Page 1

1

Side Imaging® Transducer

Thank You

Thank you for choosing Humminbird®, the #1 name in marine electronics. Humminbird has built its

reputation by designing and manufacturing top-quality, thoroughly reliable marine equipment. Genuine

Humminbird accessories offer the opportunity to upgrade and expand the capabilities of your Humminbird

product.

NOTE: Your transducer may not look exactly like the transducer shown in the illustrations, but it will mount in

exactly the same way.

Your Humminbird is designed for trouble-free use in even the harshest marine environment. In the unlikely

event that your Humminbird does require repairs, we offer an exclusive Service Policy - free of charge during

the first year after purchase, and available at a reasonable rate after the one-year period. For complete

details, see the Warranty section included in this manual.

Contact our Customer Service at 1-800-633-1468 or visit our Web site at humminbird.com.

Installation Overview

Following are instructions for the installation of this accessory. Before you start the installation, we

encourage you to read these instructions carefully in order to get the full benefit from your Humminbird

accessory.

Customer Service: If you find that any items are missing from your installation kit, visit our Web site at

humminbird.com or call our Customer Service at 1-800-633-1468.

531390-1_H

Transom Mounted Transducer

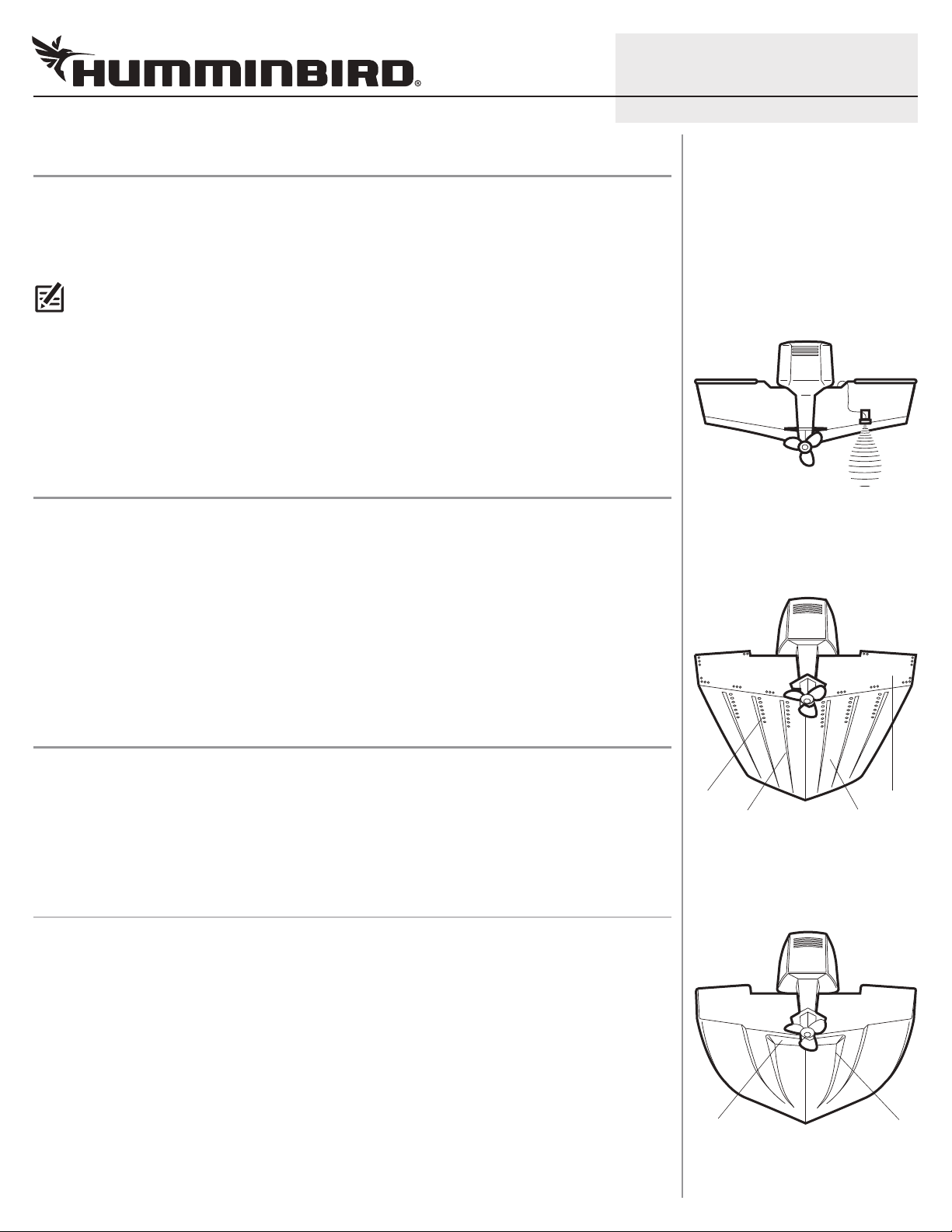

Areas of Possible Turbulence

Supplies: In addition to the hardware supplied with your transducer, you will need a powered hand drill and

various drill bits, various hand tools, including a ruler or measuring tape, level, pen or pencil, safety glasses

and dust mask, and marine-grade silicone sealant.

Installation

There are a number of ways to install a transducer on your boat. The transom mount installation provides

the least loss of signal since the transducer is mounted outside the boat hull. This installation also allows

adjustment of both running angle and depth after the transducer is mounted, which enables you to tune the

installation for best results. Also, the mounting hardware is designed to pivot the transducer body out of the

way should the boat strike debris in the water, or when trailering.

1.Locating the Transducer Mounting Position

Turbulence: You must first determine the best location on the transom to install the transducer. It is very

important to locate the transducer in an area which is relatively free of turbulent water. Consider the

following to find the best location with the least amount of turbulence:

• As the boat moves through the water, turbulence is generated by the weight of the boat and the thrust

of the propeller(s) - either clockwise or counter-clockwise. This turbulent water is normally confined to

areas immediately aft of ribs, strakes or rows of rivets on the bottom of the boat, and in the immed iate

area of the propeller(s). Clockwise propellers create more turbulence on the port side. On outboard or

inboard/outboard boats, it is best to locate the transducer at least 15" to the side of the propeller(s).

rivets transom

strakes hull

Stepped Hull

• The best way to locate turbulence-free water is to view the transom while the boat is moving. This

method is recommended if maximum high-speed operation is a high priority. If this is not possible,

select a location on the transom where the hull forward of this location is smooth, flat and free of

protrusions or ribs.

step

rib

Page 2

2

L

evel

Side Imaging® Transducer

• On boats with stepped hulls, it may be possible to mount the trans ducer on the step. Do not mount the

transducer on the transom behind a step to avoid popping the transducer out of the water at higher

speeds. The transducer must remain in the water for the control head to maintain the sonar signal.

• If the transom is behind the propeller(s), it may be impossible to find an area clear from turbulence, and a

different mounting technique or transducer type should be considered. See the FAQ (Frequently Asked

Questions) section of our Web site at humminbird.com or call Customer Service at 1-800-633-1468.

• If you plan to trailer your boat, do not mount the transducer too close to trailer bunks or rollers to avoid

moving or damaging the transducer during loading and unloading of the boat.

Find a turbulence-free location at least 15" from the propeller(s) and not in line with trailer bunks or rollers.

531390-1_H

Deadrise

deadrise angle

Transducer Mount Position

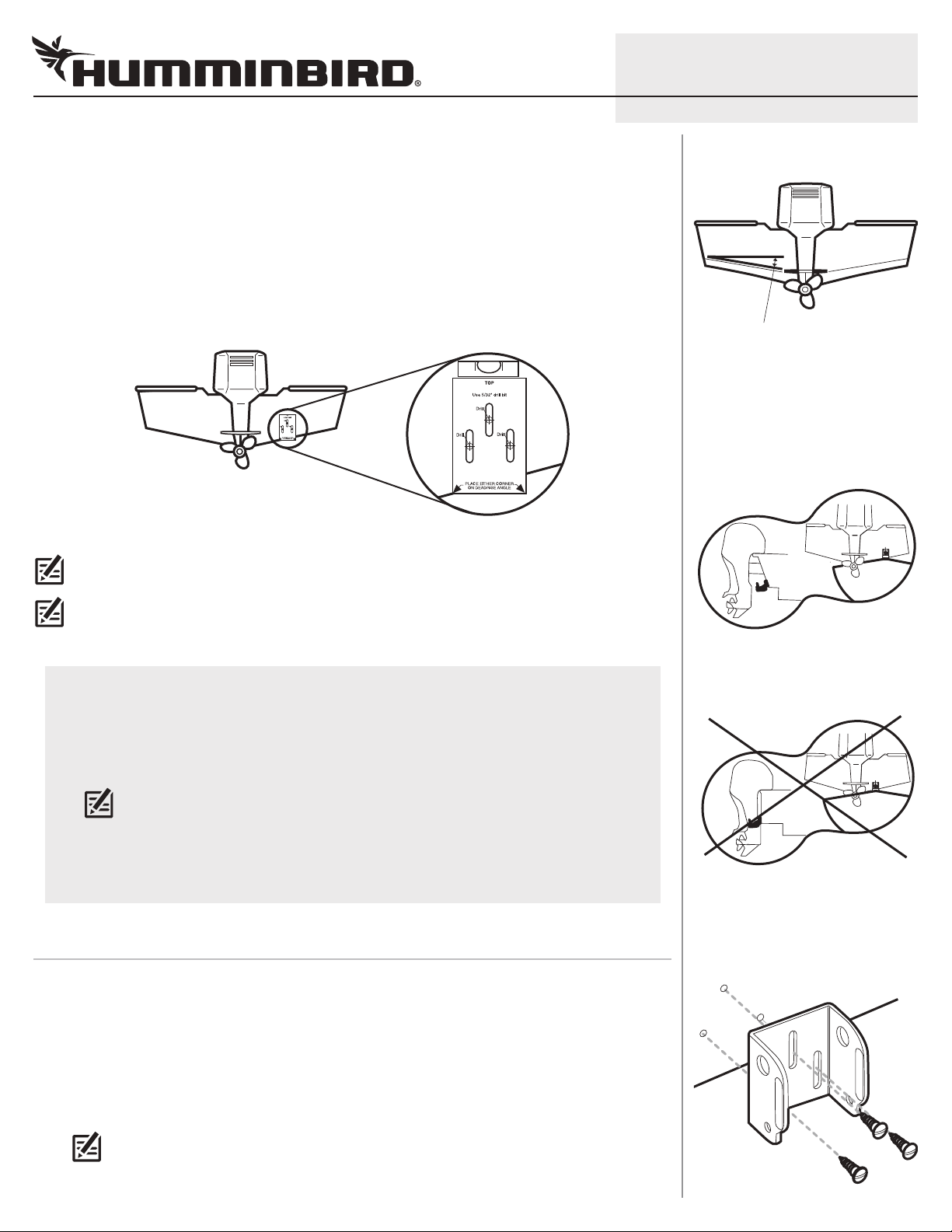

Unobstructed View: The jack plate gives the transducer

safe distance from the motor and turbulence. The Side

Imaging has a clear view side-to-side.

NOTE: The hydrodynamic shape of your transducer allows it to point straight down without deadrise adjustment.

NOTE: If you cannot find a transom mount location that will work for your high-speed application, a different

mounting technique or transducer type should be considered. See the FAQ (Frequently Asked Questions) section of

our Web site at humminbird.com or call Customer Service at 1-800-633-1468.

Side Imaging: The Side Imaging transducer has some special requirements because of its side viewing

capabilities:

• The Side Imaging transducer must NOT have anything obstructing the ‘view’ of the side looking

beams; for example, nothing can be in the line of sight of these beams (not a hull, motor, or other

transducer, etc.)

NOTE: You may need to tilt the motor up and out of the way when using the side looking beams.

• In order for the side beams to be displayed accurately, the transducer must be mounted parallel

with the waterline. This positioning allows the beam elements to point straight down without

deadrise adjustment (see the illustration Deadrise).

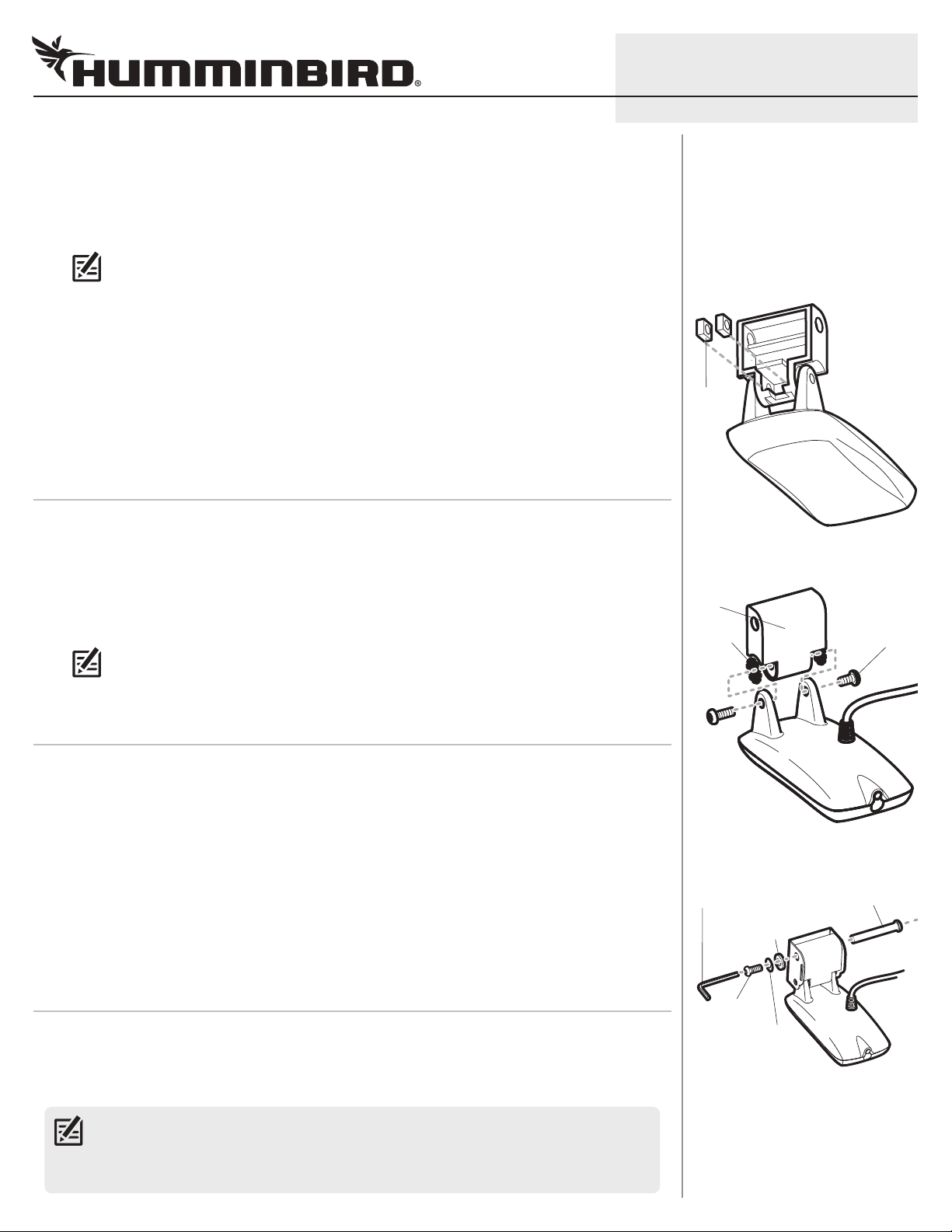

2.Mounting the Bracket

In this procedure you will mount the bracket, using the mounting template provided as a guide. This

template allows you to mark where the mounting holes should be drilled.

Obstructed View: The transducer is too close to motor

turbulence, and the Side Imaging view is blocked by the

motor. The view cannot extend from side-to-side.

Attaching the Bracket

1. Cut out the transducer mounting template from this sheet. Match the mounting bracket screw slots to

the template screw slots.

2. Hold the template on the transom of the boat in the location you have selected. Align the template

vertically, matching the lower edge of the transom with the bottom corner of the template.

NOTE: If your propeller moves clockwise as the boat moves forward (as you're facing the stern of the boat

from behind), mount the transducer on the starboard side, and use the bottom left corner of the template. If

your propeller moves counter-clockwise as the boat moves forward (as you're facing the stern of the boat from

behind), mount the transducer on the port side, and use the bottom right corner of the template.

Page 3

3

Side Imaging® Transducer

3. Continue to hold the template on the transom of the boat, and use a pencil or punch to mark where to

drill the three mounting holes shown on the template.

4. Using a 5/32" bit, drill the three holes only to a depth of approximately 1".

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the chance of chipping or

flaking the outer coating.

5. Use a marine-grade silicone sealant to fill the drilled holes, especially if the holes penetrated the

transom wall.

6. Align the metal mounting bracket with the mounting holes. The center slot of your mounting bracket

should be above the two outer slots. This bracket and all other hardware supplied is top quality stainless

steel for maximum strength and corrosion protection. Insert the three 1" flat head wood screws into the

drilled holes, but do not completely tighten.

3.Assembling the Transducer

In this procedure you will attach the pivot to the transducer using the hardware provided.

1. Attach the pivot to the transducer body as shown in the illustration using the square nuts, toothed

washers, and two 1/4–20 x 5/8" machine screws. The square nuts will be prevented from rotating by the

pocket in the back of the pivot. The toothed washers must fit on the inside of the transducer ears,

between the pivot and the ears.

NOTE: An Allen wrench is provided which fits all of the 1/4–20 screws, but do not fully tighten the screws at

this time.

Inserting the Square Nuts

square

nuts

Attaching the Pivot

pivot

toothed

washer

531390-1_H

machine

screw

4.Attaching the Transducer to the Bracket

1. Slide the assembled transducer into the metal bracket from the bottom, aligning the large hole at the

top of the bracket with the hole in the pivot.

2. Insert the headed pin through the pivot holes in the bracket and pivot. The headed pin can be inserted

from either side of the bracket.

3. Place the nylon washer over the opposite end of the headed pin. Place the stainless washer over the

1/4–20 x 5/8" screw threads, then insert into the opposite end of the headed pin and finger tighten only.

The screw has a thread locking compound on the threads to prevent loosening, and should NOT be fully

tightened until all adjustments are made.

5.Running Position Adjustment

The running position of the transducer is now completely adjustable. Subsequent adjustment may be

necessary to tweak the installation after high speed testing. The mounting bracket allows height and tilt

adjustment; the pivot screws allow angle adjustment.

NOTE: Side Imaging is best performed at boat speeds from 2 to 6 mph. If the boat is stationary, the same

information is displayed over and over. If the boat is moving too quickly, there will be gaps between the strips

of information. The best boat speed to use will depend on the side range selected. Slower speeds are good for

longer ranges, while faster speeds can be used at shorter ranges.

Attaching the Transducer to the Bracket

allen wrench

nylon washer

(fits over headed pin)

screw

stainless washer

(fits over screw threads)

headed pin

Page 4

4

Side Imaging® Transducer

1. Adjust the angle of the transducer body first, so it is parallel with the hull of the boat, and fully tighten

the two pivot screws using the supplied Allen wrench. Access to the pivot screws is provided by the

lower holes in the side of the mounting bracket.

2. Next, adjust the height of the assembly so the face of the transducer is 1/8" to 1/4" beneath the bottom

of the transom, and fully tighten the three mounting screws. In order to gain access to the mounting

screws, the transducer assembly must be pivoted up into the bracket as shown.

CAUTION! Be careful not to alter the running angle, as some force is necessary to pivot the assembly.

3. If access to the top mounting hole is not possible due to the selected height of the transducer, fully

tighten the two lower screws. Remove the headed pivot pin and the transducer assembly, tighten the

top screw, and then reassemble.

4. Confirm that the pivot angle has not changed and that all mounting screws are fully tightened.

6.Routing the Cable

The transducer cable has a low profile connector which must be routed to the point where the control head

is mounted. There are several ways to route the transducer cable to the area where the control head is

installed. The most common procedure routes the cable through the transom into the boat.

531390-1_H

Tightening the Pivot Screw

allen wrench

Tightening the Mounting Screws

NOTE: Your boat may have a pre-existing wiring channel or conduit that you can use for the transducer cable.

1. Unplug the other end of the transducer cable from the control head. Make sure that the cable is long

enough to accommodate the planned route by running the cable over the transom.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the cable insulation. Route the

cable as far as possible from any VHF radio antenna cables or tachometer cables to reduce the possibility of

interference. If the cable is too short, extension cables are available to extend the transducer cable up to a total of

50'. For assistance, contact Customer Service at humminbird.com or call 1-800-633-1468 for more information.

CAUTION! Do NOT mount the cables where the connectors could be submerged in water or flooded. If cables

are installed in a splash-prone area, it may be helpful to apply dielectric grease to the inside of the connectors to

prevent corrosion. Dielectric grease can be purchased separately from a general hardware or automotive store.

NOTE: The transducer can pivot up to 90 degrees in the bracket. Allow enough slack in the cable for this

movement. It is best to route the cable to the side of the transducer so the transducer will not damage the

cable during movement.

2a. If you are routing the cable over the transom of the boat, secure the cable by attaching the cable clamp

to the transom, drilling 9/64" diameter holes for #8 x 5/8" wood screw(s), go directly to procedure 7,

Connecting the Cable.

or...

2b. If you will be routing the cable through a hole in the transom, drill a 5/8" diameter hole above the

waterline. Route the cable through this hole, then fill the hole with marine-grade silicone sealant and

proceed to the next step immediately.

Routing the Cable

escutcheon

plate

5/8" hole

cable

clamp

3. Place the escutcheon plate over the cable hole and use it as a guide to mark the two escutcheon plate

mounting holes. Remove the plate, drill two 9/64" diameter x 5/8" deep holes, and then fill both holes

with marine-grade silicone sealant. Place the escutcheon plate over the cable hole and attach with two

#8 x 5/8" wood screws. Hand tighten only!

4. Route and secure the cable by attaching the cable clamp to the transom. Drill one 9/64" diameter x 5/8"

deep hole, then fill the hole with marine-grade silicone sealant, then attach the cable clamp using a

#8 x 5/8" screw. Hand tighten only!

Page 5

5

Side Imaging® Transducer

NOTE: If there is excess cable that needs to be gathered at one location, dress the cable routed from both

directions so that a single loop is left extending from the storage location. Doubling the cable up from this

oint, form the cable into a coil. Storing excess cable using this method can reduce electronic interference.

p

7.Connecting the Cable

1. Insert the transducer cable into the appropriate terminal slot. The cable connectors are labeled, and

there are corresponding labels on the cable holder on the rear of the fishfinder. The slots are keyed to

prevent reversed installation, so be careful not to force the connector into the holder.

8.Test and Finish the Installation

Once you have installed both the control head and the transom transducer, and have routed all the cables,

you must perform a final test before locking the transducer in place. Testing should be performed with the

boat in the water.

1. Press POWER once to turn on the control head. If the unit does not power-up, make sure that the

connector holder is fully seated in the receptacle and that power is available.

2. If all connections are correct and power is available, the Humminbird control head will enter Normal

operation.

531390-1_H

Storing Excess Cable

3. If the bottom is visible on-screen with a digital depth readout, the unit is working properly. Make sure

that the boat is in water greater than 2' but less than the depth capability of the unit, and that the

transducer is fully submerged, since the sonar signal cannot pass through air.

NOTE: The transducer must be submerged in water for reliable transducer detection.

4. If the unit is working properly, gradually increase the boat speed to test high-speed performance. If the

unit functions well at low speeds, but begins to skip or miss the bottom at higher speeds, the transducer

requires adjustment.

5. If you have the correct angle set on the transducer, yet lose a bottom reading at high speed, adjust the

transducer to a lower depth in the water. If you reach the top of the screw slots and continue to lack

high speed performance, increase the angle of the transducer by lowering the back of the transducer in

increments of 1/8".

NOTE: It is often necessary to make several incremental transducer adjustments before optimum high speed

performance is achieved. Due to the wide variety of boat hulls, however, it is not always possible to obtain high

speed depth readings.

NOTE: The deeper the transducer is in the water, the more likely that a rooster tail of spray will be generated

at high speeds, so make sure that the transducer is as high as it can be and still be submerged in the water.

6. Once you have reached a consistently good sonar signal at the desired speeds, fully tighten your

assembly to lock it into place.

Page 6

6

Side Imaging® Transducer

Maintenance

If your boat remains in the water for long periods of time, algae and

other marine growth can reduce the effectiveness of the transducer.

Periodically clean the face of the transducer with a mild, marine-safe

and plastic-safe soap or solution.

NOTE: To clean the transducer, you may need to pivot the transducer up

in the bracket.

If your boat remains out of the water for a long period of time, it may

take some time to wet the transducer after it is returned to the water.

Small air bubbles can cling to the surface of the transducer and

interfere with proper operation. These bubbles will dissipate with time,

or you may wipe the face of the transducer with your fingers after the

transducer is in the water.

531390-1_H

1-Year Limited Warranty

We warrant the original retail purchaser that products made by Humminbird

have been manufactured free from defects in materials and workmanship.

his warranty is effective for one year from the date of original retail

T

purchase. Humminbird products found to be defective and covered by this

warranty will be repaired or replaced free of charge at Humminbird's option

an d ret urned t o th e cus tomer f reight prepaid. Hummi nbird's sole

responsibility under this warranty is limited to the repair or replacement of a

product that has been deemed defective by Humminbird. Humminbird is not

responsible for charges connected with the removal of such product or

reinstallation of replaced or repaired parts; or shipping charges to the

factory or authorized service center (if outside the U.S.).

This warranty does not apply to a product that has been:

• Improperly installed;

• Used in an installation other than that recom mended in the product

installation and operation instructions;

• Damaged or has failed because of an accident or abnormal operation;

• Repaired or modified by entities other than Humminbird.

Please retain your original receipt as a proof of the purchase date. This will

be required for in-warranty service.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES ON THE PART OF HUMMINBIRD AND WILL

BE THE CUSTOMER'S EXCLUSIVE REMEDY, EXCEPT FOR ANY APPLICABLE

IMPLIED WARRANTIES UNDER STATE LAW WHICH ARE HEREBY LIMITED

IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE. IN

NO EVENT WILL HUMMINBIRD BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED

WARRANTY RELATING TO THE PRODUCTS.

Some states do not allow limitations on an implied warranty, or the

exclusion of incidental or consequential damages, so the above exclusions

may not apply to you. You may also have other rights, which vary from state

to state.

Page 7

7

Side Imaging® Transducer

Humminbird Service Policy

Even though you'll probably never need to take advantage of our incredible

service policy, it's good to know that we back our products this confidently.

e do it because you deserve the best. We will make every effort to repair

W

your unit within three business days from the receipt of your unit at our

factory. This does not include shipping time to and from our factory. Units

received on Friday are typically shipped by the following Wednesday, units

received Monday are typically shipped by Thursday, etc.

All repair work is performed by factory-trained technicians to meet exacting

factory specifications. Factory-serviced units go through the same rigorous

testing and quality control inspections as new production units.

After the original warranty period, a standard flat rate service charge will be

assessed for each repair (physical damage and missing parts are not

included). Any repairs made after the original warranty will be warranted

for an additional 90 days after service has been performed by our factory

technicians. You can contact Customer Service or visit our Web site to

verify the flat rate repair fee for your product (visit the Product Support

section):

http://www.humminbird.com

We reserve the right to deem any product unserviceable when replacement

parts are no longer available or impossible to obtain. This Service Policy is

valid in the United States only. This applies only to Humminbird products

returned to our factory in Eufaula, Alabama. This Service Policy is subject

to change without notice.

531390-1_H

Returning Your Unit for Service

Before sending your unit in for repair, please contact the factory, either by

phone or by email, to obtain a Repair Authorization Number for your unit.

NOTE: Please do not return your Humminbird to the store for service.

Please have your product model name and serial number available

before calling the factory. If you contact the factory by e-mail, please

include your product model name and serial number in the e-mail, and

use Request for Repair Authorization Number for your e-mail subject

header. You should include your Repair Authorization Number in all

subsequent communications about your unit.

For IN-WARRANTY service, complete the following steps

• Obtain a Repair Authorization Number from Humminbird Customer

Service.

• Tag product with your name, street address, phone number and

your assigned Repair Authorization Number.

• Include a brief written description of the problem.

• Include a copy of your receipt (to show proof and date of purchase).

• Return product freight prepaid to Humminbird, using an insured

carrier with delivery confirmation.

:

DOMESTIC (USA) CUSTOMERS:

PLEASE DO NOT RETURN THIS PRODUCT TO STORE FOR SERVICE

For all technical issues please call 1-800-633-1468

or visit humminbird.com, click SUPPORT.

Please reference product serial number and

model number when contacting Humminbird.

For OUT-OF-WARRANTY service, complete the following steps:

• Obtain a Repair Authorization Number from Humminbird Customer

Service.

• Include payment in the form of credit card number and expiration

date, or a money order. Please do not send cash.

• Tag product with your name, street address, phone number and

your assigned Repair Authorization Number.

• Include a brief written description of the problem.

• Return product freight prepaid to Humminbird, using an insured

carrier with delivery confirmation.

Page 8

8

Drill

Drill

Drill

Use 5/32”

drill bit.

TOP

PLACE EITHER CORNER

ON DEADRISE ANGLE

Remove and use for

Transducer Installation

Side Imaging® Transducer

Contact Humminbird

Web site humminbird.com

E-mail service@humminbird.com

Telephone 1-800-633-1468

Direct Shipping Humminbird

Service Department

678 Humminbird Lane

Eufaula, AL 36027 USA

WARN ING! This device should not be used as a navigational aid to

prevent collision, grounding, boat damage, or personal injury. When the

boat is moving, water depth may change too quickly to allow time for you to

react. Always operate the boat at very slow speeds if you suspect shallow

water or submerged objects.

WARNING! Disassembly and repair of this electronic unit should only be

performed by authorized service personnel. Any modification of the serial

number or attempt to repair the original equipment or accessories by

unauthorized individuals will void the warranty.

531390-1_H

Mounting Template

ENVIRONMENTAL COMPLIANCE STATEMENT: It is the intention

of Johnson Outdoors Marine Electronics, Inc. to be a responsible corporate citizen,

operating in compliance with known and applicable environmental regulations, and

a good neighbor in the communities where we make or sell our products.

WE E E DI R ECT I V E: EU Directive 2002/96/EC “Waste of Electrical and

Electronic Equipment Directive (WEEE)” impacts most distributors, sellers, and

manufacturers of consumer electronics in the European Union. The WEEE Directive

requires the producer of consumer electronics to take responsibility for the

management of waste from their products to achieve environmentally responsible

disposal during the product life cycle.

WEEE compliance may not be required in your location for electrical & electronic

equipment (EEE), nor may it be required for EEE designed and intended as fixed or

temporary installation in transportation vehicles such as automobiles, aircraft, and

boats. In some European Union member states, these vehicles are considered

outside of the scope of the Directive, and EEE for those applications can be

considered excluded from the WEEE Directive requirement.

This symbol (WEEE wheelie bin) on product indicates the product must not

be disposed of with other household refuse. It must be disposed of and

collected for recycling and recovery of waste EEE. Johnson Outdoors Marine

Electronics, Inc. will mark all EEE products in accordance with the WEEE

Directive. It is our goal to comply in the collection, treatment, recovery, and

environmentally sound disposal of those products; however, these requirements do

vary within European Union member states. For more information about where you

should dispose of your waste equipment for recycling and recovery and/or your

European Union member state requirements, please contact your dealer or

distributor from which your product was purchased.

© 2017 Johnson Outdoors Marine Electronics, Inc. All rights reserved.

Loading...

Loading...