Page 1

ACC

Advanced Commercial Controller

Owner’s Manual, Installation, and Programming Instructions for

ACC and ACC Decoder Controllers

■

ACC-1200 12 Station Controller, 42 Station

Capacity, Metal Cabinet

■ ACC-1200-PP 12 Station Controller, 42

Station Capacity, Plastic Pedestal

■ ACC-99D 2-Wire Decoder Controller with

99 Station Capacity, Metal Cabinet

■ ACC-99D-PP 2-Wire Decoder Controller

with 99 Station Capacity, Plastic Pedestal

Page 2

Page 3

Table of ConTenTs

ACC INTERFACE AND KEY COMPONENTS 2

WIRING COMPARTMENT INTERIOR 3

METAL CABINET, WALL MOUNT INSTALLATION 4

CONNECTING AC MAIN POWER, WALL MOUNT CABINET 5

METAL CABINET OPTIONAL PEDESTAL INSTALLATION 6

Connecting the Metal Pedestal Main AC Power 6

PLASTIC PEDESTAL INSTALLATION 6

CONCRETE BASE INSTALLATION 7

CONNECTING PLASTIC PEDESTAL AC MAIN POWER 8

120 VAC Connection 8

230 VAC Connection 8

CONNECTING EARTH GROUND (ALL CONFIGURATIONS) 10

INSTALLING STATION MODULES 11

Output Modules (ACM600, AGM600) 11

Connecting the Valve Wires 12

Decoder Output Module (ADM99) 12

Connecting Decoder Output Path Wires 12

KEY CONNECTIONS 13

24 VAC TEST TERMINAL 14

CONNECTING THE MASTER VALVE(S) AND/OR PUMP START RELAY(S) 14

CONNECTING A RAIN OR FREEZE SHUT OFF DEVICE 14

CONNECTING THE HUNTER FLOW SENSOR 15

CONNECTING OTHER FLOW SENSORS 1 6

ICR REMOTE CONTROL 16

Multiple Stations simultaneously 16

CONNECTING TO IMMS 17

Dial-up telephone (ACC-COM-POTS) 17

Cellular/GSM (ACC-COM-GSM, GSM-E) 18

UHF Radio 18

POWER FAILURES 18

QUICK START 18

CONTROLLER PROGRAMMING AND OPERATION 19

Using the Information Button 19

Setting Current Date and Time 20

Setting Program Start Times 20

To Set Program Start Times 20

Stacked Start Times 20

Overlapping Start Times 20

Multiple Start Times 21

No-Water Window 21

Page 4

Setting Station Run Time Duration 21

Changing Seasonal Adjust 22

Using the Global Setting 22

Using a Program Specific Setting (set Season Adjust by Program) 22

Timed Delay between Stations 22

Setting Days to Water 22

Set Days to Water 22

Day of the Week Watering 23

Interval Watering 23

Odd/Even Watering 23

Setting Pump and Master Valve Operation 23

Set Pump and Master Valve Operation 24

Changing from Normally Closed to Normally On and Location of P/MV 24

Setting Station Cycle and Soak Durations 24

Set Station Cycle and Soak Durations 24

Cycle and Soak Summary 24

SETTING FLOW MONITORING 25

Step 1: Select The Flow Sensor 25

Step 2: Viewing Real-Time Flow 26

Step 3: Preparing for Flow Learning 27

Step 4: Learning the Flow 27

Step 5: Review And Edit Flow 28

Flow Alarms 28

Alarm Logs 29

Tips on Flow Alarms 30

SETTING CLIK™ SENSOR OPERATION 3 0

Set Sensor Operation 31

SENSOR ALARMS (CLIK SENSORS SEN 1–4 ONLY) 32

Clear Message 3 2

Sensor Locations 33

Sensor Locations 35

SETTING PROGRAM OVERLAP OPTIONS 36

Option One: Stack or Overlap 36

Option Two: SmartStack™ 36

Option Three: SSG/SmartStack™ 36

Set Station & Program Names 37

Assign Contact Information 37

DATA HISTORY 38

Name a Program (Up to 12 Characters and Spaces) 38

Name a Station (Up to 12 Characters and Spaces) 38

View Flow Totals 38

View Alarm Logs 38

View Controller Logs 39

Page 5

View Station Logs 39

Advanced Features 39

View Version and Station Size 40

COMMON ALARM (ATTENTION) MESSAGES 4 1

Overcurrent 41

Overflow 42

Power Outage/Power Restored 43

Underflow 43

EXTENDED FEATURES 43

Contrast Adjustment 43

No Water Window 44

To set a No Water Window 44

No Water Window rules 44

Delay Between Stations 45

To set a Delay 45

P/MV Style (Normally Closed/Normally On) 45

To change the Normal condition of P/M outputs 46

Setting the Flow Sensor Size and Type 46

Additional settings for OTHER 47

SSG (Simultaneous Station Group) Setup 47

EDIT AN SSG 48

ADDING AN SSG 49

DELETING AN SSG 49

SSG FLOW DATA 49

SSG Rules 49

Custom Manual Program Setup 50

Custom Manual Rules 50

Start a Custom Manual 51

Test Program 51

Run a Test Program 51

Easy Retrieve™ Backup 52

ONE TOUCH MANUAL START 53

MANUAL OPERATION DIAL POSITION 53

SYSTEM OFF 5 4

RAIN OFF 55

RESET 55

DECODER OPERATIONS (ACC99D VERSIONS) 56

Connecting the 2-Wire Paths 56

Status Lights (ADM-99 Output Module) 57

Decoder Programming 57

Program Decoder Stations 57

Decoder Pump/Master Valves 59

ICD-SEN Sensor Decoder Setup 59

Page 6

Setup Overview 60

Connect an HFS Meter to an ICD-SEN 60

Connect a Clik Sensor to an ICD-SEN 60

SEN/DEC Setup 60

OTHER SPECIAL DECODER FUNCTIONS (ADVANCED FEATURES) 62

View Decoder Config 62

Display ADM Current 63

Sen/Dec Alarms 63

ACC SOLAR SYNC 64

Preparation 64

Facepack Version 64

Master Module 64

Base Run Times 64

Installation 65

Setup 65

Sensor Test 66

Assign Programs 67

Sensor Shutdown Programming 67

Sensor Mapping 67

Sensor Shutdown by Program 68

Operation & Adjustment 68

Making Adjustments 69

Increase or Decrease Watering 69

Check Run Times 69

Tracking the Adjustment History (Controller Log) 69

Solar-Sync Sensor Alarms 70

S-Sync Comm Failure 71

IMMS-ET AND THE ACC CONTROLLER 72

ET Setup and Operations 72

ET Functions 72

ET Operation 72

ET Sensor Check 73

View ET Sensors 73

ET Alarm Setup 73

EVENT MODE OPTIONS (AGC, SURVEYOR) 75

CENTRAL SOFTWARE AND ACC-AGC COMMUNICATION MODULES 77

Theory of Operation 77

UHF Radio 77

Hardwired Cable 78

COMMUNICATION MODULE INSTALLATION FOR WALL MOUNT CONTROLLER 78

Radio Installation, additional steps 78

Radio Connections, additional steps 79

Page 7

COMMUNICATION MODULE INSTALLATION FOR PLASTIC PEDESTAL CONTROLLER 79

Radio Installation, additional steps 79

SETUP AND ADDRESSING THE COM MODULE 80

Set the Controller Address 80

Other Com Setup Functions 80

Master Controller 80

Contrast 80

Radio Type 80

Last MR Cmd (Radio Only) 80

DTMF Wait (Radio Only) 80

MR Default Run Time (Radio Only) 81

Modem Type 81

Country Code 81

HWIM 81

Enter Diagnostics 81

Communications Status display [MOD RAD HW] 81

Radio Tone Test 82

Ping Test 82

Ping Hub 82

Soft Reset 82

Total Reset 82

Operating the Com Module 82

TROUBLESHOOTING 83

ACC/AGC LOG MESSAGES 84

Alarm Log messages 84

Alarm Log, Missed Irrigation “Mode” Labels 84

Alarm Log, “Reason” Labels 85

Controller Logs 85

Station Logs 86

SPECIFICATIONS 87

Dimensions 87

Electrical 87

Transformer Input 87

Transformer output 87

Cleaning 87

Features & General Specifications 87

PARTS 88

Wall Mount Controllers (ACC1200, ACC99D) 88

Communication Modules and Parts 88

Pedestal Controllers (ACC1200PP, AGC1200PP, ACC99DPP, AGC99DPP) 89

ACC/AGC Central System Components

(ACC1200, ACC99D, ACC1200PP, AGC1200PP, ACC99DPP, AGC99DPP) 89

INDEX 90

Page 8

INTRODUCTION

The ACC controller, in its many modular configurations, is Hunter’s premium industrial-grade controller for high-performance irrigation control. Its primary purpose is to operate 24 VAC irrigation solenoids or low-draw solid state relays

for specific durations at specific times. It can also be connected to various sensors, providing automatic shutdown and

notification in case of emergencies, and actual flow records and responses in real time.

With plug-in Com and other modules, the ACC can also communicate with a computerized central control system via

hardwired cable, radio, dial-up telephone, or cellular modem. ACC is also prewired to accept Hunter wireless remote

controls.

• This product should not be used for anything other than what is described in this document.

• This product should only be serviced by trained and authorized personnel.

• This product is designed for continuous outdoor use above sea level to 15,000 feet/4.5 km at temperatures 32–122˚ F.

• These units have an IPX4 rating.

• This controller is not intended for use by young children or infirm persons without supervision; young children

should be supervised to ensure that they do not play with the appliance.

• Hunter Technical Support: 1 (800) 733-2823

1

Page 9

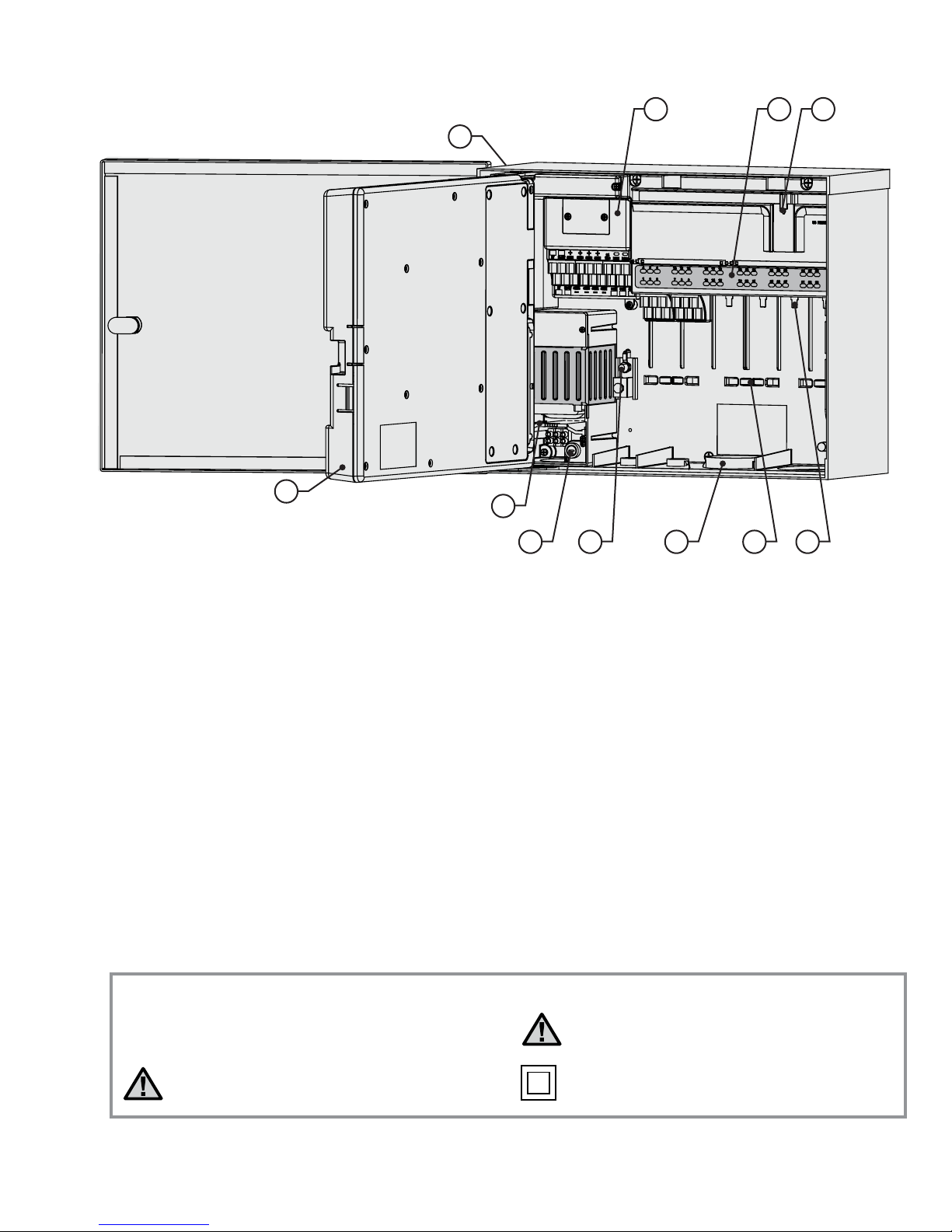

aCC InTerfaCe and Key ComponenTs .......................................

1. LCD Display – Backlit, adjustable contrast display

(re-lights when any button is pressed)

2. + Button – Increases flashing value, depending on

function

3. – Button – Decreases flashing value. Most items in

ACC screens “wrap” so that you can continue in either

direction through all the choices

4. Copy/Learn Button – Copies a time or value in a

flashing field, for pasting into similar fields. Also used

to learn typical flow (when a flow sensor has been

installed)

5. Paste/Pause Button – Pastes a copied time or value

into a new field. Also used as Pause/Resume feature

during watering, shuts off devices for 30 minutes or

until resumed

6. Programs Button – Selects one of the automatic

Programs (A-F), starts Test program, allows Reset

(with Reset button)

7. Up and Down Arrow Buttons – Used to move up and

down through adjustable functions in various screens,

and to select higher or lower numbered items

8. Left and Right Buttons – Used to move left and right in

some screens

9. Information Button – Lights display, and provides

instant help and other information, depending on dial

position. Also used to access Extended Features, when

held down while turning to specific dial positions

10. Programming Dial – Used to access all functions of

ACC. The most basic automatic watering can be set up

in the first 4 dial positions

11. Reset Button – Recessed switch erases some or

all memory when combined with pressing specific

buttons

12. Facepack Release Button – Hold down while removing

facepack from inner door panel

13. Door Grip – Convenient finger grip for opening inner

door

14. Logo Badge – Removable for installation of optional

communications modules

14

1

9

7

12

8

13

10

2

11

2 3 4 5 6

Page 10

WIrInG ComparTmenT InTerIor ................................................

7 89

10

1

1. Inner Door – Opens to main wiring compartment

2. AC Wiring compartment – For connection of 120/230V

AC power with 1 x 0.75" (19 mm) conduit opening

3. Fuse – 2 Amp (fast) 250V, 6 x 20 mm

4. Conduit Openings, Low Voltage – 2" x 2½" (64 mm),

2" x ¾" (19 mm)

5. Wire Tie Holders for Valve Wires – Valve wiring area

6. Station Output Terminals (Valve Wires) – screw

terminals on 6-station output modules

7. Upper Deck Panel with Led Status Indicators –

Numbered station lights, green for active, red for faults

8. Sliding Lock for Output Modules – Permits addition

or removal of output modules, locks wired modules

in place

2

3 4 5 6

9. Master Module – Includes sensor, Pump/Master

10. SmartPort® – Integrated connector for ICR/SRR

11. Earth Ground Lug – For connection of earth ground

11

Valve, and other accessory connections

receiver (on side of cabinet)

copper wire (for surge protection only). Do not

connect valve commons – see Master Module for

Common wiring of solenoids and valves.

Explanation of Symbols

AC

~

Consult Documentation Double Insulated

3

Hazardous Voltage Present

Page 11

meTal CabIneT, Wall mounT InsTallaTIon ...............................

31" (80

cm

)

F

acepac

k Door

Tools required:

• Long drill bit and extension

• Philips screwdriver or bit (for use with long

extension) – magnetic recommended

• Wire strippers

Location Requirement: A) a switch or circuit-breaker

shall be included in building installations; B) the switch

or breaker shall be in close proximity to the controller,

and within easy reach of the operator; C) the switch or

breaker shall be marked as the disconnecting device for

the controller.

Avoid direct exposure to sprinkler spray.

Do not install controller within 20" (7 m) of

high-voltage electrical sources, such as service

transformers, pump station motors, etc.

Shaded or partially shaded areas are preferable to

prolonged direct sunlight.

The ACC controller is relatively heavy, about 30 lbs/13.6 kg

in the metal wall mount configuration. Mounting includes

a positioning hanger to assist with installation.

Mounting hardware has been included, but it is the

installer’s responsibility to insure that adequate hardware

is used for the physical location.

ACC is approximately 15½" (40 cm) wide. Allow another

15½" (40 cm) to the left of the controller for the door to

open freely.

Before mounting, it is easier to remove the metal cabinet

door. Swing the door open, grasp the top securely, and

push up on the bottom of the door, near the lower hinge.

The hinges should disengage and the metal door can be

removed.

Positioning Hanger

Mounting Holes

Remove the facepack assembly from the controller.

1. Open the facepack door using the recess on the

right.

2. Disconnect the gray ribbon cable from the back of

the facepack. Pull gently on the ribbon cable; a slight

rocking motion may help disengage the connector.

3. Push up on the upper door hinge, and tilt the door

so that it disengages the hinge posts. Remove the

facepack and set aside in a safe location.

4. OPTIONAL: Locate the positioning hanger in the

upper center of the controller’s location on the wall,

leaving adequate clearance for the opened door to

the left.

5. Drill a pilot hole for the anchor and insert.

6. Install one #10 (5 mm) screw in this hanger position,

leaving approximately ¼" (6 mm) out of the anchor

to allow the controller to hang from this screw.

7. Hang the controller from the keyhole slot in the

positioning hanger.

8. Place a level on the top of the controller cabinet and

level.

9. Locate the 3 mounting holes in the cabinet. These

are visible from the front, with the facepack

removed, in deep recesses in the top two corners,

and another shallow recess in the bottom center.

10. Mark each of these 3 locations and install anchors.

11. Reposition controller on the hanger and use a long

screwdriver or drill extension (3"/75 mm) with

magnetic tip to install the remaining 3 screws, one

at each anchor position, and secure.

4

Page 12

ConneCTInG aC maIn poWer, Wall mounT CabIneT .................

The ACC can operate with either 120 VAC or 230 VAC power,

depending on how the incoming AC wires are connected.

Supply wires must be 14 AWG (2 mm) or larger.

The ACC is prewired for 120V operation but can easily be

changed to 230V.

Consult or hire a licensed electrician for these connections

as required.

• Turn AC power off at the source, and verify that it is

off.

• Remove the wiring compartment screws and the

wiring compartment door.

• Strip approximately ½" (13 mm) of insulation from the

end of each of the AC power wires, and route into the

wiring compartment through the conduit.

• Locate the white plastic terminal block, and wire

according to the following diagrams.

For 120V~ operation, connect the incoming black power

wire (hot) to align in the wiring block with the black wire

lead from the transformer.

Tighten screw and replace cover.

For 230V~ operation, connect the incoming power

wire (hot, brown in many wiring standards) to align

in the wiring block with the brown wire lead from the

transformer. Connect the incoming Neutral (blue in some

international standards) wire to align with the blue lead

from the transformer. Tighten screws and replace cover.

Apply AC~ power and test. Refer to Earth Ground and

Station Wiring sections for additional connections.

The green, or green-and-yellow safety ground

may not be required or permitted with this

floating ground, double-insulated transformer.

If desired and permitted, connect it to the earth

ground lug on the controller. Install a conduit

junction T-box below the supplied junction box

in the controller, and route the safety ground

out of the T to the earth ground lug of the

controller.

Insert the incoming black wire lead into the hole opposite

the black transformer wire and tighten screw securely.

Connect the incoming neutral (white) wire to align with the

blue lead from the transformer.

Cap off the brown (230 VAC) wire if applying 120V and not

using a wiring block. The brown wire will be hot and have a

230V charge.

Black (120 VAC)

Brown (230 VAC)Blue (Neutral)

ACC Transformer

Blue (Neutral)

Black (120 VAC)

Brown (230 VAC)Blue (Neutral)

ACC Transformer

Brown (230 VAC)

Black (120 VAC) U.S.White (Neutral) U.S.

or Blue (Neutral) Int'l

5

Page 13

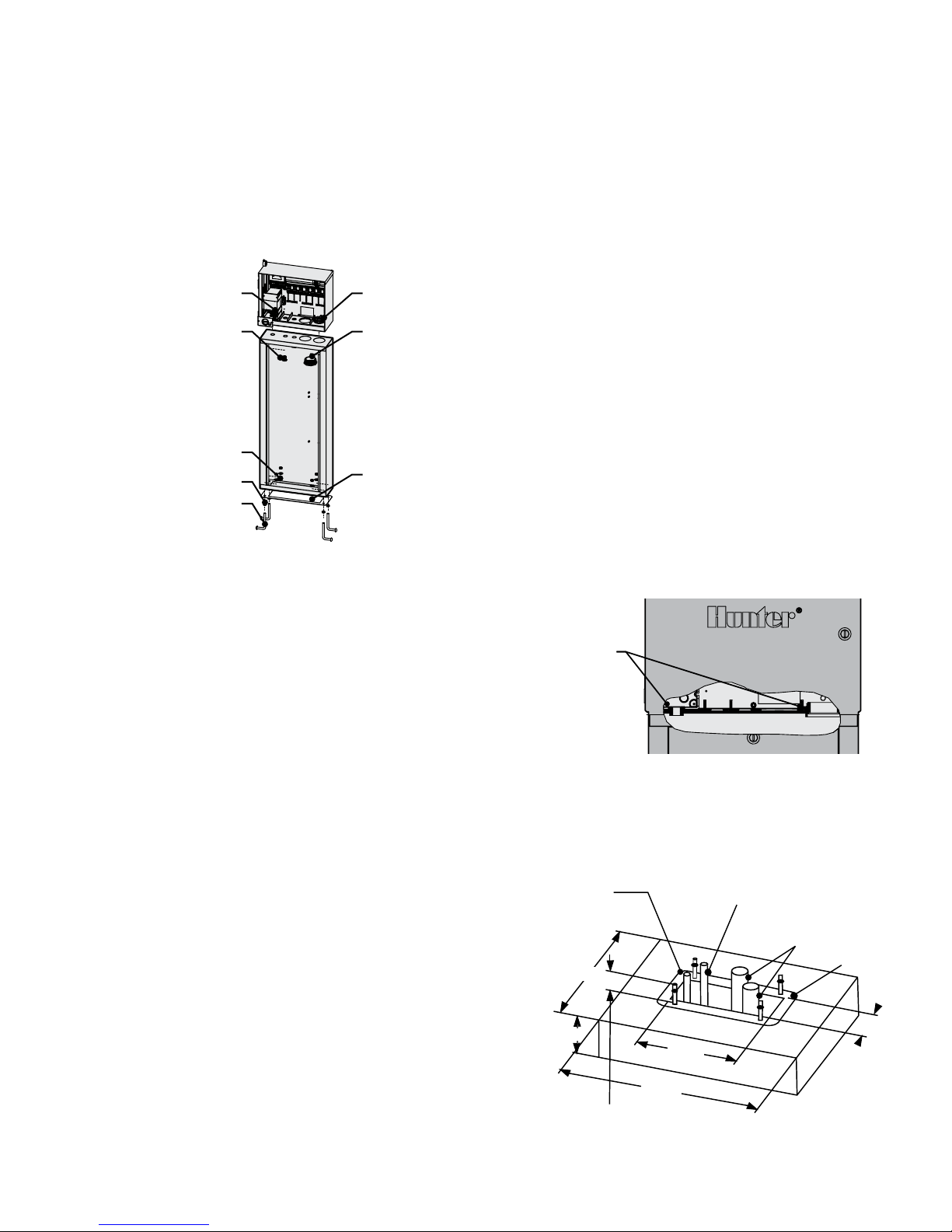

meTal CabIneT opTIonal pedesTal InsTallaTIon .....................

Conduit Nuts

GCBL Wiring (Required for IMMS)

Location Requirement: A) a switch or circuit-breaker

shall be included in building installations; B) the switch

or breaker shall be in close proximity to the controller,

and within easy reach of the operator; C) the switch or

breaker shall be marked as the disconnecting device for

the controller.

½" Conduit Nut

½" Conduit Nut

2" Conduit Nut

2" Conduit Nipple

¾" Washer (4)

³∕8" Mounting Nut (8)

Mounting Plate

³∕8" Mounting Bolt (8)

Installing the Pedestal

1. Assemble the mounting template using the

instructions provided with the pedestal.

2. Using the enclosed mounting template, locate the

bolts two inches deep in the concrete pad, in the

locations indicated. The pad can be any size but at

least a two-foot square is recommended.

3. Level the mounting bolts before the concrete sets.

4. After the concrete sets, remove the door of the

pedestal and slide the pedestal down onto the four

bolts. Secure the pedestal to the bolts using the

enclosed washers and nuts.

5. Remove the door and faceplate of the ACC and

attach the metal cabinet of the ACC to the top of the

pedestal using the ½" (13 mm) and 2" (50 mm) metal

conduit nuts in the pedestal. Tighten securely by

engaging teeth with a screwdriver and tapping in a

clockwise direction.

CONNECTING THE METAL PEDESTAL MAIN AC POWER

1. Connect AC power wiring as in the metal wall

cabinet. Route the AC power wiring through

the metal pedestal and up into the ACC wiring

compartment. Follow the AC wiring instructions for

the metal wall cabinet closely.

2. Replace the pedestal door first and then replace the

faceplate and the cabinet door. The pedestal door

cannot be removed or replaced when the cabinet

door is closed.

Refer to Earth Ground and Station Wiring sections for

additional connections.

plasTIC pedesTal InsTallaTIon .................................................

Select a location for installation of the controller based

upon these factors:

1. Availability of 120/230 VAC~ power.

2. Do not locate under overhanging branches of trees

or any structure that may attract lightning.

3. Avoid locations where sprinklers spray upward onto

4. Locate controller in a location that is central to all

6

the controller, and low areas subject to flooding.

valves/sprinklers that it controls to maintain visible

operation and reduce wire

lengths/costs.

AC Power Wire S/P

(3" Max Above Concrete)

21" Min

4"

Thread Length 2.50" Min

Above Concrete

(3" Max Above Concrete)

Field Wiring

(3" Max Above Concrete)

Template

5.00"

12.50"

26" Min

Page 14

ConCreTe base InsTallaTIon ....................................................

1. Set forms for a 21" (533 mm) wide x 26" (660 mm)

long concrete base. The base pad should be 2" (50

mm) above grade for proper drainage.

2. Position a 1½" to 3" (38 to 76 mm) diameter conduit

sweep elbow for the field wires (size will vary

depending upon the number of valve wires entering

the controller), a 1" (25 mm) conduit sweep elbow

for the power supply, and a 1" (25 mm) conduit

sweep elbow for any communication wires, if

applicable. Secure the sweeps so they will enter the

bottom of the controller correctly.

3. Allow approximately 3" (76 mm) of conduit above the

surface of the concrete pad.

4. Shape the concrete base to shed any water away

from the controller.

5. Prepare the template for insertion in the concrete.

Twist one nut on each of the four J-bolts to the

bottom of the thread and slide each bolt through the

hole in the template. Put a washer and nut on each

J-bolt to secure it to the template (allow a minimum

of 2½" (63 mm) of thread protruding above each

nut).

6. Work the J-bolts down into the concrete until the

template sits level on top of the concrete. Smooth

and allow the concrete to cure (at least 24 hours).

NOTE: It is important with plastic pedestals to

ensure a smooth mounting surface. Uneven

surfaces may cause the pedestal to distort,

preventing proper sealing of the doors.

7. Remove the nuts and washers from the concrete

base. Place the pedestal over the bolts and secure

with nuts and washers.

NOTE: Remove both doors and lift the pedestal from the

main body. Two people are required for this task.

7

Page 15

ConneCTInG plasTIC pedesTal aC maIn poWer ........................

The ACC Pedestal controller can operate with either 120

VAC or 230 VAC power.

Supply wires must be 14AWG (2 mm) or larger.

The controller power must be connected to a branch circuit

protected by a 15 A rated over-current protective device

(circuit breaker, fuse, etc).

With the main AC power OFF, route the AC power wires from

the supply panel through the sweep elbow placed for this

purpose in the concrete pad.

Do not route low voltage wiring with the AC power wires in

the same conduit.

Locate the junction box below the transformer assembly on

the left side of the controller. The AC power connections are

made to the terminal block inside this junction box.

Route the AC power lines through conduit (if applicable)

into the junction box.

All connections are to be made by qualified electrical

personnel, only. Local electrical codes must be followed

and may vary, depending upon country, state, and local

codes.

120 VAC CONNECTION

Place the Voltage Selector Switch in the “115V” position.

Connect the incoming black (or “hot”) wire to the Red wire

from the controller transformer. The Red wire is labeled

Hot, Phase, and Active. Connect either with the supplied

terminal block, or with approved high voltage electrical

wire nuts. If using wire nuts, tape the connection securely

with electrical tape.

Connect the incoming white wire (neutral) to the blue wire

from the controller transformer (labeled “Neutral”), either

with the terminal block or approved wire nuts. If using

wire nuts, tape securely.

The green or bare copper safety ground is not required

with this UL listed floating ground, double-insulated

transformer. If desired, you may connect it to the earth

ground lug on the controller. Install a conduit junction

T-box below the supplied junction box in the controller,

and route the safety ground out of the T to the earth

ground lug of the controller.

230 VAC CONNECTION

Place the Voltage Selector Switch in the “230V” position.

Connect the incoming Brown power wire to the Red wire

from the controller transformer, with the supplied terminal

block. The Red wire is labeled Hot, Phase, and Active.

Connect the incoming Blue power wire to the Blue wire

from the controller transformer at the terminal block. The

Blue wire is labeled Neutral.

The green, or green-and-yellow safety ground may not be

required or permitted with this floating ground, doubleinsulated transformer. If desired and permitted, connect it

to the earth ground lug on the controller. Install a conduit

junction T-box below the supplied junction box in the

controller, and route the safety ground out of the T to the

earth ground lug of the controller.

Place the connections up into the junction box through the

opening in the bottom. Secure conduit if applicable.

Turn breaker power on, then turn the controller power

switch on and test.

The controller is equipped with a 6 x 20 mm, 250V, 2 Amp

fast-blow fuse on the transformer assembly. Incorrect

power wiring may cause this fuse to open. Check wiring and

incoming power if the fuse opens when power is turned on.

8

Page 16

Junction

Box

Voltage Selector

Switch

Controller Power

Switch

Terminal Block:

Red Wire =

"Hot" or Active

9

120V Black

230V Brown

Terminal Block:

Blue Wire =

Neutral

White (US)

Blue (International)

Page 17

ConneCTInG earTh Ground (all ConfIGuraTIons) ...................

The ACC features a copper earth ground lug, to the

immediate right of the transformer assembly.

This earth ground connection is isolated from the primary

AC power and is used to ground incoming surges from the

communications and output valve wires.

With the controller power Off, loosen the slotted screw in

the center of the ground lug.

Route a bare 6 AWG (4.11 mm) earth ground wire into the

wiring area through the 0.75" (19 mm) conduit opening

directly beneath the ground lug, in the bottom of the

controller cabinet. Do not route the ground wire through

the same conduit as the incoming primary AC power!

Loosen the ground lug screw, insert the ground wire into

the ground lug and tighten the screw to secure the ground

wire. Do not overtighten.

Grounding hardware should be selected according to

standards established by American Society of Irrigation

Consultants Earth Grounding guideline 100-2002

(available at their website, www.asic.org).

Acceptable grounding consists of an 8' (2.5 m)

copper-clad rod or stake, or a 4" x 96" (100 mm x 240 cm)

copper plate, or both, placed in the earth at least 8' (2.5

m) away from the controller, and with the ground wire at

right angles to the communications and valve wires, if

possible. Ideal grounding resistance would be 10 Ohms

or less as measured with a “megger” or similar device.

Please consult the ASIC reference for more detailed

considerations of this critical step.

Ground Lug

Ground Wire in

½" (13 mm) conduit

Improper connection to earth ground voids the

effectiveness of the output module surge protection.

10

Page 18

InsTallInG sTaTIon modules.....................................................

Station Modules

ACC expands in 6-station increments with intelligent output modules, requiring no tools to install and only a screwdriver

for station wiring connections. The base configuration is 12 stations (two 6-station modules installed) with a maximum

station capacity in a metal wall cabinet of 42 stations (7 total output modules x 6 stations each).

ACC can be expanded at any time with either of the following types of modules:

1. ACM600, 6-station output module with surge suppression and diagnostic LEDs

2. AGM600, 6-station output module with heavy-duty surge suppression and diagnostic LEDs

These two types of modules may be mixed within the same installation if desired.

OUTPUT MODULES (ACM600, AGM600)

A. Station Output Screw Terminals – Connect no more

than two solenoids each.

B. Station Status LEDs – Green for station activity, Red

for fault or short

C. Locking lugs – For module lock

D. Gold plated electrical contacts – Lower rear of

module

E. Additional surge components, AGM versions –

Visible through module

D

1. To install expansion modules, turn the dial to the

“Run” position.

2. Open the inner facepack door, and locate the module

lock. Slide the module lock to the “Power Off”

position.

3. Flip up the upper deck cover. Slide the modules up,

into the next available position, viewed from left to

right. Do not skip slots by leaving them empty.

4. Install a module by aligning it firmly in the lower

portion of the next available slot and sliding straight

up until it clicks into place. Once module is in place,

slide power bar to the "Power On" position. The

first two lights of the bottom and top row of each

module installed will light up red for 1 second,

indicating proper contact and the new module has

been recognized. The red lights will then turn off, in

sequence, from left to right across the modules that

are installed.

5. The silver contact on the back of the controller

cabinet must engage a mating slot in the back of the

expansion module. Do not “tip” or force the module

into place. Slide straight up, from the bottom of

the slot.

6. While at the Run dial position, press the Information

button. The current station size will be shown, and

should include any new modules you have added.

B

A

E

ACM600

6-station output

module

11

6-station output module with

heavy duty surge protection

C

AGM600

ET FLOW SEN4 SEN3 SEN2 SEN1

ET FLOW SEN4 SEN3 SEN2 SEN1 COM

US PATIENT NO 6,842,667 B2

24

VAC

P/M1 P/M2

4 5 6

10 11 12

16 17 18

22 23 24

28 29 30

34 35 36

1 2 3

7 8 9

13 14 15

19 20 21

40 41 42

25 26 27

31 32 33

3837 39

Page 19

CONNECTING THE VALVE WIRES

A

B

C

D

E

ACM600

6-station output

module

AGM600

6-station output module with

heavy duty surge protection

Each station output module has 6 screw terminals for

connection of individual station wires. The terminals will

accept from 22 AWG (0.64 mm) to 12 AWG (2.05 mm) wires.

Each station output is rated for 0.56 A, max or enough to

operate two typical Hunter solenoids simultaneously.

Decoder Output Module

Upper Deck cover

Once the output module is installed in the slot, the station

numbers assigned to the output module appear in the

upper deck label above each slot.

1. The modules may be removed, if necessary, without

2. Connect the return wires from the valves to one of

3. Route valve wires between control valve location and

4. At valves, attach a common wire to either solenoid

5. Open hinged faceplate on the controller to access the

6. Route valve wires through the conduit and attach

7. Strip ½" (13 mm) of insulation from ends of all wires.

DECODER OUTPUT MODULE (ADM99)

A. Two Wire Path Terminals – Connect no more than

B. Status LEDs– Decoder Fault, Module/Line Activity,

C. Locking Lugs

D. Gold-plated Electrical Contacts

E. Programming Port – Port where decoder wires get

disconnecting the field wiring. However, they must

be reinserted into exactly the same slot, or the

station addresses will be switched.

the 3 terminals on the Master Module marked COM.

Since many valve solenoid wires will need to connect

to these 3 common terminals,

controller.

wire of all valves. This is most commonly a white

colored wire. Attach a separate control wire to

the remaining wire of each valve. All wire splice

connections should be done using waterproof

connectors.

terminal area.

conduit to the controller at the large conduit

openings on the right side of the bottom of the

cabinet.

Secure valve common wire to COM (Common)

terminals on the Master Module. Then attach all

individual valve control wires to appropriate station

terminals.

one pair of red and blue wire paths to each output

terminals

Communicating, Line Status

plugged into in order to program the decoder

Slide ADM99 in

first 3 slots

ADM99 Decoder

Output Module

1. Decoder output modules may NOT be mixed with the

“conventional” ACM/AGM-600 output modules.

2. Decoder output modules are always installed in the

first three slots.

3. Install the ADM99 by aligning it firmly into the first

three station module slots, and sliding straight up

until clicks into place. As soon as the ADM99 is slide

into place, the Module/Line Activity light will light

red for one second, and then the Line Activity light

will illuminate green. Unlike the station modules,

the ADM99 will illuminate the status lights with the

power bar in the "Power Off" position.

CONNECTING DECODER OUTPUT PATH WIRES

Up to 99 stations may be operated over a single pair of

wires (known as a “path”) using decoders. The decoder

output module allows up to 6 two-wire paths to the field

decoders. The maximum number of decoder stations is

still 99, but multiple paths allow the shortest wire runs.

You may use any number of paths to reach all 99 stations.

12

Page 20

Each path should consist of Hunter Industries Model

IDWIRE1 or IDWIRE2 color-coded decoder wire. This is

a twisted, solid-core wire suitable for direct burial, and is

always color-coded red and blue.

separate at the end of each two-wire run. Simply insert

decoders in the path until complete, and stop at the

last decoder on the path. If this is not possible, simply

cap each of the ends of the two wire path with a DBR6

waterproof connectors or equal.

All red/blue connections in the two-wire path must be

made with DBR6 waterproof connectors or equal.

Do not connect a wire path from one controller to another

controller!

Each path has a red and a blue terminal with its number on

the decoder output module.

When a decoder output module is installed, the controller

facepack will recognize it and the station size will change

1. Route decoder path wires through the conduit into

the wiring compartment. Leave adequate slack in the

wires for thermal contraction.

2. Strip ½" (13 mm) of insulation from the red and blue

to “99” (regardless of how many stations are in use). This

will also unlock the normally Extended Decoder displays in

the following dial positions. See DECODER OPERATIONS

(ACC99D VERSIONS) on page 56 for more information.

ends.

3. Connect the red wire to the red “1” terminal, and the

blue wire from the same pair to the blue “1”. Repeat

for any other paths as needed.

Do not connect the paths in a loop, or back to any other

point in the controller. Leave the red and blue paths

Key ConneCTIons .......................................................................

4

5

2

3

67

8

1

1. Common Ground Terminals (x 3) – For return wires

(often white) from stations and master valves. Field

wiring may be returned to any of these 3 terminals

2. P/M1 – Pump/Master Valve output 1, and status light

(return Pump/Master valve circuit to any of the 3 Com

common terminals). Output is 0.320 Amps max

3. P/M2 – Pump/Master Valve output 2, and status light

(return Pump/Master valve circuit to any of the 3 Com

common terminals). Output is 0.320 Amps max

4. Hardwire terminal connection cover – Remove

to install optional ACC-HWIM for hardwired

communications.

5. 24VAC – Always-on 24V test terminal, for locating

valves in the field. Can also be used to power low-draw

sensor receivers such as Hunter WRC. Output is 0.420

amps maximum

6. Flow Sensor connections (+ and -) – Connections for

Hunter HFS flow sensor

7. ET connections (+ and -) – Not used. Connections for

Hunter ET Sensor only. If upper ET terminal is colored

red, Master Module requires update for use with ET.

8. If Master Module has a sticker that says “ET Ready,” or

if the version number of the module is 4.0 or later, the

Master Module is ET ready

9. Sensor Connections (1-4) – Connections for up to 4

Clik-family sensors, or other normally closed switch

contacts

13

Page 21

24 VaC TesT TermInal ................................................................

The Master Module features a “constant-hot” 24 VAC

output which can be used as a test point for locating

valves in the field:

1. After powering up the controller, attach the common

wire to the COM terminals as described above.

2. Touch each wire to the terminal marked 24 VAC to

identify the valve location.

3. Each valve will open electrically when the wire is

touched to the 24 VAC terminal.

4. After identifying the valve location, you may then

insert the wire into the appropriate terminal. This

feature allows you to sequence the valves in the

most logical order for the user without damaging the

controller by “sparking” the wires.

5. The 24 VAC terminal may also be used to power

wireless Clik sensor receivers. See Connecting a

Rain Or Freeze Shut Off Device on page 14 for more

information..

ConneCTInG The masTer ValVe(s) and/or pump sTarT relay(s)

The Pump/Master valve connections are located in the

upper right of the Master Module, which is in the upper left

corner of the controller itself.

Locate the P/M1 and P/M2 screw terminals on the Master

Module. These outputs are designed to supply 24 VAC,

0.320 A max, for a single Master Valve solenoid or a Pump

Start Relay (or Relay Booster).

The return wire from each P/M device (solenoid or relay)

must be connected to one of the COM terminals on the

lower terminal strip of the Master Module.

Connect one output wire from each Pump relay or Master

Valve solenoid to the desired 24 VAC P/M terminal.

Connect the return wire to one of the terminals marked

COM immediately below the P/M outputs.

Configuration of the P/M terminals is covered in the

Set Pump Operation section of the Programming and

Operations portion of this manual.

ConneCTInG a raIn or freeze shuT off deVICe .......................

Up to 4 Hunter sensors can be connected to the ACC

controller, including:

• Mini-Clik

• Rain-Clik™ (including Wireless Rain Clik)

• Freeze-Clik

• Mini-weather station

Hunter Flow-Clik™ can also be connected, but it is

recommended that the HFS be used instead.

In the ACC controller, Clik sensors shut down individual

programs, not necessarily the entire controller. Each

sensor can be given its own response instructions by

program.

®

®

Hunter Clik sensors are usually normally closed, and open

on alarm. This signals the controller to suspend irrigation.

Other dry contact closure sensors can be used without

warranty, provided that a.) they require no voltage; and

b.) open the circuit when a shutdown condition is sensed.

Hunter makes no claims or representations that such

connections will be effective.

1. To connect Clik sensors, locate the SEN [1-4]

terminals on the Master Module (upper right corner

of controller).

2. Route the pair of wires from each sensor into the

cabinet through one of the low voltage conduit

openings in the bottom of the enclosure.

14

Page 22

3. The sensor connections are made in dedicated pairs:

one wire to the sensor number + terminal, the other

wire from the sensor to its – terminal. Do not twist

common wires together from different sensors and

connect them to the same terminal.

4. Loosen the screw for the first sensor terminal

(SEN1), and connect either of its wires to the +

terminal and tighten.

5. Connect the other wire from that sensor to the SEN1

– terminal and tighten.

6. To connect the wireless Rain Clik (WRC) or wireless

Rain-Freeze Clik receiver, consult the instructions

supplied with the WRC for mounting and addressing.

7. Connect either of the receiver’s Yellow power wires

to the “24 VAC” terminal on the Master Module (the

“24 VAC” terminal has a 400 mA maximum capacity

and is adequate for Clik receivers).

8. Connect the other Yellow receiver wire to any of the

COM terminals.

9. Complete the wireless Clik installation according to

the WRC instructions.

All additional programming is performed at the facepack

and is described in the Set Sensor Operation section of

Programming and Operations.

ConneCTInG The hunTer floW sensor .....................................

The HFS is the primary flow meter for which ACC flow

functions have been designed. Additional types of flow

sensor connections may also be possible. Consult flow

sensor manual for wiring and calibration information.

1. To connect a HFS, route the pair of 18 AWG (1 mm)

wires from the sensor into the cabinet through one

of the low voltage conduit openings in the bottom of

the enclosure.

2. Locate the “Flow” red and black coded terminals

near the left side of the Master Module. Connect the

red wire from the HFS to the red terminal, and the

black wire from the HFS to the black terminal.

3. Reversing the red and black connections will

probably not damage the units, but will not allow the

ACC to read flow.

4. Flow setup, learning, and configuration is described

in the Set Flow Monitoring section of Programming

and Operations.

15

Page 23

ConneCTInG oTher floW sensors ............................................

Some other brands or models of flow sensors may be

compatible with the ACC controller. One known-compatible model is Data Industrial model IR-220B (also sold as

Hunter model GENDATFL).

NOTE: The ACC flow sensor connection is a 20 VDC pulsed

output which senses interruptions as “clicks”. It is DC

voltage, and the polarity must be observed.

The red + terminal corresponds to the red wire on the HFS

sensor, and if connecting to other brands of sensor insure

that correct polarity is observed.

Connect the positive (+) wire to the red Flow terminal on

the Master Module, and the negative (–) wire to the black

terminal.

ICr remoTe ConTrol .................................................................

The ACC controller has an integrated SmartPort®‚ on

the cabinet’s upper left side, or inside the front panel of

the plastic pedestal. This connection is automatically

compatible with Hunter ICR and SRR remote receivers.

To connect: remove the weather-resistant rubber cover

(metal cabinet versions), align the remote receiver’s

pins with the mating receptacle, and push firmly until

the receiver is fully seated. If the ET System adapter is

installed, plug the receiver into the mating connector on the

adapter.

If the receiver address is to be changed, hold in the green

button while plugging the receiver into the SmartPort, in

accordance with the ICR instructions.

Refer to the remote control’s instructions for additional

addressing and operations. However, there are some

significant differences in operating the remotes with the

ACC controller, from previous Hunter controllers.

When a program or station is started by ICR, the ACC

display will (as always) show why the program or station is

running. Remote starts are followed by “ICR” in the display

(Fig.1).

To set up an ICR remote control for operations with ACC,

consult the ICR instructions. Use the Mode button on the

ICR transmitter to select a station size of “240” to allow

access to all ACC programs and stations. Only ICR Remotes

manufactured September 2006 or later are compatible with

ACC. If you have an older ICR remote, the maximum station

size is 48. Therefore, if you are using an older remote and

an ACC decoder controller, the highest station you will be

able to control is station 48. You must obtain a newer ICR

to operate correctly with any ACC controller.

MULTIPLE STATIONS SIMULTANEOUSLY

ACC is an overlapping controller, and will allow up to

6 stations to run simultaneously. While other Hunter

controllers will stop existing stations when a new ICR

remote start command is received, the ACC will continue to

run existing stations along with the new stations, until the

maximum of 6 events has been reached (Fig. 2). If 6 events

are running and an ICR command is received to start another,

the command will be ignored. No new remote commands will

be accepted until one of the 6 events times out.

Figure 1

Figure 2

16

Page 24

ACC can therefore run automatic programs, manual

Figure 3

station and programs, and ICR commands simultaneously.

Each running event will be shown on the display with

the reason for running (programs will be shown with the

program letter followed by “ICR” if they were started by

the remote), and the remaining time for the event.

The display shown here is possible with ACC: six events

are running, including ICR station starts (ICR), ICR

program starts (A-ICR), manual single-stations (MAN),

manual program starts (C-MAN), and an automatic

program (D-AUTO).

is not set to overlap, the ICR command will be ignored

when trying to start the manual program.

ICR manual single station commands will be obeyed

if the controller is in the OFF position, or in a sensor

shutdown mode. ICR manual program commands will

NOT be obeyed and will be ignored in the OFF position. If

the controller is in a sensor shutdown mode and an ICR

command is sent to activate a program, the ACC will obey

the sensor shutdown if that program is assigned to pause

or suspend according to the sensor. The manual program

ICR command will be shown in the display as in pause or

suspend mode, depending on how you have your sensor

programmed. (Fig 3) If the program that you are trying to

manually start with an ICR command is not programmed

to pause or suspend a sensor, the command will be obeyed

and the program will run.

If you are utilizing a simultaneous station group, or SSG,

you may run an individual station that is included in the

SSG. The fact that the station is included in the SSG will be

ignored, and you may run that station by itself.

If simultaneous operation is not desired, press the

Off button on ICR before starting another program or

station. Off will stop everything the controller is running,

regardless of what started it.

Stacking and SmartStack rules are not observed when

manual single station ICR commands are sent to the ACC.

Stacking and SmartStack rules do apply when manual

program ICR commands are sent to the ACC. If a program

ConneCTInG To Imms .................................................................

hunTer IrrIGaTIon manaGemenT and monITorInG sysTem

ACC controllers can upgraded to provide full two-way

communications with central control software (IMMS 2.0).

The ACC Com modules are installed in place of the logo

badge on wall mount controllers, and under the facepack

door in a special bracket (APPBRKT) in pedestal units.

ACC controllers can be connected with hardwired cable

(GCBL), dial-up telephone (POTS or “plain old telephone

service”), or GSM cellular communications (using Circuit

Switched Data or CSD).

Multiple controllers can share a connection, with

additional runs of hardwired cable or UHF radio

communications. Advance to Daylight Saving and use +/to select YES.

DIAL-UP TELEPHONE (ACC-COM-POTS)

Connection must be within 6 ft (2 m) of the telephone

company connection, via standard RJ-11 jack..

IMMS 2.0 and dial-up Com modules require analog lines

with dial tone. These products do not have digital dialing

capabilities.

Dial-up must be via dedicated line. The controller will

always answer on the first ring and must not share with

fax machines or other devices.

No tee splices are permitted within the GCBL and all

hardwired devices must be in one single continuous wire

run.

17

Page 25

CELLULAR/GSM (ACC-COM-GSM, GSM-E)

GSM cellular service must have reliable coverage at

installed site.

GSM service must permit and provide Circuit Switched

Data (CSD). IMMS 2.0 connections require CSD and will

use the Data telephone number. No other form of cellular

communications will work. There are no CDMA options for

ACC communications at this time.

UHF RADIO

All UHF radio communications require a license.

All radio communications for ACC work with RAD3 radio

module or later. IMMSR radios, designed for original

IMMS Site Interfaces and Controller Interfaces, will NOT

work with ACC controllers.

RAD3 radios are not supplied with antennas, but an

antenna must be provided for the radio to operate, and the

antenna must be installed outside of any metal enclosure

(including the ACC metal cabinet).

Radio communications for the ACC are only to

communicate with other ACCs, and do not provide

communications directly with a central computer. This

should be established with an IMMS-CCC and a hardwire

interface, or by telephone using ACC-COM-POTS or

ACC-COM-GSM (or GSM-E for international applications).

For golf applications using Surveyopr central control

software only, the AGCHUBR provides a direct radio

interface to all radio-equipped ACC/AGC controllers.

See Hunter’s ACC System Design Guide for important

details regarding design of central control systems.

poWer faIlures ........................................................................

The ACC’s real time clock is independent of external power

or the 9 VDC battery, and will keep time during a power

failure of virtually any length. When external power is

restored, the ACC will still have the correct time and will

be ready to irrigate.

A Power Outage message will be stored in the Alarm Log,

with time of the outage. Another log is stored when power

is restored.

QuICK sTarT ................................................................................

For experienced operators, the fastest steps to initial

programming are as follows.

1. Set Current Date/Time: Use the arrow buttons to

navigate, and the +/- buttons to change. Set the Date

and Time and choose Units of Measure.

2. Set Watering Start Time: Each automatic Program

has 10 start times. At this position, use the

Programs button to select individual programs,

and the 10 possible start times for that program will

appear. Use arrows to navigate and +/- to change

See SETTING PROGRAM OVERLAP OPTIONS on

page 36 for more information..

3. Set Station Run Times: At this dial position, use

the Programs button to select the program you are

setting up. Then, use the +/- buttons to change the

hours:minutes:seconds run time for each station.

Use the up and down arrows to move to the next

station. TIP: Use the Copy and Paste buttons to move

quickly through large numbers of similar stations.

Set the first station’s run time, then press Copy. Use

the Up arrow to move to the next station, and press

Paste.

4. Set Days to Water: Use the Programs button to

select the Program. Use the arrows to move to Day

Sched, and choose Schedule Type (Day of Week,

Interval, or Odd/Even).

5. Set Pump Operation (optional): The two Pump/

Master Valve outputs may be set by station at this

position. If no pump or Master Valve is in use, this is

not required.

18

Page 26

6. Return the dial to the Run position. This is all that

is required for the most basic operations. ACC will

water automatically in any dial position except

“OFF”.

7. Test: The Test program will start every station in the

controller sequentially, in numerical order, for the

specified time. The minimum time is one second

for conventional controllers, and 15 seconds for

decoder controllers. The maximum run time in Test

Program is 15 minutes per station. Turn the dial to

the Run position. Test is started by holding down the

Programs button for 3 seconds. Enter the Test time

and wait 5 seconds for the Test cycle to begin. Each

station LED on the output modules will light green

when a station is running, red if a fault is detected.

Decoder controllers cannot show individual station

activity , but the ADM99 lights will show activity on

the Communicating and Module/Line Activity lights

during operations.

Decoder controllers will start all 99 stations in the

test mode. It does not matter how many decoders

are installed in the field, the controller will try to run

all 99 stations. The controller will receive alarms

for any stations that are not present in the field, or

stations that are not assigned to a decoder. When

running the Test Program in a decoder controller,

you can manually end the Test by turning the dial to

Off after the last “real” station has run.

Test actually starts stations, and this will cause

actual watering in a fully installed system.

8. Manual Start: Turn the dial to the Manual Operation

dial position to manually start any Program, or

single station. When the display shows Manual

Program, use the Programs button to select the

Program, and turn the dial to the Run position. The

program will start in a few seconds. TIP: You can

also hold down the right arrow button for 3 seconds

to shortcut to Manual starts.

9. To start a Single Station: When “Program” is

flashing, use the + button to change to Manual “One

Station”. Use the down arrow to move to the station

number, and +/- to select a station. Use the down

arrow to move to the run time, and +/- to change

the run time (hh:mm:ss format, from 1 second to 6

hours). Turn the dial back to the Run position, and

the station will start within a few seconds.

ConTroller proGrammInG and operaTIon .............................

USING THE INFORMATION BUTTON

The Information button is used to provide programming

tips, summary information and/or to unlock extended

features, depending on the dial position. If a flow meter

is installed, press the Information button (with dial in the

Run position) to see actual flow at any time.

If the backlit display turns off while you are programming

(it will time out after 5 minutes of inactivity), press the

Information button to relight it (to prevent accidental

changing of any settings by pressing the other keys).

Pressing and holding the Information button will change

the screen to either a summary screen of that dial position

or will provide a programming tip. Releasing the button

will return you to the normal programming screen for that

dial position.

Some dial positions have extended features that are

accessible by holding down the Information button, and

then turning the dial to that position.

This will unlock the extended features. Extended

features are features that are protected from accidental

re-programming because they are critical to the proper

operation of the controller. Programming these extended

features is explained in the Extended Features section. The

ACC has the following Extended Features:

• No Water Window

• Delay between Stations

• Making the M/V circuit Normally On (instead of

Normally Off) and M/V circuit location (Controller or

ADM for Decoder controllers)

• Setting the Flow Sensor size and type

• Set individual station parameters (Flow, Limit, and

Delay) and flow sensor location (Controller or ADM

for ICD-SEN sensor decoder)

• Set sensor location: set each sensor to controller,

ADM for for ICD-SEN location, or ET for individual ET

sensors

• SSG (Simultaneous Station Group) setup

• Custom Manual program setup

• Test Program

• Easy Retrieve™ backup

19

Page 27

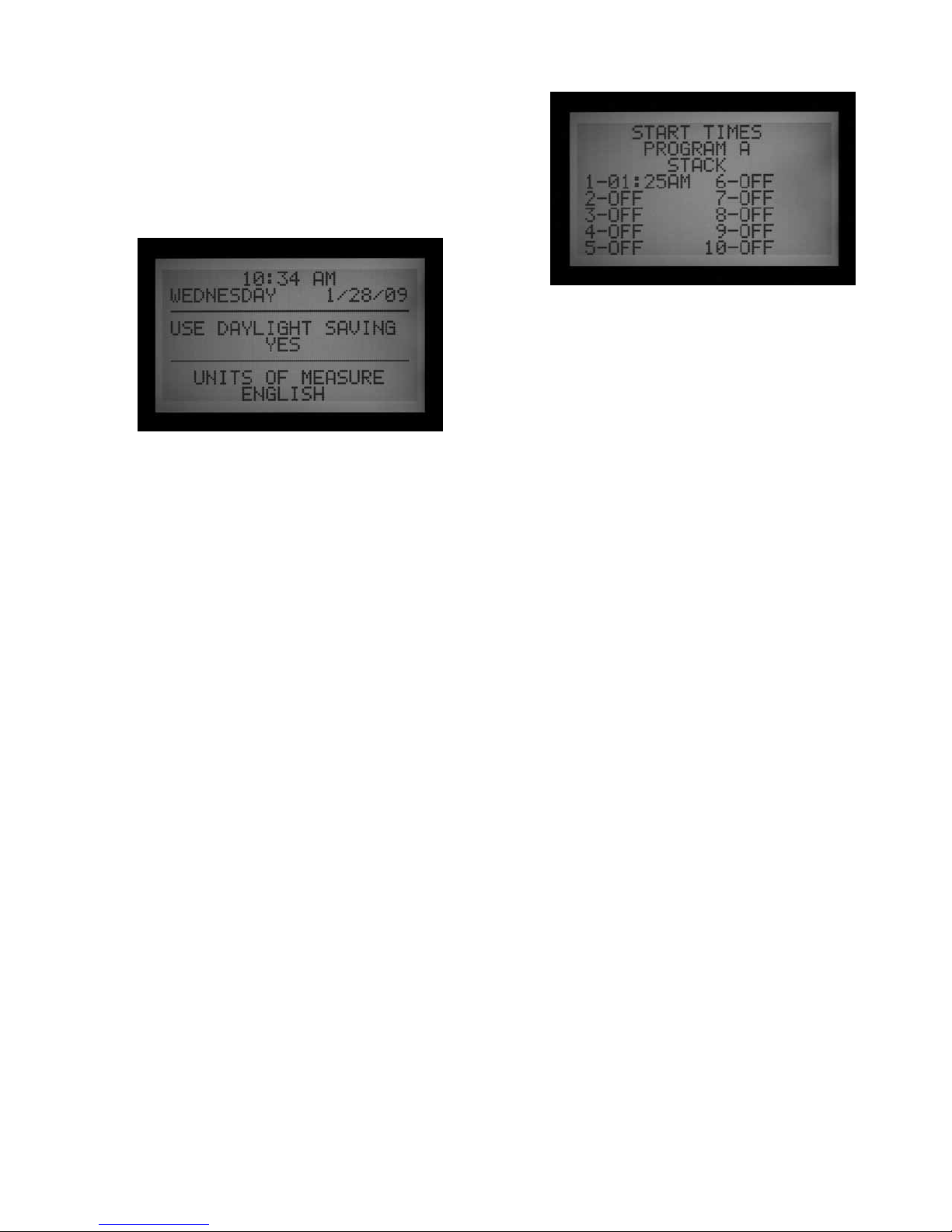

SETTING CURRENT DATE AND TIME

Three items are programmed at this position:

• Time of Day and Date, the day of the week sets

automatically

• Daylight Savings time usage

• Units of measure, English or Metric

Turn the dial to the SET CURRENT DATE/ TIME position

Press the + or – button to change the value of the flashing

cursor. Hold the button down to advance rapidly over a

large range of numbers.

Press the arrow buttons to change cursor position.

Set the hour and the minutes, then advance to the AM/

PM field. Use + or – to select AM, PM, or 24 hour clock

(international, or “military” time). If 24 hour clock is

selected, Program Start Times and other controller times

will also be displayed in 24 hour format.

Press the arrow buttons to advance and set the date in

MM/DD/YY format.

To Set Program Start Times

1. Turn the dial to the SET PROGRAM START TIMES

position

2. Select the Program (A – F) by pressing the Program

button

3. Press the arrow buttons to change cursor position

4. Press the + or – button to change the value of the

flashing cursor

5. Select Stack or Overlap for the Program. It is

important to know that if the setting within the Set

Program Overlap Options dial position is not set

to "Stack or Overlap," the option of selecting Stack

or Overlap (at the Start Times position) will not be

possible.

6. The copy and paste buttons may be used to speed

up programming (press the Copy button at any Start

Time position, then move to another position and

press the Paste button. The same Start Time will be

pasted there).

ACC Daylight Saving Time has been updated for the new

USA requirements. If set to Yes, time will offset one hour

forward at 2 AM on the second Sunday in March, and reset

("fall back") on the first Sunday in November.

Units of Measure: choose English or Metric. This will set

the unit type for the entire controller.

SETTING PROGRAM START TIMES

Three items are programmed at this position:

• Overlap or Stack start time priority

• Start times for each of the six programs (A – F)

• Extended Feature: No Water Window

20

Stacked Start Times

Stacking means that programs are not allowed to overlap;

if one Program is set to start before another Program has

completed, it will be pushed back (“stacked”) regardless

of its actual start time.

Each of the six programs (A – F) has ten start times

available, for a total of sixty available automatic starts. The

default is to stack the start times in alphanumeric order.

Program A will read Overlap, but all other programs will

read Stack. For instance, start time “Program A at 8:15

AM” would start before “Program B at 8:15 AM” because

A comes before B. The Start Time for Program B at 8:15

AM would start following the completion of Program A’s

watering.

Overlapping Start Times

Overlapping start times allows more irrigation to occur

simultaneously. Overlap starts Programs at their exact

Start Times, regardless of other Programs that may be

running (it is the opposite of Stacking). All six programs

can be programmed to Overlap and thus potentially run

simultaneously. This is great when a short watering

window is necessary and the hydraulics of the system

allows for high total water flow.

Page 28

CAUTION: Understand your irrigation system’s hydraulic

restrictions before allowing programs to overlap.

Overlapping programs may overdrive the hydraulics of

your system. Overdriving your hydraulics will damage the

components and result in inferior sprinkler performance.

More advanced programming overlap options are available

by turning the dial to the SET PROGRAM OVERLAP

OPTIONS dial position.

Normally, the cursor will be positioned at the first Start

Time hour position when turning the dial to the Set

Program Start Time position.

• To change the Stack/Overlap settings for the Program,

use the arrow key to navigate up to the Stack/Overlap

indication.

• Use + or – to change between Stack and Overlap.

• Use the arrow keys to move back down to the Start

Times if necessary.

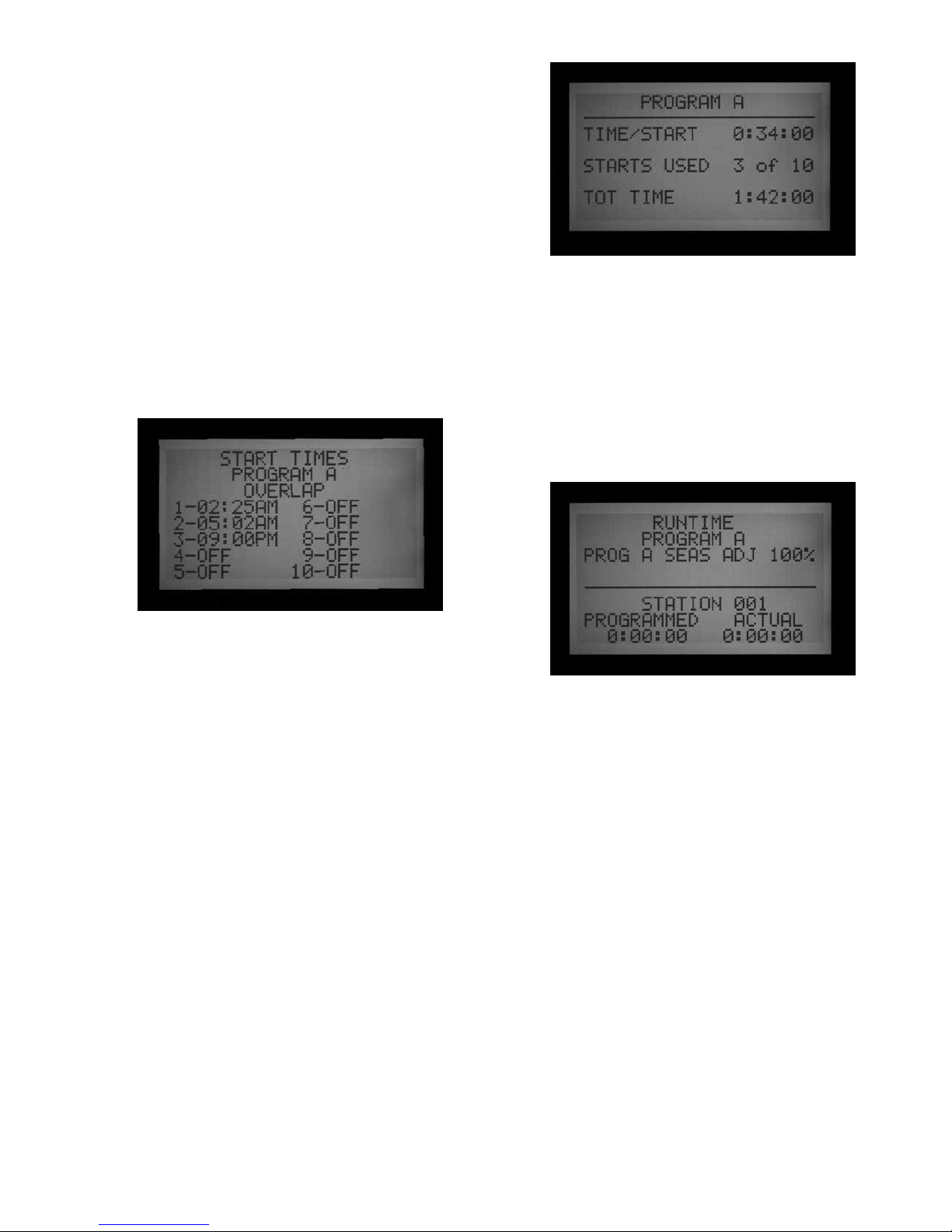

Press the Information button while in the Set Watering

Start Times position to show a summary of all Start Time

information for the selected Program. This will show total

station run time per start, number of starts, and total time

for the program.

No-Water Window

Programming this feature is explained in the Extended

Features section.

Multiple Start Times

To set Start Times for the Program, move to the Start Time

number, and use the + or – buttons to set the hour, then

minutes, and then AM/PM settings unless using 24-hour

option.

• If a Start Time is skipped (for example, a time is set

for 1, 2 is left at OFF, and a time is set for 3), the Start

Time will be accepted, but when returning to this

dial position, the Start Times will be moved to a

sequential order (the Start Time set for 3 will have

been moved to 2). This is by design.

• If an earlier Start Time is set for a higher-numbered

Start (for example, Start 1 is set to 4:00 AM, and

Start 2 is set to 3:00 AM), when returning to this dial

position the Start Times will have been reorganized

in chronological order. The lowest numbered Start

Time will always have the earliest time of day (in the

example, Start 1 will be at 3:00 AM and Start 2 will be

at 4:00 AM).

SETTING STATION RUN TIME DURATION

Three items are programmed at this position:

• Station watering duration

• Seasonal Adjust value for the Program

• Hidden Feature: Timed Delay between Stations

1. Turn the dial to the SET STATION RUN TIMES position.

2. Select the Program (A – F) by pressing the Program

button

3. Press the + or – button to change the value of the

flashing cursor. The cursor initially appears in the

minutes field.

4. Press the right and left arrow buttons to change

from minutes to hours or seconds cursor positions.

Set the run time in h:mm:ss format.

5. Run times may be from 1 second to 6 hours, or any

increment in between.

6. Press the up and down arrow buttons to change to a

different station number

7. The copy and paste buttons may be used to speed up

programming.

21

Page 29

NOTE: If the ACTUAL value is different from the

PROGRAMMED value, Seasonal adjust has been changed

from the default of 100% to a new value. The actual run

time is the duration the station will water.

Turn the dial to the SET STATION RUN TIMES position.

Using the Global Setting

Press the Information button with any station selected at

the Set Station Run Times dial position to see a summary

of all watering for a specific station, including all

programs in which it will run.

CHANGING SEASONAL ADJUST

Season adjust is used to make global or program specific

run time changes without the need to reprogram every

station’s run time. Seasonal adjust made at the controller

level is global (GLBL) , and the controller can be adjusted

in 1% increments, from 1 to 300%. This will change run

times by the set percentage.

For example, a 10 minute run time that is adjusted to 70%

will run for 7 minutes. When the controlleris set back to

100%, the station will return to a 10 minute run time.

Programs that are set to GLBL will use the Global Seasonal

Adjust setting that has been set for the controller.

It is also possible to set Seasonal Adjust percentages for

individual programs (also 1–300%). The programs will

use their own percentages and will not be affected by the

controller-level Global Setting. The percentages are not

multiplied together. If the controller is set to 150%, but

an individual program is set to 70%, the stations in the

programs will run for 70% of the original run time, not

70% x 100%.

1. Press the left arrow button until the cursor is on

the percentage below the GLBL. The percentage

immediately below GLBL is the seasonal adjustment

percentage for the entire controller.

2. Press the + and – buttons to adjust the global

seasonal adjust value between 0 and 300%.

Using a Program Specific Setting (set Season Adjust by

Program)

1. Press the left arrow button until the cursor is on the

GLBL.

2. Press the + and – buttons to adjust the season adjust

value between 0 and 300%.

NOTE: If it is desired to return to the global season

adjust, move the cursor to the season adjust

percentage then use the + and – buttons to change

the value to GLBL. GLBL is located between the 101

and 100% positions.

Timed Delay between Stations

Programming this feature is explained in the Extended

Features section.

SETTING DAYS TO WATER

Each Program’s days to water are programmed at this

position.

Set Days to Water

1. Turn the dial to the SET DAYS TO WATER position

2. Select the Program (A – F) by pressing the Program

button

3. Press the + or – buttons to change from DAYS (day of

the week), INTERVAL (1 – 31 DAYS), or ODD or EVEN

days of the month.

22

Page 30

Day of the Week Watering

3. Press the – button when the cursor is on a day that

you do not want to water. An “N” will appear, to show

that day is never able to water, regardless of the

schedule.

4. If you select Odd or Even while in the Interval

schedule, the Odd or Even days will not be watered

even if they happen to be one of the Interval days to

water.

5. To change a non-water day back to a water day, use

the arrow buttons to go to that day and press the +

button. The “-“ will disappear, and the day will be

available for Interval watering again.

1. Select the Program and DAYS .

2. Press the down arrow button to move the cursor to

Monday

3. Press the + button to water on Mondays or the –

button to not water on Mondays

4. As the cursor moves from day to day, press the +

or – button to water or not water on that day of the

week. Press the right and left arrow buttons to move

quickly to a specific day.

Inter val Watering

1. Select the Program and INTERVAL with the + or –

buttons.

2. Press the down arrow button to Interval

3. Press the + or – button to select the number of days

between watering

4. Press the down arrow button to Next Water

5. Press the + or – button to select the number of

days until the next watering. If Next Water has

"0 days" for a value, that indicates that any scheduled

watering for that day will water at its programmed

start time. If it has a value of "1 Day," the scheduled

programming will water tomorrow.

Non-Water Days: This feature can be used to omit

watering on mowing days, etc. The days with N will not

water, even if they would normally occur at one of the

Interval days set above.

1. Press the down button to MON

2. Press the right and left arrow buttons to move the

cursor between the days

23

Odd/Even Watering

1. Select the Program and ODD/EVEN with the + or –

buttons, as shown above in First Step

2. Press the down arrow button once, to select Odd or

Even.

3. Press the + or – button to toggle between ODD or

EVEN day watering

Non-Water Days: This feature is frequently used to omit

watering on mowing days, etc.

1. Press the down button to MON

2. Press the right and left arrow buttons to move the

cursor between the days

3. Press the – button when the cursor is on a day that

you do not to water. An “N” will appear, to show

that day is never able to water, regardless of the

schedule.

4. To change a non-water day back to a water day, use

the arrow buttons to go to that day and press the +

button. The “-“ will disappear, and the day will be

available for Odd or Even watering again.

SETTING PUMP AND MASTER VALVE OPERATION

Two items are programmed at this position:

• Pump or Master Valve (P/MV) operation by station.

Each station may have any combination of P/MV

outputs 1, 2, both, or neither, which will activate as

specified whenever the station is turned on.

Page 31

• Extended Feature: Change the master valve from the

default of normally closed (N.C.) to normally on (N.O.)

Change the location of the P/MV between Controller

(wired directly into the Master Module) and ADM

(P/MV is connected to a decoder on the two-wire path)

Set Pump and Master Valve Operation

1. Turn the dial to the SET PUMP OPERATION position

2. Press the right and left arrow buttons to move

between P/MV 1 and P/MV 2

3. Press the up and down arrow buttons to change the

station number

4. Press the + or – button to enable or disable the

specific Pump or Master Valve for the given station

Changing from Normally Closed to Normally On and

Location of P/MV

Programming this feature is explained in the Extended

Features section.

SETTING STATION CYCLE AND SOAK DURATIONS

Each Station’s Cycle and Soak settings are programmed at

this position. Cycle and Soak allows the user to break up

the total run time of a station into more usable watering

durations (cycles), and a minimum soak time between the

watering cycles. This feature is great to use on slopes and

tight soils because it puts the water down more slowly,

helping to prevent run off.

4. Press the + or – button to change the Cycle cursor

value. The default cursor value is N/A. Cycles can be

set from 1 minute to 6 hours.

5. Press the right arrow button to move from Cycle to

Soak, once a value has been entered into the Cycle

field.

6. Press the + or – button to change the Soak cursor

value. The default cursor value is N/A. Soaks can be

set from 1 minute to 9 hours.

7. Press the down arrow to move to the next station.

8. The Copy and Paste functions are useful for large

numbers of stations with similar Cycle and Soak

requirements. To use, set a station’s Cycle and Soak

information, then press the Copy button.

9. Use the up or down arrows to advance to the next

station, and press Paste. Both the Cycle and Soak

value will be pasted into the fields.

You can continue to advance through the stations with the

up or down arrows, and press Paste to continue pasting

the same Cycle and Soak values into subsequent stations.

CYCLE AND SOAK SUMMARY

In the Set Cycle and Soak dial position, press the

Information button to view a summary of Cycle and Soak

with any selected station’s run time. It will display the total

run time of that station per Start Time in the program, not

including the soak time. It will also display the station's

programmed cycle time and soak time, and the number

of cycles that station will incur due to the programmed

runtime and cycle time. If the station’s run time is less

than one complete programmed cycle time, the number of

cycles displayed will be shown as 0+. To view Cycle and

Soak summaries for stations in other programs, simply

release the Information button and while in the Cycle

and Soak screen, hit the Program button. Hold down

the Information button again and the display will now

show that station’s Cycle and Soak summary for the new

program.

Set Station Cycle and Soak Durations

1. Turn the dial to the SET CYCLE AND SOAK position

2. Press the up or down arrow keys to change stations

3. Press the right and left arrow buttons to move

between hours and minutes and cycle and soak

24

Page 32

seTTInG floW monITorInG ........................................................

The ACC is capable of monitoring, learning, and reacting

to Real-Time flow. The installation of the optional Hunter

Flow Sensor (HFS) or a Data Industrial flow sensor is

required for this feature to function. The ACC must first

learn the normal flow, by station, for flow sensing to

operate correctly.

Step 1: Select The Flow Sensor

If you are using a Data Industrial or similar Flow Sensor,

press the plus button until OTHER is in the display. Then

use the plus, minus and arrow buttons to set the K-Factor

and Offset. These values can be found in the Data

Industrial or similar suppliers’ literature.

Once the flow sensor is selected, turn the dial off the SET

Press and hold the INFORMATION button while you turn

the dial to the SET FLOW MONITORING position.Press the

down arrow button once so the cursor blinks on SELECT

FLOW SENSOR.

FLOW MONITORING and the flow sensor that has been

selected will be shown.

Press the plus button until the correct HFS FCT size is

displayed. HFS sensors are always installed in a Hunter

FCT fitting, and selecting the fitting size automatically

sets calibration for sensor (see sensor installation

instructions).

Location is normally set to Controller. If the controller has

a ADM99 decoder output module installed and you wish to

connect the Flow meter to an ICD-SEN sensor decoder, use

the arrow button to move to Location, and change with +

or - buttons to ADM. This will assign the single Flow Meter

to an ICD-SEN decoder down the two-wire path, instead of

the Flow terminals on the controller's master module.

Menu Choices:

FCT size

100 1" Sch. 40

150 1½" Sch. 40

158 1½" Sch. 80

200 2" Sch. 40

208 2" Sch. 80

300 3" Sch. 40

308 3" Sch. 80

Pipe

diameter

Pipe Class

25

400 4" Sch. 80

OTHER K-factor

& offset

K-factor

& offset

Page 33

Step 2: Viewing Real-Time Flow

1. Once the flow meter is configured, ACC can display