Page 1

1

High Speed Transducer

Thank You

Thank you for choosing Humminbird®, America’s #1 name in fishfinders. Humminbird® has

built its reputation by manufacturing top-quality, thoroughly reliable marine equipment.

Genuine Humminbird® accessories offer the opportunity to upgrade and expand the

capabilities of your Humminbird® product.

NOTE: Your transducer may not look exactly like the transducer shown in the

illustrations, but it will mount in exactly the same way.

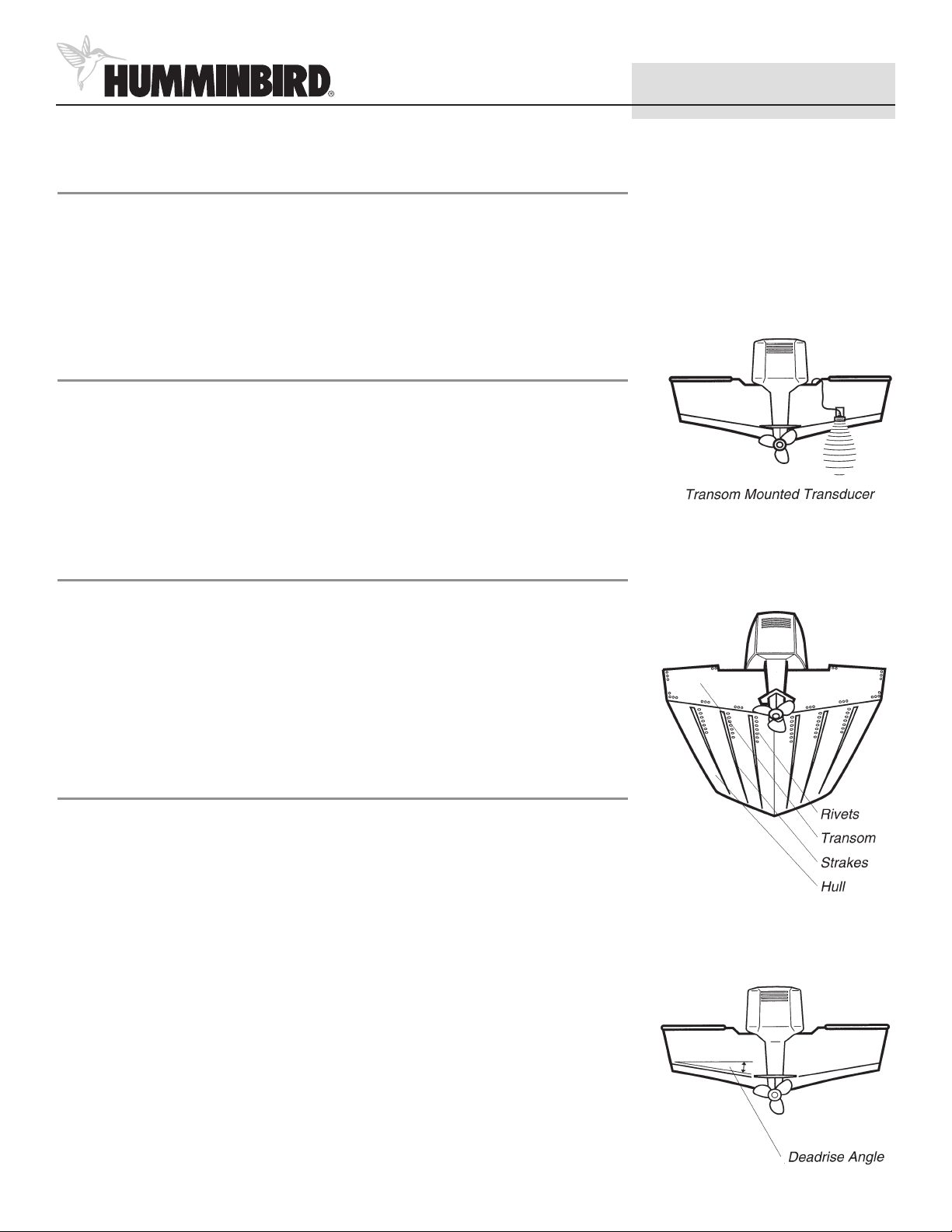

About Transom Mount Installation

There are a number of ways to install a transducer on your boat. The transom mount

installation provides the least loss of signal since the transducer is mounted outside the boat

hull. This installation also allows adjustment of both running angle and depth after the

transducer is mounted, which enables you to tune the installation for best results. Also, the

mounting hardware is designed to pivot the transducer body out of the way should the boat

strike debris in the water, or when trailering. All necessary hardware is included for this type

of installation.

Before You Start

Following are instructions for the installation of the High-Speed Transducer. We encourage

you to read these instructions carefully to get full benefit from your Humminbird® accessory.

If you find that any items are missing from your installation kit, contact our Humminbird®

Customer Resource Center at 1-800-633-1468 or visit our website at www.humminbird.com.

In addition to the hardware supplied with your transducer, you will need a powered hand drill

and various drill bits, Phillips and flat head screwdrivers, a ruler or measuring tape, pen or

pencil, and silicone sealant.

Locating the Transducer

As a boat moves through the water, turbulence is generated by the weight of the boat and

the thrust of the propeller(s). This turbulent water is normally confined to areas immediately

aft of ribs, strakes, or rows of rivets on the bottom of the boat, and in the immediate area of

the propeller(s). It is very important to locate the transducer in an area of relatively

turbulence-free water. If the propeller(s) are forward of the transom, it may be impossible to

find an area clear from turbulence, and a different mounting technique should be considered.

If possible, viewing the transom of the boat while the boat is moving will provide the best

means of locating clear water, and if maximum high-speed operation is a high priority, this is

the recommended method. If this is not possible, select an area on the transom where the

hull forward of this location is smooth and free of protrusions or ribs.

Another consideration is the angle of deadrise. The transducer, when mounted, should point

straight down. The design of the transducer will allow a deadrise of 15 degrees while

remaining pointed straight down. If the deadrise is greater than 15 degrees it will be

necessary to angle the transducer slightly. While this does not significantly degrade

performance, you must keep in mind that the area you are viewing on your fishfinder screen

may be somewhat to one side of the boat.

Page 2

2

High Speed Transducer

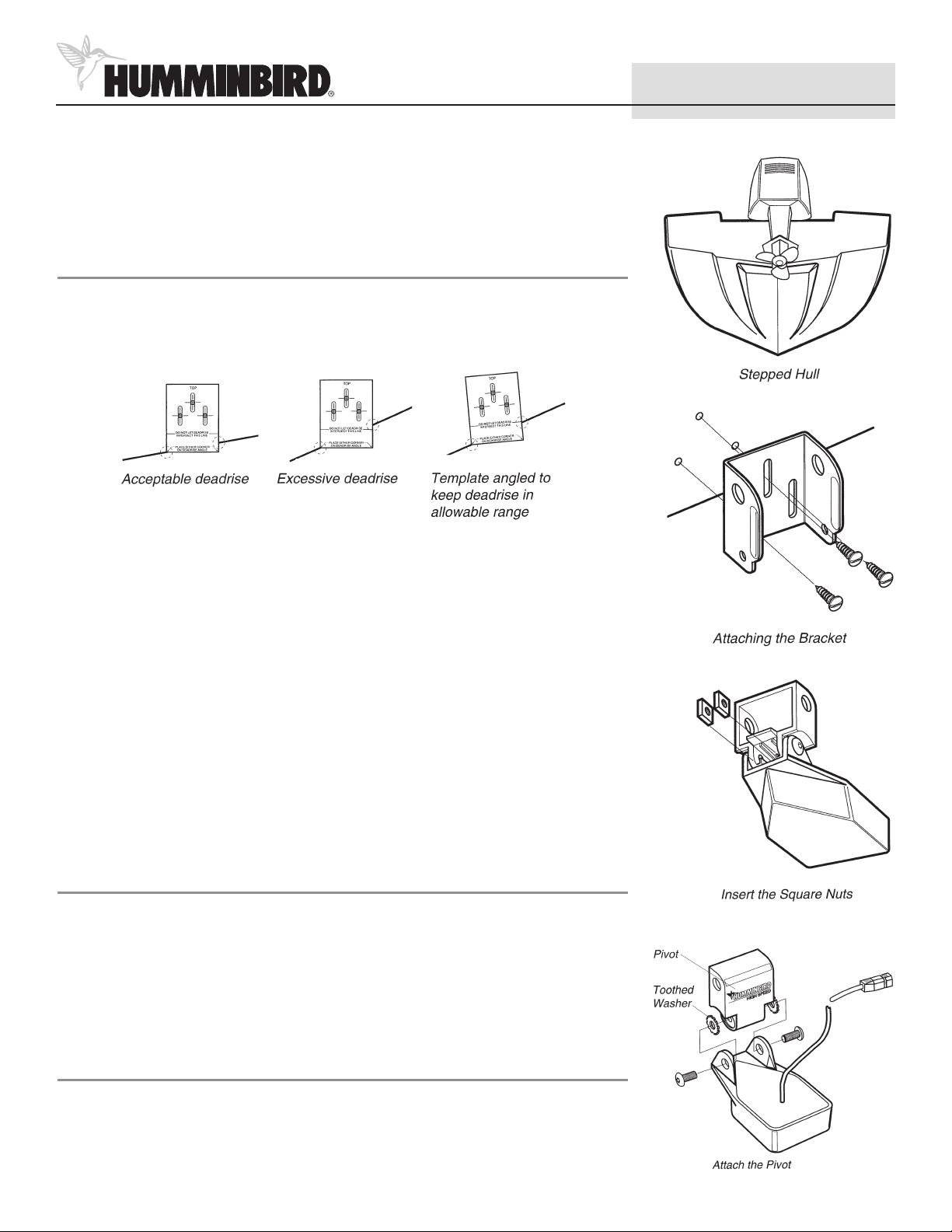

On boats with stepped hulls, it may be possible to mount the transducer on the step. Never

mount the transducer on the transom behind a step, as this area of the transom will not be

in contact with the water at high speeds.

Mounting the Bracket

Once you have identified the location, use the mounting template from the last page of these

instructions. This template serves two purposes: it provides a means of ensuring that the

deadrise of the transom falls within allowable limits, and it locates the three mounting holes

which must be drilled.

Hold the template on the transom of the boat in the location you have selected. Align the

template vertically, ensuring the lower edge of the transom on either side of the template

falls within the horizontal lines on the template. If not, tilt the template slightly so that the

lower edge of the transom on both sides of the template fall within the allowable range.

Using a pencil or a punch, mark the three mounting holes onto the transom. Using a 5/32”

(4 mm) bit, drill the three holes to a depth of approximately 1” (25 mm).

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flaking the outer hull coating.

Use a silicone sealant to fill the drilled holes, especially if the holes penetrated the transom wall.

Align the metal mounting bracket with the mounting holes. The center slot should be above

the two outer slots. (This bracket and all other hardware supplied is top quality stainless steel

for maximum strength and corrosion protection). Insert the three 1” (25 mm) flat head wood

screws into the drilled holes, but do not completely tighten.

Assembling the Transducer

Attach the pivot to the transducer body as shown in the following illustration using the two

1/4--20 x 5/8” (16 mm) machine screws, toothed washers, and square nuts. The toothed

washers must fit on the inside of the transducer ears, between the pivot and the ears. The

square nuts will be prevented from rotating by the pocket in the back of the pivot.

An Allen wrench is provided which fits all of the 1/4--20 screws, but do not fully tighten the

screws at this time.

Attaching the Transducer

Slide the assembled transducer into the metal bracket from the bottom, aligning the large

hole at the top of the bracket with the hole in the pivot.

Insert the headed pin through the pivot holes in the bracket and pivot. The headed pin can

be inserted from either side of the bracket.

Page 3

3

High Speed Transducer

Place the nylon washer over the opposite end of the headed pin. Place the stainless

washer over the 1/4--20 x 5/8” screw threads, then insert into the opposite end of

the headed pin and finger tighten only. The screw has a thread locking

compound on the threads to prevent loosening, and should not be fully

tightened until all adjustments are made.

Running Position Adjustment

The running position of the transducer is now completely adjustable. Subsequent

adjustment may be necessary to tweak the installation after high speed testing. The

metal bracket allows height and tilt adjustment; the pivot screws allow angle adjustment.

Adjust the angle of the transducer body first, so it is parallel with the hull of the boat, and fully

tighten the two pivot screws using the supplied Allen wrench. Access to the pivot screws is

provided by the lower holes in the side of the mounting bracket.

Next, adjust the height of the assembly so the face of the transducer is 1/8” (3 mm) to 1/4”

(6 mm) beneath the bottom of the transom, and fully tighten the three mounting screws.

In order to gain access to the mounting screws, the transducer assembly must be pivoted up

into the bracket as shown. Be careful not to alter the running angle as some force is necessary

to pivot the assembly.

If access to the top mounting hole is not possible due to the selected height of the transducer,

fully tighten the two lower screws. Remove the headed pivot pin and the transducer

assembly, tighten the top screw, and then reassemble.

Finally, ensure that all mounting screws are fully tightened.

Routing the Cable

The transducer cable has a low-profile connector that must be routed to the point where the

fishfinder is mounted. Every boat is different and there may be several ways to route the

cable (see the illustration on the following page).

If you choose to pass the cable through the transom of the boat, a 5/8” (16 mm) hole must

be drilled above the waterline. Fill this hole with silicone sealant, and use the supplied

escutcheon plate to dress the entry hole. This will require two #8 x 5/8” (16 mm) screws and

drilled holes of 9/64” (3.6 mm).

Remember that the transducer can pivot 90 degrees in the bracket should an object be struck,

and make sure sufficient cable slack exists for this movement. It is best to route the cable to

the side of the transducer so the cable will not be damaged by the rotating transducer.

Cable clamps are provided to secure the cable to the transom, and use the same type of

screws as the escutcheon plate.

Inside the boat, there is often a channel or conduit which is used for other wiring, which can

be used to route the transducer cable forward. Avoid routing the cable in areas where it may

be damaged or may interfere with normal boating operations. The transducer cable should

not be cut or shortened, and care should be used not to damage the cable insulation. Also,

be sure to route the cable as far as practical from the antenna cable of VHF radios to reduce

the possibility of interference.

Attaching the pivot to the bracket

Tighten the Pivot Screws

Tighten the Mounting Screws

Hand Tighten Only

Page 4

4

High Speed Transducer

This accessory works with a number of Humminbird® fishfinder products. Some products

may require disassembly of the fishfinder mounting bracket in order to connect the cable.

Refer to your operations manual and/or control head installation sheet for the correct

procedure for routing cables and cable connections.

If you find that the cable is too short for your application, extension cables are available

at a reasonable cost which can extend the transducer cable up to 50’ (15 m). Contact the

Humminbird® Customer Resource Center at 1-800-633-1468 or visit our website at

www.humminbird.com.

Maintenance

If your boat remains in the water for long periods of time, algae and other marine growth

can reduce the effectiveness of the transducer. Periodically clean the face of the

transducer with liquid detergent. Pivoting the transducer up in the bracket may allow

better access for inspection or cleaning.

In some cases it may take some time to wet the transducer when returned to the water.

Small air bubbles can cling to the surface of the transducer and can interfere with proper

operation. These bubbles will dissipate with time, or you may wipe the face of the

transducer with your fingers after the transducer is in the water.

Customer Support

Your Humminbird® accessory is designed for trouble-free operation and is backed by the

same one-year warranty as our fishfinders, VHF Marine-band radios, and GPS Navigation

equipment. Refer to your Humminbird® product operations manual for the specific

details of this warranty. If you have any questions, contact the Humminbird® Customer

Resource Center at 1-800-633-1468 or visit our website at www.humminbird.com.

Throughout the US and Canada, our hours are Monday through Friday, 8:00 a.m. to

4:30 p.m., Central Standard Time.

Humminbird

678 Humminbird Lane

Eufaula, AL 36027

www.humminbird.com

530506-2_A

Loading...

Loading...