Humminbird PIRANHAMAX 160, PIRANHAMAX 190C, PIRANHAMAX 170, PIRANHAMAX 180, PIRANHAMAX 150 User Manual

Page 1

PiranhaMAX™ 150,160,170,180,190c

PiranhaMAX™ 150,160,170,180,190c

Installation and Operations Manual

Installation and Operations Manual

531678-1_B

Page 2

Thank You!

Thank you for choosing Humminbird®, America's #1 name in fishfinders.

Humminbird® has built its reputation by designing and manufacturing

top-quality, thoroughly reliable marine equipment. Your Humminbird® is

designed for trouble-free use in even the harshest marine environment.In the

unlikely event that your Humminbird® does require repairs, we offer an

exclusive ServicePolicy-free of charge during the first year after purchase,and

available at a reasonable rate after the one-year period. For complete details,

see the Warranty section of this manual. We encourage you to read this

installation and operations manual carefully in order to get full benefit from all

the features and applications of your Humminbird® product.

Contact our Customer Resource Center at 1-800-633-1468 or visit our website

at www.humminbird.com. The PiranhaMAX™ comes in five models:

• PiranhaMAX™150 - Single Beam, 160 V x 128 H Monochrome Display

• PiranhaMAX™160 - Dual Beam, 160 V x 128 H Monochrome Display

• PiranhaMAX™170 - Dual Beam, 240 V x 160 H Monochrome Display

• PiranhaMAX™180 - Tri Beam, 240 V x 160 H Monochrome Display

• PiranhaMAX™190c - Single Beam, 320 V x 240 H Transmissive ColorDisplay.

WARNING! This device should not be used as a navigational aid to prevent collision,

grounding, boat damage, or personal injury. When the boat is moving,water depth may

change too quickly to allow time for you to react. Always operate the boat at very slow

speeds if you suspect shallow water or submerged objects.

WARNING! Do not touch an active transducer during operation, as this may cause

physical discomfort and mayresult in personalinjuryin the formof tissuedamage.Handle

the transducer only when the power to the control head is off.

WARNING! Disassembly and repair of this electronic unit should only be performed by

authorized service personnel. Any modification of the serial number or attempt to repair

the original equipment or accessories by unauthorized individuals will void the warranty.

Handling and/or opening this unit may result in exposure to lead, in the form of solder.

WARNING! This product contains lead, a chemical known to the state of California to

cause cancer, birth defects and other reproductive harm.

ENVIRONMENTAL COMPLIANCE STATEMENT:It is the intention of Humminbird®

to be a responsible corporate citizen, operating in compliance with known and

applicable environmental regulations, and a good neighbor in the communities where

we make or sell our products.

i

Page 3

WEEE DIRECTIVE: EU Directive 2002/96/EC “Waste of Electrical and Electronic

Equipment Directive (WEEE)”impactsmost distributors, sellers,and manufacturers of

consumer electronics in the European Union. The WEEE Directive requires the

producer of consumer electronics to take responsibility for the management of waste

from their products to achieve environmentally responsible disposal during the

product life cycle.

WEEE compliance may not be required in your location for electrical & electronic

equipment (EEE), nor may it be required for EEE designed and intended as fixed or

temporary installation in transportation vehicles such as automobiles, aircraft, and

boats.In some European Union member states, these vehiclesare consideredoutside

of the scope of the Directive, and EEE for those applications can be considered

excluded from the WEEE Directive requirement.

This symbol (WEEE wheelie bin) on product indicates the product must not

be disposed of with other household refuse. It must be disposed of and

collected for recyclingand recoveryof wasteEEE. Humminbird® will mark all

EEE productsin accordancewiththe WEEE Directive. It is our goal to comply

in the collection, treatment, recovery, and environmentally sound disposal of those

products; however, these requirementdo vary within European Union member states.

For more information about where you should dispose of your waste equipment for

recycling and recovery and/or your European Union member state requirements,

please contact your dealer or distributor from which your product was purchased.

ROHS STATEMENT: Product designed and intended as a fixed installation or part of

a system in a vessel may be consideredbeyond the scope of Directive 2002/95/EC of

the European Parliament and of the Council of 27 January 2003 on the restriction of

the use of certain hazardous substances in electrical and electronic equipment.

CALIFORNIA PROPOSITION 65 STATEMENT: Lead in cable jackets and boots is

restricted to 300 parts per million or less as determined by ICP-AES test methods.

NOTE: Some features discussed in this manual require a separate purchase, and

some features are only available on international or certain models. Every effort has

beenmade to clearlyidentify those features.Please read the manual carefully in order

to understand the full capabilities of your model.

NOTE: Illustrations in this manual may not look the same as your product, but your

unit will function in the same way.

Humminbird®, Piranha® , PiranhaMAX™, Fish ID+™, Structure ID®, WhiteLine™, are

trademarked by or registered trademarks of Humminbird® .

© 2008 Humminbird®, Eufaula AL, USA. All rights reserved.

ii

Page 4

Table of Contents

Installation Overview 1

Control Head Installation 2

Determine Where to Mount .............................................................................. 2

Connect the Power Cable to the Boat .............................................................. 2

Assembling the Control Head Base ............................................................ 4

Routing the Control Head Cables Under the Deck .................................... 5

Attaching the Control Head to the Base .................................................... 6

Attaching the Cables to the Control Head.................................................. 7

Transom Installation Overview 8

Transom Transducer Installation 9

Locating the Transducer Mounting Position .............................................. 9

Preparing the Mounting Location ............................................................ 11

Assembling the Transducer and Initial Mounting .................................... 12

Routing the Cable...................................................................................... 16

Test and Finish the Installation ................................................................ 18

Inside the Hull Transducer Installation 20

Determine the Transducer Mounting Location ........................................ 21

Trial Installation ........................................................................................ 22

Route the Cable ........................................................................................ 23

Permanently Mount the Transducer ........................................................ 23

Trolling Motor Transducer Installation 24

Powering ON and OFF 25

What You See On the Display 26

PiranhaMAX™ Sonar Technology 28

Single Beam Sonar .................................................................................... 29

Dual Beam Sonar ...................................................................................... 29

Tri Beam Sonar .......................................................................................... 29

iii

Page 5

Table of Contents

The Menu System 30

Light (Setting Not Saved in Memory) ........................................................ 30

Sensitivity (Setting Saved in Memory) ...................................................... 30

Depth Range (Setting Not Saved in Memory) .......................................... 31

Zoom (Setting Not Saved in Memory)........................................................ 31

Chart Speed (Setting Saved in Memory) .................................................. 32

Fish Alarm (Setting Saved in Memory) ...................................................... 32

Depth Alarm (Setting Not Saved in Memory)............................................ 32

Filter (Setting Saved in Memory) .............................................................. 33

SetUp Menu (Setting Not Saved in Memory)............................................ 33

Contrast (Setting Saved in Memory) .................................................... 33

Fish ID+™ (Setting Saved in Memory) ................................................ 34

Bottom View (Setting Saved in Memory).............................................. 34

Battery Alarm (Setting Saved in Memory)............................................ 36

Language (Setting Saved in Memory, International Only).................... 36

Units (Setting Saved in Memory, International Only) .......................... 36

Maintenance 37

Troubleshooting 38

International Purchases 41

1-Year Limited Warranty 42

Humminbird® Service Policy 43

Returning Your Unit for Service 44

Specifications 45

Contact Humminbird® 46

NOTE: Entries in thisTable of Contentswhichlist (International Only)are only available

on products sold outside of the U.S. by our authorized International Distributors. It is

important to note that products sold in the U.S. are not intended for resale in the

international market. Toobtain a listof authorized InternationalDistributors,pleasevisit

our website at www.humminbird.com or contact our Customer Resource Center at

1-800-633-1468 to locate the distributor nearest you.

iv

Page 6

Page 7

Installation Overview

Installation Overview

Before you start installation, we encourage you to read these instructions

carefully in order to get the full benefit from your PiranhaMAX™.

There are three basic installation tasks that you must perform for the

PiranhaMAX™:

• Installing the control head

• Installing the transducer

• Testing the complete installation and locking the transducer position.

1

Page 8

Control Head Installation

Control Head Installation

Determine Where to Mount

Begin the installation by determining where to mount the control head.

Consider the following to determine the best location:

• To check the location planned for the control

head, test run the cables for the power and

transducer. See the installation section for

your transducer type in order to plan the

location of the transducer.

• The mounting surface should be stable

Figure 1

Figure 2

Connect the Power Cable to the Boat

A 6' long power cable is included to supply power to the control head. You

may shorten or lengthen the cable using 18 gauge multi-stranded copper wire.

CAUTION: Some boats have 24 or 36 Volt electric systems, but the control head

MUST be connected to a 12 VDC power supply.

enough to protect the control head from

excessive wave shock and vibration, and

should provide visibility while in operation.

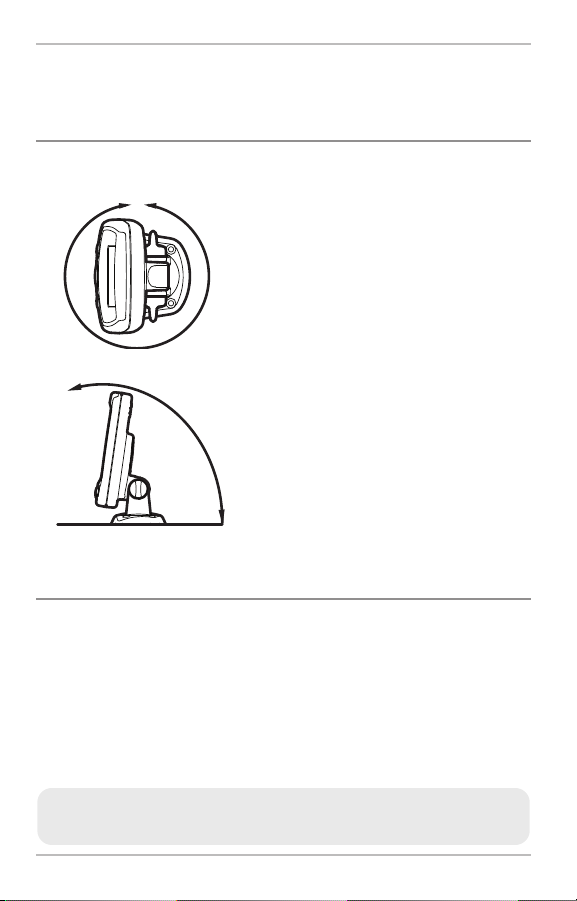

• Your PiranhaMAX™ may have one of two

different types of mounting bases, either a tilt

mounting base or a tilt and swivel mounting

base. The mounting area should allow

sufficient room for the unit to pivot freely, to

swivel if capable, and for easy removal and

installation (Figures 1 and 2).

The control head power cable can be connected to the electrical system of the

boat at two places: a fuse panel usually located near the console, or directly

to the battery.

NOTE: Make sure that the power cable is not connected to the control head at the

beginning of this procedure.

2

Page 9

GROUNDGROUND

POSITIVEPOSITIVE

Control Head Installation

NOTE: Humminbird® is not responsible for over-voltage or over-current failures. The

control head must have adequate protection through the proper selection and

installation of a 1 amp fuse.

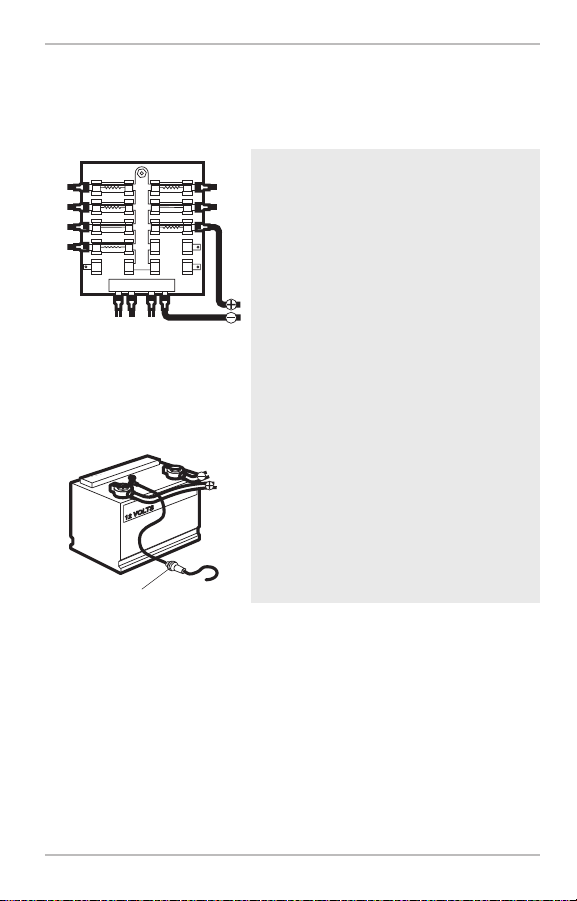

1a. If a fuse terminal is available, use

crimp-on type electrical connectors

(not included) that match the terminal

on the fuse panel. Attach the black

wire to ground (-), and the red wire to

positive (+) 12 VDC power (Figure 3).

Install a 1 amp fuse (not included) for

protection of the unit. Humminbird® is

Figure 3

not responsible for over-voltage of

over-current failures.

or...

1b. If you need to wire the control head

directly to a battery, obtain and install

an inline fuse holder and a 1 amp

fuse (not included) for the protection

of the unit (Figure 4). Humminbird® is

not responsible for over-voltage or

Inline Fuse Holder

Figure 4

over-current failures.

NOTE: In orderto minimize the potential for interferencewith other marine electronics,

a separate power source (such as a second battery) may be necessary.

3

Page 10

Control Head Installation

Assembling the Control Head Base

Your control head base will either have a tilt mount or a tilt and swivel mount.

Refer to procedures A or B below to assemble and mount the control head

base.

A. If you have a tilt mount, follow these steps:

1. Set the tilt mount control head base in place on the mounting surface.

Mark the four mounting screw locations with a pencil or punch.

2. Set the base aside, and drill the four mounting screw holes using a

9/64" bit.

3. Proceed to Routing the Control Head Cables Under the Deck.

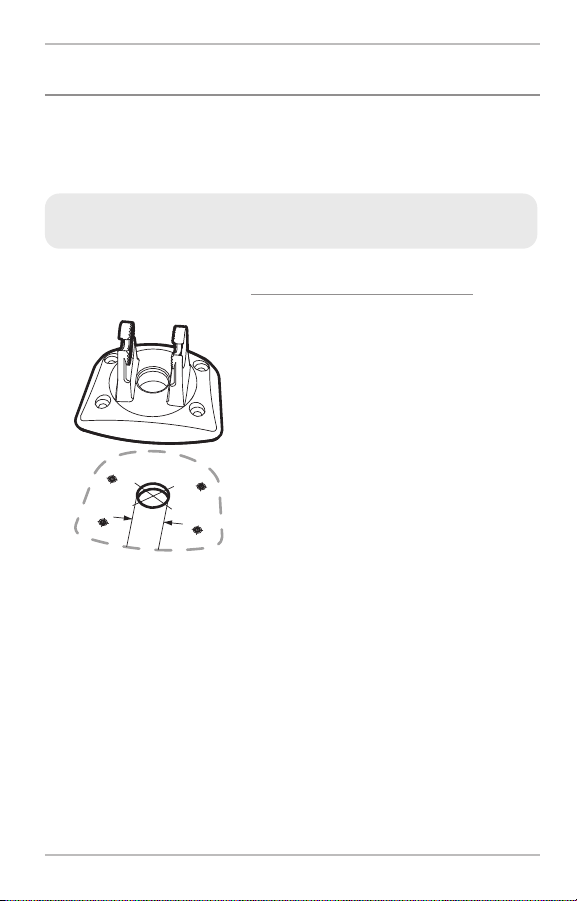

Tilt and Swivel Mount

Control Head Base Assembly

Mount Arms

B. If you have a tilt and swivel mount, follow

these steps:

1. Insert the mount arms into the base.

Then, hold the mount arms in place as

you turn the base upside down.

2. Insert the swivel ring into the base, with

Base

the countersink holes for the arm screws

facing out.

3. Secure the mount arms with the 4 #6

Swivel

Ring

screws provided (Figure 5). Hand tighten

only!

Countersink

Side Out

Arm Screws,

4 #6 x7/16"

Figure 5

4. Set the assembled control head base in

place on the mounting surface. Mark the

four mounting screw locations with a

pencil or punch.

5. Set the base aside, and drill the four

mounting screw holes using a 9/64" bit.

6. Proceed to Routing the Control Head

Cables Under the Deck.

4

Page 11

3

/

4

”

1

9

m

m

Control Head Installation

Routing the Control Head Cables Under the Deck

Use the following steps to route the control head cables under the deck.

NOTE: Under the deck cable routing is not always possible. If this is not an option,

the cables should be routed and secured above deck.

NOTE: See the installation section for your transducer type in order to plan the

location of the transducer and cable route.

Tilt Mount or Tilt and Swivel Mount

Control Head Base

Figure 6

Tilt Mount or Tilt and Swivel Mount:

1a. Mark and drill a 3/4" hole as shown in

Figure 6. Route the cables through the

hole. The cables will exit through the

center hole on the control head base.

1b. If the cables cannot be routed directly

beneath the control head base, mark

and drill a 3/4" hole that will allow you

to run the cables close to the control

head base.

5

Page 12

Control Head Installation

Attaching the Control Head to the Base

Follow these steps to attach the control head to the already-assembled base:

NOTE: The transducer cable and power cable should be routed prior to securing the

mounting bracket to the deck.

1. Apply marine-grade silicone sealant to the drilled holes for the

mounting bracket.

2. Place the mounting bracket on the mounting surface, aligning with the

drilled holes.

3. Insert the four #8 Phillips countersink wood screws into the mounting

holes and hand tighten only!

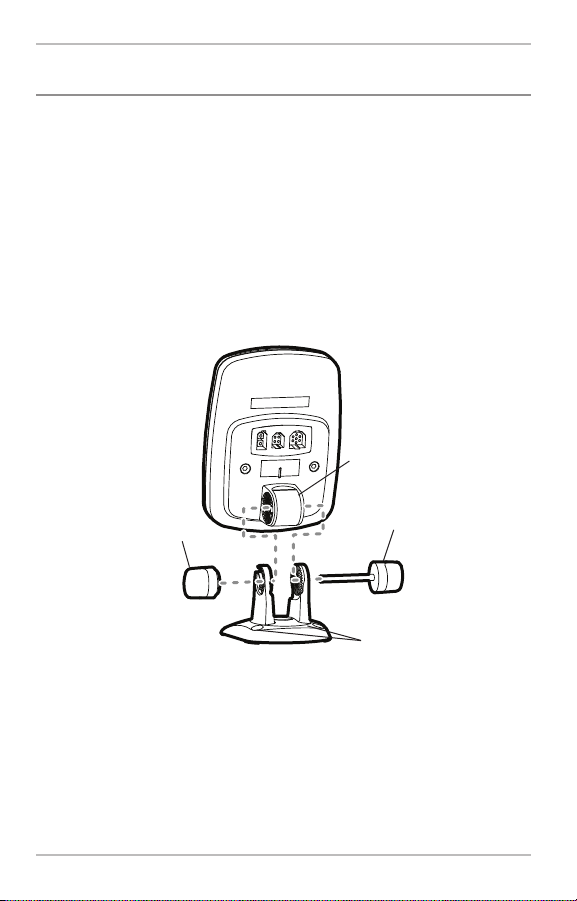

Pivot Knuckle

Gimbal Knob

Figure 7

Thumbknob Bolt

Mounting Holes

4. Insert the thumbknob bolt through the pivot knuckle on the control head

(Figure 7).

5. Align the pivot knuckle with the mount base arms and slide into place,

twisting slightly if necessary, until the unit is firmly seated.

6. Rotate the control head to the desired angle and hand tighten the

thumbknob bolt.

7. Thread the gimbal knob onto the pivot bolt and tighten.

6

Page 13

Control Head Installation

Attaching the Cables to the Control Head

Follow thesestepsto attach the power and transducer cablesto the control head:

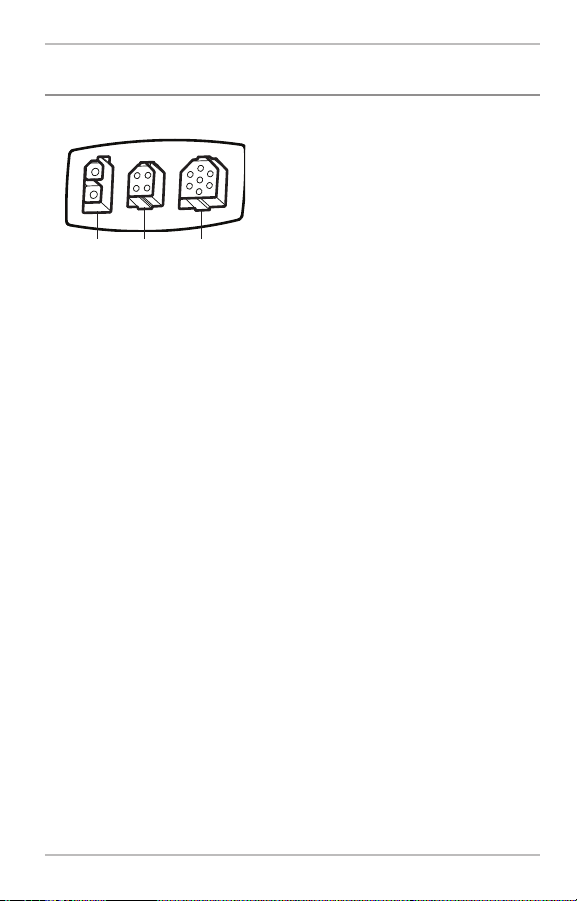

1. Matching the cable plugs to the shape

and orientation of the sockets, insert the

transducer and power cables into the

correct sockets on the control head

(Figure 8).

Power Temperature Transducer

Figure 8

You are now ready to install the transducer. See Transducer Installation

Overview and then find the section that refers to your transducer type.

2. With the control head in place, tilt

and/or swivel the unit through its full

range to make sure there is enough

cable slack for the unit to move freely.

Hand tighten the thumbknob bolt when

you achieve the desired position for the

control head.

7

Page 14

Transducer Installation Overview

Transducer Installation Overview

The transducer can be installed on the transom of the boat, inside the hull, or

onto a trolling motor, depending on your transducer type. The type of

transducer you have will also determine how the cable will be routed. Go to

the section that describes your transducer, and follow the steps to position

and mount the transducer on your boat.

NOTE: Due to the wide variety of hulls, only general instructions are presented

in this installation guide. Each boat hull represents a unique set of requirements

that should be evaluated prior to installation. It is important to read the

instructions completely and understand the mounting guidelines before

beginning installation.

NOTE: If the included transducer will not work for your application, you may

exchange it, NEW and UNASSEMBLED, with mounting hardware included, for a

transducer appropriate for your application - often at very little or no charge

depending on the transducer. Call the Humminbird® Customer Resource Center at

1-800-633-1468 for details and pricing, or visit www.humminbird.com.

NOTE: In addition to the hardware supplied with your transducer, you will need a

powered hand drill and various drill bits, various hand tools, including a ruler or

straightedge,a level, a 12" plumb line (weighted string or monofilament line), marker

or pencil, safety glasses and dust mask, and marine-grade silicone sealant.

NOTE: Whendrilling holesin fiberglass hulls,it is best to start with a smallerbit and use

progressively largerdrill bitsto reducethe chance of chipping or flaking the outer coating.

8

Page 15

Transom Transducer Installation

Transom Transducer Installation

Locating the Transducer Mounting Position

Turbulence: You must first determine the best location on the transom to

install the transducer. It is very important to locate the transducer in an area

that is relatively free of turbulent water.Consider the following to find the best

location with the least amount of turbulence:

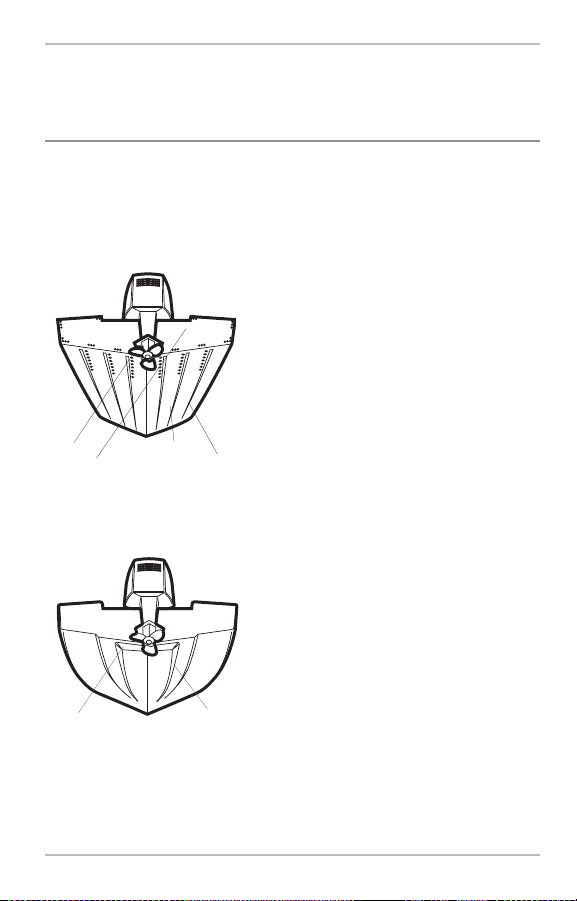

Areas of Possible Turbulence

Rivets Strakes

Transom Hull

Figure 9

Stepped Hull

Step

Figure 10

• As the boat moves through the water,

turbulence is generated by the weight of

the boat and the thrust of the propeller(s)

- either clockwise or counter-clockwise. This

turbulent water is normally confined to

areas immediately aft of ribs, strakes or

rows of rivets on the bottom of the

boat, and in the immediate area of the

propeller(s). Clockwise propellers create

more turbulence on the port side. On

outboard or inboard/outboard boats, it is

best to locate the transducer at least 15" to

the side of the propeller(s) (Figure 11).

•

The best way to locate turbulence-free

water is to view the transom while the boat

is moving. This method is recommended if

maximum high-speed operation is a high

priority. If this is not possible, select a

location on the transom where the hull

forward of this location is smooth, flat and

free of protrusions or ribs (Figure 9).

• On boats with stepped hulls, it may be

possible to mount the transducer on the

Rib

step. Do not mount the transducer on the

transom behind a step to avoid popping the

transducer out of the water at higher

speeds; the transducer must remain in the

water for the control head to maintain the

sonar signal (Figure 10).

9

Page 16

15”

Transom Transducer Installation

• If the transom is behind the propeller(s), it may be impossible to find an

area clear from turbulence, and a different mounting technique or

transducer type should be considered, such as an Inside the Hull

Transducer.

• If you plan to trailer your boat, do not mount the transducer too close to

trailer bunks or rollers to avoid moving or damaging the transducer

during loading and unloading of the boat.

• If high speed operation is critical, you may want to consider using an

In-Hull transducer instead of this Transom Mount transducer.

Level

Deadrise Angle

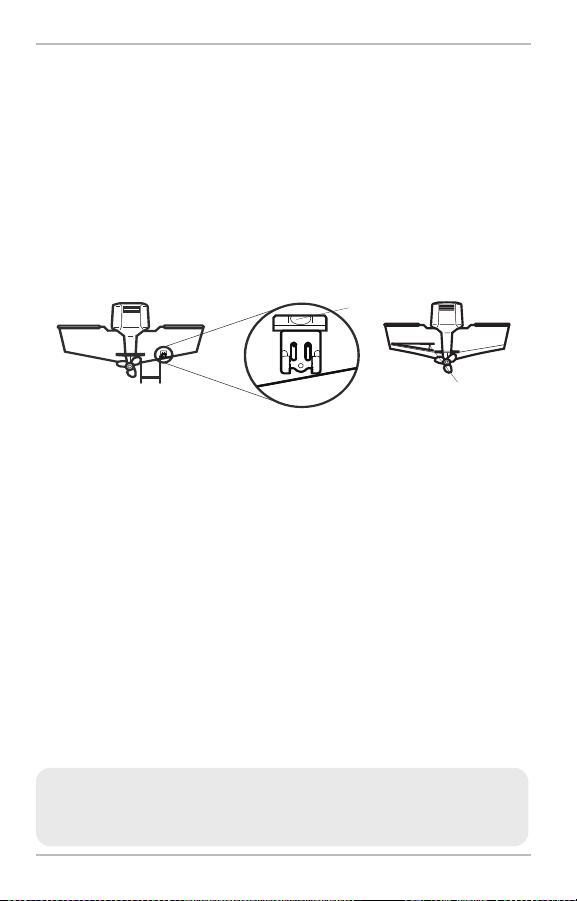

Find a turbulence-free location at least 15” from the propeller(s)

and not in line with trailer bunks or rollers. (Figure 11).

NOTE: The hydrodynamic shape of your transducer allows it to point straight down

without deadrise adjustment(Figure12).

Figure 12

NOTE: If you cannot find a transom mount location that will workfor your high-speed

application,find an In-Hull Transducer by contacting our Customer Resource Center at

either 1-800-633-1468or by visiting our website at www.humminbird.com.

10

Page 17

Preparing the Mounting Location

Positioning the MountingBracket

Level

Boat Hull Types Require

Different Mounting Positions

1/8” for aluminum

1/4” for fiberglass

Figure 14

Using the Mounting Bracket to

Mark the Initial Drill Holes

After determining the mounting location for the

transducer, follow the steps below to position and

mount the transducer bracket.

1. Make sure that the boat is level on the trailer,

Level

both from port to starboard and from bow to

stern, by placing your level on the deck of the

boat, first in one direction, then in the other.

2. Hold the mounting bracket against the transom

Figure 13

of the boat in the location you have selected

(Figure 13). Align the bracket horizontally, using

the level; make sure that the lower screw hole

protrusion does not protrude past the bottom of

the hull, and there is at least 1/4" clearance

between the bottom of the bracket and the

bottom of the transom for fiberglass boats, and

1/8" clearance for aluminum boats (Figure 14).

NOTE: If you have a flat-bottomed aluminumboat, some

additional adjustment may be needed to accommodate

therivets on the bottomof the boat(i.e.the gapmayneed

to be a littlesmaller than 1/8"). This will help you to avoid

excessive turbulenceat high speeds.

NOTE: If your propeller moves clockwise (in forward, as

you're facing the stern of the boat from behind), mount

the transducer on the starboard side. If your propeller

movescounter-clockwise (in forward,as you'refacing the

stern of the boat from behind), mount the transducer on

the port side.

3. Continue to hold the bracket on the transom of

the boat, and use a pencil or marker to mark

where to drill the two mounting holes. Mark the

drill holes near the top of each slot, making sure

that your mark is centered in the slot (Figure 15).

Transom Transducer Installation

Mark Initial

Drill Holes

3rd hole

Figure 15

NOTE: The third hole should not be drilled until the

angle and heightof thetransduceris finalized, which

youwillnot do untila later procedure.

11

Page 18

12”

-2 -1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Transom Angle (°)

Bead Alignment

Number

142531425

25 26 27328 29 30

1

Measured Distance (x)

1.1cm

1/2“

0.0 cm

0“

2.5 cm1“4.3 cm

1 5/8“

5.9 cm

2 3/8“

7.6 cm3“9.3cm

3 5/8“

11.1cm

4 3/8“

12.9cm5“14.9cm

5 7/8“

16.9cm

6 5/8“

Transom Transducer Installation

4. Make sure that the drill bit is perpendicular to the actual surface of the

transom, NOTparallel to the ground, beforeyou drill. Using a 5/32”bit, drill

the two holes only to a depth of approximately 1”.

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flakingthe outer coating.

Assembling the Transducer and Initial Mounting

In this procedure, you will assemble the transducer using the hardware provided,

thenmount it and make adjustments to its position without locking it in place.

NOTE: You will initially assemble the transducer and the mounting bracket by matching

the two ratchets to a numbered position on the transducer knuckle. Further adjustments

maybe necessary.

1a. If you already know your transom angle, refer to the chart below for the

initial position to use to set the ratchets (Figure 16). If your transom is

angled at 14 degrees (a common transom angle for many boats) use

position 1 for the ratchets. In either case, go to step 2.

Figure 16

or...

Transom Angle

in degrees (°)

Measured Distance (X)

Measuring the Transom Angle

1b. If you do not know your transom angle,

measure it using a plumb line (weighted

nylon string or monofilament line) exactly

12 inches long. Hold the top of the plumb

line against the top of the transom with

Plumb

line

your finger, and wait until the line hangs

straight down (Figure 17). Using a ruler,

measure the distance from the bottom of

the plumb line to the back of the

transom, then use the chart (Figure 16).

Figure 17

NOTE: It is important to take your measurement

Weight

in the location shown in Figure 17, from exactly 12

inches down from the top of the transom.

12

Page 19

Transom Transducer Installation

2. Place the two ratchets, one on either side of the transducer knuckle, so

that the beads on each ratchet line up with the desired position number

on the knuckle (Figure 18a). If you are setting the ratchets at position 1,

the beads on each ratchet will line up with the rib on the transducer

knuckle to form one continuous line on the assembly (Figure 18b).

NOTE: The ratchets are keyed; make sure that the square teeth on each ratchet face

the square teeth on the transducer knuckle, and the triangular teeth face outward.

Hold the ratchets on the transducer knuckle with one hand and fit the

mounting bracket over them until it snaps into place with the other hand. Refer

to the illustration (Figure 18d).

Transducer Knuckle Positions

Ratchets Placed in Position 2

Rib

Knuckle

Figure 18a

Bead

Ratchet

Figure 18c

Ratchets Placed in Position 1

Rib at

position 1

Fitting the Mounting Bracket Over the Ratchet

13

Beads

Ratchet

Figure 18b

Figure 18d

Page 20

Transom Transducer Installation

Inserting the Pivot Bolt

Figure 19

Mounting the Assembly

to the Transom

Figure 20

Figure 21

3. Put the pivot bolt through the assembly to

hold it in position and loosely install the nut,

but do NOT tighten the nut at this time

(Figure 19).

4. Align the mounting bracket transducer

assembly with the drilled holes in the

transom. With a 5/16" socket driver, mount

the assembly to the transom using the two

#10 - 1" long screws provided (Figure 20).

Hand tighten only!

NOTE: Make sure that the mounting screws are

snug,but do not fully tighten the mounting screwsat

thistime to allowthe transducer assembly to slide for

adjustment purposes.

5. Adjustthe initial angleof the transducerfrom

back to front by rotating the transducer until

the side seam on the transducer is almost

parallel with the bottom of the boat,one click

ata timein eitherdirection (Figure 21 and 22).

Adjusting the Initial Transducer Angle

One click too high

Correctly aligned

(transducer side

seam aligned

with boat bottom)

Trailing edge

Leading edge

Figure 22

One click too low

14

Page 21

Transom Transducer Installation

Adjusting the Transducer

Mounting Position

Seam aligned with boat hull

Figure 23

Leveling the Mounting

Assembly Horizontally

Level

Figure 24

6. Adjust the transducer assembly vertically,

until the seam on the leading edge of the

transducer (the edge closest to the transom

of the boat) is level and just slightly below

the hull (Figure 23).

NOTE: The transducer has a natural downward slant

of 4-5 degrees fromleading edge (closest to the boat

transom) to trailing edge (farthest away from the

boat). Looking at the back of the transducer, the

seamshould be slightlybelow the bottom of thehull.

7. Continue to adjust until the bracket is also

level from port to starboard (horizontally

level as you look at the transducer from

behind the boat (Figure 24).

8. Mark the correctposition on the transom by

tracing the silhouette of the transducer

mounting bracket with a pencil or marker.

Level

9. Tighten the pivot bolt, usingthe pivotscrew

and nut to lock the assembly. Hand tighten

only!

10. Hand-tighten the two mounting screws.

NOTE: You will drill the third mounting hole and

finalize the installation after you route the cable and

test and finish the installation in the following

procedures.

15

Page 22

Transom Transducer Installation

Routing the Cable

The transducer cable has a low profile connector, which must be routed to the

point where the control head is mounted. There are several ways to route the

transducer cable to the area where the control head is installed. The most

common procedure routes the cable through the transom into the boat.

NOTE: Your boat may have a pre-existing wiring channel or conduit that you can

use for the transducer cable.

1. Unplug the other end of the transducer cable from the control head.

(The transducer cable was connected in the earlier section Attaching

the Cables to the Control Head). Make sure that the cable is long

enough to accommodate the planned route by running the cable over

the transom.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the

cable insulation. Route the cable as far as possible from any VHF radio antenna

cables or tachometer cables to reduce the possibility of interference. If the cable is

too short, extension cables are available to extend the transducer cable up to a total

of 50'.Forassistance,contactthe Customer Resource Centerat www.humminbird.com

or call 1-800-633-1468 for more information.

NOTE: Allow enough slack in the cable for slight movement at the pivot point. It is

best to route the cable to the side of the transducer so the transducer will not

damage the cable during movement.

2a. If you are routing the cable over the transom of the boat, secure the

cable by attaching the cable clamp to the transom, drilling 9/64"

diameter holes for #8 x 5/8" wood screws, then skip directly to step 5

to connect the cable.

or...

2b. If you will be routing the cable through a hole in the transom, drill a 5/8"

diameter hole above the waterline. Route the cable throughthis hole, then

fill the hole with marine-grade silicone sealant and proceed to the next

step immediately.

16

Page 23

Transom Transducer Installation

Figure 25

Storing Excess Cable

Figure 26

Routing the Cable

3. Place the escutcheon plate over the

cable hole and use it as a guide to

mark the two escutcheon plate

mounting holes. Remove the plate, drill

two 9/64" diameter x 5/8" deep holes,

and then fill both holes with

marine-grade silicone sealant. Place the

escutcheon plate over the cable hole and

attach with two #8 x 5/8" wood screws.

Hand tighten only!

4. Route and secure the cable by attaching

the cable clamp to the transom; drill one

9/64" diameter x 5/8" deep hole, then fill

hole with marine-grade silicone sealant,

then attach the cable clamp using a

#8 x 5/8" screw. Hand tighten only!

NOTE: If there is excess cable that needs to be

gathered at one location (as shown in the

illustration), dress the cable routed from both

directions so that a single loop is left extending

from the storagelocation. Doubling the cable up

from this point, form the cable into a coil.Storing

excess cable using this method can reduce

electronic interference (Figure 26).

5. Plug the cable connector back into the

control head. The slots are keyed to prevent

reverseinstallation, so be careful not to force

the connector into the holder.

Your control head is now ready for operation.

17

Page 24

Transom Transducer Installation

Test and Finish the Installation

Once you have installed both the control head and the transom transducer, and

have routed all the cables, you must perform a final test before locking the

transducer in place. Testing should be performed with the boat in the water.

1. Press POWER once to turn the control head on. If the unit does not

power up, make sure that the connector is fully plugged into the

terminal slot and that power is available.

2. If all connections are correct and power is available, the Humminbird®

control head will enter Normal operation.

3. If the bottom is visible on-screen with a digital depth readout, the unit

is working properly. Make sure that the boat is in water greater than 2'

but less than the depth capability of the unit, and that the transducer

is fully submerged, since the sonar signal cannot pass through air.

NOTE: The transducer must be submerged in water for reliable transducer detection.

4. If the unit is working properly, gradually increase the boat speed to test

high-speed performance. If the unit functions well at lowspeeds, but begins

to skip or miss the bottom at higher speeds, the transducer requires

adjustment.

5. If you have the correct angle set on the transducer, yet lose a bottom

reading at high speed, adjust the height and the running angle in small

increments to give you the ideal transducer position for your boat. First,

adjust the height in small increments (Figure 23).

NOTE: The deeper the transducer is in the water, the more likely that a rooster tail

of spray will be generatedat high speeds, so make sure that the transduceris as high

as it can be and still be submerged in the water.

If you are still not getting good high speed readings, you may need to

disassemble the transducer mounting assembly and re-position the ratchets

(Figures 18a - 18d).

If you do change the transducer position, re-trace the position of the

mounting bracket before proceeding.

18

Page 25

Transom Transducer Installation

NOTE: It is often necessary to make several incremental transducer adjustments

before optimum high speed performance is achieved. Due to the wide variety of boat

hulls, however, it is not always possible to obtain high speed depth readings.

6. Once you have reached a consistently good sonar signal at the desired

speeds, you are ready to lock down the transducer settings. Remove the

transducer from the bracket (after noting where the ratchets are

assembled),then re-align the mounting bracketagainst the transom of the

boat to match the traced silhouette. Check the bracket position with the

level again to make sure it is still level, then mark the third mounting hole

using a pencil or marker. Unscrew and remove the mounting screws and

the transducer bracket and set aside.

7. Drill the third mounting hole, using a 5/32” drill bit. Use a marine-grade

silicone sealant to fill all three drilled mounting holes, especially if the

holes penetrated the transom wall.

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flaking the outer coating.

FullyTightenAll Three

Figure 27

Mounting Screws

8. Re-position the transducer bracket against

the transom of the boat, then hand-install

all three screws. Make sure that the

transducer location has not changed, then

fully tighten all three mounting screws

(Figure 27). Hand tighten only! Re-install

the transducer to the mounting bracket,

making sure to assemble the ratchets in the

same locationthey had before.(See Figures

18a - 18d and Figure 21 - 22). If you have

performed the preceding procedures

correctly, the transducer should be level

andat the rightheight for optimal operation.

19

Page 26

Inside the Hull Transducer Installation

Inside the Hull Transducer Installation

In-hull mounting generally produces good results in single thickness fiberglasshulled boats. Humminbird® cannot guarantee depth performance when

transmitting and receiving through the hull of the boat, since some signal loss

occurs. The amount of loss depends on hull construction and thickness, as well

as the installation position and process.

NOTE: In-hull mounting requires an installed and operational control head.

NOTE: The integral temperature probe will not work with in-hull mounting, so you

may either want to consider purchasing a Temp Sensor or obtaining a different

transducer. Humminbird® offers a transducer exchange program to swap the NEW

and UNASSEMBLED transducer, accompanied by mounting hardware, for one

without an integral temperature probe. Call the Humminbird® Customer Resource

Center at 1-800-633-1468 for details, or visit www.humminbird.com for more

information.

This installation requires slow-cure two-part epoxy. Do not use silicone or

any other soft adhesive to install the transducer, as this material reduces

the sensitivity of the unit. Do not use five-minute epoxy, as it has a

tendency to cure before all the air bubbles can be purged, thus reducing

signal strength.

20

Page 27

Inside the Hull Transducer Installation

Determine the Transducer Mounting Location

Decide where to install the transducer on the inside of the hull. Consider the

following to find the best location:

• Observe the outside of the boat hull to

find the areas that are mostly free from

turbulent water. Avoid ribs, strakes and

other protrusions, as these create

turbulence (Figure 28).

• As a general rule, the faster the boat

can travel, the further aft and closer to

the centerline of the hull the transducer

Figure 28

Preferred Mounting Area

has to be located in order to remain in

contact with the water at high speeds

(Figure 29).

Figure 29

21

Page 28

Inside the Hull Transducer Installation

Trial Installation

You will not be able to adjust the mounting after an inside the hull transducer

is installed. It is best, therefore, to perform a trial installation first that includes

running the boat at various speeds, in order to determine the best mounting

area before permanently mounting the transducer.

1. Plug the transducer into the control head, then power up the control

head. When the control head detects a functioning transducer, it will

automatically enter Normal operating mode.

2. View the sonar signal at its best by holding the transducer over the

side, immersed in the water, so that it is pointing straight down over a

known flat bottom. Use the display to benchmark against the sonar

signal that will be detected once the transducer is placed in the hull.

3. Place the transducer body face down at the identified mounting location

inside the hull, with the pointed end towards the bow (Figure 28).

4. Fill the hull with enough water to submerge the transducer body. Use

a sand-filled bag or other heavy object to hold the transducer in

position. The transducer cannot transmit through air, and the water

purges any air from between the transducer and the hull, and fills any

voids in the coarse fiberglass surface.

5. View the sonar signal on the display and compare against what was

observed in Step 2, making sure that the boat is in the same location

as it was during your observations in Step 2. If the results are

comparable, move on to Step 6. Otherwise, locate a new position in

the hull and repeat Steps 3 through 5.

6. Run the boat at various speeds and water depths while observing the

screen on the control head. If depth performance is required, test the

transducer in water at the desired depth. If the performance is

acceptable, move on to Step 7. If the performance is not acceptable,

repeat Steps 3 through 6.

7. Once you have determined the best mounting location using the above

steps, mark the position of the transducer.

22

Page 29

Inside the Hull Transducer Installation

Route the Cable

1. Once the mounting location is determined and you have marked the

position of the transducer, route the cable from the transducer to the

control head.

Permanently Mount the Transducer

1. Make sure the position of the transducer is marked.

2. You may have to disconnect the cable to the control head and

reconnect it at the end of this procedure.

3. Remove the water from inside the hull and thoroughly dry the

mounting surface. If the surface is excessively rough, it may be

necessary to sand the area to provide a smooth mounting surface.

4. Mix an ample quantity of two-part slow

cure epoxy slowly and thoroughly. Avoid

trapping air bubbles (Figure 30).

5. Coat the face of the transducer and the

inside of the hull with epoxy (Figures 28

and 30).

6. Press the transducer into place with a slight

twisting motion to purge any trapped air

from underneath, keeping the pointed end

of the transducer body pointed forward,

towards the bow (Figure 31).

Figure 30

Figure 31

NOTE: Neither water, spilled gasoline,nor oilwillaffectthe performance ofthetransducer.

NOTE: Proper operation requires the pointed end of

the transducer body to face towards the bow.

7. Weight the transducer so that it will not

move while the epoxy is curing.

NOTE: When the epoxy cures, no water is

necessary inside the hull.

8. If you unplugged the transducer cable at

the beginning of this procedure, plug it

back into the control head.

Your control head is now ready for operation.

23

Page 30

Trolling Motor Transducer Installation

Trolling Motor Transducer Installation

Several styles of the transducer are

compatible with trolling motor mounting.

(Figure 32). If you have a trolling motor

bracket, refer to the separate installation

instructions that are included with the

bracket.

Figure 32

You may purchase a Trolling Motor Adapter kit that will allow you to

mount the transducer on the trolling motor.

NOTE: Call the Humminbird® Customer Resource Center at 1-800-633-1468

for details and pricing, or visit www.humminbird.com for more information.

24

Page 31

Powering ON and OFF

Press and hold the POWER-MENU key until the PiranhaMAX™ powers on,

then release the key. To power off, press and hold the POWER-MENU key until

the unit shuts down.

When the PiranhaMAX™ powers on, the Start-Up menu

temporarily appears. From this menu, select either

Start-Up, Simulator, or SetUp.

• Use Start-Up for on the water use.

• Use Simulator for learning how to use the system with

simulated sonar data; access Simulator by pressing

the Right Arrow Key once.

• Use SetUp to display additional set-up menu choices;

access SetUp by pressing the Right Arrow Key twice

(See SetUp Menu for more information).

Display

LEFT Arrow Key

POWER/MENU Key

RIGHT Arrow Key

25

Page 32

What You See On the Display

The PiranhaMAX™ displays underwater information in an easy-to-understand

format. The top of the display corresponds to the water surface at the

transducer, and the bottom of the display corresponds to the Depth Range

automatically selected for the current water depth. The Bottom Contour varies

as the depth under the boat changes. Digital readouts provide precise

information for depth, fish and water temperature.

As the boat moves, terrain and bottom composition variations are displayed.

Fish, baitfish and thermoclines (underwater temperature changes) are

displayed when detected. Underwater conditions vary greatly, so some

experience and interpretation is needed to realize all the benefits of the

PiranhaMAX™ – use the following illustration as a guide to the most common

conditions and practice using your PiranhaMAX™ over known bottom types.

26

Page 33

PMAX150/190c (Single Beam) and

PMAX160/170 (Dual Beam) Display

2

3

7

9

10

* Units with 83 kHz Dual Beam sonar show targets in the widebeamas hollowfishicons.

1

4

5

6

8

1 - Water Surface Line

2 - Depth- Measuredat the Transducer

3 - Temperature

4 - Upper Range

5 - Surface Clutter

6 - Structure

7 - Bottom Contour

8 - Lower Range

9 - 83 kHz, Wide Beam Hollow FishSymbol (DualBeam Units only)*

10 - 200 kHz, Narrow Beam Shaded FishSymbol

11 - 455 kHz, Right Beam Fish Symbol(Tri Beam Unit only)**

12 - 455 kHz, Left Beam Fish Symbol(Tri Beam Unit only)**

PMAX180 (Tri Beam) Display

2

3

10

7

11

12

* Units with 455 kHz Tri Beam sonar show targetsin the left beamas left-looking fish

symbols, andtargetsin the right beam as right-looking fish symbols.

27

1

4

5

6

8

Page 34

PiranhaMAX™ Sonar Technology

The PiranhaMAX™ is the easiest to use fishfinder ever. For most anglers, all

you’ll ever need to do is power on and fish! The PiranhaMAX™ automatically

determines depth and makes adjustments to keep the bottom and fish visible

on the display.

The PiranhaMAX™ uses sonar technology to send sound waves from the

transducer into the water. The returned “echoes” are plotted on the display,

creating a very accurate picture of the underwater world, including distance

to underwater objects such as the bottom, fish, and structure.

Your PiranhaMAX™ will have Single, Dual, or Tri Beam sonar. Find the correct

sonar description that applies to your unit.

28

Page 35

Single Beam Sonar

The PiranhaMAX™150 and PiranhaMAX™190c use a 200 kHz single beam

sonar system with a 20° area of coverage. Boat speed, wave action, bottom

hardness, water conditions and transducer installation can all affect depth

capability.

Dual Beam Sonar

The PiranhaMAX™160 and PiranhaMAX™170 use a 200/83 kHz dual beam

sonar system with a wide (60°) area of coverage. Dual Beam sonar is optimized

to show the greatest bottom definition using a narrow (20°) beam yet can still

indicate fish found in the wide (60°) beam when the Fish ID+

on. Dual Beam is ideal for a wide range of conditions - from shallowto very deep

water in both fresh and salt water. Boat speed, wave action, bottom hardness,

water conditions and transducer installation can all affect depth capability.

TM

feature is turned

Tri Beam Sonar

The PiranhaMAX™180 uses two frequencies and three different sonar

elements, one narrow, two wide, that transmit signals to the left, right and

straight down from your boat. The downward beam is 200 kHz with a 20° area

of coverage. This beam maintains a continuous digital depth readout from the

bottom directly beneath your boat. The side beams are 455 kHz with a 35°

area of coverage, for a total 90° area of coverage. Boat speed, wave action,

bottom hardness, water conditions, and transducer installation can all affect

depth capability.

29

Page 36

The Menu System

A simple menu system allows you to access your PiranhaMAX™ adjustable

settings. To activate the menu system, press the POWER-MENU key.Press the

POWER-MENU key repeatedly to display the PiranhaMAX™ menu settings,

one at a time. When a menu setting is on the display, use the RIGHT and LEFT

Arrow keys to adjust the menu setting. Menus settings are saved and removed

from the screen automatically after several seconds. In Normal operating mode,

most menu settings savedto memorywill not return to their defaultvalues when

the unit is turned off. See individual menu choices for more information.

NOTE: Each time the POWER-MENU key is pressed, the backlight momentarily

illuminates for easy viewing at night. Adjust the LIGHT menu setting to keep the

backlight on.

NOTE: If Simulator Mode is selected from the Start-Up Menu and a transducer is

plugged in, some menu setting changes will be saved in memory even after the unit

is powered down. Menu setting changes will not be saved from Simulator mode

when a transducer is not connected.

NOTE: Turning on the SetUp menu choice from the Main Menu System allows you

to access additional set-up menu choices. See SetUp Menu for more information.

Light

(Setting Not Saved in Memory)

Press the POWER-MENU key until LIGHT appears. Use the backlight for night

fishing. Select either 0 (Off), or 1 through 5 to activate the backlight at the

desired level. (0 to 5, Default = 0 [PiranhaMAX™150/160/170/180]; 0 to 10,

Default = 10 [PiranhaMAX™190c])

NOTE: Continuous backlight operation will significantly decrease the battery life for

PiranhaMAX™ Portables.

Sensitivity

(Setting Saved in Memory)

Pressthe POWER-MENU key untilSENSITIVITY appears. Sensitivity controlshow

much detail is shown on the display. Increasing the sensitivity shows more sonar

returns from small baitfish and suspendeddebris in the water; however, the display may become too cluttered. When operating in very clear water or greater

depths, increased sensitivity shows weaker returns that may be of interest. Decreasing the sensitivity eliminates the clutter from the display that is sometimes

present in murky or muddy water. If Sensitivity is adjusted too low, the display

may not show many sonar returns that could be fish. (0 – 10, Default = 5)

30

Page 37

Depth Range

(Setting Not Saved in Memory)

Press the POWER-MENU key until DEPTH RANGE appears. Automatic is the

default setting. Whenin automatic, the lower range will be adjusted by the unit

to follow the bottom. (Auto, 15 to 600 ft [PiranhaMAX™150/160], 15 to 800 ft

[PiranhaMAX™170/180/190c], Default = Auto)

NOTE: In manual operation, if the depth is greater than the depth range setting,

the bottom will not be visible on the display. Select AUTO to return to automatic

operation.

Zoom

(Setting Not Saved in Memory)

Press the POWER-MENU key until ZOOM appears. Select Auto to magnify the

area around the bottom in order to reveal fish and structure close to the bottom

that may not be visible during normal operation. When ZOOM is set to Auto, the

upper and lower DepthRangesareautomaticallyadjusted to keep the areaabove

and below the bottom on the display. Select Off to return to normal operation.

(Off, Auto, Manual Ranges, Default = Off)

Upper

Zoom Range

Structure

Magnified Bottom

with More Detail

Lower

Zoom Range

There is also a series of manual ranges which can be selected. The manual

depth ranges are determined by the present depth conditions.

31

Page 38

Chart Speed

(Setting Saved in Memory)

Press the POWER-MENU key until CHART SPEED appears. Select a setting

from 1-5 to increase or decrease the chart speed, where 1 is the slowest and

5 is the fastest chart speed. Chart speed determines the speed at which the

sonar information moves across the display, and consequently the amount of

detail shown. A faster speed shows more information and is preferred by most

anglers; however, the sonar information moves across the display quickly. A

slower speed keeps the information on the display longer, but the bottom and

fish details become compressed and may be difficult to interpret. (1 to 5,

Default = 5)

Fish Alarm

(Setting Saved in Memory)

Press the POWER-MENU key until FISH ALARM appears. Select Off for no fish

alarm, or one of the following symbols to set the alarm. An alarm will sound

when the PiranhaMAX™ detects fish that correspond to the alarm setting.

Fish Alarm will only sound if Fish ID+™ is also set to On. (Off, Large,

Large/Medium, All, Default = Off)

Large fish only

Large/Medium fish only

All fish

Depth Alarm

(Setting Saved in Memory)

Press the POWER-MENU key until DEPTH ALARM appears. Select OFF for no

Depth Alarm, or select 3 to 99 feet to set the alarm depth. An audible alarm

sounds when the depth is equal to or less than the setting. (Off, 3 to 99 feet,

Default = Off)

32

Page 39

Filter

(Setting Saved in Memory)

Press the POWER-MENU key until FILTER appears. Select either Off or On.

Filter adjusts the sonar filter to limit interference on the display from

sources such as your boat engine, turbulence, or other sonar devices.

(On, Off, Default = Off)

SetUp Menu

(Setting Not Saved in Memory)

Press the POWER-MENU key until SetUp appears. Press the RIGHT Arrow key

to select On. (Off, On, Default = Off)

When you activate SetUp, additional menu choices will become available that

are not a part of the Main Menu system. After selecting SetUp, press the

POWER-MENU key to display the SetUp menu choices, one at a time. SetUp

Menu choices include:

• Contrast • Battery Alarm

• Fish ID+

• Bottom View • Units (International only).

Scroll through all SetUp menu choices to exit the SetUp menu.

TM

• Language (International only)

Contrast (SetUp Menu)

(Setting Saved in Memory, Monochrome only)

Make sure that the SetUp menu is selected, then press the POWER-MENU key

until CONTRASTappears. Select a setting from 1 through 5. (1 to 5, Default = 3)

Scroll through all SetUp menu choices to exit the SetUp menu.

33

Page 40

Fish ID+TM(SetUp Menu)

(Setting Saved in Memory)

Make sure that the SetUp menu is selected, then press the POWER-MENU key

until FISH ID+

view Fish symbols. Fish ID+

sonar returns, and will display a Fish Symbol when very selective requirements

are met. A select number of possible fish returns will be displayed with their

associated depth. (On, Off, Default = On)

Scroll through all SetUp menu choices to exit the SetUp menu.

T

M

appears. Select either Off to view “raw” sonar returns or On to

TM

uses advanced signal processing to interpret

Raw Sonar,

T

Fish ID+

Off

Single Beam

Raw Sonar,

TM

Fish ID+

Off

Dual Beam

Raw Sonar,

TM

Fish ID+

Off

Tri Beam

200 kHz

M

Narrow beam,

TM

On

Fish ID+

200 kHz

Narrow beam,

TM

Fish ID+

200 kHz

Narrow beam,

TM

Fish ID+

83 kHz

Wide beam,

TM

On

Fish ID+

On

455kHz

Leftand rightbeam,

TM

On

On

FishID+

NOTE: Returns from the 200 kHz narrow beam are shown with shaded fish

symbols while the 83 kHz wide beam (and 455 kHz beam) returns are displayed

with hollow fish symbols.

NOTE: Hollow fish symbols are not available on 200 kHz Single Beam sonar units.

Bottom View (SetUp Menu)

(Setting Saved in Memory)

Make sure that the SetUp menu is selected, then press the POWER-MENU

key until BOTTOM VIEW appears. Bottom View selects the method used to

represent the bottom and structure on the display. (Structure ID, Black,

WhiteLine, Inverse, Default = Inverse)

Scroll through all SetUp menu choices to exit the SetUp menu.

34

Page 41

Structure ID® represents weak returns as light pixels

and strong returns as dark pixels. This has the

benefit of ensuring that strong returns will be clearly

visible on the display.

Black (Bottom Black) displays all pixels below the

bottom contour as black, regardless of signal strength.

This has the benefit of providing a high contrast

between the bottom and other sonar returns on the

display.

NOTE: Bottom Black View is not available on color

models.

WhiteLine™ highlights the strongest sonar returns in

white resulting in a distinctive outline. This has the

benefit of clearly defining the bottom on the display.

Inverse is a method where weak returns are shown

with dark pixels and strong returns with lighter pixels.

This has the benefit of ensuring that weak signals will

be clearly visible on the display.

NOTE: Inverse View is not available on color models.

35

Page 42

Battery Alarm (SetUp Menu)

(Setting Saved in Memory)

Make sure that the SetUp menu is selected, then press the POWER-MENU

key until BATTERY ALARM appears. Select Off or 8.5 to 13.5 Volts. Battery

Alarm sounds when the input battery voltage is equal to or less than the menu

setting. (Off, 8.5 to 13.5 Volts, Default = Off)

Scroll through all SetUp menu choices to exit the SetUp menu.

Language (SetUp Menu)

(Setting Saved in Memory, International only)

Make sure that the SetUp menu is selected, then press the POWER-MENU

key until LANGUAGE appears (International Units only). LANGUAGE selects

the display language for menus. (Settings vary, Default = English)

Scroll through all SetUp menu choices to exit the SetUp menu.

Units (SetUp Menu)

(Setting Saved in Memory, International only)

Make sure that the SetUp menu is selected, then press the POWER-MENU

key until UNITS appears (International Units only). UNITS selects the units of

measure. (Feet/F, Meters/C, Fathoms/C, Default = Meters/C, where F stands

for Fahrenheit and C stands for Celsius)

Scroll through all SetUp menu choices to exit the SetUp menu.

36

Page 43

Maintenance

Your PiranhaMAX™ is designed to provide years of trouble-free operation with

virtually no maintenance. Follow these simple procedures to ensure your

PiranhaMAX™ continues to deliver top performance.

If the unit comes into contact with salt spray, wipe the affected surfaces with a

cloth dampened in fresh water.

Do not use a chemical glass cleaner on the lens - this may cause cracking in

the lens.

When cleaning the LCD protective lens, use a chamois and non-abrasive, mild

cleaner. Do not wipe while dirt or grease is on the lens. Be careful to avoid

scratching the lens.

If your boat remains in the water for long periods of time, marine growth can

reduce the effectiveness of the transducer. Periodically clean the face of the

transducer with liquid detergent.

If your boat remains out of the water for a long period of time, it may take some

time to wet the transducer when returned to the water. Small air bubbles can

cling to the surface of the transducer and interfere with proper operation. These

bubbles dissipate with time, or you can wipethe faceof the transducer with your

fingers after the transducer is in the water.

Never leave the unit in a closed car or trunk—the extremely high temperatures

generated in hot weather can damage the electronics.

37

Page 44

Troubleshooting

Do not attempt to repair the PiranhaMAX™ yourself. There are no

user-serviceable parts inside, and special tools and techniques are required

for assembly to ensure the waterproof integrity of the housing. Repairs should

be performed only by authorized Humminbird technicians.

Many requests for repair received by Humminbird® involve units that do not

actually need repair. These units are returned “no problem found.” If you have a

problem with yourPiranhaMAX™, use the followingtroubleshooting guide before

calling the Customer Resource Center or sendingyour unit in for repair.

1. Nothing happens when I turn the unit on.

Check the powercable connectionat bothends. Be sure the cable is connected

correctly to a reliable power source — red lead to positive, black lead to

negative or ground. Ensure the power available is between 10 and 20 VDC. If

the unit is wired through a fuse panel, ensure the panel is powered. Often

accessoryfusepanels arecontrolledbya separate switch or theignition switch.

Also,often a fuse can appear to be good when it is not. Check the fuse with a

tester or replace it with a fuse known to be good.

Check the power connection to the PiranhaMAX™. It is possible to force the

power cable connector into the cable holder incorrectly. If the connector is

reversed, the unit will not work. Examine the contacts on the back of the unit

to ensurethere is no corrosion.

2. There is no transducer detected.

The PiranhaMAX™ has the ability to detect and identify that a transducer

is connected. When powering on, if a message indicates “transducer not

connected”,make sure that an appropriate transducer connector is plugged

into the unit. In addition, inspect the transducer cable from end to end for

breaks, kinks, or cuts in the outer casing of the cable. Also make sure that

the transducer is fully submerged in water. If the transducer is connected

to the unit through a switch, temporarily connect it directly to the unit and

try again. If none of these actions identifies an obvious problem, the

transducer itself is probably at fault. Be sure to include the transducer if

returning the unit for repair.

38

Page 45

3. There is no bottom reading visible on the display.

If the loss of bottom information occurs only at high boat speeds, the

transducer needs adjusting – see your PiranhaMAX™ Installation Guide for

details. Also, in very deep water, it may be necessary to increase the

sensitivity setting manually to maintain a graphic depiction of the bottom. If

you are using a transducer switch to connect two transducers to the

PiranhaMAX™, make sure that the switch is in the correct position to connect

a transducer that is in the water. (If a trolling motor transducer is selected and

the trolling motor is out of the water, no sonar information appears.) If none of

theseactions solves the problem, inspect the transducer cablefromend to end

for breaks, kinks, or cuts in the outer casing of the cable. If the transducer is

connected to the unitthrough a switch, temporarily connectit directly to theunit

and try again. If none of these actions identifies an obvious problem, the

transducer itself may be at fault. Be sure to include the transducer if returning

the unit for repair.

4. When in very shallow water, I get gaps in the bottom reading and

inconsistent digital depth indication.

The PiranhaMAX™ will work reliably in water 3 feet (90 cm) or deeper.

Remember that the depth is measured from the transducer, not from the

surface of the water.

5. The unit comes on before I press the POWER-MENU key, and won’t

turn off.

Check the transducer cable — if the outer jacket of the cable has been cut

and the cableis in contactwithbare metal, you will need to repair the cut with

electricaltape.If thereis no problem with the cable, disconnect thetransducer

from the unit and see if the problemis corrected, to confirm the source of the

problem.

6. I get gaps in the reading at high speeds.

Your transducer needs adjusting. If the transducer is transom-mounted, there

are two adjustments available to you: height, and running angle. Make small

adjustments and run the boat at high speeds to determine the effect. It may

takeseveral tries to optimizehigh-speed operation. Thiscan also be a resultof

air or turbulence in the transducer location caused by rivets, ribs, etc.

39

Page 46

7. My unit loses power at high speeds.

Your PiranhaMAX™ has over-voltage protection that turns the unit off when

input voltage exceeds 20 VDC. Some outboard motors do not effectively

regulate the poweroutputof the engine’s alternator and can produce voltage

in excess of 20 Volts when running at high RPMs.

8. The display begins to fade out. Images are not as sharp as normal.

Checkthe input voltage. ThePiranhaMAX™ willnot operate on input voltages

below10 VDC.

9. The display shows many black dots at high speeds and high

sensitivity settings.

You are seeing noise or interference caused by one of several sources. Noise

can be caused by electronic devices. Turn off any nearby electronics and see

if the problem goes away. Noise can also be caused by the engine. If engine

noise is causing the interference, the problem will intensify at higher RPMs.

Increase the engine speed with the boat stationary to isolate this cause.

Propeller cavitation can also appear as noise on the display. If the transducer

is mounted too close to the propeller, the turbulence generated can interfere

with the sonar signal. Make sure that the transducer is mounted at least 15"

(380 mm) from the propeller.

40

Page 47

International Purchases

A separate warranty is providedby international distributors for units purchased

outsidethe United States. This warrantyis includedby your local distributor and

this distributor maintains local service for your unit. Warranties are only valid in

the area of intendeddistribution.Unitspurchased in the United States or Canada

must be returned to our factory in the United States for service.

41

Page 48

Humminbird® 1-Year Limited Warranty

We warrant the original retail purchaser that products made by Humminbird®

have been manufactured free from defects in materials and workmanship. This

warranty is effective for one year from the date of original retail purchase.

Humminbird® products found to be defective and covered by this warranty will

be replaced or repaired free of charge at Humminbird’s option and returned to

the customer freight prepaid. Humminbird’s sole responsibility under this

warranty is limited to the repair or replacement of a product that has been

deemed defectiveby Humminbird®. Humminbird®is not responsible for charges

connected with the removal of such product or reinstallation of replaced or

repaired parts.

This warranty does not apply to a product that has been:

• Improperly installed;

• Used in an installation other than that recommended in the product

installation and operation instructions;

• Damaged or has failed because of an accident or abnormal operation;

• Repaired or modified by entities other than Humminbird®.

Please retain your original receipt as a proof of the purchase date. This will be

required for in-warranty service.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES ON THE PART OF HUMMINBIRD® AND WILL

BE THE CUSTOMER'S EXCLUSIVE REMEDY, EXCEPT FOR ANY APPLICABLE

IMPLIED WARRANTIES UNDER STATE LAW WHICH ARE HEREBY LIMITED

IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE.IN

NO EVENT WILL HUMMINBIRD® BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED

WARRANTY RELATING TO THE PRODUCTS.

Some states do not allow limitationson an implied warranty, or the exclusion of

incidental or consequential damages, so the above exclusions may not apply to

you. You may also have other rights, which vary from state to state.

42

Page 49

Humminbird® Service Policy

Even though you'll probably never need to take advantage of our incredible

service policy, it's good to know that we back our products this confidently.

We do it because you deserve the best. We will make every effort to repair

your unit within three business days from the receipt of your unit at our

factory. This does not include shipping time to and from our factory. Units

received on Friday are typically shipped by the following Wednesday, units

received Monday are typically shipped by Thursday, etc.

All repair work is performed by factory-trained technicians to meet exacting

factory specifications. Factory-serviced units go through the same rigorous

testing and quality control inspections as new production units.

After the original warranty period, a standard flat rate service charge will be

assessed for each repair (physical damage and missing parts are not included).

Any repairs made after the original warranty will be warranted for an

additional 90 days after service has been performed by our factory technicians.

You can contact our Customer ResourceCenter or visit our website to verify the

flat rate repair fee for your product (visit the Product Support section):

http://www.humminbird.com

We reserve the right to deem any product unserviceable when replacement

parts are no longer available or impossible to obtain. This Service Policy is valid

in the United States only. This applies only to Humminbird® products returned

to our factory in Eufaula, Alabama. This Service Policy is subject to change

without notice.

DOMESTIC (USA) CUSTOMERS:

PLEASE DO NOT RETURN THIS PRODUCT TO STORE FOR SERVICE

For all technical issues please call 1-800-633-1468

Or visit www.humminbird.com, click SUPPORT

Please reference product serial number and

model number when contacting Humminbird®.

43

Page 50

Returning Your Unit for Service

Before sending your unit in for repair, please contact the factory, either by phone

or by email, to obtain a Repair Authorization Number for your unit.

NOTE: Please do not return your Humminbird® to the store for service.

Please have your productmodel name and serial number availablebeforecalling

thefactory.If youcontact the factoryby e-mail,please include yourproduct model

name and serial number in the e-mail, and use Request for Repair Authorization

Number for your e-mail subject header. You should include your Repair

Authorization Number in all subsequent communications about your unit.

For IN-WARRANTY service, complete the following steps:

• Obtain a Repair Authorization Number from the Humminbird®

Customer Resource Center.

• Tag product with your name, street address, phone number and your

assigned Repair Authorization Number.

• Include a brief written description of the problem.

• Include a copy of your receipt (to show proof and date of purchase).

• Return product freight prepaid to Humminbird®, using an insured

carrier with delivery confirmation.

For OUT-OF-WARRANTY service, complete the following steps:

• Obtain a Repair Authorization Number from the Humminbird®

Customer Resource Center.

• Include payment in the form of credit card number and expiration date,

money order or personal check. Please do not send cash.

• Tag product with your name, street address, phone number and your

assigned Repair Authorization Number.

• Include a brief written description of the problem.

• Return product freight prepaid to Humminbird®, using an insured

carrier with delivery confirmation.

44

Page 51

Specifications

Depth Capability............................................................ 600 ft (185 m) – (PMAX150/160)

800 ft (250 m) – (PMAX170/180/190c)

Power Output .................................................................800 Watts (PTP) – (PMAX150/160)

1600 Watts (PTP) – (PMAX170/180/190c)

Operating Frequency............................................. 200 kHz Single Beam (PMAX150/190c)

200 kHz and 83 kHz Dual Beam™ (PMAX160/170)

200 kHz and 455 kHz Tri Beam (PMAX180 only)

Area of Coverage (PMAX150/190c) .......................................... 20° @ -10 dB in 200 kHz

Area of Coverage (PMAX160/170).............................................. 60° @ -10 dB in 83 kHz

20° @ -10 dB in 200 kHz

Area of Coverage (PMAX180).................................................... 20° @ -10 dB in 200 kHz

90°Total Coverage (Two 35° Beams)@ -10 dB in 455 kHz

Target Separation ............................................................................ 2 1/2 Inches (63.5 mm)

Power Requirement ............................................................................................. 10-20 VDC

LCD Matrix ..........................................................................160 V x 128 H – (PMAX150/160)

240 V x 160 H – (PMAX170/180)

320 V x 240 H – (PMAX190c)

Transducer...............................................................XNT-9-20-T – (PMAX150/160/170/190c)

XNT-9-QB-90-T – (PMAX180)

Transducer Cable Length ..................................................................................... 20 ft (6 m)

NOTE: Product specifications and features are subject to change without notice.

NOTE: Humminbird® verifies maximum stated depth in saltwater conditions,

however actual depth performance may vary due to transducer installation, water

type, thermal layers, bottom composition, and slope.

45

Page 52

Contact Humminbird®

Contact the Humminbird® Customer Resource Center

in any of the following ways:

By Telephone

(Monday - Friday 8:00 a.m. to 4:30 p.m. Central Standard Time):

1-800-633-1468

By e-mail

(typically we respond to your e-mail within three business days):

cservice@johnsonoutdoors.com

For direct shipping, our address is:

Humminbird

Service Department

678 Humminbird Lane

Eufaula, AL 36027 USA

46

Loading...

Loading...