Page 1

Installation • Operation • Care

Palm Beach™ Polysatin™ Shutters

Page 2

CONTENTS

Getting Started

Installation Overview ..................................................... 1

Unpacking .................................................................... 1

Tools and Materials Needed ........................................... 1

Fasteners ..................................................................... 2

Frame Assembly

Assemble the Frame – Panel Systems ............................ 3

Assemble the Frame – Track Systems ............................ 7

Installation

Framed Standard Panel Systems .................................... 8

Standard Panel Systems with Hang Strip ...................... 11

Unframed Standard Panel Systems .............................. 13

Bi-Fold Track Systems ................................................. 15

Bypass Track Systems ................................................. 20

French Door Shutters .................................................. 29

Corner Windows.......................................................... 31

Bay Windows .............................................................. 33

Framed Stand-Alone Specialty Shapes ......................... 36

Framed Specialty Shapes Over Standard Shutter ........... 37

Unframed Specialty Shapes ......................................... 38

Decorative Sill Cover ................................................... 39

Finish Work ................................................................. 40

Operation and Care

Operation ................................................................... 43

Care ........................................................................... 43

Troubleshooting ........................................................ 44

If you have any questions about installation, application, operation,

or care and cleaning, Hunter Douglas Customer Service Shutter

Specialists are available at 1-888-727-5230 toll-free. Shutter

Specialists are available from 6:00 a.m. to 5:00 p.m. Mountain

Standard Time, Monday through Friday.

© 2016 Hunter Douglas. All rights reserved. All trademarks used herein are the property of Hunter Douglas

or their respective owners.

Page 3

GETTING STARTED

Hunter Douglas Palm Beach™ Polysatin™ shutters are built using the highest quality materials.

When properly installed, these shutters will provide a lifetime of beauty and performance.

IMPORTANT: These installation instructions are intended for professional installers who have

been certified after attending Hunter Douglas shutter training.

Installation Overview

Panel shutters come in many configurations — individually hinged, bi-fold panels, with and

without T-posts, track systems comprised of from one to many panels, and with a variety of

frames for inside or outside mounting.

Whatever the configuration, installation procedures are basically the same. The frame is

assembled and fastened to the window at two points. Then the shutter panels are individually

installed and racked, during which time frame attachment is completed. Duracatch

adjustment or magnet mounting, caulking and other finish work complete the installation.

™

lock

Unpacking

Carefully unpack the shutters. The package will include:

■ Shutter panels

■ Disassembled frames (frames for specialty shapes are typically assembled)

■ Miscellaneous hardware (hinge pins, button covers, etc.)

Tools and Materials Needed

Tools

■ Flat blade, Phillips, and Robertson #1 and #2screwdrivers

■ Power drill anddrill bits, including a 2" drill bit

■ Rubber mallet

■ Miscellaneous tools for non-typical installations (jig saw, hack saw, Dremmeltool,etc.)

Materials

■ Canvas drop cloth large enough for unpacking and frame assembly

■ Clean fabric cloth and a mild cleaning spray solution

■ Shim materials

■ Finishing supplies (caulk, sealant, etc.)

■ Instant adhesive for frame miters

■ Silcone adhesive or doubled-sided tape for Decorative Sill Cover installation

■ Measuring tape

■ Level

■ Awl

1

Page 4

GETTING STARTED

Fasteners

Screws of varying lengths and types are required to install shutters. The chart below shows the

standard fasteners, what each is used for, and the tool or driver needed to secure them. Other

types of fasteners may be needed if mounting into concrete, metal, or similar surfaces.

#8 x 3" Panel Assembly Screw

#8 x 2" Pan Head Screw

#8 x 2" Pan Head Screw

#8 x 1½" Pan Head Screw

#8 x 1" Pan Head Screw

#8 x ¾" Pan Head Screw

#8 x 2" Bugle Head Screw

#8 x ¾" Flat Head Screw

#6 x 1¾" Round Head Screw

Attaches stiles to rails; also used

as an installation screw

#2 Robertson drive

Installation screw

#1 Robertson drive

Attaches Bi-fold or Bypass bracket to wall

#2 Phillips drive

Installation screw

#1 Robertson drive

Attaches Bi-fold and Bypass carrier hardware to

panels

#2 Phillips drive

Attaches Bi-fold and Bypass track to frame or

opening, as well as track system brackets to frame

#2 Phillips drive

Attaches T-post to frame

#2 Phillips drive

Attaches Bi-fold pivot bracket to frame

#2 Phillips drive

Attaches T-post block to frame

#1 Robertson drive

#6 x ¾" Round Head Screw

#6 x ½" Pan Head Screw

#6 x 3/8" Pan Head Screw

#6 x 5/8" Flat Head Screw

#6 x 3/8" Flat Head Screw

2

Attaches magnets

#2 Phillips drive

Attaches Bi-fold bottom track pivot bracket to

bottom track

#2 Phillips drive

Attaches L-bracket to Bi-fold or Bypass frame and

valance

#2 Phillips drive

Attaches hinges to frames and T-posts, as well as

magnet strike plates to panels

#1 Robertson drive

Attaches metal corner key to frame

#1 Robertson drive

Page 5

Panel Systems

Bottom

FRAME ASSEMBLY

Assemble the Frame – Panel Systems

Prepare the work area. Lay the shutter panels on your drop cloth face up as they will appear in

the window. Then follow the procedure below.

1. Lay the side frames beside the panels, so that the panel hinges are above the frame hinges.

If one or more T-posts are used, lay them in the proper position, as well.

Top

Corner Key

Position hinge leaf

on frame below

hinge leaf on panel

Corner Key

2. Insert the plastic corner keys into the ends of the top and bottom frames.

➤ The Deluxe Casing frame, Colonial Z-frame, Classic Z-frame and Standard Z-frame

receive both the corner keys and metal brackets.

➤ Insert the side frame pieces onto the corner keys (and metal brackets, if applicable) of

the top frame.

IMPORTANT: With outside mount L-frames that have no T-posts, glue the corner keys in

position as described in Step 3 on the following page.

3

Page 6

FRAME ASSEMBLY

Panel Systems

3. Outside mount L-frames with no T-posts: Glue the corner keys in position as illustrated.

This prevents the frame from bowing.

➤ First remove the tabs off the corner key with a flat blade screwdriver.

➤ Then apply a small amount of instant adhesive or contact cement to the inside of

the frame.

➤ Insert the corner key into the end of the frame and hold firmly until set.

IMPORTANT: Be sure the frames match before gluing. The corners cannot be detached

after the adhesive has set.

Outside Mount L-Frame with No T-Posts Only

Apply

Tab

Adhesive

Inside

Frame

4. With the Deluxe Casing frame, Colonial

Z-frame, Classic Z-frame and Standard

Z-frame, secure the top frame metal

brackets to the side frames using the

provided screws.

4

Tabs

Removed

Page 7

Panel Systems

FRAME ASSEMBLY

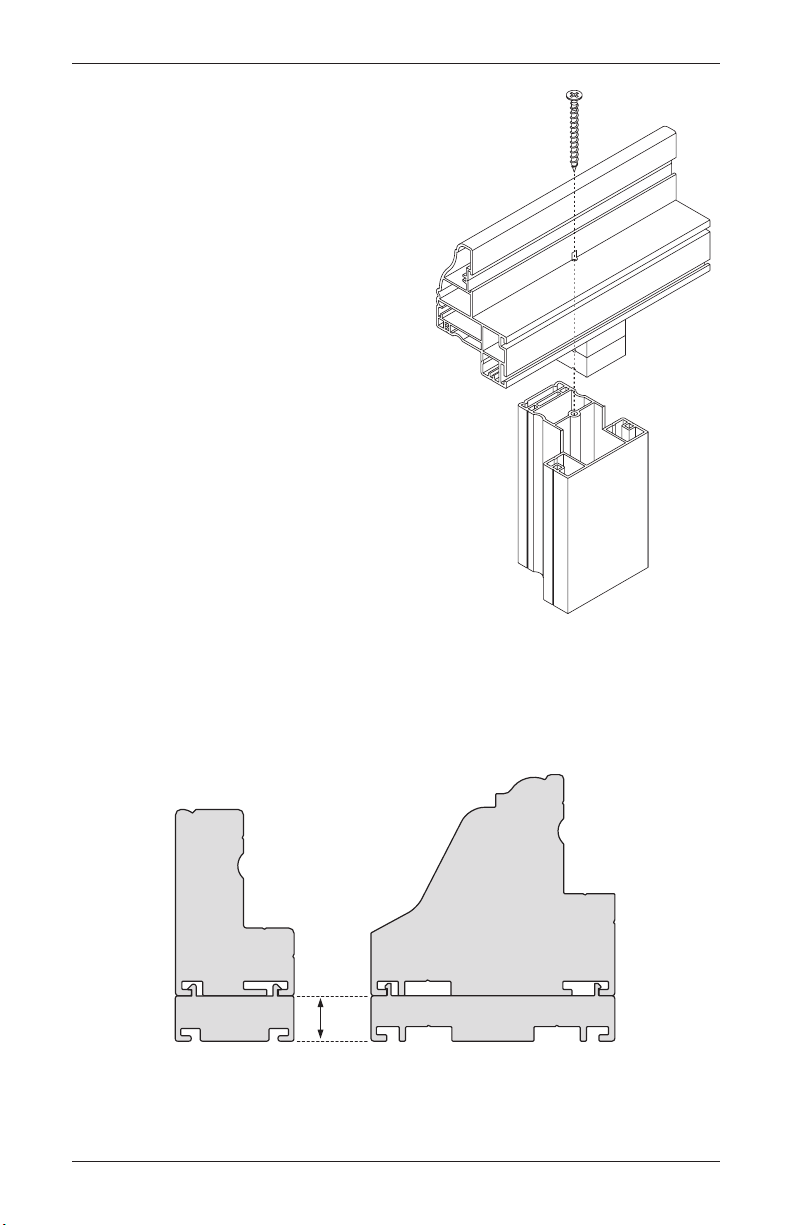

5. Frames with T-posts: Attach the T-post to

the top frame.

➤ T-post blocks will be pre-attached to the

#8 x 2"

Bugle Head

Screw

top and bottom frame pieces.

➤ Slide the T-post onto the T-post block on

the top frame piece and secure the T-post

to the block using a #2 Phillips bit to drive

the provided bugle head screw.

IMPORTANT: A long driver bit is required to

get enough access to drive the screw.

T-Post Block

NOTE: See Step 8 on page 6 if T-post blocks

were not provided, or for three-sided frames

or inside mounts with no frames.

6. Attach the bottom frame to the side frames

and T-post, repeating the methods described

T-Post

in Steps 2 through 5.

7. Deluxe Casing frame and outside mount L-frame only: If build-out is needed for

additional clearance, install the build-out onto the back of the frame.

➤ The build-out snaps onto the back of the frame.

➤ The Deluxe Casing frame build-out is also screwed into the back of the frame.

Top

Frame

L-Frame Build-Out

½"

Deluxe Casing Frame Build-Out

5

Page 8

FRAME ASSEMBLY

Panel Systems

8. With 3-sided frames or inside mounts with no frame, T-post brackets are used to attach

the T-post to the sill or casement after the frame has been installed. Refer to the illustration

below.

➤ Attach the brackets to the sill or casement using the slotted hole on the bracket to allow

for side-to-side adjustment.

➤ Be sure to square the T-post before tightening the brackets.

➤ T-post brackets can also be used to attach T-posts to frames when T-post blocks are

not provided.

IMPORTANT: When a Decorative Sill Cover is used, it must be placed between the window

sill and T-post before attaching the T-post.

T-Post

T-Post

Bracket

Sill

6

Page 9

Track Systems

¾"

Build-Out

FRAME ASSEMBLY

Assemble the Frame – Track Systems

Prepare the work area. Lay the frame pieces on your drop cloth in their proper orientation.

Thenfollow the procedures below.

1. Use four screws to attach the top frame to the side frames.

➤ With four-sided systems, attach the bottom frame to the side frames in the same way.

2. If build-out is needed for additional clearance, secure the build-out onto the back of the

frame with screws, as shown below.

3" Screws

Track System

(Bi-Fold Shown)

Build-Out

¾"

Pre-Drilled

Outside Mount

Installation

Screw Holes

Pre-Drilled

Inside Mount

Installation

Screw Holes

7

Page 10

INSTALLATION

Framed Standard Panel Systems

Optional

Cover Strip

Standard

L-Frame

(IM)

Framed Standard Panel Systems

Standard

Z-Frame

(IM)

Standard L-Frame

(OM)

Deluxe Casing Frame

NOTE: If a Decorative Sill Cover was ordered, refer to page 39.

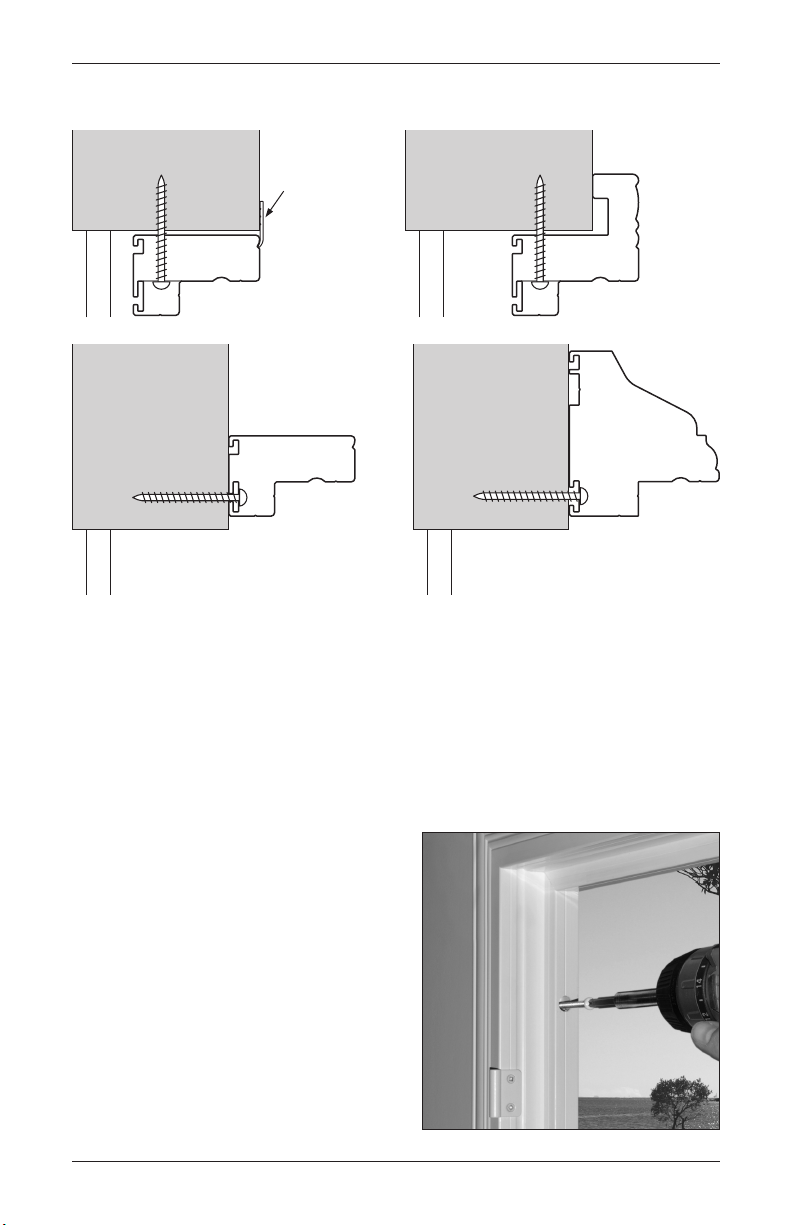

Step A. Install the Frame

1. Position the frame for mounting.

➤ Outside (OM) Mount. Center the frame over the opening. There should be a ¼" reveal

on all four sides (or an equal reveal if a larger or smaller reveal was specified on the

original order).

➤ Inside (IM) Mount. Center the frame

in the opening. Insert temporary shims

between the shutter frame and the

window to hold the frame centered.

2. Attach the side frames at the top corners

through the pre-drilled holes.

IMPORTANT: Tighten the screws snugly, but

do not overtighten.

(OM)

8

Page 11

Framed Standard Panel Systems

Step B. Mount the Panels

INSTALLATION

1. First, retract the Duracatch™ locks on the top

and bottom of the panels.

Duracatch Lock

➤ The Duracatch lock system is designed

to help level the panels within the frame.

Retracting the locks makes it possible to

rack the shutter.

➤ Using a flat blade screwdriver, push down

on the Duracatch lock and tighten the

screw a quarter-turn.

Recessed Lock

Push Down and

Tighten ¼ Turn

2. Align the panel and frame hinges, and insert the hinge pins.

3. Close the panels and check for proper alignment.

➤ If panels are misaligned, rack the shutter by grasping the frame at the bottom corners

and moving it from side to side until proper alignment is achieved.

NOTE: In the following procedures, after

each fastener is placed, close the panels

and check the alignment. If the alignment

is lost, remove the fastener, re-align the

panels, and then re-install thefastener.

IMPORTANT: For installations with multiple

T-posts, it is recommended that you begin

your racking at the center most section and

work your way out to each end.

Incorrect

Correct

9

Page 12

INSTALLATION

Framed Standard Panel Systems

4. Hold the frame in the aligned position.

➤ Outside (OM) Mount. Use a fastener to secure the center of the bottom frame. Check

alignment, and then secure the side frames at the bottom corners.

➤ Inside (IM) Mount. Use fasteners to

secure the side frames at the bottom

corners.

5. Insert screws into the remaining holes and check that the panels are still aligned after each

screw has been tightened. Re-adjust if necessary.

6. Release all Duracatch

™

panel lock assemblies by loosening the lock screws a quarter-turn.

7. Close the panels and, if needed, adjust the Duracatch locks with a flat blade screwdriver so

that all doors close easily yet stay firmly shut.

➤ If necessary, install panel lock ramps on the sill or casement (see page 40).

➤ If necessary, install magnets and plates (see page 41).

8. Perform any other necessary finish work to complete the installation (see page 42).

3

NOTE: If necessary to drill more installation holes in the frame, drill

/8" holes through the first

layer of vinyl only. Drill through the light block for both inside and outside mounts. (For sample

drilling locations, see the illustrations at the top of page 8.)

10

Page 13

Hang Strip Behind Panels

Hang Strip to Side of Panels

Standard Panel Systems with Hang Strip

Standard Panel Systems with Hang Strip

INSTALLATION

Hang Strip

Bent Leaf Hinge

3

/8" Holes for

Installation Screws

Hang Strip

Standard Hinge

3

/8" Holes for

Installation Screws

NOTE: If a Decorative Sill Cover was ordered, refer to page 39.

Step A. Install the Hang Strips

1. Attach the side hang strips inside or outside the opening.

➤ With outside mounts, be sure the hang strips are positioned the correct width apart and

at the correct height.

➤ Insert a Robertson screw into the top and bottom holes only, then set the screws into the

mounting surface.

➤ Tighten the screws snugly, but do not overtighten.

Step B. Mount the Panels

1. Hang the panels by fitting the pin end of the hinges into the hinge barrels.

2. Square and align the panels to the opening.

➤ Hang Strip Behind Panels. If

necessary, adjust the bent-leaf hinges

by loosening the hinge screws and

moving the hinge left or right.

➤ Hang Strip to Side of Panels. If

necessary, place hinge shims between

the hinge and hang strip.

➤ Re-tighten the hinge screws once the

panels are square and aligned.

Incorrect

Correct

11

Page 14

INSTALLATION

Standard Panel Systems with Hang Strip

3. Insert screws into the remaining holes and check that the panels are still level after each

screw has been tightened. Re-adjust if necessary.

4. With inside mounts, install Duracatch

™

panel lock ramps (see page 40).

5. With outside mounts, install magnets and plates (see page 41).

6. Perform any other necessary finish work to complete the installation (see page 42).

12

Page 15

Unframed Standard Panel Systems

INSTALLATION

Unframed Standard Panel Systems

Unframed inside-mounted shutters may be installed flush with the opening or projected out from

the opening using extended leaf hinges, which are

NOTE: If a Decorative Sill Cover was ordered, refer to page 39.

5

/8" wider.

Step A. Install the Bottom Leaf of the Top Hinge

1. Position the left panel in the opening so that it has equal clearance at the top and bottom.

Mark where the bottom of the top hinge is located.

2. Align the top of the bottom leaf with the mark and attach it using one screw.

3. To check for accurate placement, install the panel by its top hinge, inserting a hinge pin to

hold the panel in place. Adjust placement of the hinge, if necessary.

➤ If placement is accurate, remove the panel and install the second screw into the bottom

leaf of the top hinge.

Step B. Install the Bottom Leaf of the Bottom Hinge

1. With the panel placed in the top hinge, mark where the bottom of the bottom panel hinge is

located.

2. Align the top of the bottom leaf of the hinge with the mark and attach it using one screw.

3. To check for accurate placement, install the panel into the two hinges. Adjust placement of

the bottom hinge, if necessary.

➤ If placement is accurate, install the second screw into the bottom hinge.

4. Repeat steps A and B for the right panel, if applicable. Be sure to align the right panel to the

left panel.

Glass

Inside Mount

Flush with Opening

Top Leaf Attached

to Shutter

Bottom Leaf

Attaches to Opening

13

Page 16

INSTALLATION

Unframed Standard Panel Systems

Step C. Install the Remaining Bottom Leafs of the Hinges

1. Once the panels are level and square in the opening, install the remaining bottom leafs while

the panels are hanging.

➤ Open the panels and install the bottom leafs onto the top leafs using the hinge pins.

➤ Screw the bottom leafs in place.

➤ If necessary, shim using the provided hinge shims.

™

2. Install Duracatch

➤ When the Duracatch panel lock system is used, turn the adjustable plunger if minor

support or leveling is required.

3. Perform any other necessary finish work to complete the installation (see page 42).

panel lock ramps (see page 40) or magnets and plates (see page 41).

14

Page 17

Bi-Fold Track Systems

INSTALLATION

Bi-Fold Track Systems

Typically, bi-fold track systems have three-sided frames; however, they may also be two-sided

or four-sided. The basic installation procedure is the same whatever the configuration. (If you

haven’t already assembled the bi-fold frame, refer to page 7.)

Step A. Prepare the Frame

1. Installation screw holes are pre-drilled. If you

3

need additional attachment points, drill

/8"

holes in the frame through the first layer of

vinyl only.

➤ Drill through the screw indicator groove

on the light block for outside mounts and

through the side of the frame for inside

Screw

Indicator

Groove

mounts.

➤ With outside mounts (unless mounting

into the header), the top frame should be

mounted into studs wherever possible.

2. If an aluminum track is attached to the top frame, remove it before proceeding.

Step B. Install the Frame

IMPORTANT: Tighten the mounting screws snugly, but do not overtighten.

Inside Mount

1. Center the frame in the opening.

2. Using the provided screws, attach the top of the frame to the opening and level. Use shims

as needed to ensure a level installation.

3. Secure the pivot side frame, using a level to make sure the frame piece is plumb. Again, use

shims as needed.

➤ If there are two pivot sides (split stack), secure only one of the side frames.

Outside Mount

1. Center the frame over the opening at the

desired height.

2. Attach the top frame first, starting with one

fastener at the highest corner.

IMPORTANT: Install all mounting screws

into studs or the window header.

15

Page 18

INSTALLATION

Bi-Fold Track Systems

3. Place a four foot level on the top frame and secure the second fastener in the top frame at

the other corner, ensuring the top frame is level.

4. Finish attaching the top frame by securing

one screw at each stud, 16" to 24" apart,

depending on the type of construction.

➤ Space screws no more than 30" apart if

Pivot Side

Frame

mounting into the header.

5. Secure the pivot side frame, using a level to

make sure the frame piece is plumb. Again,

use shims as needed.

➤ If there are two pivot sides (split stack),

still secure only one of the side frames.

Step C. Attach the Aluminum Track to the Frame

1. Before attaching the track, make sure that you have inserted the correct number of carriers

and top pivot pins. For one way operation, one pivot pin and one snubber are required. For

split operation, two pivot pins are required, but no snubber.

Pivot Pin SnubberCarriers

IMPORTANT: Carriers have three wheels. Each

carrier can be loaded into the track with one

wheel to the front or two wheels to the front.

2. After inserting the carriers, check that the carrier

heights are the same as the pivot pin height, as

shown below. Adjust as necessary.

Pivot

Pin

Same Height

CORRECT

16

Different Height

INCORRECT

Page 19

Bi-Fold Track Systems

INSTALLATION

3. If the track arrived attached, use the same holes and re-attach the aluminum track to the top

frame with the screws supplied. Be sure the holes line up correctly.

➤ If the track did not arrive attached, use the screw indicator groove in the frame to align

the track screws.

Step D. Attach the Shutter Panels

1. Set the pivot pin(s) in the track so that the

5

center of the pivot pin is 1

/8" from the side

15/8"

Set Screw

frame.

2. Mount the bottom pivot bracket(s) or floor guide with bottom pivot(s).

IMPORTANT: The pivot pin receiver(s) must be directly under the top pivot pin(s). The center

of the pivot pin receiver(s) should be 1

5

/8" from the side frame(s).

➤ Bottom Pivot Bracket. Mount the bottom pivot bracket(s) centered on the screw

indicator groove in the side frame(s).

➤ Floor Guide with Bottom Pivot. Insert the bottom pivot(s) into the floor guide and

tighten the screws with the pivot pin receiver(s) in the correct position. Attach the floor

guide to the floor, centered on the screw indicator groove in the side frame(s).

Bottom

Pivot

Bracket

Floor Guide

with Bottom

Pivot

3. Mount the first panel per side into the bottom pivot pin receiver first and then onto the top

pivot pin. Rotate the lever on the receiver to lock the top pivot pin in place.

➤ When both sides have pivot pin receivers, install the first panel on the other side as well.

➤ If adjustment is necessary, mark the correct position of the top and/or bottom receiver(s)

to correctly re-position the component(s).

17

Page 20

INSTALLATION

Bi-Fold Track Systems

4. Insert the remaining shutter panels into the hinges and receivers.

➤ Using labels and hinges for correct panel positioning, lock all panels into place by

rotating the lever on the receiver.

➤ If panels are uneven make any minor adjustments with the carrier bolts.

Carrier Receiver

Step E. Finalize the Adjustment

1. For one-way operation: Secure the stile

channel.

➤ Attach the stile channel on the same side

as the snubber, approximately 3" from

the bottom of the frame, on the screw

indicator groove.

➤ Close the panels and locate the

unsecured frame so that the snubber

contacts the panel and the panel fits into

the stile channel. Secure the frame in

this position.

Stile

Channel

2. For two-way operation: Hold the loose side frame so the center split panels come

together. Then adjust the carriers, if necessary. Finally, mark the position of the side frame

and secure it.

18

Page 21

Bi-Fold Track Systems

INSTALLATION

Step F. Attach the Optional Valance

IMPORTANT: Two valances are available, standard (3½") and decorative (5"), and both are

mounted in a similar manner.

1. Attach the valance returns. Glue the miter joints and attach with L-brackets.

2. There should be approximately ¼" space between the bottom of the valance and the top

of the panels. A simple way to achieve this clearance is to place two stacked

shims onto the open panels in several places to support the valance during installation.

3. Standard valance: There are two options for installing the standard valance.

3

/8" installation holes through the first layer of vinyl only. Space the holes 20" apart

➤ Drill

and cover them with button plugs after securing the valance.

➤ Attach the valance with double-sided tape.

4. Decorative valance: Secure the valance with L-brackets, as

shown. Space the L-brackets every 20".

Step G. Complete the Installation

L-Bracket

■ Perform any necessary finish work to complete the

installation (see page 42).

1

/8" wood slat

Back of Valance

Adjustable

Screw Hole

Top of Frame

19

Page 22

INSTALLATION

Bypass Track Systems

Bypass Track Systems

Typically, bypass track systems have three-sided frames; however, they may also be two-sided

or four-sided. The basic installation procedure is the same whatever the configuration. (If you

haven’t already assembled the bypass frame, refer to page 7.)

If installing the bypass track system as an Inside Mount Without Frame, skip to Step C. After

installing the carriers, set the tracks with 2¼" between centers to allow 5/8" between tracks.

Step A. Prepare the Frame

1. Installation screw holes are pre-drilled. If you

3

need additional attachment points, drill

/8"

holes in the frame through the first layer of

vinyl only.

➤ Drill through the screw indicator groove

on the light block for outside mounts and

through the side of the frame for inside

Screw

Indicator

Groove

mounts.

➤ With outside mounts (unless mounting

into the header), the top frame should be

mounted into studs wherever possible.

2. If aluminum tracks are attached to the top frame, remove them before proceeding.

3. Outside mounts (OM) only: Attach support brackets to the top of the frame.

➤ Position the brackets where they will be mounted into studs. If stud spacing is 24",

attach support brackets to each stud. If stud spacing is 16", attach the brackets to every

other stud, so that they will be spaced 32" apart.

➤ Screw the brackets into the frame at the screw indicator grooves, with the back of the

bracket flush with the back of the frame.

➤ Use support bracket extensions with Open Bypass and Triple Track systems, or if Bypass

frame extension (build-out) is attached to the frame when greater projection or louver

clearance is needed.

Support

Bracket

Support Bracket

Extension

Support Bracket

Extension

Build-Out

Bypass Frame Bypass Frame with

Frame Extension (Build-Out)

Open Louver/Triple Track Frame

IMPORTANT: Be careful not to place support bracket screws where they will interfere with

the track screws.

20

Page 23

Bypass Track Systems

INSTALLATION

Step B. Install the Frame

IMPORTANT: Tighten the mounting screws snugly, but do not overtighten.

Inside Mount

1. Center the frame in the opening.

2. Using the provided screws, attach the top of the frame to the opening and level. Use shims

as needed to ensure a level installation.

Outside Mount

1. Center the frame over the opening at the

desired height.

2. Attach the top frame first, starting with one

fastener at the highest corner.

IMPORTANT: Install all mounting screws

into studs or the window header.

3. Place a four foot level on the top frame and

secure the second fastener in the top frame

at the other corner, ensuring the top frame

is level.

4. Finish attaching the top frame by securing one screw at each stud, 16" to 24" apart,

depending on the type of construction.

➤ Space screws no more than 30" apart if mounting into the header.

Step C. Attach the Tracks to the Frame

1. Before attaching the tracks, make sure that you have inserted the correct number of carriers

(two carriers for each panel) into the appropriate track.

2. Prior to inserting the carriers, check that the carrier heights are consistent from carrier to

carrier (see photos below). Adjust as necessary.

Different Heights

INCORRECT

Same Height

CORRECT

21

Page 24

INSTALLATION

Bypass Track Systems

3. If the tracks arrived attached, use the same holes and re-attach the aluminum tracks to the

top frame with the screws supplied. Be sure the holes line up correctly. If the tracks did not

arrive attached:

➤ Standard Bypass and Open Bypass: Center the tracks over the screw indicator

grooves and secure with screws through the pre-drilled holes in the tracks.

➤ Triple Track Systems: Install the tracks in the screw ports indicated in the illustration

below.

Step D. Prepare the Shutter Panels

IMPORTANT: If optional floor guides will be used, refer to Step G on page 25 before proceeding.

Two of the three floor guide options require mounting components to the bottom of the shutter

panels before they are hung from the carriers. In addition, privacy strips are included with the

floor guide options that should be installed on the front panels before hanging them.

1. Double panels only: If panels are designed to be operated in pairs, marry the pairs

together.

➤ Lay the pair of panels next to each other on a flat surface, with the front side up.

➤ At the top of the panels, remove the stile caps from the abutting stiles.

➤ Insert the panel couplers.

Panel

Coupler

Remove

Stile Caps

Slide in

Coupler

Sections

NOTE: The panels must lie flat to allow the couplers to slide into the stiles.

■ Place the stile caps back onto the stiles.

22

Page 25

Bypass Track Systems

INSTALLATION

2. If optional floor guides will be used: Mount any required components to the bottom of

the shutter panels.

3. If optional floor guides will be used: Attach privacy strips.

➤ Remove the liner from the adhesive on the privacy strips.

➤ Position the privacy strips on the panels as needed for the opening (see bottom

illustrations).

➤ Press each privacy strip firmly against the stile. Be sure to apply pressure at several

places along the full length of the privacy strips.

Front

Panel

Standard Bypass (Top View)

Rear Panel

Triple Track (Top View)

Rear Panel

Open Bypass (Top View)

Rear Panel

Privacy Strip

Middle Panel

Back

Panel

Privacy Strip

Front Panel

Clearance not required

for U-channel track

and floor guide only.

Privacy Strips

Front Panel

Privacy Strips

Front Panel

23

Page 26

INSTALLATION

Bypass Track Systems

Step E. Mount the Shutter Panels

1. Mount the panels onto the carriers and lock them in place by rotating the lever on the

receiver. Continue until all panels are secure.

2. Check that floor clearance is acceptable. If not, lower or raise panels by adjusting both

carrier bolts the same amount.

Carrier Receiver

Step F. Check for Alignment

1. If necessary, adjust the carrier bolts so that all panels are at the same height.

2. Open the louvers of the back panel where panels overlap and slide the front panel until the

stile is adjacent to or touching the open louvers. If gaps appear between the front panel stile

and the open louvers at the top or bottom, adjust the carrier bolts until no gaps appears.

INCORRECT CORRECT

Gaps

No

Gaps

3. Finalize alignment by locating the side frames to their adjacent panel and secure to the wall

with fasteners.

24

Page 27

Bypass Track Systems

Floor Guides

INSTALLATION

Step G. Install Optional Floor Guides

Floor guides prevent the shutter panels from swinging forward into the room or backward into

the opening. There are three floor guide options for bypass track systems.

Option 1: U-Channel Track and Floor Guide

Front

Panel

Privacy Strip

U-Channels

Back

Panel

1. Before mounting the shutter panels: Center the U-Channel on the bottom of each panel

and attach it using screws or double-sided tape.

2. After mounting the shutter panels:

Attach one or more floor guides to the floor

with screws.

➤ Align the bottom tracks with the score

lines on the frame, as shown at right.

3. After attaching the floor guide(s), align the

U-Channel into the guide(s), as shown in

the illustration above.

NOTE: A

5

/8" height deduction is taken at

the factory to ensure proper clearance.

Triple Track shown

25

Page 28

INSTALLATION

Option 2: Three-Piece Bypass Floor Guide

Bypass Track Systems

Front

Panel

Privacy Strip

Three-Piece Floor Guide

Back

Panel

1. After mounting the shutter panels: Attach one or more center pieces of the floor guides

to the floor. Refer to the diagram below for placement.

Floor Guide Attachment – Top View

PANEL 1L PANEL 1L

One Guide Two Guides Three Guides

PANEL 1CPANEL 1R

PANEL 1R PANEL 1L

PANEL 1C PANEL 1C

PANEL 1R

➤ Align the center piece of the guide directly under the shutter panel overlap.

➤ Position the center piece(s) so that each panel will always be over at least one of them.

➤ Set the center piece(s) in place with a screw.

2. After attaching the center piece(s), slide the two smaller side pieces in place.

➤ Adjust for the overall width from the front and back panels.

➤ Set the center piece(s) in place with a screw.

NOTE: A ½" height deduction is taken at the factory to ensure proper clearance.

26

Page 29

Bypass Track Systems

Option 3: Hidden Panel Bypass Guides (U-Guide and L-Guide)

INSTALLATION

Panel

1

/8"

U-Guide L-Guide

Privacy StripFront

Back

Panel

3

/8"

1. Before mounting the shutter panels: Attach the U-Guides and L-Guides to the bottom of

the shutter panels using screws or double-sided tape.

➤ These hidden guides eliminate the need to attach anything to the floor.

➤ Attach the U-Guide(s) to the bottom of the front panel(s) as illustrated above. Position

1

the front of the U-Guide

/8" from the front of the stile or flush with the front edge of the

bottom rail.

➤ Attach the L-Guides to the bottom of the back panel(s). Position the rear of the L-Guide

3

/8" from the back of the of the stile or ¼" from the back edge of the bottom rail.

2. When mounting the shutter panels: Mount the back panel(s) first, then fit the U-Guide

over the L-Guide when mounting the front panels.

NOTE: A ½" height deduction is taken at the factory to ensure proper clearance.

27

Page 30

INSTALLATION

Bypass Track Systems

Step H. Attach the Optional Valance

1. Attach the valance returns. Glue the miter joints and attach the returns with L-brackets.

2. Position the valance so that it covers the hardware and attach it to the top frame.

3. Standard valance: There are two options for installing the standard valance.

3

/8" installation holes through the first layer of vinyl only. Space the holes 20" apart

➤ Drill

and cover them with button plugs after securing the valance.

➤ Attach the valance with double-sided tape.

4. Decorative valance: Secure the valance with L-brackets,

as shown. Space the L-brackets every 20".

Step I. Complete the Installation

■ Perform any necessary finish work to complete the

installation (see page 42).

Back of Valance

Adjustable

Screw Hole

L-Bracket

Top of Frame

28

Page 31

French Door Shutters

INSTALLATION

French Door Shutters

French door shutters are mounted using the L-frame, either 3-sided or 4-sided. Installation

procedures for French door cut-outs are the same as those for full panel French door shutters.

(If you haven’t already assembled the French door frame, refer to page 3.)

French Door Shutter

with 4-Sided Frame

(FD)

French Door Shutter

with 3-Sided Frame

(FD)

French Door Cut-Out

with 4-Sided Frame

(FDC)

French Door Cut-Out

with 3-Sided Frame

(FDC)

Step A. Install the Frame

1. Center the frame over the opening. Handle three-sided frames very carefully to avoid

placing stress on the corner joints. Be sure the corner keys have been glued into position

as described on page 4.

➤ Check that the overlap (if any) is the same in the middle, top, and bottom. This will

assure that the vertical line of the door will match the vertical line of the shutter.

➤ Four-sided frames: Secure the side frame next to the knob. Place the first screw by

the door knob, second screw near the top, and third screw near the bottom.

➤ Three-sided frames: Secure the hinged side frame. Place the first screw in the top

installation hole, second screw near the bottom, and third screw in the center.

➤ Tighten the screws snugly, but do not overtighten.

IMPORTANT: Angle the screws to avoid breaking the glass.

IMPORTANT: With French door cut-outs, make sure the cut-out

is centered on the door knob.

2. Most frames have pre-drilled holes for ease of installation. If

additional installation holes are needed, drill

3

/8" holes in the

frame through the first layer of vinyl only.

L-Frame

Angle

Screw

Glass

29

Page 32

INSTALLATION

French Door Shutters

Step B. Mount the Panels

1. If the shutter uses the Duracatch™ lock system, first retract the Duracatch locks on the top

and bottom of the panels. Refer to the procedures in Step 1 on page 9.

2. Place the panel into the frame by fitting the pin end of the hinges into the hinge barrels.

IMPORTANT: Carefully support the frame while inserting the panel into the hinges. Use

supports under the hinged side of the frame to support the weight of the panel.

Step C. Racking and Securing

Four-Sided Frames

1. Close the panel and check for proper alignment.

➤ If panels are misaligned, grasp the hinged side of the frame and rack up and down until

proper alignment is achieved.

➤ Open the panel and insert a screw above the top hinge in the pre-drilled hole.

➤ Close the panel and check alignment. If misaligned, remove the screw and re-align.

➤ If proper alignment is maintained, proceed to step two.

2. Secure the bottom of the side frame through the pre-drilledholes.

3. Close the panel and adjust the center of the hinged side frame so that the gap between the

other side frame and the panel is consistent. Mark the proper position of the frame, open the

panel, and attach the frame through the pre-drilled hole.

4. Attach all remaining fasteners.

IMPORTANT: With each fastener that is placed, close the panel and check the alignment. If

the alignment is lost, remove the fastener, re-align the panel, and re-install the fastener.

Three-Sided Frames

1. Close the panel. Check that the vertical line of the door matches the vertical line of the

shutter panel and frame. Loosen and adjust the frame or hinge attachment, as necessary.

2. Align the top and bottom frames with the shutter panel and secure their ends.

3. Attach all remaining fasteners.

All frames

1. Release all Duracatch panel lock assemblies by loosening the lock screws a quarter-turn.

2. Close the panels and, if needed, adjust the Duracatch locks with a flat blade screwdriver so

that all doors close easily yet stay firmly shut.

3. If necessary, install magnets and plates (see page 41).

4. Perform any other necessary finish work to complete the installation (see page 42).

30

Page 33

Corner Windows

INSTALLATION

Corner Windows

Corner window shutters are two framed shutters connected together at a 90-degree angle.

Before performing a corner window installation, you should be familiar with the framed shutter

installation procedures described on pages 8–10. (If you haven’t already assembled the shutter

frames, refer to page 3.)

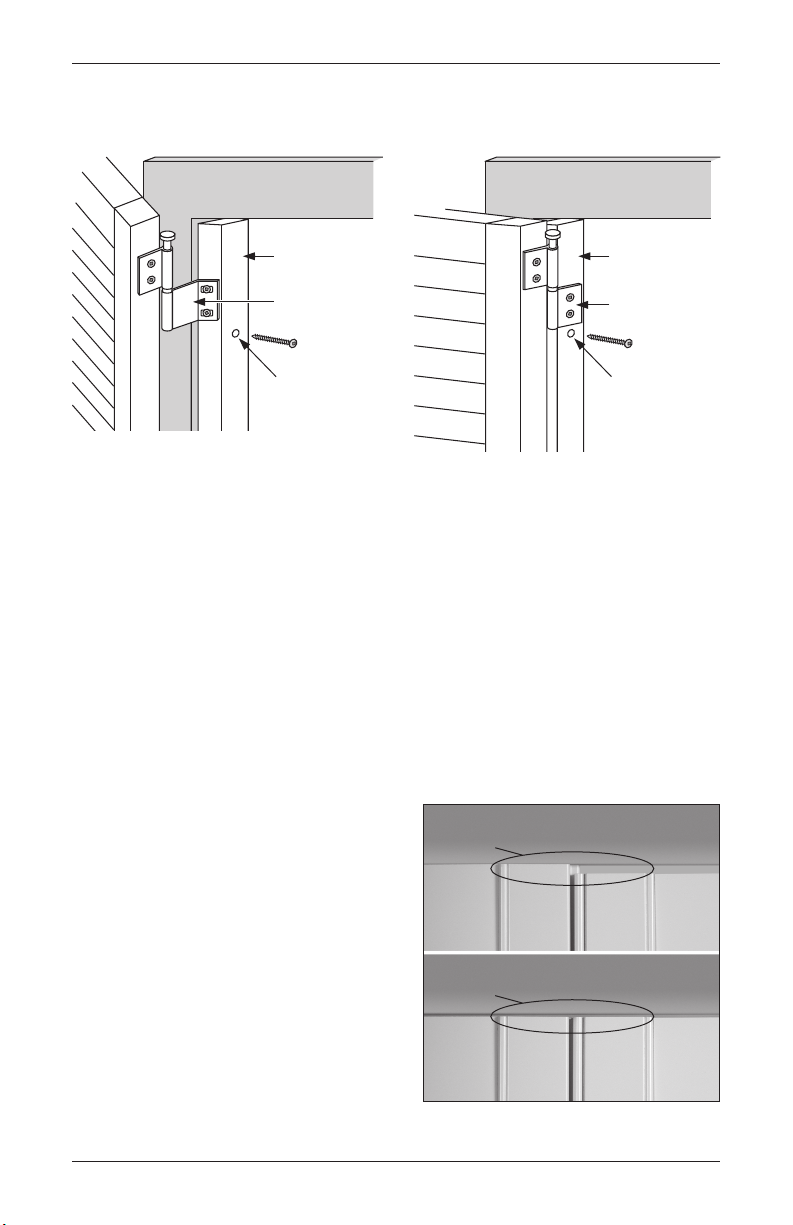

Step A. Connect the Two Assembled Frames

1. Position the provided hang strip flush with the front of the right side of the left frame. Attach

it with screws through the frame, on the screw indicator line.

2. Attach the left side of the right frame to the hang strip in a similar fashion.

Hidden Hang Strip Joins Corner L-Frames

Hang Strip

Step B. Install Frames (Inside or Outside Mount)

1. Center the attached frames (L-frame and Z/L-frame combinations) over or into the openings

and even out your reveal.

2. Secure the top and bottom inside corners of the left and right frame.

Step C. Mount the Left Corner Panel(s)

1. First, retract the Duracatch™ locks on the top and bottom of the panels. Refer to the

procedures in Step 1 on page 9.

2. Support the left side of the frame with support blocks (OM) or shims (IM) before inserting

the panel(s).

3. Place the panel(s) into the left frame by fitting the pin end of the hinges into the hinge

barrels.

31

Page 34

INSTALLATION

Corner Windows

Step D. Rack and Secure the Left Corner Panel(s)

1. After mounting the panel(s), close the panel(s) and check for proper alignment.

➤ If misaligned, grasp the left side of the

left frame at the top and bottom and

move the frame up and down until proper

alignment is achieved.

➤ Mark the position of the frame on the wall

and open the panel.

2. Attach the bottom of the frame through the

pre-drilled holes. Be sure the frame lines up

with your mark.

3. Close the panel(s) and check alignment.

4. Secure the balance of the frame. There should be one screw within 3" of each corner and no

more than 30" between fasteners.

IMPORTANT: With each fastener that is placed, close the panels and check the alignment. If the

alignment is lost, go back to the fastener, remove, re-align, and re-install.

Mark

Position

Step E. Mount the Right Corner Panel(s)

■ Repeat Step C for the right panel(s).

Step F. Rack and Secure the Right Corner Panel(s)

■ Repeat Step D for the right panel(s).

Step G. Complete the Installation

1. Release all Duracatch™ panel lock assemblies by loosening the lock screws a quarter-turn.

2. Close the panels and, if needed, adjust the Duracatch locks with a flat blade screwdriver so

that all doors close easily yet stay firmly shut.

3. If necessary, install magnets and striker plates (see page 41).

4. Perform any other necessary finish work to complete the installation (see page 42).

32

Page 35

Bay Windows

INSTALLATION

Bay Windows

If you haven’t already assembled the bay window shutter frames, refer to page 3.

Step A. Install the Middle Bay Frame (Inside or Outside Mount)

1. Center the frame of the middle bay over (OM) or into (IM) the opening.

2. Attach the top frame at the top corners with Robertson screws through the pre-drilled holes.

Tighten snugly, but do not overtighten.

Outside

Mount

Inside

Mount

Step B. Mount the Middle Bay Panel(s)

1. First, retract the Duracatch™ locks on the top and bottom of all panels. Refer to the

procedures in Step 1 on page 9.

2. Place the panel(s) into the middle bay frame by fitting the pin end of the hinges into the

hinge barrels.

Step C. Rack and Secure the Middle Bay Panel(s)

1. After mounting the panel(s), close the panel(s) and check for proper alignment.

➤ If misaligned, grasp the bottom frame and move it side-to-side until proper alignment is

achieved.

➤ Mark the position of the frame on the wall and open the panel(s).

Incorrect

Correct

Mark

Position

33

Page 36

INSTALLATION

2. Attach the frame at the bottom corners, making sure the frame lines up with your mark.

3. Close the panel(s) and check alignment.

4. Secure the balance of the frame. There should be one screw within 3" of each corner and no

more than 30" between fasteners.

IMPORTANT: With each fastener that is placed, close the panels and check the alignment. If the

alignment is lost, go back to the fastener, remove, re-align, and re-install.

Bay Windows

Step D. Install the Left Bay Frame

1. Align the right side of the left bay with the left side of the middle bay frame.

IMPORTANT: Make sure that the tops are flush, and the bead edge of the butting L-frames

are aligned properly and do not overlap.

2. Attach the top and bottom of the frame within 3" of the right corners.

Step E. Mount the Left Bay Panel(s)

1. Support the left side of the frame with support blocks (OM) or shims (IM) before inserting

the panel(s).

2. Place the panel(s) into the left frame by fitting the pin end of the hinges into the hinge

barrels.

Step F. Rack and Secure the Left Bay Panel(s)

1. After mounting the panel(s), close the panel(s) and check for proper alignment.

➤ If misaligned, grasp the left side of the left frame at the top and bottom and move the

frame up and down until proper alignment is achieved.

➤ If necessary, mark the position of the frame on the wall and open the panel.

2. Attach the frame at the left-side top and bottom corners, making sure the frame lines up

with your mark.

3. Close the panel(s) and check alignment.

4. Secure the balance of the frame. There should be one screw within 3" of each corner and no

more than 30" between fasteners.

IMPORTANT: With each fastener that is placed, close the panels and check the alignment. If the

alignment is lost, go back to the fastener, remove, re-align, and re-install.

Step G. Install the Right Bay Frame

■ Repeat Step D for the right frame.

34

Page 37

Bay Windows

INSTALLATION

Step H. Mount the Right Bay Panel(s)

■ Repeat Step E for the right panel(s).

Step I. Rack and Secure the Right Bay Panel(s)

■ Repeat Step F for the right panel(s).

Step J. Complete the Installation

1. Release all Duracatch™ panel lock assemblies by loosening the lock screws a quarter-turn.

2. Close the panels and, if needed, adjust the Duracatch locks with a flat blade screwdriver so

that all doors close easily yet stay firmly shut.

3. If necessary, install magnets and striker plates (see page 41).

4. Perform any other necessary finish work to complete the installation (see page 42).

35

Page 38

INSTALLATION

Framed Stand-Alone Specialty Shapes

Framed Stand-Alone Specialty Shapes

NOTE: If a Decorative Sill Cover was ordered, refer to page 39.

Stand-alone specialty shape shutters are installed independently of standard shutters.

1. Place the frame in or over the opening and center. Make sure the bottom frame is level.

2. Attach the frame with two screws through the curved portion of the frame.

➤ Screws should be placed in the top left and top right of the curve as illustrated below.

➤ Do not overtighten the screws — doing so could distort the shape.

First Two Screw Locations

3. Place the panel into the frame by lining up the hinge barrels and inserting the hinge pins.

Close the top and sides by depressing the specialty shape’s Duracatch

™

spring-loaded

plungers into the grooves in the frame.

4. Move the bottom of the frame left or right to create the proper gaps around the panel.

➤ Mark the bottom frame location where the proper gaps are created.

➤ Remove the panel from the frame.

5. Move the bottom frame to align it with the mark, and screw through the middle of the bottom

frame to hold it in the correct position.

6. Place the panel back into the frame and double-check that it fits properly.

7. Remove the panel from the frame and set all remaining screws, being careful not to

overtighten.

8. Place the panel into the frame. Adjust plunger depth if necessary to provide a good fit in

the frame.

➤ If fit is too tight, push in on the plunger and rotate clockwise to recess the plunger.

➤ If fit is too loose, push in and rotate the plunger counterclockwise to extend it.

9. Perform any necessary finish work to complete the installation (see page 42).

36

Page 39

Framed Specialty Shapes Over Standard Shutter

INSTALLATION

Framed Specialty Shapes Over Standard Shutter

When a specialty shape is over a standard shutter, the bottom of the shape’s frame is attached

to the top of the standard shutter’s frame. The standard shutter is always installed before the

specialty shape.

NOTE: If a Decorative Sill Cover was ordered, refer to page 39.

1. Place the frame in or over the opening.

Align the bottom frame of the shape with

the top frame of the standard shutter.

2. Set two installation screws through the

bottom frame of the shape into the top

frame of the standard shutter. Do not

overtighten the screws.

3. Place the shaped panel into the frame

by lining up the hinge barrels and

inserting the hinge pins. Spring-loaded

plungers on the shape snap into

grooves on the frame.

4. Move the top of the shaped panel’s

frame left or right to create the proper

gaps around the shape.

➤ Mark the top frame location where

the proper gaps are created.

➤ Remove the shaped panel from

the frame.

5. Move the top of the frame to align it

with the mark, and screw through the

top center to hold the frame in the

correct position.

6. Place the shaped panel back into the frame and double-check that it fits properly.

7. Remove the shaped panel from the frame and set all remaining screws; do not overtighten.

8. Place the shaped panel into the frame. Adjust plunger depth if necessary to provide a good

fit in theframe.

➤ If fit is too tight, push in on the plunger and rotate clockwise to recess the plunger.

➤ If fit is too loose, push in and rotate the plunger counterclockwise to extend it.

9. Perform any necessary finish work to complete the installation (see page 42).

Attach Shape Frame

37

Page 40

INSTALLATION

Unframed Specialty Shapes

Unframed Specialty Shapes

Unframed specialty shape shutters are always inside mounted and attached with magnets.

NOTE: If a Decorative Sill Cover was ordered, refer to page 39.

1. Place the shaped panel in the opening and center it.

2. Mark the position of the left and right edges of the shape on the bottom of the opening.

3. Measure in from each mark ½", and make another mark. The second marks indicate where

the outside edges of the magnets will be installed.

½"

Left Edge

4. At the second set of marks, measure and

3

/8" back from the front edge of the

mark 1

opening. The front of the magnet will be

of Shape

Measure in ½"

Shutter Panel

GlassSpecialty Shape

Striker

Plate

located here.

➤ Measure for magnet position at the top

center of the shape in the same way.

➤ If more than three magnets are

3

1

/8"

Magnet

provided, space them evenly in the

opening.

5. Attach all magnets to the opening using the supplied magnet screws.

6. Attach striker plates to the shape so that they will align with the magnets when the shaped

panel is installed.

7. Install the unframed specialty shape panel and center from side to side.

➤ Check that each magnet makes good contact with the striker plates.

➤ Make any necessary adjustments to magnets that do not hold securely.

8. Perform any necessary finish work to complete the installation (see page 42).

38

Page 41

Decorative Sill Cover

"

Sill Cover with

Sill Cover with

INSTALLATION

Decorative Sill Cover

For details about the Decorative Sill Cover, see the Palm Beach section of the Hunter Douglas

Reference Guide.

1. Dry fit the Decorative Sill Cover before installing. Minor adjustments may be required.

2. For standard applications, the rear of the Decorative Sill Cover is flush with the back of the

shutter frame.

3. Attach the Decorative Sill Cover. The following products may be used to secure it: silicone

adhesive, caulk, double-sided tape, or screws that are concealed by the shutter frame.

Select the one that is best for your installation.

4. If provided, attach light stop to the Decorative Sill Cover.

5. Outside mount applications may require a filler strip that should be attached to the inside

bottom lip of the Decorative Sill Cover to fill the space between the sill cover and the wall.

6. For outside mount applications without an existing sill, attach a section of filler strip to the

wall to provide a support or mounting surface for the Decorative Sill Cover.

Inside Mount Frames

Window Sill

Wall

Wall

½"

7

/8"

Projection

(or Ear)

Sill Cover with

No Sill

¾" x 1"

Filler Strip

Used as

Mounting

Strip

Outside Mount Frames

Window Sill

Wall

Filler Strip

½"

Projection

(or Ear)

7

/8

Filler Strip

39

Page 42

INSTALLATION

Spring-

Loaded

Plunger

Sill

Finish Work

Finish Work

Install Duracatch™ Panel Lock Ramp(s), If Applicable

™

The Duracatch

frames during fabrication. If your panel configuration is a 3-sided frame application, install panel

lock ramps on the bottom sill. If a 2-sided frame, install the panel lock ramps on both the top

and bottom sills.

Panel Lock System with spring-loaded plunger is installed on panels and

Panel Lock Ramps

2-Sided Frame3-Sided Frame

Panel Lock Ramps

Panel Lock Ramps

1. With the shutter panel(s) closed, make a pencil

mark on the sill to show where the center of

each spring-loaded plunger is located.

2. Mark where to drill pilot holes for the screws.

➤ Open the shutter panel(s). Place the panel

lock ramp on the sill with the sloped edge

facing front. The front edge of the ramp

should be

1

/8" behind the front edge of

the panel.

➤ Center the panel lock ramp on the line

marking the plunger location.

Mark centerline of each plunger with pencil

➤ Mark the center of the ramp’s screw

holes. Repeat for all panel lock ramps.

3. Drill pilot holes for each panel lock ramp

3

/32" drill bit.

using a

4. Attach the panel lock ramps to the sill using the Robertson screws provided.

5. Close the shutter panels to check function and closure.

6. The spring-loaded plungers can be adjusted using a flat blade screwdriver.

➤ If closure is too tight, push in on the plunger and rotate clockwise to recess the plunger.

➤ If closure is too loose, push in and rotate the plunger counterclockwise to extend it.

➤ Rotate the plunger in one-half turn increments to maintain alignment with the stile cap.

SpringLoaded

Plunger

Sill

Panel Lock Ramp

1

/8"

40

Page 43

4-Sided Frame

Individually-Hinged Panels

3-Sided Frame

Bi-Fold Panels

e

Bottom

Finish Work

INSTALLATION

Install Magnets and Plates, If Applicable

If the shutter panels do not have panel locks, you may need to install magnets and plates if they

are not already installed.

1. Review the diagrams below. Plates are installed at the top and bottom of all shutter panels.

Magnets are installed behind the plates to the frame or sill.

Plate

Rear

View

Flush with

Bottom of Rail

3

/8"

2. Using a pencil, mark the frame (top and bottom)

where the stile meets the top and bottom rails,

on the side where the shutter closes against the

frame.

➤ With three-sided frames, mark the sill at the

bottom.

3. Install the magnets to the frame’s light block

so that the magnets are

3

/8" in from the mark,

toward the center of the shutter panel.

➤ With three-sided frames, install the magnet

3

to the sill

/8" in from the mark. Align the

magnet with the frame’s light block.

4. Install the plates on the rear of the panels so

that they align with the magnets. The corner of

the plates should be 3/8" in from the stile and the

edge of the top or bottom rail.

➤ With three-sided frames, install the bottom

plates flush with the edge of the bottom rail.

5. Close the shutter panels to check function and

closure. Adjust magnet or plate position, if

necessary.

3

/8"

Side

View

3

/8"

Plate

Flush

with

of Rail

Sill

Frame

Magnet on Fram

Plate

Top Rail

4-Sided

Frame

Bottom Rail

3-Sided

Frame

Bottom Rail

Plate

Magnet on Sill

41

Page 44

INSTALLATION

Finish Work

Touch-Up and Inspection

1. If you have not done so already, cap all screw holes with the provided button plugs. For easy

installation, first insert the button plug foot with the tab on it, and then slide the remaining

feet into the installation hole.

2. If you have not done so already, on inside-mounted L-frame applications glue L-frame cover

strips to the front of the L-frame to fill gaps between the frame and window jamb.

3. Apply sealant as needed to fill gaps between frames and window jambs or between mitered

corners.

4. Wash any dirt or grease from the shutter using a clean cloth and mild detergent solution.

Never use ammonia-based products.

5. Invite the home owner to inspect the installation. Give the home owner the Hunter Douglas

warranty card and explain the added protection provided by the Palm Beach

™

Promise,

which covers shutter panel and frame

members against warping, cracking,

fading, chipping, peeling, or discoloration.

Demonstrate proper operation of the shutters

and show the customer the location of their

individual authenticity plate serial number.

42

Page 45

OPERATION AND CARE

Operation

■ Tilt the louvers by grasping one louver and moving it.

■ Open the shutter panel by grasping the stile through open louvers and pulling out. Do not

use the tilt bar to open the shutter panel.

IMPORTANT: To open the panels on a bi-fold track system, collapse the first set of panels at the

pivot side followed by each successive set of panels until all panels are collapsed.

IMPORTANT: When using floor guides with a bypass track system, use caution when operating

panels to avoid panel damage where the guides contact the stiles.

Care

■ Clean using a dry and soft feather duster, clean cloth, dust cloth or dusting mitt. A vacuum

with the soft brush attachment can also be used.

™

■ Palm Beach

ammonia-based products.

■ Ultrasonic cleaning or use of chemical solvents and scrubbing cleansers are not

recommended. This will damage the product.

■ Palm Beach Polysatin shutters may accumulate static buildup during the shipping and

installation process. Static can attract dust or smoke residue from candles or fireplaces. To

reduce static cling and help repel dust, wipe the product with a soft, clean towel moistened

with mild soap and water or a fabric dryer sheet. Never use ammonia-based products or

abrasive cleaners as they may scratch or damage the surface.

Polysatin™ shutters may be washed using a mild detergent solution. Never use

43

Page 46

TROUBLESHOOTING

Problem: Panels Won’t Stay Closed

■ Check the Duracatch™ panel lock. Check to ensure that the panel lock plunger is seated

properly in the panel lock ramp. Possible problems include:

➤ The panel lock plunger is too far inside the panel. Adjust the plunger as described in

step 6 on page 40.

➤ The plunger does not sit in the “dip” in the panel lock ramp. Reposition the ramp, if

necessary. Refer to steps 1 through 5 on page 40.

➤ Check plunger and stile cap alignment. The plunger is designed to lock into grooves on

the stile cap to prevent unwanted rotation. If they are not aligned, the plunger will remain

inside the cap. To adjust, use a flat blade screwdriver to rotate the plunger until it is

properly aligned and able to extend beyond the stile cap.

■ Check the number of magnets. If magnets are used for closure, check that there are two

per panel, one at the top and one at the bottom. Refer to the magnet installation section on

page 41. (Note: Café style shutters use only one magnet.)

■ Check magnet contact. If magnets are used for closure, check that the magnets and

magnet plates have full contact with each other. Possible problems include:

➤ The magnet and plate are not aligned. The magnet or magnet plate may need to be

moved to achieve proper alignment. Refer to the magnet installation section on page 41.

➤ The magnet is at a slight angle, with only one side of the magnet touching the plate.

Loosen one of the screws on the magnet to allow it to be straightened so that it makes

full contact with the plate.

➤ The magnet plate is not flush with the panel, so that only one side touches the magnet.

Adjust the screws so that the magnet plate becomes flush with the panel.

■ Check panel load. Load is created when the installation is not square. This places load

on the stile, which can force the panel to open with a spring-back effect. If the load is

excessive, the louvers may be difficult to close, as well. Possible solutions include:

➤ If load is detected with framed applications, tighten or loosen the installation screws on

the frame. (Do not use shims.) Start by removing all the installation screws except for the

top. Re-install the bottom installation screw until there is no load. Continue with all other

installation screws, one at a time, checking for load after each one.

➤ If there is load on a bi-fold panel, remove the second bi-fold panel and resolve the

problem with the first hinged panel as described above. Then re-attach the second panel

and check that the problem has been resolved.

➤ If load is detected with unframed applications, shim the hinges to square the panels.

Remove all hinge pins except for the top and bottom. Shim those hinges as needed until

the problem is resolved. Continue with the other hinges, one at a time, checking for load

after each one.

44

Page 47

TROUBLESHOOTING

Problem: Panels Won’t Stay Closed (continued)

■ Check for obstructions that prevent panels from closing. Possible problems include:

➤ Window cranks can prevent panels from closing. Take the crank off the rotator and

see if the panel is still obstructed. If the panel closes, replacing the window crank with

a T-crank can often solve the problem. Otherwise, build-out may be required to add

clearance. For panels without a frame, an extension hinge may be used to bring the

panel into the room an extra

➤ Window locks are other possible obstructions. Add clearance as described above.

➤ Patio door handles can prevent louvers from opening. If a handle stops a panel from

closing, the shutter must be built-out.

➤ Bowed sills or casements can prevent inside-mounted shutter panels from closing if the

narrowest height and width measurements were not ordered. Double-check the inside

measurements and compare them with the measurements ordered and received.

■ Check for a twisted panel. Panel stiles can sometimes be twisted by weight leaned

against it or by extreme heat. Fortunately, the polysatin material can be “tweaked” back

to its original shape with gentle force. To do this, use your hand to support the middle of

the panel’s outside stile and bend the top or bottom back into position until the panel

remains closed.

5

/8".

Problem: Panels Are Too Tight

■ Check that the frame is installed properly. If the frame is not installed correctly, it may

cause the inside opening of the frame to be too narrow at a specific point, causing the

panels to be too tight. To check if the installation screws have been tightened the correct

amount, measure the top or bottom frame width and compare it to the width where the

panel appears to be too tight. Adjust the installation screws to square the frame.

■ Check that the panel is in the correct opening. When multiple windows are of similar

size, panels can sometimes be placed into the wrong opening or with the incorrect panel

grouping. Check the labels and order form instructions to ensure that the panels are in the

correct opening and with the correct panel group.

■ Classic Z-frame with rubber flex: remove the rubber flex from one side of the

frame. If the opening is smaller than expected and installation screws do not pull the frame

straight, it may be necessary to remove the rubber flex from the back of one or more sides

of the frame. This can be done easily and safely by making a small cut into the rubber flex

material at one end of the frame, then peeling the rubber flex off the frame.

45

Page 48

TROUBLESHOOTING

Problem: Louvers Are Not Working Properly

■ Check panel load. Review the procedures at the bottom of page 44.

■ Check connectors. With Palmetto

➤ Duralink

™

cufflink connectors attach the louvers to the tilt bar at the front of the panel.

Check that the connectors are securely attached. Snap them back into place if they are

detached.

IMPORTANT: To ensure the long life of shutters, the front tilt bar should not be used to

open the panel.

➤ With rear tilt bars, rear connectors attach the louvers to the tilt bar at the back of the

panel. Check that the connectors are securely attached.

■ Replace Duralink cufflink connectors (front tilt). Follow this procedure:

1. Pull the tilt bar from the louvers.

2. Remove the broken connector(s).

3. Replace the broken connector(s). Snap the new connector(s) into the hole on the

tilt bar.

4. Replace the tilt bar. Insert the connectors into the louvers by holding the louvers in

place and firmly pressing the connector into the notch on the louver.

™

shutters, connectors attach the louvers to the tilt bar.

46

Cufflink

Connector

Page 49

TROUBLESHOOTING

■ Replace rear tilt bar connectors. Follow this procedure:

1. Remove the broken connector(s).

2. Snap the new connector(s) into the rear tilt bar.

3. After all the broken connectors have been replaced, connect the tilt bar to the louvers by

snapping the connectors back onto the ends of the louvers.

Rear Tilt Bar

Connector

Problem: Shutter Is Discoloring

■ Check for residue build-up. The polysatin material has UV stabilizers to prevent

discoloring. Any situation of discoloration is a direct result of residue from a cleaner or

natural build-up (smoke, dust or oil furnace). Clean the shutter with soap and water. Never

use ammonia-based products.

Problem: Shutter Is Scratched

■ Remove scratches. Scotch-Brite™ 7448 light gray hand pads can be used to remove

minor scratches. Gently rub the Scotch-Brite pad over the scratch in the direction of the

extrusion. Apply minimal pressure when rubbing to avoid dulling the finish. Using very light

pressure, carefully blend the repair area into the surrounding material. The entire piece may

need to be treated.

■ Remove deeper scratches. If a scratch cannot be removed using Scotch-Brite, a more

aggressive approach may be required. Start with 1200 grit wet or dry sandpaper first, and

then finish with the Scotch-Brite 7448 pad to blend.

47

Page 50

NOTES

Page 51

Page 52

The Hunter Douglas® Lifetime Guarantee is an expression of our desire to provide a thoroughly satisfying

experience when selecting, purchasing and living with your window fashion produc ts. If you are not thoroughly

satisfied, simply contact Hunter Douglas at (888) 501-8364 or visit hunterdouglas.com. In support of this policy

of consumer satisfaction, we offer our Lifetime Limited Warranty as described below.

COVERED

BY A LIFETIME LIMITED WA RRANTY

• Hunter Douglas window fashion products are

covered for defects in materials, workmanship

or failure to operate for as long as the original

retail purchaser owns the product (unless shorter

periods are provided below).

• All internal mechanisms.

• Components and brackets.

• Fabric delamination.

• Operational cords for a full 7 years from the

date of purchase.

• Repairs and/or replacements will be made with

like or similar parts or products.

• Hunter Douglas motorization components are

covered for 5 years from the date of purchase.

• Palm Beach

™

fading, chipping, peeling and discoloring.

Promise covers warping, cracking,

• Any conditions caused by normal wear and tear.

• Abuse, accidents, misuse or alterations to the

• Exposure to the elements (sun damage, wind,

• Failure to follow our in

• Shipping charges, cost of removal and reinstallation.

NOT COVERED

BY A LIFETIME LIMITED WA RRANTY

product.

water/moisture) and discoloration or fading

over time.

to measurement, proper installation, cleaning

or maintenance.

structions with respect

Hunter Douglas (or its licensed fabricator/distributor) will repair or replace the

window fashion product or components found to be defective.

TO OBTA IN WARRANTY SERV ICE

1. Contact your original dealer (place of purchase) for warranty assistance.

2. Visit hunterdouglas.com for additional warranty information, frequently asked questions and access to service locations.

3. Contact Hunter Douglas at (888) 501-8364 for technical support, certain parts free of charge, for assistance in obtaining

warranty service or for further explanation of our warranty.

NOTE: In no event shall Hunter Douglas or its licensed fabricators/distributors be liable or responsible for incidental

or consequential damages or for any other indirect damage, loss, cost or expense. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

Different warranty periods and terms apply for commercial products and applications.

9930011018 4/16

Loading...

Loading...