exact, or similar, species under Types.

NOTE: The included plant types are based on recognized categories of plants, by watering needs. The plant type choices in the ET System are representative of the different levels of watering requirements of typical plants, and are based on the Water Use Classifications of Landscape Species

(WUCOLS) Guide developed by the University

of California (available on the internet from the California Department of Water Resources, at http://www.owue.water.ca.gov/landscape/faq/faq.

cfm).

If an exact plant is not represented, there are two options:

1) Choose the closest type, based on the plant’s watering needs. This is generally adequate.

2) Customize one of the existing plant types. This is described in detail below the plant type table.

For further information on regional plant data, consult an agronomist or regional county extension office.

17

Page 20

ET System built-in menu selections (samples shown are representative of each variety):

TYPE Grass Shrub Ground Cover Vine Tree Perennial Desert

FESCUE

SEASONAL RYE

BLUEGRASS

BENTGRASS

BERMUDA

ST. AUGUSTINE

VARIETY

ZOYSIA

BAHIA

CENTIPEDE

BUFFALO

CARPET

KIKUYU

When all information for a station or zone has been set, use the Stations button to proceed to the next station, or turn the dial to Site Info to

continue setup for the selected zone.

Customize Plant Type: Each plant type and variety results in a Crop Coefficient, which ET System uses to determine the actual amount of watering

for the zone. Crop Coefficient is abbreviated “Kc” in the notation used in the ET calculation.

Through a hidden feature, ET System permits customization of the stored plant types for unusual or extreme types and conditions.

At the Plant Type dial position, enter the nearest Type and Variety for the station to be customized.

18

HIGH

WATERING:

Azalea

MEDIUM

WATERING:

Rose of Sharon

LOW

WATERING:

Bougainvillea

MINIMUM

WATERING:

Saltbrush

Jojoba

HIGH

WATERING:

Babys Tears

MEDIUM

WATERING:

White Clover

LOW

WATERING:

Ice Plant

MINIMUM

WATERING:

Rhagodia

HIGH

WATERING:

Climbing Rose

MEDIUM

WATERING:

Wisteria

LOW

WATERING:

Grape, Coral

MINIMUM

WATERING:

Pipestem

HIGH

WATERING:

Willow, Birch

MEDIUM

WATERING:

Pecan, Cypress

LOW

WATERING:

Primrose

MINIMUM

WATERING:

California pepper tree

HIGH

WATERING:

Horsetail

MEDIUM

WATERING:

Phlox, Geranium

LOW

WATERING:

Pampas Grass

MINIMUM

WATERING:

Daffodil

LOW

WATERING:

Turpentine

MINIMUM

WATERING:

Cactus

Page 21

Turn the dial back to the Automatic position to save the station

setting.

Hold down both the + and – buttons, and turn the dial back to the

Plant Type position. Release the + and – buttons.

The Station number will be highlighted, and the display will now also

show the Kc (crop coefficient) associated with the current selections.

Use the right arrow key to move to the Kc= position. The Kc value can

then be changed up or down, with the + or – button. Use them to set a

custom Kc for that zone.

Move the dial to another position to save the custom crop coefficient

for that zone. The change only applies to the customized station, and

must be repeated for any similar custom plant types.

When all stations have Plant Type data entered, turn the dial to save

the information. For initial setup, proceed to the Site Info dial position.

Site Info

At the Site Info dial position, select and customize the slope, soil, and

sun exposure for each zone of irrigation. There is one screen for each

zone (if there is more than condition within a zone, select the type

which predominates).

Use the arrow keys to advance to each value, and the +/- keys to cycle

through the choices.

STATION 01

SLOPE: 00%

SOIL: LOAM

SUN: PART SUN

Slope

This value (along with SOIL) is used to determine automatic cycles

and soaks for each station, based on the probable run-off of irrigation.

Use the +/- keys to set the percentage of slope, from 0 to 50% in 1%

increments. If the ground is flat, leave this setting at 0%.

Determining the slope percentage: The slope is defined as the

amount of elevation change, or Rise, divided by Run (the measured

distance), multiplied by 100. If an irrigated area rises 2 (feet or

meters) over 15 (feet or meters), the slope is approximately 13%:

(2/15)x100=13.333.

Soil

Soil type (or texture) is used together with the SLOPE information

to determine the Intake Rate of the soil, resulting in cycle and soak

scheduling.

Use the +/- key to select from the following soil types:

• Sand: Predominantly Sandy soil

• Loamy Sand

• Sandy Loam

• Loam: Predominantly loamy soil

• Clay Loam

• Silt: Predominantly silt soil

• Silty Clay

• Clay: Predominantly clay soil

Automatic Cycle and Soak: A maximum run time before runoff irrigation from the sprinklers occurs will be calculated, based on the slope

and soil settings. A station is only allowed to run continuously up to

that time limit.

If the zone needs more water, ET System will shutoff for a soak period,

determined by the Slope and Soil settings, to allow the water to soak

into the earth. Other stations can run during the station’s soak time, if

they are able. When the soak period has elapsed, the ET System will

re-activate the station at the next opportunity to continue irrigating.

This process will repeat until the full application amount is complete.

Advance to the next station with the station button, or turn the dial to

continue to Sprinkler Type setup of the selected station.

19

Page 22

Sun

Sets the average amount of sunlight for each irrigated area, according

to the following values:

• Full Sun – 100 percent of solar portion of ET

• Part Sun – 75 percent of solar portion of ET

• Part Shade – 50 percent of solar portion of ET

• Full Shade – 25 percent of solar portion of ET

The ET System is equipped with a solar radiation sensor and measures

daily sunlight (this is why the ET Sensor platform is mounted in full

sunlight). However, the irrigated areas may be in a variety of different

sunlight conditions, and this setting provides an offset for the sun

measured at the sensor, and the sun which probably reached the

plants in a given zone. Zones are assumed to be in full sun, unless you

enter a different setting here.

Set the SLOPE, SOIL, and SUN for each station. Advance to the next

station with the station button.

When all stations have Soil Type data entered, turn the dial to save

the information. For initial setup, proceed to the Sprinkler Type

dial position.

Sprinkler Type

At the Sprinkler Type dial position, select the type of sprinkler which

irrigates each station or zone. This setting determines the Precipitation Rate for each zone, which is a critical setting in determining the

Run Time for each station.

Use the arrow button to navigate to the Sprinkler Type under the station number, and use the +/- keys to choose one of the sprinkler types

available (or create a Custom type).

STATION 01

ROTOR

PRECIP IN/HR: 0.50

RUNTIME H: MM 0:00

20

To simplify setup, several standard types of irrigation devices are

included, along with typical precipitation rates. Select the type closest

to the irrigation for the zone.

• Rotor – 0.5 in/hr

• Spray – 1.6 in/hr

• Drip – 0.35 in/hr (this can vary widely and should be checked for

accuracy)

• Bubbler – 1.16 in/hr (this can vary widely and should be checked

for accuracy)

• Custom – entered by user (based on field tests)

Precip

The Precipitation Rate is specified in inches or millimeters per hour.

The Precipitation setting is based on the Sprinkler Type and cannot

be changed directly, except when “CUSTOM” has been chosen. The

longer a station runs, the more inches or millimeters it adds to the

root zone of the plants. ET determines how many inches or millimeters

were lost; Precipitation Rate determines how long the station needs to

run, to replace the lost water.

Sprinkler types should not be mixed within a single zone.

RUNTIME

RUNTIME is for information only, and cannot be set at this screen. The

RUNTIME field shows how long a station with the selected Sprinkler

Type and Precipitation rate will run, based on the current ET.

The run time shown is based on the last 24 hours ET plus the default

soil deficit of .1"/2.5mm. It is only used as a reference for the effect

that changing the precipitation rate may have, and does not indicate

how long the sprinkler is going to run at the next watering.

Determining Precipitation Rates: The sprinkler types included in the

ET System are typical values for common types of irrigation zones. If

greater accuracy is desired, a few simple tests to spot-check actual

zones can be performed, and the results can be entered at the CUSTOM Sprinkler Type selection.

Page 23

One informal method to determine a sample Precipitation Rate is to

place catchments at intervals over the area irrigated by a single zone.

There are officially calibrated catchment kits, or straight-sided metal

cans of equal height can be used.

The catchments should be placed at different distances from the

sprinkler heads. The more catchments, the better the test.

Run the zone for an exact period of time, divisible into 1 hour. 5 minutes is a good quick test for spray heads; 15 minutes might be better

for rotor zones.

Measure the amount of water in each catchment as accurately as possible. A metal ruler or machinist’s scale is good for this purpose.

Add the measurements of all the containers, and divide the total by

the number of containers, to get the average precipitation for the

test period. Irrigation consultants will generally establish a factor for

distribution uniformity (DU) that indicates the overall efficiency of a

zone. For ET System purposes, the precipitation rate entered should

be the adjusted rate, and the averaging process described here will

usually be adequate.

Multiply the results by the number of times the test period will divide

into 1 hour (12 x 5 minutes for the sprays, 4 x 15 minutes for the

rotors, in the example), to get the Precipitation Rate in inches or millimeters per hour.

This is the amount to enter for “CUSTOM” in the Sprinkler Type

dial position.

Enter a Custom Precipitation Rate: Use the +/- keys to cycle through

the choices until CUSTOM is displayed.

Use the arrow keys to advance to the PRECIP position. The Precipitation will be set to 1.6"

Use the +/- keys to change the Precipitation Rate to the desired

number.

Continue to enter Sprinkler Type data for each station, by pressing the

STA button and repeating the sprinkler selections, until finished.

When all stations have Sprinkler Type data, turn the dial to save the

information. For initial setup, proceed to the Water Days dial position.

Water Days

The Water Days dial position sets the days of the week on which it is

permissible to water. This does not necessarily mean watering will occur on Days OK to Water, only that it is permitted if conditions require

watering.

Water Days apply equally to all stations, and only need to be set up in

a single screen (not one per station).

DAYS OK TO WATER

SU MO TU WE TH FR SA

Y Y Y Y Y Y Y

EVEN ODD INTERVAL

- - -

All days will initially be set to Y (Yes). The first day (Sunday) will be

highlighted. To change the Y to N (No), use the +/- keys. Set any days

on which you are not allowed to water, or don’t wish to water, to N.

When the Y/N setting is changed, ET System will automatically jump

to the next day. Use the left key to go back, if the day Y/N setting

needs to be changed again.

Use the right arrow to skip past days that do not require changing.

Use +/- to set each day to Yes or No; when the week is set up correctly, turn the dial to the next position.

Interval Days:

ET System can be programmed to water on intervals, instead of

specific days of the week. Use the arrow keys to move to the Interval

position, and press the + button. The dash will change to a Y under

Interval, and the interval settings will replace the Day of Week display.

You may set from 1 to 31 day intervals. Use the arrow keys to move to

the Interval field, and press +/- to set the Interval.

21

Page 24

DAYS OK TO WATER

INTERVAL: 01 DAYS

REMAINING: 00 DAYS

EVEN ODD INTERVAL

- - Y

“Remaining” is used to indicate the number of days until the next

watering. If you need to set an Interval of every 3 days, but you do

not want that pattern to begin until 2 days from now, enter “2” at Remaining. In two days watering will be permitted, and the every-3-day

pattern will begin from that day.

To exit the Interval mode and return to another type of day schedule,

use the arrow keys to move back to the Interval position at the bottom

of the screen, and press the – key to change the Y to a dash [-]. The

Day of Week display will return and you can make other selections.

Even/Odd Days:

ET System can be programmed to water on Even or Odd dates of the

month to conform to local watering restrictions.

Use the arrow keys to move to the Even or Odd position, and press the

+ button. The dash will change to a Y under the selection, and all other

positions will change to a dash [-]. ET System will only permit watering on the selected Even or Odd dates in this position.

DAYS OK TO WATER

SU MO TU WE TH FR SA

- - - - - - -

EVEN ODD INTERVAL

Y - -

To exit Even/Odd mode, use the arrow keys to move back to the selection and press the – button to change the Y back to a dash. The Day of

Week display will return and you can make other selections.

22

ET System does not necessarily water on every day that has a Yes, for

OK to Water. These are only the days on which it is allowed to water.

For further information on this, refer to the section, “How ET System

Decides to Water”, in the System Overview near the beginning of this

manual.

When the days are set correctly, turn the dial to save the information.

For initial setup, proceed to the Daily Start Time position.

Daily Start Time

The Daily Start Time dial position sets the time of day at which irrigation is allowed to begin.

10:00PM

WILTGARD™: ON

WILT RUNTIME: 14MIN

If ET System decides to water on a specific day, the irrigation will

begin at the Start Time entered in this screen.

Use the +/- key to set the hour.

Use the arrow key to move to the minute position, and then use the

+/- keys to set the minute.

Use the arrow keys to move to the AM/PM setting, and use the +/keys to set AM or PM.

There is only one setting for the Daily Start Time (not one for each

station), and all irrigation for that day will run sequentially beginning

at that time.

WiltGard™

WiltGard is a unique feature that prevents damage to plants in

extremely hot conditions, by triggering watering when damage may

occur, regardless of the normal start time. WiltGard is especially well

suited to cool turf grasses in desert environments, or other sensitive

plants that can reach the wilting point due to extremes between daily

start times. In other words, WiltGard is emergency watering that will

Page 25

start whenever the plants in a zone are threatened.

The default setting is WiltGard = Off. To enable WiltGard, use the

arrow keys to advance to the OFF position, and use the +/- keys to

change the setting to ON.

If WiltGard is ON, watering may start without warning at unexpected

times of day. Do not enable WiltGard if this creates a hazardous or

inconvenient condition!

The actual Wilt Runtime cannot be set from this screen, and is only

shown for information. WiltGard’s run time is created automatically,

based on the settings for each specific zone. WiltGard will base its

“emergency” run time on 50% of the MAD (Management Allowable

Depletion)

The WiltGard watering is tracked for ET purposes, and a portion of

it will count against the daily ET (in other words, it will be deducted

from the scheduled irrigation at the automatic start time).

The WiltGard Off/On setting applies to all zones. However, WiltGard

will only start zones whose plants are in danger of damage (based on

the plant and soil settings for the individual zones).

When the Start Time and WiltGard settings are correct, turn the dial

to save the settings. For initial setup, turn the dial to the Rain Setting

position. WiltGard is automatically turned OFF if the No Water Time

feature is used.

Non Water Windows

ET System allows you to set legal watering days and a Start Time.

Non Water Windows allow you to block out periods of each day during

which watering is forbidden, by local watering restrictions.

Unfinished watering can resume after the end of the non water window, but the system can also be set to prevent watering past midnight

(into a non water day) or at any other Day End you choose to set.

To Set the Non-Water Window:

Turn the dial to the Start Times position.

Set the Start Time normally with + and – buttons.

Use the arrow buttons to move to the No Water Time position.

START: 03:00AM

NO WATER TIME: OFF

WILTGARD: OFF

DAY END: 12:00AM

DAY END STOP?: NO

Use the + or – buttons to change OFF to the time of day that starts

the No Water Time. Make sure the AM/PM selections are correct.

Use the arrow buttons to move to the No Water End, and use the + or

– buttons to set a No Water End time (Default is 8:00PM). This will

allow unfinished watering to resume where it left off.

This will automatically set the WiltGard feature to OFF. WiltGard cannot be used with No Water Times.

START: 03:00AM

NO WATER TIME: 08:00AM

NO WATER END:08:00PM

DAY END: 12:00AM

DAY END STOP?: NO

When the No Water Time is set, ET System will automatically pause

watering (wherever it is in the zones and cycles) at the No Water Time.

Whenever a No Water Time pauses during active irrigation, a status

message will appear to indicate that there are still unfinished watering

events being held during the pause.

08:15AM 04APR07

WATER WINDOW PAUSE

STATION 05

Do not touch or turn the dial during the Water Window Pause. If the

23

Page 26

dial is turned to any other position, watering will be terminated and

will not resume!

Day End

Day End is normally set to midnight (12:00AM). Watering that starts

on a legal watering day is often allowed to cross over midnight, and

when this is desired, set Day End Stop to N (no).

If Day End Stop is changed to Y (yes), the watering is not allowed to

cross over into the next day, and all further watering will be cancelled

until the next legal watering day.

You can also change the Day End time, if watering must be stopped

before midnight.

Start Time No Water Time No Water End Day End

3 AM watering

This can actually create two separate water windows within a day.

For example, if you are allowed to water until 10 PM but not after:

Use the arrow buttons to move to the Day End setting, and use + or –

to change the day end time to 10:00 PM.

Use the arrow buttons to move to Day End Stop, and use + or – to

change to Y.

Water Window Pause 8PM

8AM

watering 10PM

START: 03:00AM

NO WATER TIME: 08:00A

NO WATER END: 8:00P

DAY END: 10:00PM

DAY EMD STOP?: Y

You must set Day End Stop to Y, to prevent watering past the end

time!

Watering will then be permanently stopped for the day at 10 PM.

Unfinished Watering

With a large system and dr y weather, it is possible that the No Water

Times and Day End settings that are too short to complete all the

watering calculated for the zones.

When the No Water Time interrupts watering, the display shows Water

Window Pause. This means there is still unfinished watering that will

resume after the No Water Time ends.

11:15PM 04APR07

DAY END STOPPED!

STATION 06

CHECK HISTORY

Do not move the dial from the Automatic position while the unit is in

Pause mode.

When the No Water End is passed, the system will resume irrigating

where it stopped at the start of the No Water Window, and attempt to

complete all watering.

If the Day End is reached with Day End Stop set to Y, and there is still

unfinished watering, the system display will show Day End Stopped!

and Check History. Check the watering histories to see which zones

were missed, for special attention.

Rain Setting

The Rain Setting position determines how much natural rainfall is

required to stop irrigation. A minimum amount is preset, and it is not

necessary to adjust anything at this dial position for initial setup.

The ET Sensor is equipped with a “tipping bucket” style rain sensor.

Rain is not used directly in the calculation of ET, but it can be used to

a) shut off the irrigation, and b) adjust the next application of irrigation, by deducting a percentage of the naturally occurring precipitation

(some rainfall is assumed to run off before absorption into the soil,

and a loss factor is included).

24

Page 27

RAIN SHUTOFF

THRESHOLD: .02 IN

IN ONE HOUR

Rain water fills a small internal cup in the sensor, which tips the bucket. For rain shutoff purposes, each tip is counted as one hundredth of

an inch or .254mm.

The preset rain shutoff amount is displayed as .02"/.51mm, which

is the minimum setting. This is sufficient for most applications, and

most users can skip this dial position.

In some areas with frequent short, heavy downpours of rain, or very

high concentrations of fog, the rain shutoff threshold can be adjusted

higher. Condensing fog or dew can accumulate enough to tip the bucket over the course of a few hours, the threshold is never set below two

tips of the sensor.

Use the +/- keys to change the rain shutoff threshold.

This setting applies to all stations. Turn the dial to save the Rain setting. For initial setup, turn the dial to the ET setup position.

The rain setting amount is not exact. One tip of the bucket actually

equals .017"/.4318mm water, and ET System calculates the actual

totals internally using the exact value. Two tips would actually

equal .034"/.86mm of rain, and the ET System knows this.

However, the Rain Setting position displays these tips as rounded

inches, or millimeters, for general reference. This is only used for

the amount that will stop the sprinklers from running in the rain.

See the R24 explanation under View Sensor Data for a more complete explanation of rain measurement.

If the Rain Sensor has caused the irrigation to pause, the ET System

display will show “RAIN PAUSE”. If rainfall ceases during the automatic irrigation period, ET System may resume irrigating if the rainfall

was insufficient to fully replenish the soil reservoir. The system may

resume where it left off automatic irrigation, but with adjusted run

times for the amount of measured rainfall.

Rain Pauses always last for 15 minutes, after which ET System will

check the sensor again. If Rain is still detected, it will begin another

15 minute pause. This will continue until the Rain has stopped, and

ET System determines that watering is still required. If the measured

rainfall has replenished the soil fully, ET System will cancel the

remaining irrigation.

All sensor-based Pause modes (Rain, Freeze, and optional Wind) are

tracked in the watering history and will be reported for the days on

which they occurred.

ET Setup

The ET Setup dial position contains important settings that affect all

stations.

Enable ET: Normally this is set to YES, and that is how the ET System

is designed to operate.

ENABLE ET: YES

UNITS: INCHES

ET SOURCE: SENSOR

ET ADJUST: 80%

If Enable ET is set to NO, the ET System will not irrigate at all. If

WiltGard was enabled (at the Daily Start Time dial position) it will also

be disabled, and when the dial is returned to the Automatic position,

the display will show OFF.

To disable ET, use the +/- key to change the display to ENABLE ET: NO.

The ET System display will then show OFF when the dial is returned

to the Automatic position, and no automatic irrigation (including WiltGard) will take place. Setting ET Enable to NO is one way of shutting

the system down for winter, or other extended periods.

Turning the host controller to Off will not stop ET System from running Program A! You must also disable ET in the ET System to stop

all irrigation for an extended period.

25

Page 28

Units: The ET System can display settings in either inches or millimeters. Use the arrow key to advance to the UNITS setting, and use the

+/- keys to change the units between INCHES and METRIC.

ET Adjust: This setting adjusts the percentage of monitored ET that

will be used in irrigation calculations. The default setting is 80%,

which seems to fit most landscape applications. However, the adjustment factor can be changed from 10 to 150% in 1% increments to

tweak the irrigation calculation for individual climates.

Use the arrow keys to move to the ET Adjust position, and press +/- to

change the setting up or down.

The adjustment is applied equally to all stations, which are further

modified by their individual settings (Plant, Site Info, and Sprinkler

types). This factor may compensate for non-ideal mounting conditions, where sensor cannot be placed according to ideal specifications.

Hunter recommends obser ving performance carefully over the first

weeks of operation and adjusting the percentage only as a last resort

to tweak system performance.

ET Source: Normally this is set to SENSOR, meaning the ET Sensor station to which the ET Module is connected, and this is how ET

System was designed to operate.

It is also possible to set ET Source to MANUAL, allowing the user to

enter an ET value manually. This could be done to manually override

the Sensor for some reason, or to provide irrigation when the Sensor

is not physically connected.

To enter a Manual ET, use the arrow keys to move to the ET Source

setting, and use the +/- keys to change the display to MANUAL.

An ET value for the day will appear in the display. Use the +/- keys to

enter an ET in .01 in/.25mm increments.

When the dial is turned to the Automatic position, the display will

show the time/date, and then MANUAL ET: followed by the manually

entered value.

If ET SOURCE is set to MANUAL, it will remain the same every day

unless it is manually updated again.

26

Normal settings for proper ET operation are ENABLE ET: YES and ET

SOURCE: SENSOR. Do not change these except in unusual circumstances (such as Winter shutdown, or a disconnected Sensor).

This value will accrue each day, just like sensor-based ET. If the system is not set to every day watering, the Manual amount will be added

each day between watering days. On the next watering day the total

accrual will be replenished.

Automatic

For normal operations, the dial is returned to the Automatic position.

ET System will not irrigate unless the dial is in AUTOMATIC!

When the dial is in the Automatic position, the display should normally

show the time, date, and current ET reading from the Sensor.

3:00PM 15MAR06

DAILY ET: 0.07 IN

The Daily ET shows the last 24 hour total ET. The ET may fluctuate up

and down, since every hour the oldest hour is dropping off, and the

latest hour is added. This figure is a rolling 24 hour total and if today

is cooler or cloudier than yesterday, the ET may actually decrease. The

total ET since last watering is tracked by the ET Module, and will be

used in the final watering calculation. The daily ET is only informational, for recent conditions.

If ET has been set to ET ENABLE: NO, the display will show OFF (to