Page 1

ACC2 Decoder

BUILT TO COMMAND

EVEN THE LARGEST PROJECTS

Quick Start Guide

Page 2

POWERFUL. INTELLIGENT. FLEXIBLE.

THE ACC2 CONTROLLER DELIVERS ADVANCED WATER MANAGEMENT

TO MEET THE DEMANDS OF LARGE-SCALE COMMERCIAL PROJECTS.

TABLE OF CONTENTS

ACC2 Decoders ................................................... 4

Important Connections and Tips .................. 4

Facepack ............................................................... 4

Reversing the Facepack .................................... 4

Connecting and Disconnecting the Facepack .5

SyncPort™ Connection ......................................5

SD Card Reader ...................................................5

Battery..................................................................5

External Components ......................................... 6

Front Door ........................................................... 6

Face Frame .......................................................... 6

Facepack.............................................................. 6

Face Frame Latch ............................................... 6

Facepack Cable ................................................... 6

Spare Decoder Fuses and Tool ......................... 6

Spare Fuse Holders ............................................ 6

Wall Mount Bracket ........................................... 6

Wire Ties for Strain Relief .................................. 6

Internal Components .......................................... 6

PCU Board ........................................................... 6

Slide Lock ............................................................ 6

Output Module Slots ......................................... 6

Flow Expansion Slot ........................................... 6

Earth Ground Lug ............................................... 6

Transformer Assembly ...................................... 6

Wiring Compartment Cover ............................. 6

Power Supply Board .......................................... 6

Flow Sensor Inputs............................................. 6

Status Light ......................................................... 6

Programming Port ............................................. 6

Decoder Output Module Lights ....................... 8

Wire Ties .............................................................. 8

Transformer Fuse ............................................... 8

Flow Expansion Module .................................... 8

Field Wiring .......................................................... 9

Troubleshooting

Need more helpful information on your product? Find tips on installation,

controller programming, and more.

hunter.direct/acc2

1-800-733-2823

Operating the Controls ...................................10

Attention Messages ........................................10

Start-Up Screen ..................................................10

View Messages ....................................................11

Clear Messages ...................................................11

View Logs ............................................................. 11

Home and Activity Screens ............................11

Activity Screen.................................................... 12

Basic Programming and Setup ....................13

Names .................................................................. 13

2 hunter.direct/ACC2help

Page 3

Settings, Time/Date ......................................... 13

Pump/Master Valve Setup ...............................14

Manual Starts and Test .....................................15

Stop Commands .................................................15

Programs .............................................................16

Start Times .........................................................16

Intelligent Current Sensing ............................ 17

Run Times .......................................................... 17

Water Days ........................................................ 18

Seasonal Adjust .................................................18

Program Rules ...................................................19

Ignore Calendar Days O ...............................19

No Water Window (Start and End)................19

Station Delay (Delay Between Stations) ......19

Calendar Days O .............................................. 19

Program Summary ...........................................19

P/MV Operation (Pump/Master Valve

Operation) ..........................................................20

Sensors ...............................................................20

Clik Sensors ....................................................... 20

Sensor Response ............................................... 21

Solar Sync ........................................................ 22

Flow Sensors ..................................................... 22

Stations Menu .................................................. 23

Station Setup ..................................................... 23

Cycle & Soak ....................................................... 24

Blocks .................................................................. 24

Station Limits ..................................................... 25

Station Summary .............................................. 25

Devices Menu ................................................... 26

P/MV Operation ................................................ 26

Flow Sensors ...................................................... 26

Solar Sync .........................................................26

Clik Sensors ........................................................26

Sensor Response ............................................... 26

Flow Menu ......................................................... 27

Clear Flow Alarms ............................................. 27

Settings Menu ................................................. 27

Time/Date ......................................................... 27

Regional Settings .............................................. 27

User Management ............................................ 28

Networking ....................................................... 28

Diagnostics Menu............................................ 29

View Logs ........................................................... 29

Alarm Logs ........................................................ 29

Controller Logs ................................................ 29

Station Logs ...................................................... 30

Filter Logs ..........................................................30

Export Logs ....................................................... 30

Module Info ........................................................ 30

Clik Sensor Diagnostics ................................... 30

Station-P/MV Diagnostics ............................... 31

Flow Sensor Diagnostics .................................. 31

Solar Sync Diagnostics .....................................31

Decoder Diagnostics ......................................... 31

Advanced Features ......................................... 32

Export Logs ........................................................ 32

Easy Retrieve ..................................................... 32

Reset Memory ................................................... 33

Firmware Update .............................................. 33

Conditional Response ....................................... 33

Flow Operations ...............................................34

Flow Manager .................................................... 34

Flow Monitor ...................................................... 34

MainSafe™ ........................................................34

Set Up Flow Monitor ......................................... 35

Flow Zones ........................................................ 35

Flow Map ......................................................... 35

Flow Limits ...................................................... 36

Flow Allowances ............................................. 36

Station Setup .................................................... 37

Station P/MV Usage ...................................... 37

Flow Zone ........................................................ 37

Flow Priority .................................................... 37

Flow Measurement Settings ........................ 37

Copy and Paste ............................................... 37

Learn Flow ......................................................... 38

Schedule Flow Learning ................................ 38

Hydraulic Summary ......................................... 39

Flow Totals ........................................................ 39

View Flow ..........................................................40

Flow Alarm Handling ........................................40

Station-Level Alarms ........................................ 41

Flow Zone or MainSafe™ Alarms ..................... 41

Set Up Flow Manager ....................................... 42

Flow Zones ........................................................ 42

Flow Target ...................................................... 42

Station Setup ....................................................43

Flow Zone ........................................................ 43

Flow Priority ......................................................43

Flow Rate .........................................................43

Station Limits ....................................................44

MainSafe™ .........................................................44

Setup Screen .................................................... 45

Flow Limits Screen ........................................... 45

Maximum Flow ............................................... 45

Unscheduled Flow ..........................................45

Alarm Delay ..................................................... 45

Alarm Clear Delay ........................................... 45

Allowances Screen ...........................................46

Monthly Budget .............................................46

Manual Watering Allowance ......................... 46

Conditional Response .................................... 47

Set up a Conditional Response ....................... 48

Conditional Response Types ...........................49

SOS (Status Output Station) ........................... 50

Set up an SOS station .................................... 50

Start Stations, Programs, and Blocks ............50

Mode ................................................................ 50

Sw it ch P/MVs ....................................................51

Decoders Menu ................................................ 52

Program Decoder .............................................. 52

Serial Number ................................................... 52

Decoder Type .................................................... 52

Power Factor ..................................................... 52

Inrush ................................................................. 52

Output-Station ................................................. 52

Programming Station Decoders ................... 53

Programming Pump/Master Valve (PMV)

Decoders .......................................................... 53

Programming Sensor Decoders .................... 54

Programming Decoders via the Two-Wire

Path .................................................................... 54

View Conguration ........................................... 55

View Status ........................................................ 55

Decoder View .................................................... 55

Station Assignments ........................................ 56

Decoder Diagnostics ......................................... 56

Station Finder ................................................... 56

Wi re Te st ........................................................... 57

Decoder Inventory ............................................ 57

Filter ................................................................... 58

Comm % ............................................................. 58

Update Available ..............................................58

Export Inventory .............................................. 58

Refresh Inventory ........................................... 58

Clear Inventory ................................................. 58

Update Decoders ............................................... 58

Troubleshooting ............................................... 59

Built on Innovation® 3

Page 4

Important Connections and Tips

ACC2 Decoders

ACC2 Decoder is designed to operate

Hunter ICD decoders. The ICD decoders

must be programmed with station numbers

before they will operate. See the Decoder

menu for detailed instructions on decoder

programming.

ACC2 Decoder is very similar to the

conventionally wired ACC2 controller, with

an additional Decoder menu for all unique

decoder functions and diagnostics. Some

devices (Pump/Master Valves and sensors) may be assigned

to decoder locations, and those individual setup screens now

include this option.

Important Connections and Tips

FACEPACK

“Facepack” is a Hunter term for the enclosed, removable

control panel and display assembly. It contains the brain and

memory of the controller.

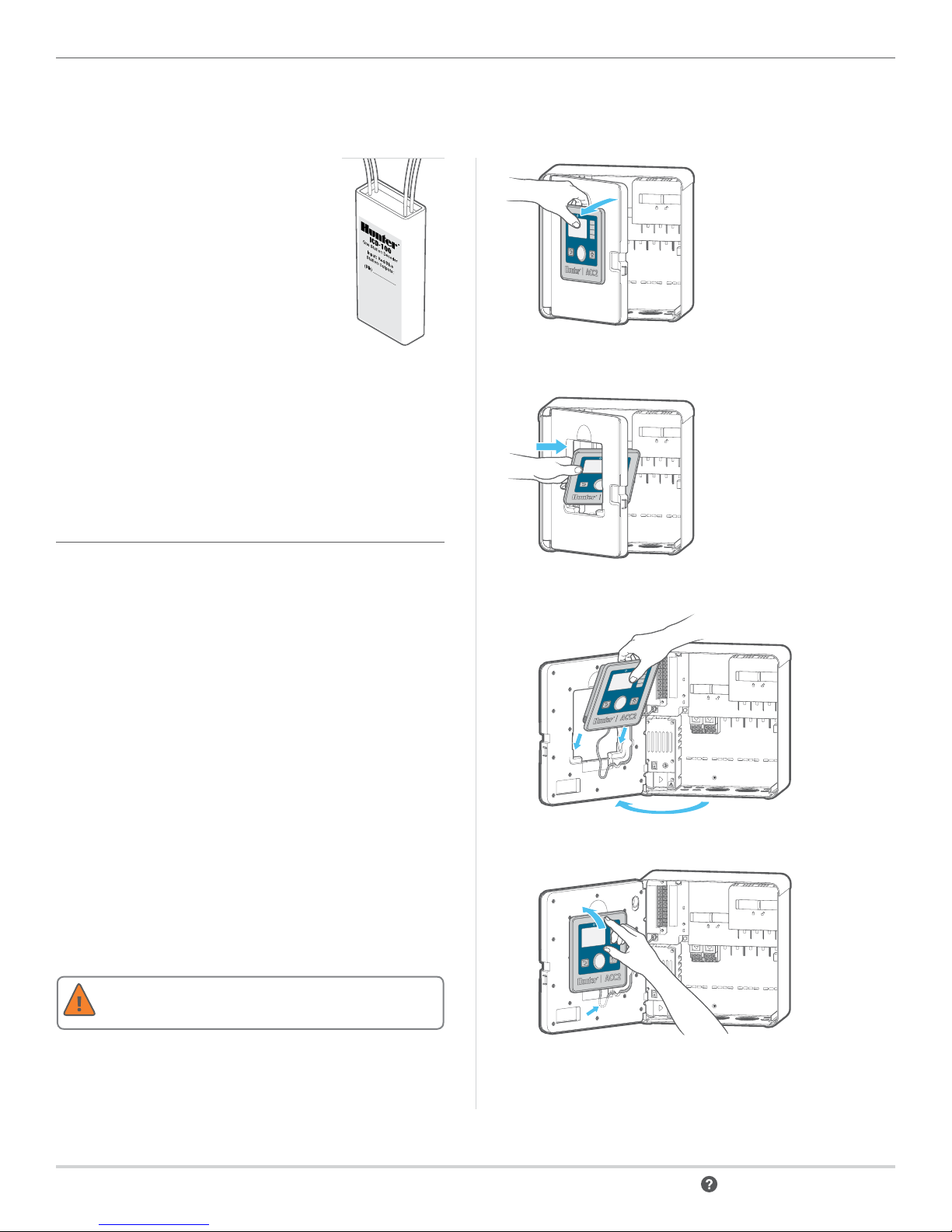

REVERSING THE FACEPACK

The ACC2 facepack and controls can be reversed in the door

frame, so they can be operated with the door open while

looking at the modules and wiring.

1. Pull the facepack away from the face frame. The facepack

is held in place by a magnet.

2. Pass the facepack through face frame.

3. Slide the facepack into the back side of the face frame

as shown.

4. Tilt the facepack into position; it will click into place and be

held securely by the magnet. Tuck the ribbon cable slack

into the provided pocket.

When the facepack detects that it is reversed, it will

automatically go to the Diagnostics, Module Info display. It

is possible to navigate to any other screen from this display,

including programming and manual operations.

The controller will water automatically with the

facepack in either position.

4 hunter.direct/ACC2help

Page 5

Important Connections and Tips

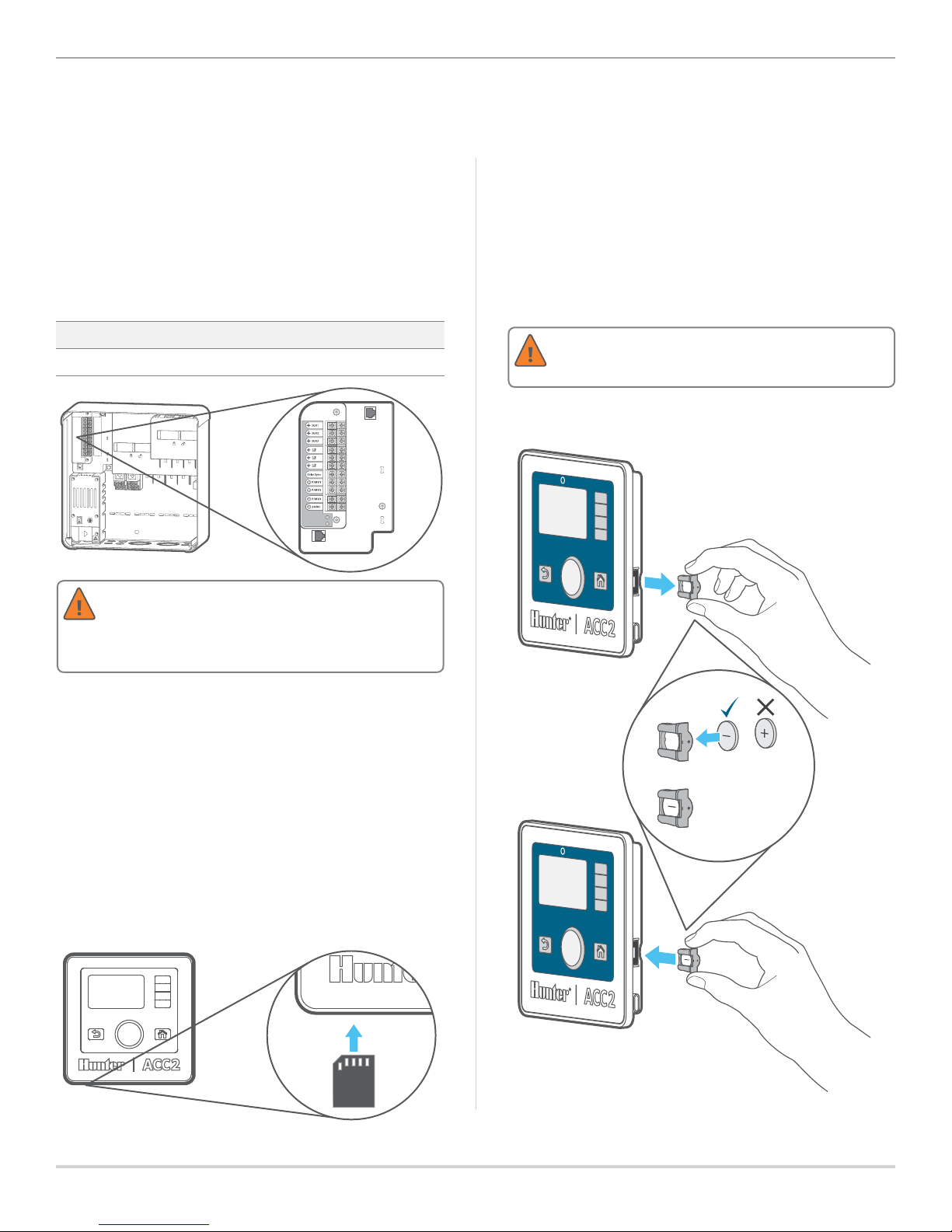

CONNECTING AND DISCONNECTING THE FACEPACK

The facepack cable connection is located just below the light

on the Power Supply Board. Turn power to controller o

before connecting or disconnecting the facepack.

SYNCPORT™ CONNECTION

The SyncPort connection is a proprietary Hunter connection

for external interface devices. It is located near the top of the

Power Supply Module.

SyncPort

Facepack Cable Connection

Do not attempt to connect the facepack cable to

this port. The connector has a protective cover

that should be le in place until the connection

is needed.

BAT TERY

The facepack has a replaceable internal lithium battery in the

side of the facepack to back up date and time settings during

power outages (Program settings and other data are nonvolatile and do not require battery backup). The battery may

last the life of the controller, but is easily replaced if necessary.

Use a standard CR2032 replacement if necessary. Be sure to

place the + side of the battery correctly.

If power to the controller is le o for extended

periods, the battery will be consumed more quickly.

Consult the connecting device’s manual for additional

instructions regarding SyncPort.

SD CARD READER

The bottom edge of the facepack includes a built-in SD card

reader. The controller is supplied with an SD card.

The SD card can:

• Upload updated rmware (saved from email or the

hunterindustries.com website) to the controller and all

its modules.

• Store logs, Easy Retrieve backups, and other information

for use later or on another device. See the Advanced

Features menu on page 32.

Built on Innovation® 5

Page 6

Components

EXTERNAL COMPONENTS

FRONT DOOR

FACE FRAME

FACEPACK

FACE FRAME LATCH

FACEPACK CABLE

SPARE DECODER FUSES AND TOOL

SPARE FUSE HOLDERS

WALL MOUNT BRACKET

WIRE TIES FOR STRAIN RELIEF

INTERNAL COMPONENTS

PCU BOARD

SLIDE LOCK

OUTPUT MODULE SLOTS

FLOW EXPANSION SLOT

EARTH GROUND LUG

TRANSFORMER ASSEMBLY

WIRING COMPARTMENT COVER

POWER SUPPLY BOARD

FLOW SENSOR INPUTS

STATUS LIGHT

PROGRAMMING PORT

FACEPACK CABLE

The facepack cable connection is located beneath the

Status Light. It is a standard connector with a locking

lever on one side, which must be pressed in to remove the

cable.

SPARE DECODER FUSES AND TOOL

ACC2 Decoder is shipped with spare 20A automotive

fuses and a fuse pulling tool. These are only for use as

replacements in the decoder output modules, to enhance

surge protection on the eld wiring. Replacements can be

purchased at most automotive parts stores.

PCU BOARD

The replaceable PCU (Power Conditioning Unit) board

has only a single screw and can be replaced if necessary.

The board plugs directly into the back plane. This board

contains components that are used by all decoder output

modules, and the status LED indicates whether the board

has power and is operational.

SLIDE LOCK

The slide lock secures the decoder output modules in

place. When it is open, power is o to the facepack, and an

orange indicator is shown. The controller will not operate

if the slide lock is open, and the Status LED will ash

orange to indicate this condition.

EARTH GROUND LUG

A heavy-duty earth ground lug is provided for lightning

and surge protection. This connection is for equipment

safety only. It should always be connected with heavy

copper wire to approved grounding hardware buried in the

earth at least 8' (2.5 m) away from the controller, and as

far as possible away from the two-wire paths.

Generally, earth ground hardware consists of an 8'

(2.5 m) copper-clad steel rod driven all the way into earth,

or a 8' (2.5 m) x 4" (100 mm) wide copper plate, or both,

or comparable earth grounding hardware as approved by

local code.

Do not connect the primary AC power earth ground wire

to this lug. ACC2 provides safety ground connection inside

the transformer wiring compartment.

Decoder wire paths also require additional earth

grounding every 1,000' (300 m), or every 12 decoders, at

minimum. ICD decoders include built-in surge protection,

with a bare copper wire for connection to earth. In highlightning areas, ground more frequently.

Decoder earth ground should meet the same specication

as the controller ground: 8' (2.5 m) copper-clad steel rod

driven all the way into earth, or a 8' (2.5 m) x 4" (100 mm)

wide copper plate, located at right angles to the two-wire

path, at least 8' (2.5 m) away from the two-wire path.

6 hunter.direct/ACC2help

Page 7

Components

POWER SUPPLY BOARD

The Power Supply Board, in the upper le corner of the

cabinet, is a vital component, and includes connections

for external sensors, Pump/Master Valve outputs,

Common wire connections, and more. The Power Supply

Board is also designed for convenient replacement, if

necessary. Three captive screws (#2 Phillips) secure the

board. Two modular wiring plugs connect the board to the

controller.

FLOW SENSOR INPUTS

Flow Sensor connections have DC voltage and polarity.

When connecting a DC ow meter, verify that the positive

lead from the sensor is connected to the red terminal, and

the negative sensor is connected to the black terminal.

There are three ow sensor inputs on the Power Supply

Board. The optional A2C-F3 ow expansion module

can add up to three more for a maximum of six ow

sensor inputs.

STATUS LIGHT

The Status Light is green to indicate power and correct

operation. If the light is orange, there is a problem.

Solid orange detects an issue within the Power Supply

Board itself.

Flashing orange indicates that one of the two slide locks

is open. The controller will not function unless both slide

locks are in the closed position.

PROGRAMMING PORT

The programming port is used to program station

numbers into the decoders. ICD decoders must be

programmed before they will operate. Reverse the

facepack for easiest operation, go to the Decoder menu,

and select Program a Decoder. Insert the red and blue

wires from the decoder (doesn’t matter which goes

where), and use the menu to select the station numbers

and program the decoder.

Built on Innovation® 7

Page 8

Decoder Wiring and Tips

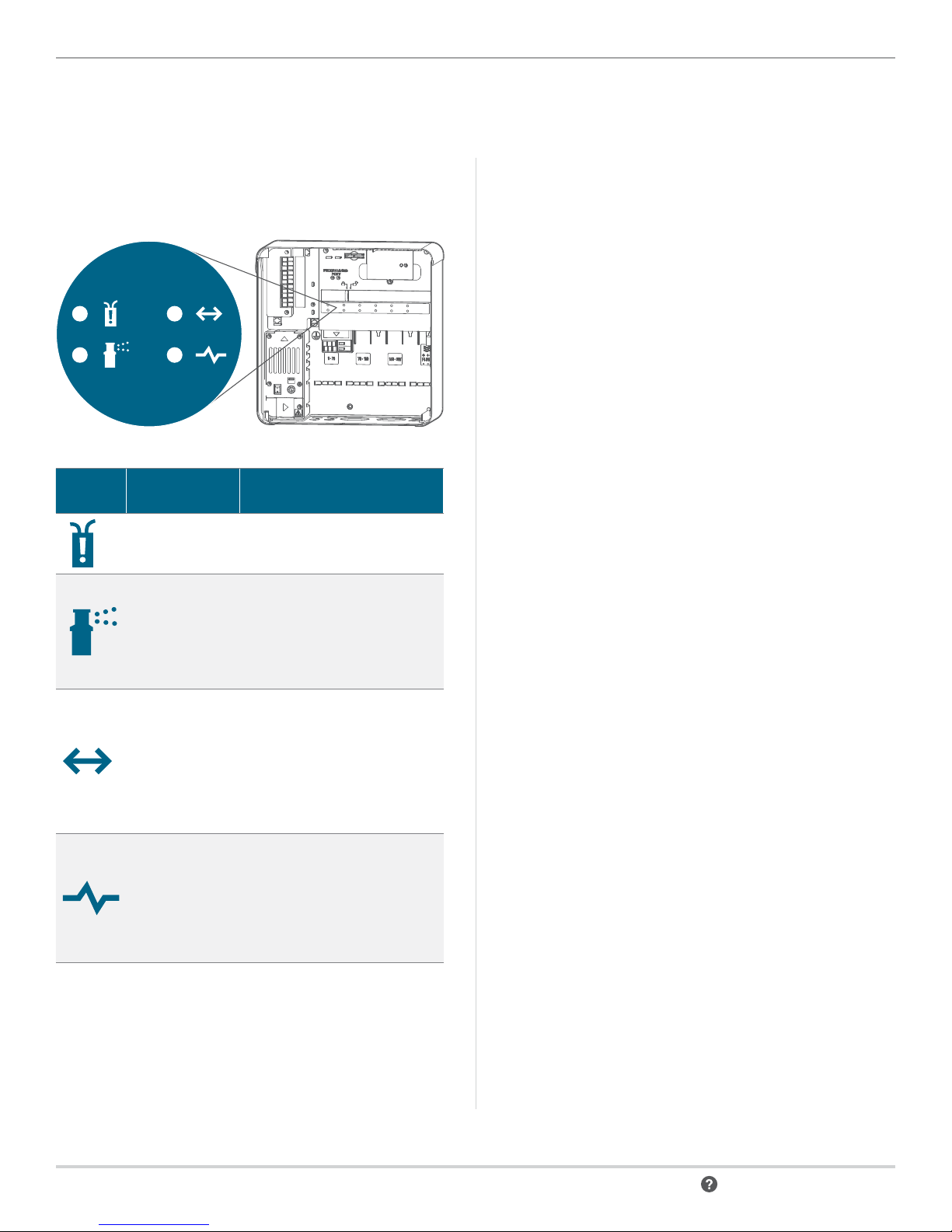

DECODER OUTPUT MODULE LIGHTS

Each decoder output module is equipped with diagnostic LED

lights. Each light is labeled on the deck lid.

Symbol Activity Type Color and Meaning

Decoder fault

Module or line

activity

Communicating

Blinking red:

Decoder has an over-current

or overload

Blinking green:

Station active

Blinking red:

Line overload (wire path short)

Also blinks during decoder

update

Blinking green:

Two-wire communications

Blinking amber:

Programming port

communications

WIRE TIES

Wire tie holders are molded into the lower back of the

wiring compartment to secure eld wiring with plastic zip

ties. This provides a strain relief to keep eld wires from

pulling downward on the modules, and keeps the inside

neat and organized.

Additional wire tie holders are provided near the Power

Supply Board for sensor and other connections.

TRANSFORMER FUSE

The transformer uses a replaceable 5 x 20 mm electrical fuse,

located next to the convenient on/o switch. Two spare fuses

are stored in the bottom rear of the facepack frame, under the

sticker labeled “Spare Fuse.”

Replacement fuses are a standard glass body 5 x 20 mm

250V, 2A fast blow, available online or from electronic

appliance retailers and hardware stores.

FLOW EXPANSION MODULE

A2C-F3 ow expansion modules add three additional

hardwired ow inputs to the controller. These modules

may only be added to the lower right module slot, one per

controller, and it is the only module that will t in this slot.

The ow expansion module has DC voltage and polarity,

and the + (or red) connection from the ow sensor must

be connected correctly to the + (positive) terminals on the

module. Finish ow expansion in the Devices, Flow Sensors

menu aer installing the module.

ACC2 Decoder controllers may also read up to six ow sensors

via the two-wire paths using ICD-SEN sensor decoders. The

controller may use any combination of hardwired inputs to

ow terminals, or connection by sensor decoders.

Solid amber:

Wire test mode

Blinking green:

Module damaged (replace)

Line status

Solid green:

Line is OK

O:

No power to module

8 hunter.direct/ACC2help

Page 9

FIELD WIRING

Proper installation and connection of the decoder two-wire

paths is very important.

• Use only Hunter IDWIRE or an approved substitute.

• Use only Hunter DBRY-6 waterproof connectors in the red

and blue two-wire path connections.

• Leave adequate slack (about 5' or 1.5 m) at each splice, to

prevent disconnection.

Each A2C-D75 output module supports up to 75 decoder

stations.

• Each module allows up to three two-wire path connections.

• Each path may be up to 10,000' (3 km) with 14 AWG

• Two-wire paths may be tee-spliced (in a valve box with

2

(2 mm

) wire, or up to 15,000' (4.5 km) with 12 AWG

(approximately 3.31 mm

2

) wire.

approved connectors), as long as the maximum distance to

each end of the paths from the controller does not exceed

the maximum for the wire used.

Decoder Wiring and Tips

You can have more than 75 stations on a single two-wire path.

If more than one A2C-D75 is installed, it is possible to assign

the additional station numbers to another decoder output

module. This must be done with the Station Assignments

function on the Decoder menu, so the controller will know

which module has the additional stations.

Built on Innovation® 9

Page 10

Operating the Controls

Operating the Controls

ACC2 has a simple control panel with unique operating

features. The dial is used to rotate through selections, and

then pushed to select, or to enter information.

1. The dial is used to rotate through selections and then

pushed to select, or to enter information.

2. To the right of the LCD display are four so keys. Their

functions will change with each menu selection, as shown

in the ACC2 display.

3. Back always goes back up a level from the current menu

selection.

4. Home will always return you to the Home screen view.

Home screen shows the status of the controller, including

anything currently running in the eld. When in the Home

screen, the bottom so key is called Main Menu, and this

takes you to all programming and setup functions.

From the Main Menu button, you may enter the setup menus

for all ACC2 functions. Turn the dial to view the main menus,

and press the dial to select one of them. Then, the dial is used

to select the items within that menu. Press to select one.

Once you’ve entered a programming screen, the dial is used to

navigate through all the elds of information. Press to select

one, rotate to see the choices or enter numbers or letters, and

press to select.

Attention Messages

A new controller installation will begin with at least one or two

Attention messages, because the controller has experienced

a power outage during shipping, and may be discovering new

modules. This is normal.

STARTUP SCREEN

When power is rst turned on (either with the power switch,

or closing one of the slide locks), the Hunter logo screen

appears, and the controller begins searching for any irrigation

events it may have missed during a power outage.

This search can be canceled if you are installing or servicing

the controller by pressing the Home button on the facepack.

Press Home at any time to return to the top level, or to

navigate to other functions.

If the controller nishes searching for missed events (about

1 minute), it will resume irrigating where it should be at the

current time of day.

In automatic operations, the controller will always perform

the search aer any power outage. Watering that was missed

during the outage will be recorded in the logs, and the

watering will resume where it should be at the time of the

power restoration.

10 hunter.direct/ACC2help

Page 11

Home and Activity Screens

VIEW MESSAGES

Messages on the screen do not interfere with normal

irrigation.

A ashing alarm symbol at the bottom of the display indicates

that something unusual has been detected. When the symbol

is ashing, a so key will link to View Messages. Press the key

to view the most recent messages in the Attention screen.

From the Attention screen, you can View Logs to get more

details about the messages and/or Clear Messages to return

to the Home screen.

CLEAR MESSAGES

Attention messages in the display can be cleared by pressing

the Clear Messages so key, aer pressing View Messages.

The message will still be available in the controller’s logs.

Attention messages do not prevent watering or normal

operation. However, they may announce a condition that can

prevent or aect watering.

VIEW LOGS

Press View Logs for more detailed information about each

message.

The so keys will link to the Alarm, Controller, and Station

logs when an attention message is displayed. The Filter Logs

function will allow you to search for logs on a specic date, or

by record number. You can also access logs at any time from

the Diagnostics menu.

Home and Activity Screens

Home screen oers basic information and so key shortcuts

to common functions.

System status is shown in the upper right.

Current date and time are displayed in the bottom le border.

If Solar Sync is installed and enabled (Devices menu), the

Solar Sync symbol shows the current adjustment percentage

in the lower right of the border.

If the red-and-white ! triangle symbol ashes in the lower

right corner, the controller has detected an important

situation. A so key will change to View Messages, for more

information about the condition. The messages screen

permits clearing the message, or a shortcut directly to the

View Logs function for more details. Messages on the screen

do not interfere with normal irrigation.

If sensors are active (alarmed), this is shown in red text in the

upper right corner.

Built on Innovation® 11

Page 12

Home and Activity Screens

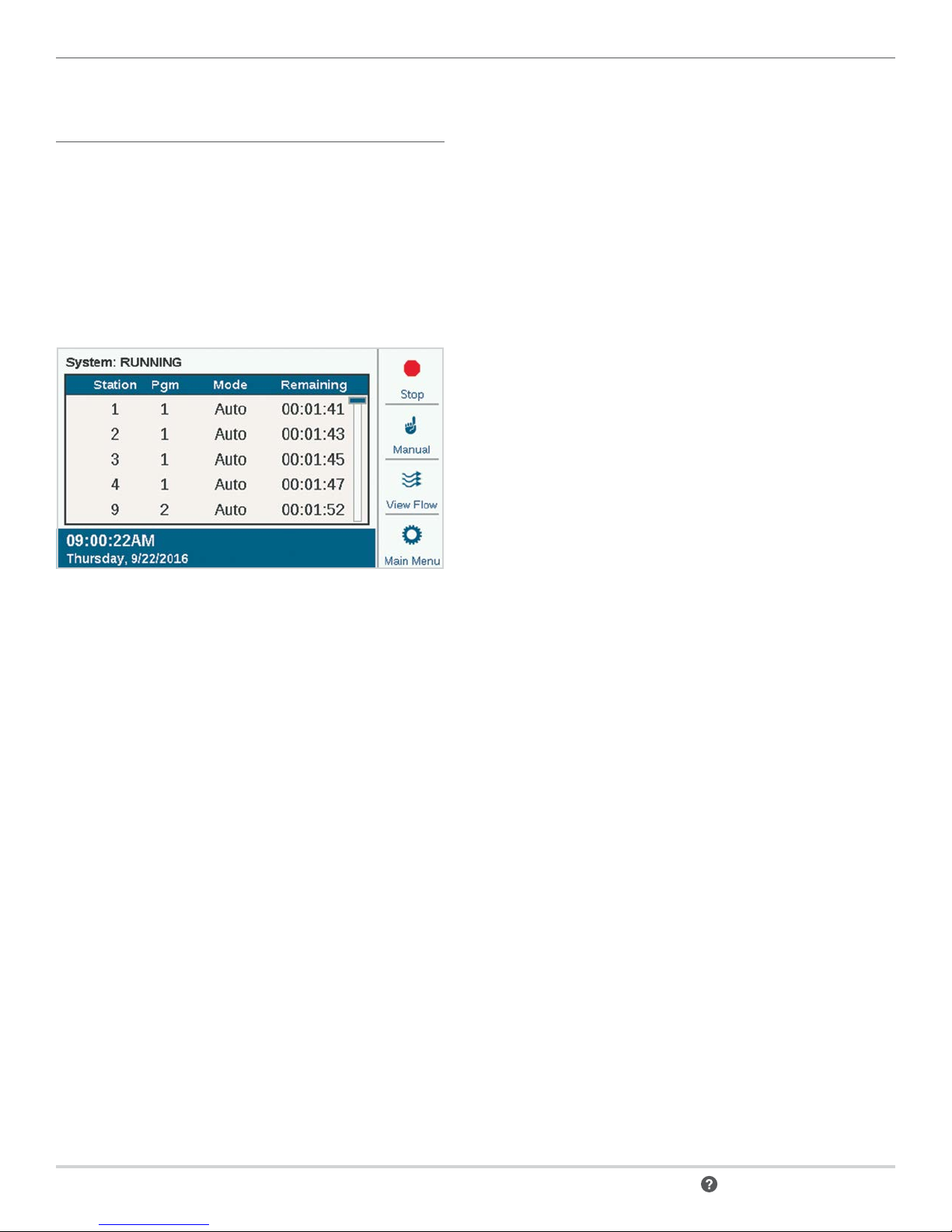

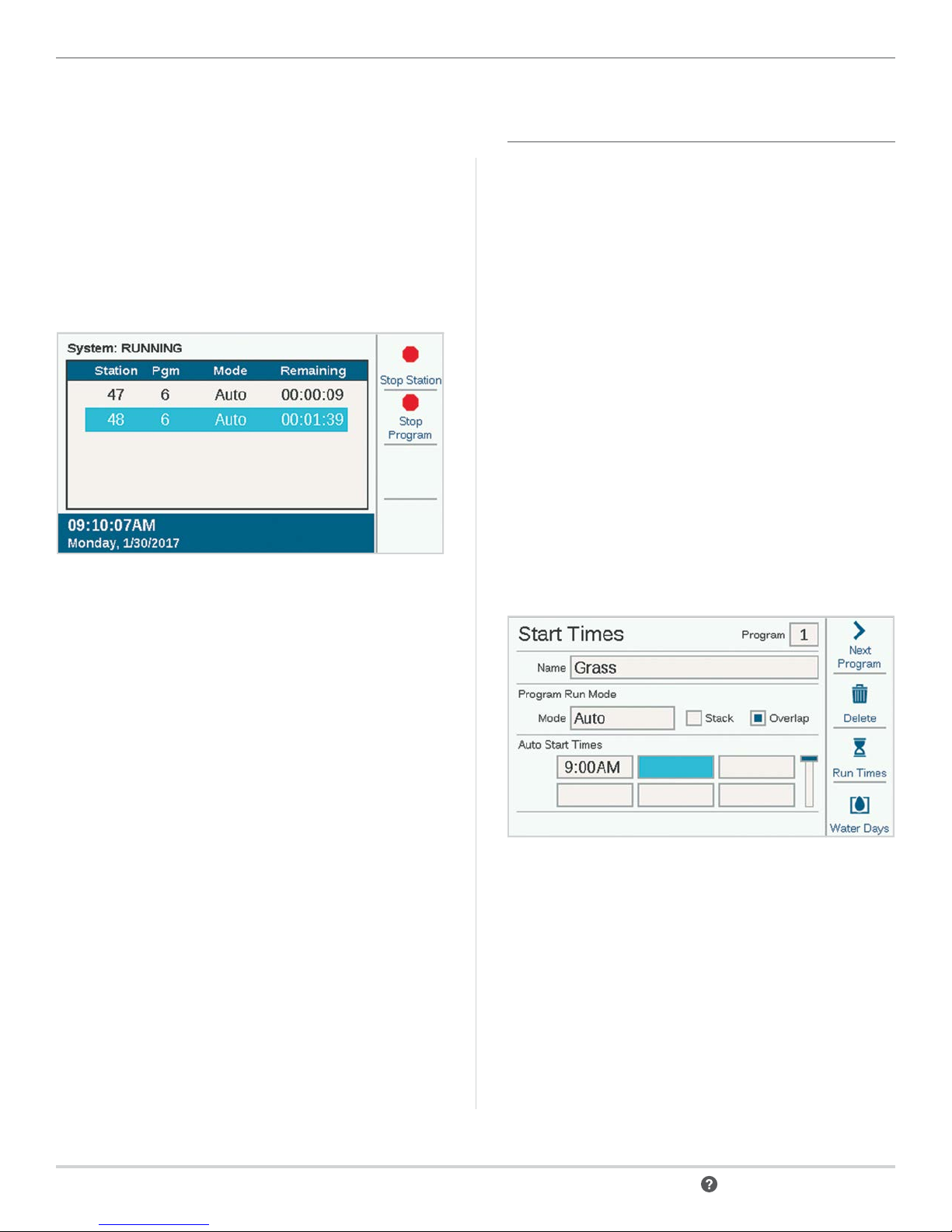

ACTIVITY SCREEN

When the controller is running stations, the Home screen

becomes the Activity screen, with additional information and

functions.

All running stations are displayed, along with the program

that is running them, the mode in which they are running, and

the amount of run time remaining on the station.

Individual items may be selected directly from the activity

screen and stopped without aecting other irrigation. See the

Selective Stop section on page 16.

The so keys normally show Stop, Manual, View Flow (shows

current ow, if a ow sensor is installed and enabled), and

Main Menu. Stop and Manual are described in the Basic

Programming section. View Flow is described in detail in the

Flow Operations section.

12 hunter.direct/ACC2help

Page 13

Basic Programming and Setup

Basic Programming and Setup

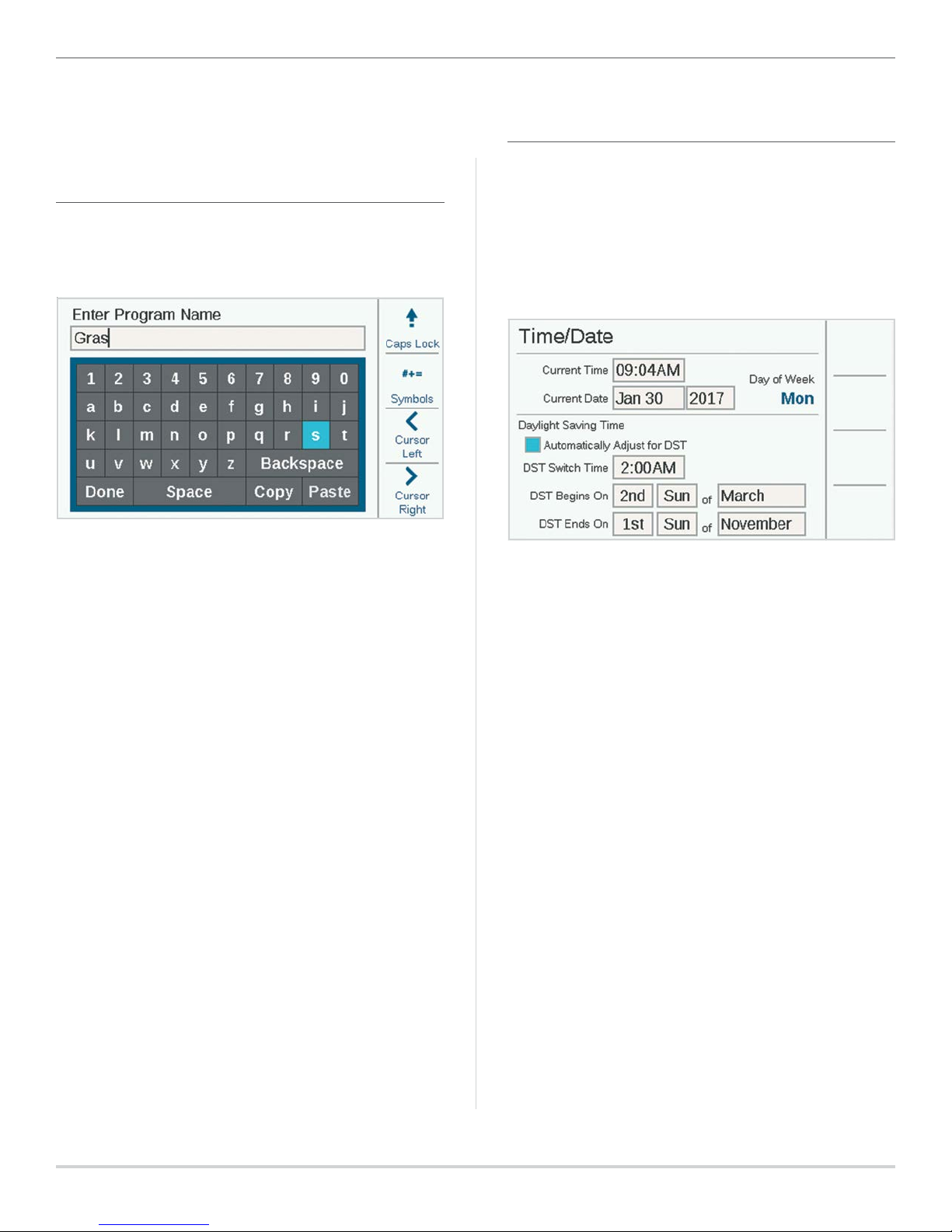

NAMES

ACC2 allows items to be named with an on-screen keyboard

that appears in the Name eld (or from a mobile device, if the

optional Wi-Fi module is installed). Names are useful in large

systems, especially in the more advanced Flow Operations.

Select the Name eld for any of these components, and a

keyboard will appear to enter an alphanumeric name.

SETTINGS, TIME/DATE

From the Home screen, press Main Menu, and dial to Settings.

Select Settings, and dial to Regional Settings.

Choose language, time and date formats, and units of

measurement. Press Back or Home to exit.

From the Settings menu, choose Time/Date: Set the current

time and date, and also Daylight Saving options. Press Back or

Home to exit.

Items that can be named are:

• Programs

• Stations

• Blocks

• Clik Sensors

• MainSafe™ zones

• Flow Zones

Built on Innovation® 13

Page 14

Basic Programming and Setup

PUMP/MASTER VALVE SETUP

In the decoder controller, P/MV outputs can be assigned to

either direct terminals in the controller, or to ICD-100 station

decoders.

P/MV outputs 1 through 3 refer to the output terminals on

the Power Supply Board, unless they are changed to decoder

locations. P/MV outputs 4, 5, and 6 must be assigned to

decoders.

All P/MV outputs are set to Normally Closed operation,

but they can be changed to Normally Open functions in

the Devices menu. See the P/MV Operation section

on page 20.

14 hunter.direct/ACC2help

Page 15

Basic Programming and Setup

MANUAL STARTS AND TEST

On the Home screen, the Manual so key lets you start

stations, programs, or a Test program. Once you press

Manual, there are three choices:

MANUAL STATIONS

Specify one or more stations to run and enter a run time for

them. You can also choose to run them simultaneously, rather

than sequentially, if you check the Simultaneous box. Press

the Start key to start the list.

MANUAL PROGRAM

Select a program number to start, and press the Start key

to start it. It is also possible to scroll down to an event in the

program, and start the program from that point forward.

STOP COMMANDS

Any running irrigation can be stopped immediately from the

Home screen. The top so key oers the following choices for

stopping irrigation:

STOP ALL IRRIGATION

This immediately stops everything that is watering or running.

The controller is still in Automatic irrigation mode, and will

resume watering at the next start time.

TIMED OFF

Like System O, this stops all stations and prevents automatic

irrigation, but for a specied period of days. When the

days have counted down to zero, the controller will resume

automatic operations.

A Manual Station or Program Start will pause any automatic

watering until the Manual Program has completed.

TEST PROGRAM

The Test program will run all stations in the controller for the

Run Time entered on the screen. It is also possible to specify

a station number, and run all remaining stations from that

number to the highest numbered station.

In the ACC2 Decoder controller, the Test Program will only run

stations that already have a run time in other programs in the

controller.

PAUSE

This interrupts whatever is currently running, until either

Resume is pressed or 30 minutes have passed. Anything

running will be resumed where it le o, and run for its

remaining time. When items are paused, the Resume button

will appear.

SYSTEM OFF

This turns o all irrigation, and places the controller in

permanent O mode. No automatic irrigation will occur.

Built on Innovation® 15

Page 16

Basic Programming and Setup

PROGRAMS

STOP COMMANDS CONTINUED

SELECTIVE STOP

You can also use the dial to scroll through the list of running

stations and programs on the Home screen and click to stop

any one of them instead of the entire list. If you highlight an

active station, the Stop button will allow you to Stop Station,

or Stop Program. Stop Program will stop the entire program

that caused the station to run, but allows other programs to

keep running.

From Main Menu, dial to the Programs menu and select. This

is where basic automatic irrigation is set up.

A basic program requires Start Times, Run Times, and

Water Days to operate automatically. There are 32 possible

automatic irrigation programs, each with up to 10 Start Times.

START TIMES

Verify that you have the correct program number, or select

and enter the program you want.

• Name (optional): You may enter a name for the program if

you wish.

• Run Mode: This must be set to Auto to run automatically.

- Manual Only: The controller does not water

automatically, but stores station run times for manual

irrigation only. These programs do not have day

schedules or start times. They may be changed to Auto

mode at any time, if automatic operation is desired.

• Stack or Overlap: Stack means the program must run by

itself, Overlap means it is allowed to run at the same time

as other programs. If a program is stacked, its actual start

time may change, if other programs overlap it in time.

• Auto Start Times: Enter the time for the program to start.

The faster you rotate the dial, the faster the times will

change. Each program may have up to 10 start times.

16 hunter.direct/ACC2help

Page 17

Basic Programming and Setup

INTELLIGENT CURRENT SENSING

ACC2 has no articial programming limits preventing

overlapping programs and stations. The controller senses

how much electrical current is being drawn, and will suspend

stations automatically if the combined current threatens the

transformer.

It is also possible to set Controller and Station Limits (Stations,

Station Limits) to control how many outputs may operate at

once.

An ACC2 Decoder controller may run as many as 20 Hunter

solenoids per module (including any P/MV outputs)

simultaneously, and up to 30 per controller (when multiple

output modules are installed) before suspending additional

stations. Environmental factors or higher-draw solenoids may

cause the overcurrent protection to activate at lower station

counts.

It is possible to view the current draw of each decoder output

module in the Decoder Diagnostics screen.

RUN TIMES

You can access Run Times from the programming menu, or

from the so key shortcuts from the Start Times screen. This

allows you to set up an entire program (start times, run times,

and water days) from the same menu.

You may continue to enter any station numbers, in any order,

in the same way.

Show Edit Tools (Shortcuts): Press the so key for Show Edit

Tools. If you are running stations in numerical order, you can

use the so key for Fill Down. This will automatically add 1 to

the previous station number, and copy the run time on the

next line. For example, if you entered Station 1, 5 minutes, and

then pressed Fill Down, it would add Station 2 for 5 minutes

on the next line. This is a shortcut for copying sequential run

times very quickly.

You can also Delete any item from the list. Scroll to the item,

and press Delete.

Verify that you are in the correct program, by number or

name.

Select the Run Type eld, and select Station or Block (“Blocks”

are described in detail in the Stations Menu section. Blocks

replace “SSGs” in the original ACC). Press the dial to select

the type.

Dial to the Number eld. Press and dial to select station or

block number. Press to enter.

Dial to the Run Time eld, press to select, and dial to enter the

run time (from 1 minute to 12 hours). You can also enter run

times in seconds, by dialing to the: SS eld (seconds), which is

adjusted separately.

You can also Insert an item above any selected line in the list.

Scroll to an item, and press Insert Line, and a blank line will

appear above it.

ACC2 can run any station or block in any order. Example: You

could insert station 3 between stations 1 and 2. The program

would run 1, 3, 2 (in that order).

Adjusted Run Times: The Adjusted Run Times show the

eects of the current Seasonal Adjust settings on the base

run time. If a run time is set to 10 minutes, but Seasonal

Adjust is at 50%, the Adjusted Run Time will show 5 minutes.

The Seasonal Adjust amount is not changed in this screen,

but can be set from the Programs menu, or automatically by a

Solar Sync sensor.

When all the Run Times for the program have been set, press

Back or Home to exit.

Built on Innovation® 17

Page 18

Basic Programming and Setup

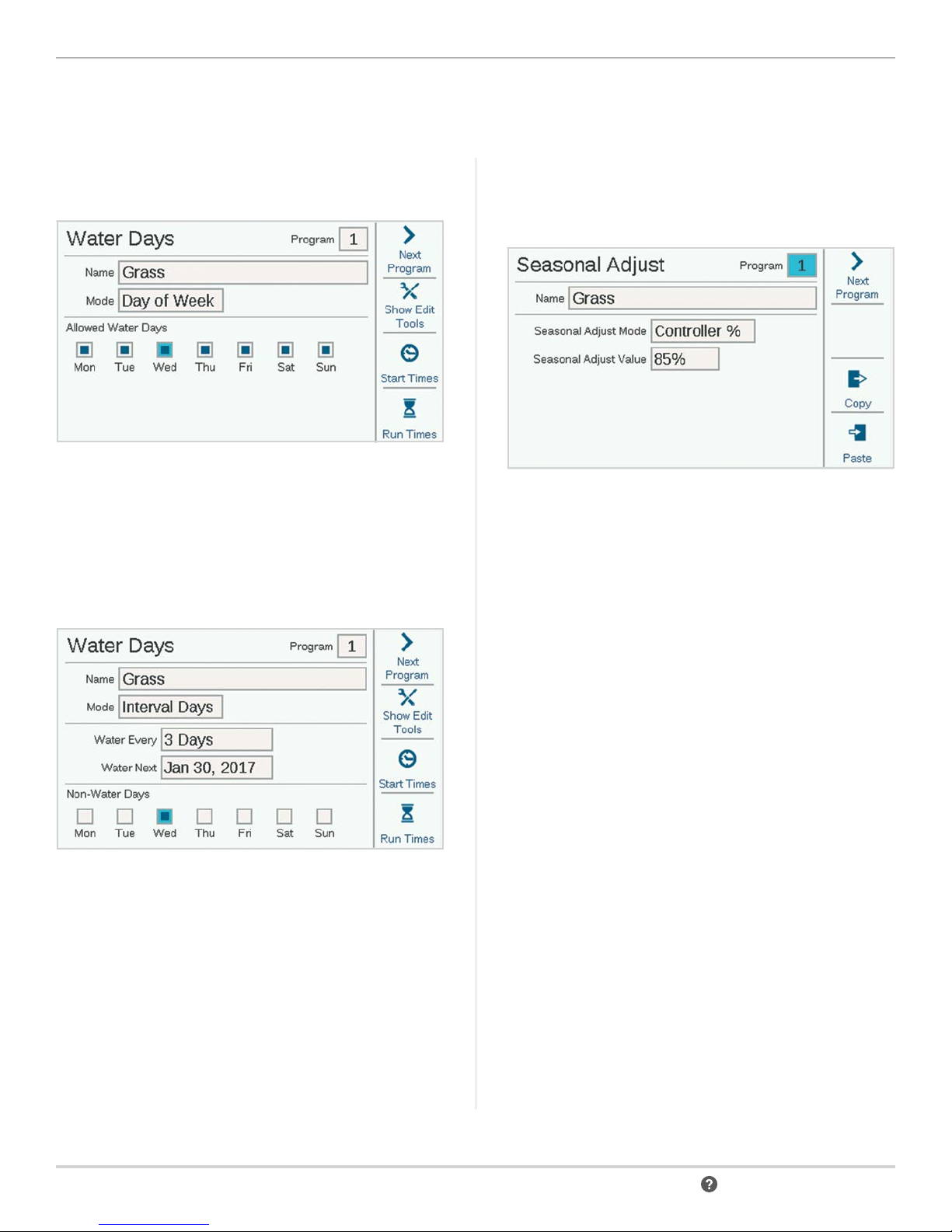

WATER DAYS

Verify you are in the correct program by number or name, and

set the days for automatic watering.

Mode selects a type of schedule.

• Day of Week: Check the boxes for the days the program

should water.

• Odd/Even: Water only on odd or even calendar dates,

to comply with water restrictions. An optional check box

allows skipping the 31st day of the month.

• Interval: Water every “x” number of days, regardless of the

day of week. Enter the desired interval days.

SEASONAL ADJUST

Programs menu, Seasonal Adjust.

When using Solar Sync, set up at Devices page rst, then go to

Seasonal Adjust.

• Seasonal Adjust Mode: Set a percentage adjustment to

all run times by Controller or Program, or set a Monthly

schedule for the controller to follow automatically, or

assign the program to Solar Sync automatic adjustment.

• Controller: The Seasonal Adjust value will follow whatever

has been set for the controller level. All programs set to

Controller will receive the same manual adjustment.

• Program: The Season Adjust factor entered here will only

apply to the selected program, and is not aected by other

adjustments.

• Monthly: Enter in advance the adjustment value for each

month of the year (usually based on historical weather

averages). These adjustments take eect automatically

on the 1st of each month, and do not change during the

month.

• Solar Sync: Adjustments are made to the selected program

automatically by a Solar Sync sensor attached to the

controller. This requires a sensor, and setup at the Devices

menu, Setup Solar Sync.

Both Odd/Even and Interval also have Non-Water Days, which

can set a day (for example, a mowing day) on which watering

will never occur, regardless of the schedule.

18 hunter.direct/ACC2help

Each Program must have a Seasonal Adjustment set. Copy

and Paste shortcuts permit copying the initial setup, and then

pasting it to all similar programs.

Page 19

Basic Programming and Setup

PROGRAM RULES

Program Rules customizes each program for special purposes.

IGNORE CALENDAR DAYS OFF

Check the box if the program should be allowed to run on

Calendar Days O that apply to other programs.

NO WATER WINDOW START AND END

Enter start and end times for the portion of the day during

which automatic irrigation is never allowed. Program will

never be allowed to run during this period, although Manual

operations will be allowed. If a program is suspended by a No

Water Window, it will be logged as an alarm, for corrective

action.

STATION DELAY DELAY BETWEEN STATIONS

Sets an interval between each station in a program. This can

be used for slow-closing valves, recharging pressure tanks,

etc. During the delay, the P/MV output will continue running

for 15 seconds, unless this is adjusted in the Devices, P/MV

Operation screen.

PROGRAM SUMMARY

Once a program has start times, run times, and water days, it

will run automatically without further setup. To see how the

program is congured, select Program Summary from the

Programming screen.

The Summary will show the total number of Programs ready

to run for the entire controller.

Press the Programs so key to view details for each program.

Press the Graph so key to view a chart of all programs

occurring over time. Turn the dial to view the graph up to 7

days in advance.

Non-Water Windows and Calendar Days O options will show

on the graph in red as Water Restrictions, meaning automatic

irrigation cannot occur during those periods.

CALENDAR DAYS OFF

Create a list of dates on which the whole controller will not be

allowed to run, regardless of Water Day settings. Programs

that have been set to Ignore Calendar Days O in the Program

Rules screen will be allowed to run anyway.

Built on Innovation® 19

Page 20

Basic Programming and Setup

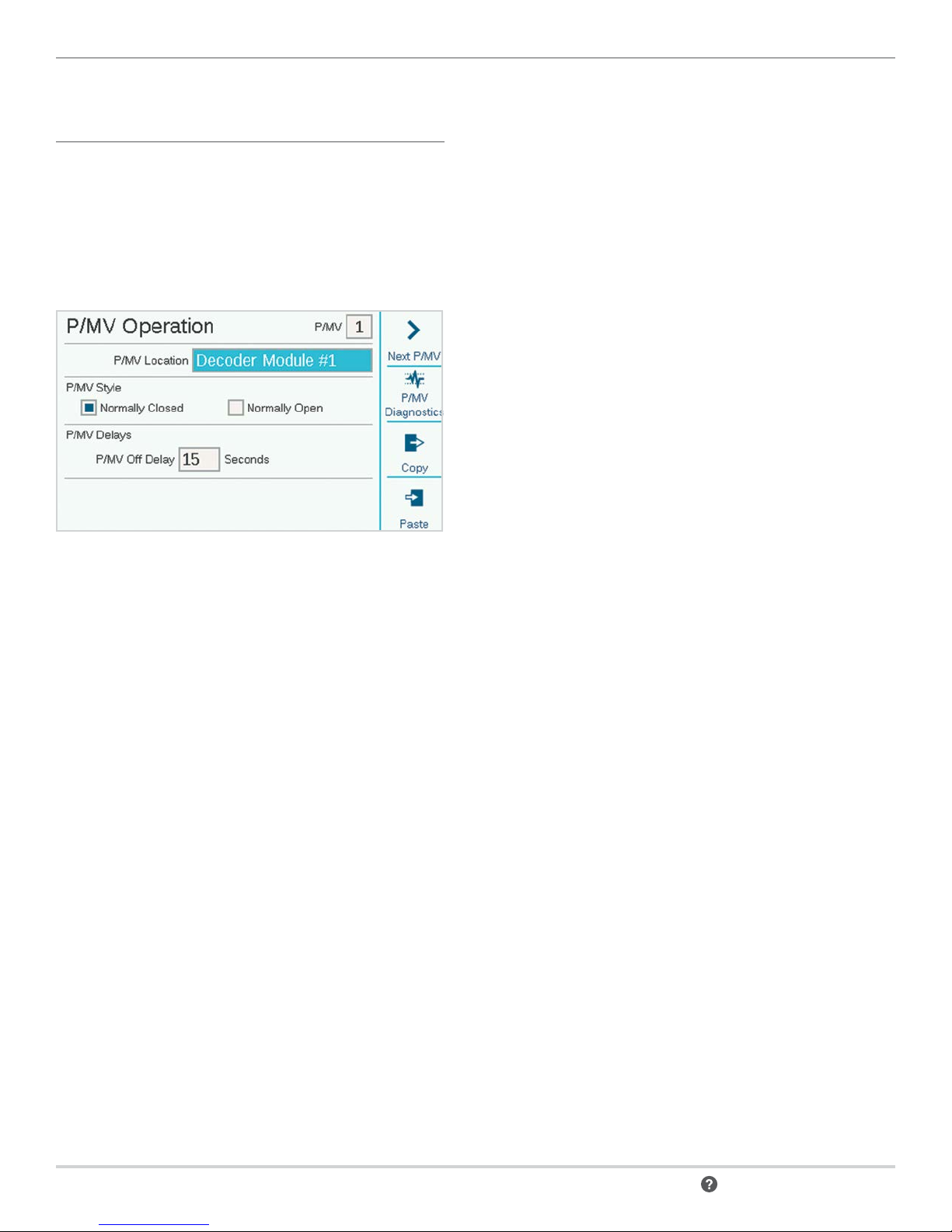

P/MV OPERATION PUMP/MASTER VALVE

OPERATION

Dial to the Devices menu, and select P/MV Operation.

The P/MV location must be set, to either Controller, or to the

correct decoder output module where a P/MV decoder will be

attached.

If the location is set to Controller, the P/MV number will refer

to the screw terminals on the Power Supply Board.

If the location is set to one of the decoder modules, the

controller knows the P/MV output is assigned to a decoder

on the two-wire path. If there are multiple decoder output

modules, it is important to specify which Decoder Module

(1, 2, or 3) it is.

Each P/MV will be checked for Normally Closed operation.

This is a station-level setting, meaning that the P/MV is

activated by stations when they begin to run. The Station

Setup menu allows you to set each station for the P/MV

outputs it need to run water.

Normally Open may also be selected, and is discussed further

in the Flow Operations section. Normally Open is not a

station level setting. The valve is always open until a problem

is detected at the Flow Zone, or MainSafe level, when the

controller activates the normally open P/MV to shut the

water o.

SENSORS

Rain shuto and other sensors must be setup in the Devices

menu. We tell the controller what sensors are connected, and

in some cases we set the response for each sensor.

CLIK SENSORS

Dial to the Devices menu, and select Clik Sensors for basic

Hunter Clik sensors.

To set up a sensor, click the box for Enable Clik Sensor Input.

The ACC2 sensor inputs are already congured as Normally

Closed, but this can be changed for other types of contactclosure sensor inputs to Normally Open.

It is also possible to enter a name for individual sensors.

Sensor location can be changed from Controller

(corresponding to the terminals on the Power Supply Board),

to any decoder output module, if the sensor is connected

to an ICD-SEN sensor decoder. Choose the decoder output

module to which it will be connected, and then select the

Sensor Decoder address and port.

P/MV Off Delay: This sets how long the P/MV output will

remain active aer a station stops calling for it (for example,

during Delay Between Stations). It is preset to 15 seconds, but

can be changed (use caution). Hunter is not responsible for

damage to pump components when longer delays are set.

P/MV Diagnostics: Press the so key for P/MV Diagnostics to

view the status and current draw of each active P/MV output.

P/MVs that are not running are not shown.

20 hunter.direct/ACC2help

Page 21

Basic Programming and Setup

SENSOR RESPONSE

Located on the Devices menu, Sensor Response sets which

sensors will shut o which programs, in basic operations.

The sensor responses are set up for each program, one

page at a time. If you want the same responses for multiple

programs, set up the responses for the rst program, then

click the Copy so key. You can then change the program

number and click the Paste so key to duplicate the settings.

There are three standard Clik sensor inputs on the Power

Supply Board. If a Hunter Solar Sync sensor has been

congured, there are also settings for Solar Sync Rain and

Freeze.

Ignore: This means the program does not respond to the

sensor.

Pause (use caution): This means that the program stops

where it is when the sensor is active. If the sensor returns to

normal, the program will resume watering where it le o,

causing the program to end later than originally scheduled.

It is not possible for a program to be set to both Pause and

Suspend for dierent sensors, because they cannot both be

active at the same time. If you change a response setting for

a sensor, and another sensor for the same program changes

automatically, this is not a bug.

Rain Delay: In the Sensor Response menu, press the so key

for Rain Delay. This optional setting will cause watering to stay

o for a set number of days, aer the sensor activation is over.

Select the number of days for watering to stay o for each Clik

sensor input.

Suspend (recommended): This means the program suspends

watering when sensor is active (alarmed) but keeps track of

time. If the sensor returns to normal, the suspended program

will resume irrigating where it should be at that time in

the schedule. The program will end when it was originally

scheduled to end.

Built on Innovation® 21

Page 22

Basic Programming and Setup

SOLAR SYNC

Aer connecting a Solar Sync sensor to the controller, set up

operation in the Devices, Solar Sync menu.

• Check the box to Enable Solar Sync.

• Choose the Region and set the Water Adjustment,

according to the Solar Sync manual instructions.

• For normal operations, this is all that is necessary. It will

take the Solar Sync two or three days to register enough

climate data to begin adjusting.

Solar Sync Delay allows a number of days to wait before

automatic Solar Sync adjustment goes into eect (to establish

new landscape, for example). Enter a number of days (1250)

to wait, and specify the Adjustment During Delay percentage

to use during the delay period. At the end of the delay, the

Solar Sync will begin adjusting automatically for the current

climate conditions.

The delay does not interfere with the Solar Sync Rain and

Temp functions. They will be operational during the delay.

Complete the setup by setting the programs to use Solar Sync

in the Program, Seasonal Adjust menu.

FLOW SENSORS

To connect one or more ow sensors, set up operation in the

Devices, Flow Sensors menu.

Select the sensor input number (1–6) to be set up. The

controller has three Flow Sensor inputs built in, but three

more can be added with the A2C-F3 Flow Expansion module.

ACC2 Decoder versions may also read ow via the two-wire

path when ow sensors are connected to ICD-SEN sensor

decoders. Use the Location window to select Controller

(corresponding to one of the Flow terminals on the Power

Supply Board or A2C-F3 ow expansion modules), or to select

the decoder output module to which the ow sensor will be

connected.

Specify the address of the sensor decoder for the ow sensor.

Flow sensors may only be connected to Port “A” of a sensor

decoder.

Check the box for either “Hunter” or “Other” ow meters.

If Hunter is checked, move to the Model eld and select the

Hunter FCT model number for the diameter of the pipe. This is

all that is necessary to calibrate the setup.

“Wireless” is only checked for use with the Hunter WFS

(wireless ow sensor), which requires a receiver installed at

the controller.

22 hunter.direct/ACC2help

If Other is checked, you must select the Flow Sensor Style

and enter the calibration information. Some use K-factor and

Oset, and others are Pulse type. Consult the ow meter

supplier’s documentation for the correct settings or contact

Hunter Technical Support for additional information.

K-Factor and Offset: Obtain these values from the ow sensor

manual, and enter here.

Page 23

Pulse type: Enter the amount equal to a single pulse.

Enter the information for each ow sensor that is connected

to a ow terminal. There are copy and paste so keys

available, if all the meters are the same type and size.

Stations Menu

Stations Menu

Most of the items in Stations are covered in more detail in

other sections.

STATION SETUP

Once this information is entered for each ow sensor input,

the controller is ready to read ow. However, each ow sensor

must be attached to a Flow Zone (Flow, Flow Zones) before

real time monitoring can occur.

Flow Totals may be viewed at the Flow menu.

Current ow rates (by sensor) can be read from the Home/

Activity screen with the View Flow so key.

Flow Monitoring: Additional setup for station level ow

monitoring is required in the Flow menu (Flow Zones), and in

the Stations, Station Setup menu.

Allows stations to be named. Most other functions are

described in more detail in the Flow Operations section.

Station P/MV Usage indicates which normally closed P/MV

outputs the station will activate, whenever it runs.

Station Flow Zone assignment (required for Flow Manager

and/or Flow Monitoring).

Flow Priority (used in Flow Manager): Check the box to make

a station is more likely to water earlier in ow management.

Flow Rate: Enter or learn the typical ow for the station. Used

in both Flow Manager and Flow Monitor.

Delay: Sets the amount of time the station can run before

high or low ows will cause an alarm. Set longer delays for

stations that take longer to stabilize ow.

P/MV boxes with the “X” are unavailable, because they are

already assigned to other Flow Zones or MainSafe™ zones.

Built on Innovation® 23

Page 24

Stations Menu

CYCLE & SOAK

This function is used to control runo and puddles when soil

or slope cannot absorb all irrigation at once.

Set the Cycle to the maximum time the station can run at

once, before runo occurs.

Set the Soak to the minimum time the station must wait

before applying another cycle. The controller will water

other stations during the Soak period. For this reason, Cycle

& Soak generally does not extend the overall watering time

signicantly.

The copy and paste shortcuts allow quick duplication of these

settings to stations with similar characteristics.

BLOCKS

A Block is an electronic group of stations that runs at the

same time, for the same run time, within a program. (Blocks

replace “SSGs” in the original ACC.)

To create a Block, dial to the Stations menu and select Blocks.

Enter a Name for the Block if you wish.

Dial down to the station spaces, click and enter the station

numbers that will be in the Block.

• Blocks may also have their own Cycle and Soak settings.

• Blocks may have up to eight stations each.

• There can be up to 64 Blocks per controller.

• They can be mixed in a program with individual stations.

• Programs with Blocks are not limited in any way by other

programs that are running. The controller will not turn on

more stations than it can handle, so there are no articial

rules governing the Blocks.

24 hunter.direct/ACC2help

Page 25

Stations Menu

STATION LIMITS

Station Limits set how many stations can run at once, at

various levels.

Stack or Overlap means that each program can be manually

set to Overlap with other programs, or be required to stack.

Programs that are set to stack can only run by themselves.

SmartStack species a maximum number of programs that

are allowed to overlap across the whole controller.

STATION SUMMARY

The Station Summary is a report available for each station

showing exactly how it is going to run, based on the current

setup and programming. It is a report only, and does not allow

changes to be made directly from this screen.

Maximum Simultaneous Stations is the total number of

simultaneous stations that can occur for any reason in the

entire controller. This is mainly for use with the Flow Manager,

but applies to all situations.

If Flow Manager is enabled, the display will also show Program

Limits. This sets the max number of stations that can run

within any one program. This might be used to force irrigation

to be spread over a larger number of programs, when Flow

Manager is scheduling stations on to reach a ow rate target.

ACC2 Decoder can operate up to 30 simultaneous stations per

controller, but only 20 per decoder output module.

Built on Innovation® 25

Page 26

Devices Menu

Devices Menu

Devices allows setup of common external devices that the

controller can use. The functions in the Devices menu are

covered in more detail in other sections.

P/MV OPERATION

Set the Location for the P/MV (terminals on the controller

power supply board, or the decoder output module if using

decoder control).

SOLAR SYNC

Solar Sync setup is covered in detail in the Basic

Programming, Sensors, Solar Sync section.

CLIK SENSORS

Clik sensor setup is covered in detail in the Basic

Programming, Sensors, Clik Sensors section. Hunter sensors

are normally-closed, and open when an alarm is active. The

sensor inputs can be changed to normally-open (close on

alarm) when used with other devices.

SENSOR RESPONSE

Sensor Response is covered in detail in the Basic

Programming, Sensors, Flow Sensors section.

A sensor response setting is required for any sensor to be able

to shut o any program in the controller.

Set the Style, Normally Closed or Normally Open, for the

Pump/Master Valve outputs.

Change Location, if the P/MV is assigned to a decoder instead

of a controller terminal.

Pumps should always be set to Normally Closed to prevent

damage.

The P/MV Delay sets how long the P/MV will remain active if a

station pauses, such as during the delay between stations.

FLOW SENSORS

Flow Sensor setup is covered in detail in the Basic

Programming, Sensors, Flow Sensors section.

26 hunter.direct/ACC2help

Page 27

Flow Menu

Flow Menu

The ow menu includes all setup for the various ow

functions. These are described in detail in the Flow Operations

section on page 34.

CLEAR FLOW ALARMS

The Clear Flow Alarm function enables a MainSafe or Flow

Zone that has had an Overow alarm to water again.

If the Alarm Clear Delay is set to Manual Only, a user must

manually clear the alarm with this function before it can water

again.

Settings Menu

TIME/DATE

This function sets time and date. See the Basic Programming

section on page 13.

REGIONAL SETTINGS

This function sets regional preferences. See the Basic

Programming section on page 13.

If Alarm Clear Delay is set to a time in HH:MM format, the

controller can run irrigation in the MainSafe or Flow Zone

automatically again, aer the time has elapsed.

Built on Innovation® 27

Page 28

Settings Menu

USER MANAGEMENT

This allows a password to be created for the controller.

Users will be required to enter the correct PIN (personal

identication number) before operating the controller. If a

single PIN is entered at the top, it is required for all users, and

provides the same level of access to all.

If passwords are enabled, and the password is lost

or forgotten, you will be locked out of the controller.

Check the box for Enable User Management to create one or

more PINs. Once it is checked, only an Admin-level user who is

successfully logged in can uncheck this box.

There are two levels of authorization, Admin and Crew.

Crew-level access allows to manual operations and the ability

to view programming.

Only Admins can modify programming and other settings.

User log-ins are tracked in the Controller Log.

To add a user, press the so key for New User. You may then

enter the user’s name with the keyboard that will appear

when the Name eld is selected. For each user, select the Type

(Admin or Crew), and create a unique PIN for that person.

It is also possible for an Admin to delete users with the Delete

User so key.

Users will be automatically logged o aer 30 minutes of no

activity.

NETWORKING

If the internal Wi-Fi or LAN modules are installed, Networking

will display the network settings of these devices.

Network Info: Displays current setup. Only Wi-Fi Direct

Connect is supported at this time. The Network shown will be

HunterACC-xxxx, where xxxx is a number code, and this is the

device address to search for in your mobile device.

It is also possible to dene dierent users, and individual PINs.

Wi-Fi Setup: The Wi-Fi Setup menu displays two check boxes,

Direct Connect (for a nearby mobile device) and Network.

The Network selection will show nearby networks, but

network connections are not supported at this time. Direct

connections from a smart mobile device will allow remote

control, text entry, and ow reporting within the range of the

mobile device.

Central Setup: This will show addresses and URLs for future

use, but this is not supported at this time.

28 hunter.direct/ACC2help

Page 29

Diagnostics Menu

Diagnostics Menu

Attention messages do not interfere with normal automatic

irrigation.

All attention messages in the Home screen create logs. The

rst step to understanding any problem or message is to

click the so key for View Logs, or access the logs from the

Diagnostics menu.

Other helpful tools are also located at Diagnostics. Decoder

controllers include separate diagnostics for decoder

conditions in the Decoder menu.

VIEW LOGS

There are three types of logs, and a lter function to narrow

the number of logs displayed.

ALARM LOGS

The controller will store up to 250 alarm logs, with date and

time, beginning with the most recent alarm. Use the dial to

advance forward and backward through the alarm list.

CONTROLLER LOGS

Other signicant messages that are not technically alarms are

stored in the controller logs (up to 250 events). They are also

arranged by date and time, with the most recent log rst.

Built on Innovation® 29

Page 30

Diagnostics Menu

STATION LOGS

Station logs record every event that occurs in the controller

(up to 1,500 events), beginning with the most recent. This can

be useful for advanced troubleshooting, or to verify that a

station actually watered.

FILTER LOGS

This allows any of the three logs to be ltered by date, or by

record number.

EXPORT LOGS

All logs can be written to the SD card. This function

is described in more detail in the Advanced Features

section on page 32.

MODULE INFO

Select Module Info to see current version of all rmware in

all modules in the controller. Modules that are empty or not

reporting are shown as Not Present.

So keys allow shortcuts to other diagnostic checks, which

are also available directly from the Diagnostics menu.

When the facepack is reversed in the frame, it will

automatically go to the Module Info screen. The facepack

is still fully operational, and pressing the Home button can

access all programming functions when the facepack is

reversed. The controller will still run automatically if the

facepack is le reversed.

CLIK SENSOR DIAGNOSTICS

• Sensor: This shows each sensor and same.

• State: This shows the current status of the sensor.

- Inactive means the sensor is normal.

- Active means the sensor is currently alarmed.

- Delayed means the sensor was recently alarmed, and is

now inactive, but a Rain Delay is in eect for the sensor.

- Disabled means the check box for the sensor (Devices

menu) is unchecked, and no responses will be caused by

the sensor.

• In Use?: This shows whether the sensor is currently in use

at the Sensor Response menu to shut down any programs.

30 hunter.direct/ACC2help

Page 31

Diagnostics Menu

STATIONP/MV DIAGNOSTICS

This shows the electrical current draw in milliamps for all

active stations and P/MV outputs.

FLOW SENSOR DIAGNOSTICS

This shows the conguration of each ow sensor and current

ow. Frequency shows the click or pulse rate from the sensor,

for diagnostic purposes.

SOLAR SYNC DIAGNOSTICS

This shows the last time the Solar Sync sensor communicated,

and the current state of its alarm sensors (Rain and Freeze).

The Test Connection so key checks for the presence of a

wired sensor, or for the presence of the receiver for a wireless

sensor. Test does not initiate communications to the wireless

sensor itself, because it is a one-way connection.

DECODER DIAGNOSTICS

A shortcut now appears in this menu to the Decoder

Diagnostics screen. See the Decoder Diagnostics section on

page 56 for more information.

Built on Innovation® 31

Page 32

Advanced Features

Advanced Features

EXPORT LOGS

Logs may be exported in a simple text format to the internal

SD card in the facepack if additional help is needed for

troubleshooting, or just for record-keeping purposes.

Enter a unique le name by clicking in the File Name box.

Select the boxes for the types of Logs desired.

Select and click the Export Logs button to save the le to the

SD card. The card may then be inserted into a computer or

other device with SD card reader, and saved or sent to another

location.

EASY RETRIEVE

This saves the current controller setup, so that it may be

restored to this point at a future date.

Controller Memory: Only one setup may be saved in

Controller Memory, and it will remain unless you make

changes and create a new Easy Retrieve backup in the future.

You can choose Restore at any time, and it will change the

whole controller to the last Easy Retrieve backup.

SD Card File: You can also save Easy Retrieve backups to the

SD card via the SD card slot in the facepack (to do this, an SD

card must be installed). You may also restore from the SD card

to any saved Easy Retrieve in the future.

When saving to SD card, you must enter a name for the le.

Click to select the File Name, and a keyboard will appear. Enter

the name for the le, and choose Done from the keyboard

when complete.

Using the SD card and dierent le names allows you to save

as many backups, under dierent names, as the card will hold.

You can restore any one of them from the SD card by entering

the correct le name. The SD card cannot display a list of the

saved les, so be sure to enter the le name exactly as it is

saved on the card.

32 hunter.direct/ACC2help

Page 33

Advanced Features

RESET MEMORY

Sometimes it is preferable to simply erase the controller,

to begin again from a clean start. There are several Reset

options.

All Programming and Devices: This erases all programs and

device setups, but keeps the Flow Totals intact.

This will require completely reprogramming all devices, ow

setups, and irrigation schedules.

Flow Totals: This clears the ow total history and resets all

to zero.

Check the boxes for the items you wish to clear, and press

Delete. The controller will ask if you are sure before erasing

any data.

FIRMWARE UPDATE

ACC2 can be updated whenever a new version of the

operating system, or any of the internal modules, is released.

These updates are usually available from the

hunterindustries.com website, or are sent via email. It is

always advisable to stay current with controller updates.

Copy the update les onto a compatible SD card, and insert in

the SD card reader.

Select Firmware Updates from the Settings menu. The

controller will detect and display available updates on the

card.

Press the so key for Update, and the les will be copied to

the controller. Wait until the automatic reboot is complete,

and the controller will be up to date.

Do not turn o power to the controller or facepack,

once the update has started. Damage may result.

ACC2 Decoder controllers can also store a new version of

decoder rmware, if available. Decoders can be updated

separately via the two-wire path, using the Decoder menu.

This is not done automatically, and must be selected from the

Decoder menu (see Update Decoders section).

CONDITIONAL RESPONSE

Conditional Response allows active responses to various

sensors or other conditions. It can be used to:

• Start a station, block, or program based on a sensor input

• Switch P/MV outputs based on a switch position

• Activate an external light (SOS) to indicate an alarm in the

controller.

This is explained in more depth in the Conditional Response

section. This is a very powerful option, and should be used

with care. Read the Conditional Response section on page

33 before using these features.

Built on Innovation® 33

Page 34

Flow Operations

Flow Operations

The two major parts of Flow Operations are the Flow

Manager, and the Flow Monitor.

Checking either will display a reminder of the steps for setting

these features up. Press the Continue so key to set up the

selected function.

FLOW MANAGER

Flow Manager uses station ow information to run

simultaneous stations to reach a ow rate target that is

specied by the user. It will turn on as many stations as it

can to stay at or near the ow target until there are no more

stations to run. This does not require a ow sensor input.

FLOW MONITOR

Flow Monitor veries that actual ow matches the learned

ow for all running stations, and performs diagnostics or

shutdowns when alarms occur. Flow Monitor requires one or

more flow sensor inputs in order to operate, and at least one

Master Valve (P/MV) per ow sensor to be eective.

At the Flow menu, check the boxes to Enable Flow Manager

and/or Enable Flow Monitor if desired. Verify that all set up

information is exactly correct according to the following steps.

MAINSAFE™

Enable MainSafe has its own check box. MainSafe is a special

function for higher level ow monitoring and mainline

protection.

Do not check the MainSafe box until the optional

feature is completely understood.

MainSafe requires a separate ow meter and master valve. It

is designed to protect longer runs of large diameter mainline

pipe that are upstream from the Flow Zones themselves. If

a mainline pipe experiences a high ow, or continues to ow

when all irrigation is suspended, MainSafe provides a rapid

shutdown response to prevent a prolonged serious leak.

MainSafe can also be congured to watch over separate,

always-on manual watering pipes, and provide an emergency

response if a break occurs.

34 hunter.direct/ACC2help

Page 35

SET UP FLOW MONITOR

Flow Operations

The Flow Monitor requires the following information to

operate correctly:

• Install and set up a ow sensor (Devices menu).

• Install and set up a P/MV (Devices menu).

• Set up a Flow Zone, and complete all information for the

Flow Zone (Flow menu).

• Attach each station to a Flow Zone (Station Setup menu).

• Learn Flow for all stations with run times (Flow menu).

FLOW ZONES

A Flow Zone denes a section of pipe and a group of stations

attached to that pipe, which is managed as a hydraulic unit.

Flow Zones are used for both Flow Manager and Flow Monitor.

FLOW MAP

In the Flow Zones menu, press the so key for Flow Map. This

tells the controller how the Flow Zone is connected, and which

devices are used in that hydraulic unit. All stations must be

downstream from the ow sensors and master valves that are

checked here.

Flow Sensor Assignment: Check the box for the Flow Sensor

or sensors connected to the Flow Zone.

If an X is in one of the Flow Sensor boxes, the sensor has

already been assigned to another Flow Zone, and is not

available for this Flow Zone.

Each Flow Zone has a check box for “Manage Flow” and

“Monitor Flow.” To monitor ow, check that box. Then

complete the settings and rules for the Flow Zone.

Overflow/Underflow Alarm Limits: ACC2 sets the over-

and underow limits for each station’s learned ow at the

ow zone level. Enter the maximum and minimum ow

percentages you want the Flow Zone to allow for the stations

attached to the Flow Zone. If these limits are set too close to

100%, there is a greater chance of false alarms, due to natural

uctuations in the ow.

If a Flow Sensor number does not appear, it has already been

assigned to a MainSafe, and is not available for Flow Zone

monitoring.

P/MV Assignment: Check the box for the Master Valve that is

installed in line with the ow sensor on this ow zone.

If an X is in one of the P/MV boxes, it has already been

assigned to another Flow Zone, and is not available for this

Flow Zone.

If a P/MV number does not appear, it has already been

assigned to a MainSafe, and is not available for Flow Zone

monitoring.

MainSafe™ Assignment: If using this optional feature, select

the MainSafe zone that is upstream from the Flow Zone. If

MainSafes are not being used, leave this set to “None.”

The Flow Sensor and P/MV assignments for the selected

MainSafe zone are shown to the right.

Built on Innovation® 35

Page 36

Flow Operations

FLOW LIMITS

In the Flow Zones menu, press the so key for Flow Limits.

Maximum Flow: This sets the highest possible ow rate

allowed in the Flow Zone for any reason. This should be

considerably larger than the maximum ow allowed in normal

irrigation (so that it does not alarm before station-level

diagnostics can be performed). When the ow sensor detects

a ow higher than this, the irrigation will be shut down.

Unscheduled Flow: This is the maximum amount of ow

allowed when no stations are actively running. This is only

to allow manual watering by hand when the controller is

not watering automatically. When the rate is exceeded, the

controller will alarm.

FLOW ALLOWANCES

In the Flow Zones menu, press the so key for Allowances.

Watering Budget: Enter the total amount of ow that can be

allowed in this Flow Zone in the calendar month. If the total

ow exceeds the monthly budget, an alarm message will

appear on the screen. The controller will not automatically

stop watering when this alarm occurs.

Manual Watering Allowance: This sets an additional ow

rate amount allowed for manual irrigation. This is added to

all other limits in the controller and prevents alarms from

occurring until the expected ow — plus the amount entered

here — is exceeded.

If Unscheduled Flow is set to OFF, the controller will not

respond to unscheduled ow.

Flow Alarm Delays: This sets an amount of time before the

Max or Unscheduled ow rates will cause an alarm, and sets

how long the Flow Zone will be shut down.

Alarm Delay: High ows will alarm immediately if this is set to

None, or they will be ignored until they have lasted as long as

the time entered here. Set in M:SS format; the longest delay

is 9 minutes, 59 seconds. This can eliminate false alarms from

temporary surges in ow.

This delay should be longer than the delays for the stations

attached to the Flow Zone.

Alarm Clear Delay: This sets the amount of time a Flow

Zone will remain shut down before allowing new automatic

irrigation attempts. Set in HH:MM format, the longest delay

setting is 23 hours, 59 minutes.

If Alarm Clear Delay is set to Manual Only, automatic

irrigation will never resume aer a high ow or unscheduled

ow alarm, until it is manually cleared by an operator at the

controller. The operator must dial to the Flow menu, select

Clear Flow Alarms, the Flow Alarms that should be cleared,

and click Clear Selected.

36 hunter.direct/ACC2help

Page 37

Flow Operations

STATION SETUP

Dial to the Stations menu, and choose Station Setup. Each

station must be assigned to a Flow Zone to complete Flow

Monitor operation.