Page 1

Page 2

TABLE OF CONTENTS

INSTALLATION PREPARATION………………………………………………………. 2

Parts Supplied……………………………………………………………………. 2

Accessories………………………………………………………………………. 2

Installation Overview……………………………………………………………. 2

Alternative Transducers and Mounting Methods…………………………….. 4

Transducer Exchange…………………………………………………………… 5

INSTALLATION………………………………………………………………………….. 6

Transom Installation…………………………………………………………….. 6

Inside the Hull Installation………………………………………………………. 10

Control Head Installation……………………………………………………….. 12

Test the Installation……………………………………………………………… 15

FEATURES AND FUNCTIONS………………………………………………………... 16

USING THE TCR ID-1………………………………………………………………….. 17

How Sonar Works……………………………………………………………….. 17

Built-In Simulator………………………………………………………………… 19

Reading the TCR ID-1 Screen………………...………………………………. 20

Functions…………………………………………………………………………. 23

SPECIFICATIONS……………………………………………………………………… 27

MAINTENANCE AND WARRANTY………………………………………………….. 28

Maintenance…………………………………………………………………….. 28

Troubleshooting…………………………………………………………………. 29

Warranty…………………………………………………………………………. 32

Service Policy…………………………………………………………………… 33

Customer Support………………………………………………………………. 34

Page 3

TRANSDUCER MOUNTING PROCEDURE

Humminbird’s high -speed transducer is supplied with your LCR. This transducer has

been designed to give good high speed readings on most all boat designs, including

aluminum.

Please carefully consider the following before in stalling your transducer.

TRANSDUCER MOUNTING OPTIONS

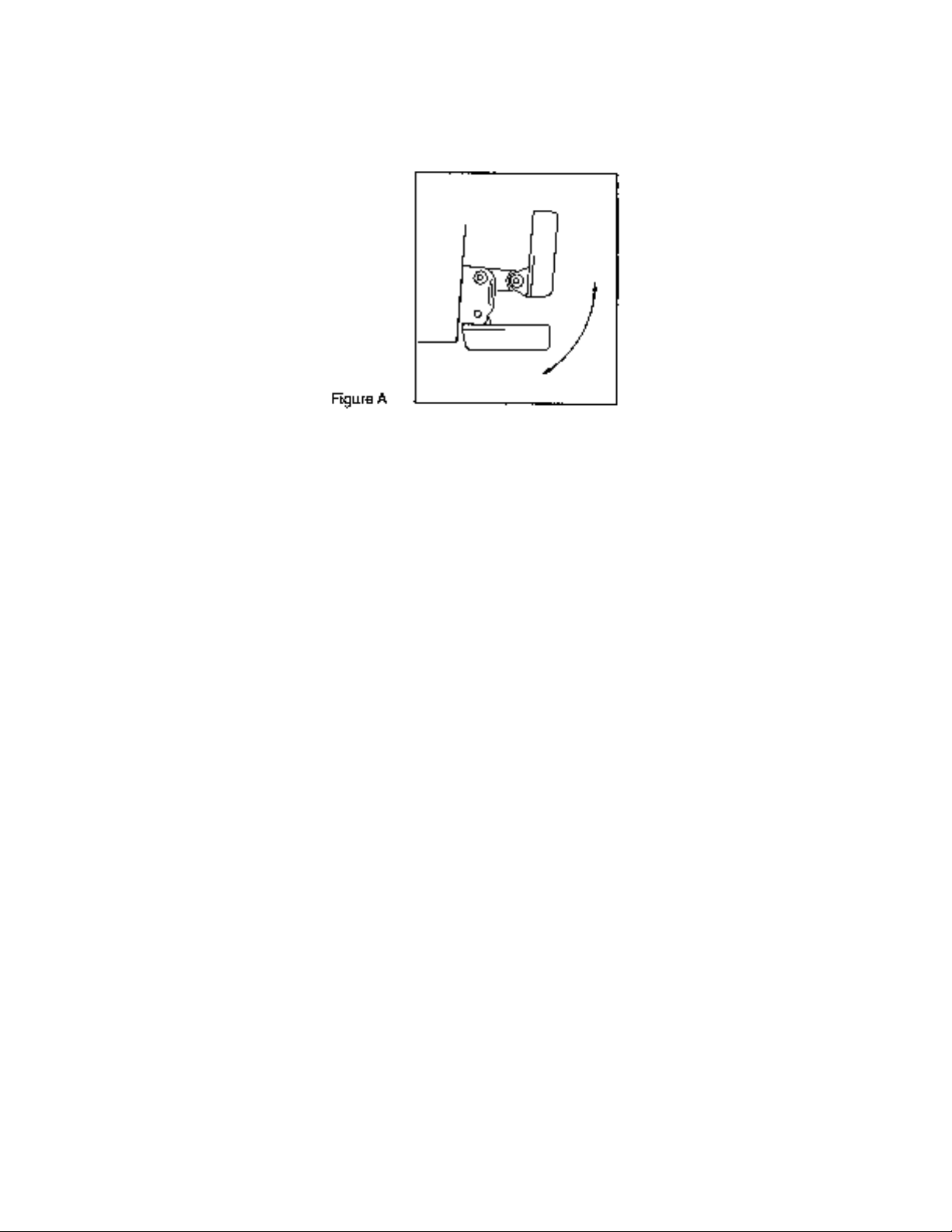

A. Transom Mount- The Humminbird high speed transducer allows the transducer

element to be mounted below the bottom of the boat hull keeping the transducer out

of turbulent water and insuring good high speed operation. The transducer will

Page 4

absorb the blow of any obstruction by rotating up out of the metal spring bracket

without harming the transducer, or your boat. The transducer can be re-engaged by

simply rotating the transducer down and snapping it back in place. (See Figure A)

B. Inside Hull Mount- The high speed transducer can be mounted inside the hull

(without pivot assembly) using the proper two-part epoxy, such as Humminbird’s

epoxy kit. Even though there is some loss of signal in shooting through the hull, your

LCR will perform well with this type of installation. You cannot shoot through the hull

of an aluminum boat.

C. Trolling motor Mount- This type of transducer is not supplied with your LCR. It is

designed to mount on the foot of a trolling motor. You may exchange your un-used

high speed transducer for a trolling motor transducer. Call the Humminbird

Customer Service Department.

D. Bronz Thru -Hull Mount- This transducer is not supplied with your LCR but for an

additional cost you may exchange y our un-used high speed transducer for a bronz

thru -hull. The bronz thru-hull transducer has a threaded stem which installs through

a hole drilled in the boat hull, leaving the housing exposed under the boat. This type

of installation must be used for many boats with in -board engines, because there is

no suitable location on the transom away from the noise and turbulence created by

the prop. A bronz thru -hull transducer should be installed by qualified personnel

only.

The LCR will operate well at high speeds with a properly mounted transducer.

Remember, a transducer will not work transmitting through air or through air

bubbles.

1. TRANSOM MOUNTING PROCEDURE

Step 1.

MOUNTING LOCATION- It is important that the transducer be mounted on the transom

where water flow is in constant contact with the transducer. You may wish to observe

the rear of the boat while it is moving through the water to determine the best mounting

location.

Step 2.

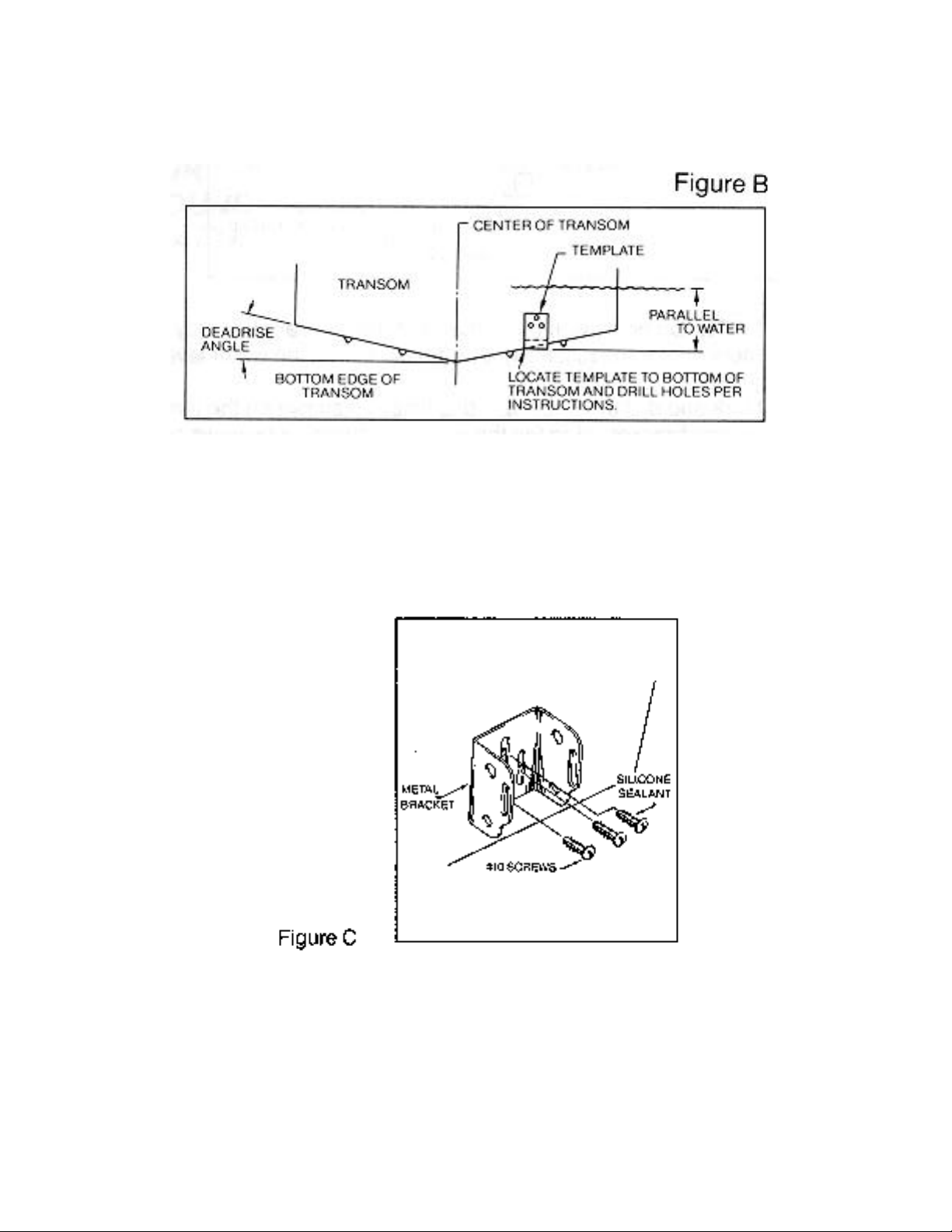

BRACKET INSTALLATION (Aluminum Boats)- To install the metal bracket on an

Page 5

aluminum boat locate the template on the transom between rows of rivets, or ribs that

are on the bottom of the boat. Align the template so that the bottom corner of the

template nearest the center of the transom is on the bottom edge of the transom.

Once the location is determined mark and drill three 7/64” dia.. holes noted on the

template. Attach the metal bracket using three #10 self threading screws supplied. Be

sure to align holes in the center of the

Bracket slots. On some aluminum boats it may be necessary to use a wood back-up

plate. It is important to use a silicone sealant between the screwhead and bracket in

order to prevent leaking. (See Figure C)

Step 2.

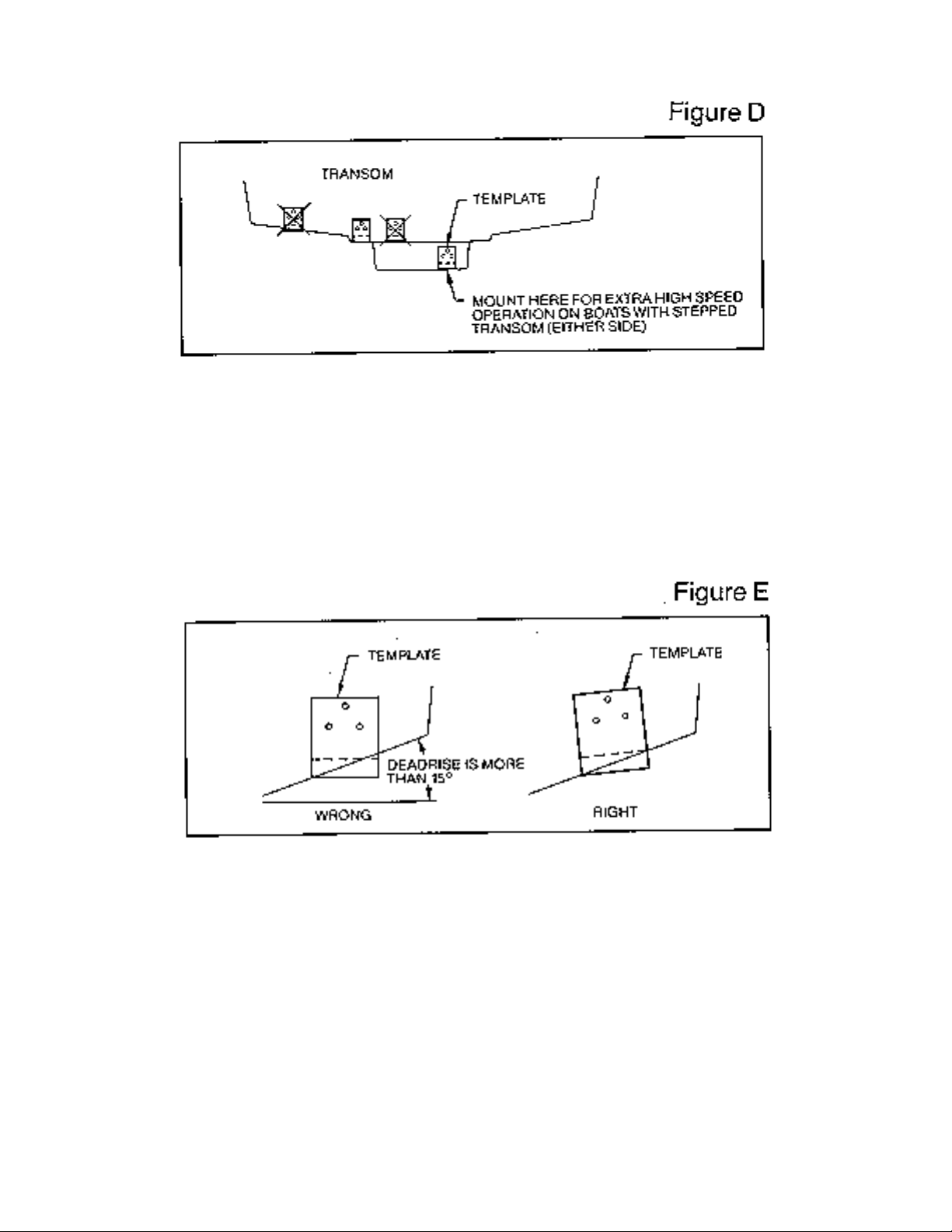

BRACKET INSTALLATION (Fiberglass Boats)- If your boat has a stepped transom

located below and under the main transom, the compact transducer design allows

mounting in this area. This mounting location is recommended for good reading at very

high speeds. (See Figure D)

To install the metal bracket on a fiberglass boat, locate the template on the transom in

the same manner as for an aluminum boat. (See Figure C)

Page 6

NOTE: On boats with more than 15 degree deadrise angle it may be necessary to

mount the transducer slightly off parallel with the water level. (See Figure E)

Mark and drill the three 9/64” dia. holes as shown on the template. Attach the metal

bracket using the three #10 self threading screws supplied. Be sure to align the holes so

that they are centered vertically in the three slots found in the bracket. It is important to

use a silicone sealant between the screwhead and bracket in order to prevent leaking.

Step 3.

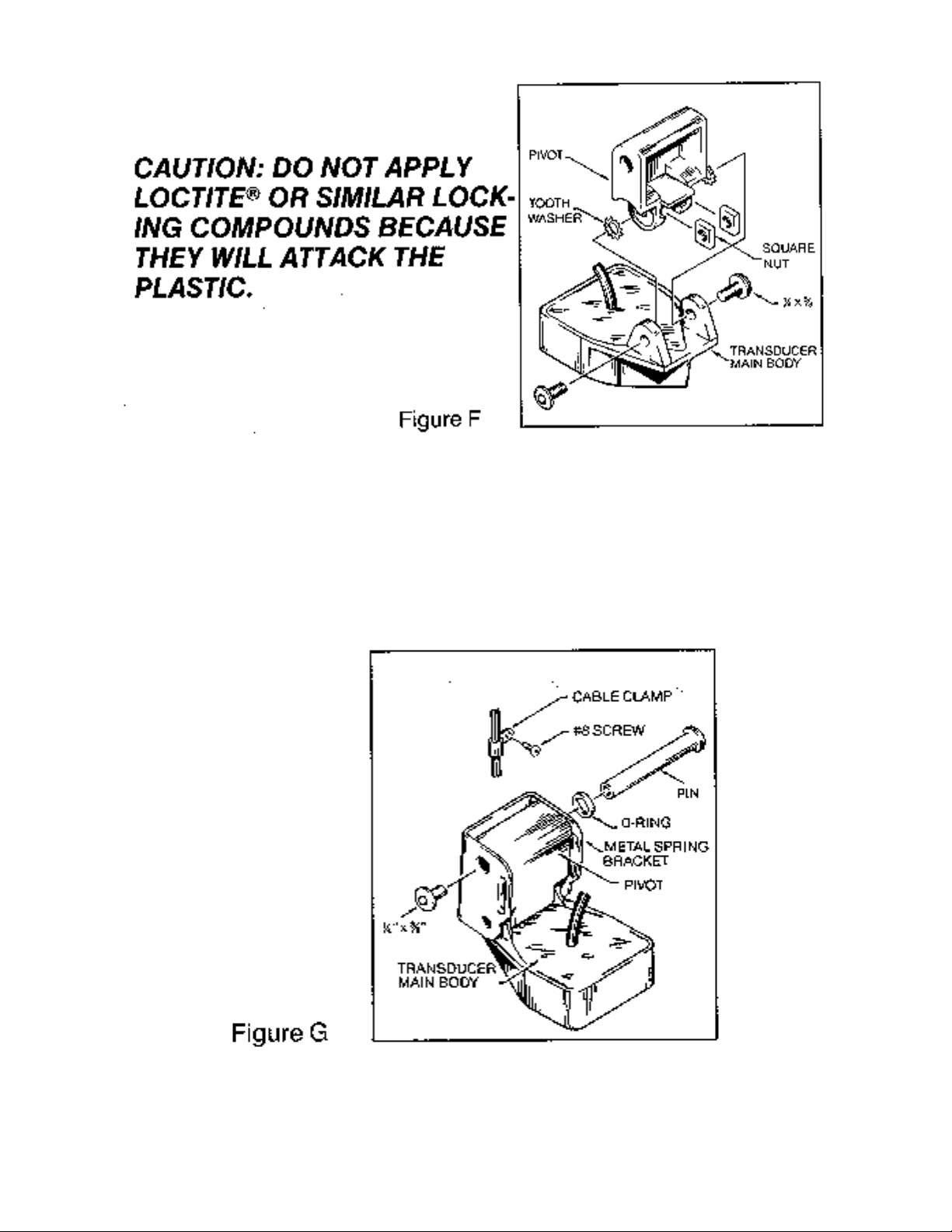

TRANSDUCER PIVOT ASSEMBLY- Assemble the pivot to the transducer main body

using the two ¼”x5/8” allen head screws, two 3/8” tooth washers and two, ¼” square

nuts. Make sure the tooth washers are sandwiched between the transducer main body

and the pivot. The square nuts are trapped inside the pivot and will not rotate as the

allen head screws are tightened. HOWEVER, DO NOT TIGHTEN AT THIS POINT.

(See Figure F)

Page 7

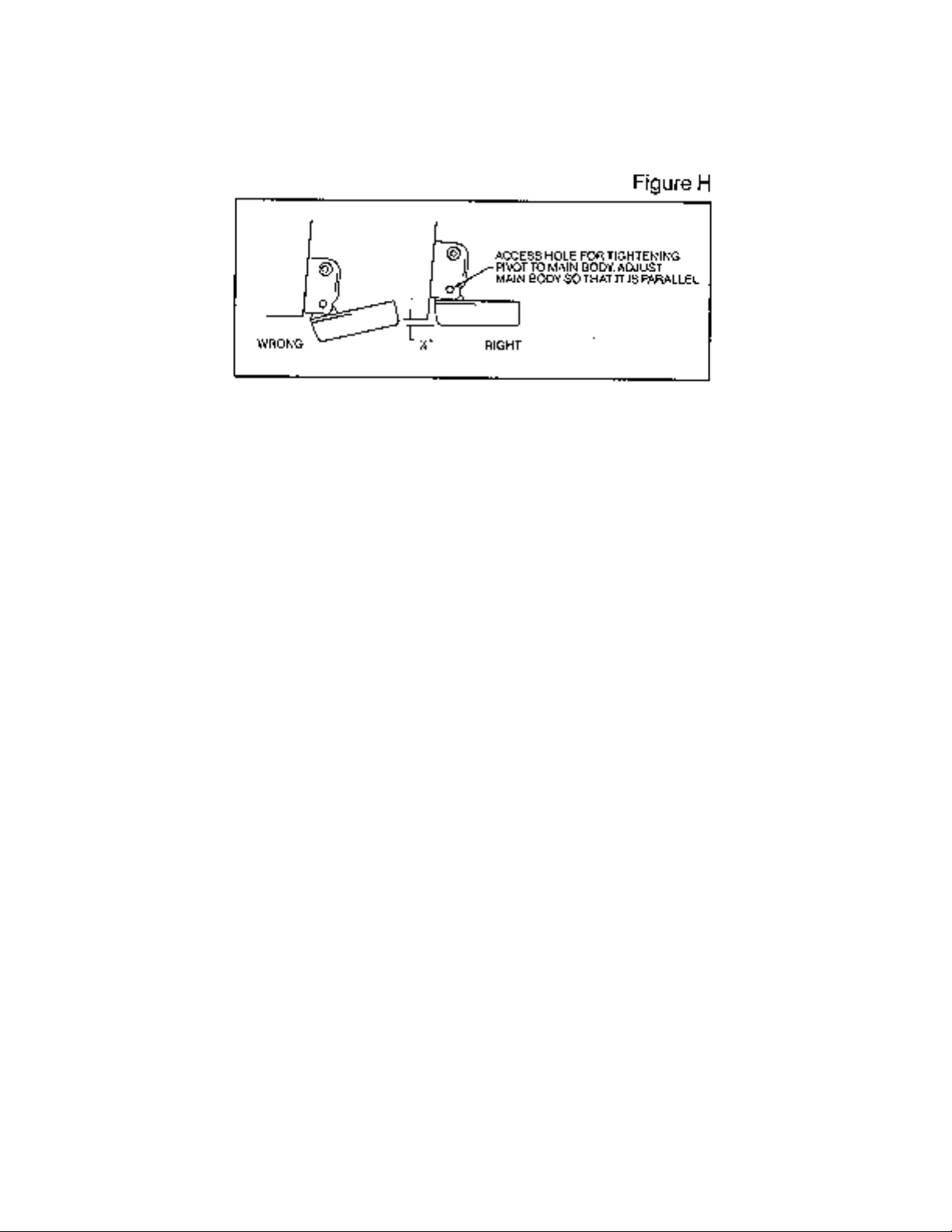

Step 4

TRANSDUCER ASSEMBLY- Insert the transducer assembly into the metal bracket

from the bottom. Push up until the holes in the plastic pivot align with the uppermost

holes in the bracket. Slide the O-ring on to the headed pin and insert it through the two

parts. Assemble by screwing the ¼”x3/8” allen head screw into the end of the pin and

tighten. (See Figure G)

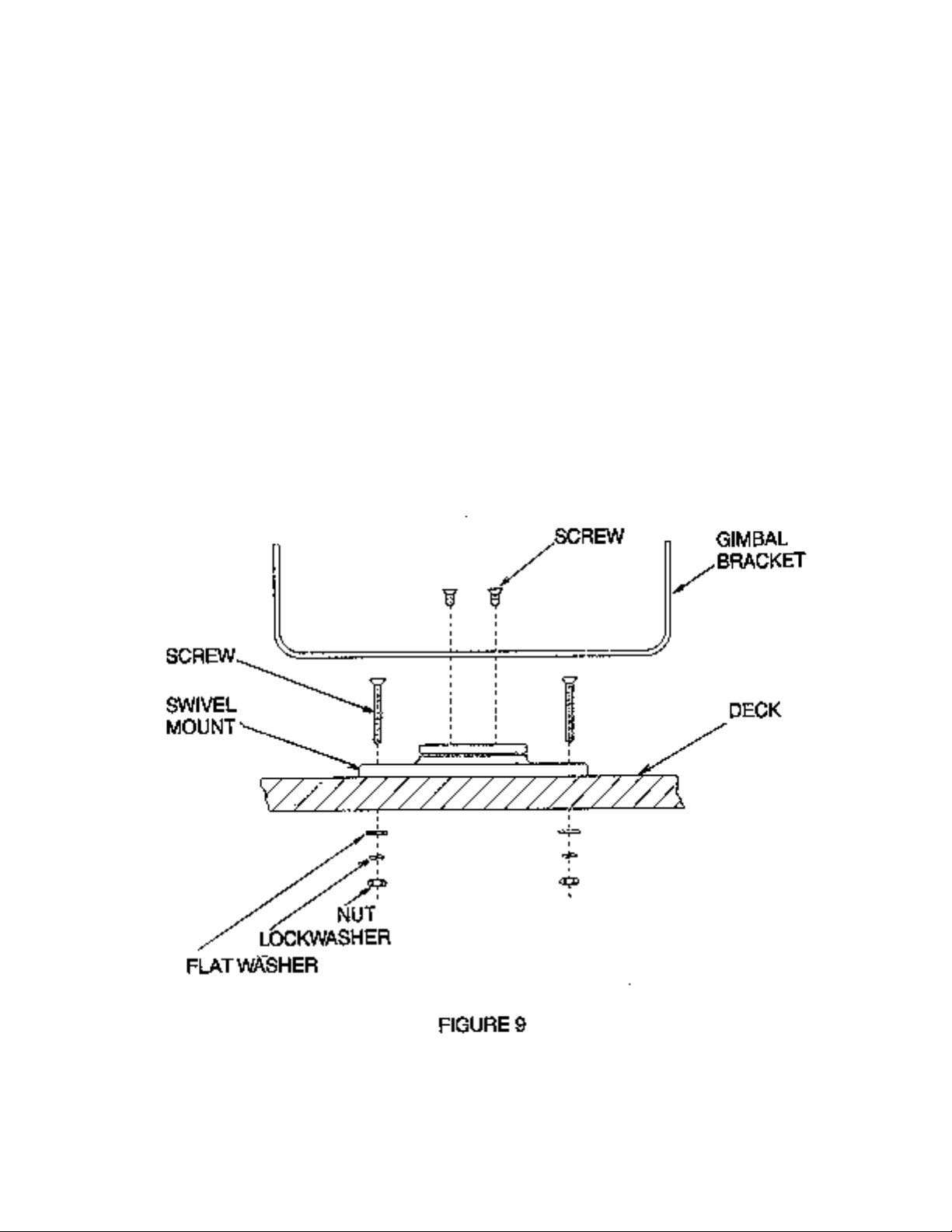

Step 5

ANGLE ALLIGHMENT- Set the transducer angle so that it is parallel with the bottom of

the boat hull. Once proper alignment is achieved, tighten the two allen head screws

Page 8

using the 5/32” allen wrench provided. The screws are visible through the access holes

on each side of the metal bracket. Check to make sure the transducer main body is

rigidly fastened to the pivot. (See Figure H)

Step 6

CHECK POSITION OF TRANSDUCER - At this point, check to see that the bottom of

the transducer is a minimum of ¼” below the bottom of the transom. (However, as noted

in STEP 2, the top of the transducer cannot fall below the bottom of the transom). If it is

not, remove the transducer assembly from the metal bracket by removing the pin

installed during STEP 3. Loosen the metal bracket mounting screws, re-position the

bracket utilizing it’s slotted holes, tighten and re-assemble. It may be necessary to

replace the silicone sealant after this adjustment is made.

NOTE: It may be necessary to make several high speed runs to adjust transducer

either UP/DOWN or to re-adjust the angle to achieve optimum results.

Step 7

CABLE CLAMPS- Install cable clamps as necessary by drilling a 1/8” dia. hole for the #

8 screw supplied.

2. INSIDE HULL MOUNTING PROCEDURE

Warning: In order to achieve proper results with this type installation, it is important that

the transducer be mounted by someone familiar with the use of two part epoxy

adhesives. For this reason, Techsonic Industries, Inc. will not be responsible for any

damage due to the mounting of your transducer in this manner.

NOTE: An Epoxy Kit (Part N. EPK) is available from Humminbird. This Epoxy Kit has

been formulated for Inside Hull Transducer Installation.

1. Select as flat an area as possible near the aft end and center of boat where the hull

is thin and not double. If the bottom has a runner down the center of boat, select an

area to one side of the runner, but as close to the runner as possible.

2. Clean the inside of the boat with lacquer thinner in the area transducer is to be

mounted. Outside of boat in this area should also be cleaned. (Not with lacquer

thinner).

3. Put approximately one inch of water in the bottom of the boat.

Page 9

4. Put transducer in the water. The bottom of the transducer should be in a flat area

and should be in good contact with the bottom of the boat.

5. Operate the LCR with the boat operating at high speed. The transducer may have to

be moved in order to find an area where satisfactory operation is observed.

6. When an area is found that produces satisfactory operation, mark the location of the

transducer.

7. Remove the water and transducer and clean the marked area and the bottom of the

transducer thoroughly.

8. Using the Humminbird Epoxy Kit or equivalent, mix an ample amount of epoxy

without causing it to bubble and pour it in the area the transducer is to be mounted.

The puddle should be larger than the bottom of the transducer.

9. Coat the bottom of the transducer with epoxy, then put it in the center of the puddle

and push down on the transducer while moving it around in a circular motion. This

forces out any air bubbles that may be trapped between the bottom of the transducer

and the hull of the boat.

10. Let epoxy cure then the transducer is ready to operate. No water is now required in

the bottom of the boat and gas and oil that is spilled inside of the boat will not

degrade performance as it will if the transducer is placed only in water.

CAUTION: Do not use the silicone seal or any soft adhesive to bond the transducer

to the hull. This will reduce the sensitivity of the unit.

CAUTIONS

1. Occasionally the “eye“ of your transducer may become dirty from storage or from

contact with oils present in boats or marina environments. (Oil will cause the “eye” to

lose the intimate contact with the water which is necessary for efficient operation.)

The “eye” may be cleaned with liquid detergent.

2. Improper installation of the transducer can alter the efficiency and accuracy of the

entire system.

3. If your boat of transducer is out of the water for a period of time, it may take a short

period of time for the transducer to become thoroughly “wetted” when returned to the

water. Also, re-entry may cause turbulence, which will create air bubbles in the “eye”

of the transducer. The bubbles will disappear in a short time or can be removed by

rubbing the transducer “eye” with your fingers while the transducer is in the water.

4. If your instrument should fail to function , be sure to check all the electrical

connections before removing the transducer or calling a serviceman.

5. Inspect your transducer cable and make sure that it has not been cut or damaged to

the point where it will affect the performance of the transducer. A slight nick or cut,

exposing the outer cable, can be repaired by wrapping with electrical tape. A

transducer can be damaged if the inner cable and outer cable are allowed to make

contact. Such a problem can sometimes be corrected by properly splicing the

coaxial cable. This should only be attempted by a qualified service technician.

6. If your LCR is not working properly and you suspect the problem might be in your

transducer, we would recommend you borrow a unit from a friend and try it on your

boat. If the symptoms are the same, you can almost be certain that the problem is in

the transducer.

Page 10

INSTALLING THE LCR

The LCR should be mounted on a flat, solid surface for maximum stability. The low

profile swivel mount has four holes drilled in the base. It is recommended that all four

holes be used.

Position the swivel base and drill four ¼” diameter holes. Note: The LCR hole pattern Is

the same as for all Humminbird flasher units. Use hardware provided to mount this base

to the boat.

Next place the gimbal bracket on the swivel base and attach with four small machine

screws, provided.

Place the LCR in the gimbal mount and make certain the rubber washers provided are

placed between the unit and the gimbal bracket Important: Note which side of the

gimbal faces forward. (Slots on gimbal bracket go towards rear). Also, rubber washer

must be located between the unit and the gimbal bracket.

Install the mounting knobs and tighten snugly. The unit can now be swiveled and tilted

to any desired position.

Page 11

cannot be rotated.

OTHER MOUNTING OPTIONS

1. The LCR gimbal bracket can also be mounted on the SM -4, quick disconnect swivel

mount.

2. The LCR gimbal bracket can also be mounted directly to the dash without the swivel

mount, however, this method is not recommended since the unit

INSTALLING THE CABLES

Your LCR comes equipped with Humminbird’s new Angle-Lock power and transducer

connectors. The power connector is identified with the letter P on the back of the plug.

It plugs into the outlet on the back of the unit marked “Power”. The transducer connector

is identified with the letter T and plugs into the outlet on the back of the unit marked

Page 12

“Transducer”. Note: An adapter (AD-4) is available to allow use of an old waterproof

(BNC) transducer with the LCR, but be sure that the transducer is a 16degree. A 32degree transducer cannot be used.

A 11/8” hole must be drilled to pull through the transducer connector. After drilling the

hole, pull the transducer connector up through the hole. If you are installing two units,

both transducer connectors can be pulled through this 1 1/8” inch hole. Next, push the

power cable wires down through the hole. A hole cover has been provided which will

dress and hold the wires. Install the hole cover after determining the necessary wire

length from the hole.

The power cable has a red lead to the positive (+) post and the black lead to the

negative (-) post. Install a 1 amp fuse between the red cable and positive post of your

12-volt battery.

If a fuse panel is available, we recommend wiring the power cable into the fuse panel.

Note: The LCR must be fused separately from any other accessory.

Your Angle-Lock connectors can only be plugged in one way. Position the connector so

the letter P or T can be read and the 90 degree bend is pointed downward. Push the

connector in as far as it will go. Turn the positive locking ring as far as it will go

clockwise until you feel it lock. Locking ring as far as it will go clockwise until you feel it

lock. Your connector is now locked into place.

Note: For easy access to the connectors, simply loosen the mounting knobs and tilt your

LCR forward. The connectors are now in full view and easy to plug or unplug.

Page 13

INSTALLATION

TEST THE INSTALLATION

TEST THE INSTALLATION

Testing should be performed with the boat in the water, however you can initially

confirm basic operation with the boat trailered.

Press POWER once to turn the unit on. There will be an audible chirp when any button

is pressed to confirm the button press. If the unit does not power-up, ensure the unit is

fully seated on the mount and that power is available.

The first screen provides four options: Start-up, Options, Simulator, and Diagnostic. A

message at the bottom of the screen indicates the transducer connection. If no

transducer is detected (or one is not connected), the message will indicate this and the

unit will go into simulator after the initial screen times out.

Note: the transducer must be submerged in water for reliable transducer

detection.

If a transducer is detected, the unit will enter “Start Up” or normal operation unless you

choose another option. If you do not press any button before the timer reaches “0”, the

normal operation screen is displayed. If the boat is in water, sonar data appears.

If the bottom is visible on screen with a digital depth readout, the unit is working

properly. Ensure the boat is in water greater than 2’ but less than the depth

capability of the unit and the transducer is fully submerged. Remember the sonar signal

cannot pass through air.

If the unit is working properly gradually increase the boat speed to test high -speed

performance. If the unit -functions well at low speeds but begins to skip or miss the

bottom at higher speeds, the transducer requires adjustment. Refer to the appropriate

transducer installation section for more detail.

Note: it is often necessary to make several incremental transducer adjustments

before optimum high-speed performance is achieved.

Important: For Transom Mount transducer installations, install the third mounting screw

after the final transducer adjustments.

Humminbird • 3 Humminbird Lane • Eufaula, Alabama 36027

Page 14

USING THE TCR ID-1

FEATURES AND FUNCTIONS

Page 15

USING THE TCR ID-1

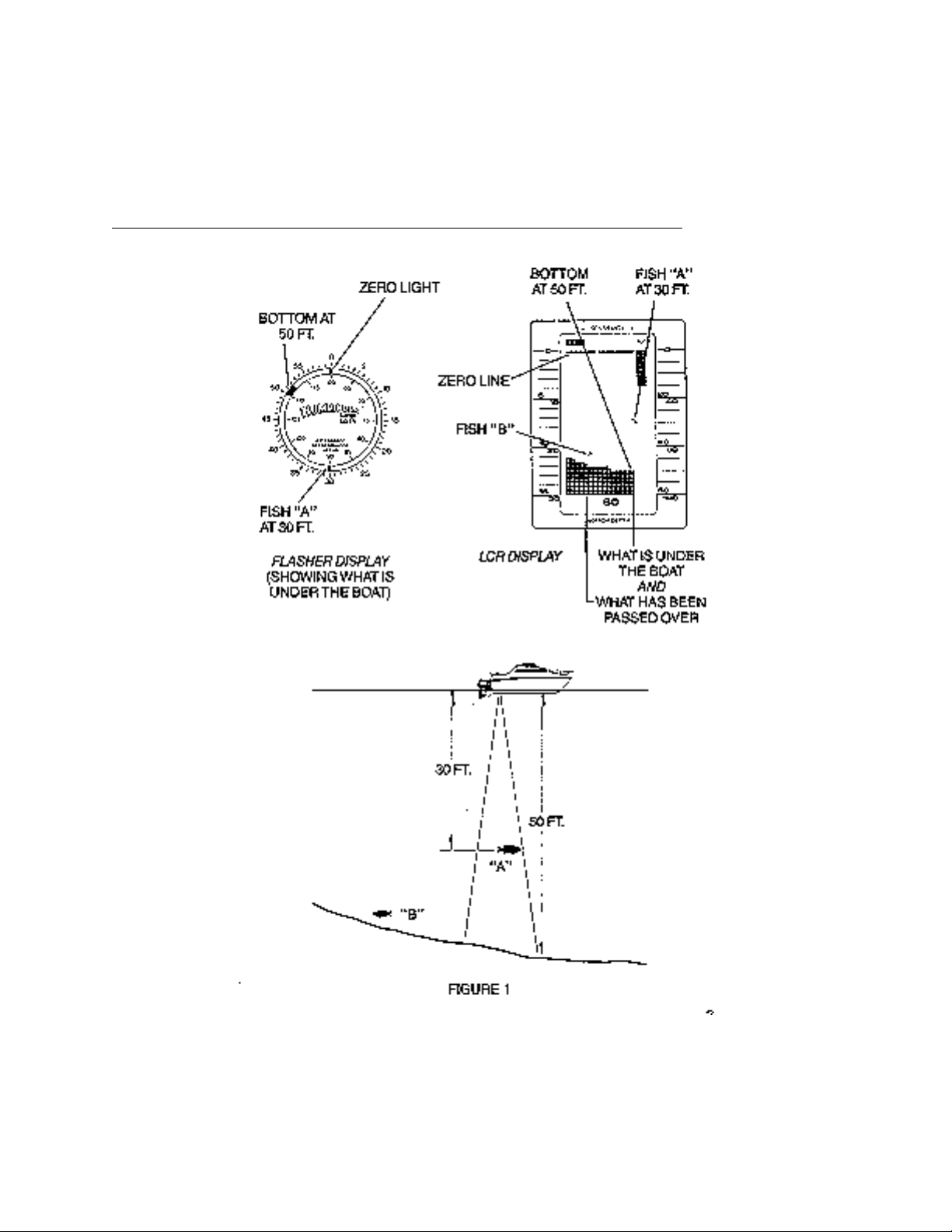

HOW SONAR WORKS

HOW SONAR WORKS

Humminbird depth sounders work on the basic principles of sonar. An electronic signal

generated in the unit is changed to an ultrasonic signal by the transducer or Sensor,

which sends the signal toward the bottom. The signal travels downward until it strikes

either the bottom or an object above the bottom. Then, signals or echoes bounce back

to the Sensor, which receives them and changes them back to electronic signals that

can be displayed on the unit’s screen.

Why 455KHz?

Deepwater depth sounders have long used 50KHz for best deepwater performance, but

they suffer with poor definition. Shallow -water units use a higher frequeney 200KHz

system for better target separation and detail. But TCR technology takes high definition

to a new level with its exclusive 455KHz operation.

What does that mean to the fisherman? TCRs have twice the frequency, three times the

power (1600 watts, peak to peak) and twice the detail of other units. You can clearly

separate fish from the bottom and from structure, and you can see individual fish in a

way that ordinary depth sounders just can’t show them. Quite simply you see more fish

with more detail!

WHAT IS A HIGH-DEFINITION DEPTH SOUNDER?

The TCR ID-I features our exclusive 455KHz high -definition performance system - twice

the frequency, three times the power (1600 walls peak to peak) and twice the detail of

other units.

Page 16

USING THE TCR ID-1

HOW SONAR WORKS

Compact, High-Definition Sensor.

To send and receive this higher-frequency signal, we developed a new High -Definition

Sensor. You can immediately see the difference between our 455KHz Sensor and older

200KHz transducers. This unique new Sensor makes bulky low -definition transducers a

thing of the past.

Our new Sensor is so compact, it’s a snap to install. It’s designed for superior high speed performance, and because of its small size you'll have less problem with drag,

turbulence, or rooster-tails. This new Sensor is actually less likely to be damaged by

debris, yet performs with all the accuracy you expect from Humminbird.

Page 17

USING THE TCR ID-1

BUILT-IN SIMULATOR

BUILT-IN SIMULATOR

To help you learn to use your new unit, Humminbird has built a simulator into the TCR

ID-1.The simulator will display a typical underwater scene, and allow you to use the

controls for practice.

Activating the simulator is easy - with the unit turned off, hold down the power button for

about 2 seconds, until a chirping sound begins. When you release the button, the builtin simulat or will be on and ready for your practice session. Turning your unit off and

back on again will disengage the simulator, for operating the TCR ID-1 in actual

conditions.

NOTE: The built-in simulator will allow you to practice adjusting the sensitivity,

but your adjustments will not change the readings being displayed on the screen.

Page 18

USING THE TCR ID-1

READING THE TCR ID-1 SCREEN

READING THE TCR ID-1 SCREEN

Your TCR has a liquid crystal display, or LCD. The liquid crystal material in the display

aligns it self to either block light or let light pass through. This blocking of light creates

images on the screen. Since the display depends on light to form its images, increasing

the light source makes it easier to see. This is why your TCR can be seen so well in

bright, direct sunlight.

You will also notice that the display can be seen better at certain angles. The TCR

mounting system has been designed for tilting and pivoting so that you can easily

maintain a good angle for viewing. Another characteristic of the display is that some

polarized glasses can affect your view by causing a rainbow or prism to appear. This

can be im proved by slightly tilting the unit.

Fish Identification

The TCR ID-1 uses Humminbird’s exclusive double-layer LCD. Ordinary LCD unit s have

2 colors - black and white. But the TCR ID-1 adds a third color - red - by using a second

layer on the display. This double-layer display gives you more information than ordinary

black and white units:

1. Objects close to the bottom are displayed in red. The bottom and any structure

attached to it are displayed in black. The microcomputer within the TCR ID-1 will detect

objects close to the bottom and display them in red no matter what depth range you're

in. This is especially helpful if you're bottom-fishing

2. Stronger signals are displayed as a black dot behind a red dot. The TCR ID-1's

microcomputer also helps you identify stronger signals, such as those from larger fish,

because they are displayed as a black dot behind a red dot. It's easy to separate them

from the weaker returns displayed in red only.

Page 19

USING THE TCR ID-1

READING THE TCR ID-1 SCREEN

Total Screen Update

Humminbird’s exclusive Total Screen Update instantly updates the entire TCR screen to

include new information each time a function is changed no waiting for the changes to

“march” onto the screen. This feature is valuable in 2 ways:

1. Changing depth ranges. When the depth range changes to a deeper or shallower

scale, the entire screen changes to display the new depth scale. For ex ample, if you’re

in the 0-60’ scale and it changes to the 0-30’ scale, the entire screen will look as if you

had been in the 0-30’ range all along.

2. Using zoom and bottom-lock. Through Pixel Memory Capacity, the memory in the

TCR ID-1 stores readings in much finer detail than is displayed in the “regular” mode.

So when you activate the zoom or bottom-lock functions, the entire screen changes to

display the up-close detail that is stored in memory. Then when you turn on the zoom or

bottom-lock, the whole screen will change back to the full depth scale.

Page 20

USING THE TCR ID-1

READING THE TCR ID-1 SCREEN

Of course, the best way to learn to read your TCR ID-1 is to use it, especially in familiar

locations. If you know what's underwater and can see it display ed on the screen, then

you're on your way to being an experienced TCR user.

Page 21

USING THE TCR ID-1

OPERATING THE TCR ID-1

OPERATING THE TCR ID-1

Your new TCR ID-1 offers unique automatic features, as well as many adjustable ones.

If you're learning to operate the TCR ID-1 with its simulator, follow the directions listed

at “Built-In Simulator” on page 16, and then come back to this page. If you’re learning to

use your TCR ID-1 using actual on -the-water readings, proceed with the following

instructions.

Power:

Pressing this button once turns the TCR ID-1 on. Pressing it once again

turns it off. When the unit is turned off, holding this button down for about 2

seconds activates the built-in simulator.

Stop:

By pressing this button once, you can stop or “freeze” the display. Pressing

the button once again re-starts the display at its previous speed setting.

Light:

The TCR ID-1 features a 2-level backlight that evenly lights up the display

from behind the screen. Pressing the “light” button once gives you a soft

glow that is ideal for night fishing because it won’t interfere with your night

vision. Press the button again for a brighter light, making the display easy to

read at dusk when it can be harder to see. Pressing the button a third time

turns off the backIight.

Select System:

The TCR ID-1 Select System commands an amazing number of functions with only four

buttons: Select, Up and Down arrows, and On/Off.

When you press the Select button, each function appears in a block on the screen with

easy-to-understand instructions for using the function. You use the Up and Down

arrows and the On/Off button to adjust the functions. Then, the Instructions disappear,

returning the display to its full screen reading.

Select System functions are “active”; that is, the last function displayed on the screen

can be adjusted without pressing the select button again. This is valuable in 2 ways.

Example 1: Readjusting a function.

If bottom alarm was the last function used, you can adjust it again by pressing one of

the arrow buttons or the On/Off button.

Page 22

USING THE TCR ID-1

OPERATING THE TCR ID-1

Example 2: Often-used function.

If you think you'll be using zoom often, you can go to the zoom function, let the

instructions disappear, and then activate the zoom when you need it simply by pressing

On/Off.

The following describes the functions and how to use them,

in order of appearance after you turn the unit on.

1. Sensitivity

Automatic setting: on, "0" or normal

As conditions change, the computer will automatically in -

crease or decrease the sensitivity setting. You can man ually

increase or decrease the automatic setting from a range of

“+5” to “-5.” This level will maintain itself as long as you

have the unit on, automatically, as a result of the TCR's

Sensitivity Bias feature. For example, if you set the

sensitivity at “+2,” the sensitivity will remain 2 settings

higher than the normal automatic settings until you turn the

TCR off.

2. Bottom Alarm

Automatic setting: off

Use the On/Off button to activate the alarm, and the alarm

cursor appears on the screen. Then use the arrow keys to

adjust the depth at which the alarm will sound. You'll hear a

continuous chirping sound when the bottom is within the

area that you've defined with the alarm cursor. This is a

great feature to use to alert you to shallow

water, or to maintain your position over structure.

3. Fish Alarm

Automatic setting: off

The fish alarm is easily activated by pressing the On/Off button. This 2-level alarm can

be set to sound for all fish, or to ign ore weaker signals and alarm only for stronger

signals, such as those from larger fish. You can also adjust the volume of the fish alarm.

The controls for this function are a little different. Pressing the Up arrow lets you switch

between alarms for all fish and large fish. The Down arrow controls volume of the alarm.

Page 23

USING THE TCR ID-1

OPERATING THE TCR ID-1

Once the instructions have disappeared from the screen, it's easy to tell which alarm

you have activated - the alarm for all fish shows both small and large fish symbols at the

bottom of the screen, while the “large only” alarm displays only a large fish symbol.

4. Zoom

Automatic setting: off

When zoom is activated by pressing On/Off, it creates a “window” of expanded, up-

close information. This win dow is marked by a cursor at the right of the screen and can

be moved up or down with the arrow buttons. The exact depths of the upper and lower

limits of the window are displayed as depth scales while you are in zoom.

The size of the zoom window changes as the depth range changes. The window

displays 7½ feet of up-close readings in the 15’ and 30’ ranges, and 15 feet in the 60'

and 120’ ranges. Keep in mind that, using your arrow buttons,

you can move the zoom window while the zoom is activated,

without having to press Select again.

5. Bottom-Lock

Automatic setting: off

You can easily turn on the bottom-lock with the On/Off button.

When on, this function shows up-close zoom readings in

reference to the bottom. The size of the zoom window

depends on the depth range - 7½ feet in the 15' and 30'

ranges, and 15 feet in the 60’ and 120' ranges. The zoom

window will automatically move up or down to stay on the

bottom, with the cursor showing you the portion of the total

depth range that is being displayed. This is an ideal feature for

finding structure or locating fish near the bottom.

6. Display Speed

Automatic setting: one setting less than highest speed

The speed at which the TCR display moves depends on the

display speed setting, and it is easily changed by pressing the

Up arrow for a faster setting and the Down arrow for a slower

setting. Generally speaking, the higher speed settings allow

faster updates while slower display speeds provide more

information.

Page 24

USING THE TCR ID-1

OPERATING THE TCR ID-1

7. Depth Range

Automatic setting: on

The TCR automatically finds the bottom and then sets and displays the ideal depth

range when you turn the unit on. If you choose to leave the auto range change on, the

bottom will remain "blacked in" for easy -to-understand readings, and the depth ranges

will change automatically.

Or, you can turn the auto change off, allowing you to change the depth range manually.

In this mode, the bot tom is not blacked in. This lets you see a double bottom echo,

which is preferred by some fishermen because the width of the second echo can

indicate bottom texture (see “Reading The TCR ID-I Screen” for details on using the

double echo).

Page 25

SPECIFICATIONS

Operating Frequency 455KHz

Power Requirement 12 volts

Power Cable Length 11½’

Sensor (standard) SHS-6-16 High -Definition, high-speed

Sensor Cone Angle 16 degrees

Sensor Cable Length 20’

Depth Ranges 0-15’, 0-30’, 0-60’, 0-120’

Zoom Ranges 7½’, 15’

Mounting (standard) All-in-One Mounting & Connector System

Unit Construction High-impact polycarbonate case

Dimensions 6 ½” W X 6 ¾”H X 1 ½”D

Display liquid crystal

Viewing Area 3” W X 4" H

Matrix Configuration 48 x 75 pixels

Page 26

MAINTENANCE AND WARRANTY

MAINTENANCE

MAINTENANCE

Your Humminbird fishfinder is designed to provide years of trouble free operation with

virtually no maintenance. Follow these simple procedures to ensure your Humminbird

continues to deliver top performance.

• If the unit comes into contact with salt spray simply wipe the affected surfaces with a

cloth dampened in fresh water. Do not use a chemical glass cleaner on the lens.

Chemicals in the solution may cause cracking in the lens of the unit.

• When cleaning the LCD protective lens, use a chamois and non -abrasive, mild

cleaner. Do not wipe while dirt or grease is on the lens. Be careful to avoid

scratching the lens.

• If your boat remains in the water for long periods of time, algae and other marine

growth can reduce the effectiveness of the transducer. Periodically clean the face of

the transducer with liquid detergen t. Pivoting the transducer up in the bracket may

allow better access for inspection or cleaning.

• If your boat remains out of the water for a long period of time, it may take some time

to wet the transducer when returned to the water. Small air bubbles can climb to the

surface of the transducer and interfere with proper operation. These bubbles

dissipate with time, or you can wipe the face of the transducer with your fingers after

the transducer is in the water.

• Never leave the fishfinder in a closed car or trunk - the extremely high temperatures

generated in hot weather can damage the electronics.

Page 27

MAINTENANCE AND WARRANTY

TROUBLESHOOTING

TROUBLESHOOTING

Do not attempt to repair the fishfinder yourself. There are no user serviceable parts

inside, and special tools and techniques are required for reassembly to ensure the

waterproof integrity of the housing. Repairs should be performed only by authorized

Humminbird technicians.

Many requests for repair received by Humminbird involve units that do not actually reed

repair. These units are returned “no problem found.” If you have a problem with your

Humminbird, use the following troubleshooting guide before calling Customer Support

or sending your unit in for repair. Your Humminbird fishfinder contains several tools that

can aid in determining if there is a problem and how to isolate and repair the problem in

many cases.

1. Nothing happens when I turn the unit on.

Check the power cable connection at both ends. Be sure the cable is connected

correctly to a reliable power source - red lead to positive, black lead to negative or

ground. Ensure the power available at the mount is between 10 and 20 VDC. If the unit

is wired through a fuse panel, ensure the panel is powered. Often accessory fuse

panels are controlled by a separate switch or the ignition switch. Also, often a fuse can

appear to be good when in fact it is not. Check the fuse with a tester or replace it with a

fuse known to be good.

Check the power connection to the unit. It is possible to force the pow er cable connector

into the cable holder incorrectly. If the connector is reversed, the unit will not work.

Examine the contacts on the back of the unit to ensure there is no corrosion. Finally,

ensure the unit is firmly seated on the mount. The electrical contacts are not made until

the unit is fully seated.

Ensure the metal cable retainer is properly installed in the mount. If not, the power

connected may push out when the unit is put on the mount.

2. There is no transducer detected.

Most Humminbird fishfinders have the ability to detect and identify that a transducer is

connected. If at power up, a message indicates "transducer not connected,” only

simulator operation is possible. First, ensure that an appropriate transducer connector is

positioned correctly in the connector holder, and that the unit is fully seated on the

mount. Your Humminbird fishfinder will work only with an appropriate transducer; check

the accessory guide for compatibility.

Page 28

MAINTENANCE AND WARRANTY

TROUBLESHOOTING

Second, inspect the transducer cable from end to end for breaks, kinks, or cuts in the

outer casing of the cable. Also ensure the transducer is fully submerged in water. If the

transducer is connected to the unit through a switch, temporarily connect it directly to

the unit and try again. If none of these items identifies an obvious problem, the

transducer itself is probably the problem. Be sure to include the transducer if returning

the unit for repair.

3. There is no bottom reading visible on the display.

There are a number of possible causes for this condition. If the loss of bottom

information occurs only at high boat speeds, the transducer needs adjusting. If the

digital depth readout is working but there is no bottom visible on -screen, it is possible

the depth range has been adjusted manually to a range lower than what is needed to

display the bottom. Also, in very deep water, it may be necessary to manually increase

the sensitivity setting to maintain a graphic depiction of the bottom.

If you are using a transducer sw itch to connect two transducers to the unit, ensure the

switch is in the correct position to connect a transducer that is in water. (If a trolling

motor transducer is selected and the trolling motor is out of water, no sonar information

appears.)

It none of the above solve the problem, inspect the transducer cable from end to end for

breaks, kinks, or cuts in the outer casing of the cable. If the transducer is connected to

the unit through a switch, temporarily connect it directly to the unit and try again . If none

of these items identifies an obvious problem, the transducer itself may be the problem.

Be sure to include the transducer if returning the unit for repair.

4. When in very shallow water, I get gaps in the bottom reading and inconsistent

digital dep th indication.

Your Humminbird fishfinder will work reliably in water 2’ (.6m) or deeper. The depth is

measured from the transducer, not necessarily from the surface.

Page 29

MAINTENANCE AND WARRANTY

TROUBLESHOOTING

5. The unit comes on before I press POWER, and won't turn off.

Check the transducer cable. If the outer jacket of the cable has been cut and the cable

is in contact with bare metal, you need to repair the cut with electrical tape. If there is no

problem with the cable, disconnect the transducer from the unit and see if the problem

is corrected, to confirm the source of the problem.

6. I get gaps in the reading at high speeds.

Your transducer needs adjusting. If the transducer is transom-mounted, there are two

adjustments available to you - height and ru nning angle. Make small adjustments and

run the boat at high speeds to determine the effect. It may take several tries to optimize

high speed operation. This can also be a result of air or turbulence in the transducer

location caused by rivets, ribs, etc.

7. My unit loses power at high speeds.

Most Humminbird fishfinders have over-voltage protection that turns the unit off when

input voltage exceeds 20 VDC. Some outboard motors do not effectively regulate the

power output of the engine's alternator and can produce voltage in excess of 20 volts

when running at high RPMs. Your fishfinder displays input voltage in the Diagnostic

screen. Use this readout to determine if the voltage exceeds 20 VDC.

8. The screen begins to fadeout. Images are not as sharp as normal.

Check the input voltage using Diagnostic. The fishfinder will not operate on input

voltages below 10 VDC.

9. The display shows many black dots at high speeds and high sensitivity

settings.

You are seeing noise or interference caused by one of several sources. Noise can be

caused by other electronic devices. Turn off any nearby electronics and see if the

problem goes away. Noise can also be caused by the engine. If engine noise is causing

the interference, the problem will intensify at higher RPMs. Increase the engine speed

with the boat stationary to isolate this cause. Propeller cavitation can appear as noise

on-screen. If the transducer is mounted too close to the propeller, the turbulence

generated can interfere with the sonar signal. Ensure that the tran sducer is mounted at

least 15" (38cm) from the prop.

Page 30

MAINTENANCE AND WARRANTY

WARRANTY

HUMMINBIRD ONE YEAR FULL WARRANTY

First year repairs (from original date of purchase) on your Humminbird fishfinder are

absolutely free. This does not include physical damage to the unit or its accessory

items. Any modification or attempt to repair the original equipment or accessories by

unauthorized individuals will void the warranty. Return the warranty registration card

and retain your bill of sale for warranty verification. Accessories not manufactured under

the Humminbird trade name are not covered by our warranty. The customer is

responsible for shipping charges to Humminbird. Humminbird will provide ground

UPS or Parcel Post shipping back to the customer free of charge. This warranty applies

to the original purchaser only.

This warranty is in lieu of all other warranties expressed or implied and no

representatives or persons are authorized to provide for any other liability in connection

with the sale of our products. Humminbird reserves the right to perform modifications or

improvement on its products without incurring the obligation to install the changes on

units previously manufactured, sold, delivered, or serviced.

THIS IS A FULL WARRANTY AS DEFINED BY THE FEDERAL WARRANTY ACT

EFFECTIVE JULY 4 1975.

Page 31

MAINTENANCE AND WARRANTY

SERVICE POLICY

SERVICE POLICY

This Service Policy is valid in the United States only. This applies to Humminbird units

returned to our factory in Eufaula, Alabama, and is subject to change without notice.

All repair work is performed by factory -trained technicians to meet exacting factory

specifications. Factory serviced units go through the same rigorous testing and quality

control inspection as new production units.

Even though you'll probably never need to take advantage of our incredible service

guarantee, it’s good to know that we back our unit this well. We do it because you

deserve the best. We will make every effort to repair your unit within three working days

from the receipt of your unit. This does not include shipping time to and from our factory.

Units received on Friday are usually shipped by Wednesday, units received Monday are

usually shipped by Thursday, etc.

We reserve the right to deem any product unserviceable when replacement parts are no

longer reasonably available or impossible to obtain.

After the original warranty period, a standard flat rate service charge will be assessed

for each repair (physical damage and missing parts are not included). Please call our

Customer Support Department to verify the service charge for your unit.

The standard service charge includes UPS or Parcel Post freight only. If charges are

not prepaid, the unit will be returned COD. If you are experiencing problems related to

bottom or depth readings please send your transducer along with your unit when

sending for repair.

Page 32

MAINTENANCE AND WARRANTY

CUSTOMER SUPPORT

CUSTOMER SUPPORT

If you have any questions, call our

Humminbird Customer Support Hotline: 1-334-687-0503

Throughout the U.S. and Canada, hours are Monday -Friday, 8:00 a.m. to 5:00 p.m.

Central time.

If after reading “Troubleshooting” you determine your unit needs factory service, please

attach a description of the problem and send it with the unit to the address below.

If y ou are including a check please attach it to the unit.

Humminbird

Service Department

Three Humminbird Lane

Eufaula, AL 36027

USA

Loading...

Loading...